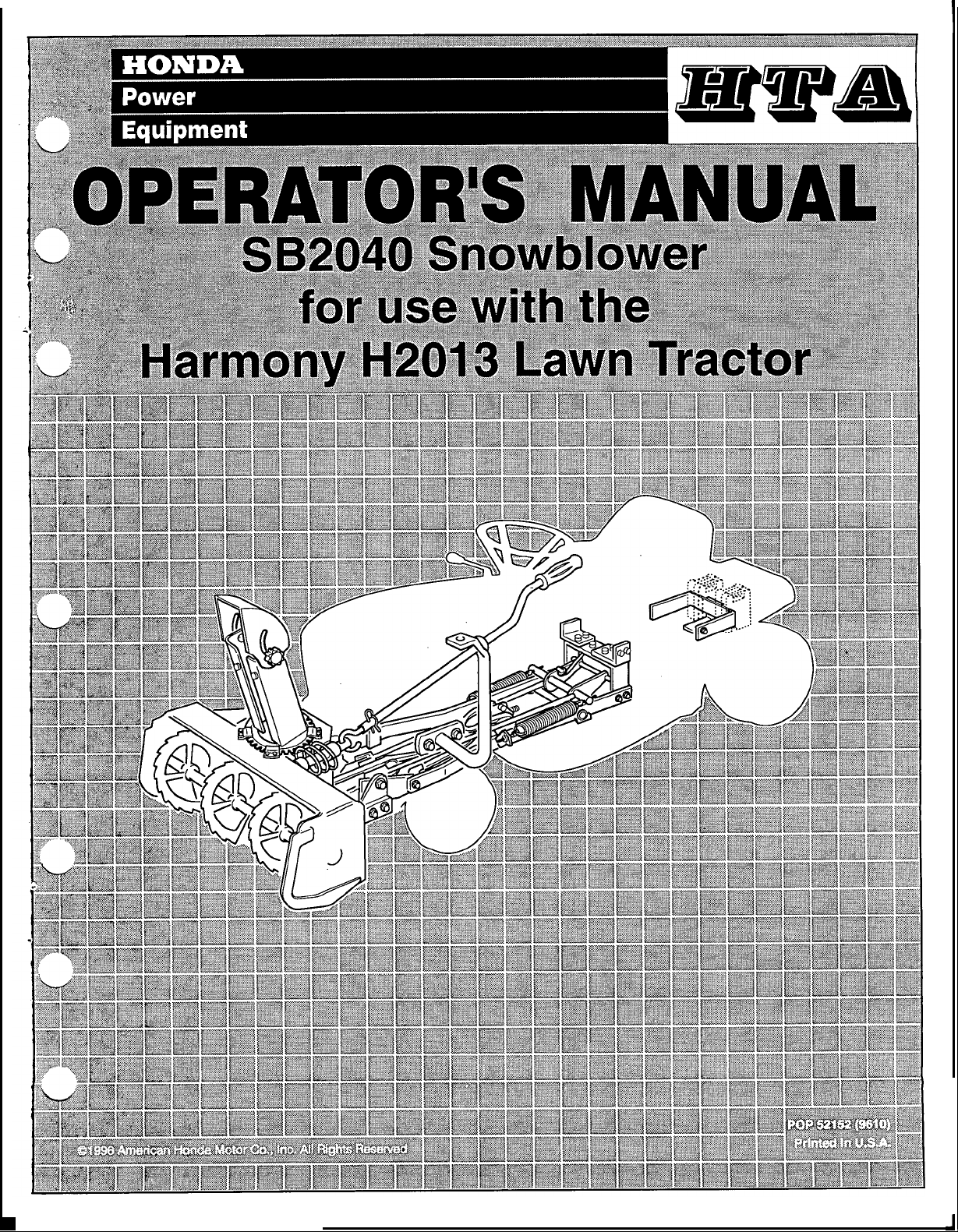

Honda SB2040 Owner's Manual

SI32040

The information in this operator’s manual is limited in application to the Honda SB2040 Snowblower

(frame serial numbers 1000001

tractor

supplied with the lawn tractor

All

printing

and without incurring any obligation

permission

Snowblower

.

1001000) when installed and used on a Honda Harmony H2013 lawn

.

Before installing or operating this equipment. read this operator’s manual and the owner’s manual

.

information in this publication is based on the latest product information available at the time of

.

American Honda Motor

.

Co.,

Inc . reserves the right to make changes at any time without notice

.

