Honeywell DS06-100-SUS-LF, DS06-101-SUS-LF, DS06-102-SUS-LF, DS06-103-SUS-LF, DS06-104-SUS-LF Installation Manual

...Page 1

33-00014EF-07

DS06 Low Lead Content

Dial Set Pressure Regulating

Valves

INSTALLATION INSTRUCTIONS

APPLICATION

The Honeywell DS06 Dial Set® Pressure Regulating

Valve is a high quality pressure regulating valve that

maintains a constant outlet pressure over a wide

range of inlet supply pressures. It is suitable for

potable water and irrigation applications. The

downstream pressure adjustment dial eliminates the

need for a pressure gauge when adjusting the

pressure setting (static pressure only).

SPECIFICATIONS

Model: DS06 Dial Set Pressure Regulating Valves.

Construction Materials:

Body: Brass.

Internal Parts: Stainless steel and engineered

plastics.

Regulator Mechanism: Fabric-reinforced diaphragm.

Seat Design: Balanced single seat construction.

Inlet Pressure (Maximum): 250 psi maximum.

Reduced Pressure Range:

25 to 90 psi (1/2 in. to 2 in.).

Outlet Pressure: Factory set at 60 psi (414 kPa).

Dial Calibration: ± 4 psi.

Differential: 14.5 psi minimum (inlet to outlet).

Fluid Temperature (Maximum):

Water: 140° F (60° C).

Ambient Temperature Range: 33° F to 140° F (1° C

to 60° C).

Pipe Sizes Available: 1/2 in., 3/4 in., 1 in., 1-1/4 in.,

1-1/2 in. and 2 in. available.

Connections:

Can be configured as female thread-by-thread,

single- or double-union, NPT threaded or sweat.

Low Lead Content: < 0.25% Lead.

Gauge Tap: 1/4" NPT.

Approvals:

ASSE 1003 Listed

CSA Certified

IAPMO/UPC Listed

NSF 61 Compliant

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to

follow them could damage the product or cause

a hazardous condition.

2. Check the ratings given in these instructions

and on the product to make sure the product is

suitable for your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out the

product operation as provided in these

instructions.

Page 2

DS06 LOW LEAD CONTENT DIAL SET PRESSURE REGULATING VALVES

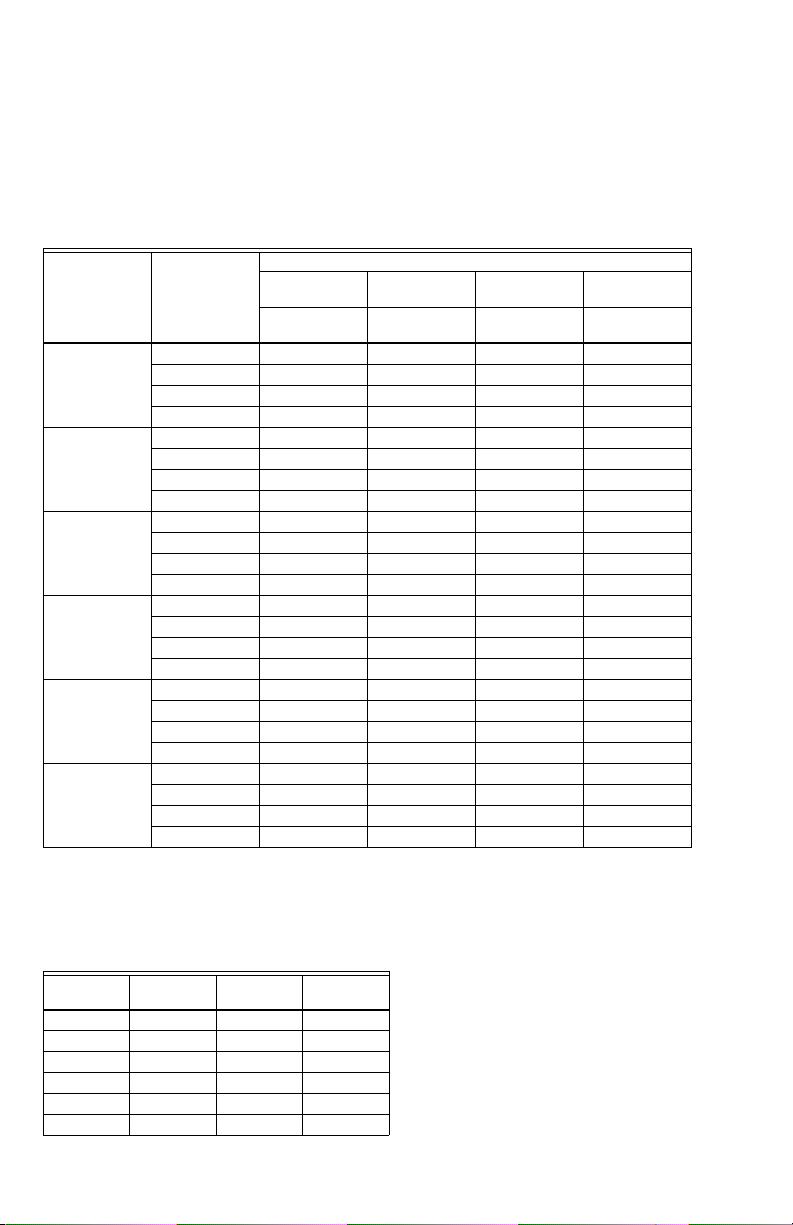

Water Capacities

The suitability of a given regulator size is dependent

on the pressure requirements where it will operate. For

the pressure regulator valve size required for a specific

installation, determine the following:

1. Pressure differential between inlet and outlet

pressure in pounds per square inch (psi),

2. Capacity in gallons per minute, and

Table 1. Water Capacities.

