Page 1

BWTM RigRat

Local Area Gas Monitor

User’s Guide

Rev. A

March 2020

P/N W03-4001-000

Page 2

IMPORTANT! BUMP TEST THE MONITOR

Prior to use, every gas detection monitor should be bump tested to confirm the response of all

sensors and activation of all alarms by exposing the monitor to a concentration of target gas that

exceeds the low alarm set point. A bump test is also recommended if the monitor has been

subjected to physical impact, liquid immersion, an Over Limit alarm event, or custody changes, or

anytime the monitor’s performance is in doubt.

To ensure greatest accuracy and safety, only bump test and calibrate in a fresh air environment.

The monitor should be calibrated every time it does not pass a bump test, but no less frequently

than every six months, depending on use and exposure to gas and contamination, and its

operational mode.

• Calibration intervals and bump test procedures may vary due to national legislation.

• Honeywell recommends using calibration gas cylinders containing the gas that is appropriate

to the sensor you are using, and in the correct concentration.

© 2020 Honeywell International

Product Registration

Register your product online by visiting:

https://www.honeywellanalytics.com/en/support/product-registration

Page 3

BW RigRat User’s Guide

Contents

1. Standard Contents .................................................................................................... 10

2. General Information ................................................................................................... 11

Certification ................................ ................................ ................................ ...... 11

General ............................................................................................................ 11

Wireless module Configuration ......................................................................... 12

Sensor configuration ........................................................................................ 12

Electrical parameters ........................................................................................ 13

Type Designation ............................................................................................. 13

3. User Interface ............................................................................................................ 16

Display Overview ............................................................................................. 16

3.1.1. Status Indicator Icons ............................................................................... 16

3.1.2. Icon Arrangement ........................................................................................ 18

3.1.3. Design & Interface.................................................................................... 21

3.1.4. Rain Protector (Optional).......................................................................... 22

Screen Display For Various Numbers Of Active Sensors ................................. 22

Info ................................................................................................................... 23

4. Mesh Wireless Control And Submenus ..................................................................... 24

Mesh Wireless Network (if supported) .............................................................. 24

4.1.1. Closed-Loop Network .................................................................................. 24

4.1.2. Connect To Controller .................................................................................. 25

4.1.3. Connect To Radiant Reader ........................................................................ 26

5. BLE ........................................................................................................................... 27

BLE Pairing ................................ ................................................................ ...... 27

Broken BLE Connection ................................................................................... 28

Wi-Fi Connection (if supported) ........................................................................ 28

5.3.1 Secure Wireless Access Point Configuration ................................................ 28

5.3.2 Setting Wi-Fi Communication Parameters in Device Configurator app .......... 29

Secure Wireless Communication...................................................................... 31

6. Battery Charging ....................................................................................................... 32

Charging Ports ................................................................................................. 32

6.1.1. AC Charging, Safe Area ........................................................................... 32

6.1.2. Intrinsically Safe Runtime Extension For Hazardous Areas ...................... 33

6.1.3. Cover Ports When Not In Use .................................................................. 35

Battery States................................................................................................... 36

7. Wired Communication ............................................................................................... 37

Serial (Not Intended To Be Used In Explosive Atmospheres) ........................... 37

Switch .............................................................................................................. 38

4-20mA IN ........................................................................................................ 40

Cover Communication Ports When Not In Use ................................................. 41

8. External Filter ............................................................................................................ 41

Filter Replacement (Pumped) ........................................................................... 41

Filter Replacement (Diffusion) .......................................................................... 43

9. Turning The RigRat On And Off ................................................................................ 45

Turning The RigRat On .................................................................................... 45

Turning The RigRat Off .................................................................................... 46

Testing Alarm Indicators ................................................................................... 47

10. Modes of Operation ................................................................................................. 48

Menu Mode ...................................................................................................... 48

10.2.1. Entering Menu Mode.................................................................................. 48

Page 4

BW RigRat User’s Guide

10.2.2. Exiting Menu Mode .................................................................................... 49

Diagnostic Mode .............................................................................................. 49

Enter Diagnostic Mode ..................................................................................... 49

10.4.1. Navigating Diagnostic Mode ...................................................................... 49

Exit Diagnostic Mode ........................................................................................ 50

11. Programming ........................................................................................................... 51

Using Device Configurator................................................................................ 51

Security Mode .................................................................................................. 51

12. Calibration And Testing ........................................................................................... 52

Bump Testing And Calibration .......................................................................... 52

Bump (Functional) Testing ............................................................................... 52

Calibration ........................................................................................................ 54

13. Maintenance ............................................................................................................ 55

Cleaning ........................................................................................................... 55

Antenna Installation ................................................................ .......................... 55

14. RAEMet Sensor Installation (not intended to be used in

explosive atmospheres) .......................................................................................... 60

15. Alarms Overview ..................................................................................................... 62

Alarm Signals ................................................................................................... 62

Alarm Signal Summary ..................................................................................... 62

Manual Alarms Test ......................................................................................... 63

16. Troubleshooting....................................................................................................... 65

17. Editing Features ...................................................................................................... 67

Error Codes ................................ ................................................................ ...... 68

18. Specifications .......................................................................................................... 71

Page 5

BW RigRat User’s Guide

5

WARNINGS

This Manual must be carefully read by all individuals who have or will have the responsibility of using,

maintaining, or servicing this product. The product will perform as designed only if it is used,

maintained, and serviced in accordance with the manufacturer’s instructions. The user should

understand how to set the correct parameters and interpret the obtained results.

CAUTION!

Only use the Honeywell-specified rechargeable lithium-ion battery pack supplied with the

instrument.

Charge the instrument Li-ion battery using the specifically supplied charger and only outside

hazardous areas. The maximum voltage from the AC charger Um must not exceed 6.0 VDC.

The battery pack can only be changed in a non-hazardous area. Only use approved

rechargeable battery pack P/N 500-0165-000 produced by Honeywell.

Any data download device connected to this instrument must be approved SELV or Class 2

equipment.

Use of non-Honeywell components will void the warranty and can compromise the safe

performance of this product.

Warning: Substitution of components may impair safe performance of this product.

When changing the sensor configuration, ensure the operator is aware of any changes to

certification restrictions

SPECIAL CONDITIONS FOR SAFE USE

This multi-gas monitor must be calibrated if it does not pass a bump test, when a new sensor

has been installed, or at least once every 180 days, depending on use and sensor exposure to

poisons and contaminants

The AC charger system of BW RigRat shall only be applied in non-hazardous areas by

charger specifically supplied for use with the unit (for example model number ADS-25SGP-06

05717E, manufactured by HONOR Electric), approved as SELV or Class 2 equipment against

IEC 60950 or an equivalent IEC standard. The maximum voltage Um from the charger shall

not exceed DC 6.0V.

The BW RigRat enclosure has an ingress protection of rating of IP-54. The user shall ensure

that the external plugs that used for IS charger, 4-20mA input, and ON-OFF switch will provide

a degree of protection of IP-54, after they are connected to the sockets.

Do not open when an explosive atmosphere is present.

Note: Users are recommended to refer to ISA -RP12.13, Part II-1987 for general information on

installation, operation, and maintenance of combustible gas detection instruments.

Page 6

BW RigRat User’s Guide

6

WARNINGS

ONLY THE COMBUSTIBLE GAS DETECTION PORTION OF THIS INSTRUMENT HAS BEEN

ASSESSED FOR PERFORMANCE.

UNIQUMENT, LA PORTION POUR DÉTECTOR LES GAZ COMBUSTIBLES DE CET INSTRUMENT

A ÉTÉ ÉVALUÉE.

CAUTION: BEFORE EACH USE, SENSITIVITY OF THE COMBUSTIBLE GAS SENSOR MUST BE

TESTED ON A KNOWN CONCENTRATION OF METHANE GAS EQUIVALENT TO 20 TO 50% OF

FULL-SCALE CONCENTRATION. ACCURACY MUST BE WITHIN 0 AND +20% OF ACTUAL.

ACCURACY MAY BE CORRECTED BY CALIBRATION PROCEDURE.

ATTENTION: AVANT CHAQUE UTILISATION VERIFIER LA SENSIBILITE AVEC UNE

CONCENTRATION CONNUE DE METHANE EQUIVALENTE A 20 to 50% DE LA PLEINE ECHELLE.

LA PRECISION DOIT ETRE COMPRISE ENTRE 0 to 20% DE LA VALEUR VRAIE ET PEUT ETRE

CORRIGEE PARUNE PROCEDURE D’ETALONNAGE.

CAUTION: HIGH OFF-SCALE READINGS MAY INDICATE AN EXPLOSIVE CONCENTRATION.

ATTENTION: DES LECTURES SUPÉRIEURES A L’ÉCHELLE PEUVENT INDIQUER DES

CONCENTRATIONS EXPLOSIVES.

Page 7

BW RigRat User’s Guide

7

FCC Compliance Statement:

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

Warning: Any changes or modifications to this unit not expressly approved by the party responsible

for compliance could void the user's authority to operate the equipment.

Class A device:

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

MPE caution (if a FCC certified RF module is inserted in & the separation distance is indicated in the

FCC grant of RF module)

To satisfy FCC / IC RF exposure requirements, a separation distance of 20 cm or more should be

maintained between the antenna of this device and persons during device operation.

To ensure compliance, operations at closer than this distance is not recommended.

