Page 1

IS220

OEM Scan Engine

User’s Guide

Page 2

Disclaimer

Honeywell International Inc. (“HII”) reserves the right to make changes in specifications and other information

contained in this document without prior notice, and the reader should in all cases consult HII to determine

whether any such changes have been made. The information in this publication does not represent a

commitment on the part of HII.

HII shall not be liable for technical or editorial errors or omissions contained herein: nor for incidental or

consequential damages resulting from the furnishing, performance, or use of this manual.

This document contains propriety information that is protected by copyright. All rights reserved. No part of this

document may be photocopied, reproduced, or translated into another language without the prior written

consent of HII.

© 2004 - 2011 Honeywell International Inc. All rights reserved.

Web Address: www.honeywellaidc.com

Trademarks

Metrologic, MetroSelect, MetroSet2, are trademarks or registered trademarks of Metrologic Instruments, Inc. or

Honeywell International Inc.

Microsoft, Windows, and Windows 95 are trademarks or registered trademarks of Microsoft Corporation.

Other product names mentioned in this manual may be trademarks or registered trademarks of their respective

companies and are the property of their respective owners.

Patents

For patent information, please refer to www.honeywellaidc.com/patents.

Page 3

T able of Contents

Introduction ..................................................................................................................................................... 1

Base Kit .......................................................................................................................................................... 1

Optional Accessories ...................................................................................................................................... 1

Dimensions .................................................................................................................................................... 2

Maintenance ................................................................................................................................................... 2

Scanner Components ..................................................................................................................................... 3

Labels ............................................................................................................................................................ 4

Indicators

Audible Indicator ............................................................................................................................................ 5

Visual Indicator ............................................................................................................................................... 6

Failure Indicators ............................................................................................................................................ 6

Diagnostic Indicator Display ........................................................................................................................... 7

Depth of Field .................................................................................................................................................. 9

Troubleshooting Guide ................................................................................................................................. 11

Design Specifications

Operational................................................................................................................................................... 15

Mechanical ................................................................................................................................................... 15

Electrical ...................................................................................................................................................... 15

Environmental .............................................................................................................................................. 16

Upgrading the Flash ROM Firmware ............................................................................................................ 17

Default Settings

Communication Parameters ......................................................................................................................... 19

Scanner and Cable Terminations

Scanner Pinout Connections ........................................................................................................................ 25

Cable Connector Configurations ................................................................................................................... 25

Limited Warranty ........................................................................................................................................... 27

Laser and Product Safety

Cautions ....................................................................................................................................................... 29

Notices ......................................................................................................................................................... 30

Index ............................................................................................................................................................... 31

ii

Page 4

iii

Customer Support

Technical Assistance .................................................................................................................................... 33

Product Service and Repair .......................................................................................................................... 34

Page 5

Introduction

The IS220 is a dual optic bench scanning engine with scan lines optimized for orthogonal orientation of 1D bar

codes. IS220 is a completely self-contained scan engine.

Base Kit

Part Number Description

IS220-16 IS220 OEM Engine ( RS232 )

00-02029 IS220 Installation and User’s Guide *

00-02407 MetroSelect

* Guides also available for download at www.honeywelladic.com.

®

Configuration Guide *

Optional Accessories

Part Number Description

52-52548 Communication/Power Cable 110 Volt

52-52547 Communication/Power Cable 220 Volt

Other items may be ordered for the specific protocol being used. To order additional items, contact the dealer,

distributor or call the customer service department.

1

Page 6

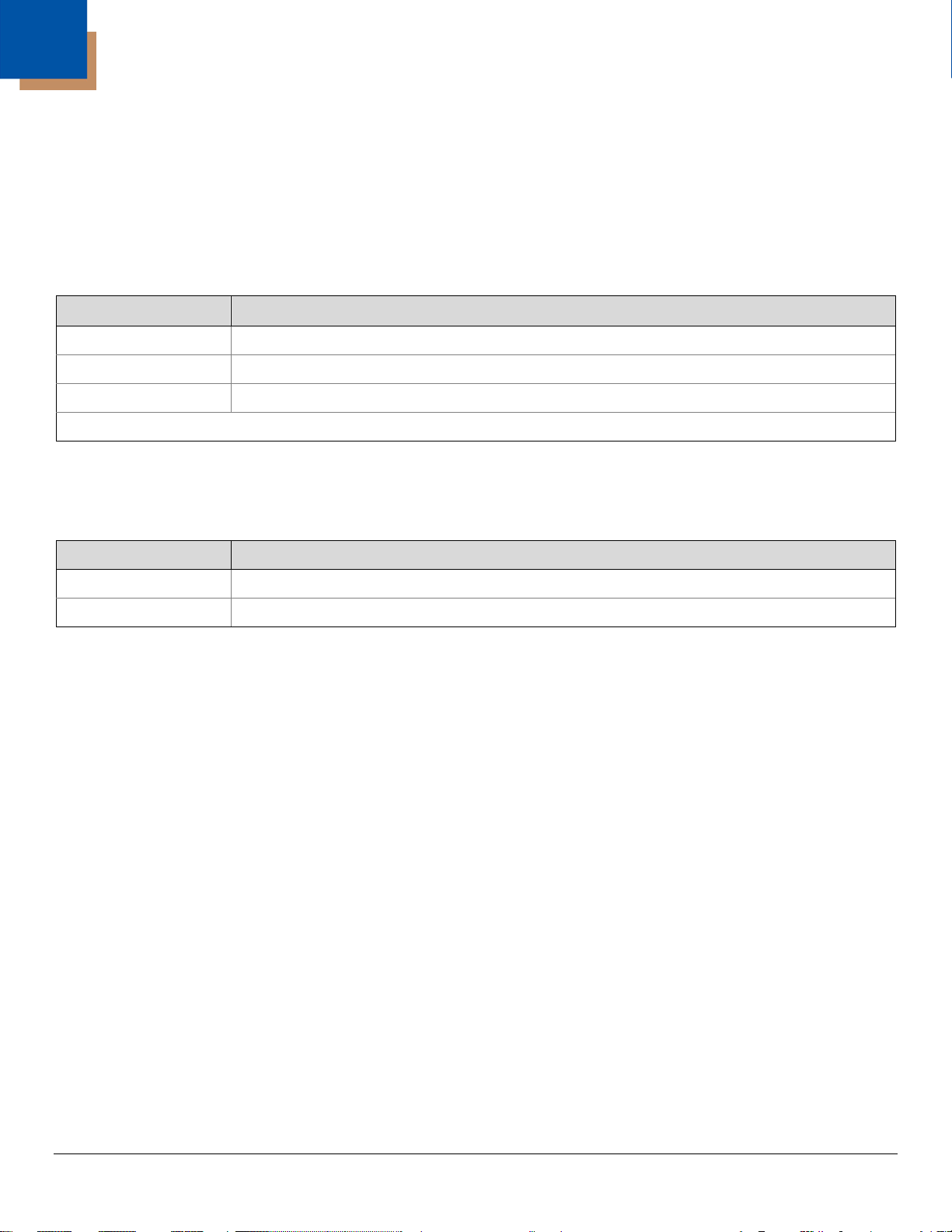

Case Dimensions

Figure 1. Case Dimensions

Specifications subject to change without notice.

