Page 1

Page 2

Page 3

I

TABLE

SPECIFICATIONS

INTRODUCTION

CHECK LISTS

GENERAL INFORMATION

SAFETY RULES

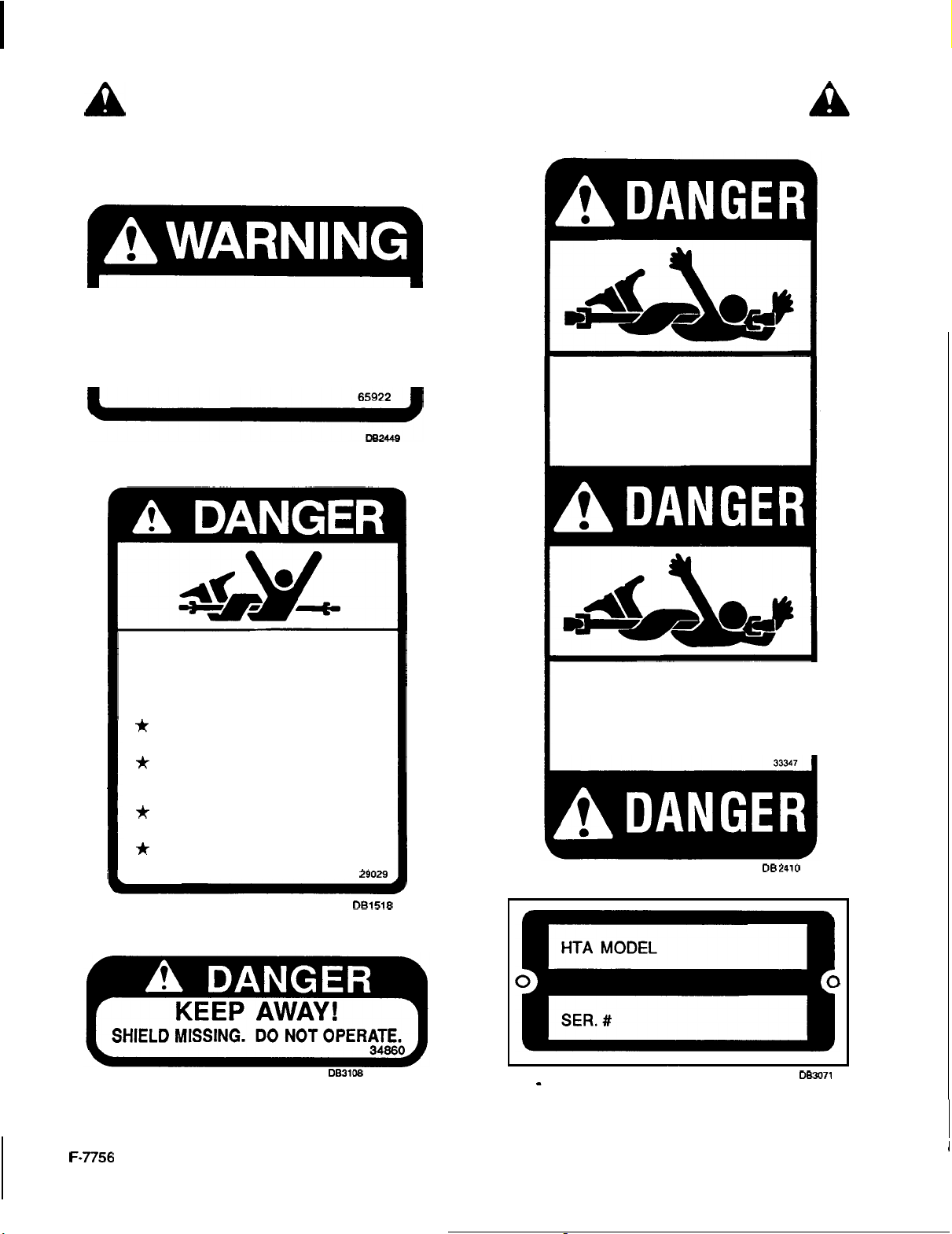

SAFETY DECALS

TORQUE CHART

ASSEMBLY

OPERATION

OWNER SERVICE

DEALER MAINTENANCE

TROUBLE SHOOTING

INDEX TO PARTS LISTS

...........................................................................................................

................................................................................................

...................................................................................................

......................................................................................................

...................................................................................................

.................................................................................................

.................................................................................................

.......................................................................................................

.............................................................................................

.......................................................................................

...................................................................................

OF

CONTENTS

...................................................................................

..................................................................................

1

2

3

3

4

6

8

9

13

18

21

28

29

INDEX

WARRANTY SERVICE

.................................................................................................................

............................................................

SPECIFICATIONS

Cutting Width

Cutting Height Range

Shipping Weight (approximate)

Blade RPM

Blade Tip Speed (feet per minute)

Blade Spindle

Number

Universal Drive

of

...........................................................................................

................................................................

.......................................................

..............................................................................................

Blades

..........................................................................................

.........................................................................................

Inside Back Cover

2-1/4" . 5-112"

..........................................................

1. 076 @ 2.

.......................

11. 831 @ 2.

000

000

42

429

Ibs

rpm PTO

rpm PTO

1

2

L6W

36

"

.

F-7756

(1 0-

89)

Maximum PTO Speed RPM

Caster Wheels (Solid Rubber)

Mower Frame Thickness

...................................................................

.......................................................................

......................................................

1

2,

000

10.25 x 3.5

10

GA

Page 4

INTRODUCTION

Thank you for purchasing an HTA attachment for your Honda Tractor.

This manual covers the assembly, operation, and maintenance of the HTA Model

Mower. For your convenience, a parts guide and detailed warranty information are also included

publication.

in

NOTE: The information

time of printing. American Honda Motor

without notice and without incurring any obligation.

No

part of this publication may be reproduced without written permission.

Pay special attention to the statements preceded by the following symbols:

Indicates that serious injury or death

Indicates a strong possibility that serious injury or death could result if instructions

are not followed.

Indicates a possibility that minor injury can result

I

UWORTANT NOTICE

not followed.

NOTE: Gives helpful information.

this publication is based on the latest product information available at the

Co.,

Inc., reserves the right to make changes at

WILL

result if instructions are not followed.

if

instructions are not followed.

I

Indicates that equipment or property damage can result if instructions are

RM752A Rear

any

in

this

time

HTA attachments are designed to give safe and dependable service if assembled and operated

according to instructions.

If a problem should arise or if you have any questions about this attachment, consult an authorized

Honda Tractor dealer.

2

Page 5

CHECK

PRE-DELIVERY CHECK LIST

I

Inspect the mower thoroughly after assembly

ensure it is set up properly before delivering it

customer. The following check lists are a reminder

of points

found satisfactory or after proper adjustment is

made.

DELIVERY CHECK

-

-

-

-

to

inspect. Check

Check that all safety decals are installed and in

good condition.

Check that

installed and in good condition.

Check all bolts

torqued.

Check that all cotter pins are properly installed.

Lubricate all grease fittings; check

sure a small amount of grease comes out

seal.

Check that blades have been properly

installed.

shieMs and guards are properly

to

off

each item as it is

be sure they are correctly

to

LIST

Inform customer

maximum.

Check mower attitude and belt alignment.

Show customer how

Explain importance of lubrication

and point

out

to

operate PTO at

to

make adjustments.

lubrication points on mower.

2,000

to

customer

to

to

the

make

of

tpm

LISTS

-

Present the Operator's Manual, and ask

customer

-

Explain

ported on road

should be used

operators of other vehicles.

DAILY CHECK LIST

Lubricate all grease fittings; check

sure a small amount of grease comes

seal.

Check that tractor PTO spring

locking collar slides freely and is seated firmly

in mower driveline spline groove.

Check that both side skids, the left side shield

and either the discharge chute

shield are installed.

Make sure blades are sharp, free of nicks

cracks and are securely fastened.

Make sure all hardware is securely fastened

and

Check that mower is properly and securely

attached

Check that all safety decals are installed and in

good

Check that shields and guards are properly

installed and

to

become familiar with all sections.

to

customer that when mower is trans

in

good condition.

to

tractor.

condition.

in

or

highway, safety devices.

to

give adequate warning

-

activated

or

good condition.

to

to

make

out

of

right side

or

-

GENERAL INFORMATION

The purpose

operating and maintaining your mower. Read it

carefully.

that will help you achieve years of dependable

performance. These instructions have been

compiled from extensive field experience and

engineering data. Some information may be general

in nature due

conditions. However, through experience and these

instructions you should be able

procedures suitable

The illustrations and data used

current at the time of printing, but due

line

production changes, your machine may vary

slightly in detail.

F-7756

(1

of

this manual is to assist you in

It

furnishes information and instructions

to

unknown and varying operating

to

develop

to

your particular situation.

in

this manual were

to

possible in

0-89)

\

We reserve the right

machines as mav be

Some lllustratlons

mower wlth shields and guards removed to

a

provide

be operated wlth any

removed.

Throughout this manual, references are made to

right and left directions. These are determined by

standing behind the equipment facing the direction

-

of forward travel.

Blade rotation is clockwise as viewed from the top

of the mower.

3

better view. The mower should never

to

redesign and change the

necessarv without notification.

In

thls manual show the

shleldlng

I

or

guards

Page 6

SAFETY

A

Safety is a' primary concern in the design and

manufacture

efforts to provide safe equipment can be wiped

out by a single careless act of an operator.

In addition to the design and configuration of

equipment, hazard control and accident

prevention are dependent upon the awareness,

concern, prudence and proper training of

personnel involved in the operation, transport,

maintenance and storage of equipment.

It has been

informed, careful operator".

that kind of an operator.

