Honda FRC800 Owner's Manual

Owner’s Manual

TILLER

FRC800

o2002-2009 Honda Motor Co., Ltd. -All Rights Reserved

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

Keep this owner’s manual handy so you can refer to it at any time. This

owner’s manual is considered a permanent part of the tiller and

should remain with the tiller if resold.

The information and specifications included in this publication were in

effect at the time of approval for printing. Honda Motor Co., Ltd.

reserves the right, however, to discontinue or change specifications or

design at any time without notice and without incurring any obligation

whatever.

INTRODUCTION

Congratulations on your selection of a Honda tiller. We are certain you

will be pleased with your purchase of one of the finest tillers on the

market.

We want to help you get the best results from your new tiller and to

operate it safely. This manual contains the information on how to do

that; please read it carefully.

As you read this manual, you will find information preceded by a

symbol. That information is intended to help you avoid

damage to your tiller, other property, or the environment.

We suggest you read the warranty policy to fully understand its

coverage and your responsibilities of ownership. The warranty policy

is a separate document that should have been given to you by your

dealer.

When your tiller needs scheduled maintenance, keep in mind that your

Honda servicing dealer is specially trained in servicing Honda tillers

and is supported by the parts and service divisions of American Honda.

Your Honda servicing dealer is dedicated to your satisfaction and will

be pleased to answer your questions and concerns.

Best Wishes,

Honda Motor Co., Ltd.

1

INTRODUCTION

A FEW WORDS ABOUT SAFETY

Your safety and the safety of others are very important. And using this

tiller safely is an important responsibility.

To help you make informed decisions about safety, we have provided

operating procedures and other information on labels and in this

manual. This information alerts you to potential hazards that could

hurt you or others.

Of course, it is not practical or possible to warnyouaboutallthe

hazards associated with operating or maintaining a tiller. You must

use your own good judgment.

You will find important safety information in a variety of forms,

including:

Safety Labels

Safety Messages

of three signal words, DANGER, WARNING, or CAUTION.

These signal words mean:

Safety Headings

Safety Section

Instructions

This entire book is filled with important safety information –– please

read it carefully.

–– on the tiller.

–– preceded by a safety alert symbol and one

You WILL be KILLED or SERIOUSLY HURT if

you don’t follow instructions.

You CAN be KILLED or SERIOUSLY HURT if

you don’t follow instructions.

You CAN be HURT if you don’t follow

instructions.

–– such as

–– such as

–– how to use this tiller correctly and safely.

IMPORTANT SAFETY INFORMATION.

TILLER SAFETY.

2

CONTENTS

.........................................................................................TILLER SAFETY . 5

................................................................................................CONTROLS . 9

..........................................................................................CONTROLS . 10

.........................................................................................Fuel Valve . 10

.....................................................................................Choke Lever . 10

......................................................................................Starter Grip . 11

...........................................................................................Drag Bar . 12

................................................IMPORTANT SAFETY INFORMATION . 5

................................................................SAFETY LABEL LOCATIONS . 8

............................................COMPONENT & CONTROL LOCATIONS . 9

..................................................................................Engine Switch . 10

..................................................................................Throttle Lever . 11

.............................................................Handlebar Height Adjuster . 11

...........................................................................Main Clutch Lever . 12

................................................................................Gearshift Lever . 12

.............................................................................BEFORE OPERATION . 13

.............................................ARE YOU READY TO GET STARTED . 13

?

.....................................................IS YOUR TILLER READY TO GO . 13

?

.............................................................................Check the Engine . 14

................................................................................Check the Tiller . 14

............................................................................................OPERATION . 15

...................................................SAFE OPERATING PRECAUTIONS . 15

....................................................................STARTING THE ENGINE . 16

.....................................OPERATING THE CONTROLS FOR TILLING . 19

..................................................................................HANDLING TIPS . 23

....................................................................STOPPING THE ENGINE . 24

.....................................................................SERVICING YOUR TILLER . 25

............................................THE IMPORTANCE OF MAINTENANCE . 25

....................................................................MAINTENANCE SAFETY . 26

..............................................................MAINTENANCE SCHEDULE . 27

.........................................................................................REFUELING . 28

.............................................................FUEL RECOMMENDATIONS . 28

................................................................ENGINE OIL LEVEL CHECK . 30

.........................................................................ENGINE OIL CHANGE . 31

..................................................ENGINE OIL RECOMMENDATIONS . 32

..................................................TRANSMISSION OIL LEVEL CHECK . 33

....................................................................AIR FILTER INSPECTION . 34

.......................................................................AIR FILTER CLEANING . 34

.......................................................................SPARK PLUG SERVICE . 36

3

CONTENTS

SERVICING YOUR TILLER (continued)

