Page 1

ONYX®FIRSTVISION™

Installation and Operation Manual

Document 53034

10/29/07 Rev:

P/N: 53034:A2 ECN: 07-706

A2

Page 2

Fire Alarm System Limitations

While a fire alarm system may lower insurance rates, it is not a substitute for fire insurance!

An automatic fire alarm system—typically made up of smoke detectors, heat detectors, manual pull stations, audible warning devices,

and a fire alarm control panel with remote notification capability—can

provide early warning of a developing fire. Such a system, however,

does not assure protection against property damage or loss of life

resulting from a fire.

The Manufacturer recommends that smoke and/or heat detectors be

located throughout a protected premise following the recommendations of the current edition of the National Fire Protection Association

Standard 72 (NFPA 72), manufacturer's recommendations, State and

local codes, and the recommendations contained in the Guide for

Proper Use of System Smoke Detectors, which is made available at

no charge to all installing dealers. A study by the Federal Emergency

Management Agency (an agency of the United States government)

indicated that smoke detectors may not go off in as many as 35% of

all fires. While fire alarm systems are designed to provide early warning against fire, they do not guarantee warning or protection against

fire. A fire alarm system may not provide timely or adequate warning,

or simply may not function, for a variety of reasons:

Smoke detectors may not sense fire where smoke cannot reach the

detectors such as in chimneys, in or behind walls, on roofs, or on the

other side of closed doors. Smoke detectors also may not sense a

fire on another level or floor of a building. A second-floor detector, for

example, may not sense a first-floor or basement fire.

Particles of combustion or “smoke” from a developing fire may not

reach the sensing chambers of smoke detectors because:

• Barriers such as closed or partially closed doors, walls, or chimneys

may inhibit particle or smoke flow.

• Smoke particles may become “cold,” stratify, and not reach the ceiling

or upper walls where detectors are located.

• Smoke particles may be blown away from detectors by air outlets.

• Smoke particles may be drawn into air returns before reaching the

detector.

The amount of “smoke” present may be insufficient to alarm smoke

detectors. Smoke detectors are designed to alarm at various levels of

smoke density. If such density levels are not created by a developing

fire at the location of detectors, the detectors will not go into alarm.

Smoke detectors, even when working properly, have sensing limitations. Detectors that have photoelectronic sensing chambers tend to

detect smoldering fires better than flaming fires, which have little visible smoke. Detectors that have ionizing-type sensing chambers tend

to detect fast-flaming fires better than smoldering fires. Because fires

develop in different ways and are often unpredictable in their growth,

neither type of detector is necessarily best and a given type of detector may not provide adequate warning of a fire.

Smoke detectors cannot be expected to provide adequate warning of

fires caused by arson, children playing with matches (especially in

bedrooms), smoking in bed, and violent explosions (caused by escaping gas, improper storage of flammable materials, etc.).

Heat detectors do not sense particles of combustion and alarm only

when heat on their sensors increases at a predetermined rate or

reaches a predetermined level. Rate-of-rise heat detectors may be

subject to reduced sensitivity over time. For this reason, the rate-ofrise feature of each detector should be tested at least once per year

by a qualified fire protection specialist. Heat detectors are designed

to protect property, not life.

IMPORTANT! Smoke detectors must be installed in the same room

as the control panel and in rooms used by the system for the connection of alarm transmission wiring, communications, signaling, and/or

power. If detectors are not so located, a developing fire may damage

the alarm system, crippling its ability to report a fire.

Audible warning devices such as bells may not alert people if these

devices are located on the other side of closed or partly open doors or

are located on another floor of a building. Any warning device may

fail to alert people with a disability or those who have recently consumed drugs, alcohol or medication. Please note that:

• Strobes can, under certain circumstances, cause seizures in people

with conditions such as epilepsy.

• Studies have shown that certain people, even when they hear a fire

alarm signal, do not respond or comprehend the meaning of the signal.

It is the property owner's responsibility to conduct fire drills and other

training exercise to make people aware of fire alarm signals and

instruct them on the proper reaction to alarm signals.

• In rare instances, the sounding of a warning device can cause temporary or permanent hearing loss.

A fire alarm system will not operate without any electrical power. If

AC power fails, the system will operate from standby batteries only for

a specified time and only if the batteries have been properly maintained and replaced regularly.

Equipment used in the system may not be technically compatible

with the control panel. It is essential to use only equipment listed for

service with your control panel.

Telephone lines needed to transmit alarm signals from a premise to

a central monitoring station may be out of service or temporarily disabled. For added protection against telephone line failure, backup

radio transmission systems are recommended.

The most common cause of fire alarm malfunction is inadequate

maintenance. To keep the entire fire alarm system in excellent working order, ongoing maintenance is required per the manufacturer's

recommendations, and UL and NFPA standards. At a minimum, the

requirements of NFPA 72 shall be followed. Environments with large

amounts of dust, dirt or high air velocity require more frequent maintenance. A maintenance agreement should be arranged through the

local manufacturer's representative. Maintenance should be scheduled monthly or as required by National and/or local fire codes and

should be performed by authorized professional fire alarm installers

only. Adequate written records of all inspections should be kept.

2 FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 3

Installation Precautions

Adherence to the following will aid in problem-free installation with long-term reliability:

WARNING - Several different sources of power can be connected

to the fire alarm control panel. Disconnect all sources of power

before servicing. The control unit and associated equipment may be

damaged by removing and/or inserting cards, modules, or interconnecting cables while the unit is energized. Do not attempt to install,

service, or operate this unit until this manual is read and understood.

CAUTION - System Reacceptance Test after Software Changes.

To ensure proper system operation, this product must be tested in

accordance with NFPA 72 after any programming operation or

change in site-specific software. Reacceptance testing is required

after any change, addition or deletion of system components, or after

any modification, repair or adjustment to system hardware or wiring.

All components, circuits, system operations, or software functions

known to be affected by a change must be 100% tested. In addition,

to ensure that other operations are not inadvertently affected, at least

10% of initiating devices that are not directly affected by the change,

up to a maximum of 50 devices, must also be tested and proper system operation verified.

This system meets NFPA requirements for operation at 0°C to 49°C

(32°F to 120°F) and at a relative humidity 93% ± 2% RH (noncondensing) at 32°C ± 2°C (90°F ± 3°F). However, the useful life of the

system's standby batteries and the electronic components may be

adversely affected by extreme temperature ranges and humidity.

Therefore, it is recommended that this system and all peripherals be

installed in an environment with a nominal room temperature of 1527° C/60-80° F.

Verify that wire sizes are adequate for all initiating and indicating

device loops. Most devices cannot tolerate more than a 10% I.R.

drop from the specified device voltage.

Like all solid state electronic devices, this system may operate

erratically or can be damaged when subjected to lightning-induced

transients. Although no system is completely immune from lightning

transients and interferences, proper grounding will reduce susceptibility. Overhead or outside aerial wiring is not recommended, due to an

increased susceptibility to nearby lightning strikes. Consult with the

Technical Services Department if any problems are anticipated or

encountered.

Disconnect AC power and batteries prior to removing or inserting

circuit boards. Failure to do so can damage circuits.

Remove all electronic assemblies prior to any drilling, filing, reaming, or punching of the enclosure. When possible, make all cable

entries from the sides or rear. Before making modifications, verify that

they will not interfere with battery, transformer, and printed circuit

board location.

Do not tighten screw terminals more than 9 in-lbs. Over-tightening

may damage threads, resulting in reduced terminal contact pressure

and difficulty with screw terminal removal.

Though designed to last many years, system components can fail

at any time. This system contains static-sensitive components.

Always ground yourself with a proper wrist strap before handling any

circuits so that static charges are removed from the body. Use staticsuppressive packaging to protect electronic assemblies removed from

the unit.

