Page 1

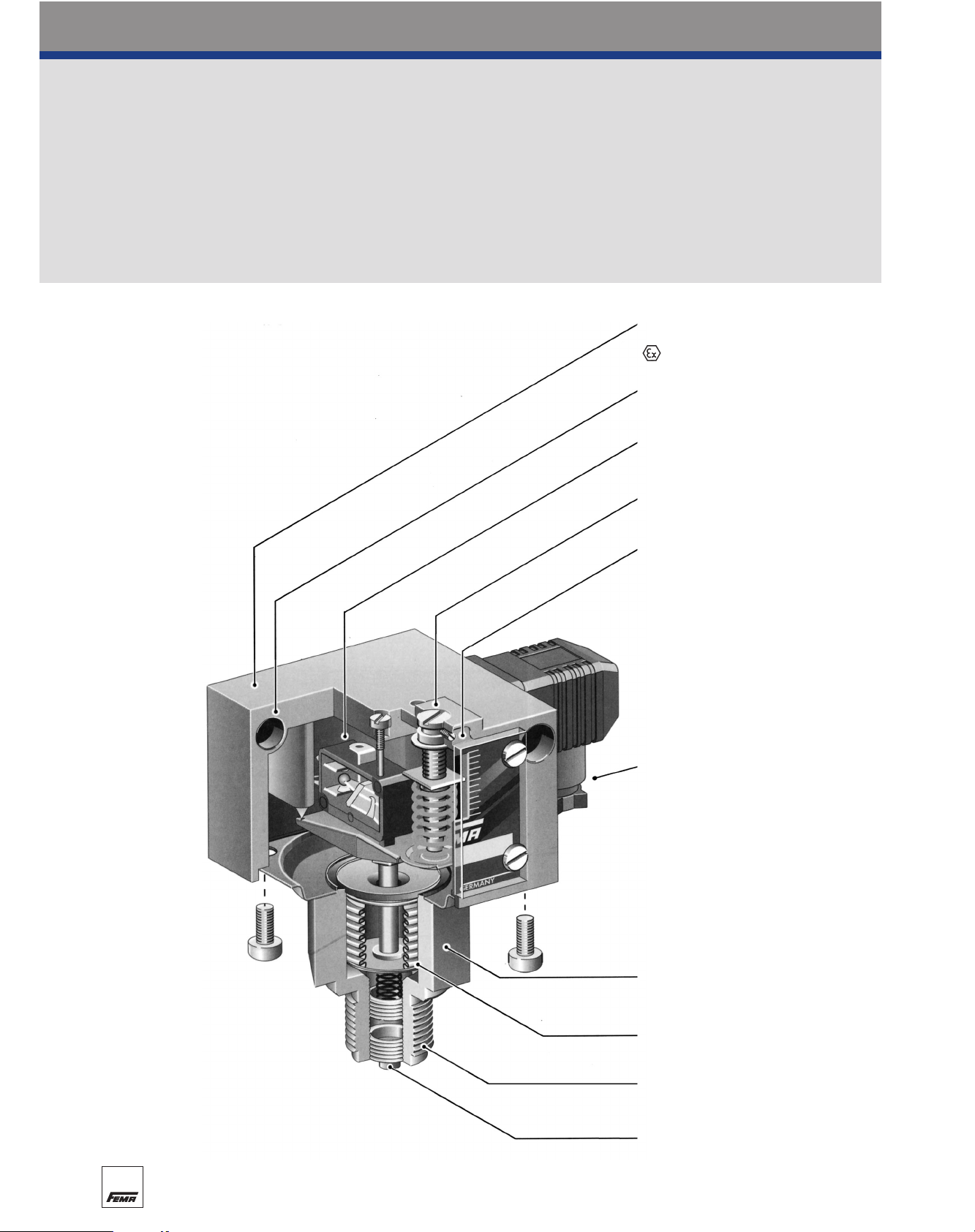

Pressure switches

Mechanical pressure switches

Mechanical pressure switches

Technical features / Advantages

Wall mounting

or directly on the pressure line

Switching element (microswitch)

