Page 1

EN2H-0221GE51 R0808

Smile SDC heating and

district heating controller

SERVICE MANUAL

Page 2

EN2H-0221GE51 R0808

Page 3

SDC / DHC Contents

EN2H-0221GE51 R0808 3

Contents

1 Software version ..........................................................................................................11

2 Safety instructions.......................................................................................................11

2.1 Intended use .....................................................................................................11

2.2 Requirements for start-up..................................................................................11

2.2.1 Power supply ........................................................................................12

2.2.2 Connection conditions ..........................................................................12

2.2.3 Cable cross-sections ............................................................................12

2.2.4 Maximum cable lengths........................................................................12

2.2.5 Cable installation ..................................................................................12

2.2.6 Grounding and zeroing .........................................................................13

2.3 Hot-water temperature greater than 60 °C ........................................................13

2.4 Connection of accessory parts ..........................................................................14

2.5 Maintenance and cleaning ................................................................................14

2.6 Safety precautions for EMC-compliant installation ............................................15

3 Overview.......................................................................................................................20

4 Abbreviations ...............................................................................................................21

5 Operation......................................................................................................................22

5.1 Display and operating elements ........................................................................22

5.1.1 Display (basic display)..........................................................................23

5.1.2 Operating elements ..............................................................................24

5.1.2.1 Input button (press / turn)........................................................24

5.1.2.2 "Daytime room temperature" button ........................................24

5.1.2.3 "Night-time room temperature" button.....................................25

5.1.2.4 "Daytime hot-water temperature" button .................................25

5.1.2.5 "Operating mode" button (basic display) .................................26

5.1.2.6 "Switching time programs / Holiday programs" button ............33

5.1.2.7 "System information" button....................................................35

5.1.2.8 "Manual mode" / "Emission measurement" button ..................44

Page 4

Contents SDC / DHC

4 EN2H-0221GE51 R0808

5.1.2.9 Access to the technician / OEM area ......................................46

5.1.2.10 Heating curve..........................................................................47

5.2 Menu-selection level..........................................................................................48

5.2.1 "Time - Date" menu ..............................................................................54

5.2.2 "Timeprograms" menu ..........................................................................55

5.2.2.1 Selection of the control circuit .................................................56

5.2.2.2 Selection of the program .........................................................56

5.2.2.3 Selection of day of the week and cycle ...................................56

5.2.2.4 Programming switching times and cycle temperatures ...........57

5.2.3 "System Parameters" menu..................................................................72

5.2.3.1 Language selection .................................................................72

5.2.3.2 Time program..........................................................................73

5.2.3.3 Operating mode ......................................................................74

5.2.3.4 Parameter reset ......................................................................76

5.2.3.5 Complete reset........................................................................77

5.2.4 "DHW" menu ........................................................................................77

5.2.4.1 Night-time hot-water temperature............................................78

5.2.4.2 Legionella protection day ........................................................78

5.2.5 "Direct Heating Circuit" / "Mixed Heating Circuit 1" / "Mixed

Heating Circuit 2" menu........................................................................78

5.2.5.1 Reduced operation..................................................................79

5.2.5.2 Heating system .......................................................................80

5.3 Error messages.................................................................................................80

5.4 Parameter settings ............................................................................................81

5.4.1 "Hydraulics" menu (HYDRAULIC) ........................................................81

5.4.2 "System parameters" menu (SYSTEM)................................................85

5.4.3 "Hot-water circuit" menu (DHW) ...........................................................89

5.4.4 "Direct heating circuit" menu (UNMIXED CIRC) ...................................92

5.4.5 "Mixed heating circuit 1 / 2" (MIX.VALVE - 1 / MIX.VALVE - 2)

menus ...................................................................................................95

5.4.6 "Heat generator" menu (HEAT GENER................................................99

Page 5

SDC / DHC Contents

EN2H-0221GE51 R0808 5

5.4.7 "District hot water" menu (DIST.HEATING) ........................................104

5.4.8 "Return increase" menu (RETURN CONTR)......................................105

5.4.9 "Solar" menu (SOLAR) .......................................................................106

5.4.10 "Solid" menu (SOLID FUEL) ...............................................................107

5.4.11 "Buffer" menu (BUFFER)....................................................................108

5.4.12 "Total flow regulation" menu (MAIN SUPPLY)....................................109

5.4.13 "Cascading" menu (CASCADE) .........................................................110

5.4.14 "Data bus" menu (BUS) ......................................................................111

5.4.15 "Relay test" menu (RELAY TEST ) ....................................................111

5.4.16 "Error messages" menu (ALARM) ......................................................112

5.4.17 "Error messages 2" menu (ALARM 2) ................................................113

5.4.18 "Sensor calibration" menu (SENSOR ADJ.) .......................................113

6 Control Functions ......................................................................................................114

6.1 Variable adjustment of the hydraulic parameters (variable inputs and

outputs) ...........................................................................................................114

6.1.1 Connection and settings table ............................................................116

6.2 Switching time program enabling ....................................................................117

6.3 Suppressing the cycle temperature on time program level..............................118

6.4 Enabling "Separate Control Mode"..................................................................118

6.5 Switching from SDC to DHC ...........................................................................119

6.6 Selection of hydraulic parameter presettings ..................................................119

6.7 The variable inputs and outputs of device series SDC/DHC 43 ......................119

6.8 General functions and their operation .............................................................120

6.8.1 Outside temperature sensing..............................................................120

6.8.1.1 Building type .........................................................................120

6.8.2 Heating circuit outside temperature assignment.................................121

6.8.3 Outside temperature emergency operation value...............................121

6.8.4 Outside temperature disable...............................................................122

6.8.5 Climate zone.......................................................................................122

6.8.6 Design temperature ............................................................................122

6.8.7 Summer switch-off..............................................................................123

Page 6

Contents SDC / DHC

6 EN2H-0221GE51 R0808

6.8.8 System frost protection.......................................................................124

6.8.9 Pump forced operation .......................................................................127

7 Hydraulic Components..............................................................................................128

7.1 Heat generator: Boiler .....................................................................................128

7.1.1 Heat generator start-up protection......................................................128

7.1.2 Heat generator minimum temperature limit.........................................129

7.1.3 Maximum temperature limit heat generator ........................................130

7.1.4 Heating circuits minimum temperature limit ........................................130

7.1.5 Heat generator sensor control mode ..................................................130

7.1.6 Minimum burner runtime.....................................................................131

7.1.7 Switching: Multi-stage heat generator/Switching differential...............131

7.1.8 Operation for modulating burners .......................................................136

7.1.9 Modulation of P part (Xp)....................................................................137

7.1.10 Modulation of sample time Ta.............................................................137

7.1.11 Modulation of integral action time Tn ..................................................138

7.1.12 Modulation of runtime .........................................................................138

7.1.13 Modulation of start time ......................................................................138

7.1.14 Modulation of start power ...................................................................139

7.1.15 OpenTherm ........................................................................................140

7.1.16 Use of boiler sensor 2.........................................................................141

7.1.17 External heat generator cut-off ...........................................................141

7.1.18 Heat generator forced discharge ........................................................141

7.1.19 Exhaust gas temperature monitoring ..................................................142

7.1.20 Burner counter mode ..........................................................................143

7.2 Heat generation, heat exchanger, district heating ...........................................144

7.2.1 On/Off operation of the district heating valve......................................145

7.2.2 Continuous heat exchanger valve control...........................................145

7.2.3 District heating return temperature limit..............................................147

7.2.4 Return temperature limit for hot-water loading....................................149

7.2.5 Hot-water pre-regulator with district heating systems .........................150

7.2.6 Mode of operation: Hot-water pre-control ...........................................151

Page 7

SDC / DHC Contents

EN2H-0221GE51 R0808 7

7.2.7 Quick hot-water control.......................................................................152

7.2.8 Mode of operation of hot-water control mode "external

operation" ...........................................................................................154

7.2.9 Conditional parallel operation for mixed heating circuits.....................155

7.2.10 Circulation pump control mode ...........................................................155

7.2.11 Switch-off of district heating control ....................................................156

7.2.12 Return interval flushing .......................................................................156

7.2.13 Heat meter for additional limitation according to the volume flow

or thermal output ................................................................................156

7.2.14 Charging pump (CHP) ........................................................................157

7.2.15 Primary pump .....................................................................................158

7.2.16 Boiler circuit pump ..............................................................................158

7.2.17 Return increase ..................................................................................159

7.2.17.1 Bypass pump (RBP)..............................................................160

7.2.17.2 Return maintenance through controlled feed water

addition 160

7.2.17.3 Indirect return increase .........................................................161

7.3 Heating circuit .................................................................................................161

7.3.1 General heating circuit functions ........................................................161

7.3.1.1 Heating curve........................................................................161

7.3.1.2

Heating curve setting (heating curve)....................................162

7.3.1.3 Reduced operation................................................................164

7.3.1.4 Heating system .....................................................................164

7.3.1.5 Heating circuit temperature limit............................................164

7.3.1.6 Heating circuit temperature offset .........................................165

7.3.1.7 Heating circuit pump extended running time .........................165

7.3.1.8 Screed function .....................................................................165

7.3.2 Heating circuit constant temperature control ......................................168

7.3.3 Fixed-value control .............................................................................168

7.3.4 Consideration of the room temperature/room influence......................169

7.3.4.1 Heating circuit room connection............................................169

7.3.4.2 Heating circuit room factor ....................................................170

Page 8

Contents SDC / DHC

8 EN2H-0221GE51 R0808

7.3.4.3 Heating circuit room controller ..............................................171

7.3.4.4 Switch-on/switch-off optimisation ..........................................171

7.3.4.5 Room setpoint ramp..............................................................175

7.3.4.6 Heating limit function.............................................................175

7.3.4.7 Heating circuit room frost protection limit ..............................177

7.3.4.8 Mixed heating circuits cooling switch-over ............................177

7.3.4.9 Heating circuit name .............................................................180

7.3.4.10 Room thermostat function (maximum room

temperature limit) ..................................................................181

7.3.5 Hot-water production ..........................................................................187

7.3.5.1 Hot-water tank loading (SLP) ................................................187

7.3.5.2 Circulation pump (CIR.).........................................................194

7.3.6 Solar/Solid fuel/Buffer.........................................................................196

7.3.6.1 Solar function ........................................................................196

7.3.6.2 Buffer tank function ...............................................................199

7.3.6.3 Solid fuel function..................................................................212

7.3.7 Tank loading switch-over....................................................................213

7.3.8 Hydraulic buffer relief (HBR)...............................................................215

7.3.9

Easy enabling and disabling of a heating pump .................................216

7.3.10 Other system components..................................................................217

7.3.10.1 Global fault message input....................................................217

7.3.10.2 Global fault message output .................................................217

7.3.10.3 Timer 217

7.3.10.4 External switching modem ....................................................218

7.3.10.5 External information ..............................................................219

7.3.10.6 Demand contact....................................................................219

7.3.11 Bus communication ............................................................................221

7.3.11.1 Bus address of central device ...............................................221

7.3.11.2 Control functions via the data bus.........................................222

7.3.11.3 Operation of wall devices ......................................................227

7.3.12 Cascading of heat generators in the bus system................................232

Page 9

SDC / DHC Contents

EN2H-0221GE51 R0808 9

7.3.12.1 General description of cascading of control devices .............232

7.3.12.2 Function of the cascade parameters.....................................233

7.3.12.3 Mode of operation of cascade control ...................................234

7.3.13 Commissioning, maintenance and troubleshooting help ....................237

7.3.13.1 Automatic set function...........................................................237

7.3.13.2 Emission measurement (not for DHC 43) .............................238

7.3.13.3 Relay/function test.................................................................239

7.4 Error messages...............................................................................................243

7.4.1 Basic display/fault stack fault messages ............................................248

7.4.1.1 Sensor calibration .................................................................249

7.4.1.2 Full controller reset................................................................249

7.4.1.3 Controller time correction ......................................................249

8 Technical data............................................................................................................250

8.1 General ...........................................................................................................250

8.1.1 Installation recommendations .............................................................251

8.2 Sensor resistance values ................................................................................251

8.2.1 NTC 20 ...............................................................................................251

8.2.2 PT 1000 ..............................................................................................252

8.3 Sensor measurement ranges ..........................................................................252

8.4 Digital inputs....................................................................................................253

9 Log ..............................................................................................................................254

Index....................................................................................................................................255

Page 10

Contents SDC / DHC

10 EN2H-0221GE51 R0808

Page 11

SDC / DHC Software version

EN2H-0221GE51 R0808 11

1 Software version

This documentation is valid for software version V 3.0 of your

control device. The software version is displayed after switch-on

for approx. 8 s. If you are using an older software version, please

contact your heating technician.

