Page 1

User/Technical Manual for 50085804, Rev. B

Digital Pressure Sensor with CANopen®, Model DPS

RELEASE INFORMATION

PERSONAL INJURY WARNING

DO NOT USE these products as safety or emergency stop

devices or in any other application where failure of the product could result in personal injury.

Failure to comply with these instructions could result in

death or serious injury.

IMPORTANT

It is recommended that you read this document thoroughly

before applying power to this unit.

Table of Contents

Chapter 1 - General Information ......................1

Chapter 2 - Technical Data and Performance Details .......3

Chapter 3 - Introduction .............................6

Chapter 4 - Setting Up ..............................7

Chapter 5 - Network Management ....................11

Chapter 6 - Heartbeat Protocol .......................13

Chapter 7 - Process Data Objects ....................13

Chapter 8 - Service Data Objects .....................14

Chapter 9 - Emergency Objects ......................15

Chapter 10 - Operation .............................15

Appendix ........................................20

Document Name Doc. ID Release

Digital Pressure Sensor with

CANopen

User/Technical Manual

Digital Pressure Sensor with

CANopen

User/Technical Manual

®

, Model DPS,

®

, Model DPS,

50085804 A May

50085804 B April

No.

Pub.

Date

2013

2016

REFERENCES

The following list identifies all documents that may be sources

of reference for materials discussed in this publication.

• Digital Pressure Sensor with CANopen

product sheet

®

, Model DPS,

Page 2

Digital Pressure Sensor with CANopen®, Model DPS 50085804, Rev. B

The following table lists those symbols used in this document to denote certain conditions.

Table 1 – Table Symbol Denitions

Symbol Denition

,

CAUTION

m

m

m

m

ATTENTION: Identifies information that requires special consideration.

TIP: Identifies advice or hints for the user, often in terms of performing a task.

REFERENCE - EXTERNAL: Identifies an additional source of information outside of the

bookset.

REFERENCE - INTERNAL: Identifies an additional source of information within the bookset.

CAUTION: Indicates a situation which, if not avoided, may result in equipment or work

(data) on the system being damaged or lost, or may result in the inability to properly operate the process.

CAUTION: Caution symbol indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. It may also be used to alert against unsafe practices.

CAUTION: Caution symbol on the equipment refers the user to the product manual for additional information. The symbol appears next to required information in the manual.

WARNING: Warning symbol indicates a potentially hazardous situation, which, if not

avoided, could result in serious injury or death.

WARNING: Warning symbol on the equipment refers the user to the product manual for additional information. The symbol appears next to required information in the manual.

ii sensing.honeywell.com

Page 3

Digital Pressure Sensor with CANopen®, Model DPS 50085804, Rev. B

CHAPTER 1 - GENERAL INFORMATION

1.1 Introduction

Honeywell’s Digital Pressure Sensor with CANopen®, Model

DPS, is an addition to Honeywell’s general-purpose pressure

sensors that are pre-configured with a variety of features and

options for use in a wide range of demanding applications.

Model DPS pressure sensors are a rugged, stainless steel, allwelded devices designed to work with a variety of media, and

built to provide consistent performance in harsh environments.

CANopen

• Connect to longer distance without losing the

• Reduce the wires to be connected

• Take advantage of robust and superior error handling

• Access calibration

• Easily track each device in the network with their

• Update rate of each device connected in the network

Configurations for digital measurements are fully temperature

compensated and calibrated for pressure ranges from 10 psi to

10K psi or 1 bar to 700 bar or 70 kPa to 70000 kPa.

Customers can choose from two different accuracies to meet

their specific application requirements:

• ≤30 psi, ±0.25 %FS

• >30 psi, ±0.1 %FS or ±0.25 %FS

®

protocol allows customers to:

accuracy

capability

unique serial numbers

which can be set at different rates

1.2 Acronyms and Denitions

Acronym Denition

ADC Analog to Digital Converter

BFSL Best Fit Straight Line

CAN Control Area Network

CiA CAN in Automation

COB-ID Communication Object - Identifier

CS Command Specifier

DLC Data Length Code

EMCY Emergency

FS Full Scale

g Weight in gram

hex Hexadecimal

Hz Hertz

IP65 Ingress Protection Rating

kbps Kilo bit per second

LSB Least Significant Bit

LSS Layer Setting Services

MIL-STD Military Standard

mS millisecond

NMT Network Management

NPT Non Plated Through

oz Ounce

PDO Process Data Object

PSI Pound-force per square inch

RD Read access

SDO Service Data Object

SYNC Synchronous

TPDO Transmission Process Data Object

Sensing and Productivity Solutions 1

Page 4

Digital Pressure Sensor with CANopen®, Model DPS 50085804, Rev. B

1.3 Features and Benets

( = Competitive Differentiator)

• Wide pressure range [from 10 psi to 10K psi or 1 bar to

700 bar or 70 kPa to 70000 kPa]: Provides support for

many unique applications

Multiple pressure engineering units (psi, bar and kPa):

Eliminates the customer having to make mathematical

conversions, increasing flexibility and simplifying use

• Rugged design: All-welded, 300 series stainless steel and

Hastelloy

environments

• Accuracy options [ ≤ 30 psi, ±0.25 %FS or >30 psi,

±0.1 %FS or ±0.25 %FS]: Allow customers to select the

accuracy level required for their application

• Output: CANbus with CANopen

• Total Error Band [±2 % FS]: Honeywell specifies Total

Error Band (TEB), the most comprehensive, clear and

meaningful measurement that includes nonlinearity,

repeatability and hysteresis as well as temperature error

• Designed for configurability: A selection of pressure types,

accuracy levels, pressure ranges, pressure connections

and electrical terminations allows customers the ability to

configure the devices to meet their specific application

needs

Connectors: 5-pin M12, which can be used in industrial

applications, and 6-pin Bendix, which can be used in

transportation applications

• Mechanical shock 100 G/11 ms: Allows the device to

withstand harsh environments

• IP65 rated: Provides protection when used in harsh

environments

• CiA (CAN in Automation) certified

®

design allow for use in a wide range of harsh

®

protocol

1.4 Potential Applications

• Transportation

- Agricultural equipment

- Automotive test benches

- Construction equipment

- Rail equipment testing

- Train communication network

• Industrial

- General industrial process control and factory

automation/industrial equipment

• Medical

- Blood dialysis equipment

- Medical equipment systems (i.e., X-ray collimator, MRI

scanning, etc.)