Lead sealable setpoint adjustment

Setting spindle locking element

Terminal connection

or plug connection to

DIN 43 650 Form A

Stainless steel sensor housing

Stainless steel bellows

with internal stop

Pressure connection

G 1/2“ external

G 1/4” internal

Centring pin

18

Diecast aluminium housing

IP 54 or IP 65

version also available

Page 2

Pressure switches

Mechanical pressure switches

Pressure switches

General description

Operating mode

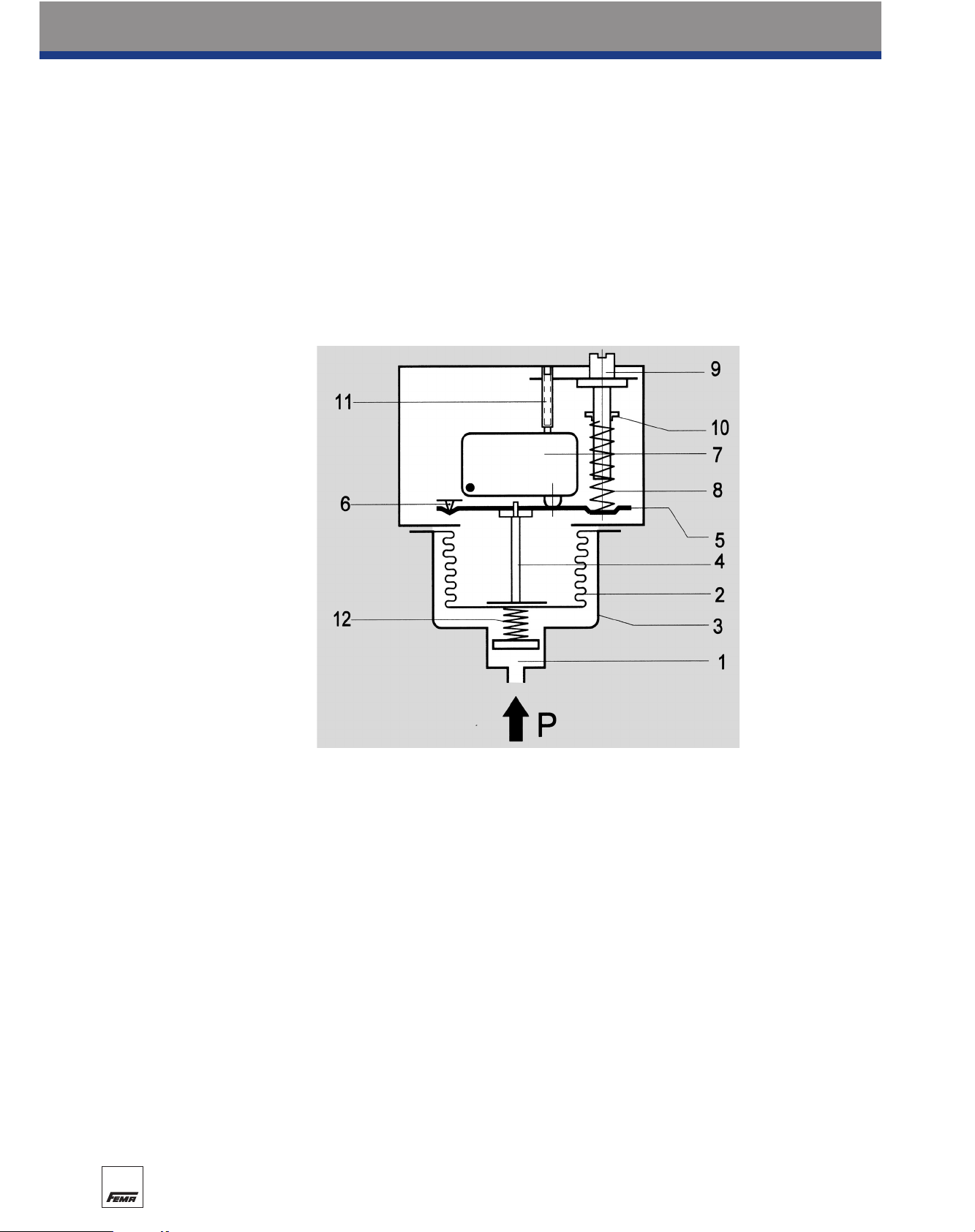

The pressure occurring in the sensor housing (1) acts on the measuring bellows (2). Changes in pressure lead to movements of the measuring bellows (2) which are transmitted via a thrust pin (4) to the

connecting bridge (5). The connecting bridge is frictionlessly mounted on hardened points (6). When the

pressure rises the connecting bridge (5) moves upwards and operates the microswitch (7). A counterforce is provided by the spring (8) whose pretension can be modified by the adjusting screw (9)

(switching point adjustment). Turning the setting spindle (9) moves the running nut (10) and modifies

the pretension of the spring (8). The screw (11) is used to calibrate the microswitch in the factory. The

counter-pressure spring (12) ensures stable switching behaviour, even at low setting values.

