Page 1

EN1I-6240

Page 2

Page 3

PREFACE

This manual is intended for use in support of day-to-day operation of the

Honeywell DCP 100T Digital Controller Programmer. For information on

installation, commissioning, configuration etc., refer to the associated

Installation Manual (see below).

Associated Documents

Title Document No.

DCP 100T Digital Controller Programmer Installation ManualEN1I-6241

In normal operation, the operator must not remove the

controller from its housing or have unrestricted access to

the rear terminals, as this would provide potential contact

with hazardous live parts.

Installation and configuration must be undertaken by

technically competent servicing personnel. This is covered

in the Installation Manual (see above).

Page 4

Con tents

1 IN TRO DUC ING THE DCP 100T 1-1

2 FRONT PANEL CON TROLS, IN DI CA TORS

AND DIS PLAYS 2-1

2.1 Con trols 2-1

2.2 In di ca tors 2-2

2.3 Dis plays 2-3

2.4 Alarm Status In di ca tion 2-4

2.5 View ing Pro gram and Con trol ler Pa rame ters 2-4

3 PRO GRAMS 3-1

3.1 Se lect ing and Run ning a Pro gram 3-1

3.2 Chang ing the Pro gram Ti me base 3-1

3.3 Hold ing a Pro gram Manu ally 3-1

3.4 Jump ing to the Next Seg ment 3-1

3.5 View ing Pro gram Pro gress/Status 3-2

3.6 Abort ing a Pro gram 3-3

3.7 “End of Pro gram” In di ca tion 3-3

3.8 View ing Pro gram and Con trol ler Pa rame ters 3-3

4 AD JUST ING THE SET POINT 4-1

5 US ING THE SELF- TUNE FA CIL ITY 5-1

6 US ING THE PRE- TUNE FA CIL ITY 6-1

7 MAN UAL CON TROL 7-1

8 DE FIN ING AND VIEW ING A PRO GRAM

(PRO GRAM DE FINE MODE) 8-1

(iii)

Page 5

8.1 En try into Pro gram De fine Mode 8-1

8.2 Pa rame ters Com mon to All Pro grams (Global) 8-2

8.3 Pa rame ters which Ap ply to a Spe cific Pro gram

as a Whole 8-3

8.4 Pa rame ters in Any/Each Seg ment In

a Spe cific Pro gram 8-5

8.5 Us ing Join, Re peat and End Mark ers

and Cy cling Pro grams 8-6

8.6 Ba sic Rules to Re mem ber 8-8

8.7 Ex it ing Pro gram De fine Mode 8-8

9 DE FIN ING THE CON TROL LER PA RAME TERS

(CON TROL LER DE FINE MODE) 9-1

9.1 Con trol ler Pa rame ters 9-2

9.2 Base Mode Dis plays 9-10

9.3 Loop Alarm And Loop Alarm Time 9-10

9.4 Ex it ing Con trol ler De fine Mode 9-11

Il lus tra tions

Fig ure 2-1 Front Panel Con trols 2-1

Fig ure 2-2 Front Panel In di ca tors 2-2

Fig ure 2-3 Front Panel Dis plays 2-3

Fig ure 2-4 Alarm Status Dis play 2-4

Fig ure 8-1 Guar an teed Soak Op era tion 8-4

Fig ure 9-1 Pro por tional Band and Dead band/Over lap 9-7

Fig ure 9-2 Alarm Op era tion 9-8

Fig ure 9-3 Alarm Hys tere sis Op era tion 9-9

(iv )

Page 6

1 INTRODUCING THE DCP 100T

The DCP 100T Digital Controller Programmer is a powerful, easy-to-use

1

4

-DIN

setpoint programmer with full PID control capability (complete with Self-Tune and

Pre-Tune facilities). Its standard features are:

• Up to eight programs of up to 16 free-format (e.g. dwell, ramp, join or

end) segments each.

• Facility to join programs to one another in any sequence (maximum

program length 121 segments).

• User can change currently-running program segment.

• Delayed Start of Program facility.

• End of Program relay output.

• Universal input - thermocouple, RTD (Pt100) or DC linear

- user- selectable).

• Universal power supply (90 - 264V ac 50/60Hz).

• Configurable from front panel.

• Comprehensive front panel displays.

• Front panel sealing to NEMA 4 standard.

• Behind-panel depth only 100mm.

Optional features include:

• Remote control and selection of program (plug-in option).

• Up to four Event relay outputs (plug-in option).

• Second control output.

• Recorder output (setpoint or process variable).

• RS485 serial communications.

• User-definable program tag names

• Real Time Clock

1-1

Page 7

• Support software (Off-Line Configurator, On-Line Graphic Program Editor) -

operates via RS485 communications link.

The Digital Controller Programmer has four operating modes:

Base Mode: Day-to-day PID control operations with no program running. In

this mode, a program may be selected to run.

Program Run Mode: A selected program is running, held or waiting for a

pre-defined delay before starting. In this mode, the operator can view

status and program information.

Program Define Mode 1: Used to view/create/edit programs. This mode is

entered either from Base Mode (selected program may be edited/created)

or from Program Run Mode (currently-running program may be edited).

Controller Define Mode 2: Used to define the Controller characteristics.

1 -2

1 Entry via Lock Code; also optional Program Lock prevents changing of program definitions

while a program is running.

