Page 1

F59A Console 3-Speed

Electronic Air Cleaner

The F59A Console Electronic Air Cleaner

cleans the air in enclosed spaces such as offices or

homes. A 3-speed fan draws room air through an

electronic cell and activated carbon filter to remove

dust, lint, pollen, tobacco smoke, cooking smoke

and household odors.

■ Furniture styled wood-grained cabinet.

■ Circulates and cleans approximately 4400 ft

[125m3] of air 4-1/2 times an hour. Typically this is

a 25 by 22 ft [8 by 7m] room. Two or more F59A units

may be used in larger rooms.

■ Up to 90 percent air cleaning efficiency as measured

according to the National Bureau of Standards Dust

Spot Method using atmospheric dust, and the Ameri-

can Society of Heating, Refrigerating, and Air-Con-

ditioning Engineers Standard 52-76.

■ Suitable for commercial or residential use.

■ Three-speed motor-driven fan circulates up to

330 cfm [560 m

■ Interlock switches prevent operation when cover is

removed.

3

/hr].

■ Neon light indicates electronic air cleaner operation.

3

■ Powered from standard grounded outlet.

■ Electronic cell is easily removed for cleaning.

■ Prefilter screens out large particles such as dust or

lint.

■ Activated carbon postfilter removes gaseous con-

taminants and odors.

■ Optional casters allow easy movement of electronic

air cleaner.

CONTENTS

Specifications ................................................ 2

Ordering Information.................................... 2

Setup and Operation ..................................... 3

Service ........................................................... 3

Electrical Troubleshooting............................ 5

Parts List ..................................................... 10

J. H. • Rev. 2-95 • ©Honeywell Inc. 1995 • Form Number 68-0086—5

1 68-0086—5

Page 2

F59A

120 Vac, 60 Hz 220 Vac, 50 Hz

Fan Speed A W A W

High 1.0 110 .60 120

Medium .74 80 .45 70

Low .65 65 .35 55

SPECIFICATIONS • ORDERING INFORMATION

Specifications

IMPORTANT: The specifications listed in this publica-

tion do not include normal manufacturing tolerances.

Therefore, this unit may not exactly match the listed

specifications. Also, this product is tested and cali-

brated under closely controlled conditions, and some

minor differences in performance can be expected if

those conditions are changed.

MODEL: F59A includes cabinet, 1 electronic cell, three-

speed propeller fan, 1 carbon postfilter, 1 prefilter and a

solid state power supply.

AMBIENT TEMPERATURE RANGE: 40° F to 100° F

[4° C to 38° C].

EFFICIENCY: 90% efficiency rating based on National

Bureau of Standards Dust Spot Method using atmo-

spheric dust and American Society of Heating, Refriger-

ating, and Air-Conditioning Engineers Standard 52-76.

CLEAN AIR DELIVERY RATINGS:

cfm m3/hr

Dust 288 489

Tobacco Smoke 270 459

Pollen 239 406

CAPACITY:

Fan Speed cfm m3/hr eff. %

High 330 560 80

Medium 265 450 85

Low 200 340 90

NEON LIGHT: Located next to three-speed switch. Indi-

cates presence of high voltage power.

DIMENSIONS:

Cell: 16 x 12-1/2 in. [406 x 318 mm].

Cabinet: 19-1/2 x 13-7/8 in. x 17-1/8 in. [496 x 352 x

435 mm].

Prefilter, Carbon Postfilter: 12-7/8 x 16-1/4 in. [327 x

413 mm].

ELECTRICAL RATINGS:

Nominal Current and Power Consumption (max):

INTERLOCK SWITCH: Interrupts supply circuit to unit

when cover is opened.

CABINET: Particle board covered with wood-grained vi-

nyl. Available in walnut or light oak finish (light oak not

available in Canada).

WEIGHT: 45 lb [20 kg] shipping; 37 lb [17 kg] device

including cell. Cell weighs 8 lb [4 kg].

ACCESSORIES: See Parts List.

UNDERWRITERS LABORATORIES INC.: Listed, File

No. E64835 (120 Vac, 60 Hz units).

CANADIAN STANDARDS ASSOCIATION: Certified,

File No. LR36354 (F59A1026 only).

