Page 1

APPLICATION

The L408A,B and L608A VaporStat® Controllers are line

voltage pressure controllers that provide operating control or

automatic limit protection for pressure systems of up to 4 psi

(0.28 kg/cm2 or 27.6 kPa).

L408A,B; L608A

VaporStat® Controllers

PRODUCT DATA

FEATURES

• Primarily for use in vapor heating systems, but also

may be used with liquids, air, and other

noncombustible gases

• Stainless steel diaphragm also allows use with

ammonia, oxygen, distilled water, and similar media.

• L408A and B models have an spst switch; L408A

breaks and L408B makes when pressure rises to the

main scale setpoint.

• L608A models have an spdt switch that breaks R-B

when pressure rises to the main scale setpoint.

• Dustproof, trouble-free mercury switch.

• Maximum surge pressure of 15 psi (103.4 kPa).

• All models have an adjustable subtractive differential.

• Adjustments are made by screws on top of case.

• Scaleplates are marked in English (psi) and metric

• Case has clear plastic cover so that pressure settings

• Leveling indicator visible through cover.

• Hexagonal fitting with 1/4-18 NPT internal threads for

• Can also be surface mounted by screws through holes

2

(kg/cm

and switch action can be observed.

direct mounting to the 14026 Steam Trap (siphon loop),

which is included.

(knockouts) in back of case.

) units.

® U.S. Registered Trademark

Copyright © 2003 Honeywell International Inc.

All Rights Reserved

Contents

Application ........................................................................ 1

Features ........................................................................... 1

Specifications ................................................................... 2

Ordering Information ........................................................ 2

Installation ........................................................................ 3

Wiring ............................................................................... 5

Setting and Checkout ....................................................... 6

Service Information .......................................................... 7

60-2158-5

Page 2

L408A,B; L608A VAPORSTAT® CONTROLLERS

SPECIFICATIONS

IMPORTANT

The specifications given in this publication do not

include normal manufacturing tolerances. Therefore,

this unit may not match the listed specifications

exactly. Also, this product is tested and calibrated

under closely controlled conditions, and some minor

differences in performance can be expected if those

conditions are changed.

Models:

L408A,B and L608A VaporStat® Controllers. See Tables 1, 2,

and 3 below. All models include a 14026 Steam Trap

(siphon loop), which is necessary for boiler installations.

