Page 1

95−7767

Honeywell IdentIPoint™ Intelligent

Smartcard System

INSTALLATION INSTRUCTIONS

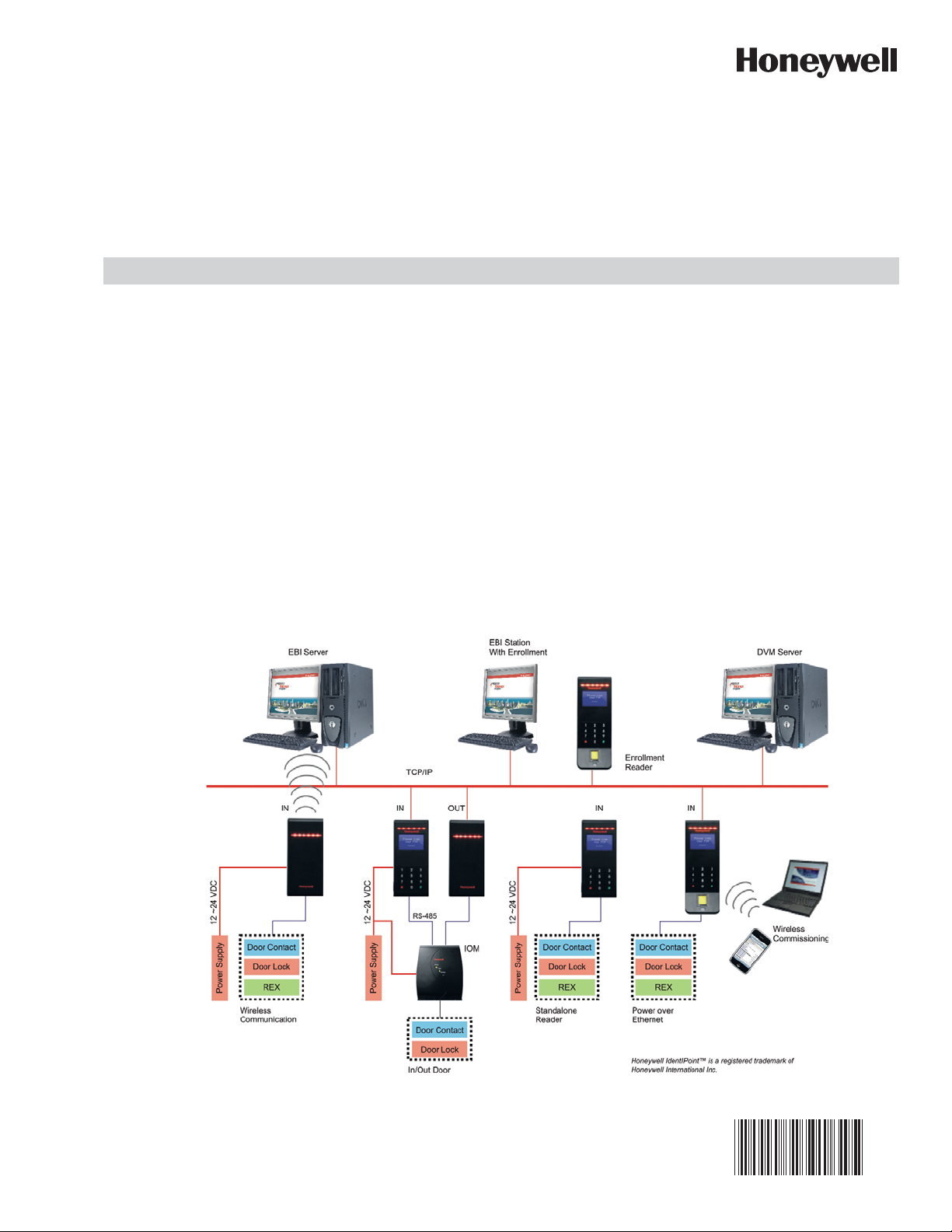

GENERAL

IdentIPoint™ is an intelligent smart card based access control

system that integrates with Enterprise Buildings Integrator™

(EBI) to provide a secure, scalable and a cost effective

solution for securing defense installations, airports, and

buildings. This document describes how to install and

configure the IdentIPoint system.

Fig. 1. IdentIPoint system architecture

Put Bar Code Here

Page 2

HONEYWELL IDENTIPOINT™ INTELLIGENT SMARTCARD SYSTEM

NOTE: For detailed connection diagrams see topics

Detailed Wiring Diagrams and Wiring Other

Devices.

NOTE: Any currently available IdentIPoint reader can be

used as an enrollment reader.

OVERVIEW

IdentIPoint is Honeywell's next generation smart card based

access control system in conjunction with Honeywell's award

winning Enterprise Buildings Integrator - EBITM. IdentIPoint

readers come with a powerful built-in controller thus

eliminating the need to install a separate multi-door access

controller. IdentIPoint offers flexible architecture options

including the option of connected and standalone readers.

The readers communicate with EBI over a wired or wireless*

Ethernet network.

The IdentIPoint hardware family consists of the following

models:

• Indoor / Outdoor basic readers - IP65 (BTBAS)

• Indoor readers with LCD & Keypad (BTSTD)

• Indoor readers with LCD, Keypad and Fingerprint

(BTFPT)2

• Remote Input Output Module (IOM) (BTIO)

IdentIPoint readers support the following Contactless Smart

Card Reader technologies:

• MIFARE Classic 1K, 4K

• MIFARE DESFire 4K

• MIFARE DESFire EV1 4K, 8K

IdentIPoint readers also support the following network

technologies:

• Wireless LAN IEEE802.11b/g standard; provides WPA

security for infrastructure mode of operation*.

• High speed 10/100 Mbps Ethernet connection for Wired

LAN via RJ45.

IdentIPoint readers support the following types of peripheral

connections:

• One RS485 serial bus (115200 baud) for IOM

• Bus Termination and BIAS for RS485 on board (jumpers or

dip switch)

• Digital Output 1 (current sinking at 1A, 24VDC max.)

• Supervised Inputs 3; capable of distinguishing 4 states

• Relay Contact 1 (1A-24VDC) - Form C

• Two Tamper Inputs:

— Inner Tamper Switch: Micro-switch (detecting casing

opening)

— Outer Tamper Switch: Optical (detecting unit dis-

mounted from wall)

The readers work with 12V to 24VDC power supply or Powerover-Ethernet (PoE)* conforming to the IEEE 802.3af

standard. All software and firmware is remotely upgradeable

over the network via EBI.

All the IdentIPoint readers are designed to work with an

optional remote IOM. The IOM is used when the control inputs

and outputs of the door are desired to be on the secure side of

the door - for high security installations. The IOM integrates

seamlessly with the readers via a secure encrypted RS485

bus. Up to four IOMs can be connected via the same bus to a

reader. The IOMs are independently addressable via DIP

switches.

The IOM supports the following types of Inputs and Outputs:

• Relay: 2 - (1A 24VDC) Form C

• Digital Input: 2

• Digital Output: 2 (current sinking; (max 24V 1A)

• Supervised Analog Inputs : 4 ; capable of distinguishing 4

states

• Supervised Analog Output 1 - repeats the last Supervisory

Input, SAI3

The IOM works with a 12V to 24VDC power supply. It is

possible to control one door using two Readers in IN & OUT

mode with the help of an IOM.

* See Table.1.

Models and Part Numbers

The IdentIPoint product-line consists of the following three

reader models and one input/output unit:

1. Basic: Basic Indoor / Outdoor reader with IP65 rating

(Part no.: BTBAS)

2. Standard: Indoor reader with LCD & Keypad (Part no.:

BTSTD)

3. Fingerprint: Indoor reader with LCD, Keypad and Fingerprint unit (Part no.: BTFPT)

4. IOM: Remote Input Output Module (Part no.: BTIO)

NOTE:

1. For device ratings, see product datasheet (Docu-

ment no. 74-5086).

2. The BTFPT module is not UL294 listed and shall

not be used for UL applications.

3. IP65 enclosure rating was not evaluated by UL.

2

3

BEFORE INSTALLATION

1. Verify the mounting locations with the job drawings.

2. Unpack the IdentIPoint reader, IOM and accessories

and check them. Report any damaged or missing components to a Honeywell representative. A claim must be

filed with the commercial carrier responsible.

95-7767 2

Page 3

HONEYWELL IDENTIPOINT™ INTELLIGENT SMARTCARD SYSTEM

WARNING

Fire Safety and Liability Notice: Never connect

card readers to any critical entry, exit door, barrier,

elevator or gate without providing an alternative

exit in accordance with all fire and life safety

codes pertinent to the installation. These fire and

safety codes vary from city to city and you must

get approval from local fire officials whenever

using an electronic product to control a door or

other barrier. Use of egress buttons, for example,

may be illegal in some cities.In most applications,

single action exit without prior knowledge of what

to do is a life safety requirement. Always make

certain that any required approvals are obtained in

writing. Verbal approvals are not valid.

IMPORTANT

Table 1.

1 For UL294 applications, only UL294 and/or UL1076 listed power supplies should be used for reader and

lock power with required 72 hour battery backup.

2 Use of PoE is not a UL294 listed configuration and should not be used on UL294 applications.

3 Wifi network configuration is not a UL294 listed configuration and should not be used on UL294

applications.

4 As a standalone or disconnected reader is not supervised, this configuration should not be used on

5 For UL294 applications using an IOM, note that the IOM needs to be kept on the secure side of the door

6 The class of these products is a UL294 Access Control System, complying with UL294 Attack

IDENTIPOINT HARDWARE

Inside the reader box

• Intelligent Reader Unit - 1

• Mounting Plate - 1

• Mounting Hardware - Screws and Wall Anchors - 6 each

• Extra Tamper Resistant Screws - 2

• Tool for Tamper Resistant Screw - 1

• Connector with cable - 2 (9 and 10 pin)

• Resistors - 2K (Color Code: RED-BLACK-RED-GOLD;

0.5W axial type, 5% tolerance) - 3

• Resistors - 1K (Color Code: BROWN-BLACK-RED-GOLD;

0.5W axial type, 5% tolerance) - 3

• Square ferrite clip - 1

• Round ferrite clip - 1

• Quick Installation Guide - 1

Inside the IOM box

• Input / Output Module Unit - 1

• Mounting Hardware - Screws and Wall Anchors - 3 each

UL294 applications.

i.e. indoors, and within a distance of 7.5 meters from the reader to which it is connected. In case the

distance between the IOM and the reader exceeds 7.5 meters, the use of lightning protection devices on

the RS485 line is mandatory.

Class I.

• Extra Tamper Resistant Screws - 2

• Tool for Tamper Resistant Screw - 1

• Connectors for termination - 12 x 2 connections; 3 x 3

connections

• Resistors - 2K (Color Code: RED-BLACK-RED-GOLD;

0.5W axial type, 5% tolerance) - 4

• Resistors - 1K (Color Code: BROWN-BLACK-RED-GOLD;

0.5W axial type, 5% tolerance) - 6

• Quick Installation Guide - 1

ASSEMBLY, MOUNTING AND

INSTALLATION

Mounting and Installing the Reader

NOTE:

• The reader can be mounted either on a drywall or on

a concrete wall using conduits and a gang box.

3 95-7767

Page 4

HONEYWELL IDENTIPOINT™ INTELLIGENT SMARTCARD SYSTEM

WARNING

WARNING

• The drywall and gang boxes shown here are just

representations of the actual hardware. During

installation, please use the hardware as per the

required dimensions and availability.

• To install IdentIPoint devices in place of older devices

that have been removed, you may use the

TRADELINE® 209651A Universal Cover Plate to

cover marks from the older devices and allow

mounting of IdentIPoint devices on vertical or

horizontal outlet boxes. See document no. 69-1093

for more details.

Earth ground all enclosures for proper installation.

It is mandatory to connect the "Frame Ground" on

the J10 terminal of the fingerprint reader to an

electronic earth. In case an electronic earth is not

available then "Frame Ground" can be connected

to the Input Power Supply earth or common

ground available nearby.

Make all electrical field connections to reader and

IOM(s) before applying DC power to configuration.

Failure to do so and connecting positive terminal

first on IOM before negative can result in failed

operation that would require power recycling. Do

not make power connections with power applied

to wiring/terminal blocks - power down all circuits

before connecting or disconnecting all terminal

blocks on reader or IOM.