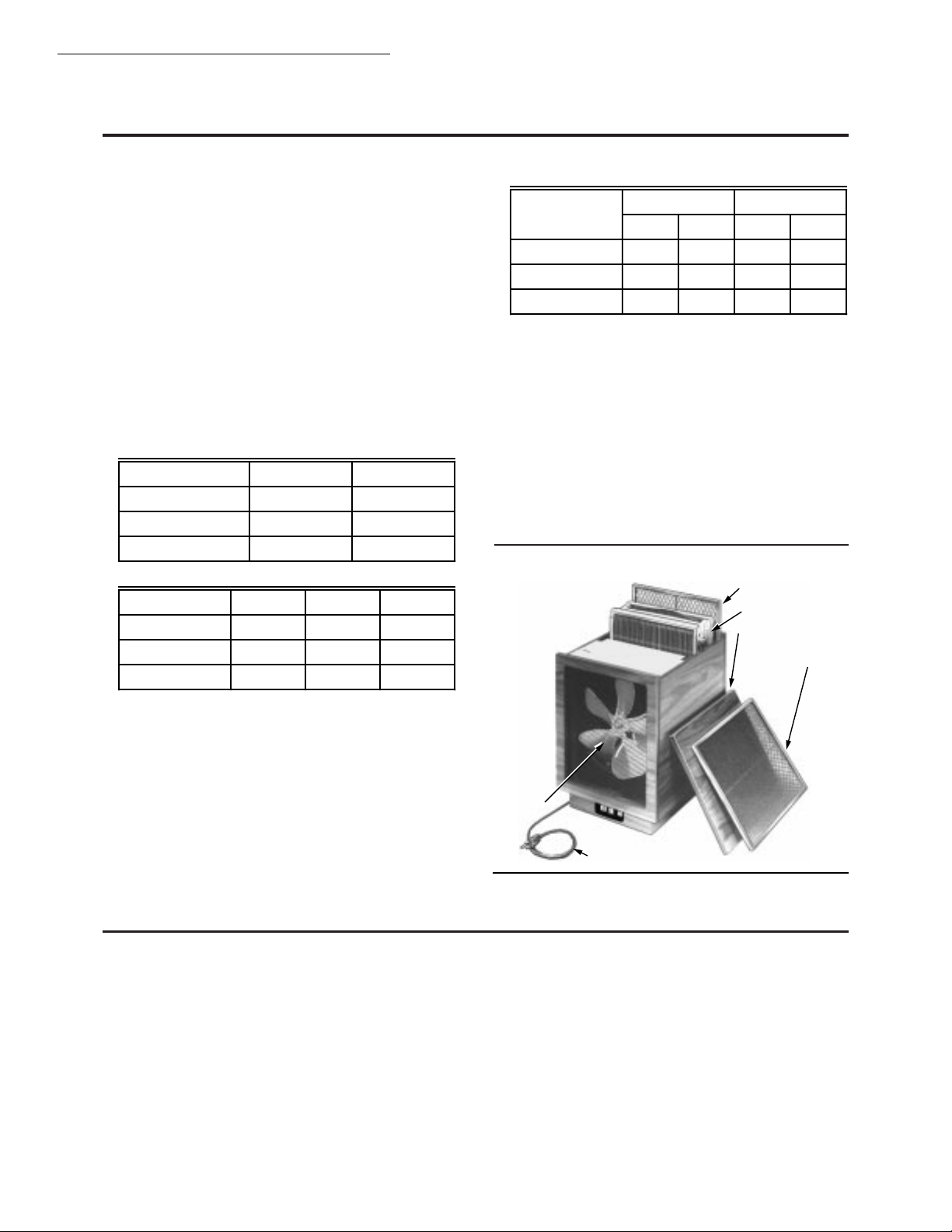

Fig. 1—F59A components.

PREFILTER

CELL

COVER

CARBON

POSTFILTER

FAN

When purchasing replacement and modernization products from your TRADELINE® wholesaler or your full service distributor, refer to

the TRADELINE Catalog or price sheets for complete ordering number, or specify—

1. Order number.

2. Cabinet color—walnut or light oak (light oak not available in Canada).

3. Voltage.

4. Accessories, if required.

If you have additional questions, need further information, or would like to comment on our products or services, please write or phone:

1. Your local Honeywell Home and Building Control Sales Office (check white pages of your phone directory).

2. Home and Building Control Customer Logistics

Honeywell Inc., 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386 (612) 951-1000

In Canada—Honeywell Limited/Honeywell Limitee, 740 Ellesmere Road, Scarborough, Ontario M1P 2V9. International Sales and

Service offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France, Germany, Japan, Mexico,

Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

68-0086—5 2

POWER CORD AND PLUG

M9680

Ordering Information

Page 3

WHEN USING THIS PRODUCT…

Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous condition.

UNPACK ELECTRONIC AIR CLEANER

Check that all components are included. The electronic

air cleaner is shipped assembled. See Fig. 1.

SET UP ELECTRONIC AIR CLEANER

■ Position the F59A so:

• the airflow in and out of the air cleaner is not

blocked or partially obstructed.

• the discharge air does not cause uncomfortable

drafts for any occupant.