This device contains license-exempt transmitter(s)/receiver(s) that comply with Innovation, Science

and Economic Development Canada’s license-exempt RSS(s). Operation is subject to the following

two conditions:

(1) This device may not cause interference.

(2) This device must accept any interference, including interference that may cause undesired

operation of the device.

L’émetteur/récepteur exempt de licence contenu dans le présent appareil est conforme aux CNR

d’Innovation, Sciences et Développement économique Canada applicables aux appareils radio

exempts de licence. L’exploitation est autorisée aux deux conditions suivantes:

1) L’appareil ne doit pas produire de brouillage;

2) L’appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est susceptible

d’en compromettre le fonctionnement.

Page 8

BW RigRat User’s Guide

8

Warning: Substitution of components may impact intrinsic safety.

Avertissement: La substitution de composants peut compromettre la securité intrinsèque.

WARNING: Read and understand instruction manual before operation or servicing.

AVERTISSEMENT: Lisez et comprenez le manual d’instructions avant d’utiliser ou service.

WARNING: Substitution of components may impact intrinsic safety.

AVERTISSEMENT: La substitution de composants peut compromettre la sécurité intrinsèque.

WARNING: To prevent ignition of a hazardous atmosphere, batteries must only be charged in an area

known to be non-hazardous. Um = 6.0V. Use only approved charger.

AVERTISSEMENT: Afin de prevenir l’inflammation d’atmosphères dangereuse, ne charger le jeu de

batteries que dans des emplacement designés non dangereux. Um = 6V Utilisez uniquement un

chargeur approuvé.

Only charge the battery in safe area in the ambient temperature range 0°C ≤ T

amb

≤ 40°C.

Page 9

BW RigRat User’s Guide

9

Proper Product Disposal At End Of Life

EU Directive 2012/19/EU: Waste Electrical and Electronic Equipment (WEEE)

This symbol indicates that the product must not be disposed of as general industrial or

domestic waste. This product should be disposed of through suitable WEEE disposal

facilities. For more information about disposal of this product, contact your local authority,

distributor, or the manufacturer.

Sensor Specifications, Cross-Sensitivities, And Calibration Information

For information on sensor specifications, cross-sensitivities, and calibration information, refer to

Technical Note TN-114: Sensor Specifications And Cross-Sensitivities. All specifications presented in

this Technical Note reflect the performance of standalone sensors. Actual sensor characteristics may

differ when the sensor is installed in different instruments. As sensor performance may change over

time, specifications provided are for brand-new sensors.

Make Sure Firmware Is Up To Date

For best operation, make sure your monitor is running the latest firmware.

Page 10

BW RigRat User’s Guide

10

1. Standard Contents

The RigRat is available in various user-specified configurations, each with the accessories shown

below.

In addition to the instrument, the following are included:

Item

Part Number

AC adapter

W03-3044-000

LCD Cover

W03-2129-000

Diffusion calibration cap assembly*

W03-3013-000

Pump calibration tube assembly*

W03-3020-000

External Filter (Pumped version only)

W03-3006-000

QuickStart Guide

W03-4002-000

Antenna 868-928MHz, RP-N**

550-7056-000

Antenna 2.4GHz, RP-N**

550-7057-000

* Depends on whether the model is pumped or diffusion.

** Depends on wireless modem (if installed).

Page 11

BW RigRat User’s Guide

11

2. General Information

Certification

Ex ia II C/ II B T4 Ga

Ex da ia II C/ II B T4 Ga

Ex db ia II C/ II B T4 Gb

II 1G Ex ia ⅡC/ⅡB T4 G

II 1G Ex da ia ⅡC/ⅡB T4 Ga

II 2G Ex db ia ⅡC/ⅡB T4 Gb

Refer to following contents to find more information about Ex marking and permissible ambient

temperature.

This apparatus is designed to be in accordance with the following Standards:

IEC60079-0:2017 Explosive atmospheres—Part 0: Equipment—General requirements;

IEC60079-11:2011 Explosive atmospheres -Part 11: Equipment protection by intrinsic safety “i”.

EN IEC60079-0:2018 Explosive atmospheres—Part 0: Equipment—General requirements;

EN 60079-11:2012 Explosive atmospheres -Part 11: Equipment protection by intrinsic safety “i”.

Refer to following contents to find more information about Ex marking and permissible ambient

temperature.

General

The BW RigRat Local Area Gas Monitor (hereinafter called “RigRat”) as a transportable equipment,

fills the gap between portable personal detectors and fixed-infrastructure fire and gas systems. Its

primary function is to alert personnel of a gas leak in their proximity, it can provide continuous

measurement of gas concentrations.

The RigRat’s main use is in temporary zone monitoring, such as repair, fence line, and inert

applications where there is a possibility of a gas release.

The overall dimensions of the RigRat are about 396mm x 288mm x 470mm (15.6” x 11.4” x 18.5”), it

consists of an enclosure, 2 rechargeable battery packs (P/N 500-0165-000) as main power, 1 Li-ion

rechargeable cell (P/N MS-621T) for RTC power, 1 LCD display, 4 LED indicators for light alarm, 2

buzzers for the audible alarm, 1 multi-function button, and printed circuit-board assemblies. In addition,

it may also be optionally equipped with a gas-intake pump, up to 6 kinds of wireless modules in 4

wireless module slots, and up to 5 kinds of sensors in 6 sensor slots.

An AC charger connector is provided to charge battery packs in a non-hazardous area. Refer to “Specific

Conditions of Use” for more information. An IS charger connector is used to connect through a safety

barrier to charge one of the battery packs in hazardous areas, likewise providing the intrinsically safe

power to the product.

The RigRat is transportable and does not require grounding (earthing). However, the circuits and the

metal parts of the enclosure can still withstand a 500V dielectric test with a leakage current no more

than 5mA.

Page 12

BW RigRat User’s Guide

12

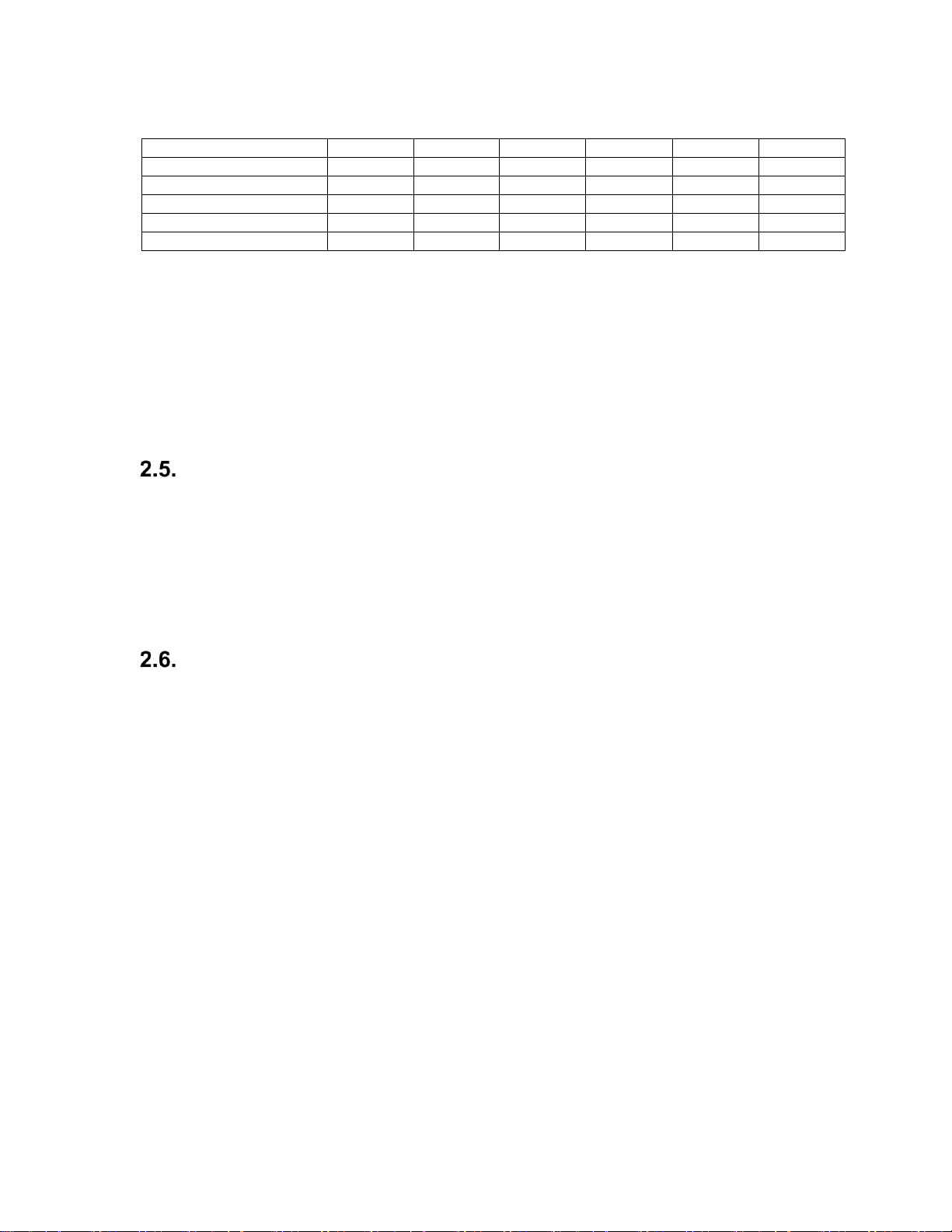

Wireless module Configuration

Depending on the configuration, the RigRat may provide GPS, GNSS, Mesh, WIFI, BLE, LoRa, and/or

NB-IoT wireless communication, the possible configurations are shown in this table:

Designator on PCB

U19

J7

J9

J8

BLE ●

either WIFI or NB-IoT

●

either Mesh or LoRa

●

either GPS or GNNS

●

● Optional wireless module

Sensor configuration

The RigRat may be configured with a MIPEX NDIR sensor, Dynament NDIR sensor, LEL sensor, PID

sensor, and EC sensor, which are mounted inside the IP-54 RigRat enclosure. These sensors have

been separately certified or tested according to IEC 60079. Refer to this table for more information

about these sensors:

Sensor

Type

Ex marking

IECEx CoC or

ExTR

Ambient

temperature

(℃)

Standard

EC

4R+EC

Ex ia II C T4 Ga

GB/SIR/ExTR10.

