Honeywell EW451 Series, EW447A0100, EW450A0100, EW447A1200, EW450A1200 Installation And Setup

...Page 1

Honeywell y All rights reserved EN0H-2601GE25 R0413

EW447-EW452 Series

Mechanical Heatmeters

FOR HEATING AND COOLING APPLICATIONS

PRODUCT DATA

Fig. 1. EW447 (cables removed)

Fig. 2. EW447F (with RF)

CONTENTS

Contents ............................................................................... 1

General ................................................................................. 2

Application .......................................................................... 2

Features ............................................................................. 2

Design ................................................................................ 2

Materials ............................................................................. 2

Approvals ........................................................................... 2

Technical Details ................................................................. 2

Specifications .....................................................................2

Flow data ............................................................................3

Sizing .............................................................................. 3

Function ............................................................................. 3

Installation and Setup ......................................................... 4

Software .......................................................................... 4

Communication and Readout ............................................. 5

Typical Readout Applications ......................................... 5

Identification ....................................................................... 6

Dimensions ........................................................................ 7

Ordering Details ................................................................... 8

Ordering Information .......................................................... 8

Scope of Delivery ............................................................... 9

Accessories ........................................................................ 9

Diagrams ............................................................................ 11

Measuring Accuracy ......................................................... 11

Flow Diagram ................................................................... 12

Page 2

EW447-EW452 SERIES MECHANICAL HEATMETERS

EN0H-2601GE25 R0413 2 Honeywell y All rights reserved

GENERAL

Application

Honeywell EW447-452 Series mechanical meters are compact

heat or chilled water meters with electronic measurement

based on the multijet principle, consisting of an electronic

energy calculator, a multijet flow sensor and two temperature

sensors.

They are used for metering of hydronic heating and/or cooling

energy in hydronic systems based on volume, supply and

return temperature.

EW447-449 models are suitable for energy metering in heating

systems (‘heat metering’).

EW450-452 models are suitable for energy metering in

heating, cooling or combined systems.

Features

• Approval for meter with dynamic range of 100:1 (qp:qi)

in class 2

• Lithium battery, battery lifetime 12 years

• Optical interface as standard

• Rotatable calculator

• Optionally with integrated radio, Open Metering

Standard, 868MHz

Design

EW447-452 Series mechanical meters consist of:

• Electronic energy calculator with power supply and fixed to

mechanical flow sensor

• Factory fitted supply and return temperature sensors

• Optionally M-Bus or pulse output function

• Flow sensor with external threads according to ISO228

(DN15…DN40) or flanges PN16 (DN32…DN100)

• EW45x versions with potted electronics

Materials

• Front panel of energy calculator made of dark grey plastic

with laser markings for approval, flow and other product

information

• Housing of energy calculator made of dark grey plastic

• EW447 and 452: housing of flow sensor made of unpainted

brass

• EW448, 449, 451 and 452: housing of flow sensor made of

brass, painted dark grey

Approvals

Heating

• DN15…20: MID class 2 (DE-07-MI004-PTB030) and

EN1434 (22.52 / 00.02)

• DN25…40: MID class 2 (DE-09-MI004-PTB001) and

EN1434 (22.52 / 06.02)

• DN50…100: EN1434 (22.52 / 01.02)

TECHNICAL DETAILS

Specifications

Sizes DN15…DN100

qp0.6…60m³/h

Medium Water, quality to VDI2035

Medium temperature 5...90°C

Ambient temperature 5…55°C

Storage temperature -20…55°C

Operating pressure max. 16bar

Protection class IP54 (EW44x)

Measuring process Fully electronic compact heat meter

with direct impeller scanning

(EW447, 448, 450 and 451) or

impeller scanning via magnetic

coupling with sensors (EW449 and

452)

