Page 1

-

Dfl©m<eyw®flfl

DPS

8

SYSTEM

INSTALLATION

MANUAL

WCPU66LB

WMMU66LB

WIOUlOOA

WIOUlOOB

W10U66LA

58010048

GHALRIWARE

l

58010048“500

REV

B

JUNE

1986

DIST.

NCO,XAN

Page 2

This

manual

has

been

prepared

to

serve

as

a

guide

for

Honeywell

personnel

to

install,

verify,

and

deinstail

a

DPS

8

System.

Each

Preinstallation

and

installation

Task

is

numerically

and

chronologically

listed

on

the

System

Checkpff

list,

providing

the

installer

with

a

synopticai

View

of

each

task

to

be

performed.

This

listing

is

printed

on

heavy

paper

and

is

found

immediately

after

the

Table

of

Contents.

After

the

Preinstallation

and

Installation

Tasks

have

been

identified,

classified,

and

listed,

they

are

defined

in

the

appropriate

section

of

the

System

Installation

manual.

Other

features

include

instructions

for

unpackaging, unpacking,

inspection,

cable

routing,

and

connections.

Power

system

checkout

procedures

to

help

assure

correct

equipment

operation

and

performance

and

deinstallation

procedures

required

for

safe

disconnection

and

return

of

equipment

are

also

included

in

this

manual.

NOTICE

1F

REV

B

The

following

notice

is

provided

in

accordance

with

the

United

States

Federal

Communications

Commission's

(FCC)

regulations:

Warning:

This

equipment

generates,

uses,

and

can

radiate

radio

frequency

energy,

and

if

not

installed

and

used

in

accordance

with

the

instruction

manual,

may

cause

interference

to

radio

communications.

The

equipment

manufactured

after

October

1,1983

has

been

tested

and

found

to

comply

with

the

limits

for

a

Class

A

computing

device

pursuant

to

Subpart

J

of

Part

15

of

FCC

Rules,

which

are

designed

to

provide

reasonable

protection

against

such

interference

when

operated

in

a

commercial

environment.

Operation

of

this

equipment

in

a

residential

area

is

likely

to

cause

interference,

in

which

case

the

user

at

his

own

expense

will

be

required

to

take

whatever

measures

may

be

required

to

correct

the

interference.

This

document

and

the

information

contained

herein

are

confidential

to

and

the

property

of

Honeywell

Information

Systems,

Inc.

and

are

made

available

only

to

Honeywell

employees

for

the

sole

purpose

of

maintaining

Honeywell’s

products.

This

document,

any

cooy

thereof

and

the

information

contained

herein

shall

be

maintained

in

strictest

confidence;

shall

not

be

copied

in

whole

or

in

part

except

as

authorized

by

the

employee’s

manager;

and

shall

not

be

disclosed

or

distributed

(a)

to

persons

who

are

not

Honeywell

employees,

or

(b)

to

Honeywell

employees

for

whom

such

information

is

not

necessary

in

connection

with

their

assigned

responsibilities.

Upon

request,

or

when

the

employee

in

possession

of

this

document

no

longer

has

need

for

the

document

for

the

authorized

Honeywell

purpose,

this

document

and

any

copies

thereof

shall

be

returned

to

the

employee's

manager.

There

shall

be

no

exceptions

to

the

terms

and

conditions

set

forth

herein

except

as

authorized

in

writing

by

the

responsible

Honeywell

Vice

President.

58010048-011

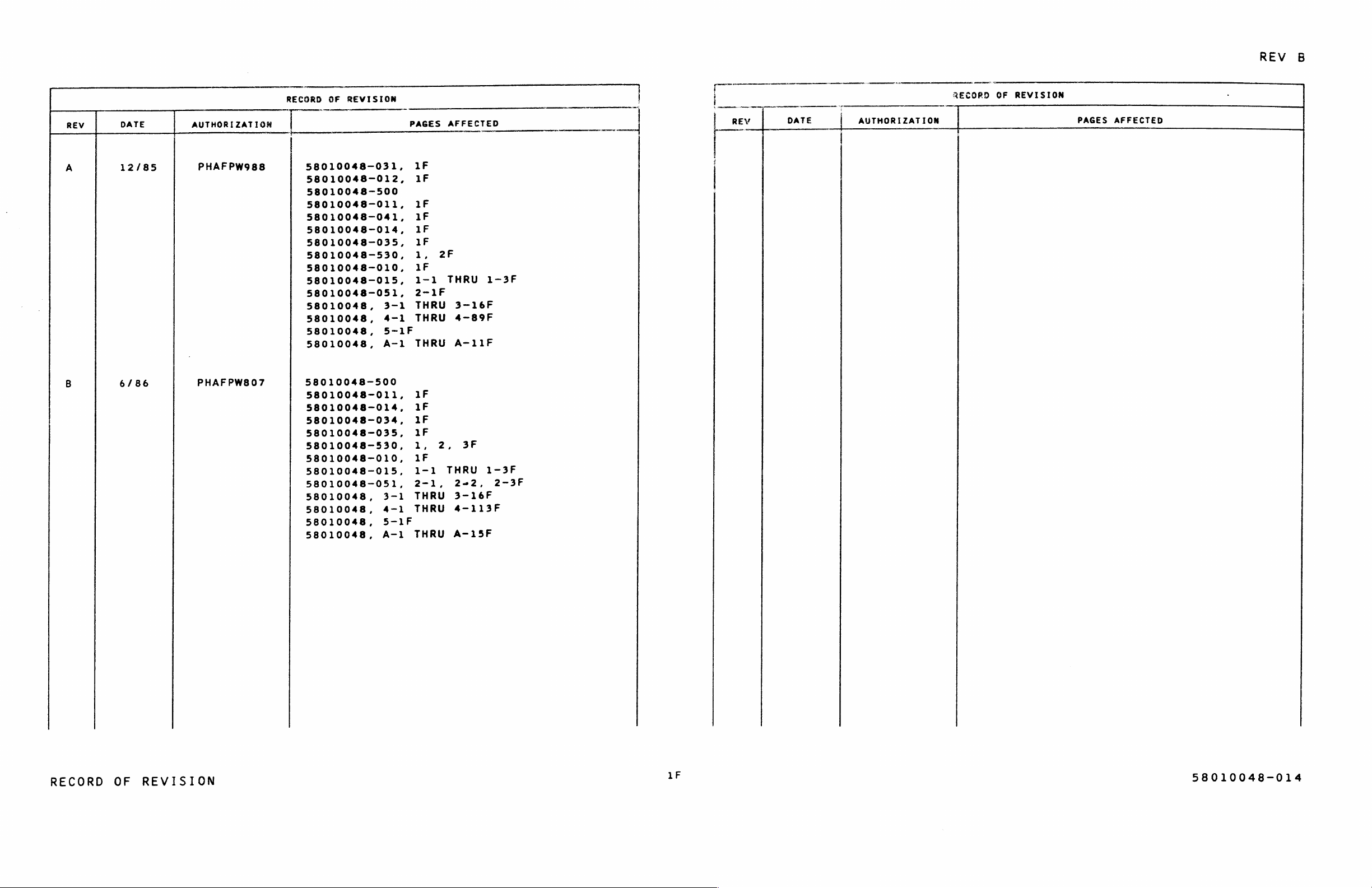

Page 3

RECORD

OF

REVISION

REV

DATE

AUTHORIZATIOfl

PAGES

AFFECTED

12/85

6/86

PHAFPW988

PHAFPWSO?

RECORD

OF

REVISION

58010048-031.

58010048-012,

58010048-500

58010048-011,

58010048-041,

58010048-014,

58010048-035,

58010048-530,

58010048-010.

58010048-015,

58010048-051,

58010048,

3-1

58010048,

4-1

58010048,

A-1

58010048-500

58010048-011.

58010048-014,

58010048-034,

58010048-035.

58010048-530,

58010048-010.

58010048-015.

58010048-051,

58010048,

3-1

58010048,

4-1

58010048.

A-l

1F

1F

1F

1F

1F

1F

1,

2F

1F

1-1

THRU

1-3F

2-1F

THRU

3-16F

THRU

4-89?

58010048,

5-1F

THRU

A-11F

1F

1F

1F

1F

1!

1?

1-1

THRU

1-3F

2-1,

262,

2-3F

THRU

3-16F

THRU

4-113F

2,

BF

58010048,

5-1F

THRU

A-15F

IF

Ithan-1mg

RECORD

OF

REVISION

REV

B

REV

DATE

AUTHORIZATION

PAGES

AFFECTED

58010048-014

Page 4

REV

8

Revised

entire

manual

to

reflect

the

shielded

cable

versions

and

their

options.

SUMMARY

OF

CHANGES

1F

58010048-034

Page 5

REV’

B

Honeywell

Large

Syatema

Hardware

@Uh?itat§aa;

P.

G.

Box

8000,

MS

cap

Phoenix,

Arizona

snoéemanon

i

-

“”"“

’”'W

'

geflgufia

e

{53010048

]

5

a

BPS

8

l

*fifiVISEOM

B

TITLEISYSTEM

INSTALLAIIQN

MAHUAL

;

‘

i

i

J

[

VDATED

[JUNE

1986

]

ERRORS

IN

PUBLICATION

SUGGESTIONS

FOR

IMPROVEMENT

TO

PUBLICATION

Your

comments

wlll

be

investigated

by

appropriate

technical

personnel

and

action

will

be

token

as

required.

Receipt

of

all

forms

will

be

acknowledced;

however,

if

you

requlre

a

detailed

reply,

check

here.

[::]

FROM:

NAME

DATE

TITLE

ADDRESS

PHONE

#

USER

REMARKS

1F

58010048*035

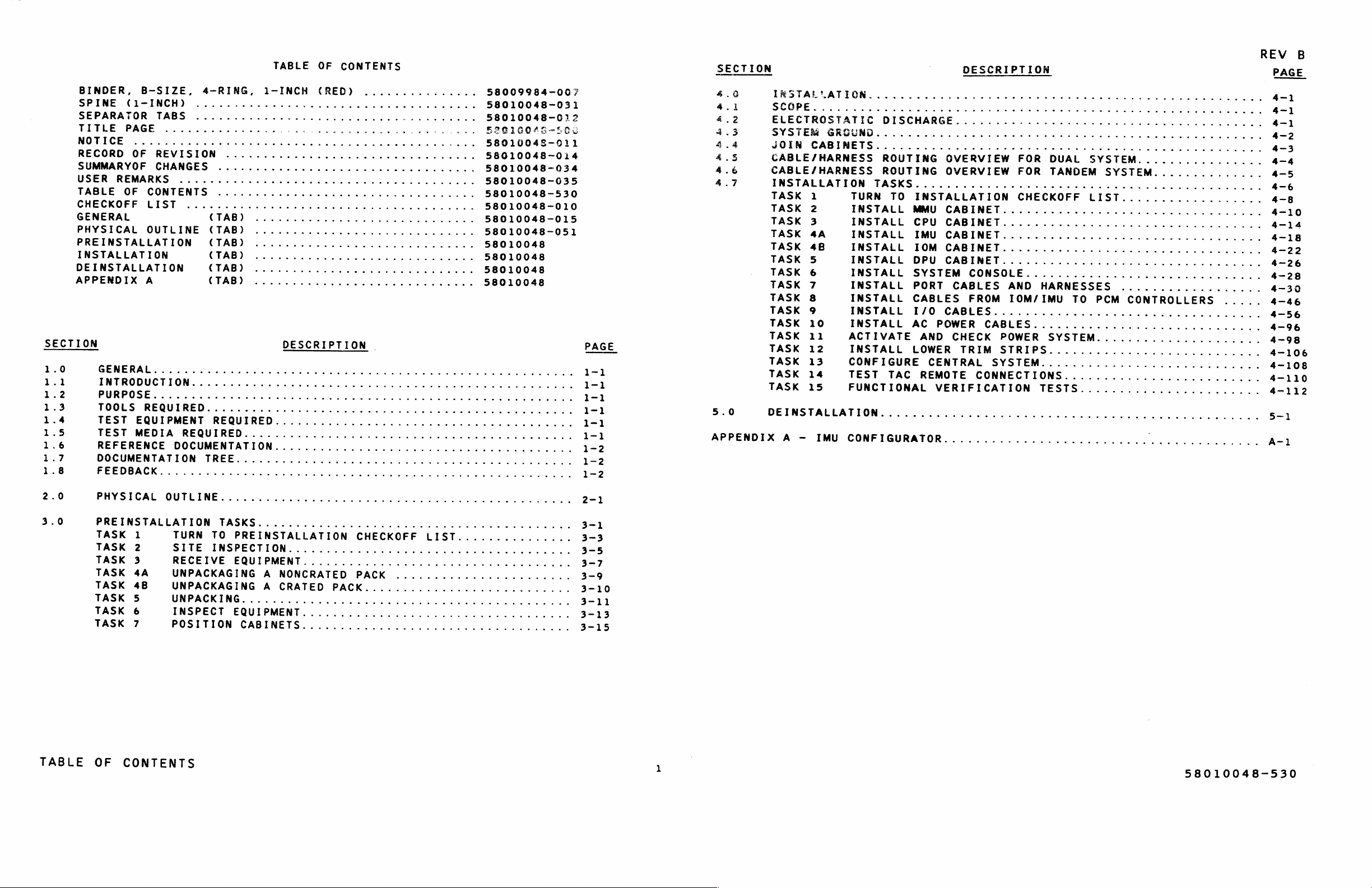

Page 6

HHHHHHHHH

GNOUIbUNO-‘O

O

BINDER.

SPINE

(1-INCH)

SEPARATOR

TABS

......................................

58010048-012

TITLE

PAGE

NOTICE

RECORD

OF

REVISION

.................................

58010048-014

SUMMARYOF

CHANGES

..................................

58010048-034

USER

REMARKS

TABLE

OF

CONTENTS

..................................

58010048-530

CHECKOFF

LIST

GENERAL

PHYSICAL

OUTLINE

(TAB)

PREINSTALLATION

INSTALLATION

DEINSTALLATION

APPENDIX

A

SECTION

B-SIZE.

4-RING,

l-INCH

(RED)

ooooooooooooooooooooooooooooooooooooooooooooo

OOOCOOI O CO.

O O‘8Q..1"Ef.-OiQ Gl‘0k‘0vC1D-k‘I5555555

TABLE

OF

CONTENTS

58009984-00?

58010048-031

ooooooooooooooo

OOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOO

agazacfiam§.g

58010043-911

.......................................

58010048-035

58010048-010

58010048-015

58010048-051

58010048

58010048

58010048

58010048

OOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOO

OOOOOOOOOOOOOOOOOOOOOOOOOOOOO

00000000000000000000000000000

(TAB)

(TAB)

(TAB)

(TAB)

ooooooooooooooooooooooooooooo

ooooooooooooooooooooooooooooo

ooooooooooooooooooooooooooooo

OOOOOOOOOOOOOOOOOOOOOOOOOOOOO

DESCRIPTION

.

GENERAL

.......................................................

INTRODUCTION

..................................................

PURPOSE

.......................................................

TOOLS

REQUIRED

................................................

TEST

EQUIPMENT

REQUIRED

.......................................

TEST

MEDIA

REQUIRED

...........................................

REFERENCE

DOCUMENTATION

.......................................

DOCUMENTATION

TREE

............................................

FEEDBACK

......................................................

PHYSICAL

OUTLINE

..............................................

PREINSTALLATION

TASKS

.........................................

TASK

TASK

TASK

TASK

TASK

TASK

TASK

TASK

1

2

3

4A

4B

5

6

7

TURN

T0

PREINSTALLATION

CHECKOFF

LIST

...............

SITE

INSPECTION

.....................................

RECEIVE

EQUIPMENT

...................................

UNPACKAGING

A

NONCRATED

PACK

.......................

UNPACKAGING

A

CRATED

PACK

...........................

UNPACKING

...........................................

INSPECT

EQUIPMENT

...................................

POSITION

CABINETS

.....................

v

..............

TABLE

OF

CONTENTS

2-1

3-1

3-3

3-5

3-7

3-9

3-10

3-11

3-13

3-15

REV

B

SECTION

DESCRIPTION

PAGE

4.0

INSTALLATION..................................................

4-1

4.1

SCOPE.

........................................................

4-1

5.2

ELECTROSTATIC

DISCHARGE

.......................................

4—1

4.3

SYSTEfi

GROUND

.................................................

4-2

4.4

JOIN

CABINETS

.................................................

4-3

4.5

CABLE/HARNESS

ROUTING

OVERVIEW

FOR

DUAL

SYSTEM

................

4-4

4.6

CABLEIHARNESS

ROUTING

OVERVIEW

FOR

TANDEM

SYSTEM

..............

4—5

4.7

INSTALLATION

TASKS

............................................

4-6

TASK

1

TURN

TO

INSTALLATION

CHECKOFF

LIST

..................

4-8

TASK

2

INSTALL

MMU

CABINET

.................................

4-10

TASK

3

INSTALL

CPU

CABINET

.................................

4-14

TASK

4A

INSTALL

IMU

CABINET

.................................

4-18

TASK

4B

INSTALL

IOM

CABINET............................

.....

4-22

TASK

5

INSTALL

DPU

CABINET

.................................

4-26

TASK

6

INSTALL

SYSTEM

CONSOLE

..............................

4-28

TASK

7

INSTALL

PORT

CABLES

AND

HARNESSES

..................