Maintenance

Smudges and dirt on the unit’s window can interfere with the unit’s performance. If the horizontal or vertical

output windows require cleaning, use only a mild glass cleaner containing no ammonia. When cleaning the

window, spray the cleaner onto a lint free, non-abrasive cleaning cloth then gently wipe the window clean.

If the unit’s case requires cleaning, use a mild cleaning agent that does not contain strong oxidizing chemicals.

Strong cleaning agents may discolor or damage the unit’s exterior.

2

Page 7

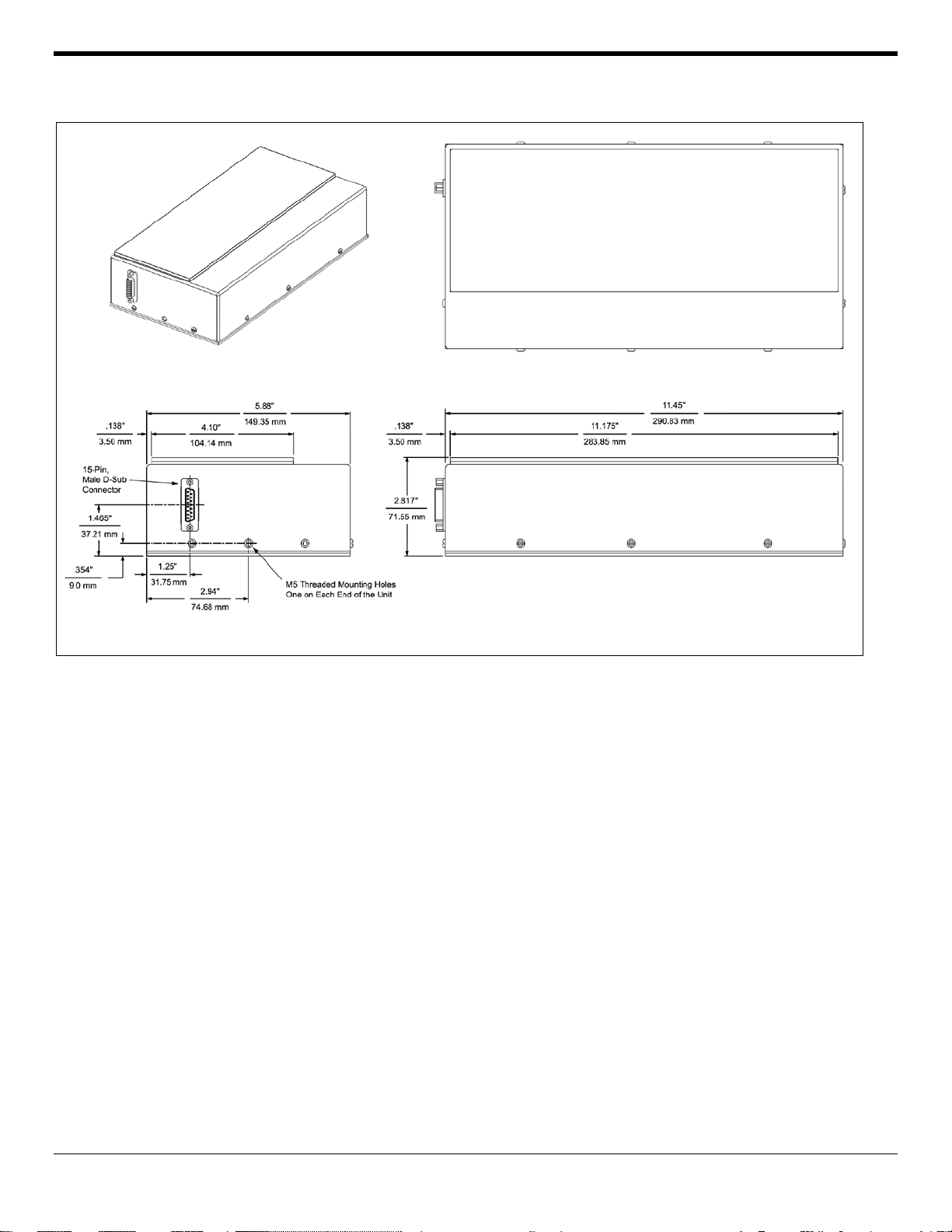

Scanner Components

Figure 2. Scanner Components

No. Description

Hardened Glass Window (Laser Aperture)

Black Metal Housing

15-pin, Male D-Sub Connector for Communication/Power Cable Connection

Two, PEM B-M5-2 Mounting Holes Provided

Red and Green LED

Diagnostic Indicator Display (Two-Digit Error Code Displa y)

