Page 1

AT20, AT40, AT72D, AT87, AT88

AT Transformers

INSTALLATION INSTRUCTIONS

APPLICATION

The AT20, AT40, AT72, AT87 and AT88 TRADELINE®

Transformers are step-down transformers used primarily

for powering 24 Vac control systems. They can be used

in any 24 Vac application that does not exceed the

transformer volt-ampere (VA) rating.

The TRADELINE® Transformers will replace all

equivalent Honeywell and competitive transformers with

similar primary voltage requirements, equal or smaller VA

ratings and similar mounting configurations.

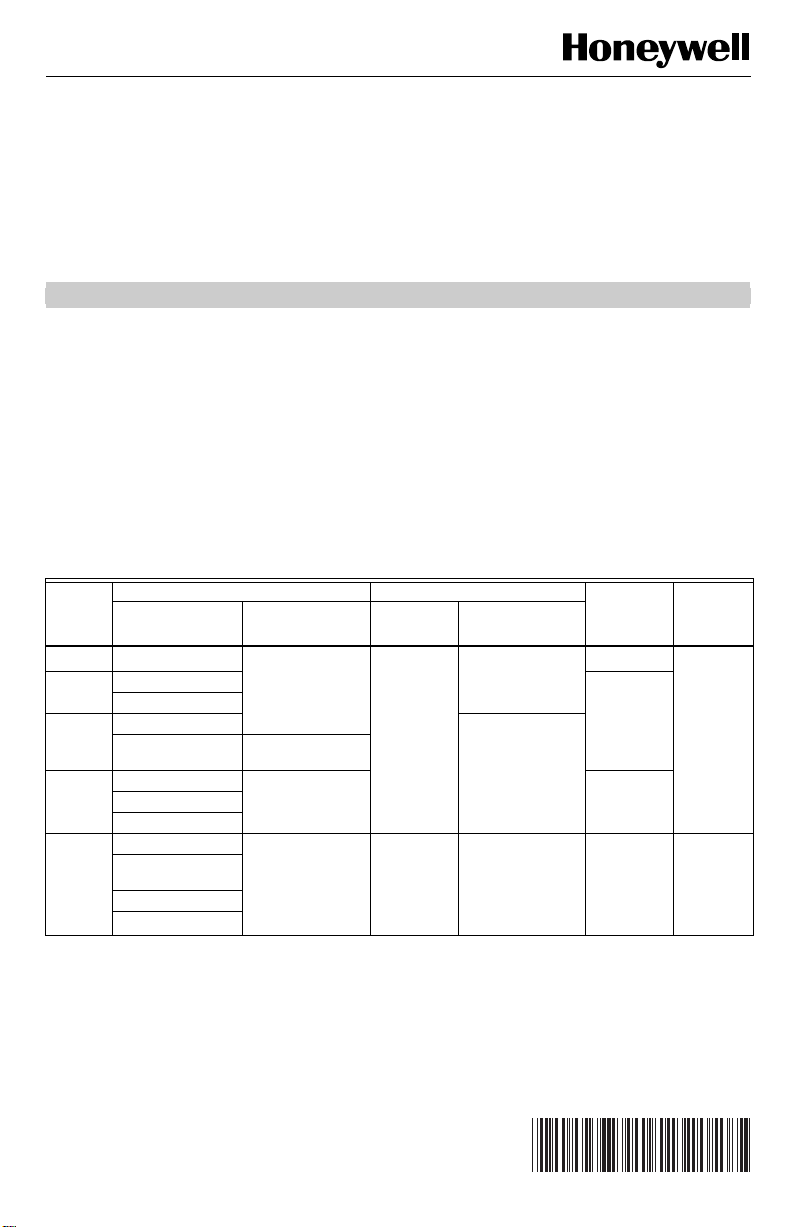

Table 1. Transformer Model and Electrical Specifications.

Primary Secondary Output at

Model

AT2 0

AT4 0

AT7 2D

AT8 7A

AT88A 120Vac, 50/60 Hz Two 12 in. (305 mm)

a

Transformer complies with 24 volt NEMA Standard DC-20.

b

Available with female quick-connect terminals on all leadwires.

c

Thermal fuses in primary on 208V/240V models for overload protection.

Voltage and

a

a

Frequency Wiring Connection Voltage Wiring Connection

120 Vac, 50/60 Hz Two 9 in. (229 mm)

120 Vac, 50/60 Hz 40 VA

240 Vac, 50/60 Hz

a

120 Vac, 50/60 Hz Two screw

240 Vac, 50/60 Hz Three 9 in. (229

a

120 Vac, 50/60 Hz Two 13 in. (330 mm)

208 Vac, 50/60 Hz

240 Vac, 50/60 Hz

208/240 Vac, 50/60

Hz

400 Vac, 50/60 Hz

480 Vac, 50/60 Hz

leadwires

mm) leadwires

leadwires

leadwires

b

Transformer voltage ratings (primary and secondary),

wiring connection type, and fusing are listed in Table 1.

The transformers are Underwriters Laboratories Inc.

component recognized and Canadian Standards

Association listed and meet NEC Class 2 not wet, Class

3 wet requirements as specified by NEMA Standard

DC-20.

SPECIFICATIONS

Models:

See Table 1.