4-30

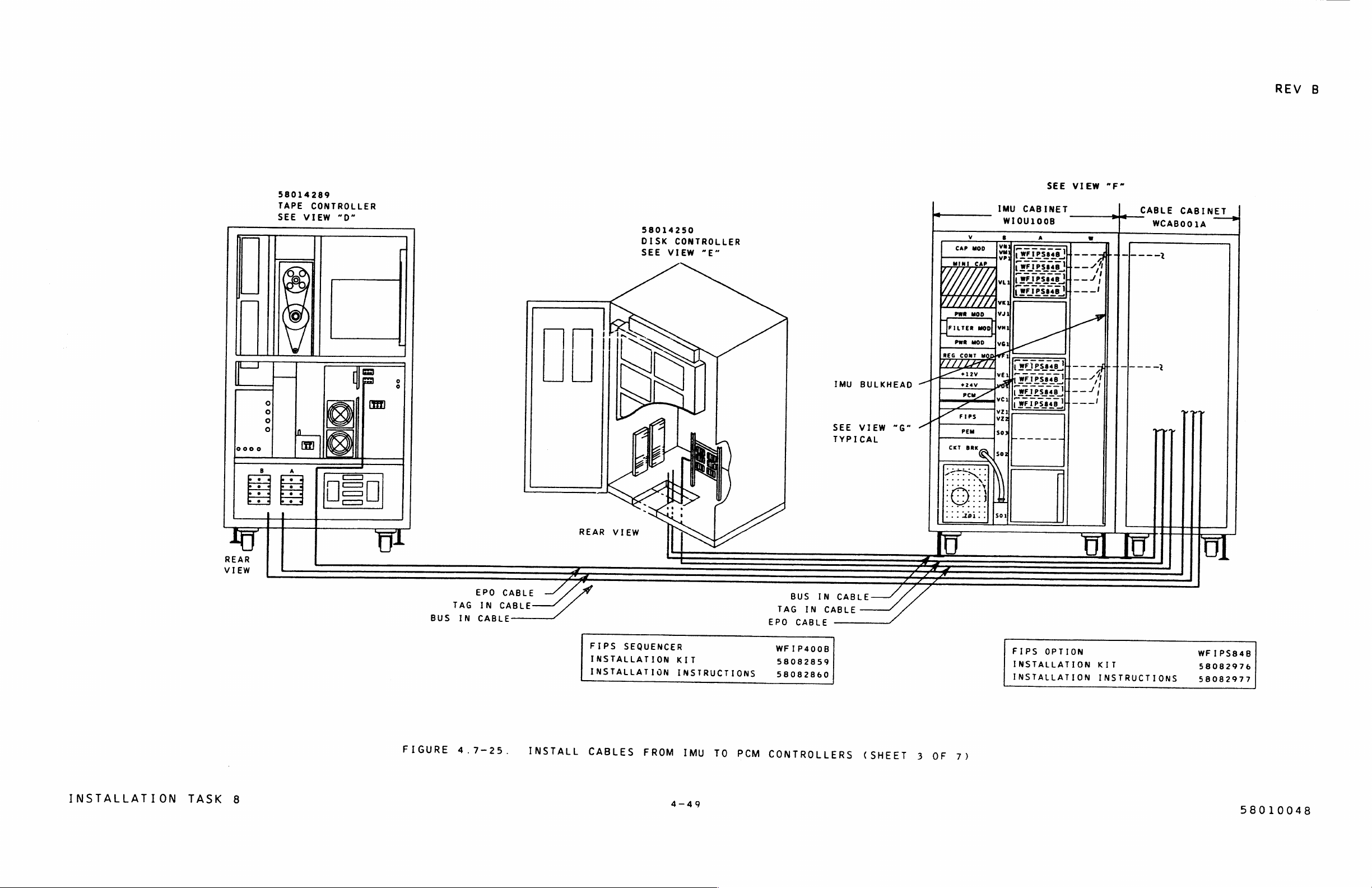

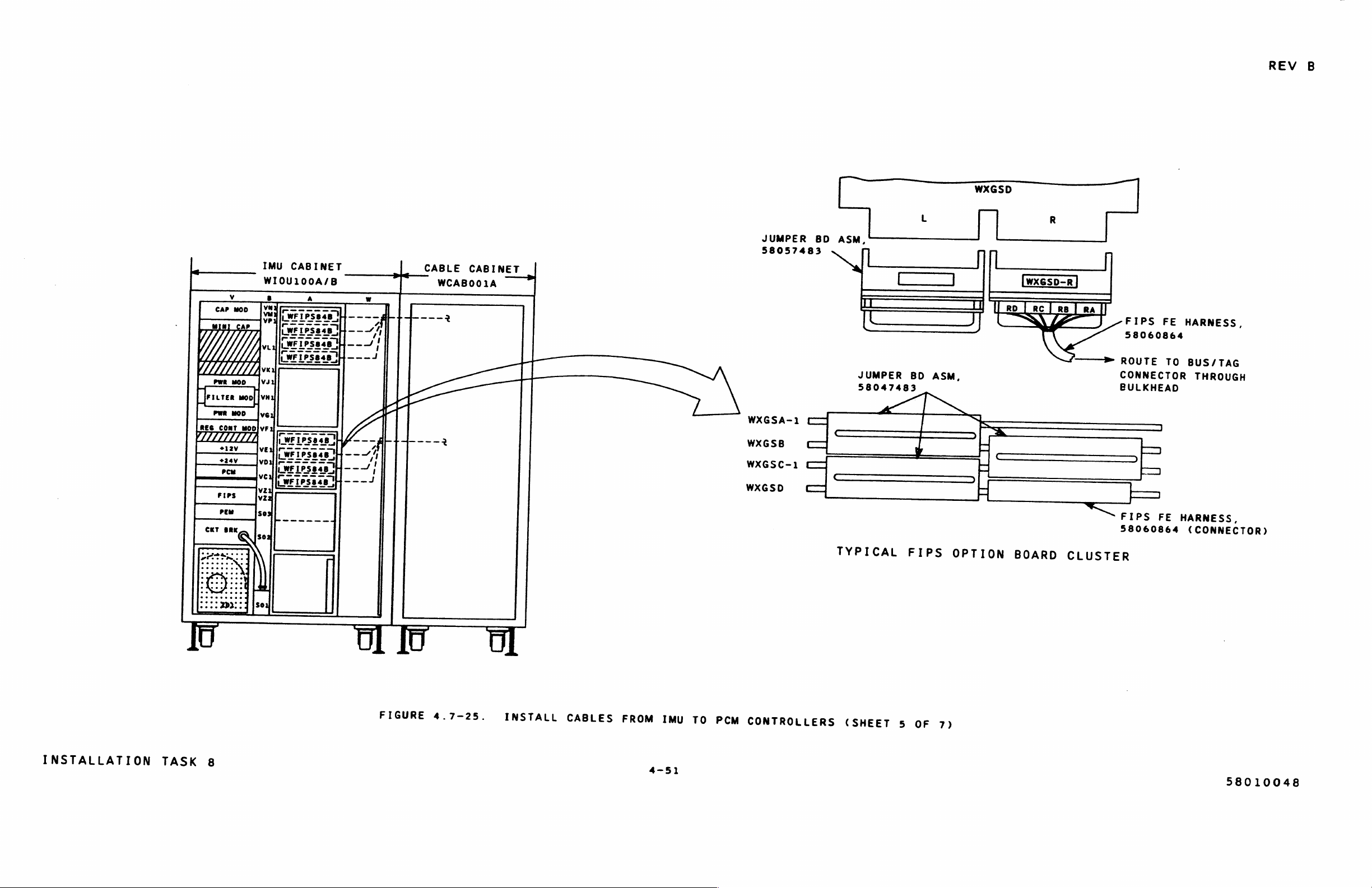

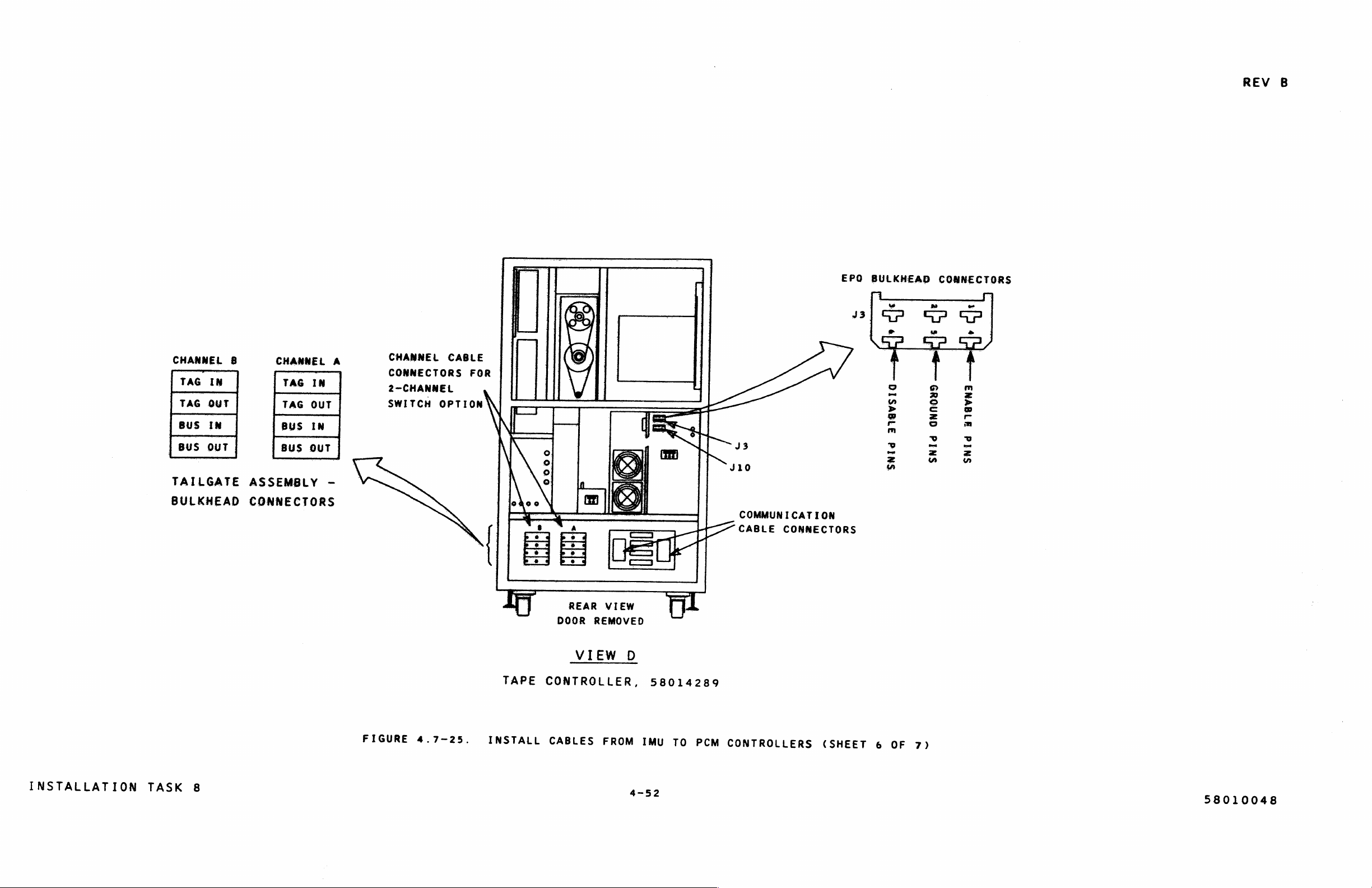

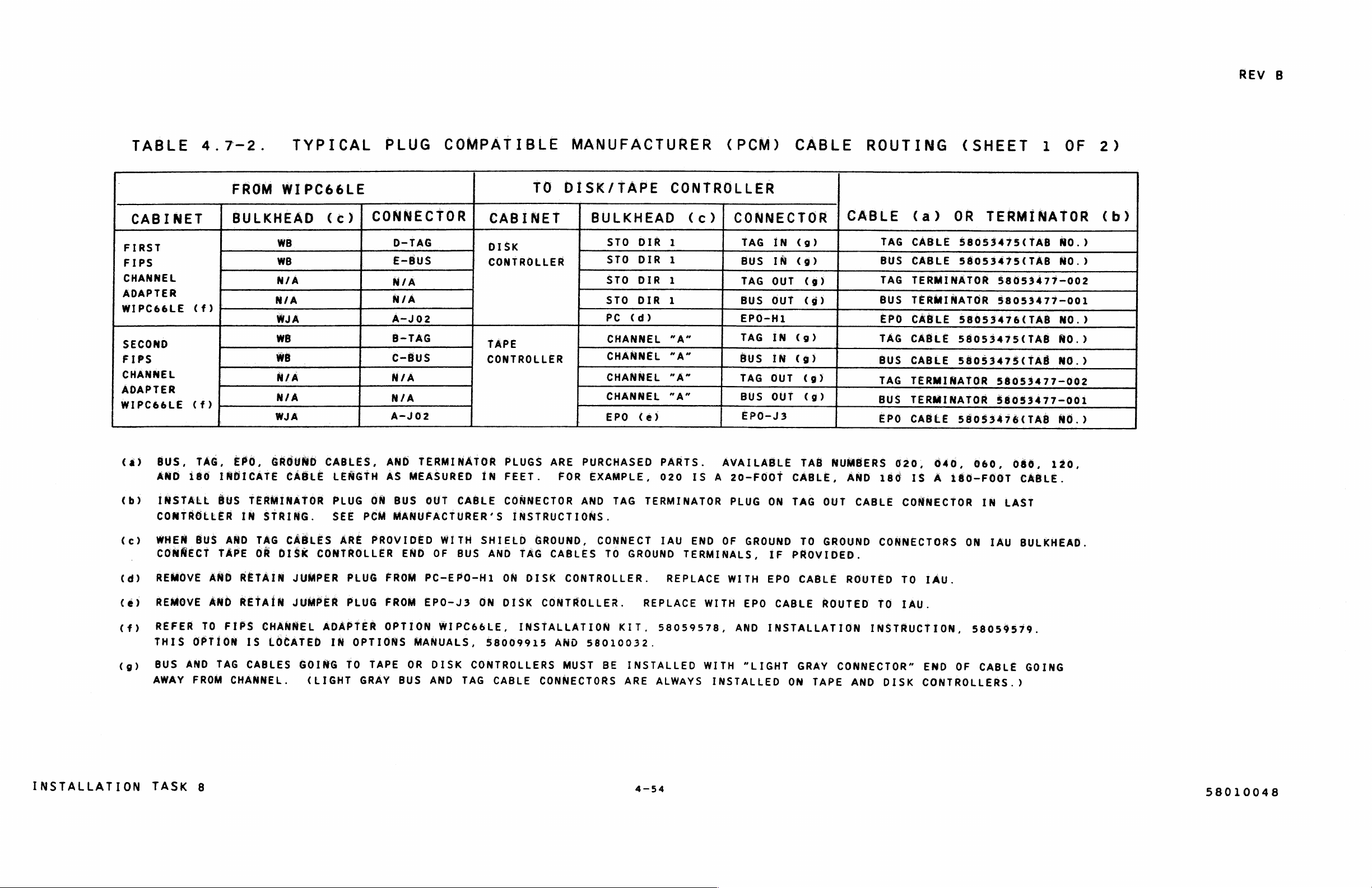

TASK

8

INSTALL

CABLES

FROM

IOM/IMU

TO

PCM

CONTROLLERS

.....

4-46

TASK

9

INSTALL

IIO

CABLES

..................................

4-56

TASK

10

INSTALL

AC

POWER

CABLES

.............................

4-96

TASK

11

ACTIVATE

AND

CHECK

POWER

SYSTEM

.....................

4-98

TASK

12

INSTALL

LOWER

TRIM

STRIPS

...........................

4-106

TASK

13

CONFIGURE

CENTRAL

SYSTEM

............................

4-108

TASK

14

TEST

TAC

REMOTE

CONNECTIONS

.........................

4-110

TASK

15

FUNCTIONAL

VERIFICATION

TESTS

.......................

4-112

5.0

DEINSTALLATION

................................................

5-1

APPENDIX

A

-

IMU

CONFIGURATOR

........................................

A-l

58010048-530

Page 7

~ru-usau-u~au-q~au<ruvb\»NIo-u

I

q

I

#-

4h9h{Obi-55:375.:«b:tP-I-IDLPD-

«It

{#75

957%

3‘

"Citah-bub

whack

hl-b

-&

ab ‘-

35

#7

DI

&

'75

It

JD

«5

b

b

b

b

N

70-0

FIGURE

IIIIIII

I

AHHOGN0U=5UN‘HH‘HH-HHHH

I

Q

I

hLH

SuTurro

N

I

ah

.7-15

.7-1Q

.7—

I7

.7

1Q

.7-17

~77§Q

7-177

.7

77

.7—

23

.7«

74

-3

35

.7-7O

.Zégl

7-73

.7-

-29

.7

3O

.7-31

.7-72

.7-

37

-7-21

LIST

OF

ILLUSTRATIONS

TITLE

PACE

OPS

a

DOCUMENTATION

TREE

....................................

1-3

PHYSICAL

OUTLINE

............................................

2-1

ELECTROSTATIC

DISCHARGE

WRIST

STRAP

APPLICATION

.............

4-1

TOP

VIEW

OF

SYSTEM

CROUNO

AREA

IN

MMU

CABINET

...............

4-2

JOINING

CABINETS

TOGETHER

...................................

4-3

OUAL

SYSTEM

CABLE/HARNESS

ROUTING

..........................

4-4

TANOEM

SYSTEM

CABLE/HARNESS

ROUTING

........................

4-5

POSITION

MMU

CABINET

........................................

4-11

MMU

CABINET

-

CIRCUIT

BOARO

LOCATION

........................

4-12

MMU

CABINET

-

PONER

PANELS

..................................

4-13

POSITION

CPU

CABINET

........................................

4-15

CPU

CAOINET

-

CIRCUIT

OOARO

LOCATION

........................

4-16

CPU

CABINET

-

PONER

PANELS

..................................

4—17

POSITION

IMU

CABINET

........................................

4-19

IMU

CAQINET

-

CIRCUIT

ROARO

LOCATION

........................

4-20

IMu

CABINET

-

POWER

PANELS

..................................

4-21

POSITION

IOM

CABINET

........................................

4-23

IOM

CABINET

-

CIRCUIT

BOARO

LOCATION

........................

4-24

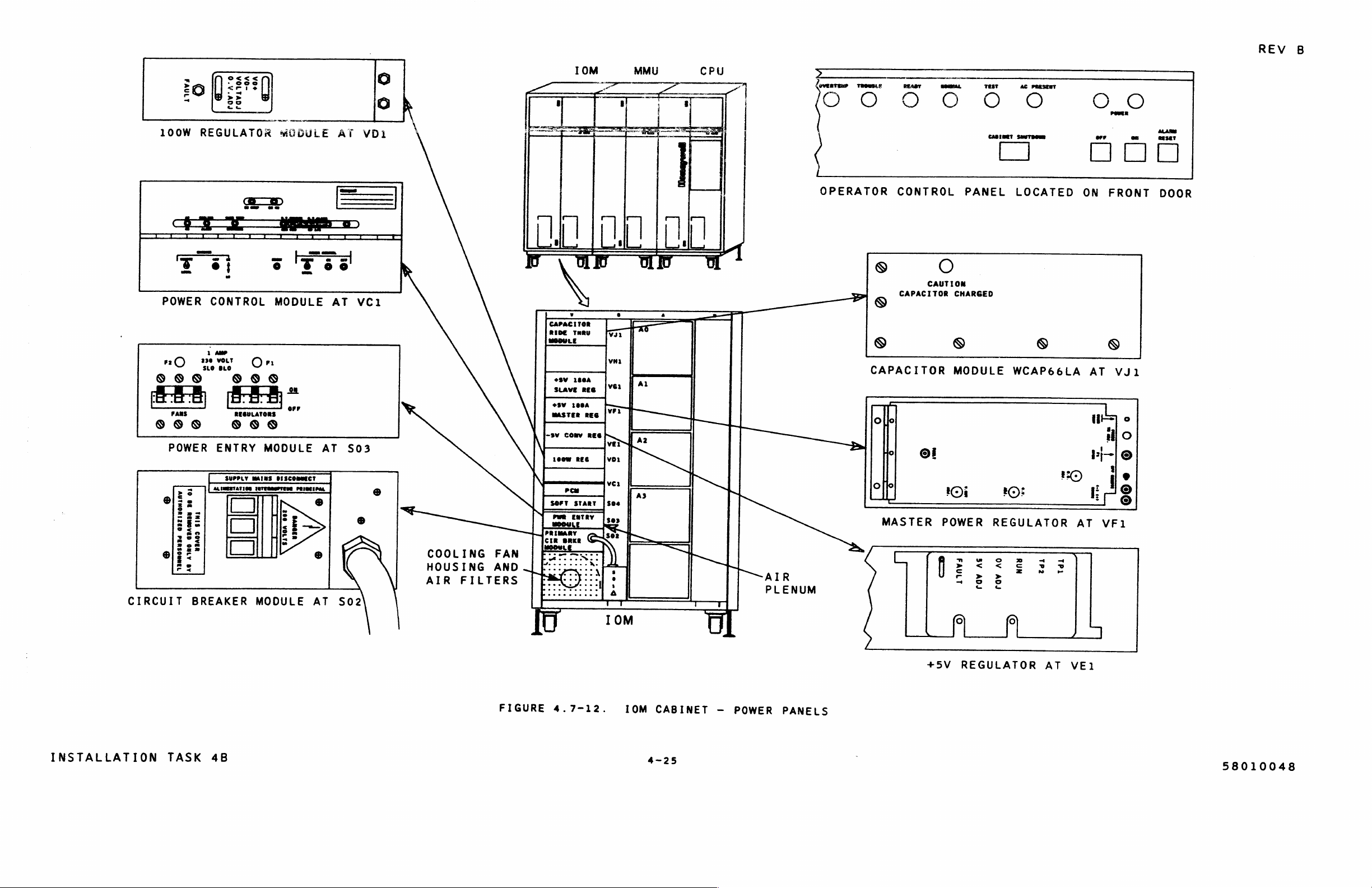

IoM

CABINET

-

PONER

PANELS

..................................

4-25

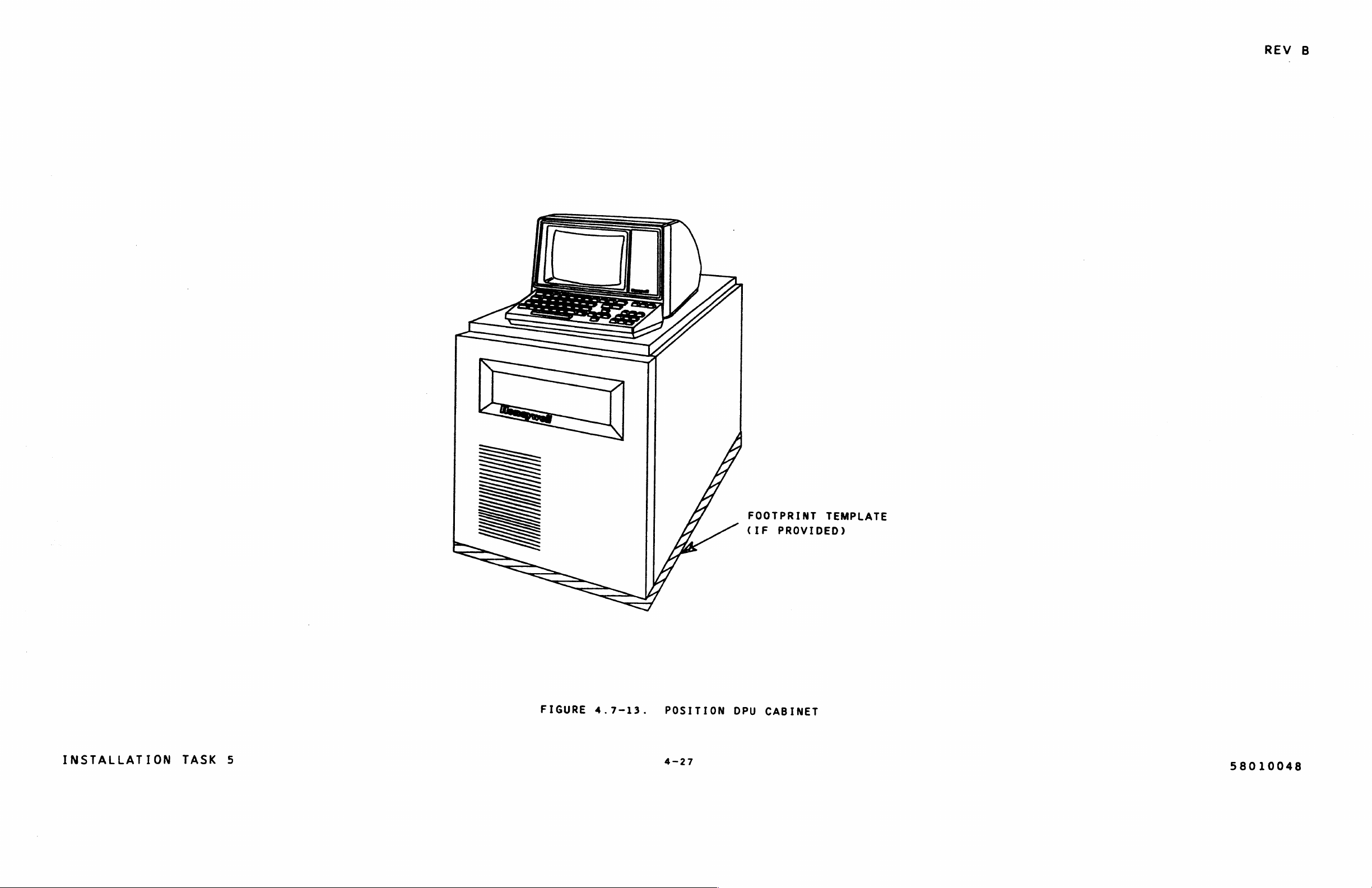

POSITION

OPU

CABINET

........................................

4-27

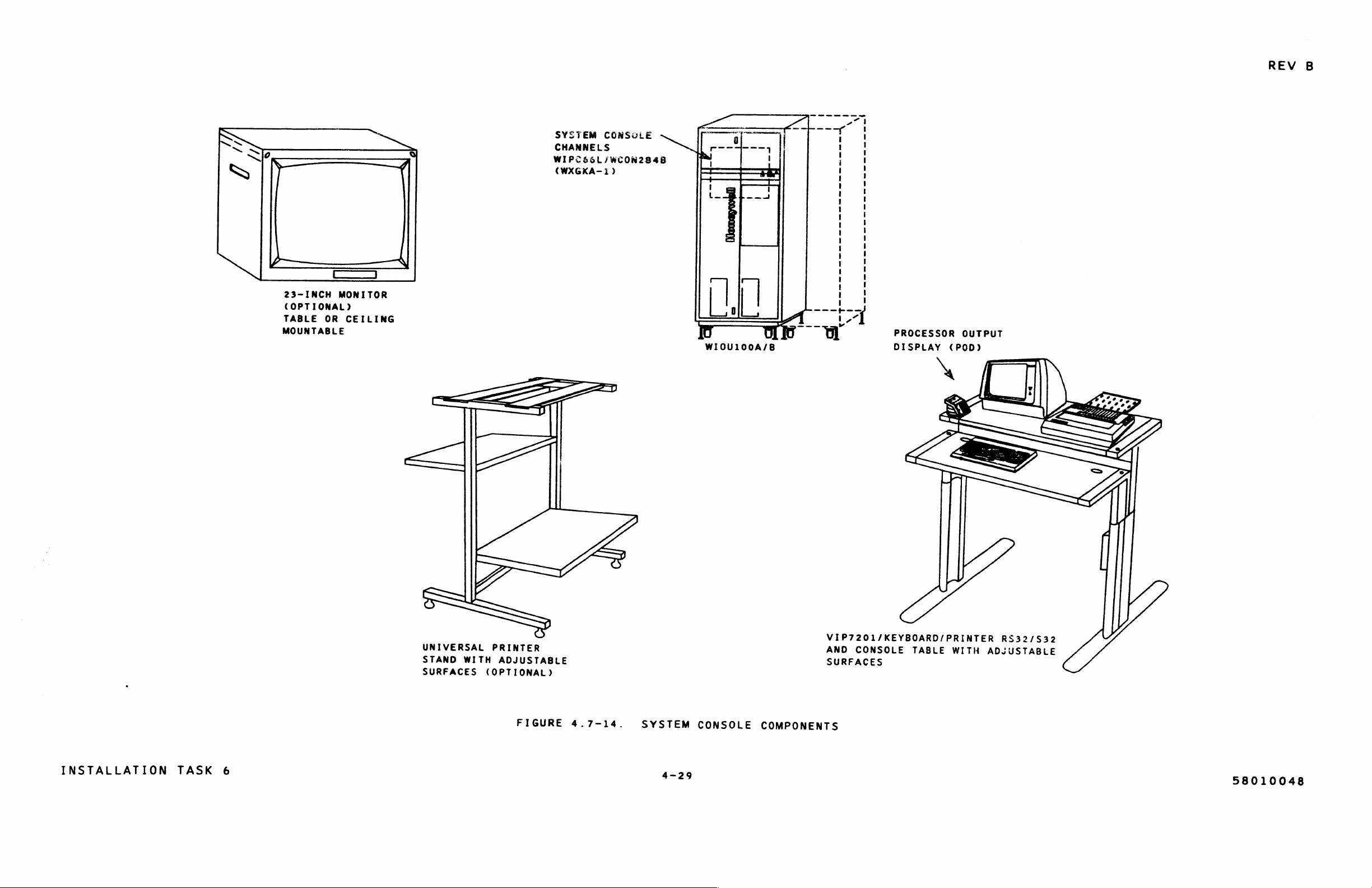

POSITION

SYSTEM

CONSOLE

.....................................

