Page 1

GX240

GX270

GX340

GX390

UT2/RT2

Technical Manual

©2010 American Honda Motor Co., Inc.

All Rights Reserved

PTR54179

Page 2

Page 3

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

Preface

This manual covers engine selection, engine installation design and engine installation testing, so the combination of a

Honda engine and your equipment will make the best possible product.

Please feel free to contact your Honda Engine Distributor at any time for additional technical information or to discuss

your engine application needs.

All information contained in this manual is based on the latest product information available at the time of printing. We

reserve the right to make changes at anytime without notice.

No part of this publication may be reproduced, or transmitted, in any form or by any means, electronic, mechanical

photocopying, recording or otherwise, without the prior written permission of the publisher. This includes text, figures

and tables.

Contents

Design Features .......................................................... 2

Emission Regulations ................................................. 2

Recommended Power Range ..................................... 3

Maximum Operation ............................................... 3

Continuous Operation ............................................ 3

Power Curve .......................................................... 3

Output Confirmation Methods ................................ 5

Cooling ....................................................................... 5

Minimum Cooling Air Flow Requirement ................ 5

Ambient Temperature Limits .................................. 5

Testing ................................................................... 5

Engine Enclosures ................................................. 6

Fuel System ................................................................ 7

Fuel Tank Position ................................................. 7

Fuel Line ................................................................ 7

Fuel Valve Installation ............................................ 7

Fuel Pump ............................................................. 7

Fuel Tank Filter Installation .................................... 7

Controls ....................................................................... 7

Engine Switch ........................................................ 7

Carburetor Controls ............................................... 8

Exhaust System .......................................................... 9

Recommended Muffler ........................................... 9

Fabricated Exhaust Systems ................................. 9

Engine Mounting ....................................................... 10

Inclination ............................................................. 10

Resonance Check ............................................... 10

Electrical System ...................................................... 11

Battery ................................................................ 11

Fuse ..................................................................... 11

Engine Switch ...................................................... 11

Charging Coil Selection ....................................... 12

Lamp Coil Kit (optional) ........................................ 12

Oil Alert® System (optional) ................................ 12

Wiring Precautions ............................................... 12

Wiring Diagrams ....................................................... 13

No Charge Coil Models ........................................ 13

Electric Start Models ............................................ 13

Power Transmission ................................................. 15

V-Belt Connections .............................................. 15

Starting Performance ...........................................16

Installation Considerations ........................................17

Maintenance Points Accessibility ........................17

Dimensional Drawings ...............................................19

GX240-270 ...........................................................19

GX340-390 ...........................................................23

PTO Dimensional Drawings ......................................27

H Type (with reduction) ........................................27

L Type (with reduction) .........................................27

P Type ..................................................................28

Q Type ..................................................................28

S Type ..................................................................29

V Type ..................................................................29

W Type .................................................................30

Dimensions and Weights ...........................................31

GX240 ..................................................................31

GX270 ..................................................................33

GX340 ..................................................................34

GX390 ..................................................................35

Specifications ............................................................36

GX240 ..................................................................36

GX270 ..................................................................36

GX340 ..................................................................37

GX390 ..................................................................38

Serviceability .............................................................39

Maintenance Schedule .........................................39

Engine Oil Level Check ........................................40

Engine Oil Change ...............................................41

Air Cleaner Check/Cleaning and Replacement ....41

Sediment Cup Cleaning .......................................44

Spark Plug Check/Adjustment ..............................45

Spark Plug Replacement ......................................46

Spark Arrester Cleaning (if equipped) ..................46

Idle Speed Check/Adjustment ..............................47

Valve Clearance Check/Adjustment .....................48

Combustion Chamber Cleaning ...........................49

Fuel Tank and Filter Cleaning ..............................50

Fuel Tube Check ..................................................50

Evaporative emissions ...............................................51

Types with OEM provided fuel tanks ....................51

© 2010 American Honda Motor Co., Inc — All Rights Reserved 1

Page 4

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

INTRODUCTION

Honda engines are designed for minimal maintenance.

When maintenance is required, the task is kept simple by

providing convenient maintenance access and procedures.

Honda engines use proven engine technology and design

innovations to make them highly reliable engines.

DESIGN FEATURES

High Performance

OHV design reduces thermal distortion of the cylinder. This

helps maintain the optimum seal between the piston rings

and cylinder, which minimizes oil and fuel consumption.

Power is also maintained in extreme operating conditions.

Smooth and Quiet Operation

OHV design provides a reduced reciprocating mass and

balanced weight distribution. The 25° inclined cylinder

produces a low center of gravity for the moving parts, which

further reduces vibration for quiet operation. These features,

and the compact design result in extremely smooth

operation.

Use of proven design technologies reduces noise from

internal engine components. The hardness of reciprocating

parts, the helical cut gears on the crankshaft and camshaft

and the use of select materials makes these engines

exceptionally quiet. The large muffler is designed to further

reduce noise.

Durability/Reliability

Honda engines are built with quality that provides proven

durability and reliability. Proven features such as OHV

design and cast iron cylinder sleeve provide long life in all

types of operating conditions. To further enhance the

reliability of these engines, a 2-stage air cleaner system,

digital electronic ignition system, mechanical centrifugal

governor and proven side-draft carburetor are standard

features.

EMISSION REGULATIONS

The Honda GX390 engines meet U.S. Environmental

Protection Agency and the California Air Resources Board

regulations.

Honda engine distributors and equipment manufacturers

that use Honda engines are required by regulation to follow

this OEM technical manual. Correct engine matching

ensures that the engine will be durable (and emission

durable) in use.

2 © 2010 American Honda Motor Co., Inc — All Rights Reserved

Page 5

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

ENGINE SPEED

(rpm)

2000 36003000

(KW)

(HP)

OUTPUT

TORQUE

13

14

15

7

6

5

4

8

9

(PS)

7

6

5

4

8

9

20

NET POWER

NET TORQUE

12

11

1.6

1.7

1.8

1.9

2.0

1.5

18

16

14

3

2

4

5

6

7

(N·m)

(lbf·ft)

(kgf·m)

RECOMMENDED OPERATING SPEED RANGE

ENGINE SPEED

(rpm)

2000 36003000

(KW)

(HP)

OUTPUT

TORQUE

13

14

15

7

6

5

4

8

9

(PS)

7

6

5

4

8

9

20

NET POWER

NET TORQUE

12

11

1.6

1.7

1.8

1.9

2.0

1.5

18

16

14

3

2

4

5

6

7

(N·m)

(lbf·ft)

(kgf·m)

RECOMMENDED OPERATING SPEED RANGE

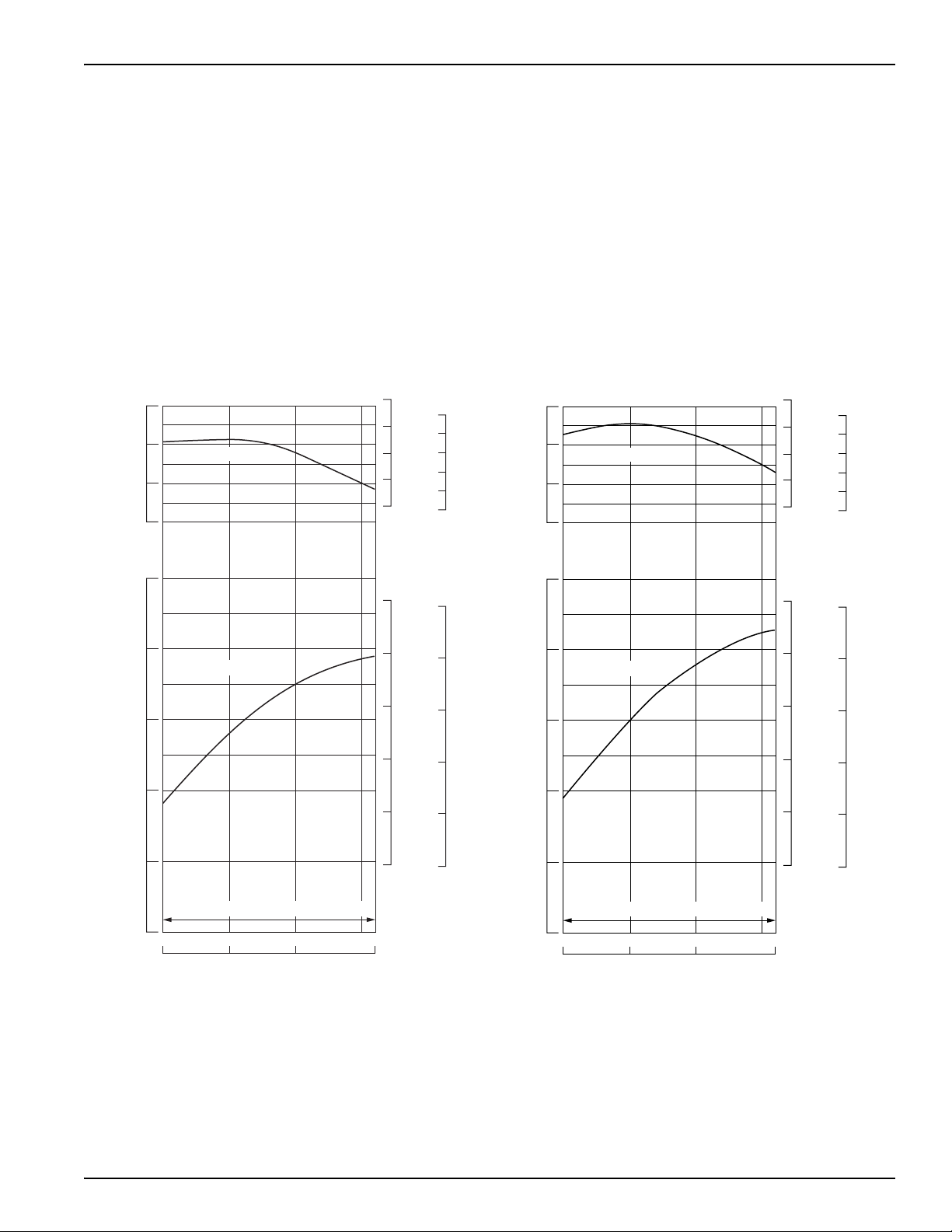

RECOMMENDED POWER RANGE

Maximum Operation

Operate the engine at not more than 90% of the maximum horsepower available at a given rpm.

Recommended maximum operating hp = 0.9 x maximum hp

Continuous Operation

For continuous operation (more than 30 minutes), operate the engine at not more than 80% of the maximum

horsepower available at a given rpm.

Continuous recommended operating hp = 0.8 x maximum hp

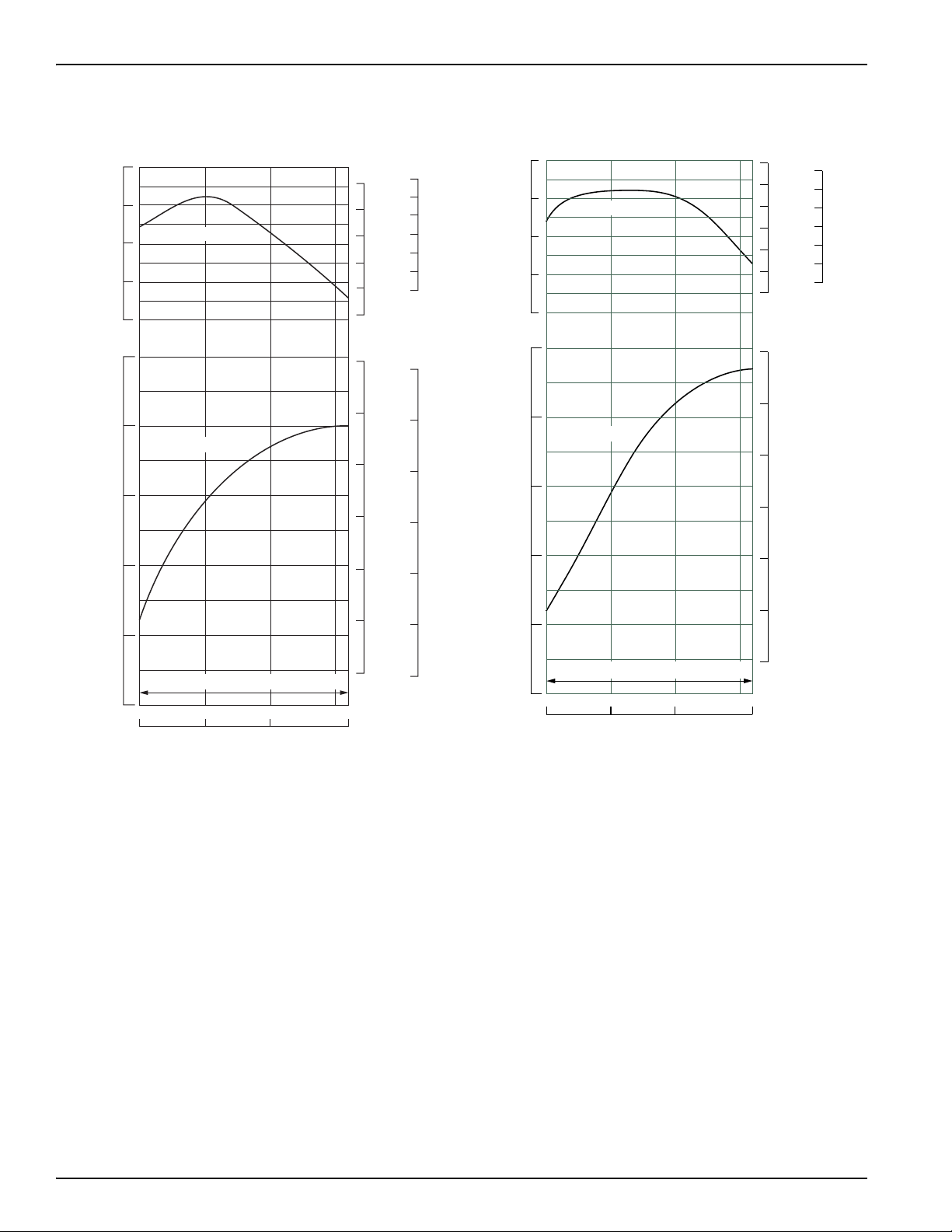

Power Curve

GX240 GX270

© 2010 American Honda Motor Co., Inc — All Rights Reserved 3

Page 6

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

ENGINE SPEED

2000 36003000

RECOMMENDED OPERATING SPEED RANGE

(min-1 [TRO])

(N·m)

28

(KW)

(HP)

(lbf·ft)

(kgf·m)

