Page 1

L6064A

Universal Two Speed Fan and Limit Controllers

PRODUCT DATA

APPLICATION

These combination warm air fan and limit controllers

are suitable for all types of forced air heating systems.

The controllers have 2 switches with 3 individually adjustable set points. One switch opens the limit circuit if

the plenum temperature exceeds the preset safety limit;

most models reset automatically. The other switch

changes fan speeds. On all the L6064 the fan speed is

switched from low to high and vice versa according to

the plenum temperature. The fan speed is switched to

low if the plenum temperature falls below the fan off set

point. All the L6064 models are intended for use with

conventional warm air systems.

All models may be used as limit controls by wiring only

the limit side.

Limit controls are suitable for line voltage, low voltage, or millivoltage circuits.

INSTALLATION

When installing this product...

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

Follow furnace or burner manufacturer’s instructions, if available. Do not exceed the ratings and limitations given in this section.

ELECTRICAL RATINGS:

NOTE: The electrical rating is at maximum case tem-

perature of 88

O

C (190OF). Use high temperature insulating material, or a mounting bracket when mounting

surface temperature exceeds 88OC (190OF).

CAUTION

!

1. Disconnect power supply before beginning installation to prevent electrical shock or equipment

damage.

2. When connecting cable or conduit to control,

avoid straining the control case.

LOCATION

If this is a replacement installation, locate the

L6064 in the same location as the control being replaced. The L6064 sensing tube length should be

the same as the old control. If this is a new installation, the element should be installed only by a

trained, experienced service technician according

to the furnace manufacturer’s instructions. The element must not touch any internal part of the furnace.

MOUNTING

The device may be mounted as follows:

All models -- Surface or Bracket.

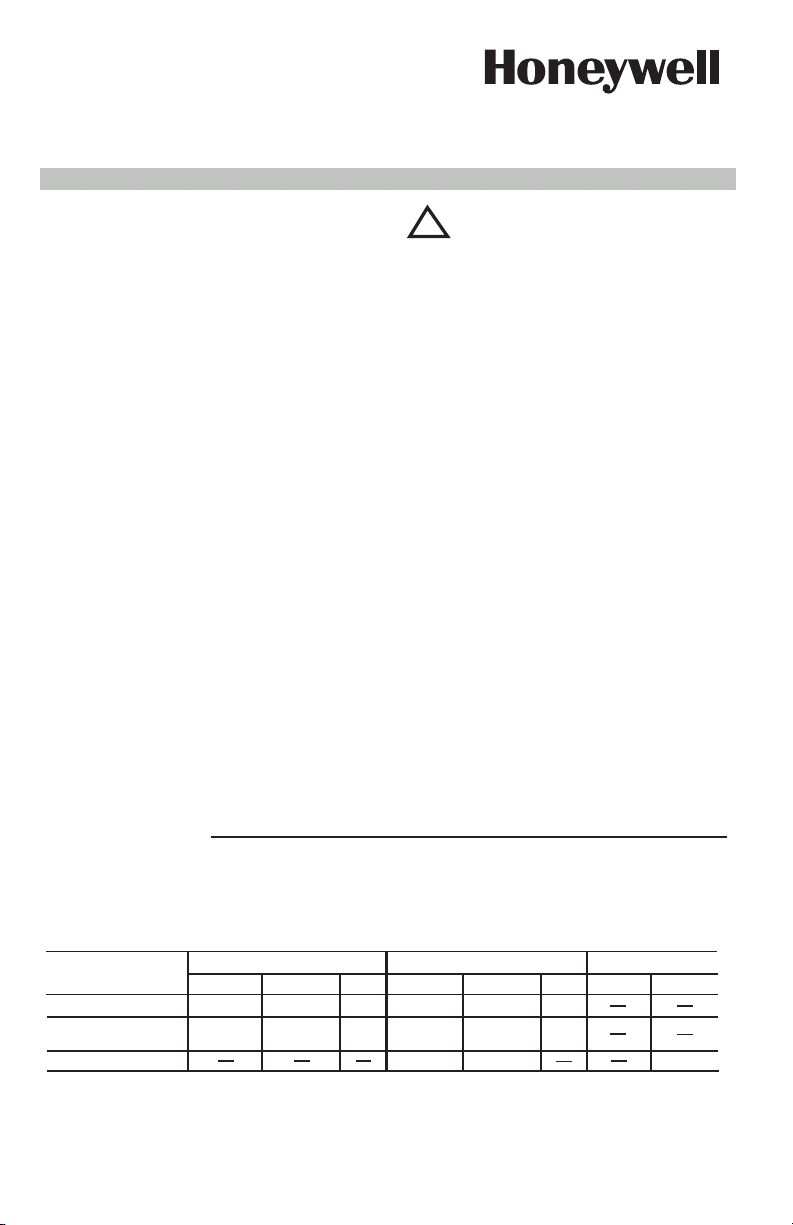

SURFACE MOUNTING

Hole in plenum should be just large enough to

accommodate the 20 mm (3/4 in.) diameter element

tube.

1. Remove cover by squeezing sides and pulling

off. Insert element in plenum and mark location of

mounting holes. Make sure the case is snug against

the plenum before marking the mounting holes.

2. Punch or drill holes for mounting screws.

3. Place insulation between plenum and case if

necessary, or use a mounting bracket.

