Page 1

上海市水泉路88弄8号503室 电话:021-56356105 传真:021-56356109

HC900 Hybrid Controller

51-52-03-31

9/03

Page 1 of 36

Technical Overview

Overview

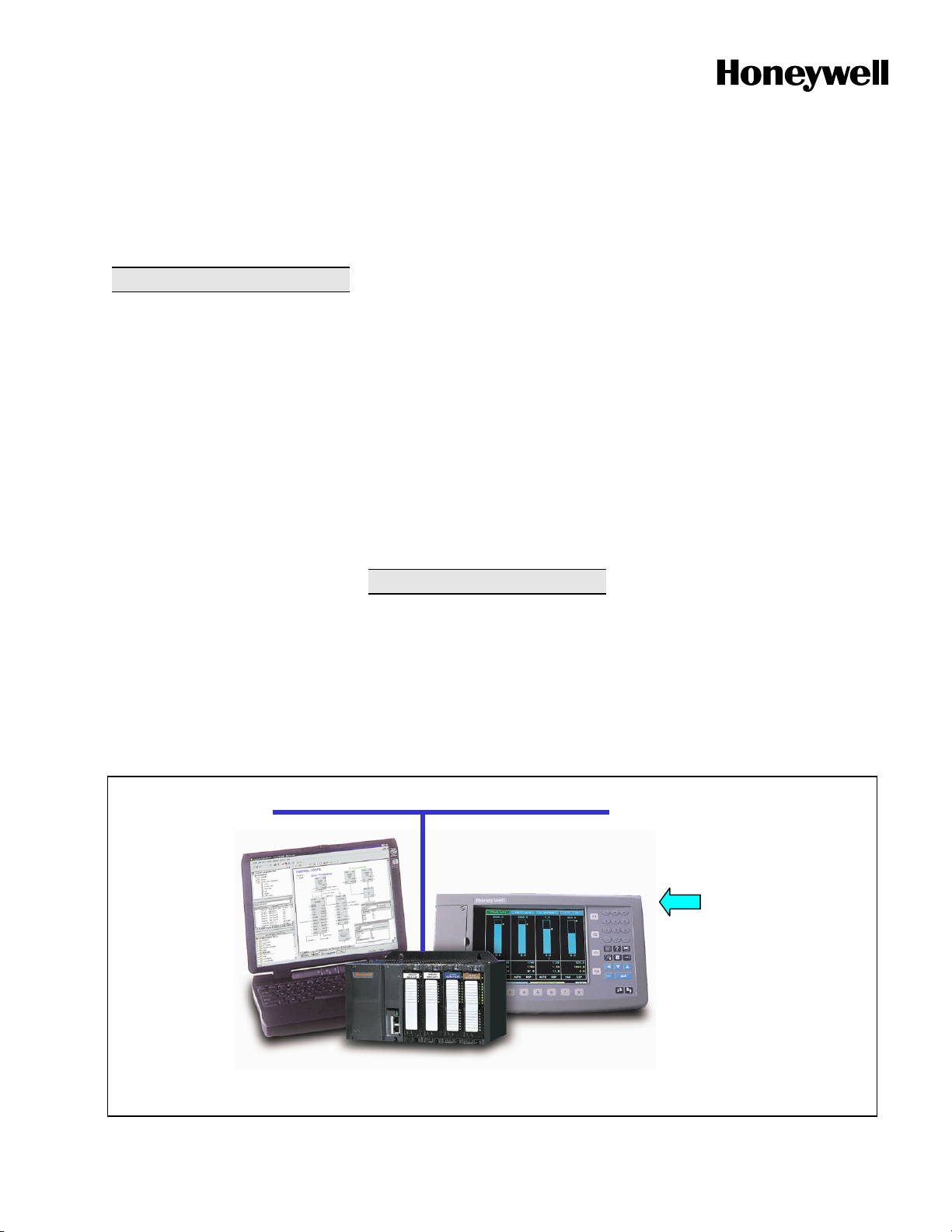

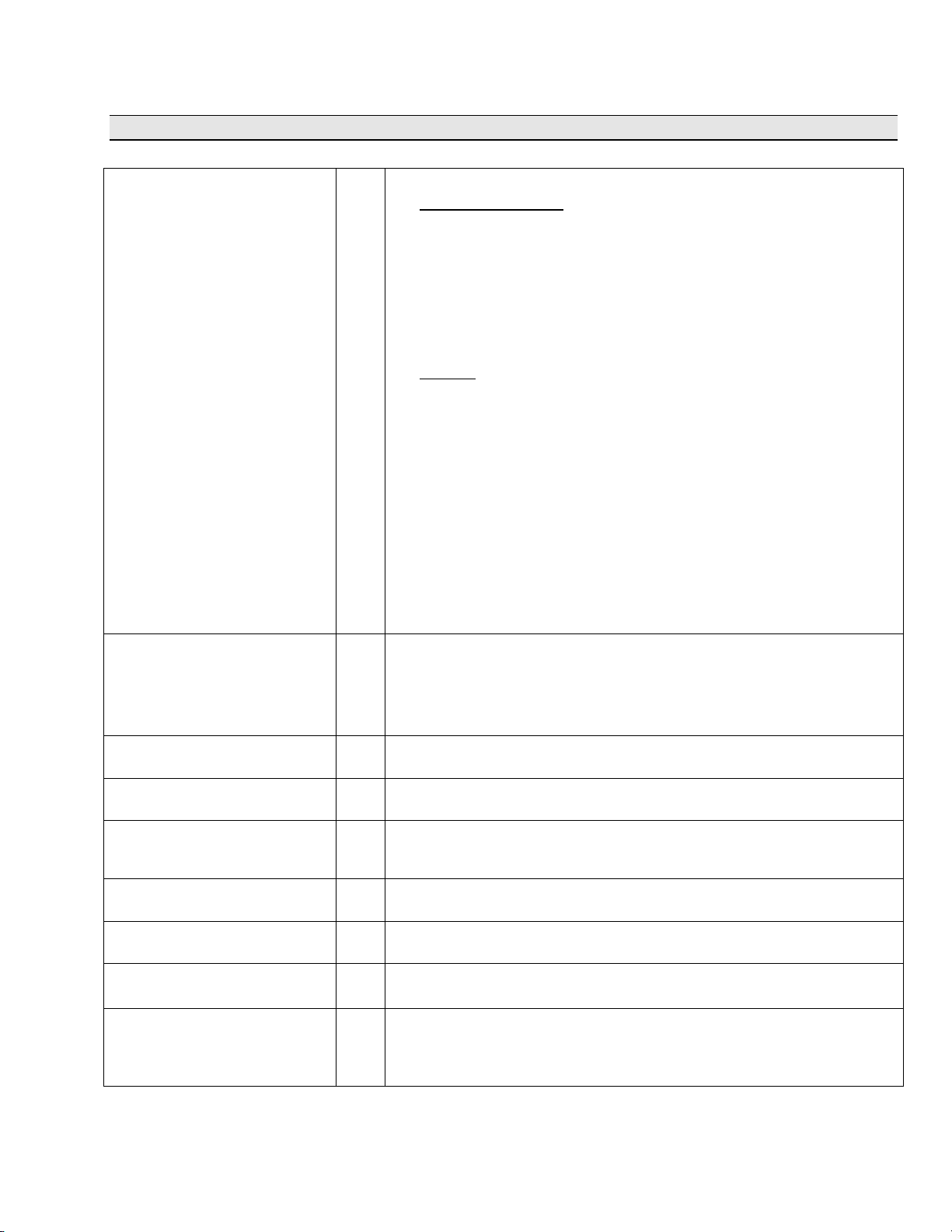

The Honeywell HC900 Hybrid

Controller is an advanced loop and

logic controller offering a modular

design sized to satisfy the control and

data acquisition needs of a wide range

of process equipment. When

combined with the optional,

performance rich 1042 or 559 Operator

Interfaces that fully integrate the

controller database, configuration and

setup time is minimized. This powerful

combination together with Honeywell's

performance proven control technology

provides users an ideal solution for

process control. Open Ethernet

connectivity also allows network

access using a variety of HMI/SCADA

software.

Easy-to-use Windows-based Hybrid

Control Designer software, operable

over Ethernet, an RS232 port or

modem connection, simplifies

controller and operator interface

configuration. It provides advanced

monitoring functions for debug, allows

run-mode configuration changes while

limiting process interruption, uploads

the complete, annotated graphic

controller and operator interface

configuration, plus supplies an array of

printouts for enhanced documentation.

The HC900 Controller provides

superior PID loop control and more

robust analog processing than most

logic controllers without compromising

logic performance. A separate, fast

scan cycle is available to execute a

rich assortment of logic and calculation

function blocks. Logic blocks may also

execute synchronous with analog

function blocks. These function blocks

may be fully integrated into a combined

analog and logic control strategy for

uncompromising control performance.

Feature Summary

• Compact size – 5.4 “(137mm) high

• Up to 32 loops of PID Control

• Up to 960 points with remote I/O

• Remote I/O Racks

• Up to 256 Isolated, Universal

Analog Inputs

Ethernet

Specification

• I/O Insert/Remove under power,

auto-configured

• LED on/off indicators on digital I/O

• Graphic Function Block

Configuration – up to 2000 blocks

• Boolean Logic programming

• Robust assortment of algorithms –

over 100

• Advanced Floating Point Math

Functions

• Fast updates – 27 ms logic, 0.5 sec

analog

• Open 10MB Ethernet interface

using Modbus/TCP protocol –

supports 5 concurrent host

connections

• Peer-to-peer communications via

Ethernet

• Extensive Alarm and Event

Monitoring

• E-mail alarm/event messaging on

priority

• 8 Ramp/Soak Setpoint

Programmers

• 2 Setpoint Schedulers with multiple

outputs

• 4 Sequencers with 16 Outputs each

• Stored recipes, SP profiles,

sequences, schedules

• Carbon Potential and RH Control

1042 OI

Hybrid

Control

Designer

Software

Figure 1—HC900 Hybrid Controller Overview

HC900 Hybrid Controller

Industrial Measurement and Control, 1100 Virginia Drive, Fort Washington, PA 19034

Printed in U.S.A. ■ © Copyright 2002 — Honeywell

· Furnaces

· Kilns

· Autoclaves

· Dryers

· Fermenters

· Water treatment

· Boilers

· Utility DAQ

· Pump stations

· Retorts

· Sterilizers

· Crystal Growing

· Extruders

· Pilot Operations

Page 2

51-52-03-31

上海市水泉路88弄8号503室 电话:021-56356105 传真:021-56356109

Page 2

HC900 Controller

The rack based HC900 Controller is

available in 3 rack sizes with 4, 8 or 12

I/O slots each to support a wide range

of requirements.

C50 CPU -For greater installation

flexibility the C50 CPU allows up to 4

additional remote racks to be

connected to a single controller (with

its local I/O rack) to reduce wiring and

installation cost. A variety of analog

and digital I/O modules are available to

support a total of 960 I/O points,

including up to 256 analog input points

and 64 analog output points per

controller.

C30 CPU -The C30 CPU supports a

single rack with 4, 8 or 12 I/O slots and

can accommodate up to 96 analog

inputs or 192 total I/O points.

A standard Ethernet communication

port on the C50 and C30 CPUs

provides open connectivity to PCs or

other supervisory interfaces and

supports peer data exchanges to other

controllers.

Inputs and Outputs - A variety of I/O

modules are available for selection in

creating a custom control solution.

These include:

8 point universal analog input cards:

Inputs may be mixed on a card and

may include multiple thermocouple

types, RTDs, ohms, voltage or

millivoltage types – all easily

assigned using the Hybrid Control

Designer configuration tool. High

point to point isolation simplifies

installation and saves the expense of

external isolation hardware.

4 point isolated analog output card:

Supports from 0 to 20mA each.

16 point digital input cards: Contact

closure type, DC voltage and AC

voltage types.

