Page 1

DPR 100 C - DPR 100 D

PRODUCT MANUAL

Page 2

DPR 100 C - DPR 100 D

PRODUCT MANUAL

Ref. : US1I-6137

Issue :19 October, 2003

Page 3

Copyright, Notices, and Trademarks

© Copyright 2000 by Honeywell Inc.

While this information is presented in good faith and believed to be

accurate, Honeywell disclaims the implied warranties of

merchantability and fitness for a particular purpose and makes no

express warranties except as may be stated in its written agreement

with and for its customer.

In no event is Honeywell liable to anyone for any indirect, special or

consequential damages. The information and specifications in this

document are subject to change without notice.

This document was prepared using Information Mapping

methodologies and formatting principles.

Information Mapping is a trademark of Information Mapping Inc.

Windows is a registered trademark of Microsoft Inc.

Modbus is a registered trademark of MODICON, Inc.

The omission of a name from this list is not to be interpreted that the

name is not a trademark.

Page 4

About This Document

Abstract

This manual describes the installation, configuration, operation, and maintenance of the Recorder.

Warranty

WARRANTY. THE FOLLOWING IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THOSE OF MERCHANTABILITY

AND FITNESS FO R PARTICULAR PURPOSE.

a) Goods/Hardware

Except as otherwise hereinafter provided, Honey well warrants goods of its manufacture to be free of def ective materials and faulty workmanship

and as conforming to applicable specifications and/or drawings. Commencing with date of shipment, Ho neywell's war ranty shal l run for the period

specified on the face hereof or, if none b e mentioned, 18 months. If warranted goods are returned to Honeywell during this period of coverage,

Honeywell will repair or replace without charge those items it finds defective.

Experimental devices (designated by the letter "X" or "E" within their part-number identification) are prototype, pre-pr oduction items that have yet to

complete all phases of prod uct-release testing; thes e items are sold "AS IS" WITH NO WARRANTY.

b) Software

Software, if listed on the face hereof and used within hardware and/or a system warranted by Honeywell, will be furnished on a medium that’s free

of defect in materials or workmanship under normal use for so long as the hardware and/or system is under warranty. During this period,

Honeywell will replace without charge any such medium it finds defective. As for the quality or performance of any software or data, they are

supplied “AS IS” WITH NO WARRANTY.

c) Services

Where hardware and/or a system is installed by Honeywell, such services are warranted against faulty workmanship for the same period (if any)

as applies to the installed items. During this concurrently r unning period, Ho neywell will correct without charge any workmanship it finds to be

faulty.

Contacts

If you encounter any problem with your recorder, please contact your nearest Sales Office. (See the

address list at the end of this manual).

An engineer will discuss your problem with you. Please have your complete model

number and serial number available. Model number and serial number are located on the

chassis nameplate.

If it is determined that a hardware problem exists, a replacement instrument or part will be shipped

with instructions for returning the defective unit. Do not return your instrument without authorization

from your Sales Office or until the replacement has been received.

Page 5

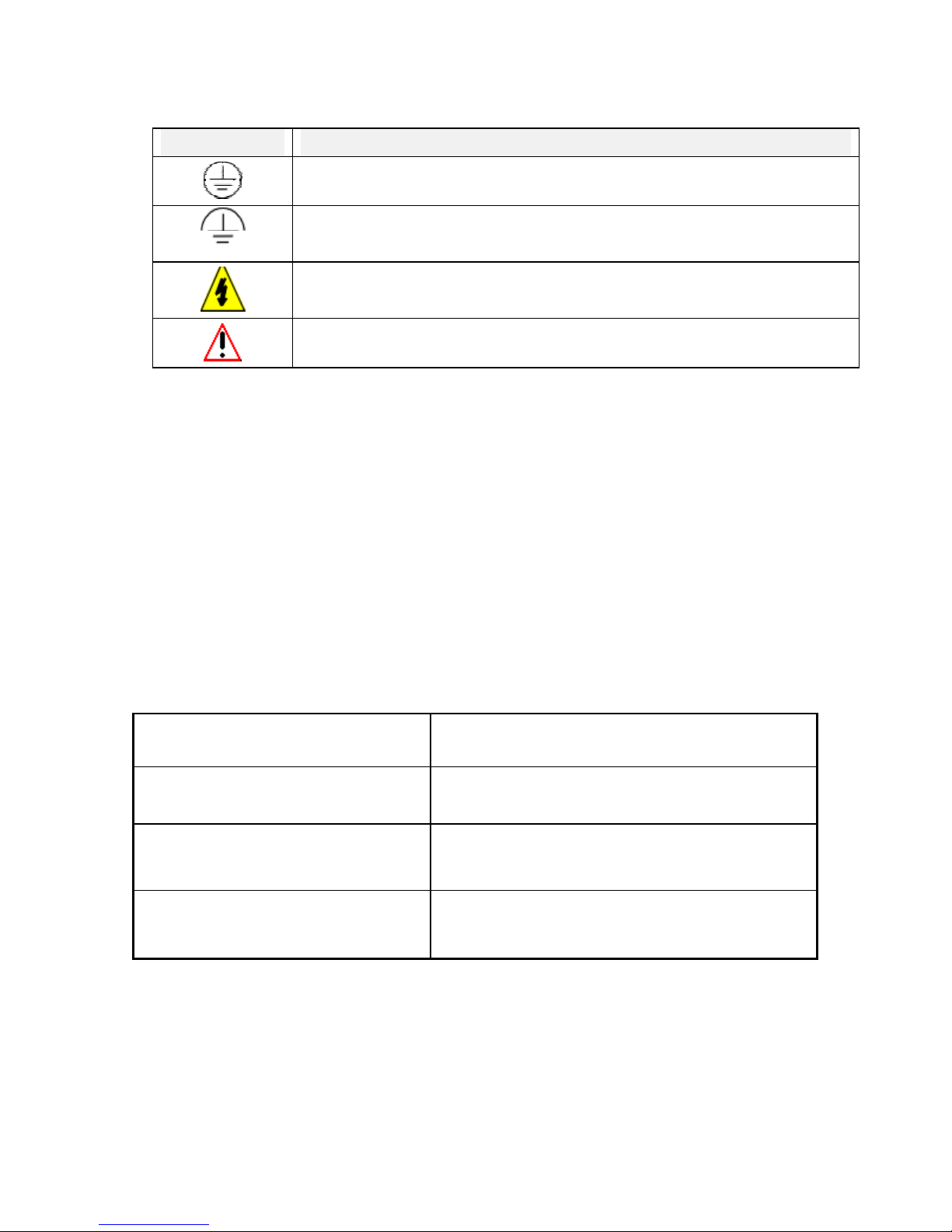

Symbol Meanings

Symbol What it means

Protective ground terminal. Provided for connection of the protective earth green (green

or green/yellow) supply system conductor.

Functional ground terminal. Used for non-safety purposes such as noise immunity

improvement.

WARNING. Risk of electric shock. This symbol warns the user of a potential shock

hazard where voltages greater than 30 Vrms, 42.4 Vpeak, or 60 Vdc may be accessible.

CAUTION. When this symbol appears on the product, see the user manual for more

information. This symbol appears next to the required information in the manual.

CE conformity

This product conforms with the protection requirements of the following European Council

Directives: 89/336/EEC, the EMC directive, and 73/23/EEC, the low voltage directive. Do

not assume this product conforms with any other “CE Mark” Directive(s).

Attention

The emission limits of EN 50081-2 are designed to provide reasonable protection against harmful

interference when this equipment is operated in an industrial environment. Operation of this equipment in a

residential area may cause harmful interference. This equipment generates, uses, and can radiate radio

frequency energy and may cause interference to radio and television reception when the equipment is used

closer than 30 meters to the antenna(e). In special cases, when highly susceptible apparatus is used in close

proximity, the user may have to employ additional mitigating measures to further reduce the electromagnetic

emissions of this equipment.

Product model number:

Serial number:

Date code:

Service department telephone

number:

Page 6

TABLE OF CONTENTS

1. OVERVIEW............................................................................................................................................... 1-1

1.1 RECORDER OVERVIEW.................................................................................................................... 1-1

2. INSTALLATION....................................................................................................................................... 2-1

2.1 WARNING.............................................................................................................................................. 2-1

2.2 UNPACKING.......................................................................................................................................... 2-2

2.3 PANEL MOUNTING THE RECORDER............................................................................................ 2-3

2.3.1 Recommendations........................................................................................................................ 2-3

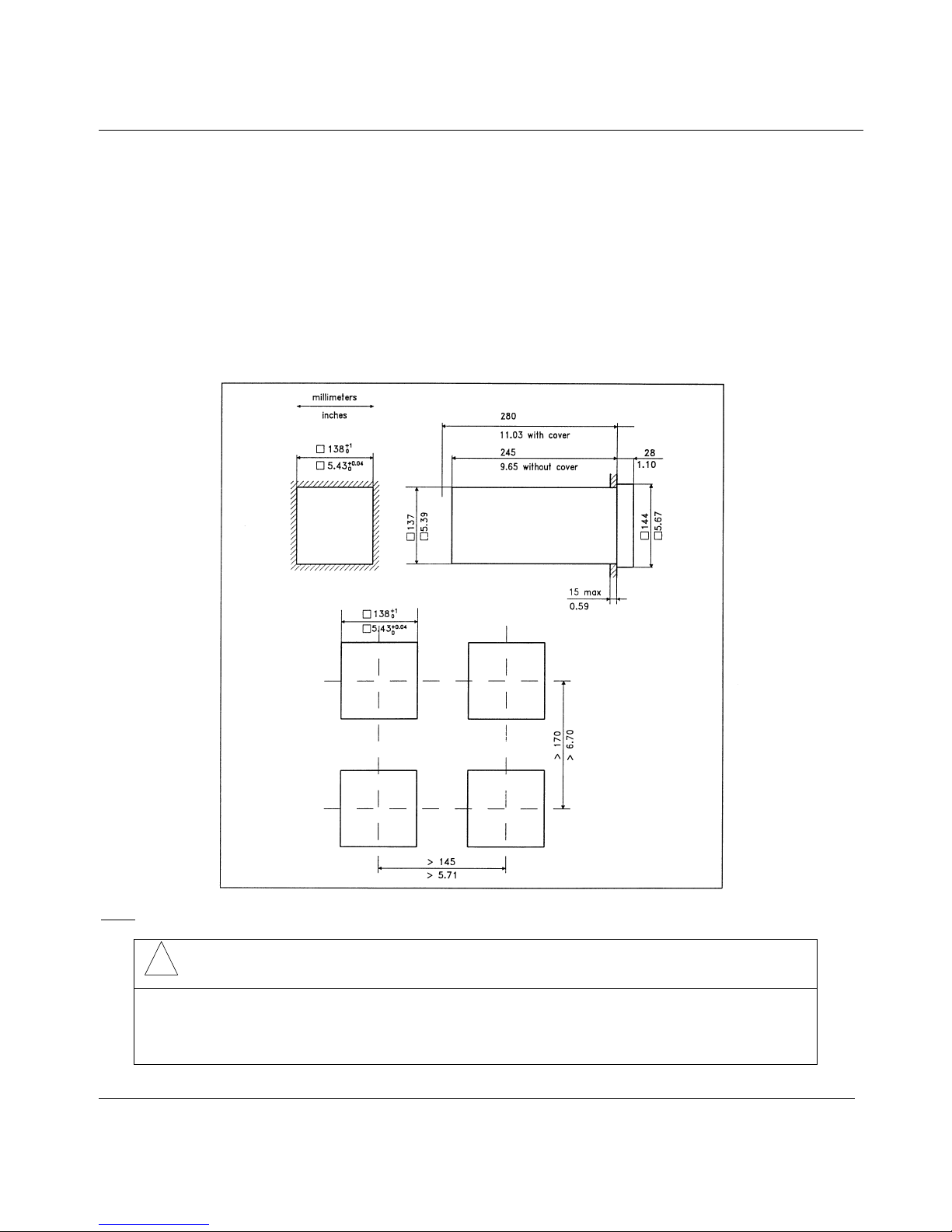

2.3.2 External dimensions and cut-out.................................................................................................. 2-3

2.3.3 Installing the recorder................................................................................................................... 2-4

2.4 WIRING THE RECORDER ................................................................................................................. 2-5

2.4.1 Recommendations........................................................................................................................ 2-5

2.5 TECHNICAL CONNECTIONS............................................................................................................ 2-6

2.6 FITTING THE CHART......................................................................................................................... 2-7

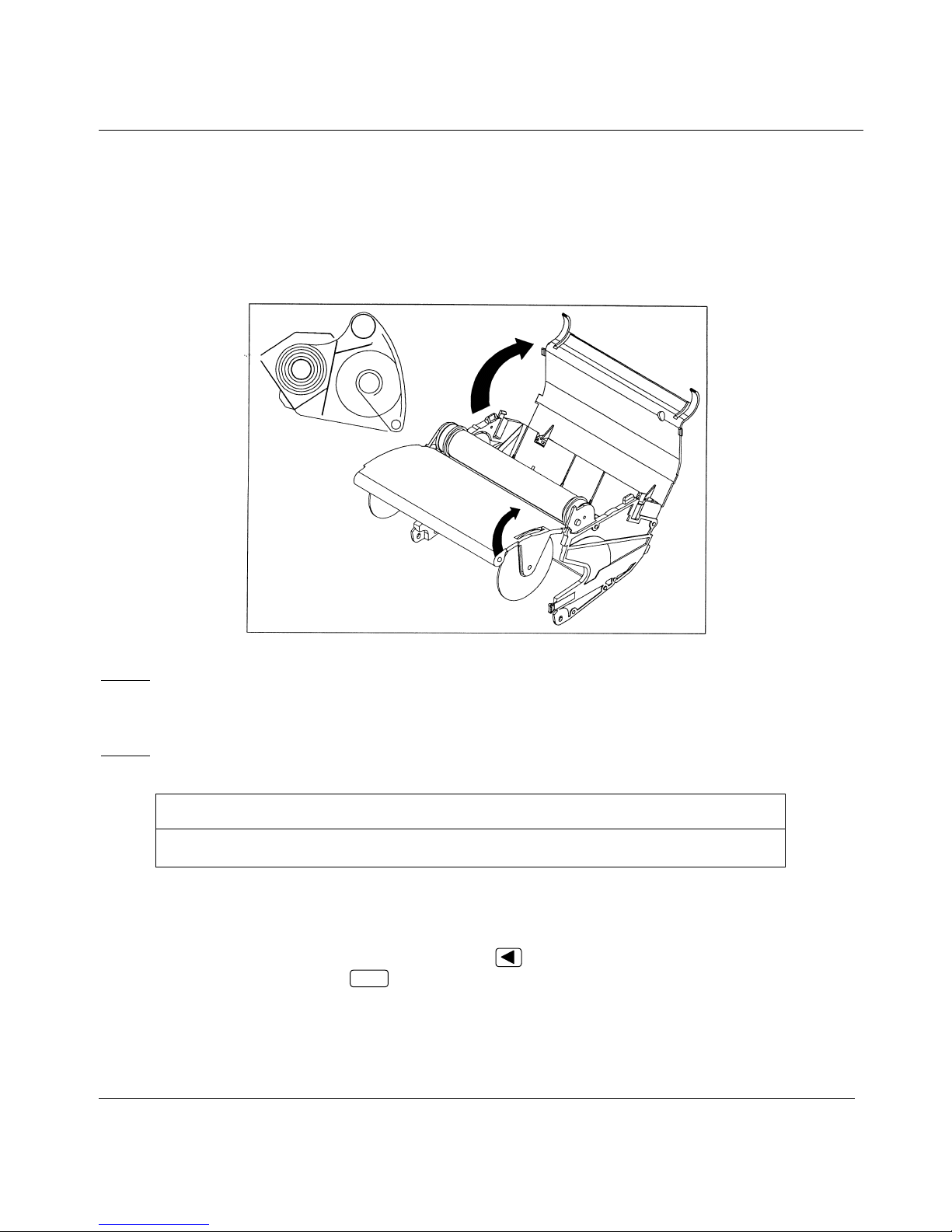

2.6.1 Roll Chart..................................................................................................................................... 2-7