• Aerospace

- Test and research labs

2 sensing.honeywell.com

Page 5

Digital Pressure Sensor with CANopen®, Model DPS 50085804, Rev. B

CHAPTER 2 - TECHNICAL DATA AND PERFORMANCE DETAILS

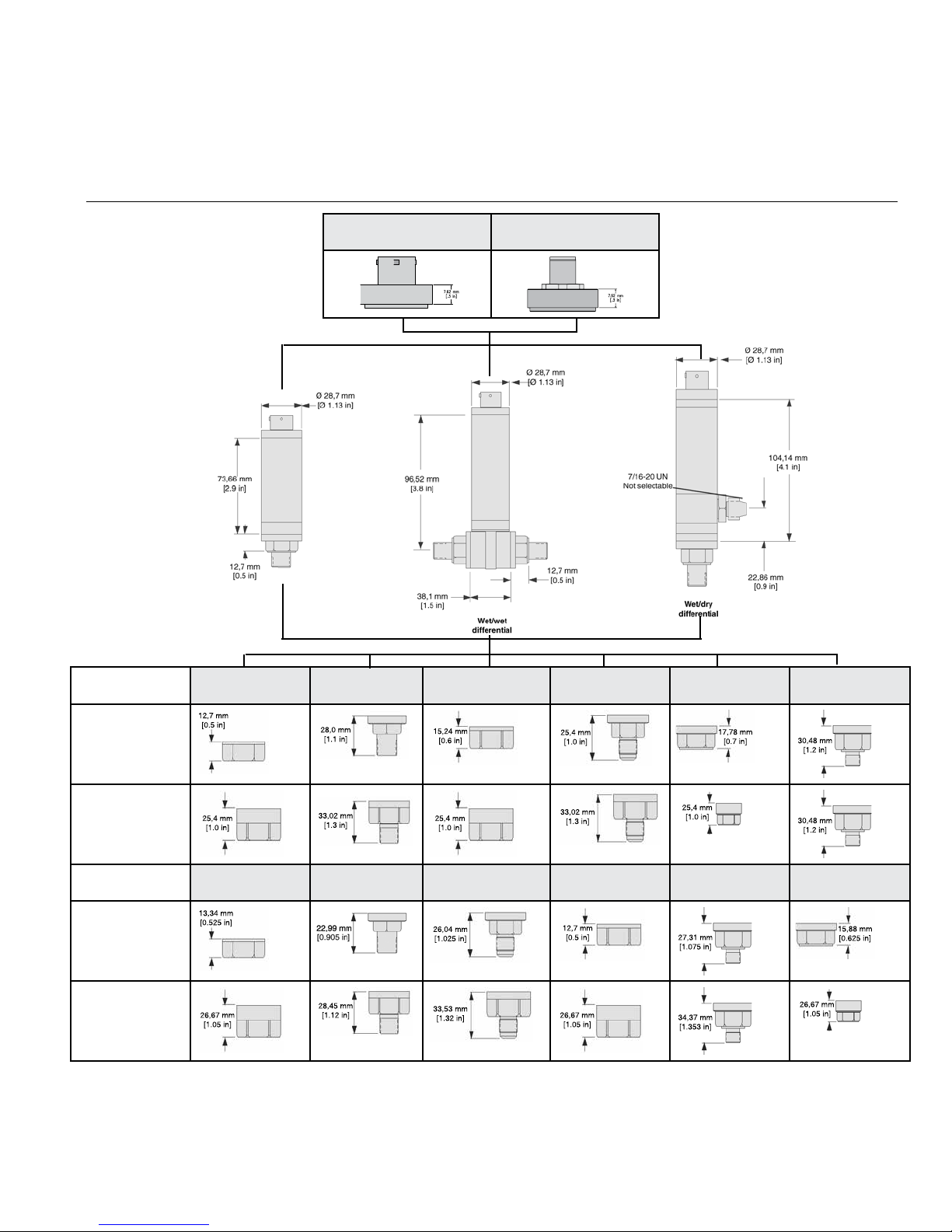

2.1 Physical Dimensions

Pressure ports

Less than

1000 psi

HPG

HPA

Code 5a

1/4-18 NPT female

Code 6a: 6-pin, vented,

Bendix style

Code 5b

1/4-18 NPT male

Code 5c

7/16-20 UNF female

Code 6bj: 5-pin vented,

M12 connector

HDW

Code 5d

7/16-20 UNF male

HDD

Code 5f

G 1/4 B female

Code 5g

G 1/4 B male

Greater than

1500 psi

Code 5h

1/8-27 NPT female

Less than

1000 psi

Greater than

1500 psi

Code 5i

1/8-27 NPT male

Code 5p

M12-1.5 male

Code 5q

M12-1.5 female

Code 5r

9/16-18 SAE male

Code 5s

9/16-18 SAE female

Sensing and Productivity Solutions 3

Page 6

Digital Pressure Sensor with CANopen®, Model DPS 50085804, Rev. B

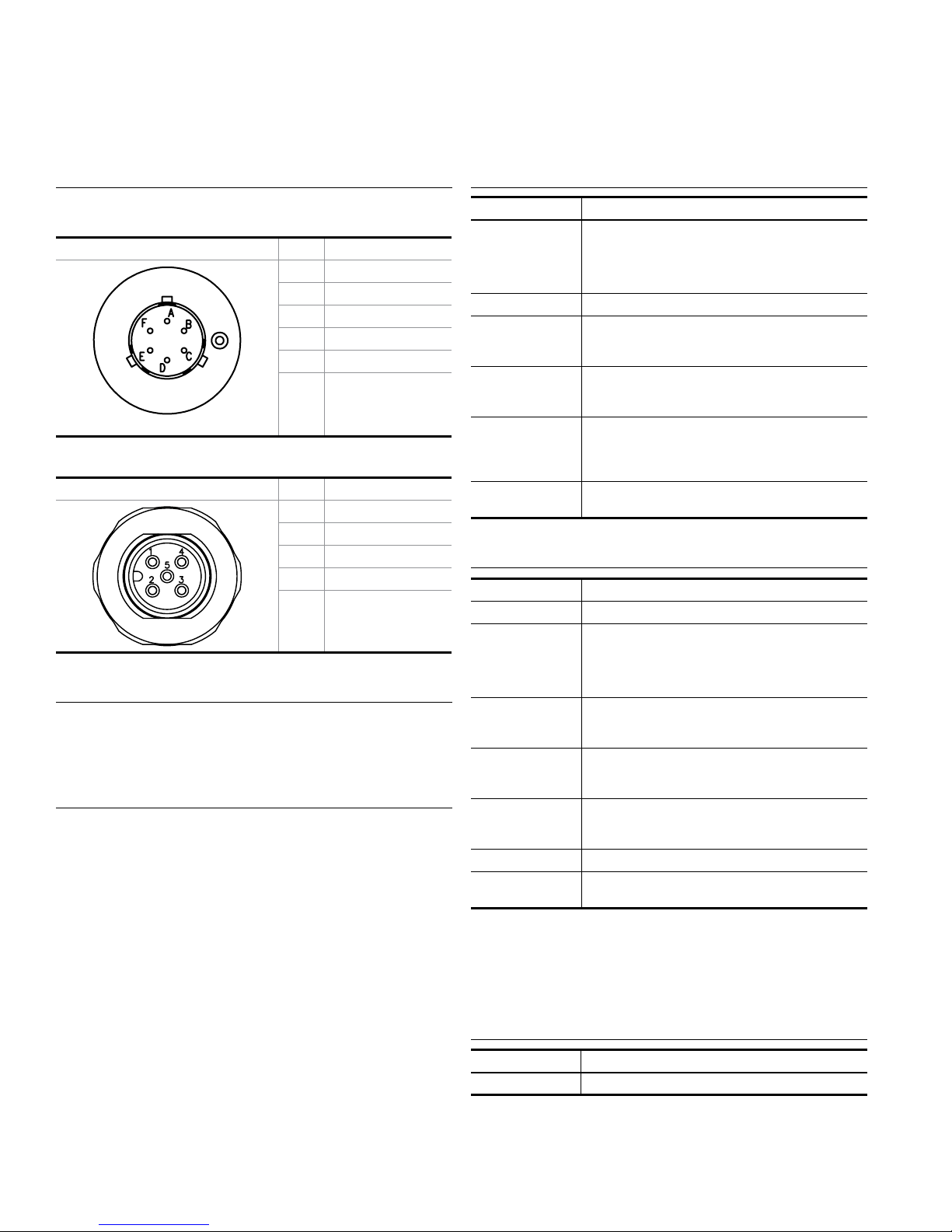

2.2 Electrical Termination and Pin Assignment

Electrical connection can be selected from 6-pin Bendix connector or 5-pin M12 connector.

6-pin Bendix connector Pin Assignment

A CAN_SHLD

B CAN_V+

C CAN_GND

D CAN_H

E CAN_L

F NC

M12 electrical connector

5-pin M12 connector Pin Assignment

1 CAN_SHLD

2 CAN_V+

3 CAN_GND

4 CAN_H

5 CAN_L

2.3 Pressure Ports

See available pressure ports in physical dimension diagram

included in Section 2.1.

2.4 Pressure Media Compatibility

Media that is compatible with stainless steel 316L and

Hastelloy

®

.

2.5 Physical and Environmental Specications

Characteristic Parameter

Weight

(representative of

HPG & HPA)

Shock 100 g [11 ms] peak

Vibration

Compensated

temperature

range

Operating

and storage

temperature

range

Approvals

100 psi: 234 g [8.25 oz]

(1/4-18 NPT port with Bendix)

100 psi: 236 g [8.32 oz]

(1/4-18 NPT port with M12)

MIL-STD-810C, Figure 514.2-5, curve AK,

Table 514.2-V, random vibration test

[overall g rms = 20.7 min.]

