Page 1

DeltaNet FS90 Operating Instructions

OPERATING INSTRUCTIONS

SYSTEM OPERATION

A normally functioning DeltaNet Fire & Security System is indicated

by the green RUN and green POWER LEDs on the powered Control

Board. If a Communication Board is installed, the Communication

Board red TRANSMIT and RECEIVE LEDs blink as data is

communicated.

Power Supply Supervision

The power supply circuits for the DeltaNet FS90 Fire & Security

system are monitored for Integrity. Trouble conditions in these circuits

are indicated by Low Battery (yellow) and Power (green) LEDs on the

CA control board. In the normal, supervisory, condition, the yellow

Low Battery LED is off and the green Power LED is on. A trouble

condition in the power supply circuits is indicated when either the

green Power LED is blinking or the yellow Low Battery LED is on. If

this occurs, contact a service technician to determine the nature of the

trouble condition by removing the batteries from the system and

testing their condition. With the batteries out of the system, proper

functioning of the power supply, battery changer and battery

supervision circuits should be verified. Any faulty component must be

replaced.

Modes of Operation

The DeltaNet Fire & Security System can operate independently

(Stand-Alone Mode) or as a Data Gathering Panel (DGP) in a higherorder system (DGP Mode). DGP Mode is in effect when a

Communication Board is plugged into the Motherboard and active

communication takes place. If communication fails, the system

operates in Stand-Alone Mode.

LJ Communication/Display Board Switch

When the LJ Board MULTIPLE ALARM-TROUBLE LED is on,

multiple abnormal conditions (alarm, trouble, prealarm) exist on AE

Board loops. The LJ Board displays one address at a time, beginning

automatically with the address of the highest-priority device.

An address remains displayed until a new, higher priority device goes

into an abnormal condition or until the PREVIOUS/NEXT switch is

pushed. Use the PREVIOUS/NEXT switch to display other addresses

as follows.

PRINTER/DISPLAY ASSEMBLY AND LH INTERFACE BOARD

OPERATING INSTRUCTIONS

The two front Printer/Display Assembly switches are:

— Printer On-Line Switch with integral LED.

— Paper Advance Switch.

LH Interface Board switches are:

— ACK—UP to acknowledge indicated point in LCD display.

— ALL PT/ALM SUM—UP to request All Point Log; DOWN to

request Alarm Summary Log.

— PREVIOUS/NEXT—UP to revert LCD display to former point;

DOWN to advance LCD display to subsequent point.

FRONT PANEL SWITCHES/LEDS

Control Board Switches

ACKNOWLEDGE

— Pushing the ACKNOWLEDGE switch silences the local audible

and changes blinking LEDs to ON. The ACKNOWLEDGE switch

does not affect indicating zone outputs and does not silence alarm

signals. Pushing the ACKNOWLEDGE switch acknowledges all

alarms present in the panel.

— If the panel is a DGP, the ACKNOWLEDGE switch does not

function when the DGP is communicating with the higher-order

system. The ACKNOWLEDGE switch becomes functional when

communication is broken.

SILENCE

Pushing the SILENCE switch does the following:

— Silences devices connected to indicating zones.

— Silences devices connected to Control Modules with indicating

characteristic set.

— Silences the local audible.

— Turns on the Control Board SILENCE LED.

— Changes blinking LEDs to on.

RESET

Pushing the RESET switch removes power to all initiating zones for

fifteen seconds and sends out a fifteen-second reset signal that

returns all input-zone status indicators to normal. After reset, zones

that return to alarm or trouble are annunciated as new alarms or

troubles.

PANEL TEST

Performing a Panel Test reveals whether all boards are controlled by

the panel microprocessor. Pushing the PANEL TEST switch turns on

all LEDs, except Communication Board LEDs and turns on the local

audible. A Panel Test does not interrupt alarms or troubles reporting in

the system.

Pushing the PANEL TEST switch turns on all LJ Communication/

Display Board LEDs and causes the LJ Board to display the address

8888.

Pushing the MANUAL EVACUATION switch does the following:

— Turns on all indicating zones.

— Turns on all AE Board Control Modules that have the indicating

characteristic set during system setup.

— Causes a common alarm indication.