No

part of this publication may be reproduced without written

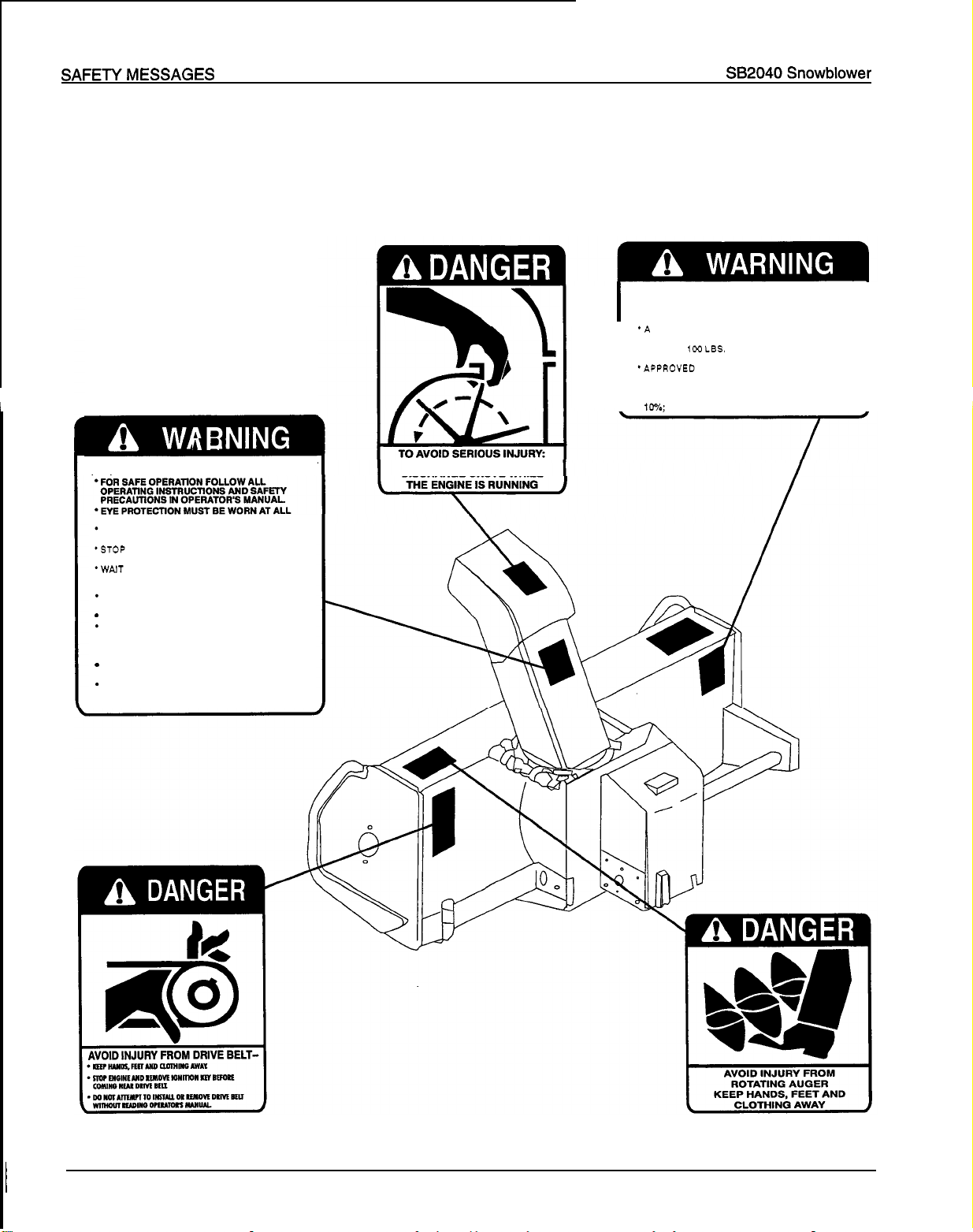

SAFETY MESSAGES

DAMAGE PREVENTION MESSAGES

THE IMPORTANCE

IMPORTANT SAFETY PRECAUTIONS

Safety Labels

Assembly and Installation

Inventory Loose Parts

Inventory Hardware Bags

Hardware Measuring

Torque Values

Assemble the Snowblower

Installing the Snowblower

Safety Recommendations

Controls

Preparing for Snow Removal

Operating the Snowblower

Snow Removal Methods

Removing the Snowblower

Maintenance

Maintenance Schedule

Adjustments

Other Maintenance Items

..........................................................................................................................................................

.........................................................................................................................................................

.................................................................................................................................................................

&

..........................................................................................................................................................

..............................................................................................................................

OF

INSTALLATION

.....................................................................................................................

.............................................................................................................................................

.......................................................................................................................................

Chart

.....................................................................................................................................

......................................................................................................................................

.....................................................................................................................................

...................................................................................................................

................................................................................................................................

....................................................................................................................................

.......................................................................................................................................

.................................................................................................................

Adjustments

.........................................................................................................................................

...............................................................................................................

......................................................................................................................................

TABLE

OF

CONTENTS

...................................................................................................................

...............................................................................................................

.................................................................................................................

2

2

3

3

4

5

5

6

8

8

9

14

21

26

27

28

28

30

34

34

34

36

Parts

Listing

Blower Head & PTO Clutch Assembly

Discharge Chute

Subframe

Optional Accessories

Tire Chains

Headlight Kit

Floor Mats

Warranty Service Information

This manual is a permanent part of the snowblower and must stay with the snowblower

POP

521

52

..........................................................................................................................................

..................................................................................................................

&

Crank Rod

..............................................................................................................................

..............................................................................................................................................................

...........................................................................................................................

............................................................................................................................................................

..........................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................

(961

0)

if

resold

38

38

40

42

44

44

44

44

45

.

1

1

SAFETY

MESSAGES SB2040

Snowblower

SAFETY MESSAGES

Your safety and the safety of others are very important. We have provided important safety messages in

this manual and on the snowblower. Please read these messages carefully.

A

safety message’alerts you to potential hazards that could hurt you or others. Each safety message is

preceded by a safety alert symbol and one of the following three words: DANGER, WARNING, or

CAUTION.

These words mean:

if

You WILL be KILLED or SERIOUSLY HURT

instructions.

You CAN be KILLED or SERIOUSLY HURT

instructions.

if

You CAN be HURT

you don’t follow instructions.

you don’t follow

if

you don’t follow

Each message tells you what the hazard is, what can happen, and what you can do to avoid or reduce

injury.

DAMAGE PREVENTION MESSAGES

You will also see other important messages that are preceded by the word NOTICE.

This word means:

(NOTICEI

The purpose of these messages is to help prevent damage to the snowblower, lawn tractor, other

property, or the environment.

Your equipment or other property can be damaged

if

you don’t follow instructions.

2

~~

POP

521 52 (961

0)

SI32040

Snowblower

SAFETY

MESSAGES

THE IMPORTANCE

OF

INSTALLATION

Proper installation is essential to operator safety and the reliability of the machine. Any error or oversight

made by the technician assembling and servicing a unit can easily result in faulty operation, damage to

the machine, or injury to the operator

Improper service can cause an unsafe

condition that can lead to serious injury or

death.

Follow the procedures and precautions in

installation instructions and shop manuals

carefully.

Some of the most important safety precautions are given below. However, we cannot warn you of every

conceivable hazard that can arise in performing this installation. Only you can decide whether or not you

should perform a given task.

Failure to properly follow installation

instructions and precautions can cause you to

be seriously hurt or killed.

Follow the procedures and precautions in

installation instructions carefully.

IMPORTANT SAFETY PRECAUTIONS

Make sure you have a clear understanding of all basic shop safety practices and that you are wearing

appropriate clothing and safety equipment. When performing this installation, be especially careful of the

following:

0

Read the instructions before you begin, and make sure you have the tools and skills required to

perform the tasks safely.

off

Make sure the engine is

before you begin any maintenance

potential hazards:

0

Carbon monoxide poisoning from engine exhaust. Be sure there is adequate ventilation whenever

you run the engine.

0

Burns from hot parts. Let the engine and exhaust system cool before touching.

0

Injury from moving parts.

Do

not run the engine unless the instruction tells you to do

then, keep your hands, fingers, and clothing away.

guard or shield is removed.

To reduce the possibility of a fire or explosion, be careful when working around gasoline or batteries.

only a nonflammable solvent, not gasoline, to clean parts. Keep all cigarettes, sparks, and flames away

-

from the battery and all fuel

related parts.

or

repairs. This will help eliminate several

so.

Do

not run the engine when any protective

Even

Use

POP

52152

(9610)

3

Safety

Labels

Immediately replace any label that becomes damaged or unreadable. Contact a servicing Honda lawn

tractor dealer for replacement label.

I

TO

AVOID

USING SNOWBLOWER

*A REAR COUNTERWEIGHT

COUNTERBALANCE SNOWBLOWER WEIGHT

*MINIMUM

RECOMMENDED

*APPROVED TIRE CHAINS ARE REQUIRED

I

'WHEN DISMOUNTING SNOWBLOWER, REMOVE

REAR COUNTERWEIGHT

'DO

NOT OPERATE ON SLOPES GREATER THAN

1%

I

INJURY WHEN

IS

REQUIRED TO

100

LBS. COUNTERWEIGHT

READ OPERATOR'S MANUAL

IS

I

I

I

mlm

FAILURE TO FOLLOW SAFE OPERATING PROCEED

URES MAY RESULT IN INJURY.

TIMES.