........................................................CLUTCH CABLE ADJUSTMENT . 37

....................................................THROTTLE CABLE ADJUSTMENT . 38

...............................................................DRIVE BELT ADJUSTMENT . 39

...............................................................SEDIMENT CUP CLEANING . 41

..............................................................SPARK ARRESTER SERVICE . 42

..........................................................................TINE REPLACEMENT . 43

.....................................................................TIRE PRESSURE CHECK . 44

.......................................................TINES AND FASTENERS CHECK . 45

................................................................................................STORAGE . 46

..................................................................STORAGE PREPARATION . 46

...........................................................................................Cleaning . 46

...................................................................................................Fuel . 47

.........................................................................................Engine Oil . 50

.................................................................STORAGE PRECAUTIONS . 51

..............................................................REMOVAL FROM STORAGE . 51

.....................................................................................TRANSPORTING . 52

...........................................................................ENGINE PROBLEMS . 53

......................................................................Engine Will Not Start . 53

........................................................................Engine Lacks Power . 54

...........................................................................TILLING PROBLEMS . 55

.........................................................................Poor Tilling Quality . 55

.....................................TAKING CARE OF UNEXPECTED PROBLEMS . 53

4

........................................TECHNICAL & CONSUMER INFORMATION . 56

..............................................................TECHNICAL INFORMATION . 56

................................................................Serial Number Locations . 56

..................Carburetor Modification for High Altitude Operation . 57

..........................................Emission Control System Information . 58

...........................................................................................Air Index . 60

..................................................................................Specifications . 61

.............................................................CONSUMER INFORMATION . 62

............................................................Dealer Locator Information . 62

.........................................................................Honda Publications . 62

.......................................................Customer Service Information . 63

...........................QUICK REFERENCE INFORMATION . Inside back cover

TILLER SAFETY

IMPORTANT SAFETY INFORMATION

Honda tillers are designed to cultivate earth outdoors. Other uses can

result in injury to the operator or damage to the tiller and other

property.

Most accidents can be prevented if you follow all instructions in this

manual and on the tiller. The most common hazards are discussed

below, along with the best way to protect yourself and others.

Operator Responsibility

Know how to stop the tiller quickly in case of emergency.

Understand the use of all tiller controls.

Be very cautious when operating the tiller in REVERSE, especially if

attachments are being used.

Keep a firm hold on the handlebars. They may tend to lift during

clutch engagement.

Be sure the drag bar is in place and properly adjusted.

Be sure that anyone who operates the tiller receives proper

instruction. Do not let children operate the tiller. Keep children and

pets away from the area of operation.

Carbon Monoxide Hazards

Exhaust contains poisonous carbon monoxide, a colorless, odorless

gas. Breathing carbon monoxide can cause loss of consciousness

and may lead to death.

If you run the tiller in a confined or even partially enclosed area, the

air you breathe could contain dangerous amounts of carbon

monoxide. To keep carbon monoxide from building up, provide

adequate ventilation.

5

TILLER SAFETY

Fire and Burn Hazards

The exhaust system gets hot enough to ignite some materials.

Keep the tiller at least 3 feet (1 meter) away from buildings and

−

other equipment during operation.

Keep flammable materials away from the tiller.

−

The muffer becomes very hot during operation and remains hotfor

a while after stopping the engine.

Be careful not to touch the muffler while it is hot. Let the engine cool

before storing the tiller indoors.

Refuel With Care

Gasoline is extremely flammable, and gasoline vapor can explode.

Allow the engine to cool if the tiller has been in operation. Refuel only

outdoors in a well-ventilated area with the engine OFF. Do not overfill

the fuel tank. Never smoke near gasoline, and keep other flames and

sparks away. Always store gasoline in an approved container. Make

sure that any spilled fuel has been wiped up before starting the engine.

Avoid Rotating Tines

Rotating tines can cause serious cuts and even amputate body parts.

