Page 1

Models DR4200, DR4300, and

DR4500 Recorders

Replacement Instruction

Chart Hub Kit (30756150-001)

Document Number Form: 44-45-33-60C

Effective: 6/07

Supersedes: 7/00

Kit Contents This Chart Hub Replacement Kit contains the following parts:

Description Quantity

• Allen wrench 1, 5 mm

• Chart hub ass’y, tamper resist.

• Chart hub ass’y, large diam.

• Compression spring

• Chart hub ass’y, small diam.

Summary Enclosed is a new chart hub kit with parts required to replace the chart

1

1

1

1

1

hub in a DR4200, DR4300, or DR4500 recorder. Use the following

procedures, as appropriate, to replace the existing chart hub assembly.

WARNING

Never access components inside the case, or remove or

install any connectors, with power applied.

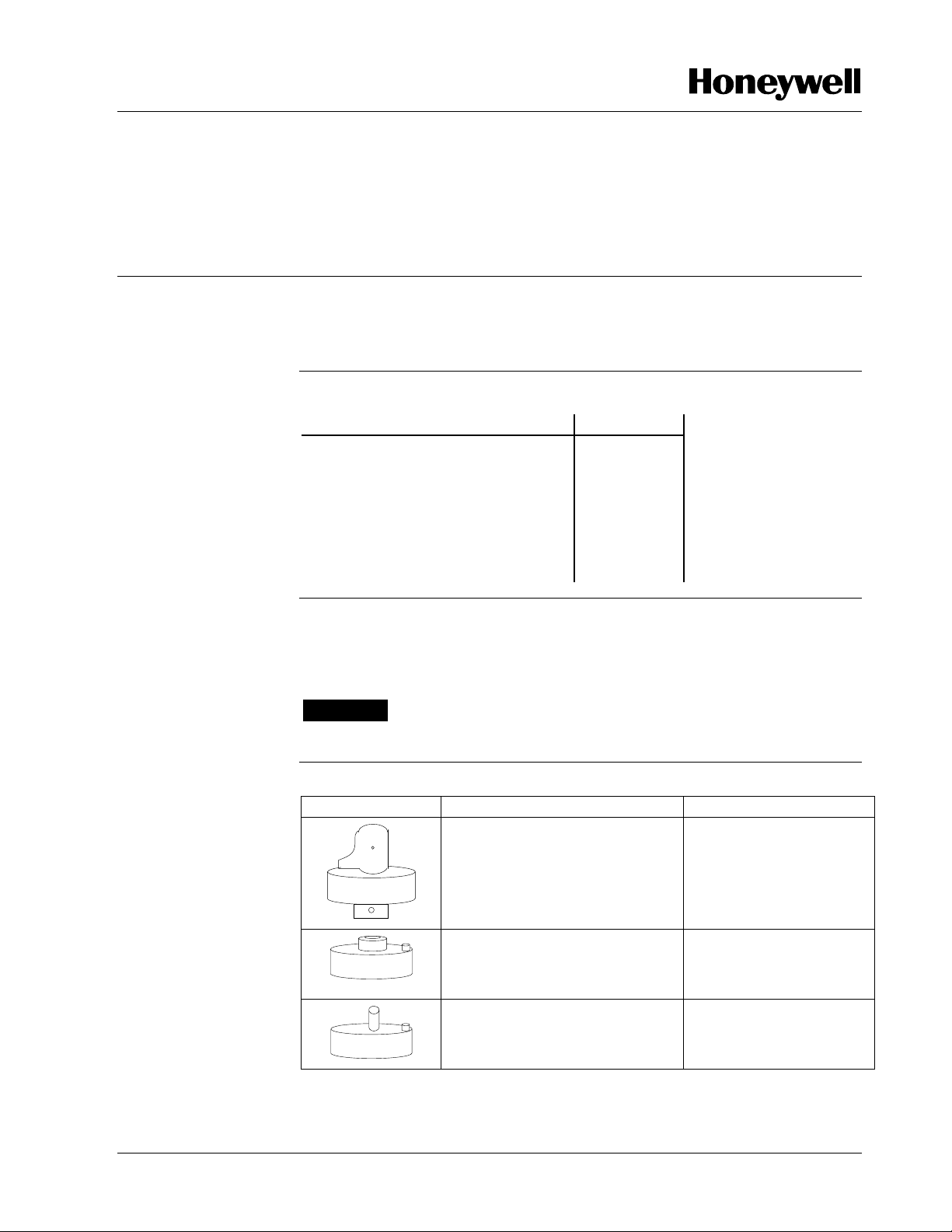

Chart hub types

Chart Hub Type Description How to intall

Hub used with ink pens and

preprinted charts when

approval bodies or process

Slide hub down to

bottom of motor shaft

and tighten set screw.

inspectors require tamper

proof operation.

Standard hub used on all

DR4500/DR4300/DR4200

Push hub onto motor

shaft.

recorders.

Hub used with ink pens and

preprinted charts that have a

small center hole.

44-45-33-60C Page 1 of 4

Push hub onto motor

shaft.