4-29

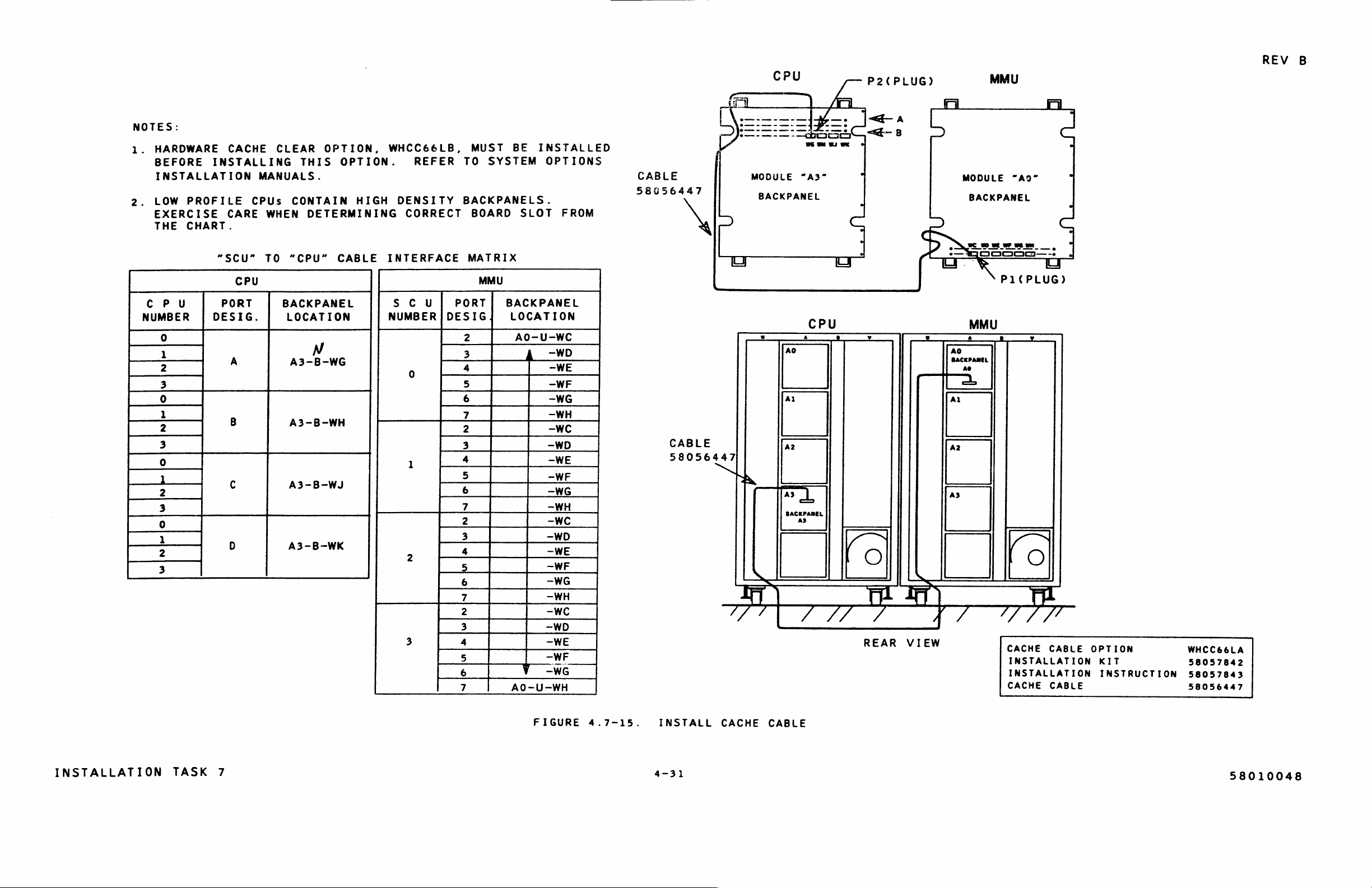

INSTALL

CACHE

CABLE

.........................................

4—31

INSTALL

ACTIVE

PORT

CABLE

...................................

4-32

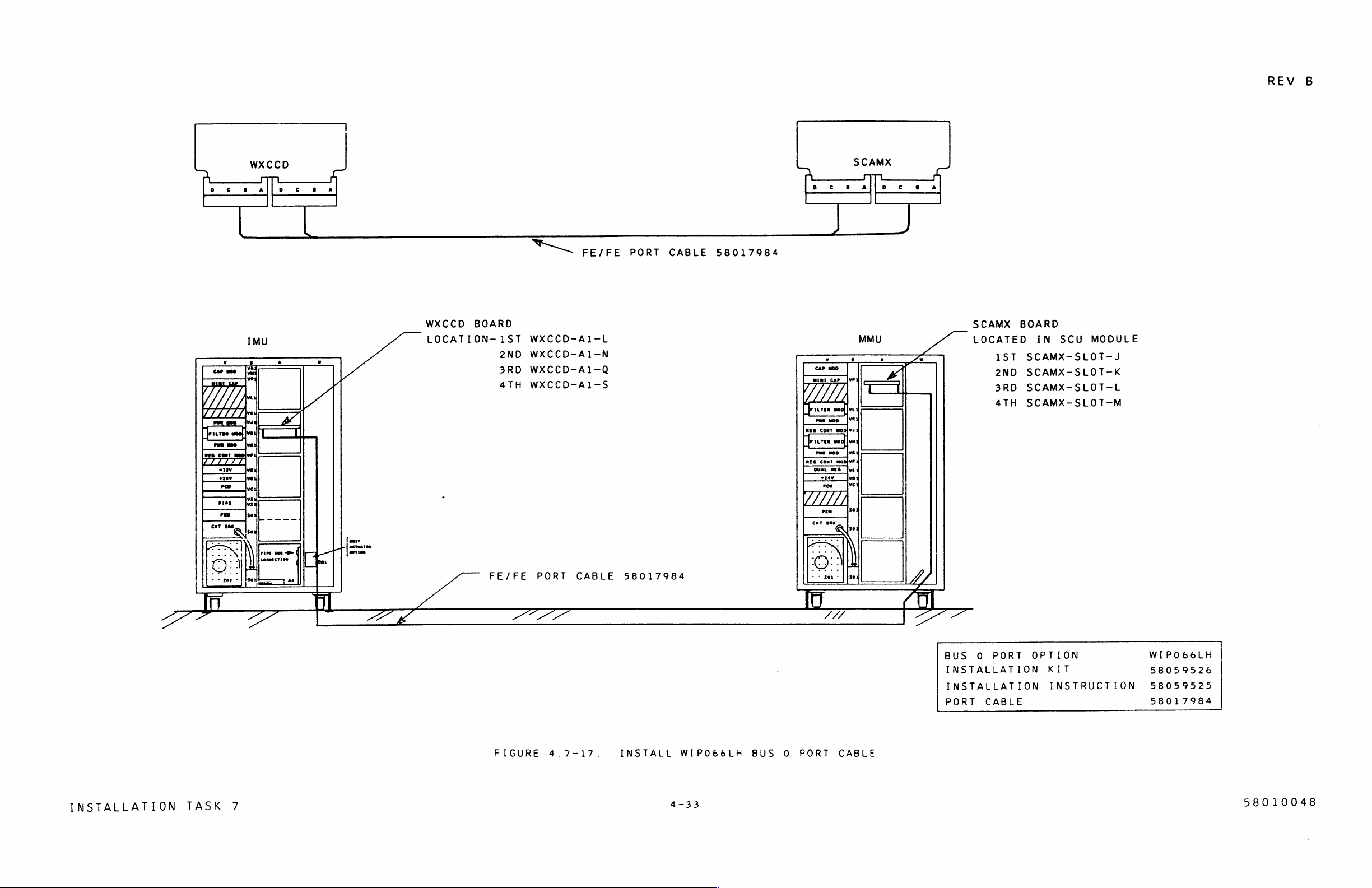

INSTALL

WIPGQQLH

OOS

O

PORT

CABLE

...........................

4-33

INSTALL

WIPOQQLH

Bus

I

9987

CAOLE

...........................

4-34

INSTALL

NIPOOOLJ

OOS

O

PORT

CABLE

...........................

4-35

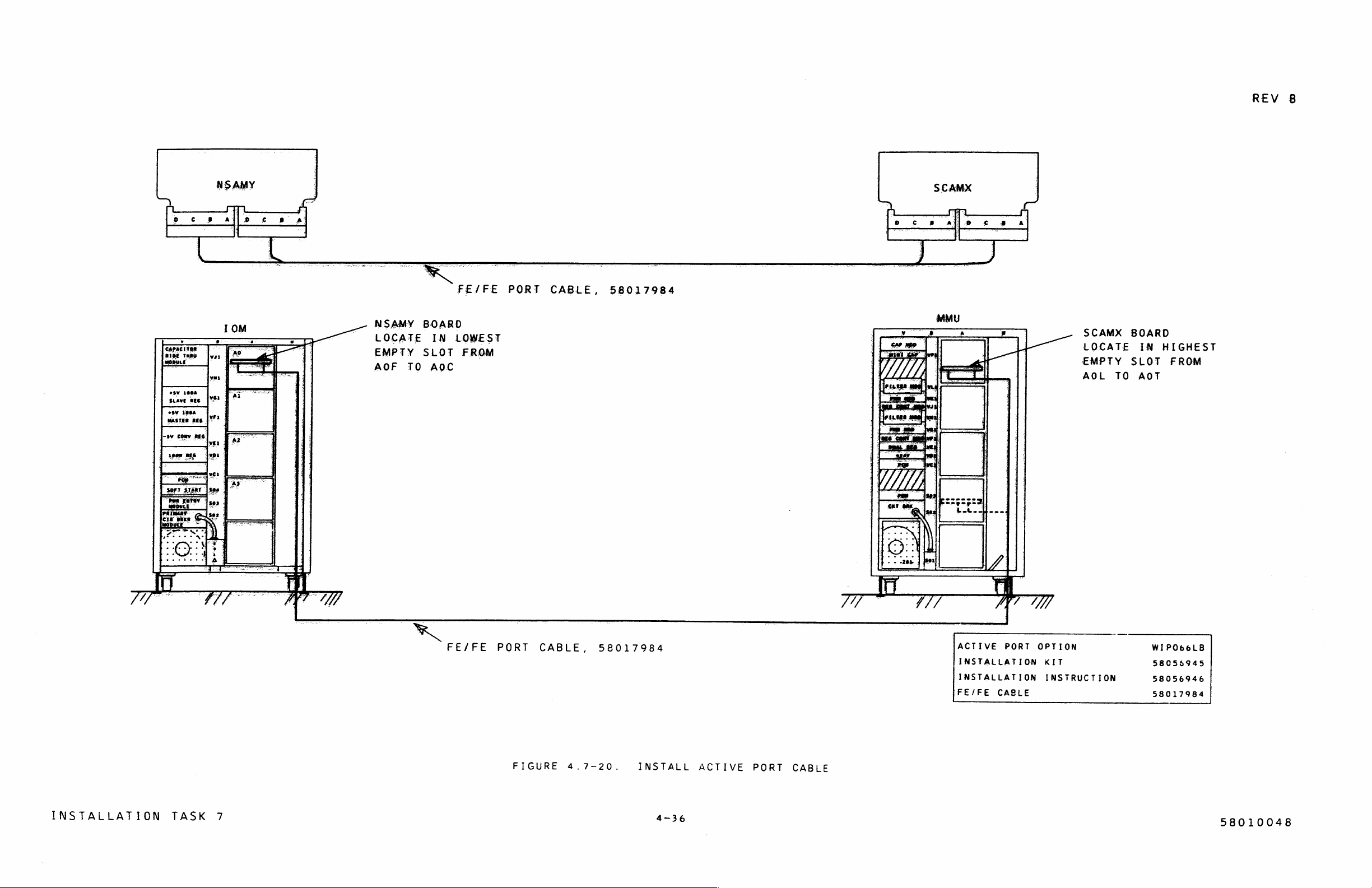

INSTALL

ACTIVE

PORI

CABLE

...................................

4-36

IN$TALL

IOM

PORT

CARLE........................

..........

....

4-37

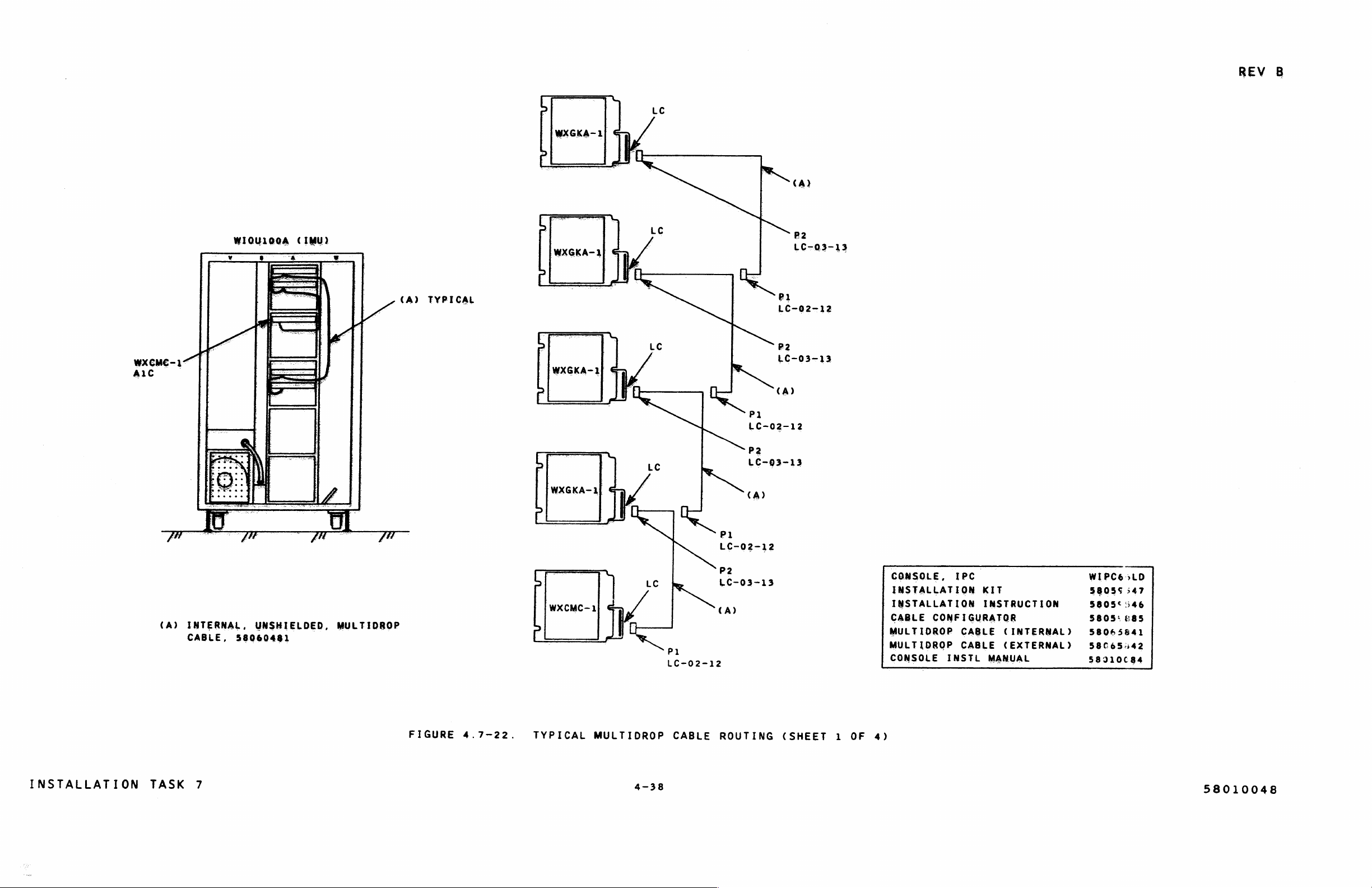

TYPICAL

MULTIOROP

CABLE

ROUTINE

.............................

4-33

INSTALL

NIPOO4LN

Bus

O

SNIELOEO

PORT

CABLE

..................

A-Az

INSTALL

NIPOOILI

OUS

O

SNIELOEO

PORT

CABLE

..................

4-44

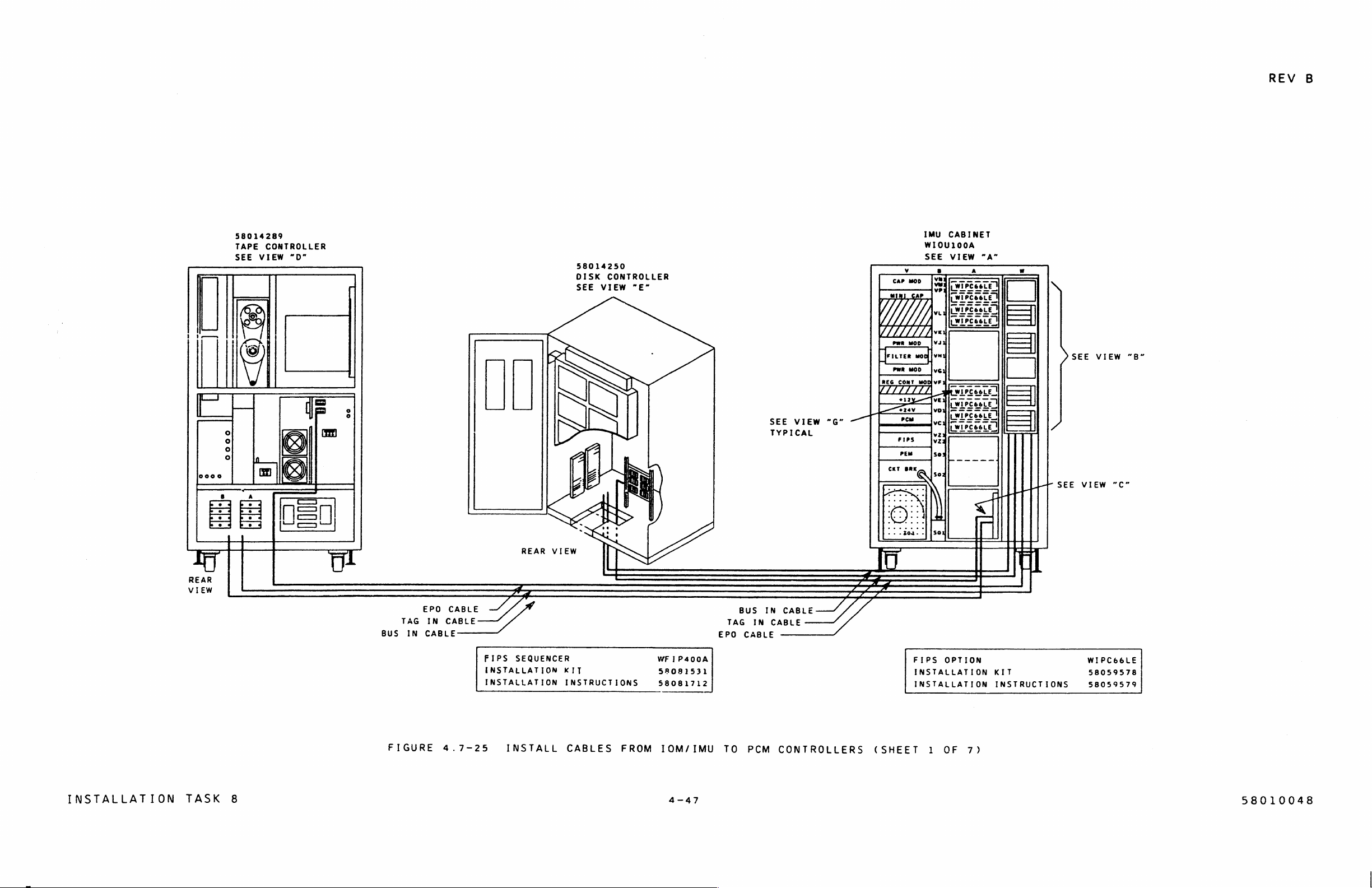

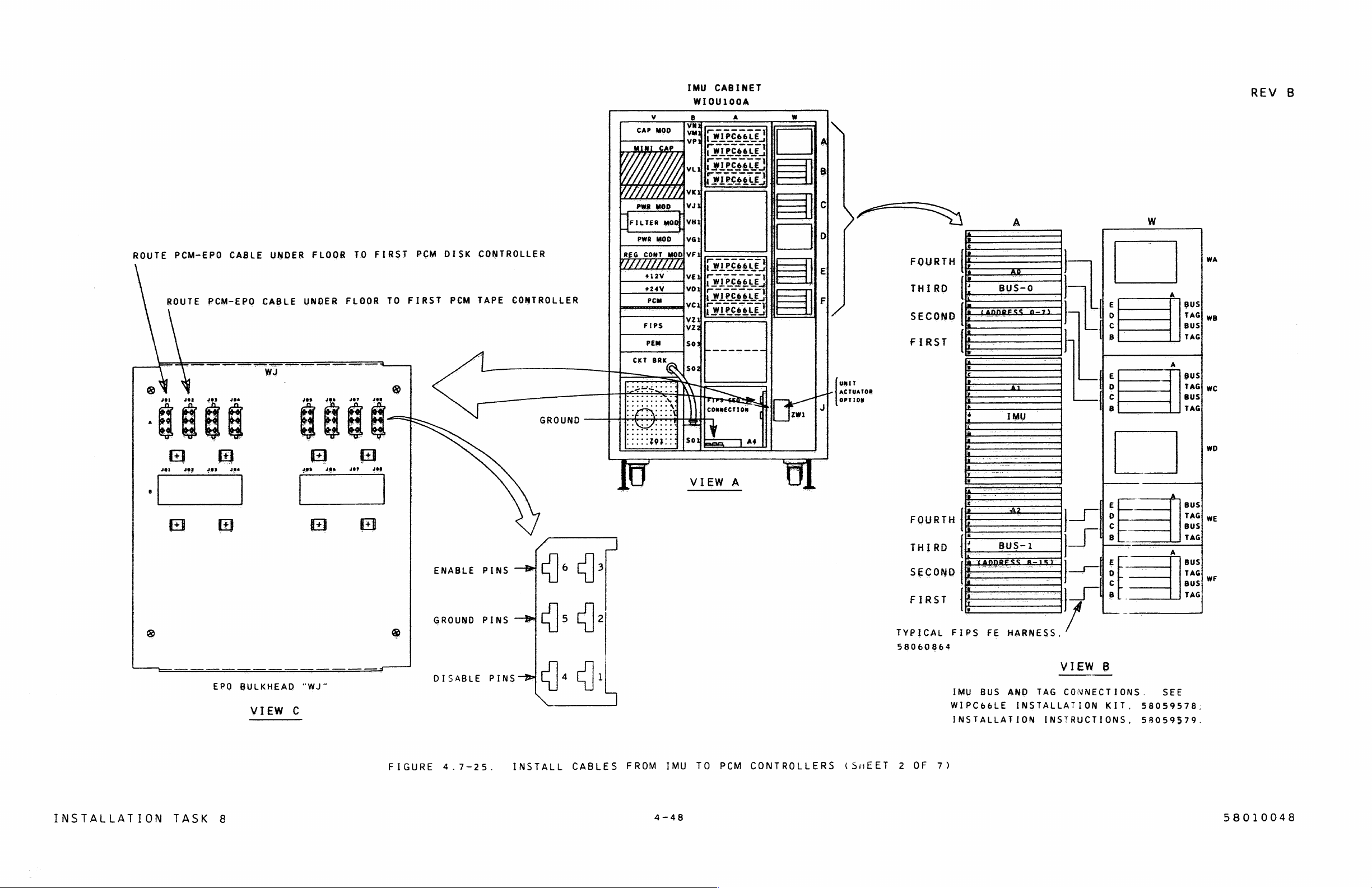

INSTALL

CABLES

PROM

IOM/IMU

TO

PCM

CONTROLLERS

..............