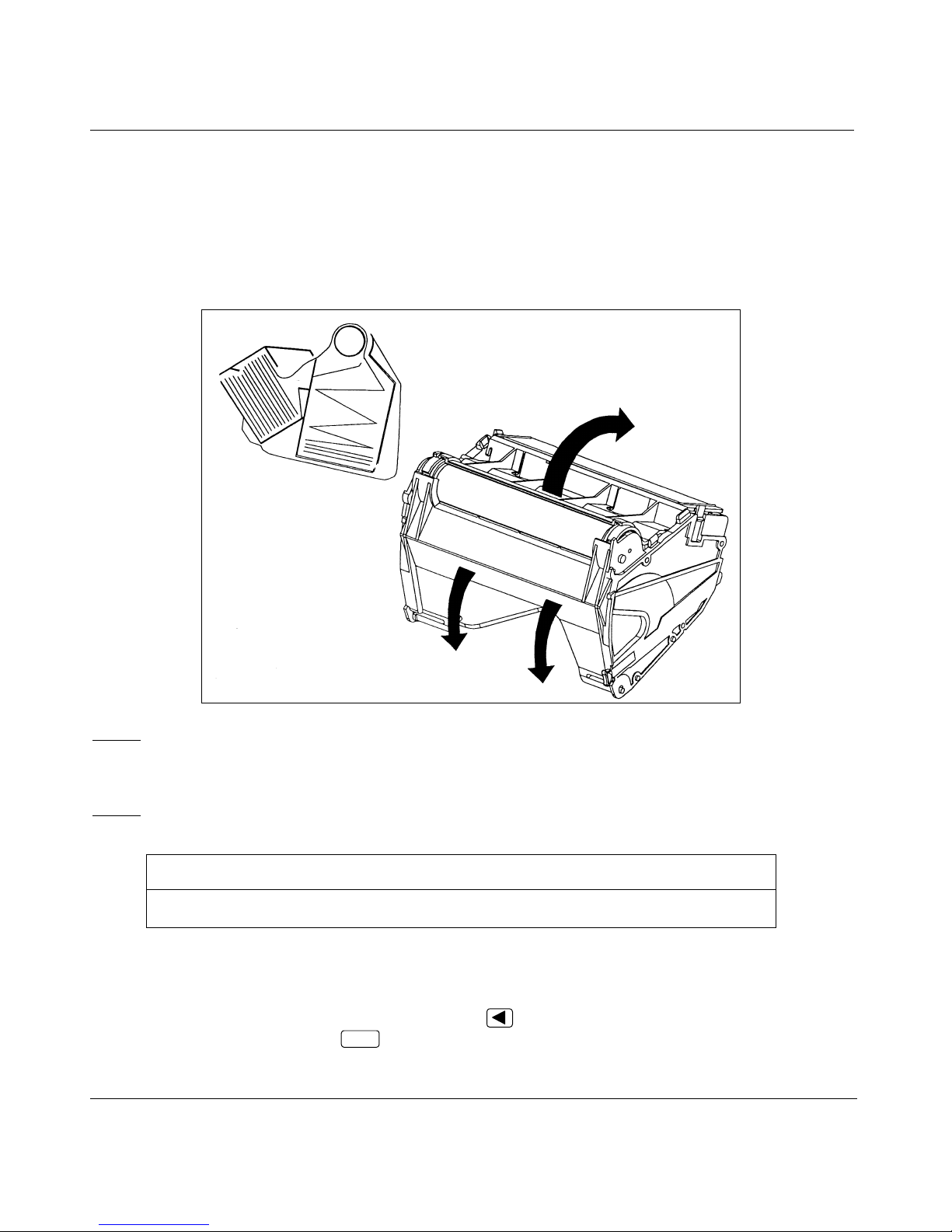

2.6.2 Fanfold Chart ............................................................................................................................... 2-8

2.7 INSTALLING THE PRINTING SYSTEM.......................................................................................... 2-9

2.8 CHECK LIST........................................................................................................................................ 2-15

3. OPERATION ............................................................................................................................................. 3-1

3.1 OPERATING INTERFACE EXPLANATION ................................................................................... 3-1

3.2 BASIC ACTIONS................................................................................................................................... 3-2

3.2.1 Opreators keys.............................................................................................................................. 3-2

3.2.2 How to select the display type...................................................................................................... 3-3

4. MODEL SELECTION GUIDE ................................................................................................................4-1

4.1 PRODUCT IDENTIFICATION............................................................................................................ 4-1

5. PRODUCT SPECIFICATION SHEET ................................................................................................... 5-1

6. CONFIGURATION................................................................................................................................... 6-1

6.1 OPERATOR INTERFACE ................................................................................................................... 6-1

6.2 ONE EXAMPLE: HOW TO SET THE CHART SPEED................................................................... 6-5

6.2 PROMPTS EXPLANATION ................................................................................................................6-6

7. DETAILED CONFIGURATION ............................................................................................................. 7-1

7.1 PARAMETER LIST .............................................................................................................................. 7-1

8. SERVICE.................................................................................................................................................... 8-1

8.1 OPERATOR INTERFACE ................................................................................................................... 8-1

8.1.1 Access to service.......................................................................................................................... 8-1

8.1.2 Passwords..................................................................................................................................... 8-1

8.1.3 Main function............................................................................................................................... 8-1

8.1.4 Access to functions during service............................................................................................... 8-2

8.2 LIST OF SERVICES.............................................................................................................................. 8-3

i

Page 7

TABLE OF CONTENTS

9. PC LOADER .............................................................................................................................................. 9-1

9.1 OVERVIEW............................................................................................................................................ 9-1

9.2 INSTALLATION.................................................................................................................................... 9-1

9.2.1 System Requirement .................................................................................................................... 9-1

9.2.2 New Installation ........................................................................................................................... 9-2

9.2.3 Upgrade old installation ............................................................................................................... 9-5

9.2.4 Uninstall....................................................................................................................................... 9-6

9.3 USE .......................................................................................................................................................... 9-7

9.3.1 Start up ......................................................................................................................................... 9-7

9.3.2 Menus........................................................................................................................................... 9-7

9.3.3 Modifying fields of parameters.................................................................................................... 9-7

9.3.4 Going from a parameter field to another one ...............................................................................9-7

9.3.5 Leaving a menu............................................................................................................................ 9-7

9.4 SET UP COMM...................................................................................................................................... 9-8

9.5 USE .......................................................................................................................................................... 9-9

9.5.1 Read and Modify.......................................................................................................................... 9-9

9.5.2 User actuation............................................................................................................................... 9-9

9.6 SERVICE PARAMETERS.................................................................................................................. 9-10

9.7 MONITORING..................................................................................................................................... 9-13

9.7.1 Parameters initialization............................................................................................................. 9-13

9.7.2 Real time display........................................................................................................................ 9-13

9.7.3 Start/stop archiving ....................................................................................................................9-13

9.8 UPDATE SOFTWARE (FOR JACK ONLY).................................................................................... 9-14

10. TROUBLESHOOTING .......................................................................................................................... 10-1

10.1 FAILURE SYMPTOMS AND TROUBLESHOOTING PROCEDURES ...................................... 10-1

10.2 TROUBLESHOOTING LIST............................................................................................................. 10-1

10.2.1 Self test mode pen recorder........................................................................................................ 10-1

10.2.2 Self test mode multipoint recorder............................................................................................. 10-5

10.2.3 Symptom: The recorder is inoperative ....................................................................................... 10-8

10.2.4 Symptom: The display is inoperative......................................................................................... 10-8

10.2.5 Symptom: The chart is inoperative ............................................................................................ 10-8

10.2.6 Symptom: The print carriage is inoperative...............................................................................10-9

10.2.7 Symptom: The print head is inoperative ..................................................................................10-10

10.2.8 Symptom: Printing incorrect color........................................................................................... 10-10

10.2.9 Symptom: Wrong date/time ..................................................................................................... 10-11

10.2.10 Symptom: The alram relay is inoperative ................................................................................10-11

10.2.11 Symptom: Analog input out of tolerance ................................................................................. 10-11

10.2.12 Symptom: Incorrect spacing between points............................................................................ 10-12

10.2.13 Symptom: No communication with PC loader......................................................................... 10-12

10.2.14 Symptom: Printed traces are unstable ...................................................................................... 10-12

10.2.15 Symptom: Chart illumination failed......................................................................................... 10-13

10.2.16 Symptom: Current output failed............................................................................................... 10-13

10.3 ERROR MESSAGES ......................................................................................................................... 10-14

11. KITS LIST................................................................................................................................................ 11-1

11.1 ELECTRONIC PARTS ....................................................................................................................... 11-2

11.2 MECHANICAL PARTS ...................................................................................................................... 11-3

11.3 MISCELLANEOUS ............................................................................................................................. 11-4

11.4 CONSUMABLES ................................................................................................................................. 11-5

12. PROMPTS TRANSLATION.................................................................................................................. 12-1

12.1 MATRICES........................................................................................................................................... 12-1

ii

Page 8

TABLE OF CONTENTS

12.2 SERVICE .............................................................................................................................................. 12-9

12.3 MESSAGES DURING THE RUN DISPLAY .................................................................................. 12-12

13. CONFIGURATION WORKSHEET...................................................................................................... 13-1

13.1 ANALOG INPUTS ............................................................................................................................... 13-1

13.2 ANALOG ALARMS ............................................................................................................................ 13-1

13.3 MATH.................................................................................................................................................... 13-2

13.4 DIGITAL INPUTS ............................................................................................................................... 13-2

13.5 MESSAGES .......................................................................................................................................... 13-3

13.6 CHART.................................................................................................................................................. 13-3

13.7 MISCELLANEOUS ............................................................................................................................. 13-4

13.8 BATCH .................................................................................................................................................. 13-4

13.9 PRINTER .............................................................................................................................................. 13-5

13.10 EVENT .................................................................................................................................................. 13-6

13.11 MMI ....................................................................................................................................................... 13-6

13.12 CURRENT OUTPUT........................................................................................................................... 13-6

SAFETY

SALES AND SERVICE

iii

Page 9

1. OVERVIEW

1.1 RECORDER OVERVIEW

This recorder is a precision measuring instrument wi th many features.

• Up to 3 pens for the pen recorder or up to 6 channels for the multipoint recorder,

• Compact size: 245 mm depth,

• 100 mm chart in either roll or fanfold presentation,

• Universal power supply: With optional 24 Vdc output voltage to supply up to 2 transmitters,

• IP54 front of panel protection,

• Universal input with wide choice of actuat i on/range,

• High accuracy: 0.1 % F.S.,

• Easy interactive product configuration,

• Large, clear operator display,

• Fast scanning rate: 330 ms for 3 channels, 640 ms for 6 channels,

• Alphanumeric chart documentation,

• Up to 12 alarm setpoints with a wide choice of alarm types,

• Event alarm: end of chart paper, sensor burnout, clock batt ery l ow , etc.,

• Up to 12 customer messages,

• 4 Batch messages,

• Event precursor,

• Standard chart illumination,

• Up to 4 digital inputs,

• Product configurability and service diagnostic with PC software,

• Supervision display via PC software,

• Chart zoning configurable,

• Complies with IEC348 and IEC1010 safety requirements,

1-1

Page 10

1. OVERVIEW

OPTIONS:

• Up to 12 alarm relay outputs,

• Maths functions,

• Up to 2 current output channels (4 to 20 mA).

For the best product performance Honeywell recommends the use of Honeywell charts and

pens, use of other manufacturer’s charts and pens may degrade product performance.

1-2

Page 11

2. INSTALLATION

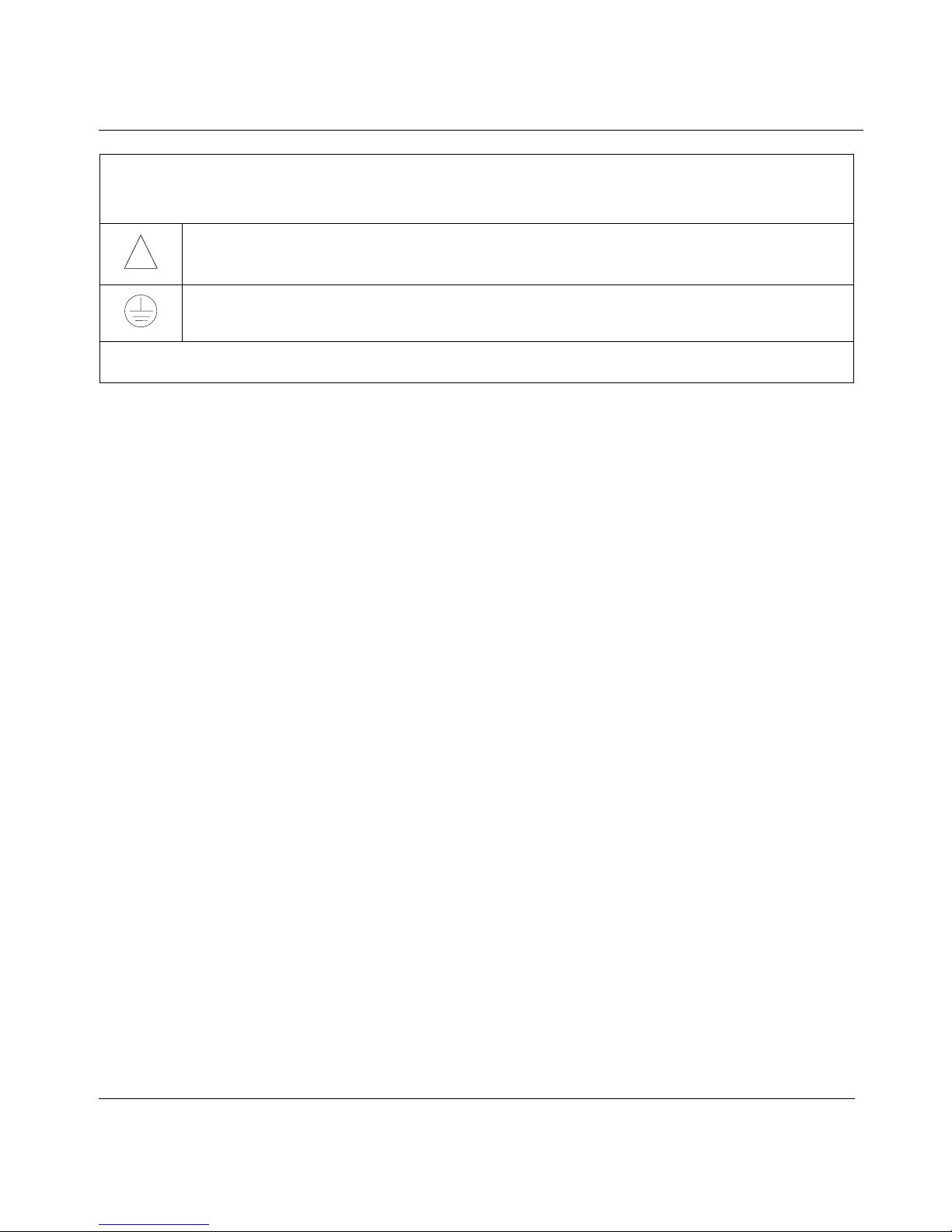

2.1 WARNING

IMPROPER INSTALLATION

To avoid the risk of electrical shock which could cause personal injury, follow all safety

!

! POWER SUPPLY

Ensure the source voltage matches the supply voltage of the recorder before power on.

! PROTECTIVE GROUNDING

Make sure to connect the protective grounding to prevent an electric shock before power on.

! NECESSITY OF PROTECTIVE GROUNDING

To avoid a potential shock hazard, never cut off the internal or external protective grounding wire or

disconnect the wiring of protective grounding terminal.

! DEFECT OF PROTECTIVE GROUNDING AND FUSE

Do not operate the instrument when protective grounding or fuse might be defective.

! FUSE

To prevent a fire, make sure to use the fuse with specified standard (current voltage, type). Before

replacing the fuse, turn off the power and disconnect the power source. Do not use a different fuse or

short-circuit the fuseholder.

! DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of flammable liquids or vapors. Operation of any

electrical instrument in such an environment constitutes a safety hazard.

! NEVER TOUCH THE INTERIOR OF THE INSTRUMENT

Inside this instrument there are areas of high voltage ; therefore, never touch the interior if the power

supply is connected. This instrument has an internal changeable system ; however, internal inspection

and adjustments should be done by qualified personnel only.

! EXTERNAL CONNECTION

To ground securely, connect the protective grounding before connecting to measurement or control

unit.

! If the equipment is used in a manner not specified by the manufacturer, the protection provided by

the equipment may be impaired.

! Do not replace any component (or part) not explicitly specified as replaceable by your supplier.

notices in this documentation.

Protective earth terminal. Provided for connection of the protective earth supply system

conductor.

Failure to comply with these instructions could result in death or serious injury

2-1

Page 12

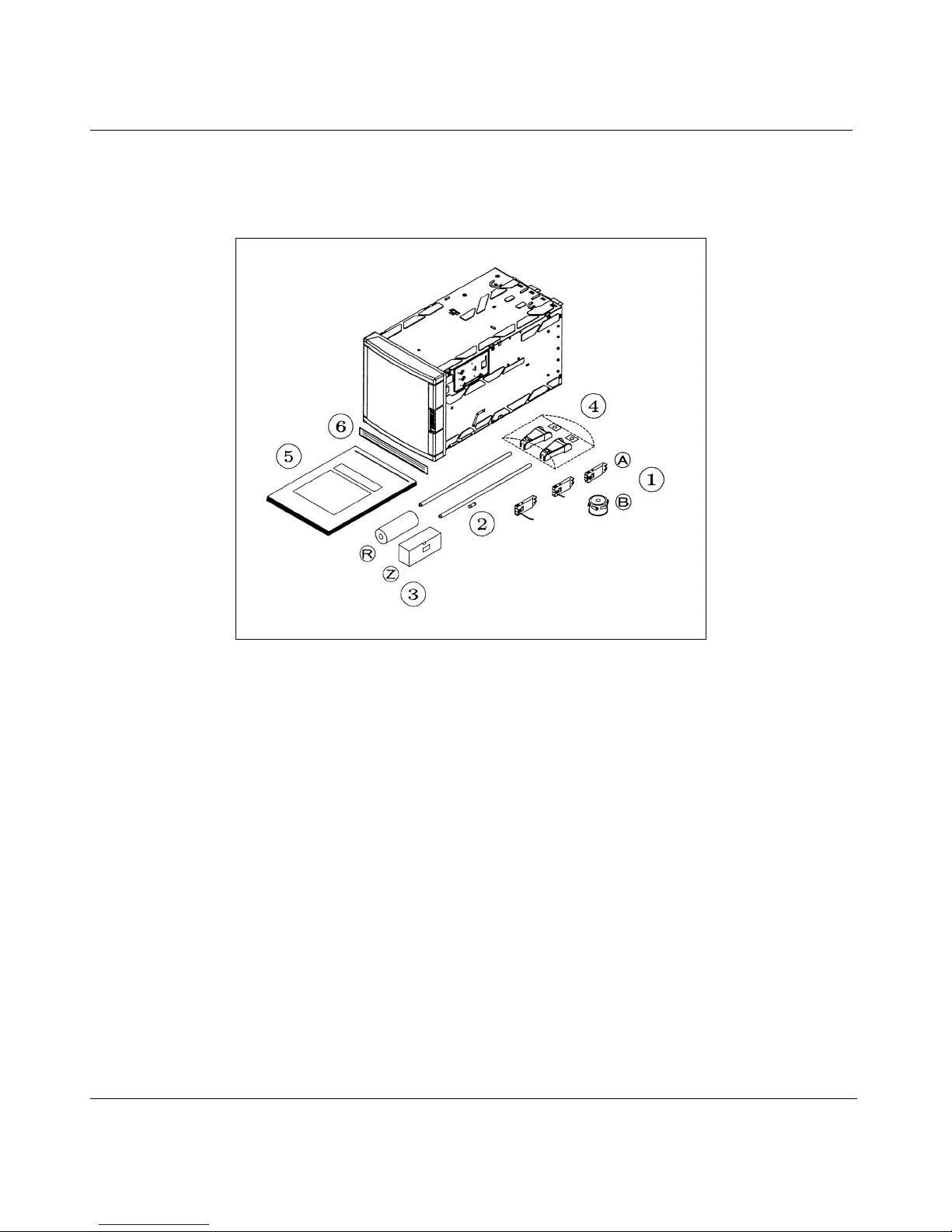

2.2 UNPACKING

Remove the accessories and check them against the figure below.

2. INSTALLATION

1. Ink cartridge(s) (A) or ink wheel (B)

2. Fuse (Spare)

3. Roll (R) or fanfold (Z) chart

4. Mounting brackets with nuts

5. Operator manual

6. Front label

NOTE: In case of missing item, please contact your nearest sales office.

2-2

Page 13

2. INSTALLATION

2.3 PANEL MOUNTING THE RECORDER

2.3.1 Recommendations

This recorder is designed to operate under specific conditions. If you need more information, refer to the

product specification sheet.

2.3.2 External dimensions and cut-out

Prepare panel cut-out as detailed below:

: Maximum panel thickness 15 mm

Note

!

CAUTION

The maximum temperature inside the cabinet should not exceed the ambient conditions

specific to the recorders. The recorder must be mounted into a panel to limit operator

access to the rear terminals.

Failure to comply with these instructions may result in product damage

2-3

Page 14

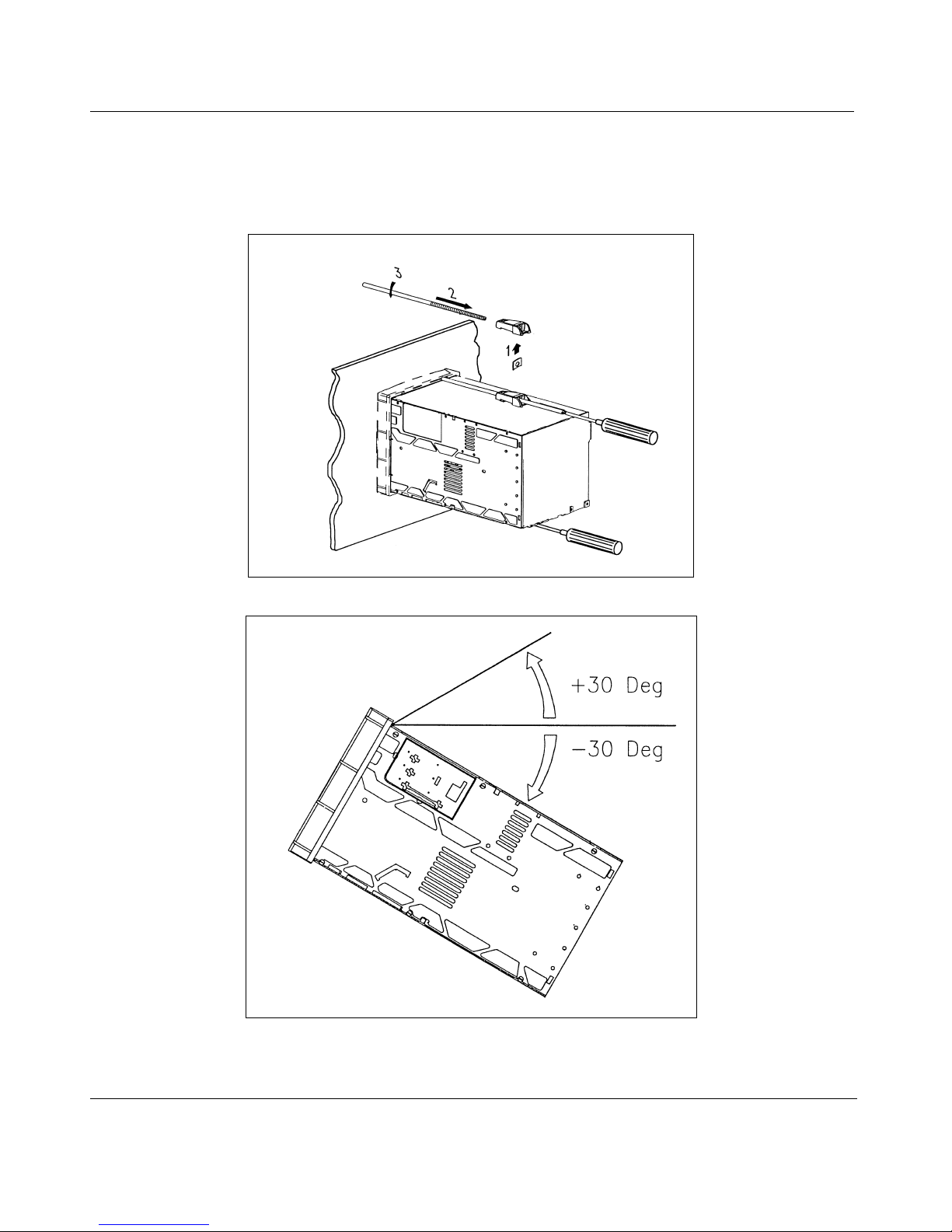

2.3.3 Installing the recorder

To install the recorder, follow the figures below:

Mounting brackets

2. INSTALLATION

Mounting angle limits

2-4

Page 15

2. INSTALLATION

2.4 WIRING THE RECORDER

2.4.1 Recommendations

# All wiring must be in accordance with local norms and carried out by authorized experienced

personnel.

# The ground terminal must be connected before any other wiring (and disconnected last).

# A switch in the main supply is required near the equipment.

# If an external fuse is used to protect the line supply to the recorder, the fuse should match the

recorder fuse rating (fuse type) as well as for the fuseholder.

# Sensor wiring should be run as far as possible from power wiring.

# To reduce stray pick-up, we recommend the use of twisted pair sensor wiring.

# EMI effects can be further reduced by the use of shielded cable sensor wiring. The shield must be

connected to the ground terminal.

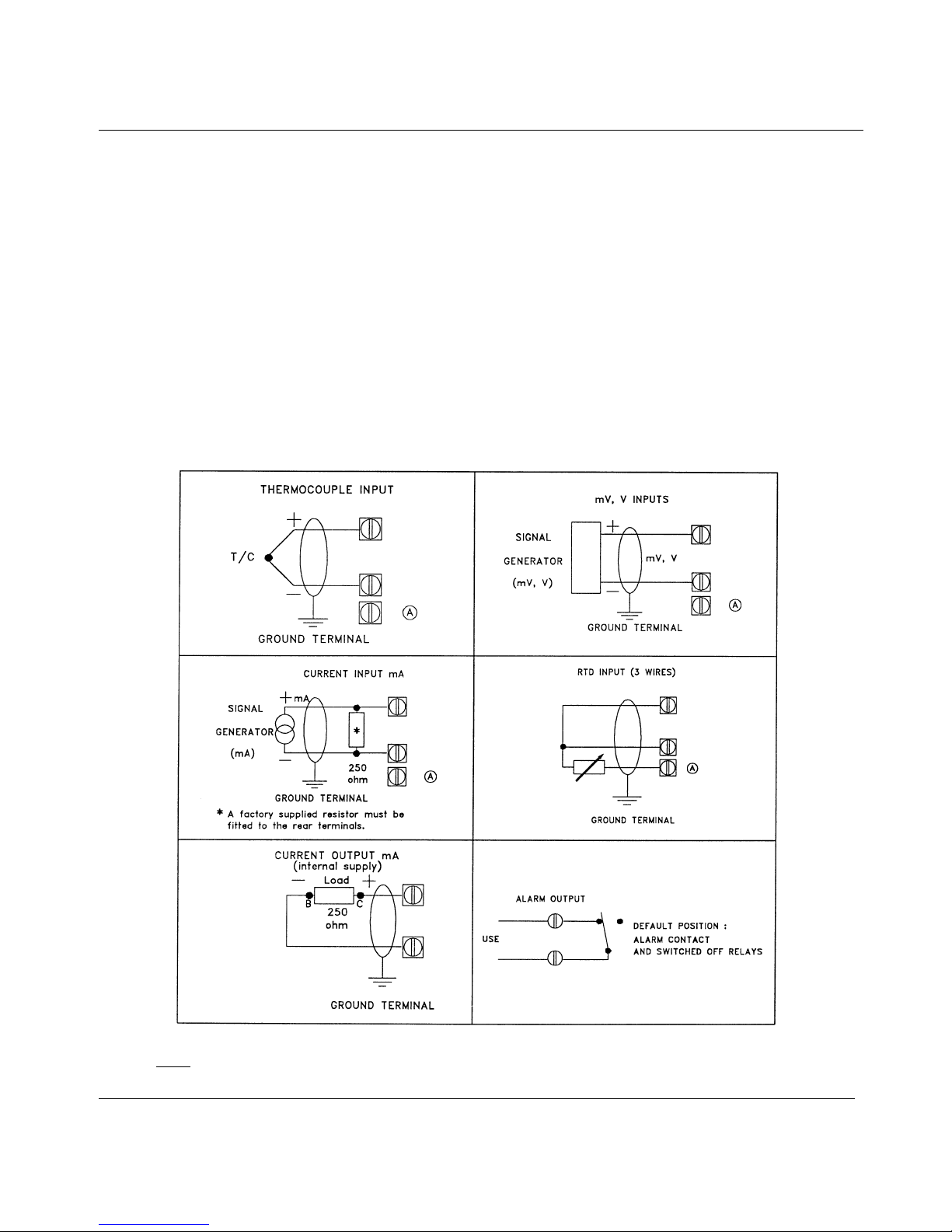

: Terminal (A) is only used for RTD. (See diagrams above.)

Note

2-5

Page 16

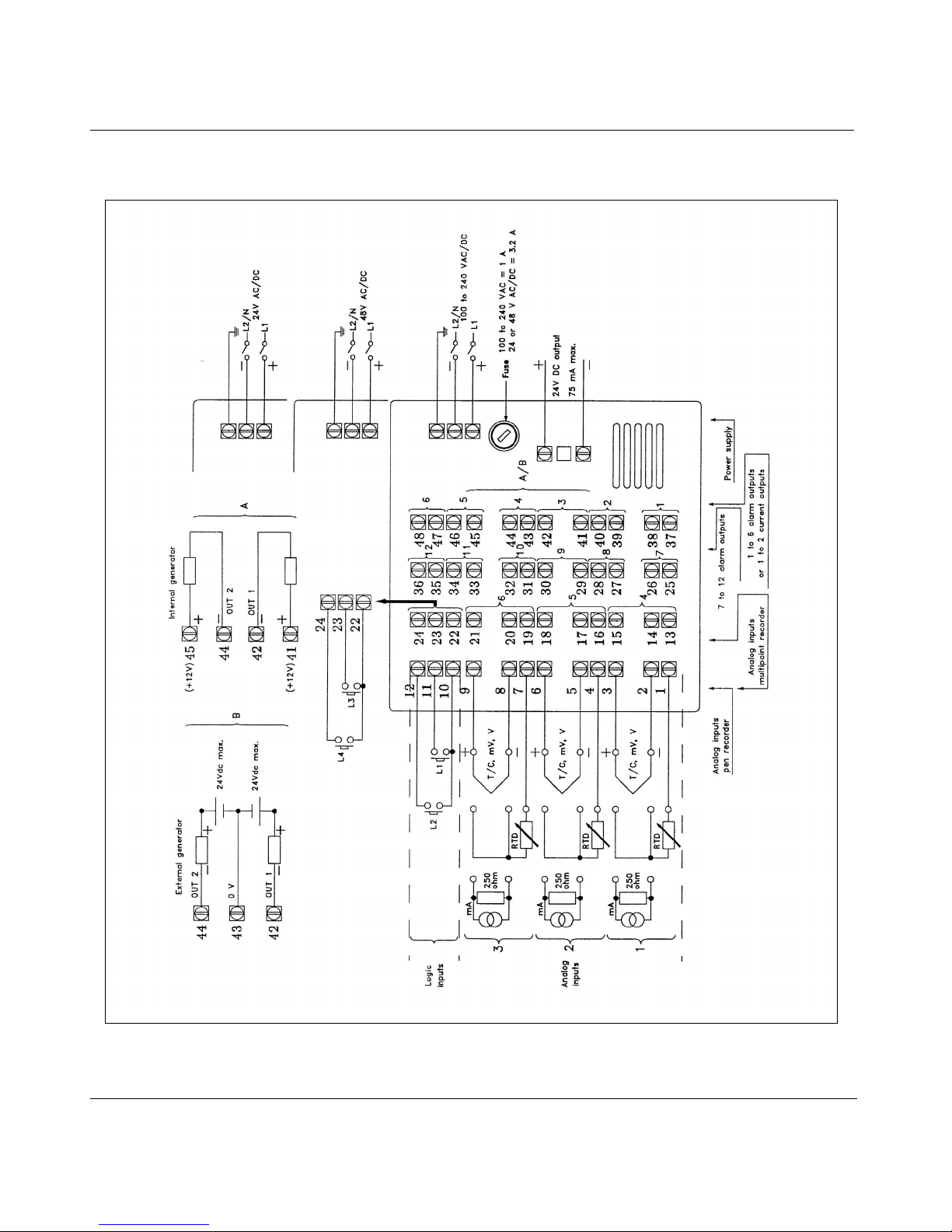

2.5 TERMINAL CONNECTIONS

2. INSTALLATION

2-6

Page 17

2. INSTALLATION

2.6 FITTING THE CHART

2.6.1 Roll chart

Open the chart cassette as shown below and install the chart using the figure on the cassette.

