Page 1

HercuLine® 2000 Series Actuator

Installation, Operation and

Maintenance Manual

Doc. No.: 62-86-25-10

Revision: 7

Date: 7/08

Honeywell Field Solutions

Page 2

Notices and Trademarks

Copyright 2008 by Honeywell

Revision 7 July 2008

Warranty/Remedy

Honeywell warrants goods of its manufacture as being free of defective materials and faulty workmanship. Contact

your local sales office for warranty information. If warranted goods are returned to Honeywell during the period of

coverage, Honeywell will repair or replace without charge those items it finds defective. The foregoing is Buyer's sole

remedy and is in lieu of all other warranties, expressed or implied, including those of merchantability and fitness for a

particular purpose. Specifications may change without notice. The information we supply is believed to be accurate

and reliable as of this printing. However, we assume no responsibility for its use.

While we provide application assistance personally, through our literature and the Honeywell web site, it is up to the

customer to determine the suitability of the product in the application.

CE Conformity

This product conforms with the protection requirements of the following European Council Directive: 89/336/EEC,

the EMC directive and 73/23/EEC, the Low Voltage Directive. Conformance of this product with any other “CE Mark”

Directive(s) shall not be assumed.

Attention

The emission limits of EN 50081-2 are designed to provide reasonable protection against harmful interference when

this equipment is operated in an industrial environment. Operation of this equipment in a residential area may cause

harmful interference. This equipment generates, uses, and can radiate radio frequency energy and may cause

interference to radio and television reception when the equipment is used closer than 30 m to the antenna(e). In

special cases, when highly susceptible apparatus is used in close proximity, the user may have to employ additional

mitigating measures to further reduce the electromagnetic emissions of this equipment.

Honeywell Process Solutions

512 Virginia Drive

Fort Washington, PA 19034

HercuLink® and HercuLine® are trademarks of Honeywell

Other brand or product names are trademarks of their respective owners.

Palm is a trademark of Palm Inc.

ii HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual Revision 7

7/08

Page 3

About This Document

Abstract

This manual describes the installation, set up, operation, maintenance, and troubleshooting of the

HercuLine 2000 series actuators.

References

The following list identifies all documents that may be sources of reference for material discussed in this

publication.

Document Title Doc ID

HercuLine 2000 Series Actuator Specification 61-86-03-14

HercuLine 2000 Series Actuator Model Selection Guide 62-86-16-21

Modbus® RTU Serial Communications User Manual

Modbus

Configuration/Remote Calibration Interfaces for HercuLine Actuators

HercuLink™ User Manual 62-86-25-11

HART Communications Installation and Operations Manual 62-86-25-12

®

RTU Serial Communications User Manual

51-52-25-66

51-52-25-103

Contacts

World Wide Web

The following lists Honeywell’s World Wide Web sites that will be of interest to our customers.

Honeywell Organization WWW Address (URL)

Corporate

Honeywell Process Solutions http://www.honeywell.com/ps

Telephone

Contact us by telephone at the numbers listed below.

United States and Canada Honeywell

Organization Phone Number

http://www.honeywell.com

1-800-423-9883 Tech. Support

1-800-525-7439 Service

Revision 7 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual iii

7/08

Page 4

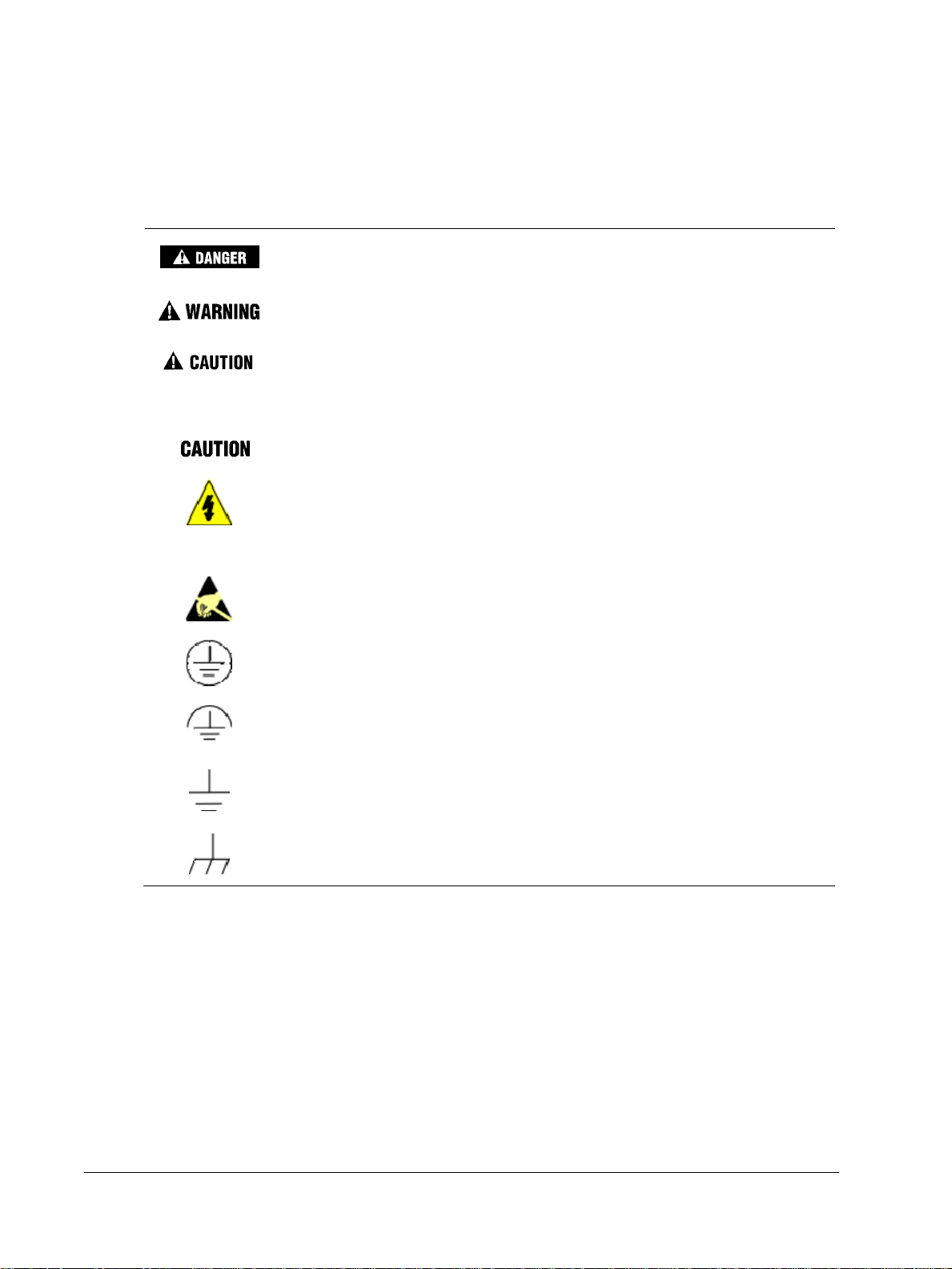

Symbol Definitions

The following table lists those symbols that may be used in this document to denote certain conditions.

Symbol Definition

This DANGER symbol indicates an imminently hazardous situation, which,

if not avoided, will result in death or serious injury.

This WARNING symbol indicates a potentially hazardous situation, which, if

not avoided, could result in death or serious injury.

This CAUTION symbol may be present on Control Product instrumentation

and literature. If present on a product, the user must consult the

appropriate part of the accompanying product literature for more

information.

This CAUTION symbol indicates a potentially hazardous situation, which, if

not avoided, may result in property damage.

WARNING

PERSONAL INJURY: Risk of electrical shock. This symbol warns the user of a

potential shock hazard where HAZARDOUS LIVE voltages greater than 30 Vrms,

42.4 Vpeak, or 60 Vdc may be accessible. Failure to comply with these

instructions could result in death or serious injury.

ATTENTION, Electrostatic Discharge (ESD) hazards. Observe precautions for

handling electrostatic sensitive devices

Protective Earth (PE) terminal. Provided for connection of the protective earth

(green or green/yellow) supply system conductor.

Functional earth terminal. Used for non-safety purposes such as noise immunity

improvement. NOTE: This connection shall be bonded to protective earth at the

source of supply in accordance with national local electrical code requirements.

Earth Ground. Functional earth connection. NOTE: This connection shall be bonded

to Protective earth at the source of supply in accordance with national and local

electrical code requirements.

Chassis Ground. Identifies a connection to the chassis or frame of the equipment

shall be bonded to Protective Earth at the source of supply in accordance with

national and local electrical code requirements.

iv HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual Revision 7

7/08

Page 5

Contents

Introduction .............................................................................................1

Product Description ......................................................................................................1

Specifications .......................................................................................... 5

Technical and Operating Specifications.......................................................................5

Model Selection Guide ...............................................................................................10

Installation ............................................................................................. 12

Installation Overview ..................................................................................................12

Mechanical Stops .......................................................................................................12

Before Starting............................................................................................................13

Contents

Actuator Mounting ......................................................................................................13

Mechanical Installation ...............................................................................................15

Electrical Installation...................................................................................................17

Burner Control/Flame Safety................................................................. 23

Series 90 Control – HercuLine

Split Range .................................................................................................................26

Master/Slave Arrangement.........................................................................................26

®

2001 model only......................................................24

Set Up and Calibration Procedures....................................................... 31

Overview.....................................................................................................................31

Local Display and Keypad..........................................................................................31

Set Up Tips.................................................................................................................33

Set Up Groups............................................................................................................34

Set Up Procedure .......................................................................................................36

Configuration Prompt Hierarchy .................................................................................38

Input Set Up Group.....................................................................................................39

Relays Set Up Group..................................................................................................44

Current Out Set Up Group..........................................................................................49

Communications Set Up Group..................................................................................50

Digital Input Set Up Group .........................................................................................51

Display Set Up Group.................................................................................................52

Revision 7 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual v

7/08

Page 6

Contents

Lock Set Up Group .....................................................................................................53

Read Status Set Up Group.........................................................................................55

Drive Set Up Group ....................................................................................................56

Maintenance Set Up Group........................................................................................59

Regions of Motor Travel .............................................................................................62

CAL POSOUT Group .................................................................................................63

Auto - Manual Drive Switch ........................................................................................64

Calibration ..................................................................................................................65

Setting End-of-Travel Limit Switches .........................................................................78

Setting Auxiliary Switches ..........................................................................................81

Start-Up/Operation ................................................................................ 83

Introduction.................................................................................................................83

Power-up Diagnostics.................................................................................................83

Operations Checklist ..................................................................................................83

Operating Displays .....................................................................................................84

Motor Stall ..................................................................................................................84

Position Sensor Operation .........................................................................................85

Remote Setpoint Operation........................................................................................85

Maintenance.......................................................................................... 87

Introduction.................................................................................................................87

Basic Maintenance .....................................................................................................87

Replacement Procedures...........................................................................................89

Replacement/Upgrade/Accessory Kits ..................................................91

Replacement Kits .......................................................................................................91

Upgrade Kits.............................................................................................................102

Accessory Kits ..........................................................................................................104

Troubleshooting .................................................................................. 105

Introduction...............................................................................................................105

Troubleshooting Procedures ....................................................................................106

Appendix A - HercuLine

®

2001/2002 Configuration Record Sheet...... 112

Index ...................................................................................................116

vi HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual Revision 7

7/08

Page 7

Contents

Tables

Table 1 Specifications - General.............................................................................................................................5

Table 2 Recommended Minimum Wire Size........................................................................................................17

Table 3 Terminal Connections: HercuLine® 2000...............................................................................................18

Table 4 Terminal Connections: HercuLine® 2001/2002 with auto/manual.........................................................19

Table 5 Split Range Set Up Procedure .................................................................................................................26

Table 6 Keypad Description.................................................................................................................................32

Table 7 Set Up Tips..............................................................................................................................................33

Table 8 Set Up Groups .........................................................................................................................................34

Table 9 Set Up Procedure Using Display and Keypad.............................................................................. ...........36

Table 10 Input Set Up Group Parameters.............................................................................................................39

Table 11 Equal Percentage Valve Characteristics................................................................................................42

Table 12 Quick Opening Valve Characteristic.....................................................................................................43

Table 13 Relay Set Up Group Parameters............................................................................................................44

Table 14 Relay Type Descriptions........................................................................................................................45

Table 15 Current Out Set Up Group Parameters..................................................................................................49

Table 16 Communications Set Up Group Parameters ..........................................................................................50

Table 17 Digital Input Set Up Group Parameters.................................................................................................51

Table 18 Display Set Up Group Parameters.........................................................................................................52

Table 19 Lock Set Up Group Parameters.............................................................................................................53

Table 20 Read Status Set Up Group Parameters ..................................................................................................55

Table 21 Drive Set Up Group Parameters............................................................................................................56

Table 22 Maintenance Set Up Group Parameters.................................................................................................59

Table 23 CAL POSOUT Group Parameters.........................................................................................................63

Table 24 Auto - Manual Switch Functions...........................................................................................................64

Table 25 Input Calibration Procedure...................................................................................................................69

Table 26 Motor Calibration Procedure.................................................................................................................70

Table 27 Output Calibration Procedure................................................................................................................ 71

Table 28 Slidewire Emulation Calibration Procedure..........................................................................................73

Table 29 NCS Position Sensor Calibration Procedure.........................................................................................74

Table 30 Potentiometer Position Sensor Calibration Procedure..........................................................................76

Table 31 Load Position Sensor Factory Calibration.............................................................................................77

Table 32 End-of-Travel Limit Switch Setting Procedure.....................................................................................79

Table 33 Auxiliary Switch Setting Procedure ...................................................................................................... 82

Table 34 Typical Operating Displays...................................................................................................................84

Table 35 Spur Gear Lubrication Procedure..........................................................................................................87

Table 36 Motor Drive Fuse Replacment Procedure .............................................................................................89

Table 37 Relay PWA Replacement Procedure.....................................................................................................90

Table 38 Replacement kits....................................................................................................................................96

Table 39 Observable Symptoms of Failure........................................................................................................105