Follow the instructions in the installation, operating, and programming manuals. These instructions must be followed to avoid damage

to the control panel and associated equipment. FACP operation and

reliability depend upon proper installation by authorized personnel.

FCC Warning

WARNING: This equipment generates, uses, and can radi-

ate radio frequency energy and if not installed and used in

accordance with the instruction manual, may cause interference to radio communications. It has been tested and

found to comply with the limits for class A computing device

pursuant to Subpart B of Part 15 of FCC Rules, which is

designed to provide reasonable protection against such

interference when operated in a commercial environment.

Operation of this equipment in a residential area is likely to

cause interference, in which case the user will be required

to correct the interference at his own expense.

Acclimate Plus™, HARSH™, NOTI•FIRE•NET™, VeriFire™, NION™ and NOTIFER Intergrated Systems™ are trademarks, and ONYX®, ONYXWorks®, FlashScan®,

UniNet®, VIEW® and NOTIFIER® are registered trademarks of Honeywell. Windows® is a registered trademark of the Microsoft Corporation.

©11/7/07 by Honeywell International Inc. All rights reserved. Unauthorized use of this document is strictly prohibited.

Canadian Requirements: This digital apparatus does not

exceed the Class A limits for radiation noise emissions from

digital apparatus set out in the Radio Interference Regulations of the Canadian Department of Communications.

Le present appareil numerique n'emet pas de bruits radioelectriques depassant les limites applicables aux appareils

numeriques de la classe A prescrites dans le Reglement sur

le brouillage radioelectrique edicte par le ministere des

Communications du Canada.

3FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 4

Documentation Feedback

Your feedback helps us keep our documentation up-to-date and accurate. If you have any comments, you can email

us.

Please include the following information:

• Product name and version number (if applicable)

• Manual page number

• Your comment

Send email messages to:

FireSystems.TechPubs@honeywell.com

Please note this email address is for documentation feedback only. If you have any technical issues, please contact

Technical Services.

4 FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 5

Table of Contents

Section 1 Introduction..............................................................................................................3

1.1: FIRSTVISION Specifications ...........................................................................................................................3

Table 1.1 F

Table 1.2 F

1.2: F

IRSTVISION Descriptions..............................................................................................................................5

1.2.1: Product Overview................................................................................................................................5

Events that F

Compatibility..........................................................................................................................................6

Table 1.3 F

1.2.2: Networking ..........................................................................................................................................7

Figure 1.1 Example F

1.2.3: Ordering Information...........................................................................................................................8

1.3: Agency Approvals .........................................................................................................................................8

NFPA Standards .....................................................................................................................................8

Underwriters Laboratories U.S. Documents ..........................................................................................8

Underwriters Laboratories Canada Documents......................................................................................8

Other......................................................................................................................................................8

1.3.1: Environmental Conditions...................................................................................................................8

1.4: Conventions Used in this Manual..................................................................................................................9

1.4.1: Notes, Cautions, and Warnings ...........................................................................................................9

1.4.2: Procedures ...........................................................................................................................................9

Figure 1.2 Example for Procedure Explanation .....................................................................................9

1.4.3: Referencing Other Manuals.................................................................................................................9

1.5: Software Download Notice............................................................................................................................9

1.6: Related Manuals ............................................................................................................................................9

IRSTVISION Cabinet Specifications ......................................................................................3

IRSTVISION LCD Specifications...........................................................................................4

IRSTVISION Processes and Annunciates ............................................................................5

IRSTVISION Node Compatibility Table ................................................................................6

IRSTVISION Network............................................................................................7

Section 2 FIRSTVISION Installation Instructions ....................................................................11

2.1: Power Sources and Outputs Overview ........................................................................................................11

Table 2.1 Power Supply Required Ranges ...........................................................................................11

2.2: Enclosure Installation ..................................................................................................................................12

Figure 2.1 F

Figure 2.2 F

IRSTVISION Dimensions (inches) ......................................................................................13

IRSTVISION Power Wiring Diagram..................................................................................14

2.3: LCD Installation ..........................................................................................................................................14

Section 3 Enabling FIRSTVISION to Monitor Your Building...................................................15

3.1: Process Overview ........................................................................................................................................15

Process Steps to Enable F

3.2: Make Connections to F

3.2.1: What To Connect and How To Make the Connections.....................................................................15

Figure 3.1 F

Figure 3.2 F

Figure 3.3 F

IRSTVISION USB Keyboard and Mouse Connections.......................................................15

IRSTVISION Standard Keyboard and Mouse Connections ................................................16

IRSTVISION LAN Connector Location..............................................................................16

Figure 3.4 Example NFN Gateway Embedded System Connections ..................................................17

Figure 3.5 Example NFN Gateway PC System Connections...............................................................18

3.3: Turn on Power to F

IRSTVISION ....................................................................................................................19

3.3.1: What Displays After the Initial Power Up of F

3.3.2: What You Should Know about F

3.3.3: What You Should Know about F

Windows Administrator Settings .........................................................................................................19

Screen Saver Settings ...........................................................................................................................19

Monitor Power 19

Screen Saver 20

Figure 3.6 Display Properties - Screen Saver Tab Window.................................................................20

3.4: Set the F

IRSTVISION Clock and Time Zone.................................................................................................21

Figure 3.7 System Clock ......................................................................................................................21

IRSTVISION ..................................................................................................15

IRSTVISION..............................................................................................................15

IRSTVISION...............................................................19

IRSTVISION IP Addresses ..............................................................19

IRSTVISION Windows Settings......................................................19

1FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 6

Table of Contents

Figure 3.8 Date and Time Properties....................................................................................................21

Figure 3.9 Time Zone Tab....................................................................................................................21

3.5: Establish Communication Between Your LAN and F

IRSTVISION ...............................................................22

Figure 3.10 Windows LAN Connection...............................................................................................22

Figure 3.11 Windows LAN Connection Properties..............................................................................22

Figure 3.12 Windows Internet Protocol Properties ..............................................................................23

Figure 3.13 Command Prompt .............................................................................................................23

3.6: Establish Gateway Communication.............................................................................................................23

How To Add a Gateway Using the Configuration Tool.......................................................................24

Figure 3.14 Gateway Configuration .....................................................................................................24

3.7: Copy Your Exported Building Design to F

Figure 3.15 F

IRSTVISION USB Connector Locations...........................................................................25

3.7.1: How To Copy Your Exported Building Design to F

IRSTVISION................................................................................25

IRSTVISION.......................................................25

Figure 3.16 XML File and Floorplans Folder ......................................................................................25

3.8: Display Your Building Design on F

3.9: Test Your Building Design on F

IRSTVISION...........................................................................................26

IRSTVISION ................................................................................................27

3.10: Touch Screen Calibration...........................................................................................................................27

3.10.1: How to Calibrate F

IRSTVISION’s Touch Screen ..............................................................................27

Section 4 Operating Basics of FIRSTVISION ........................................................................... 29

4.1: Normal Operation (No Events Being Reported)..........................................................................................29

Figure 4.1 F

Figure 4.2 F

Figure 4.3 F

Figure 4.4 F

Figure 4.5 F

Figure 4.6 F

4.2: Investigating Gateway Disconnection .........................................................................................................34

4.3: Operation When a Fire Alarm is Received ..................................................................................................35

Figure 4.7 F

Figure 4.8 F

Figure 4.9 F

4.4: Operation After a Fire Alarm Has Been Cleared.........................................................................................37

4.5: Accessing the Log File.................................................................................................................................38

Figure 4.10 Log File .............................................................................................................................38

IRSTVISION Display Example: No Alarms........................................................................30

IRSTVISION Display Example: Floor Number Button.......................................................30

IRSTVISION Display Example: Building Information .......................................................31

