Page 1

IS4910, IS4911

Area Imaging Non-Decode Engine

Integration Guide

Page 2

Disclaimer

Honeywell International Inc. (“HII”) reserves the right to make changes in specifications and other information

contained in this document without prior notice, and the reader should in all cases consult HII to determine

whether any such changes have been made. The information in this publication does not represent a

commitment on the part of HII.

HII shall not be liable for technical or editorial errors or omissions contained herein: nor for incidental or

consequential damages resulting from the furnishing, performance, or use of this manual.

This document contains propriety information that is protected by copyright. All rights reserved. No part of this

document may be photocopied, reproduced, or translated into another language without the prior written

consent of HII.

© 2009 Honeywell International Inc. All rights reserved.

Web Address: www.honeywell.com/aidc

Trademarks

Metrologic, MetroSelect, MetroSet2, Omniplanar, and FirstFlash are trademarks or registered trademarks of

Metrologic Instruments, Inc. or Honeywell International Inc.

Microsoft, Windows, and Windows 95 are trademarks or registered trademarks of Microsoft Corporation.

Molex, FFC/FPC, and SlimStack are trademarks or registered trademarks of Molex, Inc.

Other product names mentioned in this manual may be trademarks or registered trademarks of their respective

companies and are the property of their respective owners.

Patents

Please refer to page 32 for a list of patents.

Page 3

Table of Contents

Introduction

Product Overview ..............................................................................................................................................1

Models and Accessories ...................................................................................................................................2

Components of the IS4910 / IS4911 Non-Decode Engine................................................................................3

Labels................................................................................................................................................................4

Mounting Specifications

IS4910-00 / IS4911-00 Non-Decode Engine Dimensions .................................................................................5

IS4910-01 / IS4911-01 Non-Decode Engine Dimensions .................................................................................6

IS4910-02 / IS4911-02 Non-Decode Engine Dimensions .................................................................................7

Enclosure Specifications

Electrostatic Discharge (ESD) Cautions ........................................................................................................8

Airborne Contaminants and Foreign Materials...............................................................................................8

Output Window Properties .............................................................................................................................9

Output Window Coatings ...............................................................................................................................9

Optical Clearance Specifications .................................................................................................................10

System Considerations

Power Supply Decoupling ...............................................................................................................................11

Power Sequencing .......................................................................................................................................... 11

High-Speed Digital Bus ...................................................................................................................................11

Thermal Considerations ..................................................................................................................................11

Theory of Operation

Overview .........................................................................................................................................................12

Snapshot Mode ............................................................................................................................................... 14

Snapshot Illumination Waveforms................................................................................................................15

Video Mode ..................................................................................................................................................... 16

Targeting .........................................................................................................................................................16

I2C Interface....................................................................................................................................................16

Camera Bus Timings.......................................................................................................................................17

Wake Up Timing..............................................................................................................................................18

Electrical Specifications...................................................................................................................................19

ii

Page 4

Depth of Field vs. Bar Code Element

IS4910 ............................................................................................................................................................. 20

IS4911 ............................................................................................................................................................. 21

Design Specifications

Operational......................................................................................................................................................22

Mechanical ...................................................................................................................................................... 23

Electrical..........................................................................................................................................................23

Environmental .................................................................................................................................................24

Imaging Engine Terminations

IS4910 / IS4911 Pinout Connections...............................................................................................................25

Flex Cable Specifications

Pinout, Host End .............................................................................................................................................26

Dimensions......................................................................................................................................................27

Installation Notes.............................................................................................................................................28

Regulatory Compliance

Safety ..............................................................................................................................................................29

Europe..........................................................................................................................................................29

United States................................................................................................................................................30

Canada.........................................................................................................................................................30

LIMITED WARRANTY .............................................................................................................................................31

Patents...............................................................................................................................................................32

Index ..................................................................................................................................................................33

Contact Information..........................................................................................................................................35

Product Service and Repair.............................................................................................................................36

iii

Page 5

Introduction

Product Overview

The IS4910 series of non-decode miniature area imaging engines is designed for integration into customer

OEM devices. When integrated with a host processor and decoding software from Omniplanar

®

, the engine

can be used to capture images for decoding 1D and 2D bar codes in addition to OCR fonts.

The compact engine has several models available to accommodate all types of mounting requirements. All

model types provide two blind holes for self-tapping screws along with a keying location point. The IS4910-01

model provides two additional through holes located on tabs extended from the sides of the engine's chassis

and the IS4910-02 provides threaded inserts instead of through holes on the extended tabs.

The engine's physical design and low power requirements support integration into portable data terminals,

hand-held bar code scanners, ID verification devices, kiosks, portable-shopping systems, mass-storage

devices, lottery terminals, and medical/diagnostic devices.

A high-density version, IS4911 is also available.

Additional key features include:

• Designed to scan 1D bar codes as dense as 4 mil (0.102 mm) and 2D bar codes as dense as 10 mil

(0.254 mm; Matrix codes)

• High resolution (1280 × 960 pixels)

• The ability to switch between Snapshot and Video modes for different applications

• Capture and transmit high-quality black and white images

®

• FirstFlash

circuitry which automatically adjusts to environmental illumination for excellent light immunity

• Built-in aiming for easy scanning

• Standby mode for power conservation

• Low mass (< 6 g)

• Industrial standard output for seamless integration, Molex

P/N 55560-0227

• A choice of mounting options

®

0.50 mm (.020") Pitch SlimStack™ Plug,

1

Page 6

Models and Accessories

Model Description

Non-Decode Area Imaging Engine

IS4910

or

IS4911

77-77104

-00

-01

-02

Mounting option:

• two blind holes for self-tapping screws

Non-Decode Engine

Mounting options:

• two blind holes for self-tapping hardware

• two through holes located on tabs that extend from two sides of the engine's

chassis

Non-Decode Engine

Mounting options:

• two blind holes for self-tapping hardware

• threaded inserts located on tabs that extend from two sides of the engine's chassis

Flex Cable, 22-Pin, 0.50 mm (.020") Pitch SlimStack™ Receptacle,

Molex P/N 54722-0224

See page 26 for additional flex cable information.

46-00550

Software Development Kit

For detailed information on this item, contact a customer service representative

Molex and SlimStack are trademarks or registered trademarks of Molex, Inc.

2

Page 7

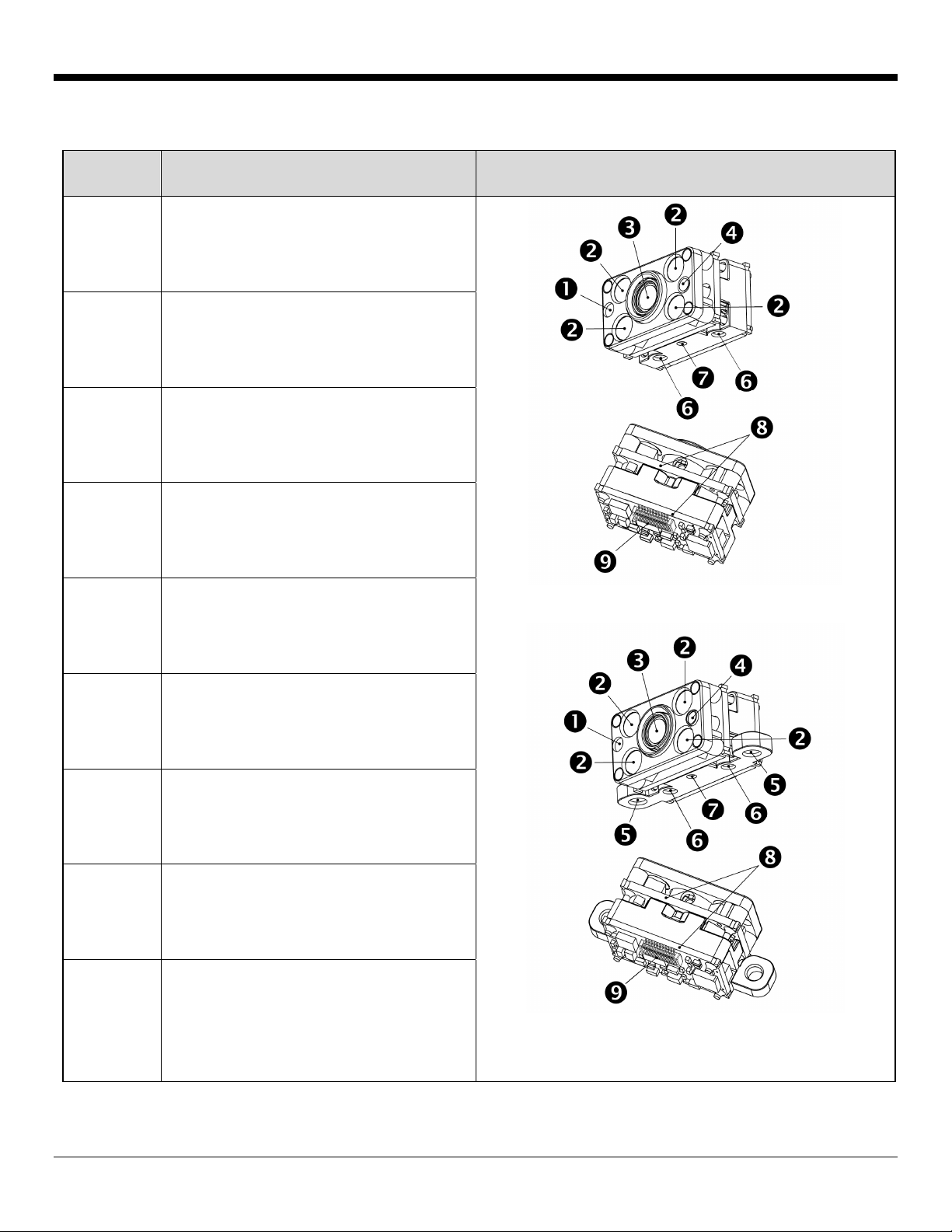

Components of the IS4910 / IS4811 Non-Decode Engine

Item No. Description Item Location

1 Targeting

2 Area Illumination

3 Camera Imager

4 FirstFlash Aperture

5 Mounting Points (see pages 6 - 7)

6

Mounting Points Provided for

Self-Tapping Screws (see pages 5 - 7)

