Page 1

-I

Page 2

Page 3

Introduction

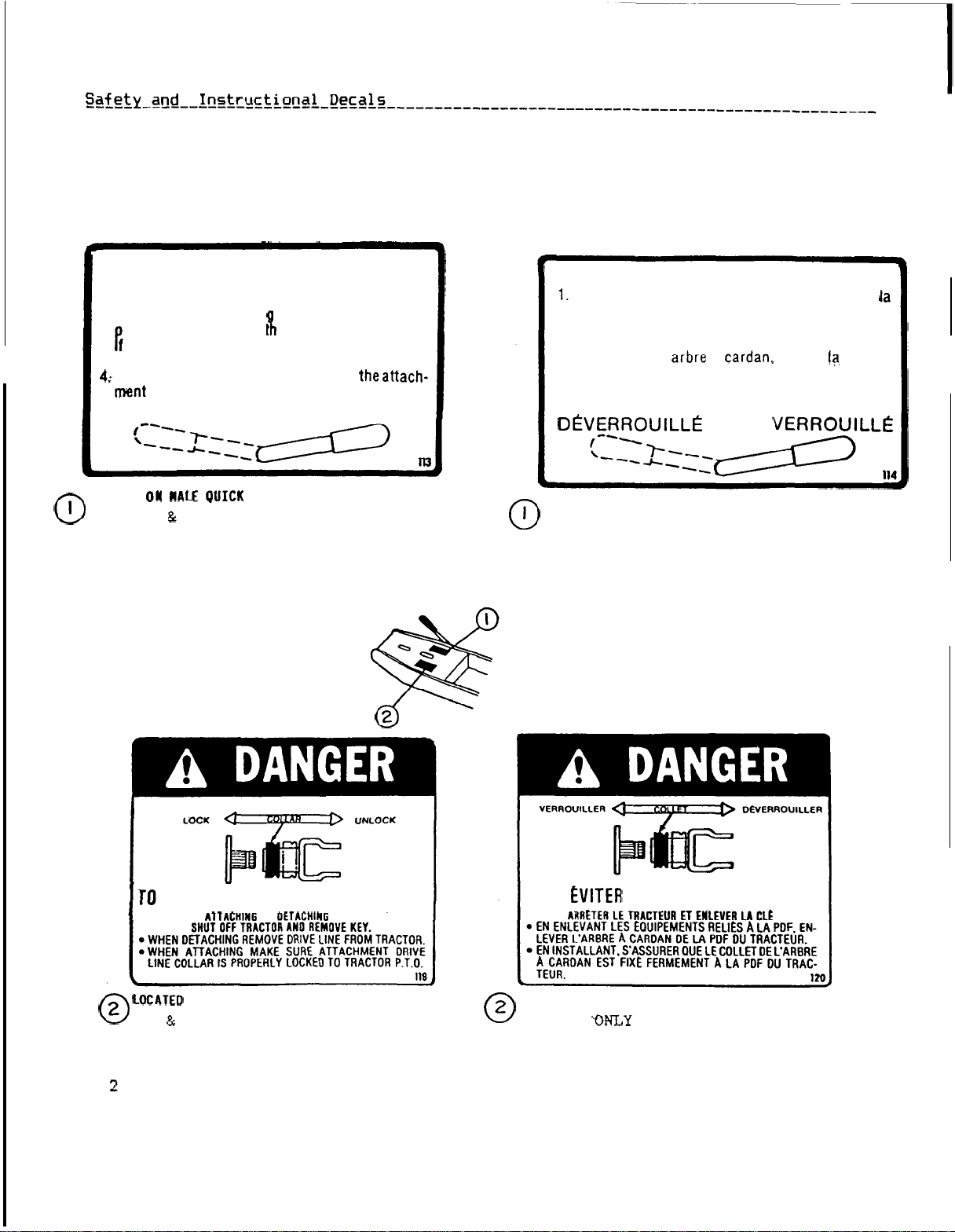

Safety and Instructional Decals

Assembly

Subframe Preparation

Lift Mechanism

Tractor Preparation

Subframe Installation

Subframe Removal

Parts Guide

Torque Specification Table

Warranty Service

Thank you for purchasing an HTA attachment for your Honda Tractor.

HTA

The

Two Stage Snowblower

Model QH4000 Front Quick Hitch makes

.....................................................

.................................. 2

.........................................................

...........................................

.................................................

............................................

..........................................

.................................................

......................................................

........................................

.................................

it

possible

or

Dozer Blade on Honda H4013, H4514 and H4518 Lawn Tractors.