24 Vac Two 9 in. (229 mm)

24 Vac Two 12 in. (305

leadwires

terminals

mm) leadwires

100 Percent

Power

Rating

20 VA Energy

50 VA

75 VA Fuse in

Overload

Protection

Limited

secondary

c

® U.S. Registered Trademark

Copyright © 2002 Honeywell • All Rights Reserved

69-1641EF

Page 2

AT20, AT40, AT72D, AT87, AT88 AT TRANSFORMERS

S

Y

4

5

7

B

S

5

H

INSTALLATION

ABCDE

in. mm in. mm in. mm in. mm in. mm

AT4 0C 2-

AT8 7A 2-

61 7/8 22 1-3/4 44 2-3/16 56 2-7/8 73

13/32

61 1 25 1-3/4 44 2-1/16 52 3 76

13/32

When Installing This Product…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a

hazardous condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for

your application.

3. The installer must be a trained, experienced

service technician.

4. After installation is complete, check out product

operation as provided in these instructions.

WARNING

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

Disconnect power supply before beginning

installation to prevent electrical shock or

equipment damage.

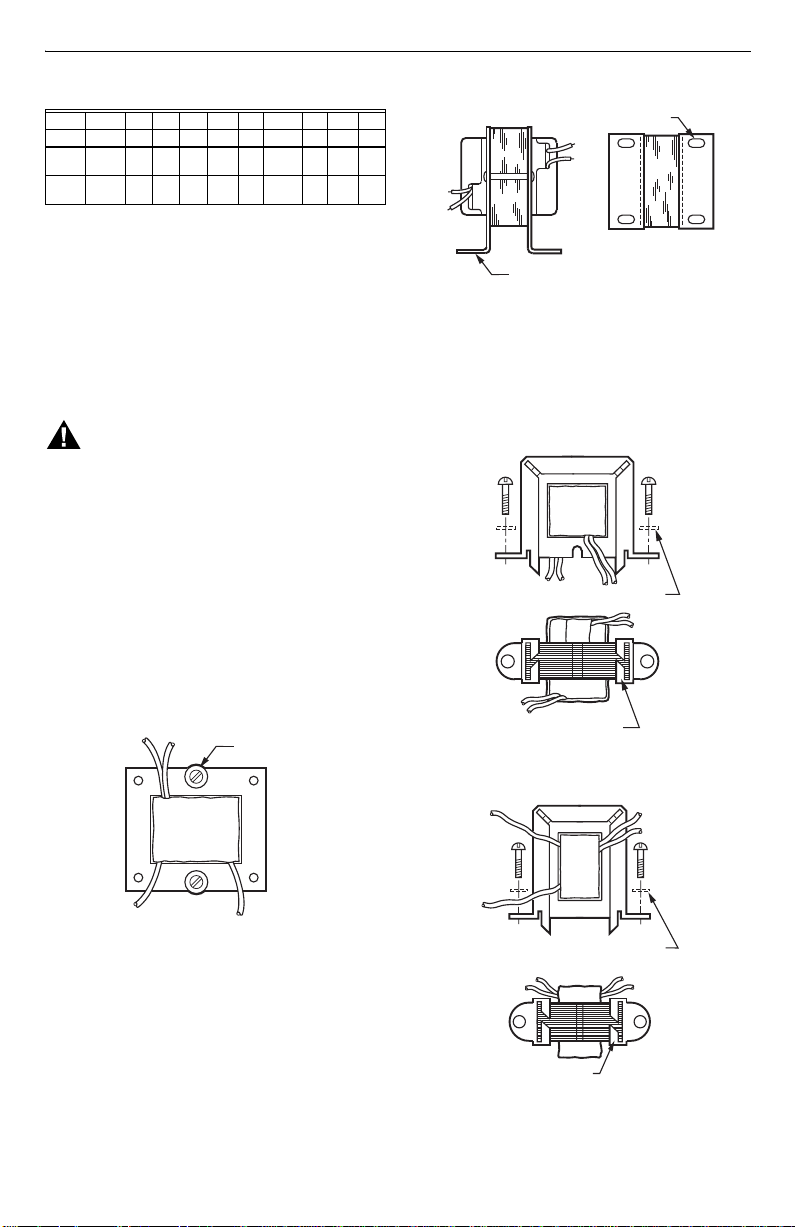

Mounting the AT20A and AT40A Transformer

1. Mount the transformer to best suit the replacement

application. The transformer may be mounted in

one of three ways:

a. Use bolts in slots for direct mounting (Fig. 6).

USE SCREWS OR BOLTS

THROUGH SLOTS (4) IN

MOUNTING FEET

MOUNTING FOOT (2)

M2065

Fig. 2. Foot mounting (AT20C shown).

c. Vertical channel mounting. Place frame over

laminations as shown in Fig. 8 and bend tabs

over to hold transformer securely in place.

Mount transformer through 3/16 in. (5 mm)

holes in mounting feet.

ORIZONTAL FOOT MOUNTING

USE WASHERS IF NECESSARY

PANEL

MOUNTING

USE WASHER

IF NECESSAR

M2065

Fig. 1. Use bolts in slots for panel mounting.

b. Horizontal channel frame. Place frame over

laminations as shown in Fig. 7 and bend tabs

over to hold transformer securely in place.

Mount transformer over 3/16 in. (5 mm) holes

in mounting feet.

69-1641EF 2

BEND OVER TABS (4) TO

SECURE TRANSFORMER

VERTICAL FOOT MOUNTING

END OVER TABS (4) TO

ECURE TRANSFORMER

Fig. 3. Use horizontal channel frame for horizontal

foot mounting; vertical channel frame for vertical

foot mounting.