0276/00

-20 to+55

IEC60079-0:2007

Edition5

IEC60079-11:2006

Edition5

IEC60079-26:2006

Edition2

MIPEX NDIR

MIPEX 02

series

Ex ia ⅡC Ga

II 1G Ex ia IIC Ga

IECEx ITS

11.0047U

Issue No.5

ITS11ATEX274

18U, isse5

-55 to+60

IEC60079-0:2011

Edition:6.0

IEC 60079-11:2011

Edition:6.0

Dynament

NDIR

MSH2ia

***

Ex db ⅡC Gb

II 2 G Exdb IIC Gb

IECEx FTZU

15.0002U Issue

No.2

FTZU 14 ATEX

0213U

-20 to+60

IEC60079-0:2011

Edition:6.0

IEC60079-1:2014-06

Edition:7.0

IEC60079-11:2011

Edition:6.0

PID

4R+PID

Ex ia II C T4 Ga

GB/SIR/ExTR10.

0203/00

-20 to+55

IEC60079-0:2007

Edition5

IEC60079-11:2006

Edition 5

IEC60079-26:2006

Edition2

LEL Sensor

(Group II, T4)

1 LEL 75

x

Ex da ia ⅡC Ga

II 1G Ex da ia IIC

Ga

IECEx ULD

16.0016U Issue

No.1

DEMKO 16

ATEX 1557U

Rev.2

-40 to+60

IEC60079-0:2011

Edition6

IEC60079-1:2014-06

Edition7

IEC60079-11:2011

Edition6

Page 13

BW RigRat User’s Guide

13

For possible sensor installation, refer to thhis table:

Slot 1

Slot 2

Slot 3

Slot 4

Slot 5

Slot 6

MIPEX NDIR Sensor

●

Dynament NDIR Sensor

● ● ● PID Sensor

● LEL Sensor

● EC Sensor

● ● ● ●

●

● Sensor locations

EC Sensor: Max.5pcs

MIPEX NDIR Sensor: Max.1pc

PID Sensor: Max.1pc

LEL Sensor: Max.1pc

Dynament NDIR Sensor: Max.3pcs

In addition, there is a noise sensor located inside of the RigRat, which can measure the ambient noise.

The RigRat also contains a THP sensor in pumped version that can measure the ambient temperature,

humidity, and gas flow outside.

Electrical parameters

The RigRat provides 5 external connectors with the following electrical parameters:

AC charger connector(use only in a non-hazardous area): Um=6V

IS charger connector: Ui=24V, Ii=150mA, Pi=1.15W, Ci=88.4nF, Li=0.013mH

ON-OFF switch connector: Ui=30V, Ii=100mA, Pi=0.75W, Ci=0, Li=0

4~20mA input connector: Ui=30V, Ii=100mA, Pi=0.75W, Ci=0, Li=0

Type Designation

BWRR100 a-b-c

a identifies product version: D, P

D: Diffusion version (without pump)

P: Pump version

b identifies sensor configuration with regard to PID, Dynament NDIR, and LEL sensor

0: Without PID, Dynament NDIR, or LEL sensor

1: With PID sensor

2: With Dynament NDIR sensor

3: With LEL sensor

4: With PID and Dynament NDIR sensor

5: With Dynament NDIR and LEL sensor

6: With LEL and PID sensor

7: With PID, Dynament NDIR, and LEL sensor

c identifies wireless modules configuration with regard to WIFI and NB-IoT

0: Without WIFI or NB-IoT

1: With WIFI

2: With NB-IoT

3: Fitted with WIFI and NB-IoT

Depending on different configurations, the RigRat may refer to different types of protection, gas

groups, and ambient temperatures, which are specified as below. The onerous restriction shall be

taken into consideration in case one of the following is applied.

Page 14

BW RigRat User’s Guide

14

1. The first digit designates the Diffusion/Pump version. The following table details the

Diffusion/pump version together with ambient temperatures.

Type

Version

Ambient Temperature

(℃)

BWRR100 D-b-c

Diffusion version (without pump)

-40 to+60

BWRR100 P-b-c

Pump version

-20 to+60

Page 15

BW RigRat User’s Guide

15

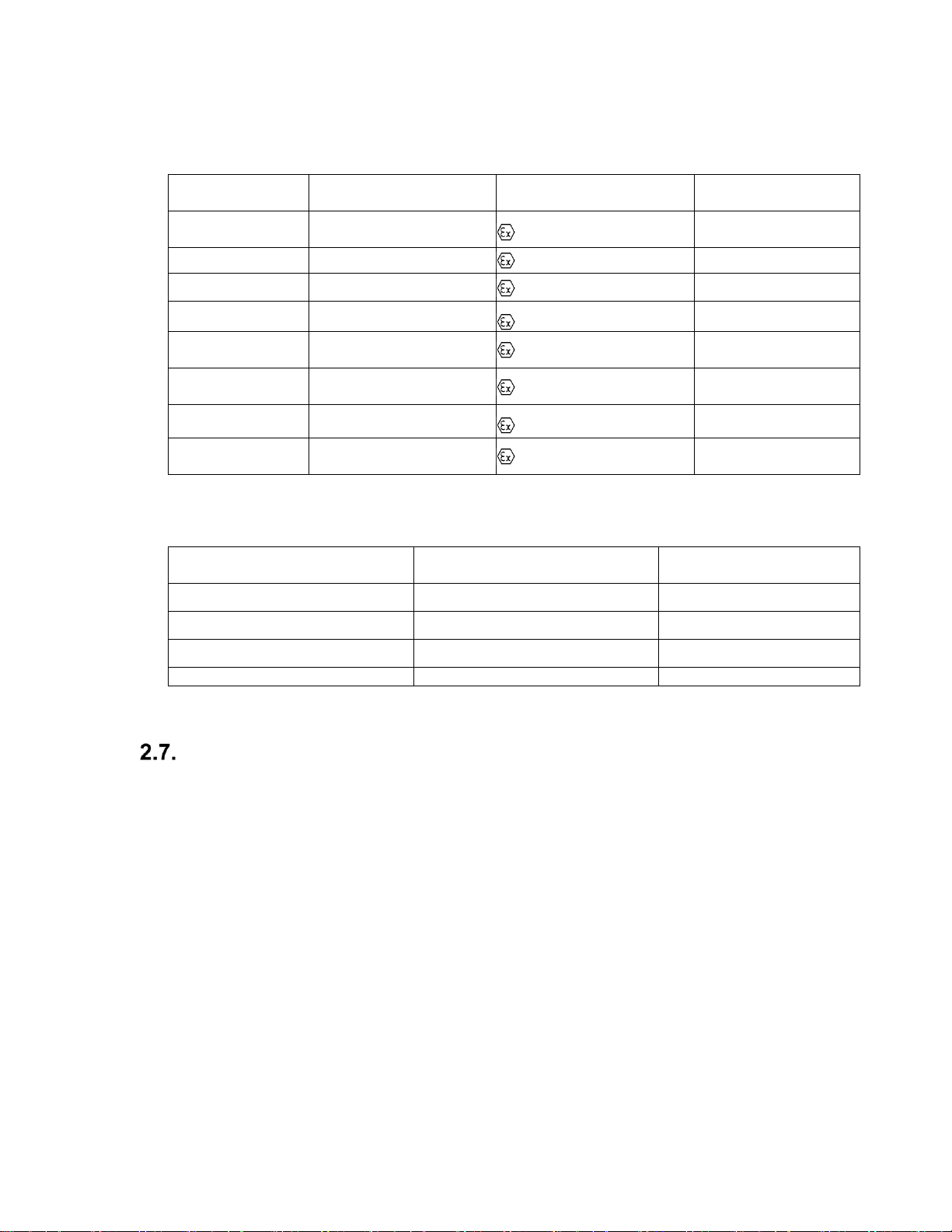

2. The second digit designates the configuration of sensors with regard to PID, Dynament NDIR, and

LEL sensor. The following table details the sensor configurations together with their Ex markings

and ambient temperatures:

Type

Sensor Configuration

Ex Marking

Ambient

Temperature (℃)

BWRR100 a-0-c

without PID, Dynament

NDIR or LEL

Ex ia II C T4 Ga

-40 to+60

BWRR100 a-1-c

with PID

Ex ia II C T4 Ga

-20 to +55

BWRR100 a-2-c

with Dynament NDIR

Ex db ia II C T4 Gb

-20 to +60

BWRR100 a-3-c

with LEL

Ex da ia II C T4 Ga

-40 to +60

BWRR100 a-4-c

with PID and Dynament

NDIR

Ex db ia II C T4 Gb

-20 to +55

BWRR100 a-5-c

with Dynament NDIR

and LEL

Ex db ia II C T4 Gb

-20 to +60

BWRR100 a-6-c

with LEL and PID

Ex da ia II C T4 Ga

-20 to +55

BWRR100 a-7-c

with PID, Dynament

NDIR and LEL

Ex db ia II C T4 Gb

-20 to +55

3. The third digit designates the configuration of wireless modules with regard to WIFI and NB-IoT.

The following table details the wireless module configurations together with their gas groups.