IRSTVISION Display Example: Zoomed Floor Plan ..........................................................32

IRSTVISION Display Example: Moving Through a Zoomed Floor Plan ...........................33

IRSTVISION Display Example: HAZMAT Information ....................................................34

IRSTVISION Display Example: Alarms..............................................................................35

IRSTVISION Display Example: Alarm Zoomed Floor Plan ...............................................36

IRSTVISION Display Example: Event List.........................................................................37

Section 5 The Development of FIRSTVISION .......................................................................... 39

5.1: The Current Situation for a Firefighter ........................................................................................................39

5.2: The Technology of F

5.2.1: Making Commissioning Easier..........................................................................................................39

5.3: Expected Firefighter Interaction with the F

5.3.1: Example Emergency Situations.........................................................................................................40

Fire Scene 1 ..........................................................................................................................................40

Figure 5.1 Fire Scene Scenario Floor Plan Information.......................................................................40

Figure 5.2 Fire Scene Scenario Roof Plan Information........................................................................41

Figure 5.3 Fire Scene Scenario HAZMAT Information.......................................................................41

Figure 5.4 Fire Scene Scenario Building Information..........................................................................42

Fire Scene 2 ..........................................................................................................................................43

Figure 5.5 Example Building Site Plan Information ............................................................................43

Figure 5.6 Example HAZMAT Information ........................................................................................44

Figure 5.7 Example Contact Information .............................................................................................45

2 FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

IRSTVISION..................................................................................................................39

IRSTVISION...............................................................................40

Page 7

Section 1 Introduction

The contents of this manual are important and must be kept in close proximity to the hardware. If

building ownership is changed, this manual and all other testing and maintenance information must

also be passed to the current owner of the facility. A copy of this manual was shipped with the

equipment and is also available from the manufacturer.

WARNING: Improper Installation

!

Improper installation, maintenance, or lack of routine testing could result in system malfunction.

CAUTION: Servicing FIRSTVISION

!

This product can only be serviced by authorized personnel. Only authorized personnel can remove

this product’s CPU back-cover or replace parts in this product. Unauthorized servicing personnel

performing product services is strictly prohibited and can void your warranty

1.1 FIRSTVISION Specifications

NOTE: ONYX®FIRSTVISION™ is for Ancillary Use Only.

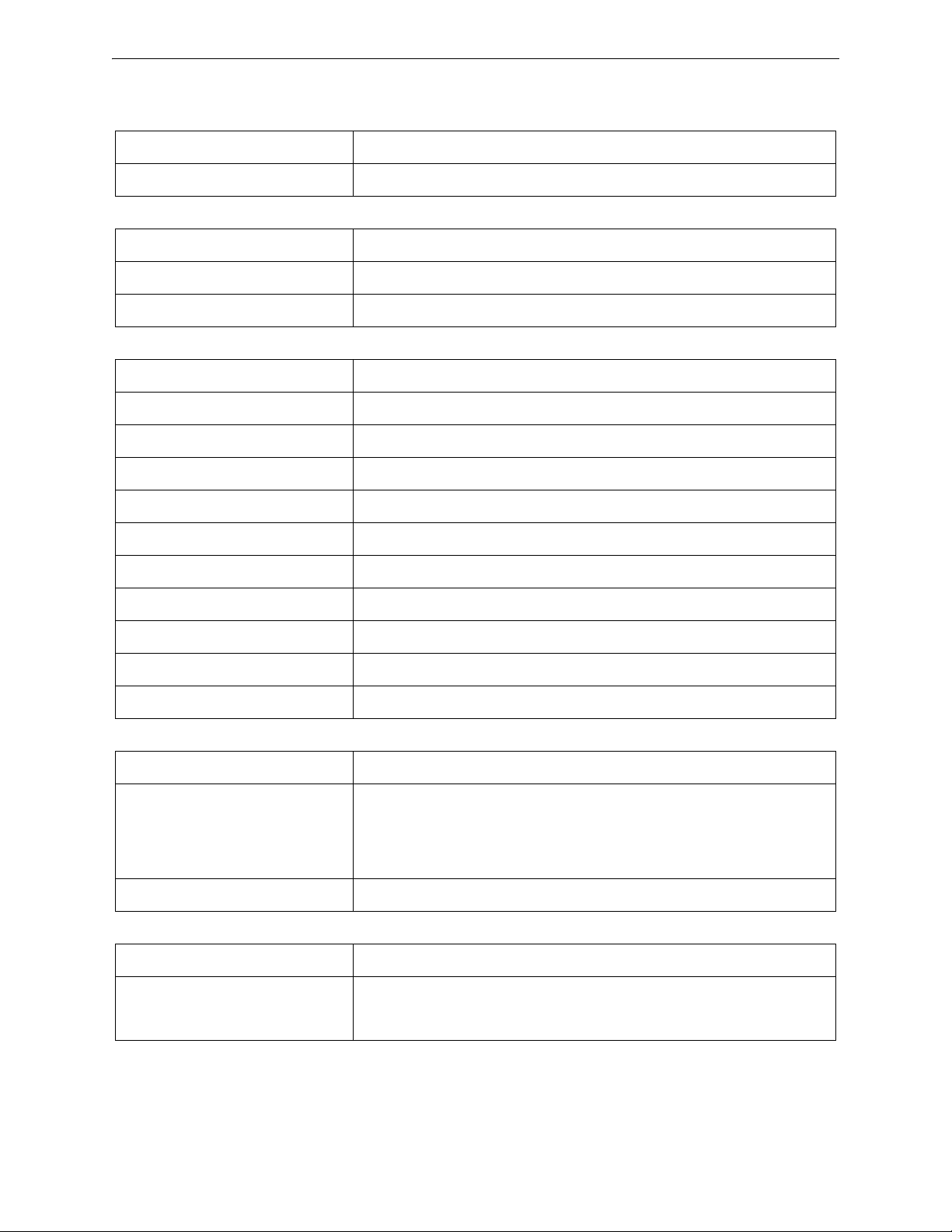

Table 1.1 FIRSTVISION Cabinet Specifications

Part Number FIRSTVISION-ENC

General:

Rough Opening Dimensions 18" W x 17.75" H x 3.5” D

Material Aluminum

Finish Black epoxy powder coat finish, fine texture

Mounting Panel

Enclosure:

Door Dimensions 20" W x 18.5" H x 0.4" D

Material 0.060 Galvaneal

Door Finish Black epoxy powder coat finish, fine texture – Door only

Door Plex shield 0.125 scratch resistant acrylic

Conduit punch outs (2) ½" and (2) ¾" on the top and bottom of the enclosure (8) total

Mounting (6) mounting holes for screw mtg. #10/12

Lock CFE – NOTIFIER® Standard Lock

Magnetic Latch Power Off/Command Latch release

3FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 8

Introduction FIRSTVISION Specifications

Table 1.2 FIRSTVISION LCD Specifications

Part Number FIRSTVISION-LCD

Product 17" Interactive Graphic Display

Display:

Size 17"

Resolution 1280 x 1024, 75 Hz, 32 Bit colors

Surface acoustic wave touchscreen USB TS controller

CPU:

Digital I/O (1) DO – Lock control, (3) DO – Brightness control

ACPI Compliant Not required

Processor Low Power VIA Fanless CPU

Speed 733MHz

Form factor Embedded

Slots NONE REQUIRED

Video Integral

Serial ports (1) RS-232

USB ports TWO

System RAM 512 MB

LAN One 10/100 Base-T interface

Peripherals:

Compact Flash Disk 2GB

Connectors (1) DB9 COM1

Operating System Windows® XP® Embedded

Other:

(1) DIN - KYBD

(1) RJ-45 10/100BT

(2) USB Ports on the front panel

(2) Speakers (2 Watts)

Motherboard Lithium Battery Battery is not field replaceable. Contact Technical Services for information.