USE WASHERS

IF NECESSARY

M2066

M2065

Page 3

AT20, AT40, AT72D, AT87, AT88 AT TRANSFORMERS

C

S

A

C

S

S

L

F

C

L

F

C

6

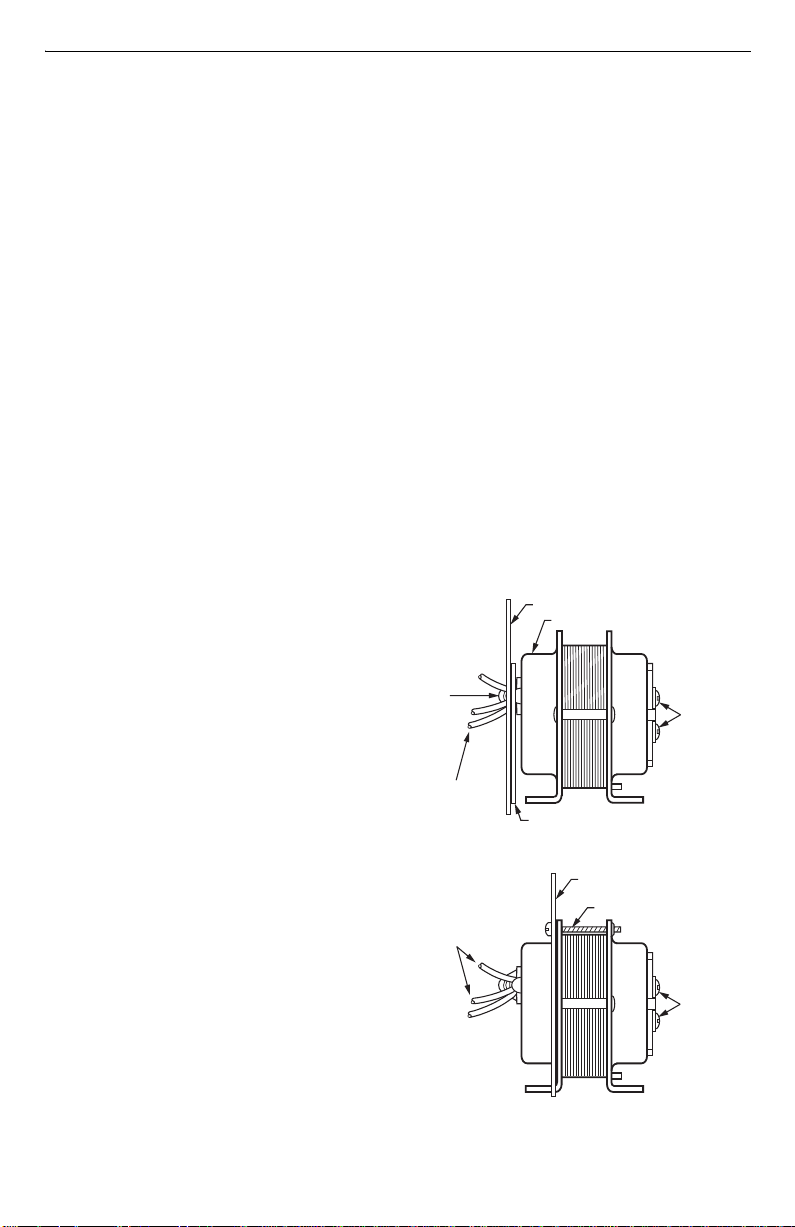

Mounting the AT72D Transformer.

Mount the transformer to meet the application. Use one

of the methods illustrated. The transformer can be

mounted in any position.

Foot Mounting.

1. Discard mounting plate.

2. Use screws or bolts through slots in mounting feet

to fasten transformer to mounting surface.

Plate Mounting.

The mounting plate allows the transformer to be mounted

on a 4 in. by 4 in. square or 4 in. octagonal junction box.

1. Remove the large center knockout in the mounting

plate (Fig. 19).

2. Take transformer in one hand and mounting plate

in the other hand. Keyhole slots on mounting plate

should be up.

3. Place large knockout in mounting plate over primary leadwires and end bell of transformer. The

small tab on the bottom center of the plate fits into

the slot in the transformer mounting feet (Fig. 20).

4. Insert the mounting screw through the holes as

illustrated.

5. Secure the plate to the transformer. Do not

overtighten.

Mounting plate to transformer (Fig. 17).

The plate can be mounted to the transformer in one of

two positions:

a. at the clamp on primary end bell (transformer

all above plate);

b. at the laminations (transformer 3/4 above plate.

To mount the plate at clamp on primary end bell

(transformer all above plate):

1. Take mounting plate in one hand. Keep the keyhole slots up and the raised portion of the large

center knockout toward you.

2. Insert the primary leadwires through the center

hole in the plate.

3. Fit the hole in the plate over the clamp attached to

the end bell. Clamp screw must be turned almost

completely out.

4. With the plate in place over the clamp, tighten the

screw securely against the rim of the round hold

See Fig. 18. Avoid damaging the leadwires with the

screwdriver.

To mount the plate at the laminations (transformer 3/4

above the mounting plate:

1. Remove the large center knockout in the mounting

plate (see Fig. 19).

2. Take the transformer in one hand. Clamp on end

bell should face you.

3. Take the mounting plate in the other hand. Keyhole

slots should be up.

4. Place large knockout in mounting plate over

primary leadwires and end bell. Small tab at the

bottom of the center of the plate fits into the

transformer mounting foot. Insert mounting screw

through holes as shown in Fig. 20.

5. Secure plate to transformer. Do not overtighten

screw.