• the power cord does not interfere with normal occupant traffic.

■ Remove and discard the cardboard liner next to the

electronic air cleaner cell.

■ Remove the cell and carbon postfilter from the cabinet;

remove and discard the plastic cover from the carbon

postfilter.

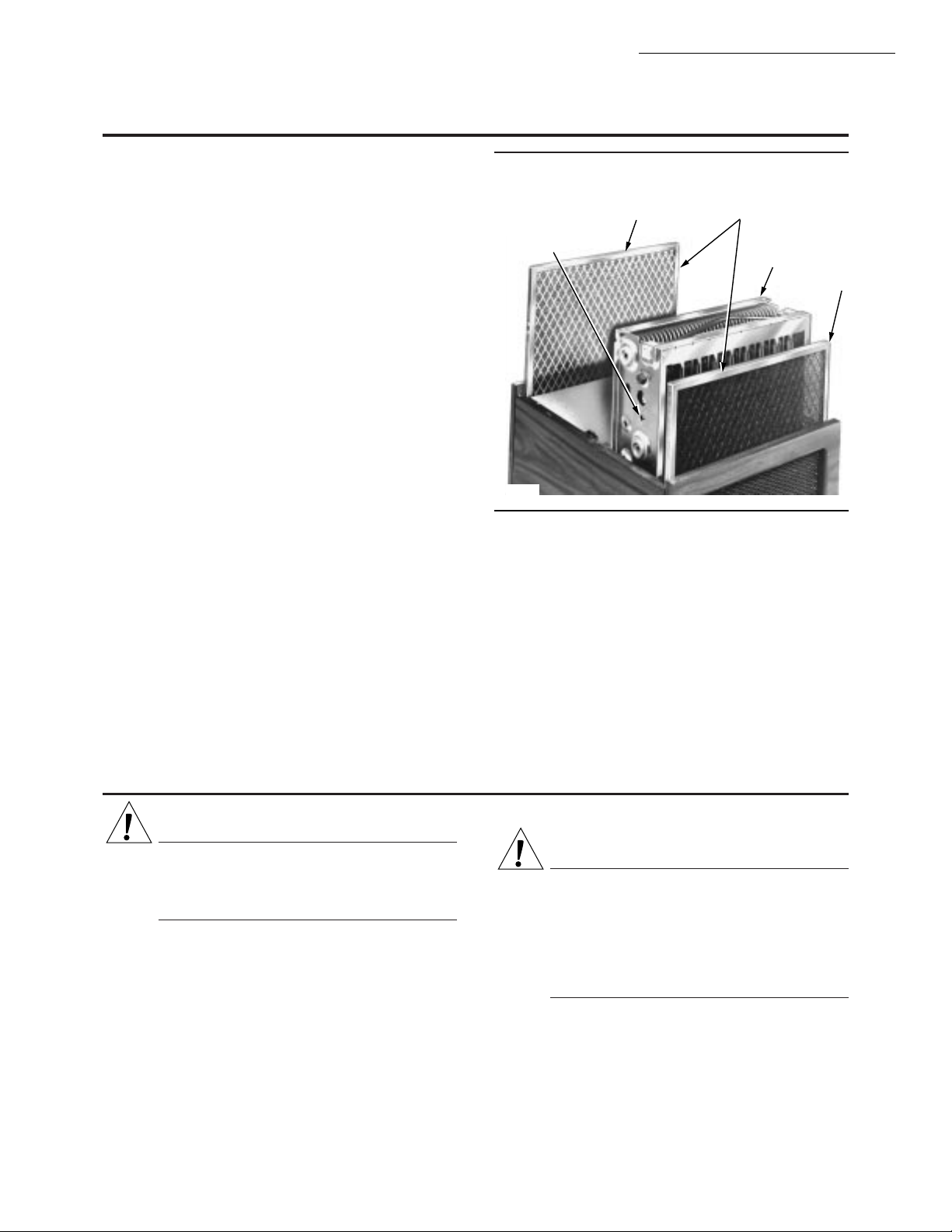

■ Replace the cell and the carbon postfilter. Make sure

cell is placed correctly, with directional arrows pointing

toward center of air cleaner cabinet. The cell directional

arrow is located on the side of the cell. The prefilter and

carbon postfilter should be placed with the wire mesh

toward the center. See Fig. 2.

■ Plug power cord into standard grounded outlet.

OPERATION OF ELECTRONIC AIR CLEANER

■ Select desired airflow rate with three-speed power

switch—LO, MED or HI. For maximum air cleaning

SETUP AND OPERATION • SERVICE

Setup and Operation

Fig. 2—Make sure cell and filters are placed

correctly.