2 Safety instructions

2.1 Intended use

The SDC / DHC Smile family of controllers was designed for the

sole purpose of regulating and controlling hot-water, heating and

district heating systems (including hot-water production) that do

not exceed a maximum flow temperature of 120 °C.

2.2 Requirements for start-up

ATTENTION

The heating system must be complete and filled with water

so that the pumps do not run dry and the heating boiler is not

damaged.

The control equipment must be installed in accordance with

the installation instructions.

All electrical connections (voltage supply, burner, mixer

motor, pumps, sensor wiring etc.) must be carried out by the

technician in accordance with the applicable VDE regulations

and correspond with the circuit diagrams.

If floor heating is connected, a limiting thermostat must also

be installed in the flow line after the heating circuit pump.

This switches off the pumps at excessive flow temperatures.

Before starting up the controller, have the heating technician

check all requirements listed above.

The current time and date are already set at the factory and are

backed up by a battery.

The time switch functions based on a basic program and the

control functions are preset for common heating systems with lowtemperature boilers.

NOTE

Page 12

Safety instructions SDC / DHC

12 EN2H-0221GE51 R0808

2.2.1 Power supply

Do not disconnect the controller from the mains supply!

The battery for saving all individualised data is otherwise

unnecessarily strained. The frost-protection function of the

controller is deactivated.

2.2.2 Connection conditions

All electrical connection work may only be carried out by qualified

personnel!

2.2.3 Cable cross-sections

1.5 mm2 for all cables carrying 230 V (power supply, burner,

pumps, actuator).

0.6 mm2 for bus cables (recommended type J-Y(St)Y 2 x 0.6).

0.5 mm2 for sensors, selectors and analog signal cables.

2.2.4 Maximum cable lengths

Sensor, selector and analog inputs

We recommend using cables no longer than 200 m. Longer

connection lines could be used, but increase the risk of

interference.

Relay outputs

Unlimited cable length.

Bus connections

Max. length of 100 m from the first bus subscriber to the last one

(incl. wall modules).

2.2.5 Cable installation

Install cables for sensors apart from the cables carrying 230 V!

Branch boxes in the sensor cable must be avoided!

Page 13

SDC / DHC Safety instructions

EN2H-0221GE51 R0808 13

2.2.6 Grounding and zeroing

Local regulations on the connection of equipment must be

observed!

2.3 Hot-water temperature greater than 60 °C

ATTENTION

Note that there is a danger of scalding at all hot-water drawoff points (kitchen, bathroom etc.) in the following cases.

Add sufficient cold water in these cases.

When the automatic anti-legionella mechanism is activated, the

hot water is automatically heated to the anti-legionella

temperature (65 °C at the factory) on the selected day and at the

selected time to kill any legionella bacteria found in the hot-water

tank.

In the manual mode / emission measurement operating mode, the

hot water is heated up to the highest possible boiler temperature,

as the burner and all pumps are switched on and the mixer is

opened fully. There is an acute danger of scalding at all

connected hot-water draw-off points! Add sufficient cold water or

switch off the hot-water loading pump (at the switch of the pump,

if present). Heating and hot water are in unregulated continuous

operation. This operating mode is for special use by the chimney

sweep for emission measurement or if the controller is defective.

The high hot-water temperatures can be prevented, however, by

setting the boiler thermostat to a max. boiler temperature of

approx. 60 °C.

Automatic anti-

legionella mechanism

Manual mode /

Emission

measurement

Page 14

Safety instructions SDC / DHC

14 EN2H-0221GE51 R0808

2.4 Connection of accessory parts

WARNING

According to VDE 0730, a separator for each mains terminal

is to be provided in the voltage supply to the control

equipment. Observe the local regulations regarding

grounding and zeroing.

As soon as the mains voltage is applied to terminals 21, 22,

2, 6, 12 and 18, headers X3 and X4 can also carry mains

voltage.

If the heating circuit and hot-water loading pumps do not

have an On / Off switch, but manual switch-on and switch-off

capability is still desired, the appropriate switches must be

installed by the customer. All accessory parts (sensors,

selectors etc.) are to be connected to the respective circuit

diagram.

2.5 Maintenance and cleaning

The controller is maintenance-free. The device can be cleaned

externally with a moist (not wet) cloth.

Page 15

SDC / DHC Safety instructions

EN2H-0221GE51 R0808 15

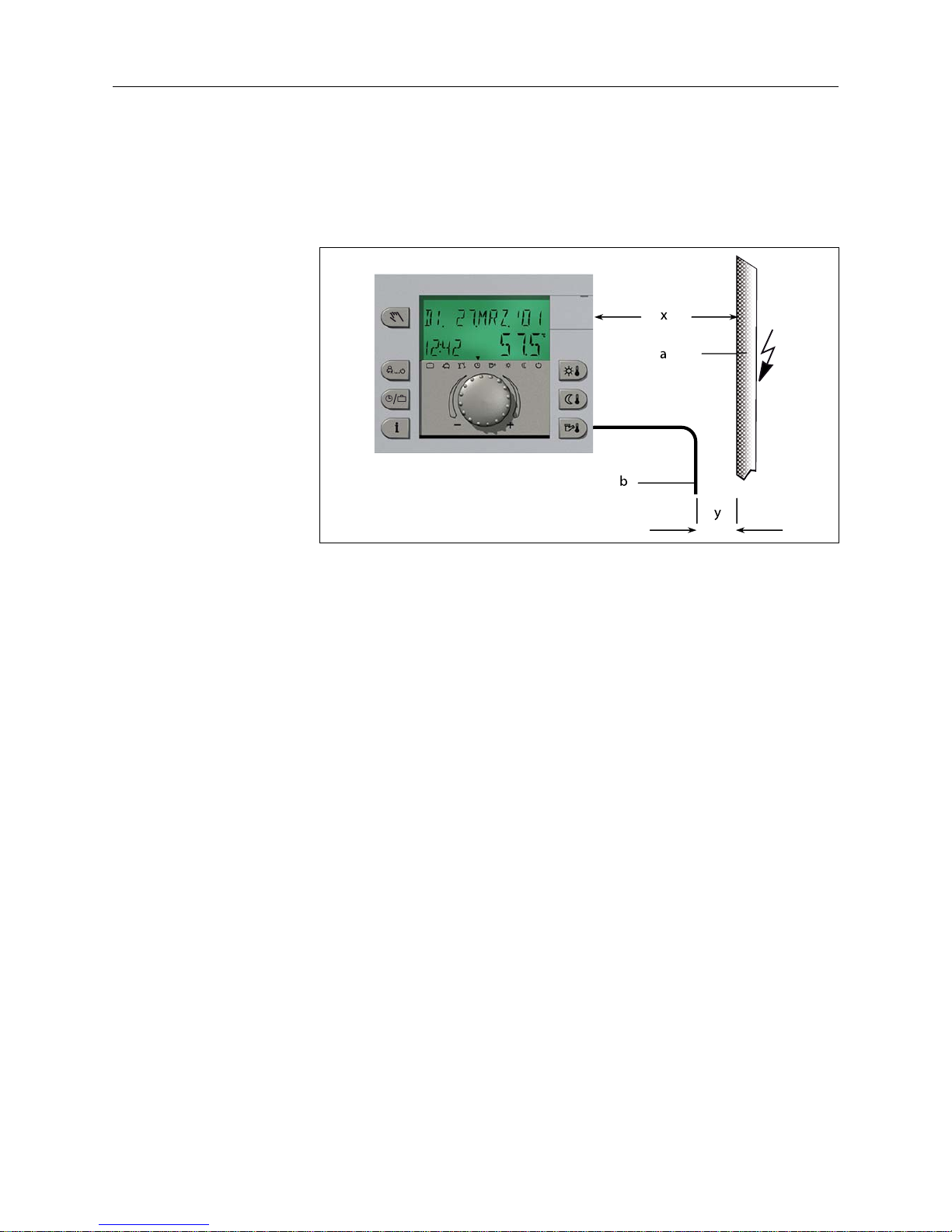

2.6 Safety precautions for EMC-compliant installation

Mains lines and sensor/data bus lines must be installed separate

from each other. A minimum of 2 cm space must be present

between the lines. It is permissible to cross lines.

x

a

b

y

ç

é

æ

a Mains 230 V AC x 15 cm

b Data bus line 12 V AC y 2 cm

For control devices with their own mains connection, separate

installation of mains and sensor/bus lines must absolutely be

ensured. If cable ducts are used, they are to be provided with cutoff bridges.

Page 16

Safety instructions SDC / DHC

16 EN2H-0221GE51 R0808

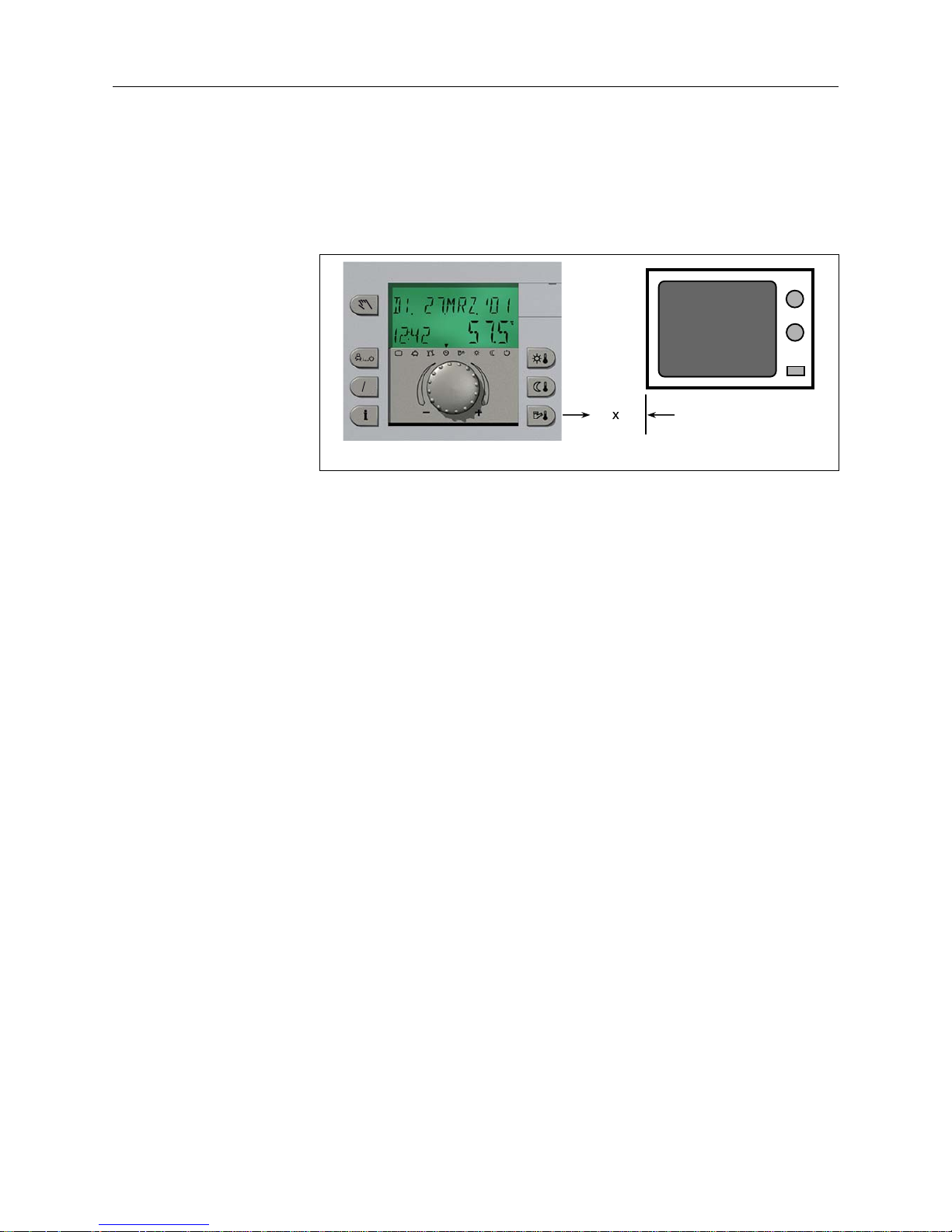

When installing control or wall devices, a minimum spacing of

40 cm to other electrical equipment with electromagnetic

emissions, e.g. relays, motors, transformers, dimmers, microwave

ovens and televisions, audio speakers, computers, cordless

telephones etc., is to be ensured.