2 Entry via a Lock Code.

Page 8

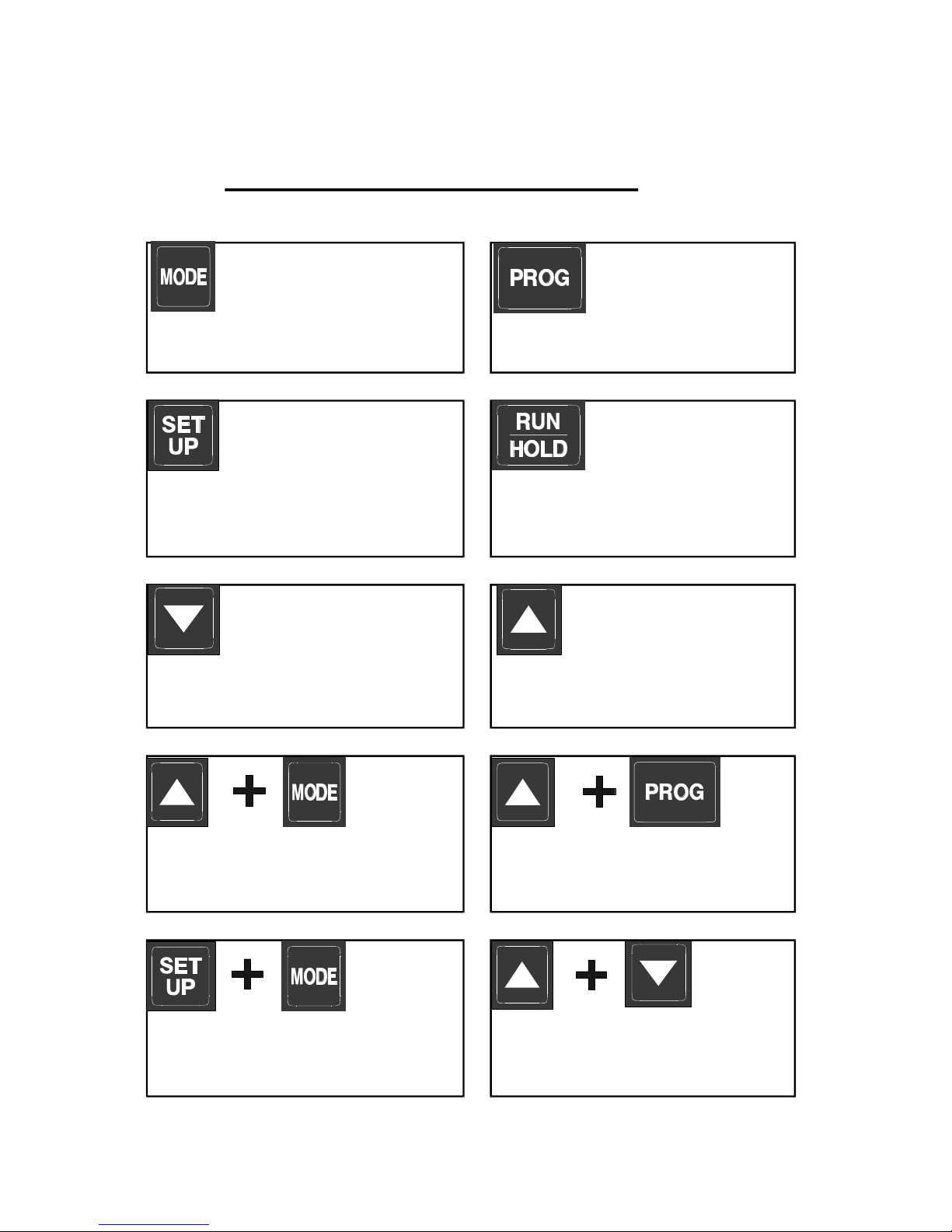

2 FRONT PANEL CONTROLS,

INDICATORS AND DISPLAYS

2.1 CONTROLS

2-1

Figure 2-1 Front Panel Con trols

MODE key

Changes mode of instrument.

SET UP key

Displays the next parameter in

sequence (indicated by Message

display - see Subsection 2.3).

Up key

Increments displayed parameter

value/cycles through options.

Down key

Decrements displayed parameter

value/cycles through options.

Program key

Cycles through Program

Numbers.

Run/Hold key:

Runs, holds or aborts current

program.

Selects/de-selects Self-Tune and

Pre-Tune (when Message Display

shows appropriate message).

Jumps to next segment, when a

program is running.

Selects/de-selects Manual Control

(see Section 7).

Sets a segment to Soak when

defining a program.

Page 9

2.2 INDICATORS

2.2.1 Control Status Indicators

AT ON - Self-Tune active; flashing - Pre-Tune active

ALM Flashes when any alarm active

OUT1 ON when primary control outputis active

OUT2 ON when secondary control output (if fitted) is active.

MAN ON when Manual Control is selected.

2.2.2 Run Status Indicators

RUN ON - Program running or (if HLD ON also) program held

Flashing - Program in Delayed state.

HLD ON - Program Held

Flashing - Program in Guaranteed Soak

x60 OFF - Timebase = hours/minutes

ON - Timebase = minutes/seconds

2.2.3 Event Indicators

Each indicates the status (active or inactive) of a user-defined

event (OFF = inactive, ON = active).

2.2.4 Mode Indicators

SET ON when Controller Define Mode or Program Define Mode

is entered; flashes when viewing parameters in Controller

Define Mode or Program Define Mode after entry from

Base Mode

PRG ON when Program Define Mode is entered.