3

Page 8

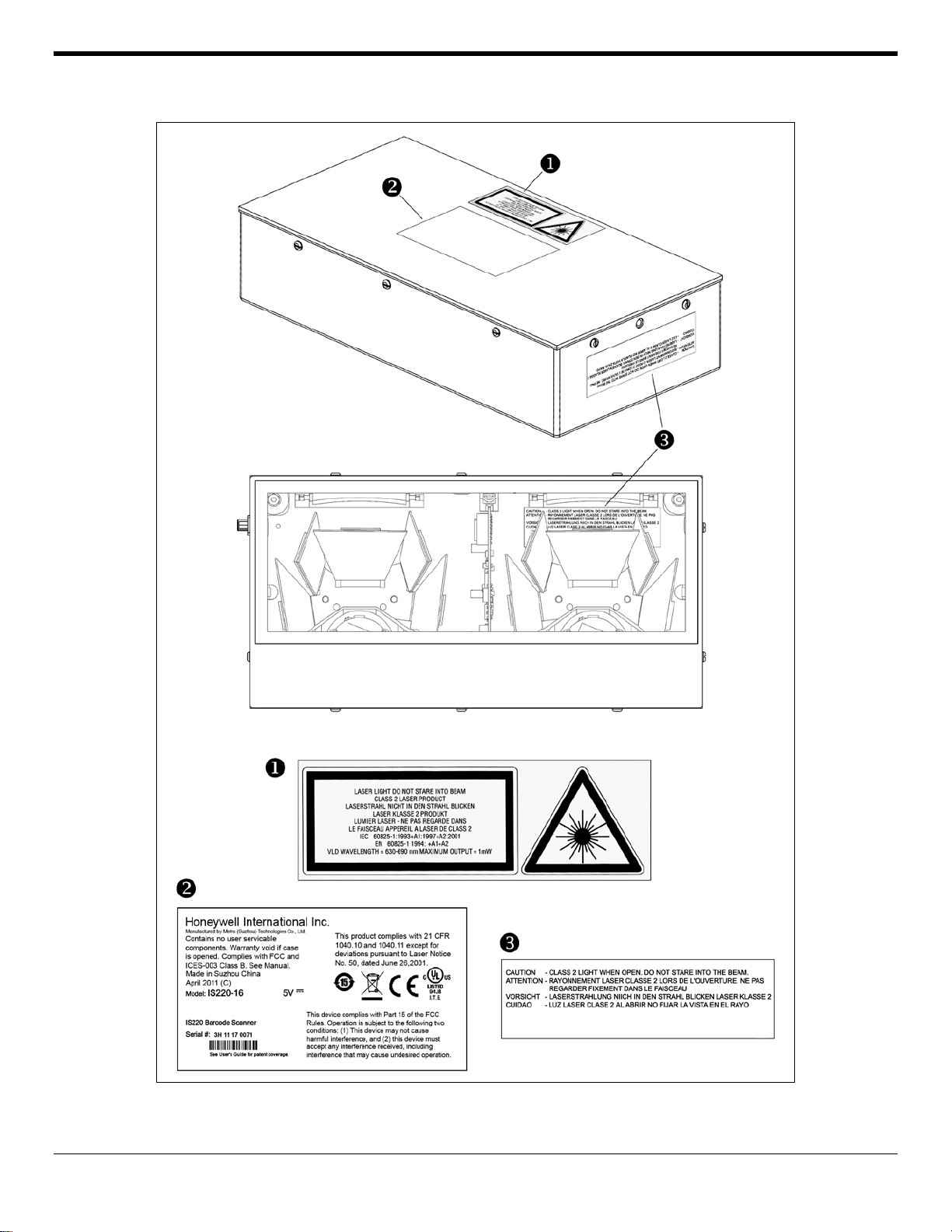

Labels

4

Figure 3. Label Locations and Examples

Page 9

Indicators

Audible Indicators

When the IS220 is in operation, it provides audible feedback. These sounds indicate the status of the scan

engine.

One Beep

The scan engine will beep once when it first receives power, the red LED will flash and the scanner will

beep once. The red LED will remain on for the duration of the beep. The scan engine is ready to scan.

When the scanner successfully reads a bar code, the red LED will flash and the scanner beeps once (if

configured to do so). If the LED does not flash, then the bar code has not been successfully read.

Razzberry Tone

This is a failure indicator. Refer to Failure Indicators on the next page.

Two Beeps - On Power Up

When a Flash ROM upgrade is needed, the scanner will beep twice followed by alternating flashes of the

red and green LEDs.

Three Beeps - During Operation

When the scan engine enters configuration mode, the red LED will flash and the unit will simultaneously

beep three times. The green and red LEDs will continue to flash while in configuration mode. Upon exiting

configuration mode the scanner will beep three times and the LEDs will stop flashing.

When configured, three beeps can also indicate a communications timeout during normal scanning mode.

When using one-code programming, the scanner will beep three times (in the current selected tone),

followed by a short pause then by a high tone and a low tone. This indicates the single configuration bar

code has successfully configured the scan engine.

Three Beeps - On Power Up

This is a failure indicator. Refer to Failure Indicators on the next page.

5

Page 10

Figure 4. Green and Red LEDs

Visual Indicators

Steady Green

When the laser is active the green LED is illuminated. The green

LED will remain illuminated until the laser is deactivated.

During the power save mode, the laser will turn on and turn off.

During this period, the green LED will remain illuminated.

Steady Green and a Single Red Flash

When the scanner successfully reads a bar code, the red LED

will flash and the scanner will beep once. If the red LED does not

flash or the scanner does not beep once, then the bar code has

not been successfully read (default mode).

Steady Green and Steady Red

After a successful scan the scanner transmits the data to the host

device. Some communication modes require that the host inform

the scanner when data is ready to be received. If the host is not

ready to accept the information, the scanner’s red LED will

remain on until the data can be transmitted.

Steady Green and Flashing Red

This indicates that the scan engine is in configuration mode.

Steady Red, Green Off

This indicates that the laser is off and the scan engine is waiting

for communication from the host.

Failure Ind ic a t ors

Flashing Green and One Razzberry Tone

This indicates that the scanner has experienced a laser subsystem failure. The scanner will try up to 3

times to correct the failure condition. If the laser subsystem continues to fail, that subsystem (left or right)

will be shut down and an error indication will be shown on the Diagnostic Indicator Display. This error

stays on the display until corrected. If the remaining subsystem is still operational, scanning will continue

using the operational components.

Flashing Green and Red and Two Razzberry Tones

This indicates that the scanner has experienced a motor subsystem failure. The scanner will try up to 3

times to correct the failure condition. If the motor subsystem continues to fail, that subsystem (left or right )

will be shut down and an error indication will be shown on the Diagnostic Indicator Display. This error

stays on the display until corrected. If the remaining subsystem is still operational, scanning will continue

using the still operational components.

Continuous Razzberry Tone with Both LEDs Off

If, upon power up, the scanner emits a continuous razzberry tone, then the scanner has an electronic

failure. Return the unit for repair at an authorized service center.

Three Beeps - On Power Up

If the scanner beeps 3 times on power up then, the nonvolatile memory that holds the scanner

configuration has failed. Return the unit for repair at an authorized service center.

