Page 1

3-WIRE DIFFERENTIAL PRESSURE TRANSMITTERS

WITH DIGITAL DISPLAY AND CURRENT/VOLTAGE OUTPUT

GENERAL

The differential pressure transmitters of the DPTM series are

used for measuring differential pressure, positive pressure,

and vacuum. The transmitters are suitable for:

• air-conditioning,

• building automation,

• environmental protection,

• valve and flap control,

• filter and blower monitoring,

• fluid and level monitoring, and

• control of air flows.

Models

order no.

DPTM50D -50...0...+50 Pa1) n.a. 20 kPa 40 kPa

DPTM110D -100...0...+100 Pa1) n.a. 20 kPa 40 kPa

DPTM550D -500...0...+500 Pa1) n.a. 20 kPa 40 kPa

DPTM1100D -1 kPa...0...+1 kPa2) n.a. 40 kPa 70 kPa

DPTM100D 0...100 Pa1) 0...250 Pa1) 20 kPa 40 kPa

DPTM250D 0...250 Pa1) 0...500 Pa1) 20 kPa 40 kPa

DPTM500D 0...500 Pa1) 0...1 kPa1) 20 kPa 40 kPa

DPTM1000D 0...1 kPa2) 0...2.5 kPa2) 40 kPa 70 kPa

DPTM5000D 0...5 kPa3) 0...10 kPa3) 60 kPa 120 kPa

1)

pressure displayed in Pa, temperature error at 0…50 °C ≤ ± 5% of full scale (FS)

2)

pressure displayed in kPa, temperature error at 0…50 °C ≤ ± 2.5% of full scale (FS)

3)

pressure displayed in kPa, temperature error at 0…50 °C ≤ ± 1% of full scale (FS)

pressure range

1 (pre-set) 2

overload

capacity

burst

pressure

DPTM50D-5000D

SPECIFICATION DATA & MOUNTING INSTRUCTIONS

FEATURES

• Monitoring gaseous, non-aggressive media

• Piezo-resistive pressure transducer

• Up to 40 kPa (60 kPa) overload capacity

• Rugged design; protection class IP54

• Easy installation and wiring connection

• Measurement range adjustable by jumper

• Response time adjustable by jumper

• Output signal adjustable by jumper

• Red digital display

• Display of values > +1000 Pa in kPa

• Re-zeroing possible by pushbutton

NOTE: These sensors are not suitable for use in

installations under periodic inspection by the U.S.

Food and Drug Administration.

SPECIFICATION

Supply voltage 18...30 Vac/dc, 50/60 Hz

Output signal 0...10 Vdc (factory setting) /

4…20 mA

Pressure medium Air, non-aggressive gases

Working temperature 0...50 °C

Linearity and hysteresis error ≤ ± 1.0% of FS

Temperature error at 0...50°C See section "Models"

Storage temperature -10...+70 °C

Humidity 0...95% rh, non-condensing

Repetition accuracy ≤ ± 0.2% of FS

Response time 1 s (factory setting) / 100 ms

Process connection 6 mm hose pipe

Electrical connection Screw terminal block for wire

up to 1.5 mm²

Housing material ABS and POM

Cable entry M20x1.5 (polyamide)

Protection class IP54 as per EN60529

EMV EN60770, EN61326

Weight approx. 130 g

® U.S. Registered Trademark EN0B-0616GE51 R1007

Copyright © 2007 Honeywell Inc. • All rights reserved

Page 2

DPTM50D-5000D DIFFERENTIAL PRESSURE TRANSMITTERS WITH CURRENT/VOLTAGE OUTPUT

j

j

A

j

FUNCTION

DPTM50D-5000D Differential Pressure Transmitters are

equipped with an integrated piezo-resistive pressure

transducer. The pressure to be measured is applied to and

thus deflects a thin membrane made of mono-silicon. The

membrane's semiconductor resistors (arranged to simultaneously compensate for the temperature response) detect

this mechanical deflection and generate an electrical output

signal. The output signal is converted into the 0…10 V or

4…20 mA analog signal which changes (within the specified

error limits) in proportion to the applied pressure and is shown

in the LED display.

NOTE: The devices are factory pre-set to pressure range 1.

This can be changed (except for +/- models) to

pressure range 2 by removing the corresponding

jumper (see Fig. 3).

NOTE: The devices are factory pre-set to a response time

of 1 second. This can be changed to 100 ms by

removing the corresponding jumper (see Fig. 3).

NOTE: The devices are factory pre-set to an output signal

of 0…10 V. This can be changed to 4…20 mA by

removing the corresponding jumper (see Fig. 3).

ACCESSORIES

DPSK: Included in delivery. Duct Kit, incl. 2 m of silicone

hose and two joining pipes

DPSL: Ordered separately. L-shaped mounting brackets

with screws.

