Page 1

Definite Purpose (DP)

Contactors

INSTALLATION INSTRUCTIONS

APPLICATION

These electromagnetically-operated Definite Purpose

Contactors provide switching for starting induction motors.

See Table 1 for contact ratings.

Table 1. Contact Ratings.

Model

Rating Line

(A) Volts

20 240/277 20.0 100 30 7.2/8.3

480 10.0 5 0 30 14.4

600 8.0 32 30 18.0

25 240/277 25.0 125 30 7.2/8.3

480 10.0 5 0 30 14.4

600 8.0 40 30 18.0

240/277 30.0 150 40 9.6/11.1

30

(1 pole)

(2 pole)

(1 pole)

(2 pole)

a

Device not tested for ARI-780 Standard at 600V;

rating shown is Underwriters Laboratories Inc. (UL)

rating.

480 15.0 7 5 4 0 19.2

600 12.5 5 0 4 0 24.0

240/277 3 0 125 40 9.6/11.1

30

480 10 50 40 19.2

600 8 32 40 24.0

240/277 40.0 180 55 13.2/15.2

40

240/277 40.0 150 55 13.2/15.2

40

600

Motor Load

Rating A/Pole

AFL ALR A kW

a

40.0 110 55 13.2/15.2

Resistive

Load Per Pole

CAUTION

Disconnect power supply before beginning

installation to prevent electrical shock or equipment

damage.

Location

Locate the contactor on a flat, solid surface as close as

possible to the equipment being controlled.

Mounting and Wiring

Disconnect power supply before beginning installation to

prevent electrical shock or equipment damage. Be sure all

wiring complies with local codes and ordinances.

IMPORTANT

Do not exceed the contact and coil ratings when

wiring the contactor into the system.

New Installation

쐃 Mount the contactor in a vertical position for best

performance. Horizontally-mounted contactors have

a 12 percent lower efficiency.

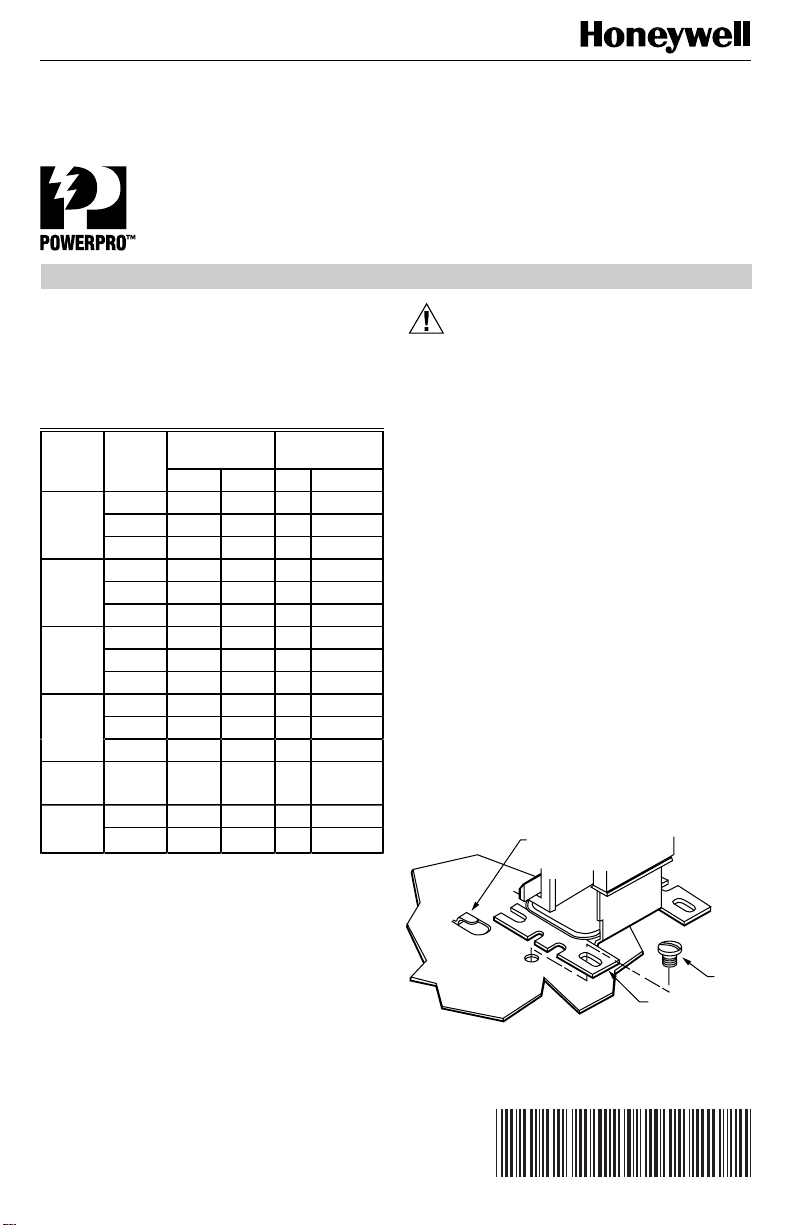

쐇 Use two screws to mount the contactor. Select

models use a shear formed panel tab to mount the

contactor. See Fig. 1.

쐋 See equipment manufacturer wiring instructions or

Fig. 2.

쐏 Attach the line wires to the contactor using terminal

clamp screws.

쐄 Attach the load wires using No. 10 binding screws.

쐂 Use pressure lugs for field wiring with wire larger

than No. 8.