Pressure Differential Between Inlet and Outlet

Pressure

Regulator

Valve Siz e

1/2" 6 7.26 8.15 7.44 6.47

3/4" 6 11.98 14.44 14.53 14.97

1" 6 11.18 11.23 9.51 9.11

1-1/4" 6 7.53 6.34 7.26 7.13

1-1/2" 6 29.81 32.27 30.87 26.81

2" 6 27.34 25.8 24.48 18.01

Reduced

Pressure

Falloff (PSI)

10 10.7 10.66 9.69 8.85

15 14.27 15.72 14.49 13.96

20 17.74 19.59 18.98 18.1

10 17.17 21.05 25.23 26.33

15 19.86 25.14 29.32 32.85

20 21.27 26.42 30.42 33.82

10 18.01 18.98 17.39 16.78

15 25.67 28.14 28.71 26.9

20 30.69 34.7 36.19 35.05

10 20.25 17.88 15.15 14

15 33.02 34.87 32.63 29.68

20 40.07 44.29 46.01 34.61

10 46.14 50.02 49.89 47.82

15 66.22 78.42 86.74 84.14

20 77.14 92.29 103.82 109.68

10 64.81 97.61 78.15 90.09

15 82.82 105.14 119.94 129.62

20 87.66 107.83 120.95 132.09

25 psi 50 psi 75 psi

Flow Capacity

(US gpm)

3. Allowable reduced pressure falloff in psi. Given

these variables, use Table 1 to determine the

proper size pressure regulator valve for your

application.

Example: An installation has 135 psi inlet pressure,

60 psi outlet pressure (75 psi pressure differential). If

a 15 gpm capacity is required with only 10 psi falloff

allowable, a 3/4 in. DS06 is required.

Flow Capacity

(US gpm)

Flow Capacity

(US gpm)

Flow Capacity

100 psi or

more

(US gpm)

DSO6 Fixture Unit

Flow rates based on submittal sheet DS06, based on

flush tank systems with a 15 psi fall-off defined by

IAPMO/ANSI UPC 1-2009.

Table 2.

Size I/s GPM

1/2” 0.99 15.72 21

3/4” 1.58 25.14 40

1” 1.77 28.14 48

1-1/4” 2.19 34.87 70

1-1/2” 4.93 78.42 270

2” 6.61 105.14 400

33-00014EF—07 2

Fixture

Units

Capacities are based on a 100 psi supply pressure and

a difference of 50 psi or more between the initial

supply pressure and the reduced no-flow pressure.

Check local water pressures before selection.

Procedure

1. Flush the system clear of sediment or debris.

2. Close the supply valve and downstream isolating

valve (if one is installed).

3. Install the DS06 with the arrow on the body

pointing in the direction of water flow. Install,

preferably, in horizontal pipework with filter bowl

downwards - vertical installation also possible.

The DS06 can be installed directly onto the pipe by

using the female NPT threads on each end. If space

limitations restrict turning the DS06, install single- or

double-unions.