DC to DC Converter Fuse Fuse is only replaceable by authorized personnel. Contact Technical Services for

information.

Fuse:10A, 250V, SLO BLO, 5x20mm.

4 FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 9

FIRSTVISION Descriptions Introduction

1.2 FIRSTVISION Descriptions

1.2.1 Product Overview

FIRSTVISION uses a graphical user interface (GUI) approach to life safety monitoring for your

building. The GUI's display method enables an authorized event responder (e.g. firefighter) to

view an event in the context of the building's floor layouts. This allows planning of routes and

methods for responding to the event.

Before it can be used by an event responder, F

IRSTVISION must be configured with information

about the building into which it is installed. Those configuration tasks are performed with the

ONYX® F

IRSTVISION™ Configuration Tool (refer to 53035ONYX® FIRSTVISION™

Configuration Tool manual). The Configuration Tool tasks include entering meaningful

information about the layout of all floors in the building (drawing background), the locations of all

sensing devices that communicate with F

IRSTVISION, building features (such as water supplies),

and hazards (such as flammable or reactive chemicals).

F

IRSTVISION should be installed in the authorized event responder’s preferred building entry

location.

Refer to “The Development of F

IRSTVISION” on page 39 for more information about this product.

Events that FIRSTVISION Processes and Annunciates

FIRSTVISION only supports SLC loop modules and devices. Only device or module events that use

formats of LxxDyyy and LxxMyyy (respectively) that are reported by the types of devices listed

below; are processed and annunciated by F

• Fire Alarms

• Supervisory

• Medical

• Security

NOTE: FIRSTVISION can simultaneously process up to 3000 events (alrms/supervisory/water/..).

IRSTVISION:

5FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 10

Introduction FIRSTVISION Descriptions

Compatibility

NOTE: FIRSTVISION1.5 (and above) must be used with gateway versions 3.x and above.

FIRSTVISION is compatible with the node types listed in the following table.

Table 1.3 FIRSTVISION Node Compatibility Table

NOTI•FIRE•NET™ Node Type

AFP-200 NAM

AFP-300/400 NAM

AFP-1010 SIB-NET

AM2020 SIB-NET

NFS-320 NCM-W/F

NFS-640 NCM-W/F

NFS2-640 NCM-W/F

NFS-3030 NCM-W/F

NFS2-3030 NCM-W/F

Network Board Used

Relative information about existing nodes (its device ID and custom label) can be imported into the

Configuration Tool. Refer to the ONYX®F

IRSTVISION™ Configuration Tool Programming

Manual (P/N: 53035) for more information.

6 FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 11

FIRSTVISION Descriptions Introduction

1.2.2 Networking

The following figure illustrates a possible NOTI•FIRE•NET™ network that includes FIRSTVISION.

Refer to “Make Connections to F

IRSTVISION” on page 15 for more information.

FIRSTVISION

NFN Gateway PC

Figure 1.1 Example F

Ethernet (TCP/IP)

Network

OR

NFN Network

FACP FACP

FACP

IRSTVISION Network

NFN Gateway

NOTE: If you are connecting FIRSTVISION to an NFN Gateway PC and plan on running the

ONYXWorks Workstation software application also, the Workstation must be set to Supervising

Station Mode (refer to the Workstation manual).

7FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 12

Introduction Agency Approvals

1.2.3 Ordering Information

Please verify part numbers with your sales representative before and when you are ordering.

Part Number Description

FIRSTVISION-ENC Enclosure

FIRSTVISION-LCD Liquid Crystal Display (LCD)

1.3 Agency Approvals

FIRSTVISION has been designed to comply with standards set forth by the following regulatory

agencies. Before proceeding, the installer should be familiar with the following documents:

NFPA Standards

• National Fire Protection Association Standards 72.

• National Electric Code (NFPA 70).

Underwriters Laboratories U.S. Documents

• UL-864 Control Units and Accessories for Fire Alarm Systems.

Underwriters Laboratories Canada Documents

• CAN/ULC-S524-91 Standard for Installation of Fire Alarm Systems.

• CAN/ULC-S527-99 Standard for Control Units for Fire Alarm Systems.

Other

• Requirements of the Local Authority Having Jurisdiction (LAHJ).

WARNING:

!

Improper installation, maintenance, and lack of routine testing could result in system malfunction.

WARNING: Wiring

!

It is recommended that the installer conform to local code requirements when installing all wiring. All

power connections must be non-resettable.

1.3.1 Environmental Conditions

FIRSTVISION must be installed in the following environmental conditions:

• Temperature range of 0ºC - 50ºC (32ºF - 120ºF).

• 10-95% humidity non-condensing at 30ºC (86ºF).

8 FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 13

Conventions Used in this Manual Introduction

1.4 Conventions Used in this Manual

1.4.1 Notes, Cautions, and Warnings

This manual contains notes, cautions, and warnings to alert the reader as follows:

NOTE: Supplemental information for a topic, such as tips and references.

CAUTION: Summary in bold

!

Information about procedures that could cause programming errors, runtime errors, or equipment

damage.

WARNING: Summary in bold

!

Indicates information about procedures that could cause irreversible equipment damage, irreversible

loss of programming data or personal injury.

1.4.2 Procedures

Figure 1.2 Example for Procedure Explanation

Example Text: Main Menu select Graphics >Add Floor.

The graphic above is represented in the Example Text. All selections, fields, buttons, and

screen titles are spelled (upper/lower case) exactly as they appear on the display.

1.4.3 Referencing Other Manuals

Example: Refer to the ONYX®FIRSTVISION™ Configuration Tool Programming Manual.

Italic text is used to reference a manual by its specific name.

1.5 Software Download Notice

In order to supply the latest features and functionality in fire alarm and life safety technology to our

distributors and their customers, NOTIFIER makes frequent upgrades to the embedded software in

our products. To ensure that you are installing and programming the latest features, NOTIFIER

strongly recommends that you visit the Magni-Fire website on a regular basis and download the

most current version of software for each product prior to commissioning any system. Contact

NOTIFIER Technical Support with any questions about NOTIFIER software and the appropriate

version for a specific application.

1.6 Related Manuals

Here are some related hardware and applications documents:

•ONYX®F

IRSTVISION™ Configuration Tool Manual - 53035

9FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 14

Introduction Related Manuals

•ONYX®FIRSTVISION™ Cabinet Installation Instructions PID - 53105

• AMPS-24/E Power Supply Manual - 51907

• NOTI•FIRE•NET™ Manual (Version 4.0 & Higher) - 51584

• NFS-320 Installation/Operation/Programming manuals - 52745/52746/52747

• NFS-640 Installation/Operation/Programming manuals - 51332/51334/51333

• NFS2-640 Installation/Operation/Programming manuals - 52741/52742/52743

• NFS-3030 Installation/Operation/Programming manuals - 51330/51344/51345

• NFS2-3030 Installation/Operation/Programming manuals - 52544/52545/52546

• AFP-200 Instruction manual - 15511

• AFP-300/400 Installation/Operation/Programming manuals - 50253/50260/50259

• AM2020/AFP1010 Installation/Operation/Programming manual - 15088

• ONYXWorks® NFN GW Embedded - 52306

• ONYXWorks® NFN GW PC - 52307

10 FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 15

Section 2 FIRSTVISION Installation Instructions

NOTE: You can use this information to install the FIRSTVISION enclosure (“Enclosure Installation”

on page 12) and to make power supply connections to the enclosure’s control board, or you can

refer to the ONYX®FIRSTVISION™ Enclosure Installation Instructions (P/N 53105).

2.1 Power Sources and Outputs Overview

• Complete all mounting procedures and check all wiring before applying power.