4 °C to 60 °C [40 °F to 140 °F]

-25 °C to 85 °C [-13 °F to 185 °F]

CiA (CAN In Automation), CE Marked, Declaration of Conformity on request

2.6 Mechanical Specications

Characteristic Parameter

1

Media

Overload

(safe), positive

direction

Overload

(safe), negative direction

Overload

(burst), positive direction

Overload

(burst), negative direction

Pressure port 200% over capacity

Wetted parts

material

NOTES:

1. The wet/wet differential pressure sensor has two separate, welded

Hastelloy® diaphragms. In wet/dry unit, the wet port (high port) has

all-welded stainless steel and Hastelloy® construction. The dry port

(low port) has no isolation diaphragm.

gas, liquid

1000 psi and below: 4X full scale or 3000

psi, whichever is less

1500 psi and above: 4X full scale or 15000

psi, whichever is less

4X full scale or 250 psi, whichever is less

1000 psi and below: 3000 psi

1500 psi and above: 15000 psi

Ha C276 & 316L stainless steel

4 sensing.honeywell.com

2.7 Electrical Specications

Characteristic Parameter

Excitation 9 Vdc to 28 Vdc

Page 7

Digital Pressure Sensor with CANopen®, Model DPS 50085804, Rev. B

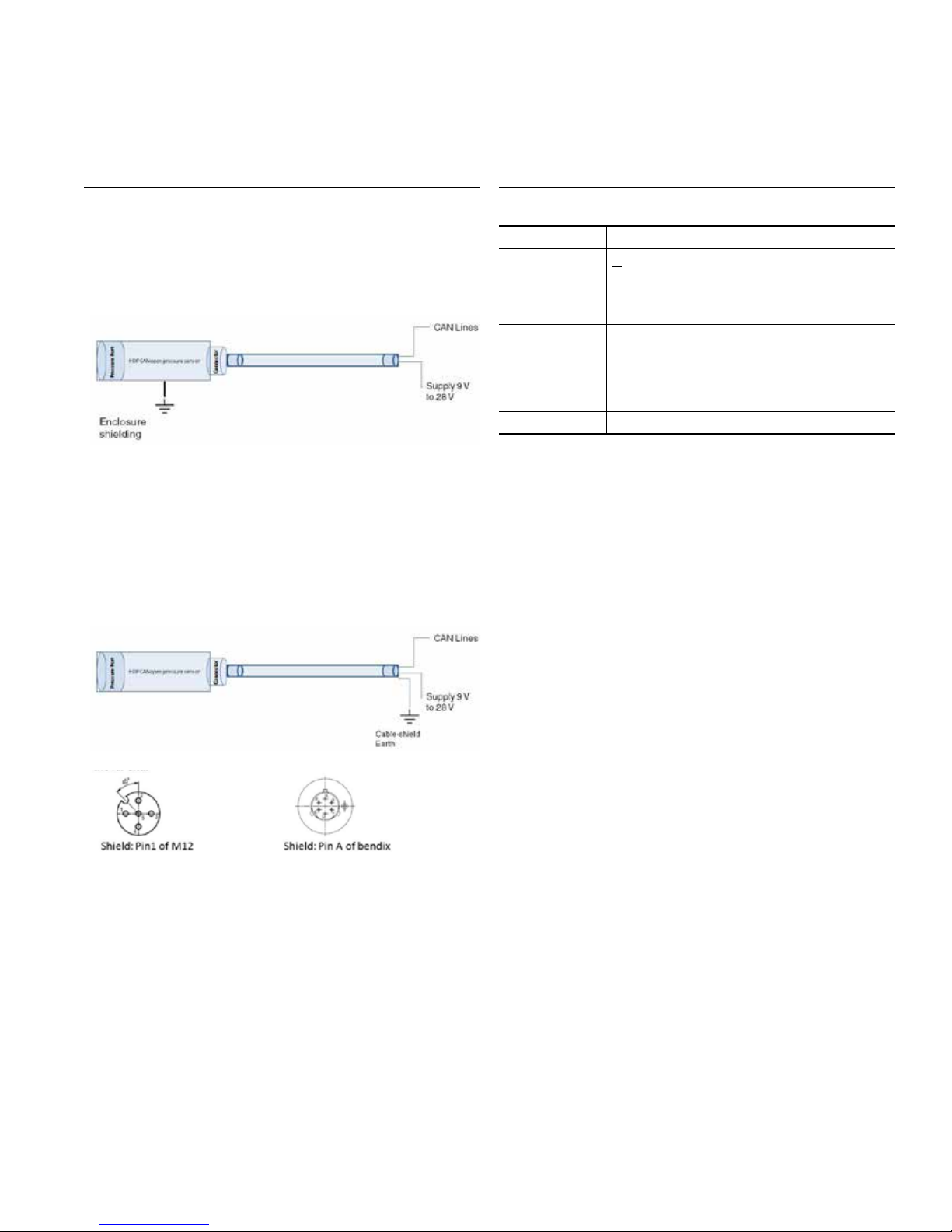

2.8 Recommended Grounding

If there is a provision to ground the enclosure at the application being used, use the recommended grounding method as

shown in Figure 1.

Figure 1. Recommended Shielding Diagram 1

If there is no provision to ground the enclosure in the application, this shielding method is preferred for wires that run longer.

The shielding of the cable can be connected to CAN_SHLD of

the connector (pin 1 of M12 or Pin A of Bendix) and it can be

grounded at the far end (see Figure 2).

Figure 2. Recommended Shielding Diagram 2

2.9 Performance Specications

At 25 °C [77 °F] and a rated excitation unless otherwise noted

Characteristic Parameter

<30 psi: ±0.25 %FS

Accuracy

ADC

resolution

Total Error

Band

User-congurable update

rate

Baud rate 125 kbps (default)

NOTES:

2. Includes pressure non-linearity (BFSL), pressure hysteresis and non-

repeatability. Thermal errors are not included.

3. Differential sensors are calibrated in positive direction and accuracy

specification is valid in positive direction only.

4. Includes zero error, span error, thermal effect on zero, thermal effect

on span, thermal hysteresis, pressure-non-linearity, pressure hysteresis and non-repeatability.

,

1. The wet/wet differential pressure sensor has two

2. Includes pressure non-linearity (BFSL), pressure

3. Differential sensors are calibrated in positive direction

4. Includes zero error, span error, thermal effect on zero,

2,3

>30 psi: ±0.1 %FS, ±0.25 %FS

12 bit

4

±2 %FS

250 Hz (max.); 10 Hz (default)

ATTENTION

separate, welded Hastelloy

unit, the wet port (high port) has all-welded stainless

steel and Hastelloy

has no isolation diaphragm.

hysteresis, and non-repeatability. Thermal errors are not

included.

and accuracy specification is valid in positive direction

only.

thermal effect on span, thermal hysteresis, pressurenon-linearity, pressure hysteresis, and non-repeatability.

®

®

diaphragms. In wet/dry

construction. The dry port (low port)

Sensing and Productivity Solutions 5

Page 8

Digital Pressure Sensor with CANopen®, Model DPS 50085804, Rev. B

CHAPTER 3 - INTRODUCTION

The Digital Pressure Sensor with CANopen®, Model DPS,

implements the standard CANopen

The CANopen

®

standards supported are shown in Table 1.

®

communications protocol.

These standards are available from CAN in Automation www.

can-cia.de.

3.1 Supported Standards

Table 1. Supported CANopen® Standards

CANopen®

CiA Standard

DS301 4.02

DR-303-2 1.1

DSP 305 2.2

DSP 404 1.0

Version Description

Application layer and communication profile

CANopen

®

units and prefixes

CANopen

®

and protocol

Measuring devices and closed

loop controllers

representation of SI

layer setting services

The Model DPS pressure sensor is provided with the CANo-

®

pen

default settings as shown in Table 2.