Type

Wireless Module

Configuration

Gas Group

BWRR100 a-b-0

without WIFI or NB-IoT

II C

BWRR100 a-b-1

with WIFI

II B

BWRR100 a-b-2

with NB-IoT

II B

BWRR100 a-b-3

with WIFI and NB-IoT

II B

Key Features

Available pumped or diffusion

Up to 6 gas sensor slots

Supports BLE/ Mesh/Wi-Fi/ GPS/LoRa (pending)

>25days’ runtime (Low Power version)

Wide operating temperature range (-40 to 60° C)

Rugged mechanical design

Page 16

BW RigRat User’s Guide

16

3. User Interface

The user interface consists of the display, LEDs, an alarm buzzer, and one multi-function button.

Display Overview

The backlit display provides visual feedback that includes the sensor types, readings, battery

condition, and other functions.

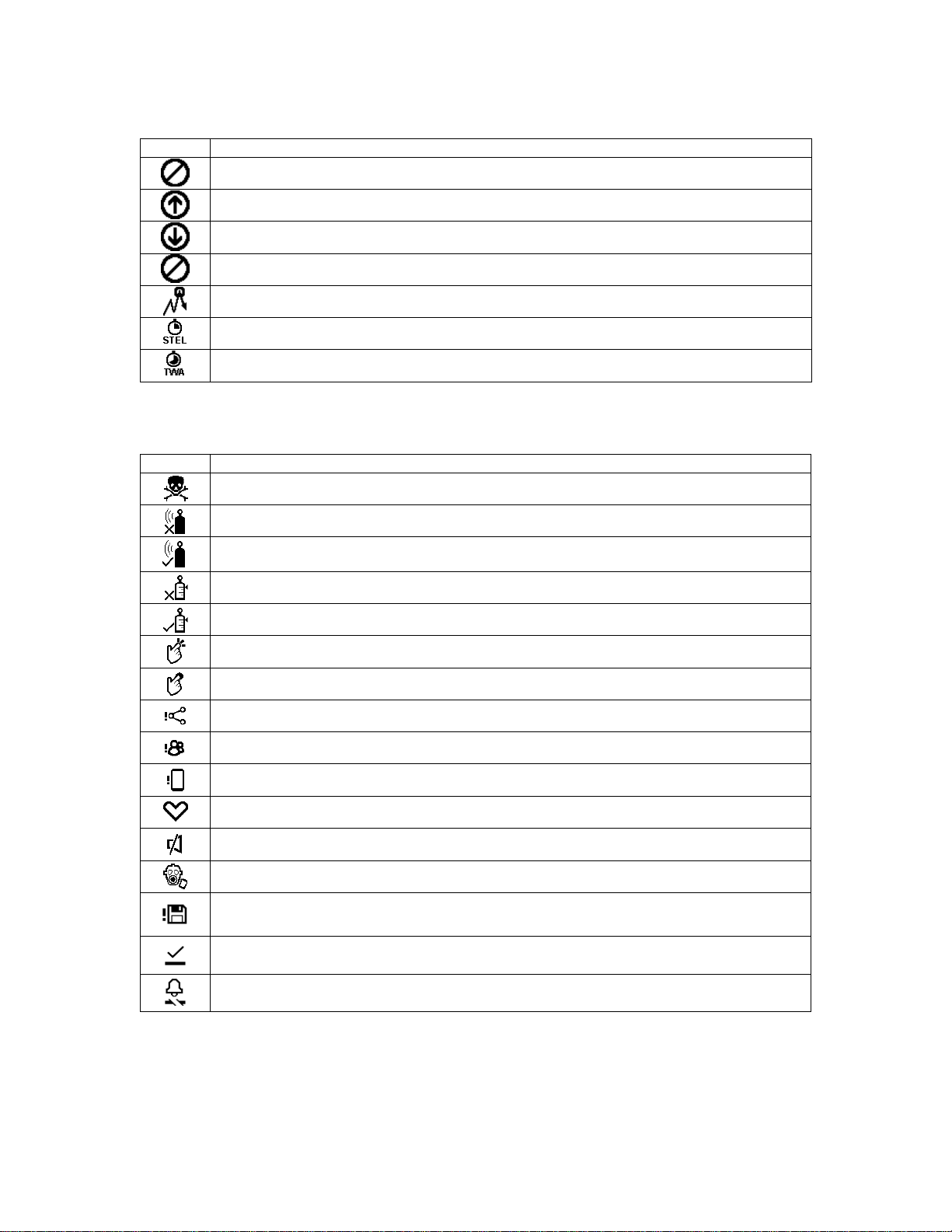

3.1.1. Status Indicator Icons

Status indicators tell you whether a function is operating and/or its strength or level, as well as alerts.

Icon

Function

Calibration passed

Calibration failed or overdue

Bump test passed

Bump failed or overdue

Status

TWA Alarm

STEL Alarm

Peak

Gas Alarm

Unit of measure

Reading value

Sensor type

Correction Factor

indicator

Communication,

Pump (if installed),

and battery status

Alerts

Page 17

BW RigRat User’s Guide

17

Inert Mode Enabled

Pump failure

Stealth/Mute

Button Press

Button Press And Hold

Mesh Wireless Signal Strength

Mesh Wireless Failed

Mesh Network Is Configured

Mesh Network Failure/Lost Connection

Closed-Loop Network Is Configured

Closed-Loop Network Failure/Lost Connection

Wi-Fi Connected (shows connection strength)

Wi-Fi Failure

BLE Enabled

BLE Failure

GPS

GPS Failure

Correction Factor

Battery (1 bar ≥ 10% remaining, 2 bars ≥ 50%, 3 bars ≥ 80%)

Battery error

Device Configurator app (shows when a new file is being pushed to RigRat)

Paired with Device Configurator app (flashes when data is transferring)

Device Configurator app failure

Data Logging

!

Page 18

BW RigRat User’s Guide

18

3.1.2. Icon Arrangement

Status and other information icons are shown at different places on the screen: The top, the “body”

(main display), and bottom.

Here is how they are organized and located on the screen:

Top

Icon

Explanation

Battery Alarm

Battery Level

Bluetooth

GPS

Pump

Signal

Wi-Fi

Menu - Disabled

Menu – Disable Sensor Selected

Page 19

BW RigRat User’s Guide

19

Body

Icon

Explanation

Battery Alarm

Low Battery

Bump Test

Inert Mode

Mobile

Network

Peak

Positive

Pump

Status

STEL

Stop

Test Detect

Test Fail

Gas Not Detected During Test

Test Positive

Test Warning

TWA

Waiting For Operation To Complete (animated)

Warning!

Correction Factor Applied

Page 20

BW RigRat User’s Guide

20

Data Readings

Icon

Explanation

Disabled

High

Low

Sensor Disabled

Peak

STEL

TWA

Bottom

Icon

Explanation

Alarm

Bump Test Fail

Bump Test Pass

Calibration Fail

Calibration Pass

Click

Hold

Mesh Network

Network

Pair Device

Status

Stealth Mode

Inert Mode

Data Logging

I/O in normal status

I/O in alarm or fault status

Page 21

BW RigRat User’s Guide

21

3.1.3. Design & Interface

The RigRat’s functions are controlled via the front-panel multi-function button. The display shows

information such as monitored threats, real-time readings and measurement units, alarm type (when in alarm,

including cal. overdue), battery status, datalog (if on), and radio and connection quality (if available).

In addition to turning the instrument on and off, the multi-function button can be used to control

different parameters and make selections within the instrument’s menus. Also, pressing the button

activates display backlighting when it is off: Press the button once when the backlighting is off to turn it

on.

Display

AC Charge

Port

Alarm

LED

Antenna

Handle

Multi-Function

Button

Alarm

Buzzer

Alarm

LED

IS Charge

Port

Noise

Sensor

Antenna

Handle

Alarm

Buzzer

Alarm

LED

Gas Inlet

(Pumped Version)

4-20mA In

Connector

Port

Front View

Rear View

Alarm

LED

Sensor

Compartment

Serial I/O

Connector

Port

(Not intended to be

used in explosive

atmospheres)

I/O Connector

Switch

Port

Page 22

BW RigRat User’s Guide

22

3.1.4. Rain Protector (Optional)

The optional Rain Protector (P/N: W03-2038-000) presses into place over the sensor compartment. It

protects the sensors from rain and large debris. It easily pulls off when you need to access the sensor

compartment.