6

Page 11

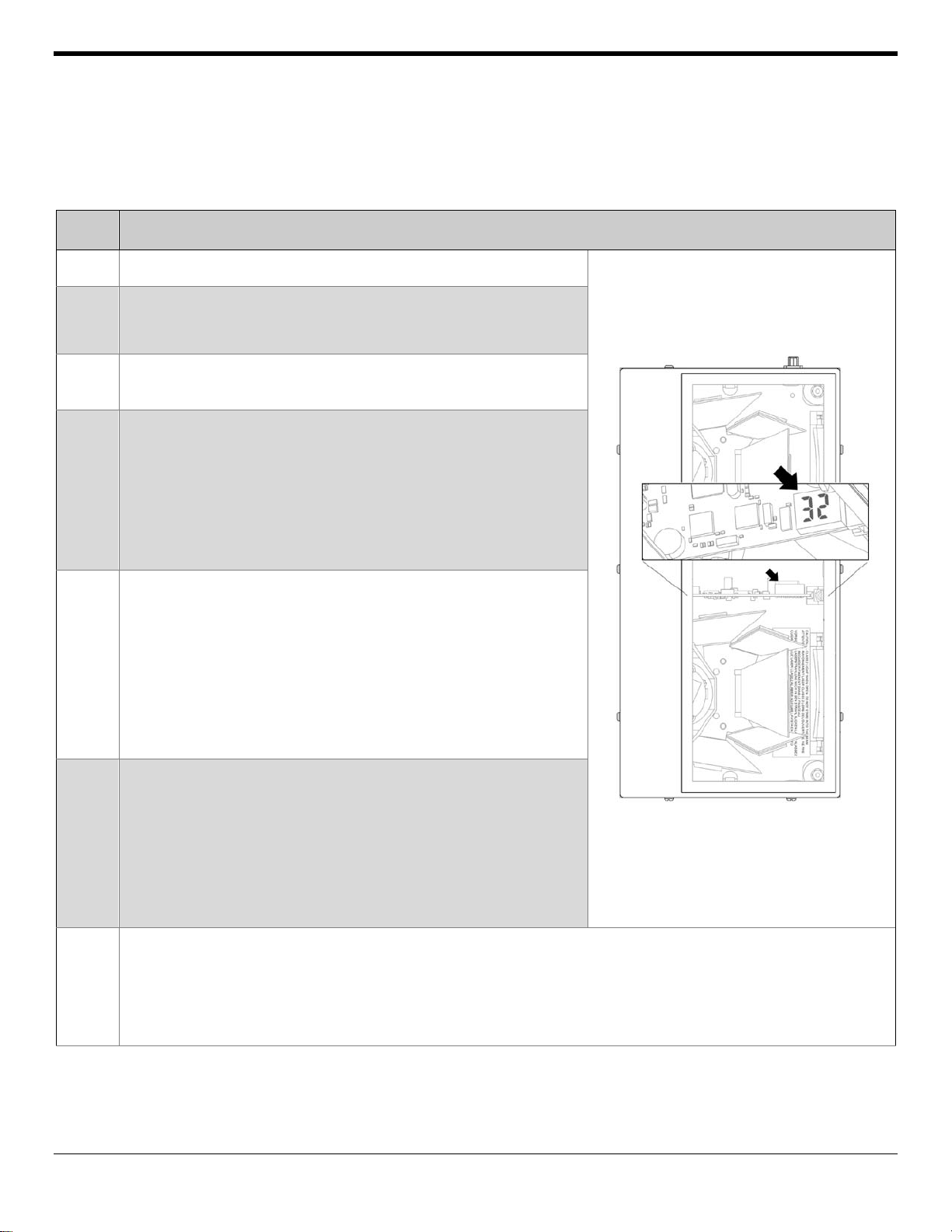

Error

Code

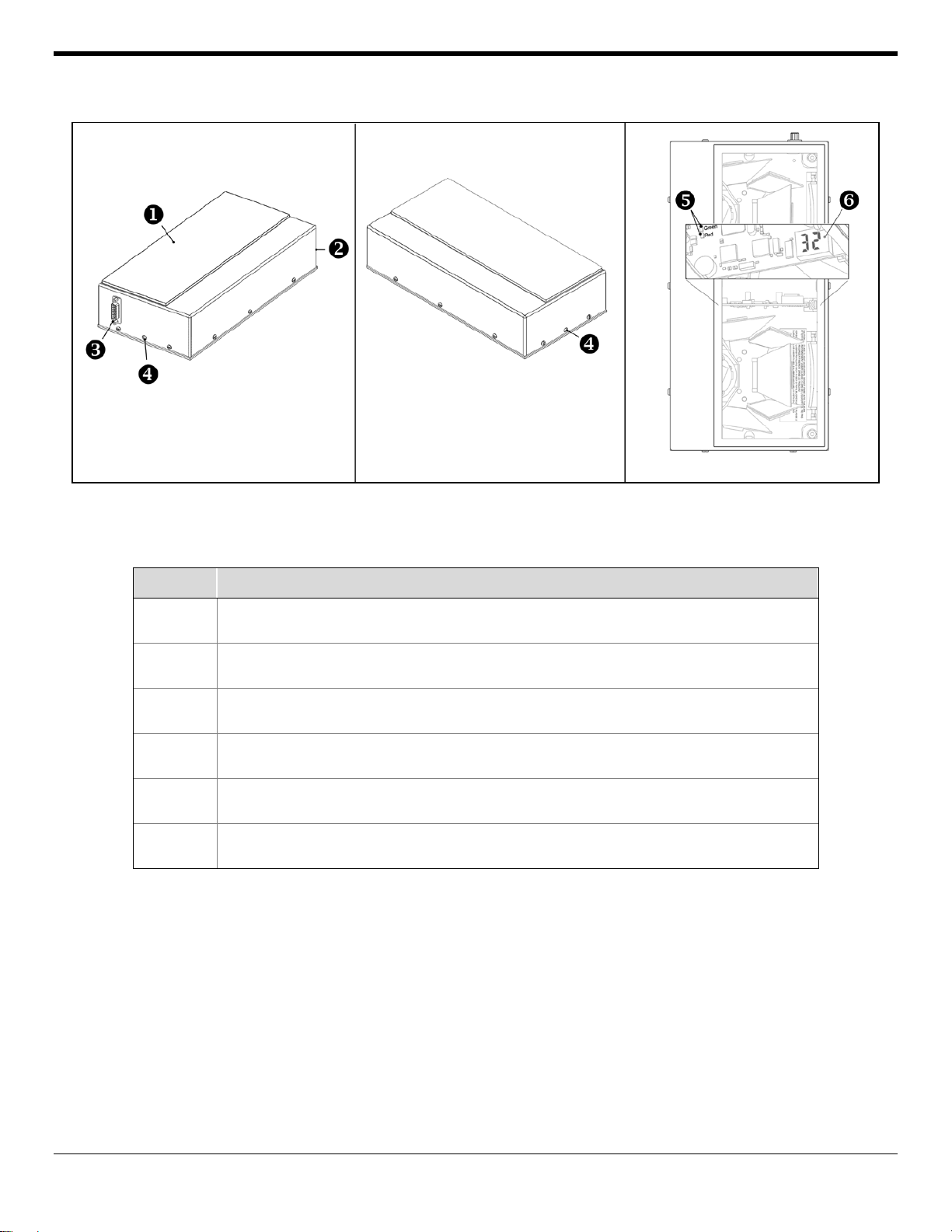

Diagnostic Indicator Display

There i s a two-digit error code display located on the center printed circuit board (see illustration below). The

following is a list of possible error codes and their meanings. Some errors will require immediate scanner

maintenance.

Description

01 Reserved

RAM ERROR – The scanner’s Random Access Memory

02

(RAM) is tested as faulty. Return the unit for repair at an

authorized service center.

03

05

06

21

PROGRAM ERROR – The scanner’s software program is

failing. Return the unit for repair.

CONFIGURATION ERROR – The non-volatile

configuration memory did not agree with the data last

saved. Default configuration data is then used and the

scanner continues operating. This error is also

accompanied by 3 beeps. This error will remain during

operation as a reminder that this power cycle is scanning

against a default-generated configuration.

COMMUNICATION ERROR - The RS232 data line is being

held active. This causes the scanner to read a “break”

signal constantly and continuous attempts are made to

enter MetroSet configuration mode. A short on the RX

Data line can cause this condition. It can also be the result

of a laptop in power save mode. The scanner will abort

attempts to enter configuration mode after a short timeout.