The designed and tested safety of this equipment

depends on

as explained in this manual.

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

of

our products. Unfortunately, our

said

"

the

best safety device is

We ask you to be

it

being operated within the limitations

an

TRAINING

Ensure. all safety decals are installed and in

good condition.

W

Ensure shields and guards are properly

installed and in good condition.

Ensure both side skids, the left side shield and

either the discharge chute or right side shield

are installed.

W

A

minimum

weight must be on tractor front wheels with

mower in transport position. Without this weight,

tractor could tip over causing personal injury or

death. The weight may be attained with front

wheel weights, ballast

weights. When attaining the minimum

weight on the front wheels, you must not

exceed the

(ROPS) weight certification. Weigh the tractor

and equipment.

ESTIMATE.

20%

of tractor and equipment

in

tires or front tractor

Roll

Over Protection Structure

DO

NOT GUESS

A

20%

OR

W

Safety instructions are important! Read this

manual, the tractor manual and all safety rules.

W

Know your controls and how to stop tractor

engine and mower quickly in an emergency.

W

Operators must

of the safe operation of the equipment, its

attachments and all controls.

anyone

proper instructions.

W

Do

operate equipment.

to

not allow children or unqualified persons to

be

instructed in and be capable

Do

not allow

operate this equipment without

PREPARATION

W

Always wear relatively tight and belted clothing

to avoid entanglement in moving parts. Wear

-

sturdy, rough

equipment for eyes, hands, hearing and head.

W

Ensure mower is properly mounted, adjusted

and in good operating condition.

W

Remove accumulated debris from mower to

avoid fire hazard.

Make sure tractor PTO spring

collar slides freely and is seated firmly in mower

driveline spline groove.

soled work shoes and protective

-

activated locking

W

Inspect area to be cut and remove stones,

branches or other hard objects that might

thrown, causing injury or damage.

OPERATIONAL SAFETY

Keep bystanders away from equipment while it

W

is in operation.

Never direct discharge toward anyone.

W

W

Operate only in daylight or good artificial light.

Keep hands and feet away from mower while

tractor engine is running. Stay clear

moving parts.

If

your tractor is equipped with a

W

must wear your seat belt.

Always comply with all state and local lighting

W

and marking requirements.

No riders are allowed on tractor or mower.

W

Start engine from operator's seat after

W

disengaging tractor PTO and placing trans

mission in neutral.

(Safety Rules continued on next page)

ROPS,

of

be

all

you

-

SR

4

F-7756

(1 0-

I1

89)

Page 7

SAFETY

RULES

A

(Safety Rules

ATTENTION! BECOME ALERT! YOUR SAFETY

continued

Operate

Do

Make sure area behind you is clear before

operating in reverse.

Do

Do

on slopes.

Use extreme care and reduce ground speed on

slopes

Watch for hidden hazards on the terrain during

operation.

Stop mower and tractor immediately upon

striking an obstruction. Turn

key, inspect and repair any damage before

resuming operation.

PTO

not operate PTO during transport.

not operate on steep slopes.

not stop, start or change directions suddenly

and rough terrain.

at

from

previous

2,000

rpm maximum.

page)

off

engine, remove

IS

INVOLVED!

H

Turn tractor engine

mower to

or

maintenance.

BIO&

neath.

Keep all persons away from operator control

area while performing adjustments, service or

maintenance.

Make certain all movement of mower compo

nents has stopped before opening blade access

cover.

Frequently check blades. They should be sharp,

free of nicks and cracks and securely fastened.

Your dealer can supply genuine replacement

blades. Substitute blades may not meet

original equipment specifications and may be

dangerous.

ground before performing-any service

mower securely before working under

off,

remove key and lower

A

-

-

Block mower securely before working under

neath.

Disengage power to mower, lower to ground,

stop engine, set parking brake and remove key

before dismounting tractor.

MAINTENANCE SAFETY

Always wear relatively tight and belted clothing

to avoid entanglement in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hands, hearing and head. Block mower securely for storage.

-

Periodically tighten all bolts, nuts and screws

and

check that all cotter pins are properly

installed to ensure mower is

Ensure all safety decals are installed and in

good condition.

Ensure shields and guards are properly

installed and

in

good condition.

STORAGE

NOTES

in

a

safe condition.

SR

I1

F-7756

(1

0-89)

5

Page 8

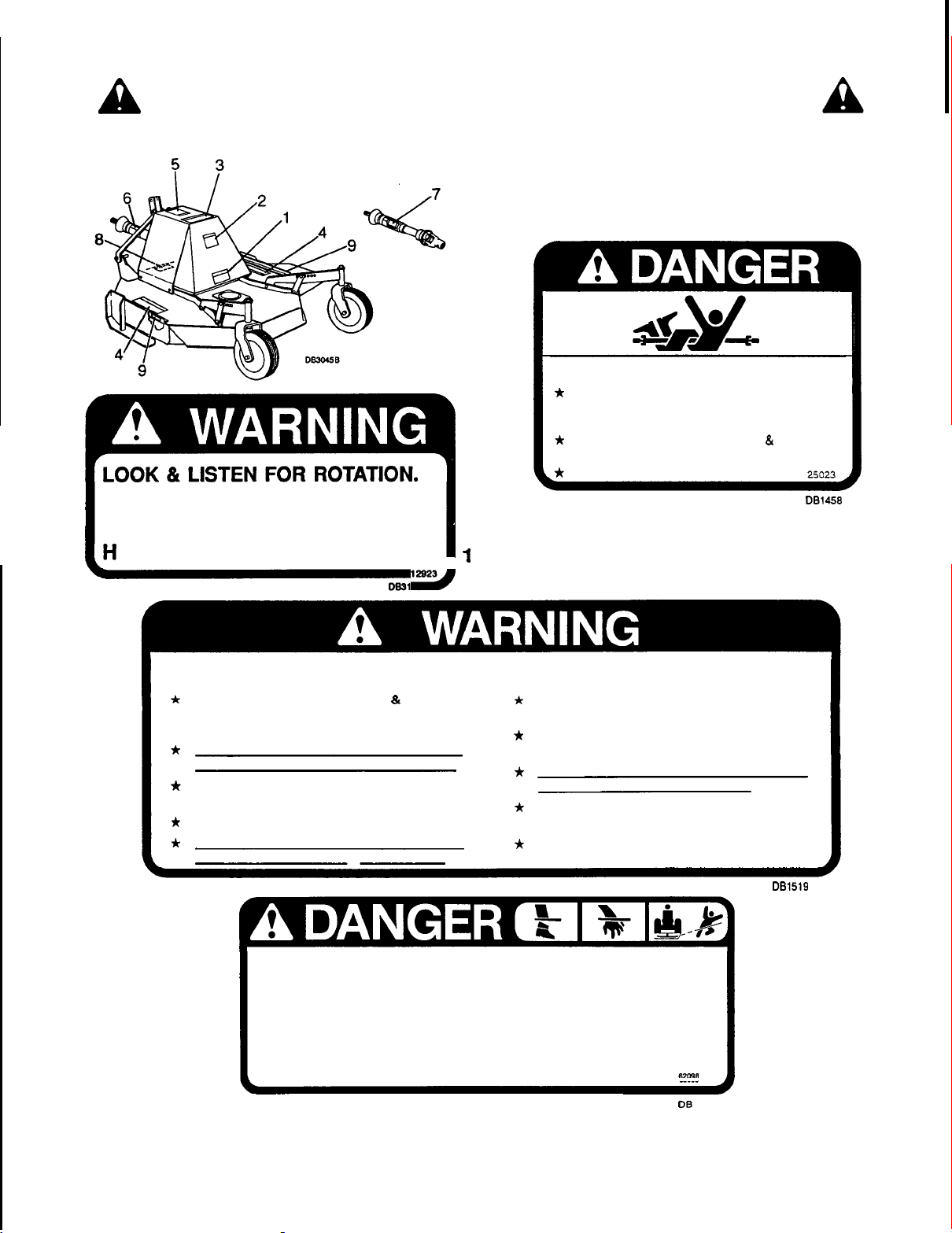

SAFETY DECALS

A

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Replace Immediately

DO NOT OPEN BLADE ACCESS

COVER UNTIL ALL COMPONENTS

AVE STOPPED.

12023/

1

If

Damaged!

*

*

*

2

A

KEEP

ENTANGLEMENT WITH ROTATING

DRIVE PARTS

CAUSE INJURY

KEEP ALL DRIVE SHIELDS & GUARDS

IN PLACE AND IN GOOD CONDITION.

ALLOW NO RIDERS.

AWAY!

OR

FALLING OFF CAN

OR

DEATH.

7507.7

DE1458

TO AVOID

Sr

READ OPERATOR'S MANUAL & FOLLOW

ALL SAFETY PRECAUTIONS. EQUIPMENT QUICKLY IN AN EMERGENCY.

(CONTACT

*

KEEP SHIELDS AND GUARDS IN PLACE. KEY BEFORE WORKING UNDERNEATH.

KEEP CLEAR OF DRIVES AND BELTS.

*

LOWER IMPLEMENT, STOP ENGINE AND PERSONS TO RUN EQUIPMENT.

REMOVE KEY BEFORE DISMOUNTING.

*

CLEAR MOWING AREA OF DEBRIS. DECREASE SPEED WHEN TURNING.

*

DO NOT OPERATE MOWER IN VICINITY

OF OTHER PERSONS. NO RIDERS.

DEALER

FOR

MANUALS.)

SERIOUS

INJURY

Sr

*

*

*

*

OR

DEATH:

KNOW HOW TO STOP TRACTOR AND

BLOCK UP IMPLEMENT AND REMOVE

ALLOW NO CHILDREN

BE CAREFUL ON UNEVEN TERRAIN.