DIRECTIONAL ARROW

(POINTING TOWARD

CENTER OF

CABINET

M9683

benefit, leave switch on HI at all times. For quiet

operation, use LO setting. Neon light and fan should be

on whenever air is running.

■ Move power switch to OFF to turn off electronic air

cleaner; neon light and fan will go off.

NOTE: An arcing (snapping) sound may be heard occa-

sionally as air cleaner operates. This sound means air

cleaner is working as it should, collecting large airborne

dust particles.

CARBON

POSTFILTER

INSERT FILTER WITH

WIRE MESH TOWARD

CENTER OF UNIT

CELL

PREFILTER

F59A

CAUTION

SHARP EDGES.

CAN CAUSE PERSONAL INJURY.

Handle the cell carefully to avoid cuts from the

sharp metal edges.

CLEANING THE CELL AND PREFILTER

Clean the cell and prefilter regularly—every one to six

months. Variables such as number of occupants, pets,

activities and smoking will determine how often cleaning is

required. Use the wash reminder schedule included with

the air cleaner to help establish and maintain a regular

cleaning schedule.

The cell can be washed in many automatic dishwashers,

by soaking in a tub or a do-it-yourself coin operated car

wash. The prefilter can be vacuumed, brushed or soaked in

a tub. Do not wash the filter in the dishwasher or carwash.

Service

Automatic Dishwasher

CAUTION

BURN HAZARD.

CAN CAUSE PERSONAL INJURY.

Allow the cell to cool in the dishwasher at the end

of the wash cycle or wear protective gloves to

avoid burns. Hot water can accumulate in the

tubes supporting the collector plates. Tip the cell

so these tubes will drain.

IMPORTANT:

• Check you dishwasher owner manual. Some manufacturers do not recommend washing electronic cells

in their dishwasher.

• If the dishwasher has upper and lower arms, carefully position the cell to allow good water circulation.

3 68-0086—5

Page 4

F59A

SERVICE

• Be careful to avoid damaging or bending the cell

plates when placing the cell in the dishwasher. If

bent, arcing will result.

• A very dirty cell, especially from tobacco or cooking

smoke, can discolor the plastic parts and lining of the

dishwasher. The discoloration is not harmful. To

minimize it, wash the cell more frequently or try a

different brand of detergent.

• Do not allow the dishwasher to run through the dry

cycle. This will bake on any contaminants not removed during the wash cycle and reduce air cleaner

efficiency.

1. Put the cell on the lower rack of the dishwasher with

the directional arrow pointing up. It may be necessary to

remove the upper rack. Do not block water flow to the

upper arm, if provided on dishwasher.

2. Using the detergent that works best for normal

dishwashing, allow the dishwasher to run through the complete wash and rinse cycle. Do not use the dry cycle. To

avoid burns, let the cell cool completely before removing,

or wear protective gloves when removing the cell. Remember that water may be trapped in the tubes that support the

collector plates. Tip the cell so these tubes can drain.

3. Wipe the ionizer wires and contact board on end of

cell with a small, damp cloth, using your thumb and forefinger.

4. Inspect the dishwasher. You may wish to rerun the

wash and/or rinse cycle with the dishwasher empty if you

see dirt or residue from washing the cell. If dirt or residue

seems excessive, wash the cell more often or try a different

detergent.

5. Inspect the cell for bent plates; bend back to normal

to prevent arcing.

Soaking in Tub

CAUTION

HAZARDOUS CHEMICAL.

CAN CAUSE PERSONAL INJURY.

Do not splash the detergent solution in eyes. Wear

rubber gloves to avoid prolonged detergent contact with skin. Keep detergent and solution out of

reach of children.

NOTE: Always wash the cell first, then the prefilter, to

keep heavy prefilter lint from getting caught in the cell.

5. Rinse the cell with a hard spray of very hot water;

rinse the tub clean, then fill the tub with clean hot water and

soak for 5 to 15 minutes. Rinse until water draining from

the cell no longer feels slippery. Rinse the filter with a

gentle spray of hot water.

6. Soak cell and filter in a final clear water rinse for ten

minutes.

7. Wipe the ionizer wires and contact board on end of

cell by using your thumb and forefinger and holding a

small, damp cloth.

Car Wash

Use the hand sprayer at a coin-operated car wash to

wash the cell. Hold the nozzle at least 2 ft [0.6m] away from

the unit to avoid damage from the high pressure stream of

water. Follow the same sequence of wash and rinse as

recommended for cars. However, do not wax the cell. Rinse

until the water draining from the cell no longer feels slippery.

REINSTALLING CELL, PREFILTER AND

CARBON POSTFILTER

■ Inspect the cell for broken ionizer wires and bent collec-

tor plates. Repair as necessary.