The scanner can automatically recover from this condition

once the short in the RX Data line is corrected.

LASER #1 (left) ERROR – The laser in the left scanning

subsystem denotes a failure. The scanner will try three

times to correct the laser operation. If the laser error

persists, the left scanning subsystem will be shut down and

error code 21 will remain on the diagnostic indicator

display. If the right scanning subsystem is still healthy, it

will remain active and scanning until the unit can be

scheduled for repair at an authorized service center.

Figure 5. Diagnostic Indicator Display

LASER #2 (right) ERROR – The laser in the right scanning subsystem denotes a failure. The

scanner will try three times to correct the laser operation. If the laser error persists, the right

22

scanning subsystem will be shut down and error code 22 will remain on the diagnostic indicator

display. If the left scanning subsystem is still healthy, it will remain active and scanning until the unit

can be scheduled for repair at an authorized service center.

7

Page 12

MOTOR #1 (left) ERROR – The motor in the left scanning subsystem denotes a failure. The

scanner will try three times to correct the motor operation. If the motor error persists, the left

31

32

scanning subsystem will be shut down and error code 31 will remain on the diagnostic indicator

display. If the right scanning subsystem is still healthy, it will remain active and scanning until the

unit can be scheduled for repair at an authorized service center.

MOTOR #2 (right) ERROR – The motor in the right scanning subsystem denotes a failure. The

scanner will try three times to correct the motor operation. If the motor error persists, the right

scanning subsystem will be shut down and error code 32 will remain on the diagnostic indicator

display. If the left scanning subsystem is still healthy, it will remain active and scanning until the unit

can be scheduled for repair at an authorized service center.

8

Page 13

Depth of Field

Figure 6. Depth of Field

Specifications subject to change without notice.

9

Page 14

10

Page 15

Troubleshooting Guide

The following guide is for reference purposes only. Contact a customer service representative to preserve the

limited warranty terms.

SYMPTOMS

POSSIBLE

CAUSE(S)

SOLUTION

No LEDs,

No beep or

No motor spin.

No LEDs,

No beep.

The unit beeps

3 times on power

up.

The unit razzes

continuously on

power up.

At power up, there

is a Razz tone and

the green LED

flashes.

At power up, there

is a Razz tone and

both LEDs flash.

No power is being

supplied to the

scanner.

No power is being

supplied to the

scanner from host.

There has been a

Non-volatile RAM

failure.

There has been a

diagnostic failure.

There has been a

VLD failure.

There has been a

scanner motor

failure.

Check the transformer, outlet and power strip.

Make sure the cable is plugged into the scanner.

Some host systems cannot supply enough current to power an

IS220. Use the power supply included with the scanner.

Contact a service representative if the unit will not hold the

programmed configuration.

Contact a service representative if the unit will not function.

Contact a service representative.

Contact a service representative.

There are multiple

scans upon

presentation of a

bar code.

The unit powers

up, but does not

beep.

The same symbol

timeout is set too

short.

The beeper is

disabled.

Adjust the same symbol timeout for a longer time .

Enable the beeper.

11

Page 16

SYMPTOMS

POSSIBLE

CAUSE(S)

The unit is scanning

a particular

symbology that is not

enabled.

SOLUTION

UPC/EAN is enabled by default.

Verify that the type of bar code being read has been enabled.

The unit powers

up, but does not

scan and/or beep.

The unit scans a

bar code, but

locks up after the

first scan (the red

LED stays on).

The unit scans,

but the data

transmitted to the

host is incorrect.

The scanner has

been configured for a

character length lock,

or a minimum length

and the bar code

being scanned does

not satisfy the

configured criteria.

The scanner is

configured to support

some form of host

handshaking but is

not receiving the

signal.

The scanner’s data

format does not

match the host

system

requirements.

Verify that the bar code being scanned falls into the configured

criteria.

Typical of Non-UPC/EAN codes.

The scanner defaults to a minimum of 4 character bar code.

If the scanner is setup to support ACK/NAK, RTS/CTS,

XON/XOFF or D/E, verify that the host cable and host are

supporting the handshaking properly.

Verify that the scanner’s data format matches the host systems

requirements. Make sure that the scanner is connected to the

proper host port.

The unit beeps for

some bar codes

and NOT for

others of the same

bar code

symbology.

The print quality of

the bar code is

suspect.

Check the character

length lock.

The aspect ratio of

the bar code is out of

tolerance.

Check the print mode. The type of printer could be the

problem. Change print settings. For example change the print

mode to

econo or high speed.

12

Page 17

The host is receiving

SYMPTOMS

The unit beeps for

some bar codes

and NOT for

others of the same

bar code

symbology.

POSSIBLE

CAUSE(S)

The bar code may

have been printed

incorrectly.

The scanner is not

configured correctly

for the type of bar

code.

The minimum symbol

length setting does

not work with the bar

code.

SOLUTION

Check if it is a check digit/character/or border problem.

Check if the check digits are set properly.

Check if the correct minimum symbol length is set.

The unit is not

transmitting each

character.

Alpha characters

show as lower

case.

Power-up OK and

scans OK but

does not

communicate

properly to the

host.

data but the data

does not look

correct.

The configuration is

not set correctly.

The computer is in

Caps Lock mode.

Com port at the host

is not working or

configured properly.

Com port not

operating properly.

Cable is not

connected to the

proper com port.

The scanner and

host may not be

configured for the

same interface font.

Increase the interscan code delay setting. Adjust if the F0

break is transmitted. It may be necessary to try this in both

settings.

Enable the Caps Lock detect setting of the scanner to detect

whether the PC is operating in Caps Lock.

Check to make sure that the baud rate and parity of the

scanner and the communication port match and the program is

looking for “RS-232" data.

Check that the scanner and the host are configured for the

same interface font.

Characters are

being dropped.

Intercharacter delay

needs to be added to

the transmitted

output.

Add some intercharacter delay to the transmitted output by

using the MetroSelect Configuration Guide (

MLPN 00-02407).

13

Page 18

14

Page 19

Design Specifications

Operational

Light Source: Two, Visible Laser Diodes @ 650 nm

Laser Power: 1 mW per VLD

Scan Pattern: 10 fields of 4 parallel lines (for ladder and picket fence)

Number of Scan Lines: 40

Scan Speed: 4000 scan lines per second +/- 5%

Depth of Scan Field, Near: 115 mm (4.5") from window surface, pattern offset

Depth of Scan Field, Far: 190 mm (7.5") from window surface, pattern offset

Minimum Bar Width: 0.2 mm (8.0 mil)

Decode Capability: Autodiscriminates all standard 1-D barcodes.

System Interface: RS232

Print Contrast: 35% minimum reflectance difference

Number of Characters Read:

Audible Indicators: Internal beeper

Visual Indicators (Default

Settings):

Mechanical

Length: 295 mm

Width: 150 mm

Depth: 75 mm

Weight: 2.5 Kg maximum excluding cable

Termination: 15-pin, Male D-sub connector with screw locks

Mounting: Two, M5 tapped holes are provided for mounting purposes

Electrical

Input Voltage: 5VDC ± 0.25V

Up to 80 data characters.