8 point AC or 16 point DC digital

output cards

8 point relay output card: four form C

type and four form A

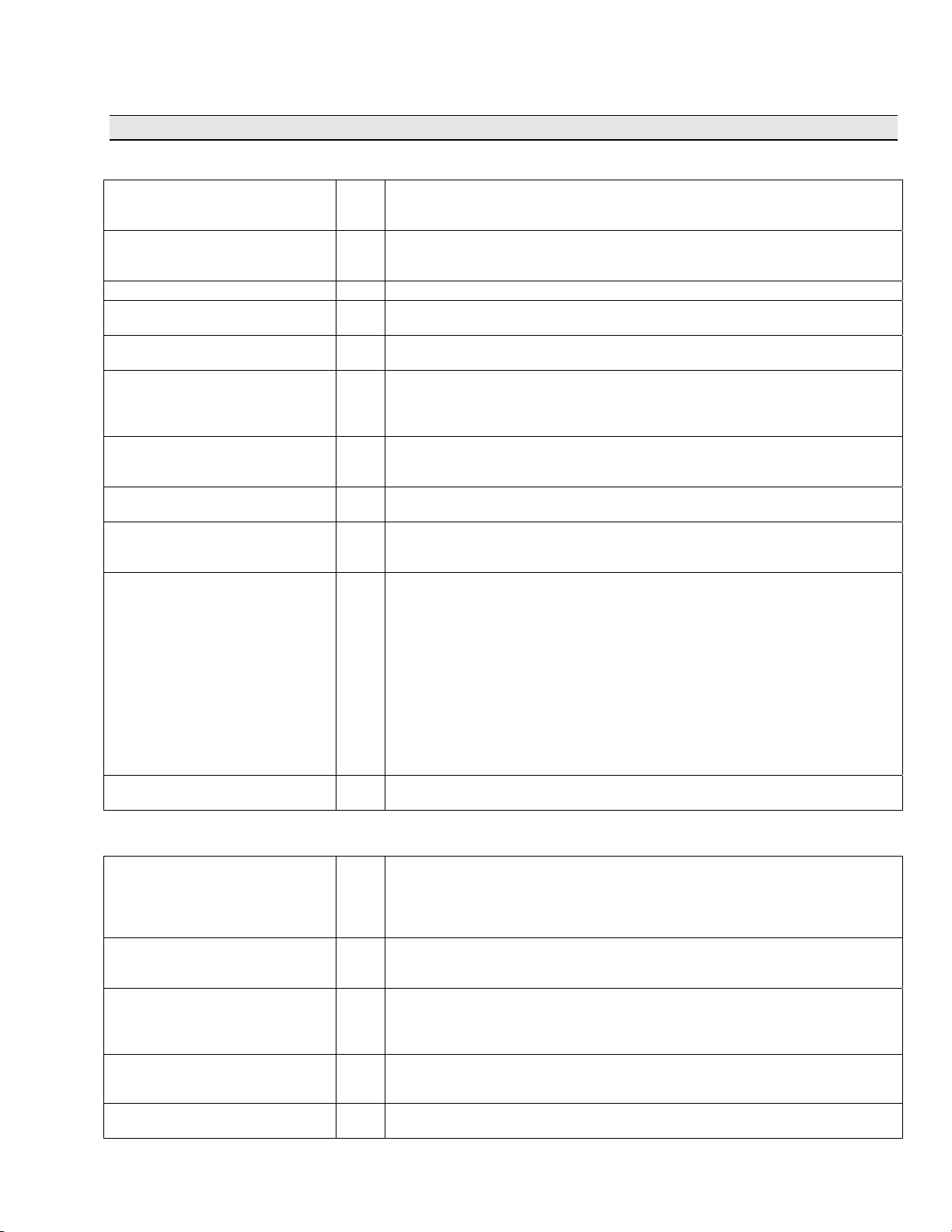

Input Type Point per Module Max. Points per C50/C30 Controller

Analog In 8 256/96

Analog Out 4 64/48

Digital In 16 960/192

Digital Out 8 AC or 16 DC 960/192

type relays.

Remote I/O- Up to 4 I/O racks may be

remotely mounted from the controller

via an Ethernet-private 10Base-T

connection at up to 300 meters (984

feet) between the controller and the

most remote rack using two Ethernet

hubs.

Insert & removal of I/O under power-

For ease of maintenance, the HC900

controller supports removing and

inserting I/O modules from the card

rack without removing power from

controller. Each card is sensed for

validity by the controller and autoconfigured on insertion.

Remote Terminal Panels - Optional

DIN rail mounted Remote Terminal

Panels (RTPs) are available for use

with pre-wired cables to reduce

installation time and labor expense.

Three types of RTPs are available:

analog inputs, relay outputs and other

I/O modules. Three cable lengths are

also available to match hardware to

installation variations. Analog input

RTPs include transmitter shunt

resistors and transmitter power

terminals with individual circuit fuses.

The RTP panels also switch field

power to allow module removal and

installation under controller power.

the

Function Blocks

Each HC900 Controller can support up

to 2000 analog or digital function

blocks. Each function block algorithm

may be used any number of times in a

control strategy unless specifically

identified with quantity limits. Of the

more than 100 function blocks

available, 12 block types have limits

imposed. These include:

C50

Control Loops – 32 8

Setpoint Programmers – 8 8

Setpoint Schedulers – 2 2

Sequencers – 4 4

Alternators – 6 6

Stages – 8 8

Ramps – 8 8

Hand/Off/Auto – 16 16

Device (Pump) Control – 16 16

Pushbuttons (4 PB’s/block) – 8 8

Sel switches (4-position) – 8 8

Position Proportional Output – 64 16

I/O Capacity

C30

User configurations are permanently

retained in flash memory in the

controller. In the event a PC

configuration file is lost or misplaced, it

can be easily reconstructed using the

upload function of the Hybrid Control

Designer configuration software or via

the 1042 and 559 OIs. Simply read the

configuration from the controller to

duplicate the original

exactly

configuration, including all text

descriptions and operator interface

display selections. In the event edits to

a controller’s configuration are required

after the unit is in operation, the on-line

download function of the HC900 Hybrid

Control Designer software allows

configuration changes while in the Run

mode, limiting process disturbances.

The dynamic control status is retained

in battery backed

controller. This function minimizes

process upsets during momentary

power interruptions and other

discontinuous operations.

Advanced control and

computational capability - A large

assortment of analog and digital

function blocks are available to solve

the most demanding control

requirements. Typical analog function

blocks include totalizers, free-form

math, average, mass flow, function

generator, periodic timers based on

real-time, carbon potential, RH, Dew

Point, signal selection

and many others. These blocks may

be configured to create control

schemes that precisely address the

needs of your process. Digital status

outputs are also provided on many of

the analog function blocks to facilitate

intelligent signal alarming and default

operation strategies. Typical logic

function blocks include AND, OR,

XOR, NOT, Latch, Flip-flop, On/Off

Delay and Resetable timers, Counters,

Free-form Boolean logic and more.

The execution of analog and digital

functions is seamlessly integrated into

a single control strategy in the

controller.

RAM memory in the

, comparison,

Page 3

Loop Control- The robust control

上海市水泉路88弄8号503室 电话:021-56356105 传真:021-56356109

loops of the HC900 Controller support

configurations from simple PID to

interactive cascade, ratio, duplex,

position proportioning and three

position step for motor positioning or

custom control strategies. Standard for

every control loop is auto-tuning using

Honeywell’s performance proven

Accutune II tuning algorithm. A

selectable "Fuzzy Logic" algorithm is

also provided for each loop to suppress

unwanted process setpoint overshoot.

A soft start feature allows output rate

limiting for protection of a process load

on startup or after power failure.

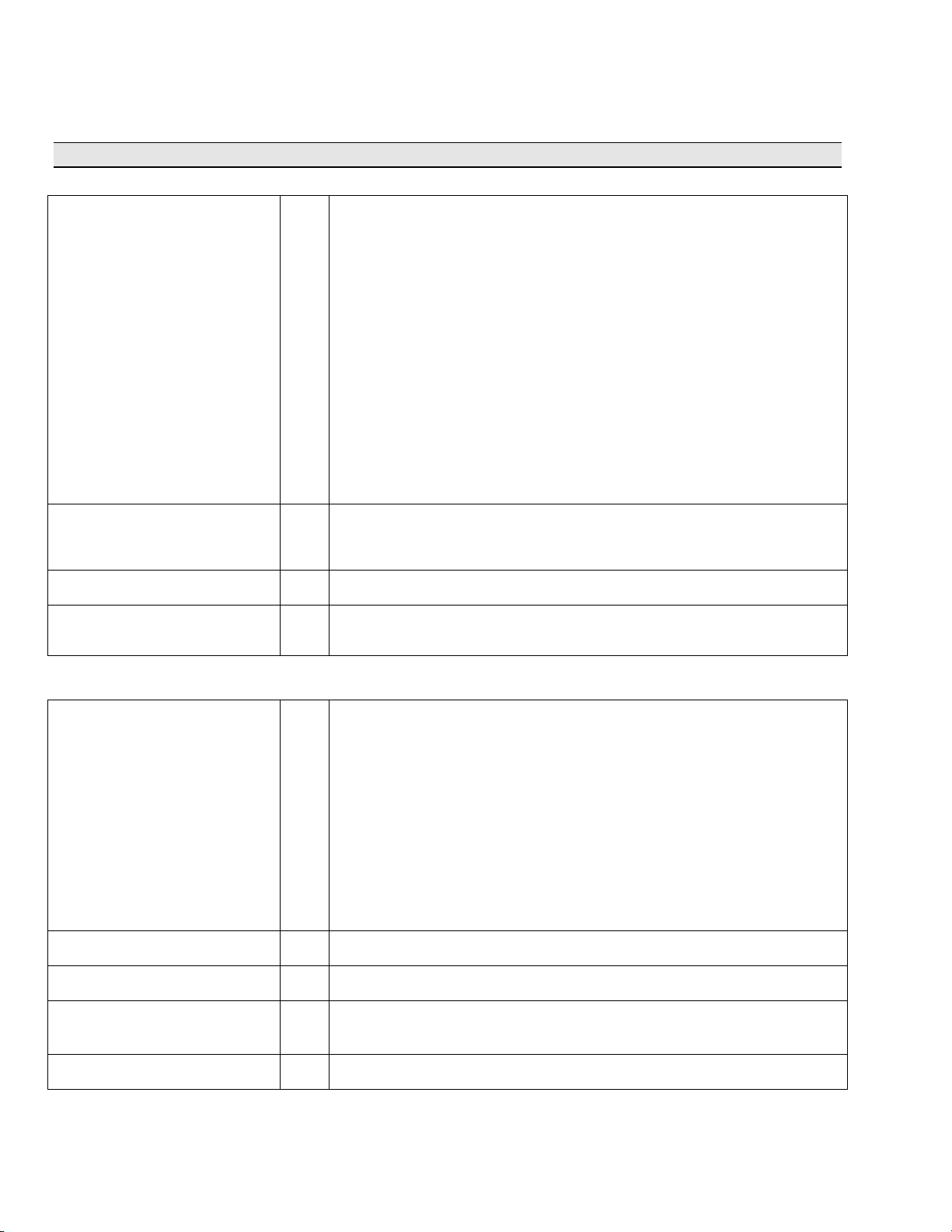

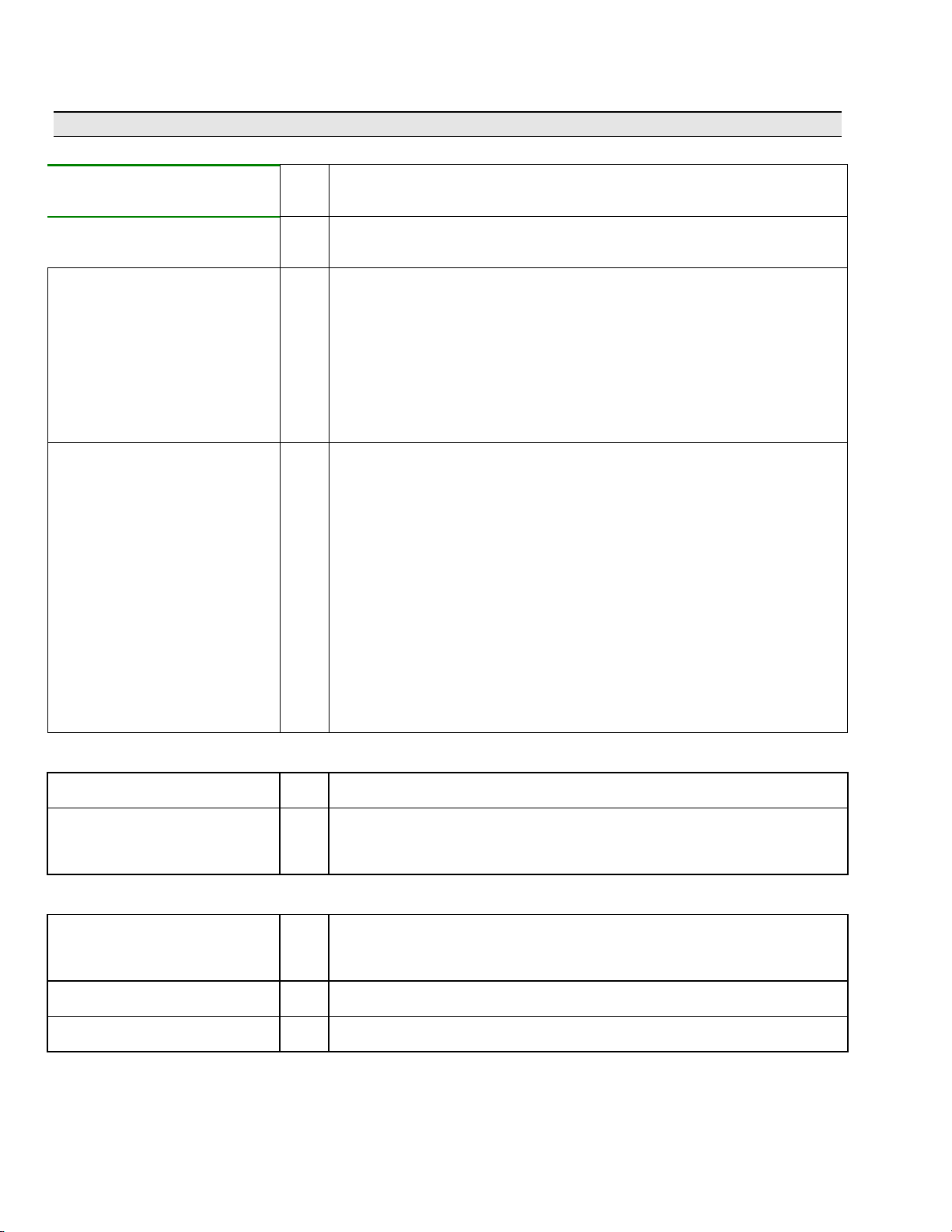

Sequencers - The HC900 controller

supports up to four sequencer function

blocks, greatly enhancing configuration

of sequence operations. Each

sequencer supports up to 16 digital

outputs that may be either on or off in

each of 50 states e.g. PURGE, FILL,

HEAT, etc. The sequencer may have

up to 64 sequential steps that activate

within the states of the process. Steps

of the sequencer may be configured to

advance based on time, on event (2

per step), or a manual advance. A

separate jog function is also provided.

