Page 1

DT8012F4 / DT8012F5 DUAL TEC® Motion Sensor – Installation Instructions

QUICK LINKS

Mounting Location Guidelines

Open the Sensor

Mount the Sensor

Sensor Components and Settings

Wire the Sensor

Walk Test the Sensor

Detection Patterns

Relay Operation

Troubleshooting

Sensor Specifications

Accessories

Approval Listings

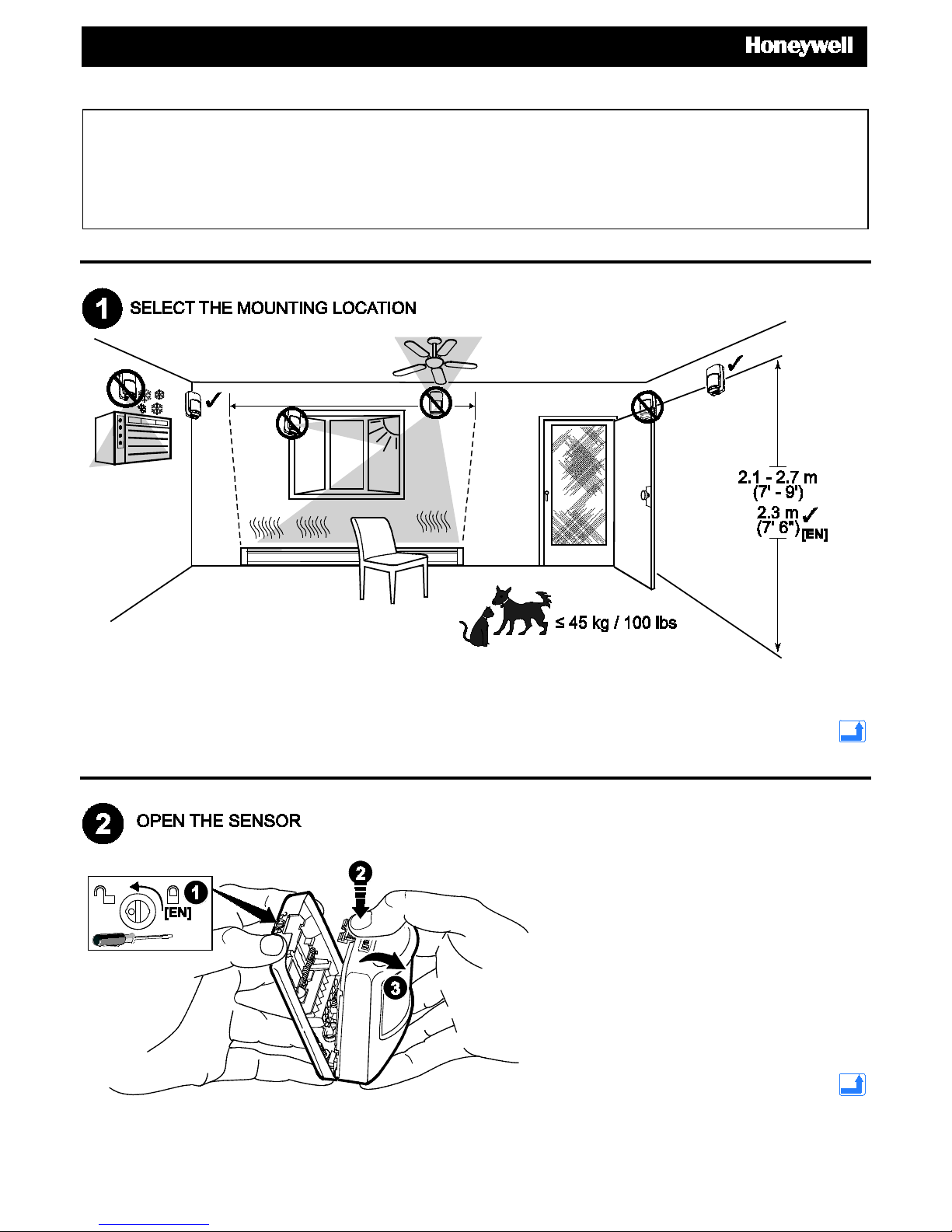

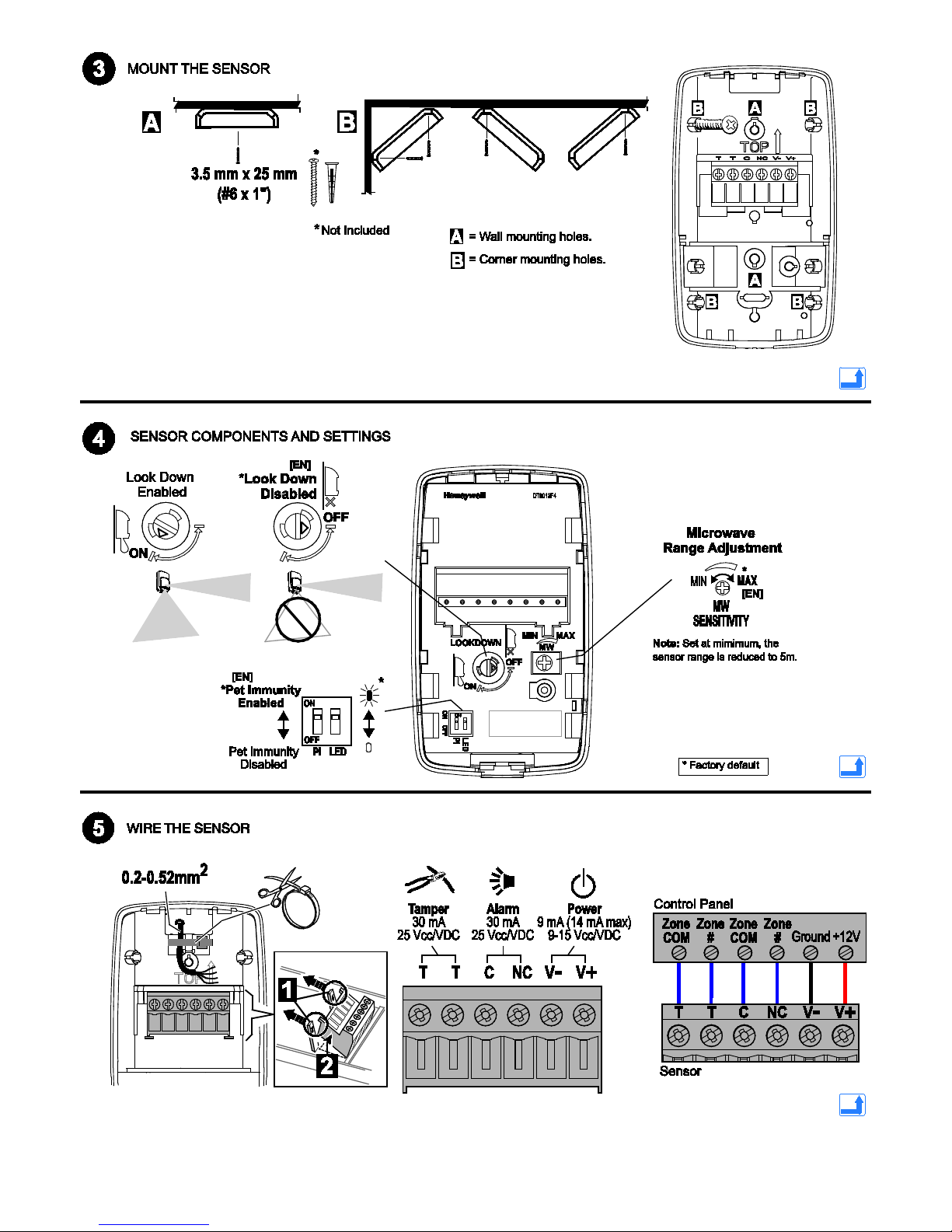

Mounting location guidelines:

• The optimal range is obtained at a mounting height of 2.3 m (7’ 6”).

• Allow a clear line-of-sight to all areas to protect.

• Do not directly face windows.

• Avoid close proximity to moving machinery, fluorescent lights and heating/cooling sources.

• For use in applications with pets up to 45 kilograms (100 pounds).

1. Turn the arrow to point to the Unlock symbol.

2. Press firmly on housing latch.

3. Gently separate the front and rear housing.

[EN] = approved installation.

Page 2

- 2 -

Page 3

- 3 -

LED

Power

Up

Walk Test Normal Trouble

Red

Slow

Blink

ON

Alarm

ON

Alarm

Fast

Blink

Yellow OFF

ON

Microwave

ON

Microwave

OFF

Green OFF

ON

PIR

ON

PIR

OFF

Zones

A

2

Look-down

B

18

Lower

C

46 Intermediate

D

36 Long

1. Close the sensor and apply power to the sensor. Initialization is complete

when the LED stops flashing slowly (about 30 seconds).

2. Walk through the detection area and observe the LED.

3. Adjust the microwave range as necessary to meet installation requirements.

Walk test mode is active for 10 minutes, then automatically exits test mode, disables the LED and enters normal

operation mode. For an additional 10 minute walk test, enable walk test mode again with the flashlight feature:

Note: During power up and walk test modes the LED is active regardless of the LED Enable/Disable DIP switch setting.