7 Keying Location (see pages 5 - 7)

8 Printed Circuit Boards

Figure 1. IS4910-00 / IS4911-00

22-Pin, 0.50 mm (.020") Pitch

9

SlimStack™ Plug, Molex

(P/N 55560-0227)

Figure 2. IS4910-01 / IS4910-02

IS4911-01 / IS4911-02

Molex and SlimStack are trademarks or registered trademarks of Molex, Inc.

3

Page 8

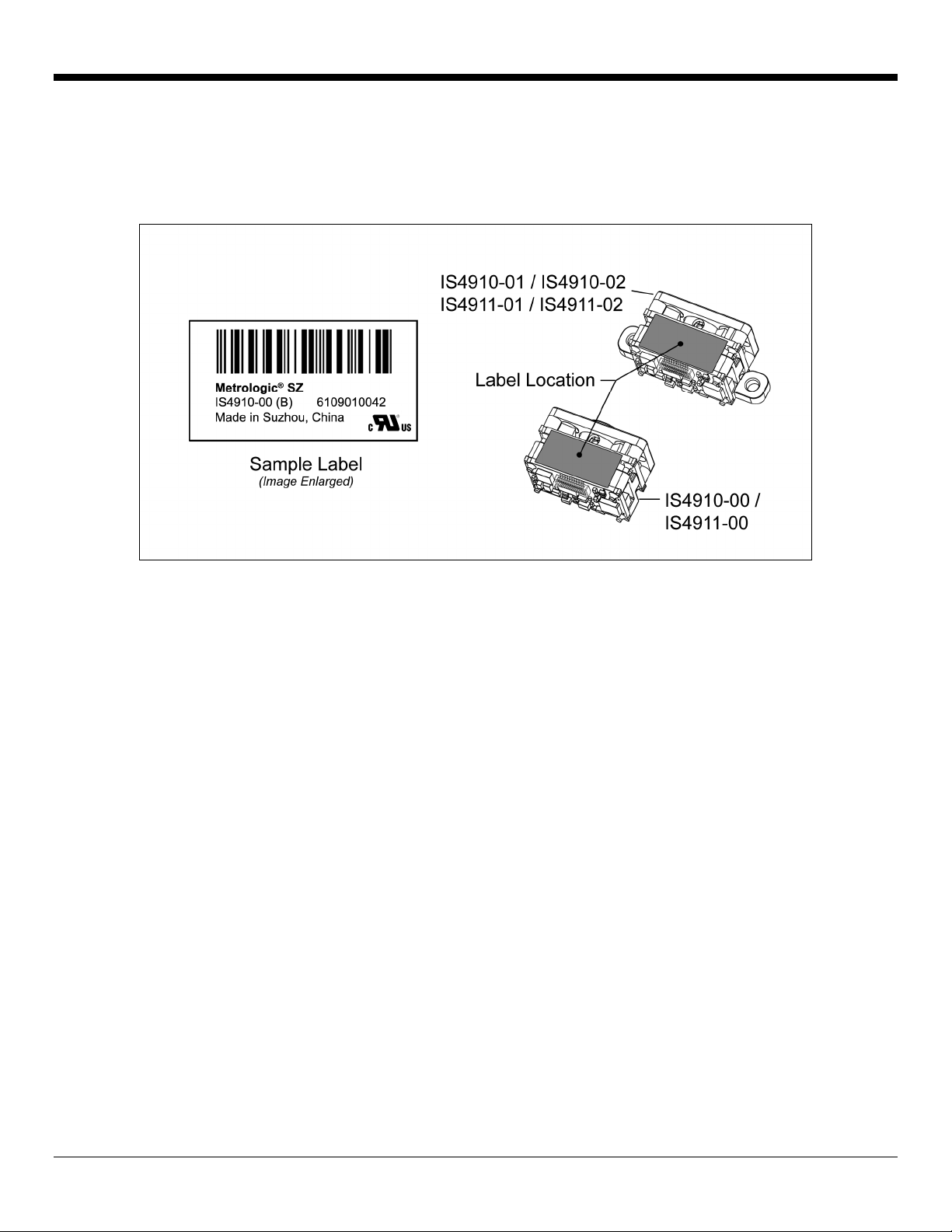

Labels

The engine’s serial number/model number label is located on the side of the engine.

Figure 3. Serial Number Label

4

Page 9

Mounting Specifications

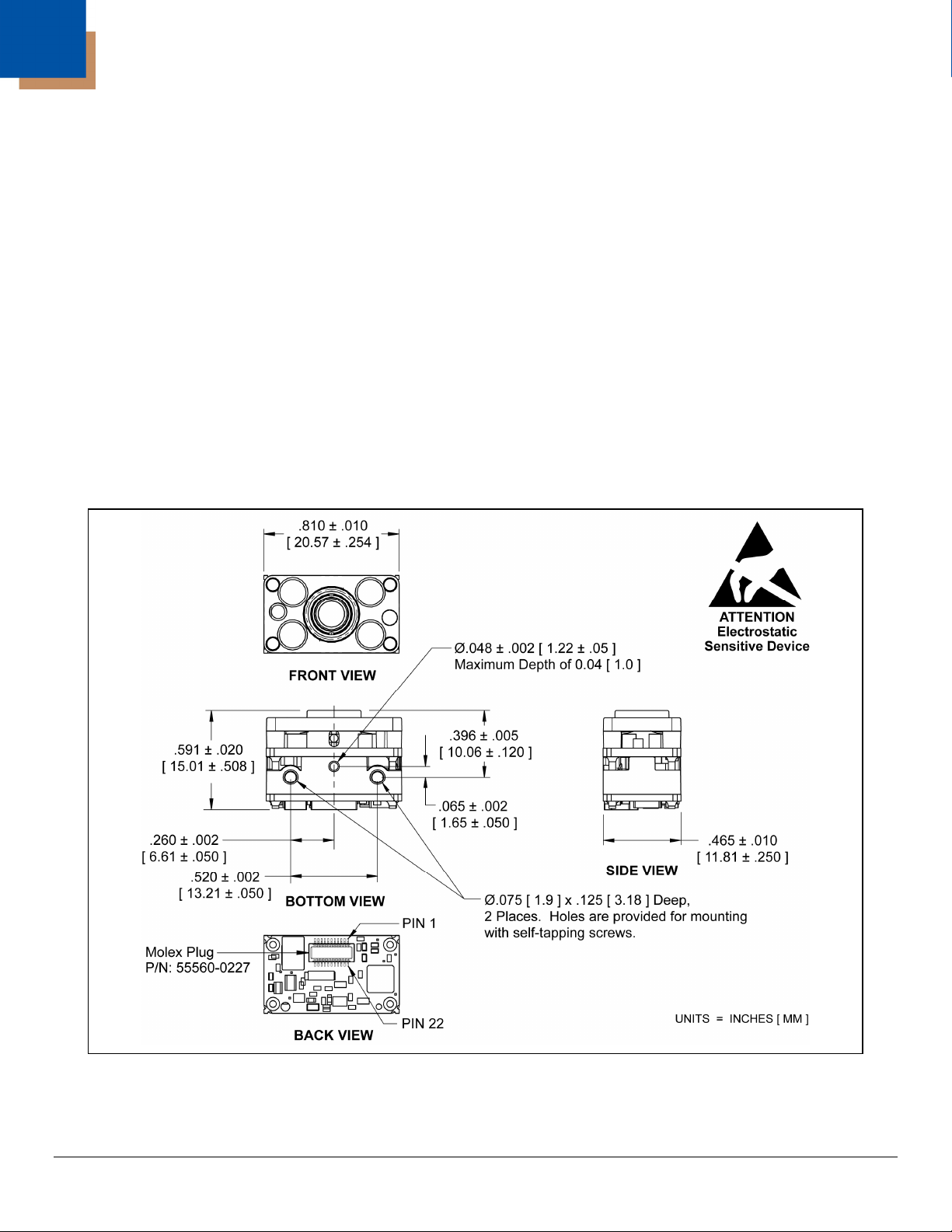

IS4910-00 / IS4911-00 Non-Decode Engine Dimensions

The -00 engine model includes two Ø .075" [1.9 mm] blind holes for mounting the engine with self-tapping

screws. The mounting holes are located on the bottom of the unit with an additional keying location point for

engine alignment.