The function can also configure an

analog output on a step basis. The

operational sequence for the steps is

retained in a separate sequence file in

the memory of the controller that

may

be selected on-demand through a user

interface or via a recipe. Up to 20

sequences may be stored.

Set Point Programming - Up to 8

independent set point programmers,

each with an auxiliary soak output may

be configured. A pool of up to 99

profiles, each with up to 50 segments

may be stored in controller memory for

user selection. Each programmer may

have up to 16 event outputs for

integration with the sequence control

functions. Features such as

guaranteed soak, jog to a segment and

looping are also provided.

Setpoint Scheduling - Up to 2

independent setpoint scheduler

functions may be configured. The

scheduler function provides up to 8

ramp and soak outputs plus up to 8

soak only outputs that operate on a

common time base. The scheduler

also supports up to 16 event digital

outputs. Soak guarantee, jog to a

segment and nested looping features

are also provided. Applications include

multi-zone diffusion furnaces, CVD

furnaces, and environmental

chambers. Up to 20 schedules can be

stored in the controller for user

selection.

51-52-03-31

Logic - Logic programming may be

used to implement more robust and

higher speed logic functions in the

controller. The fast scan program

executes all inputs, outputs and

function blocks as fast as 27

milliseconds. The fast scan instruction

set includes 2, 4 and 8 input logic

blocks with selectable input inversion

plus timers, triggers, latches, counters,

timers, math and other supporting

functions. A Sequencer function is also

included with functionality beyond

typical drum sequencers.

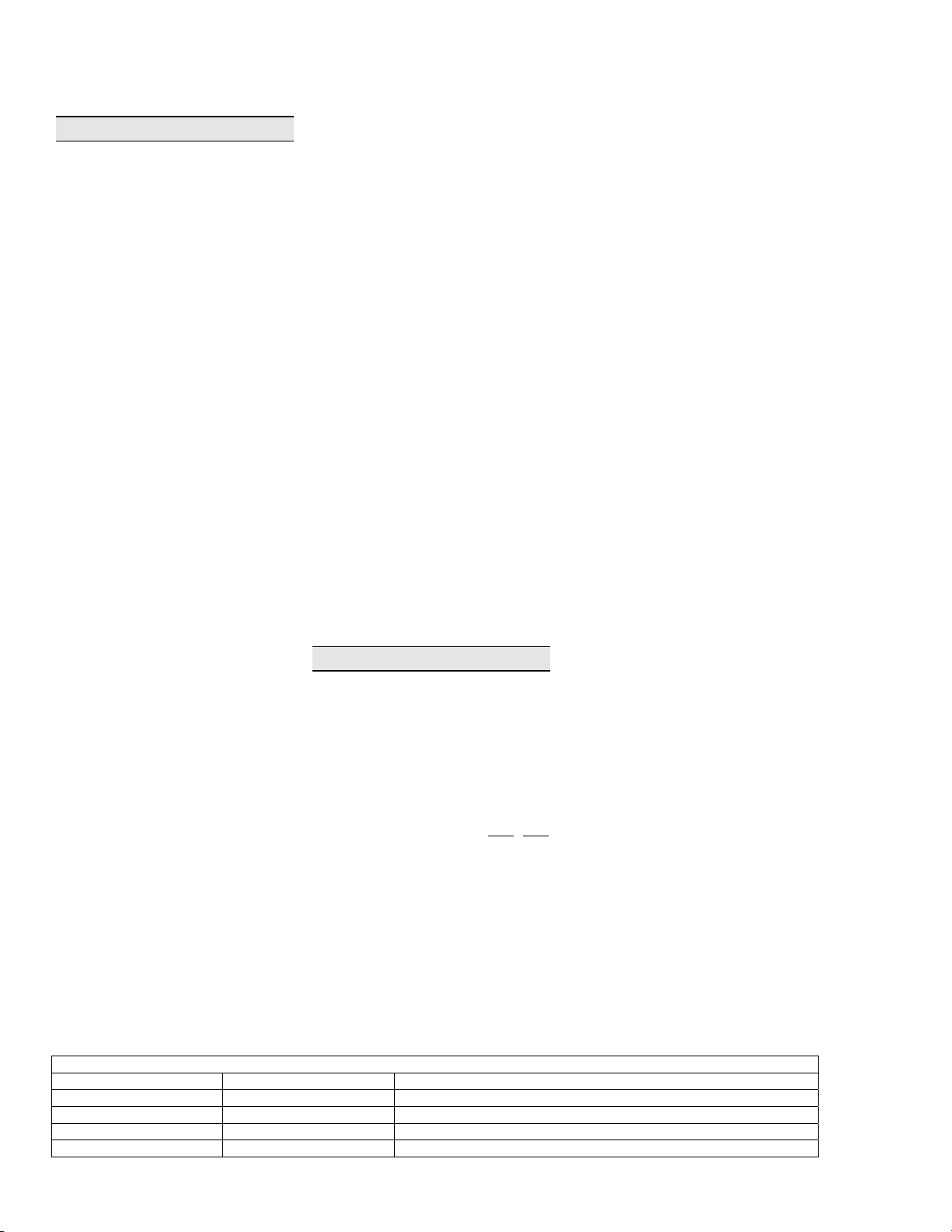

Sequence Control

Outputs

Step State State

Name

1 1 PURGE 1 0 0 1 0 1 0 0 0 1 1 0 1 0 1 1

2 5 AGITATE 1 0 1 0 1 0 1 0 0 1 1 0 1 0 1 1

3 2 FEED B 0 1 1 1 1 0 1 0 0 1 1 0 1 0 1 1

4 3 MIX 1 1 1 1 1 1 1 1 1 1 1 0 1 0 1 1

5 8 PREHEAT 0 0 0 1 0 0 1 0 0 1 1 0 1 0 1 1

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

↓

64 50 STOP 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1

Seg Ramp/

Soak

Value

1 Ramp 100 20 0.0 OFF 100110000000000

2 Ramp 500 30 1.1 OFF 100100100000000

3 Soak 1300 90 1.1 ON 101110100000000

4 Ramp 1300 50 1.1 OFF 100100100000000

5 Soak 100 0.1 0.0 OFF 00000000100000

Recipes – Up to 50 recipes are stored

in the controller. Recipes consist of up

to 50 analog and digital Variables

assigned within the configuration. This

allows Variables representing setpoint

profile, setpoint schedule, or sequencer

numbers and/or other Variables for

associated loop setpoints, bias values,

alarm setpoints, limits, setpoints to

external controllers, digital states,

tuning constants, etc. to be part of a

recipe. Recipes are selected by recipe

tag name and descriptor from the

HC900 Operator Interface or via a

Recipe Selection block with a recipe #

input.

Setpoint Profile Table

SP

Time/

Rate

Aux

Out

Tag Descriptor

PROFNUM Profile Number 2

BIAS2 TempBias–Zone2 12

BIAS3 TempBias–Zone3 18

Guar

Events

Hold

Recipe: P1023-F7

TYPE 1023 HARDEN

Variable

Up to 50 Variables

Value

↓

HIALMSP1 F1 Hi Temp Alarm 1280

Page 3

Page 4

51-52-03-31

上海市水泉路88弄8号503室 电话:021-56356105 传真:021-56356109

Page 4

HC900 Function Block Types

I/OBlocks (F=Fast Scan Rate, N=Normal Rate)

Analog Input N

Analog Output N

Digital Input (1) F,N

Universal Analog Input, with table selection of input type (See Table 3 )

Filter – 1

Bias – Input value adjust for calibration correction

Burnout – Off, Upscale, Downscale, Default Value

Warn Output – activates if thermocouple resistance > 100 ohms.

Input Disable –digital input when ON disables input, sets output to a defined

default

Regulated analog output current

Input scaling in Engineering Units, Output scaling within 0 and 20 mA

Slew rate definable, Fail output pin is ON when output fail sensed, Failsafe

definable

Provides the digital status of a digital input point. The output status may be

inverted. Both fast logic (27 ms) and normal logic (500ms analog rate) blocks

available. Fail Output – activates on failed input channel or failed remote rack

communications.

st

order lag, 0 to 120 seconds

Digital Input (Up to 8 inputs) F,N

Digital Output (1) F,N

Digital Output (Up to 8 outputs) F,N

Time Proportioning Output

(applied to any PID output)

Position Proportional Output

C50 CPU up to 64 per controller

C30 CPU up to 16 per controller

N

N

Provides the digital status of the first or last 8 digital inputs of a 16 point input

card. The output status may be inverted. Both fast logic (27 ms) and normal logic

(500ms analog rate) blocks available. Fail Output – activates on failed input

channel or failed remote rack communications

Directs a digital status to a physical logic output. Output status may be inverted.

Both fast logic (27 ms) and normal logic (500ms sec analog rate) blocks

available. Fail Output – activates on output failure or failed remote rack

communications.

Directs 8 digital statuses to 8 physical logic outputs of an 8 point output card or

to the first or last 8 physical logic outputs of a 16 point output card. Output status

may be inverted. Both fast logic (27 ms) and normal logic (500ms analog rate)

blocks available. Fail Output – activates on any one of 8 outputs with failed

output or failed remote rack communications.

Proportions the amount ON time and OFF time of a digital output.

Input scaling in engineering units

Cycle time—2 second to 120 seconds

Output minimum ON and OFF time—0 seconds to 15 seconds

A combination Input and Output function block that includes feedback input

configuration and increase/decrease digital output configuration.

Positions actuators with slidewire, current or voltage position feedback sensors.

Provides outputs for actuator position (0 to 100%), motor fail, and feedback fail –

automatically defaults to 3-position step on feedback fail.

Input scaling in engineering units

Actuator speeds from 12 to 300 seconds

Output limits – adjustable (between 0 and 100%)

Deadband – adjustable (0.5 to 5%)

Feedback filter – adjustable (0 to 3 sec.)

Feedback input types:

Slidewire 100 to 250 ohms ( requires AI card 900A01-0002)

Slidewire 250 to 1000 ohms (requires AI card 900A01-0002)

mA - 4 to 20mA

mA - 0 to 20mA

Voltage - 0 to 1V

Voltage - 0 to 5V

Feedback calibration – HC Designer, 1042 or 559 Operator Interfaces

Automatic, Semi-automatic, and Hand methods supported.

Page 5

HC900 Function Block Types (continued)

上海市水泉路88弄8号503室 电话:021-56356105 传真:021-56356109

Control Loop Function Blocks (F=Fast Scan Rate, N=Normal Rate)

51-52-03-31

Page 5

PID

C50 CPU - up to 32 per controller

C30 CPU – up to 8 per controller

PID for Carbon Potential

C50 CPU - up to 32 per controller

C30 CPU – up to 8 per controller

(displaces PID)

PID with 3 Position Step Output N Motor position control without position sensing. Standard PID features with

ON/OFF Control (32 standard)

(displaces PID)

Loop Switch Inputs N Digital interface to control loops to initiate autotuning, change control action,

Loop Mode Selection N Digital interface to control loops to select automatic or manual modes and/or

Mode Decoder (Mode Flags) N Decodes control loop mode status into a set of discrete (Boolean or digital) mode

Write Tuning Constants N

PID algorithm includes:

N

N A combined carbon potential calculation and PID algorithm for controlling the

N ON/OFF control algorithm with selectable hysteresis

• Accutune II auto-tuning

• PID A (normal) or PID B (only integral response to SP change) operation,

DUPA and DUPB operation which switches tuning constants for heat/cool

applications

• Two sets of PID constants selectable via program control. Choice of Gain or

Proportional Band entry and Integral time or Repeats/minute entry

• Setpoints—Two setpoint values or one value and one remote setpoint

• Setpoint tracking – Local SP tracks PV or RSP on a RSP to LSP change

• Setpoint limits, output limits, SP rate of change

• Soft start

with output tracking)

• Ratio and Local/Remote Bias selections for Ratio control applications

• Feedforward input (scaled in % of output)

• Back calculation output for Cascade operation (supplied to primary loop)

• Output tracking to track a remote input (for backup applications)

• Remote A/M, R/L mode switching and mode status outputs

• Function block access to tuning constants for gain scheduling

• Alarms—Two outputs with up to two high, low, or dev band conditions each

Inputs: PV, remote setpoint, feedforward, output track and track command, ratio,

Outputs: Control output, working setpoint, alarm status (2), Autotune indication,

carbon potential of furnace atmospheres using a zirconia probe input and

temperature input. Local/remote %CO adjustment, probe manufacturer selection

(4 selections), anti-sooting protection, dewpoint calculation output, and furnace

factor adjustment is supported; probe burn-off configurable.

addition of hysteresis (in %) and full stroke time (in sec.) entries for motor.

force bumpless transfer, select tuning set #1 and select tuning set #2. Connects

to PID (all) and ON/OFF block switch input.

local or remote setpoint. Connects to all control loop types.

flags.