Page 2

Kit Instruction, continued

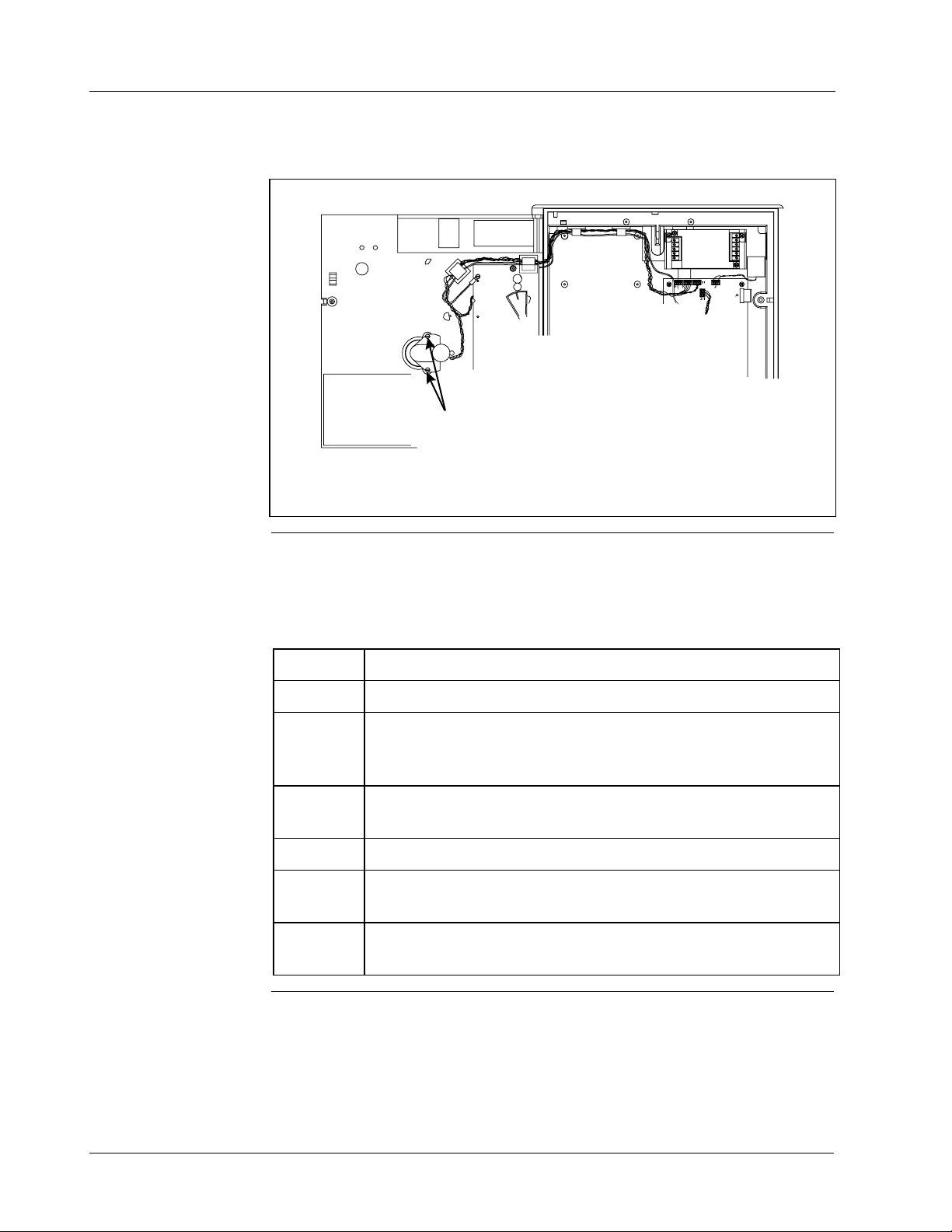

Component Location

for DR4200/DR4300 installation procedure.

Refer to Figure 1 for the component locations and Table 1 for the

Screws

24240

Figure 1 – Component Location

DR4200/DR4300 Follow the procedure in Table 1 to replace the existing chart hub

Procedure assembly in your recorder.

Table 1 –

Chart Hub Assembly Replacement for DR4200/DR4300 Recorders

Step Action

1

2

Open the chart door and swing the chart plate out.

Remove chart hub (front of chart plate) and chart motor (rear

of chart plate) by removing screws. Save screws. Pull hub

off the motor.

3

Select the chart hub from the kit that matches the one you

removed.

4

Attach hub to motor. Refer to chart hub types on page 1.

5

Hold motor in place and adjust chart hub flush with platen

and centered in platen opening.

6

Re-install motor with screws. Ensure that chart hub rotates

freely and does not bind.

Page 2 of 4 44-45-33-60C

Page 3

Component Location

for DR4500 installation procedure.

Refer to Figure 2 for the component locations and Table 2 for the

Kit Instruction, continued

Chart

Hub

Spring

24241

Chart Motor

Figure 2 – Component Location

DR4500 Procedure Follow the procedure in Table 2 to replace the existing chart hub in your

recorder.

Table 2 – Chart Hub Assembly Replacement for DR4500 Recorder

Step Action

1

2

Open the chart door and swing the chart plate out.

Remove chart hub and motor assembly by removing screws.

Save screws. Pull hub off the motor.

3

4

Select the appropriate chart hub from the kit.