■ Slide the dry filter into the filter guides, with directional

arrow pointing toward the center of the electronic air

cleaner cabinet. The directional arrow is very small, and

is located on the end of the filter frame. See Fig. 2.

■ Gently vacuum the inside and outside of the air cleaner

cabinet with the brush attachment of vacuum cleaner, or

dust with a soft cloth.

■ Slide in the dry cell so the directional arrow (located on

the side of the cell) points toward the center of the air

cleaner cabinet.

■ Replace the carbon filter if necessary. This filter slides in

or out of the guides easily.

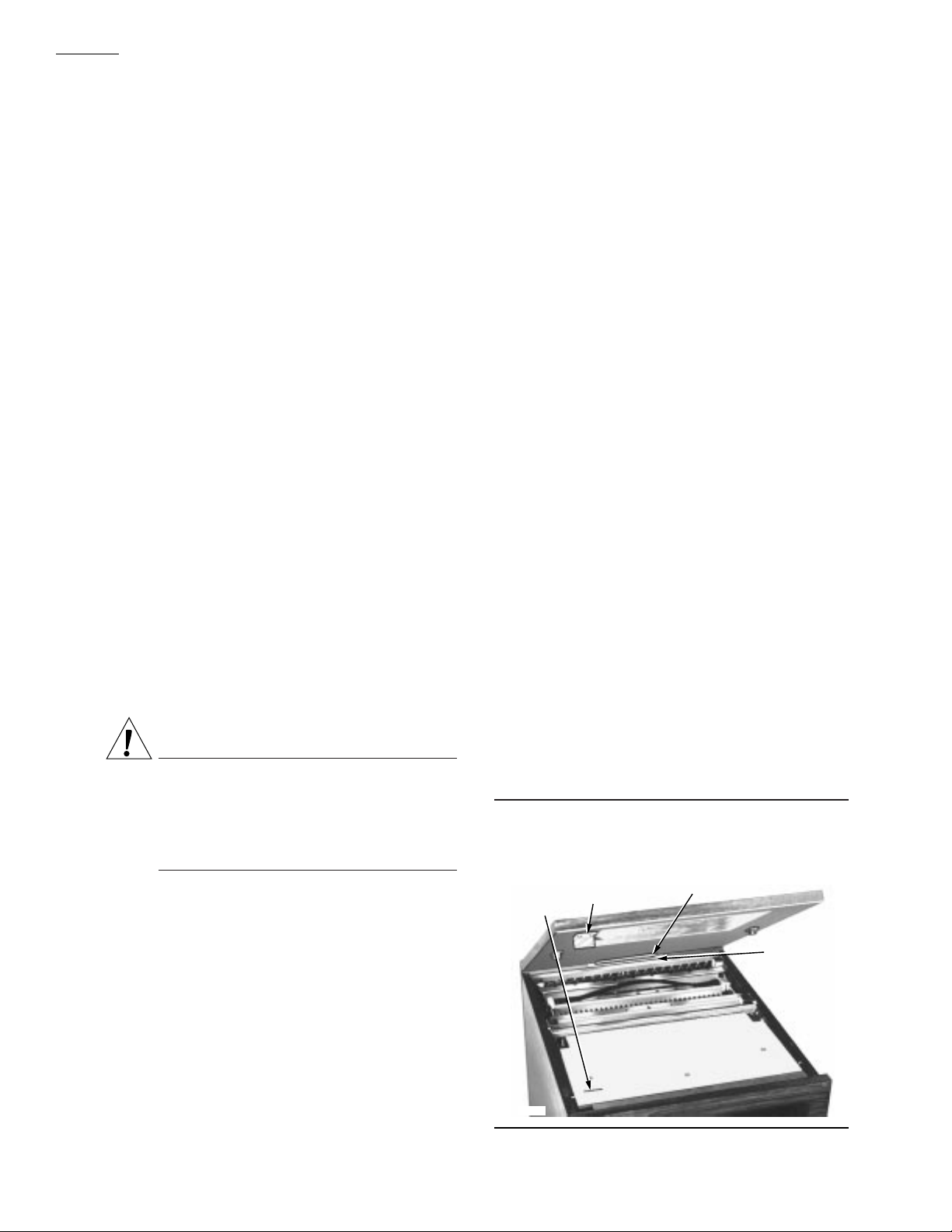

■ Replace the cover on the cabinet. The metal tab on the

cover must fit in the slot at the end of the cabinet, and the

interlock under the cover must connect with the air

cleaner cabinet for operations. See Fig. 3.

Fig. 3—Cover must fit correctly for operation.