x

ç

é

æ

x 40 cm

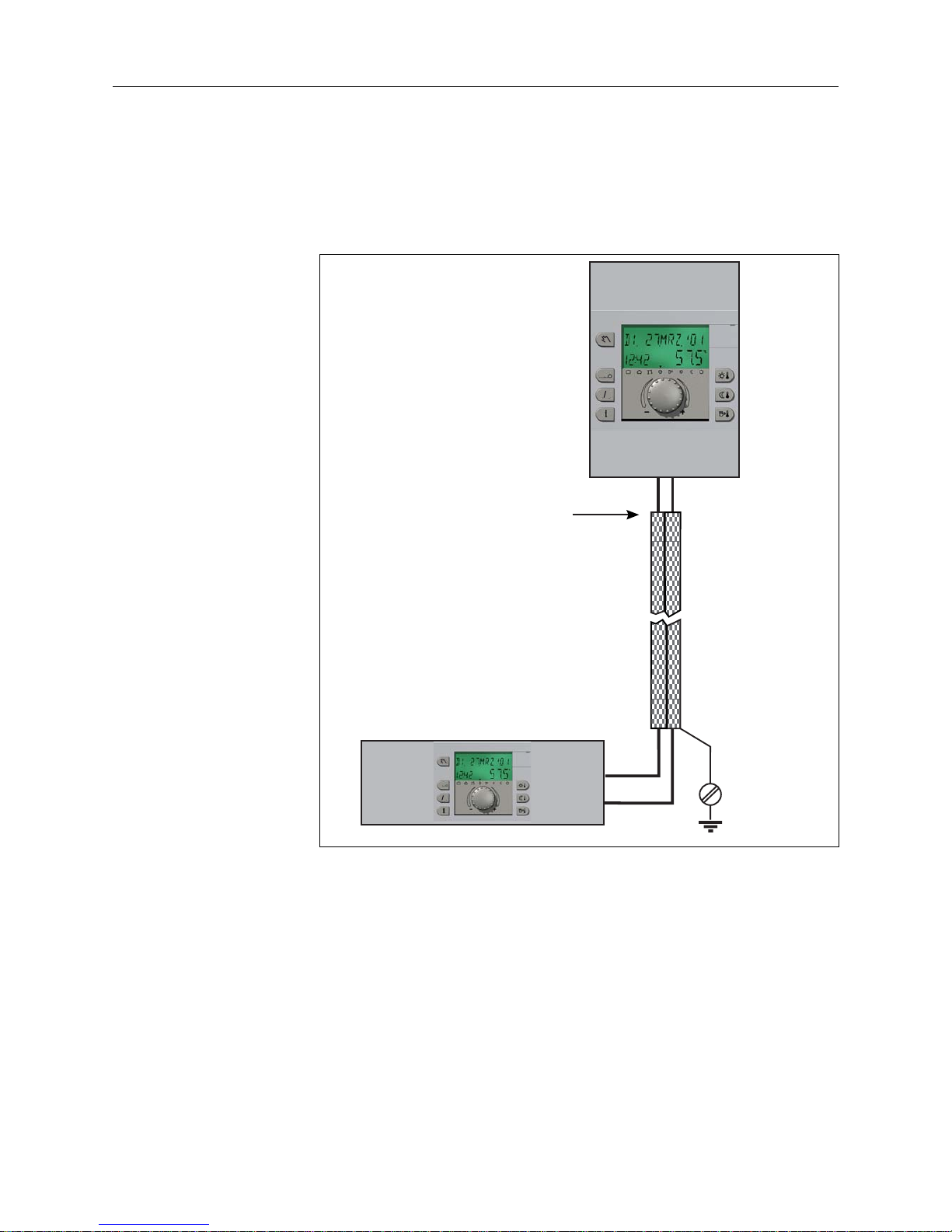

A minimum spacing of 40 cm is to be ensured between wall

devices and central devices. Multiple central devices in the data

bus system can be mounted directly next to one another.

Page 17

SDC / DHC Safety instructions

EN2H-0221GE51 R0808 17

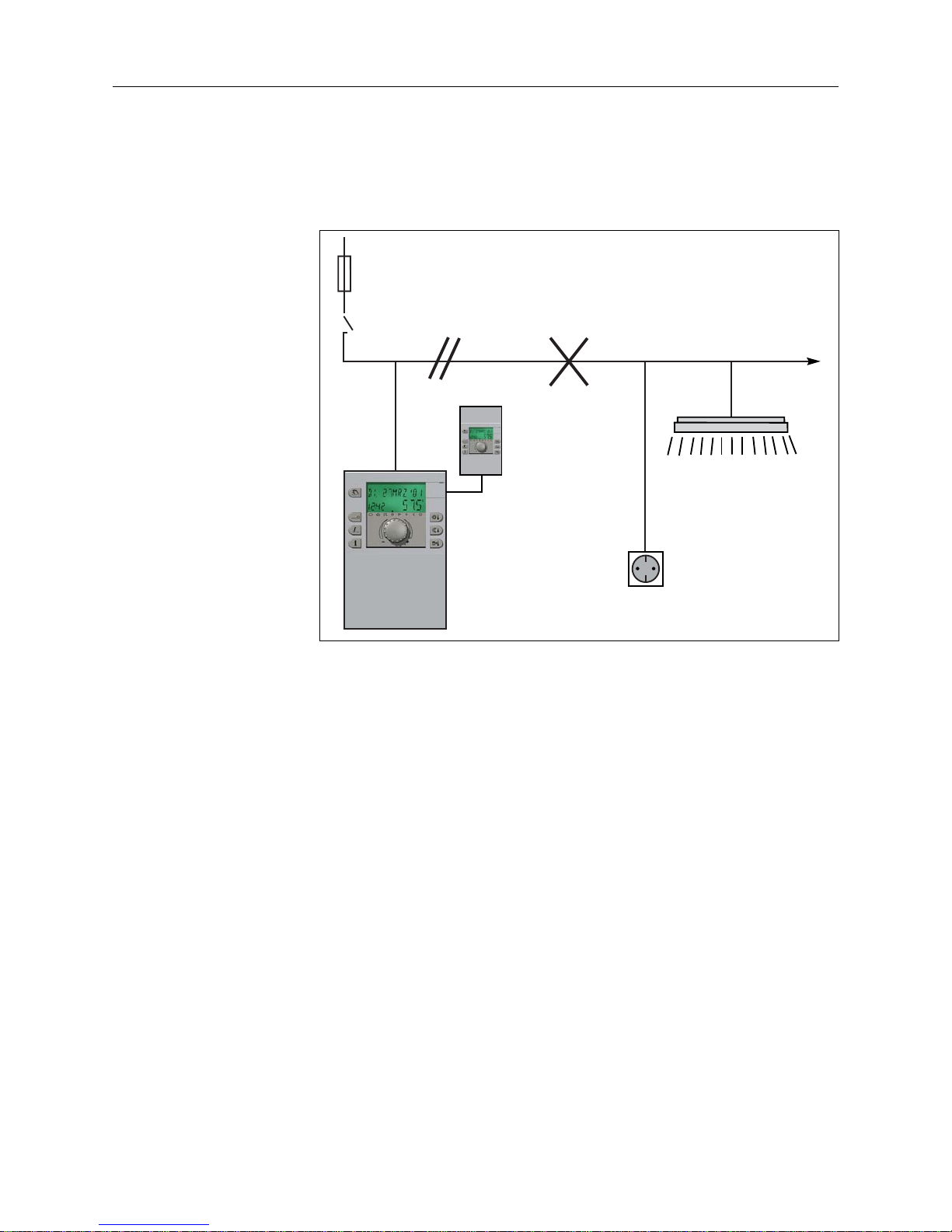

The mains connection of the heating system (boiler – panel –

control equipment) must be designed as a separate circuit.

Neither fluorescent lamps nor any machines which are potential

sources of interference may be connected/connectable.

ç

é

æ

ç

é

æ

a

b

c

d

e

a Safety fuse 16 A

b Boiler room emergency switch

c Connect boiler room lighting and electrical outlets to

separate circuits only!

d Wall devices

e Heat generator

Shielded cables must be used for the data bus lines.

For a recommended layout, see 8 Technical data, pg. 250

Page 18

Safety instructions SDC / DHC

18 EN2H-0221GE51 R0808

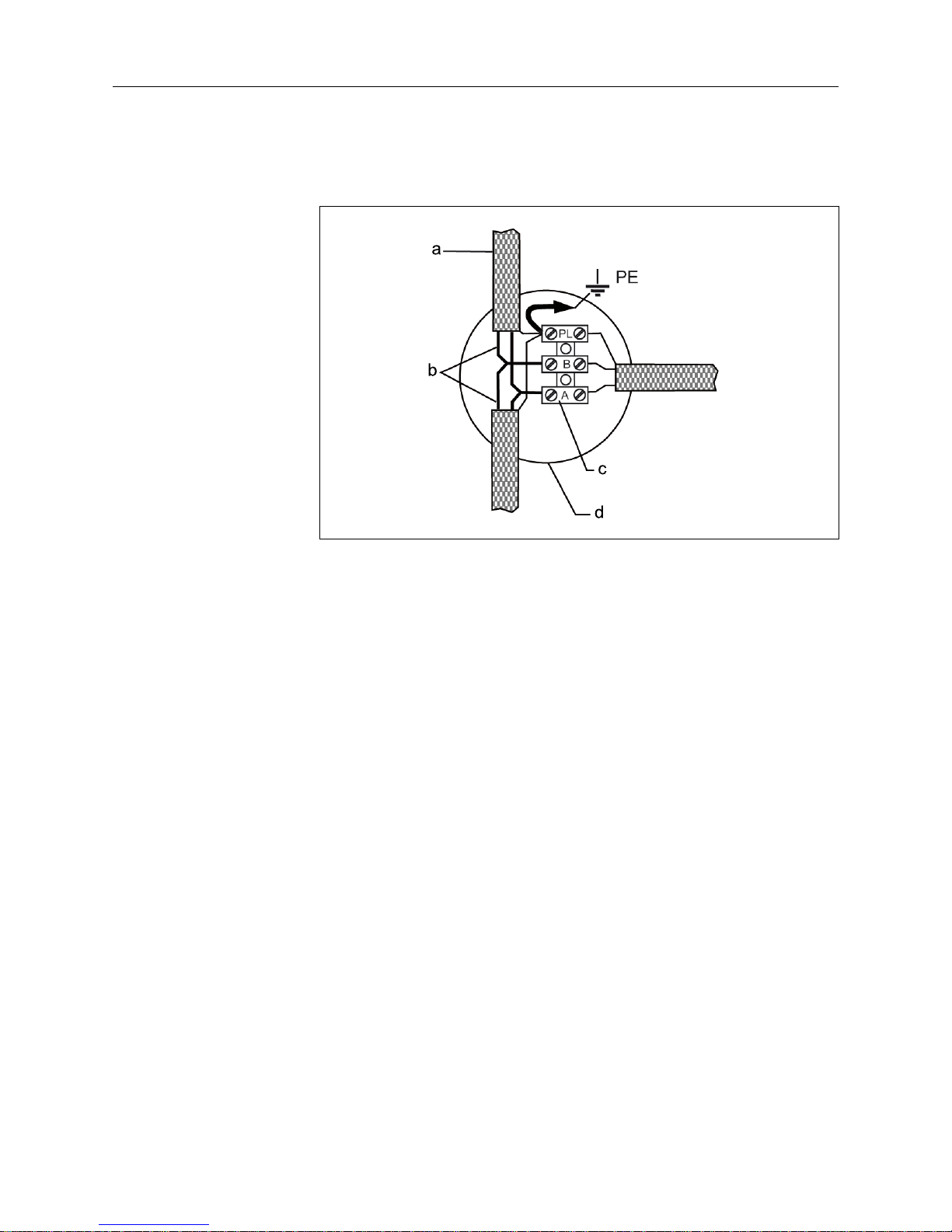

The earth connection of the cable shielding must occur on one

side at the protective conductor connection, e.g. at the cladding

plate of the heat generator, protective conductor terminal etc.

Multiple earth connections of a single cable are not permissible

(buzzing loop).

a

PE

b

ç

é

æ

ç

é

æ

a No earth connection here! b Central device

Page 19

SDC / DHC Safety instructions

EN2H-0221GE51 R0808 19

With star-topology data bus systems, double earth connections

may not be made. The earth connection must be made on one

side of the star!

a Shielding b Two-lead data bus line

c Distributor terminal d Branch box

The outside sensor may not be installed near transmitters or

receivers (e.g. on garage walls near garage door opener

receivers, amateur radio antennas, radio alarm systems or directly

next to large transmission equipment etc.).