• Electrical connections include the following:

• Primary Power Source: +24VDC, delivered through a power supply listed for fire protection

services.

• Secondary Power Source: +24VDC, delivered from batteries.

Table 2.1 Power Supply Required Ranges

TYPICAL

Input Voltage 24V

Input Current @24V 3A

WARNING: Power Sources

!

Remove all power sources to equipment while connecting electrical components. Leave the

external, main power breaker OFF until installation of the LCD is complete.

NOTE: FIRSTVISION LCD requires +24VDC @3A nominal and supervised battery backup in

accordance with local code requirements. It can be powered by any regulated, power limited

source that is approved for use with fire protective signaling units by a regulatory agency.

11FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 16

FIRSTVISION Installation Instructions Enclosure Installation

2.2 Enclosure Installation

Refer to “LCD Installation” on page 14 if the enclosure is already installed.

NOTE: You can use this information to install the FIRSTVISION enclosure and to make power

supply connections to the enclosure’s control board or you can refer to the ONYX®FIRSTVISION™

Enclosure Installation Instructions (P/N 53105).

Use the following information as a guideline to accomplish the installation of the F

enclosure and prepare the power supply components/connections for the F

IRSTVISION LCD.

IRSTVISION

Perform all installations in accordance with building construction, local code requirements, and/or

as described in the manufacturer’s documentation.

Step 1. Mount the F

Step 1a.Prepare a rough opening in the wall at the location F

IRSTVISION enclosure on an inside wall of the building.

IRSTVISION will be mounted

according to the enclosure’s dimensions specified in Figure 2.1 on page 13).

NOTE: The dimensions shown are the exact measurement of the enclosure. Make the

enclosure hole slightly larger (approximately 1/8”) than the enclosure’s dimensions for an easier

fit.

Step 1b.Remove the enclosure’s knockout(s) that will be used to route your LAN cable and

power supply’s cable through.

Step 1c.Place the enclosure inside of the rough opening (with the LCD hinges on the left).

Step 1d.Attach the enclosure to the wall at the six locations provided using field supplied

fasteners.

NOTE: Make sure the enclosure is level before fastening it to the wall.

Mounting Hole

(6 places)

Step 2. Mount the external power supply according to the manufacturer’s instructions.

Step 3. Route the external power supply wiring into the enclosure through one of the available

knockouts, and then connect it to the control board as shown in Figure 2.2 on page 14.

WARNING: Electrical Panel Breaker Lockout Procedures

!

Leave electrical panel breaker lockout safety procedures in place until you are ready to install and

connect the FIRSTVISION LCD.

NOTE: Adhere to electrical panel breaker lockout safety procedures.

12 FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 17

Enclosure Installation FIRSTVISION Installation Instructions

Step 4. Route the LAN cable into the enclosure through one of the available knockouts.

NOTE: The power supplies for FIRSTVISION and the gateway should use:

- a common ground.

- the same earth ground.

Figure 2.1 F

IRSTVISION Dimensions (inches)

13FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 18

FIRSTVISION Installation Instructions LCD Installation

b

b

a

a

c

c

k

k

o

f

o

L

f

C

L

D

C

D

d

i

s

p

l

a

y

Power Cable

from LCD

J1

The FIRSTVISION

enclosure is factory

assembled and wired to

install/connect the LCD.

P1

Enclosure’s Control Board

LCD Power Cable

WARNING: Electrical Connections

!

If power is applied to F

FIRSTVISION’s Windows® operating system before turning off the power. See “Make Connections to

FIRSTVISION” on page 15 for instructions on using FIRSTVISION like a personal computer, and then

follow standard Windows shut-down procedures.

2.3 LCD Installation

Step 1. Install the FIRSTVISION LCD onto the enclosure’s factory installed hinges (LCD hinges on

the left).

Step 2. Connect the LCD’s power cable to the enclosure’s control board as shown in Figure 2.2 on

page 14.

Step 3. Connect the customer supplied LAN cable to the LAN port as shown in Figure 3.3 on

page 16.

Step 4. Swing the LCD closed and fasten it closed by using the 2 factory supplied black pan head

machined screws.

Step 5. Close the LCD’s glass paneled door.

Step 6. Use the factory supplied door key to lock the closed door.

Step 7. Verify the door locks and unlocks with each turn of the key.

Step 8. You are now ready to perform “Enabling F

page 15.

+24VDC/3A

Common GND

Enclosure’s

Control Board

From Power Supply

Figure 2.2 FIRSTVISION Power Wiring Diagram

IRSTVISION for testing your electrical connections, you MUST shut down

IRSTVISION to Monitor Your Building” on

14 FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 19

Section 3 Enabling FIRSTVISION to Monitor Your

Building

3.1 Process Overview

The procedures documented in the section should be performed after your building’s life safety

monitoring system has been customized to F

Configuration Tool (refer to ONYX® F

for information).

Process Steps to Enable FIRSTVISION

Step 1. "Make Connections to FIRSTVISION".

Step 2. "Turn on Power to F

Step 3. "Establish Communication Between Your LAN and F

Step 4. "Establish Gateway Communication".

Step 5. "Copy Your Exported Building Design to F

Step 6. "Test Your Building Design on F

IRSTVISION".

3.2 Make Connections to FIRSTVISION

All of the procedures in this section require you to operate FIRSTVISION like a personal computer.

Because of that operation usage scenario, you MUST connect an external keyboard and a mouse to

F

IRSTVISION.

IRSTVISION using the ONYX® FIRSTVISION™

IRSTVISION™ Configuration Tool Programming Manual

IRSTVISION".

IRSTVISION".

IRSTVISION".

3.2.1 What To Connect and How To Make the Connections

Step 1. Connect a keyboard and mouse to the either of these connectors.

• USB ports on the front of F

port (for the mouse) is ideal for connecting to F

• PS/2 connectors located on the bottom of the LCD (Figure 3.2).

NOTE: You must unlock the front door of FIRSTVISION to gain access to the USB ports.

.

Figure 3.1 FIRSTVISION USB Keyboard and Mouse Connections

NOTE: To gain access to the PS/2 connectors, you must remove the screws holding the LCD

closed and then you must swing the LCD out.

IRSTVISION LCD (recommended). A keyboard with a USB

IRSTVISION (Figure 3.1).

15FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 20

Enabling FIRSTVISION to Monitor Your Building Make Connections to FIRSTVISION

.

Figure 3.2 FIRSTVISION Standard Keyboard and Mouse Connections

WARNING: Connector Damage Possible

!

Do not attempt to close the LCD with the keyboard and mouse connected because their cables will

make contact with the enclosure’s wiring tray; possibly damaging the connectors.

Step 2. If not already connected; connect F

supplied CAT-5 ethernet cable to the LAN (Local Area Network) port.

Figure 3.3 F

IRSTVISION LAN Connector Location

IRSTVISION to your IP Network by attaching customer

16 FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 21

Make Connections to FIRSTVISION Enabling FIRSTVISION to Monitor Your Building

FIRSTVISION

Three options:

* Direct connection using a crossover

Ethernet cable

* Connection using 2 standard CAT-5

Ethernet cables and a UL-listed hub

* Connection to the customer supplied

Ethernet (TCP/IP) Network.

Ethernet (TCP/IP)

Network

NFN Gateway

Embedded

NFN Network

(v5.0 or later)

NOTE: For all connection details,

see ONYXWorks®

NFN

Gateway Embedded

Installation & Operation

Manual- 52306.

FACP FACP

FACP

Figure 3.4 Example NFN Gateway Embedded System Connections

17FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 22

Enabling FIRSTVISION to Monitor Your Building Make Connections to FIRSTVISION

FIRSTVISION

Three options:

* Direct connection using a crossover

Ethernet cable

* Connection using 2 standard CAT-5

Ethernet cables and a UL-listed hub

* Connection to the customer supplied

Ethernet (TCP/IP) Network.