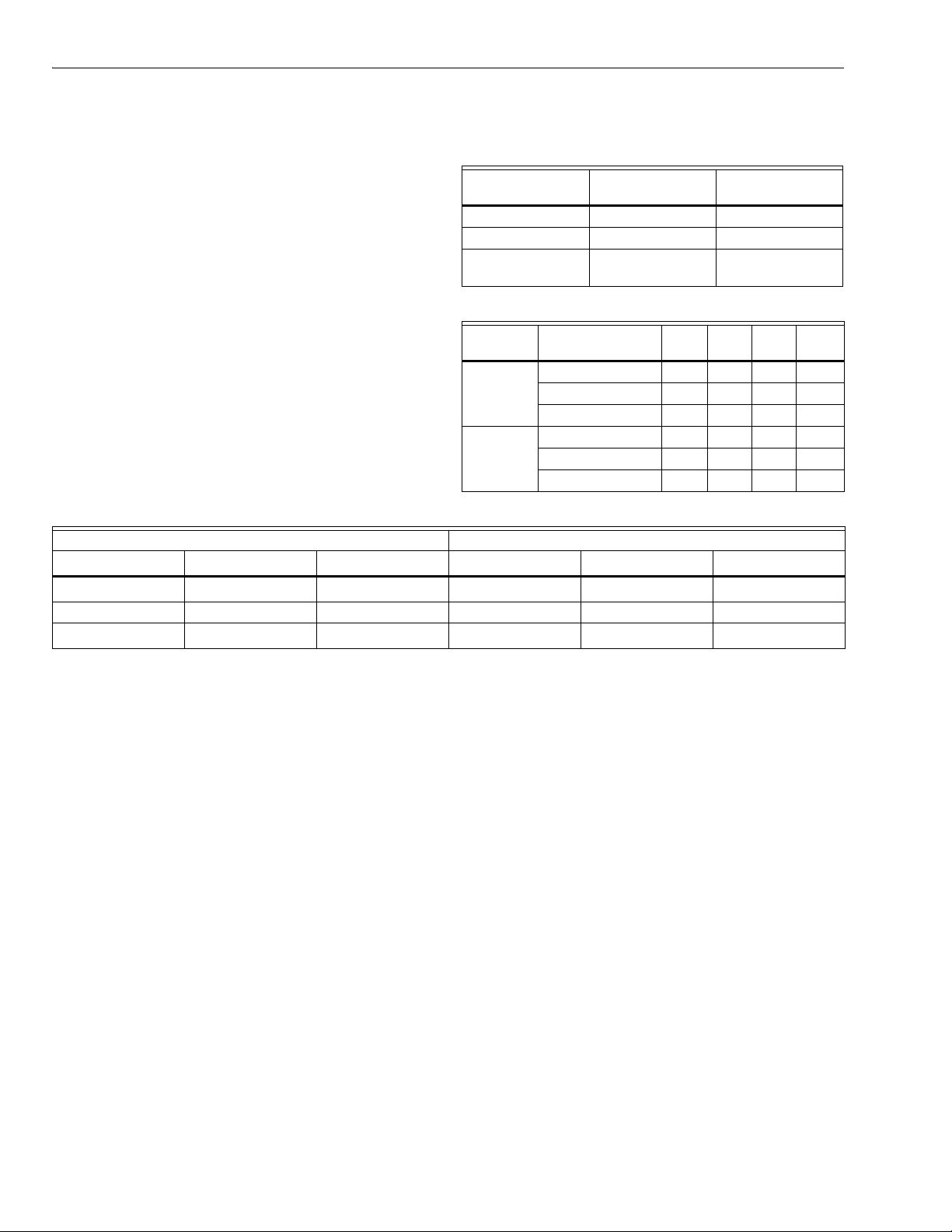

Table 3. Operating Ranges Available for All Models.

Pressure Ranges Midscale Subtractive Differential (Adjustable)

English Units kg/cm

0 to 16 oz/in.

0 to 4 psi 0 to 0.28 0 to 27.6 4 to 16 0.02 to 0.07 1.7 to 6.9

0 to 16 oz/in.

2

2

0 to.0.07 0 to 6.9 2 to 16 0.01 to 0.07 0.9 to 6.9

0 to 0.7 0 to 6.9 3.5 to 16 0.02 to 0.07 1.6 to 6.9

2

kPa oz/in.

Model Switch Type

L408A Spst Breaks

L408B Spst Makes

L608A Spdt Breaks R-B; makes

Table 2. Switch Contact Ratings (in amperes at 50/60 Hz).

Model Load

L408A,B Full Load 8.0 5.1 2.4 1.2

L608A Full Load 8.0 5.1 2.0 1.0

Table 1. Models Available.

Switch Action on

Pressure Rise

R-W.

120

240

Vac

Vac

Locked Rotor 48.0 30.6 24.0 12.0

Noninductive 10.0 5.0 5.0 2.0

Locked Rotor 48.0 30.6 20.0 10.0

Noninductive 10.0 5.0 8.0 4.0

2

kg/cm

2

120

Vdc

kPa

240

Vdc

Maximum Surge Pressure:

15 psi (1.05 kg/cm

Switch:

Mercury switch in all models.

Pressure Sensing Element:

Stainless steel diaphragm.

Maximum Ambient Temperature:

150°F (66°C).

2

or 103.4 kPa).

Minimum Ambient Temperature:

-35°F (-37°C); also refer to note under Location and Mounting

in the Installation section.

Adjustment Means:

Screws on top of controller case. Scales are marked in psi

and kg/cm

Electrical Connections:

Internal screw terminals; holes in side of case for 1/2 inch

conduit.