9

8

7

OUTPUT

TORQUE

6

6

19

2.6

2.7

2.8

20

21

7

8

9

10

11

12

5

4

26

24

NET POWER

NET TORQUE

16

17

18

15

2.3

2.4

2.5

2.2

22

20

GX340 GX390

(N·m)

28

26

24

TORQUE

22

20

(KW)

9

8

7

OUTPUT

6

NET TORQUE

NET POWER

(lbf·ft)

20

19

18

17

16

15

(HP)

12

11

10

9

8

(kgf·m)

2.8

2.7

2.6

2.5

2.4

2.3

2.2

(PS)

12

11

10

9

8

5

RECOMMENDED OPERATING SPEED RANGE

4

2000 36003000

ENGINE SPEED

(rpm)

7

6

7

6

4 © 2010 American Honda Motor Co., Inc — All Rights Reserved

Page 7

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

rpm with load

rpm without load

1-

()

100% ≤ 5%

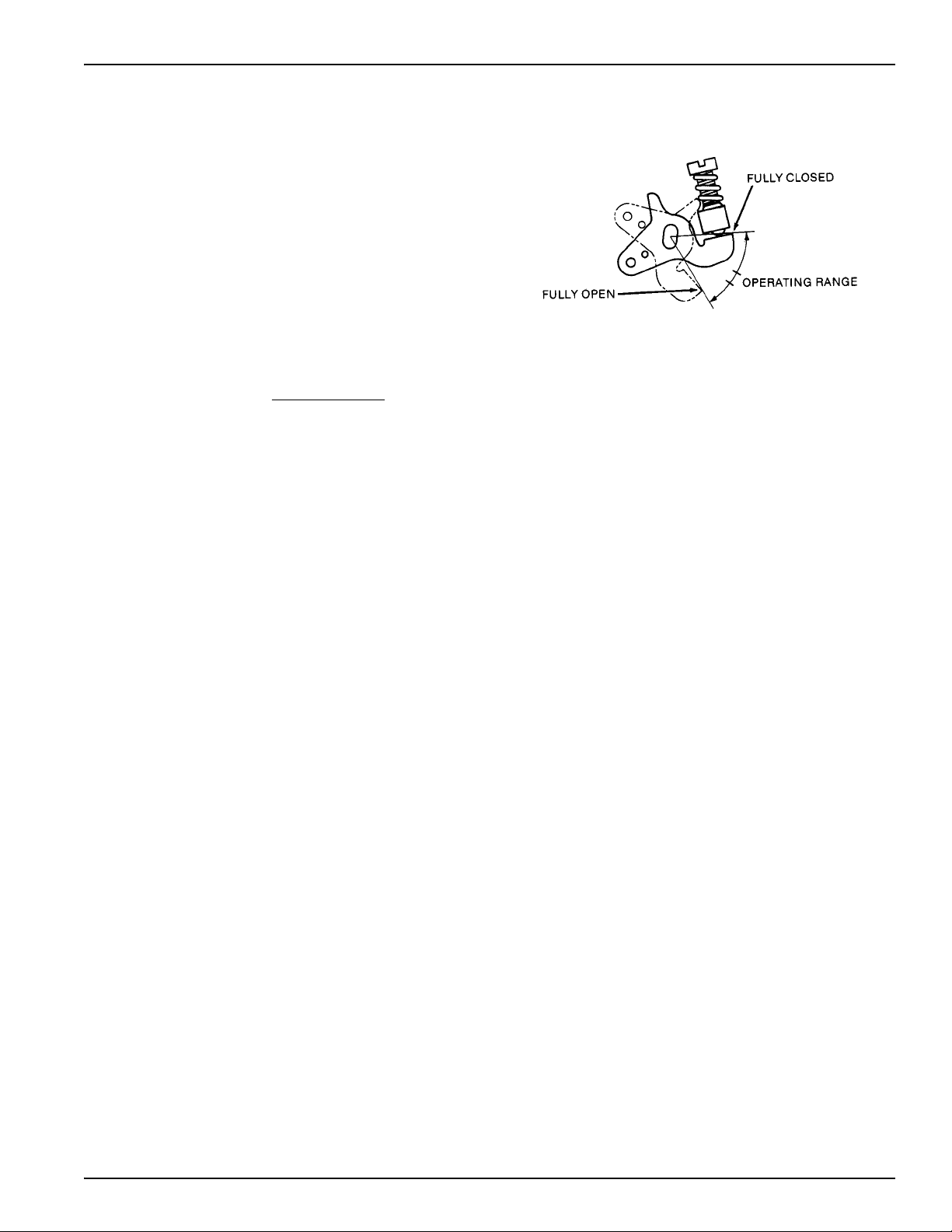

Output Confirmation Methods

Governor Rod Measurement

When the engine is properly matched and operating at

its continuous rated load, the carburetor throttle angle

should be approximately half way between full open

and full closed positions.

Bring the engine to normal operating temperature and

then apply the expected continuous load. If the throttle

is more than halfway open, the engine is being

overloaded resulting in overheating and shortened

engine life.

Tachometer RPM Measurement

Normal governor droop can also be used to measure engine load.

At rated speed:

Engine is operating within the continuous recommended power range.

COOLING

Minimum Cooling Air Flow Requirement

Engine enclosure must have the minimum cooling air flow listed below.

3

GX240/GX270: 7 m

GX340/GX390: 8 m

Ambient Temperature Limits

-15 to +40°C (+5 to +104°F)

Testing

• Use thermocouple temperature probes at the specified locations.

• Operate the engine under worst-case conditions

• An electronic data logger is required for the temperature data collection

• Set up the data logger to take multiple readings per minute. If data is being taken manually, a reading every 5

minutes is adequate.

• Take readings until the engine oil temperature is stabilized at continuous rated load

• Run the application for one hour of continuous operation; the temperatures should be stabilized in that time. If the

application is used only for short intervals, note the normal run time in the application document.

• Shut the engine down and continue to take readings. Attempt to restart the engine after heat soaking for 5 minutes.

• For enclosed applications, fuel bowl temperature should be monitored after testing until the maximum is reached -

this may take several minutes

(247 ft3) per minute at 3,600 rpm

3

(282 ft3) per minute at 3,600 rpm

© 2010 American Honda Motor Co., Inc — All Rights Reserved 5

Page 8

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

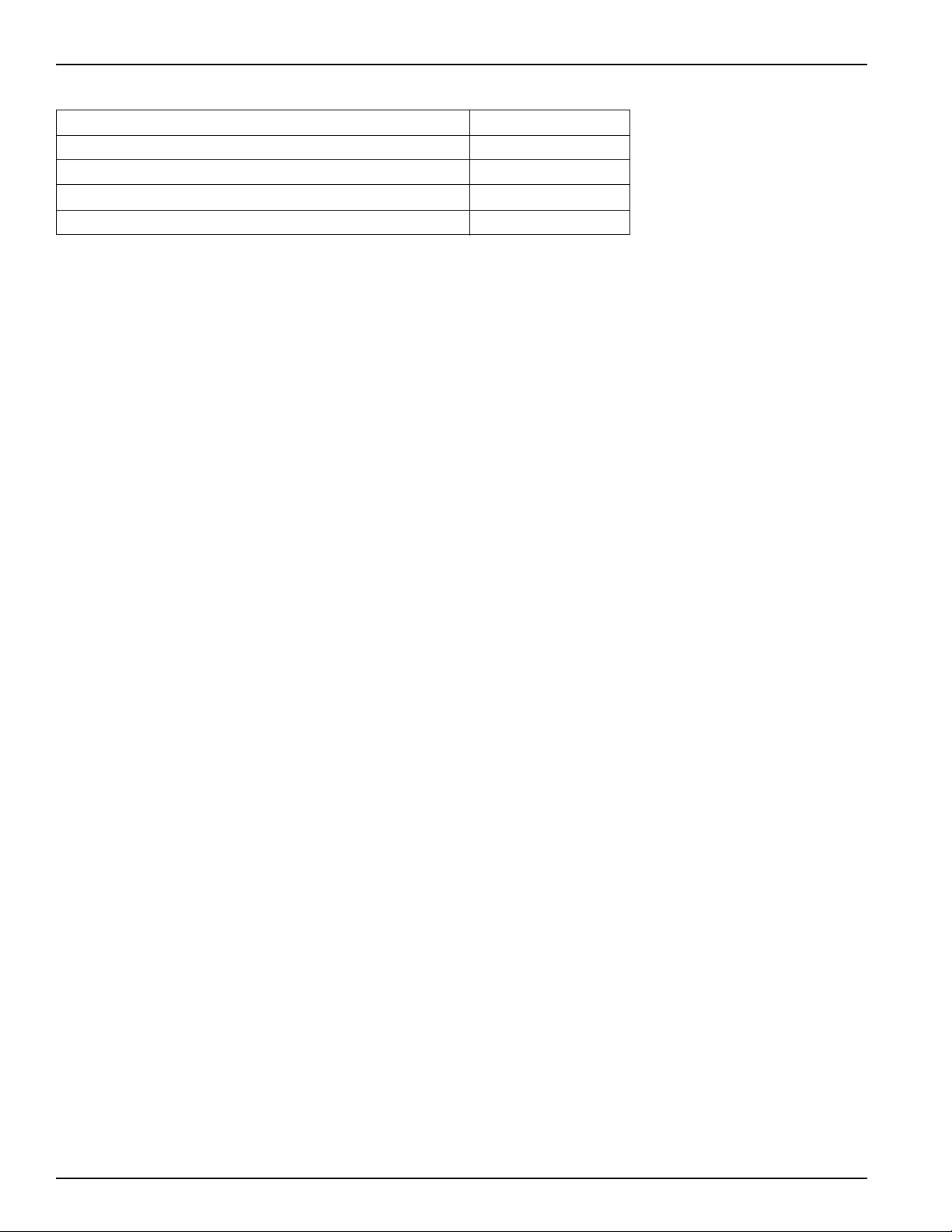

Maximum Operating Temperatures

Spark plug Seat 270 °C (482 °F)

Engine Oil 140 °C (284 °F)

Gasoline at Carburetor Float Bowl 60 °C (140 °F)

Gasoline at Carburetor Float Bowl (after 5 min. hot soak) <70 °C (158 °F)

Gasoline at Fuel Tank 60 °C (140 °F)

These temperatures are based on an ambient temperature of 40°C (104°F). Compensate for any deviation linearly; i.e.,

if the ambient temperature is 20°C (68°F), the maximum acceptable oil temperature is 120°C (248°F).

Adjusted oil temperatures of less than 40°C will require more frequent oil changes.

Engine Enclosures

When the engine installation in the equipment obscures the emission label, a duplicate label must be applied. In this

case, as part of the engine matching process, it will be necessary to establish a process for the OEM to obtain

duplicate labels. EPA requires full documentation, control, and record keeping of the duplicate label process.

Cool Air Intake

The engine must be provided with a cooling duct so that fresh air can be drawn directly from outside the enclosure

cover. Install the cooling air duct with the intake port in a place free from dust and dirt. The cooling air volume changes

according to the shape of the duct and screen and the engine installation conditions. Operate the engine under the

normal operating conditions and be sure that the engine meets all temperature requirements.

The cooling air duct must have a cross-sectional area of at least 300 cm

When the engine is operated in dusty areas, install a filter at the enclosure inlet for the cooling air. This will reduce the

effective area, so you must increase the size of the inlet accordingly. Increase the size of the inlet to the point where

the maximum operating temperatures are not exceeded when operated under maximum load.

Install the cooling air duct and filter so that the filter can be easily checked, and dust, dirt and foreign material removed.

2

(46.5 sq in).

Hot Air Discharge

Hot air must be discharged directly outside the enclosure. Provide a discharge duct if necessary. The minimum cross

section of the hot air discharge opening must be larger than that of the cooling air inlet.

Locate the discharge port so the hot discharge air does not flow back into the enclosure. Provide sufficient ventilation to

prevent the engine compartment temperature from rising above ambient temperature limits after the engine has been

stopped.

Exhaust Discharge

The exhaust system becomes hot during operation and remains hot for a while after operation. Separate the exhaust

system from the engine compartment with a partition wall and locate the exhaust system in the discharged cooling air

flow.

Be sure the exhaust gas is directly discharged outside the enclosure without being blocked or restricted by any

obstacles. The exhaust gas must not flow back or be drawn back into the enclosure.

Provide the engine with an exhaust deflector or exhaust pipe extension if necessary.

If an extension pipe is used:

• Keep the length of the pipe as short as possible to keep exhaust backpressure within limits (see page 10).

• The extension pipe must have an ID larger than the OD of the muffler outlet.

• Verify the exhaust pipe extension does not create excessive vibration at any given engine rpm. If necessary, use

an exhaust pipe holder to support the exhaust pipe extension.

Grass Cutting Applications

When the engine is operated on grass cutting equipment, install a rotary screen grid on the cooling air intake port to

prevent the accumulation of large clippings.

Do not allow the grass clippings shredded by the rotary screen grid to accumulate around the intake port.

6 © 2010 American Honda Motor Co., Inc — All Rights Reserved

Page 9

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

FUEL SYSTEM

If the engine is supplied with an incomplete fuel system (no fuel tank, no fuel hose, etc.), the OEM is responsible for

ensuring evaporative emission requirements/regulations are met, including certification.

Fuel Tank Position

If a remote fuel tank is used, it must be installed so that its maximum gasoline level is within 50 cm (19.5 in) above the

carburetor gasoline level. If a fuel pump is used, the maximum fuel level should be within 50 cm (19.5 in) above or

below the carburetor gasoline level.

Fuel Line

Use a low permeation fuel line (displaying an Executive Order number) rated for use with gasoline. The fuel line should

have an inside dimension of 5.5 mm (0.22 in). Keep the fuel line as short as possible. Install the fuel line so it will not

rest against any sharp objects or make sharp bends that can restrict the flow of fuel. If the fuel line passes through an

enclosure wall, protect the line with a rubber grommet. Route the fuel line away from hot engine and exhaust system

components and away from electrical wiring. Secure the fuel line to prevent sagging and bending.

Fuel Valve Installation

If a remote fuel tank is used, a fuel valve should be installed so it is easily accessible. Install the fuel valve at the outlet

of the fuel tank and use an easily read label to indicate valve location and operation. If under the fuel tank is not the

ideal location, securely install the fuel valve in-line with the fuel tube in a cool location, so that engine heat cannot

cause vapor lock.

Fuel Pump

A fuel pump should be selected that provides a maximum operating pressure of 0.1 kgf/cm2 (1.4 psi) and delivers 15

liters/hr (4.0 US gal/hr). If a secondary fuel pump is used, to prevent carburetor flooding, its operating pressure must

not exceed the standard fuel pump’s operating pressure.