Page 3

DS06 LOW LEAD CONTENT DIAL SET PRESSURE REGULATING VALVES

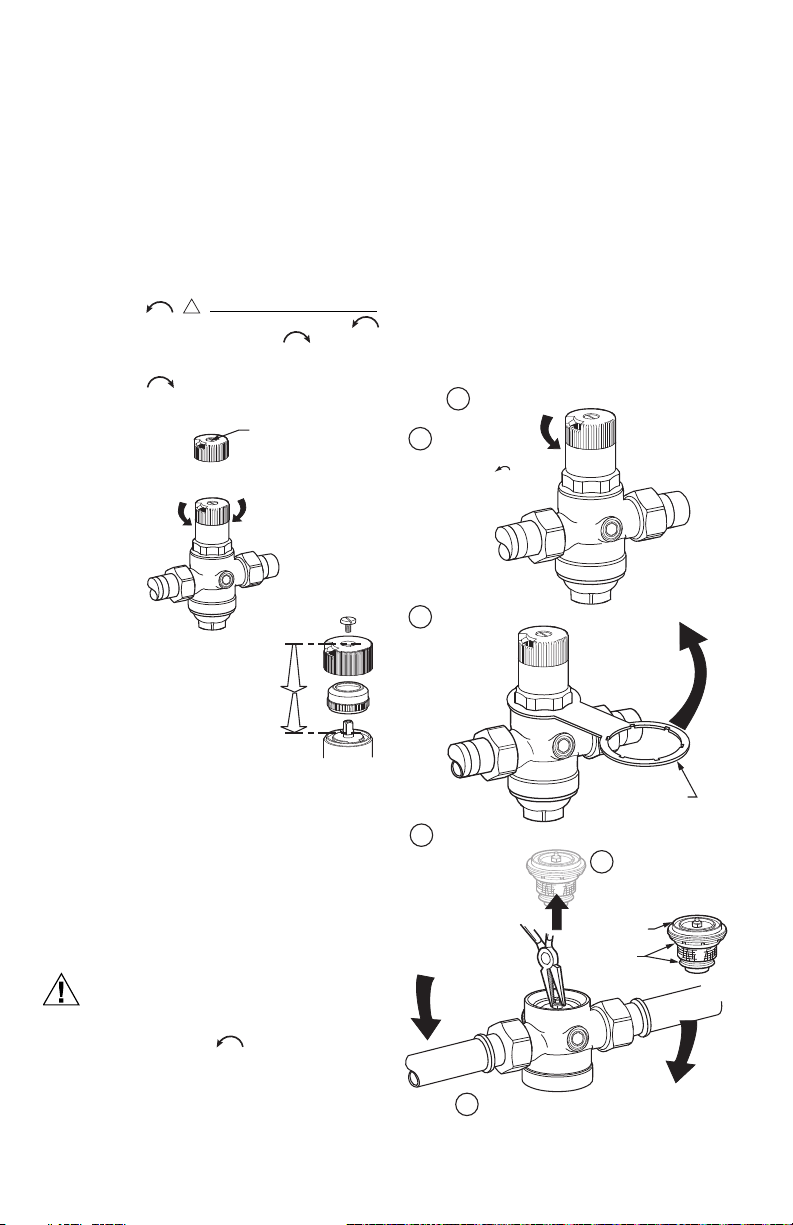

CAUTION

!

LOOSEN LOCKING

SCREW ONE TURN

ADJUST SETPOINT AT THE DESIRED VALUE BY ACTUATING SELECTOR.

INLET PRESSURE (MAXIMUM): 250 PSI

REDUCED PRESSURE RANGE:

25 TO 90PSI 1/2 IN. TO 2 IN. SIZE

NOTE: DO NOT DISMANTLE KNOB

SET-POINT READOUT HAS BEEN CALIBRATED

IN THE FACTORY AND SET AT 60 PSI.

DISMANTLING THE SELECTOR KNOB WILL

CANCEL THIS CALIBRATION. RECALIBRATE

USING A PRESSURE GAUGE. SEE RECALIBRATION.

M35046A

3

M35634A

1

4

6

2

LOOSEN THE SETPOINT DIAL LOCKING SCREW.

UNSTRESS THE

PRESSURE SPRING

BY TURNING COUNTERCLOCKWISE .

UNSCREW THE BONNET WITH A 1-5/8" WRENCH.

REMOVE CARTRIDGE USING A PLIERS AS A LEVER.

REASSEMBLE BONNET IN REVERSE ORDER.

1-5/8" WRENCH

O-RINGS

WASHER

(LIP UP)

5

WHEN REASSEMBLING,

ENSURE O-RINGS AND

WASHER ARE PROPERLY

INSTALLED

NOTE: Heat from soldering can damage internal

parts of the DS06. Always solder the tailpieces

separately from the DS06.

4. Open the supply valve slowly and check for

leakage and proper operation of the DS06.

Changing the Downstream Pressure (See Fig. 1)

Remove the dust cap from the DS06. The DS06 is

factory set to 60 psi.

To adjust the outlet pressure to a desired setting:

1. Loosen the locking screw by turning counter-

clockwise (Do not remove this screw.)

2. Turn the adjusting knob counter-clockwise

to reduce pressure or clockwise to

increase pressure.

3. Lock the setting by turning the locking screw

clockwise .

4. Replace the dust cap over the dial.

8. Remove cartridge using a pliers as a lever.

9. Reassemble bonnet in reverse order.

Recalibrate

If the dial knob assembly has been disassembled

recalibration is necessary.

1. Close shutoff valve on inlet.

2. Release pressure on outlet side (e.g. through

water tap).

3. Close shutoff valve on outlet.

4. Remove dust cap.

5. Loosen slotted screw (do not remove screw).

6. Fit pressure gauge.

7. Slowly open shutoff valve on inlet.

8. Set desired outlet pressure (e.g. 60 psi).

9. Align scale (e.g. 60 psi) in middle of viewing win-

dow.

10. Retighten slotted screw.

11. Slowly open shutoff valve on outlet.

Fig. 1. Changing outlet pressure.

Replacing the Cartridge (Fig. 2)

The working parts of the DS06, including diaphragm,

valve seat, strainer, and disk are all contained in a

replaceable cartridge. To replace the cartridge:

1. Close shutoff valve on inlet.

2. Release pressure on outlet side (e.g. through

water tap).

3. Close shutoff valve on outlet.

4. Loosen slotted screw (do not remove the screw).

To prevent injury and/or equipment damage,

loosen locknut and turn adjusting screw

counter-clockwise to remove spring

tension.

5. Slacken tension in compression spring by

turning counter clockwise until it does not move

anymore.

6. Unscrew Bonnet.

7. Remove slip ring.

Fig. 2. Replacing the DS06 cartridge.

3 33-00014EF—07

Page 4

DS06 LOW LEAD CONTENT DIAL SET PRESSURE REGULATING VALVES

Cleaning

1. Close shutoff valve on inlet.

2. Release pressure on outlet (e.g. through water

tap).