Page 20

Overview SDC / DHC

20 EN2H-0221GE51 R0808

3 Overview

The modular SDC / DHC control device is available in an

installable switch cabinet version and a surface-mounted wall

version with the following equipment features:

Type

Number of output relays

Burner stage 2

or

District heating valve

CLOSED

Burner stage 1

Direct heating circuit

Variable output 3

Mixed heating circuit 1

Mixed heating circuit 2

Tank loading pump

Variable output 2

Variable output 1

SDC 3-10

3 – x x – – x –

SDC 3-40

3 – – – x – – – –

SDC 7-21 1)

7 – x x x – x – –

SDC 9-21 2)

7

+ two

variable

relays

x x x x – x x x

SDC 12-31 3)

10

+ two

variable

relays

x x x x x x x x

1)

DHC 43-1

2)

DHC 43-2

3)

DHC 43-3

Page 21

SDC / DHC Abbreviations

EN2H-0221GE51 R0808 21

4 Abbreviations

The following abbreviations are used in this documentation/in the

display of the control device:

RED

Lowering operation

BS 2

Buffer sensor 2 (bottom)

OS

Outside sensor

BLP

Buffer loading pump

OS2

Outside sensor 2

RBP

Return bypass pump

FGS

Flue gas sensor

RP

Return pump

OT

Outside temperature

SD I

Switching differential I

BUS

System data bus

SD II

Switching differential II

OC1

Burner stage 1 operating hour

counter

TS

Tank sensor

OC2

Burner stage 2 operating hour

counter

TLP

Tank loading pump

DC

Direct heating circuit

SLS

Solar loading switch-over

DCP

Direct heating circuit pump

SLSS

Solar loading switch-over sensor

ECO

Switch-off operation

SFD

Solar forced dissipation

EHR

Electric heating rod

SLP

Solar loading pump

SFB

Solid fuel boiler sensor

STL

Stratified tank loading pump

SFR

Solid fuel buffer sensor

VO

Variable output (general)

FC

Fixed-value control

VO1

Variable output 1

SFP

Solid fuel pump

VO2

Variable output 2

PI

Pulse input

VI

Variable input (general)

BP

Boiler circuit pump

VI1

Variable input 1

CC

Constant control

VI2

Variable input 2

CRS

Collector return sensor

VI3

Variable input 3

CTBS

Collector tank/buffer sensor

FM1

Flow sensor of mixed heating

circuit 1

CFS

Collector flow sensor

FM2

Flow sensor of mixed heating

circuit 2

MM

Mixer motor

PHE

Parallel heat generator enable

MC

Mixed heating circuit

HG

Heat generator

MHP

Mixed heating circuit pump

HGS

Heat generator sensor

P1

Switching time program

WD

Wall device for room temperature

sensing

P2

Switching time program

HW

Hot water

P3

Switching time program

CIR

Circulation pump

BS

Buffer sensor (top)

CHP

Charging pump

Page 22

Operation SDC / DHC

22 EN2H-0221GE51 R0808

5 Operation

5.1 Display and operating elements

1011

2

1

3

4

7

6

8

9

5

1 "Manual mode" / "Emission measurement" button (not on

district heating controllers)

2 "Operating modes" button (basic display)

3 "Switching time programs" / "Holiday programs" button

4 "System information" button

5 Display

6 Cover clip for service socket

7 "Daytime room temperature" button

8 "Night-time room temperature" button

9 "Daytime hot-water temperature" button

10 Input button (press / turn)

11 Operating mode symbols (heating programs)

Page 23

SDC / DHC Operation

EN2H-0221GE51 R0808 23

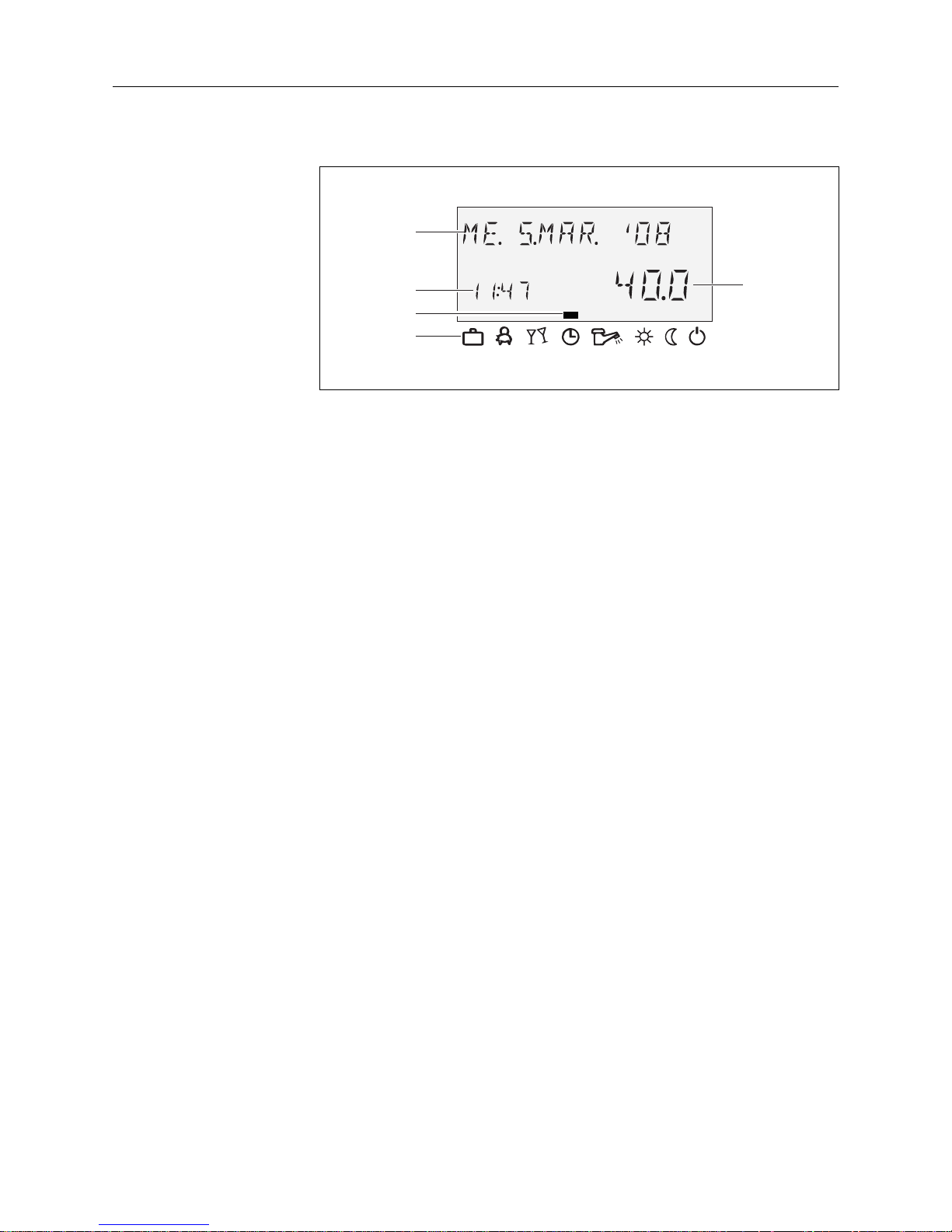

5.1.1 Display (basic display)

1

2

3

4

5

C

1 Day of the week / Date 4 Operating mode symbols

2 Time 5 Heat generator temperature

3 Active operating mode

The illumination of the display is switched on by pressing any

button or using the input button î and switches off automatically

if no buttons are pressed for a longer period of time.

During start-up of the unit and after a power failure, a segment

test with automatic fault diagnosis is carried out. The respective

device type and the software version number then appear briefly.

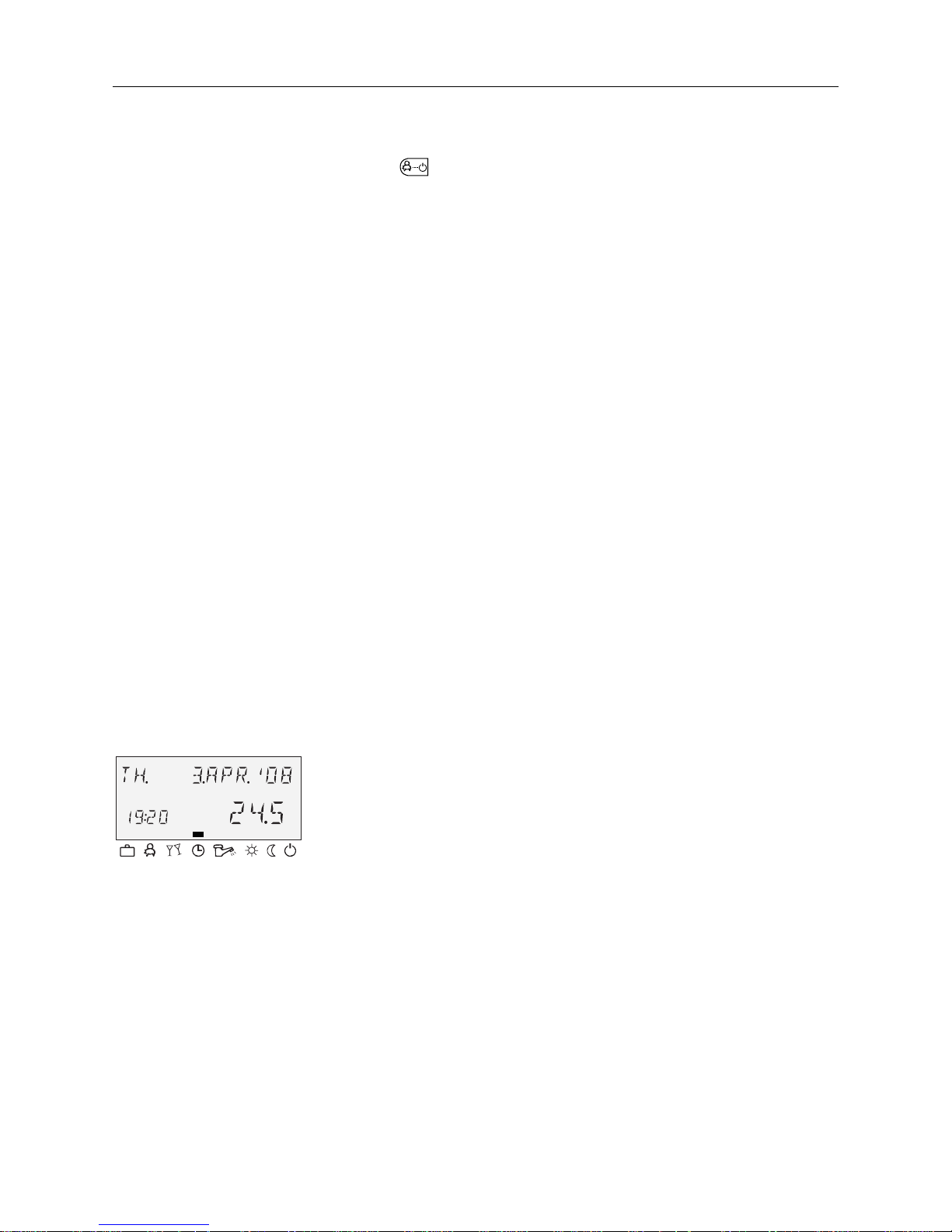

The basic display that then appears shows the day of the week,

the date, the time and the heat generator temperature in

automatic mode. Different values appear in the basic display

depending on the set operating mode (AUTOMATIC, PARTY

etc.). Thus, for example, in the ABSENT operating mode, the

indication ABSENT TIL appears instead of the date and the return

date instead of the temperature. Active summer deactivation is

indicated by a beach umbrella symbol

À, and active frost

protection is indicated by a snowflake symbol

Á.

Page 24

Operation SDC / DHC

24 EN2H-0221GE51 R0808

5.1.2 Operating elements

5.1.2.1 Input button (press / turn)

By pressing once, you can:

• Confirm input / values

By pressing and holding (approx. 3 s), you can:

• Switch to the menu-selection level

• Move up one menu level

By turning the input button î, you can:

• Change values (clockwise increases called-up values,

anticlockwise decreases them)

• Navigate through menus

5.1.2.2 "Daytime room temperature" button

Sets the desired room temperature (room setpoint) in automatic

mode during the heating cycles and in the PARTY and HEATING

operating modes. In operating mode 1, the set value for all

heating circuits is the same. In operating mode 2, the set value

applies for the respective heating circuit. To set the operating

mode, see 5.2.3.3 Operating mode, pg. 74.

► Press ¥ button.

► Set flashing room temperature specification to the desired

value by turning the input button î.

