Honda GD320, GD410 Owner's Manual

Thank you for purchasing a Honda engine.

This manual describes the operation and maintenance of the GD320 and

GD410 diesel engines. All information in this publication is based on the

latest product information available at the time of printing.

Honda Motor Co., Ltd. reserves the right to make changes at any time

without notice and without incurring any obligation.

No part of this publication may be reproduced without written permission.

This manual should be considered a permanent part of the engine and

should remain with the engine if it is resold.

On some engines, a U.S.D.A. qualified spark arrester is installed. Periodic

maintenance is required to keep it functioning as designed. In some areas,

it is illegal to operate an engine without a spark arrester.

Pay special attention to statements preceded by the following words:

m Indicates a strong possibility that serious injury or death could

result if instructions are not followed.

m

) NOTICE ] I,.,&

Indicates a possibility that minor injury can result if instructions

are not followed.

rcates that equipment or property damage can result if in-

structions are not followed.

If a problem should arise, or if you have any questions about your engine,

consult an authorized Honda engine dealer.

Honda engines are designed to give safe and dependable service if

operated according to instructions. Read and understand the Owner’s

Manual before operating the engine. Failure to do so could result in injury

or equipment damage.

NOTE: If you purchased the engine separately, be sure to follow

HONDA’s application recommendations. For details, consult your

authorized Honda engine dealer.

HONDA MOTOR CO., LTD. 1990, ALL RIGHTS RESERVED

CONTENTS

I

1. ENGINE SAFETY..

2. COMPONENT IDENTIFICATION..

3. BATTERY CONNECTIONS (For electric starter).

4. PRE-OPERATION CHECK..

5. STARTING THE ENGINE

6. STOPPING THE ENGINE ........................................................

7. MAINTENANCE ...................................................................

8. TRANSPORTING/STORAGE..

9. TROUBLESHOOTING..

10. SPECIFICATIONS..

11. WARRANTY SERVICE..

................................................................

............................................

.........................

.....................................................

........................................................

.................................................

..........................................................

...............................................................

.........................................................

3

4

9

10

13

18

20

‘26

27

28

29

2

1. ENGINE SAFETY

Honda engines are designed to give safe and dependable service if

operated according to instructions. Read and understand this Owner’s

Manual before operating the engine. Failure to do so could result in injury or equipment damage.

To prevent fire hazards and to provide adequate ventilation, keep the

engine at least 1 meter (3 feet) away from buildings and other equipment during operation. Do not place flammable objects close to the

engine.

Children and pets must be kept away from the area of operation.

Know how to stop the engine quickly, and understand the operation of

all controls. Never permit anyone to operate the engine without proper

instructions.

Diesel fuel is flammable and is EXPLOSIVE under certain conditions.

Refuel in a well-ventilated area with the engine stopped. Do not smoke

or allow flames or sparks in the refueling area or where diesel fuel is

stored.

Do not overfill the fuel tank. After refueling, make sure the tank cap is

closed properly and securely.

Be careful not to spill fuel when refueling. Fuel vapor or spilled fuel may

ignite. If any fuel is spilled, make sure the area is dry before starting the

engine.

Never run the engine in an enclosed or confined area. Exhaust contains

poisonous carbon monoxide gas; exposure can cause loss of consciousness and may lead to death.

The muffler becomes very hot during operation and remains hot for a

while after stopping the engine. Be careful not to touch the muffler or

exhaust pipe while it is hot. To avoid severe burns or fire hazards, let

the engine cool before transporting it or storing it indoors.

l Use diesel fuel only. DO NOT use gasoline, benzine or any other fuel.

l Place the engine on a stable surface. Do not tilt the engine more than

20° from horizontal.

l Do not tamper with engine parts that are sealed or secured with safety

wire; they are critical items.