3. Close shutoff valve on outlet.

4. Unscrew filter bowl using a 1-5/8" wrench.

5. Remove filter, clean and reinsert.

6. Place O-ring onto filter bowl.

7. Screw in filter cup hand-tight.

8. Slowly open shutoff valve on inlet.

9. Slowly open shutoff valve on outlets.

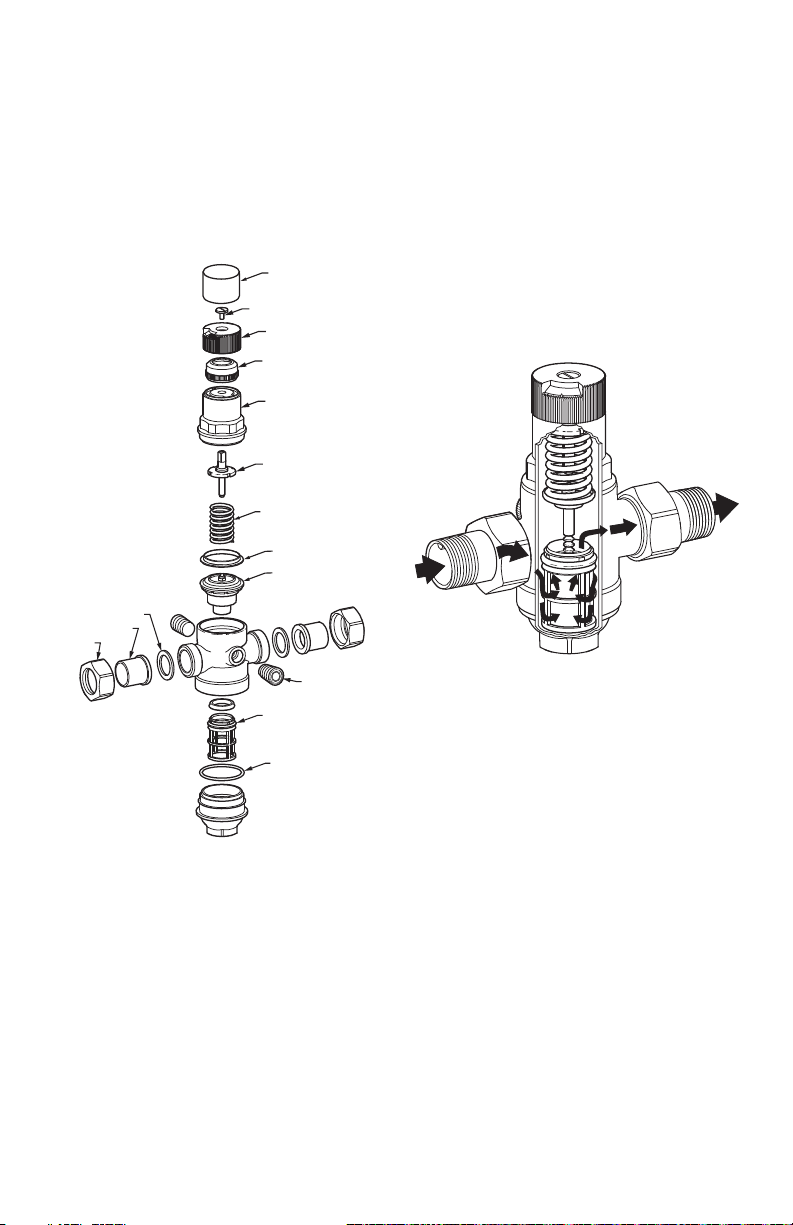

DUST CAP

(BLACK)

LOCKING SCREW

ADJUSTING

KNOB

DIAL RING

BONNET

SPINDLE

SPRING

WASHER

CARTRIDGE

GASKETS (2)

TAILPIECES (2)

NUTS

(2)

PLUGS (2)

REPLACEMENT

FILTER

OPERATION

DS06 is a spring loaded pressure reducing valve that

operates by means of force equalizing system. The

force of a diaphragm operates against the force of an

adjustment spring. If the outlet pressure and therefore

diaphragm force fall because water is dawn, the then

greater force of the spring causes the valve to open.

The outlet pressure then increases until the forces

between the diaphragm and the spring are equal

again. The inlet pressure has no influence in either

opening or closing the valve. Because of this, inlet

pressure fluctuation does not influence the outlet

pressure, thus providing inlet pressure balancing. See

Fig. 4 for the internal construction of the DS06.

NOTE: Minimum ambient rating is 33° F (1° C).

4

M35052

Fig. 4. Internal construction of DS06.

O-RING SET

FOR DO6F

M35053A

Fig. 3. DS06 exploded view.

33-00014EF—07 4

Page 5

DS06 LOW LEAD CONTENT DIAL SET PRESSURE REGULATING VALVES

TROUBLESHOOTING

Table 3 provides a troubleshooting guide for the DS06 Dial Set Pressure Regulating Valve.

Table 3. Troubleshooting the DS06 Dial Set Pressure Regulating Valve.

Problem Cause Remedy

Beating Sounds. Pressure reducing valve is too large. Refer to capacities table to find correct

Water is escaping from the

spring bonnet.

Too little or no water pressure. Shutoff valves up- or downstream of

The outlet pressure set does

not remain constant.

Diaphragm in valve insert is faulty. Replace valve insert.

the pressure reducing valve are not

fully open.

Pressure reducing valve is not set to

the desired outlet pressure.

Filter in pressure reducing valve is

contaminated.

Pressure reducing valve is not fitted in

flow direction.

Filter in pressure reducing valve is

contaminated or worn.

Valve insert, sealing ring or edge of

nozzle is contaminated or worn.

Rising pressure on outlet (e.g. in

boiler).

valve size.

Open the shutoff valves fully.

Set outlet pressure.

Clean or replace filter.

Fit pressure reducing valve in flow

direction. (Note direction of arrow on

housing.)

Clean or replace filter.

Replace valve insert.

Check check valve, safety group etc.