(inside back cover)

to

attach either an

1

7

3

3

3

5

5

8

9

11

HTA

42

"

This manual covers the assembly, operation and maintenance of the

is

Hitch. For your convenience, a parts guide

NOTE: The information in this publication

available at the time of printing. American Honda Motor

to make changes at any time without notice and without incurring any obligation.

No

part of this publication may be reproduced without written permission.

Pay special attention to the statements preceded by the following symbols:

Indicates severe personal injury or death

are not followed.

Indicates a strong possibility that serious personal injury or

,

death could result

Indicates a possibility that minor

are not followed.

if

instructions are

also included in this publication.

is

based on the latest product information

Co.,

WILL

not

followed.

injury

can result

QH4000 Front Quick

Inc. reserves the right

result

if

instructions

if

instructions

HTA

attachments are designed to give safe and dependable service

operated according to instructions.

If

a

problem should arise,

an authorized Honda tractor dealer.

OM

0149

or

if

you have any questions about this attachment, consult

if

assembled and

Page 4

REPLACE IMMEDIATELY IF DAMAGED

.

ATTACHING INSTRUCTIONS

1.

Insert subframe into attachment completely.

2.

Lock

in

place by movin lever forward to "Lock

osition and secure wit

3.

e

ui ed with

tor%.%

4:

If

equipped with lift assist springs, lift theattach-

mnt and attach springs.

and

lock

UNLOCK

a

P.T.O.

linch

drive line, connect

in place.

pin.

LOCK

to

trac

INSTRUCTIONS

1.

lntroduire completement la partie male dans la

"

-

partie femelle.

2.

Placer

le

securiser avec la goupille

3.

Si

tracteur

4.

Si

accrocher.

levier dans la position "VERROUILLE" et

equipe d'un arbre a cardan. fixer

et

equipe de ressorts. lever I'instrument et les

verrouiller en place.

DEVERROUILLE

D'ACCOUPLEMENT

a

anneau.

a

!a

PDF

du

VERROUILLE

LOCATED

(CANADA

ON

ro

HALE WICK HITCH

&

US)

AVOID

SERIOUS

WHEN

ATTACHIN6

OR

OETACHIWG

d

PERSONAL

INJURY

IMPLEMENT

PLACE

(CANADA

POUR

EVITER

ON

MALE QUICK HITCH

ONLY

)

LES BLESSURES GRAVES:

LOCATE0

(US

&

CANADA

ON

MALE QUICK HITCH

)

PLACE

ON

(CANADA

WALE QUICK HITCH

'ONLY

)

Page 5

----------

IMPORTANT:

level surface, parking brake

Before beginning assembly of this subframe, make sure tractor is on

is

set and that engine is turned off, with key removed.