4-47

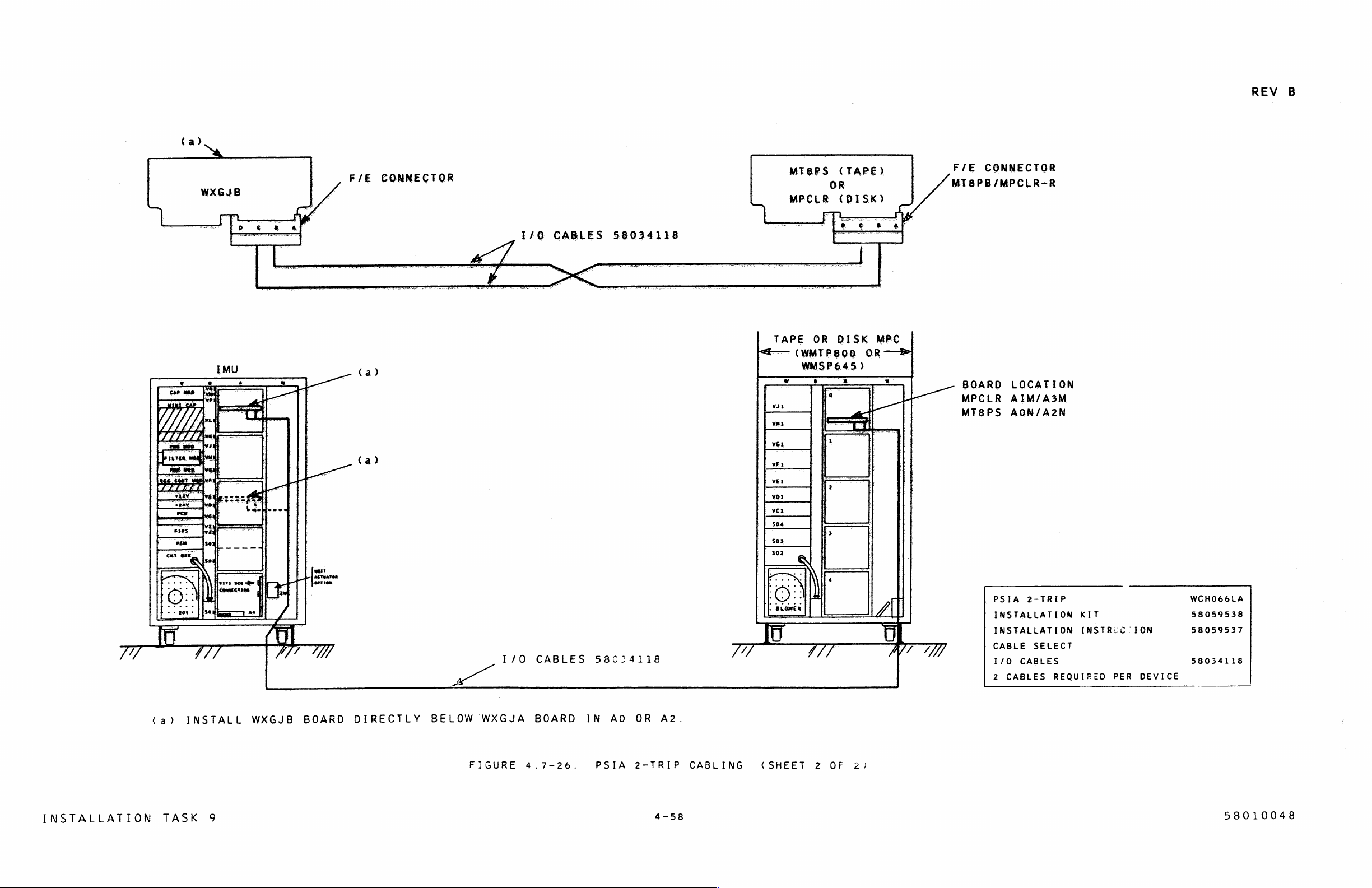

PSIA2--TOIP

CABLINC

.........................................

4-57

PSIA

A-IRIP

CAOLINC

.........................................

4-59

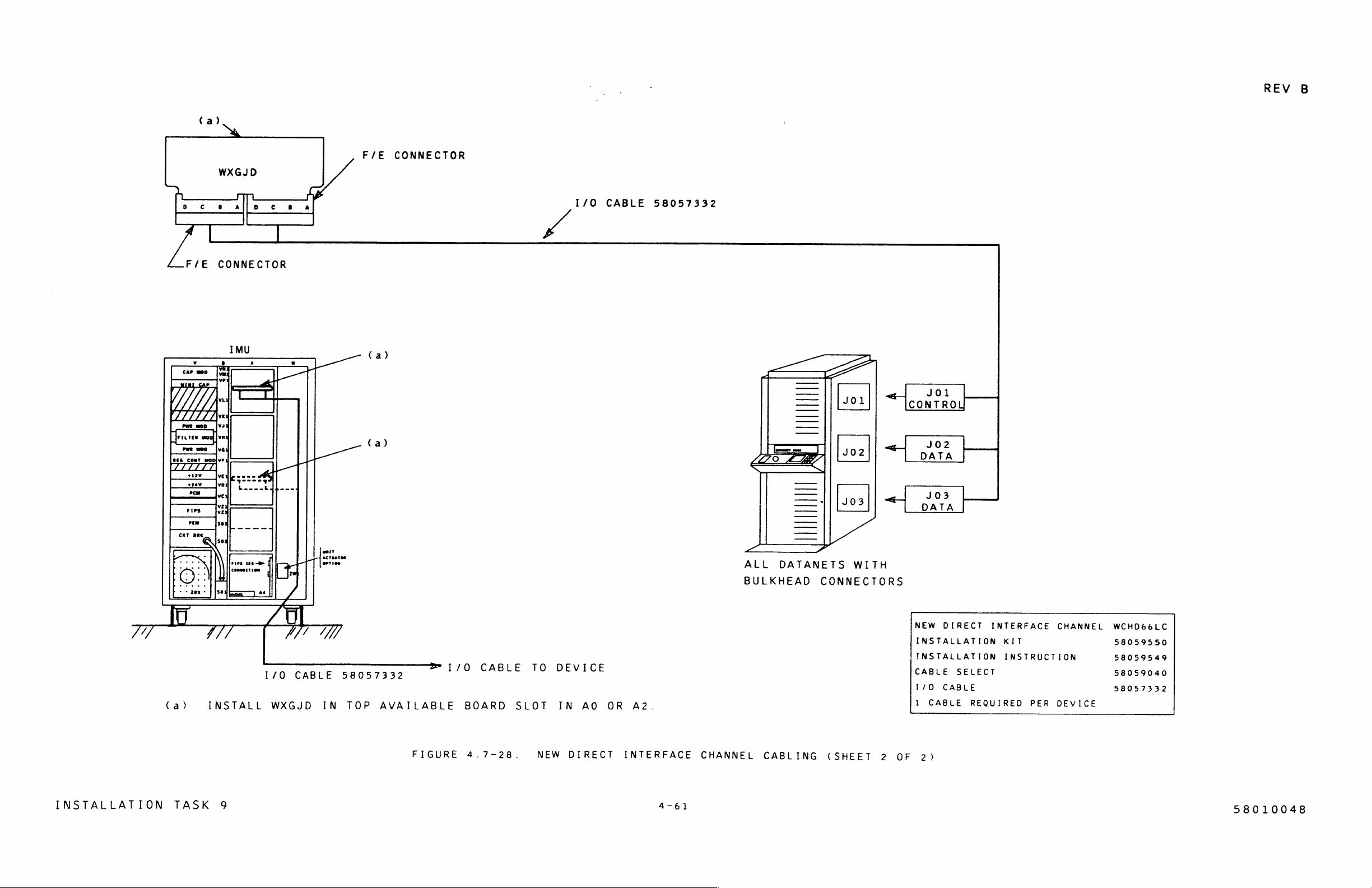

NEN

OIRECT

INTERFACE

CHANNEL

CABLINS

........................

4-50

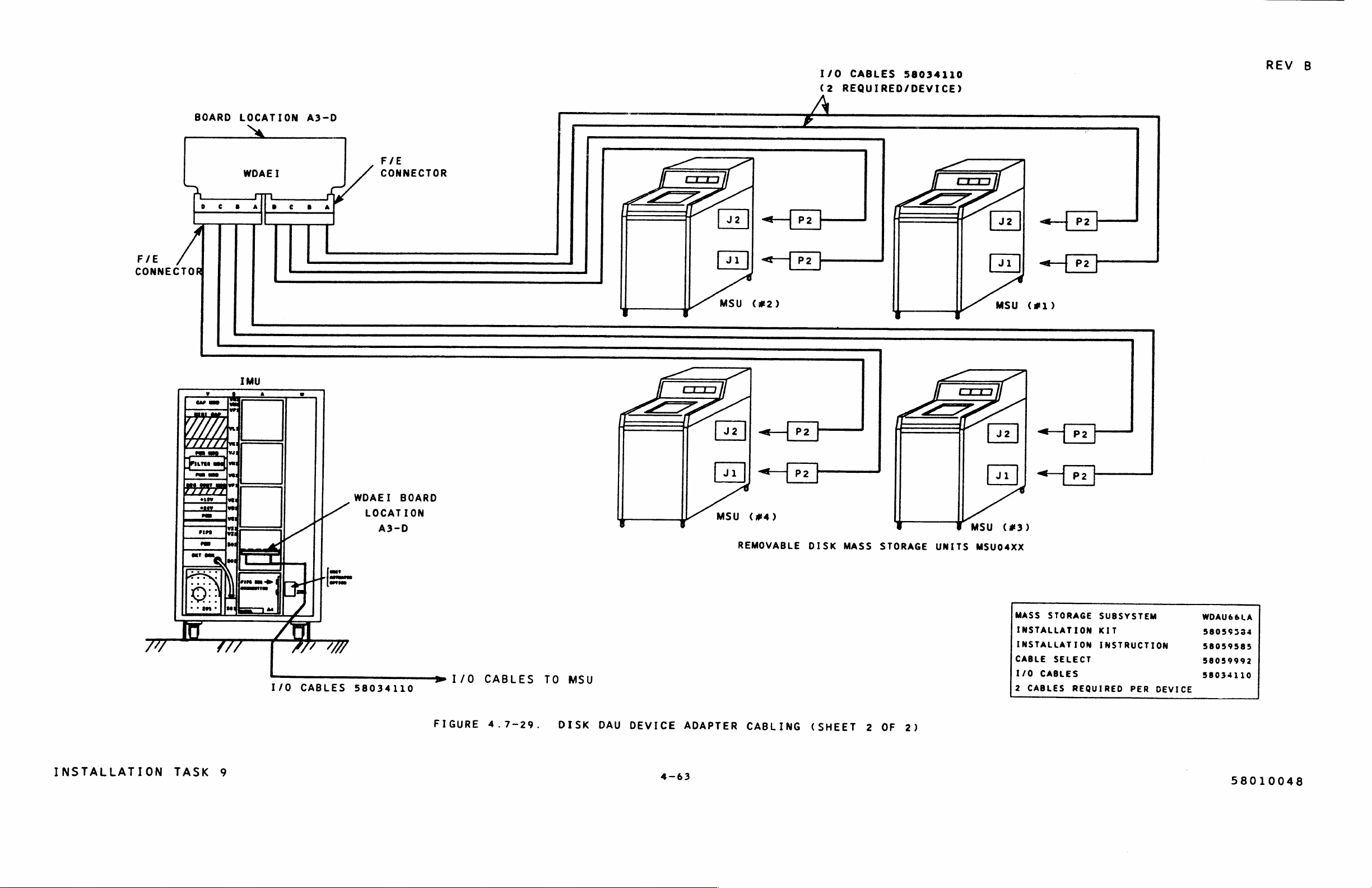

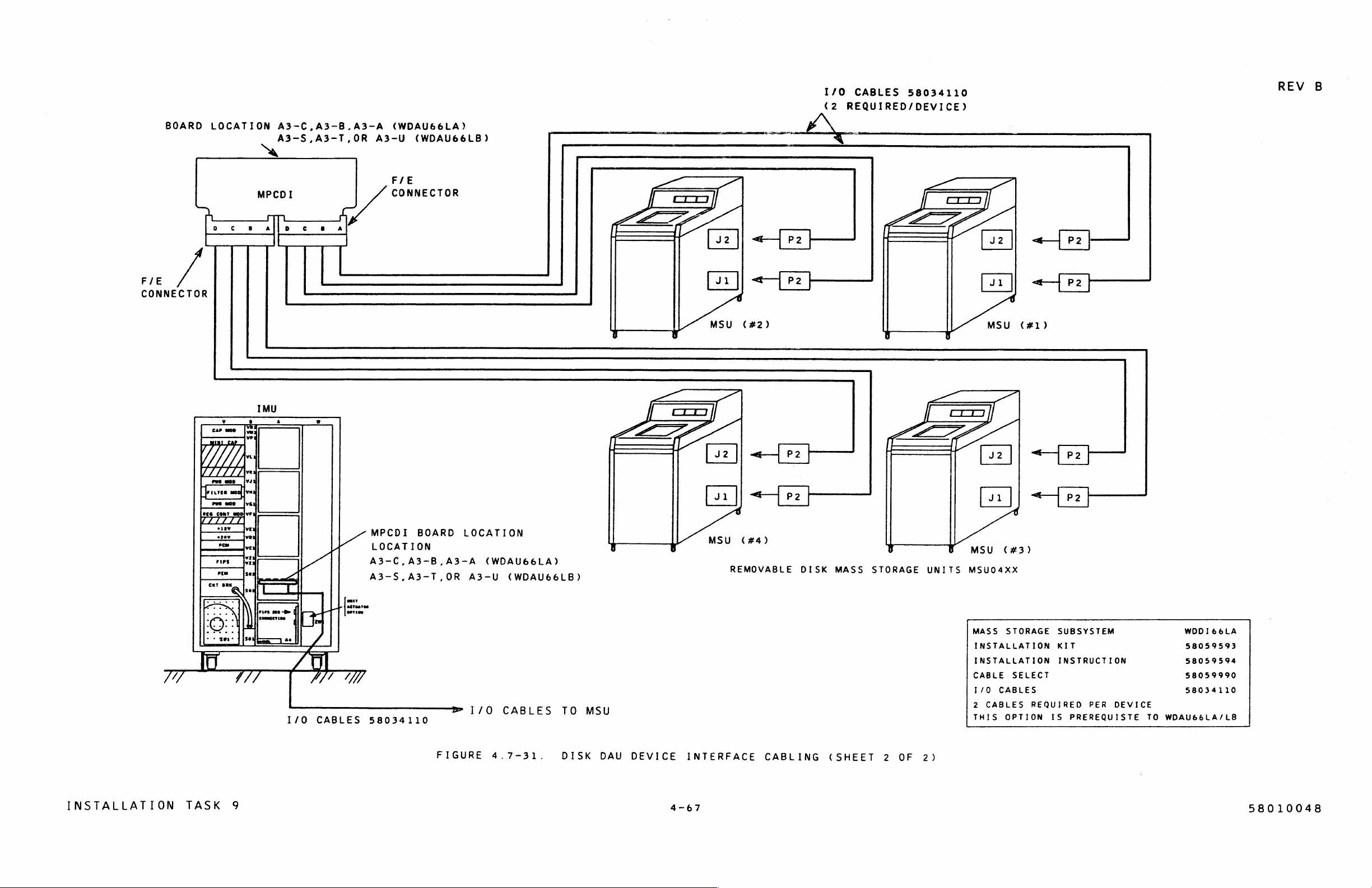

OISK

OAU

DEVICE

ADAPTER

CABLINC.................

............

4-O2

OISK

OAU

OEVICE

ADAPTER

CABLINC

.............................

4-54

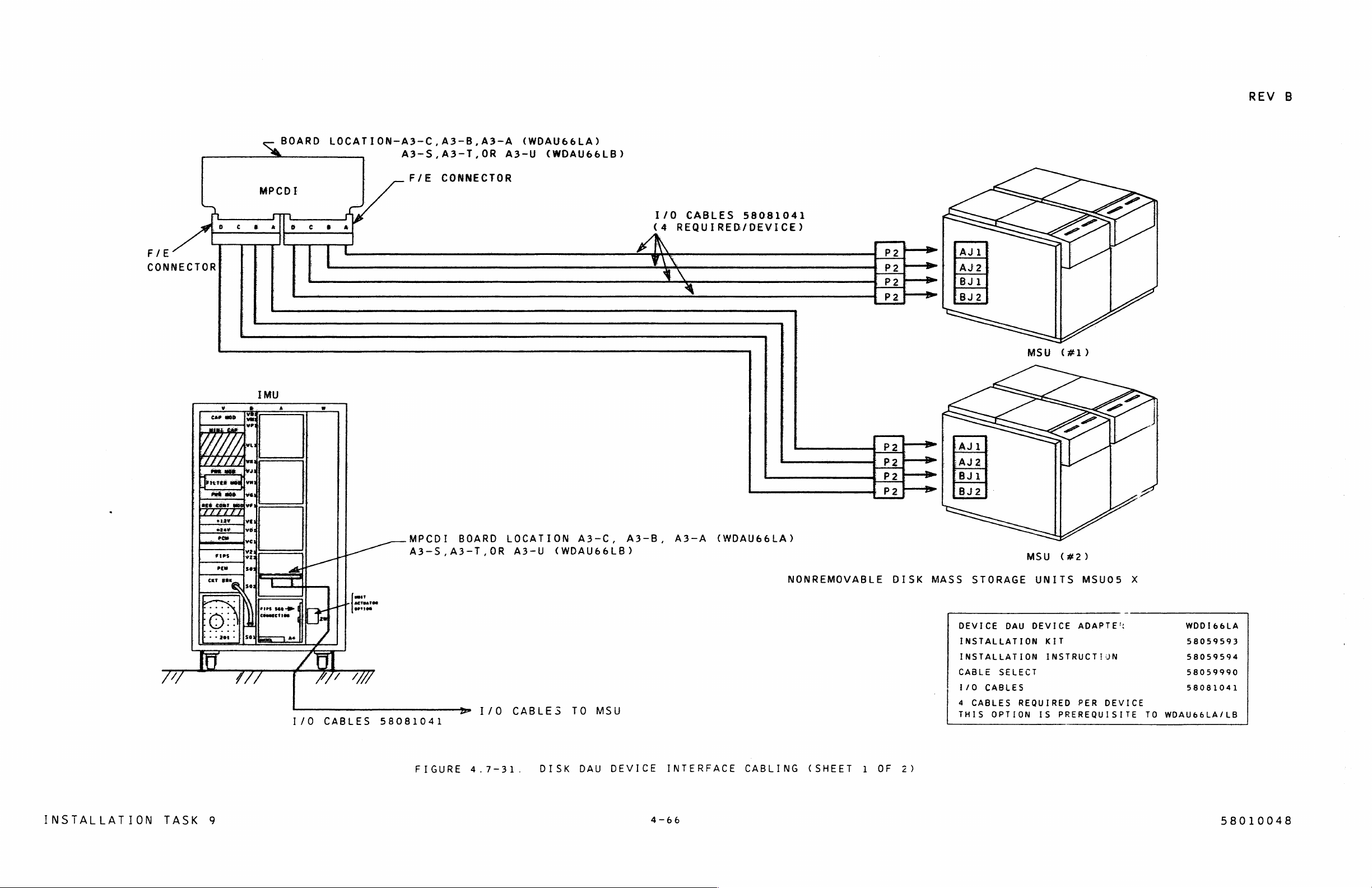

OISK

OAU

OEVICE

INTERFACE

CABLINC

...........................

4-66

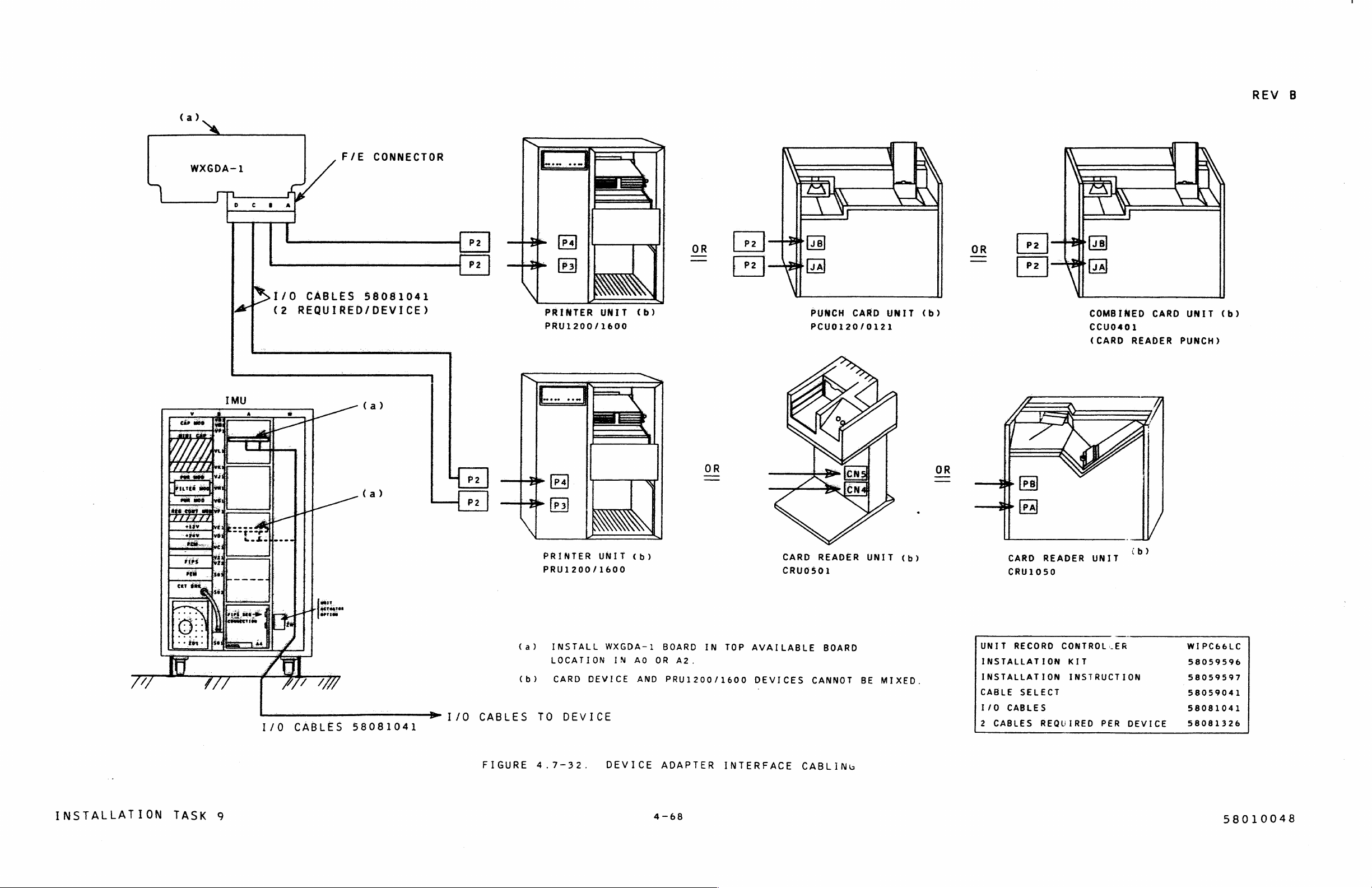

OEVICE

AOAPTER

INTERFACE

CABLINC

............................