Revision 7 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual vii

7/08

Page 8

Contents

Figures

Figure 1 HercuLine® 2000 Series Actuator 2

Figure 2 HercuLine® 2002 Actuator Internal View 3

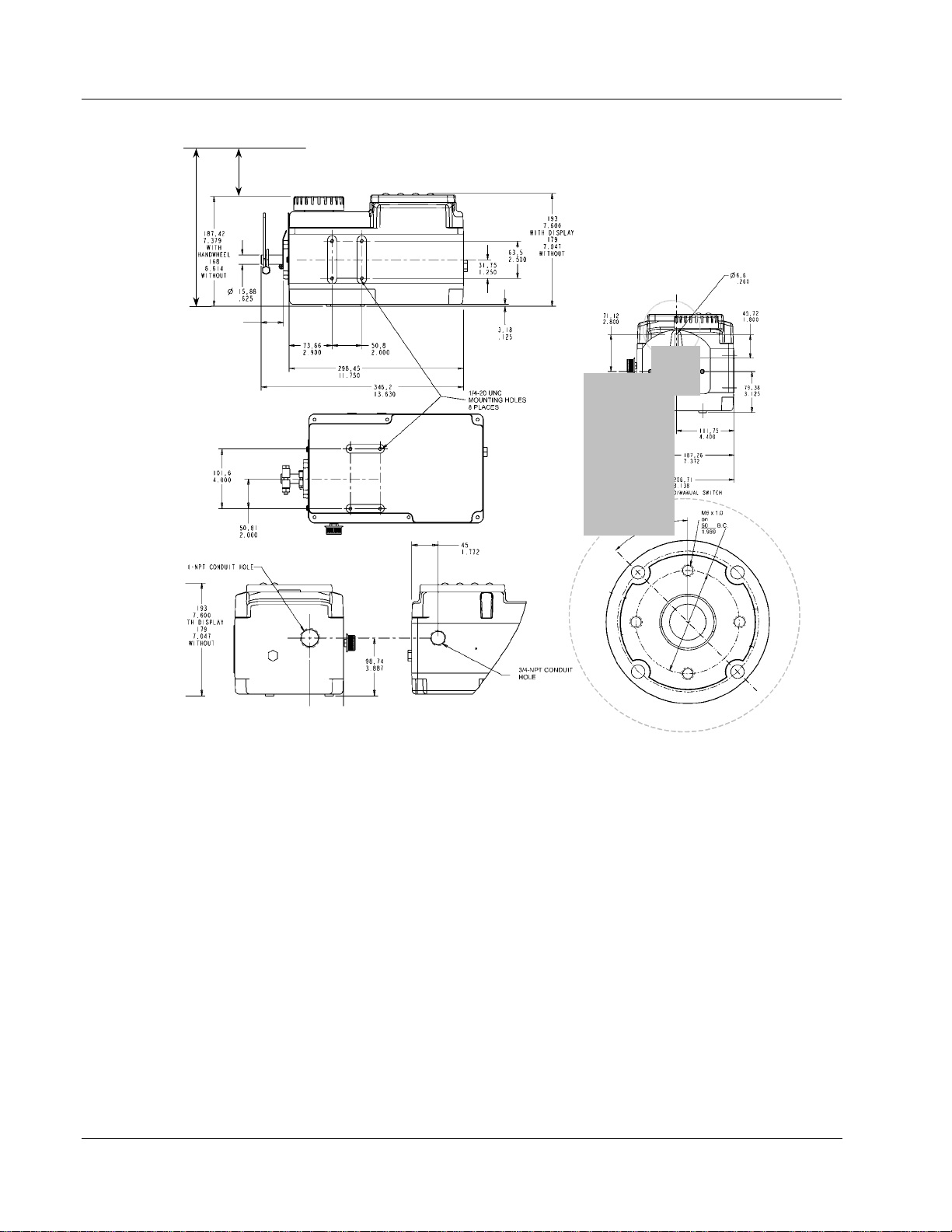

Figure 3 Outline and Dimensions of HercuLine® 2000 Series Actuators 14

Figure 4 Constant Torque Linkage 15

Figure 5 Variable Torque Linkage 16

Figure 6 Standard crank arm 16

Figure 7 Crank arm with optional ball joint and push rod 16

Figure 8 HercuLine® 2000 connections 18

Figure 9 HercuLine® 2001/2002 connections 19

Figure 10 HercuLine® 2003 connections 20

Figure 11 CE wiring part 1 21

Figure 12 CE Wiring part 2 22

Figure 13 Burner Control/Flame Safety Wiring 23

Figure 14 Series 90 connections 24

Figure 15 T775 Controller connections 25

Figure 16 Flow Diagram 27

Figure 17 Interconnection Diagram 27

Figure 18 Proportional Flow Using Multiple Actuators 28

Figure 19 Multiple Actuator Interconnection Diagrams 29

Figure 20 Interconnection Diagrams 30

Figure 21 HercuLine® 2000 Display and Keypad 31

Figure 22 Relay connectors 46

Figure 23 Regions of Motor Travel 62

Figure 24 Auto - Manual Switch 64

Figure 25 Calibration Wiring Connectio ns ( no n -sl i dewire emulation) 66

Figure 26 Calibration Wiring Connections (slidewire emulation) 67

Figure 27 Jumper Location on CPU PWA 68

Figure 28 Location of NCS Assembly 75

Figure 29 Location of potentiometer position sensor 77

Figure 30 End of Travel Limit Switch Settings 78

Figure 31 Location of End-of-Travel Limit and Auxiliary Switches 80

Figure 32 Auxiliary Switch Settings 81

Figure 33 Terminal Block Connections for Modbus Communications 86

Figure 34 Spur Gear Location 88

Figure 35 Power Distribution PWA and Relay PWA Locatio ns 89

Figure 36 Motor Drive Circuit Fuses 90

Figure 37 Replacement Kits 6, 7, 8, 11, 12, 14 91

Figure 38 Replacement Kit 10 92

Figure 39 Replacement Kits 1, 2, 3, 4, 5, 9, 15, 16, 19 93

Figure 40 Replacement Kit 13 94

Figure 41 Replacement Kits 17, 18 95

Figure 42 Test for Actuator Operation 107

Figure 43 Power Up Diagnostics 108

Figure 44 Test Power Distribution PWA 109

Figure 45 Test AUTO - MANUAL Switch 110

Figure 46 Test Relay Function 111

viii HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual Revision 7

7/08

Page 9

Product Description

Introduction

Product Description

Introduction

Honeywell’s HercuLine® 2000 series actuators are available in four versions: HercuLine® 2000,

HercuLine

®

actuators incorporating all of the high quality and reliable features of the traditional HercuLine

actuators. These precision control and high reliability actuators ensure processes operate at maximum

efficiency, with minimal downtime, and lowest lifetime cost.

Honeywell's HercuLine

accurate positioning, and low maintenance (

and quarter turn valves the HercuLine

demanding environments requiring continuous-duty, high reliability, and low maintenance.

Model distinctions

HercuLine

®

proportional with 135 or 1000 ohm feedback.

HercuLine

®

or digital control. They offer digital electronics providing for precision positioning control, easy set-up and

configuration, on board health monitoring, and network communications. Programming access is provided

through our HercuLink

communications or through the optional local keypad and display.

HercuLine

®

used for more severe service applications requiring features such as non-contact position sensing.

HercuLine

®

The keypad and display are available on the HercuLine

additional charge.

2001, HercuLine® 2002, and HercuLine® 2003. All are low torque, precision electric rotary

®

2000 series actuators are precision engineered for exceptional reliability,

Figure 1). Designed for very precise positioning of dampers

®

2000 series actuators perform especially well in extremely

series

2000 series actuators are used in applications requiring on/off or power to open/close position

2001 and 2002 are smart actuators used in applications requiring current proportional control

®

Palm PDA software connected to the actuator via a 232/485 converter, via HART

2002 smart actuators offer features and functions similar to the HercuLine® 2001 and are

2003 actuators are unidirectional/ 360 degree rotation, special purpose actuators.

®

2001 and HercuLine® 2002 products at

®

HercuLink

Software

®

HercuLink

standard with the HercuLine

Computer software enables access to programming and communication functions available as

®

2001 and 2002 actuators without the added expense of the keypad &

display HMI. Using a Palm™ PDA, laptop PC or desktop computer, HercuLink

®

software, and a

RS232/485 converter users may configure, calibrate, and access maintenance information locally or

remotely to the actuator.

®

Using HercuLink

access information to/from the actuators and to control the device. Set-up configurations may also be

stored on the computer for download to other HercuLine

software, the computer may be used as a master device over a Modbus network to

®

devices. Information may be stored on the users

PC in CSV format for use in preventative maintenance programs.

• Certified on Palm™ m125, m130, and m505.

• Compatible with Palm OS3.5 or higher.

• Compatible with Windows 2000 or XP operating systems

• Minimum system requirements:

• Windows 2000 (w/service pack 2), Windows NT (w/service p a ck 5), Windows ME, Windows XP