Fuel Tank Filter Installation

It is recommended that a fuel tank strainer with a mesh rating of #80 be installed at the fuel tank inlet to catch debris

when refueling. It is also recommended that a fuel tank sump be provided at the fuel tank outlet to reduce the chance of

contaminants entering the fuel system.

CONTROLS

Engine Switch

Use a three-position engine switch with continuity between its terminals as shown.

Wire Color

Switch Position

OFF

ON {{

START {{{{

EXT+

(Red)

EXT –

(Black)

ST

(Black/White)

BAT

(White)

© 2010 American Honda Motor Co., Inc — All Rights Reserved 7

Page 10

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

Flexible wire core

mounting

Solid wire core

mounting

WIRE

5mm

CIRCLIP

4 mm SCREW

WIRE HOLDER

THROTTLE

LEVER

OPTIONAL

THROTTLE LEVER

FRICTION NUT

WIRE HOLDER

4 mm SCREW

WIRE

5 mm CIRCLIP

SPRING

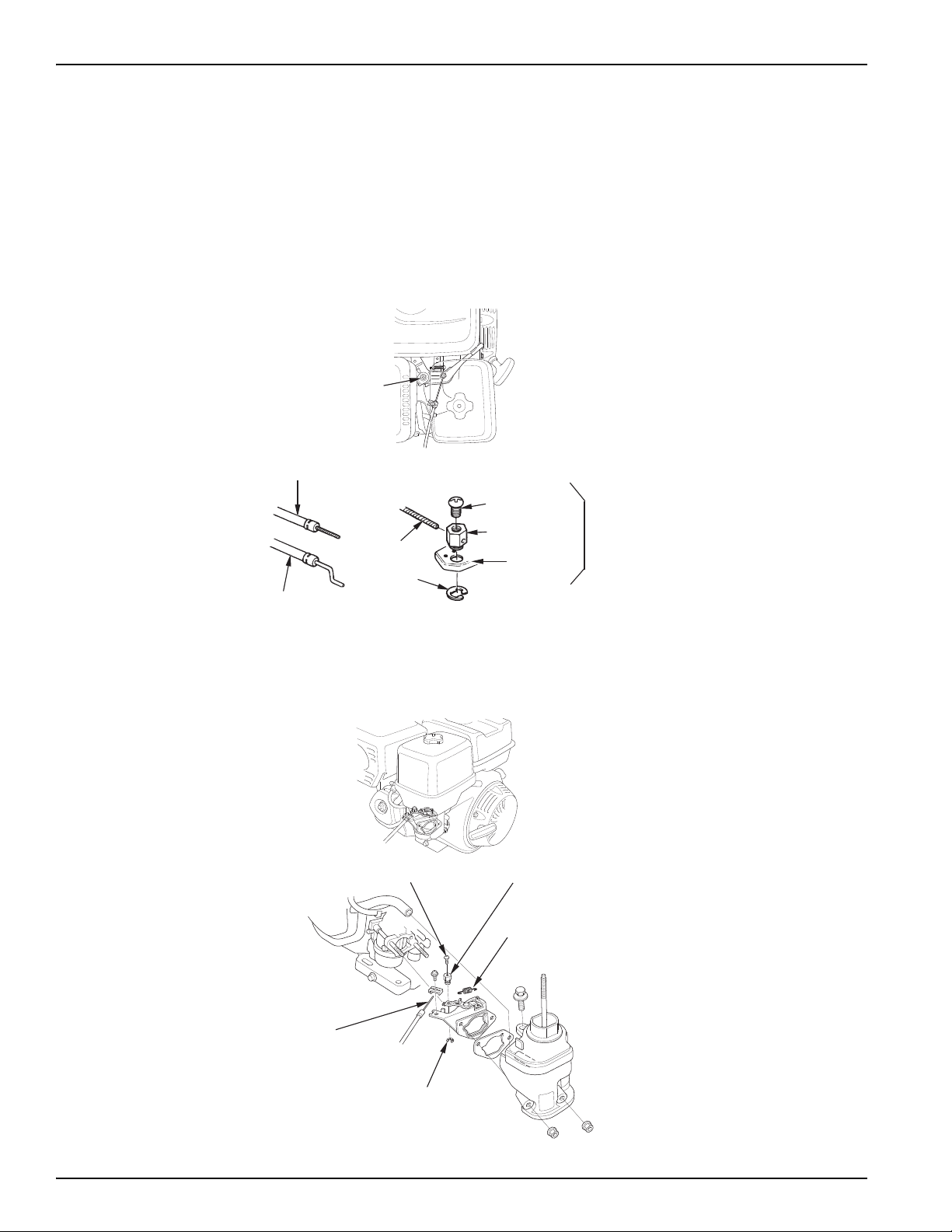

Carburetor Controls

Types of cable:

Two types can be used, flexible wire core or solid wire.

Installation:

The throttle and choke control levers are provided with holes for optional cable attachment. The following illustrations

show installation examples for a solid wire cable and for a flexible, braided wire cable. If using a flexible, braided wire

cable, add a return spring as shown. It is necessary to loosen the throttle lever friction nut when operating the throttle

with a remote-mounted control.

Remote Control Throttle

Remote Control Choke.

8 © 2010 American Honda Motor Co., Inc — All Rights Reserved

Page 11

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

EXHAUST SYSTEM

Recommended Muffler

The recommended muffler and exhaust pipe are matched to the engine in terms of emissions performance, exhaust

backpressure, sound level, and durability.

Consider the following:

• Discharge the exhaust gas directly to the open air. Do not install flammable parts or any parts with poor heat

resistance properties around the exhaust system or near the discharge port.

• The exhaust gas must not enter the cooling-air intake port. Be especially careful when using the exhaust deflector

to change the discharge direction.

• The muffler and exhaust pipe become very hot during operation and remain hot after the engine has been shut off.

Install the muffler and exhaust pipe so the fuel system and other heat-sensitive components are isolated from the

exhaust heat.

Fabricated Exhaust Systems

The muffler type and the shape and length of the exhaust pipe(s) affect emissions performance and engine power. If

you use a muffler other than a recommended Honda muffler, observe the following precautions to maintain the

engine’s peak performance:

• The shape (bends and elbows) of the exhaust pipe can affect exhaust backpressure. If exhaust backpressure is

excessive, it can affect emissions performance and/or cause detonation.

• The exhaust pipe inside diameter must be the same size as the exhaust port diameter.There must be no gap

between the port inside diameter and the exhaust pipe ID.

• The exhaust backpressure increases if the diameter is less than specified. If the diameter is larger than specified,

the effective width of the exhaust gasket is reduced which could cause an exhaust leak.

• When the exhaust pipes are connected together before the muffler, make sure that the exhaust pipe length is as

short as possible to reduce backpressure.

• Muffler volume and design will affect exhaust backpressure. Increase the volume of the muffler if exhaust

backpressure is higher than specified.

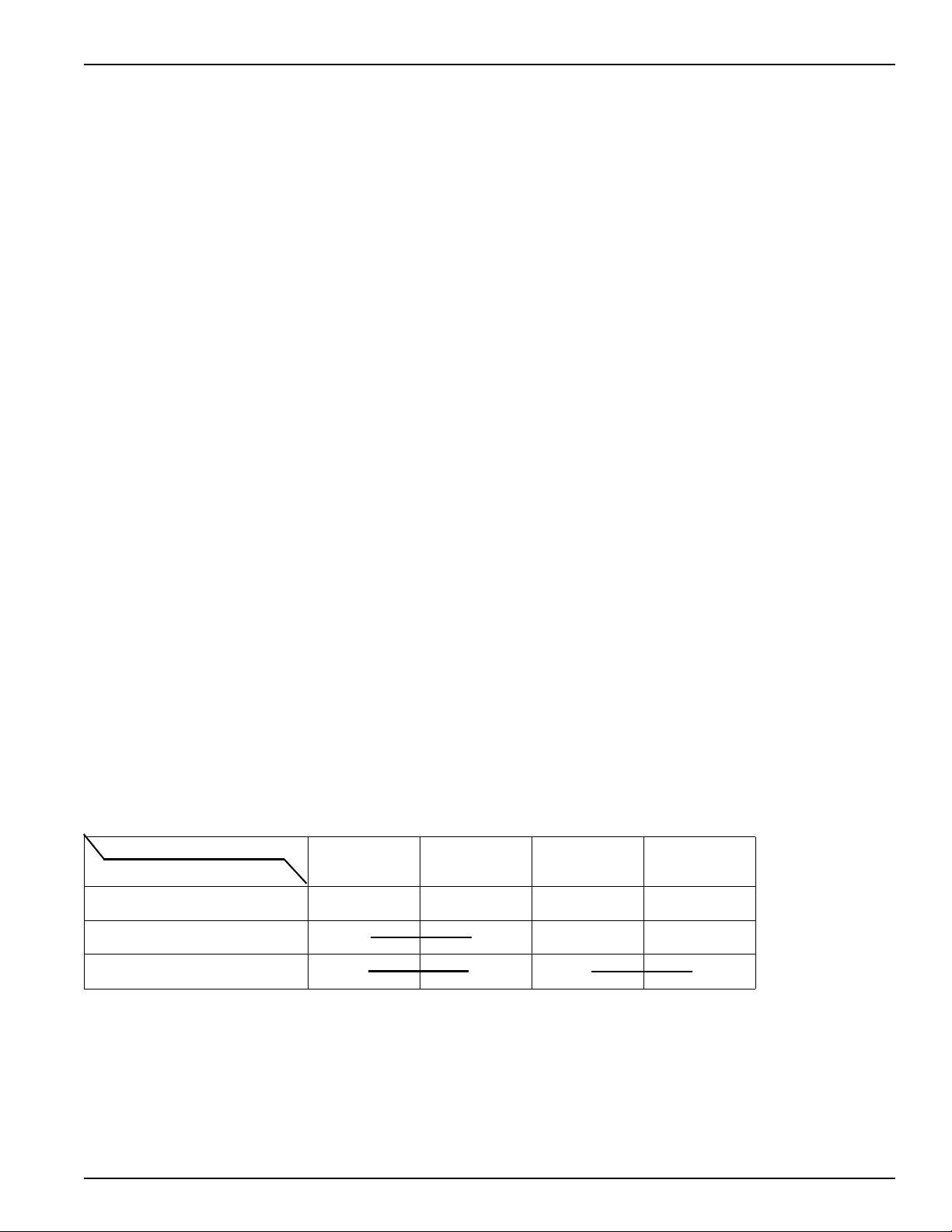

Exhaust Back Pressure Measurement

Measure the exhaust back pressure at the exhaust pipe with the engine under

continuous load (WOT), 30 mm (1.2 in) from the exhaust pipe mounting flange

as shown (make sure the test nipple does not extend beyond the inner wall of

the exhaust pipe).

3000 rpm 3600 rpm

Min. Max Min. Max

GX240

GX270

kPa 4.2 9.0 4.9 11.0

mmH

O 428 918 500 1122

2

GX340

GX390

© 2010 American Honda Motor Co., Inc — All Rights Reserved 9

kPa 4.6 10.5 6 12.5

mmH

O 469 1071 612 1275

2

Page 12

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

Rigid Engine Mount Muffler Installation.

The frame must be rigid to prevent cracking when the exhaust pipe and muffler are connected. The muffler should be

installed securely with bolts and nuts.

The muffler should be supported at two points (or more) using special rubber mounts designed for muffler support

applications.

Check to see muffler vibration does not increase at any given engine speed, causing an abnormal increase in

resonance.

Rubber Engine Mount Muffler Installation

A flexible pipe should be used between the muffler and exhaust pipe when the engine is mounted to the engine bed

with rubber mounts. The flexible pipe ID must be the same as the exhaust pipe OD or larger.

The muffler should be supported at two points (or more) and should be installed securely with bolts and nuts to prevent

muffler cracking from vibration during starting and stopping.

Check to see muffler vibration does not increase at any given engine speed, causing an abnormal increase in

resonance.

ENGINE MOUNTING

Use an engine bed or frame with enough rigidity to allow maximum durability

of the engine and attachment installation.

The engine must not wobble on the engine bed. Use an engine bed or frame

that provides a flat surface for the engine to be mounted on. If there is a gap

between the engine and the engine bed, the engine-mounting surface may

be damaged.

Inclination

Horizontal mounting and operation of the engine is recommended. If the

engine must be operated on a slope, the incline position of the engine must

not exceed 20° in any direction.

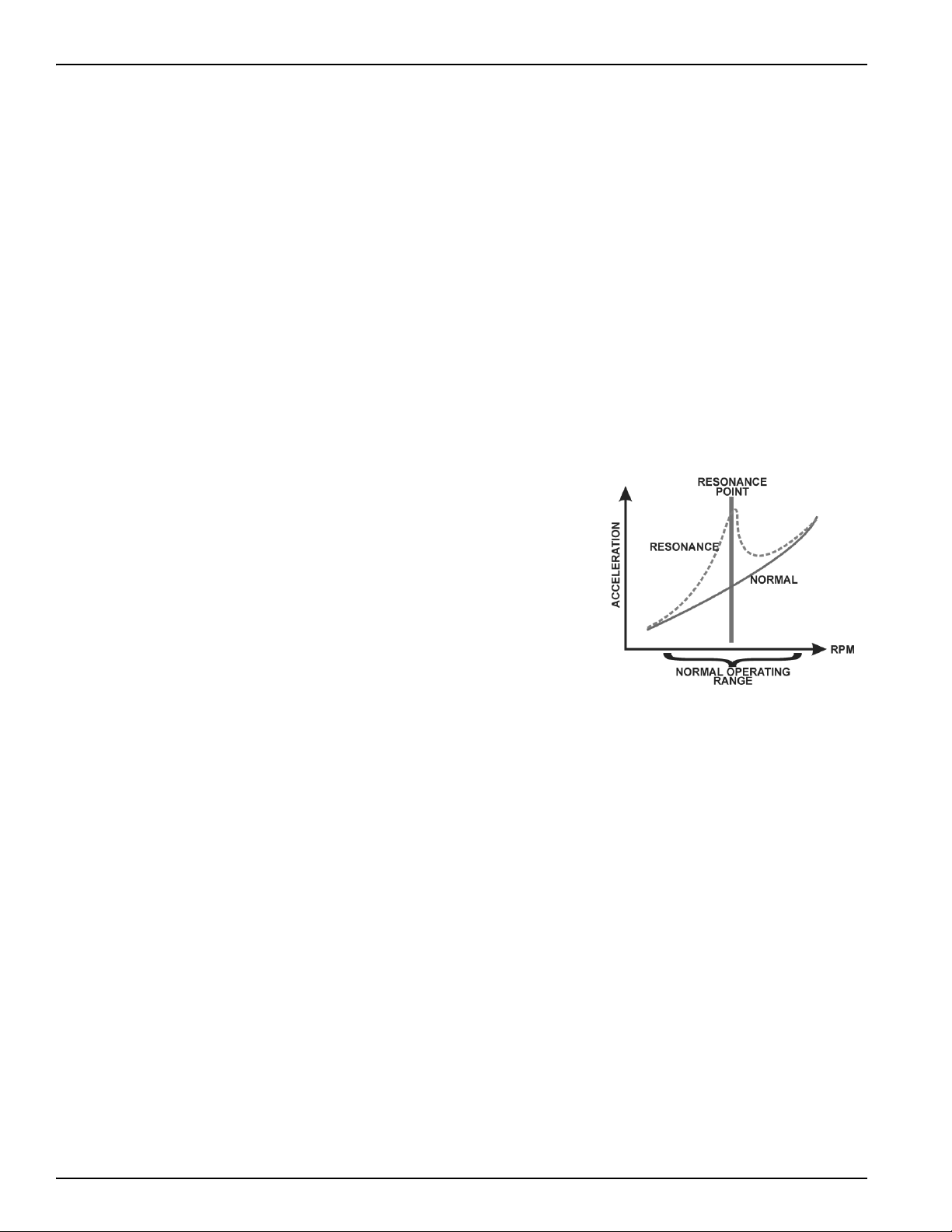

Resonance Check

There must be no resonance when the engine and attachment are operated within the designated speed range. Slowly

raise the engine speed from idle to maximum and check for resonance at any engine speed.