Display LCD, 7-digit

Display units MWh, kWh, GJ, MJ, kW, m³/h, l/h,

m³ and l

Display values 9 999 999, 999 999.9, 99 999.99,

9 999.999

Values displayed Power, energy, flow rate, tempera-

ture, energy on readout date,

readout date

Measuring cycle

volume

16s

Measuring cycle

temperature

32s

Temperature difference

max. 147K

Starting temperature

difference

0.25K

Absolute temperature

measuring range

0…150°C

Temperature sensors Pt500 with 2-wire leads

Operating voltage 3.0V

Ambient class Class C + M1

Battery lifetime 10 + 2 years

Interfaces Optical

Optional interfaces

Page 3

EW447-EW452 SERIES MECHANICAL HEATMETERS

Honeywell y All rights reserved 3 EN0H-2601GE25 R0413

Flow data

Table 1. Flow rates EW447-452 Series

Sizing

• EW447-452 Series mechanical meters should be selected in such a way that typical system flow rates are between approved

minimum (qi) and maximum flow rate (qs)

• Overload flow rate may be reached for not more than 15 minutes per day

• Flow rates below minimum and above maximum should be avoided

DN 15 15 20 25 25 40 50 65 80 100

Flow rates according to MID

Minimum (qi) l/h 6 15 25 70 120 200 300 500 800 1,200

Nominal (qp) m³/h 0.6 1.5 2.5 3.5 6 10 15 25 40 60

Maximum (qs) m³/h1.2 3 5 7 1220305080120

Dynamic range (qp/qi) 1:100 100:1 100:1 50:1 50:1 50:1 50:1 50:1 50:1 50:1

Additional flow data

Starting flowrate l/h 1.5-2 3-4 5-6 35 60 100 60 60 90 90

Overload flow rate m³/h 50 50 110 140

Pressure loss @ qp 243 243 242 170 190 240 62 142 80 100

Function

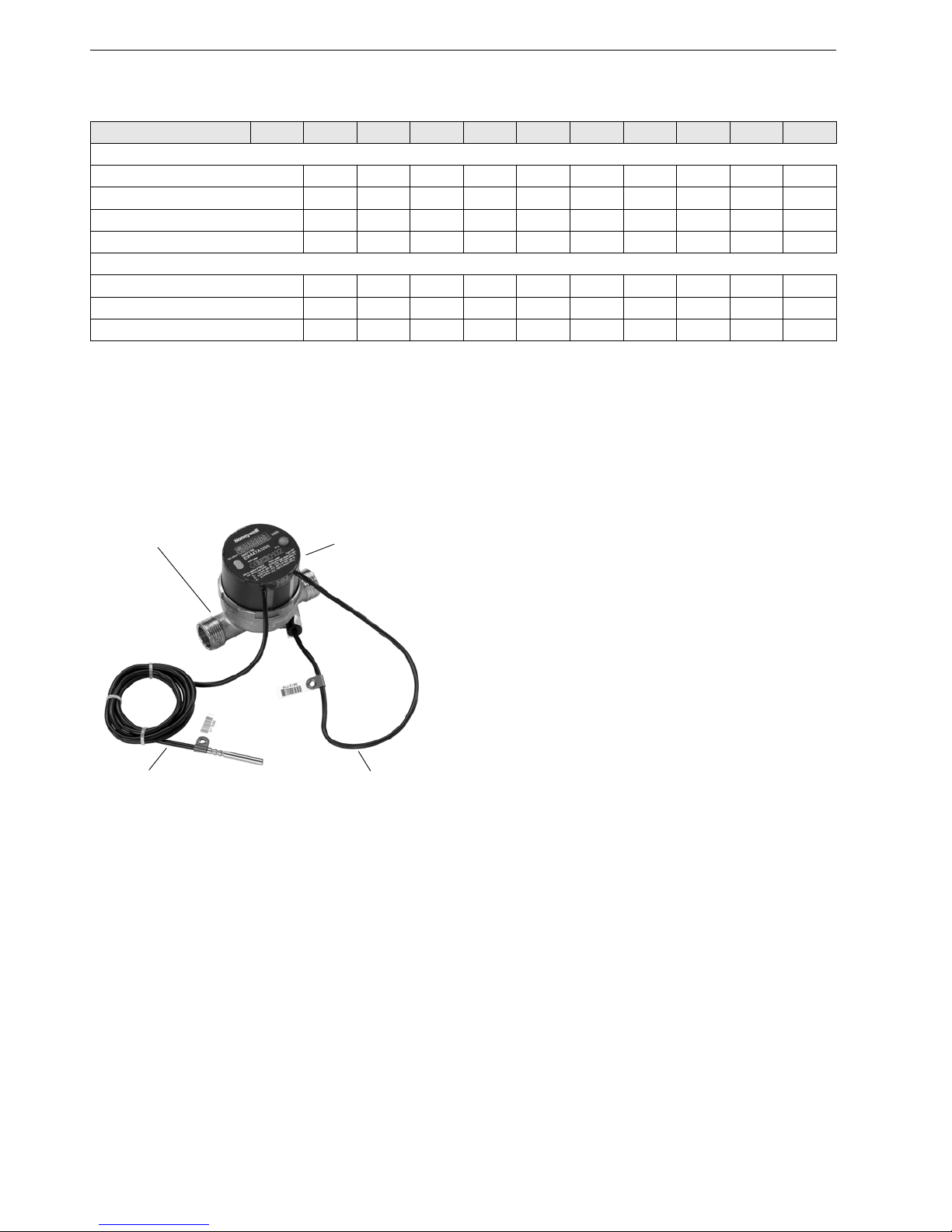

Fig. 3. EW447 components

Energy Calculator

The energy calculator (or simply ‘calculator’) contains circuits

for recording flow rate and temperature and for calculating,

logging and displaying data.

The meter can be read from a single line seven-digit display

with units and symbols. A push button provides control of

various display loops. All failures and faults are recorded automatically and displayed on the LCD screen. For protection all

relevant data is saved in a non-volatile memory (EEPROM).

This memory saves measured values, device parameters and

types of error at regular intervals.

Flow Sensor

The multijet technology of the flow sensor permits high

measuring accuracy. Standard place of installation is return

pipeline. For installation in supply a different version has to be

used. Meters cannot be reconfigured from return to supply

pipeline usage in the field.

Power Supply

Non replaceable lithium battery 3.0V DC with 10 + 2 year lifetime (10 year nominal lifetime, 1 year for storage an 1 year