Screen Display For Various Numbers Of Active

Sensors

The BW RigRat can accommodate from one to six sensors. When one or more sensors is either not

installed or turned off, the display only shows the installed, active sensors. If one is turned off, it is

shown in gray.

Page 23

BW RigRat User’s Guide

23

Info

The info screens are easy to step through by pressing the button once to advance from one to the

next. Hold the button down for secondary actions.

Note: In most cases, if no buttons are pressed at any of the menu steps for 60 seconds, the

instrument reverts to the main display.

Page 24

BW RigRat User’s Guide

24

4. Mesh Wireless Control And Submenus

When you step through the main menu, as shown in the Menus diagram, there is a screen for wireless

communication, containing information on wireless settings and status.

Note: Wireless settings are only present if the RigRat is equipped with a Mesh Network wireless

module. Settings are managed through the Device Configurator app, under the “Wireless” heading.

Settings include:

Mesh: Enable/Disable

Pan ID: 1 to 999

Channel: select

Interval: select

Off-Network Alarm: On/Off

Network Mode: Router/STD/Close Loop

Wireless Mesh Radio equipped models (that is, not Wi-Fi) allow you to check communication with

other wireless devices and get other useful information about the wireless settings.

Mesh Wireless Network (if supported)

4.1.1. Closed-Loop Network

Use the Device Configurator app to set all RigRat instruments’ mesh wireless Network Mode

to Closed Loop.

Set all RigRat instruments’ mesh wireless PAN ID/Channel so that they are all the same.

The RigRat instruments can now connect to each other.

The following are shown on the RigRat LCD:

o Mesh icon:

o Network status: Not in network or remote device is in alarm or in network

o At the Mesh Network Summary screen, you can find more other RigRat status

information.

Page 25

BW RigRat User’s Guide

25

4.1.2. Connect To Controller

Set RigRat instruments’ mesh wireless Network Mode to STD or Router by using the Device

Configurator app.

Set RigRat, Portable devices, Mesh Router, and Controller to have the same PAN ID/Channel.

The network is now ready. RigRat instruments will show on the Controller display.

Note: A router can bypass data. STD cannot bypass data, and can only act as an end device.

Enabling Router will cause the RigRat to consume more energy and decrease overall runtime before

recharging is necessary.

Mesh 868/915MHz

Mesh 2.4GHz

Page 26

BW RigRat User’s Guide

26

4.1.3. Connect To Radiant Reader

Set RigRat instruments’ mesh wireless Network Mode to STD or RTR by using the Device

Configurator app.

Set RigRat PAN ID/Channel to be the same as those in Radiant Reader.

The RigRat now joins the network and can show information on PC software.

Note: A router can bypass data. STD cannot bypass data, and can only act as an end device.

Enabling Router will cause the RigRat to consume more energy and decrease overall runtime before

recharging is necessary.

Page 27

BW RigRat User’s Guide

27

5. BLE

The RigRat is always equipped with a BLE module, it is easy to use the app on a smartphone or tablet

to perform setup functions.

BLE Pairing

Follow the device pairing instructions in Device Configurator. You will need to have the RigRat on and

showing the BLE Pairing Codes screen. Using the app, you will be given a guide to inputting the

confirmation number on the RigRat’s screen. Type the pairing code into mobile app to pair the

instrument and the smartphone/mobile app.

Connect a RigRat to Device Configurator (DC):

Open Device Configurator.

Select the Device List menu.

Push the RigRat button to wake up the display.

Click “Scan” to search for a nearby RigRat.

Select the RigRat (text such as “RigRat No, HRRD0009001” is printed on the nameplate or on

display’s “BLE pairing codes” screen).

The RigRat display will show a paring code on its bottom line. Input this code in the app’s

dialog box.

Input the password in the second dialog box. The default is 0000.

Now the RigRat (for example, RigRat HRRD0009001) connected.

TheRigRat display now shows this icon: .

Disconnect a RigRat in DC:

Click the connected RigRat icon on the Paired Devices screen.

Click Unpair to disconnect this RigRat.

Connect to another RigRat in DC:

Disconnect the connected RigRat first.

Scan and select another RigRat in the Available Devices list.

Connect it. Refer to the above steps in Connect a RigRat to Device Configurator (DC).

Note: The RigRat LCD must be at the main screen when working with the Device Configurator app.

Important! Uploading a configuration to a RigRat is not possible when the device is in gas alarm or

when the battery is near empty.

Page 28

BW RigRat User’s Guide

28

Broken BLE Connection

Sometimes a BLE connection can be disconnected. This can occur if there is too much interference, or

if the smartphone running the monitoring app is turned off or goes out of BLE range. When this

happens, the Mobile Connection icon is not shown on the RigRat display.

Check for interference (too many BLE communications nearby, too much distance between the RigRat

and the smartphone). You may need to turn off the RigRat and exit the app, and then restart both and

re-pair.

Note: The BLE connection between a smartphone and a RigRat is best within a distance of 5 meters.

The RigRat’s BLE will automatically shut down in 15 minutes if no operation is performed. It is

necessary to push the button to wake the RigRat BLE, which will then be detected by a smartphone.

Wi-Fi Connection (if supported)

RigRat Wi-Fi is designed to operate on a wireless network anchored by ProRAE Guardian monitoring

software and using Wi-Fi access points. Operational distance between the instrument and the access

point (wireless router) varies, depending on such factors as interference and obstacles. It uses the

802.11b/g/n protocol using the 2.4GHz ISM (license-free) frequency band.

Note: To ensure the best communication, it is recommended that the Wi-Fi-equipped instruments and

access point not be located close to microwave ovens, cordless telephones, or Bluetooth devices.

5.3.1 Secure Wireless Access Point Configuration

If Wi-Fi is enabled, an RigRat uses a Wi-Fi wireless network to transmit data related to its current and

past activity. To protect these data against unauthorized access, Honeywell recommends the following

when configuring your wireless network:

Set a unique network name (SSID). Do not use the default name.

Set unique administrative credentials (username and password) that control the configuration

settings of your Access Point / Router / Gateway. Do not use the default credentials. Use a

strong password (see Strong Password Tips).

Configure strong authentication and encryption in your network. Honeywell recommends

WPA2 Personal (aka WPA2-PSK) with AES encryption.

Create a strong network passphrase (see strong password tips). Do not use the default

passphrase.

Maintain the firmware of your Access Point / Router / Gateway as well as the firmware of all

devices connected to the wireless network up to date.

Page 29

BW RigRat User’s Guide

29

5.3.2 Setting Wi-Fi Communication Parameters in Device Configurator app

Wi-Fi-equipped instruments’ parameters for communication must be set in Device Configurator app.

Wi-Fi

You can enable or disable Wi-Fi.

Mac Address

Select “Use Static IP Address” if you have a static IP or “Use DHCP” if your system allows dynamic

hosting configuration. Check with your system administrator to determine which is appropriate for your

network.

If you use a static IP address, you must provide the Static IP address, Gateway, and Subnet Mask. If

you are using DHCP, you do not have to provide these, because they will be filled in automatically.

Channels and Security

Check with your system administrator for the settings in this section.

Security Mode

Different types of wireless security guard your network against possible instances of unauthorized

access. Using security, you can:

Ensure that no one can easily connect to your wireless network without permission

Personalize access regarding who can configure your wireless settings

Protect all data that is transmitted through the wireless network

Check with your system administrator for the wireless security mode you should use.

Use the drop-down menu to select the type of security:

Then set your Security Key.

Warning! Using a network with security disabled is not recommended.

Security Key

Depending on the type of security you choose, your key will have to be a different number of

characters.

IMPORTANT!

Configure strong authentication and encryption in your network. WPA2 Personal (also known as

WPA2-PSK) with AES encryption is highly recommended.

Page 30

BW RigRat User’s Guide

30

Here are characteristics of the different types, their relative security strength, and the number of

characters needed in the key:

Security Type

Security Rank

Number of Characters

WEP (Wired Equivalent Protocol)

Basic

40/64-bit (10 characters)

128-bit (26 characters)

WPA Personal

Wi-Fi Protected Access Personal

Strong

8 to 63 characters

WPA2 Personal

Wi-Fi Protected Access 2 Personal

Strongest

8 to 63 characters

WPA2/WPA Mixed Mode

WPA2: Strongest

WPA: Strong

8 to 63 characters

Strong Password Tips

Use a unique password. Do not reuse passwords used in other systems or for other purposes.

Avoid using examples found on the Internet, in literature etc.

Use a long sequence of random characters (at least eight characters).

Use a mix of different types of characters, such as uppercase and lowercase letters, numbers,

punctuation marks, etc.

To make the password easier to remember, begin with a sentence, verse, book title, line from a

song etc. Omit or change certain letters. For example, use only the first few letters from each

word, replace some letters with numbers or punctuation marks (for example replace all letters “a”

with dots “.”), etc.

Avoid using easily guessable phrases, like names, words found in dictionaries, years, birthdays,

phone numbers, etc.

Avoid using the most popular passwords, such as “123456”, “qwerty”, “password” etc.

Also avoid using them even in modified formats, such as “QWErty” or “Pa55vv0rD”.

Protect the password while archived. Use trusted and properly configured password vaults for this

purpose.

SSID

The SSID (Service Set Identifier) is a case-sensitive unique identifier attached to the header of packets

sent over a wireless local-area network. Each wireless network in your range will have its own SSID.