2

.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

60-2158—5 2

Page 3

L408A,B; L608A VAPORSTAT® CONTROLLERS

)

M19770

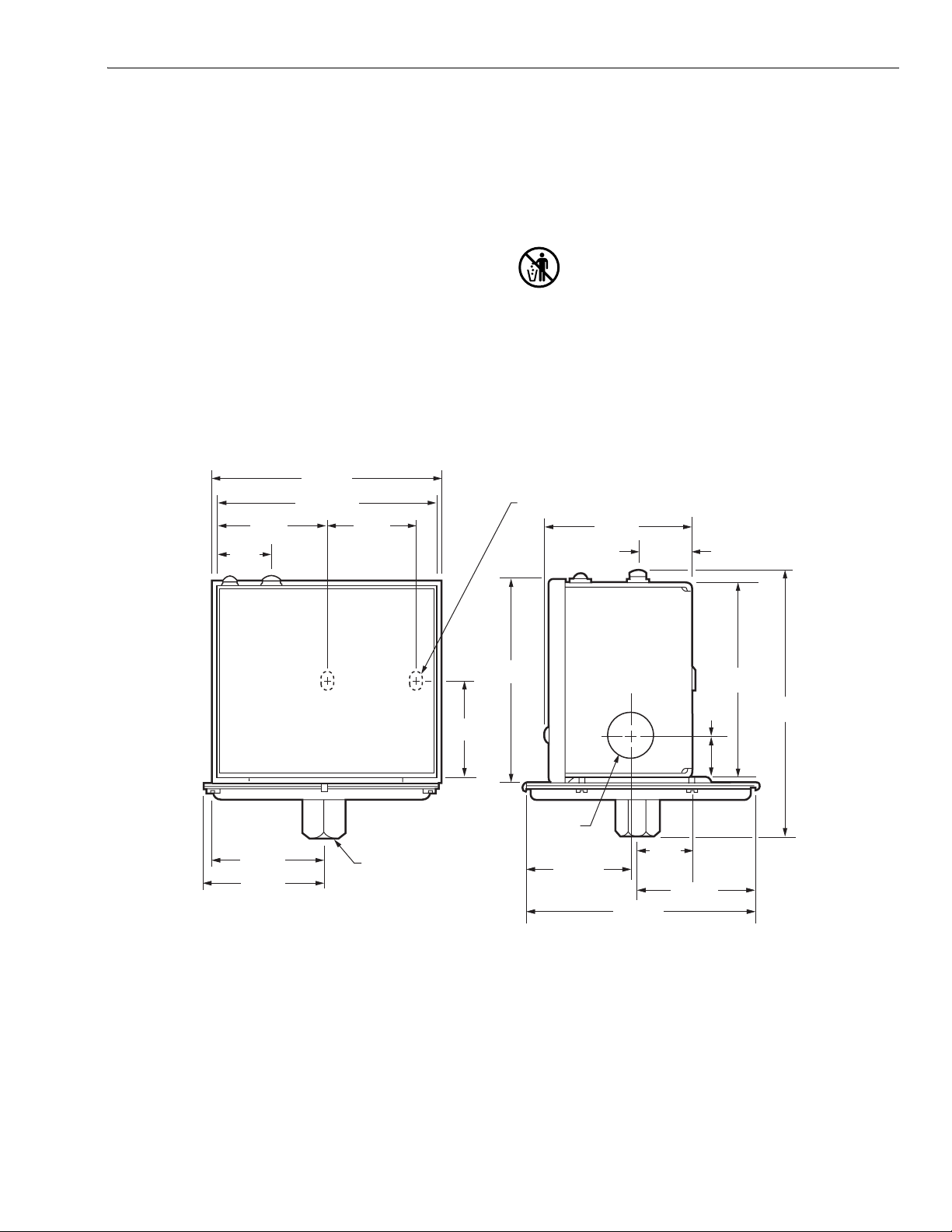

Mounting Means:

Hexagonal fitting on diaphragm has 1/4-18 NPT internal

threads for mounting on a pipe or steam trap (siphon loop).

Also can be surface mounted by screws through two holes

(knockouts) in back of case.

Dimensions:

See Fig. 1; also Fig. 2 for mounting steam trap (siphon loop).

Weight:

2 lb, 4 oz. (1.02 kg).