4. Fasten controller securely with mounting

screws.

90OC field wiring may be required.

NOTE: For applications under DIN or BEAB jurisdiction ambient temperatures must not exceed

O

70

C (158OF).

FAN

24 Vac

LIMIT

2

Full Load (Amps)

Locked Rotor

(Amps)

Max. Amp.

FAN LOW

6 14

120 Vac 240 Vac

FAN HIGH

LIMIT

FAN LOW

8

48

84

FAN HIGH

3

LIMIT

4

7

42

24

Pilot Duty: 2 A at 24 Vac; 0.25 to 12 Vdc. (Limit)

Maximum Combined Connected Load: 2000 VA. ac. Load capacity at terminal points must not exceed the rated

capacity of connected wire at its rated insulation temperature. 75

O

C minimum field wiring is required.

Page 2

FURNACE

MA

T

RIAU

THERMO-ISOLANT

SI N

CESSAIRE

PL

NUM DE

L’APP

AREIL

DE

CHAUFF

AGE

2697C

!

VIS DE MONT

AGE

APPAREIL

DE

CHAUFF

AGE

PL NUM

SUPPORT RIGIDE

50

100

150

200

250

ON/OFF

FAN LIMIT

FAN

LIMIT

BORNES-

PRESSION POUR

CONDUCTEURS

STANDARDS

(4)

PRISE FEMELLE

POUR LE

RACCORDEMENT

D’UNE BORNE ¸

COSSE M LE DE

6,4 MM (1/4 PO)

(4)

PROTØGE-FILS

POUR RETIRER UN

CONDUCTEUR

STANDARD,

POUSSER AVEC UN

TOURNE-VIS ET

TIRER LE FIL

CONDUCTEUR

STANDARD DE

COMMANDE

D’ QUIPEMENT

CONDUCTEUR AVEC

BORNE ¸ COSSE M LE

DE 6,4 MM (1/4 PO)

(POUSSER LA COSSE AU

FOND DE LA CAVIT .)

Low

CONNECTEUR

M LE RAPIDE

POUR LE

RACCORDEMENT

D’UNE BORNE ¸

COSSE FEMELLE

DE 6,4 MM (1/4 PO)

CONDUCTEUR

AVEC BORNE

EMBROCHABLE

M LE DE 6,4 MM

(1/4 PO) (POUSSER

LA COSSE AU FOND

DE LA CAVIT .)

LOAD

LINE

HIGH LINE

STRIPE GAUGE

ERS

BORNE-PRESSION

VERROUILLABLE

ORIFICE

POUR FIL

PLENUM

HEAT

INSULATING

MATERIAL IF

NEEDED

2697C

Fig. 1 - Surface mounting L6064. Requires hole

20 mm (3/4 in.) diameter in the plenum.

RIGID BRACKET MOUNTING

All models of the L6064 may be mounted using a

rigid bracket. The rigid bracket requires a hole 20

mm (3/4 in.) diameter for mounting.

1. Use bracket as a template to mark the location

of mounting holes in plenum. Drill or punch holes for

mounting screws.

2. Fasten bracket in place with screws furnished.

Tighten the screws securely.

3. Insert element tube through bracket, straighten

controller, and fasten by tightening setscrew.

WARNING

!

Be sure screw strikes tube frame and does not strike

inner sensing element.

