Page 1

43191680-1

05

tch

APPLICA TION

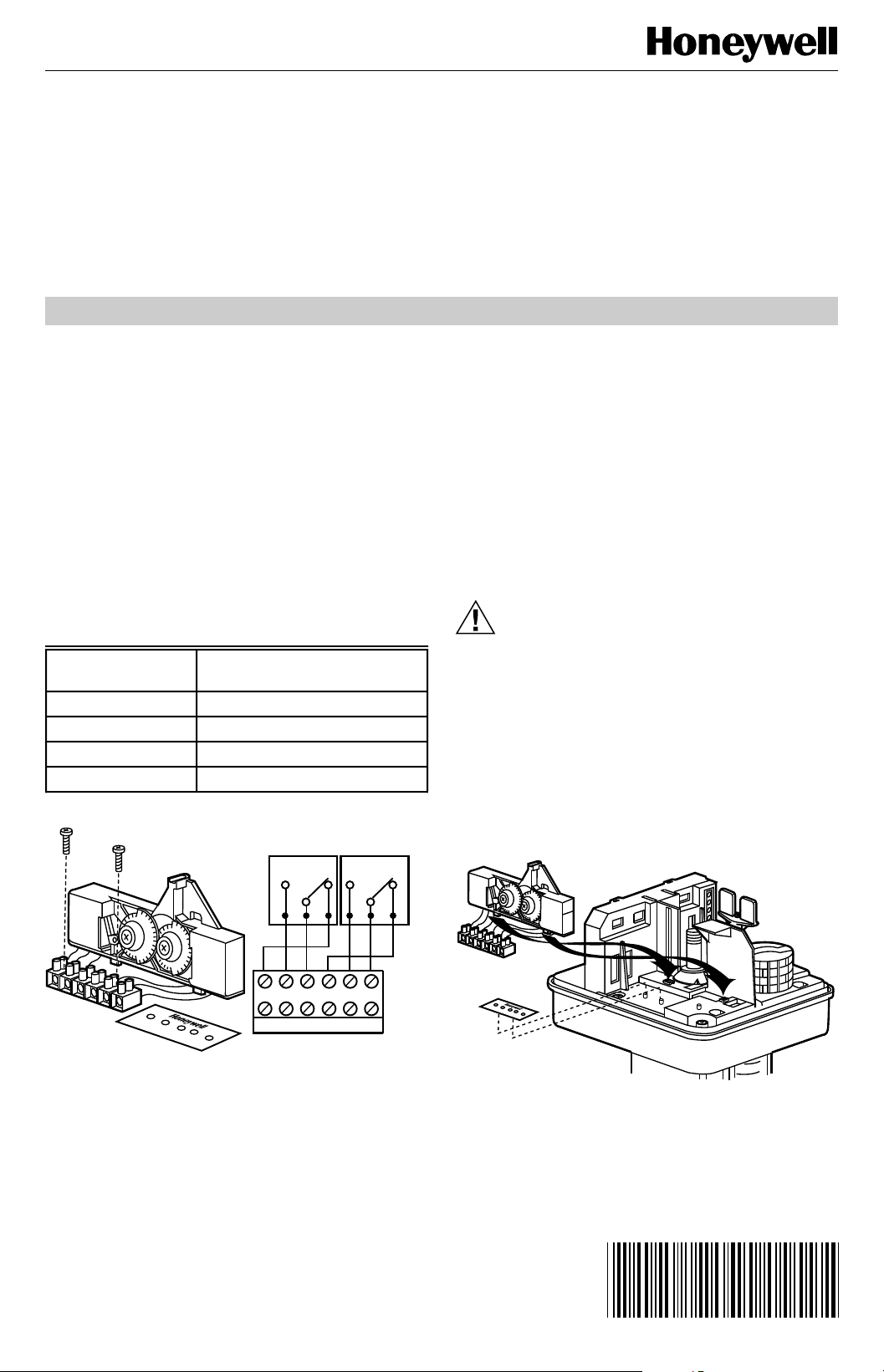

The 43191680-105 Dual Auxiliary Switch provides two

independent, spdt switching functions. Switching points

are adjustable over the full length of the actuator stroke; for

example, the switch can be used to switch pumps at any

point or to provide remote indication of any specific stroke

position. These switches are used with valve actuators as

shown in Table 1. The switches are furnished factory wired

to the terminal block. Fig. 1 illustrates the parts furnished

with this switch and the wiring connections.

