Page 1

L480B,G Temperature Controllers

PRODUCT DATA

FEATURES

• Typical applications include freezer cabinets, display

cases, beverage coolers, milk cooling tanks and air

conditioners.

• The L480B can act as a frost alarm operator in

storehouses, orchards, or other locations where frost

could damage crops or equipment.

• The L480B automatically recycles. It has a single-pole,

double-throw (spdt) switch that can be wired to make

an alarm circuit at the setpoint.

• The L480G is a manual reset model. Its single-pole,

single-throw (spst) switch locks out the control circuit

on temperature fall to the setpoint.

• A dual temperature scaleplate is provided for both

Fahrenheit and Celsius readings.

• The temperature range is 20°F to 60°F (-5°C to +15°C).

• The L480B,G has a 20 foot (6 meter) sensing element

APPLICATION

The L480B,G Temperature Controllers operate electric

dampers, valves, and compressor or fan motors to provide

temperature or limit control of air conditioning systems and

refrigeration units.

with no sensing bulb.

• The enclosed snap switch is dustproof and

moistureproof for trouble-free operation.

• The controller can be mounted horizontally or

vertically on a wall or panel, or directly on the

compressor case.

Contents

Application ........................................................................ 1

Features ........................................................................... 1

Specifications ................................................................... 2

Ordering Information ........................................................ 2

Installation ........................................................................ 2

Operation and Checkout ................................................... 4

60-2203-05

Page 2

L480B,G TEMPERATURE CONTROLLERS

CAUTION

SPECIFICATIONS

Models:

L480B Temperature Controller with spdt snap switch, auto-

matic recycling.

L480G Temperature Controller with spst snap switch, manual

reset.

Switching Action:

L480B: Breaks control circuit and makes another circuit

(makes R-B and breaks R-W) on temperature fall.

Automatically recycles.

L480G: Breaks control circuit on temperature fall. Manual

reset.

Electrical Ratings (Amperes):

See Table 1.

DC Rating: 0.2A at 120 Vdc, 0.1A at 240 Vdc.