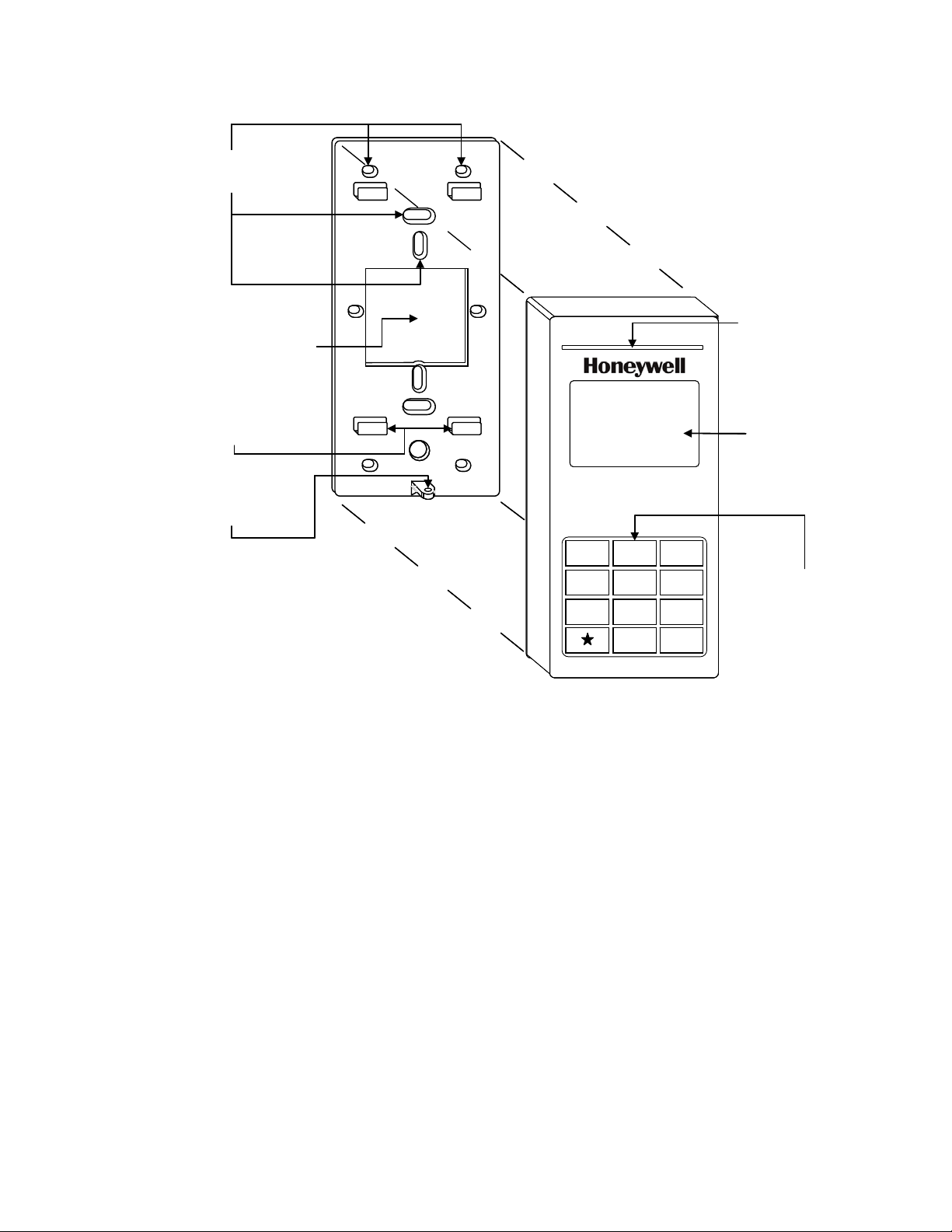

Drywall Mounting

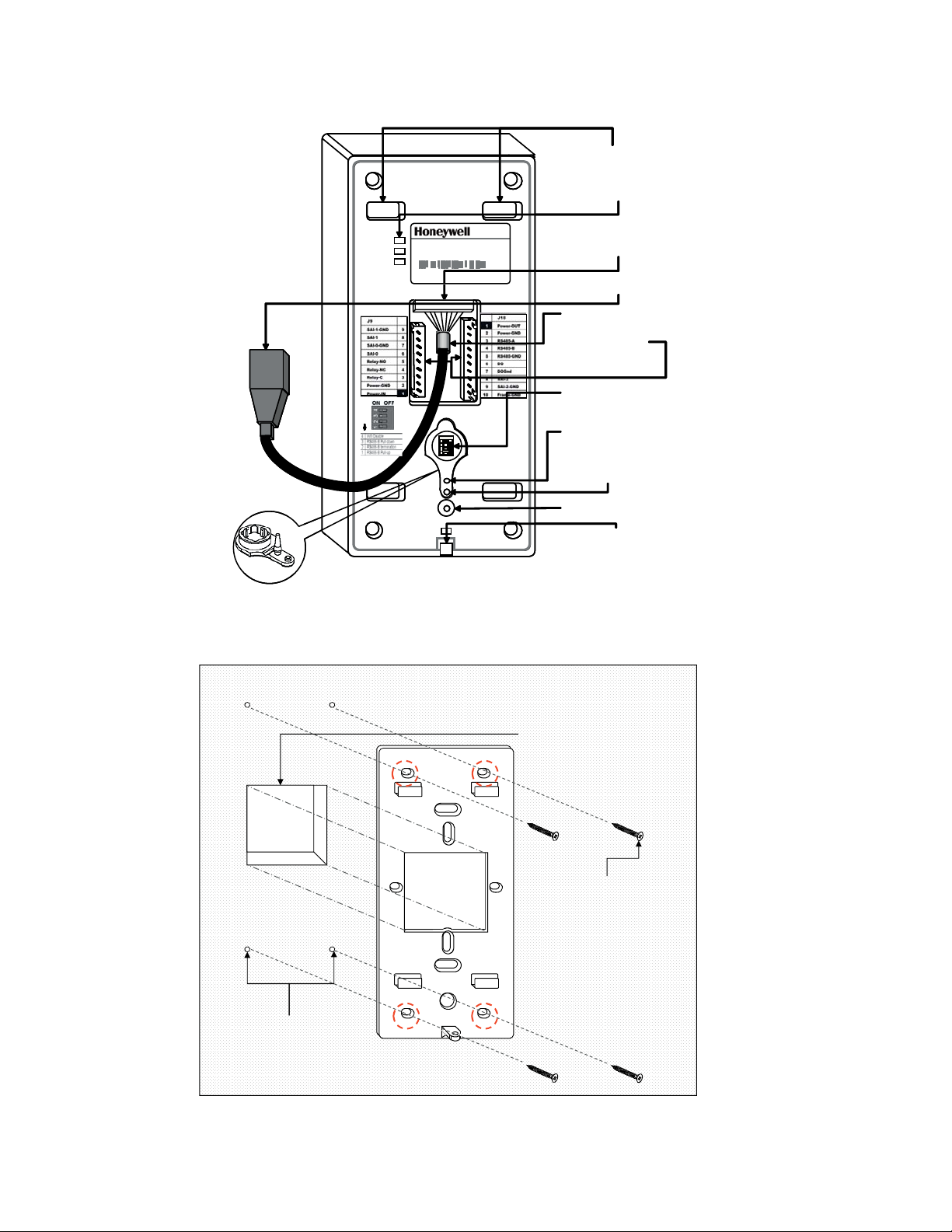

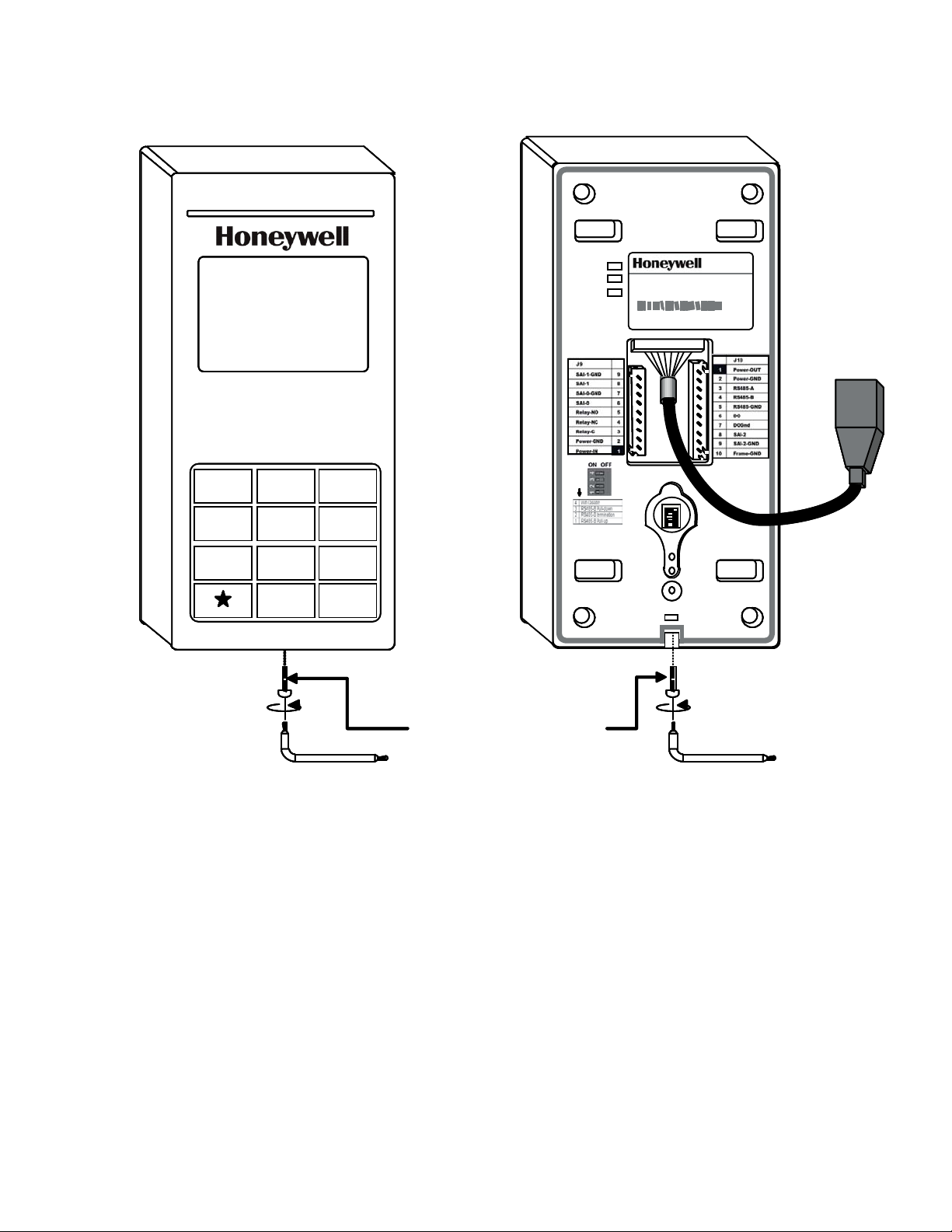

1. Fig.2 and Fig.3 show the parts of the IdentIPoint reader.

Use the back-plate of the reader to mark out the position of the reader on the drywall. Mark the positions of

the mounting screws and the opening for routing the

cables.

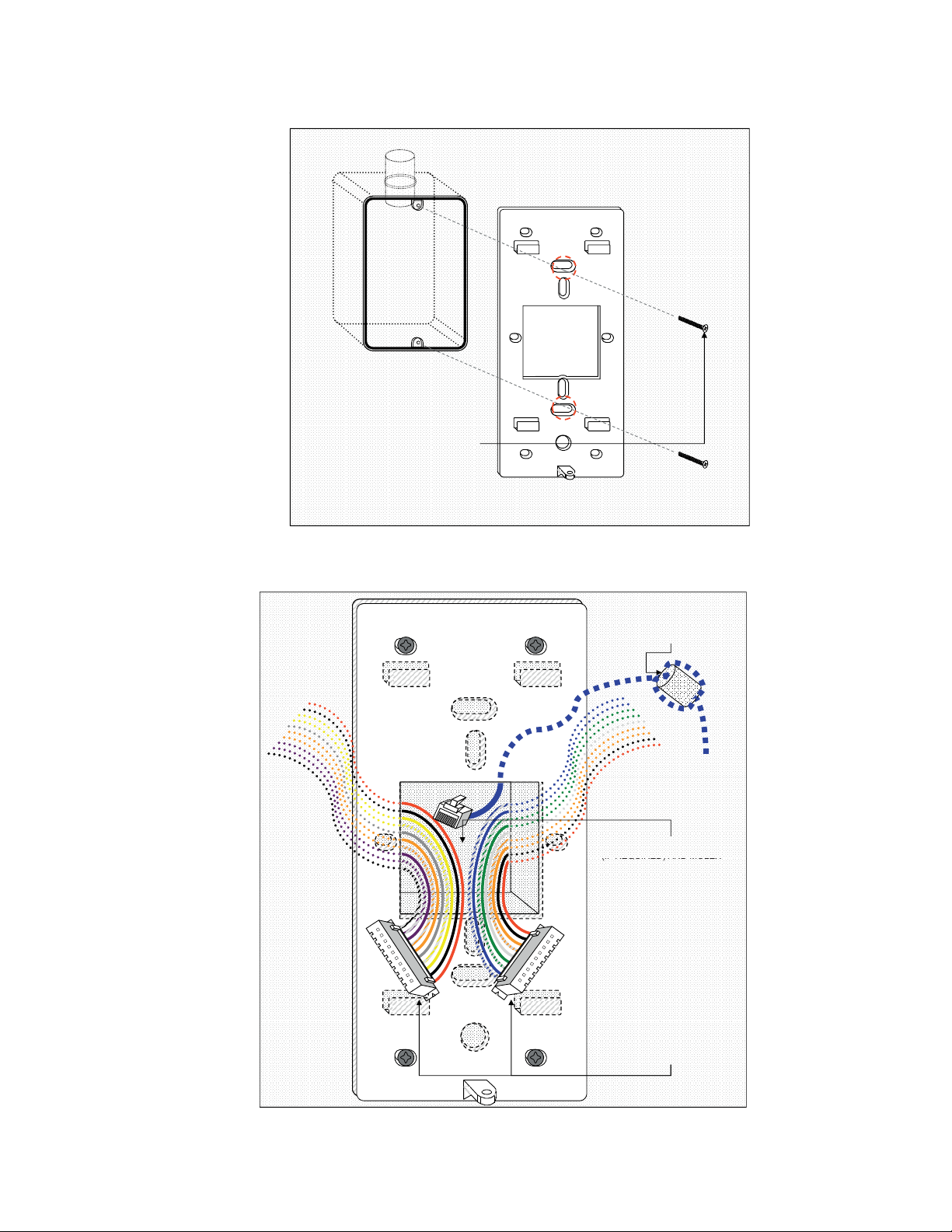

2. Cut the cable opening on the drywall using suitable

tools and punch an adequate number of holes for the

mounting screws. It is advisable to use at least four

screws to mount the reader. Use the wall anchors for

additional holding strength. See Fig.4.

3. Hold the back-plate in position on the drywall. Align the

mounting screws with their holes and fasten the backplate securely on the drywall using the screws. See

Fig.4.