• 200 MHz Pentium with 64 Megs Ram

Revision 7 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual 1

7/08

Page 10

Introduction

Product Description

Display and

keypad

Handwheel

Conduit

entry

Shaft and

position indicator

Auto/manual

switch

Figure 1 HercuLine

®

2000 Series Actuator

2 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual Revision 7

7/08

Page 11

Introduction

Product Description

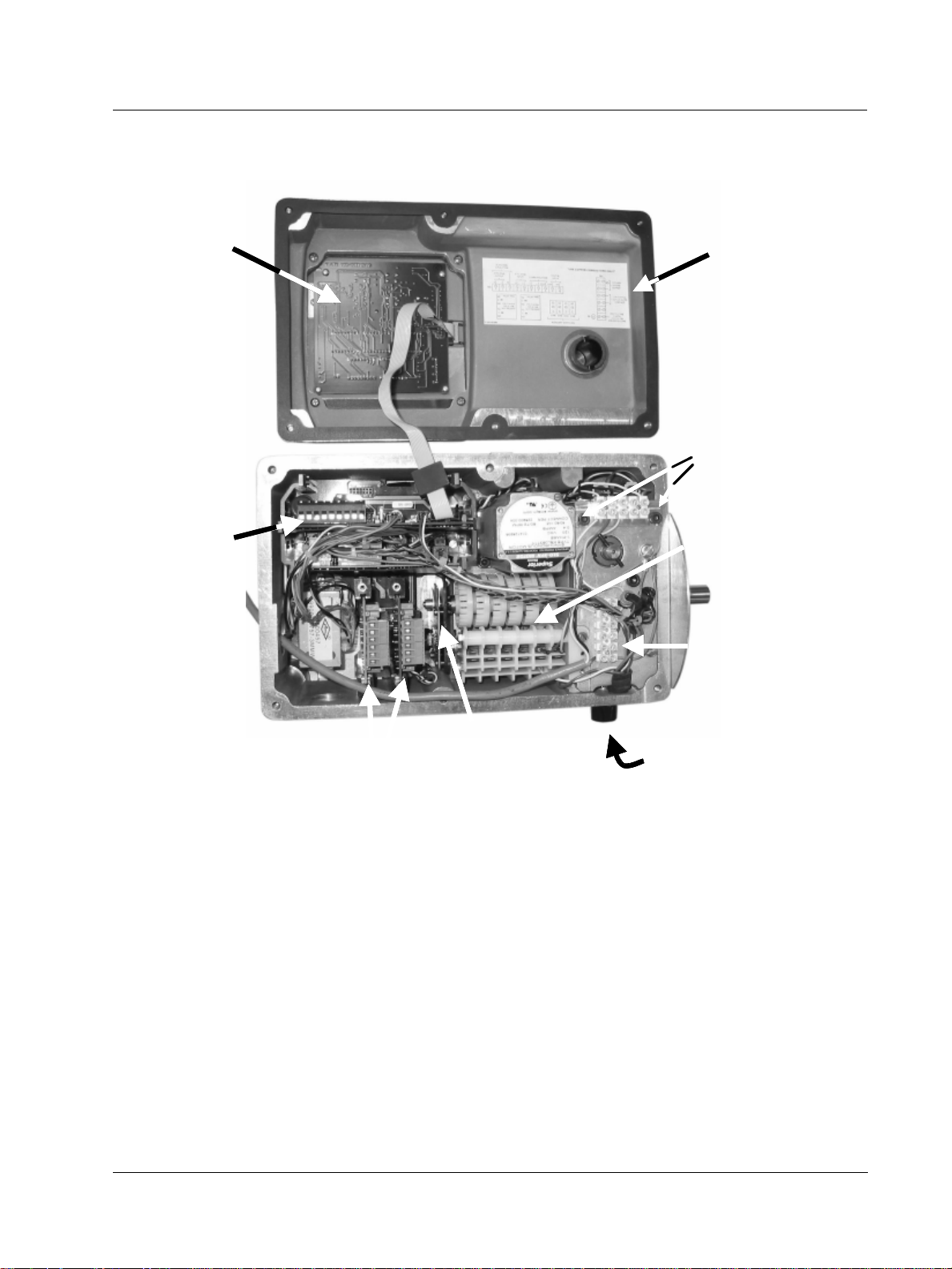

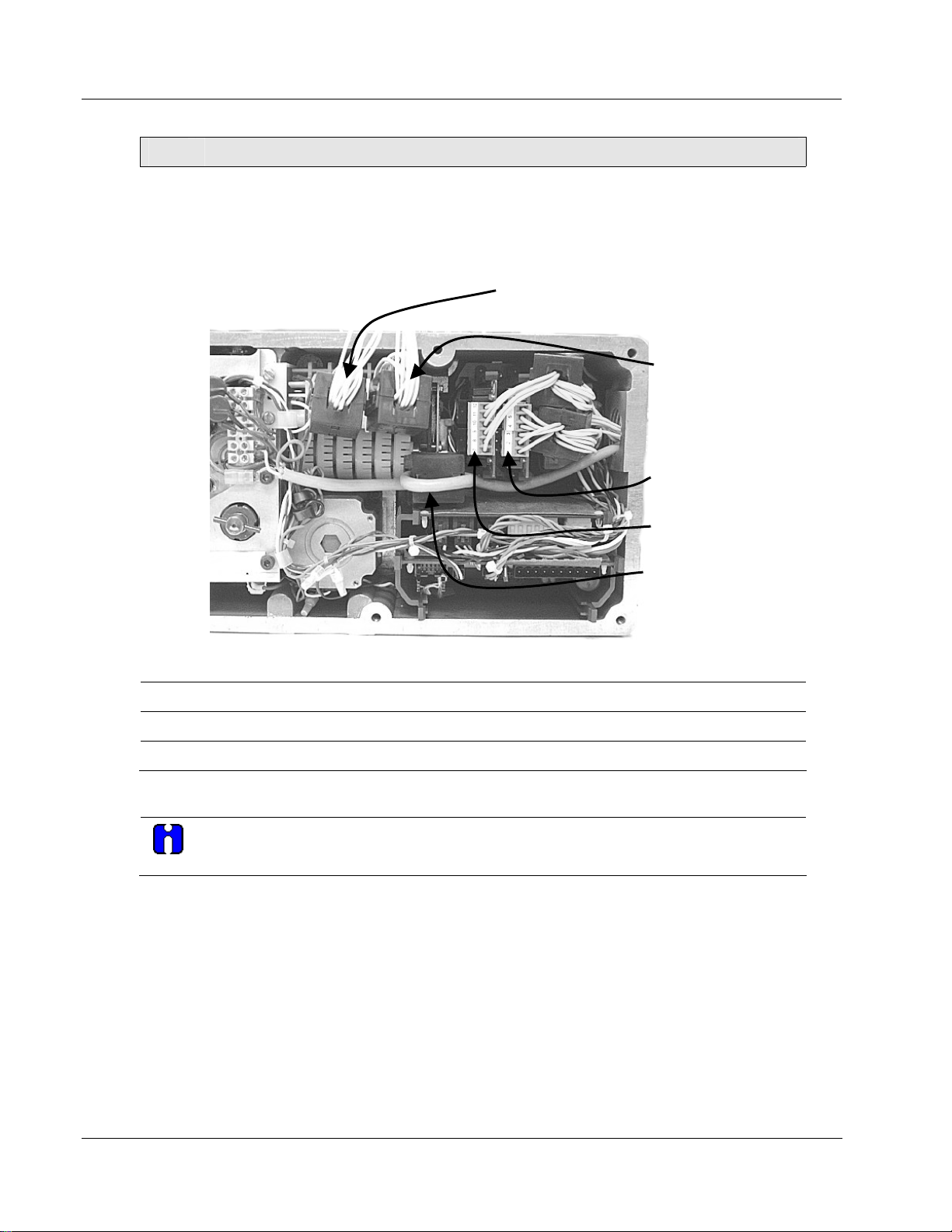

Display

Display

Keypad

Keypad

PWA

PWA

TB3

TB3

Connector

Connector

for customer

for customer

input and

input and

output

output

connection

connection

on CPU

on CPU

PWA

PWA

Wiring

Wiring

Label

Label

Mechanical Stops

Mechanical Stops

Cams and

Cams and

limit

limit

switches

switches

TB1

TB1

customer

customer

power

power

connection

connection

External

External

auto-manual

auto-manual

switch

switch

Relay PWAs

Relay PWAs

Non-contact

Non-contact

sensor

sensor

®

Figure 2 HercuLine

Revision 7 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual 3

7/08

2002 Actuator Internal View

Page 12

Introduction

Product Description

4 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual Revision 7

7/08

Page 13

Specifications

Specifications

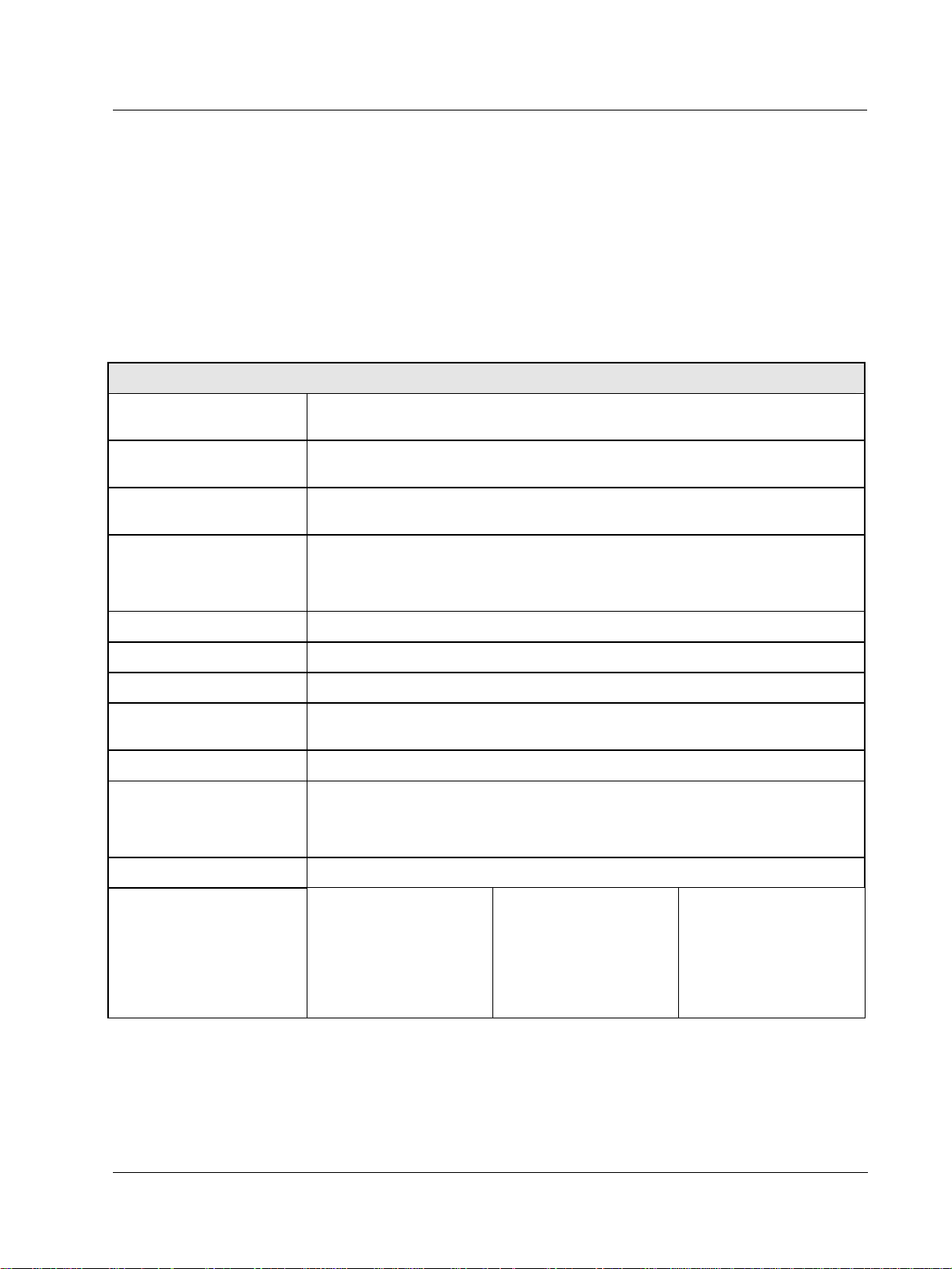

Technical and Operating Specifications

This section provides you with the technical specifications and the model selection guide for the

HercuLine

®

2000 Series Actuators.

Technical and Operating Specifications

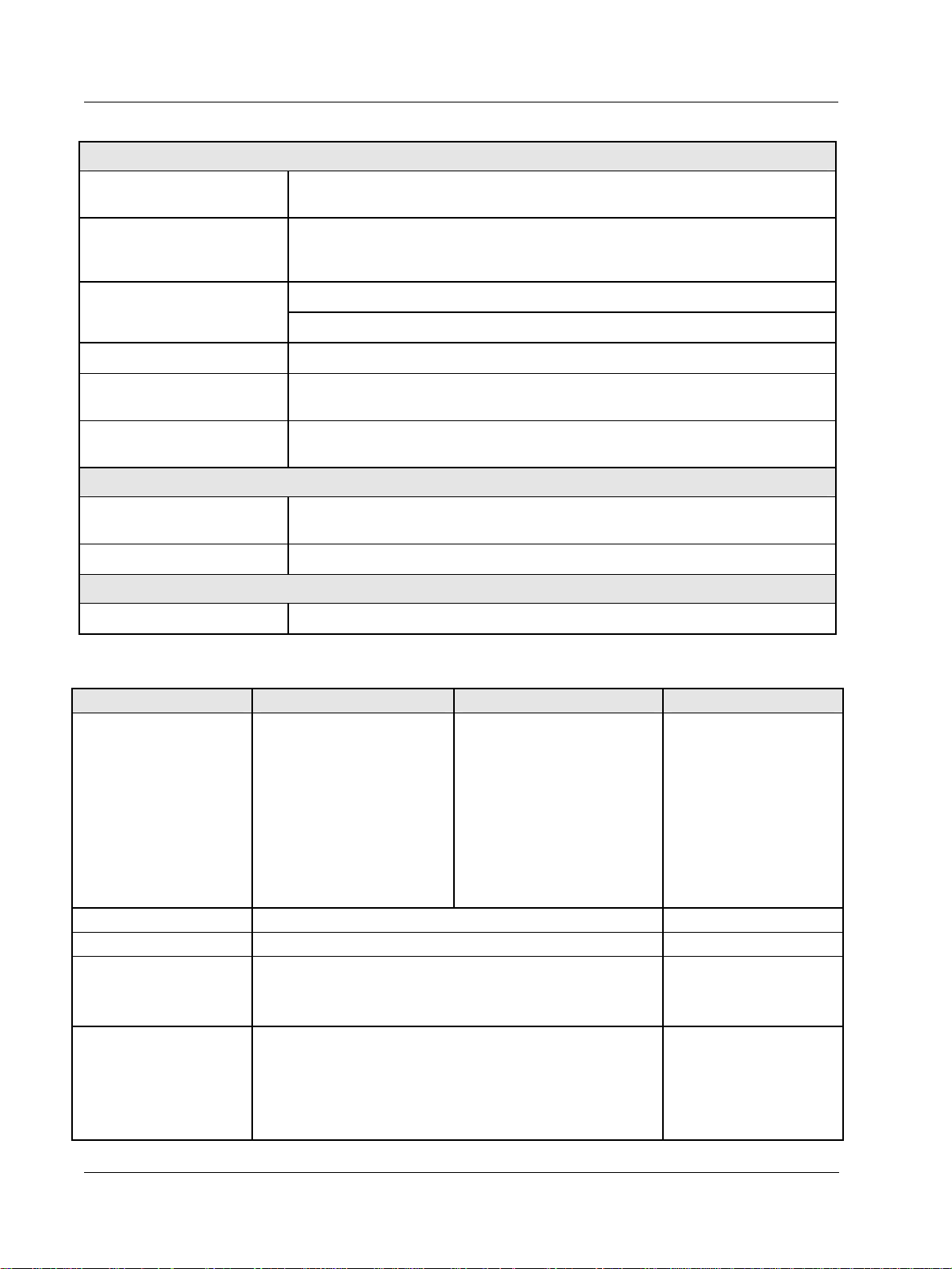

Table 1 Specifications - General

Physical

Weight

Enclosure

Gear Train

Mechanical Stops

Storage Temperature

Relative Humidity

Scale

2000: 25 lb. (11.36 kg)

2001,2002: 27 lbs. (12.27 kg)

Precision-machined die cast aluminum housing, finished in light gray powder coat

epoxy.

Alloy steel, high efficiency steel spur gear primary train. Precision ground, selflocking/self releasing worm gear final mesh.

Factory set at 90° or 150° (+/-5°).

Attention: Do not adjust the mechanical Stops. Adjusting the stops will void

the warranty

–40 °C to +93 °C (–40 °C to +200 °F)

0 % to 99 % R.H. non-condensing over the full operating temperature range.

0 % to 100 % corresponding to full crank arm travel.

Crank Arm

Output Shaft

Rotation

Manual Handwheel

Lubrication

Output Torque/Full

Travel Stroking Time

Revision 7 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual 5

7/08

Adjustable radii 1.0 in (25.4mm) to a maximum of 2.8 in (71.1mm). Position

adjustable through 360° rotation.

0.625+/-.005 in (15.88 +/-.13mm) diameter

90° or 150° degrees between 0 % and 100 % on scale, limited by mechanical stops.

Provides a means of positioning the actuator in the event of a power failure or setup.

Texaco Starplex 2 EP Grease

Torque lb-in (N

M)

50 / (6.0)

100 / (11.5)

200 / (22.5)

400 / (45.0)

400 / (45.0)

4.5 / 7.5

9 / 15

18 / 30

36 / 60

54 / 90

50 Hz (90°/150°)

60 Hz (90°/150°)

4 / 6

7 / 12

15 / 25

30 / 50

45 / 75

Page 14

Specifications

Technical and Operating Specifications

Electrical

Mains Supply

Motor

Motor Current

Loss of Power

Local Auto/Manual Switch

End of travel Limit

Switches

Auxiliary Switches/Relays

Approvals

Enclosure Rating

Clamp Bolt

100-130 Vac single phase, 50 Hz or 60 Hz

200-240 Vac single phase, 50 Hz or 60 Hz

Instant start/stop, non-coasting, non-burnout, continuous duty, permanent

magnet, synchronous induction motor. Can be stalled up to 100 hours without

damage.

= No load = full load = locked rotor = 0.4 amp for 120Vac, 0.2 amp for 240 Vac

Stays in place on loss of power

Optional – Allows local and automatic operation of the actuator.

Standard – adjustable to limit actuator travel to less than 90 or 150 degrees

respectively

Optional – Up to 4 additional SPDT switches rated at (10 A at 125 Vac, 5 A at 250

Vac).

Certifications

CSA/UL (Standard)

CE Compliant (optional)

Type 4 (NEMA 4), IP66 (standard)

Torque Settings of Crank Arm Bolts

88 lb-in (10 N-m)

Electrical and Performance Specifications

HercuLine® 2002 HercuLine® 2001 HercuLine® 2000/2003

Input Signals

Isolation

Load Requirement (4-20)

Input Impedance

Feedback

Analog:

• 0/4 to 20 mA (With CPU

PWA jumper in current

position)

• 0/1 to 5 Vdc

• 0 to 10 Vdc

Digital:

• Modbus RTU (RS485)

Analog:

• 0/4 to 20 mA (With CPU

PWA jumper in current

position)

• 0/1 to 5 Vdc

• 0 to 10 Vdc

• Series 90 control

Digital:

• Modbus RTU (RS485)

120 vac drive open/120 vac

drive close

240 vac drive open/240 vac

drive close

Input signal, output signal and power are isolated from each other. NA

Current Out — 0 to 1000 ohms NA

0/4 to 20 mA

0/1 to 5 Vdc

250 ohms

10 K ohms

NA

0-10 vdc

0 to 20 mA, 4 to 20 mA

0 to 5 Vdc & 1 to 5 Vdc with 250 ohm resistor, (0 to 16 Vdc with 800

ohm resistor)

Dual output 1000 ohms

over 90 degrees (135 ohms

with 158 resistor)

Dual output 1000 ohms

over 150 degrees (135

ohms with with 158 resistor)

6 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual Revision 7

7/08

Page 15

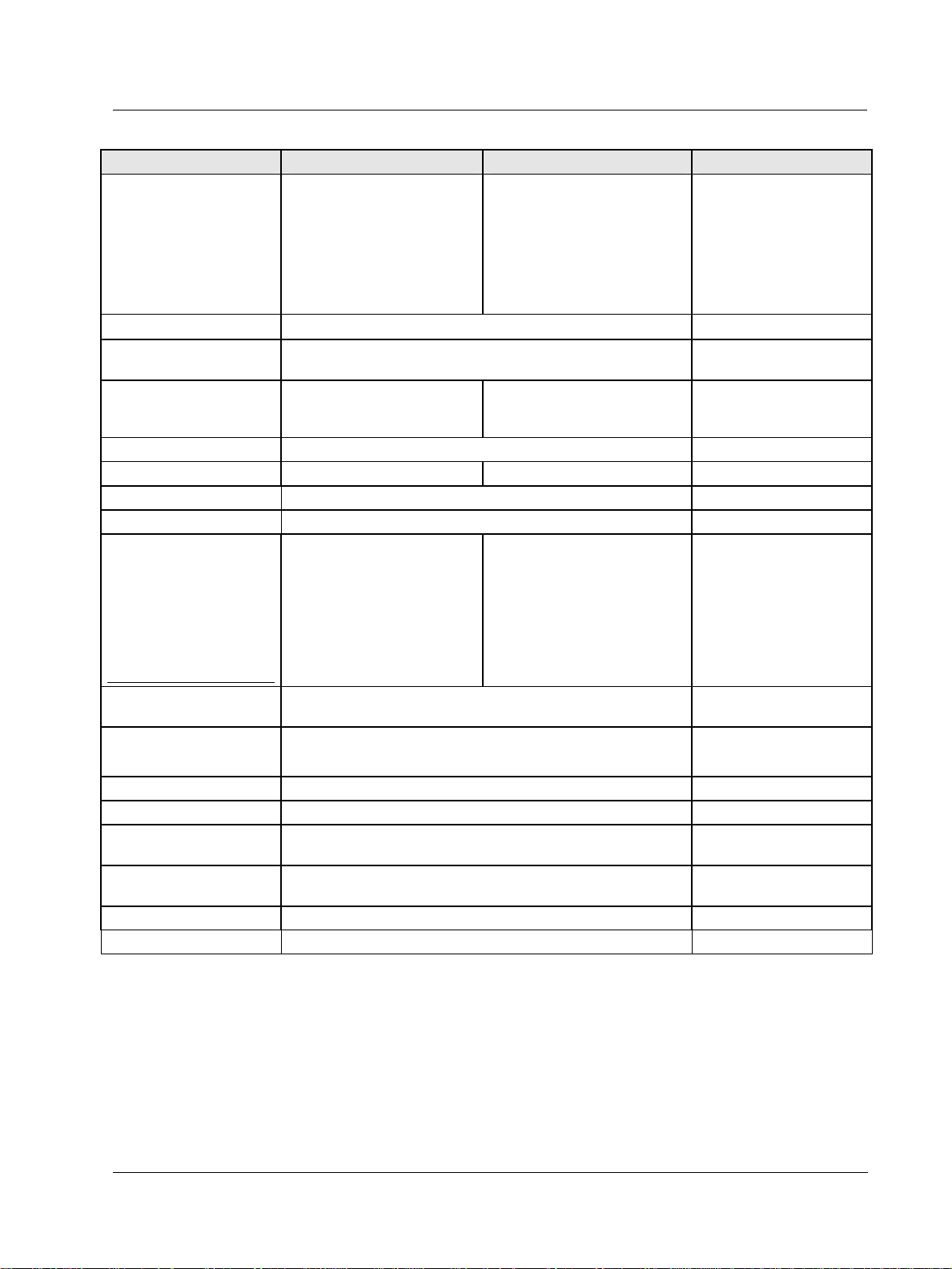

HercuLine® 2002 HercuLine® 2001 HercuLine® 2000/2003

Feedback Slidewire emulation - Provides

output voltage ratiometric to

shaft position and

potentiometric to supply voltage

(1 Vdc to 18 Vdc) without a

slidewire. Emulates a 100 ohm

to 1000 ohm slidewire. 10 mA

output maximum.