2-2

Page 10

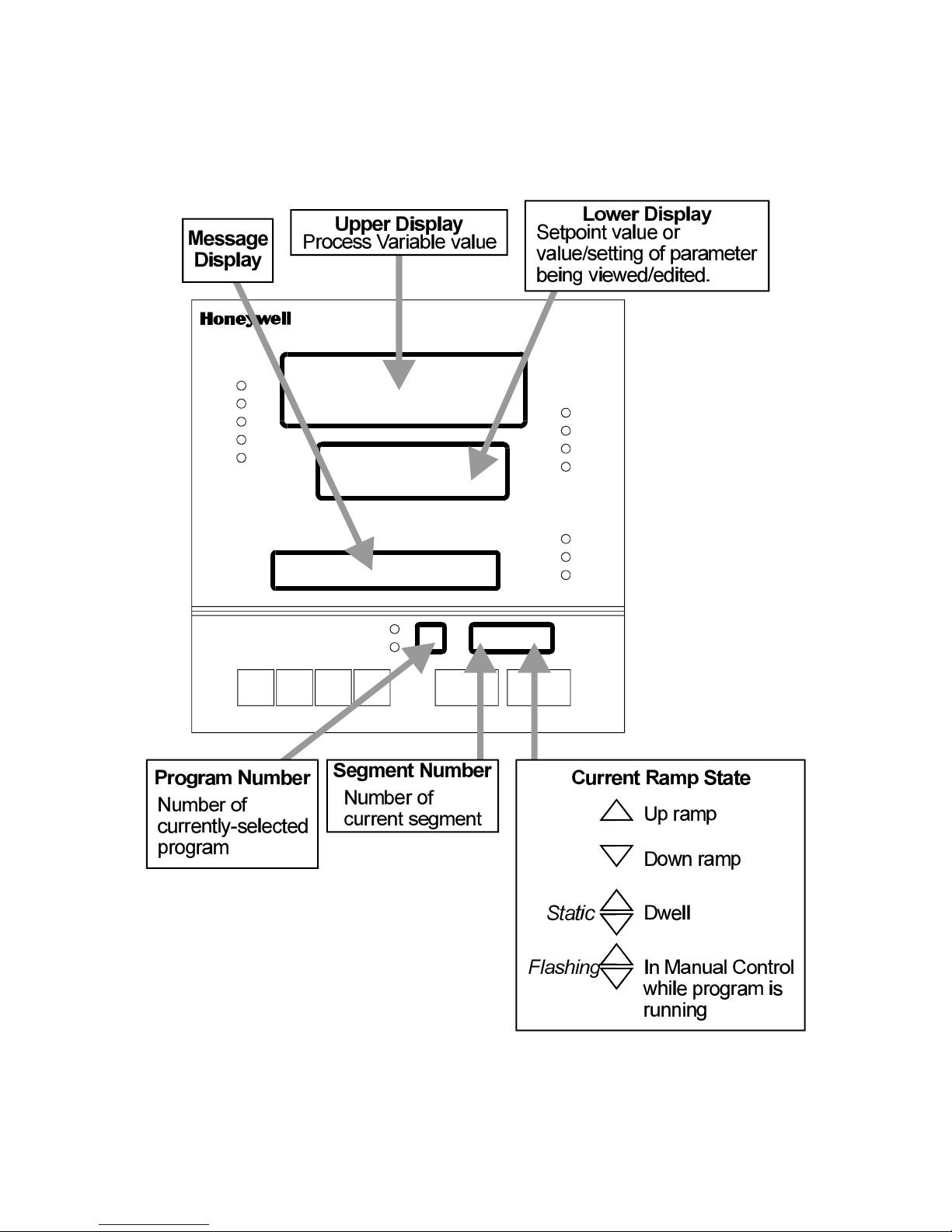

2.3 DISPLAYS

2-3

Figure 2-2 Front Panel Displays

Page 11

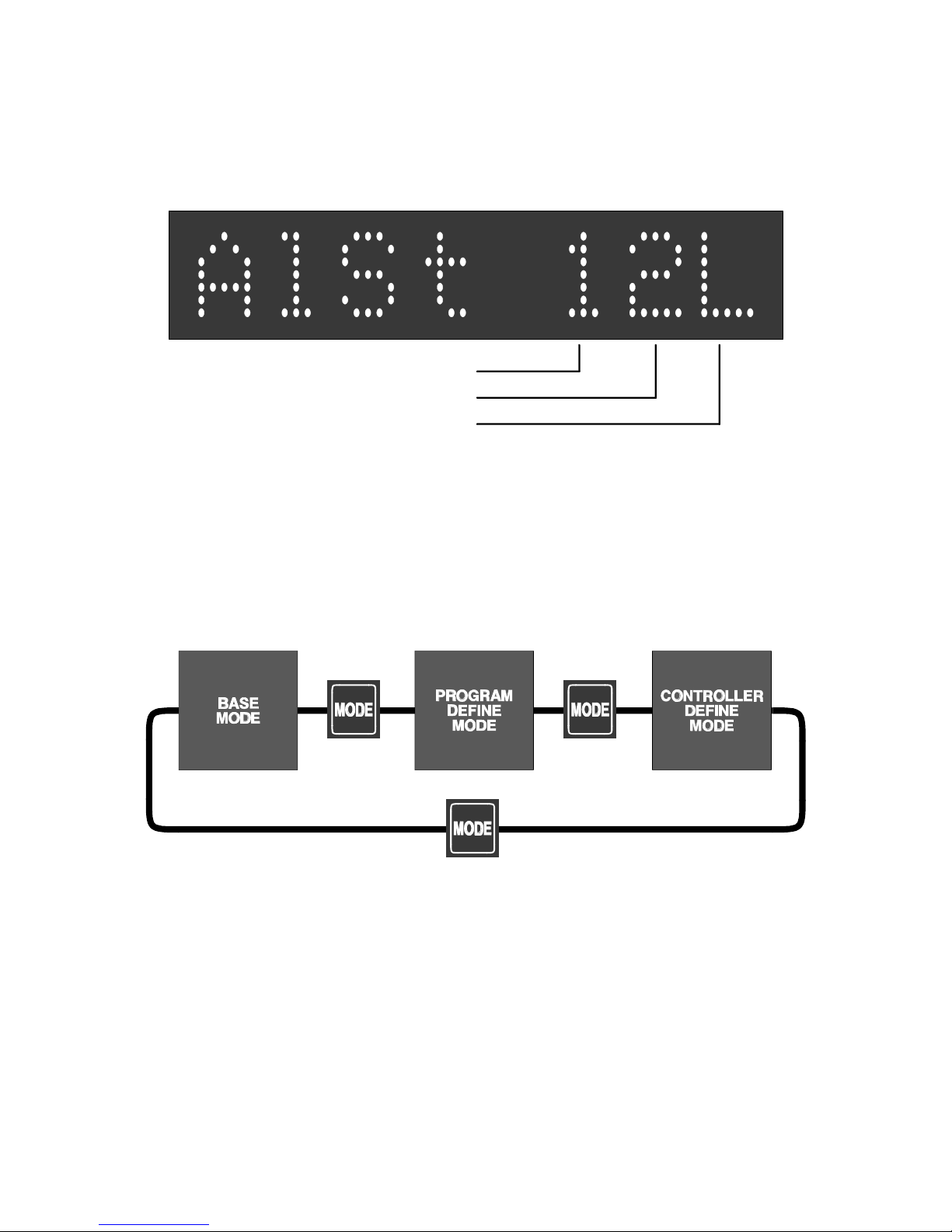

2.4 ALARM STATUS INDICATION

When any alarm is active, the ALM indicator will flash. To view the alarm status in

the Message Display, press the SET UP key until a display appears of the form:

2.5 VIEWING PROGRAM AND CONTROLLER PARAMETERS

In Base Mode (i.e. with no program currently running or held), the MODE key gives

“view only” access to Program Define Mode and Controller Define Mode:

2-4

Figure 2-3 Alarm Status Dis play

Appears only if the Loop Alarm is active

Appears only if Alarm 2 is active

Appears only if Alarm 1 is active

VIEW ONLY VIEW ONLY

See Section 8 See Section 9

Page 12

3 PROGRAMS

3.1 SELECTING AND RUNNING A PROGRAM

With no program running, the Digital Controller Programmer is in Base Mode and

the RUN and HLD indicators are OFF. In this mode, select a program as follows:

1. Hold down the PROG key un til the re quired pro gram number is

dis played.

2. Press the Run/Hold key once to start the pro gram. The RUN in di ca tor will

then go ON; the instrument is now in Pro gram Run Mode.

3.2 CHANGING THE PROGRAM TIMEBASE

Whilst a program is running, the normal timebase is hours/minutes. To change to a

timebase of minutes/seconds (i.e. select the x60 facility), press the Up key for more

than five seconds, whereupon the x60 indicator will go ON. To cancel operation

on the x60 timebase, press the Down key for more than five seconds, whereupon

the x60 indicator will go OFF.

3.3 HOLDING A PROGRAM MANUALLY

You may hold or freeze a program by momentarily pressing the Run/Hold key. The

HLD indicator will then go ON (the RUN indicator staying ON) and the program

will stop execution. The program may subsequently be restarted by momentarily

pressing the Run/Hold key again.

HLD INDICATOR FLASHING: If, before the operator holds the program

manually, the HLD indicator starts flashing, this indicates that the program

is currently subject to a Guaranteed Soak (see Subsection 8.3). If the

Run/Hold key is pressed (for a manual Hold), the HLD indicator will go ON

continuously. When the operator removes the manual Hold (by pressing the

Run/Hold key again), the HLD indicator will either flash (indicating that the

Guaranteed Soak conditions still prevail) or go OFF (indicating that the

Guaranteed Soak conditions no longer exist).

RUN INDICATOR FLASHING: This indicates that the program is in a Delay

state i.e. is timed to start after a user-defined delay has elapsed. When the

delay period has elapsed, the program will run and the RUN indicator will

come on continuously.

3-1

Page 13

3.4 JUMPING TO THE NEXT SEGMENT

At any time during a program’s execution, the operator may jump forward to the

next segment by simultaneously pressing the PROG and Up keys. Note that, since

pro grams may be joined or set to cy cle, jump ing past the last seg ment in a

pro gram may re sult in changes in the Pro gram Num ber and Cy cle Count.

3.5 VIEWING PROGRAM PROGRESS/STATUS

In Program Run Mode, a number of displays are made available to the operator

(in the Message Display area) which indicate program progress/status. Whilst the

current program is running, held or delayed, press the SET UP key to cycle

through a sequence of program status displays with the following legends in the

Message Display:

In the case of Segment Time Remaining or Guaranteed Soak Time display, the

time is in hours/minutes (if the x60 indicator is OFF) or minutes/seconds (if the x60

indicator is ON). The Delay Time display is always in hours/minutes.