KEEP HANDS, FEET

FROM

POWER DRIVEN PARTS.

*STOP ENGINE BEFORE LEAVING OPERATOR

POSITION.

*WAIT FOR ALL MOVEMENTS TO STOP BEFORE

STARTING TO ADJUST, LUBRICATE, CLEAN

UNCLOG THE MACHINE.

KEEP THE AREA OF OPERATION CLEAR OF

ALL PERSONS AND ANIMALS.

KEEP ALL GUARDS AND SHIELDS IN PLACE.

NEVER DIRECT DISCHARGE TOWARD BY

STANDERS, BUILDINGS, CARS ETC.

'ALWAYS USE A DUST MASK WHEN WORKING

IN DUSTY CONDITIONS.

KEEP PLASTIC MATERIALS AWAY FROM

INTENSE HEAT AND OPEN FLAME.

NEVER ALLOW PASSENGERS ON THE

ATTACHMENT.

AD

AND

CLOTHING AWAY

OR

-

KEEP

HANDS

OUT

OF

DISCHARGE CHUTE WHILE

THIS

/

4

POP

52152 (9610)

SI32040

Snowblower

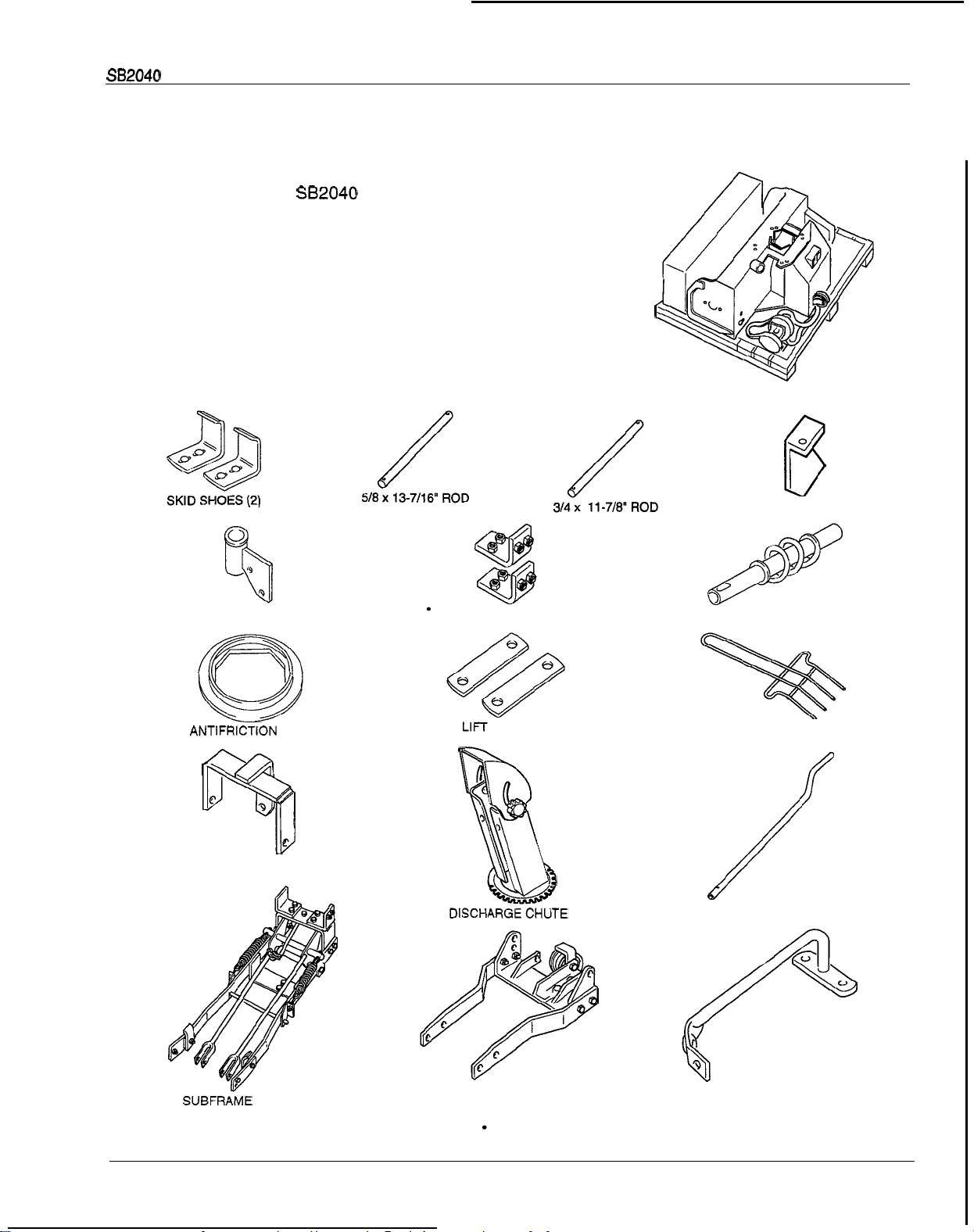

Assembly and Installation

Proper installation of the SB2040 includes installing four (4) 26-lb.

counterweights. These counterweights are not included with the

snowblower and must be purchased separately.

1.

Remove the lag bolts holding the blower head and the pulley

assembly to the shipping pallet.

2.

Remove the blower head and pulley assembly from the pallet.

3.

Remove the loose parts

box,

then inventory the contents.

Assembly

and Installation

Inventory Loose

WORM SUPPORT BRACKET L-SHAPED BRACKETS

ANTIFRICTION RING

Parts

LIFT PLATE

(2)

(2)

HOLD-DOWN

WORM GEAR

DISCHARGE

BRACKET

GUARD

POP

COUNTERWEIGHT

SUBFRAME

52152

(9610)

B

RACKET

ASSEMBLY

DISCHARGECHUTE

PUSH FRAME

These brackets (and associated hardware) are loosely installed on

the subframe of units with serial numbers from

HANDLE

HANDLE SUPPORT

1000001 - 1000500.