5 33-00014EF—07

Page 6

DS06 LOW LEAD CONTENT DIAL SET PRESSURE REGULATING VALVES

A

DS06 LOW-LEAD REPLACEMENT PARTS

Table 4. Replacement Parts.

Number Part# Sizes Part Description

1 D06FA-1/2 1/2" & 3/4" Valve Insert

D06FA-1B 1" & 1-1/4"

D06FA-1 1/2 1-1/2" & 2"

2 ES06F-1/2A 1/2" & 3/4" Replacement Filter

ES06F-1B 1" & 1-1/4"

ES06F-1 1/2A 1-1/2" & 2"

3 SB06T-1/2 1/2" & 3/4" Black Filter Bowl

SB06T-1 1" & 1-1/4"

SB06T-1 1/2 1-1/2" & 2"

Complete without

Filter

Insert

with O-Ring

1

2

DS06 LOW-LEAD ACCESSORY

Table 5. Accessories.

Part # Size Part Description

K06U1069/U 1/2" Union kit for 1/2-in. NPT

K06U1077/U 3/4" Union kit for 3/4-in. NPT

K06U1085/U 1" Union kit for 1-in. NPT valves.

K06U1135/U 1-1/4" Union kit for 1-1/4-in. NPT

K06U1037/U 1-1/2" Union kit for 1-1/2-in. NPT

K06U1045/U 2" Union kit for 2-in. NPT valves.

K06U1093/U 1/2" Union kit for 1/2-in. sweat

K06U1101/U 3/4" Union kit for 3/4-in. sweat

K06U1119/U 1" Union kit for 1-in. sweat

K06U1143/U 1-1/4" Union kit for 1-1/4-in. sweat

K06U5034/U 1-1/2" Union kit for 1-1/2-in. sweat

K06U5042/U 2" Union kit for 2-in. sweat

valves. Includes union nut,

threaded tailpiece, and gasket

valves. Includes union nut,

threaded tailpiece, and gasket

Includes union nut, threaded

tailpiece, and gasket

valves. Includes union nut,

threaded tailpiece, and gasket

valves. Includes union nut,

threaded tailpiece, and gasket

Includes union nut, threaded

tailpiece, and gasket

valves. Includes union nut,

sweat tailpiece, and gasket

valves. Includes union nut,

sweat tailpiece, and gasket

valves. Includes union nut,

sweat tailpiece, and gasket

valves. Includes union nut,

sweat tailpiece, and gasket

valves. Includes union nut,

sweat tailpiece, and gasket

valves. Includes union nut,

sweat tailpiece, and gasket

3

M35570

Fig. 5. Replacement Parts.

By using this Honeywell literature, you agree that Honeywell will have no liability for any damages arising out of

your use or modification to, the literature. You will defend and indemnify Honeywell, its affiliates and subsidiaries,

from and against any liability, cost, or damages, including attorneys’ fees, arising out of, or resulting from, any

modification to the literature by you.

Home and Building Technologies

In the U.S.:

Honeywell

1985 Douglas Drive North

Golden Valley, MN 55422-3992

customer.honeywell.com

® U.S. Registered Trademark

© 2017 Honeywell International Inc.

33-00014EF—07 M.S. Rev. 03-17

Printed in United States

Page 7

33-00014EF-07

Régulateurs de pression Dial

Set à faible teneur en plomb

DS06

NOTICE D'INSTALLATION

APPLICATION

Le régulateur de pression Dial Set® DS06 de

Honeywell est un régulateur de pression de qualité

supérieure maintenant une pression de sortie

constante sur une large plage de pressions d'entrée. Il

est adapté aux applications à l'eau potable et

d'irrigation. Le cadran de réglage de pression

descendante élimine le besoin d'un manomètre lors

de l'ajustement de la pression (pression statique

uniquement).

CARACTÉRISTIQUES

Modèle : Régulateurs de pression Dial Set DS06.

Matériaux de construction :

Corps : laiton.

Pièces internes : Acier inoxydable et plastiques

techniques.

Mécanisme de régulation : Membrane renforcée de

tissu.

Conception du siège : Construction à siège unique

équilibré.

Pression d'entrée (maximum) : 250 psi maximum.

Plage de pression réduite :

25 à 90 psi (1/2 po à 2 po).

Pression de sortie : Réglée en usine à 60 psi

(414 kPa).

Étalonnage du cadran : ± 4 psi.

Pression différentielle : 14,5 psi minimum

(entrée à sortie).

Température de fluide (maximum) :

Eau : 60°C (140°F).

Plage de température ambiante : 1°C à 60°C (33°F

à 140°F).

Tailles de conduits disponibles : 1/2 po, 3/4 po,

1 po, 1-1/4 po, 1-1/2 po et 2 po disponibles.

Connexions :

Peut être configuré avec filetage femelle, raccord

simple ou double, à filetage NPT ou à souder.

Faible teneur en plomb : < 0,25 % de plomb.

Prise de manomètre : 1/4 po NPT.

Homologations :

Répertorié ASSE 1003

Certification CSA

Répertorié IAPMO/UPC

Conformité NSF 61

INSTALLATION

Lors de l'installation du produit...

1. Lire attentivement ces instructions. Le non-

respect des instructions peut endommager le

produit ou provoquer une situation dangereuse.

2. Vérifier les caractéristiques nominales

indiquées dans cette notice et sur le produit

pour s'assurer que le produit correspond bien à

l'application prévue.

3. L'installateur doit être un technicien

expérimenté ayant reçu la formation adéquate.