Keep away from the tine area whenever the engine is running. If you

need to work around the tines to clear an object accumulation or for

any other reason, always shut off the engine. Disconnect the spark

plug cap, and wear heavy gloves when you need to clean the tine area

or handle the tines.

Clear Tilling Area

A tine can throw rocks and other objects with enough force to cause

serious injury. Before tilling, carefully inspect the area and remove all

stones, sticks, bones, nails, pieces of wire, and other loose objects. Be

aware; if children are in the shop area, stop the tiller. Never operate

the tines over gravel.

6

TILLER SAFETY

Keep Shields in Place

Guards and shields are designed to protect you from being hit by

thrown objects and to keep you from touching hot engine parts and

moving components. For your safety and the safety of others, keep all

shields in place when the engine is running.

Wear Protective Clothing

Wearing protective clothing will reduce your risk of injury. Long pants

and eye protection reduce the risk of injures from thrown objects.

Sturdy shoes with aggressive soles provide better traction.

Turn Engine Off When Not Operating the Tiller

If you need to leave the tiller for any reason, even just to inspect the

area ahead, always turn the engine off.

Slope Operation

When tilling on slopes, keep the fuel tank less than half full to

minimize fuel spillage.

Till across the slope (at equally spaced intervals) rather than up and

down it.

Be very careful when changing the direction of the tiller on a slope.

Do not use the tiller on a slope of more than 10°. Before starting the

engine, check that the tiller is not damaged and is in good condition.

For your safety and the safety of others, exercise extremecarewhen

using the tiller on a slope.

Tilling Conditions

Operate the tiller only in daylight or good artificial light. Do not

operate the tiller at night or under poor light conditions.

7

TILLER SAFETY

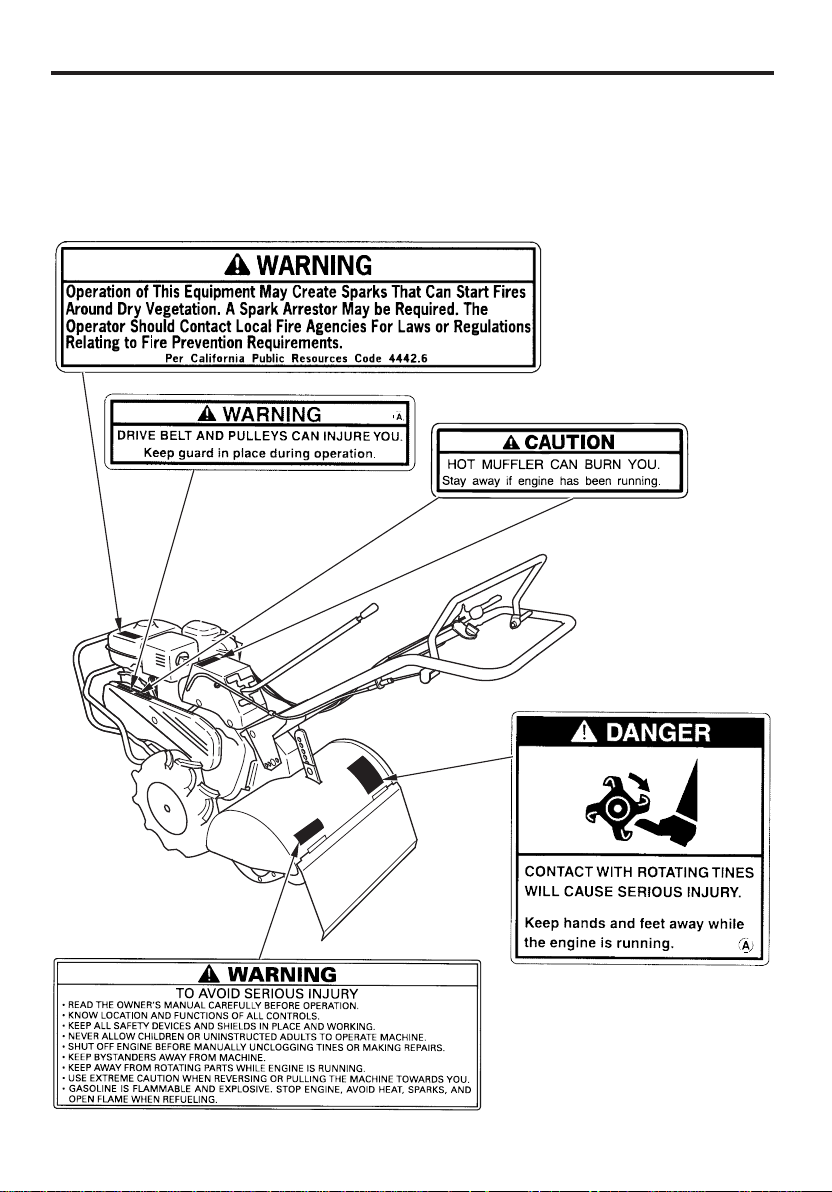

SAFETY LABEL LOCATIONS

These labels warn you of potential hazards that can cause serious injury. Read them carefully. If a label comes off or becomeshardtoread,