► Confirm set value by pressing the

¥ button or the input

button î.

Alternative: Automatic acceptance of the value after the set

information time (see 5.1.2.7 "System information" button, pg. 35).

20 °C

5 ... 30 °C

ð

¥

Setting

C

Factory setting

Setting range

Page 25

SDC / DHC Operation

EN2H-0221GE51 R0808 25

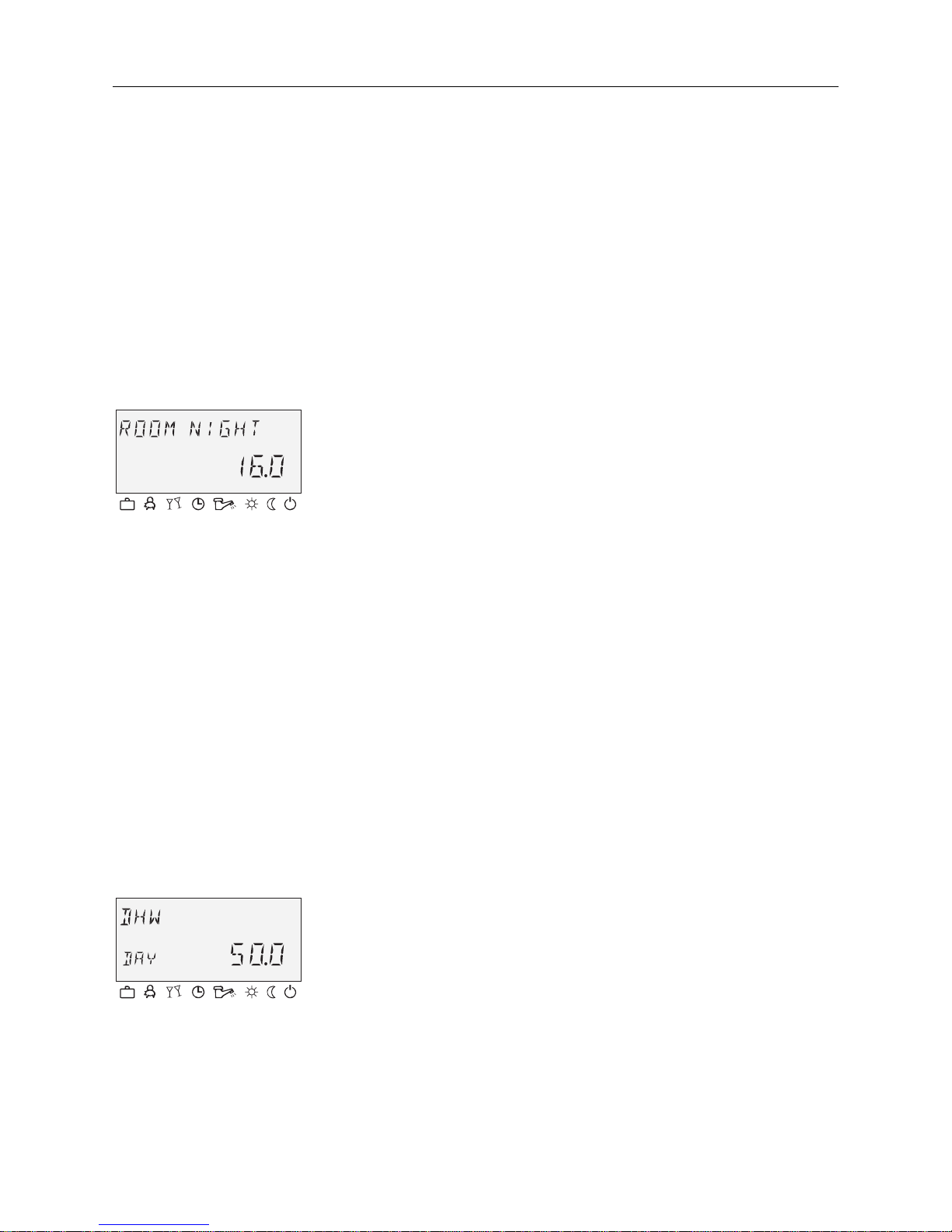

5.1.2.3 "Night-time room temperature" button

Sets the lowered room temperature in automatic mode between

the heating cycles and in the ABSENT and RED. HEATING

operating modes.

In operating mode 1, the set value for all heating circuits is the

same. In operating mode 2, the set value applies for the

respective heating circuit. To set the operating mode, see

5.2.3.3 Operating mode, pg. 74.

► Press ¦ button.

► Set flashing room temperature specification to the desired

value by turning the input button

î.

► Confirm set value by pressing the ¦ button or the input

button î.

Alternative: Automatic acceptance of the value after the set

information time (see 5.1.2.7 "System information" button, pg. 35).

16 °C

5 ... 30 °C

5.1.2.4 "Daytime hot-water temperature" button

Sets the daytime hot-water temperature during the hot-water

operational-readiness times in automatic mode and in the PARTY

and HEATING operating modes. This set value also applies for

exclusively hot-water operation (manual summer operation).

► Press § button.

► Set flashing hot-water temperature to the desired value by

turning the input button î.

► Confirm set value by pressing the § button or the input

button î.

Alternative: Automatic acceptance of the value after the set

information time (see 5.1.2.7 "System information" button, pg. 35).

50 °C

¦

Setting

C

Factory setting

Setting range

§

Setting

C

Factory setting

Page 26

Operation SDC / DHC

26 EN2H-0221GE51 R0808

5 °C (hot-water economy temperature) ... Maximum hot-water

heater temperature limit (service setting)

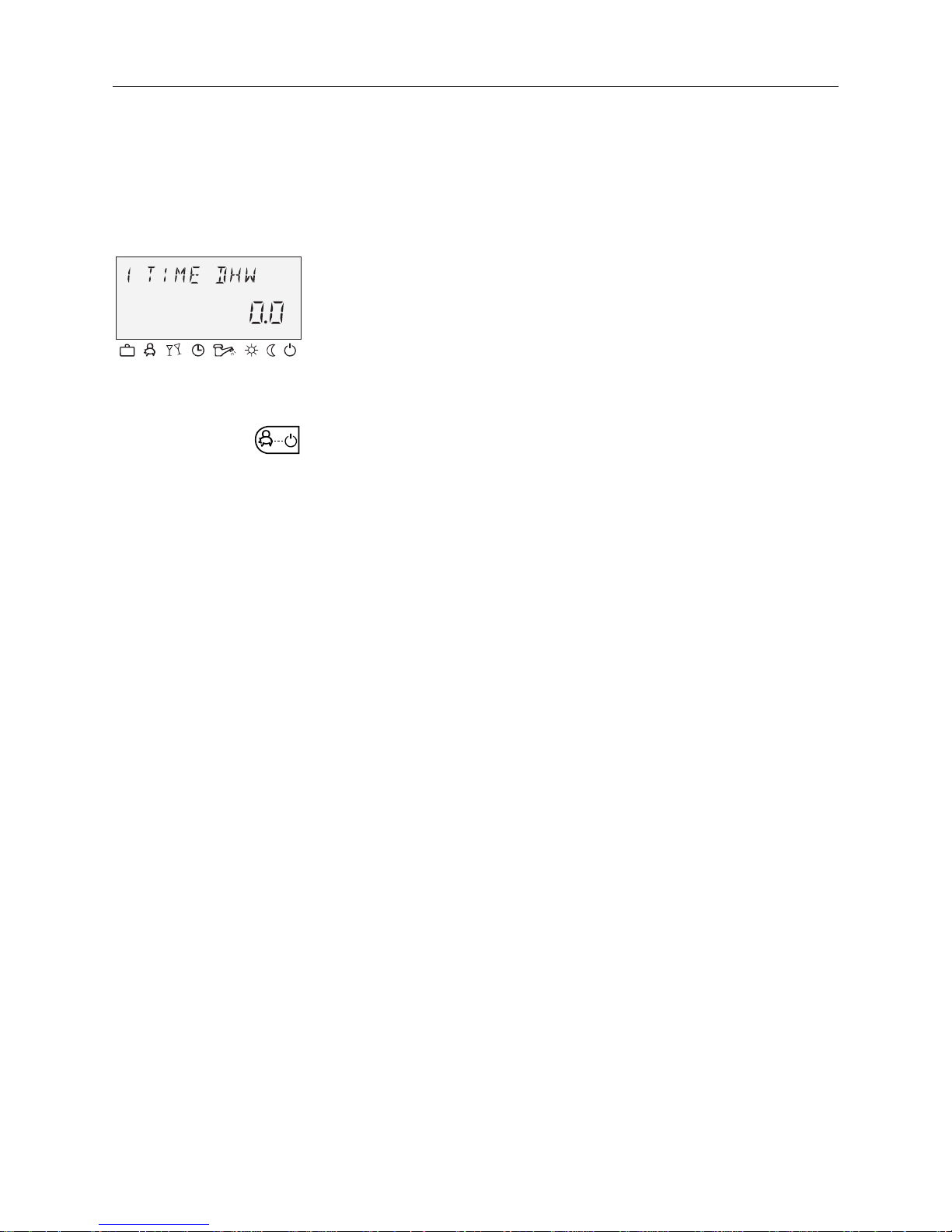

Pressing and holding (approx. 3 s) the § button brings you to

the reload function, where the reload time can be set in minutes.

With a reload time of 0 minutes, loading is started once and the

hot-water tank is loaded to the daytime setpoint. The time for this

superimposed hot-water circuit loading can be set between 0 and

240 minutes. The current week program is superimposed here.

5.1.2.5 "Operating mode" button (basic display)

Sets the operating mode and returns to the basic display from

every operating level.

Setting range

One-time hot-water

circuit loading

Page 27

SDC / DHC Operation

EN2H-0221GE51 R0808 27

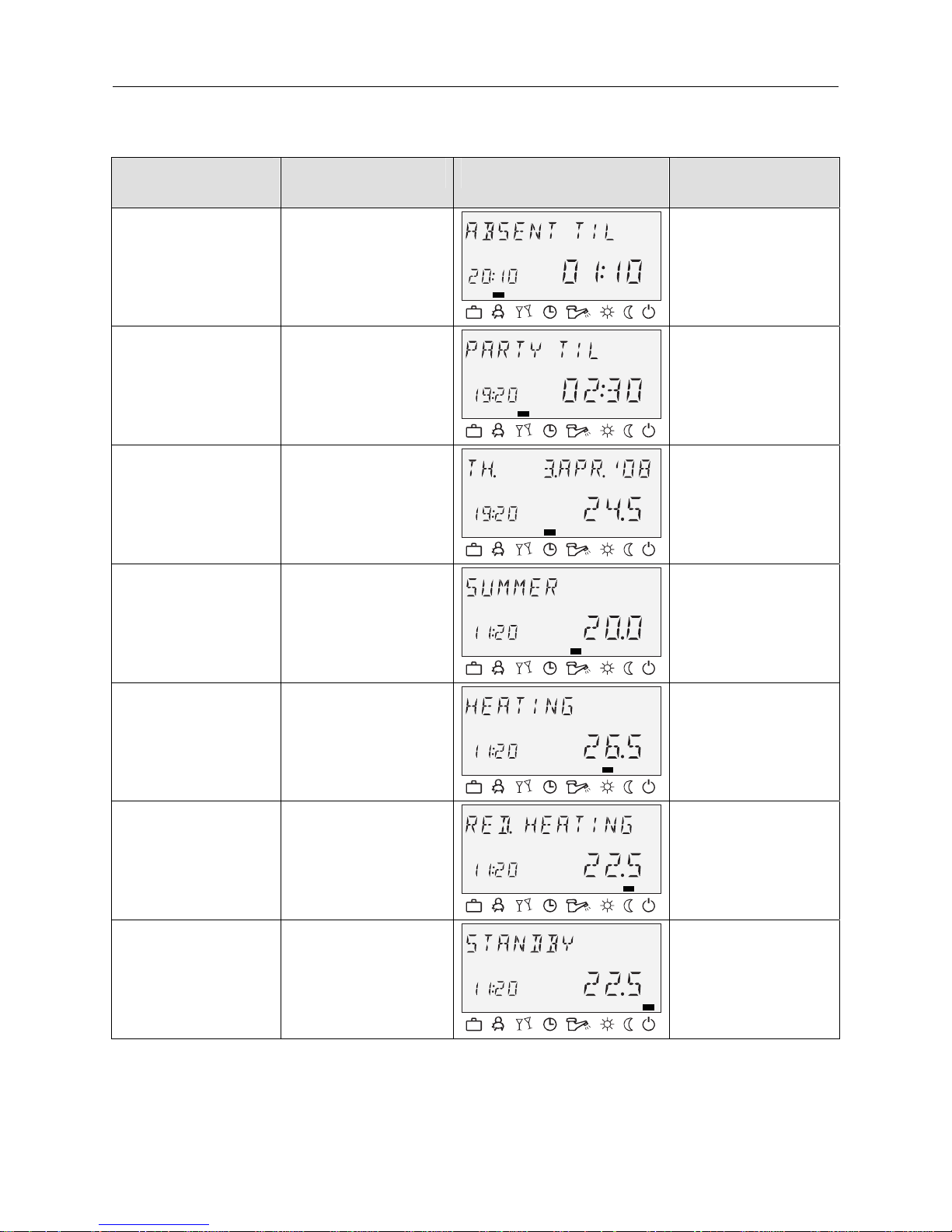

Overview of the operating modes

Symbol Operating mode Display Setting

ç

ABSENT

P1 (P2, P3)*, return

date

è

PARTY

P1 (P2, P3)*,

party end time

é

AUTOMATIC

C

P1 (P2, P3)*

ê

SUMMER

C

P1(P2, P3)*

ë

HEATING

C

ì

RED. HEATING

C

í

STANDBY

C

* P2 and P3 only after enabling, see "System Parameters"

menu, parameter 2 = P1 to P3

Page 28

Operation SDC / DHC

28 EN2H-0221GE51 R0808

The selected operating mode appears in plain text, whereby a

marking at the bottom edge of the display points to the respective

operating mode symbol at the same time. In operating mode 1,

the set value for all heating circuits is the same. In operating

mode 2, the set value applies for the respective heating circuit. To

set the operating mode, see 5.2.3.3 Operating mode, pg. 74.