5

Assembly

and

Installation

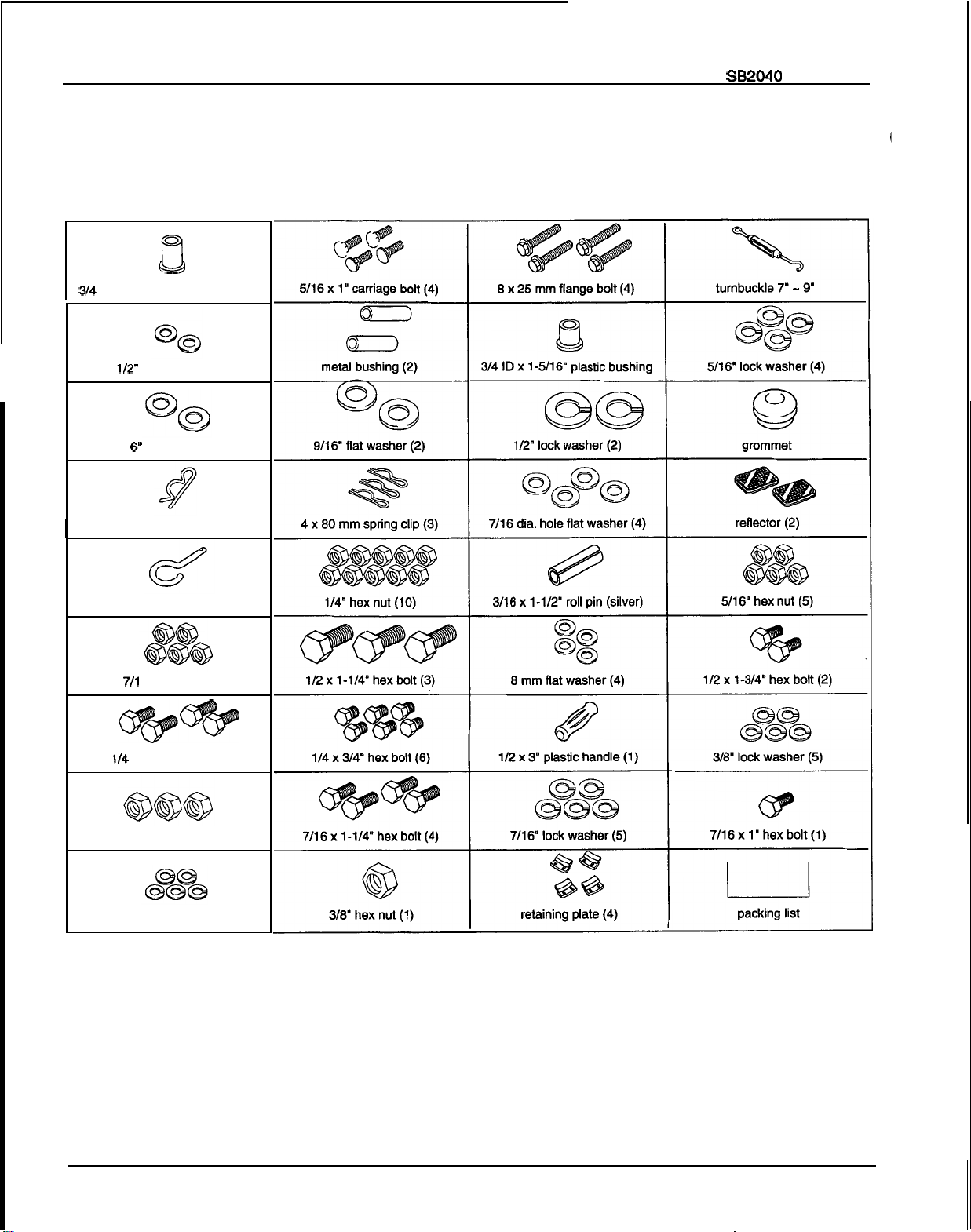

SB2040

Snowblower

Inventory

Hardware

Bags

Refer to the serial number (located on the right side of the blower head) and check all hardware.

The following parts are included with all units:

I

314 ID x 1-1 1/16" plastic bushing

112' flat washer (2)

6"

flat washer (2)

511

I

2.5 x 40

mm

handle

spring clip (1)

hook

(1)

711 6" hex nut (5)

114 x 112" hex bolt (4)

112

I

112

"

"

lock

hex nut

washer (5)

(3)

6

POP

52152 (9610)

582040

Snowblower

Assembly

and Installation

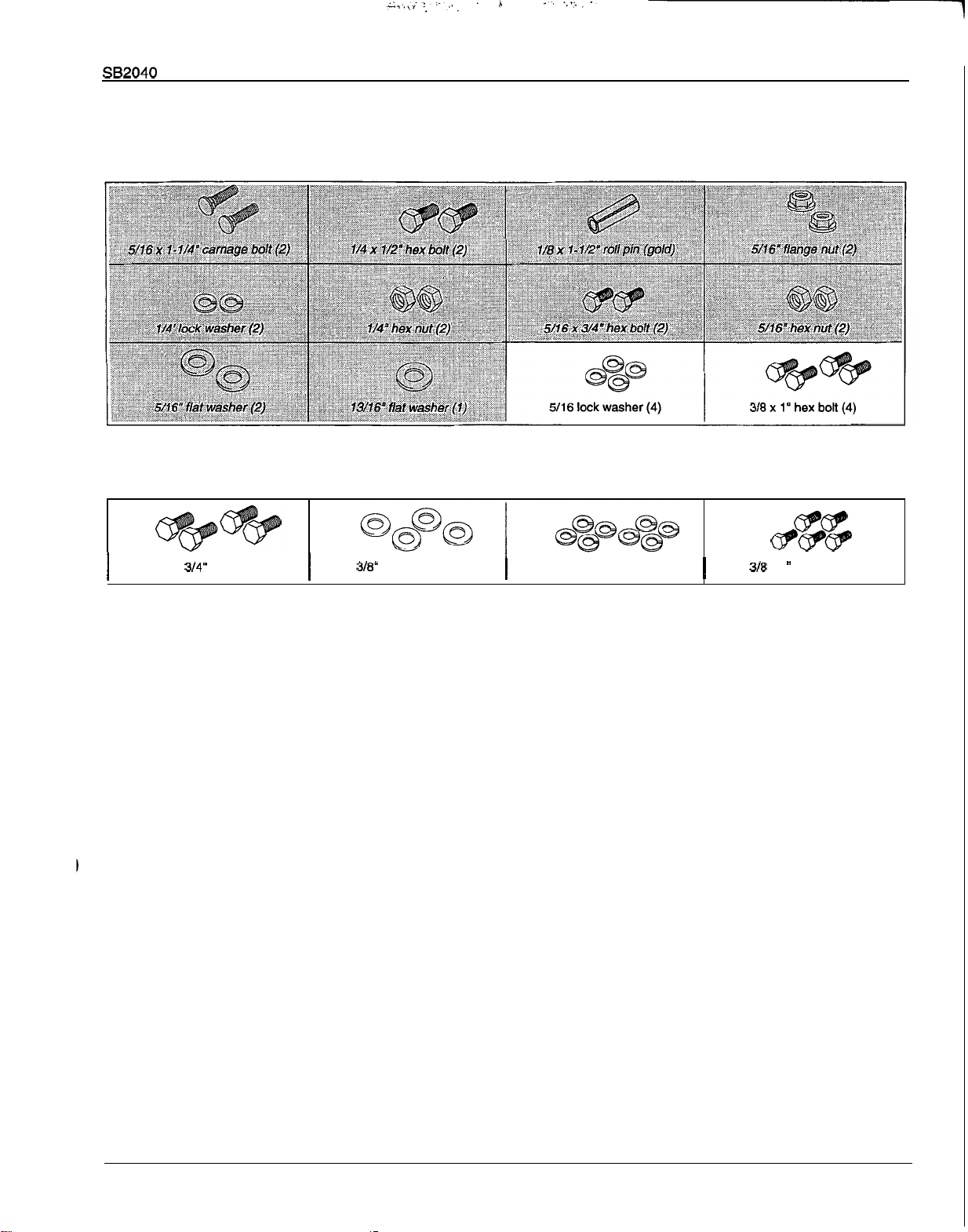

The following parts are included only with serial number

not

in the shaded boxes are

The following parts are only included with serial number

I

5/16

x

3/4"

hex bolt

(4)

required for assembly and installation

I

318"

flat washer

(4)

I

1000001

1000501

5/16

lock

-

1000500

of

and up:

washer

(E)

only.