Automatically changes the GAIN, RATE, and RESET parameters of an internal

PID loop without operator interaction. A digital input controls changes.

for output rate limiting on startup or after power fail (not available

bias, switch block connection, mode switch block connection, and back

calculations

mode status

and selectable fuzzy logic overshoot suppression

Auto-Manual Bias (32 standard,

displaces PID) (for Boiler Control

applications)

N

Allows a manually adjusted output to be maintained on transfer to automatic by

applying bias to the input signal (from a Steam master to adjust participation of

boiler). Bias value is maintained as output value tracks input value changes.

Consumes 1 loop.

Page 6

51-52-03-31

上海市水泉路88弄8号503室 电话:021-56356105 传真:021-56356109

Page 6

HC900 Function Block Types (continued)

Setpoint Programmer and Recipe Function Blocks (F=Fast Scan Rate, N=Normal Rate)

Setpoint Programmer (8

maximum)

Setpoint Program Events (up to 16

events per block)

Setpoint Program Synchronizer N Used to synchronize the operation of two setpoint programs given the Run, Hold

Recipe Block F,N Used to initiate loading of recipe values into a chosen set of controller variables

N Produces a setpoint output for a time-based ramp/soak profile that is loaded into

the block. (See Setpoint Programming description for profile details.)

Inputs:

Process Variables, up to 3, to establish setpoint guarantee operation based on

a deviation band from setpoint. Profile Number (for autoload of a profile # for

next run), New Starting Segment (uses a Set input to enter a new segment

number).

Digital Inputs:

Enable (allows programmer to be operated), Set (to load a program or new

start segment), Start, Hold, Restart (from power failure, can allow slower ramp

up to previous SP to protect product), Reset, Advance, Jog (to a specified

segment), and Guarantee Hold (to synchronize with another programmer).

Outputs:

Setpoint value, segment number, program number, time remaining in segment,

time elapsed in segment, program elapsed time.

Digital Outputs:

Status (Ready, Running, Hold, Stopped), synchronize hold state, program

state

N Provides up to 16 digital status outputs that may be ON or OFF on a per

segment basis. Inputs include program number, segment number, and program

state (READY, RUN, HOLD, GHOLD, or STOP) from setpoint program block

from program state output.

and Reset signals from each program.

based on a recipe number. Inputs include recipe number and load command,

allowing remote recipe selection.

Setpoint Scheduler Function Blocks (F=Fast Scan Rate, N=Normal Rate)

Setpoint Scheduler (2 maximum)

State Switch Block N Provides digital switch status inputs to the Scheduler block for Run, Hold, Reset,

State Flags Block N Accepts status output from the Scheduler block and provides digital output

Setpoint Scheduler Auxiliary

Output Block

Event Decoder N Provides up to 16 digital outputs that may be ON or OFF on a per segment

N Produces up to 8 ramp or soak setpoint outputs on a common single time base.

(See Scheduler description for details.)

Inputs:

Process variables, up to 8, to establish setpoint guarantee operation based on

deviation from setpoint. Schedule number is used for automatic schedule

loading and starting segment number allows first segment selection.

Digital inputs:

Dedicated input for connection to State Switch block output.

Outputs:

Up to 8 setpoint values, segment number, schedule number, time remaining in

segment, time elapsed in segment, schedule elapsed time.

Digital Outputs:

Dedicated output for connection to State Flags block input.

Ghold, Advance and Jog.

signals for Run, Hold, Ghold, Ready and Stop.

N Provides up to 8 additional analog setpoint (soak only) values for each segment

of the schedule.

Inputs: Up to 8 process variables used for display.

basis.

Page 7

51-52-03-31

上海市水泉路88弄8号503室 电话:021-56356105 传真:021-56356109

Page 7

HC900 Function Block Types (continued)

Auxiliary Control Function Blocks

Lead Lag Signal Conditioner N Modifies an analog input value to include lead and lag time constants when a

Function Generator N Generates an output characteristic curve based on up to 11 configurable

High/Low Limiter F,N Limits an analog variable between high and low limit values. Provides separate

Rate (Velocity) Limiter N Limits the rate at which an analog variable can change when a logic input is ON.

Rate of Change N Provides an output value representing the rate of change value of the input in

Read Constant F,N Provides a read access to internal static parameters of selected blocks by Block

Write Constant F,N Provides write access to internal static parameters of selected blocks by Block

Write Variable F,N Provides a write of a value to a selected analog or digital Variable number based

Track and Hold N Allows updating or holding the value of an analog input based on the state of a

BCD Translator F,N Accepts up to 8 digital inputs in sequence and interprets the ON/OFF status of

Digital Encoder N A 16 input block whose output is the decimal value of the number of ON inputs.

(F=Fast Scan Rate, N=Normal Rate)

digital input is true.

Lead time constant = 0 minutes to 99 minutes

Lag time constant = 0 minutes to 99 minutes

“breakpoints” for input and output values.

digital status outputs when high or low limit values are exceeded.

Provides independent increasing and decreasing rate of change limit values.

Separate digital status outputs indicate when high or low rate limits are active.

units per minute. Output value is positive for increasing input values and

negative for decreasing input values. Two setpoint values and digital outputs are

provided to indicate excess increasing or decreasing rates of change or

insufficient increasing or decreasing rates of change.

number and parameter index number.

number and parameter index number.

on the ON state of a digital input.

digital input.

the first 4 inputs as a BCD value between 0 and 9, and the second 4 digits as a

value between 10 and 90.

Specific Application Principal Blocks (F=Fast Scan Rate, N=Normal Rate)

Device Control (16 maximum)

(for Pump Control)

Stage (8 maximum) N Accepts one or two analog variables and compares the values to high and low

Ramp (8 Maximum) N Accepts an analog variable and re-scales the value to new, user specified units.

Alternator (6 maximum) N The alternator accepts up to 16 digital inputs and, on a one for one basis, turns

N Provides device control (pumps, etc) including Start, Stop, Feedback Delay times

along with feedback confirmation and failure check.

setpoints for each of 4 stages per block. Outputs are digital signals that remain

ON after exceeding one setpoint until exceeding the second setpoint value for

the specific stage.

Up to 4 re-scale calculations may be configured per block. The re-scale

calculation that is currently active is controlled by digital inputs to the block.

Digital inputs may also be used to force the output to a high or low limit value.

on up to 16 digital outputs as determined by a user specified alternating

sequence. Alternator sequences include:

Direct – Inputs are mapped to specific outputs.

Rotary – Outputs are managed on a Last ON/ First Off (LOFO) basis and the

mapped sequence indexes by one each time all of the outputs are off.

FOFO – First On, First Off alternates the outputs based on the sequence in

which the outputs were turned on. The first output to turn on is moved to the end

of the list once it turns off.

Fixed – The output sequence follows a user specified mapping sequence. A

manual advance causes the mapping sequence to index by one when enabled.

Both “make-before –break” and “break -before –make” selections are available

for the block with user specified time delays for output changes.

Page 8

51-52-03-31

上海市水泉路88弄8号503室 电话:021-56356105 传真:021-56356109

Page 8

HC900 Function Block Types (continued)

Signal Selector Function Blocks (F=Fast Scan Rate, N=Normal Rate)

High Selector/Low Selector F,N Provides the highest (high select) or lowest (low select) of two analog input

Switch N Output switches between two analog input values based on the status of a digital

Bumpless Analog Transfer N Output switches between two analog input values based on the status of a digital

Rotary Switch N Single output is selected from up to 8 analog values based on the numerical

Calculation Function Blocks (F=Fast Scan Rate, N=Normal Rate)

Compare F,N Compares one analog variable to a second analog variable and generates

Absolute Value F,N Provides an absolute value output for a single analog variable input.

Square Root N Output is the square root of a single analog variable input.

Mass Flow N Calculates the mass flow of gases when measuring flow using an orifice plate.

Minimum – Maximum – Average –

Sum

Negate F,N Accepts a single analog variable input and negates the output.

Totalize N Integrates an analog variable using a specified rate. Rate may be in units per

Deviation Compare N Compares up to 6 analog variables to deviation limits set around a 7th variable. If

Relative Humidity N Calculates the relative humidity using wet bulb, dry bulb, and atmospheric

Dewpoint (12 maximum) N A dewpoint PV is supplied to a PID function block for dewpoint control. Used in

Continuous Average N Provides the average value of a single analog parameter for a user-specified

variables.

input.

input. When switched, output ramps to the new value at a specified rate. A rate

value is available for each direction.

value of a select input (1 to 8).

separate digital outputs to indicate greater than, equal, or less than status.

Output = Kg * sqrt((Kx * X + Bx) (Ky * Y + By)/(Kz * Z + Bz))

with inputs X = differential pressure

Y = pressure, and

Z = temperature.

A low flow cut-off feature provides a user-specified drop-off value below which

the output goes to zero.

N Accepts inputs from up to 6 analog variables and outputs analog variables

representing the highest value, lowest value, average value, sum, and standard

deviation. Removes bad inputs and provides an alarm output for deviations of

any variable outside user-specified standard deviation.

minute, hour, or day. A preset is provided to indicate when a specific quantity

has been accumulated. Separate enable and reset inputs are provided.

any variable is outside the limits, a digital signal is provided.

pressure inputs. Output may be in degrees Fahrenheit or Celsius.

conjunction with other blocks including a PID to generate more elaborate control

strategies than that provided by the carbon potential function block.

time period, plus the running average within the time period. Average value is

updated at the end of each sample period. Time periods to 1440.0 minutes are

supported. A hold input allows excluding samples from the average when active.

Math Function Blocks

Scale and Bias F,N Output = (K * X) + b with single analog variable input X.

Two and Four Input Math F,N Executes +, – or * on two or four analog variable inputs, / on two inputs.

Free Form Math N Calculates the result of a user-specified equation with double precision. The

(F=Fast Scan Rate, N=Normal Rate)

block accepts up to 8 input signals (including Constants or Variables). Operators

include: +, -, , /, ^, and multiple levels of parentheses. Functions include:

absolute value, exp, ln, Log, neg, sqrt. Example: a*(sqrt(b+c))+d

Page 9

51-52-03-31

上海市水泉路88弄8号503室 电话:021-56356105 传真:021-56356109

Page 9

HC900 Function Block Types (continued)

Logic Function Blocks (F=Fast Logic Rate, N=Normal Rate)

AND, OR, XOR (2 inputs)

Boolean logic blocks

AND, OR (4 and 8 inputs)

Boolean logic blocks

NOT (Complement) F,N Inverts a logic input status.

Latch F,N Provides a digital output that turns ON when a digital input turns ON and remains

Edge Detection Element

(One-shot) [Trigger]

Toggle (Flip-Flop) F,N Provides an ON state output when a digital input goes from OFF to ON and the

Free Form Logic F, N Reads eight digital inputs and calculates the output based on specified Boolean

Pushbutton F, N Provides a one-shot output based on an OFF to ON change of an operator

Four Selector Switch N Provides up to 16 digital outputs in groups of four outputs each. Only one output

Sequencer (4 maximum) (Fast

logic scan only)

Hand/Off/Auto (16 maximum) N Provides Hand-Off-Automatic outputs based on digital inputs emulating a

Counters/Timers Function Blocks

Resettable Timer F, N Provides a timing function based on an enable input. Elapsed time value is

Periodic Timer N Provides an ON state output for one controller scan cycle based on a specified

Up/Down Counter F, N Counts the number of raising edge logic transitions on the input to the block up

ON-Delay Timer F, N An OFF to ON change of the digital input is delayed on the block output by a

F,N Provides a digital status output based on the digital status of two digital inputs for

logic AND, OR, or XOR (exclusive OR) operations. Input status of each input

may be inverted.

F,N Provides a digital status output based on the digital status of four or eight digital

inputs for logic AND or OR operations. Input status of each input may be

inverted.

ON (latched) after the input goes OFF until an unlatch input turns ON.