4-68

PERIPHERAL

DEVICE

SERIAL

INTERFACE

CAOLINO

..................

4-69

HIGH

SPEED

NCHOOIIO

PSIA

CABLING

............................

4-70

TABLE

OF

CONTENTS

I##b&&&w§h&&b&h«bbhfiw&&h

FIGURE

.7*35

.7’36

.7‘37

.7“38

.7“39

.7-40

.7-41

.7-42

.7“43

.7-44

.7-45

.7-46

.7‘47

.7-48

.7-49

.7-50

.7-51

.7-52

.7~53

.7~54

REA!

B

LIST

OF

ILLUSTRATIONS

TITLE

PAGE

STANDARD

SPEED

PSIA

CABLING

.................................

4-72

DIRECT

CHANNEL

CABLING

......................................

4-73

HIGH

SPEED

WCHOO4ID

PSIA

CABLING

............................

4-75

EURCB BOARD

OPTIONS

.........................................

4-77

UR

PERIPHERAL

DEVICE

SERIAL

INTERFACE

SHIELDED

CABLING

......

4-81

UR

DAI

SHIELDED

CABLING.'

....................................

4*82

PSIA

2-TRIP

SHIELDED

CABLING

................................

4-83

PSIA

4-TRIP

SHIELDED

CABLING

................................

4-85

NEW

DIRECT

INTERFACE

CHANNEL

SHIELDED

CABLING

...............

4-86

DISK

DAU

SHIELDED

CABLING

...................................

4-88

DISK

DAU

DEVICE

INTERFACE

SHIELDED

CABLING

..................

4-90

ADDITION

DATA

CHANNEL

SHIELDED

CABLING

......................

4*92

IMU

BULKHEAD CONNECTIONS

....................................

4-94

AC

POWER

ENTRY

..............................................

4-97

CONSOLE

-

EMERGENCY

OFF

SWITCH

..............................

‘-100

MMU

CABINET

-

POWER

PANELS

..................................

4-101

CPU

CABINET

-

POWER

PANELS

..................................

4-102

IMU

-

POWER

PANELS

..........................................

4-103

IOM

CABINET

-

POWER

PANELS

..................................

4-104

INSTALL

LOWER

TRIM

STRIPS

...................................

4-107

58010048-530

Page 8

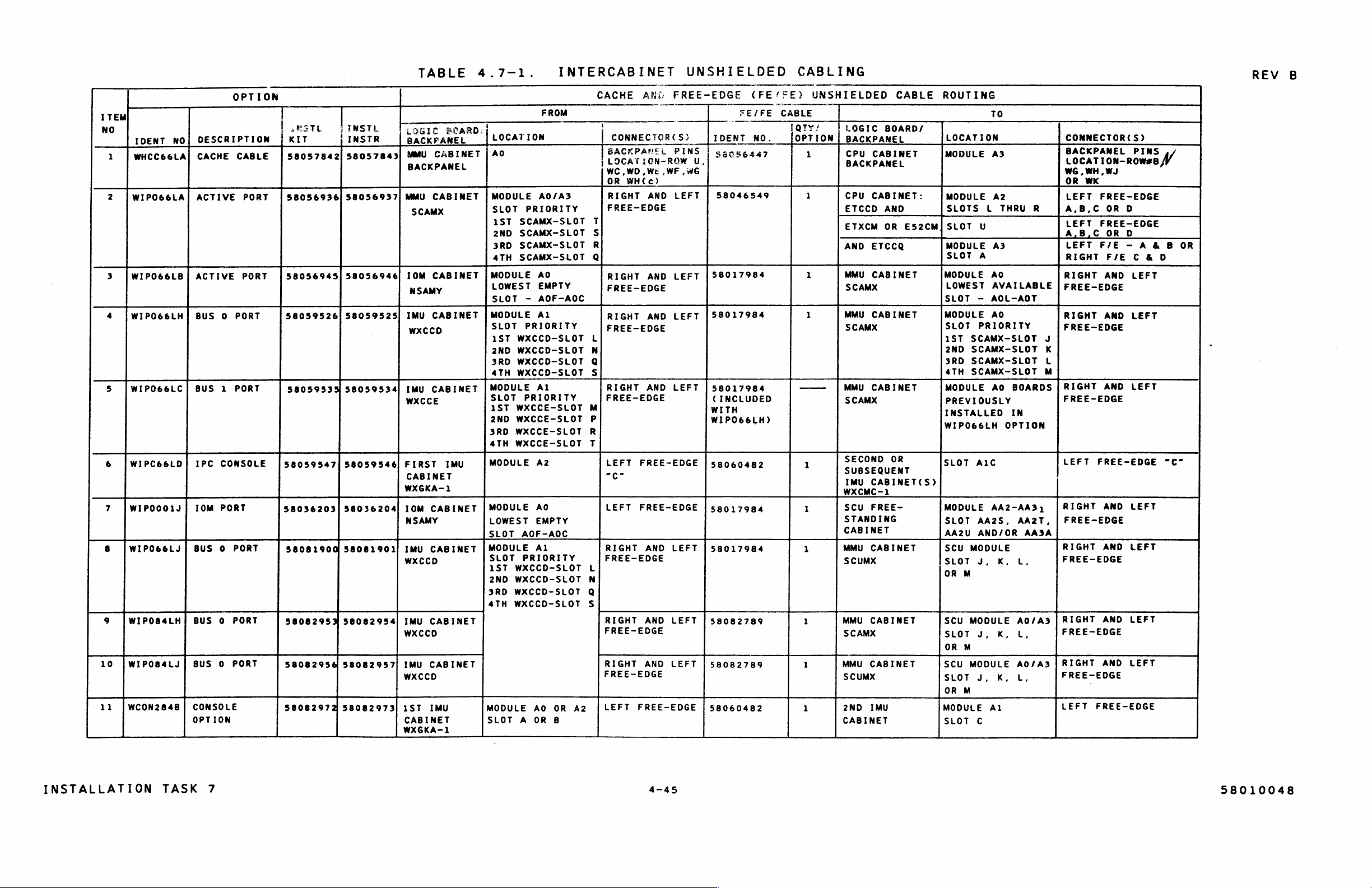

TABLE

>I>é-blsh.h¢-h

A2.

A2.

A3.

A3.

A4.

A4.

A5.

A5.

A5.

A5.

A5.

A5.

A5.

A5.

A5.

A5.

A5.

-\l\JV~J\JO‘Ul

DC)!

II

I

llmhuNHHI—I

NH

LIST

OF

TABLES

TITLE

DUAL

SYSTEM

-

CABLEiHARNESS

ROUTING

.........................

TANDEM

SYSTEM

-

CABLE/HARNESS

ROUTING

.......................

INTERCABINET

UNSHIELDED

CABLING

.............................

TYPICAL

PLUG

COMPATIBLE

MANUFACTURER

(PCM)

CABLE

ROUTING....

UNSHIELDED

I/O

CABLING

......................................

SHIELDED

IIO

CABLING

........................................

CONFIGURATION

CHART

.........................................

CHANNEL

BOARD

SLOT

REQUIREMENTS

.............................

IMU

CARD

CAGES

O

(CHANNEL

ADAPTERS/IPCS)

AND

1

(IPU

CENTRAL)

.........................................

IMU

CARD

CAGES

2

(CHANNEL

ADAPTERS/IPCS)

AND

3

(IPU

CENTRAL)

.........................................

VALID

SETS

OF

LC

NUMBERS

....................................

BACKGROUND

CONFIGURATION

LIMITS

.............................

TAPE

AND

DISK DATA

BUFFERING

................................

DISK

AND

TAPE

LOADING

COMBINATIONS.

DPS

8

52/70

SYSTEMS

.....

'PRIORITY

SEQUENCE

AND

LOAD

FACTORS

..........................

SAMPLE

CONFIGURATION,

DPS

8

52/70

SYSTEM

....................

BOARD

CAPACITY

OF

ONE

19*CARD

CAGE

USING

THE

2-BOARD

TTL

PSIA-Z

................................

BOARD

CAPACITY

OF

ONE

19-CARD

CAGE

USING

THE

l-BOARD

CMOS

PSIA~2

...............................

TYPICAL

POWER

CONSUMPTION

BY

OPTION

.........................

POWER

NEEDED

BY

STANDARD

IMU

CENTRAL

........................

POWER

NEEDED

BY

STANDARD

DAU

................................

CONNECTABILITY

MATRIX,

NO

DAUS,

TTL

PSIA-Z,

TWO

19-CARD

CAGES

(TOTAL

CAPACITY)

..........................

CONNECTABILITY

MATRIX,

NO

DAUS,

CMOS

PSIA-Z,

TWO

19-CARD

CAGES

(TOTAL

CAPACITY)

..........................

CONNECTABILITY

MATRIX,

ONE

DAU,

TTL

PSIA-Z.

TWO

19-CARD

CAGES

(TOTAL

CAPACITY)

..........................

CONNECTABILITY

MATRIX,

ONE

DAU.

CMOS

PSIA-Z.

TWO

19-CARD

CAGES

(TOTAL

CAPACITY)

..........................

CONNECTABILITY

MATRIX,

TWO

DAUS,

TTL

PSIA-Z.

TWO

19-CARD

CAGES

(TOTAL

CAPACITY)

..........................

CONNECTABILITY

MATRIX,

TWO

DAUs,

CMOS

PSIA-Z,

TWO

19-CARD

CAGES

(TOTAL

CAPACITY)

..........................

TABLE

OF

CONTENTS

PAGE

4-4

4-5

$~45

4—54

A-vq

4-95

4-109

A—1

A-z

A—2

A-4

A~5

A-7

A—a

A-IO

A-lO

A—11

A-11

A-12

A-12

A-12

A—13

A-13

A-14

A-14

A-ls

A-15

3F

REV

B

58010048*SBO

Page 9

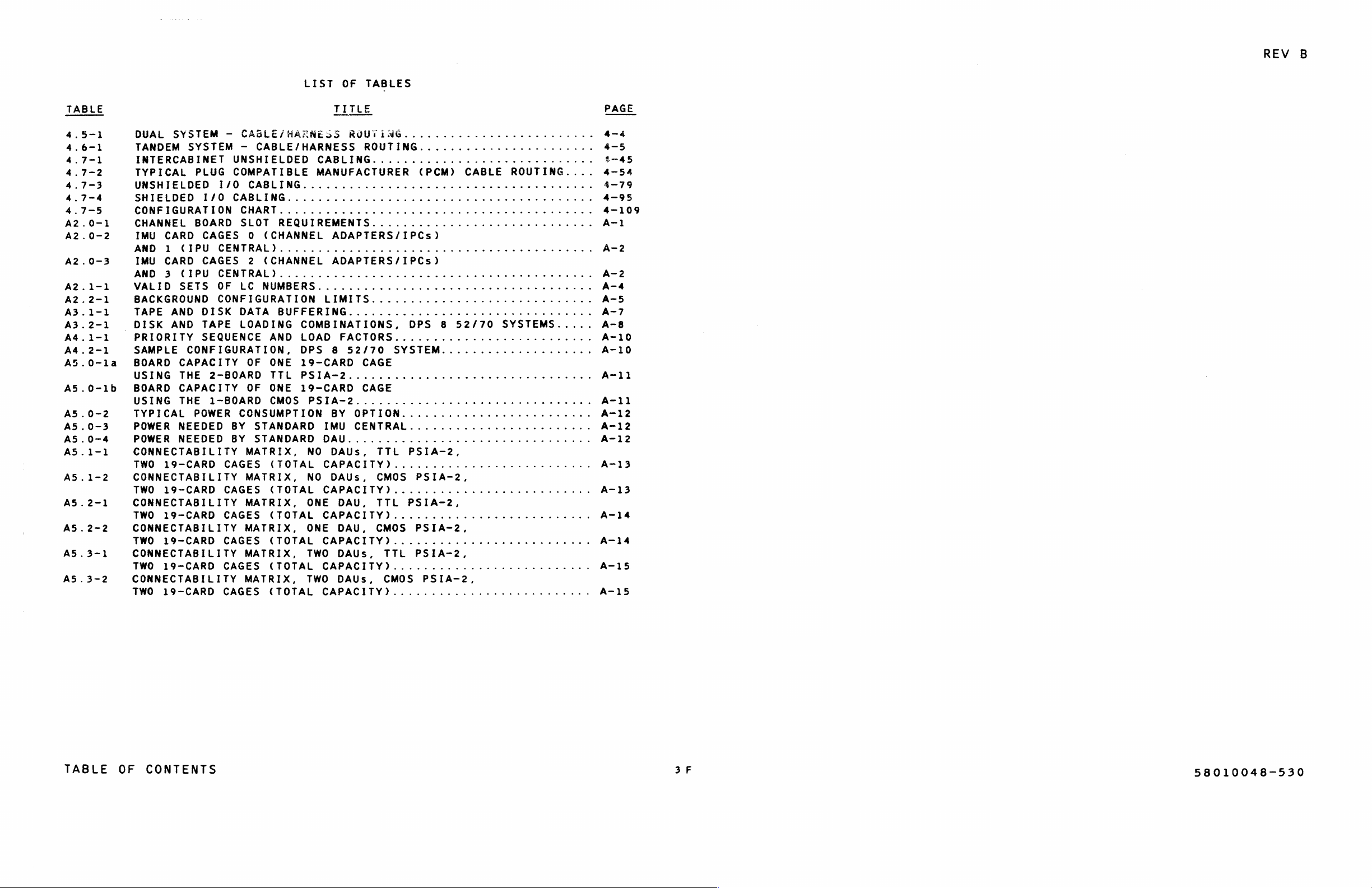

CHECKOFF

LISTS

PREINSTALLATION

CHECKOFF

LIST

TASK

NO.

4A.

4B.

CHECKOFF

LIST

TASK

PERFORMED

TASK

TITLE

BY

TURN

TO

PREINSTALLATION

CHECKOFF

LIST

SITE

INSPECTION

RECEIVE

EQUIPMENT

UNPACKAGING

A

NONCRATED

PACK

UNPACKAGING

A

CRATED

PACK

UNPACKAGING

INSPECT

EQUIPMENT

POSITION

CABINETS

TASK

CHECKED

BY

1F

TASK

NO.

4A.

4B.

10.

11.

12.

13.

14.

15.

INSTALLATION

CHECKOFF

LIST

TASK

TITLE

TURN

TO

INSTALLATION

CHECKOFF

LIST

INSTALL

MMU

CABINET

INSTALL

CPU

CABINET

INSTALL

IMU

CABINET

INSTALL

IOM

CABINET

INSTALL

DPU

CABINET

INSTALL

SYSTEM

CONSOLE

INSTALL

PORT

CABLES

AND

HARNESSES

INSTALL

CABLES

FROM

IOM/IMU

TO

PCM

CONTROLLERS

INSTALL

IIO,

PORT,

AND

SYSTEM

CONSOLE

CABLES

INSTALL

AC

POWER

CABLES

ACTIVATE

&

CHECK

POWER

SYSTEM

INSTALL

LOWER

TRIM

STRIPS

CONFIGURE

CENTRAL

SYSTEM

TEST

TAC

REMOTE

CONNECTIONS

FUNCTIONAL

VERIFICATION

TASK

PERFORMED

BY

TASK

CHECKED

BY

REV

B

58010048—010

Page 10

1.0

GENERAL

This

manual

has

been

prepared

to

serve

as

a

guide

for

the

Customer

Services

Engineer

(CSE)

to

insteii

or

deiusteil

the

DPS

a

system.

The

CSE

should

be

familiar

with

each

section

of

this

manual

and

the

Options

Installation

Manual

prior

to

installation.

Refer

to

the

System

Options

Manual,

58010049,

for

options

installation

instructions.

This

manual

does

not

include

installation

or

deinstallation

instructions

for

peripheral

devices,

peripheral

device

controllers,

or

auxiliary

processors

such

as

those

performing

front-end

processing

functions.

1.1

INTRODUCTION

This

manual

is

divided

into

the

following

sections:

SECTION

1

GENERAL

This

‘section

contains

an

introduction

to

the

manual,

including

an

overview

of

the

DPS

8

field

documentation

structure.

SECTION

2

PHYSICAL

OUTLINE

This

section

contains

an

illustration

of

the

three-cabinet

system.

SECTION

3

PREINSTALLATION

This

section

includes

procedural

steps

or

TASKS

for

receiving,

handling,

unpackaging,

unpacking,

inspection,

and

placement

of

cabinets.

SECTION

4

INSTALLATION

This

section

provides

procedural

steps

or

TASKS

to

install

the

equipment.

SECTION

5

DEINSTALLATION

This

section

includes

deinstallation,

handling,

and

shipping

procedures.

GENERAL

RE\/

8

1.2

PURPOSE

in

addition

to

the

CSE,

this

manual

will

'also

be

useful

to

Customer

Services

Training

for

classroom

studies

and

for

field

study

reference,

Training

will

usually

be

supported

with

additional

instruction

material;

however;

the

student

should

use

this

document

as

primary

reference.

This

manual

can

also

be

used

for

remote

field

support

and

should

be

included

in

the

Technical

Assistance

Center

(TAC)

library.

1.3

TOOLS

REQUIRED

standard

tool

kit

71001001-001

is

For

a

listing

of

DPS

8

system

tools,

The

Customer

Services

Department

required

to

install

this

system.

refer

to

System

Tools

List,

58059036.

1.4

TEST

EQUIPMENT

REQUIRED

Standard

test

equipment.

1.5

TEST

MEDIA

REQUIRED

o

Off—Line

T

and

D

System

Tape

(Pas

2/Monitor)

0

System

Acceptance

Test

Tape

(IMCV)

0

Integrated

Firmware

and

Diagnostic

Tape

0

NFT

Diskettes

58010048-015

Page 11

1

Thé

following

documents

are

listed

for

your

convenience

only

16-

REFERENCE

DOCUMENTATION

included

in

this

manual:

0

O

a

Providéd

by

659

Site

Layout

Plan

....................................

Site

Prenaratioh

manual

.............................

DU34

General

Packacifiy

Sfiécification...l

.................

saaaiéza

DPS

a

systém

Manna:

...........l....................

seeiooav

system

Logic

Block

Di�&fis

.........................

Sfités

fiiaaax

........................................

Tést

ina

Rébéir

flanual..........

....................

53010012

Harawaié

Ofibritibn

mafiuai..

.........................

53610911

Sistéfi

cansoae

Ifistalifitidn

Mifihal

..............

.....5§61693a

SVStefi

foals

LiSt

...................................

58é5§036

fléx

flrcuit

Sit

.....................................

pawér

ifid

éaéliha

flfiii

Mihflél

(198)

.................

sfieéééia

§6Wéi

aha

eaoiifia

Subsystefi-naauil

like,

cfiu,

fiflvi..

3&610665

.?

fiéeflfitflfaiibfl

ifiét

fifis

é

?iéld

docufithiiiiéfl

siruttafé

is

sfiawa

in

#iéure

1.7-1.

1

Eh

$6

CR

or

.fi

FEEEBACK

arder

to

maintain

this

mafiuai

as

a

funtiiofial,

tobical,

by

miillhg

you?

comments

flirectlfi

to:

Honeywell

Large

Syfitems

Hardwaré

Publications

P.

0.

Box

3006.

ߤ

€91

Phoénix,

Arizoha

3505%;3ooo

GENERAL

and

saoeéaasl

7

and

accurate

gafiefit,

alease

submit

ydur

gummént;

throuéh

the

normal

tethfiical

afiaéls

6y

utilizifig

the

Systém

Téchnical

Attibn

Reauést

(STAR)

system,

REV’E3

58010048-015

Page 12

GENERAL

SYSTEM

EANUAL

50010047

*

I

CUSTOMER

SITE

PREPARATION

0034

*

HARDWARE

OPERATION

50010011

IMU

HARDWARE

OPERATIONS

50010010

I

INSTALLATION

CONSOLE

WLCCOl1A

WLCC001/2A

50009049

CONSOLE

NIPC66LD

NCON2040

50010004

*

PERIPN

SWITCN

PSUOOOOI1I10

50010042

DPU

HPU9001

50010034

MPC

DISK

WMSP645A

50009910

MPO

TAPE

WNTP000A

50009009

SYSTEN

INSTALLATION

50010040

*_

I

UAINTENANCE

POWER

0

COOLING

CONSOLE

CENTRAL

PROCESSOR

TEST

&

REPAIR

50010012

i

IOM

WIOU66LA

50009911

UNIT/OPTIONS

WLCCOllA

WLCCOIIA

50009046

UNIT/OPTIONS

WCPU66L0

50010062

CIRCUIT

SET

50009043

CPU

NCPU66L0

50010065

IIU

T00

USER

GUIDE

50014355

§

SCU

NSCU66LC

50010065

INU

FAULT

DEFINITION

50096614

*

UPC

WUSP645A

WHTP000A

50010040

NCA

COMMAND

GUIDE

50096613

I

INU

WIOUIOOAIO

50010065

*

i"mauuuuso

FOR

IMu

SHIPMENTS

FIGURE

1.7-1.