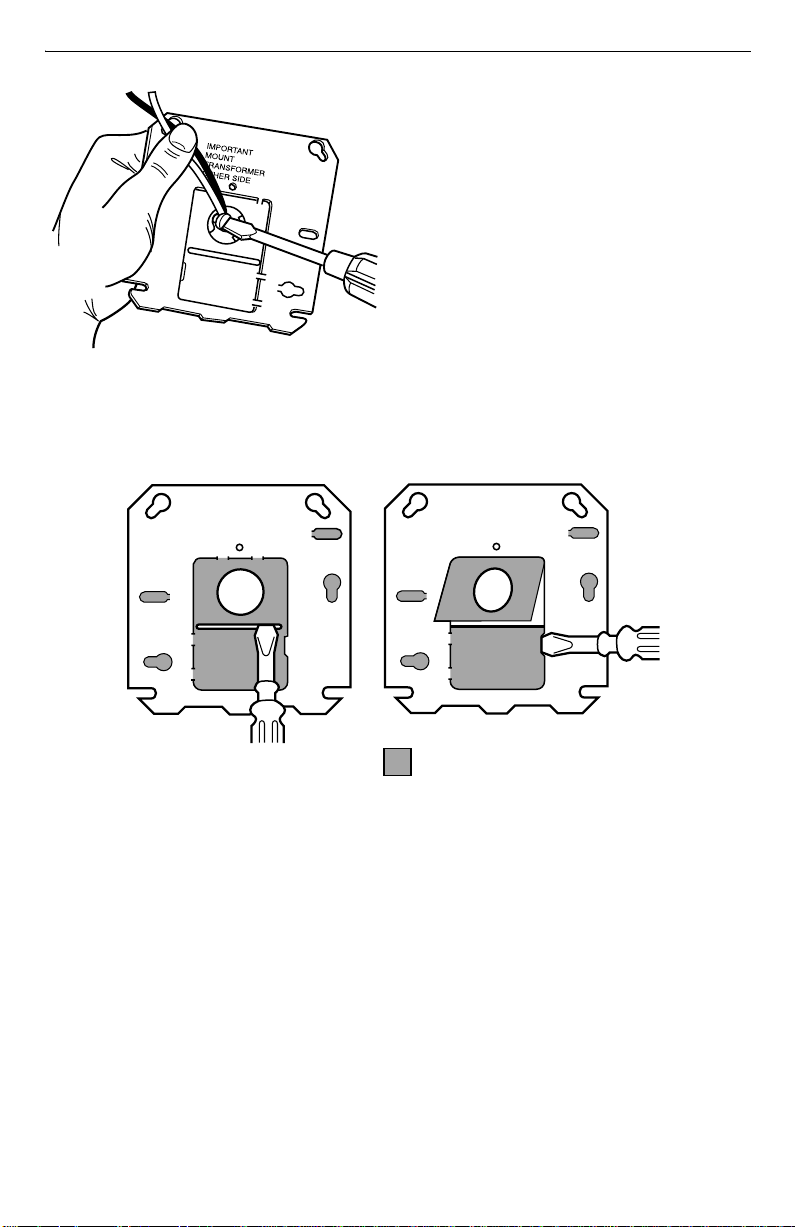

Mounting Transformer and Plate to Electrical

Box

The mounting plate can be mounted to 4 in. x 4 in. boxes

with regular and irregular spaced mounting holes, to 2 in

by 4 in. boxes and to 4 in. octagonal boxes. See Fig. 21.

1. Use the screws supplied with the electrical box.

2. Place them through the proper mounting holes in

the plate and secure the transformer and plate to

the box.

3. Punch out appropriate knockouts for plate

mounting holes, if necessary.

NOTE: Transformer feet should always be outside of

the junction box.

Clamp Mounting Using Junction Box Knockout

The transformer can also be clamp mounted using a

junction box knockout, if desired. This mounting option

does not require the use of the mounting plate. To mount

the transformer within the knockout:

1. Insert the primary leadwires and clamp and screw

on transformer end bell through suitable 1/2 in. (13

mm) knockout in junction box. Clamp screw must

be turned almost completely out in order to get

clamp through knockout.

2. Tighten clamp screw securely against rim of

knockout. Avoid damaging the leadwires with the

screwdriver.

PLATE MOUNTED AT CLAMP ON END BELL

(ALL ABOVE PLATE MOUNTING)

MOUNTING PLATE

END BELL

LAMP

CREW

ND

LAMP

EADWIRES

OR PRIMARY

ONNECTIONS

EADWIRES

OR PRIMARY

ONNECTIONS

Fig. 4. Plate may be mounted to transformer in one of

3 69-1641EF

RAISED PORTION OF LARGE CENTER KNOCKOUT

PLATE MOUNTED AT THE LAMINATIONS

(3/4 ABOVE PLATE MOUNTING)

MOUNTING PLATE

MOUNTING SCREW

two positions (AT72D shown).

SCREW

TERMINALS

FOR

SECONDARY

CONNECTION

SCREW

TERMINALS

FOR

SECONDARY

CONNECTION

M2065

Page 4

AT20, AT40, AT72D, AT87, AT88 AT TRANSFORMERS

WITH RAISED PORTION OF KNOCKOUTS FACING YOU:

1

M12126

Fig. 5. Tighten clamp securely against rim of round

.

hole.

PRY UP TOP SECTION OF LARGE KNOCKOUT

BY INSERTING SCREWDRIVER FIRST AT ONE

SIDE OF SLOT AND THEN AT THE OTHER SIDE.

THEN PRY UP BOTTOM SECTION OF KNOCKOUT.2.

Fig. 6. Removing large center knockout.

69-1641EF 4

REMOVE BOTH SECTIONS OF KNOCKOUT WITH PLIERS.3.

SHADED AREAS REPRESENT KNOCKOUTS

AND SCREW SLOTS USED WITH 2 X 4 INCH

OR OCTAGONAL OUTLET BOXES.