— Causes the local audible to pulse.

Manual evacuation is terminated by pushing either the SILENCE

or the RESET switch.

Honeywell DeltaNet FS90 Fire & Security System

Control Unit

LOCAL SERVICE REPRESENTATIVE

Name:

Address:

Phone:

Refer to Installation Instructions: Honeywell form no. 95-7421-3, issued 10-2007

74-5069

Page 2

DELTANET FS90 OPERATING INSTRUCTIONS

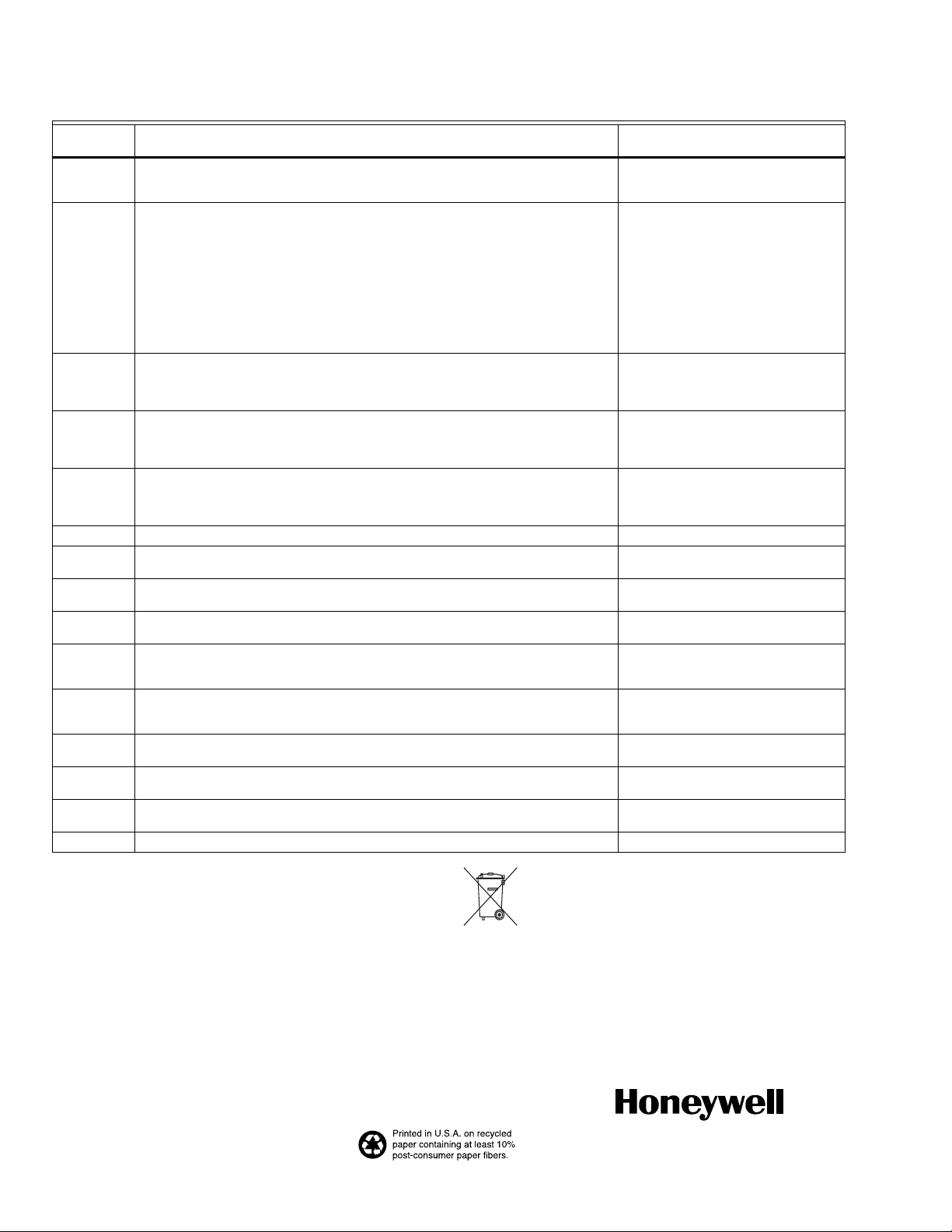

Table 1. CA Board Switch and LED Functions.