su~ERAME-PREP_ARAILoN

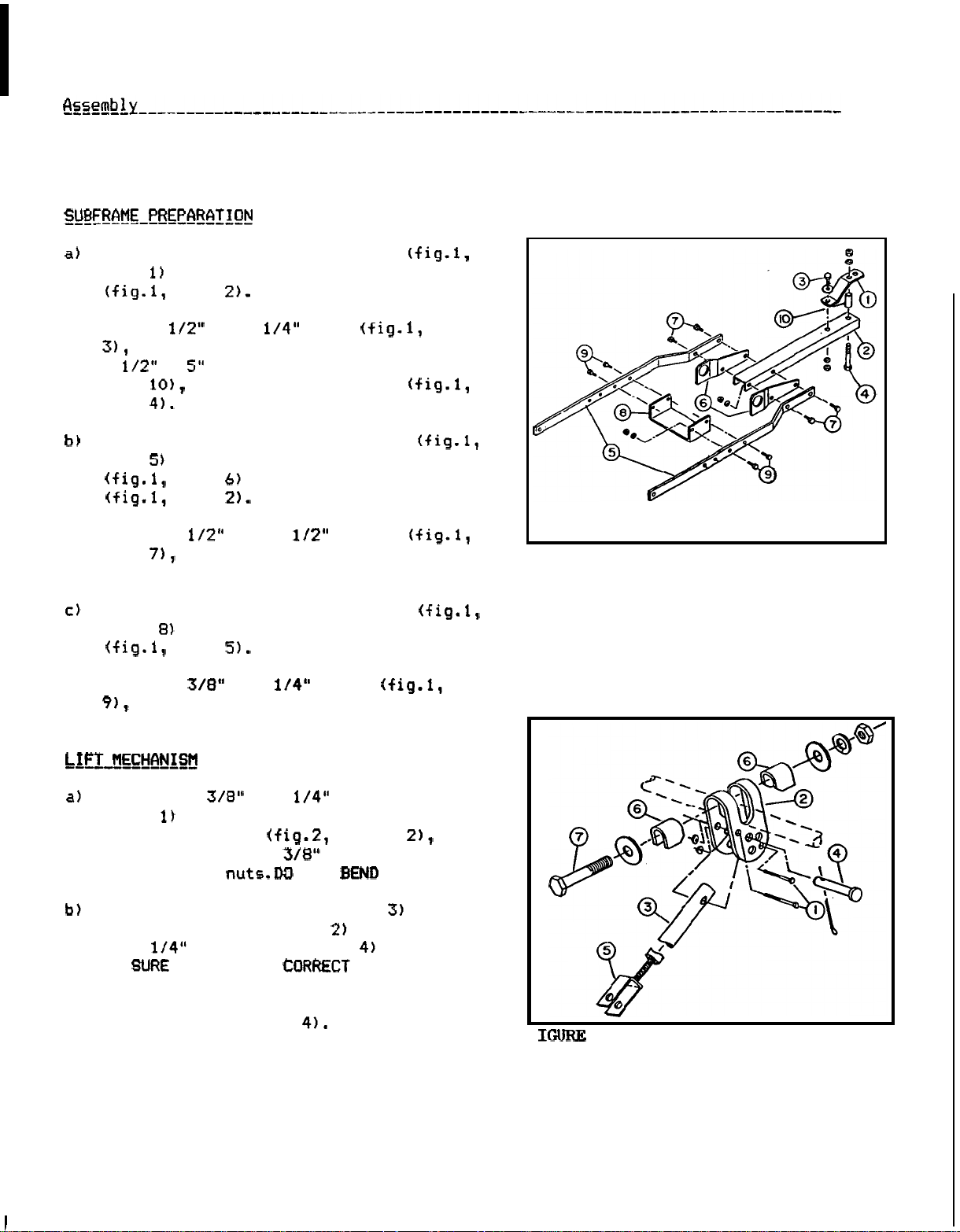

a) Loosely attach rear hitch plate (fig.1,

item

Use

31,

a

item

b) Loosely attach subframe flatbars (fig.1,

1)

to bottom of subframe channel

(fig.1, item

a

1/2"

flatwasher, lockwasher and nut, and

1/2"

x

101,

item

4).

item

5)

(fig.1, item

(fig.1, item

2).

x

1 1/4"

5"

bolt, long tube spacer (fig.

lockwasher and

Do

not tighten yet.

and the

6)

to the sides

2).

bolt (fig.1, item

nut

lift

support brackets

of

(fig.1,

channel

a

1,

Use four 1/2"

item

71,

tighten yet.

c) Loosely attach the support plate (fig.1,

item

(fig.1,

Use four

91,

yet.

8)

item

318"

lockwashers and

x

1

1/2"

lockwashers and nuts.

inside the subframe flatbars

bolts (fig.1,

Do

not

5).

x

1

1/4"

bolts (fig.1,

nuts.

Do

not tighten

item

LIELMSCHfl!!ISM

a) Insert two

item

the

lift

secure them

-

self

b) Attach push arm (fig.2, item

lift

x

BE

locking nuts.DC1

lever (fig.2, item 2)

2

1/4"

SURE

3/8"

1)

through

lever

pin (fig.2, item

TO

USE

with

x

(fig.2,

a

THE

2

1/4" bolts (fig.2,

the

smaller

3/8"

uni-torque (stover)

NOT

EMD

holes

item 21, and

THE

3)

CMiRECT

with

4)

HOLE.

a 17/32

as

in

LEVER.

to the

shown.

FIGURE

"

1

Use a

the pin (fig.2, item

OM

0149

5/32

"

x

1

"

cotter pin to secure

4).

F

IGURE

2

3

Page 6

Thread the adjustment fork (fig.2, item

5)

into the end of the push arm (fig.2,

3).

item

arm assembly to

Adjust the overall length of push

32

13/16".