Note 1

Note 2

: To maintain print quality, the print carriage guide rods should be cleaned at six-monthly intervals

with a dry cotton cloth. Lubrificant should NOT be used.

If required, the chart cassette can be cleaned with a damp cotton cloth.

: After the installation of a new chart, close the display and reinsert the chart cassette.

NOTICE

Reset the paper length if configured after installing the new chart.

See paragraph 3.2.1 "Operators keys".

"END PAPER" message: When you see " END PAPER " message on the display ("end of paper" message),

the recorder informs you that the chart arrives at the end.

To remove this message, press

and press

After that, the " END PAPER " message disappears.

ENTER

.

until you read "PAPLG=…" (paper length)

2-7

Page 18

2. INSTALLATION

2.6.2 Fanfold chart

# Open the chart cassette as shown below and install the chart using the figure on the cassette.

# Place the fanfold chart in the upper compartment with the folds in the vertical plane and the slots on

the right hand side.

# Pull out 4 folds of paper and then close the rear metal cover.

Note 1

Note 2

: To maintain print quality, the print carriage guide rods should be cleaned at six-

monthly intervals with a dry cotton cloth. Lubricant should NOT be used.

If required, the chart cassette can be cleaned with a damp cotton cloth.

: After the installation of a new chart, close the display and reinsert the chart cassette.

NOTICE

Reset the paper length if configured after installing the new chart.

See paragraph 3.2.1 "Operators keys".

"END PAPER" message: When you see " END PAPER " message on the display ("end of paper" message),

the recorder informs you that the chart arrives at the end.

To remove this message, press

and press

After that, the " END PAPER " message disappears.

ENTER

.

2-8

until you read "PAPLG=…" (paper length)

Page 19

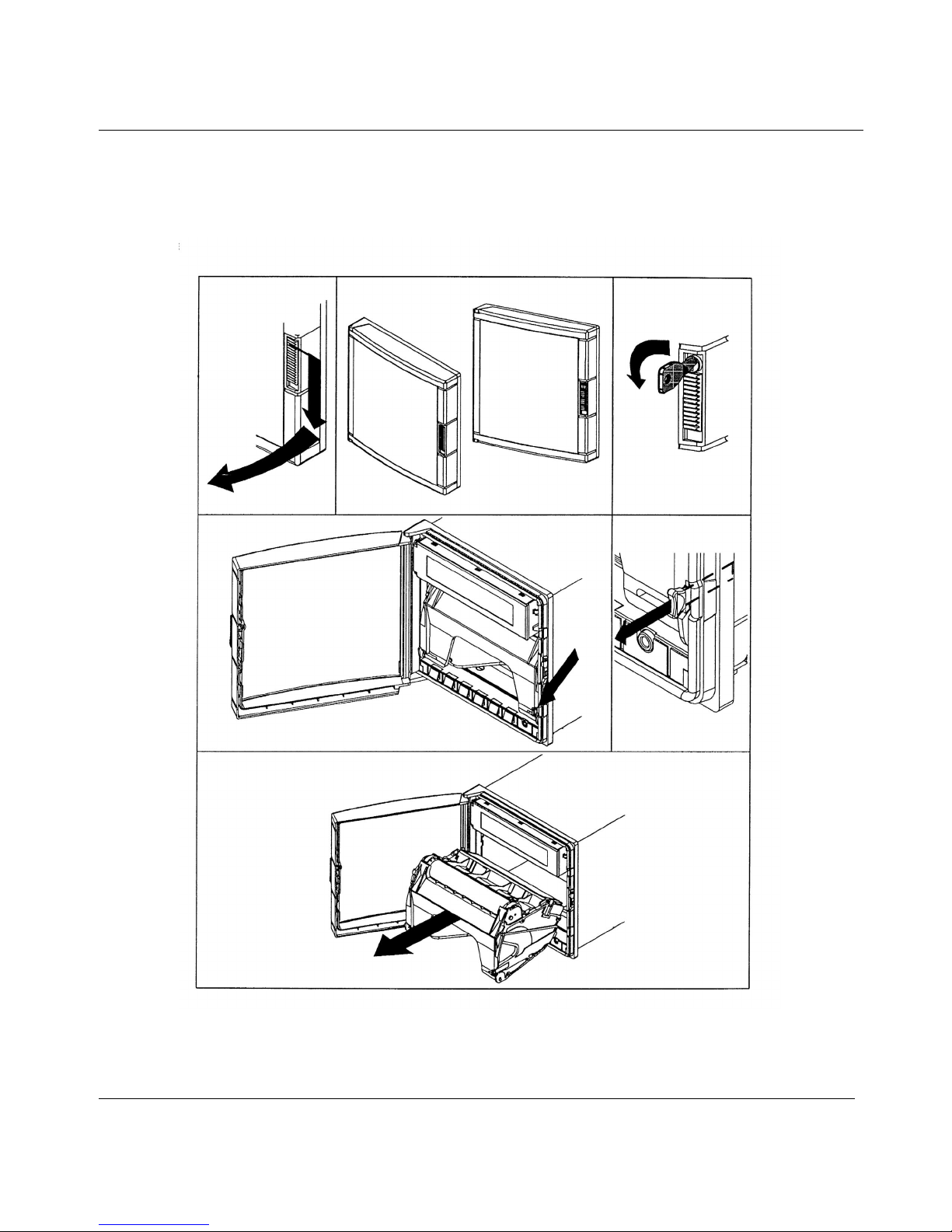

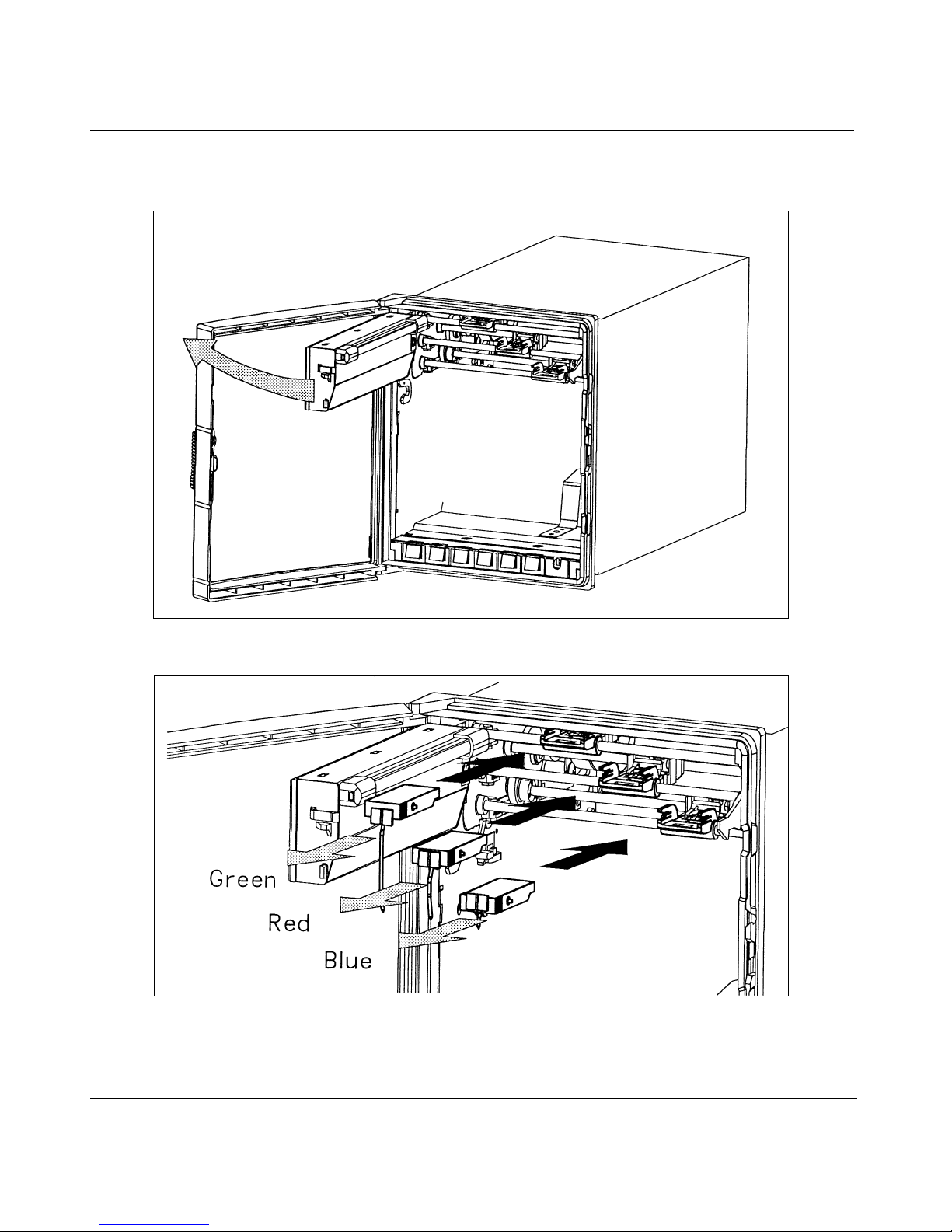

2.7 INSTALLING THE PRINTING SYSTEM

Remove the chart cassette from the chassis as shown below:

2. INSTALLATION

2-9

Page 20

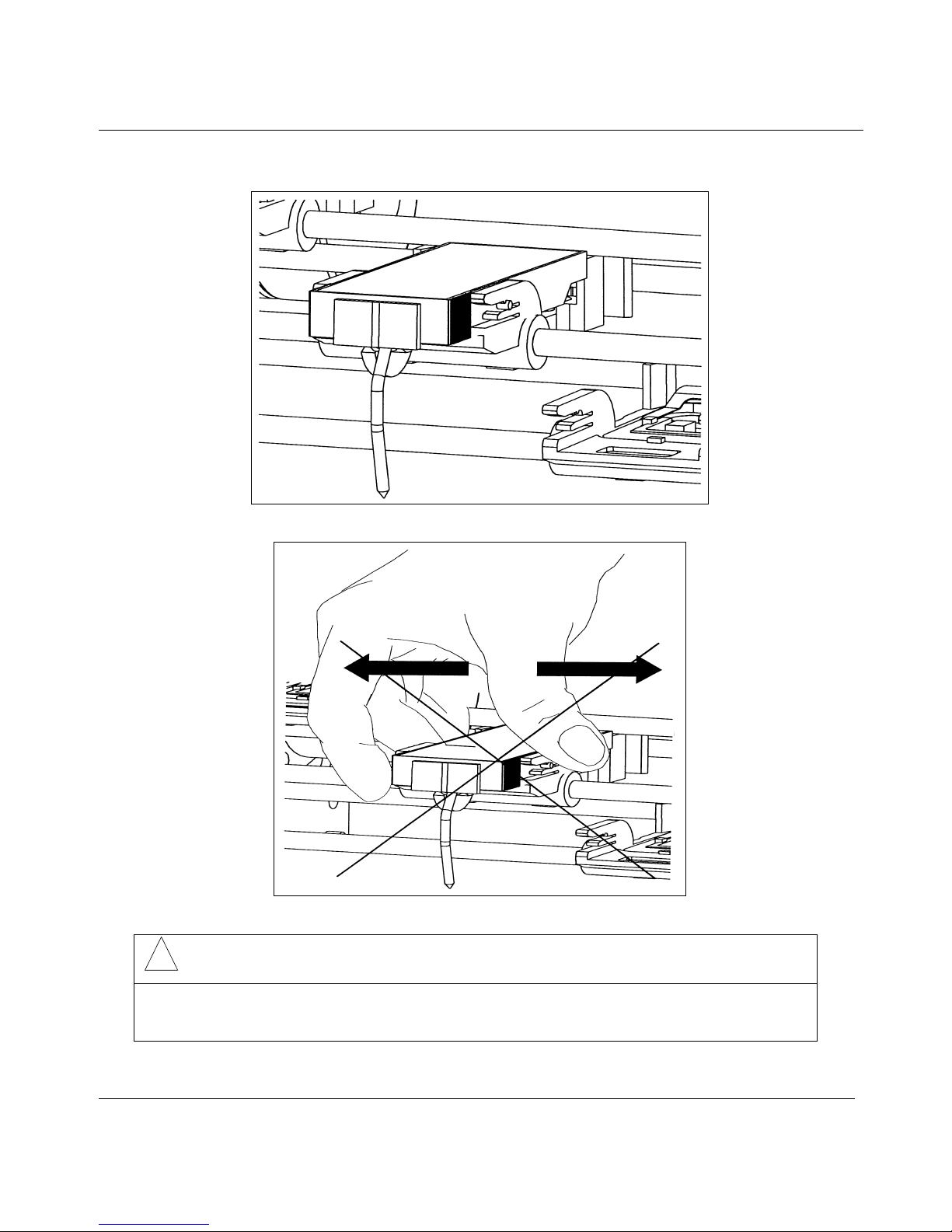

If you have a pen recorder, proceed as shown below:

Open the front display after having removed the chart cassette.

2. INSTALLATION

Insert the pen cartridges.

2-10

Page 21

Inserted pen cartridges

2. INSTALLATION

!

CAUTION

Do not move the print head mechanism when the recorder is working.