Pressure sensors

Apart from a few exceptions in the low-pressure range, all pressure sensors have measuring bellows,

some made of copper alloy, but the majority of high-quality stainless steel. Measured on the basis of

permitted values, the measuring bellows are exposed to a minimal load and perform only a small lifting

movement. This results in a long service life with little switching point drift and high operating reliability.

Furthermore, the stroke of the bellows is limited by an internal stop so that the forces resulting from

the overpressure cannot be transmitted to the switching device. The parts of the sensor in contact

with the medium are welded together without filler metals. The sensors contain no seals. Copper bellows, which are used only for low pressure ranges, are soldered to the sensor housing. The sensor

housing and all parts of the sensor in contact with the medium can also be made entirely from stainless steel 1.4571 (DNS series). Precise material data can be found in the individual data sheets.

Pressure connection

The pressure connection on all pressure switches is executed in accordance with DIN 16288 (pressure

gauge connection G 1/2A). If desired, the connection can also be made with a G 1/4 internal thread

according to ISO 228 Part 1. Maximum screw-in depth on the G 1/4 internal thread = 9 mm.

Centring pin

In the case of connection to the G 1/2 external thread with seal in the thread (i.e. without the usual

sheet gasket on the pressure gauge connection), the accompanying centring pin is not needed.

Differential pressure switches have 2 pressure connections (max. and min.) each of which are connected to a G 1/4 internal thread.

1 = Pressure connection

2 = Measuring bellows

3 = Sensor housing

4 = Thrust pin

5 = Connecting bridge

6 = Pivot points

7 = Microswitch or other switch-

ing elements

8 = Setting spring

9 = Setting spindle (switching

point adjustment)

10 = Running nut (switching point

indicator)

11 = Microswitch calibration

screw (factory calibration)

12 = Counter pressure spring

26

Page 3

General technical data

Diecast aluminium GD AI Si 12 Diecast aluminium GD AI Si 12

G 1/2 external thread (pressure gauge connection) and G 1/4 internal thread

G 1/4 internal thread for DDCM differential pressure switches

Floating changeover contact. Floating changeover contact.

With rising pressure switching With rising pressure switching

single-pole from 3-1 to 3-2. single-pole from 3-1 to 3-2.

8 A at 250 VAC 3 A at 250 VAC

5 A at 250 VAC inductive 2 A at 250 VAC inductive

8 A at 24 VDC 3 A at 24 VDC

0.3 A at 250 VDC 0.03 A at 250 VDC

min. 10 mA, 12 VDC min. 2 mA, 24 V DC

preferably vertical vertical

(see technical data sheet)

IP 54; (for terminal connection …300 IP 65) IP 65

– EEx de IIC T6 tested to EN

50014/50018/50019 (CENELEC)

– PTB 02 ATEX 1121

Plug connection to DIN 43 650 (200 series) Terminal connection

or terminal connection (300 series)

PG 11 / for terminal connection M 16 x 1.5 M 16 x 1.5

See data sheets –15 to +60°C

Adjustable via spindle. On switching device Adjustable via spindle after the

300 the terminal box cover must be removed terminal box lid is removed

Adjustable or not adjustable Not adjustable

(see Product Summary)

Only possible on plug connection housing 200

Max. 70°C, briefly 85°C Max. 60°C

Higher medium temperatures are possible provided the above limits for the switching device are

ensured by suitable measures (e.g. siphon).

All pressure switches can operate under vacuum. This will not damage the device.

< 1% of the working range (for pressure ranges > 1 bar)

No significant deviations up to 4 g.

With sinusoidal pressure application and room temperature, 10 x 106 switching cycles.