IMPORTANT

These switches are rated at 24 Vac maximum.

Table 1. Applicable Actuators for

43191680-105 Dual Auxiliary Switches.

Actuator

ML6425A Extends stem

ML6425B Retracts stem

ML7425A Extends stem

ML7425B Retracts stem

Spring Action on

Power Failure

Auxiliary Swi

INSTALLATION INSTRUCTIONS

INSTALLA TION

When Installing this Product...

1 Read these instructions carefully. Failure to follow

them could result in the equipment not operating

properly.

2 Check the part numbers in the preceding section to

be sure that the product is suitable for your application.

3 The installer must be a trained, experienced service

technician.

4 After completing installation, use these instructions

to check product operation.

CA UTION

Disconnect the power supply to the auxiliary

potentiometer and actuator before beginning

installation to prevent electrical shock or equipment damage.

Mounting, Connecting, and Adjusting

1 Remove actuator cover.

2 Mount the auxiliary switch assembly and terminal

label on the actuator base. Make sure the two tabs

on the bottom of the switch assembly slip snugly into

the slots provided. See Fig. 2.

SI

S1

S2

6 4 5 9 7 8

Fig. 1. Auxiliary switch parts and wiring.

Copyright © 1997 Honeywell Inc. • All Rights Reserved

331122

1 2 3 4 5 6

C8394

S2

S1

S2

6 4 5 9 7 8

Fig. 2. Installing auxiliary switch assembly.