► Press button.

► Select operating mode by turning the input button î. The

marking is located above the corresponding operating mode

symbol.

► Confirm set operating mode by pressing the button or the

input button î.

► With short-term operating modes (ABSENT, PARTY), set the

desired value by turning the input button î and confirm with

the button or the input button î.

Alternative: Automatic acceptance of the value after the set

information time (see 5.1.2.7 "System information" button, pg. 35).

Press the button for approx. 3 s to return to the basic display

from any operating level.

Holiday mode is set via the "Switching time programs / Holiday

programs" button (see 5.1.2.6 "Switching time programs / Holiday

programs" button, pg. 33).

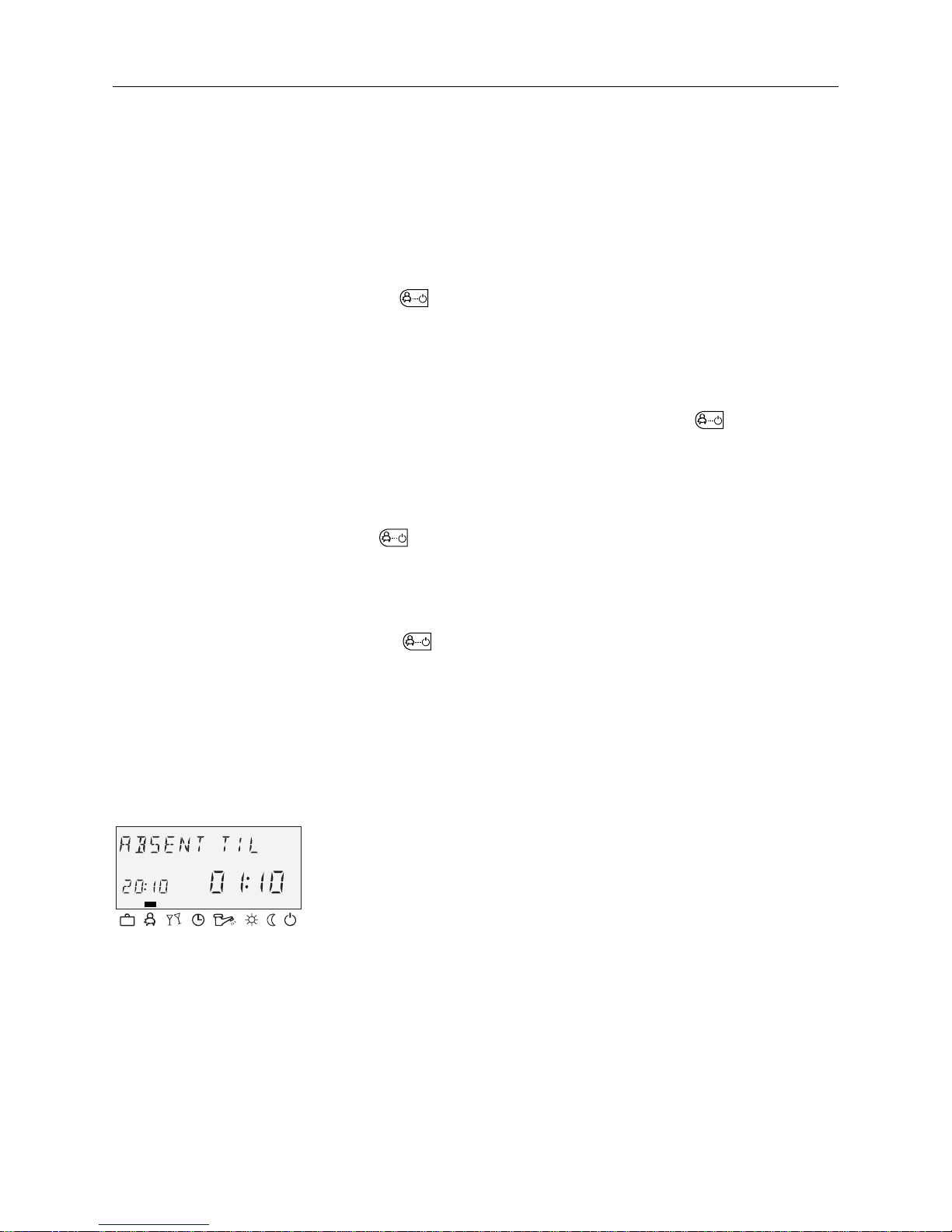

5.1.2.5.1 Absence mode (short-term program)

With the ABSENT operating mode, heating operation is

temporarily deactivated and protected from frost during brief

absences. During the absence, all heating circuits are adjusted to

the specified lowered room temperature. Once the set time

expires, the heating circuits automatically return to the operating

mode that was active before the switch to the absence operation.

Short-term programs such as PARTY or ABSENT are skipped

here.

See 5.1.2.5 "Operating mode" button (basic display) , pg. 26

Short absence while heating operation is active.

Setting

Return to the basic

display

NOTE

Setting

Application

Page 29

SDC / DHC Operation

EN2H-0221GE51 R0808 29

An active absence program can be cancelled in case of early

return.

► Press button.

► Turn input button î and switch to automatic operation.

The active absence program has been cancelled.

P1 as from activation

P1 (P2, P3) / 0.5 to 24 h to the current time

P1 (P2, P3)

Program-controlled resumption of heating operation. After

activation of the absence program, heating operation is

interrupted until the following switch-on time of the current

automatic program P1 (or P2 or P3, if enabled).

0,5 ... 24 h

The set value is added on to the current time and represents the

return time. When the absence program is called up again, the

last set value is saved and suggested as the initial value.

An active absence program appears in the basic display with

information on the return time.

5.1.2.5.2 Party mode (short-term program)

Party mode causes one-time intermediate heating of all heating

circuits up to a specified point in time and bridges an upcoming or

already active absence cycle totally or partially. Once the set time

expires, the heating circuits automatically return to the operating

mode that was active before the party program. Short-term

programs such as ABSENT or PARTY are skipped here.

See 5.1.2.5 "Operating mode" button (basic display) , pg. 26

One-time extension of heating operation or intermediate heating

during lowering operation outside the schedule.

Cancellation

Factory setting

Setting range

Display

Setting

Application

Page 30

Operation SDC / DHC

30 EN2H-0221GE51 R0808

An active party program can be cancelled early.

► Press button.

► Turn input button î and switch to automatic mode.

The active party program has been cancelled.

P1 as from activation

P1 (P2, P3) / 0.5 to 24 h to the current time P1

P1 (P2, P3)

Program-controlled resumption of heating operation. After

activation of the party program, heating operation is continued

until the following switch-on time of the current automatic program

P1 (or P2 or P3, if enabled)

0,5 ... 24 h

The set value is added on to the current time and represents the

end of the party time. When the party program is called up again,

the last set value is saved and suggested as the initial value.

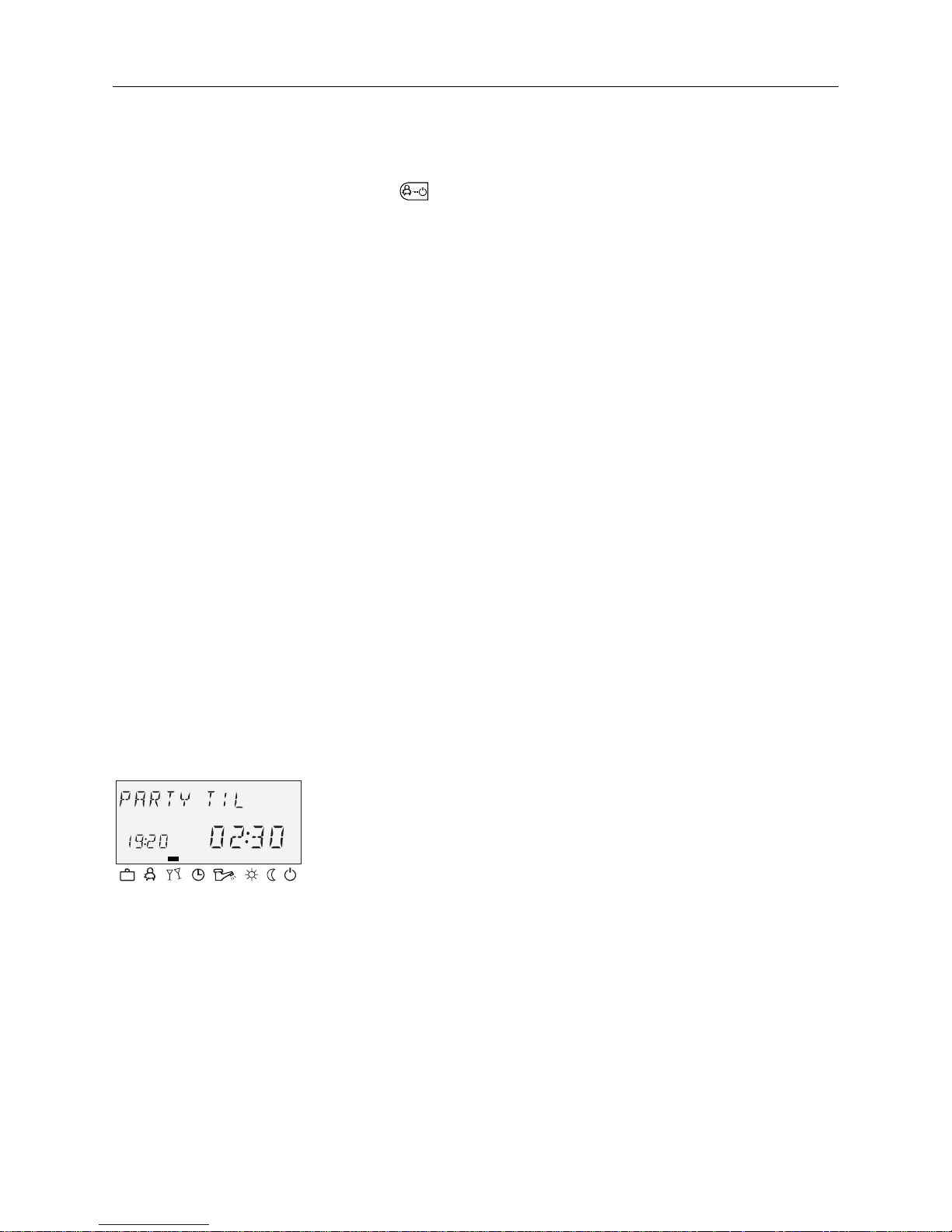

An active party program appears in the basic display with

information on the party end time.

5.1.2.5.3 Automatic mode

In automatic operation, max. three time programs with different

heating operation times are available. They are called up during

start-up as factory-set and unlosable default programs P1, P2 or

P3 and can, if necessary, be overwritten with their own switching

times in the "Timeprograms" menu (see 5.2.2 "Timeprograms"

menu, pg. 55).

Default programs P2 and P3 cannot be selected until the

PROGRAM = P1 to P3 parameter is enabled in the "System

Parameters" menu. Without enabling, only program P1 is active.