DPS

8

DOCUMENTATION

TREE

INPUT/OUTPUT

L

10M

I

UNIT

WIOU66LA

SCUIHENORY

7

PERIPHERAL

CONTROLLERS

SCU

UNIT

WSCU66LC

50009922-

L

7

UPC

I

50009099

DISK

UNIT

NHSP645A

50009916

OPTIONS

WIOU66LA

50009915

MEMORY

UNIT

WMOL64KA

50009990

DISK

OPTIONS

WNSP645A

50009921

EURC

NEUR0001.2,5

WEURCDO6,7

50010073

SCUIMEMORY

OPTIONS

50009914

L

IHU

I

TAPE

UNIT

WHTPBOOA

50009926

UNIT/OPTIONS

WIOUlOOA/B

TAPE

OPTION

WMTP66LAICIE

WHTP66LOIDIF

50010061

50010032

i

TAPE

OPTIONS

WMTP000A

50009905

[:j-usplurp-—1

DISK

WDAU66LAIBICIU

50010000

TAPE

WMTP66LCIDIEIF

50010061

I?E\/

B

58010048~015

Page 13

REV

B

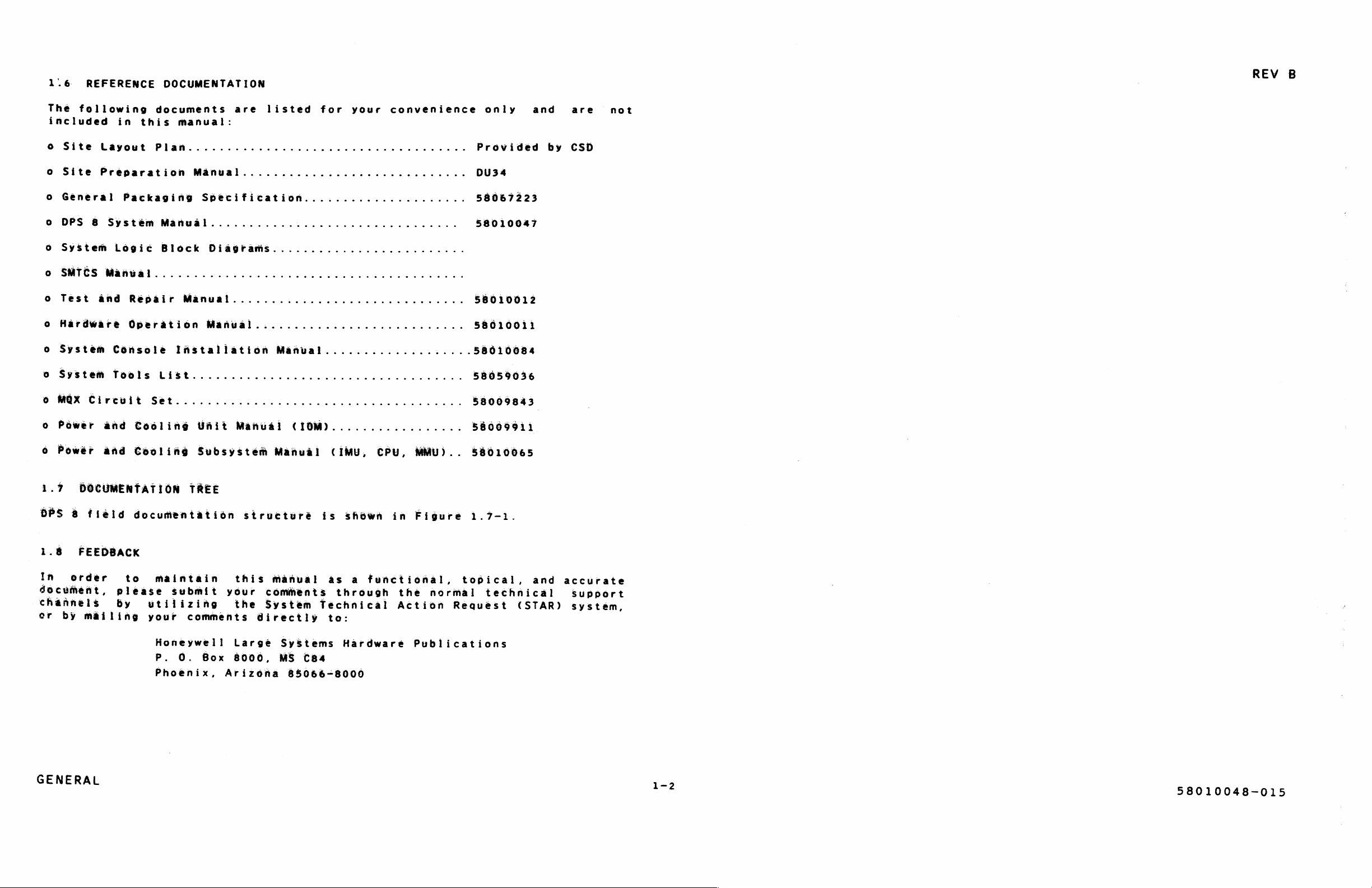

2.0

PHYSICAL

OUTLINE

A

pictorial

representation

of

the

three—cabinet

DPS

8

system

(including

cablecabinet)

is

found

in

Figure

2.0-1.

[I

l]

U

[I

A“

as:

i’

+3

2.:

”1“

533+

E

ops

a

l

I]

,U

U

U

WIOUlOOA

WCAB°°1A

WMMU66LB

WCPUbbLB

(OPTIONAL)

FIGURE

2.0-1.

PHYSICAL

OUTLINE

(SHEET

1

OF

3)

PHYSICAL

DESCRIPTION

2-1

58010048-051

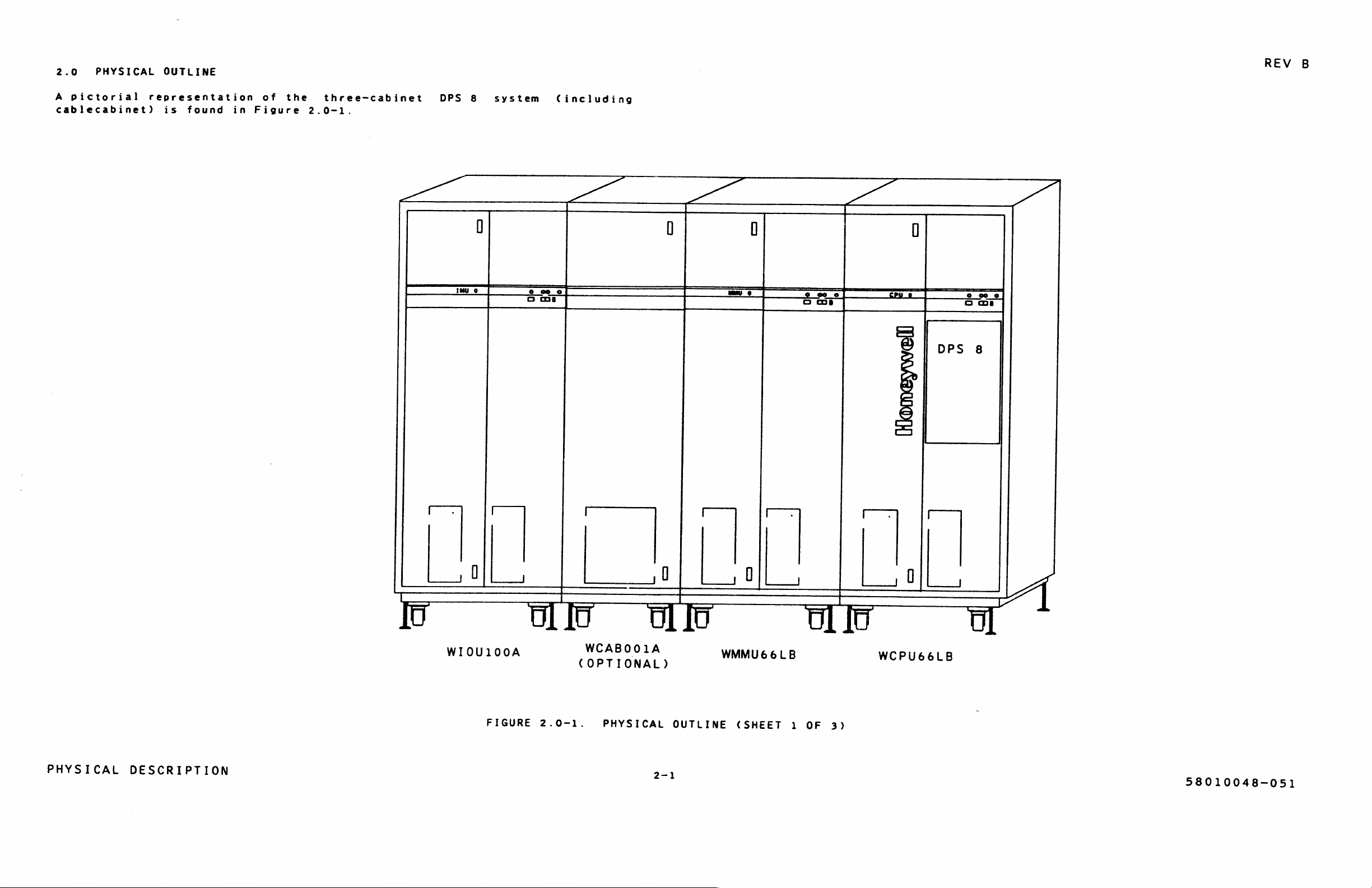

Page 14

REV

B

WIOUIOOB

WCABOOlA

(REQUIRED)

WMMU66LB

WCPUEéLB

FIGURE

2.0-1.

PHYSICAL

OUTLINE

(SHEET

2

OF

3)

PHYSICAL

DESCRIPTION

58010048-051

Page 15

L

9

.10

‘9—090

cruo

Do

9:

Marines/weal]

n

u

4

n

I.U’IWIOUbbLA

E‘WMMUbéLB

EWCPU66LB

FIGURE

2.0-1.

PHYSICAL

OUTLINE

(SHEET

3

OF

3)

PHYSICAL

DESCRIPTION

REV

B

58010048-051

Page 16

3.0

PREINSTALLATION

TASKS

Certain

Preinstallation

steps

or

TASKS

must

be

performed

after

the

site

has

been

prepared

to

receive

the

system,

but

prior

to

the

actual

system

installation.

The

PREINSTALLATION

TASKS

are

procedUral

steps

beginning

with

PREINSTALLATION

TASK

1,

"TURN

T0

PREINSTALLATION

CHECKQFF

LIST”,

and

includes

tasks

for

receiving,

handling,

and

unpackaging

the

equipment

packs

and

unpacking,

inspecting.

and

positioning

cabinets.

PREINSTALLATION

TASKS

REV

B

58010048

Page 17

RE}!

8

ifiig

Pfiéé

IN?ER?IO&ALLY

LEF?

Bkflfik

PREINSTALLATION

TASKS

3-2

58010048

Page 18

REV

B

TASK

1

TURN

TO

PREINSTALLATION

CHECKOFF

LIST

1.

TURN

TO

PREINSTALLATION

CHECKOFF

LIST.

THIS

LIST

IS

PRINTED

ON

HEAVY

PAPER

STOCK

AND

IS

LOCATED

IN

THE

FRONT

OF

THIS

MANUAL.

COMPLETE

CHECKOFF

LIST

WHEN

PROCEEDING

THROUGH

EACH

TASK.

PREINSTALLATION

TASK

1

3-3

53010043

Page 19

REV

8:

rats

PAGE

ruta#rro&aat?

asst

ELkEE

PREINSTALLATION

TASK

1

3-4

58010048

Page 20

PREINSTALLATEON

TASK

‘-

4

My

U1;

5")

WM

gflgfsfi

g

‘

94:5!“ELES

?

{{3§%

T

f“

”g“

P“

a

{-12:32

61:32

ASSURE

FHA?

THE

CUSTOMER

IS

READY

TO

RECEiyfi

AND

ENE?ALL

THE

EQUIPMENT.

REVIEW

THE

SITE

PREPARATION

CHECKLIST

QND

THE

SITE

PREPARATION

AUDIT

REPORT

FOR

COMPLETENESS.

THESE

SOCUMENTS

MAY

BE

OBTAINED

FROM

THE

HONEYWELL

DISTRICT

MANAGER,

IF

NOT

AVAILABLE

ON

SITE,

58910948

Page 21

REHIZB

Tflifi

BAQE

IQTEHTlGflALLY

LfiF?

fihAflfi

PREINSTALLAIION

TASK

2

53010043

Page 22

'TflLSl(

3

PREINSTALLATION

TASK

3

RECEIVE

EQUIPMENT

[CAUTION

HANDLE

SHIPPING

PACKS

WITH

CARE

TO

AVOID

EQUIPMENT

DAMAGE.

CSE

SHOULD

ASSURE

THAT

THE

CUSTOMER

HAS

RECEIVED

SHIPPING

DOCUMENTS

FROM

CARRIER

AND

ASSISTS

INVENTORY

OF

EQUIPMENT

AGAINST

THE

SHIPPING

DOCUMENTS

(BILL

OF

LADING,

MEMORANDUM

OF

SHIPMENT,

ETC.).

CUSTOMER

SHOULD

BE

ADVISED

AGAINST

SIGNING

ANY

PAPERS

AT

THIS

TIME.

(THE

CUSTOMER

MAY

ACCEPT

EQUIPMENT

FROM

CARRIER

AFTER

COMPLETING

PREINSTALLATION

TASK

6.)

CHECK

WRAPPING,

CRATES,

AND

CARTONS

FOR

BREAKS,

TEARS,

OR

OTHER

EVIDENCE

OF

DAMAGE

OR

ROUGH

HANDLING.

CSE

SHOULD

NOTE

ANY

LOSS,

DAMAGE,

MOISTURE,

CORROSION,

OR

MISHANDLING

ON

THE

"REPORT

OF

DAMAGE

OR

LOSS",

FORM

"HIS

2174”.

THIS

FORM

MAY

BE

OBTAINED

FROM

THE

HONEYWELL

DISTRICT

MANAGER.

CSE

SHOULD

ASSIST

CUSTOMER

WHEN

NDTIFYING

HONEYWELL

TRAFFIC

MANAGER

OF

ANY

LOSS

OF,

OR

DAMAGE

TO,

EQUIPMENT.

NOTIFICATION

MAY

BE

PERFORMED

THROUGH

TELEPHONE

CONTACT,

BUT

MUST

BE

PROMPTLY

CONFIRMED

IN

WRITING

TO

THE

HONEYWELL

TRAFFIC

MANAGER.

REFER

TO

BILL

OF

LADING

FOR

CURRENT

TELEPHONE

NUMBER.

REV

B

58010048

Page 23

REV

8

THIS

PAGE

Ifl?ENTIGNALLY

LEFT

BLANK

PREINSTALLATION

TASK

3

58010048

Page 24

REV

B

TASK

4A

UNPACKAGING

A

NONCRATED

PACK.

NOTE

EQUIPMENT

MAY

BE

PACKAGED

IN

PLASTIC-WRAPPED,

UNCRATED

PACKS

FOR

DOMESTIC

SHIPMENTS

OR

IN

CRATED

PACKS

FOR

EXPORT

SHIPMENTS

IN

ACCORDANCE

WITH

HONEYWELL

PACKAGING

SPECIFICATIONS.

UNCRATED

PACKS

ARE

SHIPPED

IN

AN

UPRIGHT

POSITION,

PROTECTED

BY

FOUR

WOODEN

CORNER

ASSEMBLIES

AND

STRAPPED

PLASTIC

WRAPPING.

CRATED

UNITS

ARE

ALSO

SHIPPED

IN

AN

UPRIGHT

POSITION.

WARNING

BEFORE

REMOVING

BINDING

STRAPS,

ENSURE

THAT

NO

ONE

IS

NEAR

THE

PACK.

WHEN

CUT,

THESE

STRAPS

MAY

SPRING

FREE,

STRIKING

ANY

CLOSE

OBJECT

OR

PERSONNEL.

CSE

SHALL

UNPACKAGE

EQUIPMENT

AS

FOLLOWS:

1.

CUT

BINDING

STRAPS.

2.

REMOVE

WOODEN

CORNER

ASSEMBLIES.

PREINSTALLATION

TASK

4A

3-9

CAUTION

DO

NOT

PULL

TAPE

OR

PLASTIC

WRAPPING

OFF

CABINETS.

CUT

PLASTIC

WRAPPING

ALONG

ALL

FOUR

CORNERS

FROM

BOTTOM

UP.

GENTLY

ROLL

CUT

PANELS

TO

TOP

OF

CABINET

AND

REMOVE

WRAPPING.

PULLING

PLASTIC

WRAPPING

FROM

CABINET

COULD

GENERATE

HIGH

POTENTIAL

OF

STATIC

ELECTRICITY

WHICH

MAY

CAUSE

EQUIPMENT

DAMAGE.

REMOVE

PLASTIC

WRAPPING.

ADMINISTRATIVELY

DISPOSE

OF

ANY

PACKAGING

MATERIAL.

58010048

Page 25

.-r'/xl53

k:

‘4

I:

I.»

I

m:

DRRDRD

RDMDVIRD

DINDIND

$TRAPS,

ENSURE

THAT

NO

DNE

IS

REAR

TNE

RACK.

WHEN

CUT,

THESE

STRAPS

MAY

SPRING

FREE,

STRIKIND

ANY

CLOSE

OBJECT

0R

PERSONNEL.

CUT

BINDING

STRAPS.

REMOVE

BOLTS

FROM

AROUND

LOWER

EDGE

OF

CRATE.

REMOVE

CRATE

FRDNT

PANEL

(IT

MAY

:5

TACKED

IN

PLACE

WITH

NAILS),

LIFT

REMAINING

PANELS,

AND

SLIDE

CRATE

BACK

AWAY

FROM

CABINET.

CUT

EXRDSRD

BINDING

STRAPS.

THIS

ACTION

FREES

THE

CARINET

FROM

PALLET.

REMOVE

ONE

BASE

BLOCK

ASSEMBLY

To

FACILITATE

REMRVAL

0F

CABINET

RRDM

THE

PALLET.

CAREFULLY

RRMDVE

CADINRT

RRDN

RALLET

WITH

A

RARR

LIRT

DR

HOIST;

EXERCISE

CARD

To

AvDID

EQUIPMENT

DAMADR.

PREINSTALLATION

TASK

48

3-10

REV

B

UNPACKAGING

A

CRATED

PACK

CSE

SHALL

UNPACKAGE

EQUIPMENT

AS

FDLLDws:

I.

OUT

AND

REMDVE

ANY

REMAINING

BINDING

STRAPS.

[pAUTI,~'

DO

NOT

PULL

TAPE

OR

PLASTIC

WRAPPING

OFF

CABINETS.

CUT

PLASTIC

WRAPPING

ALONG

ALL

FOUR

CORNERS

FROM-BOTTOM

UP.

GENTLY

ROLL

CUT

PANELS

TO

TOP

OF

CABINET

AND

REMOVE

WRAPPING.

PULLING

PLASTIC

WRAPPING

FROM

CABINET

COULD

GENERATE

HIGH

POTENTIAL

OF

STATIC

ELECTRICITY

WHICH

MAY

CAUSE

EQUIPMENT

OAMAGE.

2.

REMOVE

PLASTIC

WRAP

OR

OTHER

PACKAGING

MATERIAL

FROM

CABINET.

3.

ADMINISTRATIVELY

DISPOSE

OF

ALL

PACKAGING

MATERIAL.

58010048

Page 26

REV

B

TAS

K

5

UNPACKING

SSE

SHALL

PERFORM

THE

FOLLOWING

TASK:

1.

OPEN

CABINET

DOORS

USING

A

4mm

HEX

WRENCH,

58020342.

NOTE

UNPACKING

REFERS

To

THE

REMOVAL

OF

ANY

MATERIAL,

INCLUDING

SPECIAL

BRACKETS

0R

DEVICES,

WHICH

HAS

BEEN

PLACED

INSIDE

CABINETS

To

PROVIDE

PROTECTION

FROM

OR

HANDLING

HAZARDS.

UNPACKING

IS

PERFORMED

BY

CSE.

2.

UNPACK

CABINET.

3.

ASSURE

THAT

ALL

PACKING

MATERIAL,

INCLUDING

PACKING

BRACKETS

AND

HARDWARE,

HAS

BEEN

REMOVED

FROM

CABINET.

4.

UNPACK

DPU

CABINET

IN

ACCORDANCE

WITH

DPU

INSTALLATION

MANUAL,

58009848,

SECTIONS

1.1.1,

1.1.2,

AND

1.1.3.

5.

ADMINISTRATIVELY

DISPOSE

OF

ALL

PACKING

MATERIAL.

PREINSTALLATION

TASK

5

3-11

58010048

Page 27

RE

V

B»

ffifs

fikGE

rnrsnrrasxaav

tEFf

ssgux

PREINSTALLATION

TASK

5

58010048

Page 28

TASK

6

INSPECT

EQUIPMENT

AFTER

EQUIPMENT

HAS

BEEN

UNPACKED,

THE

CSE

SHOULD

ASSIST

CUSTOMER

IN

COMPLETING

THE

FOLLOWING

TASK:

[CAUTION]

REMOVE

ANY

VISIBLE

MOISTURE

AND

ALLOW

EQUIPMENT

TO

STABILIZE

IN

OPERATING

ENVIRONMENT

FOR

AT

LEAST

24

HOURS

PRIOR

TO

POWER

UP TO

AVOID

EQUIPMENT

DAMAGE

DUE

TO

CONDENSATION.

1.

CHECK

EQUIPMENT

FOR

DENTS

IN

DOORS

AND

END

PANELS,

BROKEN

INDICATORS,

SWITCHES,

OR

DAMAGE

TO

OTHER

PARTS,

MOISTURE

CONDENSATION,

OR

MISSING

ITEMS,

INCLUDING

SPARE

PARTS.

NOTE

CSE

SHOULD

TELEPHONE

THE

PHOENIX

INSTALLATION

CONTROL

CENTER

TO

REPORT

ANY

LOSSES,

CORROSION

OF,

OR

DAMAGE

(CONCEALED

OR

OTHERWISE)

TO

THE

EQUIPMENT,

INCLUDING

SPARE

PARTS.

PREINSTALLATION

TASK

6

REV

B

RECORD

ALL

LOSSES,

CORROSION

OF,

OR

DAMAGE

(CONCEALED

OR

OTHERWISE)

TO

EQUIPMENT,

ON

SHIPPING

DOCUMENTS.

REPORT

ANY

LOSS,

CORROSION,

OR

DAMAGE

IN

WRITING

TO

THE

HONEYWELL

TRAFFIC

MANAGER.

SHIPPING

DOCUMENTS

MAY

NOW

BE

SIGNED

BY

CUSTOMER.

RETURN

MEMORANDUM

OF

SHIPMENT

TO

HONEYWELL’S

GENERAL

ACCOUNTING

DEPARTMENT

AT:

HONEYWELL

INFORMATION

SYSTEMS

P.O.

BOX

8000

PHOENIX,

ARIZONA

85066

c/o

MANAGER,

GENERAL

ACCOUNTING

MAIL

STATION

A75

‘

58010048

Page 29

REV

Tfiis

Wkfig

riflflifléfitfi'

LE???

Mai-iii

PREINSTALLATION

TASK

6

3-14

58010048

Page 30

REV

B

TASK

7

POSITION

CABINETS

1.

CSE

SHOULD

ASSURE

THAT

SITE

IS

CLEAN

AND

FREE

FROM

EXTRANEOUS

MATERIAL

THAT

COULD

HAMPER

INSTALLATION.

CAUTION

MOVE

CABINETS

WITH

CAUTION

TO

PREVENT

THEM

FROM

TIPPING

OVER

AND

TO

AVOID

PERSONAL

INJURY

0R

EQUIPMENT

DAMAGE.

2.

POSITION

CABINETS

NEAR

FOOTPRINT

TEMPLATES.

REFER

TO

SITE

LAYOUT

PLAN.

DO

NOT

PLACE

CABINETS

ON

FOOTPRINT

TEMPLATES

AT

THIS

TIME.

3.

POSITION

SPARE

PARTS

CABINET

IN

ACCORDANCE

WITH

SITE

LAYOUT

PLAN.

PREINSTALLATION

TASK

7

3-15

58010048

Page 31

THIS?

P'kGE

INTEE‘FIQIALLV

,LEF?

SHE‘S

PREINSTALLATION

TASK

7

3-16F

58010048

Page 32

4.0

INSTALLATION

After

the

site

has

been

prepared

to

receive

equipment

and

all

PREINSTALLATION

TASKS

have

been

successfully

completed,

the

CSE

may

then

proceed

with

the

INSTALLATION

TASKS.

4.1

SCOPE

The

Installation

section

of

this

manual

sequentially

lists

and

defines

each

Installation

Task.

Option

installation

information

is

compiled

in

the

System

Option

Installation

Manual,

58010049.

4.2

ELECTROSTATIC

DISCHARGE

Electrostatic

discharge

may

be

damaging

to

certain

static-sensitive

components;

therefore,

it

is

imperative

to

exercise

caution

when

installing

or

handling

equipment.

[CAUTION'

IT

IS

MANDATORY

THAT

ALL

PERSONNEL

WEAR

AN

ELECTRO-

STATIC

DISCHARGE

(ESD)

WRIST

STRAP

WHEN

HANDLING

ANY

STATIC-SENSITIVE

COMPONENTS

SUCH

AS

LOGIC

BOARDS

TO

PREVENT

STATIC

ELECTRICITY

DAMAGE

TO

THESE

COMPONENTS.