DO NOT OPERATE IN TRANSPORT

POSITION.

OR

UNQUALIFIED

3

4

KEEP

THROWN OBJECTS OR BLADE CONTACT

CAN CAUSE SERIOUS INJURY OR DEATH.

KEEP DISCHARGE CHUTE AND

SHIELDS

AWAY!

IN

PLACE.

finm

DB

1970

(Safety Decals continued

31

399

DE1519

on

next page)

6

F-7756

(1

0-89)

Page 9

SAFETY

DECALS

A

(Safety

I

ATTENTION!

Decals continued

2000

HIGHER

CAUSE EQUIPMENT FAILURE

AND PERSONAL INJURY.

RPM

PTO SPEEDS CAN

from

PTO

previous

BECOME

Replace Immediately

ALERT! YOUR SAFETY

page)

ONLY

I

5

6

If

Damaged!

SHIELD

DO

IS

INVOLVED!

MISSING

NOT OPERATE

A

KEEP

ROTATING DRIVE LINE

*

ENTANGLEMENT CAN CAUSE

SERIOUS INJURY

*

KEEP ALL DRIVE SHIELDS AND

GUARDS IN PLACE AND IN GOOD

CONDITION.

*

TRACTOR PTO YOKE MUST BE

LOCKED IN PLACE.

*

ADJUST TRACTOR HITCH TO

PROPER DIMENSIONS.

AWAY!

OR

DEATH.

DE3108

29029

DB1518

9

SHIELD

DO

7

8

-

Serial Number Plate

NOT OPERATE

MISSING

DE2410

~~ ~~

I

Dm71

F-7756

(1

0-89)

7

Page 10

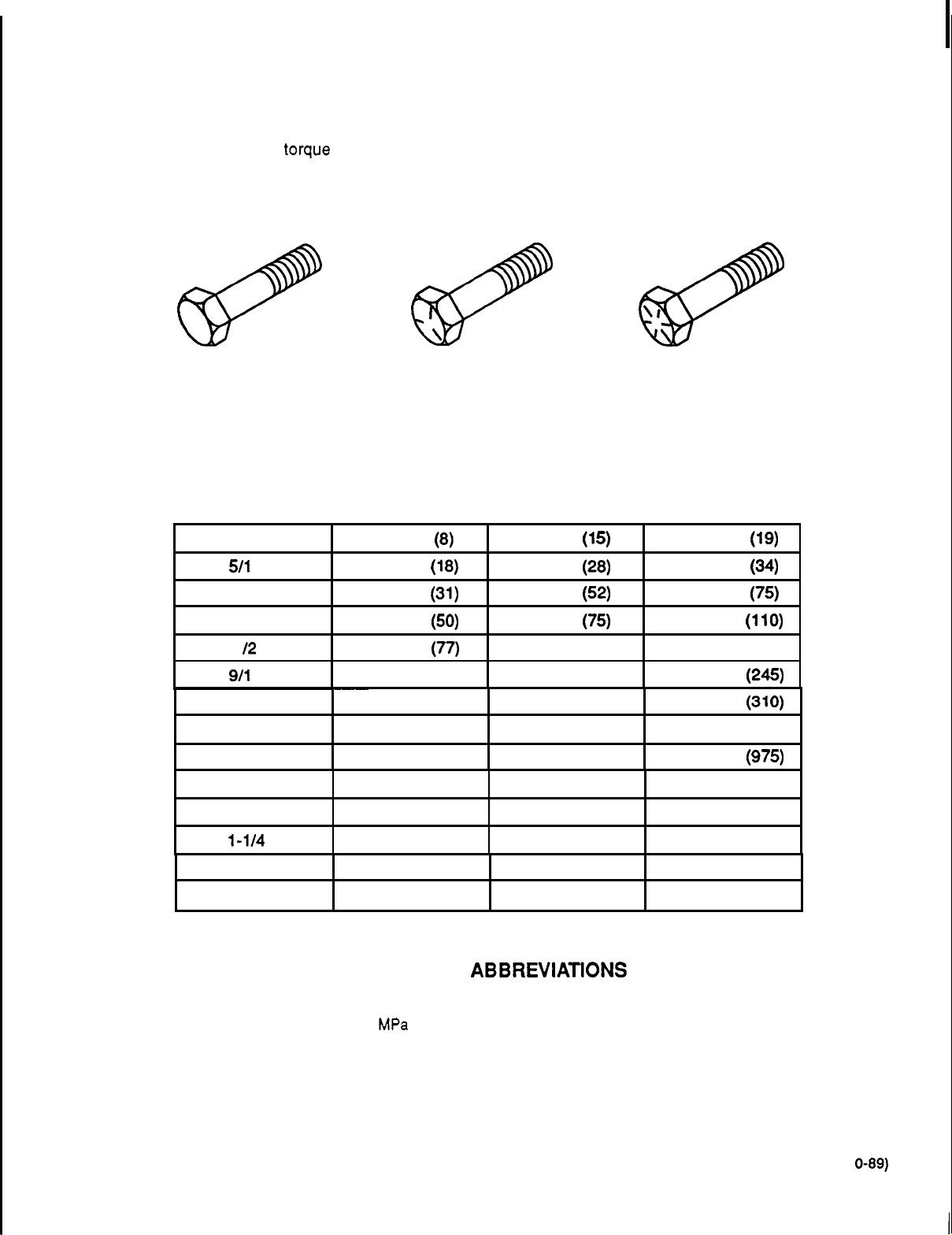

TORQUE

CHART

The chart lists the correct tightening torque for fasteners used on this equipment. When

bolts

are

to

be tightened or replaced, refer to this chart

and the proper toque

except

when specific torque values are assigned in manual text.

to

determine the grade of

bolts

Bolt Head Markings

SAE Grade

(No

Dashes)

2

SAE Grade

(3

Radial Dashes)

5

(6

Recommended Torque in Foot Pounds (Newton-Meters)

Bolt

Diameter

1 14

511 6

318

711 6

1 /2

911 6

518

314

718

1

1-118

1-114

1-318

1-112

(In.)

SAE Grade

6 (8)

23 (31)