M9188A

Page 5

IMPORTANT

TRANSFORMER

O

B

8

R

G

)

R

H

T

9

M

S

L

F

C

MOUNT

TRANSFORMER

OTHER SIDE

PLATE

AT20, AT40, AT72D, AT87, AT88 AT TRANSFORMERS

USE SCREWS O

BOLTS THROUG

SLOTS (4) IN

MOUNTING FEE

EADWIRES

OR PRIMARY

ONNECTIONS

SCREW

TERMINALS

FOR

SECONDARY

CONNECTION

M9163

Fig. 7. Secure plate to transformer with mounting

REGULAR

4 X 4 INCH

BOX (2)

CTAGON

OX

IRREGULAR

4 X 4 INCH

BOX

(MOUNTING

HOLES IN

BOX ARE

SLIGHTLY

INDENTED)

screw.

LOAD

N.E.C. CLASS 2

IRREGULA

4 X 4 INCH

BOX

(MOUNTIN

HOLES IN

BOX ARE

SLIGHTLY

INDENTED

OCTAGON

BOX

REGULAR

4 X 4 INCH

BOX (2)

M2065

Fig. 8. Location of mounting holes.

Mounting the AT87 Transformer

Foot Mounting (Fig. 22)

Use screws or bolts through slots in the mounting feet to

fasten the transformer to the mounting surface.

OUNTING FOOT (2)

M2065

Fig. 9. Foot mounting of AT87 Transformer.

Plate Mounting

The mounting plate allows the transformer to be mounted

on a 4 in. by 4 in. square or 4 in. octagonal junction box.

1. Remove the large center knockout in the mounting

plate (see Fig. 19).

2. Take transformer in one hand and mounting plate

in the other hand. Keyhole slots on mounting plate

should be up.

3. Place large knockout in mounting plate over

primary leadwires and end bell of transformer. The

small tab on the bottom center of the plate fits into

the slot in the transformer mounting feet (see Fig.

20).

4. Insert the mounting screw through the holes as

illustrated.

5. Secure plate to transformer. Do not overtighten

screw.

Mounting Transformer and Plate to Electrical

Box.

The mounting plate can be mounted in 4 in. x 4 in. boxes

with regular and irregular spaced mounting holes, and on

4 in. octagonal boxes.

1. Use the screws supplied with the junction box.

2. Place the screws through the appropriate mounting

holes in the plate and secure the transformer and

plate to the box.

3. Punch out appropriate knockouts for plate

mounting holes, as necessary.

NOTE: Transformer should always be outside of the

junction box.

Mounting the AT88 Transformer.

Use screws or bolts through slots in the mounting feet to

fasten the transformer to the mounting surface. See Fig.

10.

5 69-1641EF

Page 6

WIRING

C

0

1

C

1. Disconnect power supply before installing

transformer. All wiring must comply with local

electrical codes and ordinances. Tape all unused

exposed leadwires separately.

2. Connect primary leadwires to line voltage power

supply. See Fig. 23 through 25.

3. Connect transformer secondary leadwires to 24

Vac control system.

OMMON

WHITE (120V) OR ORANGE (240V)

1

SECONDARY CONNECTIONS ARE BLUE AND YELLOW

LEADWIRES.

2

BLACK IS COMMON WITH RESPECT TO THE TRANSFORMER

WINDING ONLY AND NOT THE EXTERNAL CIRCUIT.

Fig. 10. AT20/AT40 Transformer schematic.

208 VAC

240 VAC

1 SECONDARY CONNECTIONS ARE SCREW TERMINALS.

2 BLACK IS COMMON WITH RESPECT TO THE TRANSFORMER

WINDING AND NOT THE EXTERNAL CIRCUIT.

2

BLACK

120 VAC

2

BLACK

WHITE

RED

ORANGE

1 24 VAC

M2066

1

24 VAC

M18321

OMMON

240 VAC

1

SECONDARY CONNECTIONS ARE BLUE AND YELLOW

LEADWIRES.

2

BLACK IS COMMON WITH RESPECT TO THE TRANSFORMER

WINDING ONLY AND NOT THE EXTERNAL CIRCUIT.

208 VAC

2

BLACK

RED

ORANGE

1 24 VAC

M2066

Fig. 12. AT88 Transformer schematic.

CHECKOUT

After installation is complete, turn on power supply.

Placed controlled equipment into operation and observe

through at least one complete cycle. Make sure it

functions as intended.

Fig. 11. AT72D, AT87A Transformer schematic.

Automation and Control Solutions

Honeywell Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Scarborough, Ontario

69-1641EF G.R. 09-02 Printed in China www.honeywell.com

M1V 4Z9

Page 7

Transformateurs AT

AT20, AT40, AT72D, AT87, AT88

NOTICE D'INSTALLATION

APPLICATION

Les transformateurs abaisseurs TRADELINE® AT20,

AT72, AT87 et AT88 sont utilisés principalement pour

alimenter les systèmes de régulation 24 V c.a. Ils

peuvent être utilisés dans toutes les applications

24 V c.a. qui ne dépassent pas la valeur nominale en

voltampères (VA) du transformateur.

Les transformateurs TRADELINE® remplacent tous les

transformateurs équivalents Honeywell ou d'une autre

marque dont la tension primaire requise est similaire, la

puissance nominale est égale ou inférieure et la

configuration de montage est semblable.

Tableau 1. Modèles de transformateurs et caractéristiques électriques.

Primaire Secondaire Puissance de

Modèle

AT2 0

AT4 0

AT7 2D

AT8 7A

Tension et

fréquence Raccordement Tension Raccordement

a

a

a

a

120 V c.a.,

50/60 Hz

240 V c.a.,

50/60 Hz

120 V c.a.,

50/60 Hz

240 V c.a.,

50/60 Hz

120 V c.a.,

50/60 Hz

208 V c.a.,

50/60 Hz

240 V c.a.,

50/60 Hz

Deux conducteurs de

229 mm (9 po)

Trois conducteurs de

229 mm (9 po)

Deux conducteurs de

330 mm (13 po)

24 V c.a. Deux conducteurs de

Les tensions nominales du transformateur

(primaire et secondaire), le type de raccordement et les

fusibles sont énumérés au Tableau 1.