buffer). Nominal lifetime relates to normal usage. Battery lifetime is decreased by shorter readout intervals, longer data telegrams, etc.

Temperature sensors

EW447-452 Series mechanical meters are supplied with

installed Pt500 temperature sensors with 2-wire leads,

Ø5.2mm. The temperature sensors are permanently installed

to the meter and cannot be replaced. Sensor cable lengths are

as follows:

Interfaces

EW447-452 Series mechanical meters are equipped with a

ZVEI optical interface for communication and testing as standard. Further all meters are available with either RF, MBus or

pulse output. For more details on interfaces see chapter

“Communication and Readout” below.

Energy calculator

Return temperature

Flow sensor

Supply temperature

sensor

sensor

EW447 and 450 • Supply: 1.5m

• Return: 0.4m with sensor installed in

housing of flow sensor

EW448 and 451 • Supply: 3.0m

• Return: 1.5m with sensor installed in

housing of flow sensor

EW449 and 452 • Supply: 6m

• Return: 6m

Page 4

EW447-EW452 SERIES MECHANICAL HEATMETERS

EN0H-2601GE25 R0413 4 Honeywell y All rights reserved

Installation and Setup

Medium

Heat meters generally are only approved for metering of water

and not for water glycol mixtures or fluids other than water.

During measurement meter must be completely filled with

water.

Flow Sensor

EW447-452 Series mechanical meters must be installed in the

return pipeline. When installed in the supply pipeline measurements are either unreliable, inaccurate or nonexistent. Pipeline

configuration cannot be changed in the field.

• Avoid installation at highest point of system or system part as

air may be trapped in meter

• It is recommended to place a ballvalve before and after the

heat meter for easy replacement

• Various fittings are available for sizes DN15…DN40

• Ball valves and fittings see Accessories on page 9f

• Further it is recommended to place a strainer before the

meter to avoid dirt entering the flow sensor

Fig. 4. Flow sensor installation

Calming legs

• EW447, 448, 450 and 451: calming legs before or after meter

are not required

• EW449 and 452: a calming leg of 3 x DN before meter is

recommended, in case of a T-piece or bend before the meter

a length of 5 x DN is recommended

Installation position

• EW447 and 450 may be installed in any position

• EW448, 449, 451 and 452 may only be installed in horizontal

position

Temperature Sensors

• Temperature sensors have to be installed like for like.