4. Une fois l'installation terminée, vérifier que le

produit fonctionne comme indiqué dans cette

notice.

Capacités en eau

L'applicabilité d'une taille de régulateur donnée

dépend des exigences de pression de l'application.

Pour obtenir la taille du régulateur requise pour une

installation spécifique, il faut déterminer les points

suivants :

1. Pression différentielle entre l'entrée et la sortie

en psi (lb/po2),

2. Capacité en gallons par minute, et

3. Affaiblissement de pression réduite permis en

psi. En fonction de ces variables, utiliser le Tableau 1 pour déterminer la taille du régulateur de

pression correspondant à l'application.

Exemple : Une installation comporte une pression

d'entrée de 135 psi, une pression de sortie de 60 psi

(différentiel de 75 psi). Si une capacité de 15 gal./min

est requise avec un affaiblissement permis de 10 psi

uniquement, un régulateur DS06 de 3/4 po est

requis.

Page 8

RÉGULATEURS DE PRESSION DIAL SET À FAIBLE TENEUR EN PLOMB DS06

Tableau 1. Capacités en eau.

Pression différentielle entre l'entrée et la sortie.

Taille du

régulateur de

pression

1/2 po 6 7,26 8,15 7,44 6,47

3/4 po 6 11,98 14,44 14,53 14,97

1 po 6 11,18 11,23 9,51 9,11

1-1/4 po 6 7,53 6,34 7,26 7,13

1-1/2 po 6 29,81 32,27 30,87 26,81

2 po 6 27,34 25,8 24,48 18,01

Affaiblissement

de pression

réduite (psi)

10 10,7 10,66 9,69 8,85

15 14,27 15,72 14,49 13,96

20 17,74 19,59 18,98 18,1

10 17,17 21,05 25,23 26,33

15 19,86 25,14 29,32 32,85

20 21,27 26,42 30,42 33,82

10 18,01 18,98 17,39 16,78

15 25,67 28,14 28,71 26,9

20 30,69 34,7 36,19 35,05

10 20,25 17,88 15,15 14

15 33,02 34,87 32,63 29,68

20 40,07 44,29 46,01 34,61

10 46,14 50,02 49,89 47,82

15 66,22 78,42 86,74 84,14

20 77,14 92,29 103,82 109,68

10 64,81 97,61 78,15 90,09

15 82,82 105,14 119,94 129,62

20 87,66 107,83 120,95 132,09

25 psi 50 psi 75 psi 100 psi ou plus

Débit

(gal. US/min)

Débit

(gal. US/min)

Débit

(gal. US/min)

(gal. US/min)

Débit

Appareil de plomberie DSO6

Les débits sont déterminés par les renseignements du

formulaire de soumission DS06n en fonction des

systèmes de vidange avec affaiblissement de 15 psi

défini par IAPMO/ANSI UPC 1-2009.

Tableau 2.

Taill e I/s gal./min

1/2 po 0,99 15,72 21

3/4 po 1,58 25,14 40

1 po 1,77 28,14 48

1-1/4 po 2,19 34,87 70

1-1/2 po 4,93 78,42 270

2 po 6,61 105,14 400

Les capacités sont basées sur une pression

d'alimentation de 100 psi et une différence de 50 psi

ou plus entre la pression d'alimentation initiale et la

pression débit nul réduite.

Contrôler les pressions d'eau locales avant la

sélection.

33-00014EF—07 8

Appareil de

plomberie

Procédure

1. Purger le système de tout sédiment ou débris.

2. Fermer le robinet d'arrivée et le robinet

d'isolement en aval (le cas échéant).

3. Installer le DS06 avec la flèche sur le corps

pointant dans la direction du débit d'eau.

Installer de préférence dans une tuyauterie

horizontale avec la cuve du filtre vers le bas.

L'installation verticale est également possible.

Le DS06 peut être installé directement sur le conduit

en utilisant un filetage NPT femelle à chaque

extrémité. Si des restrictions au niveau de l'espace

empêchent de tourner le DS06, installer des raccords

simples ou doubles.

REMARQUE : La chaleur dégagée par le soudage peut

4. Ouvrir lentement le robinet d'arrivée et vérifier

endommager les pièces internes du

DS06. Toujours souder les embouts

séparément du DS06.

qu'il n'y a pas de fuites et que le DS06 fonctionne

correctement.

Page 9

RÉGULATEURS DE PRESSION DIAL SET À FAIBLE TENEUR EN PLOMB DS06

MISE EN GARDE

!

MF35046A

DÉVISSER D’UN TOUR

LA VIS DE BLOCAGE

RÉGLER LE POINT DE CONSIGNE À LA VALEUR

DÉSIRÉE À L’AIDE DU SÉLECTEUR.

PRESSION D’ENTRÉE (MAXIMUM) : 250 PSI

PLAGE DE PRESSION RÉDUITE :

25 À 90PSI 1/2 PO À 2 PO DIMENSION

REMARQUE: NE PAS DÉMONTER

LE BOUTON

LE POINT DE CONSIGNE A ÉTÉ RÉGLÉ

ET ÉTALONNÉ EN USINE À 60 PSI.

LE BOUTON DE SÉLECTION NE SERA

PLUS ÉTALONNÉ S’IL EST DÉMONTÉ.

POUR L’ÉTALONNER DE NOUVEAU,

UTILISER UN MANOMÈTRE. VOIR

LA SECTION ÉTALONNAGE.