Table 2. CANopen® Default Settings

Parameter Default

Value

(Hex)

Node-ID 7F

COB-ID PDO

COB-ID SDO

COB-ID

EMERGENCY

180 +

Node-ID

600 +

Node-ID

80 +

Node-ID

COB-ID NMT 00

COB-ID SYNC 80

LSS Master 7E5

LSS Slave 7E4

BOOTUP

HEARTBEAT

COB-ID

Bit rate

700 +

Node-ID

125

Kbps

Description

The Node-Identifier used for

CANopen

®

communications

The communications object identifier of the process data object

The communications object identifier of the service data object

The communications object identifier of the emergency object

The communications object identifier of the network management

object

The communications object

identifier of the synchronization

object

The identifier of the layer settings

service master (host)

The identifier of the layer settings

service slave (Digital Pressure

Sensor with CANopen

®

Series)

The communications object identifier for the heartbeat object

The bit rate that is used for CAN

communications. [Bit rate is

mentioned in decimal]

6 sensing.honeywell.com

Page 9

Digital Pressure Sensor with CANopen®, Model DPS 50085804, Rev. B

CHAPTER 4 - SETTING UP

4.1 Procedure to Get Started

In order to operate in the host network it is necessary to ensure:

1. The Node-ID of the Digital Pressure Sensor with

CANopen

on the CANbus network.

2. The bit rate of the Digital Pressure Sensor with CANopen

Model DPS, matches that of the network to which it is

being connected.

These parameters are configured using the layer settings services. These parameters are configured prior to connecting the

Model DPS in the host network.

Table 3. Point to Point Node-ID Conguration

®

, Model DPS, is not the same as any other node

4.2 Node-ID Conguration

The Node-ID is used to provide unique communication object

identifiers for each CANopen

ing of the Node-ID can be performed:

1. Prior to connection using the switch mode global

command called Point-to-Point Configuration.

®

,

2. On the target network using the switch mode selective

command called Network Configuration.

Table 3 shows the process of performing point-to-point NodeID Configuration. Table 4 shows the process of performing

Node-ID Configuration on network.

®

device on the network. Configur-

ID(hex) DLC Data(Hex) Comment Direction w.r.t Digital Pressure

Sensor with CANopen

®

000 2 80 7F Preoperational node ID 7F Receive

7E5 8 04 01 00 00 00 00 00 00 Configuration state Receive

7E5 8 11 7E 00 00 00 00 00 00 Set node ID 7E Receive

7E4 8 11 00 00 00 00 00 00 00 Response ok Transmit

7E5 8 17 00 00 00 00 00 00 00 Store configuration Receive

7E4 8 17 00 00 00 00 00 00 00 Response ok Transmit

7E5 8 04 00 00 00 00 00 00 00 Waiting state Receive

000 2 81 7F Reset node ID -7F Receive

77E 1 00 Boot up message Transmit

Table 4. Node-ID Conguration On Network

ID(hex) DLC Data(Hex) Comment Direction w.r.t Digital Pressure

Sensor with CANopen

000 2 80 7E Preoperational node ID 7E Receive

7E5 8 40 62 03 00 00 00 00 00 Vendor ID Receive

7E5 8 41 50 31 44 00 00 00 00 Product code Receive

7E5 8 42 00 00 01 00 00 00 00 Revision no. Receive

Serial number, where xx xx xx xx

7E5 8 43 xx xx xx xx 00 00 00

is the serial number of the device

Receive

given along with the Model DPS unit

7E4 8 44 00 00 00 00 00 00 00 Response ok Transmit

7E5 8 11 7F 00 00 00 00 00 00 Set node ID 7F Receive

7E4 8 11 00 00 00 00 00 00 00 Response ok Transmit

7E5 8 17 00 00 00 00 00 00 00 Store configuration Receive

7E4 8 17 00 00 00 00 00 00 00 Response ok Transmit

7E5 8 04 00 00 00 00 00 00 00 Waiting state Receive

000 2 81 7E Reset node ID -7E Receive

77F 1 00 Boot up message Transmit

®

Sensing and Productivity Solutions 7

Page 10

Digital Pressure Sensor with CANopen®, Model DPS 50085804, Rev. B

4.3 Bit Rate Conguration

Configuring of the Bit Rate can be performed:

1. Prior to connection using the switch mode global

command called Point-to-Point configuration.

2. On the target network using the switch mode selective

command called Network Configuration.

Table 5 shows the process of performing point-to-point Bit Rate

configuration. Table 6 shows the process of performing Bit

Rate configuration on network.

Table 5. Point-to-Point Bit Rate Conguration

ID(hex) DLC Data(Hex) Comment Direction w.r.t Digital Pressure

Sensor with CANopen

000 2 80 7f Preoperational node ID 7f Receive

7E5 8 04 01 00 00 00 00 00 00 Configuration state Receive

7E5 8 13 00 04 00 00 00 00 00 Set bit rate 125 kbit 04 Receive

7E4 8 13 00 00 00 00 00 00 00 Response ok Transmit

7E5 8 17 00 00 00 00 00 00 00 Store configuration Receive

7E4 8 17 00 00 00 00 00 00 00 Response ok Transmit

7E5 8 04 00 00 00 00 00 00 00 Waiting state Receive

000 2 01 00 Enter operational state Receive

1ff 4 Pressure data Transmit

®

Table 6. Bit Rate Conguration on Network

ID(hex) DLC Data(Hex) Comment Direction w.r.t Digital Pressure

Sensor with CANopen

000 2 80 7E Preoperational node Id 7E Receive

7E5 8 40 62 03 00 00 00 00 00 Vendor ID Receive

7E5 8 41 50 31 44 00 00 00 00 Product code Receive

7E5 8 42 00 00 01 00 00 00 00 Revision no. Receive

Serial number, where xx xx xx xx

7E5 8 43 xx xx xx xx 00 00 00

7E4 8 44 00 00 00 00 00 00 00 Response ok Transmit

7E5 8 13 00 04 00 00 00 00 00 Set bit rate 125 Kbit 04 Receive

7E4 8 13 00 00 00 00 00 00 00 Response ok Transmit

7E5 8 17 00 00 00 00 00 00 00 Store configuration Receive

7E4 8 17 00 00 00 00 00 00 00 Response ok Transmit

7E5 8 04 00 00 00 00 00 00 00 Waiting state Receive

000 2 01 00 Enter operational state Receive

1ff 4 Pressure data Transmit

is the serial number of the device

given along with the Model DPS unit

Receive

®

8 sensing.honeywell.com

Page 11

Digital Pressure Sensor with CANopen®, Model DPS 50085804, Rev. B

The new bit rate is valid after a reset of the device. It is highly

recommended to power off the CANopen

and change the bit rate of the master to the desired value (125

kbit/s in this example). Performing a NMT reset node command

will lead to error frames on the CANbus, because the master

still has the previous bit rate. The available bit rates are given

in Table 7.

®

slave device first

Table 7. Available Bit Rates

Bit Rate Table Index

1000 Kbit 0

500 Kbit 2

250 Kbit 3

125 Kbit 4

100 Kbit 5

50 Kbit 6

4.4 Activate Bit Timing Command

Send the activate bit timing command, as shown in Table 8,

to re-start with the selected bit rate, before storing the bit rate.

The switch delay is an Intel format unsigned integer number

that represents a time delay in mS, e.g. 3E816 = 1000 mS.

This time delay is used for two periods on the Digital Pressure

Sensor with CANopen

will not be applied until the delay is expired; secondly, no messages shall be sent by the Model DPS pressure sensor until the

delay has expired once more.

Start the heartbeat and let it run at 100 ms. Then, set the bit

rate. The heartbeat still runs. Then activate the bit timing and

set the activation time to 1 sec. Then after 2 sec, the heartbeats start up again at the new bit rate.