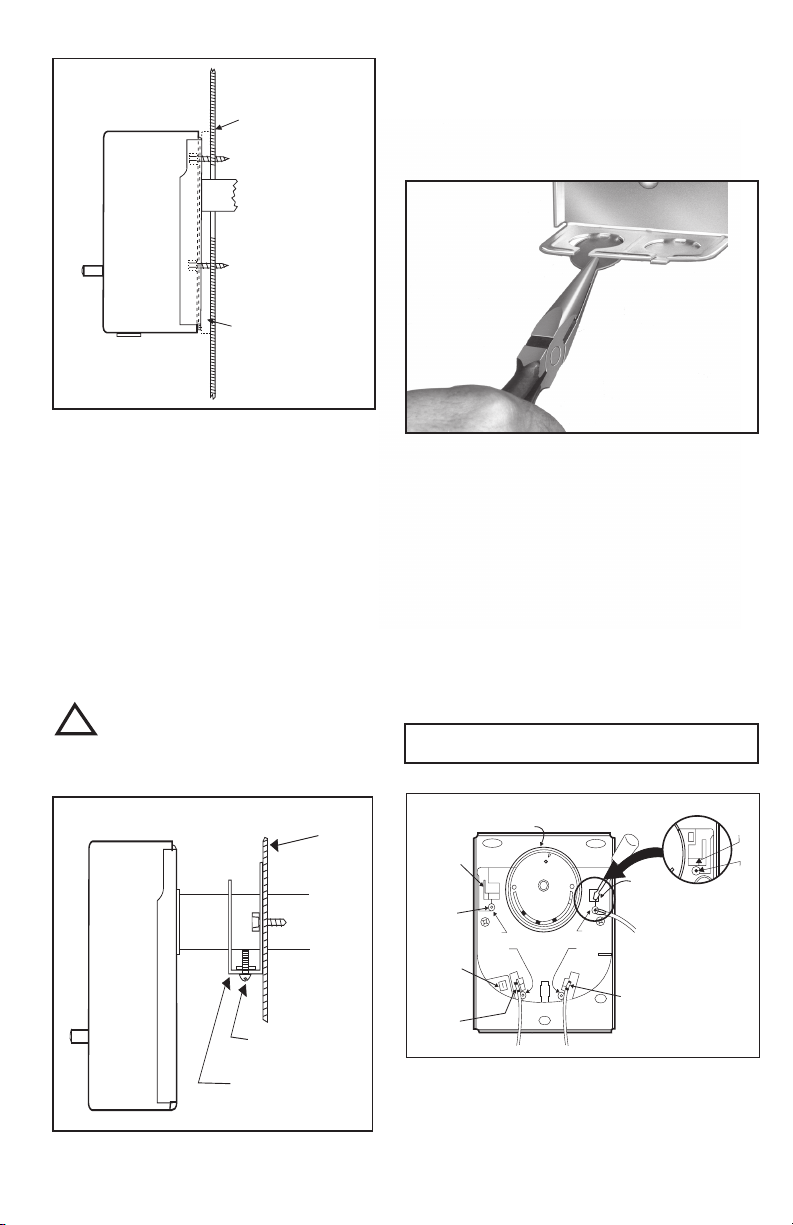

WIRING

Disconnect power supply before beginning installation

to prevent electrical shock and equipment damage.

All wiring must comply with local electrical codes and

ordinances. See Fig. 5 for typical hookups.

1. To remove the slotted knockouts, bend down and

break off with a long hose pliers. See Fig. 3.

Fig. 3 - Removing slotted knockouts.

2. Pass wires through bushing before connecting.

3. Connect wire to push-in terminals, and insert the

bushing into knockout slot.

PUSH-IN TERMINALS

1. No. 14, 16, or 18 solid or No. 14 or 16 fused stranded

wire may be connected to the terminals.

2. Strip insulation from wires the distance shown by

the strip guage on the controller.

3. Solid or solder dipped wire may be inserted by pushing into the terminal holes. If stranded wire is used, insert a small screwdriver into the slot next to the terminal. Push in and hold while inserting wire in terminal.

Then remove screwdriver.

All wires must be clear of rotating scaleplate.

IMPORTANT

RIGID BRACKET

SETSCREW

Fig. 2 - Rigid bracket mounting requires a hole 20

mm (3/4 in.) diameter for mounting.

FURNACE

PLENUM

FEMALE

RECEPTACLE FOR

CONNECTION OF

6.4MM (1/4 ") MALE

FLAG TERMINAL

(4)

STANDARD

WIRE PUSH IN

CONNECTORS

(4)

MALE

QUICKCONNECT

FOR CONNECTION

OF 6.4MM (1/4")

FEMALE FLAG

TERMINAL

LEADWIRE WITH

1/4 IN. (6.4MM)

MALE FLAG

TERMINAL (FORCE

FLAG TO BOTTOM

OF CAVITY)

WIRING GUARD

50

FAN LIMIT

ON/OFF

100

200

150

LINE

FAN

HIGH LINE

Low

250

LOAD

LIMIT

STRIPE GAUGE

ERS

TO RELEASE

STANDARD WIRE -

PUSH SCREW

DRIVER IN AND PULL

WIRE OUT

STANDARD

WIRE TO

CONTROLLED

EQUIPMENT

LEADWIRE WITH 1/4 IN.

(6.4 MM) MALE SPADE

TERMINAL (FORCE

FLAG TO BOTTOM OF

CAVITY)

Fig. 4 - Internal view of L6064 showing use of

screwdriver to connect or disconnect

wires at push-in terminals.

NOTE: Because the dial turns when the

element temperature changes, the lettering

on the dial may not be horizontal.

2

PUSH-IN

LOCK

TERMINAL

HOLE

FOR WIRE

Page 3

A

L6064

LIMIT

FAN

SIDE

SIDE

(HOT)

L1

1

L2

LOW SPEED

HIGH SPEED

L1

(HOT)