The expected life depends to a very large extent on the type of pressure application, therefore this figure can serve only as a rough estimate. With pulsating pressure or pressure impacts in hydraulic systems, pressure surge reduction is recommended.

Overvoltage category III, contamination class 3, reference surge voltage 4000 V.

Conformity to DIN VDE 0110 (01.89) is confirmed.

The parts of all pressure switches with sensors made from steel or stainless steel are oil and greasefree. The sensors are hermetically encapsulated. They contain no seals. (See also additional function

ZF 1979 Special Packing)

Switch housing

Pressure connection

Switching function and connection diagram

(applies only to version with

microswitch)

Switching capacity

(applies only to version with

microswitch)

Mounting position

Degree of protection (in vertical

position)

Ex degree of protection

PTB approval Electrical connection

Cable entry

Ambient temperature

Switching point

Switching differential

Lead seal

Medium temperature

Vacuum

Repetition accuracy of switching points

Vibration strength

Mechanical life

Isolation values

Oil and grease-free

Normal version

Plug connection Terminal connection

…200 …300

version

…700

with microswitches of the DCM, VCM, DNM, DNS and DDC series.

The technical data of type-tested units may differ slightly.

(please refer to type sheet)

Pressure switches

Mechanical pressure switches

27

Page 4

Pressure switches

Mechanical pressure switches

General information about

explosion protection

Basic principle

The basic principle of explosion protection is that:

a) combustible materials (gas, vapour, mist or dust) in dangerous quantities

b) air (or oxygen)

c) ignition sources

must not occur in the same place.

The permanent or temporary occurrence of explosive mixtures as per a) and b) is often unavoidable,

therefore when operating electrical installations care must be taken to ensure that no ignition sources

can occur.

With this in mind, the CENELEC technical committee has adopted the following European standards

which are recognized in all EU member states.

· General requirements EN 50 014 · Pressure resistant encapsulation “d” EN 50 018

· Oil encapsulation “o” EN 50 015 · Increased safety “e” EN 50 019

· Overpressure encapsulation “p” EN 50 016 · Intrinsic safety “i” EN 50 020

· Sand encapsulation “q” EN 50 017 · Cast encapsulation “m” EN 50 028

The guidelines relevant to FEMA products – besides the “General Requirements EN 50 014” – are

“Pressure resistant encapsulation d” and “Intrinsic safety i”.

In addition, all explosion protection guidelines issued up to the present time have been combined into

a single European Ex-Protection Directive 94/9EC. The aim of this new harmonized directive is to bring

the explosion protection regulations of European member states into line with one another and eliminate barriers to trade between partner states. The new Directive 94/9EC (ATEX 100a), which came

into force on 1 July 2003, replaces all previous directives.

All FEMA ex-pressure switches and ex-thermostats meet the requirements of the new European ExProtection Directive 94/9EC (ATEX 100a).

Pressure resistant encapsulation “d”

Switching elements and other electrical function units capable of igniting an explosive mixture are cast

in a housing capable of withstanding the explosive pressure caused by an explosion indoors and preventing transmission to the surrounding atmosphere.

Intrinsic safety “i”

The equipment used in the area at risk of explosion contains only intrinsically safe electric circuits. An

electric circuit is only intrinsically safe if the quantity of energy is so small that no spark or thermal

effect can occur.

The term “simple electrical equipment”

In view of the use of simple microswitches without additional capacitance or inductance generating

components, our pressure switches and thermostats designed for protection type Ex-i fall in the category of “simple electrical equipment”. These are not subject to testing or certification requirements

within the meaning of Directive 94/9EC. The units may only be used in conjunction with ATEX-tested

isolating amplifiers in areas at risk of explosion. We equip all units which are explicitly designed for

such use with microswitches having gold contacts, a grounding screw and — for ease of identification

— a blue cable entry.

EEx-d

EEx-i

21

Page 5

Pressure switches

Mechanical pressure switches

General information about

explosion protection

Zone classification

Explosion risk areas are grouped into zones according to the likelihood of a dangerous explosive

atmosphere according to EN 1127-1 occurring.

When assessing the explosion hazard, i.e. when identifying explosion risk areas, the “Guidelines for

the Avoidance of Danger due to Explosive Atmospheres with Examples (ExRL)” of the German

Insurance Association for the Chemical Industry [Berufsgenossenschaft Chemie] must be taken into

account.