®

, Model DPS. First, the new bit timing

Table 8. Activate Bit Timing

ID(hex) DLC Data(Hex) Comment Direction w.r.t Digital Pres-

sure Sensor with

CANopen

67f 8 22 17 10 00 64 00 00 00

5ff 8 60 17 10 00 00 00 00 00 Response ok Transmit

7ff 1 7f Heartbeat message every 100 millisec Transmit

000 2 80 7f Enter pre-operational state Receive

7E5 8 04 01 00 00 00 00 00 00 Configuration state Receive

7E5 8 13 00 04 00 00 00 00 00 Set bit rate 125 Kbit 04 Receive

7E4 8 13 00 00 00 00 00 00 00 Response ok Transmit

7E5 8 04 00 00 00 00 00 00 00 Waiting state Receive

7ff 1 7f Heartbeat message every 100 millisec Transmit

7ff 1 7f Heartbeat message every 100 millisec Transmit

7E5 8 04 01 00 00 00 00 00 00 Configuration state Receive

7E5 8 15 E8 03 00 00 00 00 00 Configuration state Receive

7E5 8 04 00 00 00 00 00 00 00 Waiting state Receive

7ff 1 7f Heartbeat message after 2 secs Transmit

7ff 1 7f Heartbeat message every 100 millisec Transmit

Enable heartbeat message – once

every 100 millisec

Receive

®

Sensing and Productivity Solutions 9

Page 12

Digital Pressure Sensor with CANopen®, Model DPS 50085804, Rev. B

Power-on

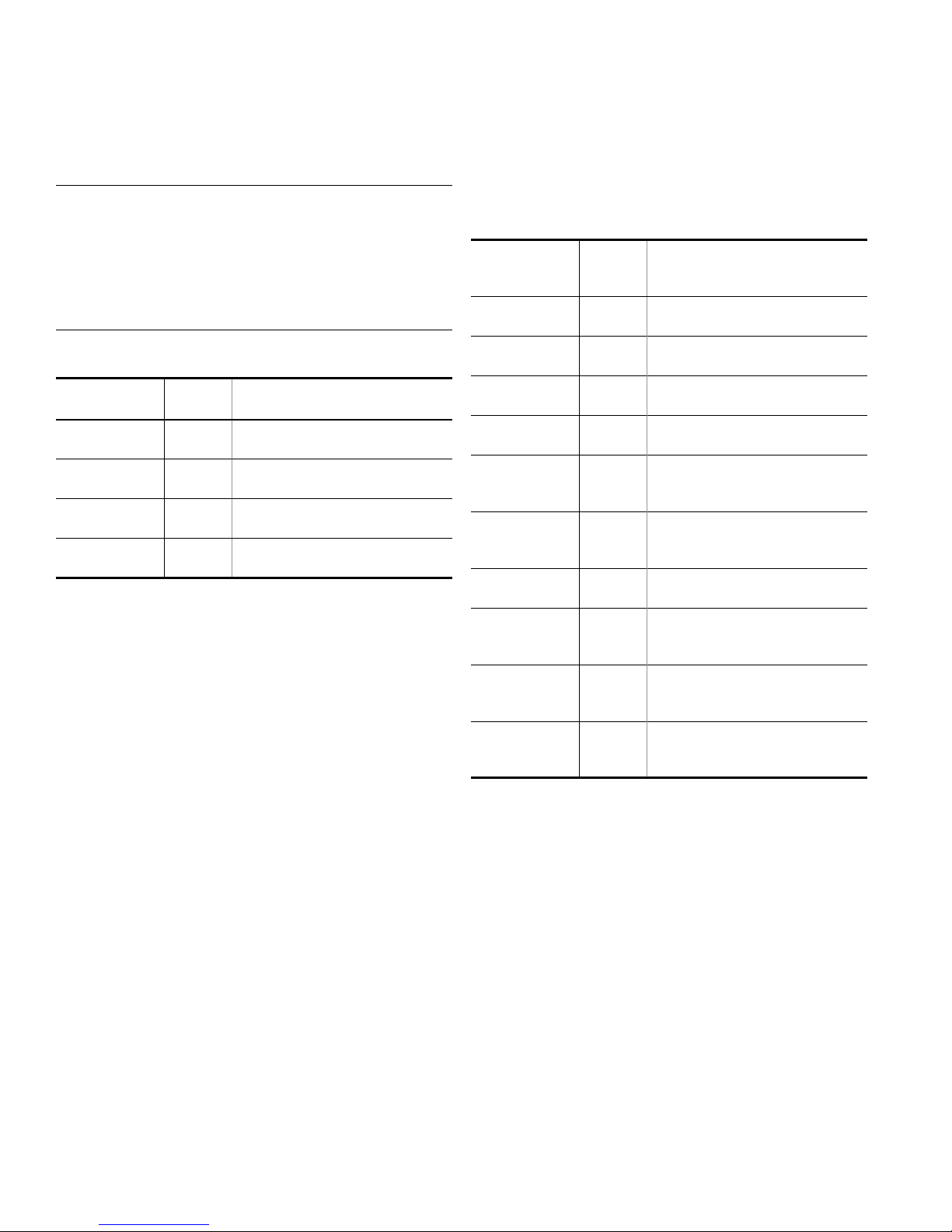

CHAPTER 5 - NETWORK MANAGEMENT

The Digital Pressure Sensor with CANopen®, Model DPS, is

a CANopen

diagram and the communication objects supported by each

state.The Model DPS pressure sensor supports minimum bootup. Minimum boot-up devices enter the pre-operational state

automatically after finishing the device initialization.

®

NMT slave. Figure 3 shows the state transition

5.1 Network Transition Diagram

In order to operate in the host network it is necessary to ensure:

1. The Node-ID of the Digital Pressure Sensor with

CANopen

on the CANbus network.

2. The bit rate of the Digital Pressure Sensor with CANopen

Model DPS, matches that of the network to which it is

being connected.

These parameters are configured using the layer settings

services. These parameters are configured prior to connecting

the Digital Pressure Sensor with CANopen

host network.

®

, Model DPS, is not the same as any other node

®

, Model DPS, in the

®

The letters (in brackets) show which communication object

types are allowed inside the different states:

a. NMT, b. LSS, c. SDO, d. Emergency, e. PDO,

f. Boot-up, g. Synchronization

The state transitions and the NMT command specifiers (in

brackets):

1: Start remote node (0x01)

2: Stop remote node (0x02)

3: Enter pre-operational state (0x80)

4: Reset node (0x81)

5: Reset communication (0x82)

6: Device initialization finished, enter pre-operational state

,

automatically, send boot-up message

The NMT message has the following format:

COB-ID Byte0 Byte1

0x0000 CS Node-Id

Figure 3. NMT State Transition Diagram

Initialising

(f)

5

Pre-operational

(a, b, c, d)

1

Operational

(a, b, c, d, e)

3

3

2

Stopped

1

2

46

(a, b)

10 sensing.honeywell.com

Page 13

Digital Pressure Sensor with CANopen®, Model DPS 50085804, Rev. B

CS is the Command Specifier, which can have the following values:

NMT

Service

Start

remote

node

Stop

remote

node

Enter preoperational state

Reset

node

Reset

communication

Command

Specier

(hex)

1

2

80

81

82

Description Table 9: Start Remote Node

®

The Digital Pressure Sensor with CANopen

into operational state when Start remote node command is sent

from the NMT master. In this state, the Digital Pressure Sensor

with CANopen

®

starts giving out pressure data every 100 mil-

lisecond.

, Model DPS, enters

ID(hex)

Byte 0

Cmd

Byte 1

Node-ID

00 1 7F

Table 10: Stop Remote Node

The stop remote node command causes the Digital Pressure

Sensor with CANopen

®

, Model DPS, to enter the stopped state.

In the stopped state the NMT and LSS are available.

ID(hex)

Byte 0

Cmd

Byte 1

Node-ID

00 2 7F

Table 11: Enter Pre-operational

State

The Digital Pressure Sensor with CANopen

®

, Model DPS, enters

preoperational state after initialization. When the pre-operational

state is entered, after initialization, a boot-up message is sent as

shown in Table 12.

ID(hex)

Byte 0

Cmd

00 80 7F

Table 12: Boot-up Message

ID(hex)

Byte 0

Cmd

700 +

Node-ID

Byte 1

Node-ID

–

–

77F 00 –

The reset node command causes the Digital Pressure Sensor

with CANopen

®

, Model DPS, to re-load the whole object dictionary from non-volatile memory. Table 13 shows the reset node

command.

The reset communications command causes the Digital Pressure Sensor with CANopen

®

, Model DPS, to re-load the communications area of the object dictionary from non-volatile memory.

Table 14 shows the reset communication command.