NOTE: If the SET UP key is held for two seconds or longer, the Digital

Controller Programmer will auto-scroll through the above display cycle (with

the exception of the Self-Tune and Pre-Tune displays). To stop the

Auto-scroll, press any key other than the SET UP key.

Af ter all ap pli ca ble pro gram status/prog ress dis plays have been shown, press the

SET UP key to re turn to the Base Mode dis plays.

3 -2

Page 14

3.6 ABORTING A PROGRAM

The operator may abort (i.e. terminate) the current program by holding down the

Run/Hold key for more than five seconds. When the program is aborted, a return is

made to the Base Mode and the Message Display will show:

This message will be removed by the next keypress.

3.7 “END OF PROGRAM” INDICATION

When the program has reached its End Marker, the Message Display shows:

and a return is made to Base Mode.

3.8 VIEWING PROGRAM AND CONTROLLER PARAMETERS

In Program Run Mode (i.e. with a program currently running or held), the MODE

key gives “view only” access to Program Define Mode and Controller Define

Mode:

3-3

VIEW ONLY VIEW ONLY

See Section 8 See Section 9

Page 15

4 ADJUSTING THE SETPOINT

With the Digital Controller Programmer in Base Mode (i.e. with the RUN, HLD, SET

and PRG indicators OFF), the two main displays will show the process variable

value (upper display) and the setpoint value (lower display - Read Only). To

change the setpoint value:

1. Press the SET UP key; the Mes sage Area will dis play one of:

whichever is appropriate to the input range used.

2. Use the Up and Down keys to change the set point value (in the lower

dis play) as re quired.

3. When the set point value is set as de sired, press the SET UP key again to

re turn to the ini tial dis play.

4 -1

Page 16

5 USING THE SELF-TUNE FACILITY

The Self-Tune facility is used to optimise tuning whilst the Controller part of the

Digital Controller Programmer is operating. Self Tune may be activated as follows:

1. With the Digi tal Con trol ler Pro gram mer in Base Mode (with the RUN and

HLD in di ca tors OFF), press the SET UP key un til the Mes sage Dis play

shows:

and the lower Main Dis play shows:

2. Press the MODE and Up keys to change the lower Main Dis play to:

in di cat ing that the Self- Tune fa cil ity is now ac ti vated.

To de-activate the Self-Tune facility, press the SET UP key to obtain the same

Message Display as above; then press the MODE and Up keys simultaneously to

change the lower Main Display from On to OFF.

5-1

Page 17

6 USING THE PRE-TUNE FACILITY

The Pre-Tune facility is used to set the Digital Controller Programmer’s PID control

parameters to values which are approximately correct in order to provide a base

from which the Self-Tune facility may subsequently optimise tuning. Pre-Tune may

be activated as follows:

1. With the Digi tal Con trol ler Pro gram mer in Base Mode (with the RUN and

HLD in di ca tors OFF), press the SET UP key un til the Mes sage Dis play

shows:

and the lower Main Dis play shows:

2. Press the MODE and Up keys to change the lower Main Dis play to:

in di cat ing that the Pre- Tune fa cil ity is now ac ti vated.

NOTES

1. If the process variable is within 5% of the input span from the setpoint,

the Pre-Tune facility cannot be activated and any attempt to do so will

have no effect.

2. Since the Pre-Tune facility is a single-shot operation, it will automatically

de-activate itself once the operation is complete.

To de-activate the Pre-Tune facility manually (with the Digital Controller

Programmer in Base Mode), press the SET UP key to obtain the same Message

Display as above; then press the MODE and Up keys to change the lower Main

Display from On to OFF.

6-1

Page 18

7 MANUAL CONTROL

In any mode except Configuration Mode or Calibration Mode, the operator may

select manual control of the process by simultaneously pressing the SET UP and

MODE keys. The Digital Controller Programmer will then enter Base Mode or (if a

program is currently running) Program Run Mode with the program held. The

Message Display will show:

and the lower Main Display will show the power output value, which may then be

adjusted using the Up and Down keys. Whilst manual control is being exercised,

the power output display is included in the displays available in Base Mode and

Program Run Mode.

To cancel manual control, press the SET UP and MODE keys simultaneously,

whereupon the power out value display and the Power Message Display will

disappear and the Digital Controller Programmer will remain in whatever mode

prevailed when manual control was cancelled (if this is Program Run Mode, the

currently-running program will be resumed from the point at which it was held).

7-1

Page 19

8 DEFINING AND VIEWING A PROGRAM

(PROGRAM DEFINE MODE)

The Digital Controller Programmer may be put into Program Define Mode from

either Base Mode or Program Run Mode (i.e. with a program currently running).

8.1 ENTRY INTO PROGRAM DEFINE MODE

1. Press the SET UP and Up keys si mul ta ne ously. The lower Main Dis play will

show 0 and the Mes sage Dis play will show:

2. Use the Up and Down keys to set the value in the lower Main Dis play to

the Lock Value (de fined by the user in Con trol ler De fine Mode) and press

the SET UP key.

The Digital Controller Programmer will enter Program Define Mode, the SET and

PRG indicators will go ON and the operator will be able to edit programs and

segments. The MODE key can then be used (a) to switch to Controller Define

Mode (see Section 9), and then (b) to show a Message Display:

To return to Program Define Mode (and re-start the Program Define/Controller

Define/Exit? display cycle), press the MODE key; to return to Base Mode, press the

SET UP key.

If an incorrect lock value is entered, a return is made to Base Mode.

Program parameters are divided into three categories:

(a) Those com mon to all pro grams - global pa rame ters

(b) Those com mon to all se gments in a spe cific pro gram

(c) Those rele vant to a spe cific seg ment in a spe cific pro gram

Upon entry into Program Define Mode, the operator will be presented with the first

of a sequence of parameter displays (see following Subsections). The operator

may then step through the sequence, using the SET UP key. The displayed

Program Number may be changed using the PROG key and the displayed

Segment Number may be changed using the Run/Hold key.

NOTE: If en try is made from Pro gram Run Mode and Pro gram Lock is On,

only Con trol ler De fine Mode will be ac ces si ble.

8-1

Page 20

8.2 PARAMETERS COMMON TO ALL PROGRAMS (GLOBAL)

Parameter

Message

Display

Function Available Settings (Lower Main Display)

Start On Defines setpoint value at the

start of each program.

Current setpoint value

Current process

variable value

End On Defines setpoint value at the

end of each program.

Final SP value

1

Controller SP value

Delay Time Defines delay (in

hours/minutes) between

initiating the program and

the program actually

starting.

Numerical value, with the decimal

point acting as the de-limiter

between the two units

(hours.minutes)

Program

Lock

Defines whether the operator

is permitted to change

program definitions whilst a

program is running/held.

Not permitted

Permitted

Power Fail

Recovery

Defines response to

restoration of power after

power failure.

0.00 or 1.00 if no Real Time Clock.

0.00 or Time (0.01 - 24.00) if Real

Time Clock fitted.

0.00 = Cold Start

2

1.00 or Time = Warm Start

3

RTC Time

4

Defines Real Time Clock

initial setting (hours.minutes).