Communications

Operating Temperature

Position sensing

Sensitivity

Hysteresis

Deadband

Repeatability

Repositions

(minimum @ 90 or 150

degree stroke)

Table 1 option –050Table 1 option –100Table 1 option –200Table 1 option –400Table 1 option –600-

Modbus RTU or optional HART™

–40°C to +75 °C (–40°F to +170 °F)

Non-contact position sensor 1000 ohm film potentiometer

0.2 % to 5 % of 90° span, proportional to deadband NA

Less than 0.4 % of full scale

0.2 % to 5 % of 90° span, programmable. Shipped at 0.5 % NA

0.2 % of 90° span NA

160

290

450

700

900

Specifications

Technical and Operating Specifications

120

250

400

400

400

NA

-40°C to +85 °C (-40°F to

+185 °F)

Dual 1000 ohm film

potentiometers

(not on 2003)

NA

500

Voltage/ Supply

Stability

Temperature

Coefficient

Zero Suppression

Input Filters

Solid State Motor

Control

Failsafe operation If input signal exceeds configured input range. Selectable and

Direction of Rotation

Duty Cycle

0.25 % of span with +10/–15 % voltage change NA

Less than ± 0.030 % of span per degree C for 0 °C to 50 °C

Less than ± 0.05 % of span per degree C for –40 °C to 75 °C

90 % of span. NA

Selectable spike and low pass filters. NA

Two triac switches for clockwise or anti-clockwise motor operation.

Transient voltage protection provided.

adjustable.

Field programmable Wire swap

Continuous

NA

NA

NA

Revision 7 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual 7

7/08

Page 16

Specifications

Technical and Operating Specifications

HercuLine® 2002 HercuLine® 2001 HercuLine® 2000/2003

Programmable

Selectable and configurable operating parameters: NA

Functions

• Input range

• Input filtering

• Input characterization

• Security

• Digital Input action

• Deadband

• Failsafe on loss of input signal

• Failsafe on loss of position sensor

• Direction of rotation

• Relay closure action

• Communication parameters

• Split range operation

• Output range

• Alarms

Specifications – Local Display and Keypad

Display

Display Design

Multi-segment LED displays that provides up to ten alphanumeric characters. Display

arrangement consists of two rows:

st

row (Upper display) – four characters

1

2nd row (Lower display) – six characters.

LED indicators Six single LEDs provide actuator status and alarm indications.

Display Operating

Temperature

-30 °C to +50 °C (-20 °F to +122 °F)

Automatically shuts off when operating temperature exceeds +50 °C

Storage Temperature -40 °C to +93 °C (-40 °F to +200 °F)

Keypad

Keys

Six single pushbutton keys allow access to all status displays and set up group

parameters.

See Set Up and Calibration Procedures (page 31) for detailed information on display and keypad functions.

8 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual Revision 7

7/08

Page 17

Technical and Operating Specifications

Specifications – Communications

Communications

Specifications

Communications

Option

Connection Twisted pair cable with shield

Maximum loop length 600 meters (2000 feet)

Communication Mode Half duplex

Baud Rate 300, 600, 1200, 2400, 4800, 9600, 19.2K

RS 485 Serial Communication, Modbus RTU Protocol

Required Specifications – PDA (customer provided)

PDA

Operating System Palm OS version 3.5 or greater

RAM At least 8 MB

Communications Serial port with RS232 compatible levels to drive external converter

Note: As of this writing only Palm devices have this feature. Honeywell has qualified

the M105, M125, M130, and M505 devices with the HercuLink application.

Revision 7 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual 9

7/08

Page 18

Specifications

)

)

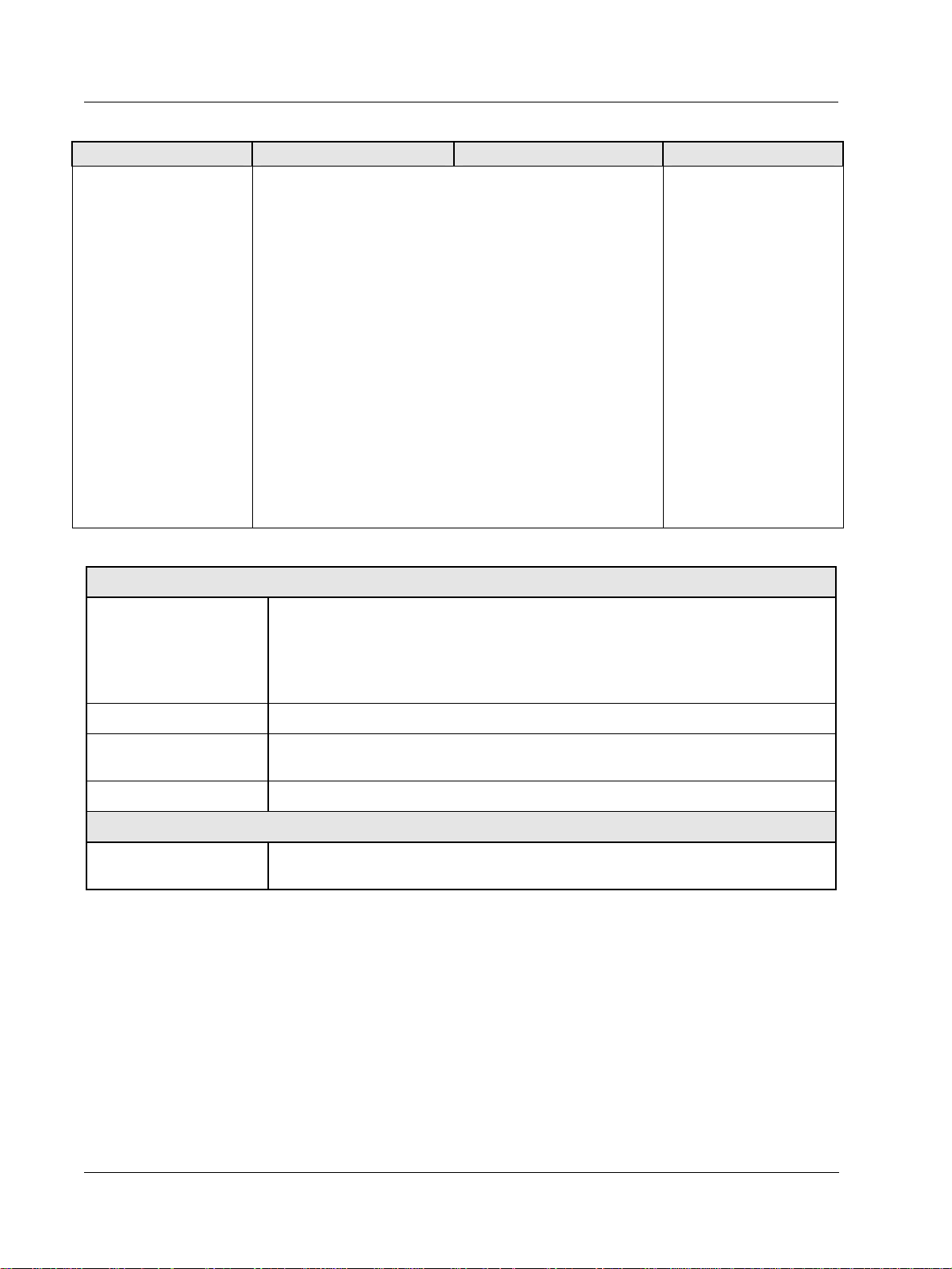

Model Selection Guide

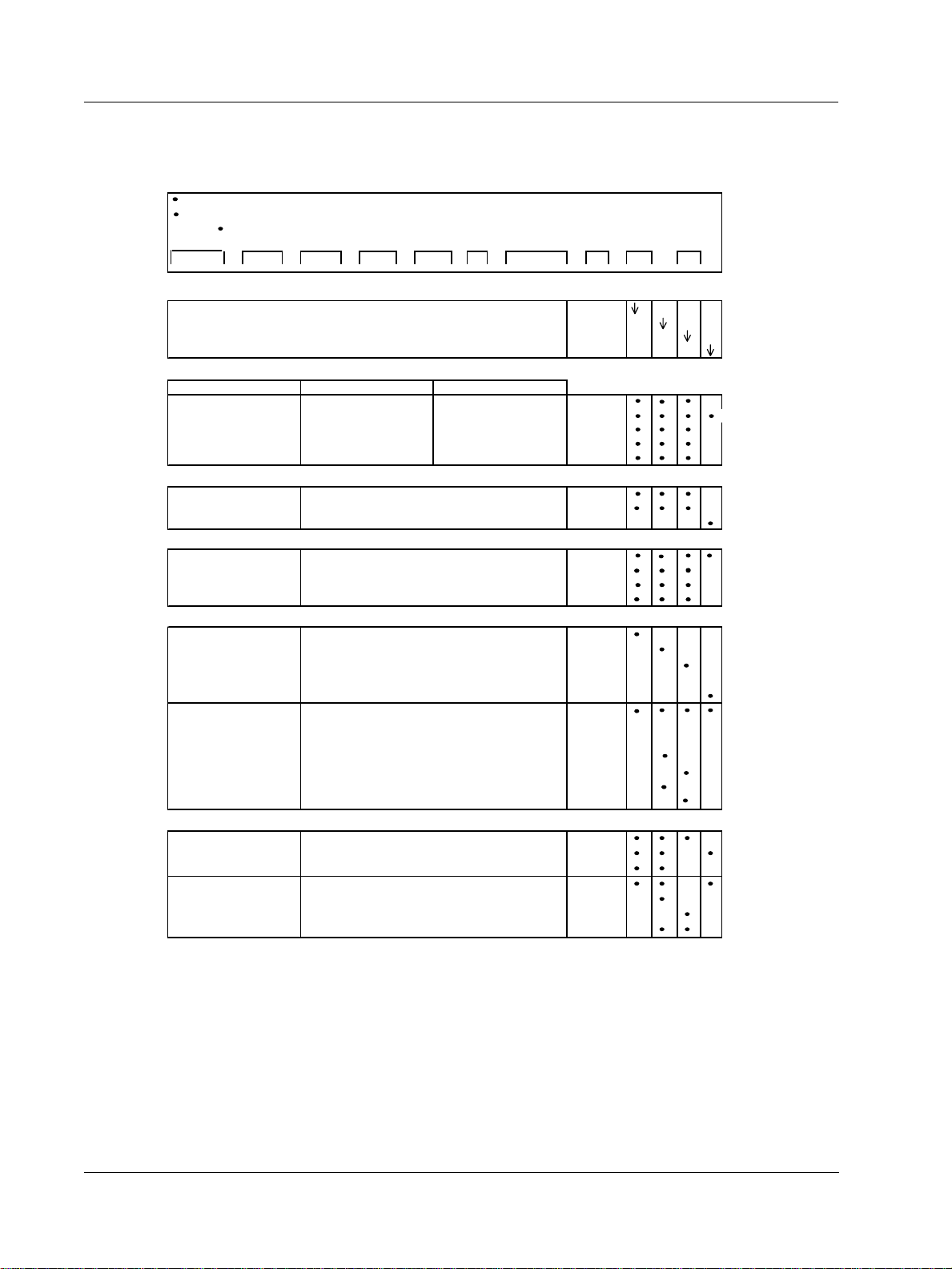

Model Selection Guide

Instructions

Select the desired key number. The arrow to the right marks the selection available.

Make the desired selections from Tables I thru VIII using the column below the arrow.

A dot ( ) denotes unrestricted availability.

Key Number V VI VII VIII IX

I

- - - - - _ _ - _ _ _ _ _ _ - _

_ _ __ _ _ _

_ _ _

III

_ _ _ _ _ _

IVII

_

-

_ _

-

KEY NUMBER - Motor Selection Availability

Basic Motor Unit (no electronics)

Basic Motor Unit plus Digital Electronics

Enhanced Performance Motor Unit with Non-contact Position Sensing

Unidirectional Motor (M640D Replacement)

TABLE I - TORQUE & SPEED SELECTION (speed per 150 degree rot ation)

Torque, lb-in/(N-M)

50 / (6.0) 7.5 sec 6 sec

100 / (11.5

200 / 22.5) 30 sec 25 sec

400 / (45.0

400 / (45.0) 90 sec 75 sec

TABLE II - ROTATION

Travel 90 degrees

TABLE III - POWER SUPPLY

Single Phase 100 - 130 Vac, 60 Hz

TABLE IV - ANALOG INPUT/OUTPUT SIGNALS

Input 3 Wire Drive up/down 0 _ _

Output None _ 00

TABLE V - SWITCH AND RELAY OUTPUTS

Auxiliary Outputs No Auxiliary Switches

Relay Outputs No Relays

15 sec 12 sec

60 sec 50 sec

150 degrees

360 degrees

100 - 130 Vac, 50 Hz

200 - 240 Vac, 60 Hz

200 - 240 Vac, 50 Hz

0/4-20 mA, 0/1-5 Vdc, 0-10 Vdc 2 _ _

0/4-20 mA, 0/1-5 Vdc, 0-10 Vdc 3 _ _

0 to 135 ohm input (Series 90 control) 4 _ _ a

Contact Input for 2003 6 _ _

(Note 1)

(Note 1)

Dual 1000 Ohm (1000 ohms over 150 degrees) _ 15

Dual 1000 Ohm (1000 ohms over 90 degrees) _ 19

Slidewire Emulation _ 60

Slidewire Emulation _ 65

0/4-20mAdc (0/1-5 Vdc, 0-16 Vdc)

0/4-20mAdc (0/1-5 Vdc, 0-16 Vdc)

2 Auxilliary Switches

4 Auxilliary Switches

2 Programmable Relay Outputs

2 Programmable Relay Outputs

4 Programmable Relay Outputs

50Hz 60Hz

(2 end-of-travel switc hes are standard)