Les composants du transformateur sont reconnus par les

Laboratoires des assureurs Inc., certifiés par

l'Association canadienne de normalisation et conformes

aux exigences de câblage du Code national de

l'électricité (NEC), classe 2 pour endroits non humides et

classe 3 pour endroits humides, énoncées dans la norme

NEMA DC-20.

CARACTÉRISTIQUES TECHNIQUES

Modèles :

Voir le Tableau 1.

229 mm (9 po)

Deux bornes à vis

sortie - facteur

de puissance

de 100%

20 VA À limitation

40 VA

50 VA

Protection

contre les

surcharges

c

d'énergie

® Marque de commerce enregistrée aux États-Unis

Copyright © 2002 Honeywell • Tous droits réservés

69-1641EF

Page 8

TRANSFORMATEURS AT AT20, AT40, AT72D, AT87, AT88

Tableau 1. Modèles de transformateurs et caractéristiques électriques. (suite)

Primaire Secondaire Puissance de

Modèle

AT88A 120 V c.a.,

a

Transformateur conforme à la norme NEMA DC-20 - tension 24 volts.

b

Offert avec des bornes femelles à connexion rapide sur chaque conducteur.

c

Fusibles thermiques au primaire sur les modèles 208 V et 240 V assurant une protection contre les surcharges.

Tension et

fréquence Raccordement Tension Raccordement

50/60 H

208/240 V

c.a., 50/60

Hz

400 V c.a.,

50/60 Hz

480 V c.a.,

50/60 Hz

Deux conducteurs de

305 mm (12 po)

b

24 V c.a. Deux conducteurs de

305 mm (12 po)

sortie - facteur

de puissance

de 100%

75 VA Fusible au

Protection

contre les

surcharges

secondaire

INSTALLATION

Avant d'installer ce produit…

1. Lire les présentes instructions attentivement. Le

fait de ne pas les suivre pourrait endommager le

produit ou constituer un danger.

2. Vérifier les caractéristiques spécifiées dans les

instructions et celles sur le produit, et s'assurer que

celui-ci convient à l'usage prévu.

3. L'installateur doit être un technicien d'expérience

ayant reçu une formation pertinente.

4. Une fois l'installation terminée, vérifier le

fonctionnement du produit en suivant les présentes

instructions.

AVERTISSEMENT

Risque de choc électrique.

Peut causer des blessures, entraîner la mort

ou endommager l'équipement.

Couper l'alimentation avant d'installer ce produit

pour éviter les risques de choc électrique ou de

dommages à l'équipement.

Montage des transformateurs AT20A et AT40A

1. Monter le transformateur à l'endroit le mieux

approprié. Le transformateur peut être installé de

trois façons :

a. Insérer des boulons dans les fentes dans le

cas d'un montage direct (Fig. 1).

b. Support en U horizontal. Installer le support

sur les lamelles (voir la Fig. 2) et replier les

pattes pour fixer le transformateur. Monter le

thermostat en utilisant les trous de 5 mm

(3/16 po) dans le socle de montage.

c. Support en U vertical. Installer le support sur

les lamelles (voir la Fig. 3) et replier les pattes

pour fixer le transformateur. Monter le transformateur en utilisant les trous de 5 mm (3/16 po)

dans le socle de montage.

MONTAGE SUR

PANNEAU

Fig. 1. Insérer des boulons dans les fentes pour un

montage sur panneau.

SOCLE DE MONTAGE (2)

UTILISER DES

RONDELLES, S'IL

Y A LIEU

MF20654A

INSÉRER DES VIS OU DES BOULONS

DANS LES FENTES (4)

DU SOCLE DE MONTAGE

MF20655A

Fig. 2. Montage sur socle (modèle AT20C illustré).

69-1641EF 2

Page 9

A

MONTAGE HORIZONTAL

A

SUR SOCLE

UTILISER DES RONDELLES,

S'IL Y A LIEU

REPLIER LES PATTES (4) POUR

FIXER LE TRANSFORMATEUR

MONTAGE VERTICAL

SUR SOCLE

UTILISER DES RONDELLES,

S'IL Y A LIEU

REPLIER LES PATTES (4)

POUR FIXER LE

TRANSFORMATEUR

Fig. 3. Utilisation d'un support en U horizontal pour

montage horizontal sur socle ou d'un support en U

vertical pour montage vertical sur socle.

MF20665

MF20657

Montage du transformateur AT72D

Monter le transformateur en tenant compte de

l'application. Choisir l'une des méthodes illustrées. Le

transformateur peut être monté dans n'importe quelle

position.

Montage sur socle

1. Mettre de côté la plaque de montage.

2. Insérer des vis ou des boulons dans les fentes du

socle de montage pour fixer le transformateur sur

la surface de montage.

Montage sur plaque

La plaque de montage permet de monter le thermostat

sur une boîte de jonction carrée de 4 po x 4 po ou une

boîte octogonale de 4 po.

TRANSFORMATEURS AT AT20, AT40, AT72D, AT87, AT88

1. Enlever la grande ouverture défonçable au centre

de la plaque de montage (Fig. 6).

2. Tenir le transformateur dans une main et la plaque

de montage dans l'autre, les fentes en trou de

serrure de la plaque vers le haut.