0.10 - 24.00

RTC Day

4

Defines Real Time Clock

initial setting (day of week)

Sun , Mon , tuE , Wed , thu , Fri or SAt

External

Selection

Defines functions which may

be controlled externally

No external selection

Program selection

only

Only Run, Hold, Abort

and x60 functions

All program selection

and run control

functions

Lock

Code

5

Lock Code for Program

Define Mode

0 - 9999. Default = 10.

8-2

Program Number = A Segment Number = Blank

1 The final setpoint value for the End Marker of each program - see Subsection 8.4

2 Cold Start = Base Mode with Program No. as when power failed and Segment No. blank

3 Warm Start = resumption from point when power failed (with RTC, if Time has not

expired, otherwise Cold Start.

4 Available only if Real Time Clock fitted.

5 Only applicable if instrument is configured to have two lock codes.

Page 21

8.3 PARAMETERS WHICH APPLY TO A SPECIFIC PROGRAM

AS A WHOLE

Parameter

Message

Display

Function Available Settings (Lower Main Display)

Cycle Count Defines the number of

times a program will be

repeated.

0 - 9999 Program will repeat

the set number of

times

Program will repeat

indefinitely

Guaranteed

Soak

Selects operation of

Guaranteed Soak facility

(relative to setpoint) - see

Figure 8-1.

No Guaranteed Soak

Above setpoint only

Below setpoint only

Above and below

setpoint

Guaranteed

Soak Band

Defines the width of the

Guaranteed Soak Band

-see Figure 8-1.

Numerical value (0 to-span)

Guaranteed

Soak On

Defines whether the

Guaranteed Soak facility

is used on ramps only, on

soaks only or on both

ramps and soaks.

On ramps and soaks

On soaks only

On ramps only

Pre-x60 Defines whether the

timebase for the program

is pre-selected to be

hours/minutes or

minutes/seconds (NOTE:

This parameter setting is

over-ruled by the

external “x60” input).

No pre-selection

Minutes/seconds

Hours/minutes

Timer (RTC

only)

Selects/de-selects timer

control of program.

Timer control selected

Timer control not

selected

Start Hour

(Timer On)

Defines start time for

program.

24.00 (0.00) to 23.59

Start Day

(Timer On)

Defines day(s) for

program to run.

Sun, Mon, tue, Wed, thu, Fri, Sat,

5 dY (Mon - Fri), 6 dY (Mon - Sat) or

ALL (all 7 days of the week)

This se quence may be viewed/ed ited for any pro gram by chang ing the Pro gram

Num ber with the PROG key, then step ping through the pa rame ters with the SET

UP key.

8 -3

Program Number = 1 to 8 Segment Number = Blank

Page 22

8-4

Figure 8-1 Guaranteed Soak Operation

Page 23

8.4 PARAMETERS IN ANY/EACH SEGMENT IN A SPECIFIC

PROGRAM

Parameter

Message

Display

Function Available Settings (Lower Main Display)

Final Setpoint

Value

Defines the final setpoint

value for this segment,

selects a Soak segment

or indicates a Join,

Repeat or End Marker.

Numeric value (limited by SPHi and

SPLo) or (by pressing the Up and

Down keys simultaneously) indicates

a Soak segment with:

or, if the segment is already a Join,

Repeat or End Marker, as shown

below.

Segment Time

or Ramp

Rate, as

selected in

Configuration

Mode (see

Installation

Manual)

or

as

appropriate

Defines the duration or

ramp rate of the

segment or whether it is

a Join Marker, Repeat

Marker or End Marker.

1

Four-digit number in the form mm.nn

(hours.minutes or minutes.seconds)

or negative values as follows:

J01 Join to Program 1

J02 Join to Program 2

J03 Join to Program 3

J04 Join to Program 4

J05 Join to Program 5

J06 Join to Program 6

J07 Join to Program 7

J08 Join to Program 8

REP Repeat Marker

End End Marker

Event

2

Defines the states of the

four Event Outputs for

this segment.

Four-bit binary number (0 = inactive,

1 = active):

8-5

Program Number = 1 to 8 Segment Number = 1 to 16

Event 1

Event 2

Event 3

Event 4

1 If a segment is set to be a Join Marker, a Repeat Marker or an End Marker, the next

depression of the SET UP key will set the segment number to A and the first parameter

common to the whole program (Cycle Count - see Subsection 8.3) will be displayed.

Otherwise, the next depression of the SET UP key will display the next segment

parameter - Event (for the current segment) if the Event Output hardware is fitted.

2 This parameter appears only if the Event Output hardware is fitted, in which case this

parameter will be followed by the Final Setpoint parameter for the next segment. If the

Event Output hardware is not fitted, this parameter is omitted from the sequence and

the segment number is advanced, causing the Final Setpoint Value parameter for the

next segment to appear immediately.

Page 24

CANCELLING JOIN, REPEAT OR END MARKERS

To cancel a Join, Repeat or End Marker:

(a) at the Fi nal Set point Value pa rame ter, press the Up and Down

keys si mul ta ne ously to pro duce a Soak seg ment, or

(b) at the Seg ment Time/Ramp Rate pa rame ter, in cre ment the value

to 0 or a posi tive value.

8.5 USING JOIN, REPEAT AND END MARKERS AND

CYCLING PROGRAMS

By default, the Digital Controller Programmer has eight programs, each 16

segments long (all 16 segments are active and, at the end of Segment 16 is an

implicit End Marker). These programs can be made shorter (using End Markers) or

longer (by creating program sequences with Join, Repeat and End Markers). The

only limit to the size of a program sequence is a maximum length of 121 active

segments plus seven Join Markers plus one End Marker (i.e. all eight programs

joined to make one program sequence).

Segments follow a free format in that ramp or dwell can be followed by dwell or

ramp, completely as desired.

Consider two example programs:

To join the two programs to form a program sequence, change the End Marker of

Program 1 to a Join Marker (Segment Time/Ramp Rate set to J02 - Join Program

2):

8-6

PROGRAM 1

(5 active segments, 1 End Marker)

PROGRAM 2

(3 active segments, 1 End Marker)

PROGRAM 1

(5 active segments, 1 Join Marker)

PROGRAM 2

(3 active segments, 1 End Marker)

Page 25

There are no restrictions on joining programs; several programs can be joined to

one program (e.g. to provide user-selectable warm-up programs, depending

upon which program is run first).

The Cycle feature can be used to make more complex program sequences.

Consider the two simple example programs previously described:

and consider the case in which Program 1 is set to perform two cycles and is

joined to Program 2. When Program 1 is run, the result would be:

If Program 2 were now set to perform ten cycles, the result would be:

Now, with Pro gram 2 set to per forn ten cy cles, if the End Marker of Pro gram 2 were

changed to a Re peat Marker (Seg ment Time/Ramp Rate set to REP), the re sult

would be:

8-7

PROGRAM 1

(5 active segments, 1 End Marker)

PROGRAM 2

(3 active segments, 1 End Marker)

PROGRAM 1 PROGRAM 2PROGRAM 1

PROGRAM 1 PROGRAM 2PROGRAM 1

10 cycles

Page 26

At the end of the tenth cycle of Program 2, the program sequence would end.