F,N Provides an ON state of its output for one controller scan when a digital input

goes from OFF to ON.

previous state of the output was OFF, and an OFF state output when the digital

input goes from OFF to ON and the previous state of the output was ON. A

reset input holds the output OFF when the digital input is ON or active high.

logic functions (e.g., AND, OR, NOT, etc.) and multiple levels of parentheses.

Example: (A*B)+C

interface key action. Supports four pushbuttons per block.

from each group may be ON at a time and when selected automatically turns

other outputs OFF. Simulates 4-position panel selector switches.

F, N The sequencer function block controls the output statuses of up to 16 digital

outputs and one auxiliary analog output. Each combination of outputs

represents a “State” of the sequence such as Heat, Mix, or Cool, for example.

The function block supports up to 50 states.

The sequencer contains up to 64 steps. Each step enables a State, allowing for

a State to be designated for several steps.

Each State supports two digital events as inputs that can designate the end of

the associated step.

Time in seconds or minutes, a manual advance, or a digital event can be used to

terminate a sequencer step and cause the sequence to advance.

A pool of 20 sequences, up to 64 steps each, may be stored in controller

memory for quick recall and assignment to any of the 4 sequencers.

standard H-O-A panel switch

(F=Fast Logic Rate, N=Normal Rate)

provided as an output. A Preset value allows settings from 1 second to 999999

seconds. A digital output is ON when time value is equal to the preset. An

up/down digital input is provided to allow reverse timing from the preset value. A

pre-load value allows initiating the timer to a non-zero starting time.

time period using the controller real-time clock. Periods may be monthly, weekly,

daily, or time period in a day.

to a preset value. When the preset value is reached a logic output is enabled. A

reset input resets the block. Value may be set to increase to the preset value or

decrease from the preset value (1–99999).

user-specified time (0.1 seconds to 999.9 seconds).

OFF-Delay Timer F, N An ON to OFF change of the digital input is delayed on the block output by a

user-specified time (0.1 seconds to 999.9 seconds).

Page 10

51-52-03-31

上海市水泉路88弄8号503室 电话:021-56356105 传真:021-56356109

Page 10

HC900 Function Block Types (continued)

Alarm and Signal Monitoring Blocks (F=Fast Scan Rate, N=Normal Rate)

High Monitor F, N Accepts two analog values and provides a digital status output if the first input is

Low Monitor F, N Accepts two analog values and provides a digital status output if the first input is

Analog Alarm N The analog alarm block accepts an analog signal as a process variable and

System Monitor Block

(1 block for normal scan and 1

block for fast logic scan) – (do not

count against the maximum block

count)

F, N Provides system and start-up status outputs including:

higher than the second input. A hysteresis adjustment is provided to prevent

output cycling.

lower than the second input. A hysteresis adjustment is provided to prevent

output cycling.

compares it to a user-entered limit value (setpoint) to determine an alarm

condition. The setpoint may be entered by the user or be another analog signal

in the controller. Alarm actions may be high, low or high deviation, low deviation

or band deviation. For deviation alarming, a second analog signal provides the

reference and setpoints represent deviation from the reference. The alarm output

may be inverted to create normally active digital output. A user selection for

latching until acknowledged or automatically reset is provided. A user-specified

hysteresis value in the engineering units of the process variable is provided. An

on-delay time value up to 240 seconds is available to prevent momentary alarm

actions. A digital reset input is available to disable alarm actions.

• Program scan cycle time

• Newstart pulse (ON for one scan cycle after a “cold” start (reset))

• Restart pulse (to activate a custom control action on power-up after power

loss)

• Two common alarm outputs - Active Unacknowledged (ON when at least one

alarm not ack’d), Active alarm (ON when at least one alarm is active), for

assignment to digital outputs

• Time off (the time that power has been off previous to restart)

• Low Battery (alert to change battery without power shutdown)

• Hardware OK (ON when all hardware including remote racks are OK)

• Hi Temp (Cold Junction temperature exceeds limits on a rack)

• Bad Block

• Master Fail

• Locked (controller toggle switch is in Run/Locked or Program position)

• DS Limit (OI data storage has reached its alarm limit)

Alarm, Signal, and System Monitoring Blocks (continued) (F=Fast Scan Rate, N=Normal Rate)

IO Rack Monitor– (do not count

against the maximum block count)

Alarm Group (Up to 20 blocks) –

(do not count against the

maximum block count)

N One monitor block per rack, 5 racks maximum (C50 CPU). Provides I/O module

fault status

N Supports acknowledgement of a group of up to 12 alarms using a controller

digital signal to block, internal or external (for remote acknowledge). Each alarm

group consists of up to 12 alarms. Outputs include Unacknowledged alarm and

Active alarm states. The 20 blocks support up to 240 alarms.

Communications Blocks (Peer to Peer) (F=Fast Scan Rate, N=Normal Rate)

PDE (Peer Data Exchange)

Control

PDE Read N Expands Read access for designated HC900 peer to an additional 16

PDE Write N Expands Writes to designated HC900 peer by an additional 8 parameters, each

N Interfaces to one HC900 peer device, accessed by controller name, supporting 8

parameter read requests and 4 event-triggered writes. Outputs may be given tag

names for use in configuration strategy. Update rate can be configured from 500

ms to 5 sec.

parameters.

triggered on event.

Page 11

51-52-03-31

上海市水泉路88弄8号503室 电话:021-56356105 传真:021-56356109

Page 11

HC900 Function Block Types (continued)

Other Diagram Items (F=Fast Scan Rate, N=Normal Rate)

Analog Variable F, N Connects to a function block’s inputs and can be changed from the operator

interface or via serial communications addressing.

Digital Variable F, N Connects to a function block’s inputs and can be changed from the operator

interface or via serial communications addressing.

T (Text) F, N Allows descriptive data to annotate a specific area of a function block diagram to

be entered. Four font sizes, four colors, bold/italics/underline supported. Text

may be entered multi-line.

Soft Wire F, N For reference only. Soft-wiring method is to double click on a block pin and then

clicks on a destination pin to complete soft-wire (or click to change direction en

route to destination pin).

Connector F, N Connects tagged signals to function block inputs.

Signal Tag F, N Allows a name to be assigned to a wire and accessed by the operator interface

or via serial communications.

Numeric Constant F, N A user-specified constant value that can be connected to function block inputs.

Page 12

51-52-03-31

上海市水泉路88弄8号503室 电话:021-56356105 传真:021-56356109

Page 12

Alarms and Events

Alarms

An alarm may be assigned to any

digital tag applied to a digital status

output of a function block. Each control

loop has two alarm status outputs,

each corresponding to alarm setpoints

of various types (e.g. PV HI, Dev

High/Low, etc.). There are specialized

alarm blocks for analog alarms with

hysteresis adjustment. An expanded

function analog alarm block also

provides selection of alarm type, an on

delay, selective latching, and a disable

input to control when the alarm is

active.

Alarm assignment is initiated by

adding the digital “alarm” tags to an

alarm group from a tag list. Alarm

group blocks allow alarm partitioning

into groups of 12 alarms. The 20

alarm group blocks allow up to 240

alarms to be defined. Each group

may be assigned an alarm

acknowledge function which permits

external, panel acknowledge via a

digital input or via a serial

communications write to an internal

Variable. Alarm groups may also be

assigned to displays for the 1042 and

559 Operator Interfaces (OI).

Alarms can be assigned a priority (one

of 4 levels - Low, Medium, High,

Emergency) for use in routing a topic

and 48 character alarm message

electronically to any of three locations

via the e-mail of alarms feature, if

selected for an individual alarm. Alarm

detection may also be on an off-to-on

or on-to off transition, selectable on a

per alarm basis. The method of

acknowledgement is also selectable on

a per alarm basis, manual or

automatic. The Manual Ack selection

requires user acknowledgement while

Auto Ack will provide automatic

acknowledgement on return to the nonalarm state. Active alarm indication is

provided on all Operator Interface

displays. Assigned alarm group

displays show alarm status and permit

group acknowledge of active alarms at

the operator interface. An alarm detail

display is provided for each alarm point

which indicates the time and date of

last alarm occurrence and offers up to

48 characters of user specified text for

alarm actions or notes. Alarms may

also be stored in an alarm file on the

operator interface diskette or ZIP drive

media (1042 only) configurable from

150 to 1500 records.

A resettable, common alarm output is

available from a System block . This

output can be directed to a DO or

intermediate logic. An

acknowledgement from any source can

reset this output.

Events

Events are used for user alerts below

an alarm priority (a non-alarm process

condition) and may be assigned to any

digital tag indicating function block

output status. Up to 64 digital tags

may be added to an event list and

assigned to:

1. Trigger an e-mail for the event

condition sent to any of up to 3

locations on occurrence

2. Be stored to the OI archive disk

3. Be displayed on the status line of

the operator interface (16

characters) on occurrence.

Any one, two, or all three of these

assignments may be selected.

Event detection may also be on an offto-on or on-to off transition, selectable

on a per event basis.

A standard operator interface Event

Summary display lists the last 150

events by date, time, tag name,

descriptor, and state text.

Communications

Ethernet Communications –

HC900 controllers communicate with

their host PC interfaces over an

Ethernet 10Base-T communication

network using the Modbus/TCP

protocol, an open protocol interface

available for most popular HMI

software packages. Up to 5 hosts

(servers or stand-alone) can be

supported concurrently over an

Ethernet network for control

supervision and data acquisition. The

Hybrid Control Designer software can

also address any of the controllers

concurrently over Ethernet for

configuration monitoring, diagnostic

interrogation, upload/ download, or online configuration changes. As a result,

a HC900 network of controllers and

operator interfaces can be partitioned

into process segments to assure

proper control performance. Each of

these process segments, in turn, can

be accessed via common HMI software

within the plant environment using an

Ethernet LAN.

Ethernet Peer to Peer

Communications

Peer data communications between

one HC900 controller and up to 8 other

HC900 controllers is supported over

Ethernet via UDP protocol for process

interlocks or data sharing. Both digital

and analog data exchange are

supported using peer data exchange

function blocks, up to 1024 parameters

between peer controllers. No

specialized software is required. Peer

data can be given signal tag references

for use in a control or data acquisition

strategy. Peer to peer data interchange

does not consume one of the host

connections.

Serial Modbus RTU

Communications -

RTU communications is available on

the RS232 and RS485 (2 wire) ports of

the HC900 Controller C50 and C30

CPU assemblies. The protocol of

these ports is user selectable between

a Honeywell private protocol for use

HC Designer software and Honeywell

operator interfaces, or Serial Modbus

to interface with other compatible

devices. (examples: 3

panels, PLCs, Modbus I/O for

monitoring.)

Modbus RTU Slave - The RS232 and

RS485 ports may be configured for

simultaneous operation as a Modbus

slave port to allow each to

communicate with a single Modbus

master. The Modbus protocol supports

read and write access to variety of

controller parameters using predefined

address locations. In addition, a 1000

register array is available to allow the

user to specify the address locations of

specific controller data to optimize

controller communications. The data in

the array may also be accessed in user

specified formats (data types) such as

analog data in Float 32, unsigned 16,

signed 16, unsigned 32, signed 32, and

digital data in signed 16 or unsigned

16. The data type selections in the

1000 register array provide

compatibility with devices such as 3

party touch panels.

HC Designer software supports

communicating with HC900 controllers

using the Honeywell private protocol or

Modbus RTU protocol.

Communications may be through a

direct cable connection or via modem.

When modem communication is

selected, Modbus RTU communication

timeouts are extended.

Serial Modbus

rd

party touch

rd

Page 13

上海市水泉路88弄8号503室 电话:021-56356105 传真:021-56356109

Modbus RTU Master - Either of the

ports may be configured as a Modbus

RTU master, one per controller. Up to

16 devices may be multi-dropped on

the RS485 port or the RS232 port with

an external, user supplied, RS232 to

RS485 converter. Function blocks are

available in the HC900 controller to

allow the user to specify read and write

operations to up to 16 external Modbus

compatible slave devices and up to

384 data points. If the RS485 port is

configured for Modbus RTU

communications, a local 559 or 1042

operator interface will not be available.

E-Mail Alarming

HC900 alarms or events can be

individually configured to send an email alarm (or event) message to any

or all of 3 e-mail addresses which have

the associated alarm priority assigned.

Remote I/O Rack Port (C50 only) – A

second private Ethernet port is

provided and is dedicated to supporting

expansion I/O racks. This 10Base-T

connection will support a single direct

connected expansion rack, or up to 4

expansion racks when connected

through available external Ethernet

hubs.

Operator Interface Port- - An RS 485

port is provided for communications

between the controller and a 1042 or

559 Operator Interface using a private

protocol. This port supports a single

Operator Interface for distances up to

2000 feet (609 meters) between the

controller and operator interface.

Controller Configuration Access –

An RS-232 configuration port is

provided and supports direct PC

connection or external Modem

connection for configuration upload,

download, debug and maintenance.

Once the HC900 controller has been

configured with its companion Hybrid

Control Designer Software, on-line

configuration changes may be made

with minimal process interruption.