Pilot Duty Rating: 125 VA

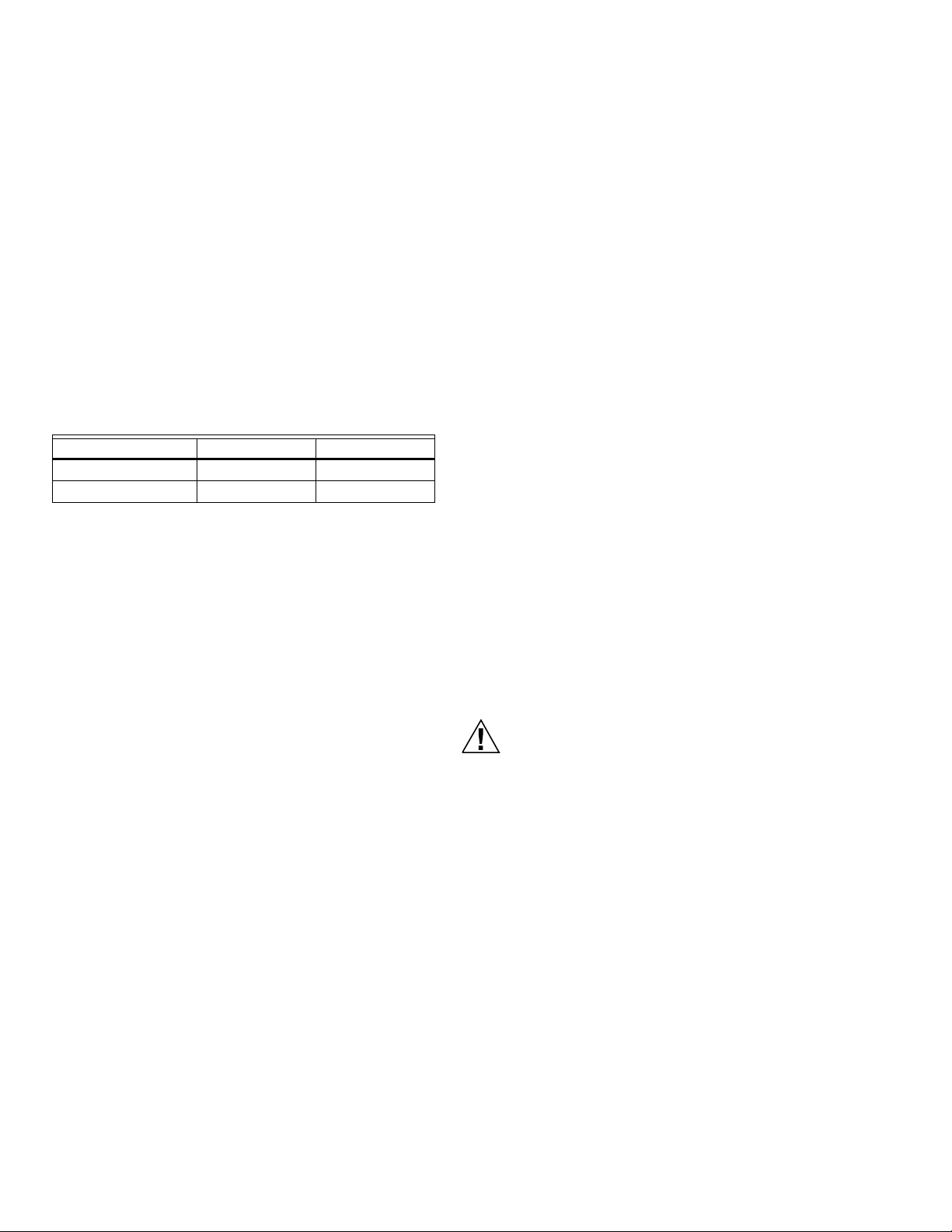

Table 1. Full Load and Locked Rotor Ampere ratings.

L480B,G 120 Vac 240 Vac

Full Load 10.2 6.5

Locked Rotor 61.2 39.0

Ambient Temperature Range:

-20°F to +125°F (-11°C to +52°C).

Maximum Sensor Temperature:

225°F (107°C).

Operating Temperature Range:

20°F to 60°F (-5°C to +15°C); Dual Fahrenheit/Celsius

scaleplate.

Temperature Sensing Means:

20 ft (6m) element, no sensing bulb.

Temperature Setting Means:

A slotted screw at the top of the controller. The setpoint is

indicated through a scale opening in the cover.

Differential:

Nonadjustable, additive, and fixed, 10°F (6°C) maximum.

Finish:

Gray.

Mounting Means:

Mounting lugs located on back of case.

Dimensions:

See Fig. 1.

Approvals:

Underwriters Laboratories Inc., Listed: File Number

SA481, Vol. No. 2, dated 02-09-66; Guide No. SDFY2.

Canadian Standards Association Certified: Listing G, File

No. LR1620; Guide No. 400-E-0.

Accessories:

314439 Clips for mounting element inside duct. Specify

quantity needed when ordering.

7640HX Assembly Kit for installing tubing when access

into duct is not possible.

For Immersion well assemblies, see Honeywell

TRADELINE® Catalog.

113665 Grommet.

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service technician.

4. After installation, check out the product as provided in

these instructions.

Disconnect the power supply before installation to

prevent electrical shock or possible equipment

damage.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number. If you have additional questions, need further information,

or would like to comment on our products or services, please write or phone:

1. Your local Honeywell Environmental and Combustion Controls Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

3. http://customer.honeywell.com or http://customer.honeywell.ca

International Sales and Service Offices in all principal cities of the world. Manufacturing in Belgium, Canada, China, Czech

Republic, Germany, Hungary, Italy, Mexico, Netherlands, United Kingdom, and United States.

60-2203—05 2

Page 3

L480B,G TEMPERATURE CONTROLLERS

CAUTION

CAUTION

7/8 (22) DIAMETER HOLE

FOR 1/2 INCH CONDUIT

CONNECTION

MANUAL RESET

MODEL ONLY

2-9/16 (65)

(MANUAL

RESET

MODEL

ONLY)

1-1/16

(27) (2)

1-1/16

(27)

3-5/16

(84)

3/16

(5) (2)

5/16

(8) (2)

3-5/16 (84)

3-11/16 (94)

2-5/16 (59)

2-9/32

(58)

M11026A

Fig. 1. L480 Temperature Controller dimensions in in. (mm).