The maximum number will vary based on symbology and density.

Green LED = Laser on, ready to scan

Red LED = Good read, decoding

Operating Power: 6.25W typical @ 5VDC

Operating Current: 1.25A typical

DC Transformers: Class II; 5VDC @1.5A

Laser Class 2: IEC 60825-1:1993+A1:1997+A2:2001

EMC: FCC, ICES-003 & EN 55022 Class B

15

Page 20

Environmental

Temperature:

Humidity: 5% to 95% relative humidity , non-condensing

Contaminants: Sealed to resist airborne particulate contaminants

Ventilation: None required

Specifications subject to change without notice.

Operating = 0°C to 40°C (32°F to 104°F)

Storage = -40°C to 60°C (-40°F to 140°F)

16

Page 21

Upgrading the Flash ROM Firmware

The IS220 is part of Honeywell’s line of scanners with flash upgradeable firmware. The upgrade process

requires, a new firmware file supplied to the customer by a customer service representative and MetroSet2

software

required to complete the upgrade.

To upgrade the firmware in the IS220:

1. Plug the scanner into a serial communication port on the host system.

2. Start the MetroSet2 software.

3. Click on the plus sign (+) next to Industrial Scanners to expand the supported scanner list.

4. Choose the IS220 from the list.

5. Click on the Configur e IS220 Scanner button.

6. Choose Utility, Flash Main Processor from the options list located on the left side of the screen.

7. Click on the Open File button in the Flash Utility window.

8. Locate and open the flash upgrade file.

. A personal computer running Windows 95 or greater with an available RS232 serial or USB port is

9. Select the COM port that the scanner is connected to on the host system.

10. Verify the settings listed in the Flash Utility window.

11. Click on the Flash Scanner button to begin the flash upgrade.

12. A message will appear on the screen when the upgrade is complete.

MetroSet2 is available for download, at no additional cost, from www.honeywellaidc.com.

17

Page 22

18

Page 23

Default Settings

Communication Param e t er s

Many functions of the scanner can be "configured" - that is, enabled or disabled. The scanner is shipped from

the factory configured to a set of default conditions. The default parameter of the scanner has an asterisk ( * )

in the charts on the following pages. If an asterisk is not in the default column then the default setting is Off or

Disabled. Every interface does not support every parameter. If the interface supports a parameter listed in the

charts on the following pages, a check mark will appear.

Parameter Default RS232

UPC/EAN *

Code 128

Code 93

Codabar

Interleaved 2 of 5 (ITF)

MOD 10 Check on ITF

Code 11

Code 39

Full ASCII Code 39

MOD 43 CD on Code 39

Transmit Mode 43 CD

Paraff

Paraff Lead “A”

Allow Paraff Failures

French PC Terminal

MSI-Plessey

Airline (15 digit) 2 of 5

Airline (13 digit) 2 of 5

Matrix 2 of 5

Telepen

UK Plessey

STD 2 of 5

MSI-Plessey 10/10 Check Digit

MSI-Plessey MOD 10 Check Dig it

ITF Symbol Lengths Variable

ITF Minimum Symbol Length 6

Symbol Length Lock None

Minimum Symbol Length 4

Trioptic

GS1 DataBar Enable

19

Page 24

Same Symbol Rescan Timeout: 500 msecs Programmable in 50 msec steps

(MAX 6.35 seconds)

Parameter Default RS232

GS1 DataBar ID “]e0” *

GS1 DataBar App ID “01” *

GS1 DataBar Check Digit *

GS1 DataBar Expanded Enable

Expanded ID “]e0” *

GS1 DataBar Limited Enable

GS1 DataBar Limited ID “]e0” *

GS1 DataBar Limited App ID “01” *

GS1 DataBar Limited Check Digit *

Beeper Tone Normal

Beep Transmit Sequence

Before

Transmit

Beeper Volume Loudest

Communication Timeout None

Razzberry Tone on Timeout

Three Beeps on Timeout

No Beeps on Timeout *

Fast Beep

Beep Twice on Supplements

No Beeps on Timeout *

5 Retries Before Timeout

Timeout In … 2 secs.

Laser Off Between Records

Variable Laser Off Delay 5 - 635 msec

Flash LED on Good Scan *

Reverse LED Convention

Flash LED on Good Scan *

Enter Power Save Mode 10 mins.

Blink Power Save Mode *

Laser OFF Power Save Mode

Laser & Motor OFF Power Save Mode

Dual Action Power Save Mode #1

Dual Action Power Save Mode #2

Intercharacter Delay Programmable in 1 msec steps (MAX 255 msecs) 1 msecs

Number of Scan Buffers 1

UPC GTIN-14 Format

EAN-8 Enable *

Transmit EAN-8 Check Digit *

20

*

Page 25

Parameter Default RS232

Convert EAN-8 to EAN-13

EAN-13 Enable *

Transmit EAN-13 Check Digit *

UPC-A Enable *

Convert UPC-A to EAN-13

Transmit UPC-A Check Digit *

Transmit UPC-A Number System *

Transmit UPC-A Manufacturers ID. *

Transmit UPC-A Item ID *

UPC-E Enable *

Empand UPC-E

Transmit UPC-E Lead ‘0’ *

Transmit UPC-E Check Digit

Disable UPC-E Auto Redundancy *

Transmit Codabar Start/Stop Characters

Codabar CLSI

Dual Field Codabar

Tab Between Dual field Codabar

Codabar CLSI Check Digit

Codabar 7-Check Check Digit

Codabar Mod-16 Check Digit

Transmit MSI Plessey Check Digits

Number of MSI Plessey Check Digits 0

UK Plessey A to X Convert

UK Plessey Special 12 Character Format

Transmit UK Plessey Check Dig it

EAN 128 Enable

Enable French Pharma

Enable Matrix 2 of 5 Check Digit

Enable Hong Kong 2 of 5

Enable Alpha Telepen

Telepen Convert Lead ‘^L’ to ‘E’

Enable Code 11 Check Digit

Parity Space

Baud Rate 19200

8 Data Bits

7 Data Bits *

Stop Bits 2

RTS / CTS Enabled

21

Page 26

Parameter Default RS232

Message RTS

Character RTS *

ACK / NAK

O / N Handshaking

Host Bell / Cancel

Xon / Xoff

No Transmit Without DTR Present

French PC Terminal Emulation

“D/E” Disable Command

“Z/R” Disable Command

“F/L” Laser Command *

“M/O” Motor Enable Commands

Beep on Bell

Razz on ‘z’

Activate on DTR

Activate on DC2 Character

Xmit No Read Message on DC2 Timeout

No Transmit LED During No Read Message

Programmable “No Read” Message

Recv “I” = Transmit “METROLOGIC”