Warning: The limited warranty (on page 31) is void if the following guidelines are not adhered to when

mounting the engine.

When securing the engine with self-tapping screws:

• Use M2.2 x 4.5 Philips pan head, type AB, Steel, zinc clear, Trivalent self-tapping screws.

• Do not exceed 1.75 +0.5 in-lb [2.02 +6 cm-kg] of torque during screw installation.

• Use a minimum mount thickness of 0.3 mm.

• Use safe ESD practices when handling and mounting the engine.

Figure 4. IS4910-00 / IS4911-00 Dimensions

5

Page 10

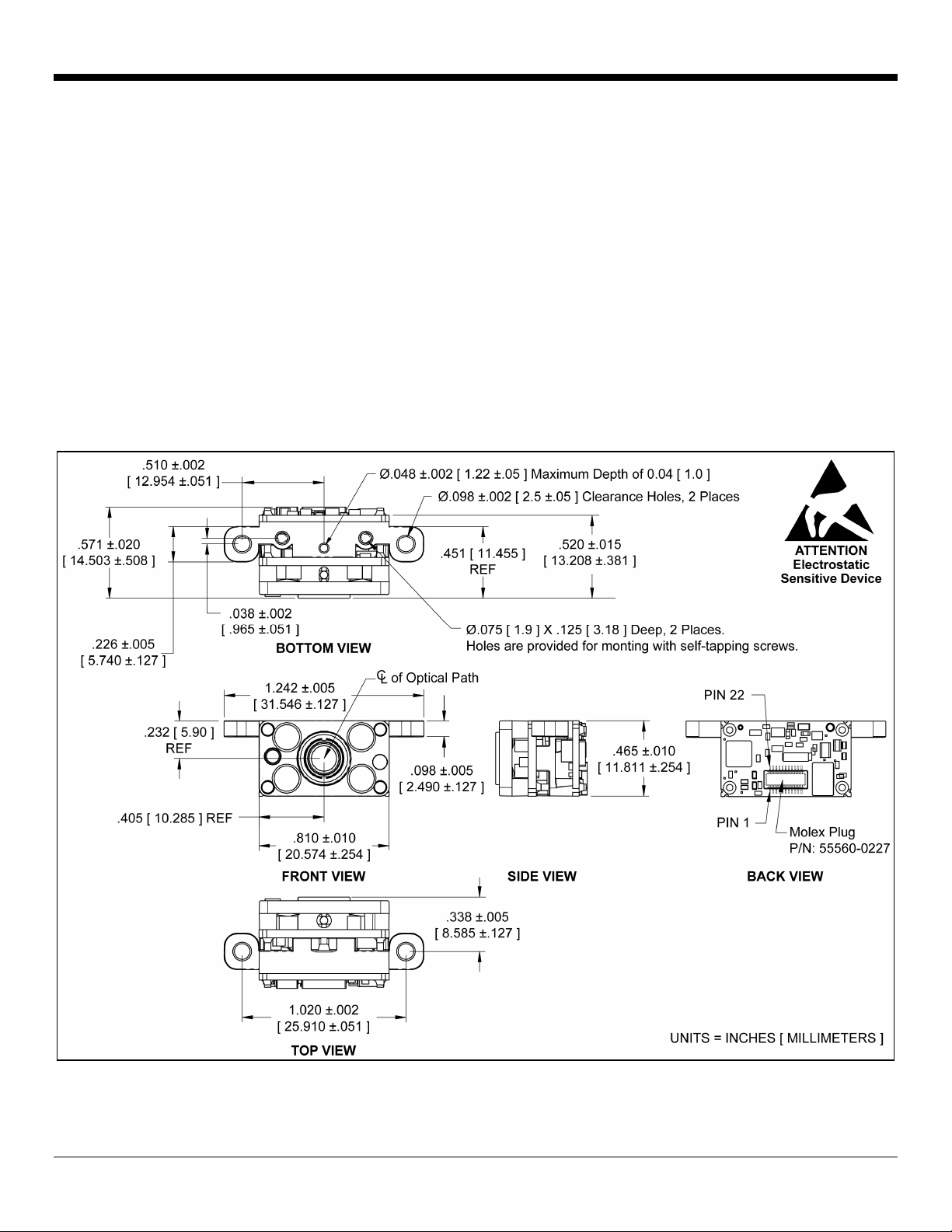

IS4910-01 / IS4911-01 Non-Decode Engine Dimensions

The -01 engine model includes two Ø .075" [1.9 mm] blind holes for mounting the engine with self-tapping

screws. Two additional Ø .098" ± .002 [2.5 mm ±.05 mm] clearance holes are provided as a secondary

mounting option. The clearance holes are located on tabs that extend from the sides of the engine's chassis.

A keying location point is provided on the bottom of the engine to assist with alignment.

Warning: The limited warranty (on page 31) is void if the following guidelines are not adhered to when

mounting the engine.

When securing the engine with self-tapping screws:

• Use M2.2 x 4.5 Philips pan head, type AB, steel, zinc clear, Trivalent self-tapping screws.

• Do not exceed 1.75 +0.5 in-lb [2.02 +6 cm-kg] of torque during screw installation.

• Use a minimum mount thickness of 0.3 mm.

• Use safe ESD practices when handling and mounting the engine.

6

Figure 5. IS4910-01 / IS4911-01 Dimensions

Page 11

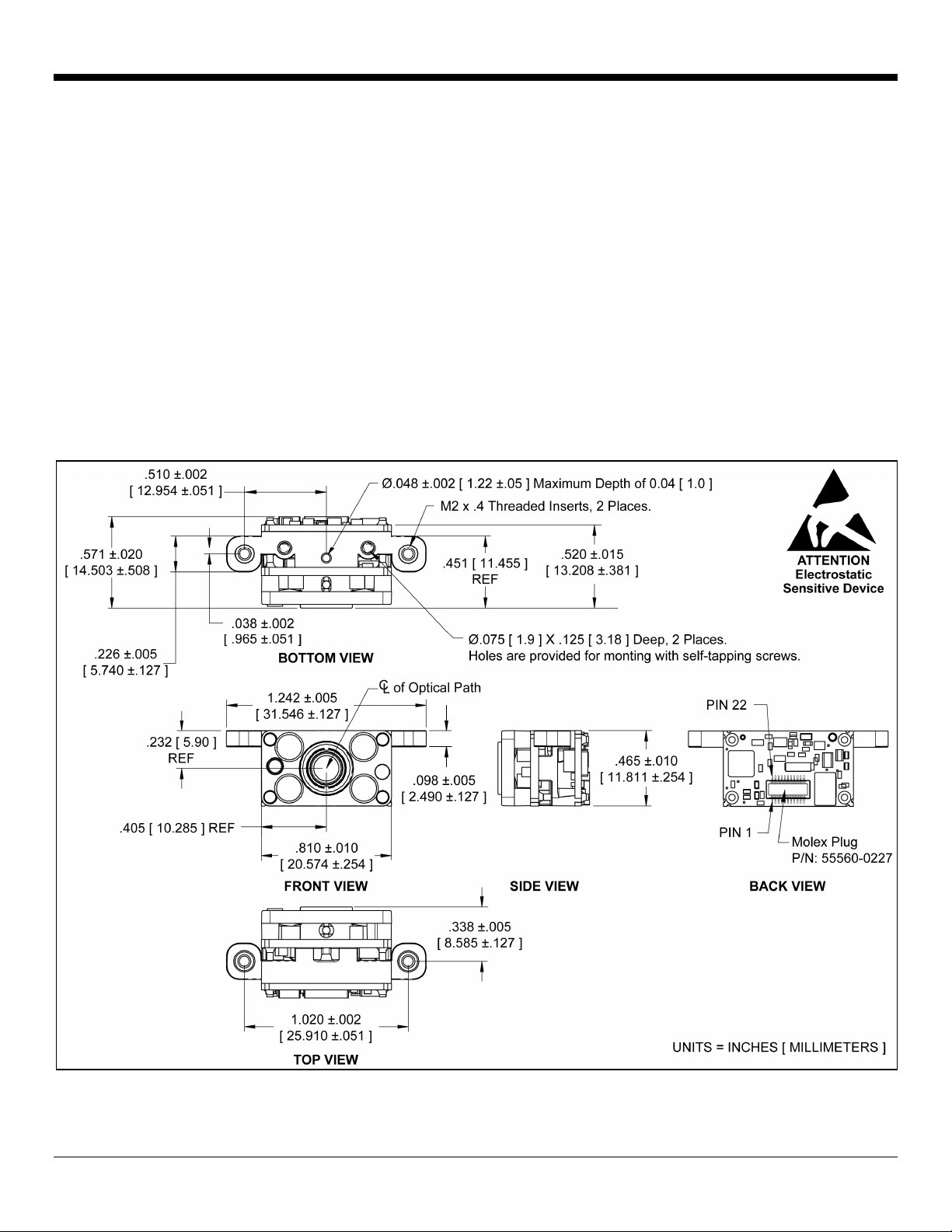

IS4910-02 / IS4911-02 Non-Decode Engine Dimensions

The -02 engine model includes two Ø .075" [1.9 mm] blind holes for mounting the engine with self-tapping

screws. Two additional M2 x .4 threaded inserts are provided as a secondary mounting option. The threaded

inserts are located on tabs that extend from the sides of the engine's chassis. A keying location point is

provided on the bottom of the engine to assist with alignment.