Table 13: Reset Node

ID(hex)

Byte 0

Cmd

Byte 1

Node-ID

00 81 7F

Table 14: Reset Command

ID(hex)

Byte 0

Cmd

Byte 1

Node-ID

00 82 7F

Sensing and Productivity Solutions 11

Page 14

Digital Pressure Sensor with CANopen®, Model DPS 50085804, Rev. B

CHAPTER 6 - HEARTBEAT PROTOCOL

The NMT master will use the heartbeat message produced by

the Digital Pressure Sensor with CANopen

determine that the node is present on the network. The Model

DPS will send a heartbeat message every n mS, where n is

the heartbeat producer time available at object 0x1017. If the

heartbeat producer time is zero then no heartbeat message will

be transmitted. Table 15 depicts the Heartbeat message. The

default heartbeat producer time for the Digital Pressure Sensor

with CANopen

®

, Model DPS, is zero.

®

, Model DPS, to

6.1 Heartbeat Message

Table 15. Digital Pressure Sensor with CANopen®

Heartbeat Message

COB-ID(hex) Byte 0

0x700+Node-ID State

Where state can have any of the following values

Table 16. Heartbeat Protocol States

COB-ID(hex) Byte 0

0 Boot-up

4 Stopped

5 Operational

7F Pre-operational

CHAPTER 7 - PROCESS DATA OBJECTS

The real-time process data transfer is performed by means of

process data objects (PDO). Upon entering the operational

state, the Digital Pressure Sensor with CANopen

starts transmitting the pressure in 32 bit signed integer format

at an update rate of 100 millisecs.

®

, Model DPS,

7.1 PDO Transmission Type

The transmission type parameter of a PDO specifies the

transmission mode (synchronous, event driven) as well as the

triggering mode.

Transmission modes:

• Synchronous

• Event-driven

Synchronous

For synchronous PDOs, the transmission type also specifies the transmission rate in the form of a factor based on the

basic SYNC object transmission period. A transmission type

of 0 means that the message shall be transmitted after occurrence of the SYNC (acyclic – not periodically), only if an event

occurred before the SYNC. The transmission type 1 means

that the message shall be transmitted with every SYNC object

(cyclic). A transmission type of n means that the message shall

be transmitted with every n-th SYNC object.

Event-driven

12 sensing.honeywell.com

Event-driven TPDOs are transmitted without any relation to the

SYNC object.

Triggering modes

In the Digital Pressure Sensors with CANopen®, Model DPS,

two message-triggering modes are distinguished:

• Event-driven

• Synchronously triggered

Event- and timer-driven

Message transmission is either triggered by the occurrence of

an application-specific event specified in manufacturer-specific

profile or if a specified time (event-time) has elapsed without

occurrence of an event.

Synchronously triggered

Message transmission is triggered by the occurrence of the

SYNC object. The trigger condition is the number of sync and

optionally an internal event. The Model DPS supports the transmission types listed in the Table 17.

Page 15

Digital Pressure Sensor with CANopen®, Model DPS 50085804, Rev. B

‘Table 17. Transmission Types Supported by the Digital Pressure Sensor with CANopen®, Model DPS

Transmission

(hex)

0

1-F0

FE

FF

Description

Acyclic, synchronous transmission. The Digital Pressure Sensor with CANopen

®

, Model

DPS, will transmit a PDO message after

occurrence of the SYNC, but only if an event

(change in the pressure data) occurred

before the SYNC.

Cyclic, synchronous transmission. The

Digital Pressure Sensor with CANopen

®

,

Model DPS, will transmit the PDO message

on reception of the nth SYNC message,

where n is 1 to 240.

Asynchronous transmission. The Digital

Pressure Sensor with CANopen

®

, Model

DPS, will transmit the PDO message at the

time interval defined by the event time (by

default it transmits pressure data every 100

millisec). The PDO is transmitted without any

relation to the SYNC object.

Asynchronous transmission. The Digital

Pressure Sensor with CANopen

®

, Model

DPS, will transmit the PDO message at the

time interval defined by the event time (by

default it transmits pressure data every 100

millisec).The PDO is transmitted without any

relation to the SYNC object.

7.2 Changing the Output Units

The default unit of the process value is psi. The physical units

of the process value can be read or modified by using the object 6131. When the units are changed using the object 6131,

the units of all the objects associated with process value is

changed internally by the Digital Pressure Sensor with CANo-

®

pen

, Model DPS. Table 18 contains the list of the objects that

are associated with process value. The Model DPS supports

only 1 PDO.

Table 18. List of Objects Affected by Unit Change

Object Description

6148 AI span start

6149 AI span end

6124 AI input offset

6130 AI input process value REAL32

2006 Span

Table 19. Command to Change Physical Units from psi to Bar

ID(hex) DLC Data(Hex) Description Direction w.r.t Digi-

Byte0 Byte1 Byte2 Byte3 Byte4 Byte5 Byte6 Byte7

67F 8 40 31 61 01 00 00 00 00

Read the current

unit

5FF 8 60 31 61 01 00 00 AB 00 Current unit is psi Transmit

67F 8 40 30 61 01 00 00 00 00 Read process value Receive

5FF 8 60 30 61 01 50 C3 00 00 50 psi Transmit

67F 8 22 31 61 01 00 00 4E 00

Change the unit to

bar

5FF 8 60 31 61 01 00 00 00 00 Return ok Transmit

67F 8 40 31 61 01 00 00 00 00

Read the current

unit

5FF 8 60 31 61 01 00 00 4E 00 Current unit is bar Transmit

67F 8 40 30 61 01 00 00 00 00 Read process value Receive

5FF 8 60 30 61 01 78 0D 00 00 3.448 bar Transmit

tal Pressure Sensor

with CANopen

®

Receive

Receive

Receive

Sensing and Productivity Solutions 13

Page 16

Digital Pressure Sensor with CANopen®, Model DPS 50085804, Rev. B

The units can be stored in EEPROM by using the store command, i.e. object 0x1010. Also the default unit of PSI can be

restored using the restore command i.e. object 0x1011. Table

20 provides a list of units that the Digital Pressure Sensor with

CANopen

®

, Model DPS, supports.

Table 20. Units Supported by the Digital Pressure

Sensor with CANopen®, Model DPS

Unit Type Unit Code

Non-SI psi 00 00 AB 00

SI Bar 00 00 4E 00

SI KPa 00 00 22 03

7.3 PDO Mapping

The Digital Pressure Sensor with CANopen®, Model DPS, allows two different objects to be mapped into the process data

object:

1. Pressure in signed integer format (default)

2. Raw pressure data

The mappable objects are shown in Table 21.

Table 21. Objects That Can Be Mapped to the PDO

Object (hex) Sub Index

(hex)

6130 1 Pressure reading REAL32

7100 1 Pressure reading INT16

The default mapping of the Digital Pressure Sensor with CANo-

®

pen

, Model DPS, is shown in Table 22.

Table 22. Digital Pressure Sensor with CANopen®

Initial PDO Map

Object

Number

(hex)

1A00 00 01 1 object mapped

1A00 01 20013061

Sub

Index

(hex)

Value (hex) Description

Description

1st object is process value

stored at 6130, sub index

1, length 32 bits. This can

be changed to filed value

7100, subindex 1, length

16 bits

CHAPTER 8 - SERVICE DATA OBJECTS

The Service Data Object (SDO) is used to access the object

dictionary (OD) of a device. The requester of the OD access

is called the client and the CANopen

®

device, whose OD is

accessed and services the request, is called the server. The

client CAN-message as well as the reply server CAN-message

always contains 8 bytes (although not all bytes necessarily

contain meaningful data). A client request is always confirmed

by a reply from the server. The Digital Pressure Sensor with

CANopen

®

, Model DPS, supports only one server SDO and no

client SDOs.

8.1 SDO Transfer

There are two mechanisms for SDO transfer:

• Expedited transfer: used for data objects up to 4 bytes in

length.

• Segmented transfer: for objects with length > 4 bytes.

The Digital Pressure Sensor with CANopen

lows only expedited SDO access (single CAN frame read/write

and response) to (and from) the object dictionary.

The Model DPS is capable of detecting errors within the SDO

protocol. If an error is detected then the Digital Pressure Sensor with CANopen

®

, Model DPS, replies with an SDO abort

message. Table 23 contains the supported abort codes and

their description.