The parts indicated

the snowblower.

PCP

e@@

I

3/E x 1

hex bolt

(5)

POP

52152

(9610)

7

Assembly and installation

SB2040

Snowblower

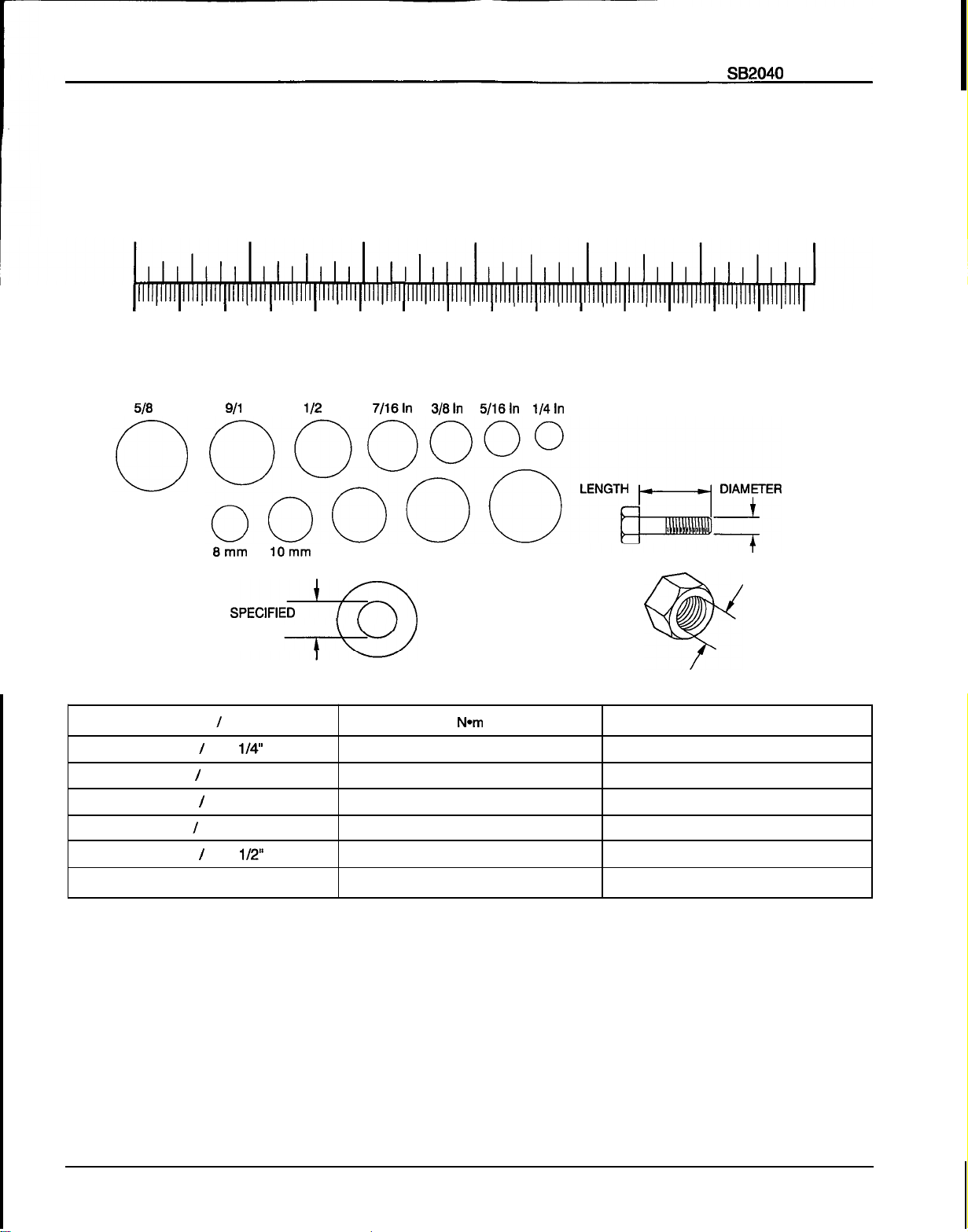

Hardware Measuring

How to measure hardware and components:

INCHES

0

I

I I

0

10

MILLIMETERS

518

in 911 6 In 112 In 7116111 318In 5116In 1141n

20

1

I I

30

00

5mm 6mm

WASHERS ARE

BY

INSIDE DIAMETER

8mm

10mm 12mm

Chart

lT

40

2

I

50

lr

I

I

60

70 80

14

rnm

3

I

I

90

100 110 120 130 140 150

16

rnm

NUTS ARE SPECIFIED

BY

INSIDE DIAMETER

(AT THREAD DEPTH)

4

I

I

5

I I

I

INSIDE

DIAMETER

6

I

Torque Values

Fastener

I

nut

mm

bolt, 114

I

bolt, 511

I

bolt, 318

/

bolt,

flange

Hex nut

Hex nut

Hex

Hex nut I bolt, 711 6

8

x

25

I

Size

1/2"

6

"

bolts

Nom

41

61

9-1

ft-lb.

5-6 6.8-8.1

-

12 14-16

10

20-23 27-31

-

47

-

70 Hex nut

9

30-35

45-52

7.2- 14

8

POP

52152

(9610)

SB2040

Snowblower

Assembly

and Installation

Assemble the Snowblower

FOLLOW THESE INSTRUCTIONS CAREFULLY. Correct installation of this snowblower is essential for

safe, reliable operation.