Warning: The limited warranty (on page 31) is void if the following guidelines are not adhered to when

mounting the engine.

When securing the engine by utilizing the two M2 threaded inserts:

• Use M2.2 x 4.5 Philips pan head, type AB, steel, zinc clear or equivalent screws.

• Do not exceeding 2.88 cm-kg [2.5 in-lb] of torque when securing the engine assembly to the host.

• Use a minimum mount thickness of 0.3 mm.

• Use safe ESD practices when handling and mounting the engine.

Figure 6. IS4910-02 / IS4911-02 Dimensions

7

Page 12

Enclosure Specifications

The imaging engine was specifically designed for integration into custom housings for OEM applications. The

imaging engine’s performance will be adversely affected or permanently damaged when mounted in an

unsuitable enclosure.

Warning: The limited warranty (on page 31) is void if the following considerations are not adhered to when

integrating the engine into a system.

Electrostatic Discharge (ESD) Cautions

All imaging engines are shipped in ESD protective packaging due to the sensitive nature of the

engine's exposed electrical components.

• ALWAYS use grounding wrist straps and a grounded work area when unpacking

and handling the engine.

• Mount the engine in a housing that is designed for ESD protection and stray electric fields.

ESD has the ability to modify the electrical characteristics of a semiconductor device, possibly

degrading or even destroying the device. ESD also has the potential to upset the normal operation

of an electronic system, causing equipment malfunction or failure.

Airborne Contaminants and Foreign Materials

The imaging engine has very sensitive miniature electrical and optical components that must be protected from

airborne contaminants and foreign materials. In order to prevent permanently damaging the imaging engine

and voiding the limited warranty (on page 31), the imaging engine enclosure must be:

• Sealed to prevent infiltration by airborne contaminants and foreign materials such as,

dust, dirt, smoke, and smog.

• Sealed to protect against water, humidity and be non-condensing.

Refer to page 11 for information on power and thermal considerations.

8

Page 13

Output Window Properties

An improperly placed window has the serious potential to reduce the imaging engine’s performance.

Careful consideration must be made when designing the output window’s distance and angle relative

to the imaging engine’s camera aperture.

Follow these guidelines when designing the output window.

• The output window material should have a spectral transmission of at least 85% from 580 nm to

680 nm and should block shorter wavelengths.

• It should have a 60-40 surface quality, be optically flat, clear, and free of scratches, pits, or seeds.

If possible, recess the window into the housing for protection or apply a scratch resistance coating

(see Output Window Coatings below).

• Apply an anti-reflective coating to the window surfaces to reduce the possibility of reflective light

interfering with the engine’s performance.

• The clear aperture of the output window should extend beyond the Field of View. Refer to page 10

and pages 20 - 21 for Field of View specifications.

• The window size must accommodate the illumination and targeting areas shown on page 10.

• The window must be parallel to the engine face.

• The distance from the engine face to the inside surface of the window of the enclosure should be

minimized and should not exceed 0.5 mm (0.02") due to possible specular reflections from internal

area illumination.

Output Window Coatings

• Anti-Reflection

An anti-reflective coating can be applied to the inside and/or outside of the window to reduce the

possibility of internal beam reflections interfering with the performance of the engine. If an antireflective coating is applied, it is recommended that it be on both sides of the window providing a

0.5% maximum reflectivity on each side from 600 - 700 namometers at the nominal window tilt angle.

The coating must also meet the hardness adherence requirements of MIL-M-13508.

• Polysiloxane Coating

Applying a polysiloxane coating to the window surface can help protect the window from surface

scratches and abrasions that may interfere with the performance of the engine. Recessing the window

into the housing can also provide added protection against surface damage such as scratches and

chips. If an anti-reflective coating is used, there is no need to apply a polysiloxane coating.

9

Page 14

Optical Clearance Specifications

The window size and enclosure design must provide unobstructed clearance for the illumination and targeting

areas shown below to avoid optical interference that decreases the engine's performance.

IS4910

IS4911

Figure 7. IS4910 Optical Clearance Specifications

Figure 8. IS4911 Optical Clearance Specifications

Specifications are subject to change without notice.

10

Page 15

System Considerations

In order to ensure proper operation of the decode engine’s electrical system; care must be taken to ensure the

following requirements are met.

Power Supply Decoupling*

The engine requires clean filtered power supplies for both the VLED and Vimager power rails. Special care

must be taken for the Vimager line as this voltage is used to power the imaging sensor. The power line must

be heavily decoupled to prevent noise from coupling into the engine, which can reduce image quality.

Power Sequencing*

All signals to and from the engine (except for VLED) are relative to Vimager. These pins are not over voltage

tolerant. As such, care must be taken to ensure that the voltage on these signals never exceed the voltage on

the Vimager pin.

Refer to page 11 for additional electrical specifications and page 25 for pinout information.

High-Speed Digital Bus*

Due to the relative high-speed nature of the Camera Data bus (48 MHz max), care must be taken to ensure

signal integrity and minimize clock skew. To reduce electromagnetic interference and ringing on the lines,

22-ohm series resistors have been added to each of the pixel data lines as well as the pixel clock and HSYN

signals. The capacitive loading and trace length on these lines should be minimal to ensure proper operation.

Thermal Considerations

The engine is qualified at temperatures from 0°C to 40°C (32°F to 104°F). Care must be taken to ensure that

ambient temperatures do not exceed this range in order to guarantee operation. The illumination LEDs

produce a considerable amount of heat when left on for extended time periods. The on time of these LEDs

should be minimized and airflow should be provided whenever possible to minimize internal heating.

Excessive heating can damage the LEDs and degrade image quality.

* See page 25 for additional information on electrical specifications.

See pages 25 and 26 for additional information on the engine and flex cable pinouts.

11

Page 16

Theory of Operation

Overview

The IS4910 imaging engine series is specifically designed for integration into handheld portable data terminals

or other OEM devices used for barcode scanning and/or OCR applications. Since the imaging engine

functions like a digital camera, the engine is capable of digital image capture, document lift, and signature

capture. With software integration, the non-decode engine will support decoding of all standard 1D & 2D

barcodes, reading OCR.

The compact engine has a 1.2M pixel CMOS imaging sensor, high intensity illumination LEDs, and an LED

targeting system. The non-decode engine also incorporates FirstFlash

®

a patented technology that regulates

the illumination time during image capture, reducing the need for multiple image acquisition.

The IS4910 series has two types of imaging modes, the Snapshot mode and the Video mode. The Snapshot

mode facilitates fast and accurate image acquisition with a minimum amount of power consumption. In this

mode, the LEDs are only activated for a very short time while FirstFlash ensures proper illumination.

The amount of images required is minimized, ultimately reducing the engine's power consumption. Detailed

information on the Snapshot mode can be found on page 14. The second type, the Video mode, enables fine

control of the camera exposure time making the mode suitable for high ambient light applications. Detailed

information on the Video mode can be found on page 16.

2

Communication with the image sensor is done over two buses, the control bus (I

C) and the data bus. The

Control bus is used to send programming commands to the image sensor. The data bus is used to transfer

images from the image sensor to the host system. The image data rate is determined by the Pixel Clock

(PCLK), which has a maximum frequency of 48 MHz. Note that on some host systems, such as those based

on the XScale PXA270 processor, the platform may not be able to support the 48 MHz pixel clock. In these

applications, the pixel clock can be configured to 24 MHz or 12 MHz via the (I

2

C) control bus. See Figure 9 on

page 13 for an illustrated depiction of the engine’s system architecture.

12

Page 17

Figure 9. IS4910 / IS4911 System Architecture

Honeywell Scanning and Mobility provides a Software Development Kit (P/N 46-00550) that will ease the

functional integration of the IS4910 or IS4911 non-decode engine. The SDK includes all the necessary

software components needed to enable an application developer to control and communicate with the engine,

acquire images, and decode barcodes. Additional information about the Software Development Kit and its

application programming interfaces (APIs) is provided in the IS4910 Series Area Imaging Engine

Programmer's Manual (P/N 00-02291). Contact a, customer service representative at 1-800-436-3876 for

additional information on this item and the Software Development Kit.

13

Page 18

Snapshot Mode

In the Snapshot mode of operation, image acquisition begins on the rising edge of the Trigger signal.