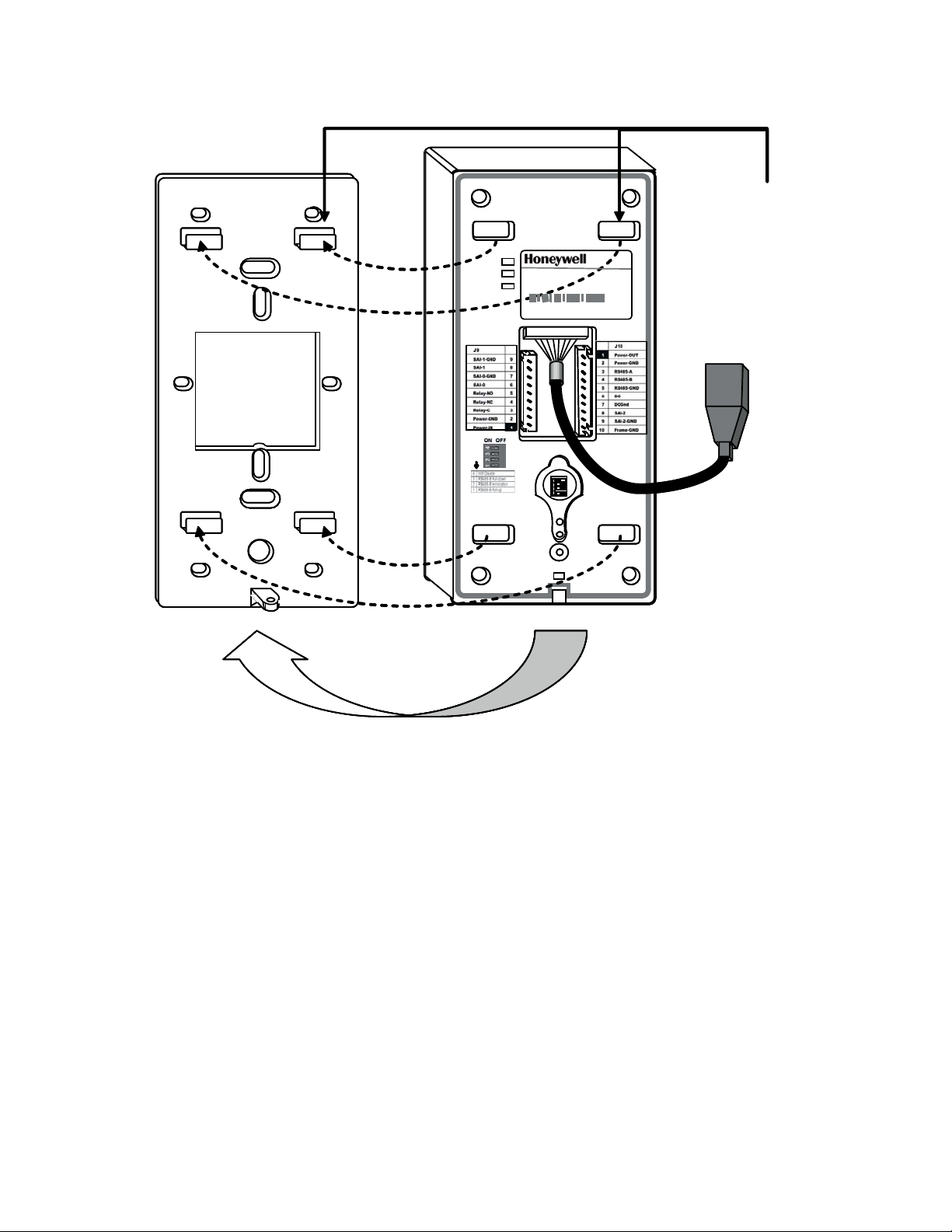

4. Route the field wires including the Ethernet cable (if

required) from behind the drywall through the cable

opening and bring them to the front of the mounting surface. See Fig.6. Clip the square* ferrite clip on the

reader's Ethernet pigtail. See Fig.7. Connect the field

wiring to the correct Molex pigtails. See Table.2 for wire

sizes and distances. For reader connection details see

Fig.11 and Table.5 and Table.6. Plug the Molex terminal(s) in ports J9 and J10 at the back of the reader. See

Fig.7. Clip (with two turns wrapped) the round** ferrite

clip on the field Ethernet cable. See Fig.6. Plug the

RJ45 connector of the field Ethernet cable into the

Ethernet port of the reader at the end of the pigtail. See

Fig.7. Drop the excess lengths of Molex and Ethernet

wires behind the drywall. Set the S1 DIP switch if the

reader is to be connected to an IOM via RS485. See

Fig.11, Table.7 and Section

Termination Setting

topic for more details.

tions

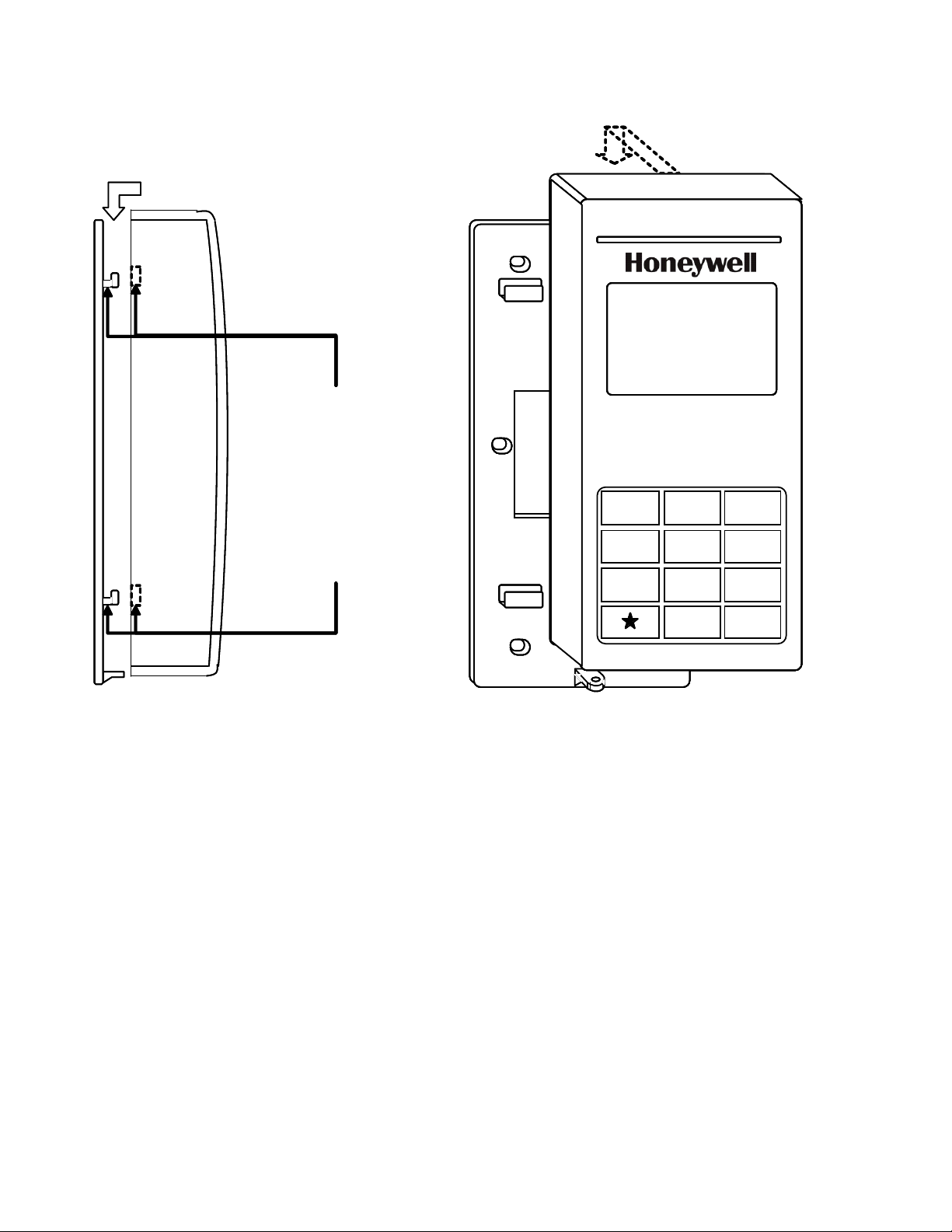

5. Once all the connections and settings are done, hold

the reader against the back-plate, aligning the mounting

slots at the back of the reader with their corresponding

catches on the back-plate and push it downwards until it

hooks into place firmly. See Fig.8 and Fig.9.

6. Use the Allen wrench to tighten the tamper-resistant

screw at the bottom of the reader into the hole provided

on the back-plate so as to fasten the reader to the backplate securely. See Fig.10.

* Required for the unit to limit emissions within FCC part 15

Class B level. Should be clipped on the reader's Ethernet

pigtail and accommodated behind the drywall.

** Required for the unit to limit emissions within FCC part 15

Class B level. Can be clipped either near the reader or at the

far end (near the network switch) of the field Ethernet cable.

of

RS485 Communication and

Connector and Switch Descrip-

Gang Box (concrete wall) Mounting

1. Fig.2 and Fig.3 show the parts of the IdentIPoint reader.

Ensure that the correct sized gang box is securely

embedded in the concrete wall. The holes provided in

the gang box for the screws should align properly with at

least two of the holes provided in the reader back-plate

for the screws.

2. Hold the back-plate in position over the gang box. Align

the mounting screws with their holes and fasten the

back-plate securely on the gang box using the screws.

See Fig.5.

3. Route the field wiring including the Ethernet cable (if

required) from the conduits into the gang box. Clip the

square* ferrite clip on the reader's Ethernet pigtail. See

Fig.7. Connect the field wiring to the correct Molex pigtails. See Table.2 for wire sizes and distances. For

reader connection details see Fig.11 and Table.5 and

Table.6. Route the Molex terminal(s) through the cable

opening on the back-plate towards the front of the

mounting surface (see Fig.6) and plug them in ports J9

and J10 at the back of the reader. See Fig.7. Clip (with

two turns wrapped) the round** ferrite clip on the field

Ethernet cable. See Fig.6. Plug the RJ45 connector of

the field Ethernet cable into the Ethernet port of the

reader provided at the end of the pigtail. See Fig.7.

Allow room for the Molex and Ethernet pigtails inside the

gang box. Set the S1 DIP switch if the reader is to be

connected to an IOM via RS485. See Fig.11, Table.7

and Section RS485 Communication and Termination

Setting of Connector and Switch Descriptions topic for

more details.

4. Once all the connections and settings are done, hold

the reader against the back-plate, aligning the mounting

slots at the back of the reader with their corresponding

catches on the back-plate and push it downwards until it

hooks into place firmly. See Fig.8 and Fig.9.

5. Use the Allen wrench to tighten the tamper-resistant

screw at the bottom of the reader into the hole provided

on the back-plate so as to fasten the reader to the backplate securely. See Fig.10.

* Required for the unit to limit emissions within FCC part 15

Class B level. Should be clipped on the reader's Ethernet

pigtail and accommodated inside the gang box.

** Required for the unit to limit emissions within FCC part 15

Class B level. Can be clipped either near the reader or at the

far end (near the network switch) of the field Ethernet cable.

95-7767 4

Page 5

MOUNTING SCREW

MOUNTING SCREW

HOLES (10)

HOLES (10)

OPENING FOR

OPENING FOR

ROUTING CABLES (1)

ROUTING CABLES (1)

CATCHES FOR

CATCHES FOR

HOLDING READER

HOLDING READER

ON BACK-PLATE (4)

ON BACK-PLATE (4)

HOLE FOR SECURING

HOLE FOR SECURING

READER TO BACK-

READER TO BACKPLATE (1)

PLATE (1)

HONEYWELL IDENTIPOINT™ INTELLIGENT SMARTCARD SYSTEM

BACK-PLATE

BACK-PLATE

READER

READER

STATUS LED

STATUS LED

LCD

LCD

123

123

456

456

789

789

0#

0#

READER FRONT

Fig. 2. Parts of IdentIPoint reader - Front of reader and Back-plate

READER FRONT

KEYPAD

KEYPAD

5 95-7767

Page 6

HONEYWELL IDENTIPOINT™ INTELLIGENT SMARTCARD SYSTEM

WIRES.THE OPENING MUST

THE DRYWALL.

Power

Power

Model: BTSTD

Model: BTSTD

IdentIPoint Standard Indoor

IdentIPoint Standard Indoor

Activity

Activity

Power 10-28 VDC, PoE

Power 10-28 VDC, PoE

MAC ID Ethernet 00 40 84 0A F 33 E

MAC ID Ethernet 00 40 84 0A F 33 E

10/100

10/100

MAC ID Wi-fi00408-IOAF33F

MAC ID Wi-fi00408-IOAF33F

Manufa ctured: 2 00 9. 0 7. 13 MA DE IN CHINA

Manufa ctured: 2 00 9. 0 7. 13 MA DE IN CHINA

ON POSI TI ONON POSI TI ON

ON POSI TI ONON POSI TI ONON POSI TI ONON POSI TI ON

1

1

1

4

4

4

4

2

2

2

3

3

3

3

3

2

3

2

3

2

2

1

1

1

1

4

4

4

READER MOUNTING

READER MOUNTING

SLOTS ( 4)

SLOTS ( 4)

STATUS LEDS (3)

STATUS LEDS (3)

ETHERNET TERMINAL

ETHERNET TERMINAL

(EPOXY POT TED FOR

(EPOXY POT TED FOR

IP65 COMPLIANCE)

IP65 COMPLIANCE)

RJ45 TERMINAL PLUG

RJ45 TERMINAL PLUG

CAT 5 PIGTAIL

CAT 5 PIGTAIL

WIRING

WIRING

TERMINAL

TERMINAL

PORTS J9, J10

PORTS J9, J10

DIP SW ITCH S1

DIP SW ITCH S1

HOLE FOR HOLDING

HOLE FOR HOLDING

RU BBER C OVER

RU BBER C OVER

(SHOWN IN CALLOUT)

(SHOWN IN CALLOUT)

FAC TOR Y RESET

FAC TOR Y RESET

SWITCH

SWITCH

OPTICAL TAMPER

OPTICAL TAMPER

SENSOR

SENSOR

HOLE FOR TAMPER-

HOLE FOR TAMPERRESIST ANT SCR EW

RESIST ANT SCR EW

Fig. 3. Parts of IdentIPoint reader - Back of reader

PUNCH AN ADEQUATE NUMBER

OF HOLES IN THE DRYWALL

FOR THE SCREWS

READER BACK

READER BACK

CUT AN OPENING IN THE

DRYWALL FOR ROUTING THE

HAVE THE SAME DIMENSIONS

AS THAT IN THE BACK-PLATE.

USE THE SCREWS PROVIDED

TO FIX THE BACK-PLATE TO

NOTE: USE A MINIMUM OF 4

SCREWS IN THE HOLES

CIRCLED IN RED

ROUTE THE WIRES FROM

BEHIND THE DRYWALL

THROUGH THE CONDUITS

95-7767 6

Fig. 4. Mounting reader back-plate on drywall

Page 7

HONEYWELL IDENTIPOINT™ INTELLIGENT SMARTCARD SYSTEM

PLATE TO THE EMBEDDED

CLIP ROUND FERRITE CLIP ON

THE FIELD ETHERNET CABLE

ROUTE THE RJ45 CONNECTOR

(IF REQUIRED) AND MOLEX

TERMINALS FROM BEHIND THE

DRYWALL OR THROUGH THE

CONDUITS (IN CASE OF

CONCRETE WALL) AND BRING

THEM TOWARDS THE FRONT

SIDE OF THE MOUNTING

SURFACE THROUGH THE

OPENING ON THE READER’S

BACK-PLATE.