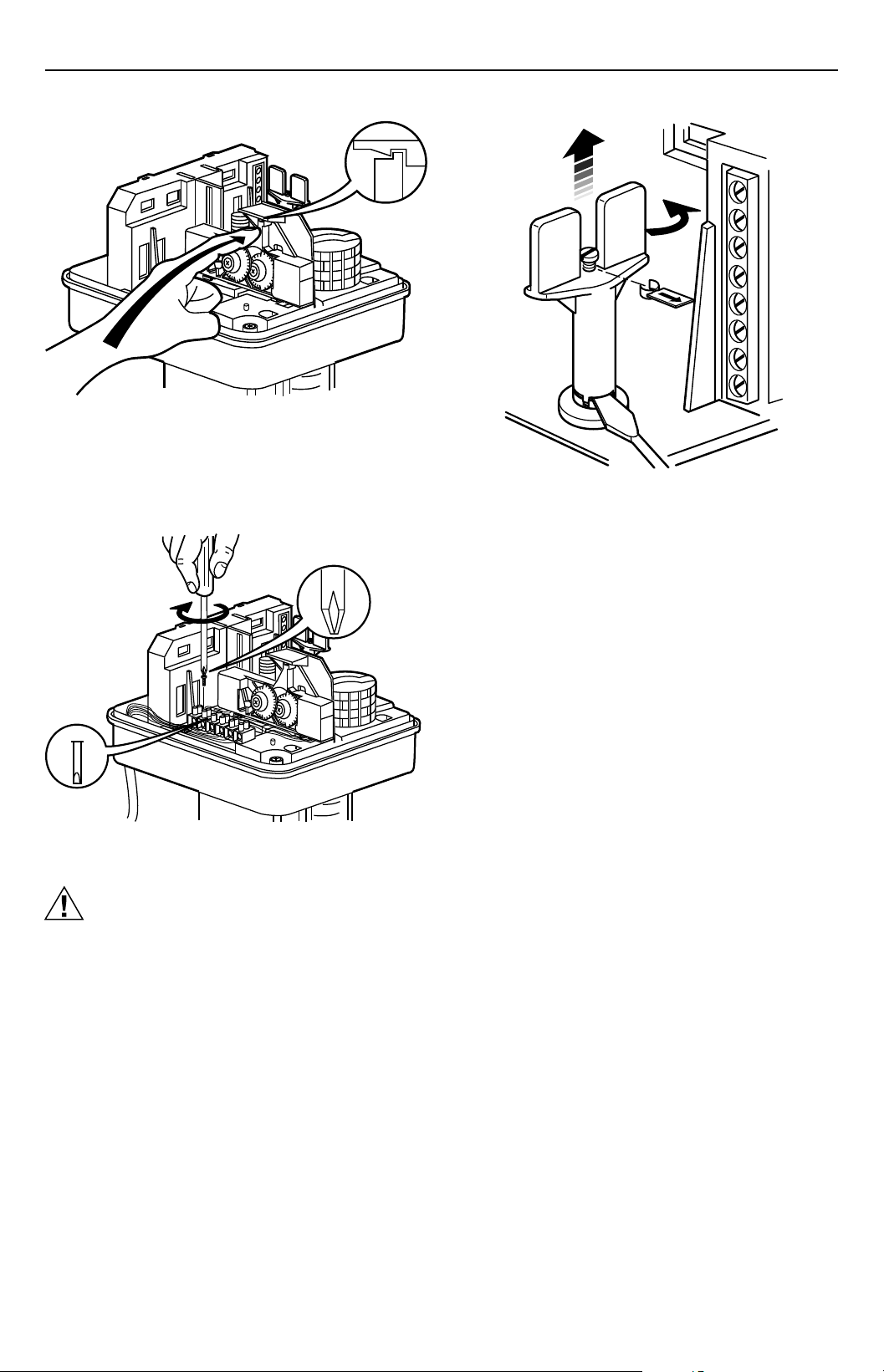

3 Secure auxiliary switch assembly by pressing top

back until assembly snaps into place. See Fig. 3.

X-XX UL

63-2524

C8393

Page 2

43191680-105 AUXILIARY SWITCH

S1

S2

C8395

Fig. 3. Securing auxiliary switch assembly.

4 Secure terminal block and terminal label with Phillips

head screws. See Fig. 4 .

4 MM

S1

S2

3 MM

C8396

Fig. 4. Securing terminal block and label.

CA UTION

The manual spring handle is under tension and

could turn quickly when lifted resulting in injury to

fingers pinched between the handle and plastic

casing. Maintain handle orientation while lifting and

remove fingers quickly when releasing.

M6629

Fig. 5. Removing spring retaining clip

and releasing manual spring handle.