Ethernet (TCP/IP)

Network

NOTE: For all connection details, see

ONYXWorks®

NFN Gateway PC

Installation & Operation

Manual- 52307.

Network Card

NFN Gateway PC

NFN Network

(v5.0 or later)

TX A

RX A

TX B

RX B

NFN Gateway PC

(Fiber Shown)

FACP FACP

FACP

Figure 3.5 Example NFN Gateway PC System Connections

18 FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 23

Turn on Power to FIRSTVISION Enabling FIRSTVISION to Monitor Your Building

3.3 Turn on Power to FIRSTVISION

Turn-on the power supply connected to FIRSTVISION. Refer to “FIRSTVISION Installation

Instructions” on page 11 for installation information.

3.3.1 What Displays After the Initial Power Up of FIRSTVISION

1. Windows® XP Embedded will start and display.

2. The software application "progress bar" will display and remain displayed until the loading of

the software application and its components are complete.

NOTE: Do NOT attempt to stop this loading.

3. After the progress bar disappears; the software application will automatically start because a

shortcut to the application has been placed in the product’s Startup folder.

NOTE: Do NOT remove this shortcut.

3.3.2 What You Should Know about FIRSTVISION IP Addresses

Your LAN IP address (setup with Windows Internet Protocol (TCP/IP) Properties) has a default of:

192.168.0.4.

• If it is necessary to change the factory LAN IP address; refer to

Between Your LAN and F

The gateway that F

setting of 192.168.0.3.

• If it is necessary to change this factory setting; refer to

on page 23

• If it is necessary to change a gateway’s IP address, refer to the gateway’s respective

installation manual.

IRSTVISION monitors (setup with Add Gateway Connection) has a factory

for information.

IRSTVISION” on page 22 for information.

“Establish Gateway Communication”

“Establish Communication

3.3.3 What You Should Know about FIRSTVISION Windows Settings

Windows Administrator Settings

NOTE: Do NOT change the factory boot setup for FIRSTVISION’s host computer (that is,

administrator is automatically logged in at startup), or add any user accounts.

It is essential that the FIRSTVISION host computer remain configured to automatically log in the

administrator account at startup, without asking for a password.

Screen Saver Settings

Monitor Power

A Monitor Power selection should NOT be changed from the factory default settings, which all are

set to Never (always on), because any setting will prevent the software application from starting

automatically after a power loss.

19FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 24

Enabling FIRSTVISION to Monitor Your Building Turn on Power to FIRSTVISION

Screen Saver

F

IRSTVISION supports Windows Screen Saver settings that extend the display’s life and prevent

screen image burn in. Only Windows screen saver application is supported, do NOT use a thirdparty screen saver application.

NOTE: A Screen Saver selection has been made at the factory. Those factory settings use a

predetermined screen saver image and "Wait" setting of 10 minutes.

F

IRSTVISION’s screen saver will be displayed when its Wait setting is reached only if:

• There are no events that F

IRSTVISION processes are being reported to FIRSTVISION.

• The gateway connection is present.

If events that F

is lost; F

screen saver will remain disabled as long as there is an event that F

reported. After all the events that F

IRSTVISION processes are being reported to FIRSTVISION or the gateway connection

IRSTVISION’s screen saver will disable and the software application will display. The

IRSTVISION processes being

IRSTVISION processes have been remedied (cleared/restored);

the screen saver will be automatically enabled after its Wait setting is reached.

Windows Screen Saver and Wait settings are made on the Display Properties window (i.e. Screen

Saver tab). The Screen saver field options are "None" and "My Picture Slideshow". You can load

and use your own screen saver images but they can NOT be of the 3D type.

CAUTION: 3D Type Animation

!

If you choose to use your own Screen-Saver file, do NOT use 3D type animation files because it may

NOT disable when an event that FIRSTVISION processes occurred in the monitored network.

Consult Windows information for details about making Display Properties settings.

Figure 3.6 Display Properties - Screen Saver Tab Window

20 FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 25

Set the FIRSTVISION Clock and Time Zone Enabling FIRSTVISION to Monitor Your Building

3.4 Set the FIRSTVISION Clock and Time Zone

The FIRSTVISION system clock is set at the factory, based on the factory time zone. Follow these

steps to configure the clock for your local time zone:

NOTE: Correct time and date settings ensure times shown on FIRSTVISION display and in event

logs are accurate—crucial information for responding Firefighters.

Step 1. Double click the digital clock on the right side of the Windows taskbar.

Figure 3.7 System Clock

Step 2. Verify the time and date are shown correctly in the the dialogue that appears, and then

click the Time Zone tab.

Figure 3.8 Date and Time Properties

Step 3. Check the box next to “Automatically adjust clock for daylight saving changes.”

Step 4. Select your local time zone from the drop menu.

Step 5. Click OK.

Figure 3.9 Time Zone Tab

21FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 26

Enabling FIRSTVISION to Monitor Your Building Establish Communication Between Your LAN and FIRSTVISION

3.5 Establish Communication Between Your LAN and

F

IRSTVISION

NOTE: A factory default IP address setting is set to: 192.168.0.4. If you need to change those

settings, then use the following information.

The following steps are performed using Windows operations on FIRSTVISION.

Step 1. If F

Step 2. Click Start >Control Panel. The Control Panel window displays.

Step 3. Double click on Network Connections. The Network Connections window displays.

Step 4. Right click on Local Area Connections 2 in the Network Connections window and select

Step 5. On the General tab click on "Internet Protocol (TCP/IP)", then click on the Properties

IRSTVISION application is running, shut it down (ESC key on direct connect keyboard).

Figure 3.10 Windows LAN Connection

Properties from the list of choices. The Local Area Connection Properties window

displays.

button. The Internet Protocol (TCP/IP) Properties window displays.

Figure 3.11 Windows LAN Connection Properties

22 FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 27

Establish Gateway Communication Enabling FIRSTVISION to Monitor Your Building

Step 6. Select the “Use the following IP address” radio button.

The “Obtain an IP address automatically” can NOT be used.

Step 7. Type in your IP address information on the Internet Protocol (TCP/IP) Properties window

(example only shown, the address is dependent on your network).

Figure 3.12 Windows Internet Protocol Properties

Step 8. Confirm that is 255.255.255.0 in the Subnet Mask field to choose the internal network (the

address is dependent on your network).

Step 9. Complete your entry by clicking on OK.

Step 10. Restart Windows. F

F

IRSTVISION and your LAN should be established.

IRSTVISION will automatically start. Communication between

Step 11. Verify the connection by doing either of the following:

• Check the Gateway icon in the upper left corner of the display (no X over icon means

connected).

• Ping the gateway:

• Shut down F

IRSTVISION

• Select Start >Command Prompt to display a command prompt window.

• Type in "Ping <Gateway IP Address>". If the response to the Ping is returned from

the Gateway, then the connection is established.

Figure 3.13 Command Prompt

Step 12. Close any remaining windows.

Step 13. You should now "Establish Gateway Communication"

3.6 Establish Gateway Communication

NOTE: FIRSTVISION1.5 (and above) must be used with gateway versions 3.x and above.

.

23FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 28

Enabling FIRSTVISION to Monitor Your Building Establish Gateway Communication

It is anticipated that the factory settings for a gateway may probably work for your application and

it is recommended you use them, if possible, instead of setting up new settings. If you want to

change the factory settings use the following information

NOTE: Your LAN connection must be established before you add a gateway.

How To Add a Gateway Using the Configuration Tool

The gateway can be changed here, but FIRSTVISION can monitor only one gateway.

NOTE: If you change the gateway IP address, you must re-export your building design to XML.

See “How to Export Your Building Design for Copying to FIRSTVISION” in ONYX®FIRSTVISION™

Configuration Tool Manual - 53035.