PLUG THE RJ45 CONNECTOR

INTO THE ETHERNET PORT OF

THE READER AT THE END OF

THE PIGTAIL.

PLUG THE MOLEX TERMINALS

INTO THE J9 AND J10 PORTS

OF THE READER

GANG BOX EMBEDDED IN WALL

USE THE SCREWS PROVIDED

TO FIX THE READER BACK-

GANG BOX.

NOTE: USE A MINIMUM OF 2

SCREWS IN THE HOLES

CIRCLED IN RED TO FASTEN

THE BACK-PLATE

Fig. 5. Mounting reader back-plate on concrete wall using gang box and conduit

WITH TWO TURNS WRAPPED

Fig. 6. Routing the wires before plugging the connectors into the reader

7 95-7767

Page 8

HONEYWELL IDENTIPOINT™ INTELLIGENT SMARTCARD SYSTEM

AT THE BACK OF THE

BACK OF THE READER AND

A

O

UG

UG

MATE WITH THE SPECIAL SLOTS PROVIDED

NOTE: Round ferrite clip is required for the unit to limit emissions within FCC part 15 Class B level. Can be clipped

either near the reader or at the far end (near the network switch) of the field Ethernet cable.

The connector wire colors shown above are only indicative. Refer to Table.5 and Table.6 for the correct colors.

HOLD THE 9 AND 10-PIN

MOLEX TERMINALS

PERPENDICULAR TO THE

ALIGN THEM CORRECTLY

WITH PORTS J9 AND J10

PORT

J9

PIN 9

PIN 1

9-PIN MOLEX

TERMINAL

Power

Model: BTSTD

ctivity

IdentIPoint Standard Indo or

Power 10-28 VDC, PoE

10/100

MAC ID Ethernet 0040840AF33E

MAC ID Wi-fi00408-IOAF33F

Manufactured: 2009.07.13 MADE IN CHINA

NNN

N

ON POSITIOON POSITIOON POSITIOON POSITI

1

1

4

4

4

2

2

3

3

3

3

2

3

2

2

1

1

1

4

4

TO PIN 1

TO PIN 9

CLIP SQUARE

FERRITE CLIP TO

THE PIGTAIL

PLUG RJ45

CONNECTOR (IF

REQD.) IN THE RJ45

TERMINAL PL

PUSH THE 9 AND 10-PIN MOLEX TERMINALS

FIRMLY INTO THE READER PORTS J9 AND J10

RESPECTIVELY. ENSURE THAT ALL 9 AND 10

PINS GO INSIDE THE HOLES OF THEIR

RESPECTIVE TERMINALS AND THAT THE

SPECIAL PROTRUSIONS ON THE TERMINALS

ON THE PORTS. THIS ENSURES THAT THE

TERMINALS CANNOT BE PLUGGED INTO

WRONG PORTS.

TO PIN 10

TO PIN 1

BOTH MOLEX TERMINALS

SHOULD FIT FIRMLY INSIDE

THEIR RESPECTIVE PORTS

READER AS SHOWN

PIN 1

PIN 10

10-PIN MOLEX

TERMINAL

PORT

J10

NOTE: Square ferrite clip is required for the unit to limit emissions within FCC part 15 Class B level. Should be clipped

on the reader's Ethernet pigtail and accommodated behind the drywall or inside the gang box. The connector

wire colors shown above are only indicative. Refer to Table.5 and Table.6 for the correct colors.

95-7767 8

Fig. 7. Plugging the connectors into the IdentIPoint reader

Page 9

HONEYWELL IDENTIPOINT™ INTELLIGENT SMARTCARD SYSTEM

ALIGN THE MOUNTING

SLOTS BEHIN D THE

READER WITH THEIR

CORRESPONDING

CATCH ES ON THE

BACK-PLATE

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

ALIGN THE MOUNTING

SLOTS BEHIN D THE

READER WITH THEIR

CORRESPONDING

CATCH ES ON THE

BACK-PLATE

Power

Power

Acti vi ty

Acti vi ty

10/100

10/100

ON POS IT IONON POS IT IONON POS IT IONON POS IT ION

ON POS IT IONON POS IT IONON POS IT IONON POS IT ION

Model: BTSTD

Model: BTSTD

IdentIPoint Standard Indoor

IdentIPoint Standard Indoor

Power 1 0-28 VDC, PoE

Power 1 0-28 VDC, PoE

MAC ID Eth ernet 0040 84 0A F33 E

MAC ID Eth ernet 0040 84 0A F33 E

MAC ID Wi-fi00408-I OA F 3 3 F

MAC ID Wi-fi00408-I OA F 3 3 F

Manufactured: 2009.07.13 MAD E IN CHINA

Manufactured: 2009.07.13 MAD E IN CHINA

1

1

4

4

4

2

2

3

3

3

3

2

3

2

2

1

1

1

4

4

Fig. 8. Aligning IdentIPoint reader with back-plate before mounting it

9 95-7767

Page 10

HONEYWELL IDENTIPOINT™ INTELLIGENT SMARTCARD SYSTEM

ALIGN THE MOUNTING

ALIGN THE MOUNTING

SLOTS BEHIND THE

SLOTS BEHIND THE

READER WITH THEIR

READER WITH THEIR

CORRESPONDING

CORRESPONDING

CATCHES ON THE

CATCHES ON THE

BACK -PLATE. PUSH

BACK -PLATE. PUSH

THE READER

THE READER

DOWNWARDS UNTIL IT

DOWNWARDS UNTIL IT

HOOKS INTO PLACE

HOOKS INTO PLACE

FIRMLY

FIRMLY

123

123

456

456

789

789

READER ASSEMBLY –

READER ASSEMBLY –

SIDE VIEW

SIDE VIEW

READER ASSEMBLY –

READER ASSEMBLY –

FRONT VIEW

FRONT VIEW

Fig. 9. Mounting IdentIPoint reader on the back-plate

0#

0#

95-7767 10

Page 11

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

USE THE ALLEN

WRENCH TO

SECURE THE

READER TO THE

BAC K-PLATE WITH

THE TAMPERRESISTANT SCREW

123

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

USE THE ALLEN

WRENCH TO

SECURE THE

READER TO THE

BAC K-PLATE WITH

THE TAMPERRESISTANT SCREW

123

HONEYWELL IDENTIPOINT™ INTELLIGENT SMARTCARD SYSTEM

Power

Power

Activity

Activity

10/100

10/100

ON POSITIONON POSITIONON POSITIONON POSITION

ON POSITIONON POSITIONON POSITIONON POSITION

Model: BTSTD

Model: BTSTD

IdentIPoint Standard Indoor

IdentIPoint Standard Indoor

Power 1 0-28 VDC, PoE

Power 1 0-28 VDC, PoE

MAC ID Eth ernet 00 40 84 0A F 33 E

MAC ID Eth ernet 00 40 84 0A F 33 E

MAC ID Wi-fi00408-IOAF33F

MAC ID Wi-fi00408-IOAF33F

Manufactured: 2009.07.13 MA DE IN CHINA

Manufactured: 2009.07.13 MA DE IN CHINA

456

456

789

789

#

0

0

#

Fig. 10. Securing the IdentIPoint reader to the back-plate

11 95-7767

Page 12

HONEYWELL IDENTIPOINT™ INTELLIGENT SMARTCARD SYSTEM

LED INDICATORS AT THE BACK

Marking Color Descripon

Marking Color Descripon

10/100 Green On when network is 100

10/100 Green On when network is 100

Acvity Orange Flashes on network acvity

Acvity Orange Flashes on network acvity

Power Blue On if power on

Power Blue On if power on

Pow er

ON POS ITIONON POS ITIONON POS ITIONON POS ITION

ON POS ITIONON POS ITIONON POS ITIONON POS ITION

Pow er

Acti v ity

Acti v ity

10/100

10/100

Model: BTSTD

Model: BTSTD

IdentIPoi nt St andard I ndoor

IdentIPoi nt St andard I ndoor

Power 10-28 VDC, PoE

Power 10-28 VDC, PoE

MAC ID Ethernet 0040840A F33E

MAC ID Ethernet 0040840A F33E

MAC ID Wi-fi 00408-IOA F33F

MAC ID Wi-fi 00408-IOA F33F

Manufactured: 2009.07.13 MADE IN CHINA

Manufactured: 2009.07.13 MADE IN CHINA

1

1

1

1

4

4

4

4

4

4

2

2

2

2

3

3

3

3

3

3

3

2

3

2

2

3

2

3

2

2

1

1

1

1

1

1

4

4

4

4

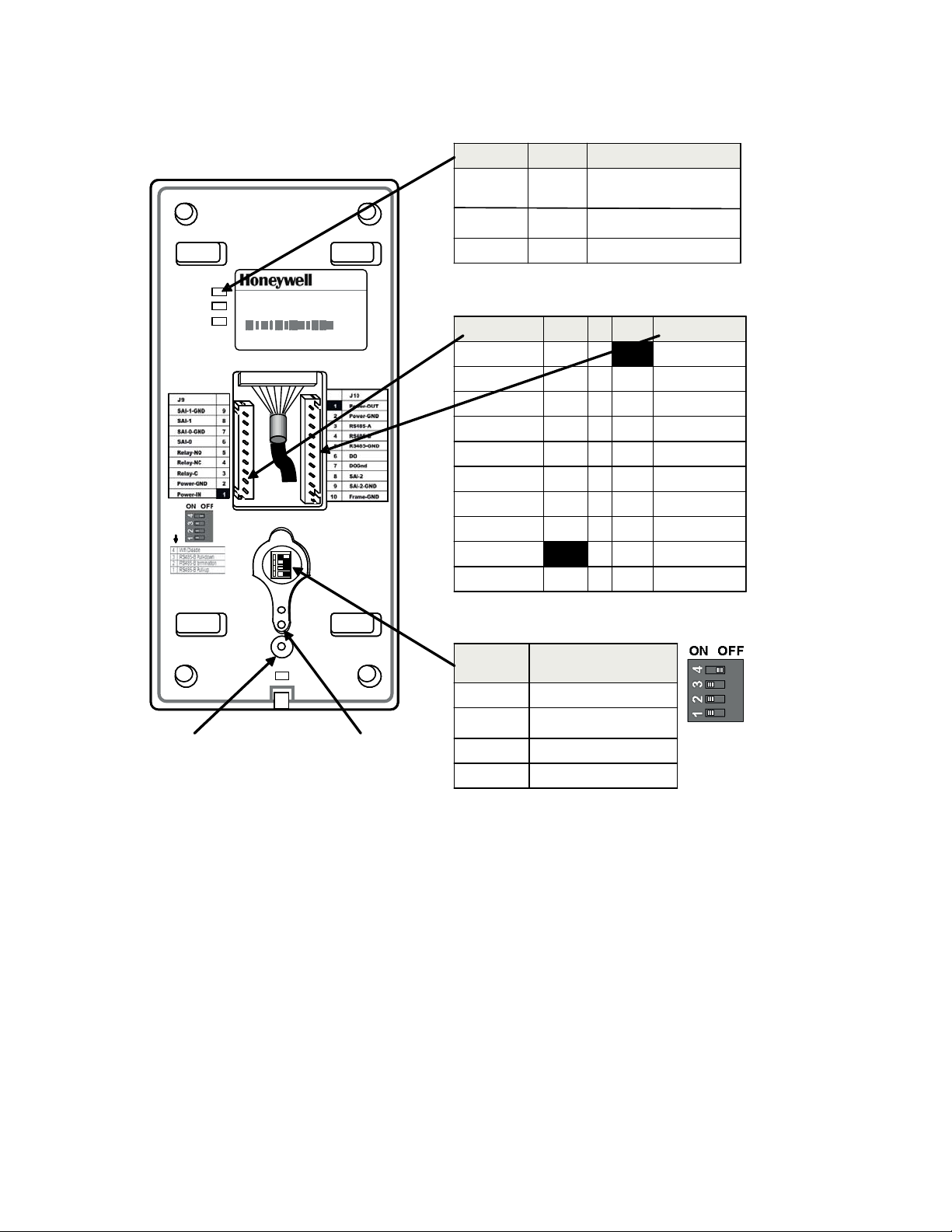

CONNECTORS AT THE BACK

J9 PIN PIN J10

J9 PIN PIN J10

SAI-1-GND

SAI-1-GND

SAI-1 8 2 Powe r-GND

SAI-1 8 2 Powe r-GND

SAI-0-GND 7 3 RS485-A

SAI-0-GND 7 3 RS485-A

SAI-0 6 4 RS485-B

SAI-0 6 4 RS485-B

Relay-NO 5 5 RS48 5-GND

Relay-NO 5 5 RS48 5-GND

Relay-NC 4 6 DO

Relay-NC 4 6 DO

Relay-C 3 7 DOGnd

Relay-C 3 7 DOGnd

Power-GND 2 8 SAI-2

Power-GND 2 8 SAI-2

Power-IN

Power-IN

MBi t

MBi t

9

9

1 9SAI-2-GND

1 9SAI-2-GND

1 Power-OUT

1 Power-OUT

10 Frame-GND

10 Frame-GND

OPTICAL

ALARM

TAMPER

FACTORY

RESET

SWITCH

Fig. 11. Reader connections

Mounting and Installing the Input/Output

Module

NOTE:

• The IOM can be mounted either on a drywall or on a

concrete wall using conduits and a gang box.

DIP SWITCH S1

Posion Effect when “ON”

Posion Effect when “ON”

1 RS485-A pull up

1 RS485-A pull up

2 RS485 terminaon

2 RS485 terminaon

3 RS485-B pull down

3 RS485-B pull down

4WifiDisable

4WifiDisable

(Posion Le)

(Posion Le)

• The drywall and gang boxes shown here are just

representations of the actual hardware. During

installation, please use the hardware as per the

required dimensions and availability.

• To install IdentIPoint devices in place of older devices

that have been removed, you may use the

TRADELINE® 209651A Universal Cover Plate to

cover marks from the older devices and allow

mounting of IdentIPoint devices on vertical or

horizontal outlet boxes. See document no. 69-1093

for more details.