3

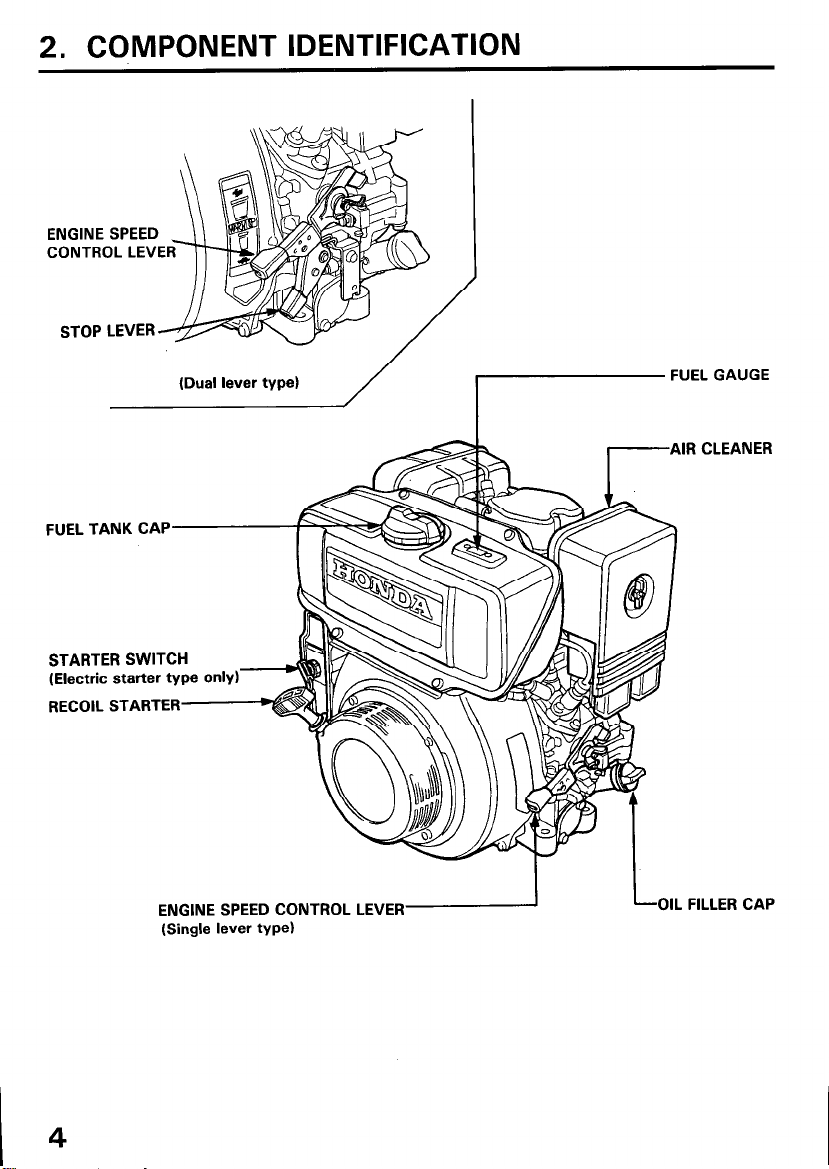

2. COMPONENT IDENTIFICATION

ENGINE SPEED

CONTROL LEVE

STOP LEVER

(Dual lever type)

FUEL TANK CAP

CLEANER

STARTER SWITCH

(Electric starter type only)

RECOIL STARTER-

ENGINE SPEED CONTROL LEVER

(Single lever type)