Place an 11/16" f

retainer plate

x

4" bolt (fig.2, item

Insert the bolt into the lever

Place another bent retainer plate and

flatwasher on the bolt, and secure

loosely with a lockwasher and nut.

a

Install

1)

into each

item

Insert the

the bearing in the right hand

support bracket.

insert the arm through the

Insert the arm through another tube

spacer, and then through the left hand

lift

of the arm should protrude

the

2)

(fig.3, item

(under the

support bracket bearing. The end

bearing.

flange bearing (fig.3, item

lift

from the inside.

lift

4)

5/8"

latwasher and a bent

(fig.2, item

7).

support bracket (fig.3,

arm (fig.3, item

Put

on the arm, and then

bo1

t)

.

6)

on the

as

shown.

3)

through

lift

a tube spacer

lift

2

lever

1/4" beyond

it

5/8"

FIGURE

3

Position the subframe channel (fig.1,

item

2)

in line with subframe flatbars

1,

(fig.

bolts

Rotate the

that its handle is parallel to the

ground, and block in that position. Set

the

the

perpendicular to the ground, and then

tighten the bolt to

Install 1"

(fig.4, item

item

4

item

(fig.1, item 7 and

lift

lever (fig.4, item

5/8"

1).

5)

and securely tighten

9).

lift

arm (fig.4, item

2)

x

4" bolt(fig.4, item 4)

50

lbs.

ft.

x

4 1/2" plastic handle

3)

on

lift

arm (fig.4,

3)

so

so that

is

Page 7

I

a)

Loosely attach the front support brackets

(fig.5, item

For

each bracket, use one

25mm bolt (fig.5, item

and two

item.

Do

not tighten yet.

Loosely attach the attaching plates (fig.5

6)

item

(fig.5, item

bolts (fig.5, item

for each plates.

Loosely install the reinforcement plate

C)

(fig.5, item

plates

314"

and nuts

the bolts heads and lockwashers from

the inside with the nut on the outside

as shown.

10mm

3)

with lockwashers for each bracket.

4)

to the front support brackets

(fig.5, item

bolts (fig.5, item

1)

to the tractor frame.

x

1.25 x 30mm bolts (fig.5,

1).

5)

Do

6)

between the two attaching

IN

THE

FRONT

Do

not tighten yet.

lOmm

x

2)

with lockwasher,

Use

three

with lockwashers

not tighten yet.

4).

Use

71,

HOLES

3/8"

two

5/16

lockwashers

MY.

1.25

x

1"

"

Install

x

x

9

I

.

FIGURE

5

W_A_RQPJg:

tractor

,the engine, remove the key and set the

parking brake.

Install male hitch (fig.6, item

a

pivot bracket

"

7/16

lockwashers and nuts. Install the bolts

from the inside

them securely.

Position the subframe assembly under

b)

the tractor. Insert the rear of the

assembly between the wheels on the

right hand side of the tractor, and

then

OM

0149

x

pull

To

avoid injury, park the

on

a level surface, turn off

(fig.6, item 2).Use four

1 1/4"

it

bolts (fig.6, item

as

shown, and tighten

forward.

1)

in the

31,

FIGURE

6

Page 8

c)

Loosely attach front of subframe flatbars

(fig.7,

plates.

(fig.7,

Install

Do

not tighten yet.

item

Use

item

the

1)

two

31,

bolts

to

the outside attaching

1/2"

x

1

1/2"

lockwashers and nuts.

from

the inside

bolts

as

shown.

dl Attach the subframe's

(fig.1,

draw

(fig. 1,

e)

Securely tighten the

(fig.5,

item

plate

item

item

1)

to

with the

4).

7).

specification table on page

f) Slide the

1)

between the attaching plates (fig.7,

item

2).

attach the hitch

5/8"

the

male

hitch assembly (fig.8,

Align the hard bushing holes and

to

x

10

5/8"

Secure the pin with

pin on one end and

clip (hair pin)

(fig.8,

rear

the

5/16

Refer

hitch plate

tractor's

1/2"

x

x

1/4" bolts

to

the torque

11.

the subframe with

pin (fig.8,

a

5/32

a

4mm

x

item

"

x

80mm

item

1

3)

other end.

NOTE: If there

male

hitch assembly and attaching plates,

is

too

much play between

use with thin flat washers included in

kit

as

shims.

g)

Attach the fork end

item

41

to

the bottom of the pivot bracket

a

with

80mm

5/8"

spring clip (hair pin).

x

1

of

5/8"

the push

pin and a 4mm

rear

5"

bolt

"

cotter

spring

at

arm

item

2).

the

(fig.8,

x

FIGURE

8

NOTE: The lift

arm

can be rotated

facilitate this installation.

h) Tighten the

&

3)

that attach the front support

brackets

tighten the three

item

51

that attach the attaching plates

to

the support brackets.

to

lOmm

the

tractor

bolts (fig.5,

frame, and then

3/8"

torque specification chart on page

bolts

Refer

to

items

(fig.5,

to

the

11-

2

Page 9

Tighten the

Refer to the

on page

Secure the rear hitch plate

item

1/2"

1)

x

then the

3).