Table 23. SDO

Abort Code

(hex)

0504

001160504

0001

0601 0001

0601 0002 Attempt to write a read only object

0602 0000 Object does not exist in object dictionary

0604 0041 Object cannot be mapped to the PDO

0609 0011

0609 0031

0800 0000 General error

Description

Client/server command specifier not valid or

unknown

Attempt to read a write only object. Attempt

to read a write only object. Attempt to read a

write only object. Attempt to read a write only

object. Attempt to read a write only object to

read. Attempt to read a write only object. Attempt to read a write only object

Sub-index does not exist. Attempt to read a

write-only object. Attempt to read a write-only

object

Value of parameter exceeded (only for write

access)Value of parameter exceeded (only for

write access) Value of parameter exceeded

(only for write access)

®

, Model DPS, al-

14 sensing.honeywell.com

Page 17

Digital Pressure Sensor with CANopen®, Model DPS 50085804, Rev. B

CHAPTER 9 - EMERGENCY OBJECTS

The Digital Pressure Sensor with CANopen®, Model DPS, will

transmit an emergency object if an internal error is detected or

a source of error is removed. The Model DPS supports the error

codes listed in Table 24.

9.1 Supported Emergency Codes

Table 24. Digital Pressure Sensor with CANopen®

Supported Emergency Codes

Emergency

Error Code

2201 03 Sensor failure

3201 05 Over flow / under flow

5000 81 EEPROM error

8120 11 CAN in error passive mode

8140 11 Recovered from bus off

Error Register Description

CHAPTER 10 - OPERATION

This section describes the fundamental operation and configurations available for the Digital Pressure Sensor with CANo-

®

pen

, Model DPS. The object dictionary supported is provided

in Appendix 1.

10.1 Getting Pressure Data

The Digital Pressure Sensor with CANopen®, Model DPS, by

default sends out 32 bit pressure data (in decimalized integer format, in psi units), every 100 millisec. Table 25 shows

the sequence of messages necessary to obtain the pressure

reading from the Model DPS. Provide the excitation voltage

to the Digital Pressure Sensor with CANopen

transmits boot-up message to PC on identifier 77F. Host application transmits START REMOTE NODE command. When

START REMOTE NODE command is transmitted, by the host,

the Model DPS

pressure data (in decimalized integer format, in psi units) every

100 millisec.

starts transmitting the PDO containing the 32-bit

®

, Model DPS,

10.2 Interpreting the Pressure Data

Table 25. Getting the Pressure Data

ID

(hex)

77F 1 00

000 2 01 7F

1FF 4 05 00 00 00

DLC Data (hex) Description Direction w.r.t Digi-

Byte0 Byte1 Byte2 Byte3 Byte4 Byte5 Byte6 Byte7

The Digital Pressure Sensor with CANopen®, Model DPS,

provides the pressure reading in 32 bit signed integer values

of Intel format, i.e. LSB first. The actual value of the pressure

reading depends on the number of decimal digits that should

be used with these integer values. The decimal digits used can

be read from the Model DPS using an SDO access to object

6132. In Digital Pressure Sensor with CANopen

the number of decimal digits is 3. So the pressure data can be

interpreted as 00000.005 psi.

Boot-up message.

Node ID 7F

Send command with

node Id 7F

Digital Pressure Sensor with CANopen

Model DPS, starts

transmitting PDO

containing the pressure data every 100

millisecs

®

,

®

, Model DPS,

tal Pressure Sensor

with CANopen

Transmit

Receive

Transmit

®

Sensing and Productivity Solutions 15

Page 18

Digital Pressure Sensor with CANopen®, Model DPS 50085804, Rev. B

10.3 Mapping Raw Pressure Data in PDO

Table 26 shows the procedure to map the Raw Pressure data

into PDO.

10.4 Transmission type conguration

The Digital Pressure Sensor with CANopen®, Model DPS, can

be configured to give out the pressure reading in three different

ways:

1. The PDO is transmitted when a SYNC pulse is received,

providing the data is marked as updated. The data is

marked as updated whenever the pressure data changes.

An example of this transmission type is shown in Table 20.

Table 26. Map Raw Pressure Data into PDO

ID

(hex)

67F 8 22 00 18 01 FF 01 00 C0 Disable PDO Receive

5FF 8 60 00 18 01 00 00 00 00 Return OK Transmit

67F 8 22 00 1A 00 00 00 00 00

5FF 8 60 00 1A 00 00 00 00 00 Return ok Transmit

67F 8 22 00 1A 01 10 01 00 71 Change mapping Receive

5FF 8 60 00 1A 01 00 00 00 00 Return ok Transmit

67F 8 2F 00 1A 00 01 00 00 00

5FF 8 60 00 1A 00 00 00 00 00 Return ok Transmit

67F 8 22 00 18 01 FF 01 00 40 Turn PDO on Receive

5FF 8 60 00 18 01 00 00 00 00 Return OK Transmit

DLC Data (hex) Description Direction w.r.t Digi-

Byte0 Byte1 Byte2 Byte3 Byte4 Byte5 Byte6 Byte7

2. The PDO is transmitted with every nth SYNC pulse

received, where n is a value

3. Between 1 and 240. An example of this transmission type

is shown in Table 21.

4. The PDO is transmitted when the Digital Pressure Sensor

with CANopen

happens every 100 millisec by default. This event timer

value can be configured using the object 1800 with

subindex 05. This transmission type is independent of

the SYNC pulse. An example of this transmission type is

shown in Table 22.

®

, Model DPS, event timer expires which

tal Pressure Sensor

with CANopen

Write TPDO MAP

disable

Write TPDO MAP

enable

Receive

Receive

®

16 sensing.honeywell.com

Page 19

Digital Pressure Sensor with CANopen®, Model DPS 50085804, Rev. B

Table 27. Synchronous Acyclic PDO Transmission

ID

(hex)

67F 8 22 00 18 02 00 00 00 00

5FF 8 60 00 18 02 00 00 00 Return ok Transmit

80 0 SYNC command Receive

1FF 4 00 10 00 00

80 0 SYNC command Receive

1FF 4 00 20 00 00

DLC Data (hex) Description Direction w.r.t

Digital Pressure

Byte0 Byte1 Byte2 Byte3 Byte4 Byte5 Byte6 Byte7

Sensor with

CANopen

®

Change the transmission type to synchronous

Receive

(acyclic)

Digital Pressure Sensor with CANopen

Model DPS, transmits the

pressure data if it has

®

,

Transmit

changed from the previous value. [1 psi]

Digital Pressure Sensor with CANopen

Model DPS, transmits the

pressure data if it has

®

,

Transmit

changed from the previous value. [2 psi]

Table 28. Synchronous Cyclic PDO Transmission (Cyclic with Every Sync)

ID

(hex)

67F 8 22 00 18 02 03 00 00 00

5FF 8 60 00 18 02 00 00 00 Return ok Transmit

80 0 SYNC command Receive

80 0 SYNC command Receive

80 0 SYNC command Receive

1FF 4 00 20 00 00

DLC Data (hex) Description Direction w.r.t Digi-

Byte0 Byte1 Byte2 Byte3 Byte4 Byte5 Byte6 Byte7

tal Pressure Sensor

with CANopen

Change the transmission type to synchronous (cyclic).

The Digital Pressure

Sensor with CANo-

®

pen

, Model DPS,

Receive

should transmit data

on 3rd SYNC

Digital Pressure Sensor with CANopen

®

,

Model DPS, transmits the pressure

Transmit

data reception of 3rd

SYNC commands.

[2 psi]

®

Sensing and Productivity Solutions 17

Page 20

Digital Pressure Sensor with CANopen®, Model DPS 50085804, Rev. B

Table 29. Asynchronous PDO Transmission

ID

(hex)

67F 8 22 00 18 02

5FF 8 60 00 18 02 00 00 00 Return ok Transmit

67F 8 22 00 18 05 E8 03 00 00

5FF 8 60 00 18 05 00 00 00 00

DLC Data (hex) Description Direction w.r.t Digi-

Byte0 Byte1 Byte2 Byte3 Byte4 Byte5 Byte6 Byte7

tal Pressure Sensor

with CANopen

®

Change the transmission type to

FE (or

FF)

00 00 00

acyclic. The Digital

Pressure Sensor with

CANopen

®

, Model

Receive

DPS, transmits PDO

every 100 millisec

Write to PDO communications object

event. Timer with

Receive

value of 1000 mS.