4

_

I

LOIL FILLER CAP

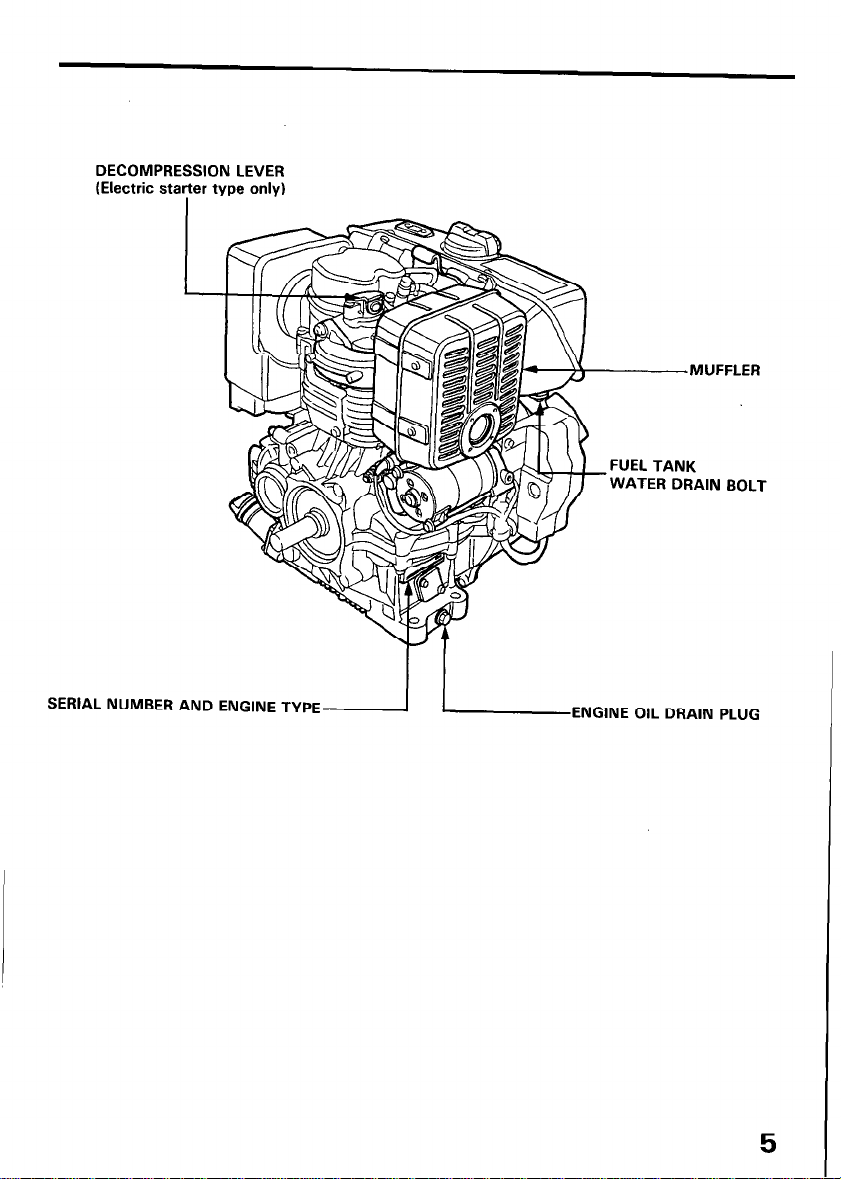

DECOMPRESSION LEVER

(Electric starter type only)