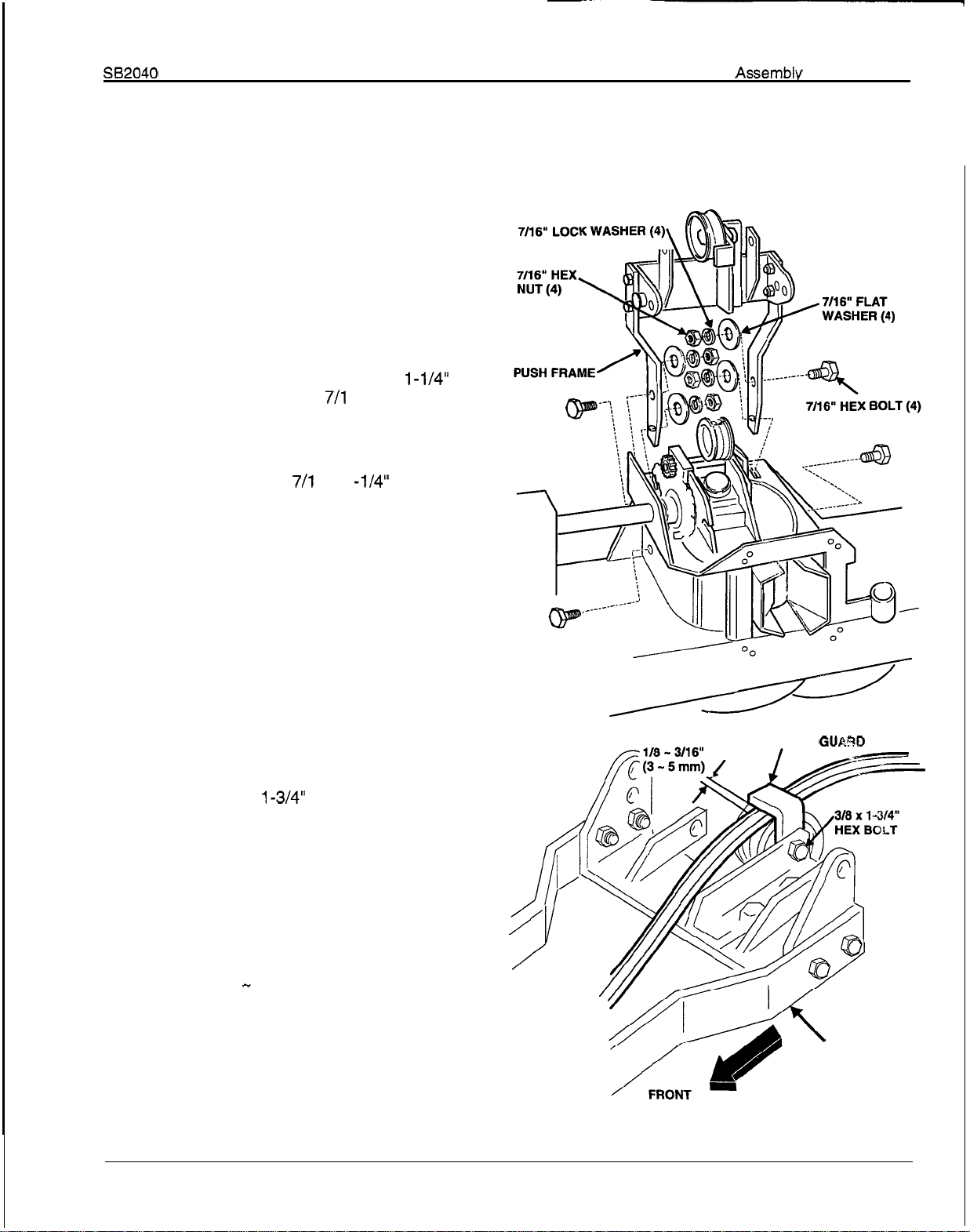

Push Frame Installation

Position the blower head on its front end as

1.

shown.

Slide the push frame assembly into the blower

2.

head.

Install and finger

3.

bolts, 7/16

7/16

4.

Install

7/16

7/16

"

hex nuts to the front holes.

two

"

flat washers, 7/16" locking washers and

"

hex nuts to the rear holes.

-

tighten two 7/16 x 1-1/4" hex

"

flat washers, 711 6" lock washers and

additional 711 6 x 1 -1/4" hex bolts,

Hold the edges of the push frame parallel to the

5.

edges of the blower head, then tighten all

hardware.

Install Belt to Idler Pulley

1. Locate the 3/8 x 1-3/4" hex bolt securing the idler

pulley

enough to allow the belt guard to be moved.

2.

Locate the belt where it exits the bottom of the

blower head. Install the belt onto the idler pulley

with the wide, flat side of the belt against the

pulley as shown.

3. Position the belt guard straight up. Adjust the

gap between the guard and the pulley to

1/8

to the push

-

3/16" (3

frame.

-

5

mm) and tighten the hex bolt.

Loosen

this bolt

BELT

GUW!W

POP

52152 (9610)

PUSH

FRAME

9

Assembly

and

Installation

,Install Push Frame to subframe

1. Position the push frame to the subframe as

shown.

two

2. Install

two

1/2 x 1-1/4" hex bob, 1/2" lock

washers, and

weld nuts

two

nuts securely.

For clarity, the drive belt is not shown in

this illustration.

1-5/16" bushings, then install

two

1/2" flat washers to the

on

the push frame. Tighten the

1-5/16

"

BUSHING

(2

SB2040

Snowblower

I

Install PTO Clutch Assembly

1.

Position the assembly as shown. Make

sure

the belt is fully enclosed inside the

push frame, and the tensioner spring

faces away from the blower head.

2.

!nstall the assembly to the push frame

using 3/8 x 1" hex bolt, 3/8" lock washer

3/8" hex nut in the front (closest to the

and

blower head) hole, then install a 7/16

"

hex bolt, 7/16

nut to the rear hole in the subframe.

lock washer and 7/16" hex

" x 1

7/16

7/16

LOCK

"

HEX NUT 318" HEX NUT

WASHER

A

10

318

x

1

"