General Methods for Preventing Resonance

When engine accessories or a part of the attachment is resonating, increase the rigidity of the resonating part to bring

the resonance point higher than the working engine speed range.

• Increase the rigidity of the engine bed and frame to bring the resonance point higher than the working engine

speed range.

• Install the muffler on the engine body, using a rigid stay to prevent resonance of the muffler when the engine speed

is within the specific operating speed range.

10 © 2010 American Honda Motor Co., Inc — All Rights Reserved

Page 13

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

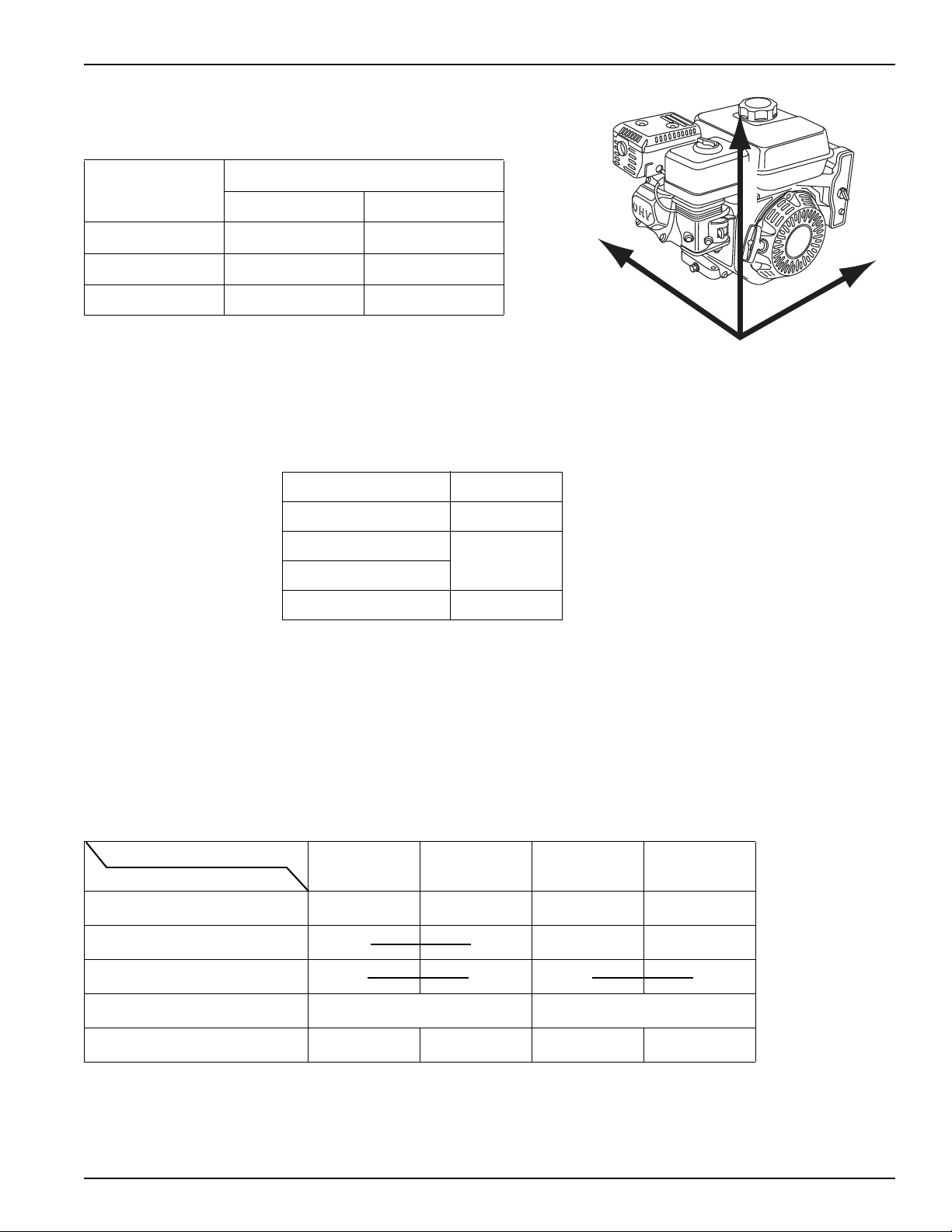

HORIZONTAL

VERTICAL

LATERAL

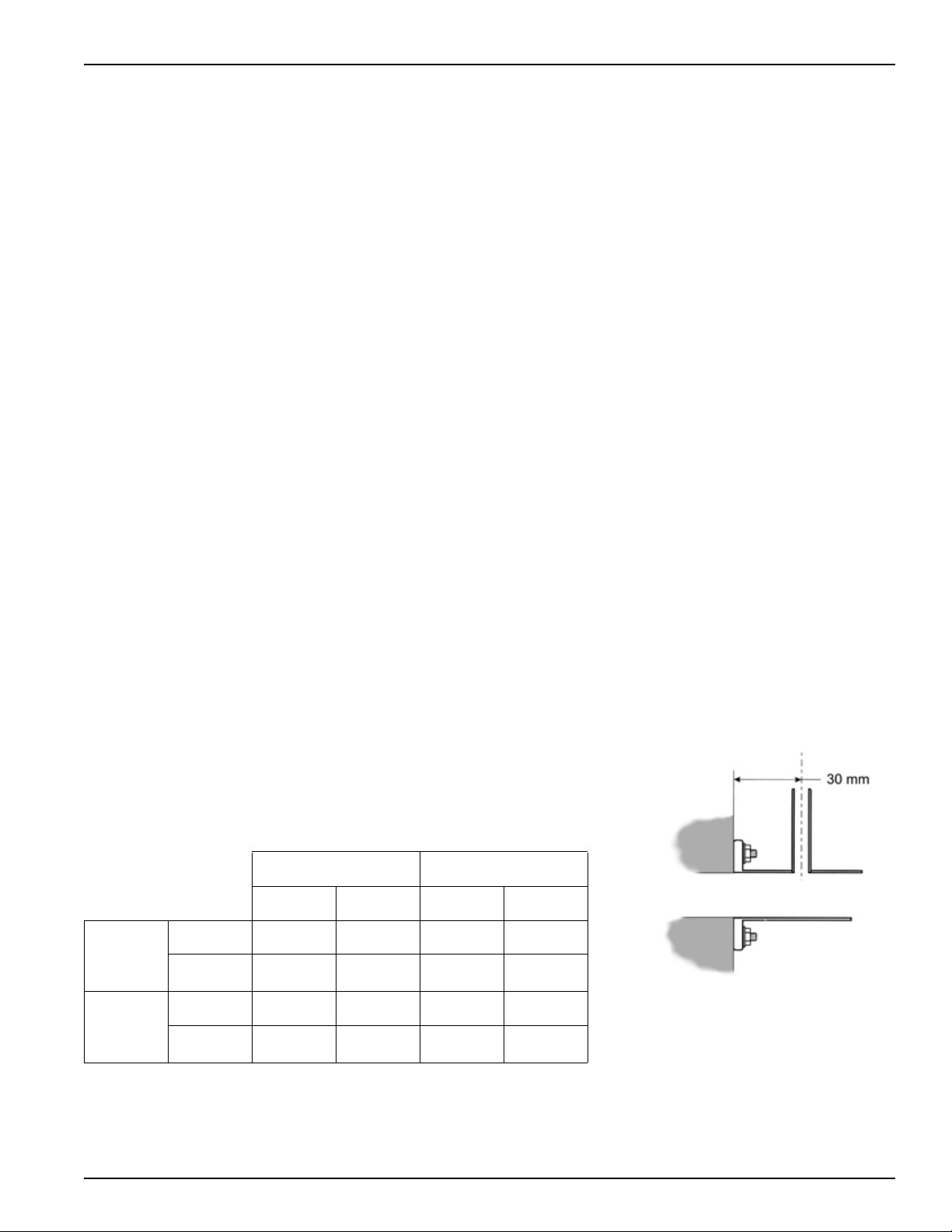

Engine Acceleration/Vibration

Using a vibration meter, measure the vibration amplitude at the base

on three axis (vertical, lateral and horizontal).

Direction Allowable G value

(Peak) (RMS)

Vertical 10 (98 m/s

Horizontal 5.9 (58 m/s

Lateral 6.9 (68 m/s

2

)6.9 (68 m/s

2

)4.2 (41 m/s

2

)4.9 (48 m/s

2

)

2

)

2

)

ELECTRICAL SYSTEM

Battery

Use a 12 V battery with a minimum capacity of 24AH.

Fuse

Recommended fuse size:

Charging system (A) Fuse (A)

1.0 5

3.0

10.0

18.0 25

15

Battery Cables

Select battery cables to avoid greater than 0.5 volt drop in the cable during starter motor operation.

Battery cable size and length: (Gauge x Length)

Positive cable: AWG No. 4 x 1.5 m (5.0 ft) maximum

Negative cable: AWG No. 4 x 2.3 m (7.5 ft) maximum

Engine Switch

Electric start

Use a three-position engine switch with continuity between its terminals as shown.

Wire Color

Switch Position

OFF

ON {{

EXT+

(Red)

EXT –

(Black)

ST

(Black/White)

BAT

(White)

START {{{{

Vdc/A (rated) AC300V, 220mA (PEAK) 12/15A

Dia. (recommended) AV0.5 AV0.5 AV2.0* AV0.75

* In combination with 1A/3A/10A charge coil, AV1.25 is acceptable.

AV0.5 = Automotive Vinyl, 0.5 mm

2

cross-sectional area

Do not run the starter motor for more than 5 seconds at a time. Always allow resting for 10 seconds before each

starting attempt.

© 2010 American Honda Motor Co., Inc — All Rights Reserved 11

Page 14

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

Manual start

Use a two-position engine switch with continuity between its terminals as shown.

Wire Color

Switch Position

OFF

ON {{

EXT+

(Red)

EXT –

(Black)

Charging Coil Selection

Four types of coils are available:

Coil Output (A) Regulated RPM

1A 0.9 No

3A 2.7 No

10A 9.5 Yes

18A 17.0 Yes

The 1A and 3A coils are only suitable for recharging a starting battery. Use the 10A or 18A coils when powering

accessories.

3,600

Lamp Coil Kit (optional)

Three types of lamp coils are available: 6v –25w, 12v –15w, 12v –25w. Two coils can be installed in parallel to provide

12V-50W, if no charging coils are applied. Use parallel connector (No. 32105-ZE1-000) to connect two coils in parallel.

A single coil (12v-25w) can be used in combination with the 3A charge coil as required.

Oil Alert® System (optional)

The Oil Alert System uses a float type switch located inside the crankcase. When the engine oil level falls below a safe

operating level, the float falls and the circuit is completed through the control box, grounding the primary side of the

ignition coil. The Oil Alert System is only recommended for use on equipment that is stationary while operating.

Wiring Precautions

• Connect the battery positive (+) cable to the positive terminal of the starter solenoid.

• Connect the battery negative (–) cable to the engine crankcase or engine frame mounting bolt.

• Do not route the battery cables on or near any hot, moving, or rotating parts, or sharp edges. Keep the battery

cables and electrical wires away from the fuel line.

• Protect positive electrical connections with a cover or insulation.