Configurations may also be loaded

into the controller via the Ethernet

TCP/IP network from a host PC. Online monitoring for program debug

and on-line program edit functions

are also supported via the Ethernet

port.

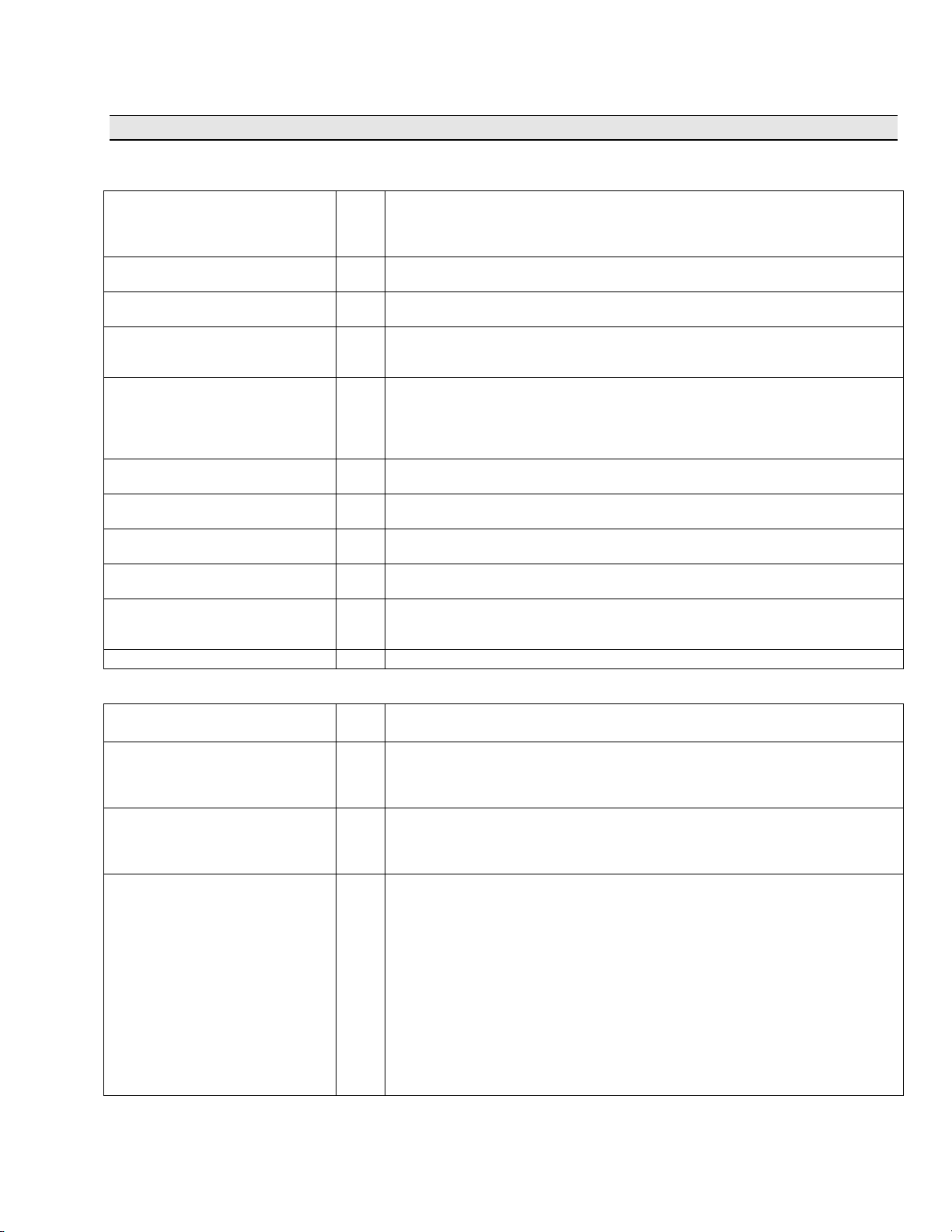

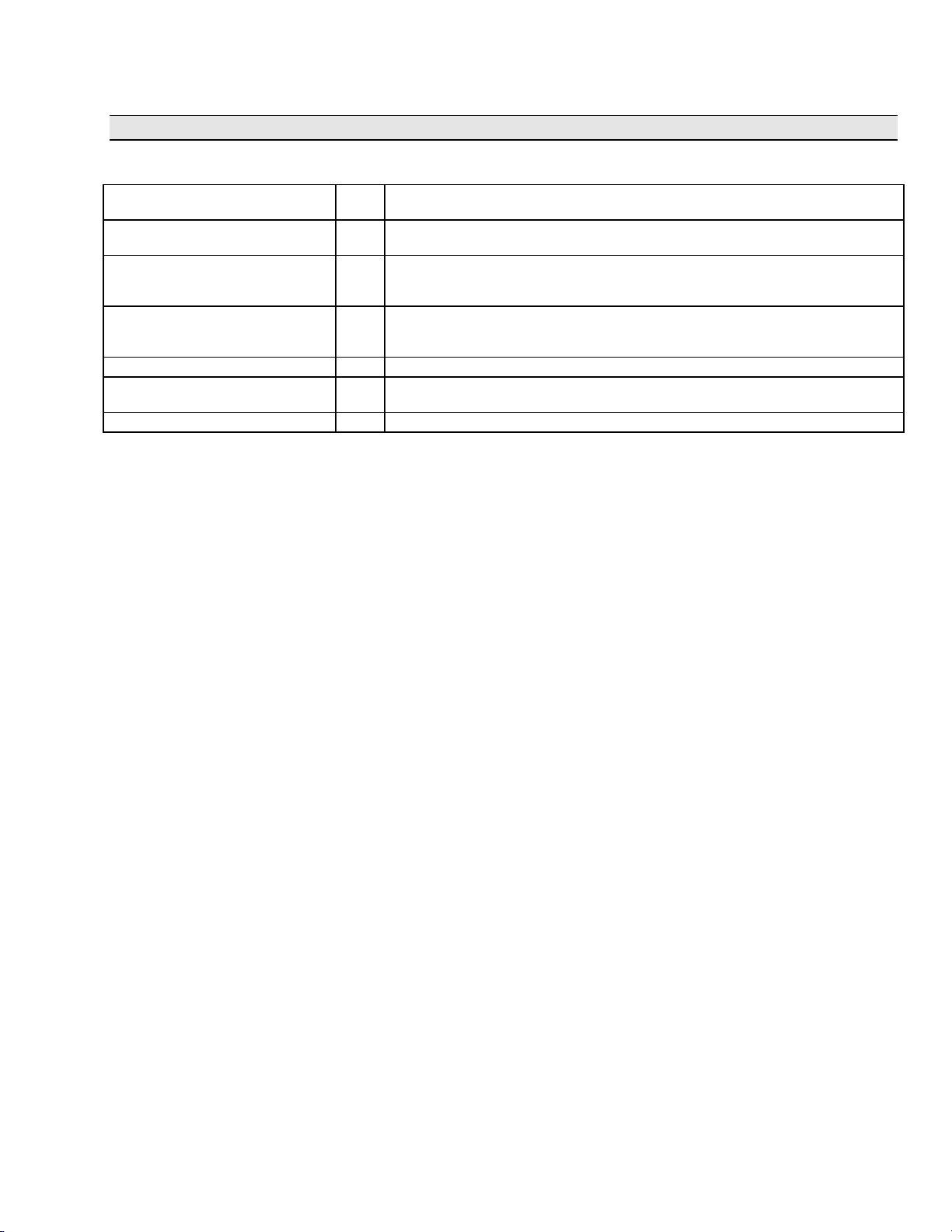

HC900 CPU

Assembly

Configuration port for

RS232

RS485

Ethernet

direct or external modem

Connection or other Modbus compatible device, 9-pin D.

Interface to 1042 Operator Interface or other Modbus

compatible device, 3-pin.

Ethernet 10Base-T

for Host, peer, web and

LAN connection.

Ethernet 10 Base-T for

remote expansion rack

connection.

E-mail addresses 3 based on alarm priority

Message

Content

Priority Levels 4 for alarms, 1 for events

PlantScape Supervisory Software

PlantScape SCADA or Vista

Software, operating under Windows

2000, is available from Honeywell

when PC-based supervisory control

and data acquisition is required.

Ethernet network interface to a

PlantScape server is via the

controller host Ethernet 10Base-T

port using Modbus/TCP protocol.

Client Stations over Ethernet allow

multiple user access to an HC900

network. Using the large selection of

standard operating display templates

in PlantScape saves development

time. When further customization is

needed, the full graphic display

development environment of

PlantScape may be used to fully

animate your process supervisory

displays.

A batch reporting option is offered in

Release 400 which enables batch

reports to be created using a

standard template. User-entered lot

data is supported and up to 50

parameters can be defined for batch

logging. The file can be exported in

.csv format using a lot numberencoded filename.

From: Controller name (up to 16 characters)

E-mail Subject: text (up to 32 characters)

E-mail content:

Alarm data including - Date, Time of alarm, alarm or

event tag name, state text

Message - 48 character alarm text (for alarms only)

SpecView32 Supervisory Software

SpecView32 software can be used as

a supervisory interface for thermalbased applications, offering historical

trending, batch reporting, recipe

development involving setpoint

programs and simplified graphics

configuration. HC900 parameters

are simply selected from categorized

lists for placement on user-configured

displays or onto display objects.

Network connection is via the

controller host Ethernet 10Base-T

port using Modbus/TCP protocol. A

variety of Windows operating

environments are supported including

Windows 98, NT, 2000.

OPC Server

Serial communication access to the

HC900 controller through third party

PC interfaces is simplified with the

OPC server software program

available from KEPware. This

software supports the Modbus/TCP

interface to the HC900 controller.

Compatible OPC client programs can

use the Ethernet connection to the

HC900 via the KEPware OPC Server

for remote supervision, data

collection or other supervisory

functions.