8.6 BASIC RULES TO REMEMBER

In any program sequence:

• A pro gram end ing in a Join Marker will per form the re quired number of

cy cles of it self be fore join ing the new pro gram.

• A pro gram end ing in a Re peat Marker (hence, by defi ni tion, the last

pro gram in the se quence) will per form the re quired number of cy cles of

it self be fore end ing the se quence.

• A pro gram end ing in an End Marker (hence, by defi ni tion, the last

pro gram in the se quence) will per form its cy cle count on the en tire

pro gram se quence be fore end ing that se quence.

8.7 EXITING PROGRAM DEFINE MODE

The operator may exit from Program Define Mode by pressing the MODE key until

the Exit ? prompt appears in the Message Display, then pressing the SET UP key,

which will cause a return to the mode from which entry was made.

NOTE: An auto matic re turn is made if there is no key ac tiv ity in

Pro gram De fine Mode for five min utes.

8-8

PROGRAM 1 PROGRAM 2PROGRAM 1

10 cycles

Page 27

9 DEFINING THE CONTROLLER

PARAMETERS

(CONTROLLER DEFINE MODE)

Entry can be made into this mode from Program Define Mode, Program Run

Mode or Base Mode.

To enter from Base Mode or Program Run Mode:

1. Press the SET UP and Up keys si mul ta ne ously. The lower Main Dis play will

show 0 and the Mes sage Dis play will show:

2. Use the Up and Down keys to set the value in the lower Main Dis play to

the cor rect Lock Code Value (for Program De fine Mode) and press the SET

UP key. The Digi tal Con trol ler Pro gram mer is now in Pro gram De fine Mode.

NOTE: If an in cor rect Lock Code Value is en tered, the Digi tal Con trol ler

Pro gram mer will re turn to its origi nal mode (i.e. Base Mode or Pro gram Run

Mode).

3. Press the MODE key. If the instrument has been configured to have only

one Lock Code, entry into Controller Define Mode is immediate and no

further action is needed. If the instrument is configured to have two Lock

Codes (one for Program Define Mode, one for Controller Define Mode), the

Lower Main Display will show 0 and the Message Display will show:

4. Use the Up and Down keys to set the value in the Lower Main Display to

the Lock Code value (for Controller Define Mode), then press the SET UP

key.

The Digital Controller Programmer is now in Controller Define Mode.

NOTE: If an in cor rect Lock Code Value is en tered, the Digi tal

Con trol ler Pro gram mer will re turn to its origi nal mode (i.e. Base

Mode, Pro gram Run Mode or Program Define Mode).

To enter from Program Define Mode, perform Step 3 and (if necessary) Step 4

above.

9-1

Page 28

Upon en try into Con trol ler De fine Mode, the SET in di ca tor will come ON and the

first of the Con trol ler pa rame ters (In put Fil ter Time Con stant) will be pre sented for

ed it ing/view ing. Us ing the SET UP key, step through the se quence of Con trol ler

pa rame ters, ed it ing as re quired (us ing the Up/Down keys).

9.1 CONTROLLER PARAMETERS

The Controller parameters appear in the following sequence:

Parameter

Message

Display

Function

Available Settings/Values

(Lower Main Display)

Input Filter Time

Constant

Defines the time constant

for the input filter

(removes extraneous

pulses from the process

variable input).

0.0 seconds (filter OFF) to 100.0

seconds on 0.5-second

increments. Default = 2.0 seconds

Process

Variable

Offset

1

Modifies actual PV value:

PV Offset + PV = PV value

For linear input, limited by Scale

Range Maximum and Scale Range

Minimum. Default = 0.

Output 1 Power Current Output 1 power

level

Read only - not adjustable

Output 2

Power

2

Current Output 2 power

level

Read only - not adjustable

Proportional

Band 1 (PB1)

Portion of input span in

which Output 1 power

level is proportional to

the (offset) process

variable value (see

Figure 9-1)

0.0% (ON/OFF Control) to 999.9%

of input span. Default = 10.0%.

Proportional

Band 2 (PB2)

Portion of input span in

which Output 2 power

level is proportional to

the (offset) process

variable value (see

Figure 9-1)

0.0% (ON/OFF Control) to 999.9%

of input span. Default = 10.0%.

Reset

3

Integral Time Constant 1 second to 99 minutes 59

seconds.

Rate

3

Derivative Time Constant 00 seconds to 99 minutes 59

seconds

Overlap or

Deadband

4

The portion of

Proportional Band (PB1 +

PB2) over which both

outputs are active

(Overlap) or over which

neither output is active

(Deadband) - see Figure

9-1

−20% to + 20% (negative value =

deadband, positive value =

overlap). Default = 0%.

Bias (Manual

Reset)

3

Bias applied to output

power, expressed as a

percentage of output

power

0% to 100% (Output 1 only)

−100% to +100% (Outputs 1 & 2)

Default = 25%

9-2

Page 29

Parameter

Message

Display

Function

Available Settings/Values

(Lower Main Display)

ON/OFF

Differential

5

Switching differential for

one output (Diff 1 or

Diff 2) or both outputs

(Diff) set to ON/OFF

control (PB1, PB2 or both

set to 0%)

0.1% to 10% of input span.

Default = 0.5%.

Setpoint High

Limit

6

Maximum limit for

setpoint adjustment.

Should be set to a value

which prevents setpoint

values causing damage

to the process.

Current setpoint value to Input

Range Maximum.

Default = Input Range Maximum

Setpoint Low

Limit

6

Minimum limit for setpoint

adjustment. Should be

set to a value which

prevents setpoint values

causing damage to the

process.

Input Range Minimum to current

setpoint value.

Default = Input Range Minimum

Motor Travel

Time

11

Time taken for valve to

travel from one end stop

to the other.

5 seconds to 5 minutes.

Default = 1 minute

Minimum

Motor ON

Time

11

Minimum drive effort

required to initiate

movement in a stationary

valve.

0.0 seconds to Motor Travel Time

plus 10 seconds.

Default = 1 minute.

Recorder

Output Scale

Maximum

7

The value of the process

variable or setpoint (as

applicable) for which the

recorder output is at a

maximum.

−1999 to 9999 (decimal point as

for the process variable input

range).

Default = Input Range Maximum

Recorder

Output Scale

Minimum

7

The value of the process

variable or setpoint (as

applicable) for which the

recorder output is at a

minimum.

−1999 to 9999 (decimal point as

for the process variable input

range).

Default = Input Range Minimum

Output Power

Limit

3

Limits the power level of

Output 1 (used to protect

the process).

0% to 100%

Output 1 Cycle

Time

8

Limits the frequency of

operation of output relay

to maximise relay life.

0.5, 1, 2, 4, 8, 16, 32, 64, 128, 256

or 512 seconds.

Default = 32 seconds

Output 2 Cycle

Time

8

Limits the frequency of

operation of output relay

to maximise relay life.

0.5, 1, 2, 4, 8, 16, 32, 64, 128, 256

or 512 seconds.

Default = 32 seconds

Process High

Alarm 1 Value

If Alarm 1 is a Process

High Alarm, the value of

the process variable at or

above which Alarm 1 will

become active (see

Figure 9-2).

Input Range Maximum to Input

Range Minimum.

Default = Input Range Maximum.