SHEAR

FORMED TAB

INSTALLATION

When Installing this Product…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for

your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

Copyright © 1996 Honeywell Inc. • All Rights Reserved

Fig. 1. Typical contactor mounting.

X-XX UL

CONTACTOR

BASE

69-0874-3

SCREW

M5513

Page 2

DEFINITE PURPOSE (DP) CONTACTORS

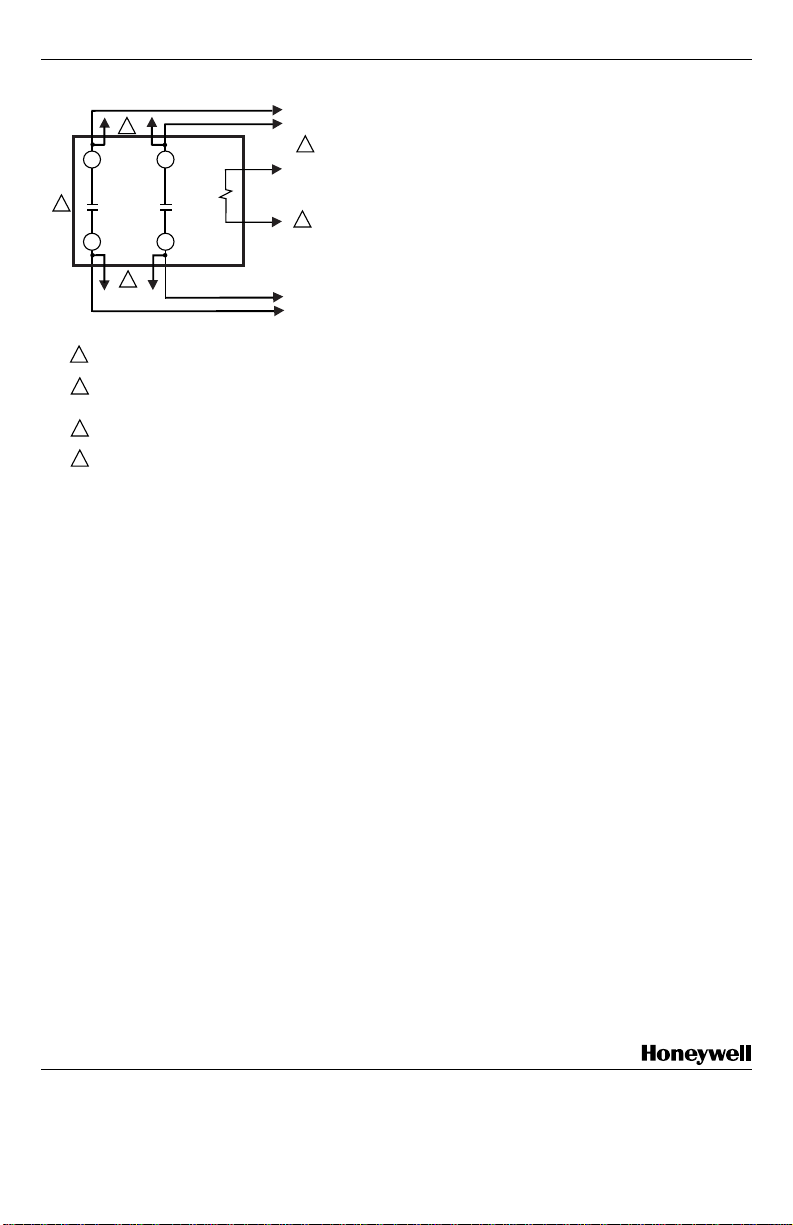

SINGLE

3

L1

4

POWER SUPPLY. PROVIDE OVERLOAD PROTECTION

1

AND DISCONNECT MEANS AS REQUIRED.

THE CONTROL CIRCUIT INCLUDES LINE VOLTAGE OR LOW

2

VOLTAGE POWER SUPPLY (DEPENDING ON MODEL USED),

CONTROLLER AND/OR SAFETY DEVICES.

QUICK-CONNECT TERMINALS FOR ACCESSORY

3

CONNECTIONS ONLY.

FOR REPLACEMENT OF SINGLE POLE CONTACTORS WITH

4

TRICKLE HEAT, A SUITABLY SIZED JUMPER WIRE SHOULD

BE PLACED BETWEEN L1 AND T1.

L2

T2T1

3

Fig. 2. Typical wiring diagram.

PHASE

POWER

1

TO

CONTROL

CIRCUIT

2

TO

CONTROLLED

LOAD

M8731A

Replacement Installation

쐃 Remove and identify contact and coil leads to

assure correct connection to the new contactor.

쐇 Remove the mounting screws from the old

contactor.

쐋 Mount the new contactor using the screws provided.

Some models include a 138550 Mounting Adapter

Plate for use when replacing competitive controls.

쐏 Reconnect the contact and coil leads to the proper

terminals.

CHECKOUT

Always conduct a thorough checkout when installation is

complete. Restore power supply and operate the contactor

and controlled equipment to assure the contactor pulls in

when the coil is energized and the controlled equipment

operates as intended.

Home and Building Control

Honeywell Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

Home and Building Control

Honeywell Limited-Honeywell Limitée

155 Gordon Baker Road

North York, Ontario

M2H 2C9

69-0874—3 2

69-0874—3 J.S. Rev. 5-96 Printed in U.S.A

Helping You Control Your World

Loading...

Loading...