For Classic models (DR45A1, DR45A2):

Assemble chart hub to chart motor—no spring is used. See

Chart hub types on page 1.

For Truline models (DR45AT, DR45AR, DR45AW,

DR45AH, DR45AP, DR45AS):

Slip new spring over chart motor shaft before pushing on the

chart hub assembly. See Chart hub types on page 1.

5

Hold motor in place and adjust chart hub flush with platen

and centered in platen opening.

6

Re-install motor with screws. Ensure that chart hub rotates

freely and does not bind.

44-45-33-60C Page 3 of 4

Page 4

Warranty/Remedy

Honeywell warrants goods of its manufacture as being free of defective materials and

faulty workmanship. Contact your local sales office for warranty information. If warranted

goods are returned to Honeywell during the period of coverage, Honeywell will repair or

replace without charge those items it finds defective. The foregoing is Buyer's sole remedy

and is in lieu of all other warranties, expressed or implied, including those of

merchantability and fitness for a particular purpose. Specifications may change

without notice. The information we supply is believed to be accurate and reliable as of this

printing. However, we assume no responsibility for its use.

While we provide application assistance personally, through our literature and the

Honeywell web site, it is up to the customer to determine the suitability of the product in

the application.

Honeywell Field Solutions

Honeywell

512 Virginia Drive

Fort Washington, PA 19034

44-45-33-60C 0700 Printed in USA www.hpsweb/honeywell.com/

Loading...

Loading...