37

~~~~~

111

350 (475)

450 (610)

600 (815)

920 (1250)

2

(50)

(77)

(150)

SAE Grade

11 (1

21 (28) 13 (1 8)

38 (52)

55

85 (115) 57

125 (170) 82 (111)

1 75

300 (410) 200 (270)

450 (610) 280 (380)

885 (1200)

1255 (1 700)

1620 (2200) 675 (915)

2200 (2990)

5

5)

(75)

(240)

SAE Grade

Radial Dashes)

SAE Grade

14

25

55

80

120 (165)

180

230

440 (600)

720

1035 (1 400) 680 (925)

8

8

(1 9)

(34)

(75)

(1 10)

(245)

(31

0)

(975)

ATF

.......

Automatic Transmission Fluid

...............................................

F

GA

..............................................

GR

(5,

etc.)

...................

HT

...................................

.................................................

m

........................................

mm

HARDWARE ABBREVlATlONS

M

.............................................

MPa

Female

Gauge N

Grade

(5,

etc.)

Heat Treated

Meter NPSM

Millimeter Mechanical

............................

.........................................

NC

.........................

NF

..............................

...........

National Pipe Straight

Mega Pascal

National Coarse

National Fine

8

Male

Newton

NPT

..................

.................................................

P

SAE

.................

UNC

............................

UNF

.................................

UNS

............................

National Pipe Thread

Society

Pitch

of

Automotive

Engineers

Unified Coarse

Unified Fine

Unified Special

F-7756

(1

0-89)

Page 11

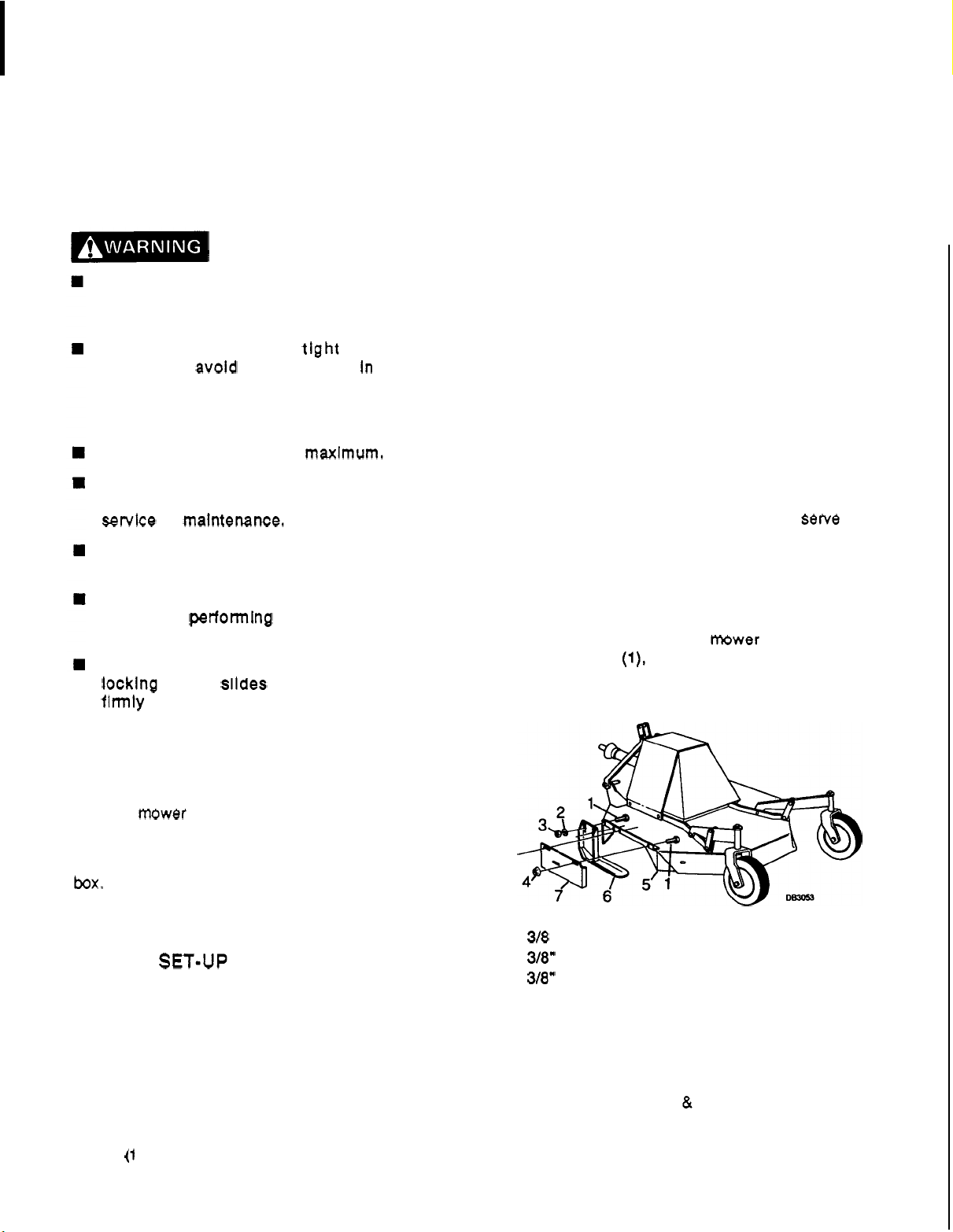

ASSEMBLY

Be familiar with all safety practices on pages 4 and

5.

Make certain all movement of cutter

components has stopped before openlng

blade

clothing to

access

Always wear relatively

parts.

and protective equlpment for eyes, hands,

hearlng and head.

Operate PTO

Turn

mower to ground before performing any

senrke

neath.

area whlle

or

flmly

Wear sturdy, rough-soled work shoes

tractor engine

Block mower securely before working under

Keep all persons away from operator control

malntenance.

Make sure tractor PTO sprlng-activated

locklng collar slldes freely and

In

cover.

tight and belted

avoid entanglement

at

2,000

rpm maxlmum.

off,

remove key, lower

or

rnalntenance.

perfonnlng adjustments, senrlce

In

Is

mower drlvellne spline groove.

moving

seated

The mower is shipped partially assembled.

Assembly will be easier

and loosely assembled before tightening hardware.

Recommended torque. values for hardware are

located on page

Select a suitable working area. Lay parts and

hardware out to make location easy. Refer to

illustrations, accompanying text, parts lists and

exploded view drawings.

'8.

Left Side Skid

(figure

NOTE:

under the mower frame to raise it

The left side shield

-

guards.

place and in good condition.

Attach left side shield

shown with

Attach left side skid

shown with

Do

adjustment when cutting height is set.

1)

To make installation easier, put blocks

Do

not operate mower unless they are in

bolts

(1)

bolts

(1).

not tighten this hardware as the skid will require

if

components are aligned

and

Shield

(7)

and skid

(7)

to mower frame

and flange locknuts

(6)

to

mower frame

lockwashers

Installation

off

the floor.

(6)

also sewe

(2)

and nuts

(4).

(5)

(5)

as

as

as

(3).

Removing Mower From

Remove mower components from the comer fillers.

Remove lag screws from crating brackets on both

sides of the mower. Remove mower frame from

box.

Box

DEALER SET-UP INSTRUCTIONS

Assembly

dealer. It should be delivered to the owner

completely assembled, lubricated and adjusted for

normal mowing conditions.

Complete check list on page

complete.

F-7756

of

this mower is the responsibility of the

3

when assembly is

(1

0-89)

9

1.

318

x

1

"

2.

318"

Lockwasher

3. 3/8"

4.

5.

6.

7.

Hex nut

318

"

Flanged locknut

Mower frame

Left side skid

Left side shield

Figure

Bolt

1.

Left Skid & Shield Installation

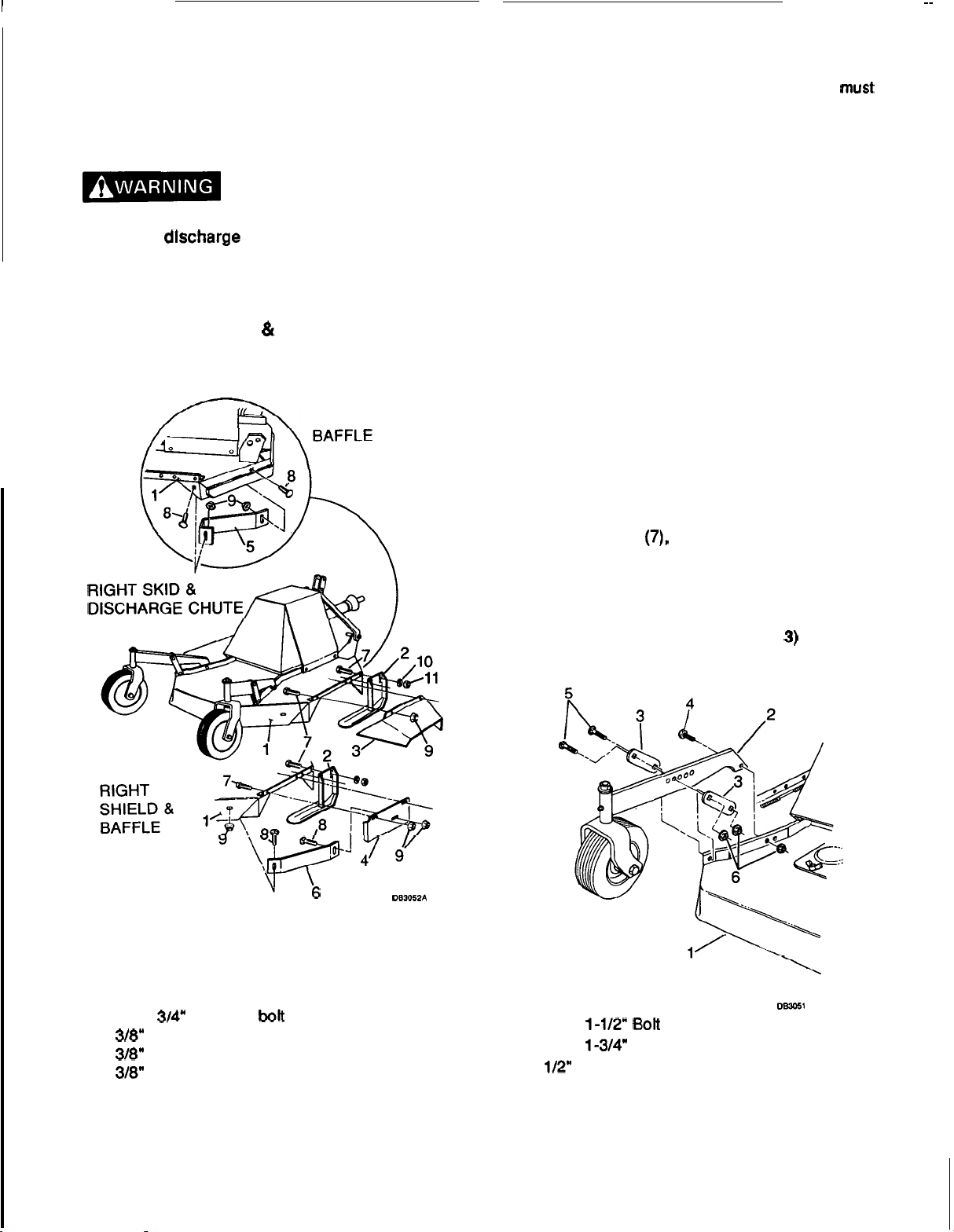

Page 12

Front Corner Baffle Installation

Attach front corner baffle

as shown and attach with

nuts

(9).

Ensure both slde skids, the left side shield and

elther the

are installed.

dkcharge chute

(5)

up under mower frame

bolts

(8)

or

rlght slde shleid

(figure

and flange lock

2)

When right side shield

install side shield baffle

baffle

(6)

-

locknut

to side shield

as shown. Attach side shield

with

to mower frame with bolt

(9)

as shown. Attach front end of baffle

(4)

with bolt

bolts

(7)

and flange locknuts

Discharge Chute Installation

(4)

is installed, you must

(6).

Attach rear portion of

(8)

and flange

(8)

and flange locknut

(4)

to mower frame

(9)

as shown.

(figure

2)

(6)

(9)

~~

I

Right Side Shield & Baffle Installation

(flgure 2)

FRONT CORNER

INSTALLATION

INSTALLATION

The discharge chute

(6)

baffle

(3)

locknuts

and side shield

to right side of mower with

(9)

as shown.

Right Side Skid Installation

The right skid

operate mower unless it is in place and in good

condition.

Attach right side skid

shown with

(11).

require adjustment when cutting height is set.

bolts

Do

not tighten this hardware as the skid will

Caster Arm Installation

(3)

may be installed

(4).

Attach discharge chute

bolts

(2)

also serves as a guard.

(2)

to mower frame

(7),

lockwashers

(figure

in

(7)

and flange

(figure

(10)

3)

place of

2)

Do

not

(1)

as

and nuts

INSTALLATION

1.

Mower

2.

Right side skid

3.

Discharge chute

4.

Right side shield

5.

Front corner baffle

6.

Side shield baffle

7.

3/8 x 1

8. 3/8 x 3/4"

9.

3/8"

10. 3/8"

11. 3/8"

Figure 2.

frame

"

Bolt

Flanged hex locknut

Lockwasher

Hex nut

Right Skid, Shield & Discharge Chute

Carriage

bolt

D83052A

1.

2.

3.

4. 1/2 X 1-1/2"

5.

6.

10

Mower frame

Caster arm

Adjustment bracket

Bolt

1/2 x 1-3/4"

1/2"

Flanged hex locknut

Figure

Carriage bolt

3.

Caster

Arm

Dm1

A

Installation

F-7756

(1

0-89)

Page 13

Attach caster arm

with bolt

(4)

adjustment brackets

(2)

as shown with carnage

nuts

(6).

Repeat for opposite caster.

(2)

to

the frame rail as shown

and flange locknut

(3)

to

frame rail and caster arm

bolts

(5)

and flange lock

(6).

Do

not tighten

Attach

this hardware as the casters will require adjustment

when cutting height is set.

Top

Link Pivot Installation

(figure

4)

-

Remove bolt

(1)

and flange locknut

(2)

from A-frame

arm installation and insert top pivot links

bolt

(1)

shown then secure with

(2)

*

1. 1/2 X 2-3/4"

2. 1/2"

3.

Flanged hex locknut

Top pivot link

Figure

3

BOR

4.

A-Frame Installation

and flange locknut

083057

A

(3)

as

1.

Tube assembly

2.

Top pivot link

3.

Tractor top link

4.

Tractor top link attachment point

5.

Quick link

6.

Check chain

7.

Check chain keyhole

8.

Caplug

9.

BoR

10.

Nut

11.

Check chain bracket

5.

Figure

Check Chain & Top Link Adjustment

Check Chain Installation

Place check chain

secure with caplug

(6)

into

(8).

Repeat for opposite check

(figure

slot

on mower frame and

5)

chain.

Insert chains through check chain brackets

(5).

Insert

bolt

secure with quick links

check chain brackets

F-7756

(1

0-89)

(1 1)

and secure with nut

(9)

(1 1)

and

through

(10).

Drive Shaft Installation

Install front drive half into rear drive half.

Ensure shlelds and guards are properly Installed

and

In

good condltlon.

11

Page 14

NOTES

12

F-7756

(1

0-89)

Page 15

OPERATION

Safety is a primary concern in the design and

manufacture of our products. Unfortunately,

our efforts

wiped out by ,a single careless act of an

operator.

In addition

equipment, hazard control and accident

prevention are dependent upon the aware

ness, concern, prudence and proper training of

personnel involved in the operation, transport,

maintenance and storage of equipment.

It

has been said

informed, careful

that kind of an operator.

to

provide safe equipment can

to

the design and configuration of

"

the best safety device is an

operator.

We ask you

to

be

be

Do

not allow children or unqualified persons

to operate equlpment.

Do

not operate

PTO

durlng transport.

Keep bystanders away from equipment while

it

is

in

operation.

-

Block mower securely before worklng under

-

neath.

Keep all persons away from operator control

area while performing adjustments,

senrlce

or maintenance.

No riders are allowed on tractor or mower.

Operate

PTO

at

2,000

rpm maximum.

The operator is responsible for the safe operation of

this mower. The operator must be properly qualified

and trained. Operators should be familiar with the