3. Placer la grande ouverture défonçable de la plaque

de montage sur les conducteurs primaires et le

flasque du transformateur. La petite patte au

centre de la partie inférieure de la plaque se glisse

dans la fente du socle de montage du

transformateur. (Fig. 4).

4. Insérer les vis de montage dans les trous, de la

façon indiquée.

5. Fixer la plaque sur le transformateur. Éviter de trop

la serrer.

Montage de la plaque sur le transformateur

(Fig. 4).

La plaque peut être montée sur le transformateur dans

l'une ou l'autre des positions suivantes :

a. au niveau de l'étrier du flasque du primaire (le

transformateur entièrement par-dessus la

plaque)

b. au niveau des lamelles (les trois-quarts du

transformateur par-dessus la plaque). Pour

monter la plaque au niveau de l'étrier du

flasque du primaire (le transformateur

entièrement par-dessus la plaque) :

1. Tenir la plaque de montage dans une main, les

fentes en trou de serrure vers le haut et la partie

soulevée de l'ouverture défonçable vers soi.

2. Passer les conducteurs primaires dans le trou au

centre de la plaque.

3. Placer le trou de la plaque par-dessus l'étrier

attaché au flasque. La vis de l'étrier doit être

presque complètement dévissée.

4. Installer la plaque sur l'étrier, puis bien serrer la vis

sur le rebord du trou rond (Voir la Fig. 5). En

utilisant le tournevis, prendre garde d'endommager

les conducteurs.

Pour monter la plaque au niveau des lamelles (les

trois-quarts du transformateur par-dessus la plaque) :

1. Enlever la grande ouverture défonçable au centre

de la plaque de montage (voir la Fig. 6).

2. Tenir le transformateur dans une main, l'étrier du

flasque vers soi.

3. Tenir la plaque de montage dans l'autre main, les

fentes en trou de serrure vers le haut.

4. Placer la grande ouverture défonçable de la plaque

de montage sur les conducteurs primaires et le

flasque. La petite patte au centre de la partie

inférieure de la plaque se glisse dans la fente du

socle de montage du transformateur. Insérer les

vis de montage dans les trous de la façon indiquée

à la Fig. 4.

5. Fixer la plaque sur le transformateur. Éviter de

trop serrer la vis.

Montage du transformateur et de la plaque sur

une boîte électrique

La plaque de montage peut être montée sur une boîte de

4 po sur 4 po avec trous de montage espacés

régulièrement ou irrégulièrement, une boîte de 2 po sur

4 po ou une boîte octogonale de 4 po. (Voir la Fig. 8).

3 69-1641EF

Page 10

TRANSFORMATEURS AT AT20, AT40, AT72D, AT87, AT88

1

S.

PLAQUE MONTÉE AU NIVEAU DE L'ÉTRIER

DU FLASQUE (LE TRANSFORMATEUR

ENTIÈREMENT PAR-DESSUS LA

PLAQUE DE MONTAGE)

PLAQUE DE MONTAGE

FLASQUE

VIS DE

L'ÉTRIER

ET ÉTRIER

BORNES

À VIS

DES

CONNEXIONS

SECONDAIRES

CONDUCTEURS

DE CONNEXIONS

PRIMAIRES

CONDUCTEURS DE

CONNEXIONS

PRIMAIRES

Fig. 4. La plaque peut être montée sur le

transformateur dans l'une ou l'autre des positions

PARTIE SURÉLEVÉE DE LA GRANDE

OUVERTURE DÉFONÇABLE AU CENTRE

PLAQUE MONTÉE AU NIVEAU DES

LAMELLES (LE TROIS-QUARTS

DU TRANSFORMATEUR PAR-DESSUS

LA PLAQUE DE MONTAGE)

PLAQUE DE MONTAGE

VIS DE MONTAGE

(AT72D illustré).

Fig. 6. Pour enlever la grande ouverture défonçable au centre.

PLACER LA PARTIE SURÉLEVÉE DE L'OUVERTURE DÉFONÇABLE VERS SOI, PUIS :

.

SOULEVER LA PARTIE SUPÉRIEURE DE LA GRANDE

OUVERTURE DÉFONÇABLE. POUR CE FAIRE,

INSÉRER UN TOURNEVIS SUR UN CÔTÉ DE

LA FENTE, PUIS SUR L'AUTRE CÔTÉ.

BORNES

À VIS

DES

CONNEXIONS

SECONDAIRES

MF20656A

Fig. 5. Bien serrer l'étrier sur le rebord du trou rond.

1. Utiliser les vis fournies avec la boîte électrique.

2. Insérer les vis dans les bons trous de montage de

la plaque et fixer le transformateur et la plaque sur

la boîte.

3. Défoncer les ouvertures défonçables correspondant aux trous de montage de la plaque, s'il y a

lieu.

REMARQUE : Le socle du transformateur doit toujours

2. PUIS, SOULEVER LA PARTIE INFÉRIEURE

DE L'OUVERTURE DÉFONÇABLE.

être monté à l'extérieur de la boîte de

jonction.

M12126

ENLEVER LE DEUX PARTIES DE L'OUVERTURE

3.

DÉFONÇABLE À L'AIDE DE PINCES.

69-1641EF 4

PARTIES OMBRÉES: OUVERTURES DÉFONÇABLES

ET FENTES POUR LES VIS À UTILISER AVEC LES

BOÎTES DE 2 PO SUR 4 PO OU LES BOÎTES OCTOGONALE

MF9188B

Page 11

TRANSFORMATEURS AT AT20, AT40, AT72D, AT87, AT88

TRANSFORMATEUR

B

E

I

(

M

B

E

T

BOÎTE 4 X 4 PO,

INSÉRER DES VIS

A

C

D

P

IMPORTANT

MOUNT

TRANSFORMER

OTHER SIDE

Fig. 7. Fixer la plaque sur le transformateur à l'aide

ESPACEMENT

RÉGULIER(2)

BOÎTE

OCTOGONALE

OÎTE 4 X 4 PO,

SPACEMENT

RRÉGULIER

TROUS DE

ONTAGE DE LA

OÎTE LÉGÈREMENT

N RETRAIT)

de la vis de montage.