12 © 2010 American Honda Motor Co., Inc — All Rights Reserved

Page 15

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

LED

OIL_ALT

EXT ( - )

EXT ( + )

R

Bl

R

Bl

Y

Y

C2

C1

1

4 3 1 2

C3

IGNITION

COIL

SPARK

PLUG

OIL LEVEL

SWITCH

ENGINE STOP

SWITCH

Bl Black

Y Yellow

Bu Blue

G Green

R Red

W White

Br Brown

O Orange

Lb Light blue

Lg Light green

P Pink

Gr Gray

TWO COLORED WIRE (EXAMPLE:YELLOW/RED)

EXT ( + ) EXT ( - )

OFF

ON

ENGINE STOP SWITCH

LED

OIL_ALT

EXT ( - )

EXT ( + )

ST

EXT ( + )

EXT ( - )

BAT

( Bl/W )

( W )

R

Gr

Gr

Gr

Gr

W

W

Bl

Gr

Gr

Gr

Gr

Bl/Y

W

Bl

W/Bu

Bl

Y

Y

Bl/W

( Bl )

R

Bl

W

W W

(W)

R

Bl

(W)

R

Bl

Bl

3

C10

C2

C1

C9

C8

T2

T3

1

4312

C3

C11

C4T1

T4

CONTROL BOX

COMBINATION

SWITCH

STARTER MOTORBATTERY

CHARGE

COIL

REGULATOR/

RECTIFIER

IGNITION

COIL

SPARK

PLUG

OIL LEVEL

SWITCH

Bl Black

Y Yellow

Bu Blue

G Green

RRed

W White

Br Brown

O Orange

Lb Light blue

Lg Light green

P Pink

Gr Gray

TWO COLORED WIRE (EXAMPLE:YELLOW/RED)

EXT ( + ) EXT ( - ) ST BAT

OFF

ON

START

461235

COMBINATION

SWITCH

MAIN FUSE

CHARGE

COIL

FLYWHEEL

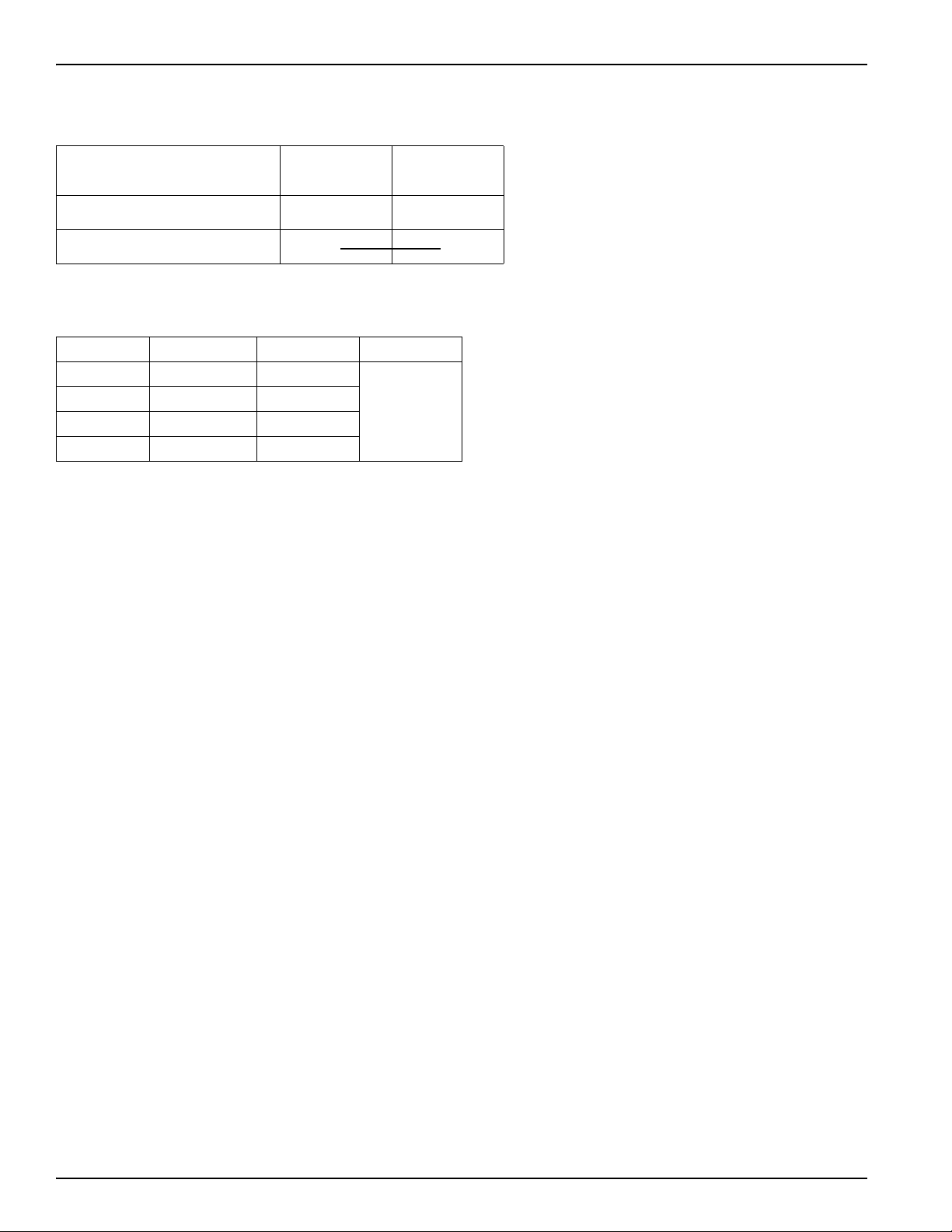

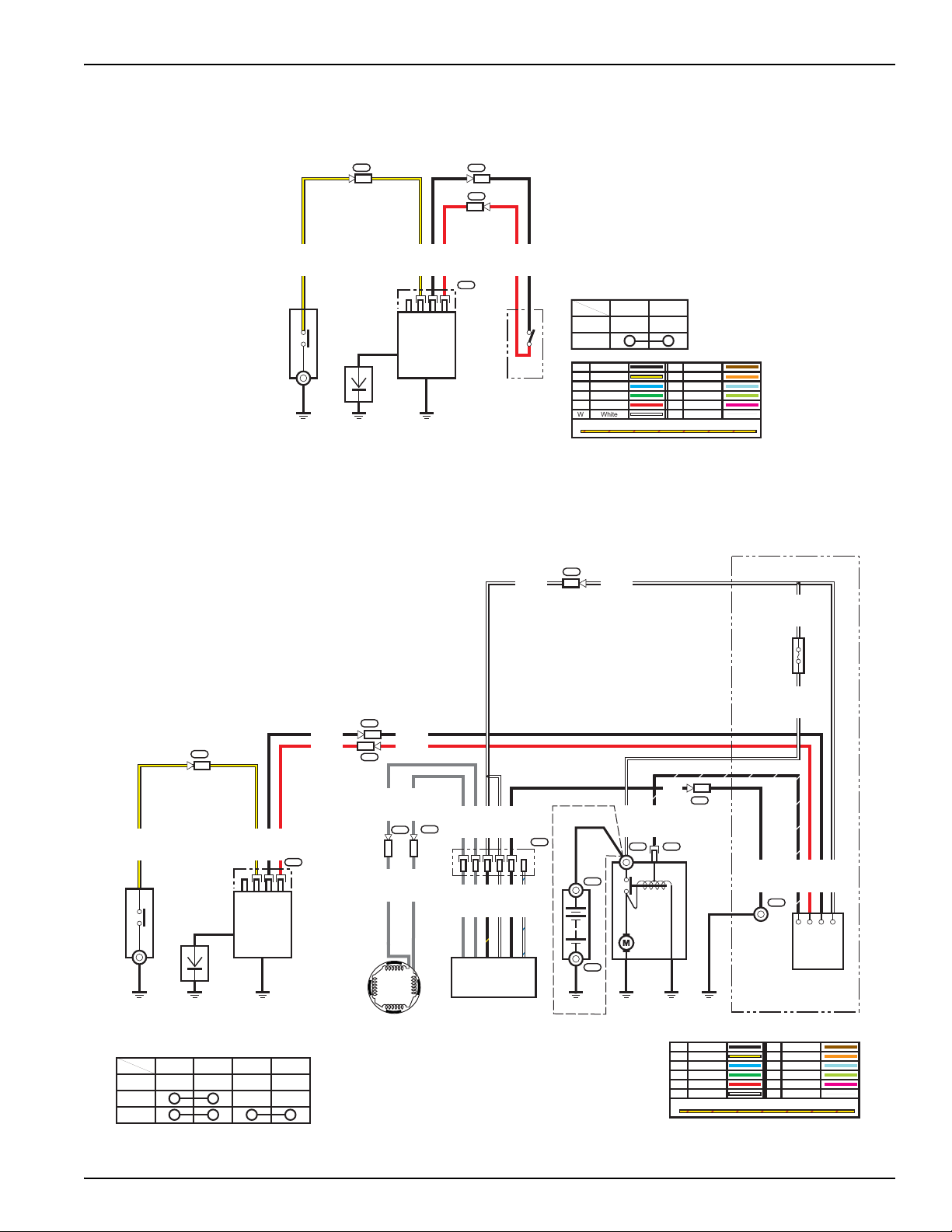

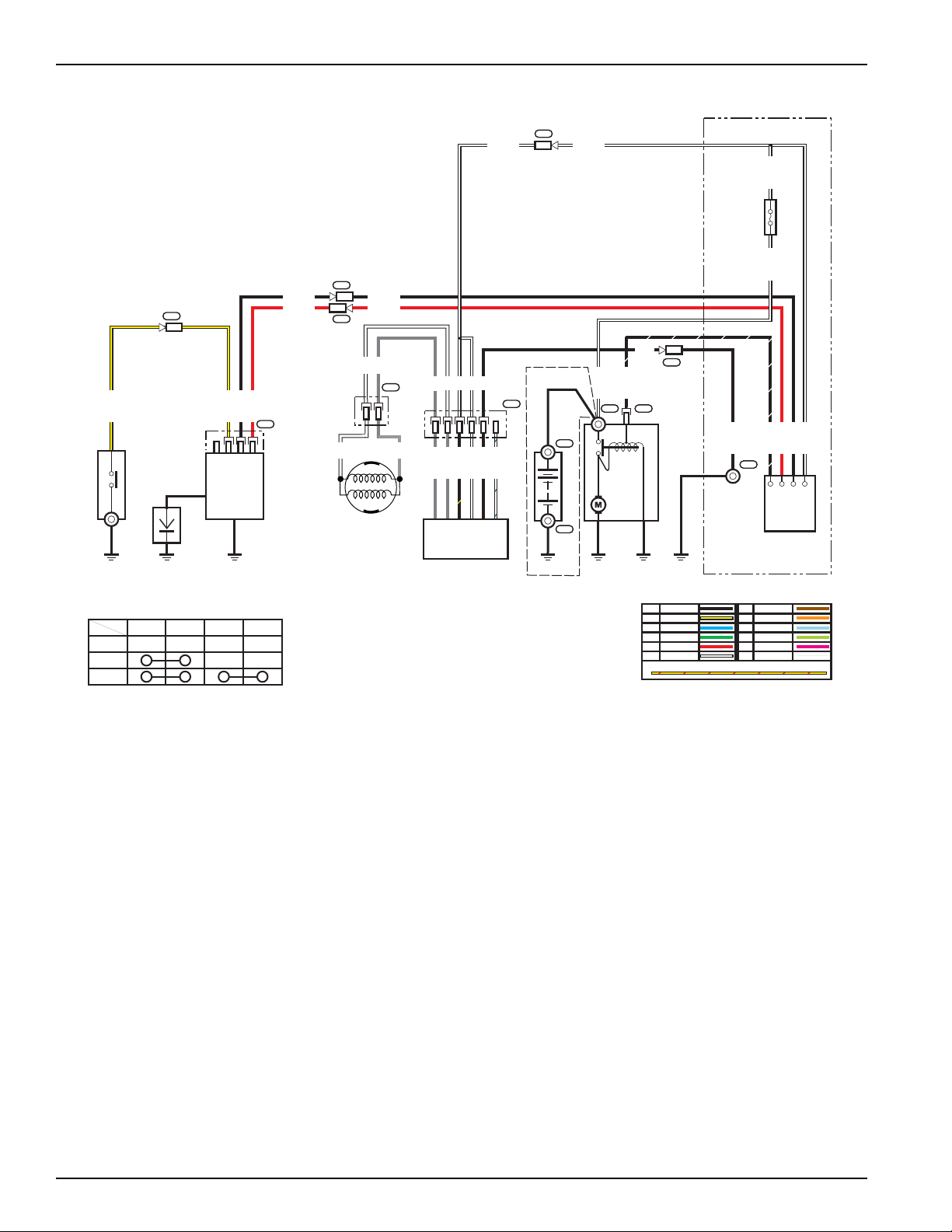

WIRING DIAGRAMS

No Charge Coil Models

Electric Start Models

18A Charging System

© 2010 American Honda Motor Co., Inc — All Rights Reserved 13

Page 16

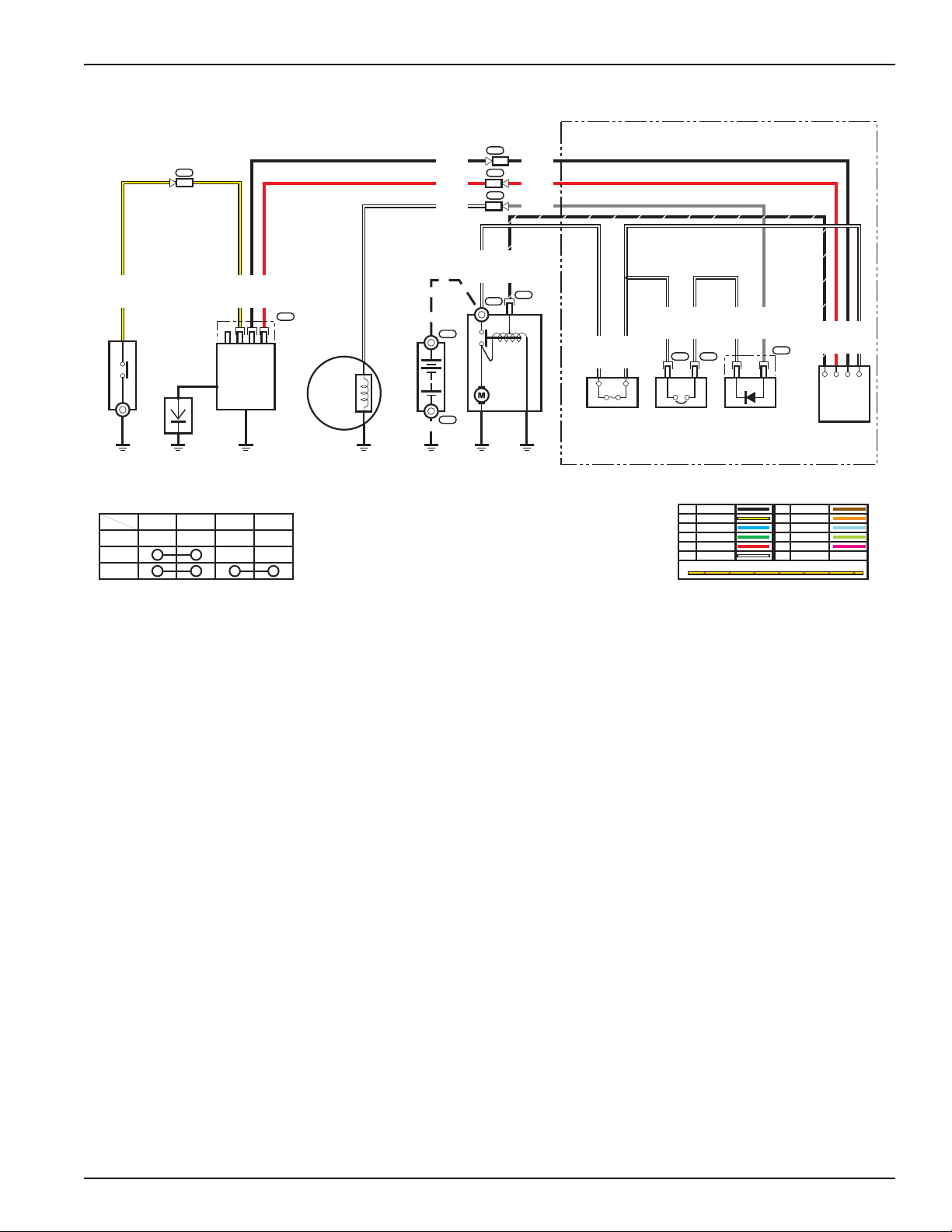

10A Charging System

LED

OIL_ALT

EXT ( - )