mower, tractor and all safety practices before

starting operation. Read the safety information

pages 4 and

5.

on

This mower is designed for light brush shredding

and grass mowing. It is especially useful in cane,

berry,

grape

shredding prunings.

and vegetable crops for mowing and

It

is equipped with low suction

blades. Optional high suction blades are available

for added suction and shredding.

Recommended mowing speed range for most

two

to

five

conditions is from

mph.

Never

dlrect

dlscharge toward anyone.

Ensure shields and guards are properly

installed and

In

good condition.

Ensure both slde sklds, the left slde shield

and either the dlscharge chute or right slde

shleld are installed.

Make certain all movement of mower

components

has

stopped before opening

blade access cover.

Stop mower and tractor lmmedlately upon

striking an obstructlon. Turn off engine,

remove key, Inspect and repair any damage

before resumlng operation.

Always wear

relatlvely tlght and belted

clothing to avold entanglement In movlng

-

parts. Wear sturdy, rough

and protective equlpment for eyes,

soled work shoes

hands,

hearing and head.

F-7756

(1

0-89)

13

Page 16

Attaching Mower to Tractor

Tractor Stability (figure

A minimum

weight must be

mower

weight, tractor could

injury

front wheel weights, ballast

tractor weights. When attaining the minimum

20%

exceed the Roil Over Protection Structure

(ROPS) weight certification. Weigh the tractor

and equipment.

or

weight

20%

on

in

transport position. Without

death. The weight may

on

the front wheels, you must

DO

6)

of

tractor and equipment

tractor front wheels with

tip

over causing personal

be

attained with

in

tires or front

NOT GUESS

OR

ESTIMATE!

this

not

A

to

The adjustments given are

starting point. Adjustments are approximate and

to

may vary due

fine tune them

I

IMPORTANT NOTICE

Avoid very low cutting heights. Striking the

ground with blades gives one of the most

damaging shock loads a mower can encounter.

Severe shock loads can damage the mower

drive and/or the tractor transmission.

Mower cutting height

tained with tractor hydraulics and top link adjust

ment, check chains and caster arms.

Place a straightedge along mower deck edge from

to

front

front corner

Use tractor 3-point arm adjustment as required.

Refer

provided for various hole

arms

rear (refer

to

figure

to

your desired cutting height.

machine wear. You may desire

for

your situation.

is

raised, lowered, and main

to

figure

to

the ground to be sure mower

7.

Approximate cutting heights are

provide you with a

to

I

8).

Measure from each

is

level.

combinations. Set caster

-

-

DBlW

Figure

Place mower on a level surface. Back tractor up

mower and attach lower 3-paint lift arms to mower

hitch pins. Secure with Kiik pins.

Make sure tractor PTO spring

collar slides freely

driveline spline groove.

Attach mower drive shaft

Attach tractor top link to mower top link pivots.

Adjust tractor top link

lo",

least

ground and top pivot links have free travel when

raised.

making sure the back end clears the

6.

Tractor Stability

-

activated locking

and

is

seated

to

tractor PTO.

to

raise mower front end at

firmly

in

mower

to

Hole

I

in

E

Hole in

Frame Rail

D

Cutting Height Adjustment

Place tractor and mower on a level surface. Check

tractor tire pressure to make sure it

equal.

(figure

is

correct and

7)

14

*Not

usable

5

-

1

12

in

these

Figure

holes

7.

Caster Adjustment

F-7756

(1

0-89)

Page 17

Dc3w

I\

Figure

With cutting height selected, measure from the

to

ground

should

than, the rear. Raise

accomplish this measurement.

Check Chain

straightedge at front and rear. The front

be

level with,

installation (figure

to

not more than 1/2" lower

or

lower tractor 3-point arms to

9)

8.

Mower Attitude Adjustment

3

Attach check chain brackets (11)

bracket

Insert check chains into check chain brackets.

Count the links between mower and brackets to

ensure you have the same number of links on each

side. Chains may be twisted to obtain finer

adjustment. Secure excess chain

quick link

With check chains properly adjusted, you will be

able

the original cutting height.

Check top

end raises at least 10

ground and top pivot links have free travel when

raised.

Side Skid Adjustment

(4).

(5).

to

raise mower with 3-point hitch and return

link

adjustment to be sure mower front

"

and the back end clears the

to

tractor top link

to

taut chain with

to

1. Tube assembly

2.

Top pivot link

3.

Tractor top link

4.

Tractor top link

attachment point 10. Nut

5.

Quick link

Figure

F-7756

9.

Check Chain & Top Link Adjustment

(1

0-89)

\-

6.

Check chain

7.

Check chain keyhole

8.

Caplug

9.

Bolt

11.

Check chain bracket

With cutting height established, adjust side skids

approximately

operate mower with weight continually on side

skids. Properly adjusted side skids are designed to

carry mower over uneven ground and minimize

scalping.

112" above the ground. Never

Removing Mower from Tractor

Place tractor and mower on a solid level surface.

Raise mower

Disengage PTO, set parking brake, stop engine and

remove key.

Place a block, that will not allow mower to fall

under front edge of mower deck. Lower mower

block.

15

to

accommodate blocking.

or

onto

tip,

Page 18

Pre-Operation Check List

Operating Technique

Operate PTO at

Ensure both side skids, the left side shield and

either the discharge chute or right side shield

are installed.

No

riders are allowed on tractor or mower.

Do

not allow children or unqualified persons to

operate equipment.

Blades should

and securely fastened.'

Ensure shields and guards are properly installed

and

in

good condition.

Inspect area to be cut and remove stones, branches

or other hard objects that might be thrown, causing

injury or damage.

Check mower cutting height and attitude adjust

ment.

Check to ensure caster wheels, spindles, drive shaft

and universal joints are lubricated.

f

IMPORTANT NOTICE

Mower vlbratlon tends to loosen bolts durlng

Operation.

regularly to malntaln proper torque.

practice

to ensure all bolts are secure.

Power for operating mower is supplied by tractor

PTO.

PTO speed of

stop tractor and mower quickly in case of an

emergency.

Should mower become plugged, causing belt to slip,

immediately' maneuver equipment into

cut area and allow mower to clear accumulated

material. Continue running at

allowing pulleys to

belt in contact with a very hot pulley

ruin belt.

to

Do

2,000

rpm maximum.

be

sharp, free of nicks and cracks

I

All

hardware should be checked

It

Is

a good

check

not exceed tractor manufacturer's rated

mower before

2,000

rprn maximum. Know how to

cool.

each

operation

a

previously

leas1

two

minutes,

Stopping the mower with

will

bake and

Proper ground speed will depend upon the terrain

and the height, type and density

cut.

Normally, ground speed will range from

mph. Tall dense material should be cut at a low

speed;

faster ground speed.

Always operate tractor PTO at

necessary to maintain proper blade speed and

produce a clean

Under certain conditions, tractor tires may

grass down and prevent it from being

same height as the surrounding area. When this

occurs, reduce your ground speed, but maintain

2,000

permit grass to at least partially rebound.

-

Under some conditions, grass will

enough to

heights give a more even cut with less tendency to

leave tire tracks. However,

frequently rather than too short. Short grass

deteriorates rapidly in hot weather and invites weed

growth during growing seasons. Follow local

recommendations for the suitable cutting height in

your area.

thin medium-height material can be

cut.

rpm PTO speed. The lower ground

be

cut even.

In

of

material to be

two

to five.

cut

at a

2,000

general, lower cutting

it

is better to cut grass

rpm. This is

roll

some

cut

at the

speed

will

not

rebound

Tips

Extremely tall material should be cut twice. Set

mower at a higher cutting height for the first pass.

Then cut at desired height at

Remember, sharp blades produce cleaner cuts and

require less power.

Analyze area to be cut to determine the best pro

cedure. Consider height and type

terrain type: hilly, level or rough.

Plan your mowing pattern to travel straight forward

whenever possible. Mow with uncut grass to the

left. This will distribute the clippings over the cut

area. Discharging clippings over uncut grass will

cause a buildup and may prevent uniform cutting.

90"

to the first pass.

of

grass and

-

Stop mower and tractor Immediately upon