HEX

BOLT

POP 52152

(961(

Sf32040

Snowblower

Assembly

and Installation

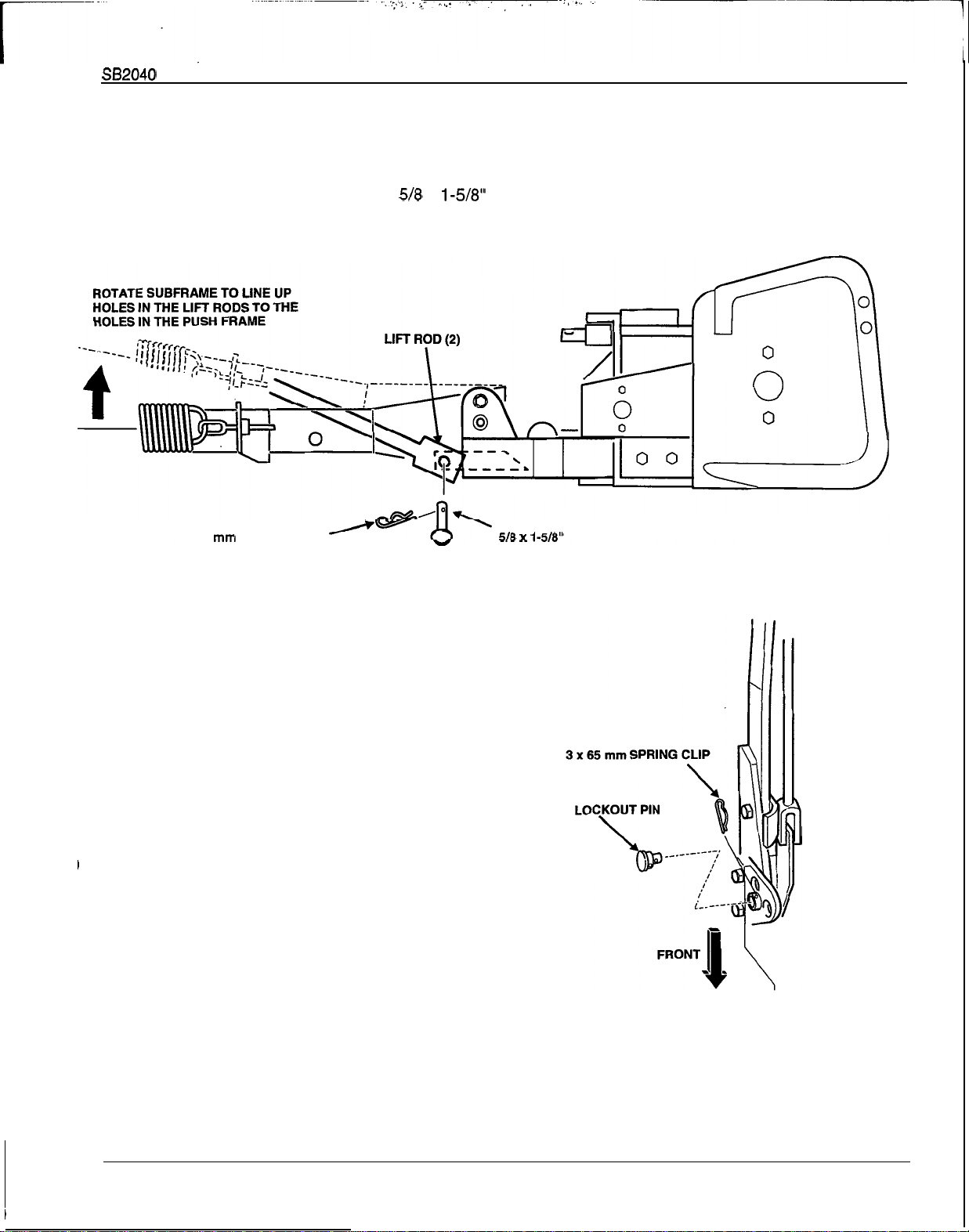

Connect Lift

1.

Allow the subframe to pivot (while the blower head remains stationary),

rods to the subframe using the

2.

Verify that the

Rods

two

5/8

x

1-5/8"

clevis pins and

two

counterbalance springs remain connected at both ends.

4

x

80

rnm

SPRING

CLIP

/

518

x

1-5/8"

CLEVIS

4

so

x

80

mm spring clips.

PIN

you can connect the

two

lift

Engage Lockout Pin

The counterbalance springs transfer the weight

frame (and blower head) against the subframe. This

arrangement allows the height adjustment lever to easily

raise and lower the entire blower head. The push frame

must be locked into position (using the lockout pin) before

the springs can be properly adjusted.

Once the counterbalance springs are adjusted, they are

under tension. The lockout pin must be kept in the locked

position until the entire snowblower is fully installed.

1.

Place a suitable block of wood or other support under

I

the push frame,

2.

Adjust the position of the subframe as needed to slide

so

the subframe can pivot downward.

the lockout pin through the push frame and into the

corresponding hole in the subframe. Secure the lockout

pin with a

3.

Verify the lockout pin is correctly installed by attempting

to pivot the subframe

3

x

65

mm spring clip.

on

the push frame.

of

the push

POP

52152 (9610)

I

11

Assembly

and Installation

SB2040

Snowblower

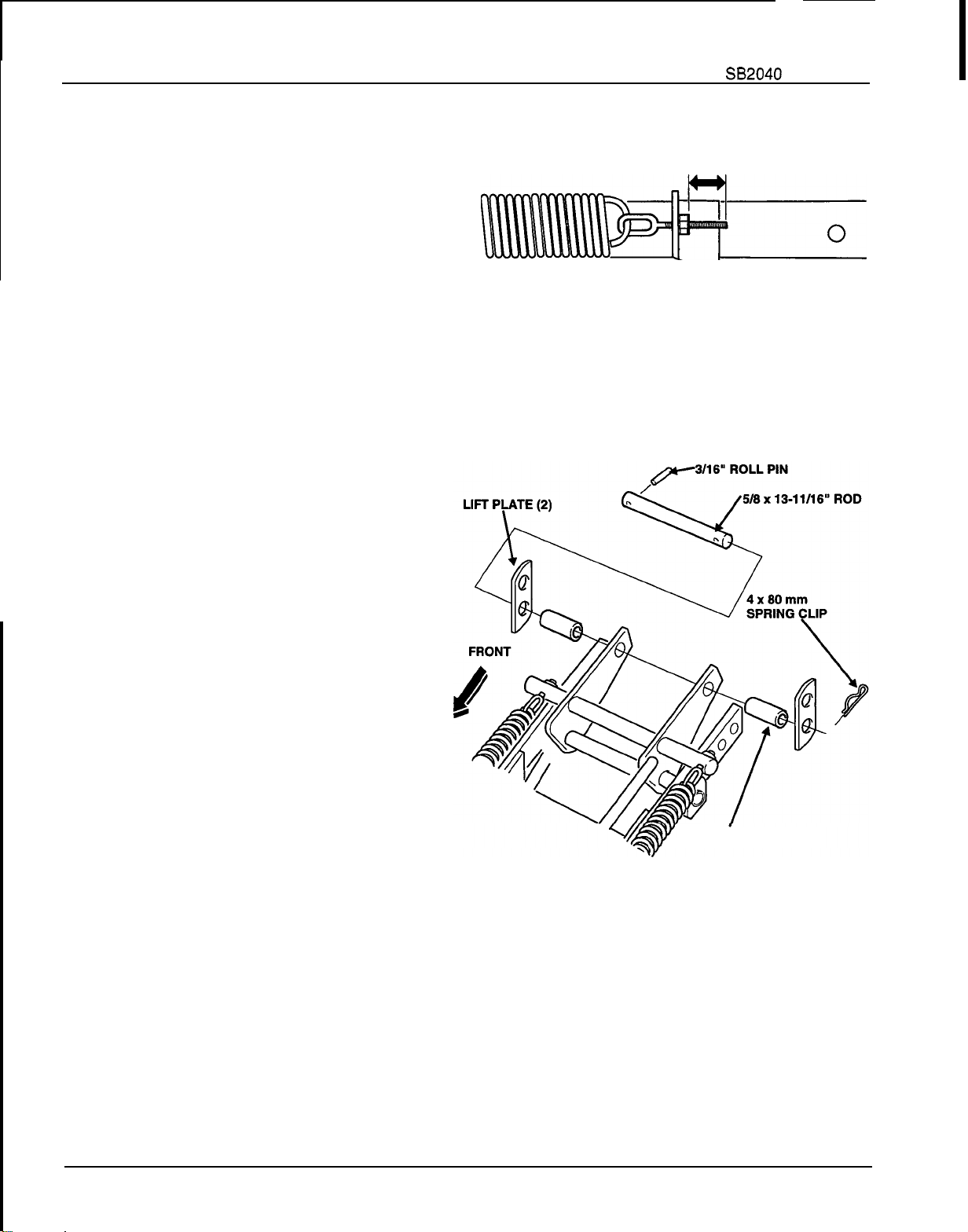

Adjust Counterbalance Springs

1.