I

WATER DRAIN BOLT

SERIAL NUMBER AND ENGINE TYPE

-

IENGINE OIL DRAIN PLUG

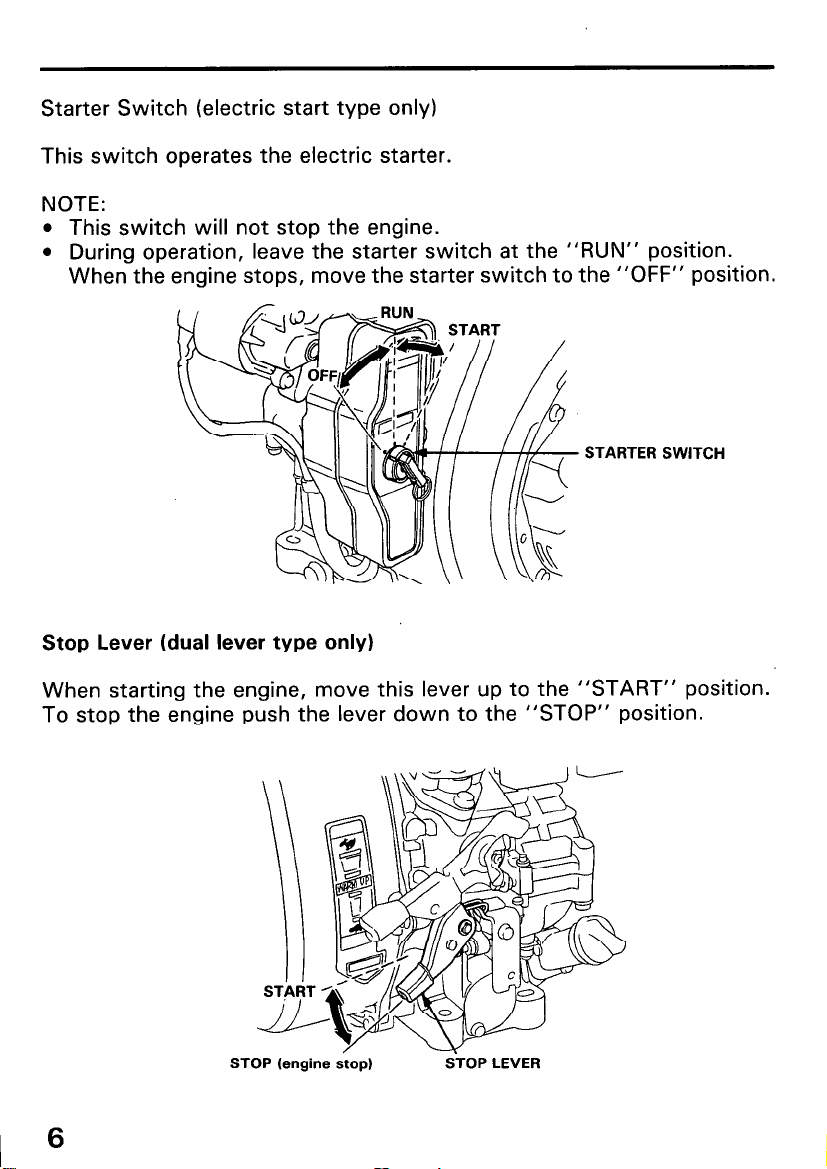

Starter Switch (electric start type only)

This switch operates the electric starter.

NOTE:

l This switch will not stop the engine.

l During operation, leave the starter switch at the “RUN” position.

When the engine stops, move the starter switch to the “OFF” position.

STARTER SWITCH

Stop Lever (dual lever type only)

When starting the engine, move this lever up to the “START” position.

To stop the engine push the lever down to the “STOP” position.

STOP (engine siop)