Refer to the Torque Specification

Table

If

item

on

necessary, adjust the

3)

1/2"

bolts

Torque

11.

to the tractor

J

bolt

1/2"

x

1

1/4"

page

11.

(fig.9,

Specification Table

by

tightening the

(fig.1,

bolt

lift

so

that the handle section

item

(fig.

arm

item

1).

(fig.1,

41,

and

1,

item

(fig.3,

is

parallel to the fender with approximately

1

"

of clearance when

the

way

back.

it

is

pulled a1

1

Tighten

4)

on

the

the

lift

5/8"

lever to

x

4

"

bolt (fig.-4, item

100

lbs-ft.

OM

0149

FIGURE

g

7

Page 10

T

M

I

I

installed on rear fender of tractor when

quick hitch

m)

ANT

POR

is

Attach the two self adhesive reflectors

to the rear fender as illustrated in

figure 10.

I

Red ref lectors

installed.

must

be

Reflectors should be approximately

(13mm) up and

corners.

tractor

engine, remove the key, and set the

parking brake before removing the subframe.

a) Lower the hitch

b) Remove

from the tractor's rear draw plate.

c) Remove the two

(fig.?, item

flatbars to the attaching plates.

on

1/2"

6

"

(150mm) in from outside

To

avoid

a level surface,

with

x

5

"

1)

that secure the subframe

injury,

the

bolt (fig.1, item

1/2"

x

turn

lift

1

park the

arm.

1/4"

1/2"

off

bo1 ts

the

4)

FIGURE

10

d) Disconnect the end of the push arm

4)

(fig. 8, item

by removing the

e) Remove the subframe from under the tractor.

f)

Carefully remove the front support

brackets (fig.5, item

frame, and then remove the male hitch

assembly from the tractor.

from the pivot bracket

5/8"

x

1

5/8"

1)

from the tractor

pin.

8

Page 11

PARTS

1

'2

!3

.4

5

6

7

8

9

10

11

12

13

14

15

16

I

17

~

18

1

19

30

GUIDE

Front support bracket

Front support bracket

Attaching plate

Attaching plate

Hex bolt

Hex

Lockwasher

Lockwasher 3/8"

Hex

Reinforcement plate

Hex

Lockwasher

Hex. nut

Pivot bracket

Pin

Cotter

Hair

Hex

Hex.

Male

10mm x 25mm

bolt

bolt

bolt

10mm x 30mm

7/16

"

3/8"

5/16

5/16

x

" x 3/4"

5/16".

"

... . .

.............

5/8"

pin 4mm x 80mm

bolt

hitch assembly

pin

nut

x

10

5/32

7/16

7/16

5/8"

" x 1

"

x

"

.

RH

LH

RH

........

LH

........

......

......

. . .

. .

. .

. .

...........

1

"

.

.. . . . . .

.......

.....

.

. . . . . .

. .

..

...

.......-

"

.....

.......

1

1/4"

. . .

. . .........

.......

..

-.

-

.

.

.

1

1

1

1

2

4

10

6

6

1

2

2

2

1

1

1

1

4

4

1

SUBFRAME ASSEMBLY

-____--______________-------------------------------------------------------

________________________________________-------______----___-_--------------

REF

--_-----_-----______--__-------------

--------____________-_----_-----__-__

1

Hitch

2

Subframe channel

Hex

2

Tube

5

Lockwasher

6

Hex

7

Hex.

8

Subframe flatbar

9

Lift

0

Lift

11

Hex

12

Hex

13

Lockwasher

14

Hex

5

Support

3

Flatwasher,

DESCRIPTION

plate

bolt

spacer

nut

bolt

bolt

nut

1/2"

bolt

support

support

3/8"

plate

...............

..........

1/2"

..

1/2"

...

1/2"

x

...

x

5"

. .

. . .

. .

1

..........

bracket

bracket

1/2" x 1

3/8"

x

3/8"

1"

.

. . . . .

..............

.............

9/16

"

. .

.

.....

. . . . . . . .

.

. .

....

.

... . . . . . .

1/4"

1/2"

...

dia-hole

L.H.

R.H.

. . ..

.....

..

...

.

.

...