THE METAL TAB ON

THE COVER MUST

FIT IN THE SLOT

METAL

TAB

SLOT

METAL

TAB

INTERLOCK

THE INTERLOCK UNDER THE

COVER MUST CONNECT WITH

THE AIR CLEANER CABINET

1. Use a container such as a laundry tub or trash container that is large enough to hold the cell. Sharp corners on

the cell can scratch the surface of a bathtub.

2. Dissolve about 3/4 cup automatic dishwashing detergent in enough hot water to cover the cell. If the detergent

does not dissolve readily, or forms a scum on the water, try

another brand, or use softened water.

3. After the detergent has completely dissolved, place

the cell in the container and let soak for 15 to 20 minutes.

Agitate up and down a few times, and remove.

4. Next, wash the prefilter the same way. Empty and

rinse the wash container.

68-0086—5 4

M9682

INTERLOCK

SLOT

Page 5

F59A

OIL

INDENTATIONS

M9681

SERVICE • ELECTRICAL TROUBLESHOOTING

■ Turn on the air cleaner. If the cell and filters are wet, the

neon light may not come on; you may also hear arcing.

If the arcing is annoying, simply turn off the air cleaner

for two to three hours or until the cell is dry. Remove wet

cell to hasten drying.

IONIZER WIRE REPLACEMENT

Broken ionizer wires can cause a short to ground, often

resulting in visible arcing or sparking. The cell should not

be used until the pieces of broken wire are removed. It can

Fig. 4—Install new ionizer wire by hooking

eyelets over spring connectors.

be used temporarily with one wire missing, although the

wire should be replaced as soon as possible. See the Parts

List, for order number.Replacement wires are supplied cut

to length with eyelets on both ends for easy installation. To

install:

■ Hook the eyelet on one end of the wire over the spring

connector on one end of the cell. See Fig. 4. Be careful

to avoid damaging the spring connector or other parts of

the cell.

■ Hold the opposite eyelet with a needlenose pliers and

stretch the wire the length of the cell. Depress the

opposite spring connector and hook the eyelet over it.

OILING THE FAN MOTOR

Oil the fan motor once a year for smooth operation:

■ Turn off air cleaner switch; unplug power cord.

■ Remove cover and cell.

■ Put two drops of electric motor oil in each of two oil

indentations in fan motor. See Fig. 5.

■ Replace cell with directional arrow (on side of cell)

pointing toward center of air cleaner cabinet; replace

carbon filter.

■ Plug in power cord; turn on the air cleaner again.

Fig. 5—Oil fan motor yearly.

SPRING

CONNECTORS

PRESS

DOWN

M1540

IONIZER

WIRE

IONIZER

WIRE

EYELETS

NEEDLENOSE

PLIERS

W ARNING

ELECTRIC SHOCK HAZARD.

CAN CAUSE PERSONAL INJURY OR

EQUIPMENT DAMAGE.

The following procedures expose hazardous live

parts. Disconnect power supply between checks

and proceed carefully.

Electrical T roubleshooting

CAUTION

The following instructions are for use by qualified

personnel only.

TOOLS AND EQUIPMENT

Troubleshooting the electronic air cleaner requires only

a few tools:

• Needlenose pliers (for stringing ionizer wires).

• Test meter with high voltage probe (10 kV minimum).

5 68-0086—5

Page 6

F59A

ELECTRICAL TROUBLESHOOTING

TROUBLESHOOTING PROCEDURE

CAUTION

ELECTRIC SHOCK HAZARD.

CAN CAUSE PERSONAL INJURY.

Always turn off power before troubleshooting.

Fig. 6—Troubleshooting the F59A.

START

MAKE SURE

ELECTRONIC CELL

IS CLEAN, DRY AND

PROPERLY

INSTALLED.

MAKE SURE

PREFILTER AND

CARBON POSTFILTER ARE

PROPERLY

INSTALLED.

REPLACE THE

COVER AND TURN

THE AIR CLEANER

ON. CHECK LO,

THEN MED, THEN HI

SPEEDS.

CHECK FAN AND

NEON LIGHT.

BOTH

ON

OPEN COVER; PUSH

IN INTERLOCK

SWITCH; WITH

PLASTIC-HANDLED

SCREWDRIVER,

SHORT FROM CELL

FRAME TO A HOT

COLLECTOR

PLATE.

ELECTRONIC AIR

CLEANER IS OK.

3

YES

TROUBLESHOOTING F59A ELECTRONIC AIR CLEANER

THESE SERVICING INSTRUCTIONS ARE FOR USE BY QUALIFIED PERSONNEL

ONLY. TO REDUCE RISK OF ELECTRIC SHOCK, DO NOT PERFORM ANY

SERVICING OTHER THAN CONTAINED IN THE OPERATING INSTRUCTIONS

UNLESS YOU ARE QUALIFIED TO DO SO.