9-3

Page 30

Parameter

Message

Display

Function

Available Settings/Values

(Lower Main Display)

Process Low

Alarm 1 Value

If Alarm 1 is a Process Low

Alarm, the value of the

process variable at or

below which Alarm 1 will

become active (see

Figure 9-2).

Input Range Maximum to Input

Range Minimum.

Default = Input Range Minimum.

Band Alarm 1

Value

If Alarm 1 is a Band

Alarm, the band of

process variable values

(centred on the setpoint)

outside which the

process variable will

cause this alarm to be

active.

±(input span) from setpoint.

Default = 5 input units.

Deviation

(High/Low)

Alarm 1 Value

If Alarm 1 is a Deviation

High/Low alarm, gives a

value above (positive

value) or below (negative

value) the setpoint. If the

process variable deviates

from the setpoint by a

margin greater than this

value, the alarm

becomes active (see

Figure 9-2).

±(input range) from setpoint.

Default = 5 input range units.

Alarm 1

Hysteresis

Value

Defines a hysteresis band

on the “safe” side of the

Alarm 1 value (see Figure

9-3).

1 LSD to 10% of input span (0 is an

invalid value).

Process High

Alarm 2 Value

If Alarm 2 is a Process

High Alarm, the value of

the process variable at or

above which Alarm 2 will

become active (see

Figure 9-2).

Input Range Maximum to Input

Range Minimum.

Default = Input Range Maximum.

Process Low

Alarm 2 Value

If Alarm 2 is a Process Low

Alarm, the value of the

process variable at or

below which Alarm 2 will

become active (see

Figure 9-2).

Input Range Maximum to Input

Range Minimum.

Default = Input Range Minimum.

Band Alarm 2

Value

If Alarm 2 is a Band

Alarm, the band of

process variable values

(centred on the setpoint)

outside which the

process variable will

cause this alarm to be

active.

±(input span) from setpoint.

Default = 5 input units.

9-4

Page 31

Parameter

Message

Display

Function

Available Settings/Values

(Lower Main Display)

Deviation

(High/Low)

Alarm 2 Value

If Alarm 2 is a Deviation

High/Low alarm, gives a

value above (positive

value) or below (negative

value) the setpoint. If the

process variable deviates

from the setpoint by a

margin greater than this

value, the alarm

becomes active (see

Figure 9-2).

±(input range) from setpoint.

Default = 5 input range units.

Alarm 2

Hysteresis

Value

Defines a hysteresis band

on the “safe” side of the

Alarm 2 value (see Figure

9-3).

1 LSD to 10% of input span (0 is an

invalid value).

Loop Alarm

Enable

Enables/disables Loop

Alarm (see Subsection

9.3)

0 = Disabled, 1 = Enabled.

Default = 0 (Disabled)

Loop Alarm

Time

If ON/OFF control is

selected (i.e. PB1 = 0)

and Loop Alarm is

enabled, this defines the

duration of the saturation

condition after which the

Loop Alarm is activated

(see Subsection 9.3).

1 second to 99 minutes 59

seconds.

Default = 99 minutes 59 seconds.

Scale Range

Decimal

Point

9

For linear inputs, defines

the decimal point

position.

0 = XXXX

1 = XXX.X (Default)

2 = XX.XX

3 = X.XXX

Scale Range

Maximum

9

For linear inputs, defines

the scaled input value

when the process

variable input is at its

maximum value.

−1999 to 9999 (decimal point

position as defined by Scale

Range Decimal Point parameter

(see above).

Default = 100.0

Scale Range

Minimum

9

For linear inputs, defines

the scaled input value

when the process

variable input is at its

minimum value.

−1999 to 9999 (decimal point

position as defined by Scale

Range Decimal Point parameter

(see above).

Default = 0.0

Auto Pre-Tune

Enable/Disable

Determines whether the

Pre-Tune facility is

automatically activated

on power-up.

OFF = Disabled, ON = Enabled.

Default = OFF.

Manual

Control

Enable/Disable

Enables/disables

operator selection of

Manual Control mode.

OFF = Disabled, ON = Enabled.

Default = OFF.

Communications

Write

Enable/Disable

10

Enables/disables

adjustment of parameter

settings/value via the

RS485 communications

link.

OFF = Disabled, ON = Enabled.

Default = OFF.

9-5

Page 32

Parameter

Message

Display

Function

Available Settings/Values

(Lower Main Display)

Lock Value

or

Defines the four-digit

code required to enter

Controller Define Mode

(and, if a common lock

code is to be used,

Program Define Mode).

0 to 9999.

Default = 10.

NOTES ON CONTROLLER DEFINE MODE PARAMETERS

1. The Process Variable Offset value should be chosen with great care. Any adjustment to

this parameter is, in effect, a calibration adjustment. Injudicious application of values to

this parameter could lead to the displayed process variable value having no meaningful

relationship to the actual process variable value. There is no front panel indication when

this parameter is in effect (i.e. has been set to a non-zero value).

2. These parameters are applicable only if the secondary control (COOL) output is fitted.

3. These parameters are not applicable if Proportional Band 1 has been set to 0 (i.e.

ON/OFF control).

4. This parameter is not applicable if Proportional Band 1 is set to 0 or if Output 2 (COOL) is

not fitted.

5. The Message Display will show Diff 1 for ON/OFF control on Output 1 only, Diff 2 for

ON/OFF control on Output 2 only and Diff for ON/OFF control on both Output 1 and Output

2.

6. Internal software prevents (a) the Setpoint High Limit being given a value less than any

setpoint value contained in the currently-resident programs, and (b) the Setpoint Low Limit

being given a value greater than any setpoint value contained in the currently-resident

programs.

7. These parameters are not applicable if the Recorder Output Option is not fitted.

8. Output 1 Cycle Time is not applicable if Proportional Band 1 is set to 0 or if Output 1 is a

DC Linear output. Output 2 Cycle Time is not applicable if Proportional Band 1 is set to 0, if

Proportional Band 2 is set to 0, If Output 2 is not fitted or if Output 2 is a DC Linear output.

9. These parameters are applicable only if a linear input is fitted

10. Applicable only if the RS485 Serial Communications Option is fitted.

11. Applicable to TPSC control only.

12. If the instrument is configured to have one lock code only (Message Display will show

Lock ), this value is used to enter Program Define Mode and Controller Define Mode. If two

lock codes are to be used (Message Display will show Lock C), this value applies to

Controller Define Mode only.

9-6

Page 33

9-7

Figure 9-1 Pro por tional Band and Dead band/Over lap

Page 34

9-8

Figure 9-2 Alarm Operation

Page 35

9-9

Figure 9-3 Alarm Hysteresis

Alarm

Op era tion

Process

Alarm Value

Hysteresis Band

Alarm Inactive Alarm Active

Alarm Inactive

Process

Variable

Process

Alarm Value

Hysteresis Band

Process

Alarm Inactive Alarm Active

Alarm Inactive

Hysteresis Band

Hysteresis Band

Process

Alarm Value

Alarm

SetpointAlarm

Inactive

Alarm Inactive

Alarm Active

Alarm Active

Alarm Inactive

Band

Alarm

Deviation

Setpoint

Hysteresis Band Alarm Inactive Alarm Active

Alarm Inactive

Process

Alarm

Setpoint

Hysteresis

Alarm Value Alarm Inactive Alarm Active

Alarm Inactive

Process

Variable

Page 36

9.2 BASE MODE DISPLAYS

Once the complete cycle of Controller Define Mode parameters has been

displayed, the user may then step through the Base Mode displays (controller

setpoint - alarm status - Self Tune - Pre-Tune), making adjustments where required,

before re-starting the Controller Define Mode parameter cycle.