SiOP LEVER

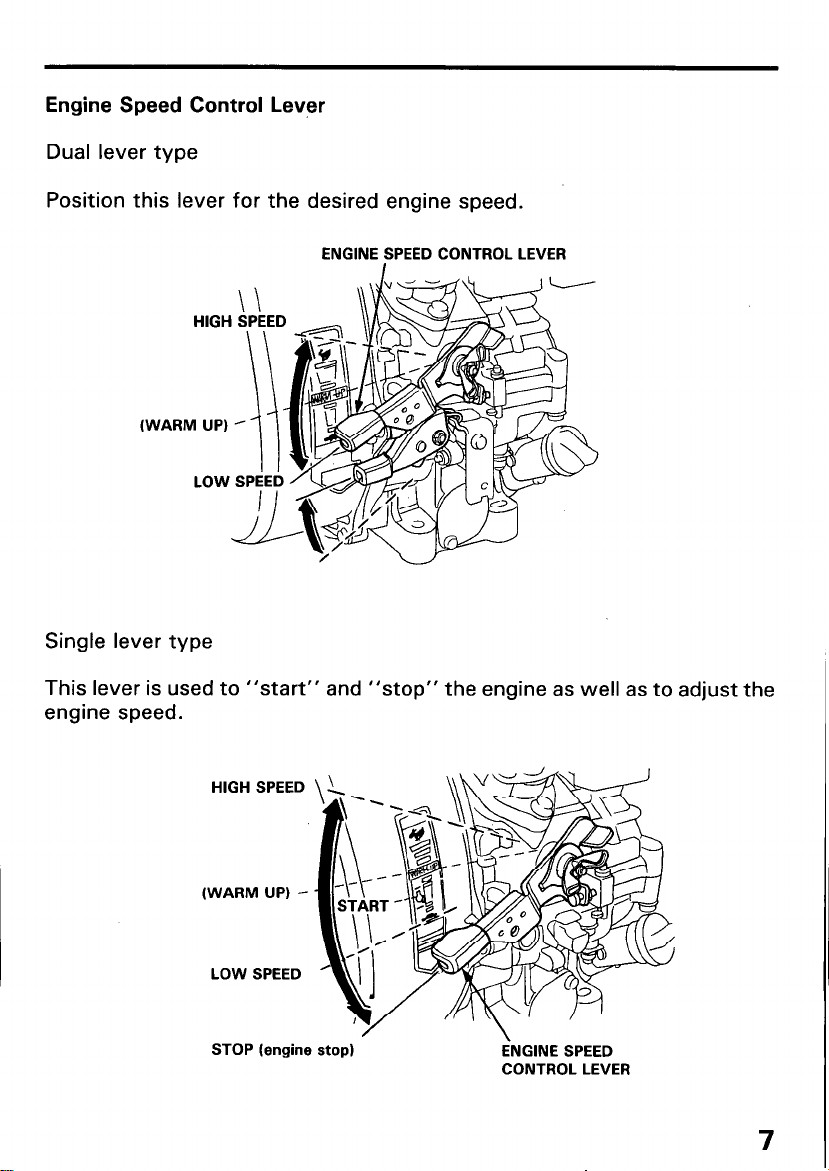

Engine Speed Control Levy

Dual lever type

Position this lever for the desired engine speed.

ENGINE SPEED CONTROL LEVER

HIGH SPEED

(WARM UP) H

Single lever type

This lever is used to “start” and “stop” the engine as well as to adjust the

engine speed.

HIGH SPEED

(WARM UP) -

LOW SPEED

STOP (engine stop)

ENGINE SPEED

CONTROL LEVER

7

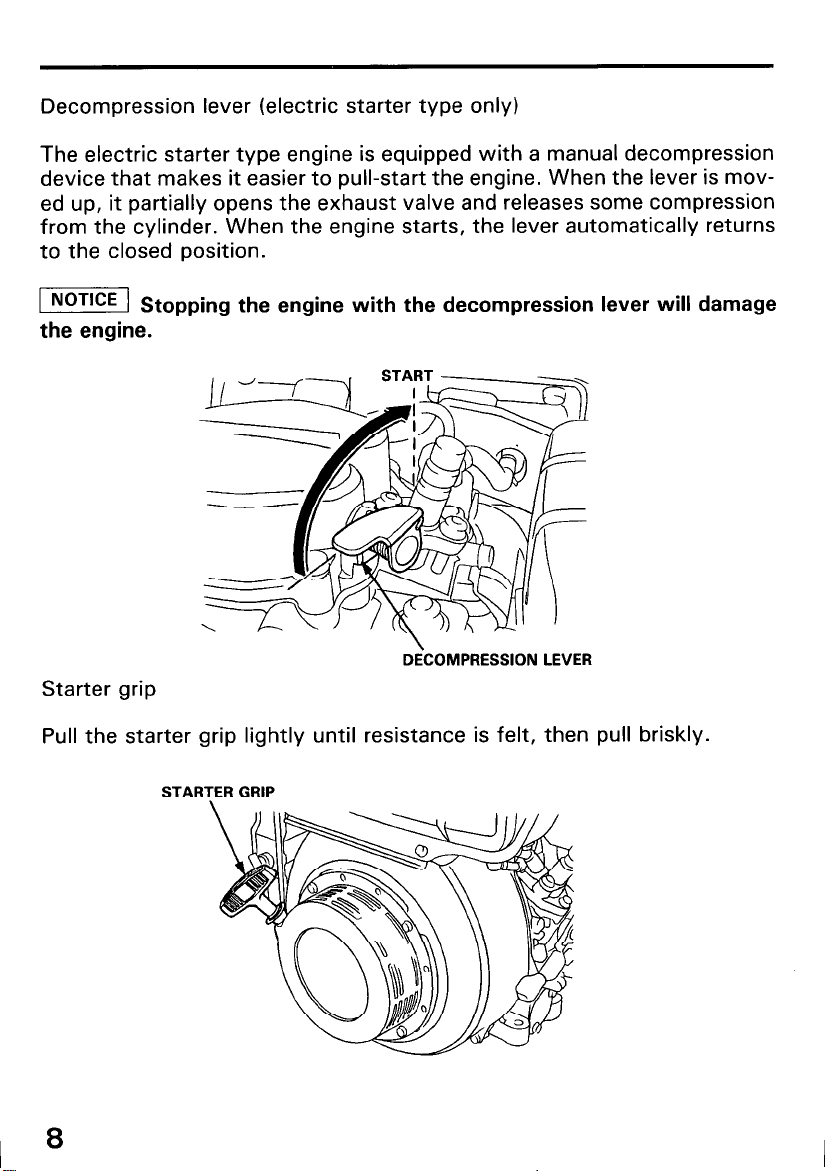

Decompression lever (electric starter type only)

The electric starter type engine is equipped with a manual decompression

device that makes it easier to pull-start the engine. When the lever is moved up, it partially opens the exhaust valve and releases some compression

from the cylinder. When the engine starts, the lever automatically returns

to the closed position.