If the situation concerns a special case or if doubts exist as to the definition of explosion risk areas, the

matter shall be decided by the supervisory authorities (Trade Supervisory Office [Gewerbeaufsichtsamt], where applicable with the assistance of the Insurance Association or the Technical Control

Boards [Technische Überwachungsvereine]).

In Zones 0 (20) and 1 (21), only electrical equipment for which a type test certificate has been issued

by a recognized testing agency may be used. In Zone 0 (20), however, only equipment expressly

authorized for that zone may be used. Equipment approved for use in Zones 0 (20) and 1 (21) may

also be used in Zone 2 (22). Under the new European Directive 94/9 EC (ATEX 100a), a distinction is

made between gas atmospheres and dust atmospheres. This results in the following zone classifi-

cations:

Zone 0 Zone 0 (gas) is a place in which a dangerous explosive

atmosphere is present continuously or for long periods. This

normally includes only the interior of containers or the interior

of apparatus (evaporators, reaction vessels etc.), if the conditions of Zone 0 are fulfilled. Continuous danger > 1000

hours/year.

Zone 1 occasionally Zone 1 (gas) is a place in which a dangerous explosive

atmosphere can be expected to occur occasionally in normal

operation. This may include the immediate vicinity of Zone 0.

Occasional danger = 10 to 1000 hours/year.

Zone 2 Zone 2 (gas) is a place in which a dangerous explosive

atmosphere can be expected to occur only rarely and then

only for short periods. This may include areas surrounding

Zones 0 and/or 1. Danger only under abnormal operating conditions < 10 hours/year.

Zone 20 Zone 20 (dust) is a place in which a dangerous explosive

atmosphere in the form of a cloud of dust in air is present

continuously or for long periods, and in which dust deposits of

unknown or excessive thickness may be formed. Dust

deposits on their own do not form a Zone 20. Continuous

danger > 1000 hours/year.

Zone 21 occasionally Zone 21 (dust) is a place in which a dangerous explosive

atmosphere in the form of a cloud of dust in air may occasionally occur in normal operation, and in which deposits or layers

of inflammable dust may generally be present. This may also

include the immediate vicinity of Zone 20. Occasional danger

= 10 to 1000 hours/year.

Zone 22 Zone 22 (dust ) is a place in which a dangerous explosive

atmosphere may be expected to occur only rarely and then

only for short periods. This may include areas in the vicinity of

Zones 20 and 21. Danger only under abnormal operating conditions < 10 hours/year.

GasDust

22

continuously or

for long periods

seldom and for

short periods

continuously or

for long periods

seldom and for

short periods

Page 6

General information about

explosion protection

Temperature class Ignition temperature °C Maximum surface temperature

°C

T1 > 450 450

T2 > 300 300

T3 > 200 200

T4 > 135 135

T5 > 100 100

T6 > 85 85

Explosion group

The requirements for explosion-protected equipment depend on the gases and/or vapours present on

the equipment and on the dusts lying on, adhering to and/or surrounding the equipment. This affects

the gap dimensions required for pressure-proof encapsulation and, in the case of intrinsically safe circuits, the maximum permitted current and voltage values. Gases, vapours and dusts are therefore

subdivided into various explosion groups.

The danger of the gases rises from explosion group IIA to IIC. The requirements for electrical equipment in these explosion groups increase accordingly. Electrical equipment approved for IIC may also

be used for all other explosion groups.

Temperature class

The maximum surface temperature of an item of equipment must always be lower than the ignition

temperature of the gas, vapour or dust mixture. The temperature class is therefore a measure of the

maximum surface temperature of an item of equipment.

Pressure switches

Mechanical pressure switches

Identification of explosion-protected electrical equipment

In addition to normal data (manufacturer, type, serial number, electrical data), data relating to the explosion protection must be included in the identification.