LOAD

N.E.C. CLASS 2

Fig. 8. Positions des trous de montage.

Montage du transformateur AT87

Montage sur socle (Fig. 9)

Insérer des vis ou des boulons dans le socle de montage

pour fixer le transformateur sur la surface de montage.

PLAQUE

BOÎTE 4 X 4 PO,

ESPACEMENT

IRRÉGULIER

(TROUS DE

MONTAGE DE LA

BOÎTE LÉGÈREMEN

EN RETRAIT)

BOÎTE

OCTOGONALE

BOÎTE 4 X 4 PO,

ESPACEMENT

RÉGULIER(2)

MF9163

MF20658

OU DES BOULONS

DANS LES

FENTES (4) DU

SOCLE DE

MONTAGE.

ONDUCTEURS

ES CONNEXIONS

RIMAIRES

BORNES Á

VIS DES

CONNEXIONS

SECONDAIRES

SOCLE DE

MONTAGE (2)

MF20659

Fig. 9. Montage sur socle du transformateur AT87.

Montage sur plaque

La plaque de montage permet de monter le

transformateur sur une boîte de jonction carrée de 4 po

sur 4 po ou sur une boîte octogonale.

1. Enlever la grande ouverture défonçable au centre

de la plaque de montage (Fig. 6).

2. Tenir le transformateur dans une main et la plaque

de montage dans l'autre, les fentes en trou de

serrure de la plaque de montage vers le haut.

3. Placer la grande ouverture défonçable de la plaque

de montage sur les conducteurs primaires et le

flasque du transformateur. La petite patte à la partie inférieure, au centre de la plaque se glisse dans

la fente du pied de montage du transformateur.

(Fig. 4).

4. Insérer la vis de montage dans les trous, de la

façon indiquée.

5. Fixer la plaque sur le transformateur. Éviter de trop

serrer la vis.

Montage du transformateur et de la plaque sur

une boîte électrique

La plaque de montage peut être montée sur une boîte de

4 po sur 4 po, avec des trous espacés régulièrement ou

irrégulièrement, ou une boîte octogonale de 4 po.

1. Utiliser les vis fournies avec la boîte électrique.

2. Insérer les vis dans les bons trous de montage de

la plaque et fixer le transformateur et la plaque sur

la boîte.

3. Défoncer les ouvertures défonçables correspondant aux trous de montage de la plaque, s'il y a

lieu.

REMARQUE : Le socle du transformateur doit toujours

être monté à l'extérieur de la boîte de

jonction.

Montage du transformateur AT88

Insérer des vis ou des boulons dans les fentes du socle

de montage pour fixer le transformateur sur la surface de

montage. Voir la Fig. 2.

5 69-1641EF

Page 12

CÂBLAGE

S

R

C

.

0

E.

1

1

C

.

S

1. Couper l'alimentation électrique avant d'installer le

transformateur. Le câblage doit être conforme aux

codes et aux règlements d'électricité locaux.

Poser un ruban sur chacun des conducteurs à

découvert non utilisés.

2. Raccorder les conducteurs primaires à l'alimentation secteur. Voir les Fig. 10 à 12.

3. Raccorder les conducteurs secondaires du transformateur au système de régulation 24 V c.a.

OMMUN

BLANC (120V) OU ORANGE (240V)

1

LES CONNEXIONS SECONDAIRES SONT LES CONDUCTEUR

BLEU ET JAUNE.

2

LE FIL NOIR EST LE FIL COMMUN DE L'ENROULEMENT POU

LE TRANSFORMATEUR SEULEMENT, NON PAS POUR LE

CIRCUIT EXTERNE.

Fig. 10. Schéma du transformateur AT20/AT40

208 V C.A.

240 V C.A.

1 LES CONNEXIONS SECONDAIRES SONT DES BORNES À VIS.

2 LE FIL NOIR EST LE FIL COMMUN DE L'ENROULEMENT POUR LE

TRANSFORMATEUR SEULEMENT, NON PAS POUR LE CIRCUIT EXTERN

Fig. 11. Schéma du transformateur AT72D, AT87A

NOIR

120 V C.A.

2

1 24 V C.A

MF2066

2

NOIR

BLANC

1

ROUGE

ORANGE

24 V C.A.

MF1832

OMMUN

1

LES CONNEXIONS SECONDAIRES SONT LES CONDUCTEUR

BLEU ET JAUNE.

2

LE FIL NOIR EST LE FIL COMMUN DE L'ENROULEMENT POUR

LE TRANSFORMATEUR SEULEMENT, NON PAS POUR LE

CIRCUIT EXTERNE.

208 V C.A.

240 V C.A.

2

NOIR

ROUGE

ORANGE

1 24 V C.A

MF2066

Fig. 12. Schéma du transformateur AT88

VÉRIFICATION

Une fois l'installation terminée, mettre sous tension.

Faire fonctionner l'appareil commandé et vérifier son

fonctionnement pendant au moins un cycle complet.

Vérifier si l'appareil commandé fonctionne de façon

normale.

Solutions de régulation et d'automatisation

Honeywell Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35, Dynamic Drive

Golden Valley, MN 55422 Scarborough (Ontario)

M1V 4Z9

69-1641EF G.R. 09-02 Imprimé en Chine www.honeywell.com

Loading...

Loading...