Flashlight Feature:

1. Use a flashlight with a bright light beam, and stand within 1.2 m (4’) of the sensor.

2. Swing the light beam past the sensor lens 3-5 times, holding the beam on the lens

for 0.5 second each pass.

The flashlight feature is only available for the first 24 hours after the first power up.

Page 4

REL AY OPER ATION

SENSOR STATUS

Normal

Intrusion

Trouble1

Alarm Relay

Closed

Open

Open

1

For information on Trouble conditions, see the Troubleshooting section.

TROUBLESHOOTING

TROUBLE*

NORMAL

Self-Test Failure1

Alarm Relay

Closed

Open

Red LED

Off

Flashing

*TROUBLE CONDITIONS:

1

Self-Test Failure conditions:

• Microwave supervision failure: The sensor is operating in PIR mode only.

• PIR self-test failure: The sensor is disabled.

• Temperature compensation failure: The temperature compensation is

disabled.

Depending on the Trouble condition, take the following corrective actions:

• Verify the power s upply is sufficient (at least 9V at the sensor).

• Cycle power to the sensor.

• Walk test the sensor.

If the Trouble condi tion does not clear, replace the sensor.

SPECIFICATIONS

Range: 12 m x 17 m

Power: 9.0 - 15 VDC; 9 mA typical, 14 mA maximum, 12 VDC;

AC Ripple: 3 V peak-to-peak at nominal 12 VDC

Alarm Relay: Energized Form A; 30 mA, 25 VDC, 22 Ohms

resistance maximum. Alarm Relay Duration: 3 seconds

Tamper: Cover; (NC with cover installed) Form A; 30 mA, 25 VDC;

Magnetic field

Microwave Frequencies: DT8012F4 – 10.525 GHz

DT8012F5 – 10.587 GHz

RFI Immunity: 20V/m 10-1000MHz, 15V/m 1000-2700MHz

PIR White Light Immunity: 10,000 Lux typical

Fluorescent light filter: 50 Hz / 60 Hz.

Operating Temperature: -10° to 55° C / 14° to 131° F

Relative Humidity: 5 to 95%; non-condensing

Temperature Compensation: Advanced Dual Slope

Dimensions: 9.8 cm H x 5.7 cm W x 4.35 cm D /

4.57” H x 2.76” W x 1.69” D

Weight: 96 g / 3.38 oz (net weight)

ACCESSORIES*

SMB-10

(P/N 0-000-110-01)

Swivel Mount Bracket

SMB-10C

(P/N 0-000-111-01)

Swivel Mount Ceiling Bracket

SMB-10T

(P/N 0-000-155-01)

Swivel Mount Bracket w/Tamper

* Accessories are not covered by certifications.

APPROVAL LISTINGS

EN50131-2-4:2008, Security Grade 2,

Environmental Class II.

Suitable for connection to an EN 60950 Class II

Limited Power Source.

Note: In EN 50131-2-4 compliant installations, mount the sensor at 2.3m,

disable look down, enable pet immunity, set the microwave sensitivity

to maximum and lock the sensor housing with the cover lock (see

“[EN]” where note d in Steps 1-4).

IMPORTAN T: The sensor should be tested at least once each year.

NF&A2P 2 boucliers (référentiel NF324-H58)

et conforme aux normes EN50131-2-4 et

RTC50131-2-4; IP30 IK04

DT8012F4 – N° de certificat: 2821420019

DT8012F5 – N° de certificat: 2821420019

Organisme de certification:

CNPP Cert. : www.cnpp.com et

AFNOR Cert.: www.marque-nf.com

Honeywell Security Group - BP1219

1198 avenue du docteur Maurice Donat

Sophia Antipolis

06254 Mougins Cedex.

TEL: +33.4.92.94.29.50

FAX: +33.4.92.94.29.60

DT8012F4

INCERT B-893-0014

DT8012F5

PD6662:2010

LARMKLASS 2

For any additional information, please refer to our Website:

http://www.honeywell.com/security/emea/hscdownload

Or contact:

Honeywell Security Group

Newhouse Industrial Estate

Motherwell

Lanarkshire ML1 5SB

United Kingdom

Please contact your local authorised Honeywell representative for product warranty information

2014 Honeywell International Inc. Honeywell and DUAL TEC are registered trademarks of Honeywell International Inc.

All other trademarks are the properties of their respective owners. All rights reserved.

P/N 800-16784 Rev A

Tel: +44(0)1698 738200

Email: UK64Sales@Honeywell.com

Corrente norminale: 12 =

Corrente massi ma

assorbita: 14 mA

Loading...

Loading...