EXT ( + )

ST

EXT ( + )

EXT ( - )

BAT

( Bl/W )

( W )

R

W

WGrW

Bl

Gr

Gr

Bl/Y

W

Bl

W/Bu

Bl

Y

Y

Bl/W

( Bl )

R

Bl

W

W W

(W)

R

Bl

(W)

R

Bl

Bl

3

C10

C2

C1

T2

T3

1

4312

C3

C11

C4T1

T4

CONTROL BOX

COMBINATION

SWITCH

STARTER MOTORBATTERY

REGULATOR/

RECTIFIER

IGNITION

COIL

SPARK

PLUG

OIL LEVEL

SWITCH

Bl Black

Y Yellow

Bu Blue

G Green

RRed

W White

Br Brown

O Orange

Lb Light blue

Lg Light green

P Pink

Gr Gray

TWO COLORED WIRE (EXAMPLE:YELLOW/RED)

EXT ( + ) EXT ( - ) ST BAT

OFF

ON

START

461235

COMBINATION

SWITCH

MAIN FUSE

4

12

Gr

W

Gr

W

CHARGE COIL

FLYWHEEL

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

14 © 2010 American Honda Motor Co., Inc — All Rights Reserved

Page 17

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

LED

OIL_ALT

EXT ( - )

EXT ( + )

ST

EXT ( + )

EXT ( - )

BAT

( Bl/W )

( W )

R

Bl

Y

( Y )

( W )

( W )

( W )

( W )

( W )

( Gr )

( Bl/W )

( R )

( Bl )

( W )

W

( R )

( Bl )

Gr

( R )

( Bl )

C6

C4

C5

C2

C1

T1

T2

T3

1

4 3 1 2

2 1

C3

C7

2

CONTROL BOX

COMBINATION

SWITCH

SILICON

RECTIFIER

CIRCUIT

PROTECTOR

MAIN FUSE

STARTER MOTOR BATTERY CHARGE

COIL

IGNITION

COIL

SPARK

PLUG

OIL LEVEL

SWITCH

Bl Black

Y Yellow

Bu Blue

G Green

R Red

W White

Br Brown

O Orange

Lb Light blue

Lg Light green

P Pink

Gr Gray

TWO COLORED WIRE (EXAMPLE:YELLOW/RED)

EXT ( + ) EXT ( - ) ST BAT

OFF

ON

START

COMBINATION

SWITCH

1A/3A Charging System

© 2010 American Honda Motor Co., Inc — All Rights Reserved 15

Page 18

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

Axial

Load =0

CRANKSHAFT

0 mm

MAXIMUM OVERHANG

PULLEY

0 40 60 80 100 120

1000

2000

3000

4000

5000

6000

(N)

DOWNWARD PULL RANGE

1200

1000

800

600

400

200

0

(lbf)

DOWNWARD PULL RANGE ONLY

ENGINE PTO

Distance from engine side cover

to center line of drive pulley

(mm)

STATIC RADIAL LOAD

Keep static radial load below the

pull limit indicated in the chart on the left.

POWER TRANSMISSION

V-Belt Connections

Be sure there is no static axial load applied

to the crankshaft.

Install the pulley as close to the base of

the PTO shaft as possible. When installing

the pulley at the end of the PTO shaft, be

sure there is no overhang.

Before securing the engine and attachment to the engine bed, verify that the V-groove of the engine pulley and

attachment pulley are aligned and that the engine PTO shaft and attachment driven shaft are parallel.

When high load, high inertia exists, we recommend using a tapered shaft pulley for added security.

The frame or engine bed must be rigid enough to prevent belt resonance in the working speed range of the engine.

Size the pulleys so they do not cause resonance of the belt(s).

16 © 2010 American Honda Motor Co., Inc — All Rights Reserved

Page 19

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

To reduce resonance, install a stay between the engine and attachment as shown below.

Starting Performance

The engine must be able to start with the attachment at the lowest recommended ambient temperature.

If the starting load of the attachment is too large when operating the starter motor, provide a clutch so you can separate

the load from the engine when operating the starter.

Due to changes in oil viscosity, there will be an increased drag in attachments such as hydraulic pumps or gear cases

as temperature drops. Start the engine with the ambient temperature at the lowest temperature recommended for

operating the attachment. Verify that the attachment, as well as the engine, can start and operate normally.

Select the proper oil viscosity for the attachment according to the attachment’s working temperature.

Minimum engine cranking voltage 10.2 Vdc

Minimum engine cranking rpm 474 rpm

Maximum engine cranking amperage 50 A

© 2010 American Honda Motor Co., Inc — All Rights Reserved 17

Page 20

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

RECOIL STARTER

ENGINE CONTROL TYPES

AIR CLEANER

MUFFLER

EXCEPT ELECTRIC

STARTER TYPES

ENGINE SWITCH

ENGINE SWITCH

CHOKE LEVER

PURGE

PORT

FUEL

VALVE LEVER

ENGINE SWITCH

ELECTRIC STARTER TYPES

STARTER GRIP

CHOKE ROD

(applicable types)

ENGINE OIL DRAIN

VALVE COVER

SPARK PLUG

SPARK ARRESTER

INSTALLATION CONSIDERATIONS

Maintenance Points Accessibility

When the engine is installed in an enclosure, provide an access panel or use an engine enclosure that can be opened

and closed easily. See also Serviceability page 40.

The emission control information label on the engine must be visible when the engine is installed in the equipment. If it

is not visible by removing a panel, lifting a hood, or other means not using tools, you must attach a supplemental

(duplicate) label. See 40 CFR part 90.114 (http://ecfr.gpoaccess.gov/cgi/t/text/textidx?c=ecfr&rgn=div5&view=text&node=40:20.0.1.1.4&idno=40#40:20.0.1.1.4.2.1.14). Contact your Engine Distributor

for supplemental labels.

Left Side

Recoil

Air cleaner cover

Engine oil drain

(Crankcases tapped for

NPT drain extensions are

available.)

Spark plug

Valve cover

Choke lever

Throttle lever

Spark Arrester

Engine switch

Emission label

18 © 2010 American Honda Motor Co., Inc — All Rights Reserved

Page 21

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

FUEL FILLER CAP

FUEL TANK

OIL DRAIN PLUG

ELECTRIC STARTER

(applicable types)

OIL FILLER CAP/DIPSTICK

ELECTRICAL

CONNECTIONS

Right Side

Fuel cap

Oil filler/cap dipstick

Engine oil drain plug

Electric starter

Electrical connections

© 2010 American Honda Motor Co., Inc — All Rights Reserved 19

Page 22

DIMENSIONAL DRAWINGS

Unit: mm (in)

150 (5.9)

With control box type: 462 (18.2)

99 (3.9)

134 (5.3)

278 (10.9)

92 (3.6)

1

3

3

.

5

(

5

.

2

6

)

116 (4.6)

192 (7.6)

1

3

(

0

.

5

)

3

4

.

5

(

1

.

3

6

)

9

6

(

3

.

8

)

105 (4.1)

195.5 (7.70)

Without control box type: 428 (16.9)

CRANKSHAFT (P. T. O.)

CONTROL BOX

STARTER MOTOR

(If equipped)

(If equipped)

4

1

8

(

1

6

.

5

)

G

X

2

4

0

U

2

/

U

T

2

:

4

2

2

(

1

6

.

6

)

G

X

2

4

0

R

2

/

R

T

2

:

3

0

3

(

1

1

.

9

)

* S:355 (14.0)

* P/Q:380 (15.0)

* E:360 (14.2)

GX240UT2 * V:400 (15.7)

* W:370 (14.6)

GX240RT2 *V:420 (16.5)

GX240-270

Without Reduction

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

20 © 2010 American Honda Motor Co., Inc — All Rights Reserved

Page 23

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

Unit: mm (in)

* H:425 (16.7)

150 (5.9)

* R:187.2 (7.37)

1

3

3

.

5

(

5

.

2

6

)

105 (4.1)

195.5 (7.70)

* L/H:68.1 (2.68)

P. T. O. SHAFT

* R:440 (17.3)

REDUCTION UNIT

* R:188.5 (7.42)

9

9

(

3

.

9

)

1

3

4

(

5

.

3

)

With control box type: 462 (18.2)

Without control box type: 428 (16.9)

116 (4.6)

192 (7.6)

4

1

8

(

1

6

.

5

)

1

3

(

0

.

5

)

3

4

.

5

(

1

.

3

6

)

9

6

(

3

.

8

)

* R:90.8 (3.57)

* L/H:209.9 (8.26)

CONTROL BOX

STARTER

MOTOR

(If equipped)

(If equipped)

* L:405 (15.9)

* L/H:140.3 (5.52)

G

X

2

4

0

U

2

/

U

T

2

:

4

2

2

(

1

6

.

6

)

With Reduction

© 2010 American Honda Motor Co., Inc — All Rights Reserved 21

Page 24

Without Fuel Tank

134 (5.28)99 (3.90)

290.8 (11.45)

361.5 (14.23)

195.5 (7.70)

105 (4.13)

103 (4.06)

M8X1.25 DEPTH 18 (0.71)

DEPTH 4 (0.16 )

DEPTH 4.5 (0.18)

(6PLCS)

184.3 (7.26)

294.6 (11.60)

45°

45°

30°

30°

70 (2.76)

311 (12.24)

CONTROL BOX

STARTER MOTOR

Unit: mm (in)

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

22 © 2010 American Honda Motor Co., Inc — All Rights Reserved

Page 25

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

307 (11.17)

57.5 (2.26)

22 (0.87)

101.8 (4.01)

96 (3.78)

34.5 (1.36)

13 (0.51)

OIL DRAIN

EVAP PURGE JOINT

107.2 (4.22)

0.9 (0.04)

153 (6.02)

432 (17.01)

150.1 (5.91)

133.8 (5.27)

135.2 (5.32)

CONTROL BOX

STARTER MOTOR

Unit: mm (in)

© 2010 American Honda Motor Co., Inc — All Rights Reserved 23

Page 26

GX340-390

Unit: mm (in)

* S:380 (15.0)

158.7 (6.25)

* P/Q:405 (15.9)

* V:425 (16.7)

With control box type: 498.6 (19.63)

4

4

7

(

1

7

.

6

)

9

8

(

3

.

9

)

1

2

1

.

8

(

4

.

8

0

)

301.3 (11.86)

100 (3.9)

1

3

3

.

5

(

5

.

2

6

)

141.5 (5.57) 200.6 (7.90)

1

7

(

0

.

7

)

2

7

(

1

.

1

)

1

0

3

(

4

.

1

)

105 (4.1)

195.5 (7.70)

Without control box type: 460 (18.1)

CRANKSHAFT (P. T. O.)

CONTROL BOX

STARTER MOTOR

(If equipped)

(If equipped)

E

X

C

E

P

T

G

X

3

9

0

U

T

2

:

4

4

8

(

1

7

.

6

)

Without Reduction

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

24 © 2010 American Honda Motor Co., Inc — All Rights Reserved

Page 27

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

Unit: mm (in)

* L:440 (17.3)

158.7 (6.25)

* H:452 (17.8)

460 (18.1)

4

4

7

(

1

7

.

6

)

233.2 (9.18)

1

3

3

.

5

(

5

.

2

6

)

141.5 (5.57) 200.6 (7.9)

1

7

(

0

.

7

)

2

7

(

1

.

1

)

1

0

3

(

4

.

1

)

105 (4.1)

195.5 (7.70)

REDUCTION UNIT

68.1 (2.68)

P. T. O. SHAFT

155 (6.1)

With Reduction Unit

© 2010 American Honda Motor Co., Inc — All Rights Reserved 25

Page 28

Without Fuel Tank

CONTROL BOX

STARTER MOTOR

121.8 (4.80)

98 (3.86)

328 (12.91)

399.5 (15.72) GX340R2 EDN2, EDE2

423.5 (16.67) GX390R2 EDT6, EDS6

103 (4.06)

105 (4.13)

195.5 (7.70)

321 (12.64)

197.3 (7.77) 312 (12.28)

OIL FILLER CAP

70 (2.76)

OIL FILLER CAP

Unit: mm (in)

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

26 © 2010 American Honda Motor Co., Inc — All Rights Reserved

Page 29

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

0.4 (0.02)

153 (6.02)

26 (1.02)

GX340R2 EDN2, EDE2

321 (12.63)

345 (13.58)

GX390R2 EDT6, EDS6

EVAPORATIVE

PURGE JOINT

100.2 (3.94)

OIL DRAIN

27 (1.06)

103 (4.06)

104.6 (4.12)

100 (3.94)

73 (2.87)

17 (0.67)

457 (18.0)

158.7 (6.25)

CONTROL BOX

STARTER MOTOR

140.8 (5.54)128.2 (5.05)

Unit: mm (in)

© 2010 American Honda Motor Co., Inc — All Rights Reserved 27

Page 30

PTO DIMENSIONAL DRAWINGS

Unit: mm (in)

45° 45°

103 (4.1)

7

0

(

2

.

8

)

85.7 (3.37)

P

.

D

.

1

2

7

(

5

.

0

0

)

Φ

2

5

.

3

7

4

-

2

5

.

4

0

0

(

Φ

0

.

9

9

9

0

-

1

.

0

0

0

0

)

16 (0.6)

62.1 (2.45)

REDUCTION UNIT

P. T. O. SHAFT

6.31- 6.36

(0.248-0.250)

80 (3.20)

63 (2.5)

2

1

.

6

9

-

2

1

.

8

2

(

0

.

8

5

4

-

0

.

8

5

9

)

M8 x 1.25

(4 PLACES)

M8 x 1.25

(2 PLACES)

Unit: mm (in)

45° 45°

103 (4.1)

7

0

(

2

.

8

)

M8 x 1.25

7.00 - 7.05

(0.276 -0.278)

64.8 (2.55)

P

.

D

.

1

2

7

(

5

.

0

0

)

Φ

2

4

.

9

7

2

-

2

4

.

9

9

3

(

0

.

9

8

3

1

-

0

.

9

8

4

0

)

16 (0.6)

68.1 (2.68)

60.0 (2.36)

42 (1.7)

REDUCTION UNIT

P. T. O. SHAFT

M8 x 1.25

(2 PLACES)

M8 x 1.25

(4 PLACES)

2

0

.