Location

Locate the sensing element where it can sense the average

temperature of the space or liquid to be controlled. The

L480B,G case must be located where the ambient temperature

is at least 20°F (11°C) above the scale range setpoint. Do not

locate the element near a hot or cold inlet.

NOTE: The L480B,G case and excess element must be

located where ambient temperature is always at

least 20°F (11°C) above the setpoint of the controlled medium. For settings above the midpoint

of the temperature range, it may be necessary to

locate the controller case close to a steam pipe or

other warmsurface and to be sure the element

does not extend across a cold surface.

Mounting

Fasten the controller to a rigid vertical or horizontal surface

through the holes in the two mounting lugs projecting from

either side of the controller case.

Do not uncoil more element or capillary than is

required for the application. Do not sharply bend

the element or capillary or more than necessary—

bending hardens the element and makes it brittle.

Bends must have at least a one in. (25 mm) radius.

Do not make bends close to the control or pull on

the element or capillary. If the element or capillary

can be subjected to vibration, protect any surface

that makes contact.

Mounting the Element

Strap the element on a coil; for example, in an area where

freezing can occur, or mounted in a duct. Use as much of the

element as necessary for maximum protection.

Use metal straps to fasten the element to the coil to be

controlled.

Use clips (available as listed in Accessories section) for

mounting the element in a duct. See Fig. 2.

WIRING

To prevent possible electrical shock or equipment

damage, disconnect power supply before wiring

the L480B,G Temperature Controller.

All wiring must be in compliance with local codes and ordinances. Refer to installation and wiring information supplied

with the equipment to be controlled and to Fig. 3 and 4.

IMPORTANT

L480B,G Temperature Controllers are approved for

use with copper wire only

3 60-2203—05

Page 4

L480B,G TEMPERATURE CONTROLLERS

DUCT

WALL

CAPILLARY

TUBING

113665

GROMMET

AVERAGING

ELEMENT

USE NO. 10

SHEETMETAL

SCREWS

314439

CLIP

BEND HERE

IF NECESSARY

M11027

L1 (HOT)

ALARM

CONTROLLED

EQUIPMENT

L2

L480B

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

SWITCH MAKES R-B, BREAKS R-W ON TEMPERATURE

FALL TO SETPOINT.

1

1

2

2

R

B

W

M11039

L1 (HOT)

CONTROLLED

EQUIPMENT

L2

L480G

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

SWITCH BREAKS ON TEMPERATURE FALL TO SETPOINT.

MUST BE MANUALLY RESET.

1

1

2

2

M11040

OPERATION AND CHECKOUT

Operation

The L480B Temperature Controller has an spdt switch and

automatically recycles. It breaks the control circuit and makes

another circuit (makes R-B and breaks R-W) on temperature

fall.

Fig. 2. Use 314439 Clips to mount L480B,G Temperature

Controller element in duct.

Fig. 3. Typical hookup for L480B Temperature Controller

with alarm circuit.

Fig. 4. Typical hookup for L480G Temperature Controller.

The L480G Temperature Controller has an spst. It breaks the

control circuit on temperature fall and must be manually reset

to resume operation.

Temperature Setting

Turn the temperature adjustment screw (located on the top of

the L480 case) to move the indicator on the front of the case

to the desired cutoff point. The L480 has a fixed, additive

differential of 10°F (6°C) above the control setpoint.

NOTE: Slight changes in temperature setting can be

required to correct for altitude changes. The

operating point drops approximately 1°F (0.6°C)

per 1000 ft (305m) above sea level.

Checkout

With the system operating, increase the temperature setting

until the switch operates. Cooling equipment should turn off

and the alarm circuit (if used) should be energized.

Decrease the temperature setting. The alarm should

deenergize, and the equipment should return to normal

operation.

By using this Honeywell literature, you agree that Honeywell will have no liability for any damages arising out of your use or modification to,

the literature. You will defend and indemnify Honeywell, its affiliates and subsidiaries, from and against any liability, cost, or damages,

including attorneys’ fees, arising out of, or resulting from, any modification to the literature by you.

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

customer.honeywell.com

On manual reset models, reset the red plunger to resume

normal operation.

® U.S. Registered Trademark

© 2014 Honeywell International Inc.

60-2203—05 M.S. Rev. 04-14

Printed in United States

Loading...

Loading...