I-NOTICE 1 St

the engine.

opping

the engine with the decompression lever will damage

DECOMPRESSION LEVER

Starter grip

Pull the starter grip lightly until resistance is felt, then pull briskly.

STARTER GRIP

8

I

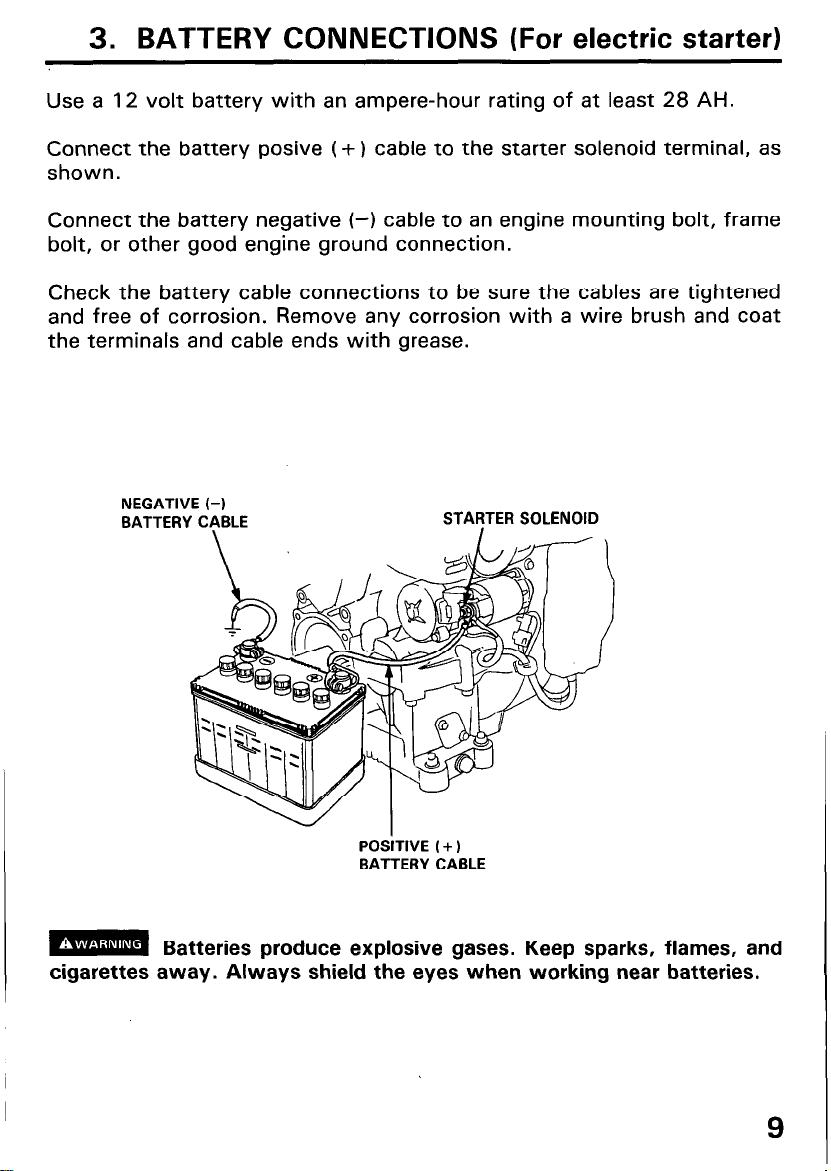

3. BATTERY CONNECTIONS (For electric starter)

Use a 12 volt battery with an ampere-hour rating of at least 28 AH.

Connect the battery posive (+) cable to the starter solenoid terminal, as

shown.

Connect the battery negative (-1 cable to an engine mounting bolt, frame

bolt, or other good engine ground connection.

Check the battery cable connections to be sure the cables are tightened

and free of corrosion. Remove any corrosion with a wire brush and coat

the terminals and cable ends with grease.