Recv “i” = Transmit Scanner ID Byte

STX Pr e fix

TAB Prefix

Metrologic Prefix

UPC Prefix

ETX Suffix

TAB Suffix

Carriage Return Suffix *

Line Feed Suffix *

UPC Suffix

Transmit LRC

Start LRC on 1st Byte

Start LRC on 2nd Byte

‘c’ Prefix for UPC

‘$’ Prefix for UPC

Programmable Prefix Characters 10 avail

Programmable Suffix Characters 10 avail

Predefined Code ID Sets

22

Multiple

Selections

Page 27

Parameter Default RS232

Programmable Prefix for Code Types

Programmable Suffix for Code Types

Programmable Code Lengths 7 avail

Code Selects 7 avail

Code Select Timeout 0.1 to 25.5 seconds 5 sec

Replace 1 Character in Transmission

Razz on Code Select Timeout *

Japan Dual Field Code Selects

EAN-13 Only in Japan Dual Field

Two Digit Supplements

Five Digit Supplements

Require Supplements

Remote Supplement Support

Two Digit Redundancy

Five Digit Redundancy

Enable Coupon Code 128

Transmit Coupon ‘]C1’ *

Group Separator *

Coupon Code Can Begin with ’4’

Enable EAN-99 Coupon Code

Bookland

Convert Bookland to ISBN

Refor mat ISBN

Transmit ISBN Check Digit

Bookland 977 2-Digit Supp Required

378 / 379 Supplements

414 / 419 Supplements

434 / 439 Supplements

Number System 2 Enables Supplements

Number System 5 Enables Supplements

100 msec to Find Supplement (100 - 800 msec) *

Allow Code ID’s with Supplements

23

Page 28

24

Page 29

Pin

Function

1

Shield GND

2

TXD

3

RXD

4

DTR

5

GND

6

DSR

7

CTS

8

RTS

9

External LED

10

+5V

11

+5V

12

GND

13

GND

14

Earth Ground

15

External Beeper

Standard 15-pin, Female D-

Sub

Pin

Function

Pin

Function

1

Shield GND

1

N/C

2

TXD

2

TXD

3

RXD

3

RXD

4

DTR

4

DTR

5

GND

5

GND

6

DSR

6

DSR

7

CTS

7

CTS

8

RTS

8

RTS

9

N/C

9

N/C

10

+5V

11

+5V

12

GND

13

GND

14

Lug

Scanner and Cable Terminations

Scanner Pinout Connections

Standard 15-pin, Male D-Sub

Cable Connector Configurations

52-52548 and 52-52547 Communication/Power Cable

Standard 9-pin, Female D-Sub

15 N/C

25

Page 30

26

Page 31

Limited Warranty

Honeywell International Inc. ("HII") warrants its products and optional accessories to be free from defects in

materials and workmanship and to conform to HII’s published specifications applicable to the products

purchased at the time of shipment. This warranty does not cover any HII product which is (i) improperly

installed or used; (ii) damaged by accident or negligence, including failure to follow the proper maintenance,

service, and cleaning schedule; or (iii) damaged as a result of (A) modification or alteration by the purchaser or

other party, (B) excessive voltage or current supplied to or drawn from the interface connections, (C) static

electricity or electro-static discharge, (D) operation under conditions beyond the specified operating

parameters, or (E) repair or service of the product by anyone other than HII or its authorized representatives.

This warranty shall extend from the time of shipment for the duration published by HII for the product at the

time of purchase ("Warranty Period"). Any defective product must be returned (at purchaser’s expense) during

the Warranty Period to HII factory or authorized service center for inspection. No product will be accepted by

HII without a Return Materials Authorization, which may be obtained by contacting HII. In the event that the

product is returned to HII or its authorized service center within the Warranty Period and HII determines to its

satisfaction that the product is defective due to defects in materials or workmanship, HII, at its sole option, will

either repair or replace the product without charge, except for return shipping to HII.

EXCEPT AS MAY BE OTHERWISE PROVIDED BY APPLICABLE LAW, THE FOREGOING WARRANTY IS

IN LIEU OF ALL OTHER COVENANTS OR WARRANTIES, EITHER EXPRESSED OR IMPLIED, ORAL OR

WRITTEN, INCLUDING, WIT HOUT LI MITATION, ANY IMPLIED WARRANTI ES OF MERCHANT ABILITY OR

FITNESS FOR A PARTICULAR PURPOSE, OR NON-INFRINGEMENT.

HII’S RESPONSIBILIT Y AND PURCHASE R’S EXCLUSIVE REMEDY UNDER THIS WARRANTY IS LIMITED

TO THE REPAIR OR REPLACEMENT OF THE DEFECTIVE PRODUCT WITH NEW OR REFURBISHE D

PARTS. IN NO EVENT SHALL HII BE LIABLE FOR INDIRECT , INCIDENTAL, OR CONSEQUENTI AL

DAMAGES, AND, IN NO EVENT, SHALL ANY LIABILITY OF HII ARISING IN CONNECTION W ITH ANY

PRODUCT SOLD HEREUNDER (WHETHE R SUCH LIAB ILITY ARISES FROM A CLAIM BASED ON

CONTRACT, WARRANTY, TORT, OR OTHE RWISE) EXCEED THE ACTUAL AMOUNT PAID TO HII FOR

THE PRODUCT. THESE LIMITATIONS ON LI ABILITY SHALL REMAIN IN FULL FORCE AND EFFECT

EVEN WHEN HII MAY HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH INJURIES, LOSSES, OR

DAMAGES. SOME STATES, PROVI NCES, OR COUNTRIES DO NOT ALLOW THE EXCLUSION OR

LIMITATIONS OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR

EXCLUSION MAY NOT APPLY TO YOU.

All provisions of this Limited Warranty are separate and severable, which means that if any provision is held

invalid and unenforceable, such determination shall not affect the validity of enforceability of the other

provisions hereof. Use of any peripherals not provided by the manufacturer may result in damage not covered

by this warranty. This includes but is not limited to: cables, power supplies, cradles, and docking stations. HII

extends these warranties only to the first end-users of the products. These warranties are non-transferable.

The duration of the limited warranty for the IS220 is two (2) year(s). The accessories have a 90 day limited

warranty from the date of manufacture.

27

Page 32

28

Page 33

Laser and Product Safety

Cautions

Caution

Use of controls or adjustments or performance of procedures other than those specified herein may result

in hazardous laser light exposure. Under no circumstances should the customer attempt to service the

laser scanner. Never attempt to look at the laser beam, even if the scanner appears to be nonfunctional.

Never open the scanner in an attempt to look into the device. Doing so could result in hazardous laser light

exposure. The use of optical instruments with the laser equipment will increase eye hazard.