QT

1

1

1

1

6

4

4

4

1

1

Y

Page 12

PARTS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

GUIDE

Hex

bolt

Hex

nut 3/8", Uni-torque

Lift lever

Adjustment

Push

Pin (17/32"

Cotter

Flange bearing

Lift

Tube

Hex

Flatwasher 11/16

Bent retainer

Lockwasher

Hex

Pin

Hair

Plastic handle

arm

arm

spacer

bolt

nut

(5/8"

pin

3/8"

x

2

1/4"

................

fork

...........

..................

x

2

1/4")

pin

5/32

"

x

............

..................

...............

4

5/8"

5/8"

x

3

5/8"

1

mm

"

x

"

hole

plate

...........

..............

5/8")

x

65

mm

grip

....

. .

.-.

.-

1"

.....

........

....

.......

-.-.-..

.....

.......

2

2

1

1

1

1

1

2

2

2

1

2

2

1

1

1

1

1

\$-

I

14

Page 13

TORQUE

SPECIFICATION

TABLE

Inch-

SEE

8011

Grad8

Size

1

Millimeten

No.

GENERAL

USE

THE

NOTE:

Thew

normal

enpioe

treme

pressure lubricants

Pounds

Min.

TORQUE

FOLLOWING

valuer

apply

oil.

They

2

Feet

Mar.

Newton-Metcrr

I

Min. Max.

SPECIFICATION

TORQUES WHEN

to

fasteners

do

not

epply

are

uud.

This

if

applies

I

SPECIAL

as

recciwd

Wcciel

praphitcd

70

both

Pounds

Feet

Min. Max.

from

UNF

TABLE

TORQUES

supplier.

or

and

6

I

dry,

moly

dirulphide

UNC

threads.

Newton-Meters

Min.

I

(Revised

ARE

0,

when

prca~s

I

Max.

2-74)

NOT

lutxicatcd

Pounds

Min.

GIVEN

or

other

Feet

with

ex-

Max.

a*

NcMm

I

Min.

Mctcn

Max.

I

I

M14

M16

M18

METRIC

I

8T

41

7T

8T

41

7T

81

4T

7T

1

8T 175-194 237.1-2629

41 108-130 146.3-1762

I

2.0

2

.o

2

.o

BOLT TORQUE SPECIFICATIONS

1

57-66

49-56

81-93 109.8-126

96-109 130.1-147.7

67-77

116-130

129-145 174.8-196.5

88

-

100

lso-168 703.3-227-6

I

66.4-75.9

90.8-104.3

157.2-176.2

119.2-136

1

61-75

I

52-64

107

-

-

69

177-199 239.8-269.6

I

202c231 273.7-313

132-1SO

I

I

124 145-168

83 935-111-5

84-101.6

705-86.7

122-143.6

162.6-187

1789-203.3

I

81

213-249 288.6-337.4 246-289 3333-391.6

Page 14

Your satisfaction and goodwill are important to your dealer and to

us.

All

Honda

warranty details are explained in the Distributor's Limited Warranty. Normally,

any problems concerning the product

If

department.

you have a warranty problem that has not been handled to your

will

be handled by your dealer's service

satisfaction, we suggest you take the following action:

Discuss your problem with a member of dealership management.

If

can be quickly resolved at that level.

the problem has already been reviewed

with the Service Manager, contact the owner of the dealership

Manager.

If

your problem still has not been resolved to your satisfaction, contact the

Power Equipment Customer Service Department of American Honda Motor

American Honda Motor Co.,Inc.

Power Equipment Customer Service Department

4475

River Green Parkway

Duluth,

Telephone:

will

We

need the following in order to assist you:

o

Your name, address and telephone number

o

Product model and seri a1 number

o

Date of purchase

o

Dealer name and address

o

Nature of the problem

After reviewing all the facts involved, you

taken. Please bear

in

Georgia 30136

(404)

497-6400

will

be advised of what action can be

mind that your problem

will

likely be resolved at the

dealership, using the dealer's facilities, equipment and personnel,

important that your initial contact be

with

the dealer.

Of

ten complaints

or

the

General

Co.,Inc:

S

O

it

is

very

Your

purchase of

a

Honda product

is

greatly appreciated by both your dealer and

American Honda Motor Company. We want to assist you in every way possible to assure

your satisfaction

For

future reference, record your unit's model number, serial number and date of

purchase

in

the spaces below. Refer to this information when ordering parts and

with

your

purchase.

when making technical or warranty inquiries.

Page 15

Page 16

H/C

3752482

(9307)

Loading...

Loading...