striking an obstructlon. Turn

key, Inspect and repair any damage before

resuming Operation.

off

engine, remove

Inspect area to be cut and remove stones,

branches or other hard objects that might be

thrown,

16

causing injury or damage.

F-7756

(1

0-89)

Page 19

A side shield and discharge chute are provided for

the right side. The side shield is best for

normal

mowing and shredding. The discharge chute is

recommended when mowing extremely heavy

material.

For a professional touch in large open areas, try the

mowing pattern in figure 10. Make

two

or three

passes' clockwise to discharge the clippings away

from bordering objects. Then cut the lawn

in

half by

mowing down center. Turn counterclockwise to the

left at end of the area over grass previously mowed.

r-

f

I

c

c

,

I

I

d

\

t

f-

/

L

k

1

10

-

5

=

15

Flgure

3

11

12

13

6

8

9

7

14

16

4

2

10.

Mowing Pattern

\

-

J

DE-

1276

Uneven Terrain

H

Do

not operate on steep

Do

not stop, start

suddenly on

rn

\

\

\

Use extreme care and reduce ground speed

on

slopes

W

Watch

slopes.

and rough terraln.

for

hidden hazards on the terraln

durlng operatlon.

7

,

1

,

J

\

\

,

J

J

Pass diagonally through sharp dips and avoid sharp

drops to prevent

"

hanging up" the tractor and

mower. Practice will improve your skills in

maneuvering rough terrain. Always mow up and

down

slopes.

Never

mow

Disengage power to cutter, lower to ground, stop

engine,. set parking brake and remove key before

dismounting tractor.

slopes.

or

change dlrectlons

across the face

of

slopes.

NOTES

F-7756

(1

0-89)

17

Page 20

OWNER

SERVICE

Be familiar with all safety practices on pages 4 and

5.

Make certain all movement of cutter compo-

a

nents has stopped before opening blade

access cover.

Always wear relatively

a

clothing to avoid entanglement

parts. Wear sturdy, rough-soled work shoes

and protective equipment for eyes, hands,

hearing and head.

Operate

a

Turn tractor engine

a

mower to ground before performing any

service or malntenance.

Block mower securely before working

m

PTO

at

2,000

Ulght and belted

In

rpm maximum.

off,

remove key, lower

moving

underneath.

Keep all persons away from operator control

a

area while performing adjustments,

or

malntenance.

a

Make sure tractor PTO spring

locking collar slides freely and Is seated

In

firmly

mower driveline spline groove.

setvice

-

activated

LUBRICATION INFORMATION

Do

not

let

excess grease collect on

particularly when operating in sandy areas.

The

accompanying illustration shows lubrication

points. The chart gives the frequency of lubrication

in operating hours, based on normal operating

or

conditions. Severe

require more frequent lubrication.

numbers have

lubricate all locations.

Use a good quality

in all locations. Be sure

before attaching grease gun.

Ref

M

1

2

3

4

5

6

7

more than one location; be sure you

Des

Front U-joint

Drive Shaft

Rear U-Joint

Drive Spindle

Caster

Blade Spindle

Caster Wheel (right & left)

Arm

Lubrication Chart

unusual conditions may

SAE

multi-purpose type grease

to

clean fittings thoroughly

..

-

Slip

Joint

(figure

or

around parts,

Some reference

11)

Freauencv

8

hrs

8

hrs

a

hrs

24

hrs

8

hrs

24

hrs

8

hrs

,3

Figure

11.

Lubrication Points

18

F-7756

(1

0-89)

Page 21

Drive

Shaft

Lubrication

Lubricate the drive shaft slip joint every 8 operating

hours. Failure to maintain proper lubrication could

result in damage

shaft.

Lower mower to ground, disconnect drive shaft and

apply a bead of grease all around the male half

where

out several times

it

meets the female half. Slide shaft in and

to

U-joints, gearbox and drive

to

distribute grease.

Blade Installation

The words "This Side Down" are stamped on the

blade. Make sure this side of the blade is placed

toward the ground. Install blade

(1).

Insert blade pin

retainer

pin. Tighten blade retainer

not over-tighten. Rotate crossbar and repeat

procedure. Replace blade access cover.

(4)

until

(figure 12)

(5)

into crossbar

(2)

from top then rotate blade

half moon is away from the blade

bolt

(3)

to

20

ft-lbs.

Do

BLADE SERVICING

Inspect blades for condition and proper installation

each time before operation. Replace any blade that

is

bent, excessively nicked, worn or has any other

damage. Small nicks can be ground out when

sharpening.

Blade Removal

Make certain ail movement

nents has stopped before opening blade access

cover.

Open blade access cover, reach through and align

one end of the crossbar with the hole. Use a block

of wood

retainer

aligned with blade pin

Remove blade

to

hold blade carrier and loosen blade

bolt

(3),

(figure

rotate retainer

(2)

(5).

2

12)

of

cutter compo

(4)

until half

and remove blade pin.

TORQUE BOLT

TO

20

moon

FT-LBS.

is

(3)

I

Your dealer can supply genuine replacement

blades. Substltute blades may not meet original

equipment specifications and may be

dangerous.

Blade Sharpening

Remove blades.

Always sharpen both blades at the same time to

maintain balance. Follow original sharpening

pattern.

Leave a

side.

-

Do

not sharpen blade

1/16

"

blunt edge.

FOLLOW ORIGINAL

PATTERN

(figure 13)

to

Do

not sharpen back

7

a razor edge.

\\,

0

I

MAINTAIN

1

CORNER

DB

2530

1.

Crossbar

2.

Blade Din

3.

Blade ietainer bolt

4.

Blade retainer

5.

Blade

Figure 12.

F-7756

(1

0-89)

Blade Assembly

Figure 13.

Belt Replacement

One

of

the major causes of belt failure is improper

installation. Before a new belt is installed, check

pulley shafts and bearings for wear. Check pulley

grooves for cleanliness. Make sure spindles turn

freely and without wobble.

cleaning, moisten a cloth with a non

non

-

toxic degreasing agent or commercial detergent

and water.

19

Blade Sharpening

(figure 14)

If

grooves require

-

flammable,

Page 22

Avoid excessive force during installation.

tools

to pry belt into pulley groove.

Do

Do

not

not use

roll

belt

over pulleys to install. This can cause hidden

damage and premature belt failure.

ALIGNMENT:

straight

off

Inside edges of belt are lined up with pulley

correct installation.

It is important that the

of the blade spindle pulley

In

the

incorrect installation

belt

(l),

comes

figure

15.

in

illustration, the belt edge rubs the pulley which will

cause belt wear and/or belt

TENSION:

ment bolt

Refer to figure

(3)

until the belt section between the left

side of the drive pulley

deflected approximately

roll

over.

14.

lighten belt adjust

.and

left idler pulley can

1/4"

with thumb pressure.

be

Rotate pulley by hand until belt makes two

revolutions and recheck tension. When proper

(1)

tension is set, tighten all four nuts

(2)

locknut

on adjustment bolt

(3).

and tighten

-

1.

Flanged hex locknut

2.

Locknut

3.

Adjustment bolt

4.

Belt

Figure

14.

Belt Replacement and Adjustment

Belt replacement is accomplished in these steps:

REMOVAL:

turns. Loosen locknut

Loosen adjustment bolt and slide spindle support

the rear and remove

INSTALLATION:

pulley, route under idler pulleys leaving a

Loosen all four nuts

(2)

belt

(4).

(l),

figure

on adjustment bolt

Install new belt over blade spindle

14,

1/4

two

(3).

to

twist

between spindle pulley and each idler pulley. Route

1/4

over drive pulley leaving a

twist between each

idler pulley and the drive pulley.

NOTES

-\

1.

Spindle pulley

2.

Idler pulley

3.

Belt

1

Figure

CORRECT

INCORRECT

3

15.

Belt Adjustment

-.-

I

20

F-7756

(1 0-

89)

Page 23

DEALER MAINTENANCE

Be familiar with all safety practices on pages 4 and

5.

Make certain ail movement of cutter compo

nents has stopped before opening blade

access cover.

Always wear relatively tlght and belted

In

clothing to avoid entanglement

-

parts. Wear sturdy, rough

protectlve equlpment for eyes, hands,

and

soled work shoes

moving

hearing and head.

Operate

a

Turn

PTO

at.

2,000

tractor engine

rpm maximum.

off,

remove key, lower

mower to ground before performing any

service or maintenance.

Block mower securely before working under

neath.

Keep ail persons away from operator control

area whlle performing adjustments, service

or maintenance.

Make sure tractor

PTO

spring-activated

locking collar slides freely and is seated

in

firmly

mower driveline spline groove.

Spindle Repair Tips

As

a reference point, the grease fitting is in the top

portion of spindle housing.

To minimize wear, bearing cups, cones and sleeves

-

are press fit to shaft and will require a press

similar device for removal.