NOTE: The factory default Gateway IP address setting is: 192.168.0.3. If you need to change

this setting, then use the following information.

Step 1. Start the Configuration Tool.

Step 2. Select Tools > Gateway Configuration.

Step 3. Enter the Gateway IP address.

Step 4. Click OK.

Figure 3.14 Gateway Configuration

Step 5. Close the Configuration Tool.

Step 6. You should now "Copy Your Exported Building Design to F

24 FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

IRSTVISION".

Page 29

Copy Your Exported Building Design to FIRSTVISION Enabling FIRSTVISION to Monitor Your Building

3.7 Copy Your Exported Building Design to FIRSTVISION

This copying task can be accomplished using various methods. The copying method will be

contingent on your connection to F

your building design Site.xml file and Floor plan folder are stored) as part of a TCP/IP network,

you can copy your building design to F

connector, located inside the locking door, on F

IRSTVISION. With FIRSTVISION and your PC both (i.e. where

IRSTVISION over the network. You can also use a USB

IRSTVISION as the connection point.

Figure 3.15 F

IRSTVISION USB Connector Locations

3.7.1 How To Copy Your Exported Building Design to FIRSTVISION

Step 1. Establish a physical connection between your PC or storage device (i.e. where your

building design Site.xml file and Floorplan folder are stored) and F

Step 2. Use Window Explorer on F

"Floorplans" folder to the following folder on F

NOTE: Overwrite the folder and files, do NOT delete the existing site.xml and Floorplans folder.

prior to this step.

IRSTVISION to find, select, and copy the Site.xml file and

IRSTVISION: C:/Facilities Monitoring/FIT.

Figure 3.16 XML File and Floorplans Folder

Step 3. You should now restart F

IRSTVISION and wait until Windows is displayed.

Step 4. You should now peform “Display Your Building Design on F

IRSTVISION.

IRSTVISION” on page 26.

25FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 30

Enabling FIRSTVISION to Monitor Your Building Display Your Building Design on FIRSTVISION

3.8 Display Your Building Design on FIRSTVISION

Step 1. Locate the FIRSTVISION icon displayed on the Desktop.

Step 2. Double click on the icon to load the Site.xml file.

NOTE: An application is loading message will display. It may take some time to load the file

depending upon the components of the building (number of floors and icons). If the message is

displayed; do NOT attempt to double click the icon again.

Step 3. You should now "Test Your Building Design on F

IRSTVISION".

26 FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 31

Test Your Building Design on FIRSTVISION Enabling FIRSTVISION to Monitor Your Building

3.9 Test Your Building Design on FIRSTVISION

It is recommended that you simulate an event that FIRSTVISION processes that will test the

interaction between your building design and F

are some items to verify that they are functioning correctly:

• Battery-backup system is functioning correctly.

•F

IRSTVISION starts monitoring your building life safety system when started.

• The floor plan background images are correctly displayed on F

• Auto unlock of F

received by F

• Activated device icons are shown in their correct locations over the floor plan background

on F

IRSTVISION.

IRSTVISION enclosure when an event that FIRSTVISION processes is

IRSTVISION.

IRSTVISION response to that event. The following

IRSTVISION.

3.10 Touch Screen Calibration

FIRSTVISION’s touch screen was calibrated in the factory and you should not have to perform this

procedure.

If you have determined that the cursor is not correctly tracking to the position of your finger then

you can use the GenCalb function to calibrate the touch screen.

3.10.1 How to Calibrate FIRSTVISION’s Touch Screen

Step 1. Unlock and open the product’s glass paneled door using the factory supplied key.

Step 2. Connect the external keyboard and mouse to the product to the appropriate connectors.

Refer to “What To Connect and How To Make the Connections” on page 15.

Step 3. Press the ESC key on the keyboard to shutdown the software application.

Step 4. Locate and click on the Desktop icon for touchscreen calibration.

Step 5. Follow the displayed instructions to calibrate the touch screen.

Step 6. Restart the software application by clicking on F

Desktop shortcut.

Step 7. Remove the external connected components.

IRSTVISION’s software application

27FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 32

Enabling FIRSTVISION to Monitor Your Building Touch Screen Calibration

28 FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 33

Section 4 Operating Basics of FIRSTVISION

Experiment with FIRSTVISION to gain a basic familiarity with its operation. This helps you ensure

F

IRSTVISION is set up and configured correctly.

4.1 Normal Operation (No Events Being Reported)

When FIRSTVISION software application is started take note of some of the user interface

characteristics, some of the displayed elements are a result of information defined using the

Configuration Tool.

• The Gateway Connection Icon in the upper left corner of the user interface indicates whether

F

IRSTVISION is connected to your gateway (a red X displayed inside the icon means that

F

IRSTVISION is not connected).

WARNING: Gateway Connection Icon with a Red X

!

When you see that the gateway disconnected (red x in icon), FIRSTVISION will not receive events. So

it is absolutely necessary to restore connectivity to the gateway to ensure the most accurate and up

to date information is being displayed. Refer to “Investigating Gateway Disconnection” on page 34

for more information.

• Corresponding to each floor in the building a Floor button (inverted style means it is selected).

• The floor chosen as the lowest floor in the Configuration Tool’s Building Layout tree hierarchy

is displayed with icons and its floor plan background. Also if applicable displayed on that

floor are icons defined for elevators, stairs (Multi-Level icons) and HAZMAT area or sprinkler

shutoff (Other icon).

• A row of larger miscellaneous buttons across the top; more information about them later in this

section.

3:41:05 PM

29FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 34

Operating Basics of FIRSTVISION Normal Operation (No Events Being Reported)

Figure 4.1 FIRSTVISION Display Example: No Alarms

NOTE: Device icons that use a device id’s are displayed on FIRSTVISION only when they

experience an event type that FIRSTVISION processes.

With the front door open; touching a floor number button displays the corresponding floor in the

building layout.

3:41:05 PM

Figure 4.2 F

30 FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

IRSTVISION Display Example: Floor Number Button

Page 35

Normal Operation (No Events Being Reported) Operating Basics of FIRSTVISION

With the front door open; touching one of the miscellaneous buttons will display an information

window or site plan.

3:41:05 PM

Figure 4.3 F

IRSTVISION Display Example: Building Information

31FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 36

Operating Basics of FIRSTVISION Normal Operation (No Events Being Reported)

With the front door open; touching a place on the floor will open a window that displays an

enlarged or zoomed view.

3:41:05 PM

Figure 4.4 F

32 FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

IRSTVISION Display Example: Zoomed Floor Plan

Page 37

Normal Operation (No Events Being Reported) Operating Basics of FIRSTVISION

With the front door open; touching inside the Zoomed Floor Plan window near the left side, right

side, top, or bottom changes the point of reference of the zoomed area. Touching near a corner of

the window will navigate your zoomed view in a combined direction, like down and right.

3:41:05 PM

Figure 4.5 F

IRSTVISION Display Example: Moving Through a Zoomed Floor Plan

33FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 38

Operating Basics of FIRSTVISION Investigating Gateway Disconnection

With the front door open; touching an icon will display information about the image.

Figure 4.6 F

IRSTVISION Display Example: HAZMAT Information

4.2 Investigating Gateway Disconnection

The Gateway Connection Icon in the upper left corner of the user interface indicates whether

F

IRSTVISION is connected to your gateway (a red X displayed inside the icon means that

F

IRSTVISION is not connected).

When you see that the gateway disconnected (red X in icon), F

It is absolutely necessary to restore connectivity to the gateway to ensure the most accurate and up

to date information is being displayed. In order to investigate connectivity issues, you need to

operate F

Step 1. Follow the steps in “Make Connections to F

Step 2. Shut down the F

IRSTVISION like a personal computer. To do this:

IRSTVISION” on page 15 to attach a keyboard

and mouse to F

IRSTVISION.