Under the new Directive 94/9EC (ATEX 95), based on IEC recommendations, the following identification is required:

For example: II G D EEx de IIC T6 IP65 T 80 °C

Ex-protection symbol

Device group II

Approved for gas

Approved for dust

Symbol for equipment built in

accordance with European standards

Explosion protection identifier

Explosion group

Temperature class

IP protection class

Approved maximum temperature

23

Page 7

Pressure switches

Mechanical pressure switches

Specially equipped pressure switches can also be used in explosion risk areas Zone 1, 2 and 21,

22. The following alternatives are possible:

1. Pressure-proof encapsulated switching device,

explosion protection EEx de IIC T6, PTB 02 ATEX 1121

The pressure switch with pressure-proof encapsulation can be used directly in the explosion risk area

(Zone 1 and 2 or 21 and 22). The maximum switching voltage, switching capacity and ambient temperature must be taken into account and the rules for installation in the explosion risk area must be

observed. All pressure switches may be equipped with explosion-proof switching devices. However,

special circuits and designs with an adjustable switching differential or internal interlock (reclosing lockout) are not permitted.

2. EEx-i pressure switches

All pressure switches of normal design can be used in explosion risk areas Zone 1 and 2 or 21 and

22, if they are integrated into an “intrinsically safe control current circuit”. Intrinsic safety is based on

the principle that the control current circuit in the explosion risk area carries only a small quantity of

energy which is not capable of generating an ignitable spark.

Isolating amplifiers, e.g. type Ex 011 or Ex 041, must be tested by the Physikalisch-Technische

Bundesanstalt (PTB) and approved for use in explosion risk areas. Isolating amplifiers must always be

installed outside the explosion risk zone.

Pressure switches designed for EEx-ia installations may be provided with blue connection terminals

and cable entries. In view of the low voltages and currents carried via the contacts of the microswitches, gold-plates contacts are recommended (additional function ZF 513).

3. Pressure switches with microswitch and resistor combination for short-circuit and line

break monitoring (see DBS series)

A combination of a pressure switch with mechanical microswitch connected to a 1.5 kOhm series

resistor and a safety-engineered isolating amplifier (type Ex 041) may also be used in explosion risk

zones 1, 2 and 21, 22 (explosion protection EEx-ia).

The safety-engineered isolating amplifier produces a separate intrinsically safe control current circuit

and at the same time monitors the supply conductors between the isolating amplifier and the pressure

switch for short-circuit and line break. In this regard, see also the section on pressure limiters for safety-critical applications and data sheet Ex 041.

Pressure monitoring in explosion risk

areas Zone 1, 2 and 21, 22

Ex-D…

Pressure-proof encapsulated

Explosion protection: EEx de

IIC T6 PTB approval for the

complete switching device.

Switching capacity at 250 V/3

A. The pressure switch can be

installed within the Ex-Zone.

D…-513 + Ex 011

Intrinsically safe

Explosion protection: EEx-ia

PTB approval for isolating

amplifiers Ex 041 Pressure

switch with gold-plated contacts, blue terminals and blue

cable entries.

The isolating amplifier must be

installed outside the Ex-Zone.

DWR…-576 + Ex 041

Intrinsically safe, line break

and short-circuit monitoring

Explosion protection: EEx-ia

PTB approval for isolating

amplifiers Ex 041 Pressure

switch with safety sensor,

positive opening microswitch,

gold-plated contacts, blue terminals and blue cable entries.

The isolating amplifier must be

installed outside the Ex-Zone.

Pressure monitoring in explosion risk areas Zone 1 (21) and 2 (22)

24

Page 8

DDCM 252

Degree of protection:

IP 54/65

s

FEMA differential pressure switches are suitable

for monitoring and controlling differential pressures, flow monitoring and automatic control of

filter systems. A double chamber system with

stainless steel bellows or Perbunan diaphragm

accurately detects the difference between the

two applied pressures. The desired switching

pressure is continuously adjustable within the

ranges mentioned in the type summary.

The settings relate to the lower switching point

(with falling differential pressure). The upper

switching point (with rising differential pressure)

is higher by the amount of the switching differential. All differential pressure monitors can also be

used in the vacuum range. Every pressure

switch has 2 pressure connections with appropriate markings.

DDCM type series

Differential pressure switch

Ex-DDCM

Technical data

Pressure connection

Internal thread G 1/4

Switching device

Robust housing (200) made of seawater-resistant diecast aluminium GD Al Si 12.

Degree of protection

IP 54, in vertical position.

IP 65, for EEx-d version.

Pressure sensor materials

DDCM 014–16:

Pressure bellows of 1.4571

Sensor housing of 1.4305.