Consult with your IT department for the SSID.

Server IP

This is the destination IP address for the instrument to communicate with a computer running ProRAE

Guardian.

Server Port

The port number is distinct from any physical port on a computer such as a COM port or an I/O port

address. It is a 16-bit address that exists only for the purpose of passing certain types of information to

the correct location above the transport layer of the protocol stack.

Test The Wi-Fi Operation

Test the RigRat in your network to ensure that it communicates properly. Always do this after

performing any changes to wireless parameters.

Page 31

BW RigRat User’s Guide

31

Secure Wireless Communication

Secure communication between a RigRat and the server via Mesh or Wi-Fi connection or mesh

closed-loop connection can be configured with the Device Configurator app in the General Settings

Mesh Security page. It can be configured to enable or disable the encryption, and the secure keys can

be changed. The Network Preshared Key is 32 characters long, and the Mesh User Key is 4

characters.

For Mesh or Wi-Fi connection to the server, both the RigRat and the server must have the

same Network Preshared Key.

For Mesh Closed Loop connection, all RigRats in the same network must have the same

Network Preshared Key and Mesh User Key.

Note: The server must be running the latest version of ProRAE Guardian to support secure

communication.

Page 32

BW RigRat User’s Guide

32

6. Battery Charging

Always fully charge the battery before using the RigRat. Its Li-ion batteries are charged by connecting

the instrument to its charger (P/N: W03-3044-000) and then plugging the charger into an AC power

source. In safe settings, use the AC Charge input with the included power adapter.

Charging Ports

There are two charging ports:

AC Charging, Safe Area

Intrinsically Safe Charging For Hazardous Areas

Remove the cover for the appropriate port by turning it counterclockwise:

Note that the ports have different pin configurations and therefore require different cables for

connection.

IMPORTANT!

Make sure the cable connector is tight. Finger-tighten the connectors, but do not use tools.

Align the connector and plug and then press in and turn the ring until it clicks.

6.1.1. AC Charging, Safe Area

For charging in safe areas, use the AC/DC adapter (P/N: W03-3044-000). Remove the dust cap on the

port labeled AC CHG SAFE AREA, align the indexing pins on the connectors, press in, and then turn

the ring until it clicks.

IMPORTANT!

Make sure the cable connector is tight. Finger-tighten the connectors, but do not use tools.

It is strongly suggested to turn off the RigRat while charging on the AC charger. Running the RigRat

while charging results in a longer charging time.

Page 33

BW RigRat User’s Guide

33

WARNING!

Do not charge the RigRat with the AC charger in a hazardous area! Always charge the RigRat with the

AC charger in a safe area.

AC CHG SAFE AREA

PIN

1

VDD

Charger port, positive, input, rated 5.7VDC/3A

PIN

2

Reserved

HW Reset

PIN

3

CHG_STA

Charging status indicate, output, In-charging/fullcharged

PIN

4

GND

Charger port, negative

6.1.2. Intrinsically Safe Runtime Extension For Hazardous Areas

If the RigRat is to be charged or powered in a hazardous area, then an intrinsically safe (I.S.) barrier

box is necessary. Use P/N: W03-3018-000, and connect it to the IS CHG HAZARDOUS port.

Note: The intrinsically safe line power is only providing runtime extension.

1. Requirements:

a. W03-3018-000 I.S. barrier, 110~230VAC/50~60Hz IN, 23.5VDC/1.15W OUT

b. W03-2168-000 I.S. barrier extension cable, 100 m, 3-pin plug

Schematic drawing shows how the IS Barrier is configured with the RigRat:

Page 34

BW RigRat User’s Guide

34

Intrinsically safe barrier terminals in use

IS Barrier

Terminal A

-

Safe area, power negative input

Terminal B

+

Safe area, power positive input, rated 110~230VAC

Terminal H

-

To hazardous area, negative output

Terminal L

+

To hazardous area, positive output, max 23.5V/1.15W

IS barrier parameters:

Input Rated 110~230VAC/50~60Hz

Consumption ≤ 3W

Output (to hazardous area) Uo=23.5V;

Io=150mA;

Po=1.15W;

Co=132nF;

Lo=1.5mH

Operating Temp. -20 to 60 ℃

Relative humidity 5 to 95% without condensing

Installation In safe area

Extension cable (W03-2168-000)

W03-2168-000 IS barrier to BW RigRat cable, 100meters, with 3-pin connector.

Total 100m cable IS parameters: (C=80pF/m; L=0.7uH/m; R=23.2mΩ/m)

Ct=8nF

Lt=0.07mH

BW RigRat IS parameters in hazardous area:

Ui=24V

Ii= 150 mA

Pi=1.15W

Ci=0.36nF.

Li=0uH

For hazardous applications, these conditions must be met:

Uo ≤ Ui

Io ≤ Ii

Po ≤ Pi

Co ≥ Ci + Ct

Lo ≥ Li + Lt

Uo/Io/Po/Co/Lo are IS barrier output parameters

Ui/Ii/Pi/Ci/Li are RigRat input parameters

Ct/Lt are extension cable additional parameters

Matched plug (P/N: 400-4105-003)

Page 35

BW RigRat User’s Guide

35

+

IS barrier output, positive

-

IS barrier output, negative

NC

Not connect

6.1.3. Cover Ports When Not In Use

Whenever a port is not in use, make sure the port is covered. This keeps the contacts clean and

prevents inadvertent short-circuiting. Finger-tighten the covers, but do not use tools.

WARNING

To reduce the risk of ignition of hazardous atmospheres, recharge, remove or replace the

battery only in an area known to be non-hazardous!

Rechargingthe battery pack can be performed in hazardous area only via IS charge port.

When power is applied and the RigRat’s battery is charging, When the battery is fully charged, the Full

Charge icon is shown accompanied by “100%.” If the instrument is off but is being charged, it shows

the charge state and percentage.

Page 36

BW RigRat User’s Guide

36

Battery States

The battery icon on the display shows how much charge is in the battery and alerts you to any

charging problems.

Battery low

≥10%

≥50%

≥80%

When the battery power is critically low, the instrument displays a warning that it will be shutting off:

The instrument automatically powers down and you will need to recharge the battery before placing

the instrument into service again.

Page 37

BW RigRat User’s Guide

37

7. Wired Communication

The RigRat has three ports for external communication. They are labeled:

Serial (not intended to be used in explosive atmospheres)

Switch

4-20mA IN

Serial (Not Intended To Be Used In Explosive Atmospheres)

The Serial port is designed to be the interface point with an option RAEMet meteorological sensor.

Pins

Pin A

VCC

Power output, rated 4VDC

Pin B

CS

Chip select, output

Pin D

RX

UART port, output

PIN E

GND

Ground

Pin F

TX

UART port, input

Others

Reserved

Note: Refer to RAEMet Sensor Installation (page 60) for details on connecting to a RAEMet Sensor.

Page 38

BW RigRat User’s Guide

38

Switch

RigRat supports three separate SPST PhotoMOS relay output switch connections for applications

where other equipment needs to be controlled (lights, sirens, etc.).

Relay Definitions:

Relay 1 Any gas sensor failed, or STEL/TWA/+OL/-OL alarms

Relay 2 Any high alarms

Relay 3 Any low alarms

IMPORTANT! This is a fixed configuration that can only be modified via Device Configurator app.

Note: Driving high current or voltage through the switch will damage the product.

Note: The default option is NO (normally open). It can be set to NC (normally closed) via the Device

Configurator app. Note that NC consumes more battery current.

PhotoMOS relay output switch parameters

Must meet IS parameters if used in hazardous area!

Item

Value

Note

Voltage

30V

AC/DC

Max power consumption on switch

0.75W

Continuous load current

100mA

On resistance

1Ω typical

Page 39

BW RigRat User’s Guide

39

SWITCH pins definition

PIN A

NO1

Solid-state relay 1, NO

PIN B

COM1

Solid-state relay 1, COM

PIN H

NO2

Solid-state relay 2, NO

PIN J

NO3

Solid-state relay 2, COM

PIN M

COM2

Solid-state relay 3, NO

PIN N

COM3

Solid-state relay 3, COM

Others

Reserved

Matched plug (P/N: 400-4105-014)

For hazardous applications, the system should meet these parameters:

Uo ≤ Ui

Io ≤ Ii

Po ≤ Pi

Co ≥ Ci + Ct

Lo ≥ Li + Lt

Uo/Io/Po/Co/Lo are IS barrier output parameters;

Ui/Ii/Pi/Ci/Li are RigRat input parameters;

Ct/Lt are extension cable additional parameters.

RigRat switch port IS parameters:

Ui=30V

Ii= 100mA

Pi=0.75W

Ci=1.1nF.

Li=0uH

Page 40

BW RigRat User’s Guide

40

4-20mA IN

The RigRat supports a 4-20mA signal input and a no source switch on/off signal input. When 4-20mA

input, RigRat will check and show the current, also will give an alarm when out of limitation value.

When switch signal input, RigRat will alarmed when switch on. This is for emergency alarm.