NEGATIVE i-1

BATTERY CABLE

POSITIVE ( + )

BATTERY CABLE

m

cigarettes away. Always shield the eyes when working near batteries.

Batteries produce explosive gases. Keep sparks, flames, and

STARTER SOLENOID

9

4. PRE-OPERATION CHECK

I

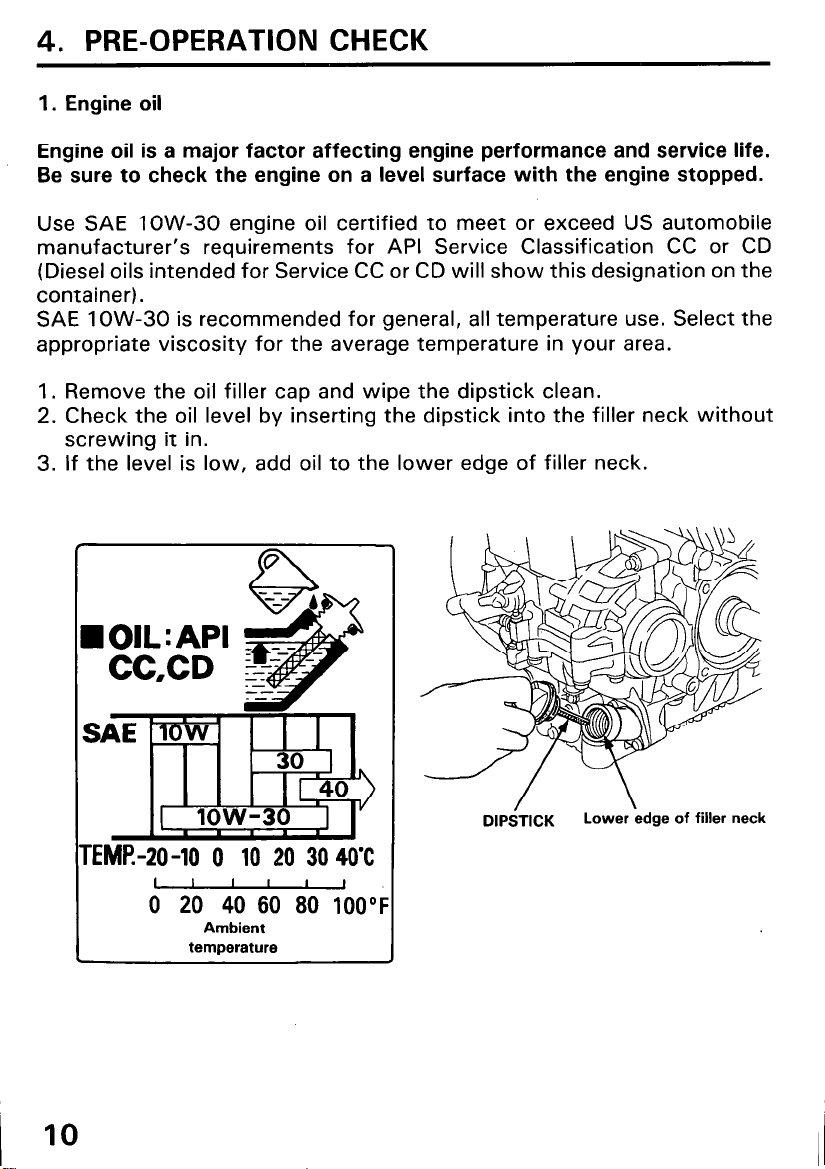

1. Engine oil

Engine oil is a major factor affecting engine performance and service life.

Be sure to check the engine on a level surface with the engine stopped.

Use SAE low-30 engine oil certified to meet or exceed US automobile

manufacturer’s requirements for API Service Classification CC or CD

(Diesel oils intended for Service CC or CD will show this designation on the

container).

SAE 1 OW-30 is recommended for general, all temperature use. Select the

appropriate viscosity for the average temperature in your area.

1. Remove the oil filler cap and wipe the dipstick clean.

2. Check the oil level by inserting the dipstick into the filler neck without

screwing it in.

3. If the level is low, add oil to the lower edge of filler neck.

rEMl?-20-10 0 10 20 30 4o'c

O~OO°F

Ambient

temperature

10

DIPiTICK

I

Lower edge of filler neck

Loading...

Loading...