Image integration continues until the trigger line is brought low at which time the Image Data is output on the

Camera bus. In this mode, the area illumination is coincident with the integration time and is activated on the

rising edge of the Trigger signal. The illumination will remain on until the FirstFlash circuitry determines that

sufficient light has reached the sensor. At that point, the FirstFlash circuitry will then automatically disable

illumination. The user can override the FirstFlash circuitry by activating the Illum_On signal along with the

Trigger signal. For additional information, refer to Snapshot Illumination Waveforms on page 15.

The minimum Trigger pulse time required to initiate image acquisition in Snapshot mode can be calculated

using the following formula:

Ttrig_min = 84 + (<image-height> + 19) * 9 / PCLK

Where PCLK is the pixel clock output of the image sensor

and can be programmed to 48 MHz, 24 MHz, or 12 MHz.

For example, in systems that cannot support 48 MHz pixel clock rates (such as Xscale PXA270 processor

based platforms) the pixel clock can be reduced to 24 MHz or 12 MHz. Thus, for the default image height of

960 rows at 24 MHz pixel clock, the Trigger pulse time should be at least 451 µs.

As mentioned above, the trigger pulse controls both the image integration time and the maximum duration of

the illumination. The maximum time is application specific. Increasing the time will typically result in brighter

images but longer exposure time will make the unit susceptible to motion blur.

Software used by the engine device driver and CamLib APIs included in the Software Development Kit provide

the ability for precise control of the timings of the Trigger signal, the image sensor, and the image dataflow

from the camera to the host system.

The actual time of the illumination flash in Snapshot mode can vary between the minimum illumination time

and the maximum illumination time. The maximum illumination time is determined by the duration of the

Trigger signal. The minimum illumination time is determined by the duration of the Illum_On signal. The actual

time of the illumination flash is determined by the internal Microcontroller based on the measurement of the

light intensity performed by the FirstFlash circuitry.

When the light intensity, as measured by the FirstFlash circuitry, exceeds a pre-set factory threshold, the

Microcontroller immediately turns illumination off if the time elapsed from the start of illumination is greater than

the minimum illumination time (i.e. if the Illum_On signal is de-asserted); otherwise, it waits until the minimum

illumination time elapses and then turns the illumination off.

Precise control of the timings of the Illum_On signal is done in software by the engine device driver and

CamLib APIs included in the Software Development Kit.

14

Page 19

Snapshot Illumination Waveforms

The following waveforms show how the illumination LEDs are controlled relative to the input signals

(Trigger and Illum_On) during the snapshot mode. The Trigger signal determines when the illumination and

image integrations begin. In addition, the duration of this signal determines the maximum integration and

illumination time. The Illum_On signal can be used in conjunction with the Trigger signal to ensure a minimum

amount of illumination.

Example 1: Snapshot mode with Illumination duration controlled by FirstFlash circuitry only (see figure below).

= Denotes the actual duration of LED light will be determined by the FirstFlash circuitry. The

duration will vary based on object, object distance, and ambient light conditions.

Figure 10. Example 1

Example 2: Snapshot mode with Illumination being forced on for a given duration after which FirstFlash

circuitry takes over (see figure below).

= Denotes the actual duration of LED light will be determined by the FirstFlash circuitry. The

duration will vary based on object, object distance, and ambient light conditions.

Figure 11. Example 2

15

Page 20

Video Mode

The Video Mode allows for streaming video from the CMOS imager. The main advantage in the mode is that

the user has fine control over the exposure time. Fine control over the exposure time makes this mode well

suitable for high ambient light applications. The Video Mode is initiated through commands via the I

2

C bus.

During this mode of operation, the Trigger signal must be held low. If lighting is required, the Illumination LEDs

can be controlled via the Illum_On control signal.

Control of all signals and image dataflow in Video Mode is done in software by the engine device driver and

CamLib APIs included in the Software Development Kit. See SDK documentation for more details.

When not in Video Mode, the image sensor is always ready for Snapshot image acquisition.

Targeting

The engine uses a targeting LED to indicate the center of the imaging field. This LED can be activated at any

time by asserting the Aimer signal. The targeting LED is independent of the mode of operation and

illumination. However, it is strongly recommended that the targeting LED not be activated during image

acquisition as the light from the targeting LED will be visible in the image and may result in “hot

spots”. Control of the aiming mechanism is done in software by the IS4910 device driver and CamLib APIs

included in the SDK.

I2C Interface

The IS4910 series engines use an I2C compliant interface to communicate with the host system. The bus

allows the host to communicate directly with the image sensor and illumination microcontroller. Both of these

devices function as auxiliary* devices on the bus. The illumination Microcontroller is capable of running at

speeds up to 100 kHz whereas the image sensor can support frequencies up to 400 kHz. The standard

configuration of the IS4900 series of imaging engines does not incorporate pull up resistors on the SDA and

SCL lines in order to allow flexibility for the end user when choosing the resistor values. These resistors must

be provided by the host system and sized to meet the I

specification must be observed in order to guarantee proper operation of the engine.

2

The two I

C devices used in the IS4910 Engine use the following addresses:

• CMOS Image: 0x10

• Illumination Micro: 0x61 and 0x70

For details regarding programming of the image sensor, please refer to documentation provided with the

Software Development Kit. For details regarding the I

2

* In the Phillips I

C specification, auxiliary is defined as slave.

2

C timing requirements. Timing provided by the I2C bus

2

C protocol, see the Phillips I2C specification.

16

Page 21

Camera Bus Timings

The non-decode engine outputs pixel data via an 8-bit parallel data bus. The rate at which data is output is

determined by the pixel clock, which can be set for 48, 24, or 12 MHz. When the horizontal and vertical synch

signals are high, valid pixel data is latched on the rising edge of the PCLK. New pixel data is then driven on to

the bus on the falling edge. The VSYNC, HSYNC, and Pixel Data timings are relative to the PCLK and are

related as shown in the following timing diagram.

Figure 12. Parallel Data Output Video Timing*

Parallel Data Interface Timings*

Symbol Description Min. Max. Unit

f

PCLK

t

PCLKL

t

PCLKH

t

DV

PCLK frequency 48 MHz

PCLK low width [1/2*1/fPCLK)] – 0.5 [1/2*1/fPCLK)] + 0.5 ns

PCLK high width [1/2*1/fPCLK)] – 0.5 [1/2*1/fPCLK)] + 0.5 ns

PCLK to output valid -0.1 +2.5 ns

Table 1. Parallel Data Interface Timings*

* © of STMicroelectronics – All rights reserved.

17

Page 22

Wake Up Timing

When exiting sleep mode the engine will require a minimum wake up time before an image can be acquired.

Wake up is initiated by pulsing the Illum_On pin for a minimum of 250 µS. The pulsing wakes up the on board

microcontroller and oscillator. After this pulse is brought low, an additional 10 mS delay is required to ensure

that the oscillator has stabilized. After the additional 10 mS delay, the oscillator is stabilized and the imager is

ready to receive its configuration via the I

During sleep, the imager looses all configuration settings therefore all applicable settings will need to be

updated. The total time for the device to wake up will be dependant on how many registers need to be

reconfigured, the running speed of the I

(i.e. repeated stop vs. no repeat stop transmission).

Wake up time calculation:

= Oscillator Stabilization Time + Illum_On pulse width + Configuration Time

T

wake up

= 10 mS + 250 µS + Configuration Time

= 10.25 mS + Configuration Time

2

C control bus.

2

C bus, and the manner in which the data is transmitted on the bus

Example: The following waveform illustrates the wake up time measured from the rising edge of the Illum_On

signal to the last byte of configuration data sent on the I

below is for a host system running the I

2

C at 100kHz and transmitting data using no repeat stop.

2

C bus (labeled as SCL). The example

In this example, 27 registers are configured. The total wake up time under the example conditions

is approximately 31.5 mS.