4-20mA IN

PIN A

GND

Switch input, GND

PIN B

I/O

Switch input, signal

PIN D

Iin+

4-20mA input positive

PIN E

Iin-

4-20mA input nagtive

Others

Reserved

Matched plug (P/N: 400-4105-010)

Page 41

BW RigRat User’s Guide

41

For hazardous applications, the following must be met:

Uo ≤ Ui

Io ≤ Ii

Po ≤ Pi

Co ≥ Ci + Ct

Lo ≥ Li + Lt

Uo/Io/Po/Co/Lo are IS barrier output parameters;

Ui/Ii/Pi/Ci/Li are RigRat input parameters;

Ct/Lt are extension cable additional parameters.

RigRat switch port IS parameters:

Ui=30V

Ii= 100mA

Pi=0.75W

Ci=0nF.

Li=0uH

Cover Communication Ports When Not In Use

Whenever a port is not in use, make sure the port is covered. This keeps the contacts clean and

prevents inadvertent short-circuiting. Finger-tighten the covers, but do not use tools.

8. External Filter

The External Filter (P/N: W03-3006-000) is designed to prevent debris from entering the RigRat in dirty

or dusty environments. Replace the filter when it appears dirty.

Filter Replacement (Pumped)

The external filter is located on the rear of the RigRat:

1. Turn off the RigRat.

Filter

Page 42

BW RigRat User’s Guide

42

2. Loosen the two Philips screws that secure the filter.

3. Lift the filter out of its docking area.

4. Dispose of the old filter properly.

5. Press a new filter into place.

6. Replace and tighten the two Philips screws. Do not overtighten.

Page 43

BW RigRat User’s Guide

43

Filter Replacement (Diffusion)

If the filters over the sensors appear dirty, replace them. The external filters are located inside the

panel on the rear of the RigRat:

1. Turn off the RigRat.

2. Remove the Rain Protector.

3. Remove the four screws that hold the Sensor Cover in place.

4. Carefully take out the O-rings in each sensor location on the plate.

5. Remove the current filters.

Page 44

BW RigRat User’s Guide

44

6. Place new filters (P/N: M01-2067-000) into each of the six locations.

7. Place the O-rings back in their original locations.

8. Put the plate back in place.

9. Tighten the four screws.

10. Replace the Rain Protector.

Page 45

BW RigRat User’s Guide

45

9. Turning The RigRat On And Off

Turning The RigRat On

With the instrument turned off, press and hold the button until LCD display starts a countdown, and

then release. During startup, the battery, buzzer, and LEDs are tested, and then it performs self-testing

of its other functions. When the main measurement screen appears, the instrument is ready for

calibration or use.

Note1: The type number is given on the LCD display during startup, refer to clause 2 for more

details about use restriction.

Note 2: When the battery’s charge falls below a preset voltage, the instrument warns you by showing

a critical error message, and turn off automatically in 3 seconds. You should charge the battery before

turning it on again.

IMPORTANT!

If a major error that prevents the RigRat from functioning is found during startup, the message

“Contact Service” is shown on the display. The instrument should be shut off and serviced.

Note: During a pumped BW RigRat’s startup, startup pauses and the display instructs you to place your finger

over the pump inlet to test the pump. Leave the inlet covered until instructed to remove your finger.

Page 46

BW RigRat User’s Guide

46

During startup, sensors and functions are checked. Also, if sensors are overdue for a bump test or

calibration, either or both of these screens will be displayed to alert you:

Note: If you do not click the button to acknowledge being informed of overdue tests, the instrument will

shut itself off in 300 seconds (5 minutes).

Turning The RigRat Off

At the main measurement screen, press and hold the button. A 3-second countdown to shutoff begins.

After that, another 3-second countdown to enter the menu begins. You must release the button during

the second 3-second countdown to shut off the instrument. The screen displays “OFF” for 3 seconds,

and then the instrument is off. If you release the button during the first 3-second countdown, the

instrument continues normal operation.

Note: if you continue to hold the button during the second 3-second countdown, it enters the main

menu.

Note: You cannot turn off the RigRat if it is in gas alarm.

Page 47

BW RigRat User’s Guide

47

Testing Alarm Indicators

Under normal-operation mode and non-alarm conditions, the backlight can be tested by turning the

instrument on. If you perform a bump test, the buzzers and LEDs are tested.

IMPORTANT!

If any alarm does not respond, check alarm settings to make sure all alarms are enabled. If any alarms

are enabled but not functional, the instrument should not be used.

Calibration Status

If any sensor requires calibration, then you are alerted on the screen during startup, and the sensor

requiring calibration is shown in red:

Calibration is required if:

The sensor module has been replaced with one whose calibration is overdue.

The defined period of time between calibrations has been exceeded, according to the policy

set for the instrument.

If you have changed the calibration gas type without recalibrating the instrument.

The sensor has failed a previous calibration.

Bump Status

If any sensor requires a bump test, then during startup, the screen displays “Bump Overdue,” with a

list of those sensors shown in red:

A bump test is required if the defined period of time between bump tests has been exceeded. This

interval is set by an administrator using Device Configurator.

Page 48

BW RigRat User’s Guide

48

10. Modes of Operation

The RigRat has three modes, Operation Mode, Menu Mode, and Diagnostic Mode.

Operation Mode

Menus in Operation Mode are easy to step through by pressing the button.

Note: There is only one button.

Note: There are two types of button presses: Short press (Click) and longer press (Hold).

Menu Mode

In Menu Mode, the RigRat provides access to start calibration, enable/disable sensors, and enter

Mesh Network Assistant.

This mode can only be accessed with the instrument turned on and then holding the button down

through the 3-2-1 countdown, followed by a second 3-2-1 countdown.

10.2.1. Entering Menu Mode

1. With the RigRat on, hold the button down through the 3-2-1 countdown, followed by a second

3-2-1 countdown.

2. The password screen appears, release the keys.

3. Enter the 4-digit password (the default password is 0000).

Step from one position in the four-character string to the other by holding the button down.

Press the button repeatedly to select a desired number. Numbers increase from 0 to 9.

Once 9 is reached, pressing again “wraps” around back to 0.

4. When you are done, hold down the button. If you input the correct password, you receive

access.

Start Calibration

Initiate a calibration by holding the button. Calibration will begin with fresh air calibration. Follow the

instructions on the screen for other calibrations.

Enable/Disable Sensors

You can individually enable or disable a sensor.

1. Press the button to scroll through the sensors.

2. Hold the button down to enable/disable a selected sensor.

Mesh Network Assistant

The screen shows these:

Unit ID

Signal quality

Ping Tx

Ping Rx

Signal quality shows how well signal is being received. Ping Tx (Ping transmission) “pings” other

wirelessly connected devices on the network. Each ping is counted. Ping Rx (Ping received) indicates

how many pings have been received by other devices on the network.

Page 49

BW RigRat User’s Guide

49

10.2.2. Exiting Menu Mode

There are two ways to exit Menu Mode:

If you do not press a button, after 20 seconds it will revert to the main screen.

Press the button until you reach “Exit.”

Diagnostic Mode

In Diagnostic Mode, the RigRat provides information about the instrument, battery, pump, etc., as well

as a list of installed sensors and information about them (expiration date, serial number, etc.). Most of

these screens are useful only to service technicians.

Enter Diagnostic Mode

When the instrument is off, press and hold the button for more than 10 seconds after the 3-second

countdown. The instrument starts self-testing and then enters Diagnostic Mode. In Diagnostic Mode,

briefly press the button to navigate through the screens of instrument status, test LCD, LED, buzzer

and pump.

10.4.1. Navigating Diagnostic Mode

Step through Diagnostic Mode by pressing the button. The first screen shows information about the

product, including the serial number, firmware version, etc. Exit Diagnostic Mode at any time by

shutting the instrument off at this screen (hold the button for the 3-second countdown).

Instrument model name and ID number (in hexadecimal)

Serial number

Instrument firmware Version

Firmware build date

Firmware build time

RTC

Sensors Installed

Socket Raw Counts (for all enabled sensors)

Sensors Serial Number

Sensors Zero and Span raw counts

Sensors produced date and warranty

Battery capacity/voltage/current/temperature/SOH/cycle counts

Battery current at idle mode (Hold button to enter idle mode and calculate)

RAEMet readings (if installed)

Noise sensor information (if installed. Hold to start calibration.)

GPS information (if installed)

LCD test (Hold to start test procedure.)

LED and Buzzer test (Hold to start test procedure)

Switch output/Digital input/4~20mA information (Hold to test switch output.)

Page 50

BW RigRat User’s Guide

50

Exit Diagnostic Mode

In Diagnostic Mode, press the button to navigate to the following screen. If you hold the button now,

the screen displays “OFF”. Release the button. The instrument is now off.

Note: Keep holding the button down at this screen for 10 seconds. The RigRat will ask for the 4-digit

password. When the correct password is used, the RigRat enters normal operation mode with

diagnostic mode datalogging.

Page 51

BW RigRat User’s Guide

51

11. Programming

Using Device Configurator

The Honeywell Device Configurator Mobile App for mobile devices provides easy control over the BW

RigRat’s settings and functions. After pairing the BW RigRat with your mobile device, change settings,

manage firmware updates, examine datalogs, upload configuration data, and more.

Download the free Device Configurator Mobile App. Then follow the instructions for installation.

Android

iOS

Go to Device List to see which devices are paired. Click Scan.

If your RigRat is in the Paired Devices list, click on it. When it connects, it says, “Connected.”

You can disconnect from a paired device by clicking its name. A confirmation box is shown. Click “OK”

to disconnect.