95-7767 12

Page 13

WARNING

Make all electrical field connections to reader and

WARNING

WARNING

CAUTION

IOM(s) before applying DC power to configuration.

Failure to do so and connecting positive terminal

first on IOM before negative can result in failed

operation that would require power recycling. Do

not make power connections with power applied

to wiring/terminal blocks - power down all circuits

before connecting or disconnecting all terminal

blocks on reader or IOM.

Grounds need to be affixed first before applying

any power to a configuration. The dedicated

ground connector J3 on the IOM (see Fig.18) can

be used for the above purpose.

No components should be added to a hot i.e.

powered up configuration.

Electro-static discharge (ESD) can damage CMOS

integrated circuits and modules. To prevent

damage always follow these procedures:

— Use static shield packaging and containers to trans-

port all electronic components, including completed

reader assemblies.

— Handle all ESD sensitive components at an approved

static controlled workstation.

Drywall Mounting

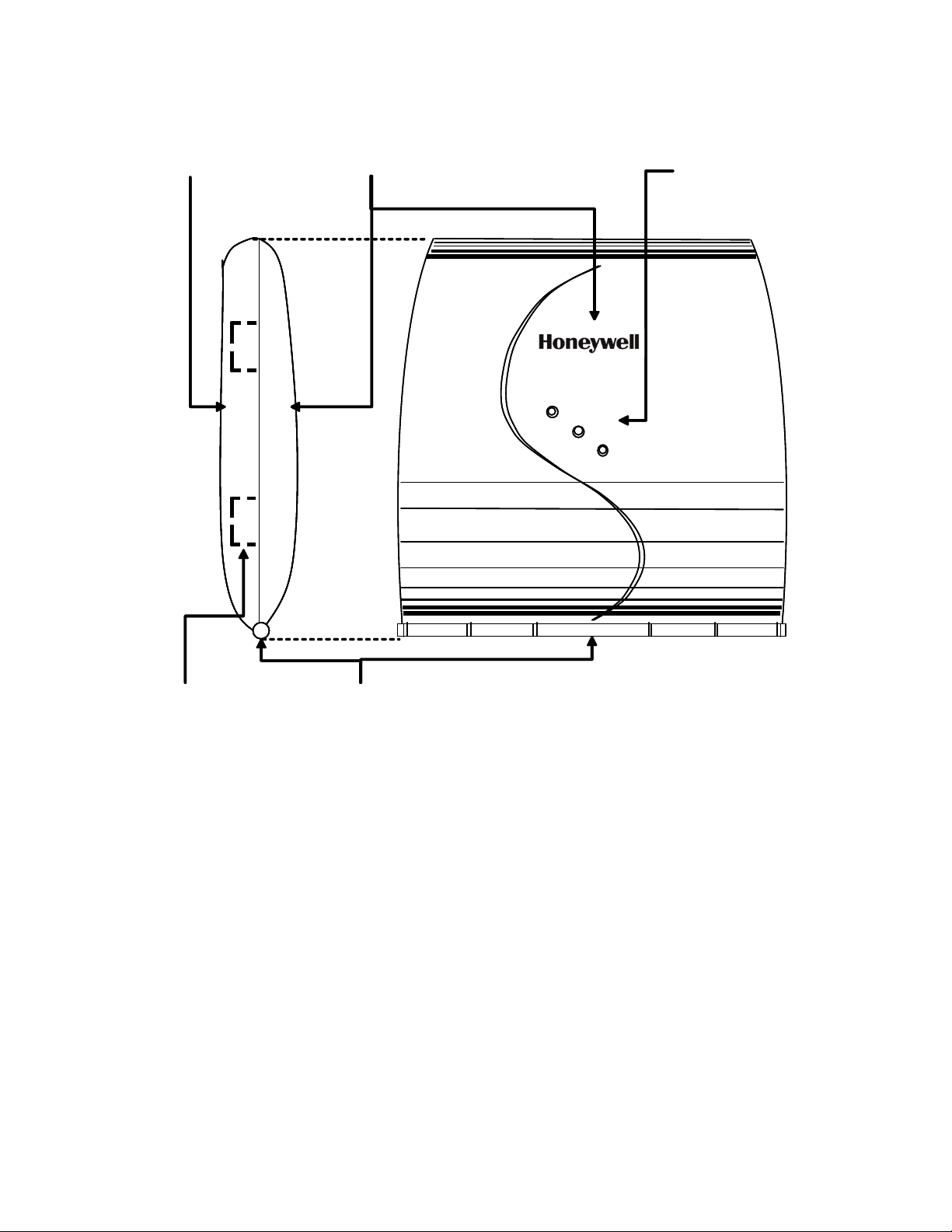

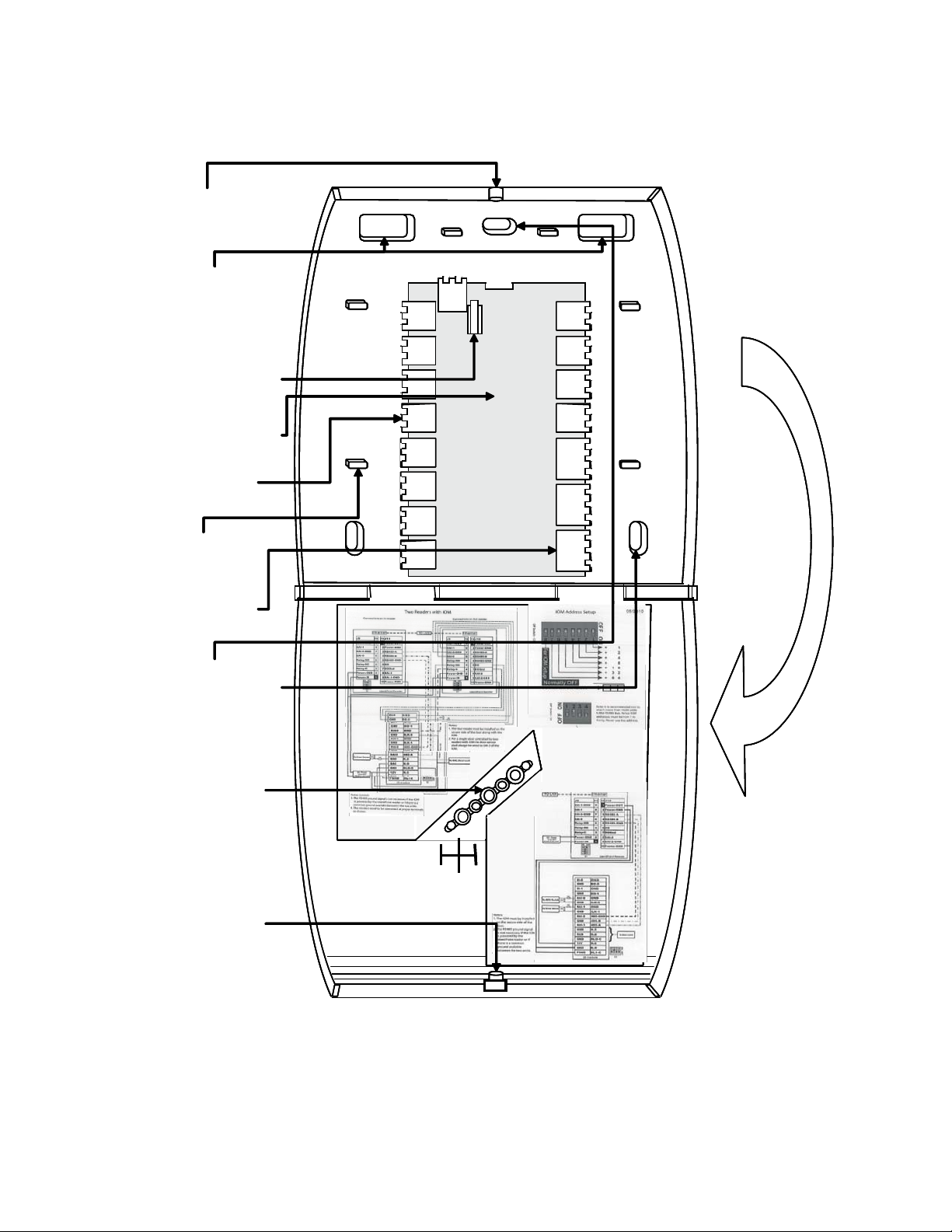

1. The IOM has a clamshell plastic case. The back half of

the case has the electronic circuit board fastened to it

while the front case cover swings open to allow access

to the electronics and wiring. Pull open the front cover.

This reveals the mounting holes and other components

inside the IOM. See Fig.12 and Fig.13.

2. Use the back half to mark out the position of the IOM on

the drywall. Also mark the positions of the mounting

screws and the openings for routing the cables. See

Fig.14.

3. Cut the two cable openings on the drywall using suitable

tools. The openings should be aligned with the knockout holes provided on the back half for routing the

cables. Also punch three holes at suitable places in the

drywall for the mounting screws. Use the wall anchors

for additional holding strength. See Fig.14.

4. Ensure that the knock-out holes on the back half have

been opened up. (Knock-out holes are also provided on

both sides of the IOM enclosure in case field conditions

require routing the wires from the sides.) Hold the back

half in position on the drywall. Align the mounting

screws with their holes and fasten the back half securely

on the drywall using the three screws. See Fig.14.

5. Route the field wires from behind the drywall through

the cable opening and bring them inside the IOM via the

knock-out holes. See Table.2 for wire sizes and dis-

HONEYWELL IDENTIPOINT™ INTELLIGENT SMARTCARD SYSTEM

tances. Connect the wire terminals to the ends of the

wires and plug the wire terminal(s) in their correct slots

on the PCB. See Fig.16. For IOM connection details see

Fig.18 and Table.8. Drop the excess wire lengths behind

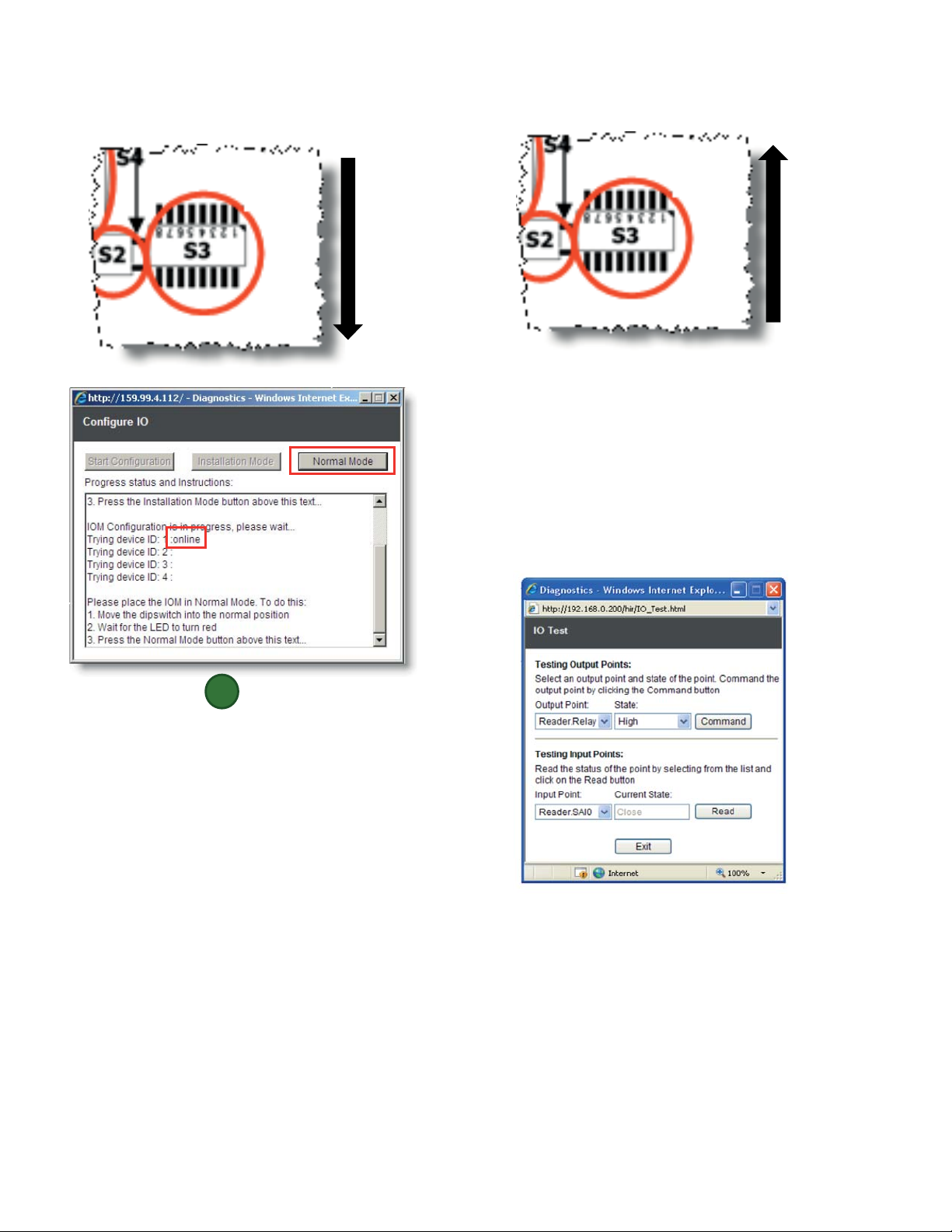

the drywall. Set the S1 DIP switch if the IOM is to be

connected to a reader via RS485. See Fig.18, Table.10

and Section

Setting

more details.

6. Set the IOM address as per Fig.18, Table.11 and Section

IOM Address Setup

Descriptions

7. Once all connections and settings are done, close the

IOM enclosure by pressing the front case cover over the

back half. See Fig.16.

8. Use the Allen wrench to tighten the tamper-resistant

screw at the top of the IOM enclosure. See Fig.17.

RS485 Communication and Termination

of

Connector and Switch Descriptions

of

topic for more details.

Connector and Switch

topic for

Gang Box (concrete wall) Mounting

1. The IOM has a clamshell plastic case. The back half of

the case has the electronic circuit board fastened to it

while the front case cover swings open to allow access

to the electronics and wiring. Pull open the front cover.

This reveals the mounting holes and other components

inside the IOM. See Fig.12 and Fig.13.