Finish:

Gray.

Approvals:

Underwriters Laboratories Inc. Listed: File No. MP466, Vol.

10; Guide No. MBPR.

Canadian Standards Association Certified: File No. LR1620;

Guide No. 400-E-0.

Replacement Parts:

129178 Thermoplastic Cover.

4-1/2 (114)

COVER

4-11/32 (110)

CASE

1-61/64

(50)

1-5/32

(29)

1-15/16

(49)

14026 Steam Trap (siphon loop)—1/4 inch black iron pipe;

included with all models.

Accessories:

33312B Knurled Adjustment Knob—with setscrew; fits on

main scale pressure adjusting screw.

4074BWJ Limit Stop Assembly—to limit setpoint ranges:

includes 129564 Range Stop, 107194 Range Stop Screw,

and 23466 Wrench.

MERCURY NOTICE

If this control is replacing a control that contains

mercury in a sealed tube, do not place your old control

in the trash. Dispose of properly. This control also

contains mercury in a sealed tube. It must also be

disposed of properly when it is replaced.

Contact your local waste management authority for

instructions regarding recycling and the proper

disposal of an old control.

3/16 (9) x 21/64 (8) KNOCKOUT (2)

2-3/4 (70)

1-1/16 (27)

1-13/16

2-1/8 (54)

2-1/4 (57)

1/4 – 18 NPT

Fig. 1. Mounting dimensions of the L408A,B and L608A VaporStat® controllers in inches

(millimeters in parentheses).

INSTALLATION

When Installing This Product…

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

(46)

3-7/8

(98)

7/8

(22) DIA.

1-3/16 (30)

product to make sure the product is suitable for your

application.

4-1/2 (114)

1-1/16

(27)

2-1/4 (57)

13/16

(21)

3-23/32

(95)

5-1/8

(130

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

3 60-2158—5

Page 4

L408A,B; L608A VAPORSTAT® CONTROLLERS

(

PRESSURE

A

WARNING

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

Disconnect the power supply before beginning

installation to prevent electrical shock or possible

equipment damage.

CAUTION

Equipment Damage Hazard.

Improper use with a compressor can damage the

controller.

When using the controller with a compressor, install a

dampening device (such as a needle valve, header, or

surge tank) to dampen pulsations that can damage the

controller or reduce its life.

IMPORTANT

1. Locate the controller where the ambient temperature

will not exceed 150°F (66°C).

2. Use pipe compound sparingly to avoid clogging the

hole in the pipe or diaphragm fitting.

3. Do not tighten the controller by hand by holding the

case.

4. The controller must be accurately leveled for proper

operation.

Location and Mounting

Leveling

A VaporStat® Controller must be accurately leveled for proper

operation. It is level when the leveling indicator hangs freely

with its pointer directly over the index mark inside on the back

of the case. Level the controller by carefully bending the

steam trap (siphon loop).

Mounting Alongside a Pressure Gauge

To mount the controller alongside a pressure gauge, remove

the gauge. In its place, install a steam trap (siphon loop) with a

tee on top. Using elbows and pipe nipples, mount the

controller and pressure gauge on the ends of the tee. See Fig.

2. Level the controller after installation.

GAUGE

1

2-1/4

(57.2)

DIA.

INCORRECT

4-1/2 TO 5-1/2

114.3 TO 139.7)

PRESSURE

CONTROLLER

TEE

CORRECT

14026

STEAM TRAP

(SIPHON LOOP)

NOTE: For most accurate operation, supplemental heat

BOILER

BOILER

should be added to installations where the

temperature falls below -20°F (-29°C). Never locate

1

the controller where the temperature falls below

-35°F (-37°C), as mercury in the switch will freeze at

this temperature.

When used with steam boilers, always mount the controller

above the water line in the boiler. A steam trap (siphon loop)

must always be connected between the controller and the

Fig. 2. Correct and incorrect mounting of a steam trap

(siphon loop) with approximate dimensions in inches

1/4 IN. BLACK IRON PIPE WITH 1/4 - 18 NPT EXTERNAL

TRHEADS ON BOTH ENDS. BEND THE STEAM TRAP

(SIPHON LOOP) TO LEVEL THE CONTROLLER.