CHECK LINE

POWER; CORRECT

AS NEEDED.

BOTH

OFF

JUMPER FAN

LIGHT

SWITCH CONTACTS

ON

- FOR EACH SPEED

IN TURN.

FAN

ON

REMOVE CELL.

REPLACE COVER.

CHECK NEON

NO

LIGHT.

LIGHT

INSPECT CELL FOR

– BENT COLLECTOR

PLATES

– BROKEN IONIZER

WIRES

– DIRT ON

INSULATORS

– DAMAGED

CONTACT TABS

WITH OHMMETER

CHECK FOR SHORT

BETWEEN

– CELL FRAME AND

IONIZER SECTION

– CELL FRAME AND

COLLECTOR

SECTION

ON

NO CELL

DAMAGED NOTED

INFINITE

RESISTANCE

CELL OK.

The troubleshooting chart shows how to quickly isolate

a problem in the air cleaner. See Figs. 6 through 10.

The solid state power supply assembly provided in this

air cleaner has no field-serviceable components. If troubleshooting indicates a power supply assembly problem, replace the entire power supply assembly. See Parts List

section, for order number.

TO USE THIS CHART:

1. Be sure to follow the steps sequentially.

2. Each time you isolate and fix a problem, go back to START.

3. Repeat ALL the steps until the air cleaner checks out OK.

WARNING

RISK OF ELECTRIC SHOCK

CHECK LAMP/FAN. REPLACE SWITCH.

FAN

ON

FAN

OFF

LIGHT

OFF

CELL

DAMAGED

CELL

SHORTED

REPLACE SWITCH.

TURN OFF POWER.

MAKE SURE SHAFT

ON FAN MOTOR

ROTATES FREELY.

REPLACE MOTOR IF

NECESSARY.

REMOVE COVER.

CHECK FOR

CORRECT INPUT

VOLTAGE BETWEEN

P1 AND P2

TERMINALS ON

POWER SUPPLY.

REPAIR OR

REPLACE CELL.

REPLACE CELL.

VOLTAGE

CORRECT

VOLTAGE

NOT

CORRECT

CHECK VOLTAGE

ACROSS NEON

LEADS.

REPLACE LIGHT.

CHECK WIRING

BACK THROUGH

SWITCH, POWER

CORD, AND OUTLET

TO CIRCUIT

BREAKER OR FUSE.

LAMP

OFF

VOLTAGE

ABOVE

120 Vdc

1

LAMP ON

VOLTAGE

BELOW

120 Vdc

LIGHT OK. REPLACE

COMPLETE POWER

SUPPLY.

2

1

NEON LIGHT MUST BE REPLACED TO ENSURE PROPER AIR CLEANER OPERATION.

2

ELECTRONIC COMPONENTS ON POWER SUPPLY BOARD ARE NOT FIELD REPLACEABLE. ATTEMPTED SERVICE WILL DAMAGE BOARD.

A HIGH VOLTAGE METER CAN BE USED TO MEASURE IONIZER AND COLLECTOR VOLTAGE.

3

68-0086—5 6

M1312B

Page 7

ELECTRICAL TROUBLESHOOTING

3

Fig. 7—Push screwdriver down to close interlock switch (left); short from cell frame to hot collector

plate to product arcing (right) as instructed in Fig. 6.

PUSH SCREWDRIVER DOWN

TO CLOSE INTERLOCK SWITCH

CELL

FRAME

COLLECTOR

PLATES

F59A

M5637

Fig. 8—Internal schematic for 120 Vac, 60 Hz F59A.

NEON

GREEN

GR OU ND

LIGH T

ON-OFF/

3 SPEED

FAN

SWITCH

2

2

ON (C OM)

1

MED

LOW

(L)

BLACK

WHITE

HI

4

3

2

1

BLACK

BLACK

BLUE

RED

YELLOW

GREEN

FAN

MOTOR

RED -IONIZER

BLACK-COLLECTOR

N EON L AMP

GROUND

ON (COM) SW I TCH CONTACT IS MADE IN

1

ALL SWITCH POSITIONS EXC EPT OFF.

INTERLO CK SAFETY SWIT CH ON CO VER.

2

M5634

POWER SUPPLY

P3

P4

P5

P2

P1

M315

7 68-0086—5

Page 8

F59A

2

ELECTRICAL TROUBLESHOOTING

Fig. 9—Internal schematic for 220 Vac, 50 Hz F59A.