2

1

ADD DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED

TO CONTROL LOW VOLTAGE EQUIPMENT

2

1

L2

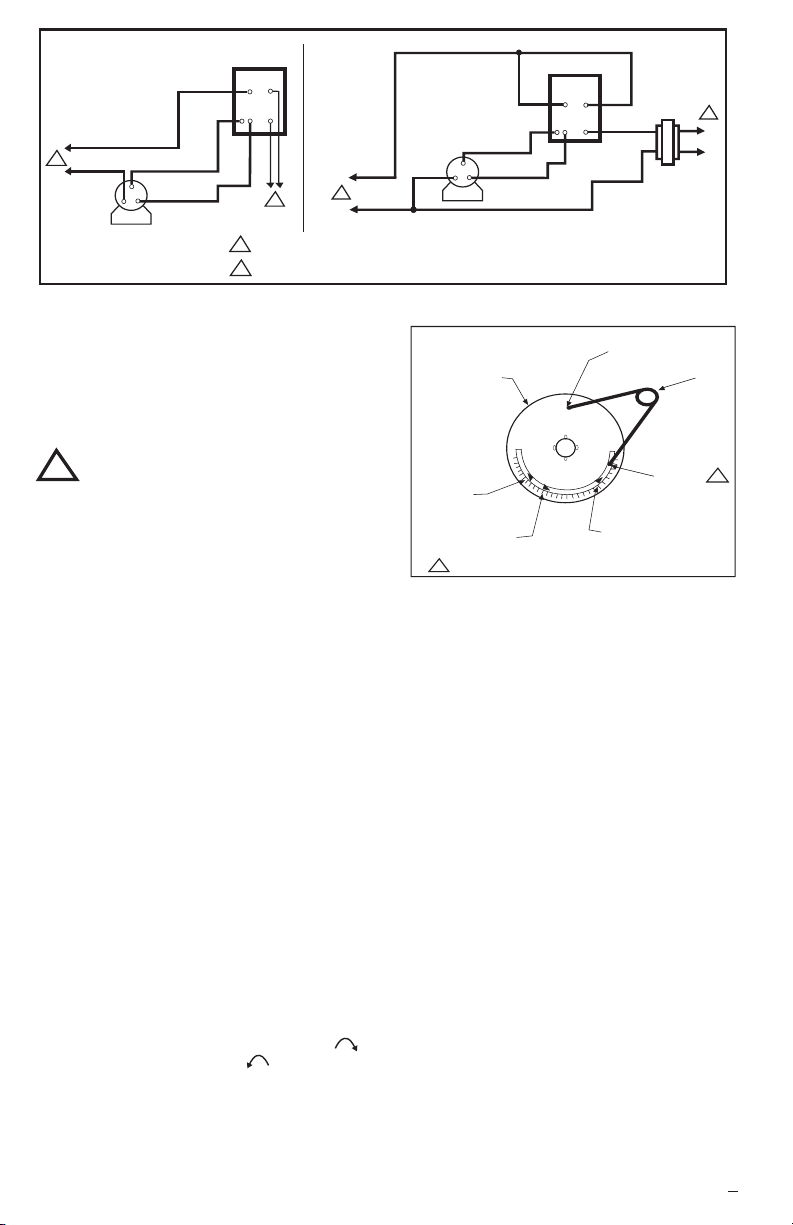

Fig. 5 - A: Limit in low voltage circuit.

B: Limit in line voltage circuit.

OPERATION

During normal operation, the L6064 sensing element

will rotate and close the fan switch for high speed once

plenum temperature reaches the factory-set fan on set

point.

SETTINGS AND ADJUSTMENTS

CAUTION

!

When adjusting the fan and limit setting levers, hold

the scalepale dial to keep it from turning and straining

the sensing element.

Move the setting levers to the control points recommended by the burner or furnace manufacturer. Use

gentle finger pressure.

1. Move the FAN OFF (continuous low speed) setting

lever to the temperature at which the fan is to run low

speed for continuous air circulation.

All L6064 models - FAN ON (heating fan speed) range

is from 8.3

O

C (15OF) above the FAN OFF (continuous

low speed) setting to 17OC (30OF) below the LIMIT OFF

setting.

2. Move the LIMIT setting lever to the temperature at

which the high limit switch is to break the primary control circuit.

All L6064 models - limit range is 35

O

to 250

F).

O

C to 120OC (95OF

LIMIT SETTING ADJUSTMENT

These controllers have a limit stop which prevents the

limit indicator lever from being adjusted beyond the equipment manufacturer’s specifications.

1. Push the small end of Limit Adjust Tool (196722)

through hole in scaleplate (located at caution marking) to

depress the stop disc not more than 1/16 in. (1.6 mm) to

release stop lock (Fig. 10). Stop disc is on back of

scaleplate.

2. While depressing the stop disc, insert the long end of

Limit Adjust Tool next to limit stop (Fig. 10) and move the

stop to desired setting.

If the L4064 is a replacement control, high limit stop setting should be the same as that of

the control being replaced.

(Move stop clockwise to

lower the setting, counterclockwise to raise it.) Then

remove the limit stop adjust tool.

3. Set the LIMIT OFF lever to the temperature at which

the high limit switch is to open to stop the burner. If the

high limit stop has been properly set, the LIMIT OFF lever

should be as high as the stop permits.

B

L6064

LIMIT

FAN

SIDE

SIDE

LIMIT STOP

ADJUSTABLE

LIMIT STOP

O

C)

TOOL

O

F

2

24V

1

LOW SPEED

HIGH SPEED

SCALEPLATE

CAUTION

DO NOT ROTATE - HOLD DIAL

WHEN SETTING POINTERS

50

FAN

AN

F

OFF

OFF

100

ON

FAN OFF SET

POINT LEVER

FAN ON SET

POINT LEVER

HOMEOWNER: THIS IS A "SAFETY STOP". DO NOT ALTER

1

150

L1

120V

TO RELEASE STOP,

PRESS STIFF WIRE

IN HOLE

250

200

LIMIT SET POINT LEVER

(FACTORY-SET AT 200

L2

(93

Fig. 6 - Changing the high limit stop.

CHECKOUT

Always conduct a thorough checkout immediately following completion of the installation. Operate the system

through at least one complete cycle to ensure that the system operates as intended, especially with respect to the

proper function of the limit control.