IRSTVISION software application by pressing the Esc key.

See “Establish Communication Between Your LAN and F

Gateway Communication” on page 23 for information about gateway connectivity.

34 FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

IRSTVISION will not receive events.

IRSTVISION” on page 22 and “Establish

Page 39

Operation When a Fire Alarm is Received Operating Basics of FIRSTVISION

4.3 Operation When a Fire Alarm is Received

When FIRSTVISION receives a fire alarm from a panel it is monitoring, its front door unlocks and a

display change in the floor number button takes place indicating which floor the fire alarm is on. If

multiple fire alarms have been reported, the device icons on that floor blink in a sequence that

indicates the order in which they registered trouble.

3:41:05 PM

Figure 4.7 F

IRSTVISION Display Example: Alarms

35FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 40

Operating Basics of FIRSTVISION Operation When a Fire Alarm is Received

With the front door open; touching the display near the device icons being displayed will zoom to

the area.

3:41:05 PM

Figure 4.8 F

IRSTVISION Display Example: Alarm Zoomed Floor Plan

36 FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 41

Operation After a Fire Alarm Has Been Cleared Operating Basics of FIRSTVISION

With the front door open; touching the Event List button will display a listing of the current alarms.

3:41:05 PM

Figure 4.9 F

IRSTVISION Display Example: Event List

4.4 Operation After a Fire Alarm Has Been Cleared

If fire alarm was the only event being reported; then after a fire alarm has been cleared from the

panel that F

• The fire alarm is cleared from the Event List.

• Any flashing fire alarm related device icons will no longer be displayed.

• If a screen saver is being used; the screen saver will automatically start when the screen saver’s

•F

NOTE: Remember to go to FIRSTVISION after a fire alarm has been cleared from the monitored

network because FIRSTVISION’s door will need to be latched closed.

IRSTVISION monitors; the following takes place on FIRSTVISION:

Wait setting is reached.

IRSTVISION returns to normal monitoring operation.

37FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 42

Operating Basics of FIRSTVISION Accessing the Log File

4.5 Accessing the Log File

FIRSTVISION maintains a log of the most recent 1,000 events from attached devices. Each log entry

contains an event number, a time and date stamp, information identifying the device involved, and

the state of the device during the event. How you access the log file depends on your connection to

F

IRSTVISION.

With F

IRSTVISION and your PC connected over a TCP/IP network, you can browse across the

network to C:/Facilities Monitoring/FIT/Event-log.txt on the F

IRSTVISION machine.

You can also use a USB connector, located inside the locking door, on F

connection point. To access the log file by using F

IRSTVISION like a personal computer:

IRSTVISION as the

Step 1. Connect a USB mouse and keyboard. Refer to “What To Connect and How To Make the

Connections” on page 15.

Step 2. Hold down the Ctrl key, and press the Esc key to open the Windows Start Menu.

Step 3. Use Window Explorer to browse to the file C:/Facilities Monitoring/FIT/Event-log.txt.

Figure 4.10 Log File

38 FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 43

Section 5 The Development of FIRSTVISION

5.1 The Current Situation for a Firefighter

When Firefighters arrive on the scene of a building fire emergency, they must gather information to

accurately assess the situation and plan their attack on the fire. Prompt assessment is essential—the

sooner the seat of the fire and its progression are identified, the sooner the attack on the fire can be

planned and launched. With speed and accuracy of response comes a reduction in loss of property

and life.

Current fire annunciation panels used in commercial buildings provide the primary source of

information for Firefighters arriving on the scene. This is particularly true at night when building

occupants may not be available to report their observations. However, current alarm panels provide

sensor/detector information in formats that are not always easily interpreted. Typically, these panels

present activated smoke/heat detectors as items in a scrolling alphanumeric Event List. Each

activated smoke or heat detector is described only by an alphanumeric location code and an

activation time.

5.2 The Technology of FIRSTVISION

FIRSTVISION is simple and intuitive because it cannot be assumed that the Firefighters have either

computer experience or training in its use. It enables the Firefighter to reduce the time to

understand the situation.

F

IRSTVISION has an interactive display that orients Firefighters to the building using floor by floor

layouts. It decreases situation assessment time by showing the location of water supplies,

evacuation routes, access routes and points, fire barriers, shutoffs for gas and power. F

also shows structural hazards.

During installation F

sensors, hazards, water supplies, and other important devices and information about building

configuration. F

building when responding to an event.

IRSTVISION is set up with the layouts for each floor that show the locations of

IRSTVISION is installed in a location where Firefighters are expected to enter the

5.2.1 Making Commissioning Easier

To customize FIRSTVISION for a building—making it possible to pinpoint fires and their progress,

to see where important building features and hazardous materials are located, and so on—the

building manager must commission the system with building-specific data.

Data to drive F

of building floor and site plans from CAD files, sensor data from building fire panels, location data

for objects such as standpipes, and textual data associated with hazardous materials documentation.

One of Honeywell’s goals was to design a software application that gave the building manager the

flexibility to pull in the best data available from different but existing sources. The resulting

Configuration Tool provides an interface into which building managers enter or add fire detection

information that customizes F

IRSTVISION display comes from a wide range of sources. Sources include drawings

IRSTVISION to the building.

IRSTVISION

39FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 44

The Development of FIRSTVISION Expected Firefighter Interaction with the FIRSTVISION

5.3 Expected Firefighter Interaction with the FIRSTVISION

FIRSTVISION supports tasks that help Firefighters determine whether a fire is occurring. To

illustrate how F

"Fire Scene 2", provide a fire scene scenario and a description of the how Firefighters might use

F

IRSTVISION in that fire scene emergency.

5.3.1 Example Emergency Situations

Fire Scene 1

A fire has started in a second floor office near the front (above the lobby) of a building with a twolevel roof. That is, part of the building has three floors above ground and the other part only two.

The office that contains the fire is directly under the roof on the shorter side of the building. The

building roof is reinforced with high-tension steel cable.

The Fire Department arrives at the building in less than five minutes after the department receives

the alarm. Possible Firefighter responses to this fire scene are described in the following

information.

IRSTVISION helps the Firefighter, example emergency situations, "Fire Scene 1" and

0 seconds

0 seconds

5 seconds

3:41:05 PM

1. The enclosure unlocks and the touch screen displays the floor on which the alarm

activated.

2. The Incident Commander enters the building at the main entrance, goes to F

and opens the enclosure to view the screen.

3. The Commander:

– Verifies that the address is for the building that sent the alarm. (as shown in the

example in Figure 5.1)

– Sees the floors where the detector activations have occurred.

IRSTVISION

Figure 5.1 Fire Scene Scenario Floor Plan Information

40 FIRSTVISION™ Installation and Operation Manual - P/N: 53034:Rev: A2 10/29/07

Page 45

Expected Firefighter Interaction with the FIRSTVISION The Development of FIRSTVISION

10

seconds

3:41:05 PM

4. After verifying the building and seeing fire location, the Commander radios firefighting

team. As he calls, he continues observation:

– Checks layouts of other floors and the roof (as shown in the example in Figure 5.2) to

be sure the fire is contained on only those levels.

– Checks which detector(s) is activated. If multiple detectors are activated he can

determine the progression of the fire by interpreting the blinking rate of the detectors

and base his assessment of the situation on that displayed information.

– Checks for presence of hazardous materials near the fire on its respective floor. (as

shown in the example in Figure 5.3)

– Checks for the location of elevators, stairways, water supplies, and entry and exit

routes.

Note: Notice the Caution on this background. It was added when the background was

developed in the graphics software application. It was not added with the Annotation because

an Annotation can only be added to a Building Site Plan.