9

-

2

1

.

0

(

0

.

8

2

-

0

.

8

3

)

28 (1.1)

H Type (with reduction)

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

L Type (with reduction)

28 © 2010 American Honda Motor Co., Inc — All Rights Reserved

Page 31

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

Unit: mm (in)

30°

30°

45°

45°

103 (4.1)

7

0

(

2

.

8

)

89 (3.5)

Φ

2

5

.

3

7

5

-

2

5

.

4

0

0

(

Φ

0

.

9

9

9

0

-

1

.

0

0

0

0

)

14NF2 Thread R. H.

26-27

(1.0-1.1)

72.5 (2.85)

P

.

D

.

1

6

5

.

1

(

6

.

5

0

)

P

.

D

.

1

2

7

(

5

.

0

0

)

Φ

1

1

0

.

0

0

-

1

1

0

.

0

5

(

Φ

4

.

3

3

0

7

-

4

.

3

3

2

7

)

5/16-24UNF-2B

(2 PLACES)

5/16-24UNF-2B

(4 PLACES)

3/8-16UNC-2B

(4 PLACES)

CRANKSHAFT (P. T. O.)

Unit: mm (in)

30°

30°

45°

45°

103 (4.1)

7

0

(

2

.

8

)

88.5 (3.48)

56 (2.2)

Φ

2

5

.

3

7

5

-

2

5

.

4

0

0

(

Φ

0

.

9

9

9

0

-

1

.

0

0

0

0

)

3/8 - 24UNF - 2B TAP

28 (1.1)

72.2 (2.84)

P

.

D

.

1

6

5

.

1

(

6

.

5

0

)

P

.

D

.

1

2

7

(

5

.

0

0

)

6.3 - 6.35

(0.2480 - 0.2500)

2

1

.

6

9

-

2

1

.

8

2

(

0

.

8

5

3

9

-

0

.

8

5

9

1

)

CRANKSHAFT (P. T. O.)

Φ

1

1

0

.

0

0

-

1

1

0

.

0

5

(

Φ

4

.

3

3

1

-

4

.

3

3

3

)

5/16-24UNF-2B

(2 PLACES)

5/16-24UNF-2B

(4 PLACES)

3/8-16UNC-2B

(4 PLACES)

P Type

Q Type*

© 2010 American Honda Motor Co., Inc — All Rights Reserved 29

Page 32

S Type

Unit: mm (in)

30°

30°

45°

45°

103 (4.1)

7

0

(

2

.

8

)

63 (2.5)

41 (1.6)

Φ

2

4

.

9

4

7

-

2

4

.

9

8

0

(

Φ

0

.

9

8

2

2

-

0

.

9

8

3

5

)

M8-1.25

28 (1.1)

60 (2.4)

P

.

D

.

1

6

5

.

1

(

6

.

5

0

)

P

.

D

.

1

2

7

(

5

.

0

0

)

7.00 - 7.03

(0.276 - 0.277)

2

0

.

9

-

2

1

.

0

(

0

.

8

2

-

0

.

8

3

)

Φ

1

1

0

.

0

0

-

1

1

0

.

0

5

(

Φ

4

.

3

3

1

-

4

.

3

3

3

)

SNC TYPE:

5/16-24UNF-2B

TAP (2 PLACES)

SNC TYPE:

3/8-16UNC-2B

TAP (4 PLACES)

CRANKSHAFT (P. T. O.)

SM32 TYPE:

M8 x 1.25

(2 PLACES)

SM32 TYPE:

Φ8.5 (Φ0.33)

(4 PLACES)

SNC TYPE:

5/16-24UNF-2B

TAP

(4 PLACES)

SM32 TYPE:

M8 x 1.25

(4 PLACES)

Unit: mm (in)

30°

30°

45°

45°

103 (4.1)

7

0

(

2

.

8

)

105.5 (4.15)

46.5 (1.83)

2

2

.

1

3

6

-

2

2

.

1

6

1

(

Φ

0

.

8

7

1

5

-

0

.

8

7

2

4

)

5/16 - 24UNF - 2B TAP

18 (0.7)

75.5 (2.97)

P

.

D

.

1

6

5

.

1

(

6

.

5

0

)

P

.

D

.

1

2

7

(

5

.

0

0

)

Φ

1

1

0

.

0

0

-

1

1

0

.

0

5

(

Φ

4

.

3

3

1

-

4

.

3

3

3

)

CRANKSHAFT (P. T. O.)

5/16-24UNF-2B

(2 PLACES)

5/16-24UNF-2B

(4 PLACES)

3/8-16UNC-2B

(4 PLACES)

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

V Type

30 © 2010 American Honda Motor Co., Inc — All Rights Reserved

Page 33

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

Unit: mm (in)

80 (3.1)

75 (3.0)

15.5 (0.61)

30°

30°

45°

45°

P

.

D

.

1

6

5

.

1

(

6

.

5

0

)

P

.

D

.

1

1

3

.

1

(

4

.

4

5

)

7

0

(

2

.

8

)

Φ7.15(Φ0.281)

(2 PLACES)

CRANKSHAFT (P. T. O.)

M8 x 1.25

(4 PLACES)

Φ8.51(Φ0.335)

(4 PLACES)

Φ

8

9

(

Φ

3

.

5

)

103 (4.1)

M

2

0

x

1

.

5

55 (2.2)

W Type

© 2010 American Honda Motor Co., Inc — All Rights Reserved 31

Page 34

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

DIMENSIONS AND WEIGHTS

GX240

P.T.O. VARIATION

Model P.T.O. GX240R2 GX240RT2 GX240U2 GX240UT2

Overall

length

Overall

width

Overall

height

Dry weight E type 21.4 kg (47.2 lbs) - - -

Operating

weight

E type 360 mm (14.2 in) - - H type - - - 425 mm (16.7 in)

L type - - 405 mm (15.9 in) 405 mm (15.9 in)

P type - - - 380 mm (15.0 in)

Q type - - - 380 mm (15.0 in)

R type - - - 440 mm (17.3 in)

S type - - - 355 mm (14.0 in)

V type - 420 mm (16.5 in) - 400 mm (15.7 in)

W type - - - 370 mm (14.6 in)

E type 428 mm (16.9 in) - - H type - - - 428 mm (16.9 in)

L type - - 428 mm (16.9 in) 428 mm (16.9 in)

P type - - - 428 mm (16.9 in)

Q type - - - 428 mm (16.9 in)

R type - - - 428 mm (16.9 in)

S type - - - 428 mm (16.9 in)

V type - 428 mm (16.9 in) - 428 mm (16.9 in)

W type - - - 428 mm (16.9 in)

E type 303 mm (11.9 in) - - H type - - - 422 mm (16.6 in)

L type - - 422 mm (16.6 in) 422 mm (16.6 in)

P type - - - 422 mm (16.6 in)

Q type - - - 422 mm (16.6 in)

R type - - - 422 mm (16.6 in)

S type - - - 422 mm (16.6 in)

V type - 303 mm (11.9 in) - 422 mm (16.6 in)

W type - - - 422 mm (16.6 in)

H type - - - 26.5 kg (58.4 lbs)

L type - - 26.5 kg (58.4 lbs) 26.5 kg (58.4 lbs)

P type - - - 25.8 kg (56.9 lbs)

Q type - - - 25.8 kg (56.9 lbs)

R type - - - 30.1 kg (66.1 lbs)

S type - - - 25.8 kg (56.9 lbs)

V type - 21.4 kg (47.2 lbs) - 25.8 kg (56.9 lbs)

W type - - - 25.8 kg (56.9 lbs)

E type 26.1 kg (57.5 lbs) - - H type - - - 31.5 kg (69.4 lbs)

L type - - 31.5 kg (69.4 lbs) 31.5 kg (69.4 lbs)

P type - - - 30.5 kg (67.2 lbs)

Q type - - - 30.5 kg (67.2 lbs)

R type - - - 35.0 kg (77.2 lbs)

S type - - - 30.5 kg (67.2 lbs)

V type - 26.1 kg (57.5 lbs) - 30.5 kg (67.2 lbs)

W type - - - 30.5 kg (67.2 lbs)

32 © 2010 American Honda Motor Co., Inc — All Rights Reserved

Page 35

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

EQUIPMENT VARIATION

Indicates the difference compared with values of P. T. O. variation above.

Variation No balancer type Cyclone air cleaner

Overall length difference----+ 20 mm (0.8 in)

Overall width difference - + 96 mm (3.8 in) - + 34 mm (1.3 in) -

Overall height difference----- 119 mm (4.7 in)

Dry weight difference - 0.9 kg (2.0 lbs) + 0.2 kg (0.4 lbs) + 2.5 kg (5.5 lbs) + 3.2 kg (7.1 lbs) - 4.4 kg (9.7 lbs)

Operating weight

difference

*1: No fuel tank, muffler, and low profile type air cleaner.

- 0.9 kg (2.0 lbs) + 0.2 kg (0.4 lbs) + 2.5 kg (5.5 lbs) + 3.2 kg (7.1 lbs) - 4.4 kg (9.7 lbs)

type

Starter motor type Control box type Low profile type *1

© 2010 American Honda Motor Co., Inc — All Rights Reserved 33

Page 36

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

GX270

P.T.O. VARIATION

Model P.T.O. GX270UT2

Overall length E type 340 mm (13.4 in)

H type 425 mm (16.7 in)

P type

Q type

S type 355 mm (14.0 in)

V type 400 mm (15.7 in)

R type 440 mm (17.3 in)

Overall width E type

H type

P type

Q type

S type

V type

R type

Overall height E type

H type

P type

Q type

S type

V type

E type

Dry weight E type 25.0 kg (55.1 lbs)

H type 26.5 kg (58.4 lbs)

P type

Q type

S type

V type

R type 30.0 kg (66.1 lbs)

Operating

weight

E type 29.7 kg (65.5 lbs)

H type 31.5 kg (69.4 lbs)

P type

Q type

S type

V type

R type 35.0 kg (77.2 lbs)

380 mm (15.0 in)

428 mm (16.9 in)

422 mm (16.6 in)

25.8 kg (57.0 lbs)0

30.5 kg (67.0 lbs)

EQUIPMENT VARIATION

Indicates the difference compared with values shown in the table of P. T. O. variation on (page 28).

Variation No balancer type Cyclone air cleaner

Overall length difference----+ 20 mm (0.8 in)

Overall width difference - + 96 mm (3.8 in) - + 34 mm (1.3 in) -

Overall height difference----- 119 mm (4.7 in)

Dry weight difference - 0.9 kg (2.0 lbs) + 0.2 kg (0.4 lbs) + 2.5 kg (5.5 lbs) + 3.2 kg (7.1 lbs) - 4.4 kg (9.7 lbs)

Operating weight

difference

*1: No fuel tank, muffler, and low profile type air cleaner.

34 © 2010 American Honda Motor Co., Inc — All Rights Reserved

- 0.9 kg (2.0 lbs) + 0.2 kg (0.4 lbs) + 2.5 kg (5.5 lbs) + 3.2 kg (7.1 lbs) - 4.4 kg (9.7 lbs)

type

Starter motor type Control box type Low profile type *1

Page 37

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

GX340

P.T.O. VARIATION

Model P.T.O. GX340R2 GX340RT2 GX340U2 GX340UT2

Overall

length

Overall

width

Overall

height

Dry weight E type 27.3 kg (60.2 lbs) - - -

Operating

weight

E type 365 mm (14.4 in) - - -

H type - - - 452 mm (17.8 in)

L type - - - 440 mm (17.3 in)

P type - - - 405 mm (15.9 in)

Q type - - 405 mm (15.9 in) 405 mm (15.9 in)

S type - - - 380 mm (15.0 in)

V type - 430 mm (16.9 in) - 425 mm (16.7 in)

E type 460 mm (18.1 in) - - H type - - - 460 mm (18.1 in)

L type - - - 460 mm (18.1 in)

P type - - - 460 mm (18.1 in)

Q type - - 460 mm (18.1 in) 460 mm (18.1 in)

S type - - - 460 mm (18.1 in)

V type - 460 mm (18.1 in) - 460 mm (18.1 in)

E type 313 mm (12.3 in) - - H type - - - 448 mm (17.6 in)

L type - - - 448 mm (17.6 in)

P type - - - 448 mm (17.6 in)

Q type - - 448 mm (17.6 in) 448 mm (17.6 in)

S type - - - 448 mm (17.6 in)

V type - 313 mm (12.3 in) - 448 mm (17.6 in)

H type - - - 35.2 kg (77.6 lbs)

L type - - - 35.2 kg (77.6 lbs)

P type - - - 31.7 kg (69.9 lbs)

Q type - - 31.7 kg (69.9 lbs) 31.7 kg (69.9 lbs)

S type - - - 31.7 kg (69.9 lbs)

V type - 27.3 kg (60.2 lbs) - 31.7 kg (69.9 lbs)

E type 33.4 kg (73.6 lbs) - - H type - - - 41.2 kg (90.8 lbs)

L type - - - 41.2 kg (90.8 lbs)

P type - - - 37.8 kg (83.3 lbs)

Q type - - 37.8 kg (83.3 lbs) 37.8 kg (83.3 lbs)

S type - - - 37.8 kg (83.3 lbs)

V type* - 33.4 kg (73.6 lbs) - 37.8 kg (83.3 lbs)

EQUIPMENT VARIATION

Indicates the difference compared with values of P. T. O. variation above.

Variation Cyclone air cleaner

Overall length

difference

Overall width

difference

Overall height

difference

Dry weight

difference

Operating weight

difference

*1: No fuel tank and muffler, use low profile type air cleaner.