Atención

La modificación de los procedimientos, o la utilización de controles o ajustes distintos de los especificados

aquí, pueden provocar una luz de láser peligrosa. Bajo ninguna circunstancia el usuario deberá realizar el

mantenimiento del láser del escáner. Ni intentar mirar al haz del láser incluso cuando este no esté

operativo. Tampoco deberá abrir el escáner para examinar el aparato. El hacerlo puede conllevar una

exposición peligrosa a la luz de láser. El uso de instrumentos ópticos con el equipo láser puede

incrementar el riesgo para la vista.

Attention

L'emploi de commandes, réglages ou procédés autres que ceux décrits ici peut entraîner de graves

irradiations. Le client ne doit en aucun cas essayer d'entretenir lui-même le scanner ou le laser. Ne

regardez jamais directement le rayon laser, même si vous croyez que le scanner est inactif. N'ouvrez

jamais le scanner pour regarder dans l'appareil. Ce faisant, vous vous exposez à une rayonnement laser

qú êst hazardous. L'emploi d'appareils optiques avec cet équipement laser augmente le risque

d'endommagement de la vision.

Achtung

Die Verwendung anderer als der hier beschriebenen Steuerungen, Einstellungen oder Verfahren kann eine

gefährliche Laserstrahlung hervorrufen. Der Kunde sollte unter keinen Umständen versuchen, den LaserScanner selbst zu warten. Sehen Sie niemals in den Laserstrahl, selbst wenn Sie glauben, daß der

Scanner nicht aktiv ist. Öffnen Sie niemals den Scanner, um in das Gerät hineinzusehen. Wenn Sie dies

tun, können Sie sich einer gefährlichen Laserstrahlung aussetzen. Der Einsatz optischer Geräte mit dieser

Laserausrüstung erhöht das Risiko einer Sehschädigung.

Attenzione

L’utilizzo di sistemi di controllo, di regolazioni o di procedimenti diversi da quelli descritti nel presente

Manuale può provocare delle esposizioni a raggi laser rischiose. Il cliente non deve assolutamente tentare

di riparare egli stesso lo scanner laser. Non guardate mai il raggio laser, anche se credete che lo scanner

non sia attivo. Non aprite mai lo scanner per guardare dentro l’apparecchio. Facendolo potete esporVi ad

una esposizione laser rischiosa. L’uso di apparecchi ottici, equipaggiati con raggi laser, aumenta il rischio

di danni alla vista.

Class 2 Laser Product

Laser Klasse 2 Produkt

Appareil A Laser De Classe 2

29

Page 34

Notices

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1)

This device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to

Part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference to

radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the interference by

one or more of the following measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the equipment and receiver

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected

• Consult the dealer or an experienced radio/TV technician for help

Notice

This Class B digital apparatus complies with Canadian ICES-003.

Avertissement

Cet appareil numérique de la class B est conforme à la norme NMB-003.

30

Page 35

Index

A

Accessories ........................................................... 1

Application ............................................................. 7

Audible Indicators .......................................... 11–13

B

Beeper ....................................................... 5, 19–23

C

Cable

Communication ......................................... 1, 3, 25

Configuration .................................................... 25

Pinouts ............................................................. 25

Power ....................................................... 1, 3, 25

Troubleshooting .......................................... 11–13

Case

Components ....................................................... 3

Dimensions ......................................................... 2

Caution ............................................................ 4, 29

CE ....................................................................... 29

Communication

Default Settings .......................................... 19–23

Troubleshooting .......................................... 11–13

compliance .......................................................... 27

Configuration ............................................. 7, 11–13

Guide ............................................................ 1, 13

customer service ................................................. 27

Customer Service .................................................. 1

Ground ................................................................ 25

H

Host .............................................................. 19–23

I

Indicators

Audible ....................................... 5, 11–13, 19–23

Error Codes .................................................... 3, 7

Failure ............................................................ 3, 5

Visual ...................................... 3, 5, 11–13, 19–23

L

Label

Caution ............................................................... 4

Location ............................................................. 4

Serial Number .................................................... 4

Laser Aperture ................................................ 3, 10

Laser Class ......................................................... 15

Laser Light .................................................. 4, 7, 29

M

Maintenance ................................................... 7, 10

Meteor ................................................................. 17

MetroSet2 ........................................................... 17

Mounting Holes ................................................. 2, 3

N

Notices ................................................................ 29

D

Default Settings ............................................. 19–23

Depth of Field

Far .................................................................... 10

Near ................................................................. 10

Diagnostic Indicator Display .............................. 3, 7

E

EMC .................................................................... 15

Error Codes ....................................................... 3, 7

F

Failure Modes ........................................................ 5

FCC ..................................................................... 29

Flash ROM Firmware .......................................... 17

G

Green LED ........................................................ 3, 5

P

Parameters ................................................... 19–23

PC ................................................................. 19, 22

Product

Safety ............................................................... 29

R

Red LED ........................................................... 3, 5

repair ................................................................... 27

Repair ................................................................... 7

RMA .................................................................... 27

RS232 ........................................................... 19–23

S

Scanner

Pinouts ............................................................. 25

service................................................................. 27

31

Page 36

Specifications

Electrical ........................................................... 15

Environmental ................................................... 15

Mechanical ....................................................... 15

Operational ....................................................... 15

Symbol Length .............................................. 11–13

T

Troubleshooting ............................................. 11–13

U

Upgrade .............................................................. 17

V

Visual Indicator

Green LED .............................. 3, 5, 11–13, 19–23

Red LED ................................. 3, 5, 11–13, 19–23

W

warranty .............................................................. 27

Window ....................................................... 3, 7, 10

32

Page 37

Customer Support

Technical Assistance

If you need assistance installing or troubleshooting your device, please call your distributor or the nearest

technical support office:

North America/Canada

Telephone: (800) 782-4263

E-mail: hsmnasupport@honeywell.com

Latin America

Telephone: (803) 835-8000

Telephone: (800) 782-4263

E-mail: hsmlasupport@honeywell.com

Brazil

Telephone: +55 (21) 3535-9100

Fax: +55 (21) 3535-9105

E-mail: brsuporte@honeywell.com

Mexico

Telephone: 01-800-HONEYWELL (01-800-466-3993)

E-mail: soporte.hsm@honeywell.com

Europe, Middle East, and Africa

Telephone: +31 (0) 40 7999 393

Fax: +31 (0) 40 2425 672

E-mail: hsmeurosupport@honeywell.com

Hong Kong

Telephone: +852-29536436

Fax: +851-2511-3557

E-mail: aptechsupport@honeywell.com

Singapore

Telephone: +65-6842-7155

Fax: +65-6842-7166

E-mail: aptechsupport@honeywell.com

China

Telephone: +86 800 828 2803

Fax: +86-512-6762-2560

E-mail: aptechsupport@honeywell.com

Japan

Telephone: +81-3-6730-7344

Fax: +81-3-6730-7222

E-mail: aptechsupport@honeywell.com

Online Technical Assistance

You can also access technical assistance online at www.honeywellaidc.com.

33

Loading...

Loading...