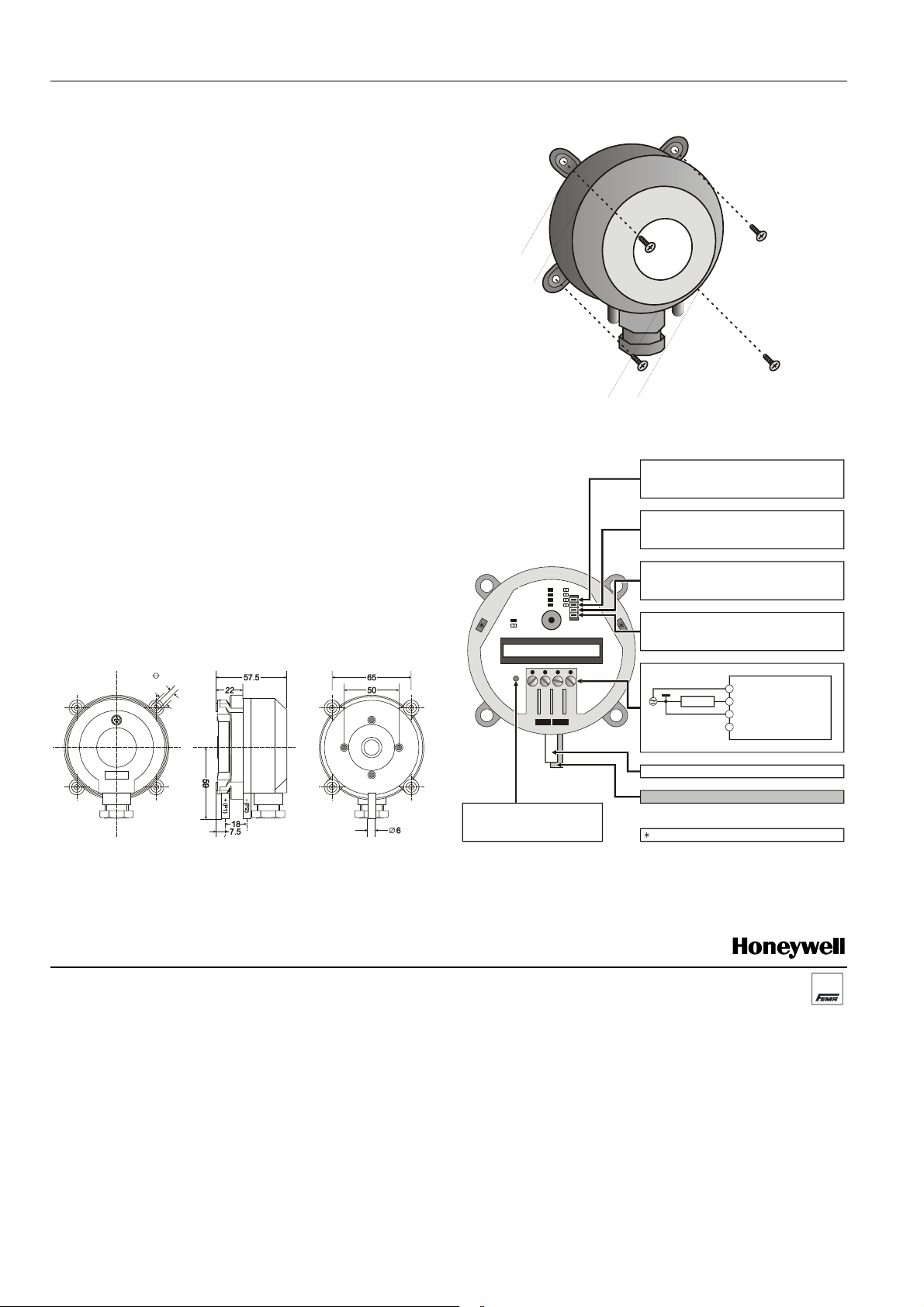

DIMENSIONS

4.5

8.5

MOUNTING

WIRING

Range:

high

low

Response:

fastmAslow

Mode:

Output:

V

Jumper yes

Jumper no

Differential Pressure Transmitter

DIGITAL DISPLAY

2341

Fig. 2. Mounting

PRESSURE RANGE

jumper inserted = pressure range 1

jumper removed = pressure range 2

RESPONSE TIME

umper inserted = 1 sec

umper removed 100 msec=

NOT USED

NALOG OUTPUT

umper inserted = 0...10 V

jumper removed = 4...20 mA

1

2

LOAD

3

4

18...30Vac/dc

0...10 V / 4...20 mA

GROUND

DO NOT USE!

IP 54

Fig. 1. Dimensions (in mm)

REZEROING:

Remove tubes and push

button approx. 5 sec.

Fig. 3. Wiring details

P2 (LOW PRESSURE)

P1 (HIGH PRESSURE)

STORAGE POSITION FOR JUMPERS

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Ecublens, Route du Bois 37, Switzerland by its Authorized Representative:

Fema Controls

Honeywell GmbH

P.O. Box 1254

71099 Schönaich

Germany

phone: (49) 7031-637-02

fax: (49) 7031-637-850

http://www.honeywell.de/fema

Subject to change without notice.

EN0B-0616GE51 R1007

Loading...

Loading...