(millimeters in parentheses).

M8934

boiler (see Fig. 2) to prevent boiler scale and corrosive vapors

from attacking the diaphragm. The loop on the steam trap

must always be perpendicular to the face of the controller. If

the loop is parallel to the controller, expansion or contraction

of the loop will tip the controller and cause the switch to

operate inaccurately.

The controller can be mounted (1) alongside the pressure

gauge, (2) in a fitting on the boiler provided by the

manufacturer, (3) at a remote location in case of excessive

vibration, or (4) in a special mounting on a low water cutoff.

Make all pipe connections in accordance with approved

standards. When making pipe connections, use pipe

compound sparingly to seal the joints. Excess pipe compound

may clog the small hole in the fitting and prevent the controller

from operating properly. To avoid leaks and damage to the

case, use a parallel jaw wrench on the controller hexagonal

Mounting on a Boiler

If it is not convenient to mount the controller alongside the

pressure gauge, install a steam trap (siphon loop) in the fitting

provided by the boiler manufacturer. Screw the controller

directly on the steam trap and level the controller.

Mounting at a Remote Location

If there is excessive vibration at the boiler which may

adversely affect the operation of the controller, the controller

should be mounted at a remote location.All piping from the

boiler must be suitable and solidly mounted. The piping must

be properly pitched to drain all condensation back to the

boiler. A steam trap (siphon loop) must be mounted between

the remote piping and the controller. Level the controller after

installation.

fitting. Do not tighten the controller by hand by holding the

case.

60-2158—5 4

Page 5

L408A,B; L608A VAPORSTAT® CONTROLLERS

L

(

D

D

SPDT

WIRING

WARNING

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

Disconnect the power supply before beginning wiring.

More than one disconnect may be required.

1. All wiring must comply with applicable electrical codes,

ordinances and regulations. Use NEC Class 1 (line

voltage) wiring.

2. For normal installations, use moisture-resistant NO. 14

wire suitable for at least 167°F (75°C) if you are using

the controller with a flame safeguard primary control or

at least 194°F (90°C) if you are using it with a

programming control.

3. For high temperature installations, use moisture-

resistant No. 14 wire, selected for a temperature rating

above the maximum operating temperature.

4. Disconnect the power supply before beginning wiring to

prevent electrical shock and equipment damage.

5. All models have a terminal block inside the cover (see

Fig. 3) and a 7/8 in. (22 mm) hole in one side for 1/2 in.

(13 mm) conduit, cable or wires. Remove the front cover

by loosening the screw at the bottom of the main scale.

6. Refer to Fig. 4 through 7 for typical hookups. Follow the

burner or boiler manufacturer wiring diagram, if

provided.

7. Make sure the loads do not exceed the Switch Contact

ratings in the Specifications section.

8. Replace the front cover when wiring is complete.

RISE

RISE

RISE

SPST

CONTROLLER

2

L1

(HOT)

POWER

SUPPLY

L2

1

L2

1

PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION

AS REQUIRED.

HIGH LIMIT–L408A BREAKS WHEN PRESSURE RISES TO SET POINT.

2

LOW LIMIT–L408B BREAKS WHEN PRESSURE FALLS TO SET POINT

MINUS DIFFERENTIAL.

OPERATING CONTROLER–L408A BREAKS WHEN PRESSURE RISES

TO SET POINT, AND MAKES AGAIN WHEN PRESSURE FALLS TO

SET POINT MINUS DIFFERENTIAL.

FLAME

SAFEGUARD

CONTROL,

MOTOR, OR

OTHER LOAD

M19772

Fig. 4. L408 used as a limit or as an operating controller.

CONTROLLER

(HIGH LIMIT)

2

B

W

R

1

HOT)

POWER

SUPPLY

L2

1

L2

ALARM

FLAME

SAFEGUAR

CONTROL,

MOTOR, OR

OTHER LOA

1

PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION

W

R

B

L408A L408B L608A

BREAKS ON

PRESSURE

RISE TO

SETPOINT

Fig. 3. L408A,B and L608A terminal blocks and internal

MAKES ON

PRESSURE

RISE TO

SETPOINT

schematics.