2. Ensure that the correct sized gang box is securely

embedded in the concrete wall. One of the holes provided in the gang box for the screws should align properly with at least the top hole provided in the IOM's back

half for the screw. For the remaining screws punch additional holes at the correct places directly in the concrete

wall. Use the wall anchors for additional holding

strength. The gang box itself should be large enough to

cover both the knock-out cable holes at the back of the

IOM. See Fig.15.

3. Route the field wires from the conduits into the gang box

and bring them inside the IOM via the knock-out holes.

See Table.2 for wire sizes and distances. The IOM can

now be mounted on the wall. Hold the back half in position over the gang box and wall. Align the three mounting screws with their holes and fasten the back half

securely on the gang box and wall using the screws.

See Fig.15.

4. Connect the wire terminals to the ends of the wires and

plug the wire terminal(s) in their correct slots on the

PCB. See Fig.16. For IOM connection details see Fig.18

and Table.8. Allow room for any excess wire lengths

inside the gang box. Set the S1 DIP switch if the IOM is

to be connected to a reader via RS485. See Fig.18,

Table.10 and Section RS485 Communication and Ter-

mination Setting of Connector and Switch Descriptions

topic for more details.

5. Set the IOM address as per Fig.18, Table.11 and Section IOM Address Setup of Connector and Switch

Descriptions topic for more details.

6. Once all connections and settings are done, close the

IOM enclosure by pressing the front case cover over the

back half. See Fig.16.

7. Use the Allen wrench to tighten the tamper-resistant

screw at the top of the IOM enclosure. See Fig.17.

NOTE: The power supply wiring for the BTIO IOM shall

be enclosed by conduit.

13 95-7767

Page 14

HONEYWELL IDENTIPOINT™ INTELLIGENT SMARTCARD SYSTEM

FRONT COVER

BACK HALF OF

BACK HALF OF

THE IOM

THE IOM

FRONT COVER

OF THE IOM

OF THE IOM

Pow er

Pow er

Data

Data

Tamper

Tamper

POWER,

POWER,

DATA AND

DATA AND

TAMPER

TAMPER

INDICATION

INDICATION

LEDS

LEDS

SIDE KNOCK -OUTS

SIDE KNOCK -OUTS

FOR CABLE HOLES

FOR CABLE HOLES

HINGE AT THE

HINGE AT THE

BOTTOM HOLDING

BOTTOM HOLDING

THE TWO PARTS

THE TWO PARTS

TOGETHER

TOGETHER

Fig. 12. Outer structure of IOM - Front and side view

95-7767 14

Page 15

PRINTED CIRCUIT

BOARD

BACK KNO CKOUTS F OR CABLE

HOLES (2)

WIRING

TER MIN ALS –

2 WIRE (13)

WIRING

TER MIN ALS –

3 WIRE (3)

IOM FRONT COVER -OPEN

HOLE FOR

TAMPERRESISTANT

SCREW

IOM BACK HALF -OPEN

HOLE FOR

TAMPERRESISTANT

SCREW

LIGHT GUIDES

CABLE

GUIDES (6)

COVER TAMPER

DETECTION

SWITCH

PULL O PEN THE

FRONT COVER OF

THE IOM AND ALLO W

IT TO HANG FROM

THE HINGE

MOUNTING

SCREW HOLES

(3)

PRINTED CIRCUIT

BOARD

BACK KNO CKOUTS F OR CABLE

HOLES (2)

WIRING

TER MIN ALS –

2 WIRE (13)

WIRING

TER MIN ALS –

3 WIRE (3)

IOM FRONT COVER -OPEN

HOLE FOR

TAMPERRESISTANT

SCREW

IOM BACK HALF -OPEN

HOLE FOR

TAMPERRESISTANT

SCREW

LIGHT GUIDES

CABLE

GUIDES (6)

COVER TAMPER

DETECTION

SWITCH

PULL O PEN THE

FRONT COVER OF

THE IOM AND ALLO W

IT TO HANG FROM

THE HINGE

MOUNTING

SCREW HOLES

(3)

HONEYWELL IDENTIPOINT™ INTELLIGENT SMARTCARD SYSTEM

Fig. 13. Internal structure and components of IOM

15 95-7767

Page 16

HONEYWELL IDENTIPOINT™ INTELLIGENT SMARTCARD SYSTEM

IOM

CUT OPENINGS IN THE

DRYWALL FOR ROUTING THE

WIRES. THE OPENINGS MUST

HAVE THE SAME DIMENSIONS

AS THAT IN THE BACK HALF OF

THE IOM.

PUNCH THREE HOLES IN

THE DRYWALL FOR THE

SCREWS

USE THE SCREWS

PROVIDED TO FIX THE

BACK HALF OF THE IOM

TO THE DRYWALL.

NOTE: USE ALL THREE

HOLES TO FASTEN THE

Fig. 14. Mounting the IOM on a drywall

95-7767 16

Page 17

GANG BOX EMBEDDED IN WALL

HONEYWELL IDENTIPOINT™ INTELLIGENT SMARTCARD SYSTEM

PUNCH ADDITIONAL HOLES

IN THE WALL FOR THE

OTHER SCREWS

USE THE SCREWS PROVIDED

TO FIX THE BACK HALF OF IOM

TO THE GANG BOX AND THE

WALL.

NOTE: USE ALL 3 SCREWS TO

FASTEN THE IOM

Fig. 15. Mounting the IOM on a concrete wall using gang box and conduit

17 95-7767

Page 18

HONEYWELL IDENTIPOINT™ INTELLIGENT SMARTCARD SYSTEM

ROUTE THE WIRES

THROUGH THE KNOCK OUT HOLES AND FIX

THEM TO THE C ORRECT

TERMIN ALS ON THE PCB

USIN G THE PROVIDED

WIR E TERMINAL BLOC KS

AFTER WIRING AND

OTHER HARDWARE

CONFIGURATIONS ARE

DONE, SHUT THE FRONT

COVER OF THE IOM

ROUTE THE WIRES

THROUGH THE KNOCK OUT HOLES AND FIX

THEM TO THE C ORRECT

TERMIN ALS ON THE PCB

USIN G THE PROVIDED

WIR E TERMINAL BLOC KS

AFTER WIRING AND

OTHER HARDWARE

CONFIGURATIONS ARE

DONE, SHUT THE FRONT

COVER OF THE IOM

Fig. 16. Routing the wires and connecting them to the IOM PCB

95-7767 18

Page 19

USE THE ALLEN

USE THE ALLEN

WRENC H TO

WRENC H TO

SEC URE THE FRON T

SEC URE THE FRON T

COVER OF THE IOM

COVER OF THE IOM

TO THE BACK HALF

TO THE BACK HALF

WITH TAMPER-

WITH TAMPERRESISTANT SCREW

RESISTANT SCREW

HONEYWELL IDENTIPOINT™ INTELLIGENT SMARTCARD SYSTEM

Pow er

Pow er

Pow er

Data

Data

Data

Tamper

Tamper

Tamper

Fig. 17. Securing the front cover onto the back half of the IOM

19 95-7767

Page 20

HONEYWELL IDENTIPOINT™ INTELLIGENT SMARTCARD SYSTEM

DIP s witch

-S1

Posion Eff ect when “ON”

(Posion Up)

1 RS485-A pull up

2 RS485 terminaon

3 RS485-B pull down

4Reserved

Posion Eff ect when “ON”

(Posion Up)

1 RS485-A pull up

2 RS485 terminaon

3 RS485-B pull down

4Reserved

Switc h Descripon

S1 RS485 Terminaon Control DIP switch

S2 Inializaon Buon

S3 IOM Addr ess set up DI P swi tch

S4 Cover tampe r detecon switch

Switc h Descripon

S1 RS485 Terminaon Control DIP switch

S2 Inializaon Buon

S3 IOM Addr ess set up DIP switch

S4 Cover tampe r detecon switch

S2: Inial izaon

Buon

DIP switch

S3 -

IOM address

Posion Descripon

1 Address value 1

2 Address value 2

3 Address value 4

4 Address value 8

5 Address value 16

6 Address value 32

7 Address value 64

8 For IOM setup, normally set to OFF

Posion Descripon

1 Address value 1

2 Address value 2

3 Address value 4

4 Address value 8

5 Address value 16

6 Address value 32

7 Address value 64

8 For IOM setup, normally set to OFF

S4: Cover tamper

detecon switch

95-7767 20

Fig. 18. IOM connections

Page 21

HONEYWELL IDENTIPOINT™ INTELLIGENT SMARTCARD SYSTEM

WARNING

WARNING

Mounting and Installing the Power

Supply

Personal injury or death could occur and the

equipment could be damaged beyond repair if this

precaution is not observed!

— Before installation, turn off the external circuit

breaker which supplies power to the system,

including door locks.

— Before connecting the device to the power supply,

verify that the output voltage is within specifications of the power supply.

— Do not apply power to the system until after the

installation has been completed.

Power Supply Recommendations

FOR READERS

DC Power Supply:

• Power must be provided to the IdentIPoint readers from a

UL294 and/or UL1076 listed power supply for access

control or one approved by local authority having

jurisdiction.

• Power supply should be 12-24VDC.

• When powered by an external DC source such as the

above, IdentIPoint readers provide a power output for

powering devices like the IOM or a door strike. The max

current provided by the reader in this case is 300mA at 1.5

V less than the input voltage.

• The IdentIPoint readers consume a maximum of 12W

power when supplying power to IOMs and/or other external

devices such as a door strike or magnetic lock relay.

• Any UL Security listed power supply may be used such as

the Honeywell HP400ULPD8CB power supply.

NOTE: For UL294 installations, only UL294 and/or

UL1076 listed power supplies should be used for

reader and lock power with required 72 hour battery backup.

Power-over-Ethernet

1. If Power-over-Ethernet (PoE) devices are used to power

the IdentIPoint readers, they must conform to the IEEE

802.3af standard. See section Power over Ethernet

(PoE) wiring of Wiring the Readers and IOM topic for

details on selecting PoE devices.

2. When powered by an IEEE802.3af compliant PSE

(Power Supply Equipment), IdentIPoint readers provide

a power output for powering devices like the IOM or a

door strike. The max current provided by the reader in

this case is 300mA at 10.5VDC.

3. The IdentIPoint readers consume a maximum of 12W

power when supplying power to IOMs and/or other

external devices such as a door strike or magnetic lock

relay.

4. Where it is not feasible to use PoE switches, PoE midspans may be alternatively used.

NOTE: Use of PoE is not a UL294 listed configuration

and should not be used on projects where a

UL294 certificate will be issued.

FOR IOM

1. Power must be provided to the IdentIPoint IOM from a

UL294 and/or UL1076 listed power supply for access

control or one approved by local authority having jurisdiction.

2. Power supply for IOM should be 12-24VDC.

3. Power consumption is 1.2W max.

NOTE: For UL294 installations, only UL294 and/or

UL1076 listed power supplies should be used for

reader and lock power with required 72 hour battery backup.

Circuit Protection for Readers and IOM

1. IdentIPoint readers and the IOM are able to withstand

power on wrong terminal up to 24VDC on any of the

exposed terminals of the reader.

2. IdentIPoint readers and the IOM are able to withstand

power connection of up to 24VDC with reverse polarity.

3. IdentIPoint readers and IOM are able to withstand I/O

short circuit on all inputs and outputs.

Installation Instructions

1. Mounting: The power supply should be installed in

accordance with all applicable codes and standards.

2. Power Supply Input Connection: Before connecting

power review the entire wiring diagram provided with the

power supply for correct installation. Make input connections as instructed in the manual provided with the

power supply.

NOTE: For countries that use input voltage other than

120VAC, check the available literature on the

power supply for details on configuring the

power supply to accept 230VAC input voltage.

3. Output Connections: Connect the power supply outputs

to the desired devices observing polarity. See Table.2

for wire sizes and distances.

To reduce risk of electric shock, do not expose

unit to rain or excess moisture, and disconnect

power before servicing unit. For continuous

protection against hazards, replace fuses only

with exact type and rating. A readily accessible

switched circuit breaker must be available to

disconnect main power as required. All 120V

wiring should be routed so that it cannot touch

24V wiring; minimum spacing 3/8" (0.953cm).

Installation and servicing should only be made by

qualified personnel; contains no user-serviceable

parts. Install in accordance with all local

regulations and the National Electrical Code.

Maintenance

The power supply unit should be tested at least once a year to

verify correct operation in accordance with the following

recommendations:

Output Voltage Test - Voltage output should be tested under

normal load conditions to verify correct levels.

Battery Test - Battery should be checked for full charge under

normal load conditions. This check should verify correct

voltage at both battery terminals and also at the battery output

21 95-7767

Page 22

HONEYWELL IDENTIPOINT™ INTELLIGENT SMARTCARD SYSTEM

CAUTION

point on the board to ensure the integrity of all connecting

wiring. The battery should be replaced every 4 years or more

often under severe conditions.

WIRING THE READERS AND

IOM

General Descriptions

Power to the Reader:

Power can be supplied to the IdentIPoint reader either via the

Ethernet cable when it is connected to a router/switch that is

equipped with PoE (Power over Ethernet) PSE (Power Supply

Equipment) feature, or through a 12-24VDC power source.

NOTE: The PoE PSE can supply power up to 12.95 Watt.

It can supply power for one reader, one door

strike/magnetic lock which consumes a steady

current of less than 300mA (e.g. ASSA ABLOY

HES 5200) and one IOM. For the IOM module, DC

12V is needed.

Use of PoE is not a UL294 listed configuration and should not

be used on UL294 applications.

Data Communication:

Each IdentIPoint reader is equipped with an RJ45 connector

for Ethernet communication. It also has a wireless LAN

module that supports IEEE802.11b/g. The reader can

communicate with one or more IOMs via the RS485 bus.

NOTE: Wifi network configuration is not a UL294 listed

configuration and should not be used on UL294

applications.

The RS485 bus is a multi-drop 2-wire bus running differential

signal in half duplex. A third wire, the common ground, is also

recommended for more reliable communication. Multiple IOM

units can be attached to an IdentIPoint reader through this bus

in daisy chain mode. See Fig.24.

NOTE: It is recommended not to attach more than 4 IOM

units to the RS485 bus to maintain a reasonable

signal/response time delay between the reader

and IOMs.

Digital Input (DI) (IOM only):

The Digital Input is an active high input, which can be read by

the IOM and reported back to the reader through the RS485

interface.

