Page 1

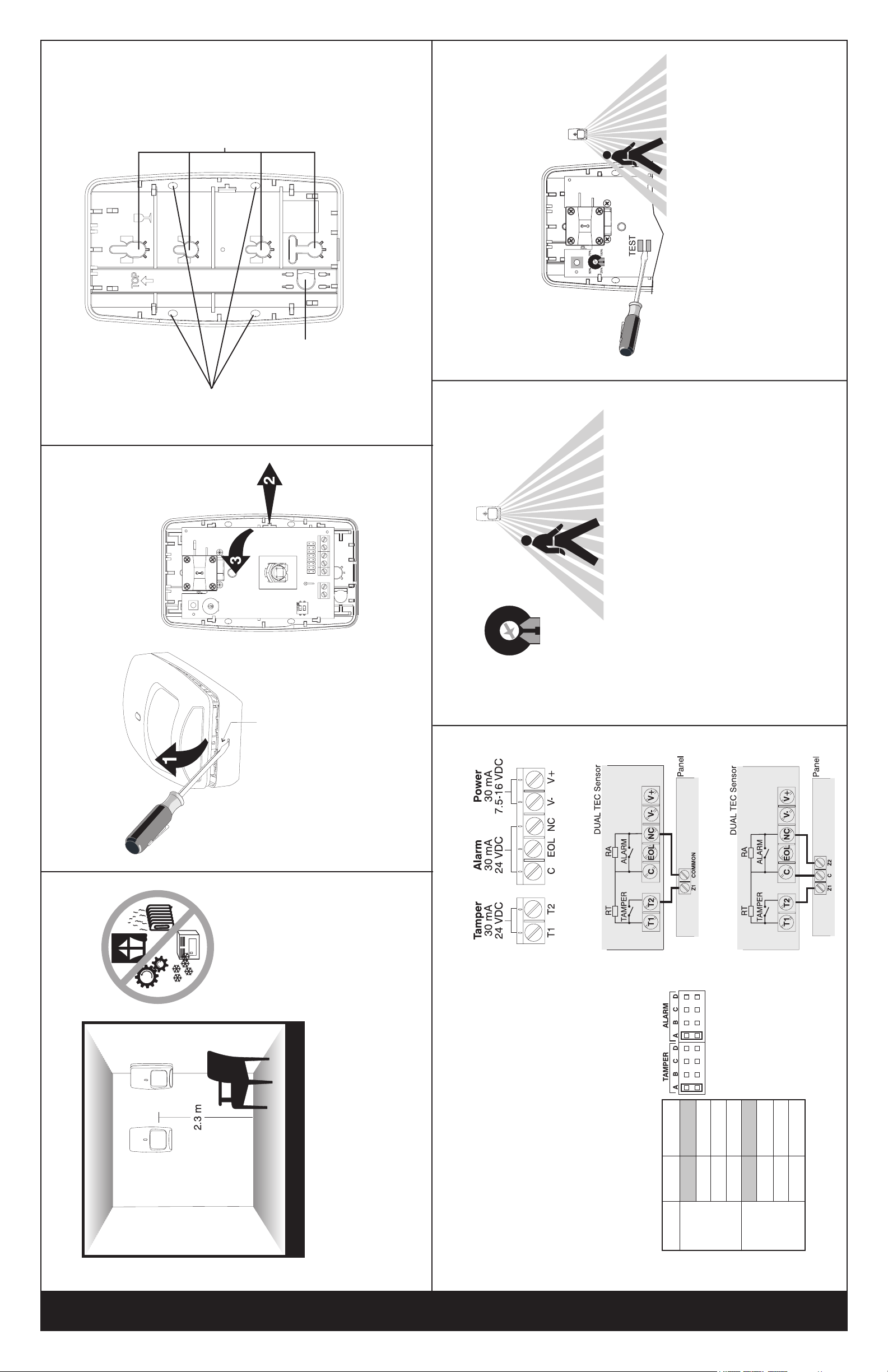

❸ Mount the unit.

Wall Mount

Corner

Mount

Wire Channel

Use the Zone Finder mode to identify the PIR and/or

microwave pattern. In Zone Finder mode the red LED is

disabled.

❺b Optional: Walk-test using Zone Finder.

the back housing.

• Slide the wire through the wire channel and wire access in

• Mount the back housing flat against a wall or in a corner.

• Replace the PCB.

- green for one second for every PIR detection;

• Use a screwdriver to short the test pads.

- yellow for two seconds for every microwave detection.

• During the Zone Finder walk-test mode, the LED turns:

• Adjust the microwave range as necessary.

• Zone finder mode times out after ten minutes.

Note: The cover

screw, when used,

is installed here.

❷ Separate the sensor housings and remove the printed

circuit board (PCB).

75%

50%

100%25%

LED stops flashing slowly.

turning the range adjustment counterclockwise using a small

• Apply power to the unit. Initialization is complete when the

screwdriver.

• Adjust the microwave range to minimum setting (25%) by

• Replace the front housing.

• Begin walking through the detection area.

❺a Walk-test the sensor.

housings.

• Use a small screwdriver to unfasten the housing latch. Gently pull apart the

• Push outward on the PCB latch and lift the PCB out of the housing.

- The LED will turn red, indicating an alarm detection.

obtained.

• Increase the microwave range as necessary.

• Repeat the items in step 5a until proper detection range is

❶ Select the mounting location.

wire size.

2

Observe proper polarity.