Example: if one temperature sensor is installed directly in the

flow, the second temperature sensor also has to beinstalled

directly in the flow

• Temperature sensors may only be installed directly in the

flow or, for sizes DN65 and larger, with MID approved sensor

pockets. See Accessories

• Sensor pockets can also be used for smaller sizes, although

installation directly in the flow is preferred

• Various fittings and other accessories are available for

temperature sensor installation, see Acessories on page 9f

Meter (exemplary)

Ball valve Connection fitting Connection fitting Ball valve

Fig. 5. Temperature sensor

installation with ballvalve

Fig. 6. Temperature sensor

installation with sensor

pocket

Ball valve

Temperature

Temperature sensor

sensor

installation kit

Sensor

Temperature

sensor

T-piece

pocket

Software

In general it is not necessary to parametrise EW447-452

meters in the field unless standard values should be changed.

Such changes can be done with the HydroSet software which

you can download free of charge from

http://metering.ecc.emea.honeywell.com/.

Page 5

EW447-EW452 SERIES MECHANICAL HEATMETERS

Honeywell y All rights reserved 5 EN0H-2601GE25 R0413

Communication and Readout

Model Overview

EW447-452 Series mechanical meters have an optical interface on the front panel and optionally one additional internal interface.

Model OS# starting Sizes available

A type: no interface EW44xA…, EW45xA… All sizes

F type: for RF networks EW447F…, EW450F… DN15…20

M type: for M-Bus networks EW44xM…, EW45xM… All sizes

P type: with pulse output EW44xP…, EW45xP… All sizes

Communication Options

Optical interface on front panel

Included as standard in all EW447-452 Series mechanical

meters. ZVEI interface, M-Bus protocol, for readout and

parametrisation. Required for access to meter:

• Bluetooth optohead (EWA3001799)

• PC with HydroSet software

Onboard RF

Transmission interval 64 seconds, suitable for walk by and

fixed RF networks. Open Metering Standard protocol,

frequency 868MHz.

Onboard M-Bus interface

According to EN1434-3, data reading and parametrisation via

two wires with polarity reversal protection.

Onboard pulse output

Two open collector outputs for energy and volume of heat

meters and cooling energy and heat energy for heat and chilled

water meters.

Typical Readout Applications

Direct Readout

The meter is visited at its point of installation and desiredvalues

are directly read off display and recorded manually.

Recommended model: A model

Alternative

Any EW447-452 Series mechanical meter allows direct

readout over the display.

Wired M-Bus Network

The meter is attached to a wired M-Bus network which allows

remote configuration and readout over the M-Bus master.

Recommended model: M model

The factory fitted M-Bus interface allows direct wiring to MBus

networks.

Wireless Networks

Generally there are three kinds of wireless networks:

• Wired M-Bus networks which use RF links for selected parts

of the network. Normally an RF capable meter transmits to

RF/M-Bus converter EW535M0131 which in turn is wired to

an M-Bus master unit

• Mobile RF networks, also called ‘walk by’. An RF capable

meter is read out by a person walking or driving past the

meter and equipped with a suitable receiver

• Fixed RF networks. An RF capable meter is read out by a

permanently installed receiver which automatically transmits

the data on to an FTP server

All wireless networks mentioned above use the same kind of

meter, i.e. all RF capable meters listed below are suitable for

use in partially wireless M-Bus networks as well as mobile and

fixed RF networks.

Recommended model: F model

The meter is equipped with an onboard RF interface which

enables the meter to be attached to a suitable RF network.

Alternative : M model + EW9100AEZ001

The M-Bus interface allows direct wiring to external RF trans-

mitter EW9100AEZ001.

Page 6

EW447-EW452 SERIES MECHANICAL HEATMETERS

EN0H-2601GE25 R0413 6 Honeywell y All rights reserved

Pulse Output Signal

The meter is attached to another device which is capable of

counting pulses or a converter which converts the pulses into

another signal.

Recommended model: P model

The onboard pulse output allows direct wiring to a suitable

device. Pulse unit and value cannot be changed.

Setup

On board RF

To activate RF function in the field the red pushbutton on the

front side of the meter has to be pushed once. RF can be deactivated with HydroSet software.

On board M-Bus

No field setup required at meter itself. M-Bus parametrisation,

for example primary address setting, can be done via M-Bus

master unit.