Security Mode

Different types of wireless security guard your network against possible instances of unauthorized

access. Using security, you can:

Ensure that no one can easily connect to your wireless network without permission

Personalize access regarding who can configure your wireless settings

Protect all data that is transmitted through the wireless network

Check with your system administrator for the wireless security mode you should use. Then set your

Security Key.

Warning! Using a network with security disabled is not recommended.

Page 52

BW RigRat User’s Guide

52

12. Calibration And Testing

Bump Testing And Calibration

To ensure greatest accuracy and safety, only bump test and calibrate in a fresh air environment.

The monitor should be calibrated every time it does not pass a bump test, but no less frequently than

every six months, depending on use and exposure to gas and contamination, and its operational

mode.

• Calibration intervals and bump test procedures may vary due to national legislation.

• Honeywell recommends using calibration gas cylinders containing the gas that is appropriate to

the sensor you are using, and in the correct concentration.

When a bump test is done manually, the instrument makes a pass/fail decision based on sensor

performance, but the user still has the responsibility to make sure all the alarms are enabled and

functional.

Bump (Functional) Testing

The same gas is used for a bump test as for calibration. A constant-flow regulator producing 0.5 liters

per minute should be used, and the calibration adapter must be installed on the diffusion model of the

RigRat. The instrument must be connected to a cylinder of calibration gas with supplied tubing.

Note: If LEL% and VOL% sensors are installed always bump test the LEL% sensor first.

1. Turn on your RigRat by pressing and holding the button, and allow the instrument to boot up

fully until the main measurement screen with sensor names and readings is shown.

Important! Make sure all of the instrument’s sensors have warmed up before performing a bump

test. The instrument will take the time to warm up the sensors prior to enabling access to bump

test menus. You can tell a sensor has warmed up if you see a reading next to it name on the

display. If it has not warmed up, you see three dashes (“---”) next to it.

2. Diffusion: Install the calibration adapter on the RigRat by setting it on over the sensors and

pressing until it is snug against the surface of the instrument.

Pumped: Connect tubing from the filter’s inlet to the regulator on the gas cylinder.

Diffusion

Pumped

3. To start the bump test, hold the button for 3 seconds at the “Bump Due” screen.

4. The 3-color LED and buzzer will activate (this tests the alarms).

5. Hold the button for 3 seconds if the audible and visible alarms are fully functional. Otherwise,

press the button once to confirm that you understand there are faults.

Page 53

BW RigRat User’s Guide

53

6. After the audio-visual test, bump test, the instrument is ready for calibration.

7. Mount the calibration adapter and apply gas when the display shows “Apply test gas now.”

Otherwise, the bump test will fail. Also, it may be necessary to change gas cylinders to provide

the necessary gas for each sensor bump test.

8. When the test is complete, test results are shown on the display.

Page 54

BW RigRat User’s Guide

54

If the Audio-Visual test fails or some sensors fail their bump test, the display will show results

like this:

Important! Gas must be applied only after RigRat shows “Apply test gas now.” Otherwise, the bump

test will fail.

Important! If one or more sensors fails a bump test, be sure to calibrate those sensors.

The bump test is now complete.

If all the alarms and all sensors have passed and no sensor is due for a calibration, the instrument is

now ready for use.

Calibration

This operation sets the zero and span points of the sensor calibration curve.

Note: If LEL% and VOL% sensors are installed, always calibrate the LEL% sensor first..

1. Hold the button for 3 seconds at main screen for the 3-second countdown.

2. After 3-second countdown for power off, keep holding the button, and the screen shows

another 3-second countdown for entering Menu Mode.

3. Enter the password and accept the number.

4. Press the button to advance to the next menu.

5. Press and hold the button for 3 seconds to enter calibration.

6. Press the button to start zero calibration.

Note: If the RigRat has CO2 or Oxygen sensor, after zero of fresh air, it will continue to

nitrogen for a zero calibration.

7. Install the calibration adapter and apply nitrogen.

8. Turn off the gas or remove the calibration adapter when the nitrogen calibration completed.

9. Install the calibration adapter again and apply span gas to continue span calibration.

Page 55

BW RigRat User’s Guide

55

13. Maintenance

The RigRat requires little maintenance, aside from replacing sensors and filters. Maintenance and

service shall only be performed by trained personnel and following the Honeywell guidelines provided

in Honeywell training programs.

IMPORTANT!

Honeywell cannot guarantee the IP rating of an instrument that has been opened and not reassembled

according to instructions.

Cleaning

Use water and a soft cloth to clean the RigRat. Do not use detergents or solvents. Do not submerge

the instrument underwater.

Antenna Installation

Attach the antenna by opening the compartment, aligning the antenna, and turning the base of the

antenna until it is snug. (Tighten by turning clockwise, and loosen by turning counterclockwise.)

A number is marked on the antenna body for easy identification:

** Depends on wireless modem (if installed).

IMPORTANT!

Make sure the antenna type is correct, or wireless communication distance will be reduced. Always

tighten the antenna completely. Failure to do so will result in reduced communication distance.

Description

P/N

Mark on body

Antenna 868-928MHz, RP-N**

550-7056-000

0188-1101

Antenna 2.4GHz, RP-N**

550-7057-000

0188-3101

Antenna

Page 56

BW RigRat User’s Guide

56

Removing Sensors

WARNING! Do not replace sensors in hazardous locations.

All sensors are located inside the sensor compartment on the rear of the instrument. To access the

sensors:

1. Turn off the instrument.

2. Remove the four screws that hold the sensor cover.

3. Lift off the cover.

4. Carefully lift out each sensor you wish to inspect or replace.

Sensor slots are keyed so that they can only accommodate specific types of sensors:

1 Slot 1: IR, IR low-power, or CO2

2 Slot 2: PID or IR or CO2 or EC

3 Slot 3: Catalytic combustion LEL or

EC

4 Slot 4: IR or CO2 or EC

5 Slot 5: EC

6 Slot 6: EC

Page 57

BW RigRat User’s Guide

57

Replacing Sensors

1. Gently lift out the desired sensor module with your fingers. If it is seated very tightly in the

socket, do not pull it with heavy force. Gently rock it slightly back and forth while lifting.

2. Install the replacement sensor. It can only go into its slot one way. The connector inside the

instrument and the indexing guides are good visual indicators of how to set the sensor into

position. Make sure the indexing keys are aligned, and press the sensor into place to ensure it

is seated firmly.

3. Replace the cover and tighten the four screws.

WARNING!

It is extremely important that sensors are installed in the correct orientation.

When installing a new sensor, the plastic film should be on top of the sensor. Once the sensor is

installed, remove the plastic film.

IMPORTANT! Always perform a full calibration after replacing sensors.

Battery Replacement

If the two rechargeable batteries ever need replacement, the work should only be performed by those

trained by Honeywell to service this instrument. Replacements should only be of the same type: P/N

500-0165-000.

WARNING! Do not replace battery in hazardous locations.

Match index keys on

sensor module with

socket

Sensor

indexing

key

Page 58

BW RigRat User’s Guide

58

Replacing The Pump

If the pump requires replacement, follow this procedure. The pump assembly part number is P/N:

W03-3016-000.

1. Turn off the RigRat.

2. Remove the four screws that hold the sensor compartment cover.

3. Lift off the sensor compartment cover and turn it over.

4. Remove the four screws that hold the pump assembly.

5. Lift the pump assembly from the side farthest from the gas plate and slightly pull it away from

the gas plate.

Page 59

BW RigRat User’s Guide

59

6. Remove the pressure sensor block by pulling it away from the pump.

7. Attach the pressure sensor block to the new pump by pressing it into place.

8. Install the pump assembly. Note the two inlets to the inlet and outlet for the pump, which

require tilting the pump assembly when you reassemble the system.

9. Reverse the disassembly process to reassemble the system.

10. When you are sure all parts are secure, turn on the instrument and test the pump to ensure

that it is operational.

IMPORTANT!

After replacing a pump, perform a pump test and perform a full calibration.

Gas inlet and outlet

Pressure sensor block

Page 60

BW RigRat User’s Guide

60

14. RAEMet Sensor Installation (not intended to be used in

explosive atmospheres)

If your RigRat is equipped with a RAEMet meteorological sensor (P/N: W03-3045-000), it is typically

removed for storage and must be attached before using it.

1. If the RigRat is on, turn it off. (Never attach or remove the RAEMet sensor without first turning

off the instrument’s power.)

2. Attach the RAEMet to the instrument‘s handle using the two U-shaped bolts and the wingnuts.

Then attach the sensor to the bracket.

3. Remove the cover over the Serial receptacle.

4. Align the RAEMet’s connector plug with the RigRat’s receptacle using the indexing keys and

slots as a guide.

Note locations of

indexing slots in

receptacle

Page 61

BW RigRat User’s Guide

61

5. Press the RAEMet’s base into place, and then turn the locking ring to tighten the connection.

Never force the connector in or out of the receptacle.

6. Tighten the locking ring until the RAEMet sensor is firmly seated. Do not turn the entire

RAEMet sensor.

IMPORTANT!

If the RAEMet and RigRat’s receptacle are not aligned properly, electrical connections will not be

made and the RAEMet sensor will not operate. Also, when the RAEMet sensor is not attached to the

instrument, make sure the cover is securely closed to keep moisture and debris from entering the

base.

Note: Do not remove the RAEMet sensor from the instrument while it is in operation.