See 5.1.2.5 "Operating mode" button (basic display) , pg. 26

Cancellation

Factory setting

Setting range

Display

C

NOTE

Setting

Page 31

SDC / DHC Operation

EN2H-0221GE51 R0808 31

Disabling / enabling default program P2 to P3

Disabling

"System Parameters" menu, program parameter = P1. All heating

circuits and the hot-water circuit solely refer to the default /

individually programmed switching times in the program P1

parameter. Program P1 does not appear in the display in this

operating mode (see 5.2.2 "Timeprograms" menu, pg. 55 and

5.2.3.2 Time program, pg. 73).

Enabling

"System Parameters" menu, program parameter = P1 to P3 (see

5.2.2 "Timeprograms" menu, pg. 55 and 5.2.3.2 Time program,

pg. 73).

An active automatic program appears in the basic display with the

current date and time. If default programs P2 and P3 were

enabled, the corresponding symbol, Â,Ã or Ä, is also

displayed depending on the selected program. The symbols are

only displayed with the time program P1 to P3 active.

5.1.2.5.4 Manual summer operation (excluding heating operation)

With manual summer operation, only the hot-water circuit remains

operation and controls the heat generator temperature based on

the specified hot-water temperature and the specified hot-water

switching time program. Heating operation is stopped, and

protection from frost is provided. This feature is only available

when control mode is set to 1.

See 5.1.2.5 "Operating mode" button (basic display) , pg. 26

Disabling / enabling default programs P2 to P3

Disabling

"System Parameters" menu, program parameter = P1. All heating

circuits and the hot-water circuit solely refer to the default /

individually programmed switching times in the time program = P1

parameter. Program P1 does not appear in the display in this

operating mode (see 5.2.2.1 Selection of the control circuit, pg. 56

and 5.2.3.2 Time program, pg. 73).

C

C

Display

C

Setting

C

Page 32

Operation SDC / DHC

32 EN2H-0221GE51 R0808

Enabling

"System Parameters" menu, program parameter = P1 to P3 (see

5.2.2.1 Selection of the control circuit, pg. 56 and 5.2.3.2 Time

program, pg. 73).

Manual summer operation appears in the basic display with the

information SUMMER. If default programs P2 and P3 were

enabled, the corresponding symbol, Â, Ã or Ä, is also

displayed depending on the selected program. The symbols are

only displayed with the time program P1 to P3 active.

5.1.2.5.5 Continuous heating operation

The HEATING operating mode ensures continuous heating

operation without time limitations based on the specified daytime

room temperature. Hot-water production occurs continuously

based on the specified daytime hot-water temperature.

The HEATING operating mode remains active until another

operating mode is activated.

Activated continuous heating operation appears in the basic

display with the information HEATING.

5.1.2.5.6 Continuous lowering operation

The RED. HEATING operating mode causes continuously

reduced heating operation based on the specified lowered room

temperature. On the heating circuit levels, the reduced operating

mode ECO (frost-protected deactivation mode) or RED (lowering

mode) is set accordingly. The minimum temperature limit of the

respective heating circuit must be taken into account.

See the "Direct Circuit" or "Mixed Heating Circuit 1" / "Mixed

Heating Circuit 2" menu, reduced parameter = reduced operation

and 12 parameter = minimum temperature limit.

Hot-water production occurs continuously based on the specified

hot-water economy temperature (see "DHW" menu, hot water

parameter = hot water at night).

C

Display

C

NOTE

Display

C

Page 33

SDC / DHC Operation

EN2H-0221GE51 R0808 33

The RED. HEATING operating mode remains active until another

operating mode is activated.

Activated continuous lowering operation appears in the basic

display with the information RED. HEATING.

In standby mode, the entire system is switched off and protected

from frost (all frost-protection functions active).

Hot-water production is disabled and protected from frost. At

storage temperatures below 5 °C, a reload to up to 8 °C takes

place.

Total deactivation of heating and hot water with full building

protection.

The heat generator and hot-water production remain in operation

in case of external demand or demand by other heating circuits

on the bus network. The heating circuit pumps are switched on

briefly every day (pump anti-blocking protection).

The standby mode remains active until another operating mode is

activated.

Activated continuous standby mode appears in the basic display

with the information STANDBY.

5.1.2.6 "Switching time programs / Holiday programs" button

Using this button, you can create individualised switching time

programs for heating and hot-water operation and set holiday

mode.

See 5.1.2.6.1 Holiday mode, pg. 34 and 5.2.2 "Timeprograms"

menu, pg. 55.

NOTE

Display

C

Application

NOTE

Display

Page 34

Operation SDC / DHC

34 EN2H-0221GE51 R0808

5.1.2.6.1 Holiday mode

In holiday mode, the heating circuits can be switched off and

protected from frost or operated based on the settings for the RED.

HEATING operating mode for the duration of the holiday based on

the presetting ("Direct circuit" or "Mixed heating circuit 1" / "Mixed

heating circuit 2" menu, parameter 25 = holiday operating mode).

► Press button.

The menu-selection level Switching time programs / Holiday

programs appears in the display.

► Turn input button î to the left.

HOLIDAY appears in the display.

► Press input button î.

HOLIDAY 01 appears in the display.

► Press input button î.

The year flashes in the display.

► Set year with the input button î.

► Press input button î.

The day on which the holiday is to begin flashes in the display.

► Set the day the holiday will begin with the input button î.

► Press input button î.

TIL - - appears in the display.

► Set the day you will return from holiday with the input

button î.

► Press input button î.

The desired holiday timeframe is saved.

You can now enter additional holiday timeframes (up to 15 holiday

blocks).

Longer absence while heating operation is active.

Setting

Application

Page 35

SDC / DHC Operation

EN2H-0221GE51 R0808 35

At outside temperatures below the frost-protection limit (see

5.2.3 "System Parameters" menu, pg. 72) the heating circuits are

controlled as follows:

• Without wall devices: Based on a lowered room temperature

specification of 3 °C.

• With wall devices: Based on the room frost-protection limit of

the respective heating circuit of 10 °C (see "Direct Heating

Circuit" or "Mixed Heating Circuit 1", "Mixed heating circuit 2"

menu, parameter 08 = room frost-protection limit).

An active holiday program can be cancelled in case of early

return.

► Press and hold the button for approx. 3 seconds until the

following appears in the display: "Holiday off".

Current date

Current date... (current date + 250 days)

An active holiday program appears in the basic display with

information on the return date.

5.1.2.7 "System information" button

Calls up system information, such as temperatures and counter

data.

The information on the outside temperature appears first after the

¤ button is pressed. Turning the input button î causes the

system temperatures and the counter and consumption states

and operating states of the connected system components to

appear. Pressing the input button

î causes the respective

setpoint values to appear.

Collector flow temperature: No setpoint

Solar tank temperature: No setpoint

Outside temperature: Averaged value

The displayed information (see the following example) is

independent of the installed or enabled system components and

control circuits.

Control during

holidays

Cancellation

Factory setting

Setting range

Display

¤

Exceptions

NOTE

Page 36

Operation SDC / DHC

36 EN2H-0221GE51 R0808

Operating overview

Average/current outside

temperature value

Outside temperature

min. to max. (0:00 to 24:00 hours)

Heat generator temperature

setpoint/actual value

Hot-water temperature

setpoint/actual value

Flow temperature

setpoint/actual value

Flow temp of mixed heating circuit 1

setpoint/actual value

Variable input 1

setpoint/actual value

Operating hours

Activations of heat generator

Program/operating mode

direct heating circuit/pump status

Program/operating mode

mixed heating circuit 1/pump status

Actuator of

mixed heating circuit 1/status

Program/operating mode

mixed heating circuit 2/pump status

Actuator of

mixed heating circuit 2/status

Program/operating mode

hot-water circuit/pump status

Heat generator

status

Direct heating circuit

pump function/status

Variable output 1

function/operating state

Turn input button to the left Turn input button to the right

Press button

Variable output 2

function/operating state

Flow temp of mixed heating circuit 2

setpoint/actual value

Variable input 2

setpoint/actual value

Variable input 2

setpoint/actual value

Page 37

SDC / DHC Operation

EN2H-0221GE51 R0808 37

If the ¤ button is pressed and held for approx. 3 s, the INFO

TIME parameter appears.

With this parameter, the time it takes for automatic return to the

basic display can be specified.

OFF No return. The last selected information display

continuously remains in the basic display until the

next change.

1 ... 10 min Automatic return from the information level after the

specified time (in 0.5 minute increments).

OFF

5.1.2.7.1 Temperature displays

Information Display Condition Remarks

Outside

temperature (1)

Determined

value/Current

value

Outside

temperature (1)

Min./max. value

(0:00 to 24:00

hours)

Outside sensor

connected and no fault

message

Outside

temperature (2)

Determined

value/Current

value

Variable input

configured as OS2

Connection OS2 to variable

input VI1, VI2 or VI3

Outside

temperature (2)

Min./max. value

(0:00 to 24:00

hours)

OS2 connected, no fault

message

EM-SET (energy

management

setpoint)

"EM-SET" Highest hot-water setpoint

and highest heating circuit

setpoint in the system

Heat generator

temperature (1)

Setpoint/Actual

value

Heat generator

specified

Code 1 only appears if BS2

is present

Heat generator

temperature (2)

Setpoint/Actual

value

Variable input

configured as BS2

Connection BS2 to variable

input VI1, VI2 or VI3

Setting time for

automatic return

Setting range

Factory setting

Page 38

Operation SDC / DHC

38 EN2H-0221GE51 R0808

Information Display Condition Remarks

Return

temperature

Setpoint/Actual

value

Return sensor

connected and one of

the functions for return

increase is active

Connection of return sensor

to associated variable input

1 or 2, VI can no longer be

called up

Flow sensor of

district heating

valve VF1

Setpoint/Actual

value

With district heating

controllers

Return sensor of

district heating

valve VFB

Setpoint/Actual

value

With district heating

controllers

External heat

generator disable

Disabled mode

ON/OFF

External heat generator

disable (VI1-VI3)

specified

External contact to variable

input VI1, VI2 or VI3

Flue gas

temperature

Limit signal

value/Actual

value

Variable input

configured as AGF

Connection only to variable

input VI1

Water heater

temperature (1)

Setpoint/Actual

value

If hot-water circuit is

present

Code 1 only appears if SF2

is present

Water heater

temperature (2)

Setpoint/Actual

value

Variable input

configured as SF2

Connection to variable input

VI1, VI2 or VI3

Water heater

temperature

controller

Load condition

ON/OFF

Thermostat mode Thermostat instead of sensor

(SF1 only)

Demand via

switching contact

(VI1)

Demand

ON/OFF

VI configured as

demand contact

External contact to variable

input VI1, VI2 or VI3

Demand via

switching contact

(VI2)

Demand

ON/OFF

VI configured as

demand contact

External contact to variable

input VI1, VI2 or VI3

Demand via

switching contact

(VI3)

Demand

ON/OFF

VI configured as

demand contact

External contact to variable

input VI1, VI2 or VI3

Mixed heating

circuit 1 flow

temperature

Setpoint/Actual

value

Mixed heating circuit 1

specified

Mixed heating

circuit 1 return

temperature

Actual value Return temperature with

return maximum limit

Page 39

SDC / DHC Operation

EN2H-0221GE51 R0808 39

Information Display Condition Remarks

Mixed heating

circuit 2 flow

temperature

Setpoint/Actual

value

Mixed heating circuit 2

specified

Mixed heating

circuit 2 return

temperature

Actual value Return temperature with

return maximum limit

Direct heating

circuit room

temperature

Setpoint/Actual

value

Direct heating circuit

specified

Setpoint inquiry without room

temperature sensing:

Current room setpoint of

direct heating circuit

Mixed heating

circuit 1 room

temperature

Setpoint/Actual

value

Mixed heating circuit 1

specified

Setpoint inquiry without room

temperature sensing:

Current room setpoint of

mixer heating circuit 1

Mixed heating

circuit 2 room

temperature

Setpoint/Actual

value

Mixed heating circuit 2

specified

Setpoint inquiry without room

temperature sensing:

Current room setpoint of

mixed heating circuit 2

Direct heating

circuit thermostat

function

DC

THERMOSTAT

Thermostat function

specified

OFF = temperature limit

exceeded

Mixed heating

circuit 1

thermostat

function

MC1

THERMOSTAT

Thermostat function

specified

OFF = temperature limit

exceeded

Mixed heating

circuit 2

thermostat

function

MC2

THERMOSTAT

Thermostat function

specified

OFF = temperature limit

exceeded

Solid fuel boiler

temperature

Actual value VO1/2 configured as

solid fuel loading pump

Connection of FSKF to

associated variable input 1

or 2, VI can no longer be

called up

Solid fuel boiler

buffer

temperature

Actual value Solid fuel loading pump at

variable output, corresponds

to KSPF or FPF, depending

on configuration

Page 40

Operation SDC / DHC

40 EN2H-0221GE51 R0808

Information Display Condition Remarks

Buffer tank

temperature at

top

Setpoint/Actual

value

VO1/2 configured as

buffer tank loading

pump

Connection of PF1 to

associated variable input 1

or 2, VI can no longer be

called up

Buffer tank

temperature at

bottom

Setpoint/Actual

value

VO1/2 configured as

buffer tank loading

pump

Connection of PF2 to

variable input VI1, VI2 or VI3

Solar collector

flow temperature

Actual value VO1/2 configured as

solar tank loading pump

Special sensor

Solar tank

temperature

Actual value VO1/2 configured as

solar tank loading pump

Solar collector

return

temperature

Actual value VO1/2 configured as

solar tank loading pump

Connection of KRLF to

variable input VI1, VI2 or VI3

Solar tank switchover temperature

Actual value Solar loading valve activated

5.1.2.7.2 Operating states

An operating state inquiry occurs after the information menu is

called up by turning the input button anti-clockwise. The following

displays appear only under the specified conditions and may not

be available (depends on device version).