Selection

2000

2001

2002

2003

050

100

200

400

600

090

150

360

126

125

246

245

b

c

_ 80

_ 85

0 _

2 _

4 _

_ 0

_ 2

_ 3

_ 4

continued

10 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual Revision 7

7/08

Page 19

Specifications

TM

Model Selection Guide

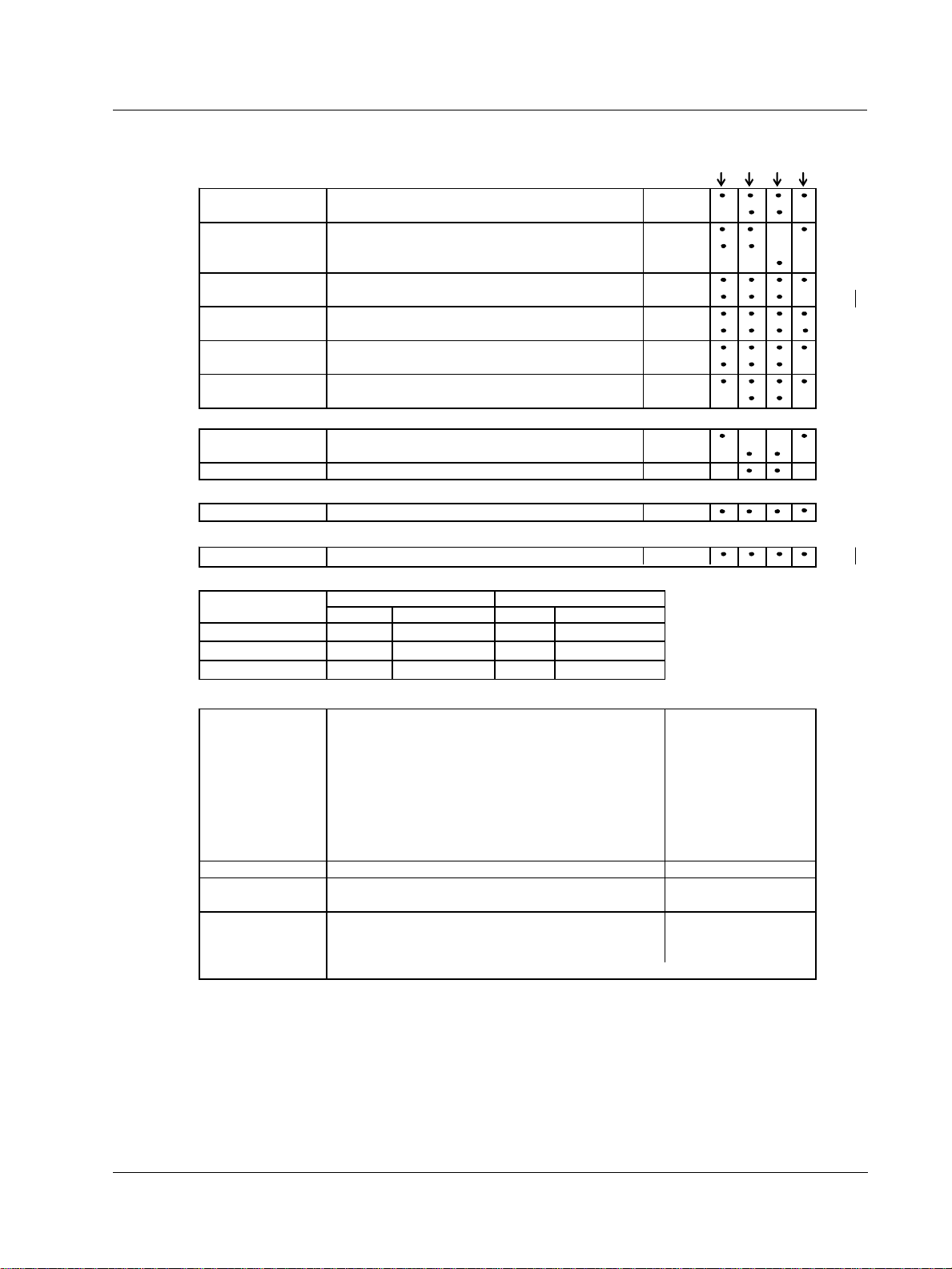

TABLE VI - OPTIONS Selection

Local keypad/ No local display interface supplied

display Integrally mounted local display/keypad interface

(Note 2) 0_ _ _ _ _

1_ _ _ _ _

Local Auto/ No auto/manual switch _ 0_ _ _ _

manual switch Auto/manual switch with "Out of Auto Contact"

Auto/manual switch with "Out of Auto Contact"

_ 1_ _ _ _

_ 2_ _ _ _

Handwheel No Handwheel _ _ 0_ _ _

Handwheel

Certificates None

_ _ 1_ _ _

_ _ _ 0 _ _

Certificate of Conformance _ _ _ 1_ _

Approvals UL Type 4/IP66, CSA

(Note 4) _ _ _ _ 0_

CE _ _ _ _ 1_

Shipped Rotation Counter clockwise shaft rotation on increasing signal

Clockwise shaft rotation on increasing signal

_ _ _ _ _0

_ _ _ _ _1

TABLE VII - COMMUNICATIONS/PROTOCOL

None No communications option board or protocol 0

Modbus RTU RS485 RS-485 Modbus compliant - standard with EEU 1

HART 5 HART Communications Protocol 2

TABLE VIII - MANUALS

Standard English 0

TABLE IX - FACTORY OPTIONS

Factory Options None

00

Restrictions

Restriction

Letter

a

b

c

Available Only With

Table Selection

Not Available With

Table Selection

IV _ 00 IV _ 60, _ 80

II II

II II

150

090

090

150

2000 2001

2002 2003

ACCESSORIES

Mounting Hardware Mounting plate adapter for Barber Colman Series MP495

Mounting plate adapter for Landis & Staefa SQM53/56

Direct Couple Valve Hardware

North American Valve Retrofit Kit

Linkage Assembly Ball joint for 5/16" dia. Pushrod

Pushrod 12 in. (304,5 mm) long, 5/16 " dia.

Pushrod 18 in. (457,2 mm) long, 5/16 " dia.

Pushrod 24 in. 609,6 mm) long, 5/16 " dia.

Pushrod 48 in. (1219,2 mm) long, 5/16 " dia.

51452354-501

51452354-502

51452354-503

51452354-511

51452354-504

51452354-505

51452354-506

51452354-507

51452354-508

HART Turk Cable for Handheld Connection 51452352-501

Handheld Config.

(Note 3)

HercuLink

Battery powered 232/485 converter with cable

Remote Mount Remote 4-20 mA requires 135 ohm fdbk, 120V 50/60Hz

Control Remote 4-20 mA requires 1000 ohm fdbk, 120V 50/60Hz

Remote 4-20 mA requires 135 ohm fdbk, 220V 50/60Hz

Remote 135 ohm input requires 135 ohm fdbk, 120V 50/60Hz

Notes:

1. 135 ohm available by parallelling 1K potentiometer with 158 Ohm resistor (supplied).

2. HercuLink

TM

customer supplied Palm

Palm Software

51452354-509

51452354-510

R7195A1031

R7195A1056

R7195A1064

R7195B1021

software (pn 51452354-509), RS232/485 converter (pn 51452354-510),

TM

PDA running OS3.5 or higher and Palm serial cable are required

for the 2001 and 2002 actuators if no display is selected.

3. Requires PDA manufacturer's serial interface cable.

4. CSA approval is good for 75°C and a maximum relay load of 3.5 amps or 70°C with a

relay load of 5 amps.

Revision 7 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual 11

7/08

Page 20

Installation

Installation Overview

Installation Overview

The procedures to install the HercuLine® 2000 Series actuator and place it in service require that you:

• Select a suitable location for installation. (See Installation Considerations below.)

• Mount the actuator securely.

• Install mechanical connections or linkage between control arm and final control element. Use HAL software

application to aid in mechanical installation.

• Make all electrical connections for actuator according to local and national electrical codes.

• Power up actuator.

• Enter, verify and adjust set up parameters for proper operation.

• Adjust control arm linkage for accurate operation of final control element.

Installation

This section provides you with mechanical and electrical installation information required to mount and connect

the HercuLine

®

2000 Series Actuator to your specific application. Unpacking instructions, installation

consisderations, electrical and safety precautions also included in this section should be observed.

Mechanical Stops

Factory set at 90° or 150° (+/-5°).

See Figure 2 for location.

Attention: Do not adjust the mechanical stops. Adjusting the stops will void the warranty.

12 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual Revision 7

7/08

Page 21

Before Starting

Unpacking

If there are visible signs of damage to the shipping container, notify the carrier and Honeywell immediately.

If there is no visible damage, compare the contents with the packing list. Notify the carrier and Honeywell

immediately if there is equipment damage or shortage.

Please do not return goods without contacting Honeywell Applications Center in advance. The contact number

is 1-800-423-9883.

Installation Considerations

Mount the actuator in a location where it will be easily accessible for maintenance and for manual operation by

means of the handwheel. The exact location must be determined in accordance with the linkage used.

It is important that the actuator be mounted securely to a solid foundation commensurate with the maximum

torque developed. Use studs or bolts that are as large as the foot mounting holes.

Allocate sufficient clearance around the actuator for the removal of all covers to permit inspection of internal

parts and to provide access to the handwheel.

Installation

Before Starting

Actuator Mounting

Firmly bolt the actuator to a mounting surface that will not distort when subjected to the torque stresses

generated by the actuator. The output shaft of the actuator should be parallel to the output shaft of the driven

device. The output shaft crank arm is fully adjustab le through 360°.

Mounting holes (bottom and side) and location of shaft/crank arm duplicate mounting for Honeywell

Actionators M640A, 740A, 940A for drop-in replacement. Optional adaptor plates available for replacing

Landis and Staefa SQM53/56 and Barber Coleman series MP495 models.

Revision 7 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual 13

7/08

Page 22

Installation

Actuator Mounting

289

289

11.379

11.379

25.4

25.4

1.00

1.00

CLEARANCE FOR TOP REMOVAL:

CLEARANCE FOR TOP REMOVAL:

101,6

101,6

4.0

4.0

mm

inches

Figure 3 Outline and Dimensions of HercuLine® 2000 Series Actuators

14 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual Revision 7

7/08

Page 23

Mechanical Installation

Linkage Set-up

Many applications require the use of a linkage assembly and often the final control element does not have a

linear torque curve. The actuator linkage can be set up to achieve an optimal delivered torque distribution for

specific applications. To assist with linkage design, Honeywell offers a linkage analysis software application

(HAL). The software can be ordered as P/N 51197910-001.

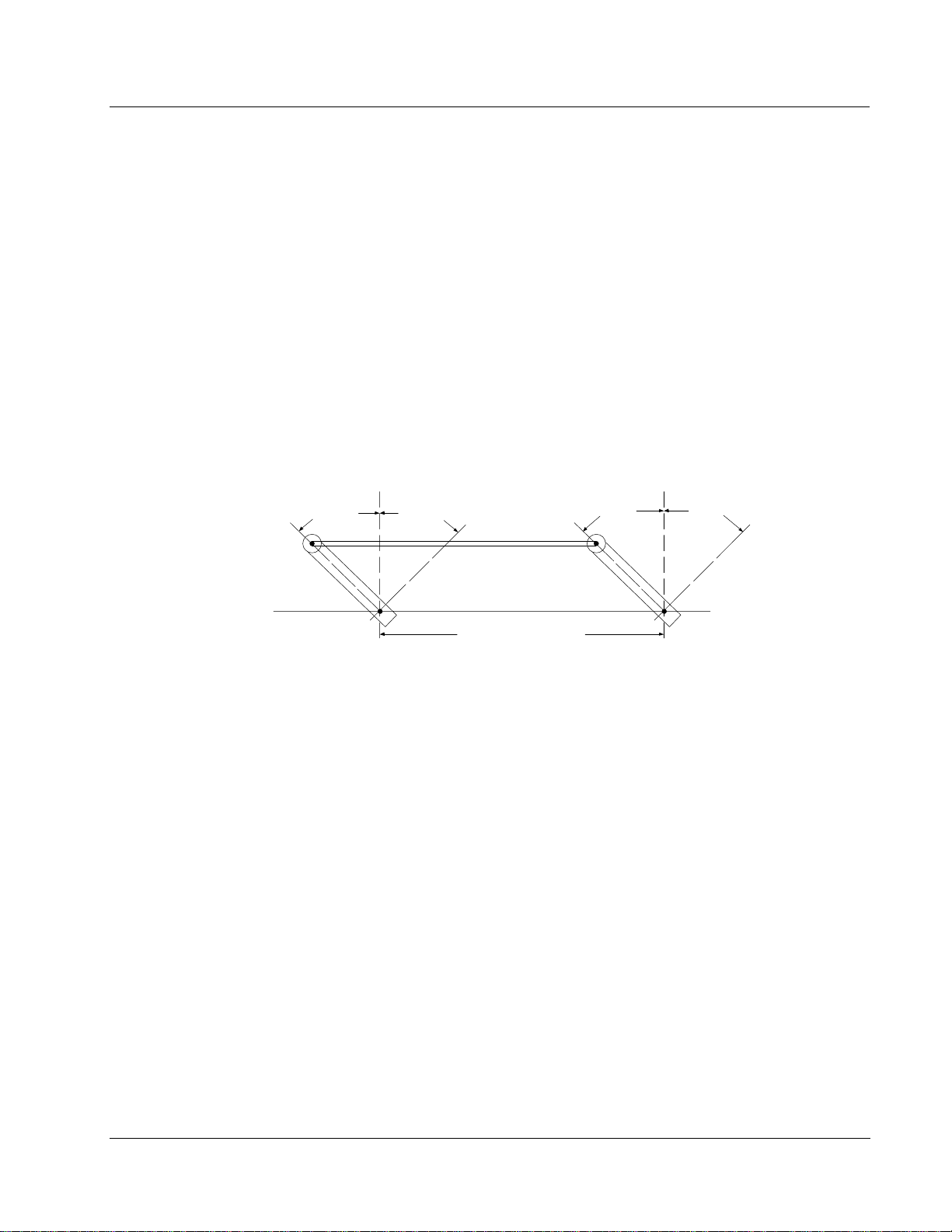

Constant Torque Linkage (typical)

A constant torque linkage is employed when it is desired to provide a linear torque profile throughout the full

range of final control element travel. In this situation, the actuator and driven crank arms will be set-up

proportionally with respect to each other.

profile.