Switch/

LED Normal Operation Setup Mode

MicroProcessor

Reset Switch

Acknowledge

/Silence

Switch

Reset Switch Resets FS90. The system removes power to all initiating zones for 15 seconds,

Panel Test

Switch

Manual

Evacuation

Switch

Setup Switch Enters Setup Mode. Exits Setup Mode.

Alarm LED Indicates a common alarm in the system via blinking LED. Indicates the system is ready to enter

Trouble LED Indicates a common trouble via a blinking yellow LED. Indicates the system is ready to enter

Silence LED Indicates the Silence switch has been activated to silence the outputs. Indicates the system is ready to enter

Low Battery

LED

Ground Fault

LED

Isolate LED Indicates one of the Disconnect switches on a module is activated or a point has been

Power LED Indicates power is on. Indicates system is ready to enter

Run LED Indicates system is ready to operate. Indicates system is ready to enter input

Setup LED Off On to show system is in Setup Mode.

Resets microprocessor. Exits Setup Mode. Any changes made

Acknowledges troubles and alarms or silences outputs as follows:

Acknowledge position (UP): The local audible silences and blinking LEDs change to

steady on. The Acknowledge/Silence switch does not affect indicating zone outputs or

silence alarm signals.

NOTE: Zones set up as central are acknowledged when the new status reports to

the central processor. FS90 acknowledgement of these zones is not required

Silence position (DOWN): The indicating zone devices silence, the FS90 local audible

silences, the CA Board Silence LED turns on and blinking LEDs change to steady on.

activates the CA Board reset out signal for 15 seconds and returns all input zone status

indicators and their associated outputs to normal. After the 15-second reset time any

zone(s) remaining in alarm or trouble annunciates as a new alarm or trouble.

Initiates a test of all LEDs except the communication board transmit and receive LEDs.

The test turns on the LEDs and sounds the local audible. The test indicates that all

function boards are operational and controlled by the CA Board microprocessor. The

panel test does not affect alarm or trouble reporting in the system.

Initiates a manual evacuation signal. All indicating zones turn on and a common alarm

indication and pulsing local audible occur (if audible is selected and the system is in the

stand-alone mode). Toggle the Acknowledge/Silence switch to silence the output and

then toggle the Reset switch to return the system to normal.

Indicates a low battery condition if system power supply is off. If a Battery Supervision

Module is installed, this LED indicates low battery or absence of batteries at all times.

Indicates a ground fault in the system. Indicates various time menus when

isolated or locked out.

unless communication with the central fails and stand-alone mode is in effect.

NOTE: Operators may also silence zones set up as central from the central

processor.

during Setup Mode will be lost if this

switch is activated.

Advances pointer to next function.

Selects or deselects characteristics.

Enter characteristics into date file and

moves pointer.

Not used.

group address menu.

code menu.

the special options menu.

Indicates various time menus when

used with ground fault and disconnect

LEDs.

used with low battery and disconnect

LEDs.

Indicates various time menus when

used with low battery and ground fault.

output menu.

menu.

MAINTENANCE PROCEDURES

The system must be maintained in accordance with the system

documentation and procedures and practices contained in applicable

NFPA and UL standards, including NFPA 70, 72, 90A, 92A and 92B.

DeltaNet FS90 Systems Maintenance and Repair Manual for further

details, including testing, fuse replacement and replacement parts.

For service, contact your local Honeywell Automation & Control

Solutions office as listed in the phone book, or contact a regional

office as shown at the end of this document.

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Toronto, Ontario M1V 4Z9

www.honeywell.com/buildingsolutions

® U.S. Registered Trademark

© 2007 Honeywell International Inc.

74-5069 J.I. 11-07

Directive 2002/96/EC of the European parliament and the Council of

27 January 2003 on Waste Electrical and Electronic Equipment

(WEEE).

This product may contain small amounts of chemicals

and substances that may be banned from disposal in

landfills. At the end of the useful life of this product, it is

the owners’ responsibility to safely decommission the

product and arrange for disposal in accordance with all

applicable environmental laws and regulations, including

Loading...

Loading...