Failure to comply with these instructions may result in product damage

2-11

Page 22

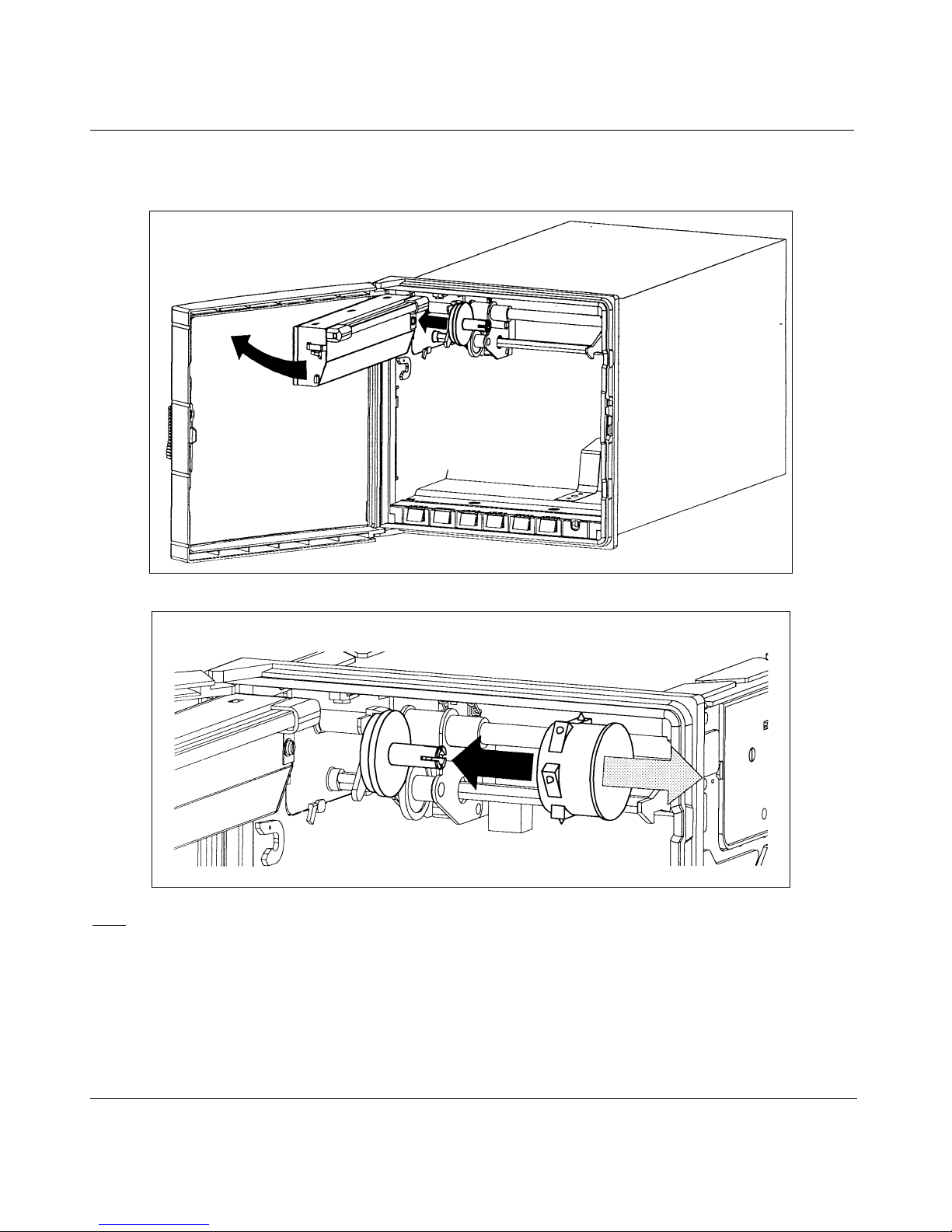

If you have a multipoint recorder, proceed as shown below:

Open the display after having removed the chart cassette.

2. INSTALLATION

Insert the ink wheel.

: The ink wheel should be inserted and rotated counter-clockwise until ratchet engages.

Note

2-12

Page 23

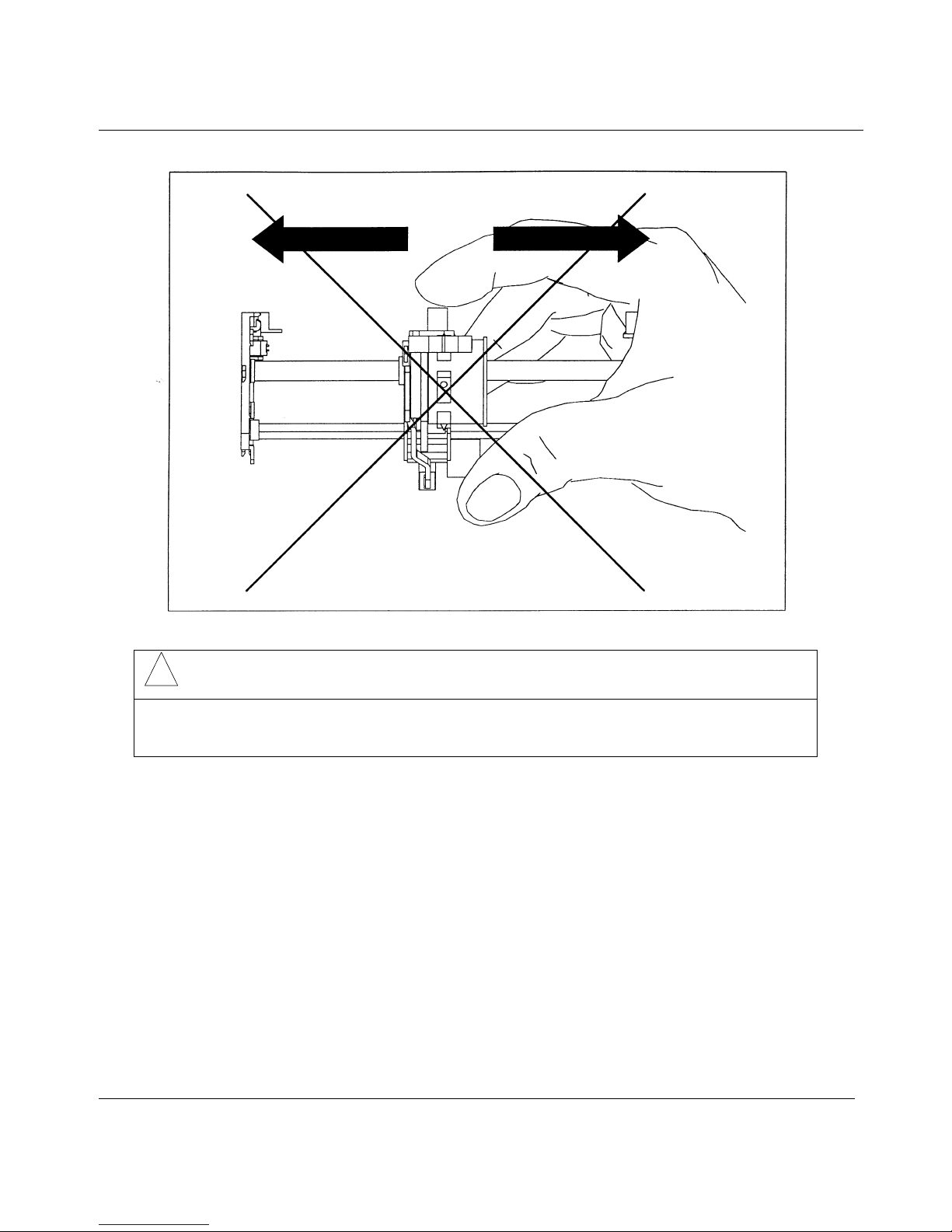

2. INSTALLATION

!

CAUTION

Do not move the print head mechanism when the recorder is working.

Failure to comply with these instructions may result in product damage

NOTE: After each change of chart, it is recommended to make a calibration again.

(See 0% and 100% CHART.)

2-13

Page 24

2. INSTALLATION

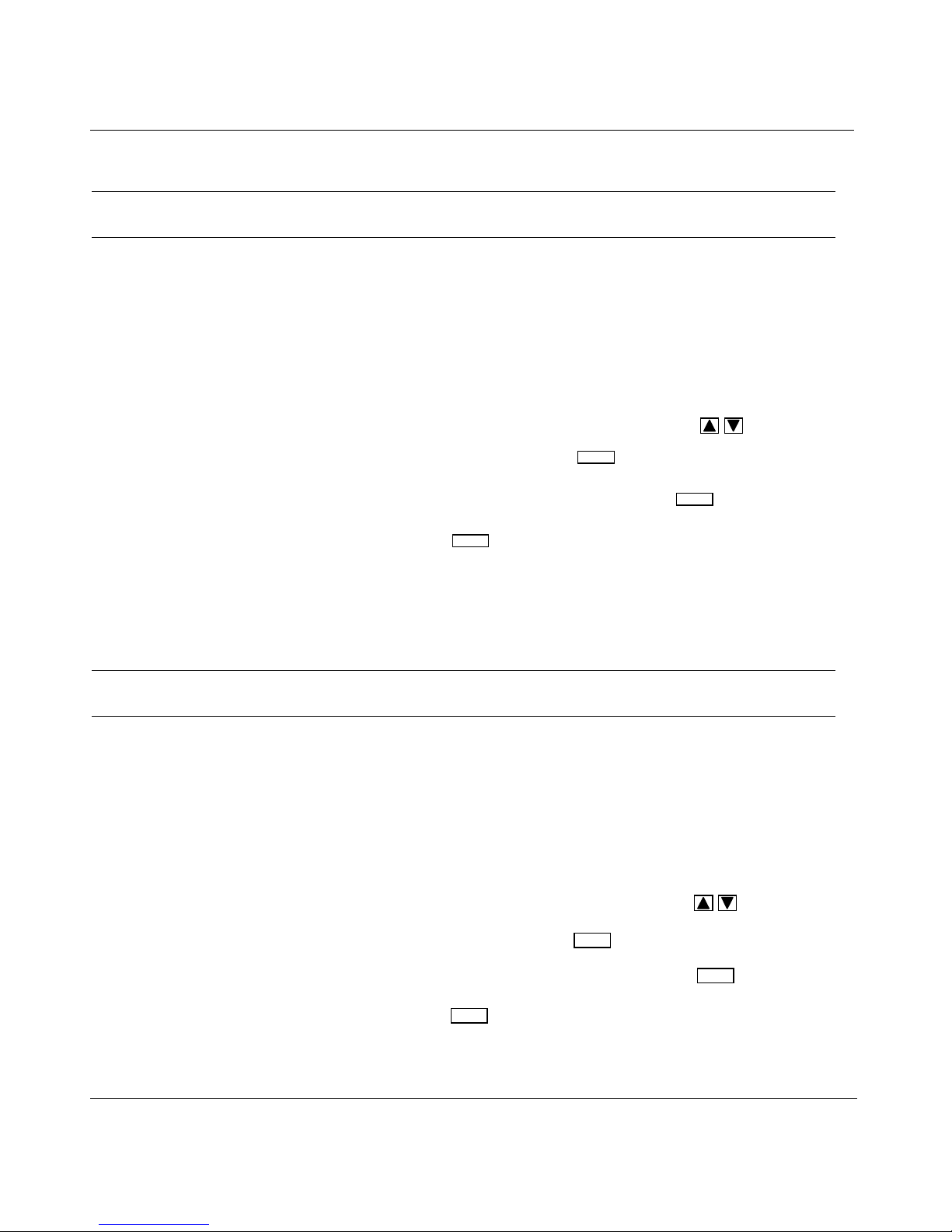

FUNCTION TYPE OF SERVICE

PRINTER 0% CHART

DEFINITION: Chart certification to show the current 0% chart position with 0%

print carriage. This is a mechanical adjustment.

HOW TO USE/EXECUTE IT: The message "(channel nb) CAL 0%" with a flashing number. This

number corresponds to the present adjustment (= step motor).

To move to the right, increase this number or to the left, decrease the

number. (You may introduce a negative number.)

You can change the distance value by pressing the keys.

You accept the value by pressing .

You can leave the 0% chart service by pressing .

NOTE: When you press , the head moves and prints at the new 0%

ENTER

ENTER

SETUP

chart calibration.

FUNCTION TYPE OF SERVICE

PRINTER 100% CHART

DEFINITION: Chart certification to show the current 100% chart position with

100% print carriage. This is a mechanical adjustment.

HOW TO USE/EXECUTE IT: The message "(channel nb) CAL 100%" with a flashing number. This

number corresponds to the present adjustment (= step motor).

To move to the right, increase this number or to the left, decrease the

number. (You may introduce a negative number.)

You can change the distance value by pressing the keys.

NOTE: When you press , the head moves and prints at the new 100%

You accept the value by pressing .

You can leave the 100% chart service by pressing .

ENTER

ENTER

SETUP

chart calibration.

2-14

Page 25

2.8 CHECK LIST

1 Have you connected the ground terminal ?

2 Have you connected the sensor(s) correctly ? (Wire type, polarity, etc.)

3 Have you tightened all terminal screws ?

4 Have you installed the ink cartridge(s) or wheel ?

(See figures on pages 2-10 to 2-15.)

5 Have you installed the chart correctly ?

(See figures on pages 2-8 and 2-9.)

2. INSTALLATION

6 Have you closed the display ?

7 Have you fitted the chart cassette in the recorder ?

2-15

Page 26

2-16

Page 27

3. OPERATION

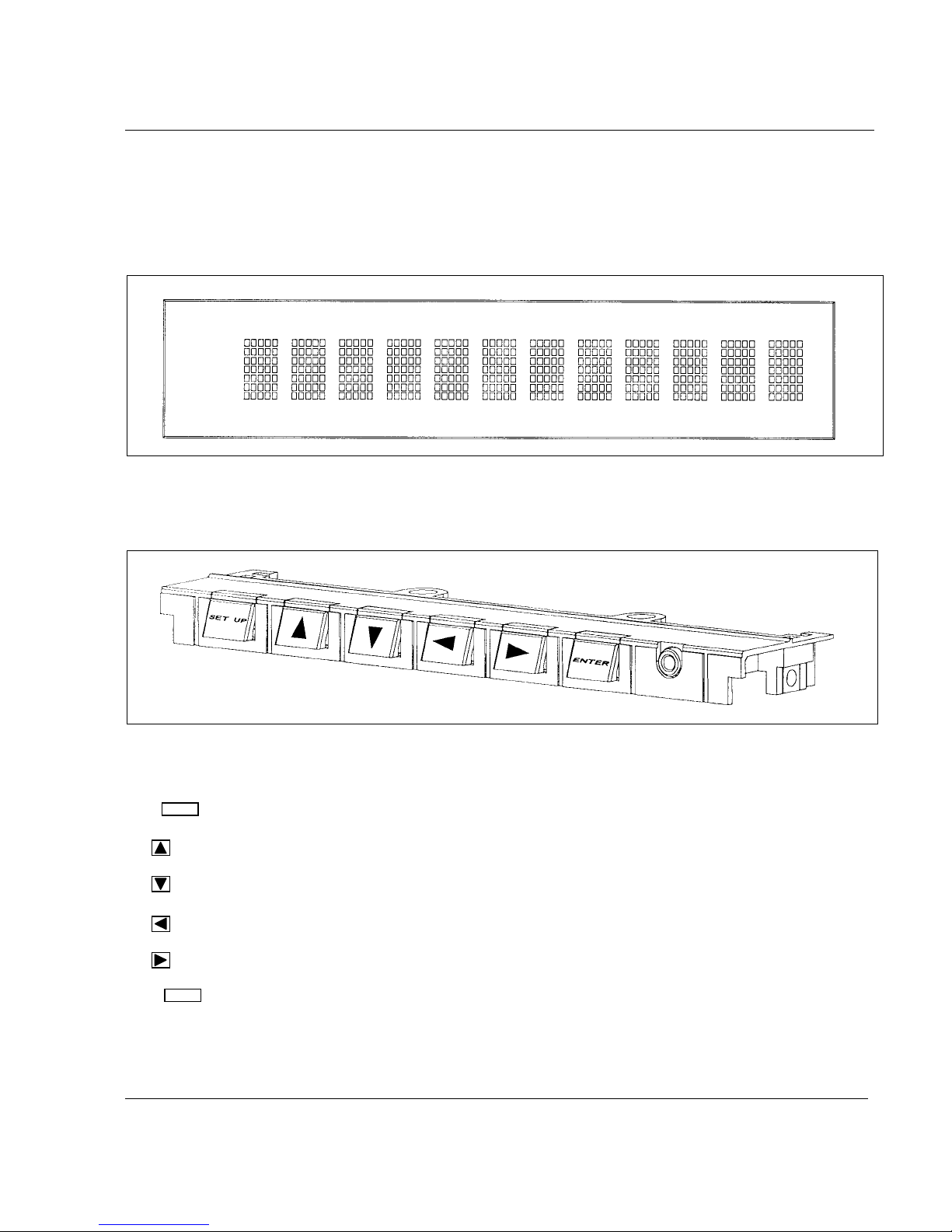

3.1 OPERATOR INTERFACE EXPLANATION

The operator interface comprises the display and keypad.

DISPLAY

The display gives a clear indication of action prompts by means of one li ne of 12 characters.