Mounting Location Guidelines

• 2.3 m mounting height

• Avoid direct or reflected sunlight

• Aim sensor away from windows or heating/cooling devices

• Sensor must have a clear line-of-sight to protected area

• Connect wires as shown using 0.2 - 1.3 mm

❹ Wire the unit.

Alarm and Tamper configured to one loop.

1K

2.2K

A

B

Position EOL Value

proper EOL selection.

loop wiring diagrams on the right).

alarm pin options (see table below).

Notes:

jumpers from all pins.

1. Connect the sensor to the panel (see one and two

• If not using the integrated EOL resistors, remove

• If using the integrated EOL resistors:

2. Place the jumpers on the appropriate tamper and

• Consult the Control Panel manual to determine

EOL settings.

• Fit only one jumper each for the tamper and alarm

Jumper

EOL Settings

TAMPER

Alarm and Tamper configured to two loops.

4.7K

5.6K1K2.2K

C

D

(RT)

A

4.7K

B

C

(RA)

ALARM

5.6K

D

Factory default settings are shown in grey.

Motion Sensor Installation Instructions

®

DT7450UK2 DUAL TEC

Page 2

Long Range Curtain Lens Kit (P/N DT7000-LRLK)

SMB-10 Swivel Mount Bracket

SMB-10T Swivel Mount Bracket w/Tamper

Accessories:

Optional Lens Kit -

Mounting Brackets -

PRODUCT SPECIFICATIONS

Range:

15 m x 18 m

Alarm relay:

Energized Form A

30 mA, 24 VDC,

SMB-10C Swivel Mount Ceiling Bracket

(P/N 0-000-110-01)

(P/N 0-000-155-01)

(P/N 0-000-111-01)

TS 50131-2-4 Compliant Accessories:

SMB-10T Swivel Mount Bracket w/ Tamper

40 Ohms resistance maximum

Tamper switch:

(NC) 30 mA, 24 VDC

Power requirements:

7.5 - 16 VDC

25 mA typical, 30 mA maximum,

PD6662

EN 50131-1 and TS 50131-2-4 Security Grade 2,

Environmental Class II.

Suitable for connection to an EN 60950 Class II

Limited Power Source.

Note: In TS 50131-2-4 compliant installations:

mount the sensor at 2.3 m, select the high

sensitivity setting, and install a cover screw

(included).

To obtain applicable EU compliance Declaration of

(P/N 0-000-155-01)

Long Range Curtain Lens Kit (P/N DT7000-LRLK)

Approvals/listings:

CE

F)

o

F to +131

o

C (14

o

C to +55

o

12 VDC nominal

Microwave frequencies:

24.200 GHz

PIR white light immunity:

6,500 Lux typical

Fluorescent light filter:

50 Hz

Operating temperature:

-10

5 - 95% relative humidity (non-condensing)

(Indoor use environment)

Conformities for this product, please refer to our

Temperature Compensation:

Advanced dual slope.

Website, http://www.security.honeywell.com/hsce/

international/index.html. For any additional

information regarding the compliance of this

product to any EU specific requirements, please

contact:

Quality Assurance Department,

Honeywell Security & Custom Electronics,

Newhouse Industrial Estate

Motherwell,

Lanarkshire ML1 5SB,

Scotland,

United Kingdom.

Self-tests:

Microwave Supervision

PIR Self-Test

Temperature Compensation

PIR fields-of-view:

High Security Lens

22 long range edges

12 intermediate edges

6 lower edges

4 look-down edges

Weight:

174 g;

Packaged Product Approx.: 213 g

Tel: +44(0)1698 738200

Email: UK64Sales@Honeywell.com.

Dimensions:

11.9 cm H x 7.1 cm W x 4.2 cm D

Sensitivity:

High (Pulse Count 1) 1 - 2 steps

Low (Pulse Count 2) 3 - 4 steps

Please contact your local authorised Honeywell

representative for product warranty information.

DETECTION PATTERNS

Top View

Wide Angle Lens

Maximum Detection Pattern

Minimum Detection Pattern

Side View

ON

OFF

Zone Finder

Fast

Blink

Slow

Blink

ON

Alarm

Red

OFF

OFF

ON

Yellow

Fault

OPERATION MODE

Power Up

Normal

LED

LED INDICATORS

ON

PIR

Microwave

OFF

OFF

ON

PIR

Microwave

Green

ON

LED enabled

High Sensitivity

(Pulse Count 1)

OFF

LED disabled

Low Sensitivity

(Pulse Count 2)

1

2

Switch

DIP SWITCH SETTINGS (SW1)

Factory default settings are shown in grey.

TROUBLESHOOTING

Problem: Red LED is flashing rapidly.

Explanation: The sensor is in one of three conditions:

Microwave supervision failure: The sensor continues operating using

PIR as the only detection method. When detection occurs on the PIR

channel, the alarm relay will latch open until the Microwave fault is

removed.

PIR self-test failure: Alarm relay does not actuate.

Temperature compensation failure: When alarm occurs, the alarm relay

will latch open until the fault is cleared.

Solution: Power down the sensor or enter zone finder mode which will

perform self-test. If the fault does not clear, replace the sensor.

Motion Sensor Product Information

®

DT7450UK2 DUAL TEC

© 2008 Honeywell International Inc. • Honeywell, IntelliSense and DUAL TEC are registered trademarks of Honeywell International Inc.

All other trademarks are the properties of their respective owners. All rights reserved. Made in China

800-02414 Rev B

Loading...

Loading...