3

MF35634A

1

4

6

2

5

DÉVISSER LA VIS DE BLOCAGE DU POINT DE CONSIGNE.

RELÂCHER

LA PRESSION

DU RESSORT EN

FAISANT TOURNER

DANS LE SENS

ANTIHORAIRE .

RETIRER LA CARTOUCHE EN SE SERVANT DE DEUX

TOURNEVIS COMME LEVIERS

REMETTRE LE CHAPEAU EN PLACE DANS L’ORDRE INVERSE.

RONDELLE

(LÈVRE VERS

LE HAUT)

AU MOMENT DE RÉ-ASSEMBLER

LE TOUT, S’ASSURER QUE LES

JOINTS TORIQUES ET

LA RONDELLE SONT

BIEN PLACÉS.

DÉVISSEZ LE CHAPEAU AVEC UNE CLÉ DE 1-5/8 PO.

CLÉ DE 1-5/8 PO

Modification de la pression descendante (Voir la Fig. 1)

Retirer le bouchon antipoussière du DS06. Le DS06

est réglé en usine à 60 psi.

Pour régler la pression de sortie à un réglage désiré:

1. Desserrer la vis de verrouillage en la tournant

dans le sens antihoraire (Ne pas la

retirer.)

2. Tourner le bouton de réglage dans le sens

antihoraire pour réduire la pression ou

dans le sens horaire pour l'augmenter.

3. Verrouiller le réglage en tournant la vis de

verrouillage dans le sens horaire .

4. Replacer le bouchon antipoussière sur le cadran.

8. Retirer la cartouche en se servant d'une pince

comme un levier.

9. Réinstaller le chapeau dans le sens inverse.

Réétalonner

Si le bouton du cadran a été retiré, un réétalonnage est

nécessaire.

1. Fermer le robinet d'arrêt sur l'arrivée.

2. Dissiper la pression sur la sortie (par exemple

par le robinet).

3. Fermer le robinet d'arrêt sur la sortie.

4. Retirer le bouchon antipoussière.

5. Desserrer la vis fendue (sans la retirer).

6. Installer le manomètre.

7. Ouvrir lentement le robinet d'arrêt sur l'arrivée.

8. Régler à la pression de sortie désirée (par exem-

ple 60 psi).

9. Aligner l'échelle (par exemple 60 psi) au milieu

du regard.

10. Resserrer la vis fendue.

11. Ouvrir lentement le robinet d'arrêt sur la sortie.

Fig. 1. Modification de la pression de sortie.

Remplacement de la cartouche (Voir la Fig. 2)

Les pièces actives du DS06, y compris la membrane, le

siège de vanne, le tamis et le disque, sont toutes

contenues dans une cartouche remplaçable. Pour

remplacer la cartouche:

1. Fermer le robinet d'arrêt sur l'arrivée.

2. Dissiper la pression sur la sortie (par exemple

par le robinet).

3. Fermer le robinet d'arrêt sur la sortie.

4. Desserrer la vis fendue (sans la retirer).

Pour éviter les blessures et/ou les dégâts

matériels, desserrer l'écrou de blocage et

tourner la vis de réglage dans le sens

antihoraire pour dissiper la tension du

ressort.

5. Réduire la tension dans le ressort de

compression en le tournant dans le sens

antihoraire jusqu'à ce qu'il ne bouge plus

6. Dévisser le chapeau.

7. Retirer la bague collectrice.

Fig. 2. Remplacement de la cartouche DS06.

9 33-00014EF—07

Page 10

RÉGULATEURS DE PRESSION DIAL SET À FAIBLE TENEUR EN PLOMB DS06

BOUCHON

ANTIPOUSSIÈRE (NOIR)

TIGE

RESSORT

RONDELLE

CARTOUCHE

FILTRE DE RECHANGE

ENSEMBLE DE JOINTS

TORIQUES POUR DO6F

BOUCHONS (2)

ÉCROUS (2)

EMBOUTS (2)

JOINTS (2)

CHAPEAU

BAGUE DE CADRAN

BOUTON DE RÉGLAGE

VIS DE VERROUILLAGE

MF35053A

Nettoyage

1. Fermer le robinet d'arrêt sur l'arrivée.

2. Dissiper la pression sur la sortie (par exemple

par le robinet).

3. Fermer le robinet d'arrêt sur la sortie.

4. Dévisser la cuve du filtre à l'aide d'une clé

de 1-5/8 po.

5. Retirer le filtre, le nettoyer et le réinsérer.

6. Placer le joint torique sur la cuve du filtre.

7. Visser la cuve du filtre à la main.

8. Ouvrir lentement le robinet d'arrêt sur l'arrivée.

9. Ouvrir lentement le robinet d'arrêt sur la sortie.

FONCTIONNEMENT

Le modèle DS06 est un régulateur de pression à

ressort qui fonctionne par le biais d'un système

d'égalisation des forces. La force de la membrane agit

contre la force du ressort de réglage. Si la pression de

sortie, et en conséquence la membrane, forcent la

chute puisque de l'eau est tirée, la force supérieure du

ressort cause l'ouverture de la vanne. La pression de

sortie augmente ensuite jusqu'à ce que la force entre

la membrane et le ressort soit de nouveau égale. La

pression d'entrée n'a aucune influence sur l'ouverture

ou la fermeture de la vanne. En conséquence, les

fluctuations de la pression d'entrée n'influencent pas

la pression de sortie, fournissant ainsi une pression

d'entrée équilibrée. Voir la Fig. 4 pour la construction

interne du DS06.