NEON

LIGH T

YELLOW

GREEN

RED -IONIZER

BLACK-COLLECTOR

N EON L AMP

GROUND

POWER SUPPLY

P3

P4

P5

BLUE

GREEN /YEL LOW

BROWN

BROWN

GR OU ND

ON-O F F/

3 SPEED

FAN

SWITC H

BLUE

GREEN /

YELLOW

2

2

ON (C OM)

1

ORA NGE

MED

LOW

A6

BLACK

A5

BLACK

D2

HI

BLACK

BLUE

C2

RED

B2

WHITE

WHI T E

When measuring high voltage, use a good quality multimeter and HV probe. When measuring ionizer and collector

voltage, they should be between 6900 and 7800 Vdc.

REDUCING OZONE ODOR

CAUTION

ELECTRIC SHOCK HAZARD.

CAN CAUSE PERSONAL INJURY.

Always disconnect power before working on power

supply.

Only a trained service technician should perform

the following procedure.

The electronic air cleaner generates a small amount of

ozone in normal operation. During the first week or two of

operation, the amount may be higher because of sharp

edges on some of the new high voltage metal parts. Normal

use dulls these edges in a short time.

P2

P1

ON (COM) SW I TCH CONTACT IS MADE IN

FAN

MOTOR

1

ALL SWITCH POSITIONS EXC EPT OFF.

INTERLO CK SAFETY SWIT CH ON CO VER.

2

M315

The average person can detect the odor of ozone in

concentrations as low as 0.003 to 0.010 parts per million

(ppm). The electronic air cleaner contributes 0.005 to

0.010 ppm of ozone to the indoor air. The U.S. Food and

Drug Administration and Health and Welfare Canada recommend that indoor ozone concentration should not exceed 0.050 ppm. As a comparison, the outdoor ozone level

in major cities is sometimes as high as 0.100 ppm. However, if desired, the ozone generated by the air cleaner can

be reduced by clipping out the J2 jumper on the power

supply. This will reduce ozone production about 20 to 25

percent, and reduce efficiency about 7 to 10 percent depending on actual airflow delivered by the furnace blower.

a. Turn off power to the air cleaner; tip unit upside

down and remove bottom plate to access power

supply.

b. Find the J2 jumper on the power supply, and clip it

out. See Fig. 11.

c. Replace the air cleaner bottom plate; turn on power.

Regular replacement of the carbon filter (every 3 to 6

months) will also help reduce ozone odor.

68-0086—5 8

Page 9

ELECTRICAL TROUBLESHOOTING

Fig. 10—Use an ohmmeter to check the cell for short circuits as instructed in Fig. 6.

COLLECTOR

TERMINAL

IONIZER

TERMINAL

COLLECTOR

TERMINAL

M6155

F59A

Fig. 11—Clip out the J2 jumper to reduce ozone production about 20 to 25 percent.

J2 JUMPER. CLIP OUT TO REDUCE

OZONE PRODUCTION

P3

P4

J2

2

4

3

1

P2

P1

CABLE CLAMP CLIP

M6148

9 68-0086—5

Page 10

F59A

PARTS LIST

Parts List

Part Number

Number Description 120 Vac, 60 Hz 220 Vac, 50 Hz

1 Prefilter 190356 190356

2 Electronic Cell FC37A1130 FC37A1130

3 Contact Panel 138889A 138889A

4 Solid State Power Supply 203362J 203362W

5 Neon Light 190340 190340

6 Fan Motor 203634 203635

7 Fan Blade 205345 205345

8 Interlock Switch 190070 190070

9 Cell Removal Handle 190358 190358

10 Cell Handle Fastener (2) 190359 190359

11 Cover Latches (male) (2) 190361 190361

12 Cover Latches (female) (2) 190362 190362

13 Mounting Feet (4) 190360 190360

14 Interlock Actuator Bracket 197675 197675

15 Control Switch 190382 196934

16 Carbon Postfilter 203638 203638

Parts and Accessories Not Illustrated

Part Number

Description 120 Vac, 60 Hz 220 Vac, 50 Hz

Casters and Hardware 190364A 190364A

Ionizer Wires (multiples of 5) 136434BA 136434BA

Interlock Switch Assembly 4074EBC 4074EBC

68-0086—5 10

Page 11

Fig. 12—F59A parts are keyed to parts list.

F59A

PARTS LIST

10

9

12

14

6

7

1

2

11

16

8

3

5

15

4

13

M3151

This equipment is a class B digital apparatus which complies with Canadian Radio Interference Regulations, CRC c.

1374.

11 68-0086—5

Page 12

Home and Building Control Home and Building Control Helping You Control Your World

Honeywell Inc. Honeywell Limited—Honeywell Limitée

1985 Douglas Drive North 740 Ellesmere Road

Golden Valley, MN 55422 Scarborough, Ontario

M1P 2V9

68-0086—5 12Printed in U.S.A.

Printed in U.S.A.

QUALITY IS KEY

Loading...

Loading...