The recommended method of checking out the limit control function without disturbing any of the furnace manufacturer’s fan or limit settings is as follows:

1. To stimulate fan motor failure, a broken fan belt, or a

plugged filter, remove the belt driving the fan. On direct

drive fans disconnect the wiring to the fan motor - at the

motor terminal panel - and insulate any live conductors

which might result.

2. Turn the thermostat to the highest setting to ensure

that the burner will run continuously.

3. Watch the operation of the furnace to be sure that

the limit control shuts off the burner when the plenum temperature reaches the limit setting, and that the fan motor

continues to operate. On direct drive fans check to be

sure that voltage is evident on the disconnected leads to

the fan motor when the limit stops the burner.

4. If the installation checks out satisfactorily, replace the

fan belt-or reconnect any direct drive fan wiring-and lower

the thermostat temperature adjustment to the normal setting.

5. If the installation does not check out satisfactorily,

recheck the wiring, correct any wiring discrepancies, and

repeat items 1 through 4. If the installation cannot be made

to function properly DO NOT LEAVE THE FURNACE

OPERATIONAL, PARTICULARLY IF THE LIMIT OR FAN

CONTROLS DO NOT FUNCTION CORRECTLY. REMOVE THE FUSE IN THE CIRCUIT POWERING THE

FURNACE until assistance can be enlisted to correct the

installation.

3

95C-10617B 1

Page 4

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN, 55422 Toronto, ON, M1V 4Z9

www.honeywell.com/building/components

08/06 RB

© Honeywell 2006 Printed in Canada

95C-10617B 1

Page 5

L6064A

!

120 V c.a.

240 V c.a.

Pleine charge (A)

Rotor bloque (A)

24 V c.a.

Maximum (A)

Ventil. au min.

Ventil. au min.

Ventil. au max.

Limiteur

6 14

84

8

48

3

7

42

4

24

2

Ventil. au max.

Limiteur

Ventilateur

Limiteur

Limiteur-régulateur universel de ventilateur à deux vitesses

FICHE TECHNIQUE

APPLICA

Ces

air

ai

et

des

température

préréglée;

des

du

commutateur

à élevée,

dans

l

d

conçus

traditionnels

T

seulement

Les

basse tension et millivolts.

TION

limiteurs

chaud

conviennent

r

p

ul

s

é.

Les

de

trois

co

mmutateur

m

odèl

ventilate

l

e

pl

é

ors

qu

e

l

a

u

poi

nt

de

pour

ous

les

modèles

limiteurs

INSTALLA

AVANT

D’INST

1.

Lire

attentivement

suivre

risque

un

danger

2.

V

ér

ifie

instructions

celui-ci

correspond

3.

L

’installateur

reçu

une

formation pertinente.

4.

U

ne foi

s l

et régulateurs

ré

gul

ateurs

points

de

dans

la

réinitialisation

es

.

L

’

a

utre

ur.

S

fait

passer

et inversement,

num

.

Le

v

tem

pé

rature

c

ons

i

gne.

être

utilisés

à air

chaud.

peuvent

le

côté

limiteur

conviennent

TION

ALLER

d’endommager

.

r

les

car

et indiquées

doit

’i

nstall

ation

à

tous

s

o

consigne,

s

ouvr

e

le plénum

c

om

m

u

ur

tous

la

vitesse

e

nti

l

ateur

dans

T

o

us

avec

servir

.

aux

CET

les

instructions.

ac

tér

istiques

sur

bien

à l’application

être

un

t

erm

combinés

les

systèmes

nt

dotés

réglables

le

c

ir

dépasse

est

automatique

tateur

s

les

modè

du

en

fonction

pas

s

e

l

e

pl

énum

l

es

modè

des

systèmes

de

circuits

APP

AREIL…

le

produit

le produit

technicien

inée, v

érifier

pour

de

de

deux

séparément.

cuit

du

la

limite

ert

à

c

hanger

les

du

ventilateur

de

la température

au

m

ode

de

s

c

end

l

es

du

limiteur

à tension

Le

fait

ou

spécifiées

et s’assurer

prévue.

d’expérience

le

fo

ventilateurs

chauf

fage

c

om

m

utateurs

L

li

miteur

si

de sûreté

sur

la

plupart

l

a

v

i

tes

L606

4,

de

basse

bas

s

e

v

i

tes

en

d

es

s

L606

4

s

de

chauf

fage

si

on

raccorde

secteur

de

ne

pas

de constituer

dans

ayant

nc

tionnement

que

du produit comme l’indiquent les présentes instructions.

Sui

vre

les

directi

ves

du fabri

cant de l

’appareil

de

ou du brûleur si elles

les caractéristiques

cette

section.

sont disponibles.

nominales

et

les limites

chauffa

Ne

pas dépasser

décrites dans

CARACTÉRISTIQUES ÉLECTRIQUES NOMINALES:

REMARQUE : Les caractéristiques électriques

nominales sont établies pour une température maximale

du boîtier de 88

surface de montage dépasse 88

°

C (190 °

F). Si la température de la

°

C (190

°

F), employer

un matériau isolant résistant aux températures élevées

ou

un support de montage.

MISE EN GARDE

1.

C

oupe

r

raccordements

l’al imenta

dommage à l’équipement.

2.