Information Display Condition Remarks

Direct heating

circuit operating

status

Direct heating circuit

specified

Heating program: Holiday,

Absent Til, Party Til, Auto,

Summer, Heating, Red.

Heating, Standby

Switching time program:

P1 (P2, P3) control mode:

Day, RED, ECO

Mixed heating

circuit 1 operating

status

Mixed heating circuit 1

specified

Heating program: Holiday,

Absent Til, Party Til, Auto,

Summer, Heating, Red.

Heating, Standby

Switching time program:

P1 (P2, P3) control mode:

Day, RED, ECO

Page 41

SDC / DHC Operation

EN2H-0221GE51 R0808 41

Information Display Condition Remarks

MC1 actuator

operating status

Mixed heating circuit 1

specified

Mixed heating circuit 1

opens, closes or does not

move

Mixed heating

circuit 2 operating

status

Mixed heating circuit 2

specified

Heating program: Holiday,

Absent Til, Party Til, Auto,

Summer, Heating, Red.

Heating, Standby

Switching time program:

P1 (P2, P3) control mode:

Day, RED, ECO

MC2 actuator

operating status

Mixed heating circuit 2

specified

Mixed heating circuit 2

opens, closes or does not

move

District heating

valve operating

status

District heating valve

opens, closes or does

not move

With district heating

controllers

Heat generator

operating status

(st. 1)

Heat generator specified Information on the switching

state of the multi-stage heat

generator

Heat generator

operating status

(st. 2)

Multi-stage heat

generator specified

Information on the switching

state of the second stage of

the heat generator

Operating status

of modulating

heat generator

Modulating burner

specified

If a single-stage modulating

heat generator is set,

display of actual value and

setpoint occurs in %

Hot-water circuit

operating status

Hot-water circuit

specified

Hot-water program: Holiday,

Absent Til, Party Til, Auto,

Summer, Heating, Red.

Heating, Standby

Switching time program:

P1 (P2, P3) control mode:

Day, RED, ECO

Page 42

Operation SDC / DHC

42 EN2H-0221GE51 R0808

Information Display Condition Remarks

Function and

status of direct

heating circuit

pump

Outputs specified

based on function

Solar (SOP), circulation

(CIR), electric heating rod

(ELH), feeder (CHP), boiler

circuit (KKP1, KKP2), fault

message (SMA), return

(RLP), buffer (PLP), solid

fuel (FSP), heating circuit

(HKP), constant (KP), timer

(CLOCK)

Function and

status of variable

output 1

Outputs specified

based on function

Solar (SOP), circulation

(CIR), electric heating rod

(ELH), feeder (CHP), boiler

circuit (KKP1, KKP2), fault

message (SMA), return

(RLP), buffer (PLP), solid

fuel (FSP), heating circuit

(HKP), constant (KP), timer

(CLOCK)

Function and

status of variable

output 2

Outputs specified

based on function

Solar (SOP), circulation

(CIR), electric heating rod

(ELH), feeder (CHP), boiler

circuit (KKP1, KKP2), fault

message (SMA), return

(RLP), buffer (PLP), solid

fuel (FSP), heating circuit

(HKP), constant (KP), timer

(CLOCK)

District heating

valve volume flow

Heat generator specified With district heating

controllers

District heating

valve capacity

Heat generator specified With district heating

controllers

Heat generator

(1) start-ups

Heat generator specified Information on the number

of heat generator switch-ons

(burner start-ups) of the

multi-stage heat generator.

Operating hours

of heat generator

(1)

Heat generator specified Information on the number

of heat generator operating

hours of the multi-stage heat

generator.

Page 43

SDC / DHC Operation

EN2H-0221GE51 R0808 43

Information Display Condition Remarks

Heat generator

switch-ons stage

2

Multi-stage heat

generator specified

Information on the number

of heat generator switch-ons

(burner start-ups) of the

second stage.

Heat generator

operating hours

stage 2

Multi-stage heat

generator specified

Information on the number

of heat generator operating

hours of the second stage.

Test temperature

for measurement

purposes

KVT sensor connected

and VI configured.

Controller-independent test

temperature, sensor

connection to variable input

VI1, VI2 or VI3

Operating status

of ext. switching

modem

VI configured as

switching modem

Control modes based on the

switching state of the

modem: AUTO (automatic)

STBY (standby), HEAT

(continuous heating), RED

(continuously reduced).

Solar heating

capacity

VO1/2 configured as

solar tank loading pump

Solar loading pump at

variable output

Solar heat

balance

VO1/2 configured as

solar tank loading pump

Solar loading pump at

variable output

Switch-ons

Solar loading

pump

VO1/2 configured as

solar tank loading pump

Solar loading pump at

variable output

Operating hours

Solar loading

pump

VO1/2 configured as

solar tank loading pump

Solar loading pump at

variable output

Page 44

Operation SDC / DHC

44 EN2H-0221GE51 R0808

5.1.2.8 "Manual mode" / "Emission measurement" button

5.1.2.8.1 Manual mode

If this button is pressed and held longer than 5 s in the basic

display, the controller is switched to manual mode. In this

operating mode, the required heat generator temperature is

specified manually with the input button î according to the

respective heating need.

A controller set to manual mode has no effect in heat circuit

expansion.

The heat generator setpoint is set between the minimum and

maximum heat generator temperatures and appears flashing at

the bottom left-hand side. The current heat generator temperature

appears statically on the right-hand side in the basic display. The

set switching differential corresponds to the value of automatic

control and is symmetrical to the set value.

Controller malfunctions (emergency operation), errors

The maximum heat generator temperature limit is paramount to

the heat generator switching differential and stops the heat

generator in case of exceedance.

With control devices operated purely as a heating circuit

expansion, the setting of the temperature has no effect.

The last value to which the control device adjusted the heat

generator temperature appears as a recommendation.

Press button or button, to return to the last selected

operating mode.

C

C

Application

NOTE

Cancellation

Page 45

SDC / DHC Operation

EN2H-0221GE51 R0808 45

5.1.2.8.2 Emission measurement (not with district heating controllers)

ATTENTION

Emission measurements may only be carried out by the

chimney sweep.

Pressing the button controls the heat generator for a duration

of 20 min based on the set maximum temperature limit. The

remaining time is displayed and counted down.

With two-stage heat generators, both stages are in operation

(measurement at nominal output).

The heat generator is adjusted to the maximum heat generator

temperature. All heating circuits and the hot-water production

adjust their setpoint to the respective maximum temperature.

ATTENTION

There is a danger of scalding by hot water, as the hot-water

temperature can exceed the set setpoint temperature.

Emission measurement by the chimney sweep.

Emission measurement can be cancelled at any time with the

or button.

Function

Application

Cancellation

Page 46

Operation SDC / DHC

46 EN2H-0221GE51 R0808

5.1.2.9 Access to the technician / OEM area

Entering a technician or OEM code enables additional setting

options in the parameter menu. The technician code is: 1234.

For access to the OEM area, please ask your field-service contact

partner.

Procedure:

► Press the and buttons simultaneously. The first

number of the 4-digit code flashes.

► Set the first code number by turning the input button.

► Press the input button. The second number flashes.

► Enter all remaining code numbers as described in Steps 2 and

3. After entering the last code number, the controller is

enabled for the respective area (technician or OEM).

► Press and hold the rotary button longer than 3 seconds. You

reach the menu-selection level and can enter / modify

parameters.

Pressing the button jumps back to the previous selection.

Pressing the button, pressing and holding the input button

longer than 3 seconds or waiting until the set info time expires

causes a jump back to the basic display.

Page 47

SDC / DHC Operation

EN2H-0221GE51 R0808 47

5.1.2.10 Heating curve

Determines the heating curve for the heating circuits.

The heating curve describes the relationship of the flow

temperature change to the outside temperature change. With a

larger heating surface, such as with floor heaters, the heating

curve has a less extreme slope than with a smaller heating

surface (e.g. radiators).

The set value refers to the lowest outside temperature used for

heat demand calculation.

ATTENTION

This parameter must be set by the technician and should no

longer be changed.

► Press and hold input button î for 3 s.

► Turn the input button î to select the desired heating circuit (HC,

MC-1 or MC-2) and confirm it by pressing the input button î.

The design temperature (system) appears at the bottom righthand side of the display.

► Press input button î.

The slope of the heating curve appears at the bottom left-hand

side of the display.

► Set the flashing heating curve value by turning the input button

î (design temperature also flashes and is changed

automatically depending on the slope of the heating curve).

► Confirm by pressing the input button î.

Alternative: Automatic acceptance of the value after the set

information time (see 5.1.2.7 "System information" button, pg. 35).

► Press

button to return to the basic display.

0,2 ... 3,5

C

Setting

Setting range

Page 48

Operation SDC / DHC

48 EN2H-0221GE51 R0808

Direct heating circuit (HC) = 1,5

Mixed heating circuit 1

(MC-1) = 1

Mixed heating circuit 2

(MC-2) = 1

x

y

a

x Boiler / flow temperature [°C]

y Outside temperature [°C]

a T

room

[°C]

5.2 Menu-selection level

The control device contains a menu-selection level that is

structured differently, depending on the respective device version.

► Press and hold input button î for approx. 3 seconds.

The menu selection always begins with the TIME – DATE

menu.

► Turn input button î to select additional menus.

► Press input button

î to confirm the selected menu.

Factory setting

Access

Page 49

SDC / DHC Operation

EN2H-0221GE51 R0808 49

9

Variable input 2

Climate zone

Temperature offset

of heat generator

during hot-water

circuit loading

Room thermostat

function

Room thermostat

function

Burner switching

differential II

Starting point of

flexible district

heating return

temperature

Heat balance

Buffer discharge

protection

Quick hot-water

connection

Variable output 2

test

Fault message 9

Sensor of variable

input 2

8

Variable input 1

Demand contact

module for variable

input 3

Tank discharge

protection

Room frost

protection limit

Room frost

protection limit

Burner switching

differential I

Max. return

temperature

setpoint

Priority parallel

switch-over

Buffer start-up

protection

Switch-over of

base load with

grouping

Variable output 1

test

Fault message 8

Sensor of variable

input 1

7

Variable output 2

Demand contact

module for variable

input 2

Hot-water circuit

control mode

Heating limit

Heating limit

Minimum burner

runtime

Runtime of district

heating valve 2

Heat generator

cycle disable

Follow-up switch-

off differential

Peak-load stage

Tank loading pump

test

Fault message 7

Buffer sensor of

collector

6

Variable output 1

Demand contact

module for variable

input 1

Max. temperature

limit for hot-water

circuit

Sensor control

mode

Runtime of district

heating valve 1

Control mode

Switch-on

differential

extension

Guidance stage

Mixer motor 2 test

Fault message 6

Collector sensor

5

Direct heating

circuit pump output

System frost

protection

Transducer for hot-

water circuit

Limit mode of

maximum limit

Adjustment time

Buffer maximum

temperature limit

Heat generator

cycle disable

Forced discharge

Stage reversal

Mixed heating

circuit pump 2 test

Fault message 5

Mixed heating

circuit 2 flow

sensor

4

Switch-over

Mixed heating

circuit 2 output

Summer/Heat limit

Legionella

protection

temperature

Room factor

Room factor

Maximum

temperature limit

Secondary flow

boost

Collector

maximum

temperature

Switch-off

differential

Buffer switching