Digital Output (DO)

The Digital Output is a current sinking output, capable of

sinking up to 1A at the rated supply voltage. The output can

thus be used to drive the door strike/magnetic lock, lights as

well as other Digital Inputs or Supervisory Inputs. See Figures

25 through 28.

Wire the Readers and IOM

1. Run the field wiring to the readers as per the job draw-

ings. Figures 21 through 24 show typical wiring

schemes for IdentIPoint devices. Wires of a minimum

gauge of 18 AWG are recommended for all wiring with

the upper limits specified for some applications. See

Table.2 for details on wire sizes and maximum permissible distances. 18 AWG wires (0.3 sq. mm) must be limited to 1A loading. When used for carrying

communication data as in RS485, the wires must be a

twisted pair.

2. To power the reader, plug the Molex terminal into the J9

port of the reader such that the red and black wires of

the terminal, connected to the +ve and -ve pins of the

power supply connect with pins 1 (Power IN) and 2

(Power GND) of the J9 port.

3. Ensure the other wires of the Molex terminal are connected to the correct corresponding wires from the other

devices such as IOMs, door sensors, door strikes etc.

(see Detailed Wiring Diagrams and Wiring Other

Devices topics and Fig.11). For wires that are not used,

ensure proper insulation at the free ends.

4. To power the IOM, plug the terminal block into the J1

port of the IOM such that the wires connected to the +ve

and -ve pins of the power supply, connect with the pins

for DC-IN and GND of the J1 port. The IOM may also be

alternatively powered through an IdentIPoint reader

(see Fig.22).

5. Ensure the other ports of the IOM are similarly connected to the correct corresponding wires from the other

devices such as readers, door sensors, door strikes etc.

(See Detailed Wiring Diagrams and Wiring Other

Devices topics and Fig.18).

6. Use proper crimping and/or insulation while connecting

the wires.

Transmission Protection The system may require

external lightning protection. For details, refer to

Lightning Protection topic.

Supervised Analog Input (SAI):

The Supervised Analog Input is designed to detect

supervisory loop tamper. See section Supervisory Analog

Input (SAI) termination circuit of Wiring Other Devices topic for

details. Such a loop circuit can be connected to the SAI of an

IdentIPoint reader as well as the IOM. This loop can detect

tampering by shorting across or cutting the loop. Four states

can be detected by the IdentIPoint device: open, short, cut

and closed.

95-7767 22

Grounding Recommendations

The FRAME-GROUND signal (pin 10 of J10) of the reader

has to be connected to the POWER-GND at all times to

ensure good ESD protection and low electromagnetic

radiation.

The FRAME-GROUND signal (port J3) of the IOM has to be

connected to the POWER-GND before making any other

connections to minimize the introduction of error in the RS485

communication line during hot signal insertion. It also should

be the last signal to be disconnected.

NOTE: FRAME-GROUND is also known as CHASSIS-

GROUND in some countries including USA.

Page 23

HONEYWELL IDENTIPOINT™ INTELLIGENT SMARTCARD SYSTEM

Power Wiring

IMPORTANT

Use a shielded power cable with a three-pin (or as

per local regulations) plug to draw mains power for

the power supply assembly. (The shielded wire is

required to meet FCC RF radiation limits.)

To route the power wiring

1. Using proper conduits, route the input power cable from

the mains supply to the input block of the power supply.

2. Route the +ve and -ve pairs of wires from the output

block of the power supply out of the power supply enclosure via proper conduits.

Table 2. Wire Sizes and Distances

Connection Wire Gauge Maximum Distance

Power Source to

Device (Reader

or IOM)

Reader/IOM to

Digital Inputs

18 AWG

(0.8mm

2

) to 15

AWG (1.7mm2)

18 AWG

2

(0.8mm

)

See reader/IOM power requirements

(section

of

Power Supply Recommendations

Assembly, Mounting and Installation

topic) and compensate for drop in voltage.

100m 2 per i/p Optional

3. Connect the +ve and -ve of wires to IdentIPoint devices.

For readers, connect the +ve to the red and the -ve to

the black wires of the 9-pin Molex terminal respectively.

(See Fig.6 for details on Molex terminal wire colors.)

Tamper Protection

IMPORTANT

IdentIPoint readers are equipped with tamper protection features. They must be permanently mounted

before commissioning. Attempting to open a reader

case without putting it in maintenance mode will disable the reader, and require recommissioning. For

details on how to deal with a tampered reader please

refer the EBI documentation set.

Minimum

number of

conductors Shielding

3 Unshielded

cable

recommended

Reader/IOM to

Digital Output or

Lock

Reader to IOM

(Power)

Reader to IOM

(RS485 comm.)

Reader to IOM

(other than Power

and RS485

18 AWG

(0.8mm

2

) to 15

AWG (1.7mm2)

18 AWG

(0.8mm2) to 15

AWG (1.7mm

2

18 AWG

2

(0.8mm

)

18 AWG

2

(0.8mm

)

100m subject to adequate power reaching

2 per o/p Required for

the output device or lock

See IOM power requirements (section

2 Required

Power Supply Recommendations of

Assembly, Mounting and Installation topic)

)

and compensate for drop in voltage.

500m 3 Recommended

100m 2 per connection

type

comm.)

IOM to IOM

(RS485 comm.)

18 AWG

(0.8mm

2

500m 3 Recommended

)

Ethernet CAT5 100m Standard as in

CAT5

EACH DOOR STRIKE REQUIRES A 14507020-001 DIODE

SUPPRESSION NETWORK. DOOR STRIKE MAY DRAW A

MAXIMUM CURRENT OF 2A; REGULATED 12/ 24 VDC.

DOOR STRIKE AND REX MUST BE UL LISTED. SEE

FIG.25 THROUGH FIG.28 FOR TYPICAL DIODE SUPPRESSION NETWORK WIRING.

DOOR CONTACTS MUST BE UL LISTED. MAXIMUM WIRE

LENGTH 500 FT (152 M). WIRE TYPE 18 AWG (0.8 SQ

MM), 50 OHM 60 mA MAXIMUM. DOOR CONTACTS ARE

ONLY INTENDED FOR MONITORING DOOR POSITION.

THEY ARE NOT INTENDED FOR CONNECTION TO A

BURGLAR ALARM PANEL

power cable

connected to

output device or

lock

Optional

Recommended

EXIT SWITCH: WIRING MUST BE COMPLETED WITHIN

THE PROTECTED AREA OR NOT READILY ACCESSIBLE

OUTSIDE THE PROTECTED AREA. THE EXIT SWITCH

MUST BE UL LISTED.

23 95-7767

Page 24

HONEYWELL IDENTIPOINT™ INTELLIGENT SMARTCARD SYSTEM

Rc+

Rc-

Tx+

Tx-

,

,

ALL WIRING MUST CONFORM TO APPLICABLE LOCAL

CODES, ORDINANCES, AND REGULATIONS.

NOTE: FOR COMMUNICATION CIRCUITS AND OTHER

APPLICABLE WIRING CIRCUITS WHERE WIRING

ENTERS AND EXITS THE BUILDING, REFER TO

DO NOT ROUTE COMMUNICATION WIRES WITH POWER

OR LOCKING DEVICES.

TABLE 13 FOR APPROPRIATE LIGHTNING PROTECTOR USAGE.

Power over Ethernet (PoE) wiring

PoE integrates data and power on the same wires, without interfering with concurrent network operation. PoE delivers 48V of DC

power over unshielded twisted-pair wiring for terminals consuming less than 13 watts of power.

PoE can be used with IEEE 802.3af compliant devices in either of the two modes described in Table.3 and shown in Fig.19 and

Fig.20. The detailed pin-outs are shown in Table.4.

, DC+

, DC+

, DC-

DC-

Rc+

Tx+

DC+

DC-

Rc-

DC+

8 NIP1 NIP

PIN 1 PIN 8

Tx-

DC-

Fig. 19. Straight cable pinouts for PoE in Mode A Fig. 20. Straight cable pinouts for PoE in Mode B

95-7767 24

Page 25

HONEYWELL IDENTIPOINT™ INTELLIGENT SMARTCARD SYSTEM

Table 3. PoE Modes

Pin Model A Model B

1 Vport positive

2 Vport positive

3 Vport negative

4 Vport positive

5 Vport positive

6 Vport negative

7 Vport negative

8 Vport negative

Table 4. PoE pin-outs for the two modes.

STANDARD SOURCE LOAD REMARKS

Ethernet RJ-45 connector pin number

IEEE

802.3af

using data

Source

Volta ge

48 V DC

protected

1 2 3 4 5 6 7 8 Load

Volta ge

RX

DC

+

RX

DC

+

TX

DC-

spare spare TX-DCspare spare (embedded) Industry

DC Load

Connector

pairs

IEEE

802.3af

48 V DC

protected

RX RX TX DC + DC + TX DC - DC - (embedded) Industry

using spare

pairs

NOTE: Use of PoE is not a UL294 listed configuration and should not be used on UL294 applications.

standard

for

embedded

PoF

standard

for

embedded

PoF

25 95-7767

Page 26

HONEYWELL IDENTIPOINT™ INTELLIGENT SMARTCARD SYSTEM

DC Power

28SAI2Power

GND

Signal

Min.18 AWG

DETAILED WIRING DIAGRAMS

Single Reader with REX and without IOM

To LAN

To Door Sensor

To REX Switch

To Door Lock

–

12 to 24V

If PoE is not used.

To electrical

earth.

If unavailable,

connect to

Power-GND.

2KΩ

2KΩ

1KΩ

1KΩ

SAI-1-GND

SAI-1

SAI-0-GND

SAI-0

Relay-NC

Relay-C

-

Power-IN

Ethernet

9

8

7

6

5

4

3

1

IdentIPoint Reader

1

2

3

4

5ON-yaleR

6

7

9

10

J10PINPINJ9

Power-OUT

Power-GND

RS485-A

RS485-B

RS485-GND

DO

DOGnd

-

SAI-2-GND

Frame-GND

S1

LEGEND

Power – Min. 18 AWG

Power Gnd – Min. 18 AWG

Ethernet – CAT5

Signal/Power – Min. 18 AWG

Signal – Min. 18 AWG

Fig. 21. Connections for single reader with REX and without IOM

In the above configuration, one IdentIPoint reader operates in

stand-alone mode to control door access. It authenticates

users as well as releases the door lock using its relay contact.

Minimum Connections:

1. Connect the Ethernet/PoE cable to the RJ45 port of the

reader through the CAT5 pigtail. (Frame-GND connection to building GROUND Earth is recommended for

better electro-static discharge resilience.) See Fig.7.

2. If PoE switch is not used, connect a 12-24VDC power

supply to pins 1-2 (Power-IN - Power-GND) of port J9 of

the reader. See section Wire the Readers and IOM of

Wiring the Readers and IOM topic for details on power

supply connections.

3. Connect pin(s) 3/4/5 (Relay-C/Relay-NC/Relay-NO) of

port J9 to the door lock depending on the type of lock

(magnetic lock or door strike) used and the safety codes

to be followed. Also connect a power line to the lock.

See Wiring Other Devices topic for detailed wiring of

locks.

4. Connect pins 6-7 (SAI-0 - SAI-0-GND) and 8-9 (SAI-1 SAI-1-GND) to a Request-to-Exit (REX) switch and door

sensor with proper termination circuit as described in

section Supervisory Analog Input (SAI) termination cir-

cuit of Wiring Other Devices topic. An additional sensor

can be connected to SAI-2 of port J10.

95-7767 26

Page 27

HONEYWELL IDENTIPOINT™ INTELLIGENT SMARTCARD SYSTEM

earth

SAI2485

GND

RL0-C

NOTE: REX and Door Sense support only Normally

Closed and not Normally Open positions, i.e.,

REX is detected when SAI switch is open, Door is

sensed as open when SAI switch is open.

Single Reader with REX and IOM

To LAN

DC – Power

12 to 24V

If PoE is not used

To electrical

.

If unavailable,

connect to

Power-GND.

SAI-1-GND

SAI-1

SAI-0-GND

SAI-0

Relay-NO

Relay-NC

Relay-C

Power-GND

Power-IN

Ethernet

9

8

7

6

5

4

3

2

1

J10PINJ9 PIN

Power-OUT

1

2

Power-GND

RS485-A

3

4

RS485-B

5

RS485-GND

DO

6

DOGnd

7

SAI-2

8

SAI-2-GND

9

Frame-GND

10

To REX Switch

To Door Sensor

Separate Power Supply

can also be used for IOM.

To electrical

earth.

If unavailable,

connect to

Power-GND.

2KΩ

2KΩ

1KΩ

1KΩ

DI-0 GND

GND DO-0

DI-1 GND

GND DO-1

SAI-0 GND

GND ILK-0

SAI-1 GND

GND ILK-1

GND

GND 485-B

SAI-3 485-A

GND N.C

SAO N.O

12V N.C

GND N.O

FGND RL1-C

IO Module

IdentIPoint Reader

LEGEND

-

To Door Lock

S1

Power – Min. 18 AWG

Power Gnd – Min. 18 AWG

Ethernet – CAT5

Signal/Power–Min. 18 AWG

Signal – Min. 18 AWG

Signal – Min. 18 AWG

Comm. – Min. 18 AWG

Comm. – Min. 18 AWG

Comm. – Min. 18 AWG

S1

Fig. 22. Connections for single reader with REX and IOM (S1 DIP switch settings shown)

27 95-7767

Page 28

HONEYWELL IDENTIPOINT™ INTELLIGENT SMARTCARD SYSTEM

In the above configuration, one IdentIPoint reader and one

IOM are connected through a secure RS485 connection to

control door access. While the IdentIPoint reader

authenticates users, the IOM releases the door lock upon the

reader's command. A Request-to-Exit (REX) switch can be

connected to the IOM's Digital Input or Supervised Analog

Input (SAI). The reader can read the state of the REX switch

and give instructions to the IOM regarding the door.

Minimum Connections:

1. Connect the Ethernet/PoE cable to the RJ45 port of the

reader through the CAT5 pigtail. (Frame-GND connection to building GROUND Earth is recommended for

better electro-static discharge resilience.) See Fig.7.

2. If PoE switch is not used, connect a 12-24VDC power

supply to pins 1-2 (Power-IN - Power-GND) of port J9 of

the reader. See section

Wire the Readers

Wiring the Readers and IOM

topic for details on power

and

IOM of

supply connections.