KEYPAD

The keypad consists of 6 keys:

SETUP

The key allows you to escape from any action menu and return to normal operating m ode.

•

allows ou to HOLD or SCAN the channel display.

•

allows you to select the DIS P LAY TYPE desired.

•

allows you to select the PR I NT action desired.

•

allows you to select the MATH or BATCH action desired.

ENTER

The key allows you to confirm your selected action.

3-1

Page 28

3. OPERATION

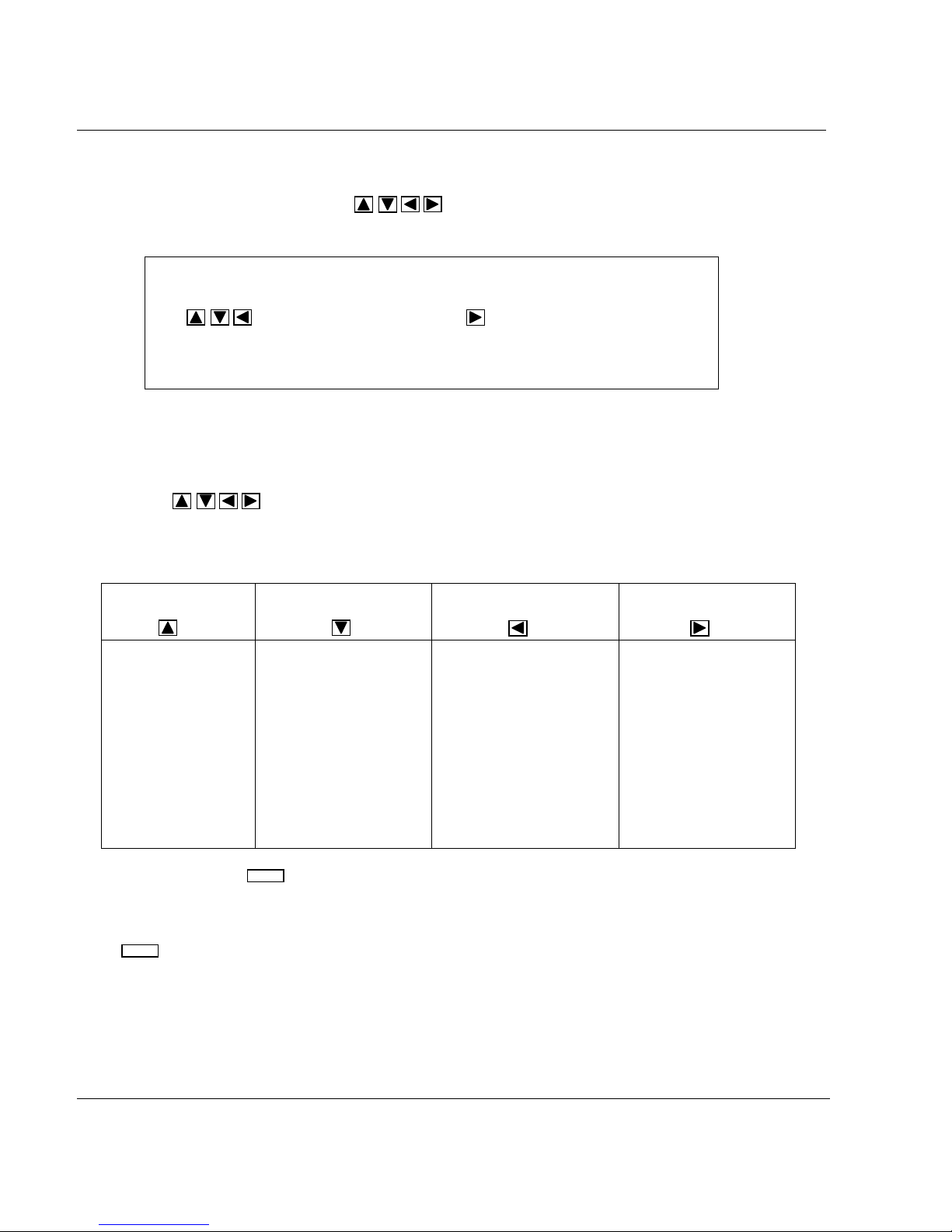

3.2 BASIC ACTIONS

Basic actions are executed by using keys wi thout entering the configurati on m ode.

No configuration parameter can be modified.

NOTE:

The keys are enabled and the key is disabled by the default

factory configuration. S ee MMl sub-matrix in the "CONFIGURATION" chapter

to modify the actions abov e.

3.2.1 Operators keys

The 4 keys can be used as operators keys.

These keys can be enabled or disabled in configuration (MMI ).

The selections are:

HOLD DISPLAY SELECT

DISPLAY TYPE

- on CH1

- on CH2

- on CH3

- on CH4

- on CH5

- on CH6

- Display scan

- Analog Input

- Math Res

- Traces

- Traces and Tag

- 1 Bargraph

- 2 Bargraphs

- Date and Time

- Speed in use

- Alarm

- Comm inputs***

* As long as you keep

ENTER

pressed, the chart advances.

** Only if the Math package is enabled.

*** Optional

ENTER

Press to confirm the choice.

- Print Time

- Print PV Values

- Chart Hold

- Chg Speed

- Chart Advance*

- Reset Chart Length

- Print Math Results **

PRINTER MATH/BATCH

- Reset Math 1

- Reset Math 2

- Reset Math 3

- Reset Math 4

- Reset Math 5

- Reset Math 6

- Reset All Math

- Reset Batch #

- Incr. Batch #

3-2

Page 29

3. OPERATION

3.2.2 How to select the display type

Ten display types are available:

• ANALOG INPUTS

Analog input numbers, measured values and temperature actuation units will be displayed.

1 I N 3 2 7 1 . ° C

IN = mnemonic for analog input

Note: For linear actuations, if the low est or the highest values are changed, the unit i s no m ore

displayed.

• COMMUNICATION CHANNELS

Communication channel numbers, values will be displayed.

C 1 1 2 9 5 2 0 . 5

COM = mnemonic for communication channel

• MATHS RESULTS

Maths channel numbers, maths results will be displayed.

M 1 6 1 7 5 5 0 . 8

M = mnemonic for maths results

• CHART TRACES

Channel numbers, measured values and engineering units (configured in the CHART matrix) will be

displayed.

1 3 2 7 . 2 U N I T S

If the channel is in alarm then t he uni ts

UNI T S

will be replaced by the alarm number

AL 1 2

3-3

Page 30

3. OPERATION

• TAG NAMES AND TRACES

Channel numbers and tag names will be displayed.

1 T A G N A M E

then alternately channel number value and unit will be displayed.

1 3 2 7 . 2 U N I T S

If the trace is in alarm condition then the units

UNI T S

will be replaced by the alarm number

AL 1 2

• ONE BARGRAPH

A channel is represented by a 20 segment bargraph.

Channel number and bargraph will be displayed.

!!!!!!!!!

!

1

An "A" will be displayed at the end of the bargraph if the channel is in alarm.

When there is no alarm, the last di gi t shows the trend of the channel.

!!

>

> if the values are increasing, < if the values are decreasi ng.

• TWO BARGRAPHS

(Only for 2 or 3 pen recorder)

Two channels are represented by a 2x20 segment bargraphs.

I

!!!!!!!!!!!!!!!!!!!!

II

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

The first digit represents t he channel num bers di splayed by the bargraphs.

("I" means trace #1, "II" means trace #2, "III" means trace #3)

An "A" will be displayed at the end of the line if one of the channels is in alarm.

3-4

Page 31

3. OPERATION

• DATE & TIME

Day/month, hour: min will be displayed.

3 0 / N O V 1 2 : 0 1

• CHART SPEED

In the trend mode number, speed number, value and unit will be displayed.

S P 1 1 2 0 0 m m / h

• SP1 or SP2 = mnemonic for speed

If the recorder prints in tabular format, then tabular number, tabular interval and unit will be displayed.

T A B 1 1 2 0 m i n

TAB = mnemonic for tabular interval

min = mnemonic for minute

• ALARMS

For each operated alarm, alarm number, alarm state, relay number and relay state will be displayed.

A L 1 1 R L 1 1

ON OFF

ACTIVE INACTIVE

AL = mnemonic for alarm

RL = mnemonic for relay

DI = mnemonic for digital input

EV = mnemonic for event

Then alternately the time of a larm a ctivation will be d isp layed . (Analo g a nd d igita l alar ms dis play)

A L 1 1 1 2 : 1 5

3-5

Page 32

3. OPERATION

3-6

Page 33

4. MODEL SELECTION GUIDE

_ _ _ _ _

_ _

_ _

_

_

_

_ _ _ _ _

_ _ _

_ _

X

)

4.1 PRODUCT IDENTIFICATION

Instructions

Select the desired Key Number. The arrow to the right marks the selections available.

Make one selection each from Tables I through VII.

A complete Model Number must have the designated number of digits in each table.

Ke y Num ber s I II III IV V VI VII

-

-

-

-

VIII

-

KE Y NUMB E R (N ote 1 ) Sele c tion Availa b ilit y

Description

1 Pen Recorder DP101

2 Pen Recorder DP102

3 Pen Recorder DP103

3 Channel Recorder DM103

6 Channel Recorder DM106

TABLE I - MATH FUNCTION (Note 2)

Standard - Channel Difference, Square Root 0

Math Package 1: Add, Multiply, Divide 1

Math Package 2: Pack. 1 + Fo., Group Average, Totalizer, 2

Gas/Liquid Mass Flow

Math Package 3: Pack. 2 + Integ., Group Max, Min, 3

Max-Min, Steam Flow Totalization,

Energy Consumption

Math Package 4:

Pack. 3 + RH, 10

IX

, Envelope, Timers,

4

Carbon Potential

TA BLE II - V OL T AG E (Note 3

85 to 264 Vac/dc 50 Hz Chart speed mm/hr A

85 to 250 Vac/dc 60 Hz Chart speed inch/hr B

24 Volt ac/dc 50 Hz Chart speed mm/hr E

24 Volt ac/dc 60 Hz Chart speed inch/hr

48 Volt ac/dc 50 Hz Chart speed mm/hr G

48 Volt ac/dc 60 Hz Chart speed inch/hr H

ddddd

F

4-1

Page 34

00000

(

)

y

n

4. MODEL SELECTION GUIDE

DDDDD

PPPMM

11111

TA BLE III- OU TP UT S

Selectio

None 0_

Universal Comm unication Option 1 _

RS422/485 Modbus R TU , RS422/485 ASC II,

RS232/V24 ASC II

Modem

2 4 - 2 0 mA A u x ilia r y Ou t p u ts 2 _

2 4 - 2 0 mA A u x ilia r y Ou t p u ts plu s Un iv e r s a l 3 _

Co mmun ic a tion s Option

Alarm Relays: None _ 0

6 Alarm Output _ A

12 Alarm Output _ B

2 Alarm Output _ C

TABLE IV - LOGIC INPUTS

None 0

2 Rem ote Contacts A

4 Rem ote Contact B

TABLE V - CHART CASSETTE

Fan Fold Z

Roll R

12336

eeeee

fffff

ggggg

TABLE VI - DOOR AND CASE

Dark Gra

Door, Plastic Window with Latch 1

Dark Gray Door, Plastic Window, Key Lock 2

Portable Case

Protective Case

(Note 4)

(Note 7)

4-2

5

6

Page 35

4. MODEL SELECTION GUIDE

00000

g

TABLE VII - OPTIONS

None 0 _ _ _ _

Power Supply for Transmitter 24 Vdc (50 mA m ax) B _ _ _ _

None _ 0 _ _ _

Rear Terminal Cover

None _ _ 0 _ _

UL/CSA Approved _ _ C _ _

None _ _ _ 0 _

Additional 3 Inputs for Math Use _ _ _ A _

None _ _ _ _ 0

Certificate of Conformance (F2474) _ _ _ _ B

Certificate of Calibration (F3399)

Certificate of Conformance & User Actuation

Certificate of Cal + Config & User Actuation

User Actuation Configuration

Configuration to customer requirement

(Note 5)

(Note 8)

(Note 6)

(Note 6 & 8)

(Note 6)

(Note 8)

_ G _ _ _

ccccc

_ _ _ _ C

_ _ _ _ D

_ _ _ _ E

_ _ _ _ K

_ _ _ _ L

TABLE VIII - SPECIALS

Selection

None 0 0 0

ST Num ber (Consult Honeywell representative or IM&C M arketing) X X X

TABL E IX - M a n ua ls

lish Operator Manual and Prompts E _

En

French Operator Manual and Prompts F _

German O perator Manual and Prompts G _

Italian Operator Manual and Prompts I _

Spanish Operator Manual and Prompts S _

Swedish Operator Manual and Prompts W _

English, U.S. Format, Product Manual and Prompts U _

None _ 0

English Product Manual _ 1

French Product Manual _ 3

German P roduct Manual _ 4

DDDDD

PPPMM

11111

12336

4-3

Page 36

4. MODEL SELECTION GUIDE

pply

r

Note 1: The units are built with universal input and are delivered with 250 ohm resistors to convert input current

signal 4 to 20 mA into 1 to 5 Volt dc (or 0 to 5 Vdc). These are packed in the product accessories.

Note 2: Models DP1XX P en units supplied with 3 analog inputs when Math Option is ordered. Additional 3

inputs can be selected by specifying Table VII, Optio n XXXAX.

Note 3: The chart speed and frequency can be modified on the unit from key pad.

Note 4: Portable case supplied with dark gray door, plastic window, latch, rear main switch and IEC main plug

connector.

Note 5: Rear cover is used to cover field wiring, this is in addition to the cover on the power supply terminals

which is standard.

Note 6: User defined actuation worksheets need to be completed and supplied with the order.

Note 7: Supplied with metal sleeve, used on portable case option, no rear main switch or IEC main power

plug connector supplied.

Note 8: Customer must su

of the order for the factory to supply the Custom Calibration Test Report (F3399).

RESTRICTIONS

Restriction Lette

Table Selection Table Selection

cVI5, 6

Input Actuation Type and Range for each input in the Free Form section

Av a ila b le On ly With

Not Available With

d VII _ _ C _ _

e III _ A, _ B, _ C

f III 1 _, 2 _, 3 _

o

C Maximum tem perature limit

g

50

4-4

Page 37

4. MODEL SELECTION GUIDE

USER D EFINED AC TU ATION D PR100C /D

Fax to your Honeyw ell Customer Service

CUSTOMER ORDER No.

SALES ORDER No.

TYPE OF ACTUATION - T/C LINEAR (mV) Ma V RTD (Check one)

If thermocouple - complete table for Recorder Operating Temperature for Cold Junction Compensation

Actuation Cold Junc. Eng. Unit Electrical Actuation Cold Junc. Eng. Unit Electrical

1 Value Deg. C Value (mV) 2 Value Deg. C Value (mV)

Lowest Lowest

Average A verage

Highest Highest

USER DEFINED ACTUATION TABLE 1

Enter values for custom actuation (max 50 SEGM E N TS )

Segm ent ENG E lectrical Segment ENG Electrical Segm ent ENG Electrical

Number VALUE VALUE Number VALUE VALUE Number VALUE VALUE

11835

21936

32037

42138

52239

62340

72441

82542

92643

10 27 44

11 28 45

12 29 46

13 30 47

14 31 48

15 32 49

16 33 50

17 34 51

4-5

Page 38

4. MODEL SELECTION GUIDE

USER DEFINED ACTUATION TABLE 2

Enter values for custom actuation (max 50 SEGMEN TS )

Segmen t ENG E lectrical Segment ENG Electrical Segment ENG Electrical

Number VALUE VALUE Number VALUE VALUE Number VALUE VALUE

11835

21936

32037

42138

52239

62340

72441

82542

92643

10 27 44

11 28 45

12 29 46

13 30 47

14 31 48

15 32 49

16 33 50

17 34 51

4-6

Page 39

5. PRODUCT SPECIFICATION SHEET

Technical data

Technology Microprocessor based, with non-volatile memory. Flash memory for

software upgrade via the front jack.