contact your Honda tiller dealer for a replacement.

California type

California type Non-California type

8

CONTROLS

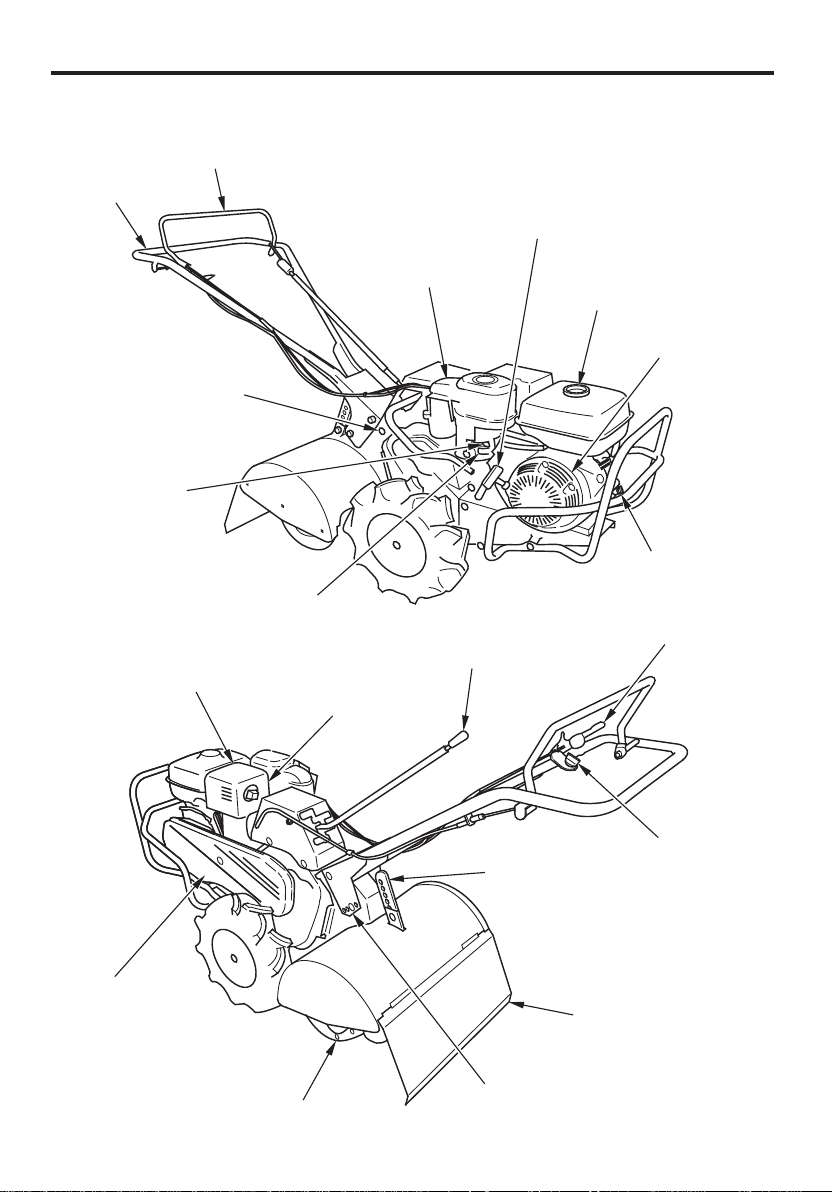

COMPONENT & CONTROL LOCATIONS

MAIN CLUTCH LEVER

HANDLEBAR

AIR CLEANER

TRANSMISSION

OIL FILLER CAP

CHOKE LEVER

FUEL VALVE LEVER

GEAR SHIFT LEVER

MUFFLER

SPARK PLUG

STARTER GRIP

FUEL TANK CAP

RECOIL STARTER

ENGINE OIL FILLER

CAP/DIPSTICK

THROTTLE LEVER

V-BELT COVER

ENGINE SWITCH

DRAG BAR

MUD GUARD

HANDLE HEIGHT ADJUSTER

ROTARY TINES

9

CONTROLS

CONTROLS

Fuel Valve

The fuel valve opens and closes the

connection between the fuel tank

and the carburetor.