THIS

STRAP

MUST

BE

PLUGGED

INTO

AN

ESD

SOCKET

LOCATED

ON

CABINET

FRAME

AS

SHOWN

IN

FIGURE

4.2~l.

THIS

FRAME

MUST

BE

GROUNDED

WITH

THE

ASSURANCES

LISTED

BELOW:

1.

ASSURE

THAT

CABINETS

ARE

PROPERLY

JOINED

TOGETHER

IN

ACCORDANCE

WITH

SECTION

4.4

AND

THAT

MMU

CABINET

IS

PROPERLY

GROUNDED

T0

SITE

EARTH

GROUND

IN

ACCORDANCE

WITH

SECTION

4.3.

2.

ASSURE

THAT

WHEN

CABINETS

ARE

NOT

BOLTED

TOGETHER,

EACH

CABINET

IS

PROPERLY

GROUNDED

T0

SITE

EARTH

GROUND

IN

ACCORDANCE

WITH

SECTION

4.3.

INSTALLATION

CONNECT

ESD

GROUND

D

STRAP

FIGURE

4.2-1.

REV

B

ELECTROSTATIC

DISCHARGE

(ESD)

WRIST

STRAP.

CHECK

EVERY

90

DAYS

OR

SOONER

FOR

PROPER

RESISTANCE

VALUE

OF

I

MEG

OHM.

ELECTROSTATIC

DISCHARGE

WRIST

STRAP

APPLICATION

58010048

Page 33

4.3

SYSTE“

GROUND

Ground

DPS

8

system~in

eccordance

with

the

following

steps:

1.

Assure

all

MES

or

UPSs

are

connected

to

site

earth

oraund.

Refer

to

Sectidn

4

of

Site

Prewaration

Mutual,

0034.

2.

Assure

that

the

”MU

cabinet

was

Weew

wrouwded

to

earth

around

in

accordance

with

Figure

£.3*I

awd

Site

Freperwtien

”inner,

903‘.

bolted

tagether

in

3.

Assure

that

tfie

system

cabinets

are

properly

accardance

witw

Sectian

£.¢.

5

eyefI:te-

to

each

NOTE:

Ground

both

the

CPU

and

[MB

cabinets

to

Hug

cabinet

with

orawnfi

straés

whenever

these

cabinets

are

not

bolteé

other.

wefer

ta

site

plea.

INSTALLATION

REV

3-

‘(/'M6

HEX

HEAR

SCREW

zfihkflfi

as

chK

KASKER

no

FEAT

KKKKER

H

GRGKKK

STRAP

0}

[so

0}

lo

0!

e}[0d}

[O

jg”

p

«#1

E9

:51{0"on

raeKr

QF

KKK

KKKIKEI

,

BABIUET

FKQQR

:

(TYPICAL

KKQKKK

STRAP

CLAMP)

TYPICAL

GRQUUB

$TRAP.

A=aeurg

ERKKKK

573595

19

pERIPKERAL

A

I

[o

OI

lo.e]~_

?

GOUIROLLERS

FRGN-T

EMU

PROCESSORS

AUUIOR

CPU

AND

IMU

CABINEIS

fiHEH

APPLICABLE

ACfiESS

HOLE

13

CABIQEI

FLOQR

RQUYE

QRQUHQ

STRAP

TU

SKI;

IseLArtou

TRAHSFGRMER

an

to

MOTOR

GENERATGR

SET

IF

AVAILABLE.

REFER

TO

SECTION

4

OF

SITE

PREPARATIQK

MANUAL,

4u34,

REAR

0F

MMU

CABINET

FIGURE

4.3‘1.

TOP

VIEW

OF

svsrsu

GROUNG

AREA

IN

MMU

CABINET

58010048

Page 34

REV

B

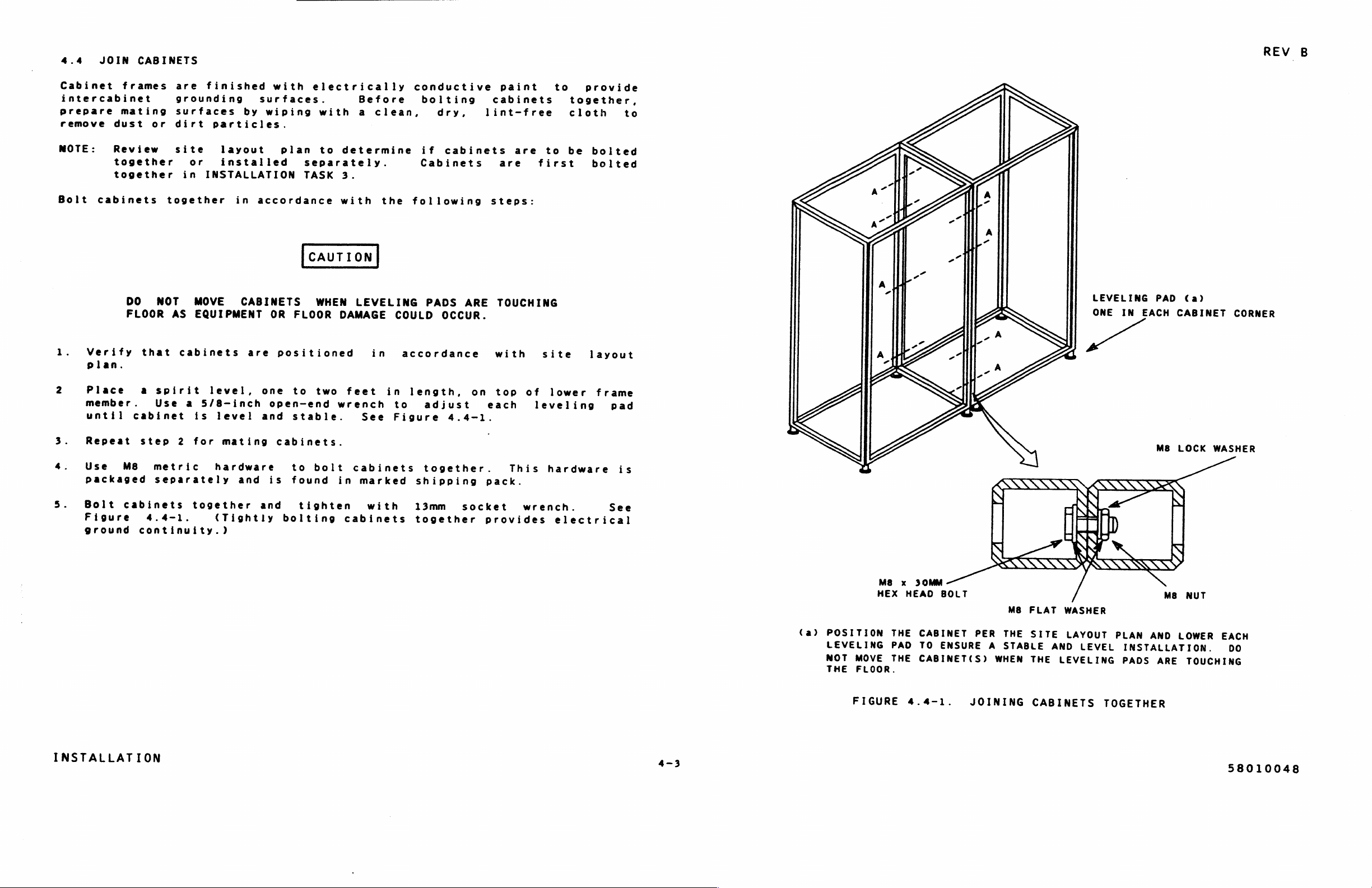

4.4

JOIN

CABINETS

'

Cabinet

frames

are

finished

with

electrically

conductive

paint

to

provide

intercabinet

grounding

surfaces.

Before

bolting

cabinets

together,

prepare

mating

surfaces

by

wiping

with

a

clean.

dry,

lint-free

cloth

to

remove

dust

or

dirt

particles.

NOTE:

Review

site

layout

plan

to

determine

if

cabinets

are

to

be

bolted

together

or

installed

separately.

Cabinets

are

first

bolted

together

in

INSTALLATION

TASK

3.

Bolt

cabinets

together

in

accordance

with

the

following

steps:

[CAUTIONI

LEVELING

PAD

(a)

ONE

IN

EACH

CABINET

CORNER

DO

NOT

MOVE

CABINETS

WHEN

LEVELING

PADS

ARE

TOUCHING

FLOOR

AS

EQUIPMENT

OR

FLOOR

DAMAGE

COULD

OCCUR.

1.

Verify

that

cabinets

are

positioned

in

accordance

with

site

layout

Dian.

2

Place

a

spirit

level.

one

to

two

feet

in

length,

on

top

of

lower

frame

member.

Use

a

SIB-inch

open-end

wrench

to

adjust

each

leveling

pad

until

cabinet

is

level

and

stable.

See

Figure

4.4-1.

M8

LOCK

WASHER

3.

Repeat

step

2

for

mating

cabinets.

4.

Use

M8

metric

hardware

to

bolt

cabinets

together.

This

hardware

is

packaged

separately

and

is

found

in

marked

shipping

pack.

l\‘fi&§fifififl§fi§‘FflflaEfiE§?\\

L.

5.

Bolt

cabinets

together

and

tighten

with

13mm

socket

wrench.

See

u§§.

&

Figure

4.4-1.

(Tightly

bolting

cabinets

together

provides

electrical

Iii'"

ground

continuity.)

_

n§§3

~

.

aduuuuuu§3§mmuwauu

M8

x

JOMM

HEX

HEAD

BOLT

M8

NUT

MB

FLAT

WASHER

(a)

POSITION

THE

CABINET

PER

THE

SITE

LAYOUT

PLAN

AND

LOWER

EACH

LEVELING

PAD

TO

ENSURE

A

STABLE

AND

LEVEL

INSTALLATION.

DO

NOT

MOVE

THE

CABINETIS)

WHEN

THE

LEVELING

PADS

ARE

TOUCHING

THE

FLOOR.

FIGURE

4.4-1.

JOINING

CABINETS

TOGETHER

INSTALLATION

4-3

58010048

Page 35

.

REA!

8-

4;5.

CABLE/HARNESS

Rourruc

ovenvrew

FOR

DUAL

svsreu

'

TO

BE

SUPPLIED

TABLE

4.5—1.

DORE

SVSTEHE-

CKBtEIflkRflESS

fiOfiTFRfi=

w

3*:

gap-fit

raw

f0

SE

$$PF£IEB

FIGURE

4.5~1.

fivAL

SYSTEM

*

CABLE/HARNESS

ROUTING

INSTALLATION

58010048

Page 36

REV

B

4.6

CABLE/HARNESS

ROUTING

OVERVIEW

FOR

TANDEM

SYSTEM

TO

BE

SUPPLIED

‘TABLE

4.6-1.

TAHOE”

SVSTEM

-

CABLEiHARflESS

ROUTING

TO

BE

SUPPLIED

TO

BE

SUPPLIED

FIGURE

4.6-1.

TANDEM

SYSTEM

-

CABLE/HARNESS

ROUTING

INSTALLATION

4-5

58010048

Page 37

.

REV

B

421

INSTALLATION

TASKS

Installation

Tasks

'are

procedural

steps

designed

to

aid

the

656

in

installing

a

OPS

8

system.

Installation

Tasks

to

install

cabinets,

harnesses,

and

cables,

to

activate

and

check

power

system,

to

install

trim

strips,

and

to

perform

functional

verification

tests

are

included

in

this

section.

-

INSTALLATION

4-6

58010048

Page 38

REV

8

"HS

PAGE

INTENTIONALLY

LEFT

BLANK

INSTALLATION

58010048

Page 39

fiEV

B

‘9TALLATION

CHECKOFF

LI;T

x.

ffififi

f5

ffigffittfifféfi

GfiééfifiF?

Liéf.

ffii§

Eiéf

E§

fififfiféi

éfi

WEEV?

afifiéfi

éfééfi

Kfifi

I§

L06§fE§

Ifi'THé

#fiéfif

é?

ffifé

fififififié.

ééfifiééfé

éfiéézééé

Ef§f

Wfiéfi

Séacsésrfié

Tfifiifiéfi

éfiéfi

ffi§é.

IfiSTALLRTION

TASK

1

4-8

58010048

Page 40

REV

3

THIS

PAGE

INTENTIONALLY

LEFT

BLANK

INSTALLATION

TASK

1

58010048

Page 41

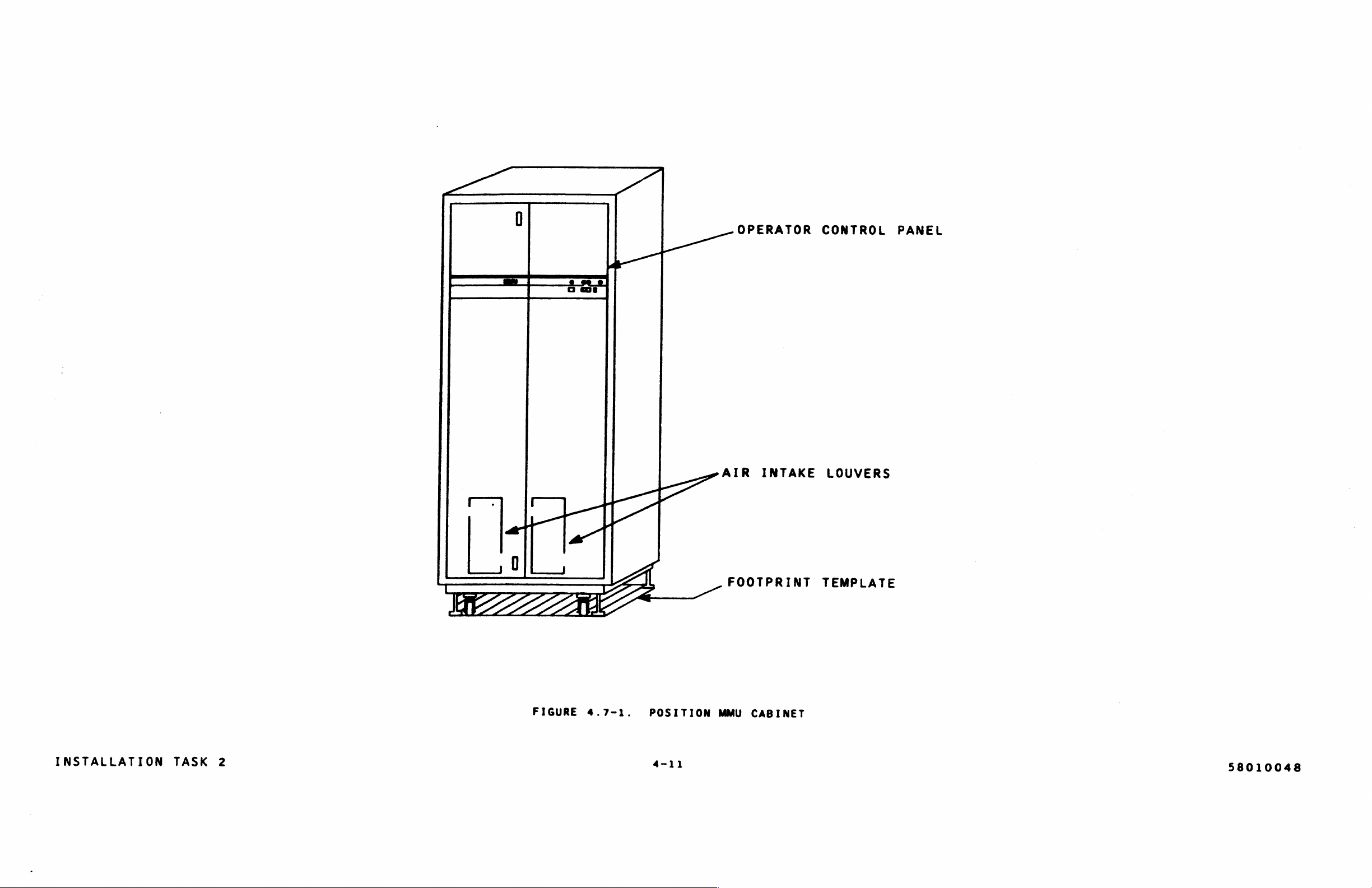

T

--SJ<

-2

INSTALL

MMU

CARINET

PQSITION

MMU

CABINET

usrne

EQRTRRINI

TEMPLATE.

SEE

FIGURE

4.7~1.

VERIFY

THAT

MMU

CABINET,

FISURE

4.7“1.

IS

GLEAN

AND

FREE

OF

FOREIGN

MATERIAL.

LOWER

LEVELING

PADS

INTO

PQSITIflN

WITH

5/8-INCH

OPEN-END

WRENCH.

LEVEL

CABINET

WITH

SPIRIT

LEVEL.

REFER

TO

SEETION

4.4.

VERIFY

eaeuno

FRQM

MOTOR

GENERATOR.

REFER

TO

SECTION

4.3

AND

SECTION

4

as

THE

$ITE

PREPARATION

MANUAL,

DU34.

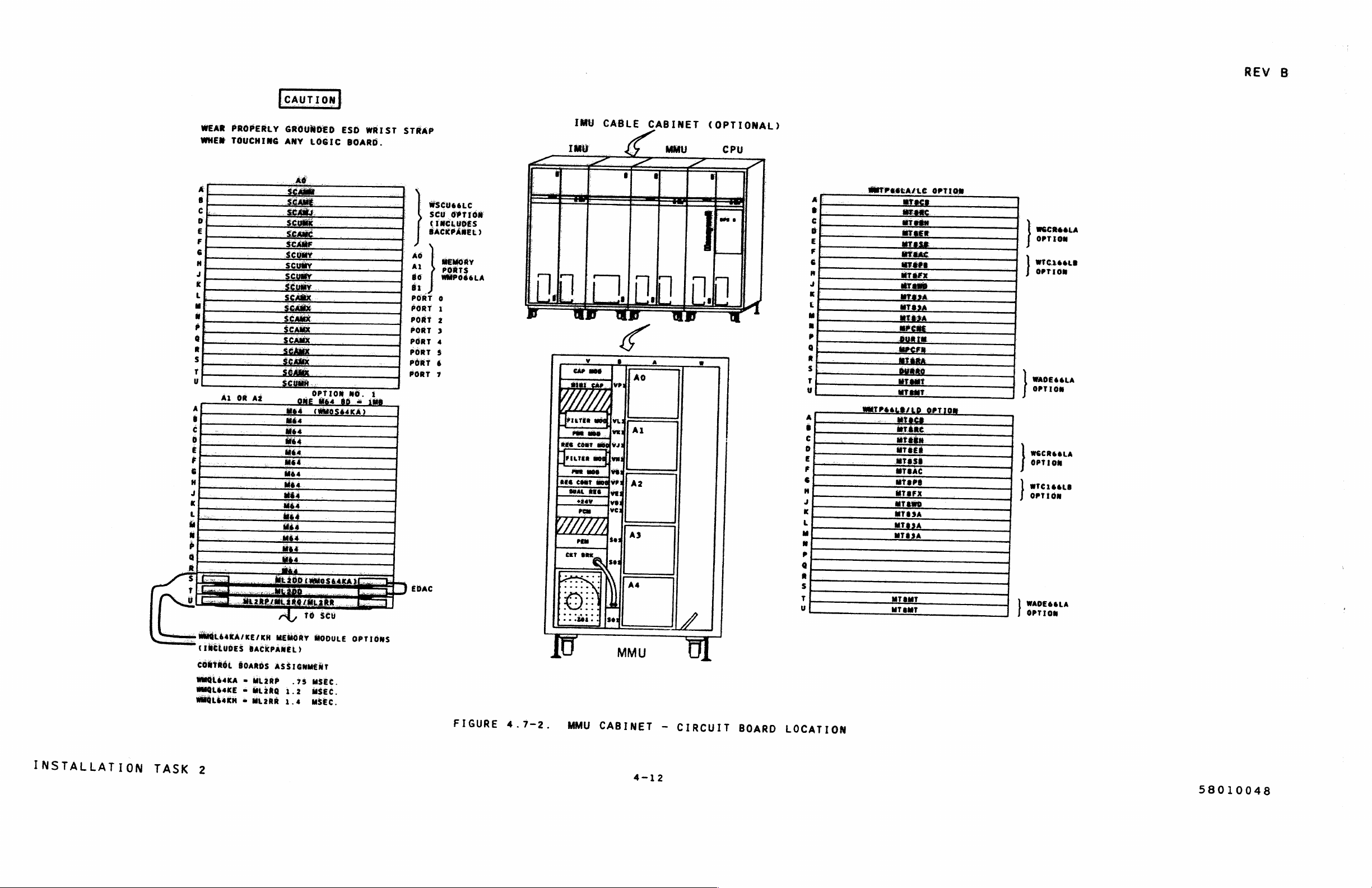

WEAR

E50

STRAP

ARR

VERIFY

THAT

ALL

CIRCUIT

ROARRS

ARE

PROPERLY

SEATED.

REFER

TR

FIGURE

4.7?2.

WEAR

Esa

STRAE

ARR

VERIFY

THAT

ALL

FREE—EDGE

QQNNECTORS

ArrAeHER

fa

CIRCUIT

RRARRS

ARE

PROPERLY

SEATED.

REFER

To

EIRURE

4.7-2.

CAREFULLY

REMOVE

czReRI?

BQARD

RESTRAIN‘NG

TAEE

€AN9

ANY

TAPE

RERIRREI

TR

AVQID

BQARD

DAMAGE

ANQ

PAINT

REMRVAL.

1

INSTALLATION

TASK

2

REV

A

VERIFY

THAT

CQOLINQ

SYSTEM

AIR

FILTER$.

BLOWER

HQUSEMQE

ELéfiUM.

AND

AIR

INTAKE

LOUVERS

ARE

CLEAN

AME

FREE

FRQM

AMY

DESTRUCTIQNS.

REFER

TO

FIGURE

4

.

7-—-3

.

EMSURE

THAT

QAQIMET

SHUTEQWN

$WITCH,

LOCATED

ON

OPERATQR

CEMFRQL

PANEL.

15

1M

GUT

POSITION.

REFER

TO

FIGURE

497*3.

ENSURE

IRA?

Ag;

RIRERIT

RREARERS

LOGAEED

AT

502

AND

5R3

ARE

1R

REE

RQSIIIRR.

REFER

TQ

FIGURE

4.2—2.

VERIF¥

THAT

RRRAARR

FARR

ARE

RAT

AI

LQW

SPEER

AND

5R

RR

RARE.

As

RERRIGARLR-

REEER

T0

INSTRUCTION

LABEL

IRSIRE

GARLIRE

EAR

Reuszua

ARR

FIGURE

4.7—3.

58010048

Page 42

fl

fl”””,OPERATOR

CONTROL

PANEL

.'==:'

4

"

D

an

AIR

INTAKE

LOUVERS

.7%

l

/‘

fl

FOOTPRINT

TEMPLATE

FIGURE

0.7-1.

POSITION

WU

CABINET

INSTALLATION

TASK

2

4-11

58010048

Page 43

gcauxxovy

“Ell

9n0fis§tv

anuibfo

£56

wiTST

STifiP

umew

Taucurnc

ANY

Lacie

EOARG.

=4

muovxgr-

ice-1.,

f6

$69

'

fifiiiééiilkt/KR

uEfiéhT

fiODULE

ovtlous

(Iifiiufizé

bAckfiifiéL)

Cdiiiét

éothés

AschnufifiT

*ifilé¢kt-“1239

.73

«32¢.