BREAKS R-B,

MAKES R-W ON

PRESSURE RISE

TO SETPOINT

M19771

Fig. 5. L608A used as a high limit, with an alarm circuit.

AS REQUIRED.

BREAKS R TO B AND MAKES R TO W WHEN PRESSURE

2

RISES TO SETPOINT.

M8938

5 60-2158—5

Page 6

L408A,B; L608A VAPORSTAT® CONTROLLERS

L

(

D

D

SPDT

9

MAIN SCALE SETPOINT

L

L

))

)

3

L

Y

MAIN SCALE

S

CONTROLLER

(LOW LIMIT)

2

B

W

R

1

HOT)

POWER

SUPPLY

L2

1

L2

FLAME

SAFEGUAR

CONTROL,

MOTOR, OR

OTHER LOA

the differential adjusting screw until the differential setting

indicator is at the desired value. The scales are marked in psi

and kg/cm

408A

2

.

PRESSURE

RISE

(SWITCH BREAKS)

SUBTRACTIVE

DIFFERENTIAL

DIFFERENTIAL SETTING

(SWITCH MAKES)

MAIN SCALE SETPOINT

(SWITCH MAKES)

ALARM

1

PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION

AS REQUIRED.

BREAKS R TO W AND MAKES R TO B WHEN PRESSURE

2

FALLS TO SETPOINT MINUS DIFFERENTIAL.

M8937

Fig. 6. L608A used as a low limit, with an alarm circuit.

SPDT

CONTROLLER

W

2

B

L1

(HOT)

POWER

SUPPLY

1

2

1

L2

PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION

AS REQUIRED.

BREAKS R TO B AND MAKES R TO W WHEN PRESSURE

RISES TO SETPOINT.

WHITE

RED

R

BLUE

BLACK

BLACK

LINE VOLTAGE

TWO-POSITION MOTOR

CLOSED

W1

(LOW FIRE)

R1

OPEN

B1

(HIGH FIRE)

L1

L2

M644B

M893

Fig. 7. L608A controlling an M644B Motor.

408B

608A

PRESSURE

RISE

PRESSURE

RISE

SUBTRACTIVE

DIFFERENTIAL

DIFFERENTIAL SETTING

(SWITCH BREAKS)

MAIN SCALE SETPOINT

(BREAKS R-B, MAKES R-W

SUBTRACTIVE

DIFFERENTIAL

DIFFERENTIAL SETTING

(MAKES R-B, BREAKS R-W

Fig. 8. L408A,B and L608A operating points.

DIFFERENTIAL

ADJUSTING

SCREW

CALEPLATES

DIFFERENTIAL

SETTING

INDICATOR

DIFF.

MAIN

3.5

3

12

.8

10

2.5

.7

.6

2

8

.5

1.5

6

.4

.3

4

1

.2

2

.5

.1

0

PSI

50

40

30

20

10

0

ADJUSTING

SCREW

M1977

MERCUR

SWITCH

SETTING AND CHECKOUT

Setting

In all models, the differential is subtractive from the main scale

setpoint. The upper operating point is determined by the main

scale setpoint, while the lower operating point is determined

MAIN SCALE

SETTING

INDICATOR

DIAPHRAGM

ASSEMBLY

LEVELING

INDICATOR

Fig. 9. Setting a VaporStat® Controller.

INDEX

MARK

POINTER

M19774

by the main scale setting less the differential setting.

Operating points are shown in Fig. 8.

Adjust the main scale setpoint for the desired operating

pressure by turning the main scale adjusting screw (see Fig.

9) on the top of the case until the main scale setting indicator

is at the desired value. Adjust the differential setting by turning

60-2158—5 6

Checkout

After the controller has been installed, wired, and set, it should

be tested with the system in operation. First allow the system

to stabilize. Then observe the operation of the controller while

rasing and lowering its setpoint. Pressure should increase

when the setpoint is raised and decrease when the setpoint is

lowered.