Installation

Mechanical Installation

Figure 4 shows a general linkage setup to achieve a linear torque

Start Stop Close Open

Drive Unit

Crank Arm

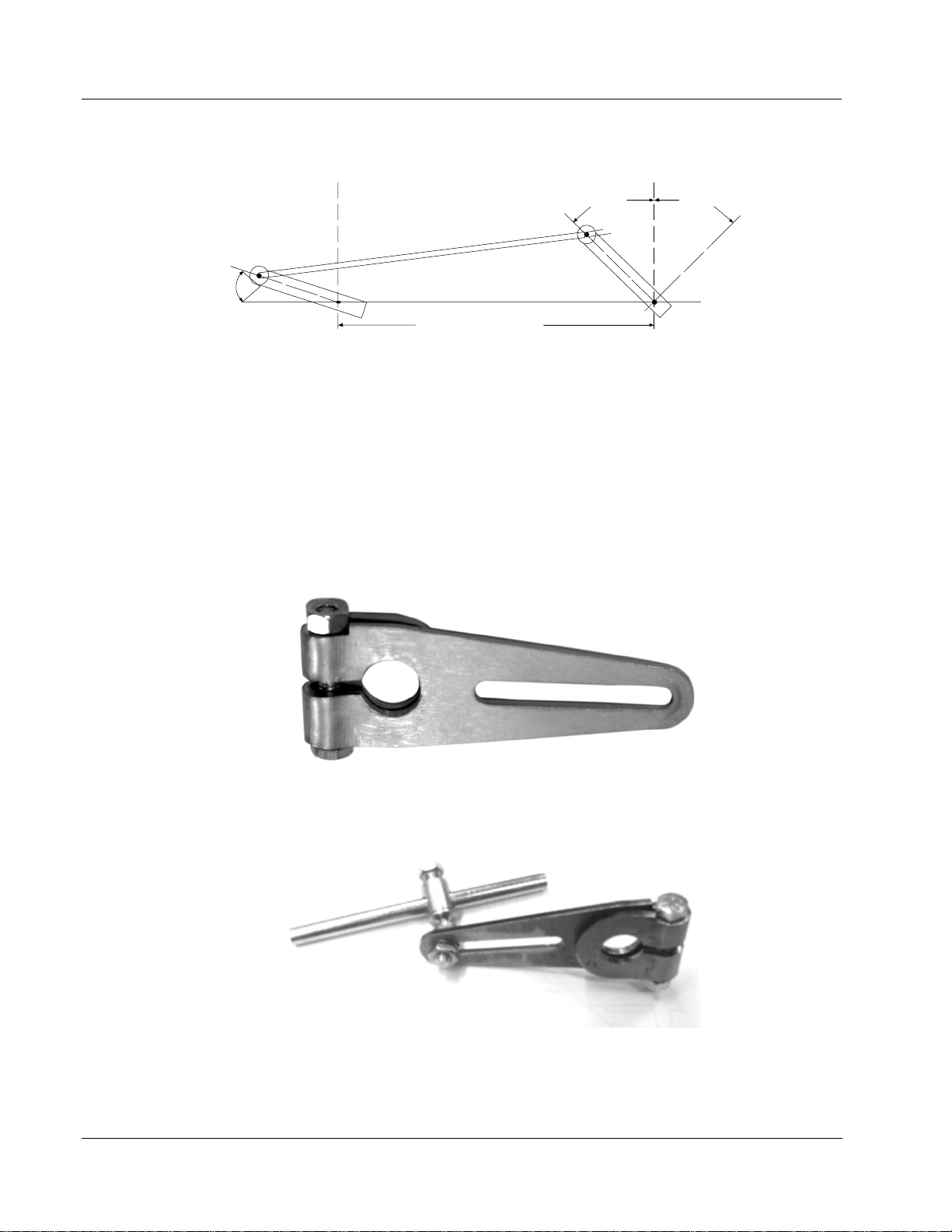

Variable Torque Linkage

A variable torque linkage is employed when it is desired to provide a non-linear torque profile throughout the

full range of final control element travel. In this general situation, the actuator and driven crank arms will be set

up to provide a higher torque for seating or unseating the final control element.

linkage setup to achieve a non-linear torque profile. Note that this linkage can be characterized in many

different ways by varying start angles and rotation requirements of both the Actuator Crank Arm and the Driven

Arm.

Vertical

Centerline

45° 45°

Horizontal Offset

Figure 4 Constant Torque Linkage

Linkage

Vertical

Centerline

45° 45°

Damper

Crank Arm

a/n 23199

Figure 5 shows a general

Revision 7 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual 15

7/08

Page 24

Installation

Mechanical Installation

Actuator Crank Arms

The HercuLine

(25.4mm) to 2.80 in (71.12mm). See

Vertical

Centerline

Vertical

Centerline

45° 45°

Actuator

Linkage

Crank Arm

Close Open

5°

a/n 23200

Horizontal Offset

Damper

Crank Arm

Figure 5 Variable Torque Linkage

®

2000 Series Actuator comes standard with a crank arm with adjustable radius of 1.0 in

Figure 6.

Figure 6 Standard crank arm

Figure 7 Crank arm with optional ball joint and push rod

16 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual Revision 7

7/08

Page 25

Electrical Installation

General Wiring Recommendations

Only qualified personnel should perform wiring.

Wiring must conform to national and local electrical codes.

In general, copper wire used. Unless locally applicable codes dictate otherwise, the recommended minimum

wire sizes in

Table 2 should be observed.

AWG Description

14 Earth ground wire to common power supply.

Installation

Electrical Installation

Table 2 Recommended Minimum Wire Size

18

Safety Precautions

Actuator Connections

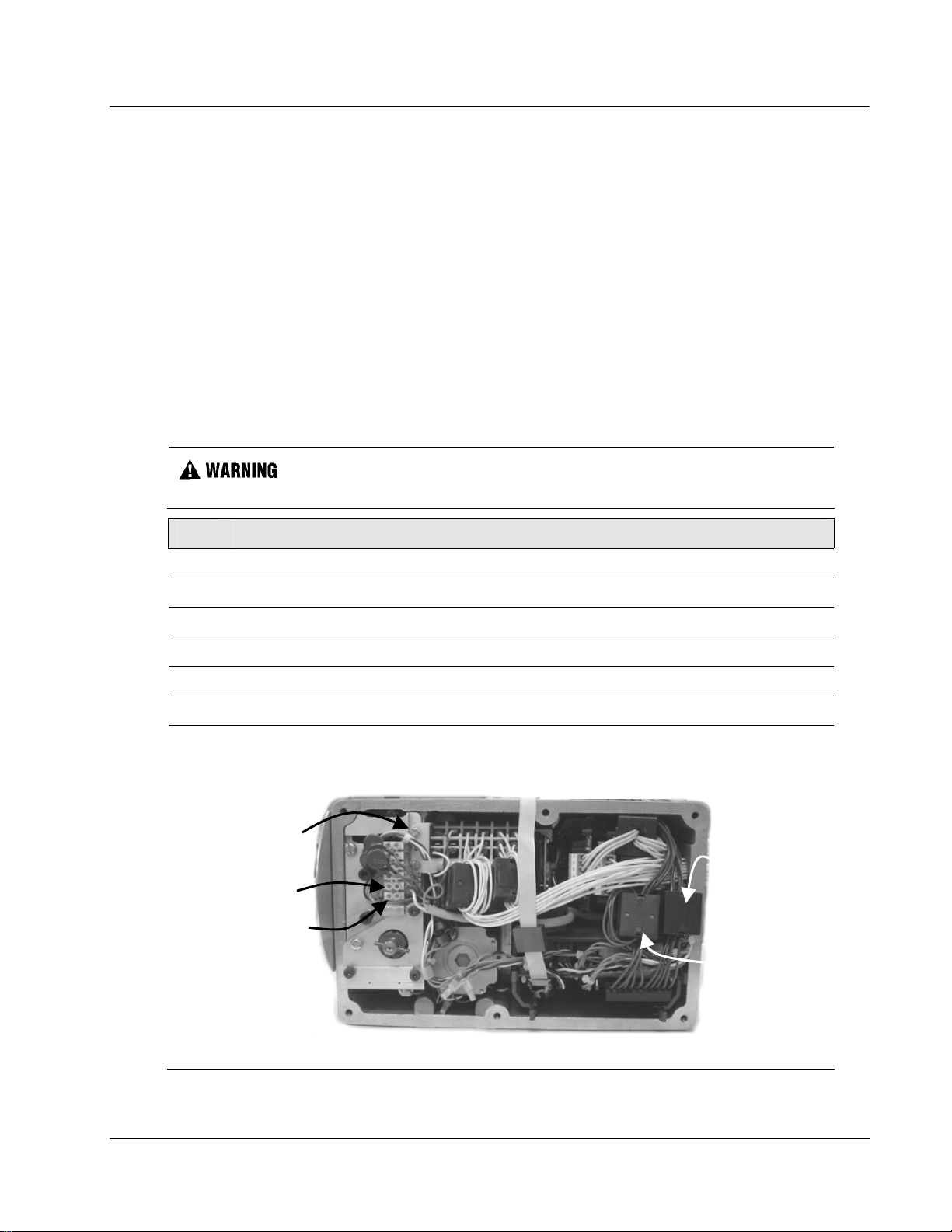

ATTENTION

The actuator terminal connections for the field wiring are located behind the cover on the actuator case as

shown in

Figure 2. Power and field wiring is brought into the actuator through two access holes located on the

side of the actuator case.

Earth ground wire to single actuator. 120/240 V ac line leads. +24 V and common

signal leads. Common signal leads, relays, and aux switches.

An external disconnect switch must be installed to break all current carrying

conductors connected to the actuator. Turn off power before working on

conductors. Failure to observe this precaution may result in serious personal injury.

The ground terminal must be connected to a reliable earth ground.

While the unit is powered, a potentially lethal shock hazard exists inside the case.

Do not open the case while the unit is powered. Do not access the terminals while

the unit is powered.

Use both openings: one for low level wiring (control signal) and the other for high

level wiring (120Vac).

Do not run both the High Level and Low Level wiring through the same

opening.

The screw terminals, locations, and descriptions for all customer connections are identified in the tables and

figures that follow.

Revision 7 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual 17

7/08

Page 26

Installation

Electrical Installation

HercuLine® 2000 Terminal Connections

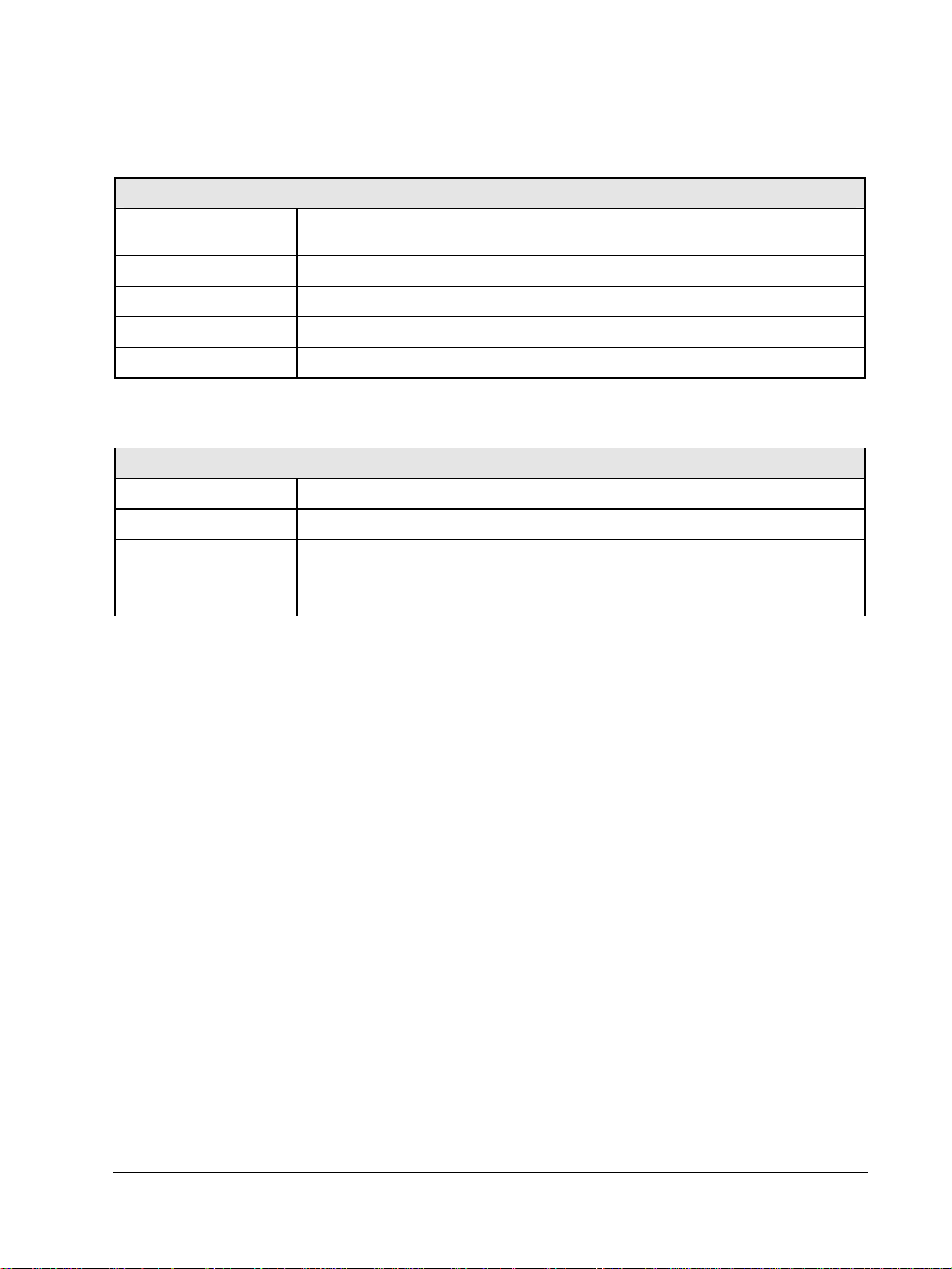

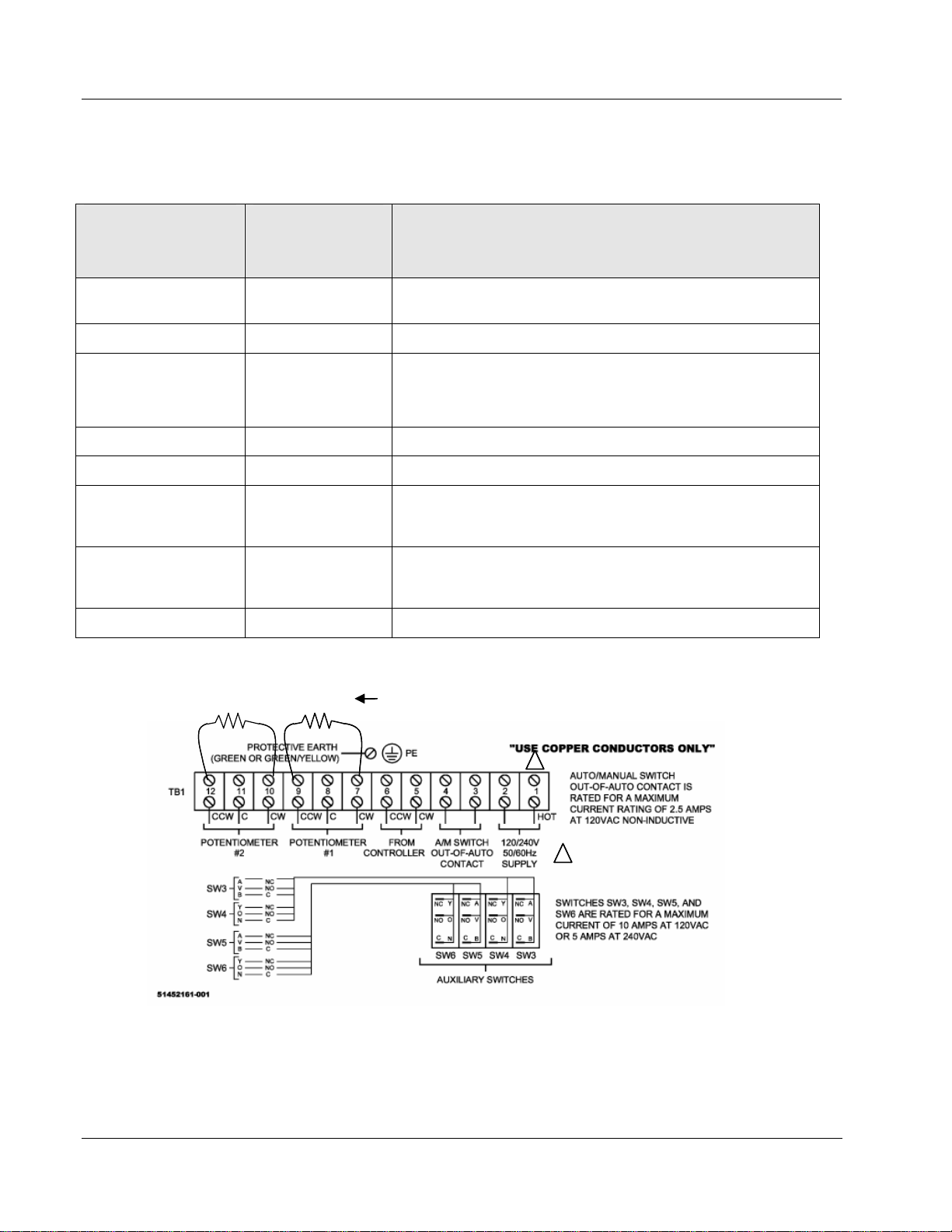

Table 3 Terminal Connections: HercuLine

Connection

Terminal Numbers

and LABEL

See Figure 8

®

2000

Descriptions

Hot 1

Hot wire for 120/240VAC mains supply. Use only if Auto/Manual

switch is present.