939t$4¥5éfiténg

1.2

assc.

*fifiliiifi6“taut

1.£

uSfic.

INSTALLATION

TASK

2

‘

O

t

4

V

Qflfi-bfluuo

i

i3¢UG¢LC..

;

scu_svrraw

Tifiéuuvfis

Cletfiifltt)

7

asuoév

99135.

_

;

wflrotsLA

{DAG

FIGURE

4.7-2.

‘7

71

i

*1

IHU

CABLE

CABINET

(OPTIONAL)

;_J

cw

V,m.I.

iiidhia”?*

twicwqufijv;

“.9.

“if.

if!

9'

In".in1';

95;?

_v§

n3

9:

.”zsfii

ufiA»VL

:

iltfti

"';vu

'

‘,

Al

‘

[‘2

'A3

A4

hflhflLJ

11M

‘4

WI~Q‘E.'ZB§‘I—

Cd

OHIO-'"PR‘L:

MMU

CABINET

-

CIRCUIT

BOARD

LOCATION

}

}

I

I‘Cfii‘kt

OPTION

ufiaxcsau

ovrxau

NKOEGCLA

OPTIGN

IGCRG‘LA

}

}

OFTIGN

utcg¢sta

optxou

IIOE6§LA

OPTION

RIE\I

l3

58010048

Page 44

INSTALLATION

o

O

=°

:03?“

m

0

+12

DUAL

100'

REGULATOR

AT

VEl

‘

(.52?

{5C}?

JJ

'1

r:

.1":

'

j

POWER

ENTRY

MODULE

AT

503

SUPPLY

IAIN!

DISCOINICT

’

=

Inns-nuc-

lmm

"I'lm

°

[:1

°

533

o

3::

I:

:o:

9

‘g‘g’

E3

9

I

2:

CIRCUIT

BREAKER

MODULE

AT

502

TASK

2

/

IMU

CABLE

CABINET

(OPTIONAL)

mu

(

MMU

CPU

/

COOLING

.

FANS.

HOUSING

AND

AI

R

FILTERS

mm:

H

[i]:

Ll

'

a:

u

€°E

O

O

O

CAP

IOU

IIII

CAP

VP!

\

nu

I00

vs:

are

con

non

vn

‘

DUAL

use

vn

ats'zzlfzoow.

lFILTEI

hog

vm‘

\u“

‘\\\\\\

024V

v03

pm

VCI

V///////

K\

PE"

SD!

~

cm

In

\

.a‘

5°

N

..........

\

(317753;;1

xxxe

\

Emu..3.:::i

\AIR

::u.:§§:

PLENU”

::3zmn::sox

_A/7

UT

MMU/SCU

FIGURE

4.7-3.

MMU

CABINET

-

POWER

PANELS

OPERATOR

CONTROL

PANEL

LOCATED

ON

FRONT

DOOR

e

O

CAUTION

CAPACITOR

CHARGED

.

(I.

CAPACITOR

MODULE

WCAP66LB

AT

VPI

OR

WCAPIOOA

AT

VH1

C3

1'

(3

-W

+5

PLANAR

CONTROL

MODULE

AT

VFl

AND

VJI

30

AIS

A0

133

JSNBS

(*3

ITOVJ

I.)

MNITI-P

F“lfi$3lw

All

Futons-q

ac

lOC

Ill

LO”!!!

0-

u

on

H

OCH?

OCH!

I

I

CAUTIOI:

IITI

LOCIIflI

II.II

LOO

POSITION

CAI.

LOOIC

IILL

IOT

AUTO-IIITIALIIE.

POWER

CONTROL

MODULE

AT

VCl

REV

8

58010048

Page 45

REVIB

3

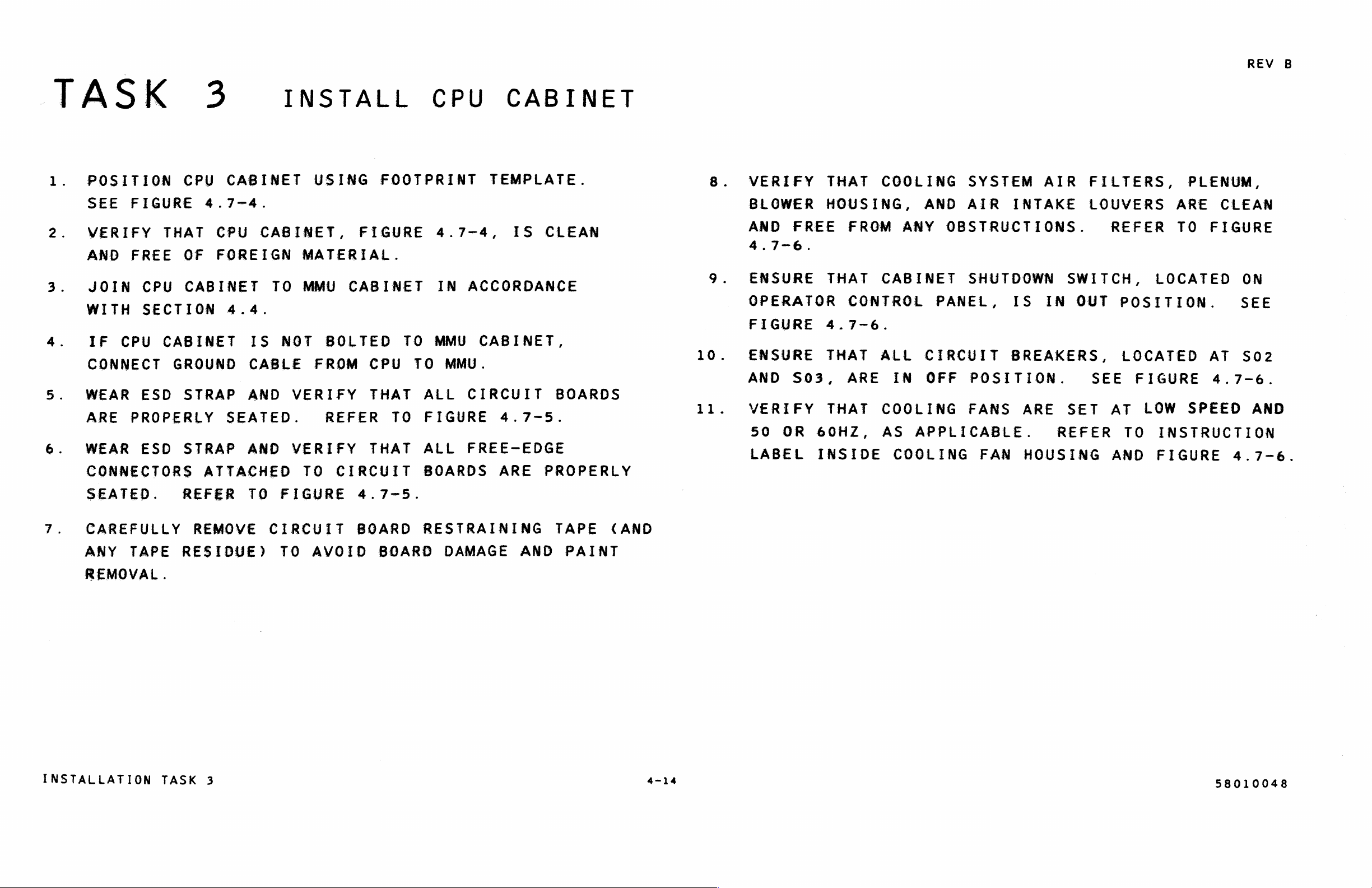

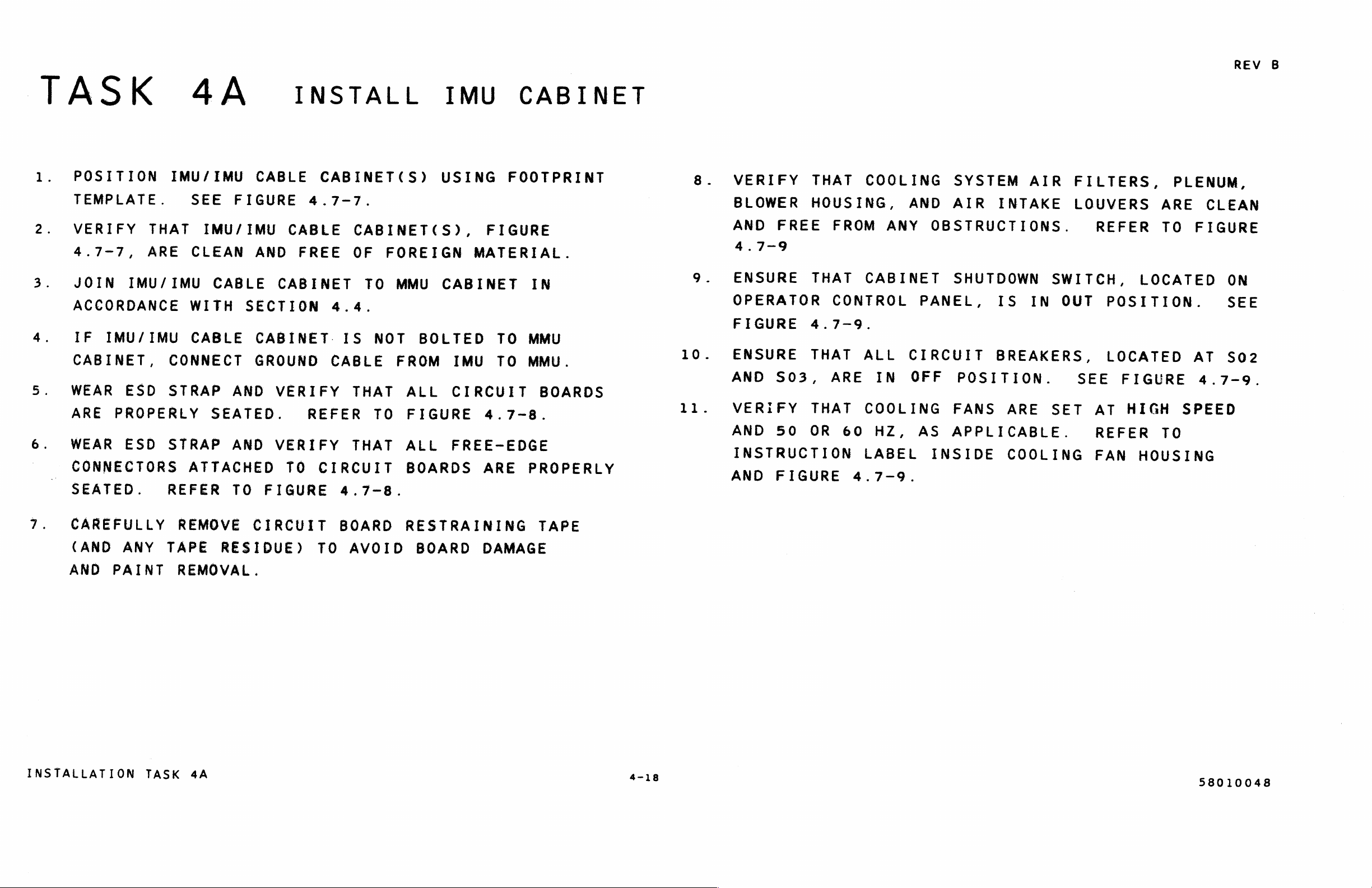

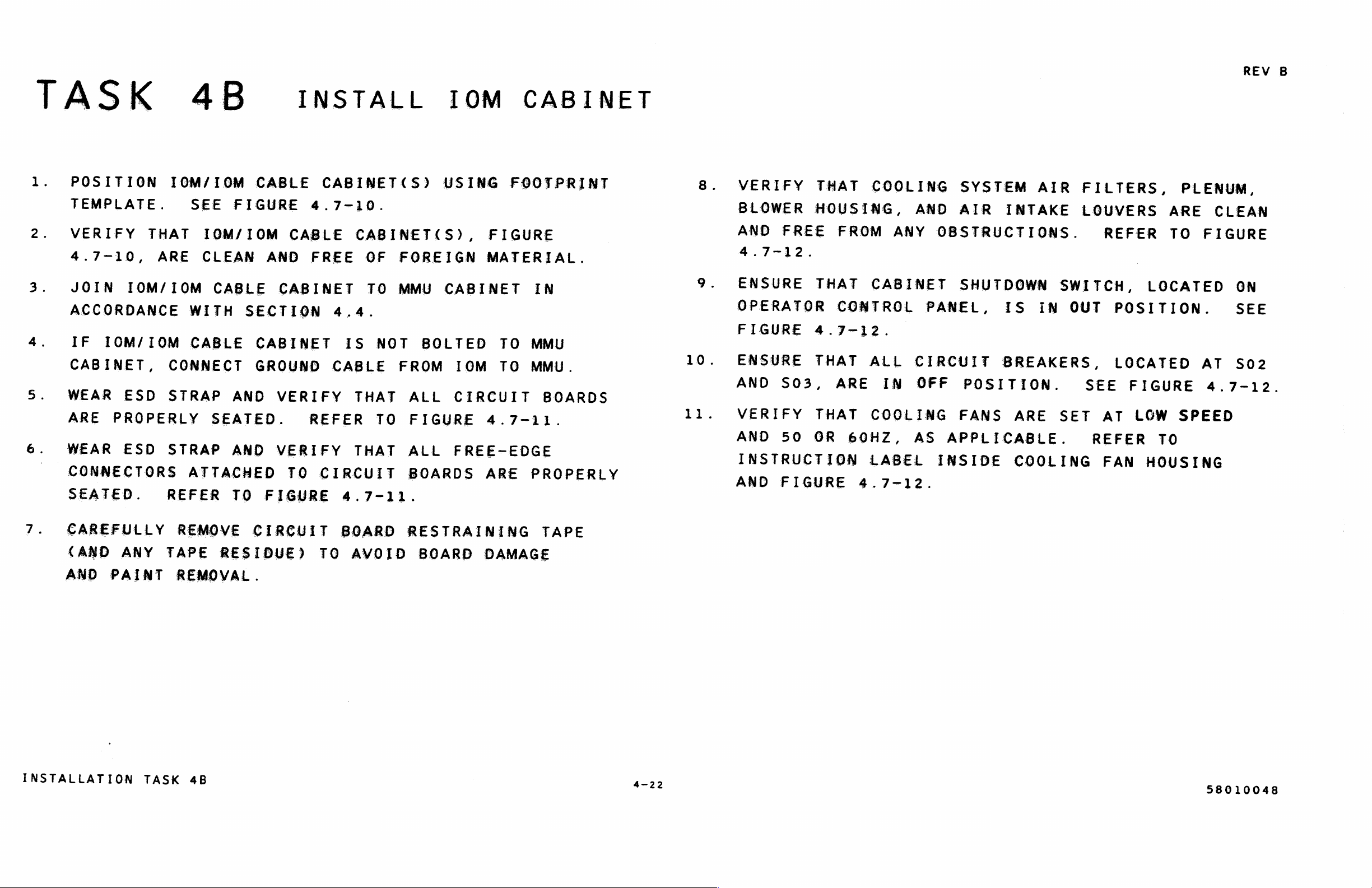

INSTALL

CPU

CABINET

1.

POSITION

CPU

CAQIflET

USING

FOOTPRINT

TEMPLATE.

8.

VERIFY

THAT

COOLING

SYSTEM

AIR

FILTERS,

PLENUM,

SEE

FIGURE

4.7?4.

BLOWER

HOUSING,

AND

AIR

INTAKE

LOUVERS

ARE

CLEAN

AND

FREE

FROM

AflY

OBSTRUCTIOflS.

REFER

TO

FIGURE

2.

VERIFY

THAT

CPU

CABTNET,

FTGURE

4.7*4,

IS

CLEAN

4

7

6

AND

FREE

OF

FOREIGN

MATERIAL.

9.

EHSURE

THAT

CABINET

SHUTDOWN

SWITCH,

LOCATED

ON

OEERATOR

CONTROL

PANEL,

Is

IN

OUT

POSITION.

SEE

FIGURE

4.7-6.

IO.

EflSORE

THAT

ALL

CIRCUIT

BREAKERS,

LOCATED

AT

502

AND

503.

ARE

IN

OFF

POSITION.

SEE

FIGURE

4.7-6.

3.

JOIN

CPU

CABINET

TO

MMU

CABIEET

IN

ACCORDANCE

:WITH

SECTION

4.4.

4.

IF

CPU

CABINET

IS

NOT

BOLTED

TO

MMU

CAQINET,

CONNECT

GROUND

CABLE

FROM

CPU

TO

MMU.

5.

AWEAR

ESD

STRAP

AND

VERIFY

THAT

ALL

CIRCUIT

BOARDS

ARE

PROPERLY

SEATED.

REFER

To

FIGURE

4.7_5.

11

JERIFY

THAT

COOLING

FANS

ARE

SET

AT

Lo

5

EED

ANB

so

OR

OGHZ,

AS

APPLICABLE.

REFER

TO

INSTRUCTION

6.

WEAR

E50

STRAP

Afii

VERiFY

THAT

ALL

FREE-EDGE

LABEL

INSIDE

COOLING

FAN

HOUSTNG

AND

FIGURE

4.7-5.

CONNECTORS

ATTACHED

TO

CIRCUIT

OOAROS

ARE

PROPERLY

SEATEO.

REFER

TO

EIOOEE

4.7»5.

7.

CAREFULLY

REM©V£

CIRCUTT

BOARD

RESTRAINING

TAPE

(AND

ANY

TAPE

RESIDOE)

TO

AVOIO

BOARD

DAMAGE

AND

PAINT

EEMOVAL.

INSTALLATION

TASK

3

4*1‘

58010048

Page 46

REV

B

TYPICAL

OPERATOR

,z”/’CONTROL

PANEL

095

a

,,,

TYPICAL

AIR

INTAKE

f,,/”

LOUVERS

A/

D

D

FOOTPRINT

TEMPLATE

111

‘5

/

FIGURE

4.7-4.

POSITION

CPU

CABINET

INSTALLATION

TASK

3

4~15

58010048

Page 47

REV

B

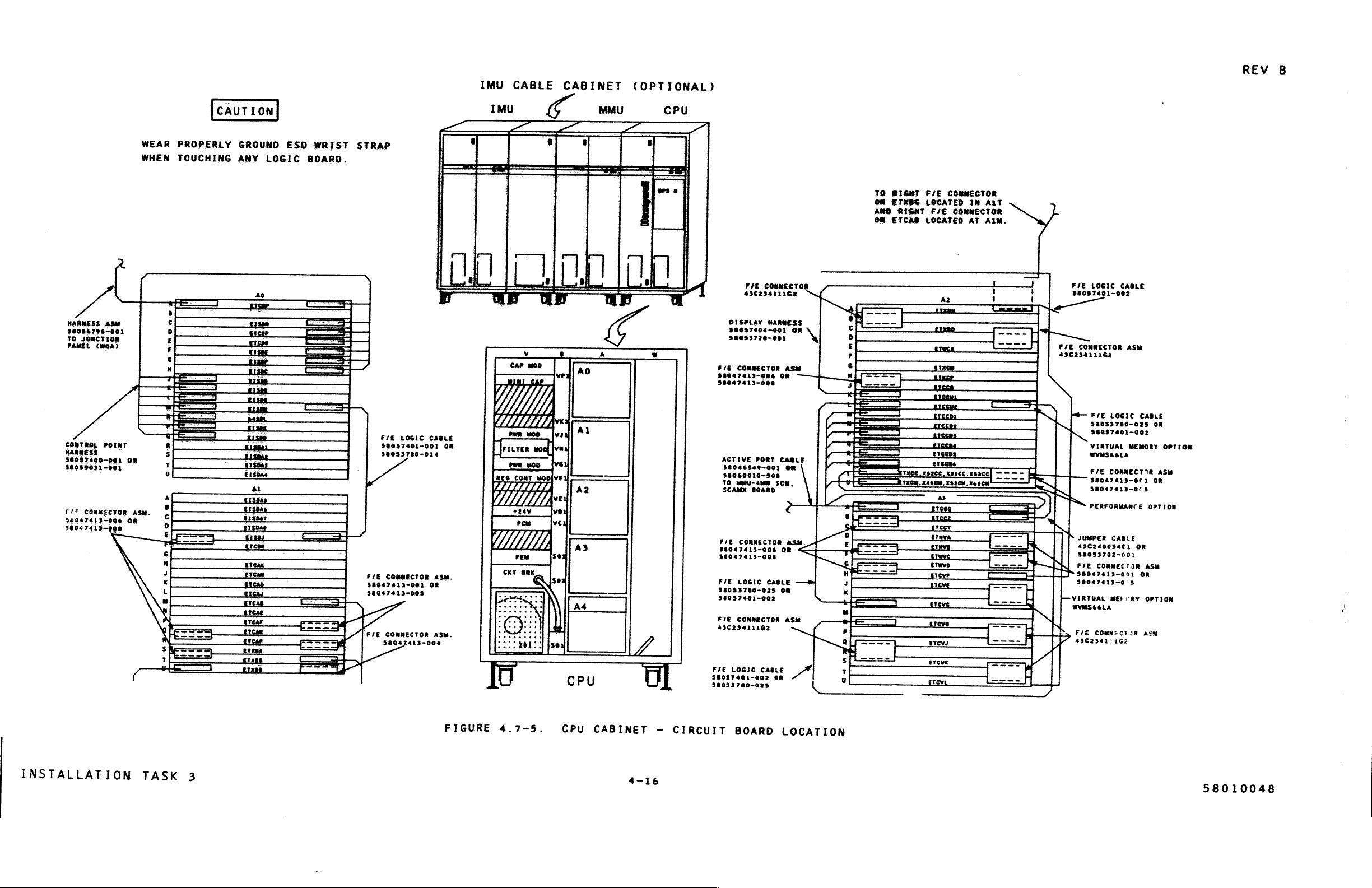

IMU

CABLE

CABINET

(OPTIONAL)

'b‘:)sl’T-I()"]

{I'll}

‘zjg’f’

I

hfllflll

(:l’l’

if”

.

‘1’,/r

WEAR

PROPERLY

excuse

ssn-yaxsr

518A?

.g

EF

':

I

,

‘

wusu

rcucnxus

Any

LOGIC

BOARD.

:

A

:

:

,

1

:

mo

T0

I16!”

FIE

CW8?“

‘4

C

CH

E7x35

LCCATEB

IQ

A11

£39

iii”?

FIE

COINECTOR

OI

EVCAD

LOCATED

A?

A1”.

FIE

tOGIC

CAILE

"t

a

1'

‘

I

‘

3

A

‘

.

,

"

"

,

A

.

A

'

"E

“unfit

5“”

1-003

43C234111‘2

OISPLAV

”ARIESS

3.957‘0¢~001

Oi

5'953720-.OI

”AIQESS

AS-

SIOSOIQb-OOI

TO

403C130!

PANEL

(IDA)

FIE

CONNECTOR

ASH

EJCISOIIIGQ

V

I.

A

j

l

'"

t

§s§:§3355253'«=“

//////

I

FIE

Loczc

CAILE

53053700-025

on

scosvaoz-ooz

V

I

v

FIE

LOGIC

CAILE

_

"'

moo

’

VIRTUAL

atuoav

OFYIOI

CGITIOL

291g!

1

59’57‘°1*°91

0*

3111::

no

I?!

IvasosLA

u;nness

‘

s

5.95,

1‘

-

ACIIVE

roar

caan

slosv¢oo-ooz

on

t

an:

moo

V6