51-52-03-31

Page 13

Page 14

51-52-03-31

上海市水泉路88弄8号503室 电话:021-56356105 传真:021-56356109

Page 14

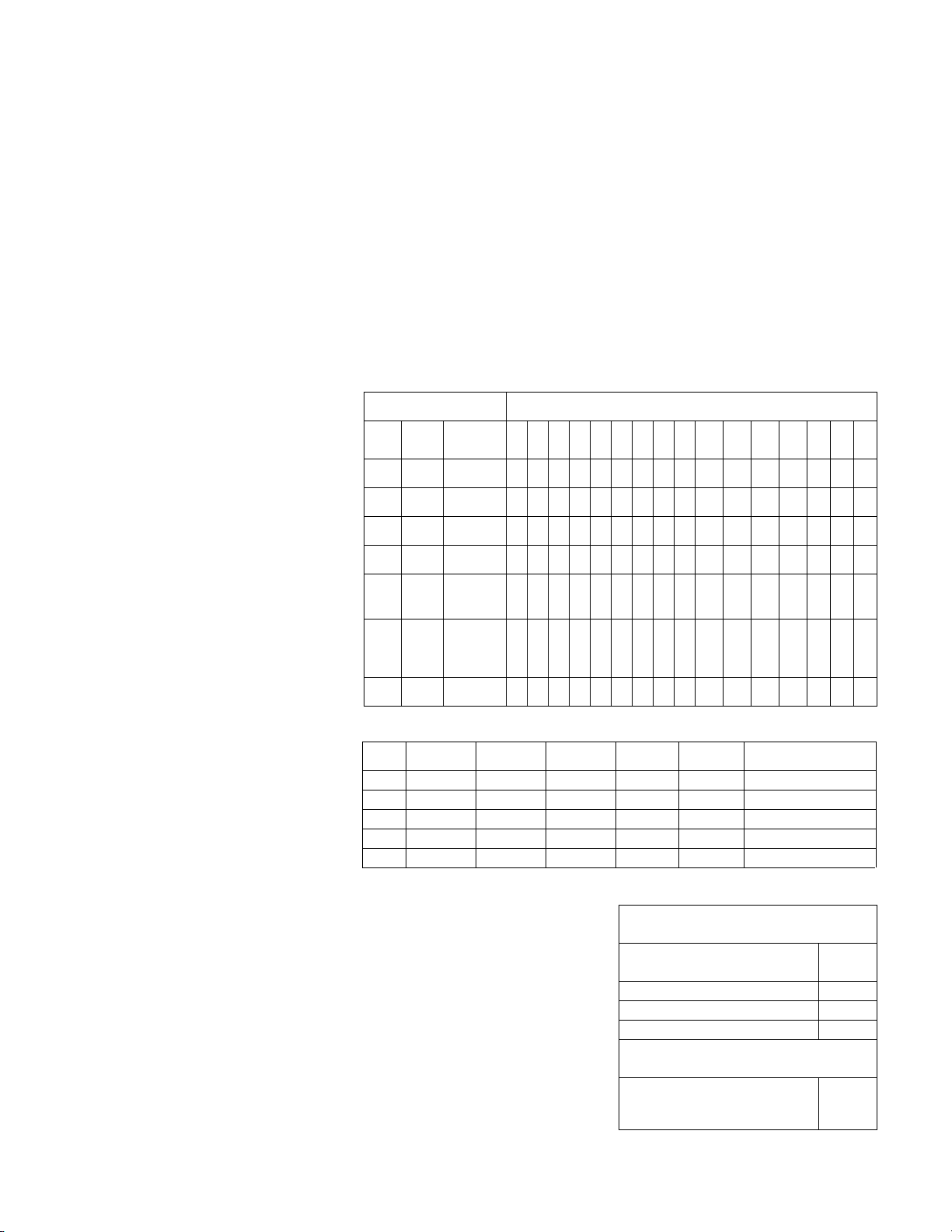

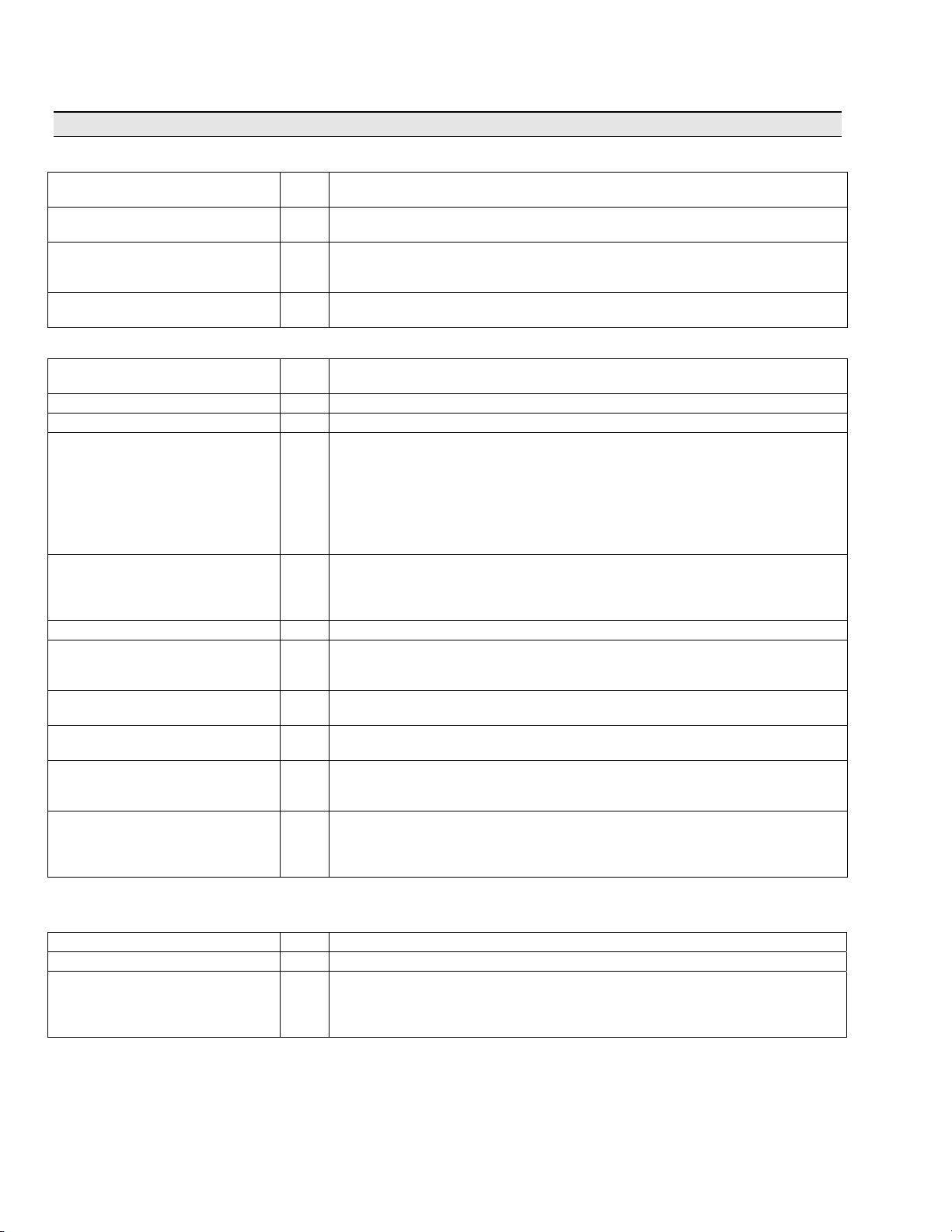

Architecture

Below are typical system configuration

architectures:

PC HMI

Ethernet 10Base-T

100m each

RS-485 twisted pair

1042 or 559 -OI

1042 or 559 -OI

Ethernet 10Base-T

100m each

Single Process, Multiple Remote I/O Racks

Ethernet

Switch

Multiple Processes

HC900 C30 or C50

Single Process

Hub

Hub

HC900

Ethernet 10Base-T 100m

HC900 C50 Only

Remote

Process

I/O Rack

Process

1042-OI

Remote I/O

Process

Racks

A

B

C

Page 15

上海市水泉路88弄8号503室 电话:021-56356105 传真:021-56356109

1042 Operator Interface

Features

• 10.4 in. bright, active matrix color

LCD display

• Over 100 standard displays via a

menu listing for setup, I/O

summary displays, system

diagnostics, I/O calibration,

alarms, event summary, loop

tuning, etc.

• Up to 80 operator displays, user-

assigned to function keys

• 36 operator display formats for

accessing loops, process data, or

operator entry

• Setpoint programmer, Setpoint

Scheduler, Sequencer interface

• Recipe and profile selection

• Recipe, Profile, Schedule and

Sequence loading via floppy disk

or ZIP.

• Data Archiving on floppy disk or

Zip drive.

• Uses Hybrid Control Designer

software for configuring display

setup

• Controller configuration loading

from floppy including on-line

downloads

• Type 4X Front, CE Mark

The 1042 Operator Interface offers a

wide assortment of standard display

templates to get you up and running

quickly. Single and multiple PID loop

operate displays, setpoint program,

setpoint scheduler, and sequencer

operate displays, multi-pen trend

graphs, bar charts, push button

displays, text-based help displays,

and overview displays are just a few

of the many standard formats. Using

the common HC900 Hybrid Control

Designer configuration software,

simply select the desired display

format, select and visually apply the

appropriate data for the display, then

assign the display to a display button

on the 1042 Operator Interface. Up

to 10 displays may be assigned to

each of 8display buttons.

The 1042 OI configuration is

automatically uploaded from the

controller for synchronization. This

simplifies replacement and also allows

occasional use. The rugged 1042

panel mounted interface offers

4X ingress protection for the exposed

components. A secure access door

Type

LOOPTAG1

2500.0

1500.0

PV 2205.0

SP 2000.0

OUT 83.5

AUTO RSP

LOOPTAG5

2500.0

1500.0

PV 2205.0

SP 2000.0

OUT 83.5

AUTO RSP

ALARM

disk drive or optional 100

MESSAGE TEXT

D

8-Loop Display Format

Meg ZIP

disk drive.

Trend Displays – A selection of

horizontal or vertical trend format

displays are available to provide a

historical record of recent control

performance. Up to 4 trend displays

may be configured with up to 6 analog

or digital points on each display. Trend

displays allow a user selectable time

period of from 0.5 to 24 hours each.

Each display will retain from 1.5 to 6

screens of historical data that may be

recalled from memory.

Loop trends - A loop trend display is

provided for each control loop for

tuning or for short-term monitoring.

Loop trend displays begin to collect

FURNACE TEMPERATURE DEC08

AI2 12:18

2200.00 DEGF

ALARM D MESSAGE TEXT RUNSH Z

Horizontal Trend with Bars

LOOPTAG2

2500.0

1500.0

PV 2205.0

SP 2000.0

OUT 83.5

AUTO RSP

LOOPTAG6

2500.0

1500.0

PV 2205.0

SP 2000.0

OUT 83.5

AUTO RSP

11:18

51-52-03-31

Page 15

LOOPTAG3

2500.0

1500.0

PV 2205.0

SP 2000.0

OUT 83.5

AUTO RSP

LOOPTAG7

2500.0

1500.0

PV 2205.0

SP 2000.0

OUT 83.5

AUTO RSP

data when the display is accessed at

approximately 1 sec. updates.

Alarms and Events - Alarms may be

grouped and priority assigned to

streamline on-line access to critical

alarms. Each alarm point provides a

detail display with the time and date

of the recent alarm occurrence, plus

an information field to further define

the alarm condition, or to provide

suggested operator action. Event

messages are provided to prompt

operators when a discrete action has

occurred such as a completion of a

batch segment. Up to 64 event

messages may be configured. A

time-stamped event summary display

of the most recent 150 events is also

provided.

11:30

PV 2205.0

SP 2000.0

OUT 83.5

AUTO RSP

PV 2205.0

SP 2000.0

OUT 83.5

AUTO RSP

LOOPTAG4

2500.0

1500.0

LOOPTAG8

2500.0

1500.0

RUNSH Z

0

Page 16

51-52-03-31

上海市水泉路88弄8号503室 电话:021-56356105 传真:021-56356109

Page 16

Data Storage – The 1042 Operator

Interface provides a 1.44 Meg floppy

disk drive that may be configured to

store process data. Up to 2 trend

files of 12 points each may be

configured. A point log file of 12

points may also be setup to log

asynchronous data based on digital

events. Up to 5,000 records may be

logged in a point log file. In addition

to tabular data records, alarm and

event records are also stored in

individual files on the disk. When

additional data storage capacity is

needed, an optional 100 Meg ZIP

drive is available in place of the 1.44

Meg. floppy drive.

559 Operator Interface

The 559-T4 and 559-T12 Operator

Interfaces provide all the interface

features of the 1042 Operator

Interface, but use a 5.4 inch display

window and increment and

decrement keys for parameter

entries. See Operator Interface

specification 51-52-03-32 for product

differences.

The OI 559-T4 is packaged in a

TYPE 4X enclosure to withstand

wash-down at the front panel. The

panel-mounted OI 559-T4 provides

rear access to the floppy disk drive to

protect the drive and your valuable

data during wash-down operations.

The OI 559-T12 Operator Interface is

packaged in a TYPE 12 enclosure

ready to use with pre-packaged

display formats and front panel

access to the floppy disk drive for

data archiving and configuration

loading.

HC900 Hybrid Control

Designer Software

Features

• Graphic drag and drop, soft-wire

configuration

• Supports configuration edit

downloads in RUN mode

• Configures:

- Controller and

(OI)

- Peer-to-peer data exchange

- OI data storage

- Recipes, SP profiles, SP

schedules, Sequences with file

management and on-line

operation

- Alarms, events, e-mail

alarms/events

• Allows function block configuration

partitioning using “worksheets”, up to

400 configuration pages.

Operator Interface

• Configuration upload includes

graphic configuration, OI

assignments, and annotations

• Extensive on-line monitoring tools

including the following:

User defined and pre-defined watch

windows

Power flow indication

Pin value indication

Multiple block access,

Signal traceback

More

5 Zoom levels for detail

viewing

• On-line diagnostic windows for

analyzing controller, I/O, network

host and controller peer connections

• Windows NT, 2000, Me support

• Use Ethernet, RS-232 direct, or RS-

232 modem connection to access

controller

The HC900 Hybrid Control Designer

software expands on the field proven

concepts of the UMC800 Control

Builder program (see Tables 3-5). The

user-friendly graphic development

environment allows partitioning of the

control strategy into up to 20

“worksheets” of 20 pages each. This

allows the configuration to be

organized according to process

function, providing faster configuration

access, and improved documentation.

In addition, OEMs may apply additional

security to specific worksheets to

prohibit access to proprietary

operations while allowing their

customers to modify unprotected

worksheets.

Blocks are selected from a categorized

list, dropped on a selected worksheet

page, and soft-wired to other blocks

directly or via tag references. Editing

tools such as box copy and paste

speed development. You may also

copy and paste portions of strategies

from other configurations.

On-Line Monitoring Features

Hybrid Control Designer on-line

monitoring tools allow quick analysis of

configuration problems. These include:

1. Multiple function block monitor

access on a single display from

multiple worksheets. Most internal

parameters are available for

read/write plus block outputs may be

forced including I/O and logic

blocks. Principle blocks such as

PID, Setpoint Programmer and

Sequencers have dialog boxes to

allow operation and test. Stored

profiles or sequences may also be

selected on-line.

Logic Power Flow indication is

provided when monitoring function

blocks. Both color and line style

changes are used to indicate the

ON and OFF status of logic signals

on the graphic configuration

diagram.

2. User-selected Watch Window lists

allow access to digital and analog

I/O, Signal Tags, Variables), and

custom display data groups by tab

selection. A user defined Watch

Window may also be created by

selecting parameters from the

configuration diagram. Write

capability from Watch Windows is

supported.

3. Dynamic function block input and

output values are provided when

monitoring the function blocks of

the configuration diagram. The

dynamic value presentation may

be limited to a single pin, a single

function block or it may encompass

the entire display window.