Figure 13. Example of wake up timing with I2C running at 100 kHz

18

Page 23

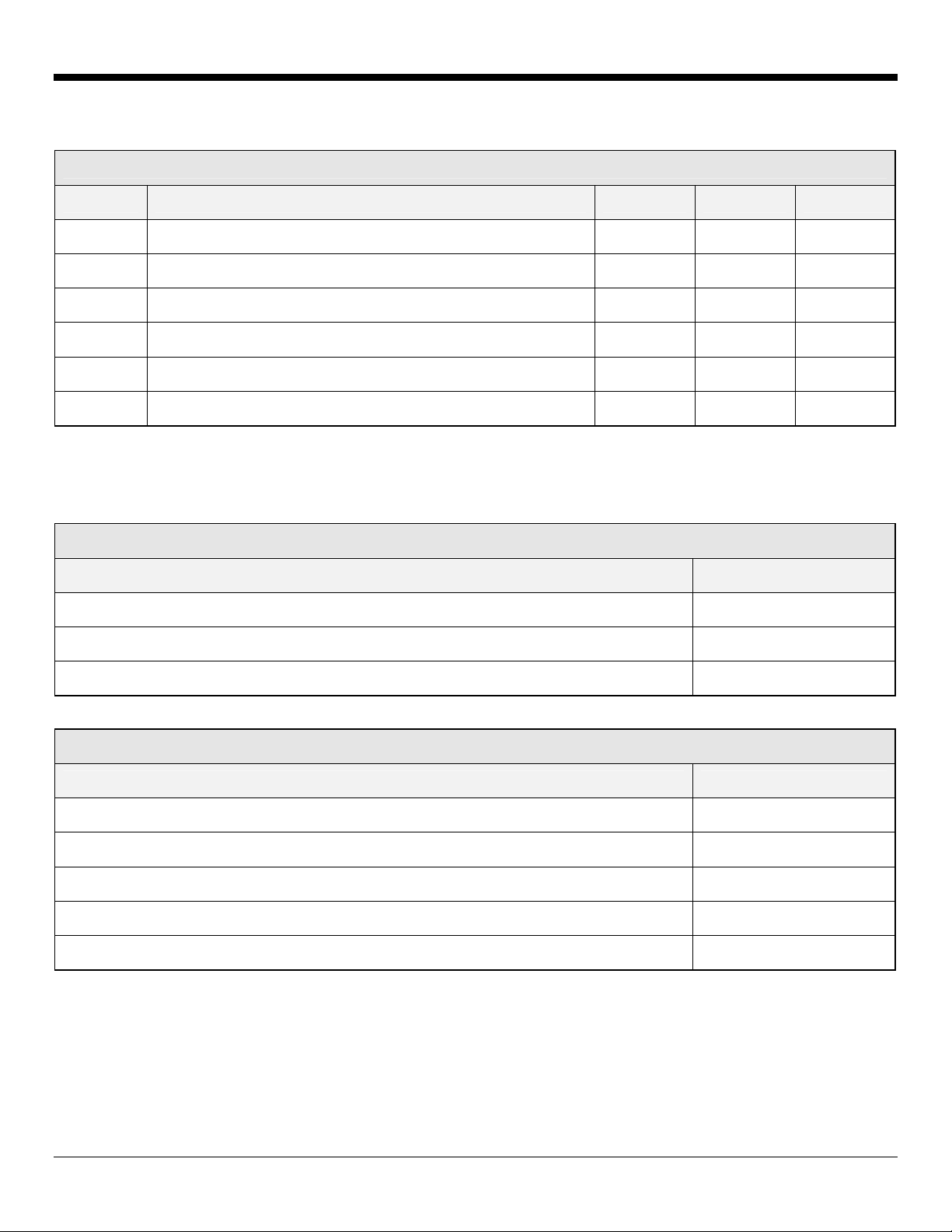

Electrical Specifications

Signal Levels

Signal Description Min. Typical Max.

Vimager Power to Imager and Supporting Circuitry 3.1V 3.3V 3.5V

VLED Power to Illumination and Targeting LEDs 3V - 5.5V

VIL1 Input Low (Aimer, Illum_On, Trigger) .6V

VIH1 Input High (Aimer, Illum_On, Trigger) 2.1V Vimager

VOH2 Output High Voltage (Data, PCLK, VSYNC, HSYNC) 2.71

VOL2 Output Low Voltage (Data, PCLK, VSYNC, HSYNC) .3V1

1

Sink / Source current = 2mA

2

Voltages listed are at the engine. A voltage drop should be expected when using a flex cable.

V_Imager Current (Vimager = 3.3V)

Description Typical

Stand By Current (V_imager = 3.3V) 450 µA

Idle Current (V_camera = 3.3V) 55 mA

Operating Current (V_camera = 3.3V) 90 mA

VLED Current

Description Typical

idle (VLED = 5V or 3.3V) 50 µA

Peak Current (VLED = 5V or 3.3V) Note: Peak duration of less than 20µS 350 mA

LED enabled (VLED = 5V) 90 mA

LED enabled (VLED = 3.3V) 155 mA

Targeting LED 24 mA

See page 11 for information on system considerations.

19

Page 24

Depth of Field vs. Bar Code Element

IS4910

Depth of Field* in the Field of View

Bar Code Element Width

(From Engine Face)

.127 mm 5 mil 50 mm (2.0") 145 mm (5.7") 95 mm (3.7")

Start

End

(From Engine Face)

Total

1D

.254 mm 10 mil 30 mm (1.2") 210 mm (8.3") 180 mm (7.1")

.330 mm 13 mil 25 mm (1.0") 310 mm (12.2") 285 mm (11.2")

.127 mm 5 mil 45 mm (1.8") 160 mm (6.3") 115 mm (4.5")

PDF

.254 mm 10 mil 25 mm (1.0") 270 mm (10.6") 245 mm (9.6")

.254 mm 10 mil 50 mm (2.0") 95 mm (3.7") 45 mm (1.8")

Data Matrix

.381 mm 15 mil 35 mm (1.4") 160 mm (6.3") 125 mm (4.9")

.508 mm 20 mil 40 mm (1.6") 260 mm (10.2") 220 mm (8.7")

* Depth of field information is for reference only. Depths of field distances were measured with decoding

software from Omniplaner

®

, a division of Honeywell Scanning and Mobility. Actual values may vary

depending on environmental conditions, host hardware, and decoding software.

20

Figure 14. IS4910 Field of View, Divergence Angle (model -01 shown)

Page 25

IS4911

Bar Code Element Width

Depth of Field* in the Field of View

Start

(From Engine Face)

(From Engine Face)

End

Total

.076 mm 3 mil 68 mm (2.7") 105 mm (4.1") 37 mm (1.4")

1D

.127 mm 5 mil 50 mm (2.0") 120 mm (4.7") 70 mm (2.75")

.330 mm 13 mil 50 mm (2.0") 170 mm (6.7") 120 mm (4.7")

PDF .127 mm 5 mil 45 mm (1.8") 130 mm (5.0") 85 mm (3.2")

Data Matrix

and QR

.127 mm 5 mil 75 mm (3.0") 115 mm (4.5") 40 mm (1.5")

* Depth of field information is for reference only. Depths of field distances were measured with decoding

software from Omniplaner, a division of Honeywell Scanning and Mobility. Actual values may vary

depending on environmental conditions, host hardware, and decoding software.

Figure 15. IS4911 Field of View, Divergence Angle (model -01 shown)

21

Page 26

Design Specifications

Operational

Light Source: Four, 650 nm Red Light Emitting Diode LED

Depth of Field*:

Field of View:

Scan Area:

IS4910

IS4911

IS4910

IS4911

IS4910

IS4911

25 mm – 310 mm (1.0" to 12.2") for 0.330 mm (13 mil) 1D Bar Codes

See page 20 for additional information on engine depth of field.

50 mm – 170 mm (2.0" to 6.7") for 0.330 mm (13 mil) 1D Bar Codes

See page 21 for additional information on engine depth of field.

50° Horizontal

37.5° Vertical

38° Horizontal

28.5° Vertical

118.4 mm x 86.2 mm (4.7" x 3.4")

at 127 mm (5.0") from the Face of the Engine

236.8 mm x 172.4 mm (9.3" x 6.8")

at 254 mm (10.0") from Face of the Engine

37 mm x 28 mm (1.45" x 1.08")

at 80 mm (3.15") from the Face of the Engine

78 mm x 58 mm (3.09" x 2.3")

at 170 mm (6.69") from the Face of the Engine

Rotation Sensitivity: 360° Around the Optical Axis

.10 mm (4.0 mil) 1D, PDF

IS4910

.254 mm (10 mil) 2D

Minimum Element Width:

.063 mm (2.5 mil) 1D, PDF

IS4911

.10 mm (4.0 mil) 2D

Resolution: 1.2 mega pixels (1280 x 960)

Symbologies Supported: Software Dependent*

Print Contrast: 20% Minimum

* Depth of field information is for reference only. Depth of field distances were measured with decoding

software from Omniplaner, a division of Honeywell Scanning and Mobility. Actual values may vary

depending on environmental conditions, host hardware, and decoding software.

** Contact a customer service representative at 1-800-436-3876 for information on available decoding

software.

22

Page 27

Mechanical

Dimensions: See pages 5 - 7 for detailed specifications.

Weight: < 6 g (.21 oz.)

Engine Termination:

Mounting: See pages 5 - 7 for detailed specifications.

Key Location: See pages 5 - 7 for detailed specifications.

SlimStack is a trademark of Molex, Inc., all rights reserved.

22-Pin, 0.50 mm (.020") Pitch SlimStack™ Plug, Molex P/N 55560-0227

See page 25 for engine pinouts. See page 26 for flex cable specifications.

Electrical

Engine Input Voltage: 3.3VDC ± 0.2

Camera Current: 90 mA, typical

150 mA, typical

Illumination Current:

350 mA, peak for less than 20 µs

Aiming Current: 24 mA

Peak Operating Current: < 450 mA

Snapshot Mode 85 mA

Typical Operating Current:

Video Mode 250 mA

Power Save Mode Current: 0.5 mA Typical

See page 19 for additional electrical specifications.

See page 29 for regulatory compliance information.

23

Page 28

Environmental

Operating Temperature: 0°C to 40°C (32°F to 104°F)

Storage Temperature: -20°C to 70°C (-4°F to 158°F)

See page 11 for additional information on thermal considerations.