Analog inputs

Pen recorder 1, 2 or 3 continuous traces

Multipoint recorder 3 or 6 channels inputs are scanned by solid state switches and are

galvanically isolated, except for RTD sensors.

Signal source Thermocouple with individual cold junction compensation.

Line resistance up to 1000 ohms T/C, mV, mA, V

RTD Pt 100 3-wire connections, lead resistance per wire 40 Ω balanced.

Basic mathematic functions

Filter A digital filter is configurable per input, 0 to 99 seconds.

Field calibration A channel field calibration - 0% and 100% span - may be made to certify

Burnout T/C, mV, Volt, configurable to upscale, to downscale or none.

Scanning time

(solid state relays)

Input impedance

Stray rejection

Display 12 digit fluorescent display: 8.5 mm high (function display)

Brightness The display brightness is configurable.

Recording span

Scaling Per input, up to 2 analog scales can be configured to be printed on the

Zoning Each input can be configured on 0 to 100%, or 0 to 50%,

Pen offset (Pen recorder) Distance between pen: 2 mm - Offset compensation configurable.

Pen carriage speed 1 second full scale

Square Root extraction (√) ; Differential = (∆T)

input sensor loop.

RTD: inherent upscale. mA: inherent downscale

Pen:

1 pen = 160 ms

2 pens = 240 ms

3 pens = 330 ms

Multipoint:

3 channels = 330 ms

6 channels = 640 ms

10 Mohm for T/C, mV inputs, > 1 Mohm for volt inputs.

Series mode ≥ 60 dB. Common mode at 250 Vac ≥ 130 dB.

configurable in:

- digital PV values with engineering unit in accordance with the input range

- 1 or 2 bargraphs

Can display analog input, tags, maths results, communication, alarms or

event messages.

chart with the engineering unit, channel reference and tag name.

Each input can be configured differently.

or 50 to 100% of the chart.

Chart definition: 1 step = 0.2 mm

5-1

Page 40

5. PRODUCT SPECIFICATION SHEET

Technical data

Chart length

Pen trace

Pen

Multipoint

Chart speed 1 or 2 chart speeds, fully configurable, selected by a logic input, alarm or

Speed setting Pen: 1 to 6000 mm/h (0.04 to 240 inch/h).

Stepping chart motor Resolution 0.12 mm

Product configuration

Front configuration - 2 product configurations can be stored and selected by the front keys.

PC configuration Through the front jack the unit can be configured from a PC through a PC

Logic inputs

Actions Up to 4 dry contact inputs (1.5 mA, 12 Vdc)

Alarms

Setpoint 12 alarm setpoints, freely assignable to any channel and output relay.

Function Can trigger a message, print channel red in alarm, print in alarm, change

Output 2, 6 or 12 SPST relay outputs: 2 A, 250 Vac on resistive load.

Fanfold 18 m (as DIN 16230)

Roll 24 m

1400 m per pen

250 m per color

configuration.

Speed 1: fully adjustable per step of 1 mm/h, within limit

Speed 2: fully adjustable per step of 1 mm/h, within limit

Mpt: 1 to 1500 mm/h (0.04 to 60 inch/h)

Continuous traces in color, dotted traces in configurable color with regular

chart documentation (configurable).

- A very simple and interactive product configuration can be carried out on

the product with 6 front keys. A friendly program with prompt messages

confirms the operation. The prompt messages can be selected in the

different languages: English, German, French, Spanish, Italian or Swedish.

A 2-level password protects the unit from non-authorized modification

(level 1 = limited access ; level 2 = full protection)

interface. This provides the facility to copy the configuration, modify,

store, upload or download the product configuration or make a service

diagnostic, or upgrade a new software or linearize 2 special customer

sensors. (50 segments each).

Change chart speed 1 to speed 2, tab interval 1 to tab interval 2, digital

print-out, print message, print inhibit, event trace, print a batch message,

tabulate maths calculations. Event marking: Pen: Pen 1 used as operation

marker on the right side of the chart for event 1 and on the left side of

the chart for event 2.

Mpt: 4 traces maximum on the chart. The trace position and the color are

configurable.

Full configurability of setpoint, hysteresis and alarm type (high, low rate

of change, deviation).

the range, change the speed, print digital PV values, trigger the event

precursor.

Contact N.C. in alarm condition (configurable in N.O.)

5-2

Page 41

5. PRODUCT SPECIFCATION SHEET

Technical data

Alphanumeric documentation

Messages 12 freely assignable and configurable messages of 14 characters each,

Batch header One batch message of 4 lines of 14 characters, fully configurable, with

Process variable The traces can be assigned to analog input, mathematics calculations or

Tag name Each channel can be named by 8 characters

Event precursor

Stand-by

Downloading

Mathematics package

(optional)

Digital communication (optional)

Protocols

PC supervision Through ASCII communication, application software gives the facility to

Autodial The RS232 ASCII communication can dial automatically a phone number

Event The recorder can be configured to deliver an output signal (alarm relay)

including the specific German and Swedish letters.

Can be printed with the date/time on top of the traces by alarms, logic

inputs or communication.

incremented batch numbers and date/time. Printed through digital input

and saved upon power interruption.

communication inputs, and are printed in channel color. Periodic digital

printing at time intervals configurable from 1 to 1440 minutes. Digital

print-out of PV values through alarms, digital inputs, communication or

front keyboard.

The acquisition data is stored in a buffer memory. (FiFo)

A stand-by message is periodically printed.

On event (alarm, digital input, front key, communication) the data is

downloaded to be printed on the chart at pre-configured speed.

The history before and after the event represents about 50 mm of chart

paper.

Many functions are available such as: - Energy consumption

- Basic mathematics functions - Vacuum pressure

- Square root - Averages

- Fo sterilization - Min., max.

- Totalization - Timers

- Mass flows - Carbon potential

The maths calculations and results are stored during power interrutpions

RS232 ASCII communication to PC application. RS422 or RS485 ASCII

communication output. RS422 or RS485 Modbus RTU communication

output.

read PV's, alarms or event status, to store the information on a file, to

send a message to the recorder or to modify the product configuration.

of a remote station to send via modem an alarm message or a periodic

report.

Use of this feature can cause communications conflicts if data

acquisition software attempts to communicate with the recorder at the

same time. During an Autodial the recorder becomes the master on the

communications link.

on a recorder event such as burnout, paper cassette out, battery fail,

alarm condition, communication interrupted.

5-3

Page 42

5. PRODUCT SPECIFICATION SHEET

Technical data

Current output (optional) 2 current output, signals 4 to 20 mA reference conditions. Configurable

on analog inputs, mathematic calculations, communication signals.

Accuracy 0.1% reference conditions.

(Add measure accuracy for analog outputs.)

Temperature drift of 0.1% per 10°C in the rated limits. (0 to 50°C ;

85 to 264 V). Voltage supplied by the recorder: +12 V with a max.

resistance load of 400 ohms.

Or

External supply voltage: ≤24 V with a max. resistance load such as

(Vext - 12) / 0.02 ≤R ≤(Vext - 4) / 0.02

Power supply 85 to 264 Vac 50 Hz or 24 or 48 Vac/dc (+10-15% nominal)

To transmitters 24 V, 75 mA max. (optional) (75 mA available from 100 V)

Power consumption 3 pens or Mpt: 55 VA max. (active power 30 W)

Supply voltage 100 - 240 Vac

Frequency range 50/60 Hz

Power max. 55 VA

Clock timer

Format Year, month, hour, minute can be set.

Power interruption Battery backed (10 years time, 3 years off power)

-

Accuracy ±10

Packaging

Weight Pen or Mpt: 3.5 kg

Front face

Depth 245 mm/9.7 inch behind panel, including terminals and line protection cover

Front window Polycarbonate

Front protection IP 54 (IEC 529)

Lock Latch or key (DIN 43832-N)

Construction Silicon-free

Chart illumination Fluorescent light

Option Rear terminal cover, portable case.

Mounting

Wiring

5

144 × 144 mm according to DIN 43718

Panel mounting ±30° from horizontal

Rear screw terminals. Terminal modules are plugged on the instrument.

5-4

Page 43

5. PRODUCT SPECIFICATION SHEET

Technical data

Writing

Pen 1 cartridge per pen, fiber tip, 1400 m of trace per color (blue, red,

green)

Multipoint 1 print wheel, 6 colors, 250 m of trace per color (purple, red, black,

green, blue, brown).

Noise immunity This product is in conformity with the protection requirements of the

following European council directives:

• 73/23/EEC – Low Voltage directive

• 89/336/EEC – EMC Directive

Conformity of this product with any other “CE Mark” Directive(s) shall

not be assumed.

EMC Classification:

• EN 50081-2-1993 Electromagnetic Compatibility – General

Emission Standard, Part 2: Industrial Environment.

• EN 50082-2-1995 Electromagnetic Compatibility – General

Immunity Standard, Part 2: Industrial Environment

Safety protection Complies with IEC 61010-1 and UL 3121-1 for process control

instrumentation Pollution Degree 2, Installation category II.

Electrical insulation

Input to input Test voltage 280 Vac or Vdc for 1 minute (except for RTD input)

Input to ground Test voltage 2.1 kVdc for 1 minute

Input to line voltage Test voltage 2.1 kVdc for 1 minute

Line voltage to ground Test voltage 2.1 kVdc for 1 minute

Alarm relay to ground Test voltage 2.1 kVdc for 1 minute

Logic input to ground Test voltage 500 Vdc for 1 minute

Temperature

Ambient 0 to 50°C (32 to 122°F) for Fan Fold

Storage

Humidity

Roll

Fanfold 15 to 80% RH non-condensing

Vibrations Frequency:

0 to 60° C (32 to 140°F) for Roll Chart

-40 to 70°C (-40 to 158°F)

10 to 90% RH non-condensing

10 to 60 Hz, amplitude 0.07 mm

60 to 150 Hz, acceleration 1 g

5-5

Page 44

5. PRODUCT SPECIFICATION SHEET

Technical data

Reference conditions

Temperature

Humidity

Line voltage nominal

Source resistance

Series mode 0 V

Common mode 0 V

Frequency nominal

Accuracy Accuracy of displayed values: 0.1 % of the selected input range * (IEC 873)

Rated limits and associated

drifts

Parameter Rated limits Influence on accuracy

Temperature 0 to 50°C

Supply voltage 85 to 264 Vac No influence

Source resistance T/C, mV

RTD

Humidity 10 to 90% RH at 25°C 0.1% max.

Long-term stability 0.1% per year

Vibrations 1.25 mm at 0 to 14 Hz

Extreme conditions

Operating

Temperature 0 to 60° C (32 to 140°F)

Humidity 10 to 90% RH non-condensing

Storage

Temperature -40 to 70°C (-40 to 158°F)

Humidity 5 to 95% RH non-condensing

* Refer to "Available ranges" tables for exceptions.

23°C ± 2°C (73°F ± 3°F)

65% RH ± 5% RH

± 1 %

0 Ω

± 1 %

For a 4/20 mA input, you must add the resistor accuracy.

Cold junction accuracy: 0.5°C

Chart resolution: 0.2 m

0.1% per 10°C of change

(32 to 122° F)

1 g at 14 to 250 Hz

Cold junction 0.3°C/10°C

6 µV per 100 Ω of line

0.1°C per Ω in each wire

resistance

1000 Ω max.

balanced leads

40 Ω max.

5-6

Page 45

5. PRODUCT SPECIFICATION SHEET

Available ranges

Linear RTD/OHMS Thermocouple

0/10 mV

-10/10 mV

0/20 mV

-20/20 mV

0/50 mV

-50/50 mV

10/50 mV

0/100 mV

-100/100 mV

0/500 mV

-500/500 mV

0/1 V L -200/870°C N -20/1300°C

-1/1 V L -328/1598°F N -4/2372°F W-W 26 -20/2320°C

0/2 V W-W 26 -4/4208°F

-2/2V

0/5 V

-5/5 V

1/5 V

0/10 V

0/20 mA

4/20 mA

∗∗∗∗

∗∗∗∗

OHM 0/2000 K -200/1370°C T -200 /400°C B 40/1820°C

K -328/2498°F T -328/752°F B 104/3308°F

R -20/1760°C

R -4/3200°F

∗∗∗∗

mA inputs for 250 ohms input resistor

(Accuracy: The tolerance for the resistor

must be added to the specifications.)

Notes:

For non-linear temperature transmitter (1 to 5 Vdc, 4 to 20 mA, 0 to 5 Vdc, 0 to 20 mA), the transmitter

range must be identical to the full actuation range of the recorder.

Provision for T/C input for remote compensation box at fixed temperature of 50°C or 60°C. When

temperature is not fixed, any input can be used as remote compensation temperature measurement.

Pt 100 Ω at 0° C

IEC -50/150°C

IEC -58/302°F

IEC 0/100°C

∗∗∗∗ ∗∗∗∗

IEC 32/212°F

IEC 0/200°C

∗∗∗∗ ∗∗∗∗

IEC 32/392°F

IEC 0/400°C

∗∗∗∗ ∗∗∗∗

IEC 32/752°F

IEC -200/500°C

IEC -328/932°F

Ni 50 Ω -80/320°C

Ni 50 Ω -112/608°F

Ni 508 Ω -50/250°C

Ni 508 Ω -58/482°F

Cu 10 Ω -20/250°C

Cu 10 Ω -4/482°F

OHM 0/200 K 32/2192°F T 122/302°F

J -50/150°C S 0/1600°C U -50/150°C

∗∗∗∗ ∗∗∗∗

JIS -50/150°C

∗∗∗∗ ∗∗∗∗

JIS -58/302°F

JIS 0/100°C

∗∗∗∗ ∗∗∗∗

JIS 32/212°F

JIS 0/200°C

∗∗∗∗ ∗∗∗∗

JIS 32/392°F

JIS 0/400°C

∗∗∗∗ ∗∗∗∗

JIS 32/752°F

∗∗∗∗ ∗∗∗∗

JIS -200/500°C

∗∗∗∗ ∗∗∗∗

JIS -328/932°F

∗∗∗∗ ∗∗∗∗

J -58/302°F S 32/2912°F U -58/302°F

∗∗∗∗ ∗∗∗∗

J 0/400°C S -20/1760°C U 0/150°C

∗∗∗∗ ∗∗∗∗

∗∗∗∗ ∗∗∗∗

∗∗∗∗ ∗∗∗∗

∗∗∗∗ ∗∗∗∗

J 32/752°C S -4/3200°F U 32/302°F

∗∗∗∗ ∗∗∗∗

J -200/870°C U 50/150°C

J -328/1598°F N 0/400°C U 122/302°F

∗∗∗∗ ∗∗∗∗

N 32/752°F U -200/400°C

L -50/150°C N 0/800°C U -328/752°F

∗∗∗∗ ∗∗∗∗

L -58/302°F N 32/1452°F

∗∗∗∗ ∗∗∗∗

L 0/400°C N 0/1200°C NiMo 0/1400°C

∗∗∗∗ ∗∗∗∗

L 32/752°F N 32/2192°F NiMo 32/2552°F

W5-W 26 -

20/2320°C

∗∗∗∗ ∗∗∗∗

∗∗∗∗ ∗∗∗∗

∗∗∗∗ ∗∗∗∗

∗∗∗∗ ∗∗∗∗

∗∗∗∗ ∗∗∗∗

K 0/400°C T -50/150°C W5-W 26 -4/4208°F

K 32/752°F T -58/302°F

K 0/800°C T 0/150°C

K 32/1452°F T 32/302°F PR 20-40 0/1800°C

K 0/1200°C T 50/150°C PR 20-40 32/3272°F

∗ ∗

Accuracy: 1°C or 1.8°F

5-7

Page 46

5. PRODUCT SPECIFCATION SHEET

5-8

Page 47

6. CONFIGURATION

6.1 OPERATOR INTERFACE

The operator interface comprises the display and keypad used for recorder configuration.

DISPLAY

The display gives a clear indication of the configuration prompts by m eans of one line of 12 characters.

KEYPAD

The keypad consists of 6 keys:

SETUP

A clear understanding of keypad use is vital for any operation like Reading/Writing (R/W ), Printing

(PRN) or Service (SRV).