The Digital Pressure

Sensor with CANo-

®

pen

, Model DPS,

starts transmitting

Transmit

the PDO every 1000

millisec

18 sensing.honeywell.com

Page 21

Digital Pressure Sensor with CANopen®, Model DPS 50085804, Rev. B

10.5 Calibration

The Digital Pressure Sensor with CANopen®, Model DPS, allows auto zero correction by using the object 0x6125. When

autozero correction is applied, all the objects associated with

process value are changed internally by the Model DPS. The

objects related to process value are given in Table 18. An example of how to achieve zero correction is shown in the Table

30.

The auto zero value can be stored in EEPROM by using the

store command, i.e. object 0x1010. Also the default offset can

be restored using the restore command, i.e. object 0x1011.

Table 30. Auto Zero Command

ID

(hex)

67F 8 22 25 61 01 7A 65 72 6F

5FF 8 60 25 61 01 00 00 00 00 Return ok Transmit

DLC Data (hex) Description Direction w.r.t Digi-

Byte0 Byte1 Byte2 Byte3 Byte4 Byte5 Byte6 Byte7

Apply Zero Pressure

Performs an auto

zero on the current

pressure reading.

Whatever was the

offset when zero

pressure is applied

will now be nullified

tal Pressure Sensor

with CANopen

Receive

®

Sensing and Productivity Solutions 19

Page 22

Digital Pressure Sensor with CANopen®, Model DPS 50085804, Rev. B

APPENDIX - OBJECT DICTIONARY

Communication Prole Objects 0x1000 – 0x1FFF

Index SubIndex Name Description

0x1000 0x00 Device type The object describes the type of the logical device and its functionality

®

0x1001 0x00 Error register

0x1003 0x00

0x1005 0x00

0x1008 0x00

0x1009 0x00

0x100A 0x00

Pre-defined error

field

COB-ID sync message

Manufacturer

device name

Manufacturer

hardware version

Manufacturer software version

This object provided error information. The CANopen

into this object. It is a part of an emergency object

This object provides the errors that occurred on the CANopen

signaled via the emergency object. In doing so it provides an error history

This object indicates the configured COB-ID of the synchronization object (SYNC).

Further, it defines whether the CANopen

®

device generates the SYNC

This object provides the name of the device as given by the manufacturer

This object provides the manufacturer hardware version description

This object provides the manufacturer software version description

This object controls the saving of parameters in non-volatile memory. This command

0x1010 0x00-0x01 Store parameters

stores: 1) input offset, 2) span end, 3) span start, 4) heartbeat time, 5) physical

units, 6) auto zero, and 7) span

With this object, the default values of parameters according to the communication

0x1011 0x00-0x01

Restore default

parameters

profile, device profile, and application profile are restored. This command restores

1) input offset, 2) span end, 3) span start, 4) heartbeat time, 5) physical units, 6)

autozero, and 7) span

0x1014 COB-ID EMCY This object indicates the configured COB-ID for the EMCY write service

0x1017

Producer heartbeat time

The producer heartbeat time indicates the configured cycle time of the heartbeat

0x1018 0x00-0x04 Identity object This object provides general identification information of the CANopen

0x1200 0x00-x02

0x1800

0x00-0x02

and 0x05

0x1A00 0x00-0x08

SDO server parameter

TPDO communication parameter

TPDO mapping

parameter

This object contains the communication parameters for the PDOs the CANopen

device is able to transmit

This object contains the mapping for the PDOs the device is able to transmit

device maps internal errors

®

device and were

®

device

®

20 sensing.honeywell.com

Page 23

Digital Pressure Sensor with CANopen®, Model DPS 50085804, Rev. B

APPENDIX - OBJECT DICTIONARY, continued

CiA Device Prole Objects 0x6000 – 0x9FFFF

Index SubIndex Name Description

0x6110 0x00-x01 AI sensor type Specifies the type of sensor, which is connected to the analogue input

0x6124 0x00-0x01 AI input offset

0x6125 0x00-0x01 Auto sero

0x6131 0x00-x01 AI physical units

0x6132 0x00-x01 AI decimal digits

0x6148 0x00-0x01 AI span start

0x6149 0x00-0x01 AI span end

0x6130 0x00-x01

0x7100 0x00-x01

AI process value

(integer)

AI field value

(integer)

This object defines the additional offset value for the analogue input channel. It is

scaled in physical unit of process value

Writing a signature value of "zero“ to this object way that the actual AI input PV becomes zero. Along with the input offset value, this cycle is performed one time

This object assigns SI units and prefixes for the process values within the analogue

input function block

This object describes the number of decimal digits following the decimal point for

interpretation of data types Integer8, Integer16, and Integer32

This value specifies the lower limit where process values are expected. Process

values that are lower than this limit are marked as negative overloaded

This value specifies the upper limit where process values are expected. Process

values exceeding this limit are marked as positive overloaded

This object represents the result of the input scaling block and gives the measured

quantity scaled in the physical unit of process values

This object represents the raw ADC counts

Manufacturer Specic Objects 0x2000- 0x27FF

Index SubIndex Name Description

0x2002 0x00 Acquisition time

0x2003 0x00

0x2004 0x00

0x2005 0x00

0x2006 0x00 Pressure span Pressure span value RD

0x2007 0x00

0x2008 0x00

0x2009 0x00

0x200A 0x00 Pressure coeff1 Coefficient 1 used for calibration RD

0x200B 0 Pressure coeff2 Coefficient 2 used for calibration RD

0x200C 0 Pressure offset Offset used for calibration RD

0x200D 0 Sensor type Type of sensor: 1 for absolute, 2 for gauge, 3 for differential RD

0x200E 0 Serial number Serial number of the device RD

Acquisition interval

Pressure span

overflow count

Pressure span

underflow count

Last calibration

year

Last calibration

month

Last calibration

day

The time taken by the ADC to acquire data. The value to be expected is

15 microsecs

Time at which the data is captured form the ADC. The value to be expected is 1 millisec

Counts the number of times the pressure value crosses the maximum

span

Counts the number of times the pressure value crosses the minimum span RD

The year of the date on which it was calibrated last time RD

The month of the date on which it was calibrated last time RD

The day of the date on which it was calibrated last time RD

RD

RD

RD

Sensing and Productivity Solutions 21

Page 24

WARRANTY/REMEDY

Honeywell warrants goods of its manufacture as being free of

defective materials and faulty workmanship. Honeywell’s stan-

dard product warranty applies unless agreed to otherwise by

Honeywell in writing; please refer to your order acknowledge-

ment or consult your local sales office for specific warranty

details. If warranted goods are returned to Honeywell dur-

ing the period of coverage, Honeywell will repair or replace,

at its option, without charge those items it finds defective.

The foregoing is buyer’s sole remedy and is in lieu of all

other warranties, expressed or implied, including those of

merchantability and tness for a particular purpose. In no

event shall Honeywell be liable for consequential, special,

or indirect damages.

While we provide application assistance personally, through

our literature and the Honeywell web site, it is up to the custom-

er to determine the suitability of the product in the application.

Specifications may change without notice. The information we

supply is believed to be accurate and reliable as of this print-

ing. However, we assume no responsibility for its use.

Find out more

Honeywell serves its customers through

a worldwide network of sales offices,

representatives and distributors. For

application assistance, current specifications, pricing or name of the nearest

Authorized Distributor, contact your local

sales office.

To learn more about Honeywell’s test

and measurement products,

call +1-614-850-5000, visit

measurementsensors.honeywell.com,

or e-mail inquiries to

info.tm@honeywell.com

Honeywell Sensing and Productivity Solutions

9680 Old Bailes Road

Fort Mill, SC 29707

honeywell.com

50085804, Rev. B IL50 GLO

April 2016

Copyright © 2016 Honeywell International Inc. All rights reserved.

Hastelloy

CiA

®

is the registered trademark name of Haynes International, Inc.

®

and CANopen® are registered trademarks of CAN in Automation e.V.

Loading...

Loading...