9.3 LOOP ALARM AND LOOP ALARM TIME

The Loop Alarm is a special alarm which detects faults in the control feedback

loop by continuously monitoring process variable response to the control

output(s).

The Loop Alarm facility, when enabled, repeatedly checks the control output(s) for

saturation i.e. either or both outputs being at the maximum or minimum limit. If an

output is found to be in saturation, the Loop Alarm facility starts a timer; thereafter,

if the saturated output has not caused the process variable to be corrected by a

pre-determined amount V after a time T has elapsed, the Loop Alarm goes active.

Subsequently, the Loop Alarm facility repeatedly checks the process variable and

the control output(s). When the process variable starts to change value in the

correct sense or when the saturated output comes out of saturation, the Loop

Alarm is de-activated.

For PID control, the Loop Alarm Time T is always set to twice the value of the Reset

(Integral Time Constant) parameter. For On/Off control, the user-defined value of

the Loop Alarm Time parameter is used.

The value of V is dependent upon the input type:

o

C ranges: 2oC or 2.0oC

o

F ranges: 3oF or 3.0oF

Lin ear ranges: 10 least sig nifi cant dis play units

For single output Controllers, the saturation limits are 0% and Output Power Limit.

For dual output Controllers, the saturation limits are –100% and Output Power Limit.

NOTES

1. Correct operation of the Loop Alarm depends upon reasonably

accurate PID tuning.

2. The Loop Alarm is automatically disabled during Manual Control Mode

and during execution of the Pre-Tune facility. Upon exit from Manual

Control Mode or after completion of the Pre-Tune routine, the Loop Alarm is

automatically re-enabled.

9-10

Page 37

When full ON/OFF con trol is se lected (i.e. Pro por tional Band 1 is set to 0) and Loop

Alarm is en abled, the Loop Alarm Time pa rame ter de ter mines the du ra tion of the

satu ra tion con di tion af ter which the Loop Alarm will be ac ti vated. It may be

ad justed within the range 1 sec ond to 99minutes 59 sec onds. This pa rame ter is

omit ted from the dis play se quence if ON/OFF con trol is not se lected or Loop Alarm

is dis abled. The de fault set ting is 99:59.

9.4 EXITING CONTROLLER DEFINE MODE

The operator may exit from Controller Define Mode by pressing the MODE key

until the Exit ? prompt appears in the Message Display, then pressing the SET UP

key, which will cause a return to the mode from which entry was made.

NOTE: An auto matic re turn is made if there is no key ac tiv ity in

Con trol ler De fine Mode for five min utes.

9-11

Page 38

Alphabetical Index

A

Aborted Program

Indication of 3-3

Alarm 1 Hysteresis Value 9-4

Alarm 1 Value

Band Alarm 9-4

Deviation (High/Low) Alarm

9-4

Process High Alarm 9-3

Process Low Alarm 9-4

Alarm 2 Hysteresis Value 9-5

Alarm 2 Value

Band Alarm 9-4

Deviation (High/Low) Alarm

9-5

Process High Alarm 9-4

Process Low Alarm 9-4

Alarm Status

Display of 2-4, 3-2

Auto Pre-Tune Enable/Disable 9-5

Auto-Scroll Feature 3-2

B

Bias 9-2

C

Communications Write Enable/Disable

9-5

Controller Define Mode

Automatic exit from 9-11

Entry from Base Mode or Program

Run Mode 9-1

Entry from Program Define Mode

9-1

Exit from 9-11

Indication of entry 9-2

Controller Define Mode Parameters

"Read Only" access from Base

Mode 2-4

"Read Only" access from Program

Run Mode 3-3

D

Deadband 9-2

Delay State

Indication of 3-1

Delay Time 8-2

Delay Time Remaining

Display of 3-2

Derivative Time Constant 9-2

Down key

Function 2-1

E

End Marker

Cancellation of 8-6

End of Program Sequence

Indication of 3-3

End On parameter 8-2

External Selection 8-2

F

Front Panel Displays

Functions 2-3

Front Panel Keys

Functions 2-1

G

Guaranteed Soak

Indication of 3-1

Guaranteed Soak Time

Display of 3-2

1

Page 39

I

Input Filter Time Constant 9-2

Integral Time Constant 9-2

J

Join Marker

Cancellation of 8-6

L

Lock Code (Controller Define Mode)

Setting 9-6

Using 9-1

Lock Code (Program Define Mode)

Setting 8-2

Using 8-1, 9-1

Loop Alarm

Description 9-10

Loop Alarm Enable 9-5

Loop Alarm Time 9-5

Definition 9-10

M

Manual Control

Front panel display 7-1

Selection/de-selection 2-1,

7-1

Manual Control Enable/Disable 9-5

Manual Program Hold

Indication of 3-1

Manual Reset 9-2

Minimum Motor ON Time 9-3

MODE key

Function 2-1

Motor Travel Time 9-3

N

Next Segment

Jump to 2-1 - 3-2

Number of Cycles Completed

Display of 3-2

O

ON/OFF Differential 9-3

Output 1 Cycle Time 9-3

Output 1 Power 9-2

Output 2 Cycle Time 9-3

Output 2 Power 9-2

Output Power Limit 9-3

Overlap 9-2

P

Power Fail Recovery 8-2

Pre-Tune Facility

Limitations on use 6-1

Selection/de-selection 2-1,

6-1

Status display 3-2

Process Variable Offset 9-2

PROG key

Function 2-1

Program Define mode

Indication of 8-1

Program Define Mode

Automatic exit from 8-8

Entry into 8-1

Exit from 8-8

Global parameters 8-2

Parameters specific to

a segment 8-5

Program Define Mode Parameters

"Read Only" access from Base

Mode 2-4

"Read Only" access from Program

Run Mode 3-3

Program Lock 8-2

Program Running 3-1

2

Page 40

Program Selection 3-1

Program Tag

Display of 3-2

Program Timebase

Changing 3-1

Proportional Band 1 9-2

Proportional Band 2 9-2

R

Rate 9-2

Recorder Output Scale Maximum

9-3

Recorder Output

Scale Minimum 9-3

Repeat Marker

Cancellation of 8-6

Reset 9-2

RTC Day 8-2

RTC Time 8-2

Run/Hold key

Function 2-1

S

Scale Range Decimal Point 9-5

Scale Range Maximum 9-5

Scale Range Minimum 9-5

Segment Time Remaining

Display of 3-2

Self-Tune Facility

Selection/de-selection 2-1,

5-1

Status Display 3-2

SET UP key

Function 2-1

Setpoint

Adjustment of 4-1

Setpoint High Limit 9-3

Setpoint Low Limit 9-3

Soak Segment

Setting of 2-1

Start On parameter 8-2

U

Up key

Function 2-1

3

Page 41

Page 42

Loading...

Loading...