The fuel valve lever must be in the

ON position for the engine to run.

After stopping the engine, turn the

fuel valve lever to the OFF position.

Choke Lever

The choke lever opens and closes

the choke valve in the carburetor.

The CLOSED position enriches the

fuel mixture for starting a cold

engine.

The OPEN position provides the

correct fuel mixture for operation

after starting and for restarting a

warm engine.

OFF

CHOKE

LEVER

CLOSED

FUEL VALVE LEVER

ON

OPEN

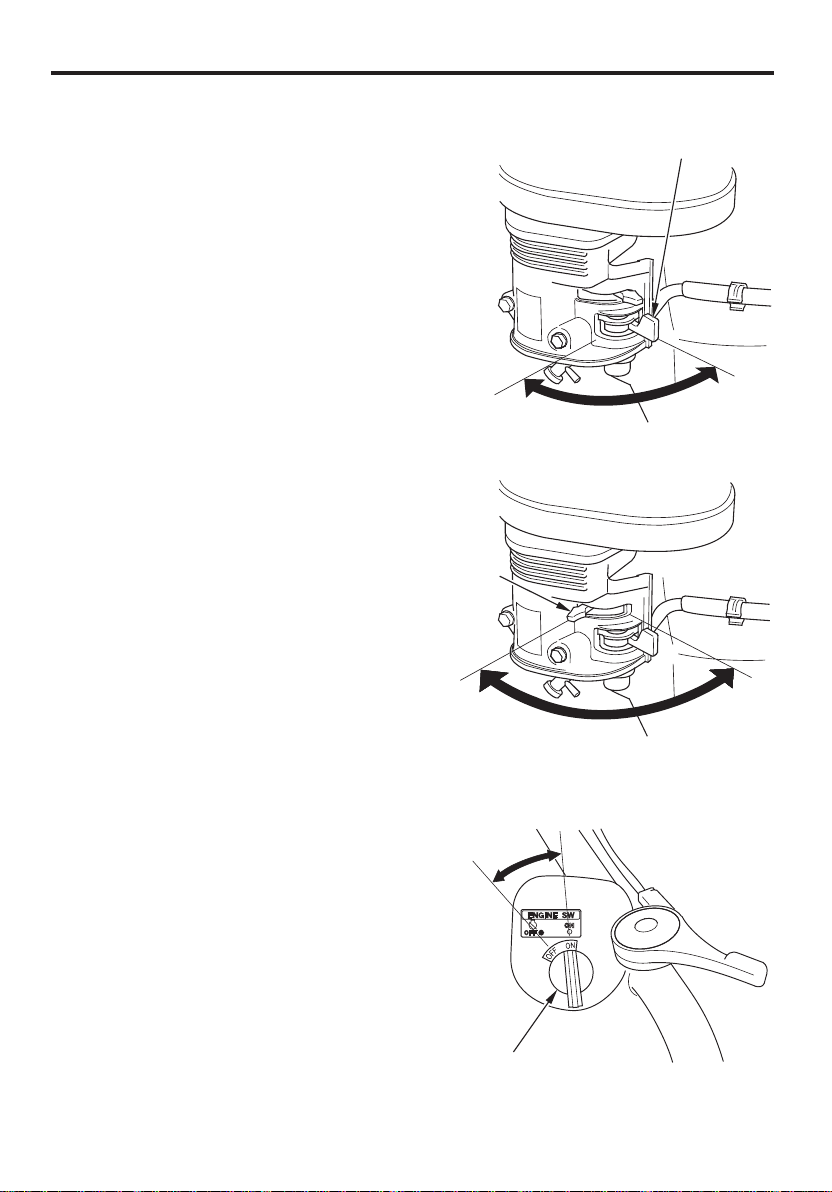

Engine Switch

The engine switch controls the

ignition system.

OFF Stops the engine.

−

ON Running position.

−

10

ON

OFF

ENGINE SWITCH

CONTROLS

Starter Grip

Pulling the starter grip operates the

recoil starter to crank the engine.