When disassembling, support housing casting

prevent damage.

Remove bearing cups by placing a punch in housing

slots

and driving cup out. Alternate punch positions

from side

to

side. Use care

to

prevent housing

damage.

Permatex

Aviation Form-A-Gasket@

or

30

lent is recommended as a sealant for spindle repair.

Blade Spindle Disassembly

-

Top and bottom washers

welded to shaft. You must grind

before pressing shaft and crossbar

(3)

and sleeve

(figure

(2)

or

break weld

(9)

housing.

Support spindle in a press and push shaft and

crossbar

through housing

(6).

(9)

down

Remove seals from housings.

Remove bearing cups from housing as described in

Tips section above.

or

to

equiva

16)

are tack

off

out

of

-

SPINDLE REPAIR

Blade Spindle Removal

Remove blade from spindle.

Remove belt from pulleys.

Remove split taper bushing (located on top of

pulley) by removing the

into the threaded holes in bushing flange. Tighten

bolts

alternately

to

Remove key and pulley.

Remove four

bolts

and remove spindle.

F-7756

(1

0-89)

two

bolts

and insetting them

remove split taper bushing.

attaching spindle

to

mower frame

Blade Spindle Assembly

(figure

16)

Bearing cups and cones are designed to work

it

together.

is important

cone taper mates with bearing

Lubricate new cups

spindle housing

Seat cups

with a press

(6)

(7)

against machined shoulder of housing

or

by placing a large soft drift on the

to

position them

cup

taper.

(7)

with a light oil. Place them in

so

they will mate with cones

flat lip and driving them into housing.

Place bottom bearing cone

bearing cup

Pennatex

of

21

the

Permatex

(7).

3D

Aviation Form-A-Gasket is

Corporation.

(5)

into housing against

a

registered

so

bearing

trademark

(5).

Page 24

-4

5

Place seal squarely on housing. Select a piece of

pipe or tubing with an outside diameter that will set

on

outside edge of seal. A tube that is too small will

bow seal cage.

Carefully press seal into housing, preventing

to

distortion

and squarely against machined shoulder in housing.

metal seal cage. Seal should seat firmly

083048

1.

Blade spindle

2.

Sleeve

3. 1-3/4 x 2-3/8"

4.

Seal

5.

Bearing cone

6.

Spindle housing with cups

7.

Bearing cup

8.

Grease fitting

9.

Spindle shaft and crossbar

10.

Blade pin retainer washer

11.

QD

Blade pin

12. 1/2 x 3/4"

13.

Key

14.

Blade

Flgure

I

IMPORTANT NOTICE

Improper positioning

fallure.

Proper seal installation is important. An improperly

installed seal will leak and could cause bearing

failure.

Coat area

Permatex.

Pull the rubber portion

spring.

Apply a thin coat of lubricant

install with spring up toward center of housing.

of

Flat washer

Nylok bolt

16.

Blade Spindle Assembly

I

of

seals can cause seal

housing where seals seat, lightly with

of

seal back and locate

to

bottom seal and

Make sure seal lip

seal cage

leak. Damaged seals must be replaced.

Place bottom washer

Place housing assembly with bottom seal

bottom cone

crossbar

press shaft into housing.

Fill housing cavity with a medium grade grease.

Place

Press sleeve and bearing onto shaft until all bearing

free play is removed and there is a slight drag

(similar

automobile). Check by spinning spindle.

turn freely.

I

IMPORTANT NOTICE

Bearing adjustment

agalnst bearing until proper adjustment

attained. Adjustment is maintained

weldlng sleeve

shaft.

Be careful not

bearing adjustment is essential

Should you over-tighten bearings, hold spindle

housing and rap spindle shaft with a lead hammer

to

loosen bearings. Adjust to obtain proper setting.

Place a damp rag over bearings

Tack weld sleeve

Also tack weld top and bottom washers in

180"

[

IMPORTANT NOTICE

When welding bottom washer, connect welder

ground

washer and sleeve, connect welder to top of

splndle shaft. Failure to connect welder ground

properly can

to shaft.

Install top seal with spring up away from center of

housing. Top seal should be flush with,

above, housing.

or

(5)

(9).

top

bearing cone

to

adjusting the front wheel bearings on an

apart.

dlcectiy to crossbar. When weldlng top

did

not

roll

under. Distortion

damage to seal lip will cause seal to

(3)

on shaft and crossbar

and cup

Carefully guide seal over shaft and

(7)

installed over shaft and

(5)

and sleeve

(2)

on shaft.

It

to

(9).

(4),

should

1

Is

set by pressing sleeve

is

by

tack

(2)

and washers

to

over-tighten bearings. Proper

to

shaft in

two

(3)

to spindle

to

good bearing

to

protect them.

spots

180'

apart.

two

life.

spots

I

cause.bearlngs to become welded

to

1/16

-

22

F-7756

(1

0-89)

Page 25

Lubricate spindle with a medium grade grease.

Rotate housing on spindle shaft, checking

for

free

movement.

Blade Spindle Installation

Insert spindle through bottom of mower deck and

bolts.

secure with four mounting

grease fitting toward lubrication access area. Refer

to Lubrication in Owner Service section.

Install pulley and key on spindle shaft. Place split

taper bushing on pulley and drive down to seat

against spindle shaft shoulder and alternately

tighten split taper bushing

Drive Spindle Removal

Be sure to position

bolts

to

12

ft-lbs.

(figure

17)

Remove the four bolts attaching spindle to spindle

support and remove spindle.

Remove split taper bushing (located on top of

pulley) by removing the

into the threaded holes

bolts

alternately to remove split taper bushing.

two

bolts and inserting them

in

bushing flange. Tighten

Spindle Repair Tips

As

a reference point, the grease fitting is in the top

portion of spindle housing.

To minimize wear, bearing cups,

are press fit to shaft and will require a press

similar device for removal.

When disassembling, support housing casting to

prevent damage.

cones and sleeves

or

Remove drive shaft from drive spindle. Tape key to

spindle shaft.

1.

Drive spindle assembly complete

2.

Drive spindle shaft

3. 3/16 x 1

4.

Seal

5.

Bearing cone

6.

Housing with cups

7.

Bearing cup

8.

Grease fitting

9.

Bearing cup

10.

Bearing cone

11. 3/4"

12. 3/4"

13.

Dust cap

"

Cotter pin

Flat washer

Slotted hex nut

17.

Figure

Drive Spindle Assembly

Remove bearing cups by placing a punch in housing

slots and driving cup out. Alternate punch positions

from side to side. Use care to prevent housing

damage.

Permatex 3D Aviation

Form-A-Gasket@

or

equiva

lent is recommended as a sealant for spindle repair.

Drive Spindle Disassembly

Remove dust cap

Press shaft

Remove seal

Remove bearing cups

(13).

cotter pin

(2)

down through housing.

(4).

(7)

and

(figure

(3)

and nut

(9)

refer to Tips

17)

(12).

section above.

Drive Spindle Assembly

Bearing cups and cones are designed

together.

It

is

important to position them

(figure

17)

so

to

work

bearing

cone taper mates with bearing cup taper.

Lubricate new cups

them in spindle housing

cones

(5 & 10).

(7

&

Seat cups

9)

with a light oil. Place

(6)

so

they will mate with

(7

&

9)

against machined

shoulder of housing with a press or by placing a

large

soft

drift on the flat lip and driving them into

housing.

Place bottom bearing cone

(5)

onto spindle shaft

(2)

with taper up. Seat on bottom shoulder of shaft with

a press.

Insert shaft and bearing

bottom

of

housing

(6).

cone assembly through

Fill

housing cavity

with

a

medium grade grease.

-

F-7756

(1

0-89)

23

Page 26

Place top bearing cone

with top bearing cup

Install washer

(1

1)

(10)

(9).

and nut

on shaft

(12)

on shaft

(2)

to

(2)

mate

and

tighten until all bearing free play is removed and

to

there is a slight drag (similar

adjusting the front

wheel bearings on an automobile). Check by

spinning spindle.

Be careful not

bearing adjustment is essential

Should you over

It

should turn freely.

to

over-tighten bearings. Proper

to

good bearing life.

-

tighten bearings, hold spindle

housing and rap spindle shaft with a lead hammer

to

loosen bearings. Adjust

to

obtain proper setting.

Alternately tighten split taper bushing bolts

to

secure pulley in proper alignment. Continue

alternate tightening sequence until assembly is tight

bolts

and all

are torqued to

Check drive pulley

and

12

adjust

ft-lbs.

if

necessary. When

aligned, peen keyway to prevent key from working

out.

Universal Joint Repair

(figures

18

-

23)

6

IMPORTANT NOTICE

I

Improper posltlonlng of seals can cause seal

fallure.

Proper

Seal installation is important.

An

improperly

installed seal will leak and could cause bearing

failure. Coat area of housing where seals seat,

lightly, with Permatex.