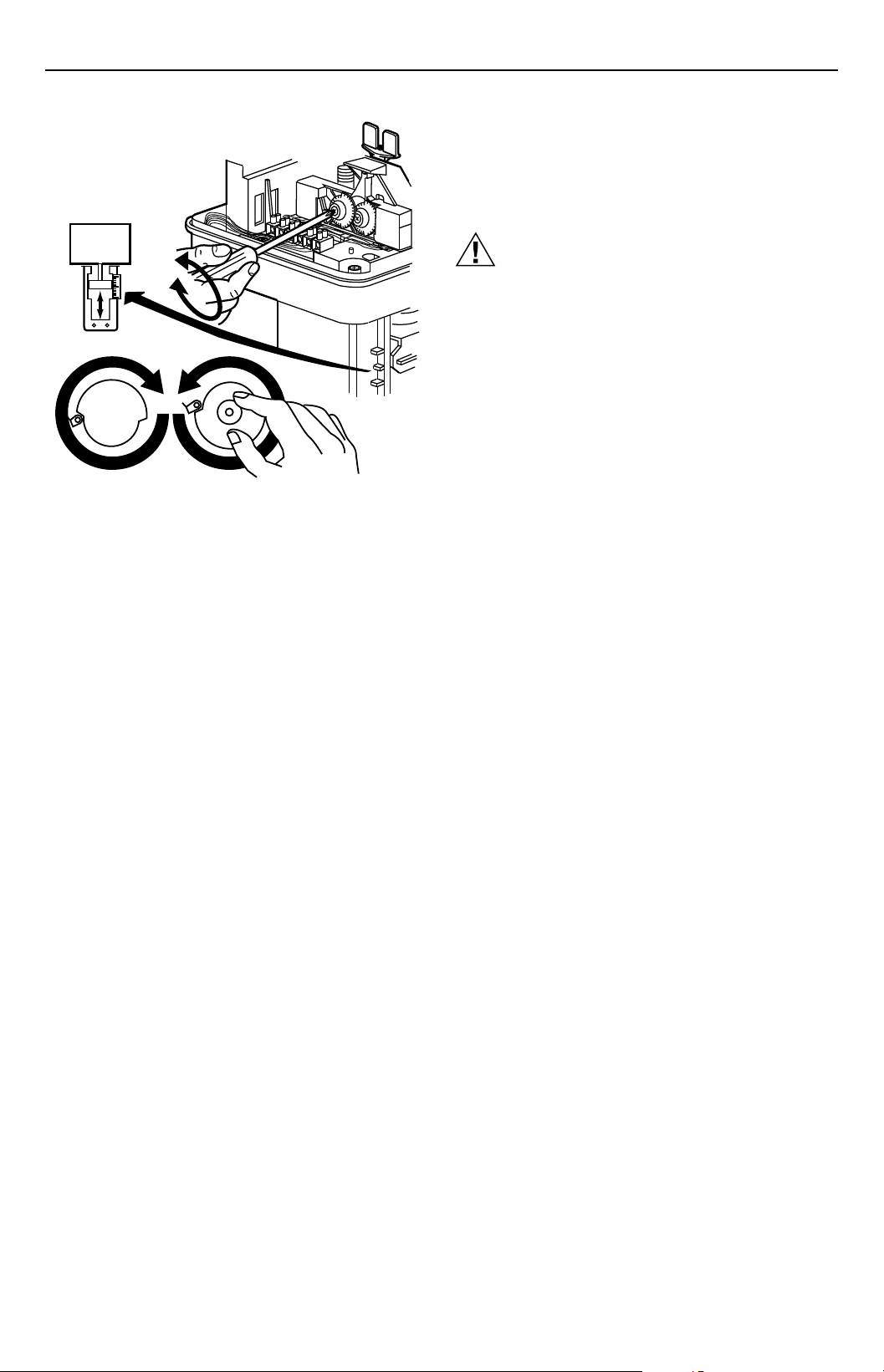

6 Adjust switching point for each switch. See Fig. 6.

a. Using manual spring handle on the actuator,

adjust the actuator shaft to the required

switching point for Switch S1.

NOTE: Turning the spring handle clockwise

extends the actuator shaft. When the

shaft gets to the required position,

press the handle down to hold the

shaft in position. Turning the spring

handle requires two hands, one to

turn the handle and the other to hold

it in place on each consecutive turn.

Observe the preceding caution and

release the handle only as noted in

the preceding Step 5.

b. Loosen the Phillips head set screw on the

cam for Switch S1, set the cam to the required

position, and tighten the set screw.

c. Repeat the preceding Steps 6a and 6b for

Switch S2.

5 Remove manual spring handle retaining clip, if

necessary, and lift and release the handle. See

Fig. 5. The easiest way to perform this operation

safely is to:

a. Remove the retaining clip (shipping stop) and

discard.

b. Wedge a small, flat-bladed screwdriver under

the manual spring handle at the point marked

in Fig. 5 and pry up the handle.

63-2524 2

Page 3

1 X MAX.

43191680-105 AUXILIARY SWITCH

Wiring

Route field wiring in through the conduit opening in the

bottom of the actuator, connect to the switch assembly

S1

S2

terminal block according to the job drawings, and replace

the actuator cover. See Fig. 1 for terminal identification.

CA UTION

Disconnect the power supply to the auxiliary

switches and actuator before wiring to prevent

electrical shock or equipment damage.

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

Fig. 6. Adjusting switching points.

100

All wiring must comply with local codes, regulations, and

ordinances.

0

CHECKOUT

Drive actuator shaft fully up and fully down and check the

C8397

function of the auxiliary switches in the control system.

3

63-2524

Page 4

43191680-105 AUXILIARY SWITCH

Home and Building Control

Honeywell Inc.

Honeywell Plaza

P.O. Box 524

Minneapolis, MN 55408-0524

63-2524 4

63-2524 G.C. 1-97 Printed in U.S.A

Home and Building Control

Honeywell Limited-Honeywell Limitée

155 Gordon Baker Road

North York, Ontario

M2H 2C9

Helping You Control Your World

®

Loading...

Loading...