Identification

All EW447 – EW452

• Dark grey calculator housing with Honeywell logo and OSNumber starting with ‘EW4xx…’ lasered onto front panel

• 7-digit LCD display

• Models with MID approval: CE mark and MID approval on

centre of front panel

• Models with EN1434 approval: CE mark and EN1434

approval mark on front panel

• Serial number and meter specs centre bottom

• Red push button

EW447 and EW450

• Unpainted brass flow sensor housing with external threads

on inlet and outlet

• One temperature sensor installed in flow sensor housing

EW448 and EW451

• Dark grey powder coated flow sensor housing with external

threads on inlet and outlet

EW449 and EW452

• Dark red powder coated flow sensor housing with flanges on

inlet and outlet

Fig. 7. Top view of EW447A1200

Page 7

EW447-EW452 SERIES MECHANICAL HEATMETERS

Honeywell y All rights reserved 7 EN0H-2601GE25 R0413

Dimensions

Table 2. Dimensions threaded versions

Table 3. Dimensions flanged versions

NOTE: All dimensions in mm unless stated otherwise.

Length L2 is approximate and varies depending on type of fitting used

Weight is without fittings or any other accessories

Fig. 8. Dimensions DN15…DN20 Fig. 9. Dimensions DN25…DN40

DN Length

L

Length

L2

Meter

thread

Height

H

Height

H1

Diameter

B

Weight

15 110 190 G3/4" B 20 75 63 0.9 kg

20 130 210 G1" B 20 75 63 1 kg

25 260 378 G11/4" B 45 110 63 2.9 kg

40 300 438 G2" B 60 125 63 5.1 kg

Fig. 10. Dimensions DN50…DN100

DN Length

L

Height

H

Height

H1

Flange ∅

D

Bolt ∅

D1

Bolt circle

∅ D1

Weight

50 270 85 125 165 18 125 14 kg

65 300 97 125 185 18 145 18 kg

80 300 102 160 200 18 160 24 kg

100 360 113 170 220 18 180 28 kg

Page 8

EW447-EW452 SERIES MECHANICAL HEATMETERS

EN0H-2601GE25 R0413 8 Honeywell y All rights reserved

ORDERING DETAILS

Ordering Information

Table 4. Standard Configurations

Table 5. Special Configurations

OS-No.:

Item DN size Flowrate qp Length for heating only for heating and

chilled water

EW447-452 Series without interfaces

Threaded

connections

15 0.6 m³/h 110 mm EW447A0100 EW450A0100

15 1.5 m³/h 110 mm EW447A1200 EW450A1200

20 2.5 m³/h 130 mm EW447A2000 EW450A2000

25 3.5 m³/h 260 mm EW448A2800 EW451A2800

25 6.0 m³/h 260 mm EW448A3600 EW451A3600

40 10 m³/h 300 mm EW448A4600 EW451A4600

Flanged

connections

50 15 m³/h 270 mm EW449A5100 EW452A5100

65 25 m³/h 300 mm EW449A5900 EW452A5900

80 40 m³/h 300 mm EW449A6900 EW452A6900

100 60 m³/h 360 mm EW449A7700 EW452A7700

EW447 and 450 Series with RF onboard

Threaded

connections

15 15 m³/h 110 mm EW447F1200 EW450F1200

EW447-452 Series with M-Bus interface

Threaded

connections

15 0.6 m³/h 110 mm EW447M0100 EW450M0100

15 1.5 m³/h 110 mm EW447M1200 EW450M1200

20 2.5 m³/h 130 mm EW447M2000 EW450M2000

25 3.5 m³/h 260 mm EW448M2800 EW451M2800

25 6.0 m³/h 260 mm EW448M3600 EW451M3600

40 10 m³/h 300 mm EW448M4600 EW451M4600

Flanged

connections

50 15 m³/h 270 mm EW449M5100 EW452M5100

65 25 m³/h 300 mm EW449M5900 EW452M5900

80 40 m³/h 300 mm EW449M6900 EW452M6900

100 60 m³/h 360 mm EW449M7700 EW452M7700

EW447-452 Series with pulse output

Threaded

connections

15 0.6 m³/h 110 mm EW447P0100 EW450P0100

15 1.5 m³/h 110 mm EW447P1200 EW450P1200

20 2.5 m³/h 130 mm EW447P2000 EW450P2000

25 3.5 m³/h 260 mm EW448P2800 EW451P2800

25 6.0 m³/h 260 mm EW448P3600 EW451P3600

40 10 m³/h 300 mm EW448P4600 EW451P4600

Flanged

connections

50 15 m³/h 270 mm EW449P5100 EW452P5100

65 25 m³/h 300 mm EW449P5900 EW452P5900

80 40 m³/h 300 mm EW449P6900 EW452P6900

100 60 m³/h 360 mm EW449P7700 EW452P7700

OS-Number

Item DN size Flowrate qp Length for heating only for heating and

chilled water

For fallpipe installation, with M-Bus interface

Threaded

connections

25 3.5 m³/h 135 mm EW6001FM2500

For riser installation, with M-Bus interface

Threaded

connections

25 6.0 m³/h 135 mm EW6001RM3300

40 10 m³/h 150 mm EW6001RM4200

Page 9

EW447-EW452 SERIES MECHANICAL HEATMETERS

Honeywell y All rights reserved 9 EN0H-2601GE25 R0413

Scope of Delivery

• EW447-452 Series mechanical meter consisting of energy calculator and flow sensor

• Supply and return temperature sensors installed to energy calculator

• One or two installation kits EWA3001305 for pipe installation of temperature sensors:

• DN15…20: one kit included (one sensor is already installed in meter housing)

• DN25…50: two kits included

• DN65 and larger: no kits included as immersion pockets are to be used

• Two paper sealings

• Operating and setup instructions

• M-Bus cable (only types with M-Bus)

• Pulse cable (only types with pulse output)

Accessories

Unless stated otherwise accessories are sold in single packs. Table 6 below shows which connection set and ball valve can be

used for which meter size. The meter size is given in the top line and refers to the last four characters of the OS number.

Example: Items listed in the column headed ‘2000’ can be used for ‘EW447A2000’, EW447P2000’ or ‘EW450M2000’ and so on.

Table 6. Cross reference: connection sets and ballvalves / meter

EW4xxX… 0100, 1200 2000 2800, 3600 4600

DN size DN15 DN20 DN25 DN40

Connection size G 3/4” G 1” G 1 1/4” G 2”

Connection sets

Connection set with

externally threaded

tailpiece

1 x EWA1500035 1 x EWA1500042 1 x EWA1500062 1 x EWA1500072

Connection set with

internally

threaded tailpiece

2 x VA7405A015 2 x VA7405A020 2 x VA7405A025 n.a.

Connection set with

Sanpress crimp fitting

2 x VA7404A015 2 x VA7404A020 2 x VA7404A025 n.a.

Connection set with

Mapress crimp fitting

2 x VA7403A015 2 x VA7403A020 2 x VA7403A025 n.a.

Ball valves

Ball valve with additional

port

EWA087HY003 EWA087HY004 EWA087HY005 n.a.

Page 10

EW447-EW452 SERIES MECHANICAL HEATMETERS

Honeywell y All rights reserved 10 EN0H-2601GE25 R0413

Connection Sets for Flow Sensor

NOTE: Union nuts of connection sets EWA15000 are drilled

for sealing with locking wire. Union nuts of connection

sets VA7403, VA7404 and VA7405 are not sealable

with locking wire

Connection Sets for Temperature Sensors

Modules

Other Accessories

Set of two union nuts, two sealings and two externally

threaded brass tailpieces (one pack per meter required) –

sealable with locking wire

For DN15, R1/2” x G3/4” EWA1500035

For DN20, R3/4” x G1” EWA1500042

For DN25, R1” x G1 1/4” EWA1500062

For DN40, R1 1/2” x G2” EWA1500072

Set of union nut, sealing and Sanpress red bronze crimp

fitting (two packs per meter required)

For DN15, for 15mm pipe-Ø VA7404A015

For DN15, for 18mm pipe-Ø VA7404A018

For DN20, for 22mm pipe-Ø VA7404A020

For DN25, for 28mm pipe-Ø VA7404A025

Set of union nut, sealing and Mapress stainless steel

crimp fitting (two packs per meter required)