3. Connect the RS485-A, RS485-B and RS485-GND (pins

3, 4 and 5 on port J10 of the reader) to their corresponding RS485 points on J14 of the IOM. See section

RS485 Communication and Termination Setting

nector and Switch Descriptions

topic for details on

of

Con-

RS485 wiring and termination settings. Set the S1 DIP

switch on the reader and the IOM accordingly.

4. Power to the IOM can be given by connecting the

Power-OUT - Power-GND (pins 1-2 on J10) of the

reader to 12V - GND (J1) respectively of the IOM. Alternatively, power to the IOM can also be supplied through

a separate 12-24VDC power supply or a common rail.

5. Connect pin(s) NC/NO/RL0-C or RL1-C (J12/J13) of the

IOM to the door lock depending on the type (magnetic

lock or door strike) used and the safety codes to be followed. Also connect a power line to the lock. Detailed

wiring for locks is shown in

Wiring Other Devices

topic.

6. Connect J6, J7, J8 or J9 of the IOM (SAI-n - SAI-nGND) to a door sensor and a REX switch with proper

termination circuit as described in section

Analog Input (SAI) termination circuit

Devices

topic. Alternatively, the REX switch can also be

Supervisory

of

Wiring Other

connected to DI-0 - GND or DI-1 - GND (J4 or J5) of the

IOM without any termination circuit.

NOTE:

• The IOM must be installed on the secure side of the

door.

• The RS485 ground signal is not necessary if the IOM

is powered by the IdentIPoint reader or if there is a

common ground available between the two units.

• REX and Door Sense support only Normally Closed

and not Normally Open positions, i.e., REX is

detected when SAI switch is open, Door is sensed as

open when SAI switch is open.

95-7767 28

Page 29

Two Readers with IOM

Power – Min. 18 AWG

Power Gnd–Min. 18 AWG

Ethernet – CAT5

Signal – Min. 18 AWG

Signal – Min. 18 AWG

Comm. – Min. 18 AWG

Comm. – Min. 18 AWG

Comm. – Min. 18 AWG

Comm. – Min. 18 AWG

LEGEND

Comm. – Min. 18 AWG

Ethernet

IdentIPoint Reader

S1

DC – Power

12 to 24V

If PoE is not used.

To

electrical earth.

If unavailable, connect

to Power-GND.

1KΩ

2KΩ

2K

Ω

1KΩ

* 1KΩ for 12V

2KΩfor 24V

Secure deru

cesnUediS Side

To EML

Door Lock

1

Power-OUT

SAI-1-GND

2

Power-GND

SAI-1

3

RS485-A

SAI-0-GND

4

RS485-B

SAI-0

5

RS485-GND

Relay-

NO

6

DO

Relay-NC

7

DOGnd

Relay-C

8

SAI-2

Power-GND

9

SAI-2-GND

Power-

IN

Frame-GND

J10PIN

HONEYWELL IDENTIPOINT™ INTELLIGENT SMARTCARD SYSTEM

-

on

Out

r

PIN

PIN

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

To electrical earth.

If unavailable, connect

to Power-GND.

GND

GND

SAI

SAI

-0

-0

SAI-2

SAI-2

FGND

IO

To electrical earth.

If unavailable, connect

to Power-GND.

module

dae

S1

GND

GNDDI-0

DO

DO

GND

GNDDI-1

DO-1DO-

GND

GND

ILK-0GND

ILK-0GND

GNDSAI-1

GNDSAI-1

ILK

ILK

485-

485GND

GND

485-BGND

485-BGND

485-ASAI -3

485-ASAI -3

N.CGND

N.CGND

N.OSAO

N.OSAO

RL0 -CGND

N.C12V

N.C12V

N.OGND

N.OGND

RL1-C

RL1-C

-0GND

-0GND

-1GND

-1GND

CGND

* Can also internally connect

12V to RL0-C

S1

Connecons

DC –Power

24V

12 to

If

is

PoE

not used.

To Door Sensor

DC –Power

12 to 24V

If PoE is not used.

J9

To LAN

J9

SAI-1-GND

SAI-1

SAI-0-GND

SAI

-0

Relay-NO

Relay

Relay

Power-GND

Power-IN

-reader

noCre

on In

snoitcen

Ethernet

J10PIN

PIN

PIN

9

8

7

6

5

4

-NC

3

-C

2

1

IdentIPoint Reader

Power-OUT

1

1

2

2

Power-GND

-A

RS485

3

3

RS485-B

4

4

5

5

RS485-GND

DO

6

6

DOGnd

7

7

SAI-2

8

8

SAI-2-GND

9

9

GND

Frame-

10

10

Fig. 23. Connections for two readers with IOM (S1 DIP switch settings shown)

29 95-7767

Page 30

HONEYWELL IDENTIPOINT™ INTELLIGENT SMARTCARD SYSTEM

In the above configuration, two IdentIPoint readers and one

IOM are inter-connected to control an IN/OUT door. While the

IdentIPoint readers authenticate users on both sides of the

door, the IOM releases the door lock upon the readers'

commands. A Request-to-Exit (REX) button is not required in

this setup.

Minimum Connections:

1. Connect the Ethernet/PoE cable to the RJ45 port of the

reader through the CAT5 pigtail. (Frame-GND connection to building GROUND Earth is recommended for

better electro-static discharge resilience.) See Fig.7.

2. If PoE switch is not used, connect a 12-24VDC power

supply to pins 1-2 (Power-IN - Power-GND) of port J9 of

the reader and pins 12V - GND (J1) of the IOM through

a common rail. This is the recommended power supply

configuration as it is necessary to provide a common

ground to all three devices. See section

ers and IOM

of

Wiring the Readers and IOM

Wire the Read-

topic for

details on power supply connections.

3. Connect the RS485-A, RS485-B and RS485-GND (pins

3, 4 and 5 on port J10 of the In-reader) to their corresponding RS485 points on J14 of the IOM. See section

RS485 Communication and Termination Setting

nector and Switch Descriptions

topic for details on

of

Con-

RS485 wiring and termination settings. Set the S1 DIP

switch on the In-reader and the IOM accordingly.

4. Connect pin(s) NC/NO/RL0-C or RL1-C (J12/J13) of the

IOM to the door lock depending on the type (magnetic

lock or door strike) used and the safety codes to be followed. Also connect a power line to the lock. Detailed

wiring for locks is shown in

Wiring Other Devices

topic.

5. Connect J6, J7, J8 or J9 of the IOM (SAI-n - SAI-nGND) to a door sensor with proper termination circuit as

described in section

mination circuit

Supervisory Analog Input (SAI) ter-

of

Wiring Other Devices

topic.

6. Make all other interconnections between the Out-reader

and IOM as shown in Fig. 23.

NOTE:

• The Out-reader must be installed on the secure side

of the door along with the IOM.

• For a single door controlled by two readers with IOM

the door sensor shall always be wired to SAI-3 of the

IOM.

• The RS485 ground signal is not necessary if the IOM

is powered by the IdentIPoint reader or if there is a

common ground available between the two units.

• The resistors need to be connected at proper

terminals as shown in the diagram.

• REX and Door Sense support only Normally Closed

and not Normally Open positions, i.e., REX is

detected when SAI switch is open, Door is sensed as

open when SAI switch is open.

95-7767 30

Page 31

Reader with Multiple IOMs

SAI-1-GND92

P

GND

SAI-1-GND92

P

GND

2

2

If unavailable

N.C

12V

N.C

12V

N.C

12V

N.C

12V

N.C

12V

N.C

12V

S1

S1

S1

Comm. Min. 18 AWG

To LAN

DC – Power

12 to 24V

If PoE is not used.

To electrical

earth.

,

connect to

Power-GND.

SAI-1-GND

SAI-2-GND

SAI-2-GND

SAI-1

SAI-0-GND

SAI-0

Relay-NC

Relay-C

Power-GND

ower-

ower-

Power-IN

HONEYWELL IDENTIPOINT™ INTELLIGENT SMARTCARD SYSTEM

Ethernet

Ethernet

J10PINPINJ9

PINPINJ10

PINPINJ10

J9

1

1

1

2

3

4

56DO

56DO

5ON-yaleR

6

7

8

9

10

J9

Power-OUT

Power-IN

Power-IN

Power-GND2

Power-GND2

Power-GND

Relay-C38SAI-2

Relay-C38SAI-2

RS485-A

Relay-NC47DOGnd

Relay-NC47DOGnd

RS485-B

Relay-NO

Relay-NO

RS485-GND

SAI-065RS485-GND

SAI-065RS485-GND

DO

SAI-0-GND74RS485-B

SAI-0-GND74RS485-B

DOGnd

SAI-183RS485-A

SAI-183RS485-A

SAI-2

SAI-2-GND

Frame-GND

OFF ON

OFF ON

S1

S1

1

1

3

3

4

4

S1

9

10Frame-GND

10Frame-GND

9

9

8

7

6

5

4

3

2

1

1Power-OUT

1Power-OUT

IdentIPoint Reader

BOTAC reader

BOTAC reader

LEGEND

GNDDI-0

GNDDI-0

DO-0GND

DO-0GND

GNDDI-1

GNDDI-1

D1-0GND

D1-0GND

DO-1 DO-1

GND

GND

SAI-0

SAI-0

ILK-0GND

ILK-0GND

GNDSAI-1

GNDSAI-1

ILK-1GND

ILK-1GND

485-

485-

SAI-2

SAI-2

GND

GND

485-BGND

485-BGND

485-ASAI-3

485-ASAI-3

N.C

N.C

GND

GND

N.OSAO

N.OSAO

RLO-CGND

RLO-CGND

N.OGND

N.OGND

FGND

RL1-C

RL1-C

IO module

IOM 1 IOM 2

DC – Power

12 to 24V

To electrical

earth.

If unavailable,

connect to

Power-GND.

Power – Min. 18 AWG

Power Gnd – Min. 18 AWG

Ethernet – CAT5

SAI-0

SAI-0

SAI-2

SAI-2

GND

GND

NGF

DC – Power

12 to 24V

IO module

GNDDI-0

GNDDI-0

DO-0GND

DO-0GND

GNDDI-1

GNDDI-1

D1-0GND

D1-0GND

GND

GND

ILK-0GND

ILK-0GND

GNDSAI-1

GNDSAI-1

ILK-1GND

ILK-1GND

485-

485GND

GND

485-BGND

485-BGND

485-ASAI-3

485-ASAI-3

N.C

N.C

N.OSAO

N.OSAO

RLO-CGND

RLO-CGND

N.OGND

N.OGND

RL1-C

RL1-C

To electrical

If unavailable,

connect to

Power-GND.

earth.

SAI-0

SAI-0

SAI-2

SAI-2

GND

GND

DC – Power

12 to 24V

DNGFD

IOM 3

IO module

GNDDI-0

GNDDI-0

DO-0GND

DO-0GND

GNDDI-1

GNDDI-1

DO-1

D1-0GND

D1-0GND

GND

GND

ILK-0GND

ILK-0GND

GNDSAI-1

GNDSAI-1

ILK-1GND

ILK-1GND

485-

485GND

GND

485-BGND

485-BGND

485-ASAI-3

485-ASAI-3

N.C

N.C

N.OSAO

N.OSAO

RLO-CGND

RLO-CGND

N.OGND

N.OGND

RL1-C

RL1-C

To electrical

If unavailable,

connect to

Power-GND.

earth.

Comm. – Min. 18 AWG

Comm. – Min. 18 AWG

Fig. 24. Connections for reader with three IOMs on a RS485 bus (S1 DIP switch settings shown)

31 95-7767

Page 32

HONEYWELL IDENTIPOINT™ INTELLIGENT SMARTCARD SYSTEM

WARNING

In the above configuration, three IdentIPoint IOMs are interconnected with a reader in a master-slave configuration. Such

connections are necessary when a reader needs to connect

with more than one IOM.

Minimum Connections:

1. Connect the RS485-A, RS485-B and RS485-GND (pins

3, 4 and 5 on port J10 of the In-reader) to their corresponding RS485 points on J14 of IOM1. See section

RS485 Communication and Termination Setting

nector and Switch Descriptions

topic on RS485 wiring

of

Con-

and termination settings. Set the S1 DIP switch on the

reader accordingly.

2. Connect the RS485-A, RS485-B and RS485-GND on

J14 of IOM 1 to their corresponding RS485 points on

J14 of IOM2 and similarly connect IOM2 to IOM3 in a

daisy chain. See section

Termination Setting

topic for details on RS485 wiring and termination

tions

RS485 Communication and

of

Connector and Switch Descrip-

settings. Set the S1 DIP switch on the IOMs accordingly.

3. Make all other connections between the reader, IOMs

and other devices as needed and explained in section

Single Reader with REX and IOM

Diagrams

topic.

of

Detailed Wiring

Strike Latch

Strike latch connected directly to the reader:

NOTE:

• Although, Fig. 24 shows separate power supplies for

all the devices, it is also possible to provide them

power from a single power source as long at it

delivers the required power for all devices.

• The IOMs must be installed on the secure side of the

door.

• The RS485 ground signal is not necessary if the IOM

is powered by the IdentIPoint reader or if there is a

common ground available between the two units.

WIRING OTHER DEVICES

Use suppressors on door strikes and magnetic

locks wherever required. Use 14507020-001 diode

suppression network. Honeywell recommends

only DC locks. See Fig.25 through Fig.28 for

typical diode suppression network wiring.

LEGEND

LEGEND

LEGEND

1457020-001

1457020-001

Diode Suppression

Diode Suppression

Network

Network

Power – Min. 18 AWG

Power – Min. 18 AWG

Power – Min. 18 AWG

Power Gnd – Min. 18 AWG

Power Gnd – Min. 18 AWG

Power Gnd – Min. 18 AWG

DC – Power

DC – Power

12VDC/24VDC

12VDC/24VDC

Strike L atch

Strike L atch

_

__

+

++

+

++

_

_

_

BLK

BLK

RED

RED

Ethe rne t

Ethe rne t

Ethe rne t

9

9

SAI- 1-GND

SAI- 1-GND

SAI- 1-GND

SAI- 1

SAI- 1

SAI- 1

SAI- 0-GND

SAI- 0-GND

SAI- 0-GND

SAI- 0

SAI- 0

SAI- 0

Relay-NO 5

Relay-NO 5

Relay-NO 5

Relay-NC

Relay-NC

Relay-NC

Relay-C

Relay-C