Humidity: 5% to 95% relative humidity, non-condensing

0 - 110,00 Lux

Light Levels:

Shock: 5 ft. (1.5 m)

Vibration Protection: 7G, 10 – 500 Hz

Contaminants: See page 8.

Note: Immunity against high levels of ambient light is achieved in Video

Mode. See page 16 for additional information on the Video Mode and

the Software Development Kit.

24

Page 29

Imaging Engine Terminations

IS4910 / IS4911 Pinout Connections

Figure 16. Non-Decode Engine Termination

Pin Signal Name Function

1 Aimer High enables Targeting LED (Input)

2 Illum_On High forces on Illumination LEDs (Input), Wake up Scanner

3 Trigger Controls Integration and Illumination in Snapshot mode (Input)

4 SDA I2C data (Bi-Directional) – Devices Functions as Auxiliary Devices

5 SCL I2C clock (Bi-Directional) – Devices Function as Auxiliary Devices

6 VLED Voltage Supply for Targeting and Area LEDs (3V - 5.5V)

7 D0 Pixel Data0 (LSB) (Output)

8 Vimager Camera Voltage (3.1V - 3.5V)

9 D1 Pixel Data1 (Output)

10 D2 Pixel Data2 (Output)

11 D3 Pixel Data3 (Output)

12 PCLK Pixel Clock (Output)

13 D7 Pixel Data7 (Output)

14 D6 Pixel Data6 (Output)

15 D5 Pixel Data5 (Output)

16 D4 Pixel Data4 (Output)

17 VSYNC Vertical Sync (Output)

18 HSYNC Horizontal Sync (Output)

19 GND Power and Signal ground

20 Reserved Terminate with Resistor, Pulled Low, or Leave Unconnected

21 GND Power and Signal Ground

22 NC No Connection

* In the Phillips I2C specification auxiliary is defined as slave.

25

Page 30

Flex Cable Specifications

Pinout, Host End

Figure 17. Flex Cable Pin Arrangement

Pin Signal Name Function

1 GND Power and Signal Ground

2 Reserved Terminate with resistor, Pulled low, or Leave Unconnected

3 GND Power and Signal Ground

4 HSYNC Horizontal Sync (Output)

5 VSYNC Vertical Sync (Output)

6 D4 Pixel Data4 (Output)

7 D5 Pixel Data5 (Output)

8 D6 Pixel Data6 (Output)

9 D7 Pixel Data7 (Output)

10 PCLK Pixel Clock (Output)

11 NC No Connection

12 D3 Pixel Data3 (Output)

13 D2 Pixel Data2 (Output)

14 D1 Pixel Data1 (Output)

15 Vimager Camera Voltage (3.1V - 3.5V)

16 D0 Pixel Data0 (LSB) (Output)

17 VLED Voltage supply for Targeting and Area LEDs (3V - 5.5V)

18 SCL I2C clock (Bi-Directional) – Devices Function as Auxiliary Devices

19 SDA I2C Data (Bi-Directional) – Devices Function as Auxiliary Devices

20 Trigger Controls Integration and Illumination in Snapshot Mode (Input)

21 Illum_On High Forces on Illumination LEDs (Input)

22 Aimer High Enables Targeting LED (Input)

26

Page 31

Dimensions

Figure 18. Flex Cable Dimensions, P/N 77-77104

See installation warning on page 28.

27

Page 32

Installation Notes

Note 1. Warning!

The flex cable must be installed in the orientation shown below in Figure 19. If the cable is

incorrectly installed, the engine can be damaged, and the warranty voided, see page 31.

Figure 19. Flex Cable Orientation

Note 2. Proper installation of the flex cable is essential for engine performance. When installing the flex

cable, verify that the flex cable receptacle is fully seated in the engine plug. To achieve a full

connection, ensure that the alignment of the mating parts is not angled during installation.

Flex cable P/N 77-77104 is designed with universal ends.

Note 3. Once installed, it is recommended that the flex cable be secured properly in the enclosure to

prevent loss of connection due to vibration or physical drop.

28

Page 33

Regulatory Compliance

Safety

The IS4910 series area imaging engines are designed to meet the requirements of IEC Class 1 in accordance

with IEC 60825-1:1993+A1+A2. IEC Class 1 is defined as follows:

The specifications required for agency approval are not obtainable until the IS4910 / IS4911 area imaging

engine is used in its final configuration. Honeywell International Inc. is unable to fulfill these requirements

because the imaging engine will operate differently depending upon where the engine is used as a component.

If the product containing the IS4910 series engine is to be used in another country, the manufacturer who

incorporates the imaging engine into their product is responsible for fulfilling any regulatory

compliance requirements for that country. Refer to one of the following sections for further explanation.

Europe

The CE Mark is required on products that incorporate the IS4910 series engine if the products are to be

imported into European Economic Area (EEA) countries. Use of the CE Mark requires compliance with

directives and standards dependent upon the type of product. Information may be found at

http://europa.eu.int/comm/enterprise/newapproach/

.

LED Safety

IEC 60825-1:1993+A1+A2,

EN 60825-1:1994+A1+A2

“Safety of LED products”

Compliance with either of the standards listed above is required for the product to bear the CE mark.

Note: Non EEA countries may impose additional testing/certification requirements.

EMC

All combinations of IS4910 area imaging engines and associated electronics will require certification of

compliance with the European EMC Directive. EMC compliance of finished products in Europe can be

accomplished by the following method:

The manufacturer may certify to the EC’s Electromagnetic Compatibility Directive 89/336/EEC.

Compliance is required for the product to bear the CE Mark.

Note: Non EEA countries may impose additional testing/certification requirements.

The IS4910 series area imaging engine is designed to meet EN55022 Radiated Class B emission limits.

The engine was installed in a representative system and tested for compliance.

Electrical Safety

The IS4910 engines are built to conform to the European Low Voltage Directive 73/23/ EEC.

29

Page 34

United States

EMC

All combinations of imaging engines and associated electronics will require testing to insure compliance with

the following Federal Communications Commission regulation: 47 CFR Part 15

Note: When using the imaging engine with RF equipment, modems, etc. may require examination(s) to the

standard(s) for the specific equipment combination. It is the manufacturers’ responsibility to comply

with the applicable federal regulation(s).

The IS4910 series area imaging engine is designed to meet EN55022 Radiated Class B emission limits.

The engine was installed in a representative system and tested for compliance.

Canada

EMC

Products meeting FCC 47 CFR Part 15 will meet Industry Canada interference-causing equipment standard for

digital apparatus, ICES-003. Additional testing is not required.

A written notice indicating compliance must accompany the apparatus to the end user. The notice shall be in

the form of a label that is affixed to the apparatus. The notice may be in the form of a statement included in the

user’s manual if, because of insufficient space or other restrictions, it is not feasible to affix a label to the

apparatus.

30

Page 35

Limited Warranty

Honeywell International Inc. ("HII") warrants its products and optional accessories to be free from defects in

materials and workmanship and to conform to HII’s published specifications applicable to the products

purchased at the time of shipment. This warranty does not cover any HII product which is (i) improperly

installed or used; (ii) damaged by accident or negligence, including failure to follow the proper maintenance,

service, and cleaning schedule; or (iii) damaged as a result of (A) modification or alteration by the purchaser or

other party, (B) excessive voltage or current supplied to or drawn from the interface connections, (C) static

electricity or electro-static discharge, (D) operation under conditions beyond the specified operating

parameters, or (E) repair or service of the product by anyone other than HII or its authorized representatives.

This warranty shall extend from the time of shipment for the duration published by HII for the product at the

time of purchase ("Warranty Period"). Any defective product must be returned (at purchaser’s expense) during

the Warranty Period to HII factory or authorized service center for inspection. No product will be accepted by

HII without a Return Materials Authorization, which may be obtained by contacting HII. In the event that the

product is returned to HII or its authorized service center within the Warranty Period and HII determines to its

satisfaction that the product is defective due to defects in materials or workmanship, HII, at its sole option, will

either repair or replace the product without charge, except for return shipping to HII.

EXCEPT AS MAY BE OTHERWISE PROVIDED BY APPLICABLE LAW, THE FOREGOING WARRANTY IS

IN LIEU OF ALL OTHER COVENANTS OR WARRANTIES, EITHER EXPRESSED OR IMPLIED, ORAL OR

WRITTEN, INCLUDING, WITHOUT LIMITATION, ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE, OR NON-INFRINGEMENT.

HII’S RESPONSIBILITY AND PURCHASER’S EXCLUSIVE REMEDY UNDER THIS WARRANTY IS LIMITED

TO THE REPAIR OR REPLACEMENT OF THE DEFECTIVE PRODUCT WITH NEW OR REFURBISHED

PARTS. IN NO EVENT SHALL HII BE LIABLE FOR INDIRECT, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES, AND, IN NO EVENT, SHALL ANY LIABILITY OF HII ARISING IN CONNECTION WITH ANY

PRODUCT SOLD HEREUNDER (WHETHER SUCH LIABILITY ARISES FROM A CLAIM BASED ON

CONTRACT, WARRANTY, TORT, OR OTHERWISE) EXCEED THE ACTUAL AMOUNT PAID TO HII FOR

THE PRODUCT. THESE LIMITATIONS ON LIABILITY SHALL REMAIN IN FULL FORCE AND EFFECT

EVEN WHEN HII MAY HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH INJURIES, LOSSES, OR

DAMAGES. SOME STATES, PROVINCES, OR COUNTRIES DO NOT ALLOW THE EXCLUSION OR

LIMITATIONS OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR

EXCLUSION MAY NOT APPLY TO YOU.