Page 7

Also check the make and break points of the controller. If they

M19775

do not agree with a separate, accurately calibrated, pressure

gauge, a slight adjustment of the scaleplate(s) may be

necessary.

Use accurate pressure testing equipment when checking out

the controller. Do not rely on inexpensive gauges. The

controllers are carefully calibrated at the factory.

Boiler Installation

If the controller is being used on a boiler installation, test it as

follows:

1. Note the boiler pressure by checking the boiler pressure

gauge. (To perform this test properly, the boiler should

have a pressure reading near the middle of the

controller main scale range.)

2. Turn the main scale adjusting screw (see Fig. 9) until

the main scale setting indicator on the controller

corresponds to the boiler pressure gauge reading.

3. The L408A should break the control circuit automatically

when the boiler pressure gauge reading equals or

slightly exceeds the controller setting.

OHMMETER

L408A,B; L608A VAPORSTAT® CONTROLLERS

DIFF.

MAIN

50

3.5

3

12

40

.8

10

2.5

.7

.6

30

2

8

.5

1.5

6

.4

20

.3

4

1

.2

10

2

.5

.1

0

0

PSI

W

R

B

SET POINT

DECREASE

NOTE: The L408B should make the circuit under the same

circumstances. The L608A should make the R-W

and break the R-B circuit under the same

circumstances.

4. If the controller is operating properly, turn the main scale

adjusting screw (see Fig. 9) until the main scale setting

indicator is at the desired setpoint.

If a Controller Seems to Operate Improperly

If the controller is suspected of operating improperly, it may be

checked further as follows (see Fig. 10):

1. Disconnect all power to the controller, loosen the cover

screw and remove the cover.

2. Disconnect the wires from the controller.

3. Connect an ohmmeter between the switch terminals.

4. Lower the setpoint of the controller (simulating a

pressure increase) through a range greater than the

differential. The switch should either make or break,

depending on the model of the controller. (An L408A

should break, an L408B should make, and an L608A

should break R-B and make R-W.) If it makes, the

ohmmeter will read zero; if it breaks, the ohmmeter will

read infinity.

5. Raise the setpoint of the controller (simulating a

pressure decrease) through a range greater than the

differential. The switch should break or make, just the

opposite of the result in step 4.

ZERO

ADJ

AN L608A IS SHOWN. AN L408 HAS ONLY 2 TERMINALS (SPST

1

SWITCHINGS); AN L408A WILL BREAK AND AN L408B WILL MAKE

WHEN THE SET POINT IS DECREASED FAR ENOUGH.

(ZERO OHMS WHEN R-W MAKES)

Fig. 10. Checking a VaporStat

INFINITY

®

controller.

CAUTION

Equipment Damage Hazard.

Failure to follow checkout instructions can

damage components or systems.

Do not put the system into service until you have

satisfactorily completed all applicable tests described

in this Checkout section, in the Checkout section of

the applicable instruction sheet for the flame

safeguard control,

SERVICE INFORMATION

Calibration

The controller was carefully calibrated during manufacture

and should not require recalibration. Most calibration errors

are caused by improper leveling. The controller should be

level if the pointer on the leveling indicator is directly over the

index mark (see Fig. 9). In some cases, the leveling indicator

may not be accurate enough. The pointer may be over the

index mark but the controller still may not be operating within

the tolerance of its scale setting. In that case, carefully bend

the steam trap (siphon loop) until the controller switches

properly.

7 60-2158—5

Page 8

L408A,B; L608A VAPORSTAT® CONTROLLERS

Maintenance

The cover of the controller should be in place at all times to

protect the internal components for dirt, dust, and physical

damage. Routine maintenance should consist of occasional

inspection and blowing or brushing away an accumulated dirt

and dust. To ensure proper functioning of the controller at all

times, an operational check of the entire system should be

performed during routine maintenance checks.

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Scarborough, Ontario

60-2158—5 G.R. Rev. 10-03 www.honeywell.com

M1V 4Z9

Printed in U.S.A. on recycled

paper containing at least 10%

post-consumer paper fibers.

Loading...

Loading...