© 2010 American Honda Motor Co., Inc — All Rights Reserved 35

type

---+ 6 mm (0.2 in)

+ 93 mm (3.7 in) ± 5 mm (0.2 in) + 39 mm (1.5 in) -

- - - - 135 mm (5.3 in)

+ 0.2 kg (0.4 lbs) + 2.5 kg (5.5 lbs) + 3.2 kg (7.1 lbs) - 4.4 kg (9.7 lbs)

+ 0.2 kg (0.4 lbs) + 2.5 kg (5.5 lbs) + 3.2 kg (7.1 lbs) - 4.4 kg (9.7 lbs)

Starter motor type Control box type Low profile type *1

Page 38

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

GX390

P.T.O. VARIATION

Model P.T.O. GX390RT2/R2 GX390T2 GX390UT2/T2

Overall length H type - - 452 mm (17.8 in)

L type - - 440 mm (17.3 in)

P type - - 405 mm (15.9 in)

Q type 405 mm (15.9 in)

S type - - 380 mm (15.0 in)

V type 425 mm (16.7 in) - 425 mm (16.7 in)

Overall width H type - - 460 mm (18.1 in)

L type - - 460 mm (18.1 in)

P type - - 460 mm (18.1 in)

Q type 458 mm (18.0 in) 460 mm (18.1 in) 460 mm (18.1 in)

S type - - 460 mm (18.1 in)

V type 458 mm (18.0 in) - 460 mm (18.1 in)

Overall height H type - - 447 mm (17.6 in)

L type - - 448 mm (17.6 in)

P type - - 448 mm (17.6 in)

Q type 447 mm (17.6 in) 448 mm (17.6 in) 448 mm (17.6 in)

S type - - 448 mm (17.6 in)

V type 447 mm (17.6 in) - 448 mm (17.6 in)

Dry weight H type - - 35.2 kg (77.6 lbs)

L type - - 35.2 kg (77.6 lbs)

P type - - 31.7 kg (69.9 lbs)

Q type 29.9 kg (65.9 lbs) 31.7 kg (69.9 lbs) 31.7 kg (69.9 lbs)

S type - - 31.7 kg (69.9 lbs)

V type 29.9 kg (65.9 lbs) - 31.7 kg (69.9 lbs)

Operating weight H type - - 41.2 kg (90.8 lbs)

L type - - 41.2 kg (90.8 lbs)

P type - - 37.8 kg (83.3 lbs)

Q type 31.4 kg (69.2 lbs) 37.8 kg (83.3 lbs) 37.8 kg (83.3 lbs)

S type - - 37.8 kg (83.3 lbs)

V type 31.4 kg (69.2 lbs) - 37.8 kg (83.3 lbs)

EQUIPMENT VARIATION

Indicates the difference compared with values of P. T. O. variation above.

Variation Cyclone air cleaner

Overall length

difference

Overall width

difference

Overall height

difference

Dry weight

difference

Operating weight

difference

*1: No fuel tank and muffler, use low profile type air cleaner.

36 © 2010 American Honda Motor Co., Inc — All Rights Reserved

type

---+ 6 mm (0.2 in)

+ 93 mm (3.7 in) ± 5 mm (0.2 in) + 39 mm (1.5 in) -

- - - - 135 mm (5.3 in)

+ 0.2 kg (0.4 lbs) + 2.5 kg (5.5 lbs) + 3.2 kg (7.1 lbs) - 4.4 kg (9.7 lbs)

+ 0.2 kg (0.4 lbs) + 2.5 kg (5.5 lbs) + 3.2 kg (7.1 lbs) - 4.4 kg (9.7 lbs)

Starter motor type Control box type Low profile type *1

Page 39

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

SPECIFICATIONS

GX240

Model GX240R2 GX240RT2 GX240U2 GX240UT2

Description code GCBPK GCBJT GCBPK GCBJT

Type 4 stroke, overhead valve, single cylinder, inclined by 25°

Displacement 270 cm3 (16.5 cu–in)

Bore x stroke 77.0 x 58.0 mm (3.0 x 2.3 in)

Net power (SAE J1349)*1 5.9 kW (7.9 HP) / 3,600 min-1 (rpm)*2

Continuous rated power 4.6 kW (6.1 HP) / 3,600 min-1 (rpm)

Maximum net torque (SAE J1349)*1 18.3 N·m (1.86 kgf·m, 13.4 lbf·ft) / 2,500 min-1 (rpm)

Compression ratio 8.5: 1

Fuel consumption (at continuous rated

power)

Ignition system C.D.I.(Capacitor Discharge Ignition) type magneto ignition

Ignition timing B.T.D.C. 10° / 1,400min-1 (rpm)

Spark advancer performance B.T.D.C. 10°- 20°

Spark plug BPR6ES (NGK) / W20EPR-U (DENSO)

Lubrication system Forced splash

Oil capacity 1.1 Liters (1.16 US qt, 0.97 Imp qt)

Recommended oil SAE 10W-30 API service classification SJ or later

Cooling system Forced air

Starting system Recoil, Recoil and Starter motor

Stopping system Ignition exciter coil circuit open

Carburetor Horizontal type, butterfly valve

Air cleaner Dual element type, Cyclone type, Oil bath type, Low profile type

Governor Mechanical centrifugal

Breather system Reed valve type

Fuel used Unleaded gasoline with a pump octane rating 86 or higher

Reduction case oil capacity (1/2

reduction with clutch)

Clutch

(1/2 reduction

with clutch)

Type Centrifugal

Engagement

start

Lock 2,200 min-1 (rpm)

2.2 Liters (0.58 US gal, 0.48 Imp gal) / h

0.3 Liters (0.32 US qt, 0.26 Imp qt)

1,800 min-1 (rpm)

*1: The power rating of the engine indicated in this document is the net power output tested on a production engine for the engine

model and measured in accordance with SAE J1349 at 3,600 rpm (net power) and at 2,500 rpm (max net torque). Mass production

engines may vary from this value. Actual power output for the engine installed in the final machine will vary depending on numerous

factors, including the operating speed of the engine in application, environmental conditions, maintenance, and other variables.

*2: Base type includes a balancer, dual type air cleaner, and standard type muffler.

GX270

Model GX270R2 GX270RT2 GX270U2 GX270UT2

Description code GCBMK GCBGT GCBMK GCBGT

Type 4 stroke, overhead valve, single cylinder, inclined by 25°

Displacement 270 cm3 (16.5 cu–in)

Bore x stroke 77.0 x 58.0 mm (3.0 x 2.3 in)

Net power (SAE J1349)*1 6.3 kW (8.4 HP) / 3,600 min-1 (rpm)

Continuous rated power 5.1 kW (6.8 HP) / 3,600 min-1 (rpm)

Maximum net torque (SAE J1349)*1 19.1 N·m (1.94 kgf·m, 14.1 lbf·ft) / 2,500 min-1 (rpm)

Compression ratio 8.5: 1

Fuel consumption (at continuous rated

power)

Ignition system C.D.I.(Capacitor Discharge Ignition) type magneto ignition

Ignition timing B.T.D.C. 10° / 1,400min-1 (rpm)

Spark advancer performance B.T.D.C. 10°- 20°

Spark plug BPR6ES (NGK) / W20EPR-U (DENSO)

Lubrication system Forced splash

Oil capacity 1.1 Liters (1.16 US qt, 0.97 Imp qt)

Recommended oil SAE 10W-30 API service classification SJ or later

Cooling system Forced air

2.4 Liters (0.63 US gal, 0.53 Imp gal) / h

© 2010 American Honda Motor Co., Inc — All Rights Reserved 37

Page 40

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

Starting system Recoil, Recoil and Starter motor

Stopping system Ignition exciter coil circuit open

Carburetor Horizontal type, butterfly valve

Air cleaner Dual element type, Cyclone type, Oil bath type, Low profile type

Governor Mechanical centrifugal

Breather system Reed valve type

Fuel used Unleaded gasoline with a pump octane rating 86 or higher

Reduction case oil capacity (1/2 reduction with clutch)

Clutch

(1/2 reduction

with clutch)

*1: The power rating of the engine indicated in this document is the net power output tested on a production engine for the engine

model and measured in accordance with SAE J1349 at 3,600 rpm (net power) and at 2,500 rpm (max net torque). Mass production

engines may vary from this value. Actual power output for the engine installed in the final machine will vary depending on numerous

factors, including the operating speed of the engine in application, environmental conditions, maintenance, and other variables.

Type Centrifugal

Engagement

start

Lock 2,200 min-1 (rpm)

0.3 Liters (0.32 US qt, 0.26 Imp qt)

1,800 min-1 (rpm)

GX340

Model GX340R2 GX340RT2 GX340U2 GX340UT2

Description code GCBKK GCBET GCBKK GCBET

Type 4 stroke, overhead valve, single cylinder, inclined by 25°

Displacement 389 cm3 (23.7 cu–in)

Bore x stroke 88.0 x 64.0 mm (3.5 x 2.5 in)

Net power (SAE J1349)*1 8.0 kW (10.7 HP) / 3,600 min-1 (rpm)*2

Continuous rated power 6.3 kW (8.4 HP) / 3,600 min-1 (rpm)

Maximum net torque (SAE J1349)*1 26.4 N·m (2.69 kgf·m, 19.5 lbf·ft) / 2,500 min-1 (rpm)

Compression ratio 8.2: 1

Fuel consumption (at continuous rated

power)

Ignition system C.D.I.(Capacitor Discharge Ignition) type magneto ignition

Ignition timing B.T.D.C. 10° / 1,400min-1 (rpm)

Spark advancer performance B.T.D.C. 10°- 22°

Spark plug BPR6ES (NGK) / W20EPR-U (DENSO)

Lubrication system Forced splash

Oil capacity 1.1 Liters (1.16 US qt, 0.97 Imp qt)

Recommended oil SAE 10W-30 API service classification SJ or later

Cooling system Forced air

Starting system Recoil, Recoil and Starter motor

Stopping system Ignition exciter coil circuit open

Carburetor Horizontal type, butterfly valve

Air cleaner Dual element type, Cyclone type, Oil bath type, Low profile type

Governor Mechanical centrifugal

Breather system Reed valve type

Fuel used Unleaded gasoline with a pump octane rating 86 or higher

3.1 Liters (0.82 US gal, 0.68 Imp gal) / h

*1: The power rating of the engine indicated in this document is the net power output tested on a production engine for the engine

model and measured in accordance with SAE J1349 at 3,600 rpm (net power) and at 2,500 rpm (max net torque). Mass production

engines may vary from this value. Actual power output for the engine installed in the final machine will vary depending on numerous

factors, including the operating speed of the engine in application, environmental conditions, maintenance, and other variables.

*2: Base type includes a balancer, dual type air cleaner, and standard type muffler.

38 © 2010 American Honda Motor Co., Inc — All Rights Reserved

Page 41

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

GX390

Model GX390R2 GX390RT2 GX390U2 GX390UT2 GX390T2

Description code GCBHK GCBCT GCBHK GCBCT GCBDT

Type 4 stroke, overhead valve, single cylinder, inclined by 25°

Displacement 389 cm3 (23.7 cu–in)

Bore x stroke 88.0 x 64.0 mm (3.5 x 2.5 in)

Net power (SAE J1349)*1 8.7 kW (11.7 HP) / 3,600 min

Continuous rated power 7.0 kW (9.4 HP) / 3,600 min-1 (rpm)

Maximum net torque (SAE

26.5 N·m (2.7 kgf·m, 19.5 lbf·ft) / 2,500 min

J1349)*1

Compression ratio 8.2 ± 0.2: 1

Fuel consumption

3.5 Liters (0.92 US gal, 0.77 Imp gal) / h

(at continuous rated

power)

Ignition system C.D.I.(Capacitor Discharge Ignition) type magneto ignition

Ignition timing B.T.D.C. 10° / 1,400 min-1 (rpm)

Spark plug BPR6ES (NGK) / W20EPR-U (DENSO)

Lubrication system Forced splash

Oil capacity 1.1 Liters (1.16 US qt, 0.97 Imp qt)

Recommended oil SAE 10W-30 API service classification SJ or later

Cooling system Forced air

Starting system Recoil, Recoil and Starter motor

Stopping system Ignition primary circuit open

Carburetor Horizontal type, butterfly valve

Air cleaner Dual element type, Cyclone type, Low profile type

Governor Mechanical centrifugal

Breather system Reed valve type

Fuel used Unleaded gasoline with a pump octane rating 86 or higher

-1

(rpm)

-1

(rpm)

* The power rating of the engine indicated in this document is the net power output tested on a production engine for the engine

model and measured in accordance with SAE J1349 at 3,600 rpm (Net power) and at 2,500 rpm (Max. net torque). Mass

production engines may vary from this value. Actual power output for the engine installed in the final machine will vary depending

on numerous factors, including the operating speed of the engine in application, environmental conditions, maintenance and other

variables.

© 2010 American Honda Motor Co., Inc — All Rights Reserved 39

Page 42

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

SERVICEABILITY

The following Maintenance section is duplicated from the applicable shop manual and is accurate at the time of

publication of this manual. Page number cross references refer to the shop manual it was copied from. It is provided for

your reference in considering serviceability issues.

Maintenance Schedule

REGULAR SERVICE PERIOD (2)

ITEM Perform at every indicated

month or operating hour

interval, whichever comes

first.

Engine oil Check level

Change

Air cleaner Check

Clean (1) (*)(1)

Replace (**)

Sediment cup Clean

Spark plug Check–adjust

Replace

Spark arrester

(If equipped)

Idle speed Check–adjust

Valve clearance Check–adjust

Combustion chamber Clean After every 1000 hours

Fuel tank and filter Clean

Fuel tube Check Every 2 years (Replace if ne cessary)

(1) Service more frequently when used in dusty areas.

(2) For commercial use, log hours of operation to determine proper maintenance intervals.

(*) Internal vent carburetor with dual element type only.

(**) Replace paper element type only.

Clean

Each

use

(Cyclone type) Every 6 months or 150 hours

(Cyclone type) Every 2 years or 600 hours

First

month

or

20 hrs.

Every

3

months

or

50 hrs.

Every

6

months

or

100

hrs.

Every

year

or

300

hrs.

40 © 2010 American Honda Motor Co., Inc — All Rights Reserved

Page 43

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

(1)

(3)

(2)

(4)

(2)

(3)

(1)

SAE VISCOSITY GRADES

AMBIENT TEMPERATURE

Engine Oil Level Check

Place the engine on a level surface.

Remove the oil filler cap (1), and wipe the oil level gauge (2) clean.

Insert the oil filler cap without screwing it into the oil filler neck (3).

Remove the oil filler cap and check oil level shown on the oil level gauge.

If the oil level is low, fill with recommended oil to the upper level (4) of the oil

filler neck.

SAE 10W - 30 is recommended for general use. Other viscosities shown in

the chart may be used when the average temperature in your area is within

the recommended range.

RECOMMENDED OIL:

SAE 10W-30 API service classification SJ or later

Tighten the oil filler cap securely.

© 2010 American Honda Motor Co., Inc — All Rights Reserved 41

Page 44

GX240 • GX270 • GX340 • GX390 (UT2/RT2) Technical Manual

(1)

(2)

(3)

(5)

(2)

(3)

(4)

(1)

Engine Oil Change

Drain the oil in the engine while the engine is warm. Warm oil drains quickly

and completely.

Place the engine on a level surface, and place a suitable container under the

drain plug bolt.

Remove the oil filler cap (1), drain plug bolt (2), and drain plug washer (3) to

drain the oil into the suitable container.

Please dispose of used motor oil in a manner that is compatible with the