All provisions of this Limited Warranty are separate and severable, which means that if any provision is held

invalid and unenforceable, such determination shall not affect the validity of enforceability of the other

provisions hereof. Use of any peripherals not provided by the manufacturer may result in damage not covered

by this warranty. This includes but is not limited to: cables, power supplies, cradles, and docking stations. HII

extends these warranties only to the first end-users of the products. These warranties are non-transferable.

The duration of the limited warranty for the IS4910 and IS4911 is two year(s)

limited warranty from the date of manufacture.

. The accessories have a 90 day

31

Page 36

Patents

This Honeywell product may be covered by, but not limited to, one or more of the following U.S. Patents:

U.S. Patent No.;

7,086,595; 7,128,266

No license, right or sublicense is granted, either expressly or by implication, estoppel, or otherwise, under any

Metrologic, Honeywell or third party intellectual property rights (whether or not such third party rights are

licensed to Metrologic and/or Honeywell), including any third party patent listed above, except for an implied

license only for the normal intended use of the specific equipment, circuits, and devices represented by or

contained in the products that are physically transferred to the user, and only to the extent of those license

rights and subject to any conditions, covenants and restrictions therein.

Other worldwide patents pending.

32

Page 37

Index

A

Aiming...................................................... 12, 16, 23

Ambient Light..................................... 12, 14, 15, 16

Ambient Temperture ............................................ 11

B

Bar Code.............................................. 1, 20, 21, 22

Bus............................................... 11, 12, 14, 16, 17

C

Cable

flex .................................................... 2, 22, 26–28

Camera Aperture ............................................... 3, 9

CMOS ............................................................ 12, 16

Connector .......................... 3, 14, 22, 25, 26, 27, 28

Contaminants................................................... 8, 23

Contrast ............................................................... 22

Controller ............................................................. 14

Current........................................................... 19, 23

Customer Service .......................................... 22, 31

D

Depth of Field .......................................... 20, 21, 22

Divergence Angle .................................... 10, 20, 21

I

Illum_On ...............................................................18

Illumination .....................3, 9, 10, 11–16, 23, 25, 26

Imaging Field ........................................................16

Imaging Sensor ..............................................11, 12

Input..........................................1, 15, 19, 23, 25, 26

Interface..........................................................16, 17

K

Keying Location ..............................................3, 4–7

L

Label.......................................................................4

Light Levels ..........................................................23

Light Source .........................................................22

Limited Warranty ..................................................31

M

Mode

Snapshot ...............................1, 12, 14, 15, 23, 26

Video ...........................................1, 12, 16, 23, 26

Mounting.........................................................3, 4–7

O

E

Electrical Specification............................. 19, 23, 29

Electrostatic Discharge .................................... 8, 23

EMC............................................................... 29, 30

Enclosure................................................... 8–10, 28

F

Field of View ........................................ 9, 20, 21, 22

FirstFlash® .............................................. 12, 14, 15

Flex Cable............................................ 2, 22, 26–28

G

Ground....................................................... 8, 25, 26

H

Humidity........................................................... 8, 23

Optical Clearance .................................................10

Oscillator...............................................................18

Output...........................................14, 17, 19, 25, 26

P

PCLK ........................................................12, 14, 17

Pin ..................................................................25, 26

Pixel..............................................12, 14, 17, 25, 26

Plug ............................................................3, 22, 25

R

Receptacle..........................................12, 26, 27, 28

Regulatory Compliance ..................................29, 30

Resolution.........................................................1, 22

RMA......................................................................31

S

Self-Tapping Screw ....................................2, 3, 4–7

33

Page 38

Sensor ............................................... 11, 12, 16, 17

Service................................................................. 31

Shock............................................................. 23, 28

Signal................................................. 11–19, 25, 26

Sleep.................................................................... 18

Snapshot Mode........................ 1, 12, 14, 15, 23, 26

Software............................................... 2, 13, 14, 16

T

Targeting........................................ 3, 16, 19, 25, 26

Temperature ........................................................ 23

Threaded Inserts.................................................... 7

Timing .................................................................. 18

Torque ............................................................... 4–7

Trigger ............................................... 14, 15, 25, 26

V

Video Mode ....................................1, 12, 16, 23, 26

Voltage ...............................1, 19, 23, 25, 26, 29, 30

W

Wake ....................................................................18

Warranty ...............................................................31

Watt(s) ..................................................................29

Waveforms ...........................................................15

Weight ........................................................1, 22, 23

Window

coatings ...............................................................9

materials ..............................................................9

specifications .......................................................9

transmission.........................................................9

34

Page 39

Contact Information

The Americas (TA) Germany Guangzhou Sales Office

Tel: 86-20-38823476

USA Tel: 49-89-89019-0 Fax: 86-20-38823477

Fax: 49-89-89019-200 Email: info@cn.metrologic.com

Tel: 800.436.3876 (Customer Service) Email: info@de.metrologic.com

866.460.8033 (Customer Support) Beijing Sales Office

888.633.3762 (Technical Support) Italy Tel: 010-82253472/84583280

Fax: 856.228.6673 (Sales) Fax: 010-82253648/84583102

856.228.1879 (Marketing) Tel: +39 0 51 6511978 Email: info@cn.metrologic.com

856.228.0653 (Legal/Finance) Fax: +39 0 51 6521337

Email: info@it.metrologic.com Chengdu Sales Office

Brazil Tel: 028-66135066/86786348

Poland Fax: 028-86787061

Tel: 55.11.5185.8222 Email: info@cn.metrologic.com

Fax: 55.11.5185.8225 Tel: +48 (22) 545 04 30

Email: info@br.metrologic.com Fax: +48 (22) 545 04 31 Hong Kong

Email: info@pl.metrologic.com

Mexico Tel: 852-2331-9133 (main line)

Russia Fax: 852-2511-3557

Tel: 55.5365.6247

Fax: 55.5362.2544 Tel: +7 (495) 737 7273 India

Email: info@mx.metrologic.com Fax: +7 (495) 737 7271

Email: info@ru.metrologic.com India Sales Office

North America Tel: +91 80 4125 6718

Spain Fax: +91 80 4125 6719

Tel: 856.537.6400 Email: info@in.metrologic.com

866.460.8033 (Customer Service) Tel: +34 913 272 400

888.633.3762 (Technical Support) Fax: +34 913 273 829 Japan

Fax: 856.537.6474 Email: info@es.metrologic.com

Email: info@us.metrologic.com Tel: 81-3-3839-8511

United Kingdom Fax: 81-3-3839-8519

South America (Outside Brazil) Email: info@jp.metrologic.com

Tel: +44 (0) 1256 365900

Tel: 55.11.5182.7273 Fax: +44 (0) 1256 365955 Korea

Fax: 55.11.5182.7198 Email: info@uk.metrologic.com

Email: info@sa.metrologic.com Korea Sales Office

Asia Pacific Tel: (82) 2-6205-5379

Omniplanar, Inc. (82) 11-9363-5379 (mobile)

Australia Fax: (82)-2-3444-3980

Tel: 856.374.5550 Email: info@kr.metrologic.com

Fax: 856.374.5576 Tel: 1 800 99 88 38

Email: info@omniplanar.com Fax: +61 2 8916-6471 Singapore

Email: info@au.metrologic.com

NOVODisplay Tel: (65) 6842-7155

China Fax: (65) 6842-7166

Tel: 856.537.6139 Email: info@sg.metrologic.com

Fax: 856.537.6116 Tel: 86-21-58356616

Email: info@NOVOdisplay.com 86-21-58358830 Thailand

Fax: 86-21-58358873

Europe, Middle East and Africa Email: info@cn.metrologic.com Tel: +662-610-3787

Fax: +662-610-3601

France Suzhou Sales Office Email: info@th.metrologic.com

Tel: 86-512-67622550

Tel: +33 (0) 1 48.63.78.78 Fax: 86-512-67622560

Fax: +33 (0) 1 48.63.24.94 Email: info@cn.metrologic.com

Email: info@fr.metrologic.com

35

Page 40

Product Service and Repair

North America Suzhou Sales Office European Repair Center

Tel: 800.436.3876 (Customer Service) Tel: 86-512-67622550 Tel: +34 913 751 249

866.460.8033 (Customer Support) Fax: 86-512-67622560 Fax: +34 913 270 437

888.633.3762 (Technical Support) Email: info@cn.metrologic.com

Fax: 856.228.6673 (Sales)

Email: info@metrologic.com

36

Page 41

Page 42

Honeywell Scanning and Mobility

90 Coles Road

Blackwood, NJ 08012-4683

00-02285 Rev D

March 2009

Loading...

Loading...