Lors du

raccordem

régulateur

, éviter de forcer le boîtier du régulateur

EMPLACEMENT

S

’

i

l

s

’

agi

t

d’

e

endroit

de

pour

l’ancien

tallation,

être

en

de

AGE

appareils

l

e

s

m

AGE EN

un

l’élément

l’é

d’expérience

de l’appareil

c

chauf

odèl

mêm

longueur

que

ins

technicien

du fabricant

doit

l’appareil

MONT

Les

T

ous

MONT

L

’ouverture dans le plénum doit être juste assez

grande pour y passer le tube de l’élément dont le

diamètre est de 20 mm (3/4 po).

afin

d’éviter

rempl

qu

e

régulateur

lément

ontac

t

fage.

peuvent

es

–

m

SURF

tion

avan t

tout

ent

du

a

c

ement,

le

régulate

sensible

. S’il

dev

rait

conformément

de chauf

av

ec

auc

être

montés

ontage

e

n

ACE

choc

fil

o

i

ns

ur

devrait

s’agit

être

une

s

urfac

fage.

’un

ous

ont

les

les

à

à

la

s

e

le

s

e

,

1. Enlever le couvercle en pressant les côtés et en

tirant. Insérer l’élément dans le plénum et marquer

l’emplacement des trous de montage. S’assurer que

le boîtier est bien ajusté sur le plénum avant de

marquer

les trous

de

montage.

2. Percer les trous pour les vis de montage à l’aide

d’une perceuse ou d’un poinçon.

ge

3. Si nécessaire, installer un isolant entre le plénum et

le boîtier

, ou utiliser un support de montage.

4. Fixer le régulateur solidement à l’aide des vis de

montage.

Du fil pouvant résister à une température de 90

peut être nécessaire.

REMARQUE : Dans les applications conformes aux

normes DIN ou DEAB, la température ne doit pas

dépasser

70

°C

(158 °F).

tal

d’effectu er

électrique

u

du

condui

l

er

l

e

L60

à

rempla

être la même

d’une

insta

llé

aux

directives

L

’élément

piè

c

e

interne

comme

suit:

e

ou

s

ur

l

es

et

tout

t

au

.

64

cer.

La

nouvelle

par

un

s

upport

°

C

au

ne

d

e

.

Circuit de commande

Charge raccordée maximale (combinée)

capacité nominale du fil raccordé, à sa température d’isolation nominale. Utiliser du fil pouvant résister à une

température de 75 °C.

: 2

A sous 24 V c.a.; 0,25 sous 12 V c.c. (limiteur)

: 2000 V

A c.a. La capacité de la charge aux bornes ne doit pas dépasser la

Page 6

MA

T

RIAU

THERMO-ISOLANT

SI N

CESSAIRE

PL

NUM DE

L’APP

AREIL

DE

CHAUFF

AGE

2697C

Fig. 1 – Montage en surface du L6064. Percer un

!

VIS DE MONT

AGE

APPAREIL

DE

CHAUFF

AGE

PL NUM

SUPPORT RIGIDE

50

100

150

200

250

ON/OFF

FAN LIMIT

FAN

LIMIT

BORNES-

PRESSION POUR

CONDUCTEURS

STANDARDS

(4)

PRISE FEMELLE

POUR LE

RACCORDEMENT

D’UNE BORNE ¸

COSSE M LE DE

6,4 MM (1/4 PO)

(4)

PROTØGE-FILS

POUR RETIRER UN

CONDUCTEUR

STANDARD,

POUSSER AVEC UN

TOURNE-VIS ET

TIRER LE FIL

CONDUCTEUR

STANDARD DE

COMMANDE

D’ QUIPEMENT

CONDUCTEUR AVEC

BORNE ¸ COSSE M LE

DE 6,4 MM (1/4 PO)

(POUSSER LA COSSE AU

FOND DE LA CAVIT .)

Low

CONNECTEUR

M LE RAPIDE

POUR LE

RACCORDEMENT

D’UNE BORNE ¸

COSSE FEMELLE

DE 6,4 MM (1/4 PO)

CONDUCTEUR

AVEC BORNE

EMBROCHABLE

M LE DE 6,4 MM

(1/4 PO) (POUSSER

LA COSSE AU FOND

DE LA CAVIT .)

LOAD

LINE

HIGH LINE

STRIPE GAUGE

ERS

BORNE-PRESSION

VERROUILLABLE

ORIFICE

POUR FIL

trou de 20 mm (3/4 po) dans le plénum.

MONT

T

un

ous

AGE SUR

les

support

modèles

rigide.

SUPPORT

du

L6064

Le

cas

échéant,

RIGIDE

peuvent

être

percer

montés

un

trou de

20 mm (3/4 po) de diamètre.

1.

Se

servir

du

support

comme

gabarit

pour

l’emplacement

Perc

er

l

es

perceuse

2.

Serrer les

3.

placer

de

S’as

l’élément

trous

ou

Fi

x

er

l

e

s

upport

vis

Insérer

le

le

régulateur

montage.

A

VER

surer que l

sensible à l’intérieur.

des

trous

de

montage

r

l

es

v

i

s

de

pl

ac

e

en

d’un

pou

poinçon.

en

solidement.

tube de l’élément

bien

droit

TISSEMEN

a v

is

serre

T

le boîti

montage

uti

l

i

s

ant

à travers

et

le

e

r

du tube s

dans

l

fixer

le

à

l

’

ai

es

v

i

s

le support,

avec

marquer

plénum.

de

d’

fourni

les

an

s

c

CÂBLAGE

Couper

l’alimentation

d’

em

pêcher

t

out

choc

l’équipement.