Neutral 2 Neutral wire for 120/240VAC mains supply

Auto/Manual Switch

Contact

3

4

Switch contact to indicate setting of actuator AUTO/MANUAL

switch.

Switch is closed when actuator is “NOT-IN-AUTO”

CW from Controller 5 CW motor drive

CCW from Controller 6 CCW motor drive

Potentiometer #1

Potentiometer #2

7

8

9

10

11

12

Clockwise-End

Slider

Counterclockwise-End

Clockwise-End

Slider

Counterclockwise-End

Protective Ground Ground wire connection for mains supply

158 ohm 158 ohm Install resistors to convert 1000 ohm

158 ohm 158 ohm Install resistors to convert 1000 ohm

potentiometer to 135 ohms

potentiometer to 135 ohms

1

11

REQUIRED ONLY IF AUTO/MANUAL

REQUIRED ONLY IF AUTO/MANUAL

1

11

SWITCH IS PRESENT

SWITCH IS PRESENT

Figure 8 HercuLine

®

2000 connections

18 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual Revision 7

7/08

Page 27

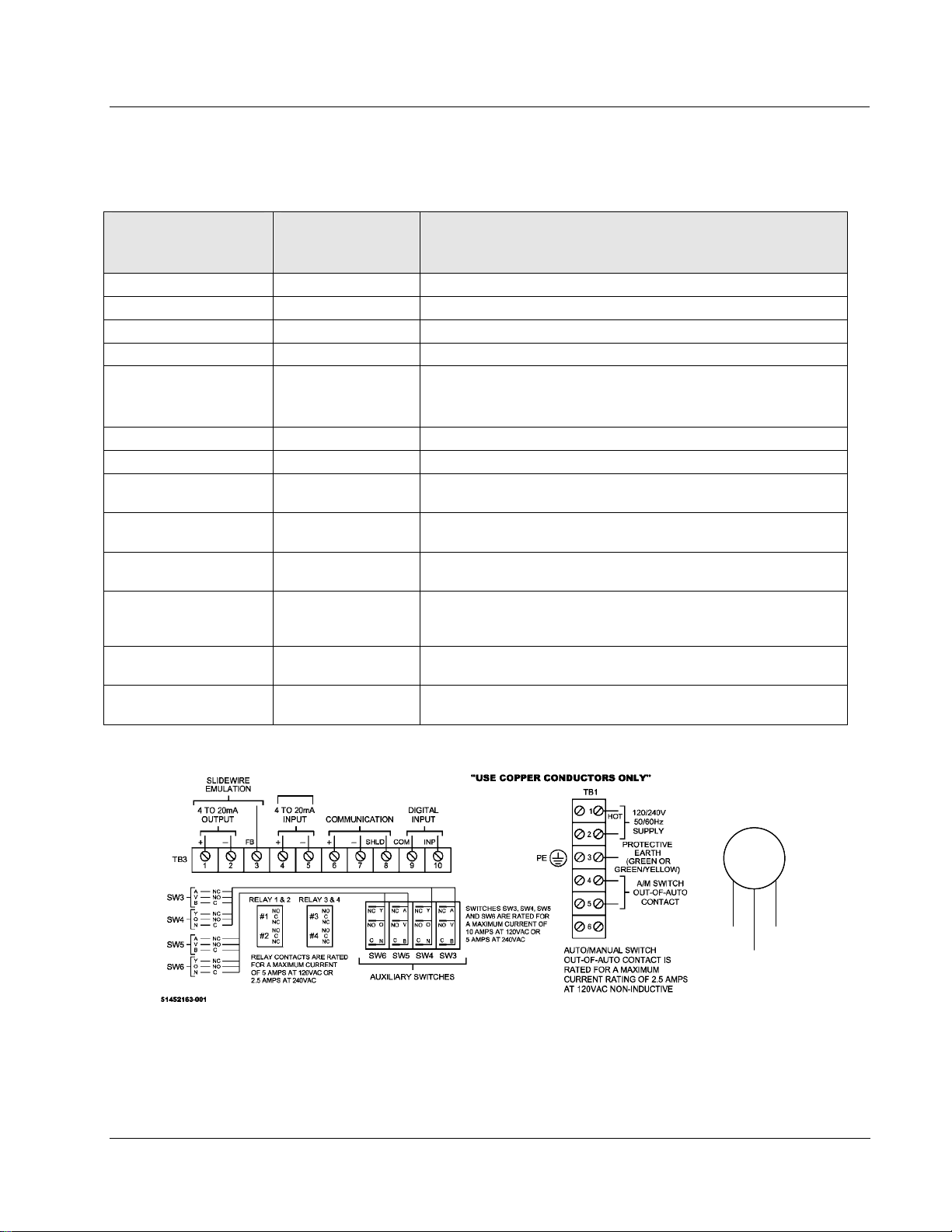

HercuLine® 2001/2002 with Auto/Manual Terminal Connections

Table 4 Terminal Connections: HercuLine

®

2001/2002 with auto/manual

Connection

Hot 1 Hot wire for 120/240VAC mains supply

Neutral 2 Neutral wire for 120/240VAC mains supply

Protective Ground 3 Ground wire connection for mains supply

Auto/Manual Switch

Contact

6

4 to 20mA Output*

Feedback 3

4 to 20mA Input

Modbus

Communication

HART Communications

Digital Input

Terminal Numbers

and LABEL

See Figure 9

TB1

4

5

TB3

1 (+)

2 (-)

4 (+)

5 (-)

6 (+)

7 (-)

8 Shield

4 (+)

5 (-)

9 Com

10 Input

Descriptions

Switch contact to indicate setting of actuator AUTO/MANUAL

switch.

Switch is closed when actuator is “NOT-IN-AUTO”

Analog signal output

Feedback signal used in conjunction with 4 to 20mA OUTPUT

voltage when using Slidewire Emulation

Analog signal input

Connection for RS485 Modbus loop wires

HART Communication is 4-20 mA only.

Customer’s contact closure

Installation

Electrical Installation

HART

HART

Communications

Communications

Connection

Connection

_

_

+

+

HART connection using

HART connection using

HART connection using

external Turck connector

external Turck connector

external Turck connector

Auxiliary

Auxiliary

Auxiliary

Connector

Connector

Connector

_

_

_

Brown

Brown

Brown

Black Wire Not Used

Black Wire Not Used

Black Wire Not Used

Black

Black

Black

Blue

Blue

Blue

+

+

+

®

Figure 9 HercuLine

Revision 7 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual 19

7/08

2001/2002 connections

Page 28

Installation

Electrical Installation

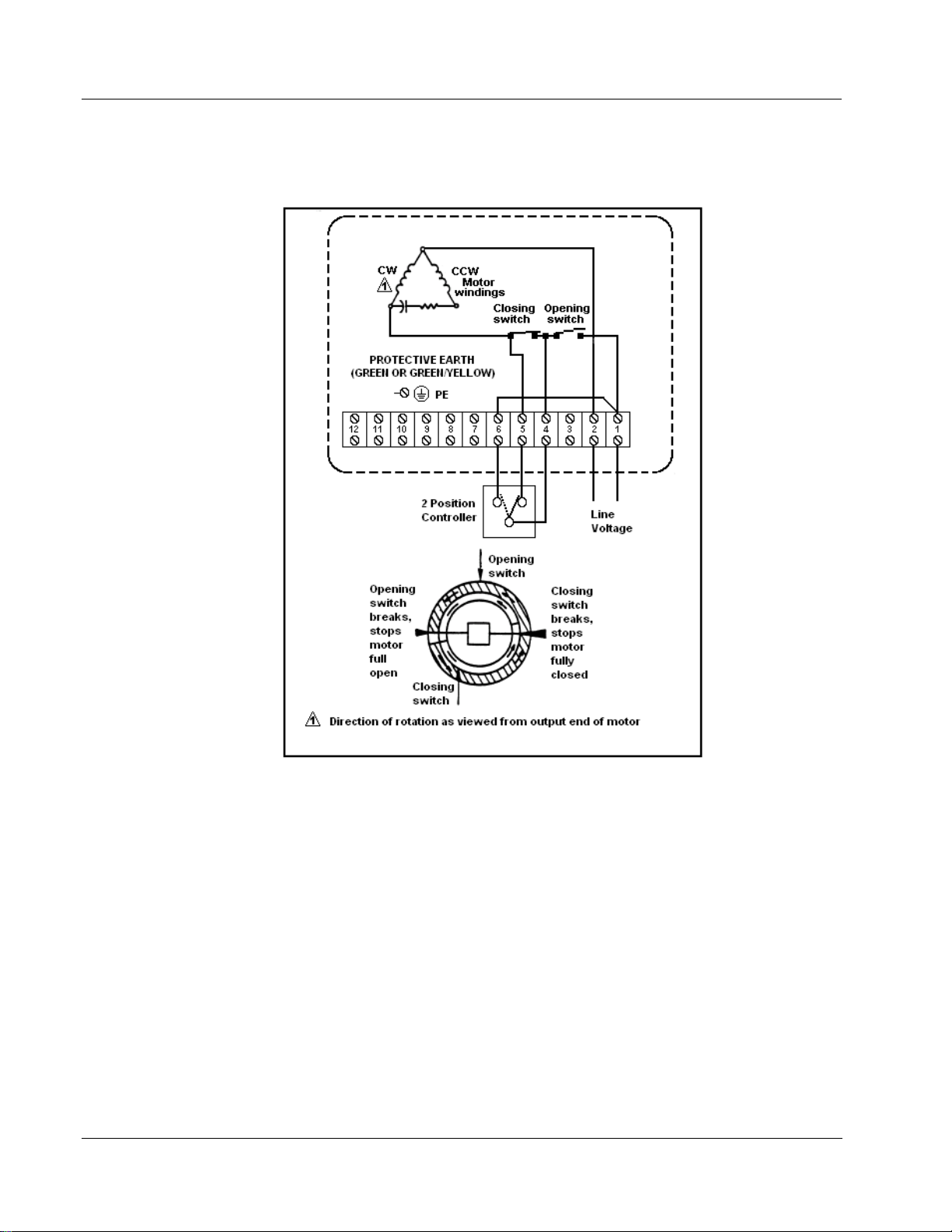

HercuLine® 2003 Wiring Connections and Operation (Actionator 640D Replacement)

Wiring

®

Figure 10 HercuLine

2003 connections

Operation

The 2003 actuator is uni-directional (it does not reverse rotation with a reversal in control action).

Figure 10 illustrates the internal wiring and the external connections.

The smaller insert of the figure describes the limit switch action for one complete cycle. When the two-position

controller detects a sufficient fall in temperature in a heating application, the switch portion between the “4” and

“5” terminals will close.

The motor then rotates for 180º or until the opening switch breaks (stops are adjustable, factory set at 180º), and

stops in full open position.

A subsequent rise in temperature causes the controller to close the switch between the “4” and “6” terminals

when the motor will start to rotate (in the same direction) for 180º or until the closing switch breaks.

The motor stops in the closed position and completes one cycle.

20 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual Revision 7

7/08

Page 29

Power Connections

Depending on which power supply selection is ordered for your actuator, wire the power input (MAINS

POWER) as described in the previous tables and figures. Wiring must conform to national and local electrical

codes.

CE Wiring

When wiring the actuator power input for CE approved units, you must also install a MOV and ferrite beads

supplied with the CE unit.

You need the following tools:

• 5mm hex key

• small flat blade screwdriver

• small needle nose pliers

Step Action

Electrical Installation

While the unit is powered, a potentially lethal shock hazard exists inside the case.

Do not open the case while the unit is powered. Do not access the terminals while

the unit is powered.

Installation

1 Remove AC power to actuator.

2 Loosen the 6 captive screws (use 5mm hex key) and remove the cover.

3 Locate the terminals TB1-1, TB1-2 and ground screw.

4 Loosen the screws at terminals TB1-1 and TB1-2. Remove screw used for ground.

5 Install the appropriate MOV assembly as shown in Figure 11.

6 All ferrites require 1 loop of wire per ferrite. Connect as shown in following steps.

7 • Current input and output (slidewire emulation) connection

• Communications and digital input connection

Ground

screw

Current input

and output

(slidewire

TB1-2

emulation)

TB1-1

Communications

and digital input

Figure 11 CE wiring part 1

Revision 7 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual 21

7/08

Page 30

Installation

Electrical Installation

Step Action

8 • AC power connection

• Auxiliary switches connection

• Relay contact connection

Aux switches

1 and 2

(SW3 and SW4)

Aux switches 3

and 4

(SW5 and SW6)

Relays 1 and 2

9 Install new gasket and top cover. Secure top cover with 6 captive screws.

10 Reapply AC power to the actuator.

11 Actuator is ready for use.

Input Signal Connections

ATTENTION

Shielded and grounded cables are recommended.

0/4-20 mA Input Signals

For current signal input, ensure jumper W2 on the CPU PWA is in the “Current” position. See

68. Observing polarity, connect the signal input wires TB3–4(+) and TB3–5(-) on CPU terminal board.

page

Relays 3 and 4

AC power

connection

Figure 12 CE Wiring part 2

Figure 27 on

0/1-5 Vdc and 0 to 10 Vdc Input Signals

For voltage signal input, ensure jumper W2 on the CPU PWA is in the “Voltage” position. See

68. Observing polarity, connect the signal input wires to terminals TB3–4(+) and TB3–5(-) of the terminal

page

Figure 27 on

block.

22 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual Revision 7

7/08

Page 31

Output Signal Connections

0/4-20 mA, 0/1-5 Vdc Feedback Signal Connections

ATTENTION

Shielded and grounded cables are recommended.

Actuator output is a 4 to 20 mA analog signal. If a voltage input is required for custo mer devices, a range

resistor is needed at the device input. Refer to (page

Slidewire Emulator Connections

ATTENTION

Shielded and grounded cables are recommended.

If you ordered the Slidewire output option for your actuator, it is set at the factory to provide an output that

emulates 100 to 1000 ohm slidewires. Refer to (page

Burner Control/Flame Safety

Electrical Installation

19) for more information.