DDCM 252–6002:

Perbunan diaphragm.

Aluminium sensor housing.

Mounting position

vertically upright.

Ambient temperature at switching device

–25…+70 °C

For EEx-d versions: –15…+60 °C

Max. medium temperature

The maximum medium temperature at the

pressure sensor must not exceed the permitted ambient temperature at the switching

device. Temperatures may reach 85°C for

short periods (not EEx-d). Higher medium temperatures are possible provided the above limit

values for the switching device are ensured by

suitable measures (e.g. siphon).

Mounting

Directly on the pressure line or on a flat surface with two 4 mm Ø screws.

Note the connection of pressurized lines:

P (+) = high pressure

S (–) = low pressure

Switching pressure

Adjustable from outside with screwdriver.

Switching differential

Not adjustable. For values see Product

Summary.

Scale

Types 252–6002 without graduation. Set

according to pressure gauge.

Switching

capacity

Pressure switches

Mechanical pressure switches

250 VAC 250 VDC 24 VDC

(ohm) (ind) (ohm) (ohm)

Normal 8 A 5 A 0.3 A 8 A

EEx-d 3 A 2 A 0.03 A 3 A

Type Setting range Switching Max.** Materials in- Dimen-

(differential differential permissible contact with sioned

pressure) (mean values) pressure medium drawing

Switching differential not adjustable

DDCM 252* 4…25 mbar 2 mbar 0.5 bar

DDCM 662* 10…60 mbar 15 mbar 1.5 bar Aluminium 1 + 20

DDCM 1602* 20…160 mbar 20 mbar 3 bar + Perbunan

DDCM 6002* 100…600 mbar 35 mbar 3 bar

DDCM 014* –0.1…0.4 bar 0.15 bar 15 bar

DDCM 1 0.2…1.6 bar 0.13 bar 15 bar Stainless steel

DDCM 4* 1…4 bar 0.20 bar 25 bar 1.4305 +

DDCM 6 0.5…6 bar 0.2 bar 15 bar 1.4571 1 + 21

DDCM 16 3…16 bar 0.6 bar 25 bar

* without graduation (only ± scale). For smaller pressure ranges see

** also loadable on one side also HCD and DPS datasheets.

Product Summary

Type Setting range Switching Max.** Materials in- Dimen-

(differential differential permissible contact with sioned

pressure) (mean values) pressure medium drawing

version · Explosion protection EEx de IIC T6

Ex-DDCM 252* 4…25 mbar 2 mbar 0.5 bar

Ex-DDCM 662* 10…60 mbar 15 mbar 1.5 bar Aluminium 3 + 20

Ex-DDCM 1602* 20…160 mbar 20 mbar 3 bar + Perbunan

Ex-DDCM 6002* 100…600 mbar 35 mbar 3 bar

Ex-DDCM 014* -0.1…0.4 bar 0.15 bar 15 bar

Ex-DDCM 1 0.2…1.6 bar 0.13 bar 15 bar Stainless steel

Ex-DDCM 4* 1…4 bar 0.2 bar 25 bar 1.4305 + 3 + 21

Ex-DDCM 6 0.5…6 bar 0.2 bar 15 bar 1.4571

Ex-DDCM 16 3…16 bar 0.6 bar 25 bar

* without graduation (only ± scale)

** also loadable on one side

Accessories: · Threaded joint with male adapter union G 1/4”/8 mm MAU 8/Ms and

MAU 8/Nst, page 63

· Valve combinations VKD 3 and VKD 5, page 63

Calibration

The DDCM series is calibrated for falling pressure. This means that the adjustable switching pressure

on the scale corresponds to the switching point at falling pressure. The reset point is higher by the

amount of the switching differential. (See also page 30, 1. Calibration at lower switching point).

+

37

Page 9

Pressure switches

Dimensioned drawings

Dimensioned drawings of switch housings

Dimensioned drawings of pressure sensors

Housing 200 (plug connection) Housing 300 and 500 (terminal connection)

FORM A

1

1110

Housing 700 (Ex)3

2

58

Page 10

Dimensioned drawings of pressure sensors

Pressure switches

Dimensioned drawings

SW

12 13

14 15

20 21

59

16 19

Dimensioned SW

drawing

16 22

17 24

18 30

19 32

Loading...

Loading...