!

! ACCESS TO CONFIGURATION

!!

Access to Read/Write Configuration (R/W), P ri nt Configuration (PRN ) or Service (SRV) i s obtained by

pressing the key.

SETUP

ENTER

!

! THE PASSWORDS

!!

To protect the recorder against unauthorized access, the operator has to enter a password. There are

two possible levels of access:

• Password #1 allows limited access to conf i guration.

• Password #2 allows full access to Read/Write Configuration, Print Configuration or Service.

!

! HOW TO ENTER THE PASSWORDS

!!

• Use of keys allows you to modify the value of one digit of the password and the

keys are used to select the different digits of the modifi ed v alue.

• Press to update your modification.

• Or Press to exit configuration mode.

ENTER

SETUP

NOTE: If you lost your password, please contact your nearest service center.

6-1

Page 48

NORMAL RU N

SET UP

PASSWORD

SET UP

ENTER

TO ENTER

A NEW VALUE

6. CONFIGURATION

SET UP

TO RETURN TO M ENU

OR TO NORMAL RUN

TO CHOOSE THE DESIRED

PARAMETER

ENTER

R/W

PRN

SRV

TO ACCESS

FUNCTIONS

ANALOG

MATH

(option)

ALARM AN

DIGITAL

CHART

BATCH

TO ACCESS

PARAMETERS

ENTER

SENSOR RANGE

FUNCTION

COEF A COEF B COEF C VAR IAB A VARIAB B

*

TYPE CH DIFF

POSITION #RED TRAC *TR COLOR *TRACE *PRNT MSG

MESSAGE iMESSAGES

TAG NAME ENG UNIT DECIMAL MIN RG1 MAX RG1 RG1 COL

RG USED TRACE

TIME DATE LANGUAGE IDNTIF

T/C COMP FILTER LOW VAL HIGH VAL

*

CH

#

MESSAG #

RG2 COL

ACTION RELAY #PRNT MSGAL=RED

MESSAG #MSG COL

#

MAX RG2 M IN RG 2

*

FREQUNCY PASSWRD 1MISCEL

#

BACKUP BATCH

VARIAB CSTARTRESETBACKUP

CH DIFFAL TYPECHA NN ELOCCURNCEHYSTERESSP VALUE

PASSWRD 2MATH PAKUSE CONF

ZERO ADJ STD MATH BURN OUT

MSG COL

ACTION RELAY

ZONING

*

*

RESETSTARTLINE 4LINE 3LINE 2LINE 1

#

MODE

PRINTER

EVENT

MMI

CUR OUT

(Option)

FUNCTION

PRT RANG

PRT TIME PRT TAG

TYPE RELAY

#

CH

LOW VAL HIGH VAL

*

SPD USEDSPEED 2

REC MODE

SPEED 1SPD UNITCHART LG

PRT INTVPRT PV

*

PEN OFFS

#

DISPLAY

KEY LEFTK EY UPKEY DOWN KEY RIGH DISPLAY BRIGHT

PARAMETER

PRT MODE

**

TABULAR 1

TABULAR 2

*

*

* Available on Multipoint recorders only.

** Available on Pen recorders only.

FUNCTION ORGANIZATION WITH PASSWORD #2

6-2

Page 49

NORMAL RUN

SET UP

PASSWO RD

ENTER

SET UP

TO ACCESS

FUNCTIONS

ENTER

ENTER

TO ENTER

A NEW VALUE

6. CONFIGURATION

SET UP

TO RETURN TO MENU

OR TO NORMAL RUN

TO CHOOSE THE DESIRED

PARAMETER

R/W

ANALOG

ALARM AN

MESSAGES

CHART

MISCEL

PRINTER

MMI

MMI

TO ACCESS

PARAMETERS

FILTER

SP VALUE HYSTERES

MESSAGE i

TAG NAME MIN RG1 MAX RG1 RG1 COL

TIME DATE IDNTIF

DISPLAY BRIGHT

MODE FUNCTION PARAMETER

*

MIN RG2 MAX RG2

ZONING

RG2 COL

#

SPEED 2SPEED 1SPD UNIT SPD USED TABULAR 1*TABULAR 2

*

*

FUNCTION ORGANIZATION WITH PASSWORD #1

* Available on Multipoint recorders only.

6-3

Page 50

6. CONFIGURATION

!

! READ/WRITE ACCESS TO PARAMETER VALUES

!!

• Parameter selection

Use of keys allows you to select the parameter you want to read/write.

Use of keys allows to select the channel on wich you want to read/write the parameter.

ENTER

Press to confirm your selection, or press to return to main function.

If necessary, the recorder stops measuring and print i ng duri ng configuration access. In this case, the

"CONFIRM." message will be displayed. Press to confirm or press to scape.

• Value of parameter

If you leave a key for a few seconds, the recorder will display alternately the name and the current

value.

• Parameter modification

Press to begin the modificat i on of param eter.

ENTER

The current value blinks.

Some parameters require text select i on w hi l e ot hers requi re num eri cal v al ues.

and keys permit, as applicable, t he sel ection of desired text or increment /decrement of

numerical value.

and keys can be used to shift the position of the digit to be changed.

Press to confirm your change.

ENTER

Or press to come back to parameter selection.

SETUP

SETUP

ENTER

SETUP

6-4

Page 51

6. CONFIGURATION

6.2 ONE EXAMPLE: HOW TO SET THE CHART SPEED

! Press key.

! Enter password #1.

! Press .

! Use of keys allows you to select the R/W configurati on m ode (read/write configurat i on).

! Use of keys allows you to select the PRINTER function.

! Press to confirm your funct i on t ype selection.

! Parameter selection

Use of keys allows you to select SPEED 1.

Press to confirm your selection.

Use of keys allows you to modify the value of one digit. If necessary, the

keys are used to shift the positi on of the digit to be changed.

Press to confirm your modification.

Press to come back to main function.

Press to return in normal operation.

SETUP

ENTER

ENTER

ENTER

ENTER

SETUP

SETUP

6-5

Page 52

6.3 PROMPTS EXPLANATION

6. CONFIGURATION

PARAMETERS:

SENSOR

RANGE DISPLAY ACTUATION RANGE

T/C COMP To select the channel number to measure the temperature of a remote

FILTER ♣

LOW VAL Engineering value corresponding t o l ow l i m i t of the selected input

HIGH VAL Engineering value corresponding to high limi t of the selected input

BURN OUT Allows you to define the safety backup position to activate alarms

STD MATH 2 mathematical functions are included as standard in the recorder.

CH # Second channel used w hen O P T M AT H = CH DIFF

ZERO ADJ Zero adjustment means to offset /bias the calibration of t he i nput .

ANALOG FUNCTION

Basic sensor type used on each channel.

Factory configuration

position.

For directly connected temperature sensors and non- l i near

temperature transmitters, the actuation selection defines the

linearisation routine used to produce a linear chart scal e. F or l i near

transmitters, the selection simply defines the transmitter's electrical

range/span.

The choice of actuation offered by the recorder during configuration

will depend upon the sensor selected.

compensation box. This setti ng eliminates the variable cold j unction

and implements the hot box tem perature.

Application: To use an uncontrolled rem ote compensation box channel

#.

You may wish to apply a fi l ter to noisy signals. However i f you want

to display and record pulses, square waves or other rapidl y changing

inputs without damping, choose 0 f ilter value.

actuation range.

actuation range

(if configured) in case of sensor burnout. The trace can go either on

the right (upscale) or on the left (downscale).

These functions apply only to anal og i nputs.

Otherwise choose 0 Value = Factory Cal i bration.

Adjustments are made directly in Engi neeri ng uni t . (Ex.: 5 = 5° C)

: All CH are configured in T/C, mV , V range

♣ Accessible with the password #1

6-6

Page 53

6. CONFIGURATION

ALARM AN FUNCTION

PARAMETERS:

SP VALUE

HYSTERES ♣

Hysteresis is expressed in Engineering units and is added to low

OCCURNCE

CHANNEL

AL TYPE

CH DIFF

RELAY #

ACTION

MESSAG #

MSG COL

PRNT MSG

AL = RED

♣

The alarm switches from OFF to ON when the SP value is

reached.

Establishes the alarm hysteresis. Al arm s sw i tch ON at set point

but switch OFF value depends on t he hy steresis setting.

alarm and subtracted from high alarm set points to establish the

alarm release value.

Defines the number of alarm occurrences needed after power on

for alarm operation or after start up a new batch.

Channel on which alarm is applied (Anal og 1..6, com 1..6 , math

1..6)

Type of alarm (High, low, differential, ...)

Second channel used if alarm type is di fferential.

Selection of relay activ ated in alarm

Action on printer in case of alarm

(None, print on alarm, change range, ...)

Selection of alarm message to be pri nted

Multipoint only

Color of alarm message

Defines the conditions to pri nt the message on alarm change.

Multipoint only

Specifies if the trace of channel must be printed in red during alarm.

♣ Accessible with the password #1

6-7

Page 54

6. CONFIGURATION

DIGITAL FUNCTION

PARAMETERS:

TYPE

CH DIFF Second digital input to use if t he type is differential

ACTION Acti on on pri nt er in case of digital input change

RELAY # Selection of relay activated

MESSAG # Selection of message to be printed

MSG COL Multipoint onl y

PRNT MSG Defines the condition to print the message on Event Change.

TRACE Enables/disables the trace of t he ev ent.

TR COLOR Multipoint only

RED TRAC Multipoint only

POSITION

Type of digital input

Color of the message

Defines color of trace.

Specifies if digit al i nput trace must be printed in red on event .

Multipoint only

Defines the trace positi on (open contact) on the chart. (In %)

MESSAGES FUNCTION

PARAMETERS:

MESSAGE

♣

To configure the messages. (14 characters)

♣ Accessible with the password #1

6-8

Page 55

6. CONFIGURATION

CHART FUNCTION

PARAMETERS:

TAG NAME

ENG UNIT

DECIMAL

MIN RG1 ♣

MAX RG1 ♣

RG1 COL ♣

MIN RG2 ♣

MAX RG2 ♣

RG2 COL ♣

ZONING ♣

TRACE

♣

Tag of name corresponding chart channel

Chart channel units

Decimal point configurat i on

Lower limit of chart range 1

Upper limit of chart range 1

Multipoint only

Color of range 1

Lower limit of chart range 2

Upper limit of chart range 2

Multipoint only

Color of range 2

Defines chart zone for printing. (0%-50%, 50% - 10 0 % , 0%-

100%)

Defines the variable to print ( A nal og i nput 1 ..6, Comm 1..6,

Math 1..6, None)

RG USED You may select whether the input channel will be printed

normally (range 1 or 2) or on alarm ( w i th range 1 or 2).

♣ Accessible with the password #1

6-9

Page 56

6. CONFIGURATION

MISCEL FUNCTION

PARAMETERS:

TIME

DATE ♣

LANGUAGE

IDNTIF # ♣

FREQUNCY To select the line frequency

PSSWRD 1 Used to provide a li m ited access to configuration

PSSWRD 2 Used to provide f ul l access to configuration

MATH PAK Type of optional mat hs package

USE CONF Selection of the desi red conf iguration number

♣

Real time clock setti ng

Real time clock date

Operator information and configuration language

Identification number of the instrument which will be printed on

the chart.

♣ Accessible with the password #1

BATCH FUNCTION

PARAMETERS:

LINE 1 Configuration of the first line of t he batch message

LINE 2 Configuration of the second line of the batch message

LINE 3 Configuration of the third line of the bat ch m essage

LINE 4 Configuration of the fourth line of the bat ch m essage

START

RESET

BATCH # Batch number used at RESET condition.

BACKUP Store the batch number i n case of power interruption.

BATCH ACTIVATION CONDITION:

The START condition defi nes w hen bat ch pri nting must start.

The recorder pauses each time the start condition occurs and

then prints the batch description and i ncrem ent s the batch

number.

BATCH NUMBER RESET CONDITION:

The RESET condition defines w hen the batch number must

reset.

6-10

Page 57

6. CONFIGURATION

PRINTER FUNCTION

PARAMETERS:

CHART LG

SPD UNIT ♣

SPEED1 ♣

SPEED2 ♣

SPD USED ♣

TABULAR 1 ♣

TABULAR 2 ♣

REC MODE Recording mode allows you to print normally, to st op the printer,

PRT MODE Multipoint only

PRT INTV

Total chart length of the chart rol l or fanfold

Speed unit (mm/h or inch/h)

Value of speed 1 (Using speed unit )

Value of speed 2

Defines the speed in use or the tabular in use.

Multipoint only

Tab 1 prints interval. (I n m i nute)

Multipoint only

Tab 2 prints interval.

to trigger the printer on alarm wit h (or without) return to standby.

Under this heading you must choose whether recording will be

trend mode or tabular mode.

Separation (in millimeters) of PRT PV interval for periodic

printing.

PRINT PV Periodic of P V values, time and digit al i nput status.

PRT RANG Periodic printing of the chart ranges.

PRT TIME P eri odi c pri nt i ng of "TIME, DATE, SPEED , CHANNEL ID"

PRT TAG Multipoint only

Printing of the tag name w i th the channel number

PEN OFFS Pen only

Pen offset

♣ Accessible with the password #1

EVENT FUNCTION

PARAMETERS:

TYPE

RELAY # Selection of relay activated i n ev ent condition

DISPLAY Enabl es/disables a display warning in event occurrence

Type of event

6-11

Page 58

6. CONFIGURATION

MMI FUNCTION

PARAMETERS:

KEY DOWN

KEY UP

KEY LEFT

KEY RIGH

DISPLAY ♣

BRIGHT ♣

To modify the display indi cation in normal operation.

To stop the display scanning in normal operation.

To modify the printer operation.

To reset the maths functions or batch num ber.

Type of i nf orm ation to display in run mode at power on.

To modify the display brightness during operat i on.

♣ Accessible with the password #1

* See paragraph 3.2 "Basic actions" in Operation section.

CUR OUT FUNCTION *

PARAMETERS:

SLOT 4

*

*

*

*

SLOT 4

SW 1

CURRENT GENERATOR

SUPPLIED FROM

THE RECORDER

CH #

LOW VAL Low value for a 4 mA out put

HIGH VAL High value for a 20 mA output

Defines the variable to out put. (Analog input 1.. 6 , comm 1..6,

math 1.6, none)

CURRENT GENERATOR

SUPPLIED FROM

THE RECORDER

* This function appears only if the current output board is present.

6-12

SW 1

Page 59

7.1 PARAMETERS LIST

FUNCTION PARAMETER CLASSIFICATION

NAME OF THE

FUNCTION

DEFINITION :

HOW TO MODIFY IT :

POSSIBLE VALUES :

SEE ALSO :

EXAMPLE :

NOTE :

WARNING :

7. DETAILED CONFIGURATION

IMPORTANCE OF THE

PARAMETER :

NAME OF THE

PARAMETER

EXPLAIN THE ROLE OF THE PARAMETER

2 POSSIBILITIES :

- BY SELECTING A NEW VALUE I.E. USING THE KEYS

- BY ENTERING A NEW VALUE

LIST OF POSSIBLE VALUES OR LIMITS

! RARELY USED

!! NOT OFTEN USED

!!! OFTEN USED

7-1

Page 60

7. DETAILED CONFIGURATION

!ANALOG

!ALARM AN

!DIGITAL

!MESSAGES

!CHART

!MISCEL

!BATCH

!PRINTER

!EVENT

!MMI

!CUR OUT

7-2

Page 61

7. DETAILED CONFIGURATION

FUNCTION !

ANALOG

PARAMETERS ! SENSOR

! RANGE

! T/C COMP

! FILTER

! LOW VAL

! HIGH VAL

! BURN OUT

! STD MATH

! CH #

! ZERO ADJ

7-3

Page 62

FUNCTION

ANALOG

DEFINITION :

HOW TO MODIFY IT :

POSSIBLE CHOICES :

7. DETAILED CONFIGURATION

PARAMETER

S E N S O R

Basic sensor type used on each channel.