Pull the rubber portion of seal back and locate

spring.

Apply a thin

coat of lubricant to bottom seal and

install with spring up toward center of housing.

Place seal squarely on housing. Select a piece of

pipe or tubing with an outside diameter that will set

on outside edge of seal. A tube that

is

too small will

bow seal cage.

Carefully press seal into housing, preventing

distortion to metal seal cage. Seal should seat firmly

and squarely against the machined shoulder

in

housing.

Make sure seal lip did not roll under. Distortion to

seal cage or damage to seal lip will cause seal to

leak. Damaged seals must be replaced.

W

1.

Yoke

2.

Journal cross

m

llll

3. Seal

4.

Snap ring

5.

Cup and bearings

6. Yoke

Figure

18.

U-Joint

Exploded

View

Disassembly

1.

Remove snap rings from inside of yokes in four

in

figure

locations as shown

19.

Lubricate spindle with a medium grade grease.

Rotate housing on spindle shaft, checking for free

movement.

When desired adjustment is obtained, secure nut

in

position with cotter key and install dust cap (13).

Drive Spindle

Installation

Place key in shaft and position pulley on spindle

with

shaft

split taper bushing

the pulley is 2

-

13/16 (+1/16

so

the center line of

,-0)

from the top rear

face of the spindle housing.

24

Flgure

19

F-7756

(1

0-89)

Page 27

2.

With snap rings removed, support drive in vise,

hold yoke in hand and tap on yoke to drive cup out

of yoke. See figure

20.

082513

4.

Place universal cross in vise'as. shown in figure

22

and tap on yoke

to

remove cup. Repeat step

three for final removal. Drive remaining cup

drift

and

hammer.

out

with

Figure

3.

Clamp cup in vise as shown in figure

20

21

and tap

on yoke to completely remove cup from yoke.

Repeat steps

opposite

cup.

two

and

three

for

M

Figure

22

Assembly

1.

Place seals securely on bearing cups. Insert

cup into yoke from outside and press in with hand

pressure as far as possible. Insert journal cross into

bearing cross with grease fitting away from shaft.

Be careful not to disturb needle bearings. Insert

another bearing cup across from first cup and press

in as far as possible with hand pressure.

Trap cups in

a

vise and apply pressure. Be sure

journal cross is started into bearings and continue

pressure with vise, squeezing in as far as possible.

Tap yoke to aid in process.

F-7756

(1

0-89)

DB2514

Figure

21

2.

Seat cups

by

placing a drift (slightly smaller

than the cup) on cup and rapping with hammer.

(See figure

23.)

Install snap ring and repeat on

opposite cup.

25

Page 28

NOTES

Figure

3.

Repeat assembly steps one and

remaining cups in remaining yoke.

Move both yokes in all directions to check for free

movement. Should movement be restricted, rap on

yokes sharply with a hammer to relieve any tension,

both

Repeat until

without restriction.

Make sure tractor

collar Slides freely and is seated firmly In

driveline spilne groove.

yokes move in all directions

PTO

23

two

to install

spring-activated locking

mower

26

F-7756

(1

0-89)

Page 29

NOTES

F-7756

(1

0-89)

27

Page 30

TROUBLE

SHOOTING

Problem

Grass cut lower

of swath than at edge

Streaking conditions

swath

Material discharges from

mower unevenly;

bunches of material along

swath

in

center

in

MOWING

Possible

Height of mower lower at rear

or front

Conditions too wet for mowing

Blades unable to cut that part

of grass pressed down by

of

path

Dull

Material too high and too

much material

tractor tires

blades

CONDITIONS

Cause

Solution

Adjust mower height and attitude

mower rear and front are within

same height. See instructions on page 14.

Allow

grass to dry before mowing.

Slow ground speed of tractor but keep

engine running at full

lower will help.

Sharpen or replace blades.

Reduce ground speed but maintain 2,000

rpm

at

tractor

over material. Raise the mower for the first

pass and lower to desired height for the

second and cut at

rear of mower high enough to permit mate

rial to discharge,

tions listed above occur.

PTO,

PTO

or

make

90"

to first pass. Raise

but

not

so

so

that

1/2" of

rpm. Cutting

two

passes

high that condi

-

-

Grass wet

Rear of mower too low, trap

ping material under mower

28

Allow grass to dry before mowing. Slow

ground speed of tractor but keep engine

PTO

running at full

help.

-

Adjust mower height and attitude. See in

structions

on

rpm. Cutting lower will

page 14.

F-7756

(1

-

0-89)

Page 31

INDEX

TO

PARTS

LISTS

MAIN FRAME ASSEMBLY

MOUNTING FRAME ASSEMBLY

FRONT DRIVE

REAR DRIVE

DRIVE SPINDLE ASSEMBLY

BLADE SPINDLE ASSEMBLY

81

SHIELD ASSEMBLY

&

SHIELD ASSEMBLY

.................................................................................

............................................................................

...........................................................................

......................................................................

..............................................................

................................................................

30

32

34

34

35

35

F-7756

(1

0-89)

29

Page 32

MAIN FRAME ASSEMBLY

18

-

COMPLETE ENGLISH DECAL SET

19

-

ENGLISH SAFETY DECAL

20

-

FRENCH SAFETY DECAL SET

SET

30

F-7756

(1

0-89)

-

I

Page 33

MAIN FRAME ASSEMBLY

Ref No.

Mllsaci

1 1

2 1

3

4 2

5 2

6 2

6 2

6

6

7

7

8 2

8 2

9

10 2

11 4

12 1

1

2

2

2

2

2

Mower frame

Left side

skid

Left side shield

Caster wheel yoke assembly

10-1/4

5/8

Caster wheel with sleeve

ID

Flange bearing for

1

-1/8

bore wheel

-or-

3/4

ID

Flange bearing for

1 -1/8

bore wheel

-or-

5/8

ID

Flange bearing for

13/8

bore wheel

-or-

3/4

ID

Flange bearing with groove

for

1 -3/8

bore polyethylene wheel

1/4

Straight

setf-tap grease

(for steel wheel)

-or-

Straight

fitting

1/2 x 3/4 x 3-3/8

1/8

pipe thread grease

(for

polyethylene wheel)

Sleeve

-or-

17 GA

Wall x

5/8 x 3-3/8

Caster arm assembly

1/4 - 28

Tapered thread grease

fitting

Caster arm adjustment bracket

Access

hole cover assembly

fitting

sleeve

Ref

Mi

13

14

15

16

17

18

19

20

Ref

hlp

29

30

31

32

33

34

35

36

37

38

39

40

No,

llsaci

1

PescrW

Discharge chute (for use on

mowers with CW blade rotation)

Side shield baffle

Right side shield

Right side

skid

Front corner baffle

Complete English decal set

English safety decal set

French safety decal set

HARDWARE

1

/4

x

1-1

/4

Spirol pin

3/8

NC x

3/4

Carriage bolt

318

NC x 1 Hex head cap screw

3/8

Standard lockwasher

3/8

NC Hex

3/8

NC Flanged hex locknut

318

NC Wing nut

1/2

NC x

1/2

NC

112

NC x 5 Hex head cap screw

1/2

NC Flanged hex locknut

3/4

SAE Flat washer

1-1/2

x

1-3/4

nut,

plated

Hex head cap screw

Carriage

..

bolt

GR5

GR5

HT

GR5

F-7756

(1

0-89)

31

Page 34

MOUNTING FRAME ASSEMBLY

i

32

F-7756

(1

0-89)

Page 35

MOUNTING FRAME ASSEMBLY

HARDWARE

Ref Na

JlhIlSeca

51 1

52 2

52 2

53 2

54 2

55 2

56 2

57

581

59 1

60

61 1

62 2

631

641

65 1

66 2

67

682

69 1

70 1

71 2

--

1

2

CW Blade spindle (see page

35)

Twisted QD blade (for right hand

rotation)

-or-

fin

CW Welded

hand rotation)

Mounting pin

long

A-Frame bar

1-1/16 - 121

caplug

Check chain with hardware

&

Front

H

rear drives (see page

1

-3/8

Straight bore bushing

(includes item

1

BK,

3.9

W44

V-Belt

Drive spindle assembly (see page

35)

Top pivot link

Top link tube assembly

Drive shield

Idler bracket assembly

V

-

Groove idler with bearing

4.50

OD

bearing

.626

ID

x

P1 1-1/4

1

TB,

7.25

Check chain bracket

blade (for right

-

Category

D

SAE

#104)

0,

3-7/8

Thread plastic

H Sheave

V-Groove idler less

1.85

OD Ball bearing

Straight bore bushing

Sheave

P

34)

Ref

NQ

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

1

04

105

106

107

DescriDtion

114 x 114 x 1-114

114

NC x

3/4

1/4 x 38 x 2

5/16

NC x 1 Hex head cap screw GR5

5/16 x 1-34

Link, screw type

4/0

Twisted link chain,

1/2

NC

x 1 Carriage

1/2

NF

x

1

1/2

NC x

1-114

/2

NC x

NC x

NC x

NC x

1-314

2-314

3-3/4

4-1/2

1

112

112

1/2

thread

1/2

Extra-heavy lockwasher

112

Standard f tat washer

112

NC Flanged hex locknut

1/2 x 314 x 318

17

GA Wall x

518

NC

x

2-1/4

518

Heavy lockwasher

518

Standard flat washer

518

NC Hex nut

518

NC

Hex

5/16

x

5/16 x 2-114

item

#58

-

112

NC Heavy hex nut

3/16 x 1

5/8

Klik pin

NC

x 3 Hex head cap screw GR5

Key

Hex head cap screw GR5

Key

Spirol pin

27

"

bolt

-1/4

Hex head cap screw

Hex head cap screw

Hex head cap screw GR5

Hex head cap screw