For DN15, for 15mm pipe-Ø VA7403A015

For DN15, for 18mm pipe-Ø VA7403A018

For DN20, for 22mm pipe-Ø VA7403A020

For DN25, for 28mm pipe-Ø VA7403A025

Set of union nut, sealing and internally threaded red

bronze tailpiece (two packs per meter required)

For DN15, thread Rp1/2” VA7405A015

For DN20, thread Rp3/4” VA7405A020

For DN25, thread Rp1” VA7405A025

Temperature sensor installation kit (bulk pack of 20pcs)

Brass, max. 130°C EWA3001303

Plastic, max. 90°C EWA3001305

Tailpiece for direct connection of temperature sensor to

T-piece with 1/2” internal thread. Temperature sensor

installation kit required

R1/2" external thread,

M10x1 sensor thread

EWA087HY003

R1/4" external thread,

M10x1 sensor thread

EWA354830

Ballvalve with direct connection for temperature sensor.

Temperature sensor installation kit required

DN15, G1/2” internal thread EWA087HY004

DN20, G 3/4” internal thread EWA087HY005

DN25, G1”internal thread EWA087HY006

Brass immersion pockets

35mm, for DN25…32 EWA3002684

52mm, for DN40…65 EWA3002685

85mm, for DN80…100 EWA3004406

Ballvalve with connection for supply temperature sensor

G1/2" internal thread EWA087HY004

G3/4" internal thread EWA087HY005

G1" internal thread EWA087HY006

Tailpiece for connection of supply temperature sensor

R1/2" external thread,

M10x1 sensor thread

EWA087HY003

Brass immersion pocket (for use with MID meters)

35mm, for DN15...32 EWA3002684

52mm, for DN40...65 EWA3002685

85mm, for DN80...125 EWA3004406

External RF module

M-Bus, for all EW773 with

M-Bus module

EW9100AEZ001

M-Bus cable, length=3m

For all EW4xxM EWA812851

Bluetooth optohead

For all EW447-452 EWA3001799

Calibration certificates

For up to five meters EWA3003095A

For six to 20 meters EWA3003095B

For more than 20 meters EWA3003095C

Page 11

EW447-EW452 SERIES MECHANICAL HEATMETERS

Honeywell y All rights reserved 11 EN0H-2601GE25 R0413

DIAGRAMS

Measuring Accuracy

Fig. 11. EW447 and EW450 Series

Fig. 12. EW448 and EW451 Series

Fig. 13. EW449 and EW452 Series

Q1 Q2 Q3

-7

-6

-5

-4

-3

-2

-1

0

1

2

3

4

5

6

7

Flow rate [m

3

/h]

Error [%]

Q1 Q2 Q3

-7

-6

-5

-4

-3

-2

-1

0

1

2

3

4

5

6

7

Flow rate [m

3

/h]

Error [%]

Q1 Q2 Q3

-7

-6

-5

-4

-3

-2

-1

0

1

2

3

4

5

6

7

Flow rate [m

3

/h]

Error [%]

Page 12

EW447-EW452 SERIES MECHANICAL HEATMETERS

Flow Diagram

Fig. 14. Pressure drop diagram EW447-EW452 Series

100

2 4 5 6 7 8 1000

kg/h

Flow rate

9

0.25

0.50.028

0.10

5.0l/sec

3 2 4 5 6 7 8 100009324563 7 8 10000092

1.0

2. 25

10

1

0

0

0

1

0

0

2

3

4

5

6

7

8

9

1

0

0

0

0

2

3

4

5

6

Pressure loss

1

0

P

a

m

b

a

r

qp 2.5 qp 3.5 qp 6 qp 10 qp 15 qp 25 qp 40 qp 60qp 1.5qp 0.6

Environmental and Combustion Controls

Honeywell GmbH

Hardhofweg

74821 MOSBACH

GERMANY

Phone: +49 (6261) 810

Fax: +49 (6261) 81393

http://ecc.emea.honeywell.com

EN0H-2601GE23 R0413

April 2013 (Rev. E)

© 2013 Honeywell International Inc.

Subject to change without notice

Manufactured for and on behalf of the Environmental and Combustion

Controls Division of Honeywell Technologies Sàrl, Z.A. La Pièce 16,

1180 Rolle, Switzerland or its Authorized Representative.

Loading...

Loading...