T

out

le

câblage

èg

l

em

doit

ent

s l

types.

ouvertures

aux r

raccordements

1.

Enlever les

les brisant avec une pince à long bec. V

sur

Fig. 3 – Enlèvement des ouvertures défonçables à fente.

2.

Pa

sser

les

fils

dans

les fils aux

les

bornes-pression,

18

ou

du

la

longueur

massifs

ou

insérés

s

ant.

Pour

rac

dans

la

fente

une

es

vis

oincer

3. Raccorder

manchon dans l’ouverture défonçable.

BORNES-PRESSION

1.

Avec

.

14,

16

ou

2

.

D

énuder

dénudage du régulateur

3.

Les

fils

être

directement

l

es

pou

s

tournevis

maintenir au fond pour insérer les fils. Puis le retirer

Tous les fils doivent être éloignés du cadran rotatif.

avant

de

procéder

él

ect

r

i

que

et

être

conforme

oc

aux.

défonçables

La f

aux

i

g

ur

e 5 pr

à

codes

fente

oir la figure 3.

le

ma

nchon

avan

bornes-pression et insérer le

utiliser

fil

torsadé

de

fusionné

fil

indiquée

du

n

.

les

fils

dans

c

order

à côté

IMPORT

fusionnés

d

les

ouvertures

es

fi

l

s

de

la borne.

ANT

par brasage

tors

ad

à

l’installation

t

out

do

d’électricité

és

en

t

de

les

fil

massif

o

14

ou

s

ur

le

des

és

,

i

ns

Le

afin

m

m

age

ent

e de s

les

pliant

r

acc

or

der.

de

calibre

o

n

18.

gaba

rit

peuvent

bornes,

érer

un

peti

pousser et le

.

à

et

et

de

en

t

sur support rigide, il

Fig. 2 – Dans le cas de montage

faut percer un trou de montage de 20 mm (3/4 po).

Fig. 4 – Vue interne du L6064

tournevis pour raccorder

pression.

REMARQUE : Étant donné

température

varie, il est possible que les lettres sur celui-ci

ne soit pas à l’horizontale.

2

montrant comment utiliser un

ou enlever

les fils sur les bornes-

que le cadran tourne lorsque

la

Page 7

L6064

A

B

C T

VENT

C T

LIMITEUR

BASSE VITESSE

1

2

2

1

L1

L2

AJOUTER, AU BESOIN, UN DISPOSITIF DE COUPURE ET

UNE PROTECTION

CONTRE LES SURCHARGES.

R

GULA

TION D’

QUIPEMENT

¸ BASSE

L1

L2

1

120V

L6064

24V

2

VITESSE

LEV

E

L1

L2

C T

LIMITEUR

C T

VENT

(SOUS

TENSION)

(SOUS

TENSION)

BASSE VITESSE

VITESSE

LEV

E

Fig. 5 –

!

50

100

150

200

250

ON

F

AN

OFF

F

AN

OFF

DO NOT ROT

ATE - HOLD DIAL

WHEN SETTING POINTERS

CAUTION

1

1

NOTE

AU PROPRI

T

AIRE : BUT

E DE S

CURIT

. NE PAS MODIFIER

CURSEUR DE

R

GLAGE

ARR

T DU

VENTILA

TEU

CURSEUR DE

R

GLAGE

MARCHE DU

VENTILA

TEUR

CADRAN

POUR D

GAGER LA

BUT

E,

APPUYER DANS L’OUVER

TURE

AVEC

UN FIL RIGIDE

BUT

E DE FIN

DE COURSE

R

GLABLE

CURSEUR DE R

GLAGE

DU LIMITEUR

R

GL

EN USINE ¸ 93 ¡C

(200 ¡F)

OUTIL

DE

R

GLAGE DU

LIMITEUR

A

: Limiteur dans un circuit à basse tension

FONCTIONNEMENT

Au cours

du

et

ferme

à la

l

e

pl

énum

fonctionnement

le

commutateur

vitesse

a

attei

tourne

passer

dans

élevée,

nt

l

e

poi

B

nt

: Limiteur dans un circuit à tension secteur

normal,

l’élément

du

régl

pour

é

capteur

le

en

us

de

ventilateur

une fois

de

c

ons

que la température

i

g

ne

RÉGLAGE ET AJUSTEMENTS

MISE EN GARDE

Lors

du réglage

bien

tenir

pas

forcer

Déplacer

par

l

e

fa

N’appliquer

1.

Déplacer

la

température

vitesse pour assurer une circulation continue de l’air

Sur tous

de chauf

position

en dessous du réglage LIMIT

2.

Déplacer

commutateur à maximum doit ouvrir le circuit primaire.

Sur tous

de 35 ˚C à 120 ˚C (95 ˚F à 250 ˚F).

RÉGLAGE DE LA

Ces régulateurs sont munis d’une butée de fin de course

empêchant que le réglage du curseur ne dépasse les

spécifications du fabricant de l’équipement.