REMARQUE : La température ambiante nominale

minimum est 1°C (33 °F).

4

M35052

Fig. 4. Construction interne du DS06.

Fig. 3. Vue éclatée du DS06.

33-00014EF—07 10

Page 11

RÉGULATEURS DE PRESSION DIAL SET À FAIBLE TENEUR EN PLOMB DS06

DÉPANNAGE

Le Tableau 3 fournit un guide de dépannage du régulateur de pression Dial Set® DS06.

®

Tableau 3. Dépannage du régulateur de pression Dial Set

Problème Cause Solution

Sons de battements. Le régulateur de pression est trop

De l'eau s'échappe du chapeau

à ressort.

Pression d'eau insuffisante ou

absente.

La pression de sortie n'est pas

constante.

grand.

La me mbrane dans l'inse rt de la van ne

est défectueuse.

Les robinets en amont ou en aval du

régulateur de pression ne sont pas

complètement ouverts.

Le régulateur de pression n'est pas

réglé à la pression de sortie désirée.

Le filtre dans le régulateur de pression

est contaminé.

Le régulateur de pression n'est pas

installé dans la direction du débit.

Le filtre dans le régulateur de pression

est contaminé ou usagé.

L'insert de la vanne, la bague

d'étanchéité ou le bord de la buse sont

contaminés ou usagés.

Augmenter la pression sur la sortie

(par exemple sur la chaudière).

Consulter le tableau des capacités

pour déterminer la taille correcte.

Remplacer l'insert de la vanne.

Ouvrir complètement les robinets

d'arrêt.

Régler la pression de sortie.

Nettoyer ou remplacer le filtre.

Installer le régulateur de pression

dans la direction du débit. (Noter la

direction de la flèche sur le boîtier.)

Nettoyer ou remplacer le filtre.

Remplacer l'insert de la vanne.

Vérifier la vanne, le groupe de sécurité,

etc.

DS06.

11 33-00014EF—07

Page 12

RÉGULATEURS DE PRESSION DIAL SET À FAIBLE TENEUR EN PLOMB DS06

A

DS06 PIÈCES DE RECHANGE À FAIBLE TENEUR EN PLOMB

Tableau 4. Pièces de rechange.

NoNo pièce Formats

1 D06FA-1/2 1/2 po et

D06FA-1B 1 po et

D06FA-1 1/2 1-1/2 po et

2ES06F-1/2A 1/2 po et

ES06F-1B 1 po et

ES06F-1 1/2A 1-1/2 po et

3 SB06T-1/2 1/2 po et

SB06T-1 1 po et

SB06T-1 1/2 1-1/2 po et

3/4 po

1-1/4 po

2 po

3/4 po

1-1/4 po

2 po

3/4 po

1-1/4 po

2 po

Description de la

Nécessaire de

mécanisme de vanne

sans filtre

Nécessaire de filtre de

rechange

Filtre de réserv oir noir

avec joint torique

1

2

pièce

ACCESSOIRE À FAIBLE TENEUR EN PLOMB DS06

Tableau 5. Accessoires.

Réf. de pièce Taille Description de la pièce

K06U1069/U 1/2 po Nécessaire de raccordement

K06U1077/U 3/4 po Nécessaire de raccordement

K06U1085/U 1 po Nécessaire de raccordement

K06U1135/U 1-1/4 po Nécessaire de raccordement

K06U1037/U 1-1/2 po Nécessaire de raccordement

K06U1045/U 2 po Nécessaire de raccordement

K06U1093/U 1/2 po Nécessaire de raccordement

K06U1101/U 3/4 po Nécessaire de raccordement

K06U1119/U 1 po Nécessaire de raccordement

K06U1143/U 1-1/4 po Nécessaire de raccordement

K06U5034/U 1-1/2 po Nécessaire de raccordement

K06U5042/U 2 po Nécessaire de raccordement

pour vannes 1/2 po NPT. Inclut

écrou-union, embout fileté et

joint.

pour vannes 3/4 po NPT. Inclut

écrou-union, embout fileté et

joint.

pour vannes 1 po NPT. Inclut

écrou-union, embout fileté et

joint.

pour vannes 1-1/4 po NPT.

Inclut écrou-union, embout

fileté et joint.

pour vannes 1-1/2 po NPT.

Inclut écrou-union, embout

fileté et joint.

pour vannes 2 po NPT. Inclut

écrou-union, embout fileté et

joint.

pour vannes à raccord à souder

1/2 po. Inclut écrou-union,

embout à souder et joint.

pour vannes à raccord à souder

3/4 po. Inclut écrou-union,

embout à souder et joint.

pour vannes à raccord à souder

1 po. Inclut écrou-union,

embout à souder et joint.

pour vannes à raccord à souder

1-1/4 po. Inclut écrou-union,

embout à souder et joint.

pour vannes à raccord à souder

1-1/2 po. Inclut écrou-union,

embout à souder et joint.

pour vannes à raccord à souder

2 po. Inclut écrou-union,

embout à souder et joint.

3

M35570

Fig. 5. Pi

èces de rechange.

Home and Building Technologies

Aux États-Unis :

Honeywell

1985 Douglas Drive North

Golden Valley, MN 55422

customer.honeywell.com

® Marque de commerce déposée aux États-Unis

© 2017 Honeywell International Inc.

33-00014EF—07 M.S. Rev. 03-17

Imprimé aux États-Unis

Loading...

Loading...