4. Signal Trace-back for any function

block input. Used to find the signal

source for quick identification of

potential errors. A FIND function

allows location of multiple

instances of specific tags across

all worksheets.

5. A separate Recipe Management

feature allows creating, editing ,

copying and exporting recipes,

profiles, schedules and sequences

to allow transferring this

information between configurations

and controllers.

Configuration Edits-RUNMode

Configuration changes such as block

additions or substitutions and softwiring can be transferred to the active

configuration during the RUN mode,

avoiding initialization. All outputs and

status are held during a minimal

transfer time after which processing

continues at the start of a scan.

Operator Interface

Configuration

Setup of the Operator Interface is an

integral part of the controller

configuration. Controllers configured

for a 1042 or 559 interface can accept

any 1042 or 559 OI and provide the

necessary display format data without

process interruption. This unique

attribute guarantees compatibility of

the controller and user interface

databases, simplifying maintenance.

Hybrid Control Designer software

uses the database of the function

block program to develop operating

displays for the Operator Interface.

Simply select a display format and

apply tags to the format from a dropdown menu. A large selection of

display templates is provided that

may be assigned to the display

access hierarchy of the Operator

Interface. Graphic objects

Page 17

are used to identify the different

上海市水泉路88弄8号503室 电话:021-56356105 传真:021-56356109

classes of display types to simplify user

selection.

In addition to creating displays and

defining display access, Hybrid

Control Designer software allows

users to setup data archiving

schedules, create alarm grouping,

establish operator security, and

define a number of other operator

interface attributes.

Hybrid Control Designer Reports

Documenting your configuration is

supported through a variety of report

formats. Each can be print-previewed.

A few of these include a summary of

the controller I/O used, function block

worksheet selection (each page of

diagram worksheet printed as 8.5 x 11”

sheet), function block properties, tag

parameters, recipe listings, setpoint

profile listings, sequencer listings,

setpoint scheduler listings, OI display

groups, and controller setup. For

signal tracing, a Where Used list is also

provided.

File Export for database transfer

When interfacing the HC900 controller

to PC software programs, a time

saving service is provided to export tag

and variable definitions in CSV or tab

delimited formats. In addition, the

Modbus addresses of each configured

data parameter may also be exported

to a file.

Conversion from UMC800

Configurations

Users of UMC 800 controllers will

benefit from their application

engineering investment by converting

UMC800 Release 5.0 (or later)

configurations for file compatibility with

HC900 controllers. There is no need to

re-engineer the application.

HC Designer Revision Support

The latest revision of HC Designer may

be used to configure any previous

version of HC900 controllers and

operator interfaces. Any features not

supported in the previous version are

ignored.

51-52-03-31

Page 17

HC900 Hybrid Control

Utilities Software

HC Utilities is a separate optional PC

software application that provides

many of the user maintenance and

diagnostic functions of HC Designer

software but restricts configuration

changes. This software is an ideal

program for OEMs and Integrators

who wish to provide a maintenance

program to their customers without

the risk of unauthorized changes to

the controller’s program.

Files created in HC Utilities for

Recipes, and Data Storage schedules

may be loaded into the system via

serial communications, network

communications or by using a disk

media through an operator interface.

The serial and network interface

capabilities also allow users to

download new controller

configurations or perform equipment

firmware upgrades without using an

operator interface.

The following are a few of the

services supported in HC Utilities:

Recipe development: (Variables,

Setpoint Profiles, Setpoint

Schedules, Sequences)

Data storage schedules

Set controller communication

ports

Calibrate controller I/O

Configuration reloads

Firmware Upgrades

View controller diagnostics

Monitor controller configurations

of unlocked worksheets

Page 18

51-52-03-31

y

A

上海市水泉路88弄8号503室 电话:021-56356105 传真:021-56356109

Page 18

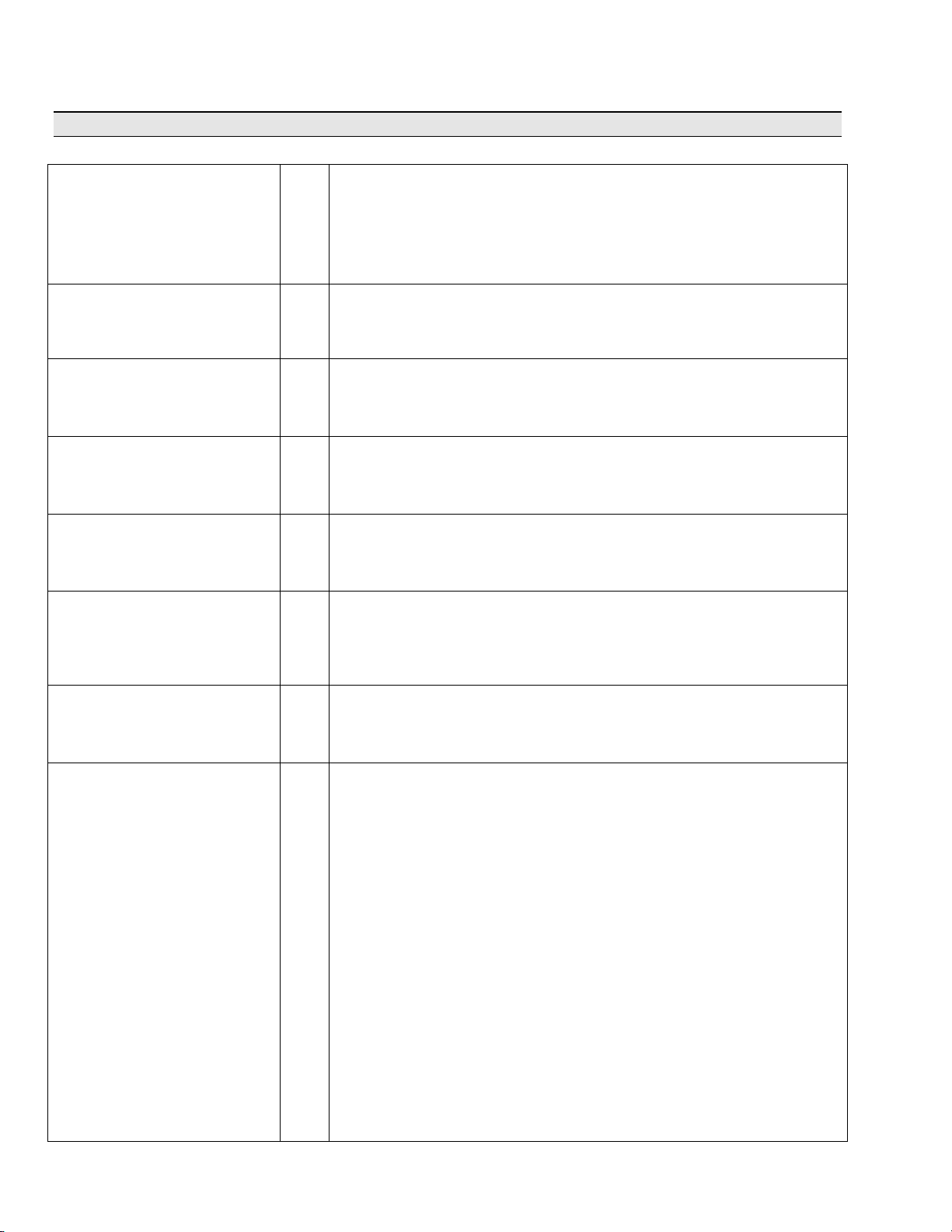

File Browser shows all open files

(configurations, recipes, data storage)

Hybrid Control Designer Software – Edit Mode

Main Tool Bar Main Menu

Function-related Tool Bar

Worksheet Toolbox for Function

Blocks and softwire tools,

categorized by Normal/Fast Scan &

b

block type

nalog Input

Properties

Functional Tabs:

Status Bar

Controller (lists I/O used, e-mail alarms)

Display (format select, tag assignment, F-key assignment)

Function Blocks (graphic configuration)

Utilities (setup for ports, data storage, time, calibration and diagnostics)

Page 19

上海市水泉路88弄8号503室 电话:021-56356105 传真:021-56356109

Hybrid Control Designer Software – Monitor Mode

User-defined Watch Summary Traceback Window

51-52-03-31

Page 19

Monitor Toolbar

Zoom in/out

Function Block Monitor Windows Function Block Pin Monitoring

Shows Pin Data

Digital Signal Connector State Indicators:

Solid green = ON

Dashed red = OFF

Page 20

51-52-03-31

上海市水泉路88弄8号503室 电话:021-56356105 传真:021-56356109

Page 20

HC900 Hybrid Controller Specifications

Controller Design

Modular design with metal rack enclosure, power supply, controller CPU and user selectable I/O module types.

Controller System

Network

Communications Port

Ethernet 10Base-T, RJ-45

connection.

Supports Modbus/TCP Protocol to PC supervisory and data

acquisition software packages, OPC server, and Hybrid

Control Designer configuration software

Max. number of concurrent

Ethernet hosts

Peer-to-Peer

Communications

No. of Peers/Controller 8 (9 total peer controllers)

Update rate 500 ms to 5 sec., selectable

Peer Data Digital and Analog Signal Tags, Variables - up to 1024

RS-232 Configuration

Port

Baud rates 9600, 19.2K, 38.4K, 57.6 K, configured by Hybrid Control

Modem connection For remote connection to Hybrid Control Designer software,

1042, 559, or third

party Operator

Interface Support

Cable type 2-wire plus shield, Belden 9271 or equivalent

Distance from controller 2000 ft.(600 m.)

Power to OI 24VDC, user-provided at OI

Ethernet 10Base-T via

Network port

Ports per controller One, 9-pin “D”, private or Modbus RTU protocol. Supports link

Ports per controller One, RS-485 (connector supplied), private or Modbus RTU

Up to 5 (peer data exchange does not consume a host

connection)

Supports UDP protocol and Peer Data Exchange function

blocks for peer data exchange.

parameters, addressed numerically

to PC running Hybrid Control Designer software or third party

applications.

Designer software or OI.

requires external modem at controller, 9600 baud to 57.6KB

protocol

Remote I/O (C50 CPU

only)

Remote racks One without hub, using Ethernet direct cable

Distance 328 ft. (100 m.) - controller to remote rack or controller to hub.

Performance Normal Scan Time 500ms. Each analog input card has its own A/D converter,

C50 CPU Fast Scan Time 27ms for up to ~250 fast logic blocks

C30 CPU Fast Scan Time 53ms for up to~250 fast logic blocks

Interface Type Separate Ethernet 10Base-T port on CPU, RJ-45 connection,

private communications link

Up to 4 with recommended Ethernet hub(s)

Up to two hubs per connection, 984 ft. (300 m.), maximum

distance.

providing parallel processing.

53ms for up to~500 fast logic blocks

67ms for up to ~780 fast logic blocks

107ms for up to ~1040 fast logic blocks

133ms for up to ~1300 fast logic blocks

67ms for up to ~315 fast logic blocks

107ms for up to ~400 fast logic blocks

Page 21

上海市水泉路88弄8号503室 电话:021-56356105 传真:021-56356109

HC900 Hybrid Controller Specifications (continued)

C50 CPU Performance

with Remote I/O

Fast Scan Time 27ms minimum for I/O within CPU rack, 53ms minimum with

Run-Mode Edit Transfer Time 3 normal scan times (1.5 sec. typical) for all configuration edits

Modes 3-position switch on controller – Run/Locked (No configuration download in this position), Run

Normal Scan Time 500ms, included in normal scan

remote I/O

not applicable to I/O

(Download allowed), Program/Locked (Outputs Off, initialization on download). Offline mode

is available via software selection (for AI calibration).

51-52-03-31

Page 21

I/O Capacity Maximum per controller C50 CPU

Combined Analog &

Digital – Up to 960

Analog Inputs Up to 256 Up to 96

Analog Outputs Up to 64 Up to 64

Size 4 I/O slot chassis 5.4"(137mm) H” x 10.5"(266.7mm) W x 6” (151.7 mm) D (rear

mounting plate extends height to 6.9” (175.3mm)

8 I/O slot chassis 5.4"(137mm) H x 16.5"(419.1mm) W x 6” (151.7mm) D

(rear mounting plate extends height to 6.9” (175.3mm)

12 I/O Slot chassis 5.4"(137mm) H x 22.5"(571.5mm) W x 6."(151.7mm) D

(rear mounting plate extends height to 6.9” (175.3mm)

Power (P01, P02) Voltage Universal power, 90 to 264VAC, 47 to 63 Hz

Rating P01 Power Supply

130 VA

In Rush Current 7 Amps peak-to-peak for

150 ms at 240VAC

Wiring Type Removable terminal blocks

Combined Analog & Digital

- Up to 192

7 Amps peak-to-peak for 120 ms

at 240VAC

C30 CPU

P02 Power Supply

90 VA

Styles 2, Screw terminal or Euro-style, tin-plated or gold-plated (for

DC connections)

Gauge wires Screw terminal – #14 to 26 AWG, solid or stranded