1. Insérer l’extrémité courte de l’outil d’ajustement du

limiteur (196722) dans l’ouverture du cadran sous le mot

« CAUTION

mm (1/16 po) pour dégager l’arrêt de sûreté (figure 10). Le

disque d’arrêt est situé au dos du cadran.

2. En tenant le disque abaissé, insérer l’extrémité longue

de l’outil d’ajustement du limiteur près de la butée de fin de

course (figure

le L6064 remplace un autre régulateur

butée de fin de course maximum devrait être le même que

sur le régulateur remplacé.

horaire pour abaisser le réglage et dans le sens

antihoraire , pour l’augmenter.) Retirer l’outil

d’ajustement du limiteur.

3. Placer le curseur LIMIT OFF à la température

le commutateur à maximum ouvre le circuit pour arrêter le

brûleur. Si la butée de fin de course maximum a été réglée

correctement, le réglage

élevé que la butée le permet.

VÉRIFICATION

Il faut toujours effectuer une vérification complète une fois

l’installation terminée. Faire fonctionner le système pendant

des

curseurs

le

cadran

l’élément

les

curseurs

bri

c

ant

de

qu’une

légère

le

curseur

à laquelle

les

modèles

fage) s’étend

FAN OFF

les

le

curseur

modèl

(basse

e

s

pour

du

l

’

du

l’empêcher

capteur

aux

apparei

FAN

le

du

L6064,

de 8,3

vitesse

LIMIT

L6

du ventilateur

.

points

de

l

de c

pression

OFF

(basse

ventilateur

la

°C

OFF

à la

064,

la gam

de tourner

réglage

hauffage

du

doigt.

vitesse

fonctionne

gamme

FAN ON

(15

°

F)

au

continue)

à 17

.

température

me du

lim

ou

BUTÉE

» afin d’abaisser le disque d’arrêt d’au plus 1,6

10)

et

déplacer

celle-ci

au

réglage

, le réglage de la

(Déplacer la butée dans le sens

LIMIT OFF devrait être aussi

et du limiteur

et pour

recommandés

du

brûl

continue)

à basse

.

(vitesse

dessus

°

C

(30

à laquelle

iteur s

’étend

voulu.

à laquelle

.

faire

i

ne.

,

ne

eur.

à

Figure 6 –

Ajustement de la butée de fin de course maximum.

un

c

y

c

l

e

c

om

pl

et

afi

n

de

s

’

as

s

ure

r

qu’

i

l

et surveiller attentivement le fonctionnement du limiteur

L

a

m

éthode

s

ui

v

ante

es

t

rec

om

m

and

de

la

du limiteur

°

F)

limi

chauf

le

1. Pour simuler

bris de

enlever la

cas de

sans

effectu

:

nuire

és

teur

fage

une

la courroie du

courroie d’entraînement

ventilateurs

moteur au bornier du moteur et isoler

2. Régler

le

thermostat

aux

par

le

panne

ventilateur

à

entraînement

au

réglages

f

abr

icant

du moteur

ou

du ventilateur

direct,

point de

ée

du ventilateur

l’obstruction

tout

consigne maximum

de façon à faire fonctionner le brûleur continuellement.

3.

Surveiller

afin

l

orsque

r

églée et que le m

fonctionner

direct, s’ass

moteur

le limiteur provoque l’arrêt du brûleur

Si

4. Si

place la

du ventilateur à

à son point de consigne normal

5. Si

à nou ve au le câblage, corr ig er les problèmes de

raccordement et répéter les étapes 1 à 4. S’il est impossible

de faire fonctionner

LAISSER L’APPAREIL DE CHAUFFAGE EN MODE

MARC HE, SU RT OUT SI LE LIMITEU R ET LE

RÉGU LATEUR NE FONCTI ONNENT PAS

CORRECTEMENT. ENLEVER LE FUSIBLE DANS LE

d

e

s’

assurer

l

a

température

. Dans

du

ventilateur

le fonctionnement

qu

e

le

oteur

le cas des

urer

que

de

dans le

d

u ven

l’appareil de

p

rov

oqu

pl

énu

tilateur

li

miteur

ventilateurs

les conducteurs déconnectés du

sont

toujours sous

.

l’installation

l’installation ne fonctionne pas comme prévu, vérifier

courroie du

entraînement

fonctionne

comme

ventilateur ou raccorder

direc

t. Abaiss

l’installation correctement, NE PAS

CIRCUIT D’ALIMENTATION DE L’APPAREIL jusqu’à

qu’on obtienne de l’aide pour corriger les problèmes de

l’installation.

3

réagi

t

c

om

m

e

prév

pour

l

a

v

éri

fi

c

ati

et du

de

l’appar

eil

du ventilateur

du

, un

filtre,

. Dans le

déconnecter

fil

sous tension.

chauf

t

du brûleur

fage

e

l’

arrê

m

atteint la lim

continue de

à entraînement

tension

lorsque

prévu, remettre en

tous les fils

er le thermos

u

.

on

d

e

le

ite

tat

ce

Page 8

Solutions de régulation et d’automatisation

Honeywell International Inc. Honeywell Limited

1985 Douglas Drive North

Golden Valley, MN, 55422 Toronto, ON, M1V 4Z9

www.honeywell.com/building/components

08/06 RB

© Honeywell

95C-10617B 1

2006 Printed in Canada

35 Dynamic Drive

Loading...

Loading...