Tighten the adjustment nut on each

counterbalance spring bolt

75

mm

length is

2.

Lift the subframe and remove the block of wood or

(3.0

support.

After the counterbalance springs have been

adjusted, they are under tension.

the lockout pin until the entire snowblower is fully

installed on the lawn tractor.

The effort required to raise and lower the blower

head can be adjusted by varying the length of

exposed thread on the spring bolts. See the

Maintenance

Install

1.

Install a

5/8

section for details.

Lift

Plates

3/16

"

roll pin into one hole on the

x

13-1

1/16

"

rod. Install one lift plate and

metal bushing on the rod and slide them

against the roll pin.

so

inches).

the exposed thread

Do

not remove

75

mm

U

(3.0

inches)

2.

Insert the other end of the rod through the

holes

in

the subframe as shown. Install the

other metal bushing and lift plate, then a

4

x

80

mm spring clip.

The remaining holes on each lift plate will

attach to the

tractor when the snowblower

two

lifting arms on the lawn

is

installed.

METAL

BUSHING

(2)

12

POP

52152 (9610)

i

SB2040

Snowblower

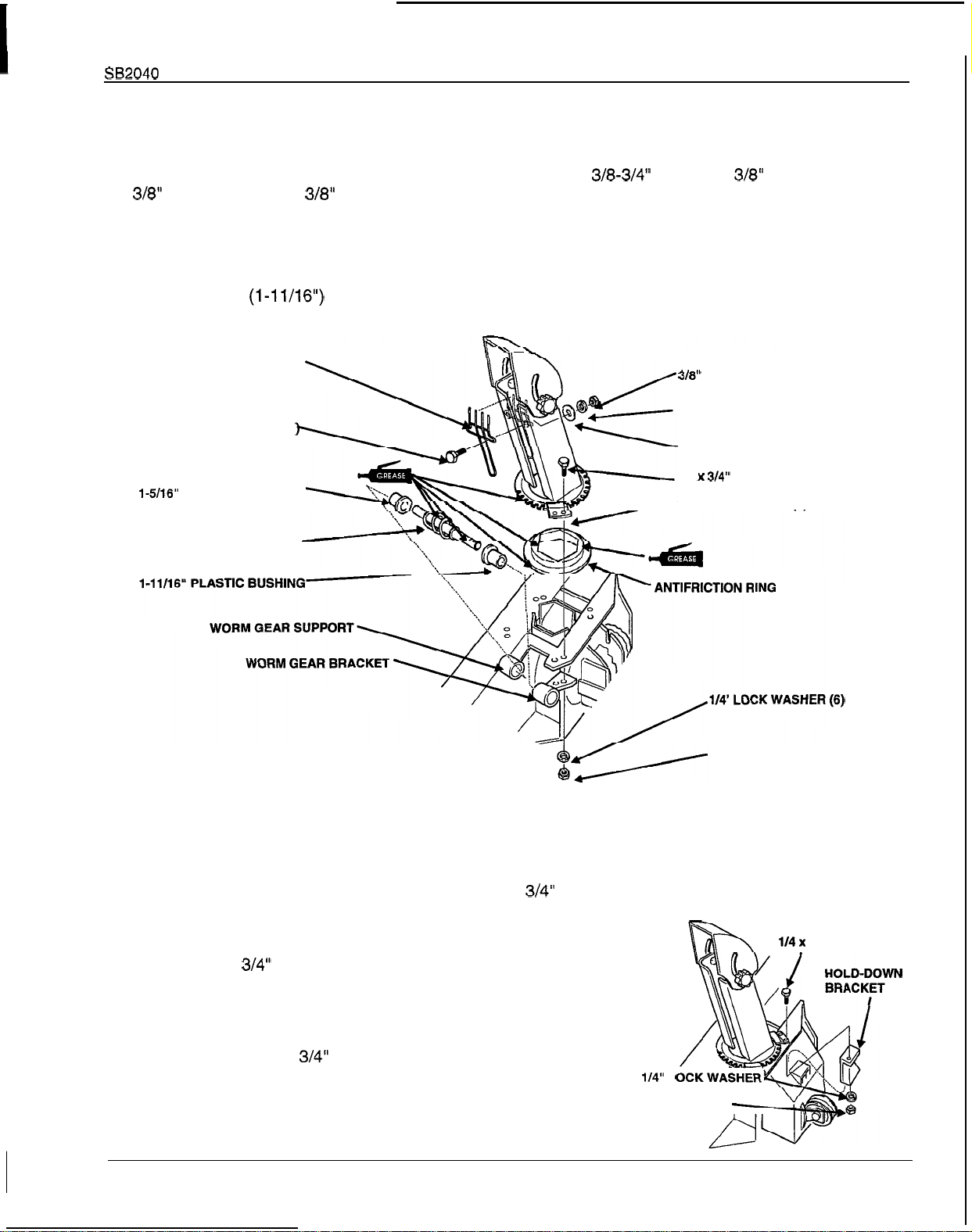

Discharge Chute Assembly

1. Install the discharge guard on the chute as shown using

3/8" lock washers and 3/8" hex nuts.

2.

Place the antifriction ring onto the blower head; the ring is keyed to the blower head

position fits.

two

3/8-3/4" hex bolts, 3/8" flat washers,

Assembly

so

only one

and

Installation

3. Apply a generous amount

of

general purpose grease to the top lip

of

the antifriction ring.

4. Install the long (1-11/16") plastic bushing into the worm gear bracket. Apply grease to the inside

surface of the bushing.

DISCHARGE GUARD

3/8"

114 x 314" HEX BOLT (2

1-5/16'' PLASTIC BUSHING

WORM GEAR

HEX NUT

318

"

LOCK WASHER

318

"

FLAT WASHER

114 X 314"

-

RETAINING PLATE

(2)

(2)

(2)

HEX BOLT (6)

(3)

$//

5.

Grease the inside

gear. Grease the long shaft on the worm gear, and install

6.

Position the chute on the blower head. Get a helper to hold it in place

7.

Install the

two

8. Install the short shaft of the worm gear (with bushing) into the

bracket on the blower head.

9.

Use the 1/4 x 3/4" hex bolts to install the left rear retaining plate

along with the crank handle bracket.

10. Apply a generous amount of general purpose grease to the worm

gear and chute gear teeth.

11. Use the longer, 1/4 x

retaining plate, hold

POP

521

52

(961

0)

of

the shorter

(1-5/16")

plastic bushing then slide it onto the short shaft

it

into the bushing on the worm gear bracket.

front retaining plates using four 1/4 x 3/4" hex bolts, lock washers and hex nuts.

314" hex bolts to secure the right rear

-

down bracket, and the plastic chain cover.

114" HEX NUT (6)

if

needed.

114"

L

114" HEX NUT

of

the

314

"

HEX BOLT

worm

13

Loading...

Loading...