19) for more information.

Burner Control/Flame Safety

Introduction

Often, Gas Fired control applications use a Fl ame Safety System that drives the gas valve to full closed and full

open during the start-up sequencefor the burner. HercuLine® 2000 Series actuators have been designed to be

compatible with the Flame Safety Systems and to perform the required operations.

Configuration

39), configure the parameter FSTYPL to Down .

51), configure the parameter DIG INP to Up.

To TB3 #10

To TB3 #10

To TB3 #10

To TB3 #10

To TB3 #10

To TB3 #10

To TB3 #10

To TB3 #10

To TB3 #10

To TB3 #10

To TB3 #10

To TB3 #10

To TB3 #10

To TB3 #10

To TB3 #10

To TB3 #10

To TB3 #10

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

To TB3 #5

To TB3 #5

To TB3 #5

To TB3 #5

To TB3 #5

To TB3 #5

To TB3 #5

To TB3 #5

To TB3 #5

To TB3 #5

To TB3 #5

To TB3 #5

To TB3 #5

To TB3 #5

To TB3 #5

To TB3 #5

To TB3 #5

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Wiring

In the Input Set Up Group (Page

In the Digital Input Set Up group (Page

Figure 13 Burner Control/Flame Safety Wiring shows a Typical Flame Safety Module wiring diagram.

High Fire

High Fire

High Fire

High Fire

High Fire

High Fire

High Fire

High Fire

High Fire

High Fire

High Fire

High Fire

High Fire

High Fire

High Fire

High Fire

Common

Common

Common

Common

Common

Common

Common

Common

Common

Common

Common

Common

Common

Common

Common

Common

Low Filter

Low Filter

Low Filter

Low Filter

Low Filter

Low Filter

Low Filter

Low Filter

Low Filter

Low Filter

HercuLine TB3

HercuLine TB3

HercuLine TB3

HercuLine TB3

HercuLine TB3

HercuLine TB3

HercuLine TB3

HercuLine TB3

HercuLine TB3

HercuLine TB3

HercuLine TB3

HercuLine TB3

4

+

+

+

+

+

+

+

+

+

+

+

4

–

–

–

–

–

–

–

–

–

–

–

Add Jumper

Add Jumper

Add Jumper

Add Jumper

Add Jumper

Add Jumper

Add Jumper

Add Jumper

Add Jumper

Add Jumper

Add Jumper

Add Jumper

1 2 3 4 5 6 7 8 9 10

11 22 33 44 55 66 77 88 99 10

11 22 33

1 2 3 4 5 6 7 8 9 10

11 22 33 44 55 66 77 88 99 10

11 22 33

1 2 3 4 5 6 7 8 9 10

11 22 33 44 55 66 77 88 99 10

11 22 33

1 2 3 4 5 6 7 8 9 10

11 22 33 44 55 66 77 88 99 10

11 22 33

1 2 3 4 5 6 7 8 9 10

11 22 33 44 55 66 77 88 99 10

1 2 3 4 5 6 7 8 9 10

11 22 33 44 55 66 77 88 99 10

11 22 33

+ 4 to 20 Output from Controller

+ 4 to 20 Output from Controller

+ 4 to 20 Output from Controller

+ 4 to 20 Output from Controller

+ 4 to 20 Output from Controller

+ 4 to 20 Output from Controller

+ 4 to 20 Output from Controller

+ 4 to 20 Output from Controller

+ 4 to 20 Output from Controller

+ 4 to 20 Output from Controller

+ 4 to 20 Output from Controller

+ 4 to 20 Output from Controller

+ 4 to 20 Output from Controller

+ 4 to 20 Output from Controller

+ 4 to 20 Output from Controller

+ 4 to 20 Output from Controller

Modulate

Modulate

Modulate

Modulate

Modulate

Modulate

Modulate

Modulate

Modulate

Modulate

Modulate

Modulate

Modulate

Modulate

Modulate

Modulate

Typical Flame

Typical Flame

Typical Flame

Typical Flame

Typical Flame

Safety Module

Safety Module

Safety Module

Safety Module

Safety Module

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

+ 4 to 20 Output from Controller

– 4 to 20 Output from Controller

– 4 to 20 Output from Controller

– 4 to 20 Output from Controller

– 4 to 20 Output from Controller

– 4 to 20 Output from Controller

– 4 to 20 Output from Controller

– 4 to 20 Output from Controller

– 4 to 20 Output from Controller

– 4 to 20 Output from Controller

– 4 to 20 Output from Controller

– 4 to 20 Output from Controller

– 4 to 20 Output from Controller

– 4 to 20 Output from Controller

– 4 to 20 Output from Controller

– 4 to 20 Output from Controller

– 4 to 20 Output from Controller

– 4 to 20 Output from Controller

Figure 13 Burner Control/Flame Safety Wiring

Revision 7 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual 23

7/08

Page 32

Burner Control/Flame Safety

Series 90 Control – HercuLine® 2001 model only

Series 90 Control – HercuLine® 2001 model only

Series 90 Controls are commonly used in building environmental systems and flame safeguard systems to

provide modulating control. The control is affected by balancing a 135 ohm potentiometer. The HercuLine

2001 provides an emulation of this system as follows. The current output is used to excite the potentiometer in

the controller. To do this it is set permanently at 11 ma. This produces a 1.5 volt span. The wiper is then

connected to the HercuLine 2001 input, which is operating in voltage mode. The returns from both the input

and the output are tied together.

Series 90 terminals are typically color coded white, red and blue. Conventionally, red is the wiper and white

and blue are the two ends of the potentiometer. On a drop in temperature, the wiper moves toward the blue

terminal.

Connections

TB3

Considerations

This connection performs an emulation of a series 90 motor. If the controller being used is also an

1.

emulation of a Series 90, the connections required may be different. Shown in

connections found necessary to connect a T775 controller through an S443A S9 0 Auto/Manual Control. If

the controller has the capability to provide a 4/20 or voltage output, it is easier to use that mode. It will

require only two wires and it will allow the independent use of the 4/20 output. If help is required, contact

Honeywell.

Due to variations in the definition of rotation directions, it may be necessary to reverse the action of the

2.

actuator from CCW to CW or vice versa.

4-20mA output

4-20mA input

Figure 14 Series 90 connections

1+

2-

4+

5-

White

Red

Blue

Figure 15 are the

24 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual Revision 7

7/08

Page 33

Burner Control/Flame Safety

A

Series 90 Control – HercuLine® 2001 model only

I out from

uto

W

W

T775 B 3

HercuLine2001

W

R

T775 W 1

+ Signal to

HercuLine2001

R

Man

GND to

HercuLine2001 (2)

B

B

T775 R 2

Figure 15 T775 Controller connections

In the T775 controller manual there are several examples of using resistances or potentiometers as high and

3.

low limit controls. Because of the mode of emulation of Series 90, it is likely that these connections will

not work as intended. Instead, use the output or input limits which are programmable in the

HercuLine

®

2001.

Revision 7 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual 25

7/08

Page 34

Burner Control/Flame Safety

Split Range

Split Range

The HercuLine® 2001/2002 actuators can be set up to operate within a narrow input range (for example,

4 to 12mA input) in certain applications. The procedure in

to operate as part of a split valve configuration.

Step Action

To Set Actuator span to operate from 4 to 12 mA input.

1 Enter Set Up mode by pressing SET UP key

2 Select SET INPUT group

3 Press FUNCTION key until INP HI (on lower display) is selected.

4 Set INP HI value to 50.0

Table 5 describes how to set up an actuator

Table 5 Split Range Set Up Procedure

5 Press FUNCTION key to select INP LO and set value to 0.0

6 Press DISPLAY key to exit Set Up mode.

To Set Actuator span to operate from 12 to 20 mA input.

1 Enter Set Up mode by pressing SET UP key

2 Select SET INPUT group

3 Press FUNCTION key until INP HI (on lower display) is selected.

4 Set INP HI value to 100.0

5 Press FUNCTION key to select INP LO and set value to 50.0

6 Press DISPLAY key to exit Set Up mode.

ATTENTION

Be sure to review failsafe strategy for your process application.

Master/Slave Arrangement

Introduction

With the motor positioner, the controlling signal for the actuator is a 4 to 20mA from a current output

controller as shown in the flow diagram in

Figure 16.

Unlike the position output controller, the current output controller must produce a continuous analog

signal or the actuator will revert to one of its failsafe states. Signal failure is not a problem since the

available failsafe settings allow you to set the actuator position on signal loss.

26 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual Revision 7

7/08

Page 35

Basic Flow Control

When the process variable signal is below set point, the controller increases current (4 to 20mA) to the

actuator input and opens the valve. Controller set point governs valve position to obtain desired flow

rate.

Burner Control/Flame Safety

Master/Slave Arrangement

PV

Positioner & Actuator

Controller

SP

FIC

4 to 20 mA

Position

MP

Linkage

mA

Orifice Plate

FT

Valve

Figure 16 Flow Diagram

Current Output Controller

+

4 to 20 mA

-

Actuator

See Figure

27 for jumper

location

Jumper W2

= Current

250 Ohms

1 to 5 VDC

Hot

Neutral

Ground

120/240

VAC

Figure 17 Interconnection Diagram

Proportional Flow using Multiple Actuators

Refer to flow diagram in

flow rate in one burner. Only that

Figure 18 and interconnection diagrams in Figure 19. The controller governs

flow is measured. Since #2 and #3 motor positions receive the same

signal as #1 motor positioned, valves #2 and #3 will deliver the same amount of fuel. This is true when

the span and zero adjustment are all set the same as in curve 2 of the graph. Other relationships between

units exist if the span adjustment (3) for ratio or if the zero adjustment is changed (1) for bias.

Revision 7 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual 27

7/08

Page 36

Burner Control/Flame Safety

Master/Slave Arrangement

SP

Position

FIC

with Bias

mA

PV

Controller

4 to 20 mA

Proportional

Ratio

Positioner & Actuator

MP

#1

MP

#2

Linkage

Orifice Plate

FT

Linkage

MP

#3

Valve

Linkage

Valve

Valve

Figure 18 Proportional Flow Using Multiple Actuators

Current Output Controller

+

4 to 20 mA

-

Note: Controller must

be capable of sourcing

the impedance.

See Figure

27 for jumper

location

Preferred

Wiring

NOTE: If using HART® communications, for this application HART®must be configured for Multi-drop operation.

Actuator #1

10260S Series Actuator #1

Jumper W2

= Current

250 Ohms

1 to 5 VDC

Actuator #2

10260S Series Actuator #2

Jumper W2

= Current

250 Ohms

1 to 5 VDC

Actuator #3

10260S Series Actuator #3

Jumper W2

= Current

250 Ohms

1 to 5 VDC

Hot

Neutral

Ground

Hot

Neutral

Ground

Hot

Neutral

Ground

120/240

VAC

120/240

VAC

120/240

VAC

28 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual Revision 7

7/08

Page 37

Burner Control/Flame Safety

Master/Slave Arrangement

Current Output Controller

+

4 to 20 mA

-

See Figure

10260S Series Actuator #1

Actuator #1

Jumper W2

= Current

250 Ohms

1 to 5 VDC

10260S Series Actuator #2

Actuator #2

Jumper W2

= Voltage

Hot

Neutral

Ground

Hot

Neutral

Ground

120/240

VAC

120/240

VAC

27 for jumper

location

10260S Series Actuator #3

Actuator #3

Alternate

Wiring

Jumper W2

= Voltage

Hot

Neutral

Ground

120/240

VAC

Figure 19 Multiple Actuator Interconnection Diagrams

NOTE: If using HART® communications, for this application HART® must be configured for Multi-drop operation.

Revision 7 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual 29

7/08

Page 38

Burner Control/Flame Safety

Master/Slave Arrangement

Split Valve Configuration

A common heat or cool type process requires two valves. In this case the controller has only one output.

The two motor positioners are calibrated differently, one responds to 4 to 12mA and the other responds

to 12 to 20mA. At 12mA, both valves are closed; one opening below 12mA and th e other above 12mA.

Refer to

Figure 20 for an interconnection diagram for split valve operation using two actuators.

Current Output Controller

+

4 to 20 mA

-

Note: Controller must

be capable of sourcing

the impedance.

Preferred

Wiring

NOTE: If using HART® communications, for this application HART® must be configured for Multi-drop operation.

Current Output Controller

+

4 to 20 mA

-

10260S Series Actuator #1

Actuator #1

Jumper W2

= Current

250 Ohms

1 to 5 VDC

Actuator #2

10260S Series Actuator #2

Jumper W2

= Current

250 Ohms

1 to 5 VDC

Actuator #1

10260S Series Actuator #1

Jumper W2

= Current

250 Ohms

1 to 5 VDC

Actuator #2

10260S Series Actuator #2

Hot

Neutral

Ground

Hot

Neutral

Ground

Hot

Neutral

Ground

120/240

VAC

See Figure

27 for jumper

location

120/240

VAC

120/240

VAC

See Figure

27 for jumper

location

Alternate

Wiring

Jumper W2

= Voltage

Hot

Neutral

Ground

120/240

VAC

Figure 20 Interconnection Diagrams

NOTE: If using HART® communications, for this application HART® must be configured for Multi-drop operation.

30 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual Revision 7

7/08

Page 39

Overview

Set Up and Calibration Procedures

Overview

Set Up and Calibration Procedures

Once you have installed the actuator, you can verify, set or change certain operating parameters. Set up is

accomplished through use of the local display and keypad interface through your PDA with HercuLink

software (see HercuLink® manual 62-86-25-11) or via the HART® communication option. Please keep in

mind that the unit is calibrated at the factory for your application and can be placed into service right out of

the box. Changing operating parameters may require recalibration of the actuator. This section details the

various operating parameters and functions of the actuator available using the local display and keypad

interface, and calibration procedures.

Local Display and Keypad

The alphanumeric display and keys on the keypad are the local operator interface for con t rol, monitoring,

and configuration of the actuator. The display consists of a four character upper display and a six character

lower display. Six LEDs of various colors indicate actuator-operating status. Directly below the display

are six keys that allow you to setup, monitor, and control the actuator locally, as well as call up various

operating parameters and configuration values on the display.

display and keypad.

descriptions of the status indicators.

Upper Display

(Four Characters)

Table 6 summarizes the various functions you can perform using the keys as well as

®

Figure 21 shows the physical features of the

STALLED

ALARM

MANUAL

AUTO

Lower Display

(Six Characters)

FUNCTIONSET UP

MAN/AUTO

DISPLAY

®

Figure 21 HercuLine

2000 Display and Keypad

Revision 7 HercuLine™ 2000 Series Actuator - Installation, Operation and Maintenance Manual 31

7/08

Page 40

Set Up and Calibration Procedures

Local Display and Keypad

Key or

LED Indicator

SET UP

FUNCTION

MAN/AUTO Alternately selects:

DISPLAY

INCREMENT

DECREMENT

☼

☼

☼ STALLED

☼ ALARM

☼ MANUAL

☼ AUTO

Places the actuator in the set up group select mode. Sequentially displays the set

up groups and allows the FUNCTION key to display function parameters within the

set up group.

See Set Up and Calibration Procedures (page 31)Error! Reference source not

found. for descriptions of the various options available in the set up groups.

Used in conjunction with the SET UP key to select the individual functions of a

selected configuration set up group.

Used during field calibration procedure.

MAN - Actuator is in Manual mode.