Throttle Lever

The throttle lever controls engine

speed.

Moving the throttle lever in the

directions shown makes the engine

runfasterorslower.

Tine speed is controlled by

adjusting the throttle lever. At

maximum throttle position, the

tines will rotate at the highest speed.

Moving the throttle lever toward the

idle position will decrease the tine

speed.

FAST

STARTER GRIP

THROTTLE

LEVER

SLOW

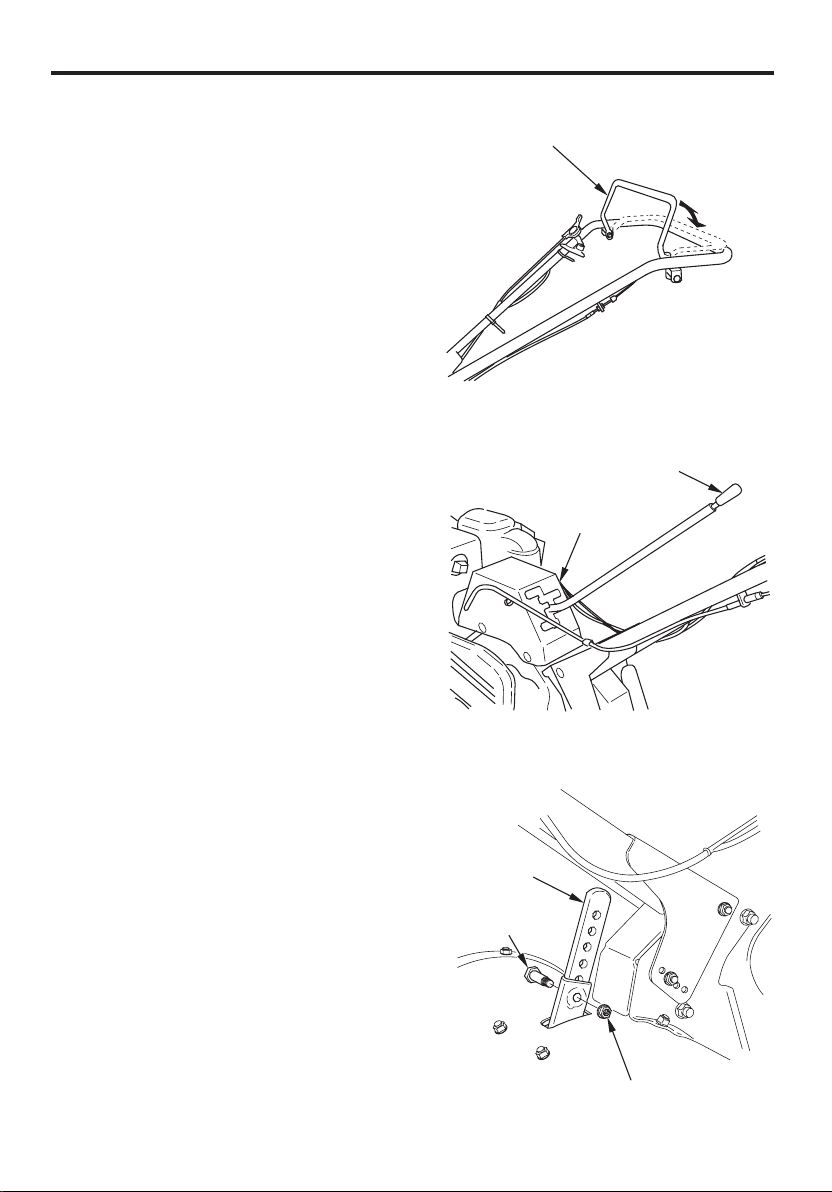

Handlebar Height Adjuster

Handlebar height can be adjusted to

match operator height.

For normal tilling, the most

comfortable operator position is

with the handlebars at waist height.

HEIGHT ADJUSTING BOLT

HANDLEBAR LOCK NUT

11

CONTROLS

Main Clutch Lever

The main clutch lever engages and

disengages the transmission that

drives the tines.

MAIN CLUTCH LEVER

DISENGAGED

EENNGGAAGGEEDD

Gearshift Lever

The transmission offers a choice of

three forward speeds, neutral, and

one reverse speed. Shift lever

positions are indicated on the

gearshift lever bracket.

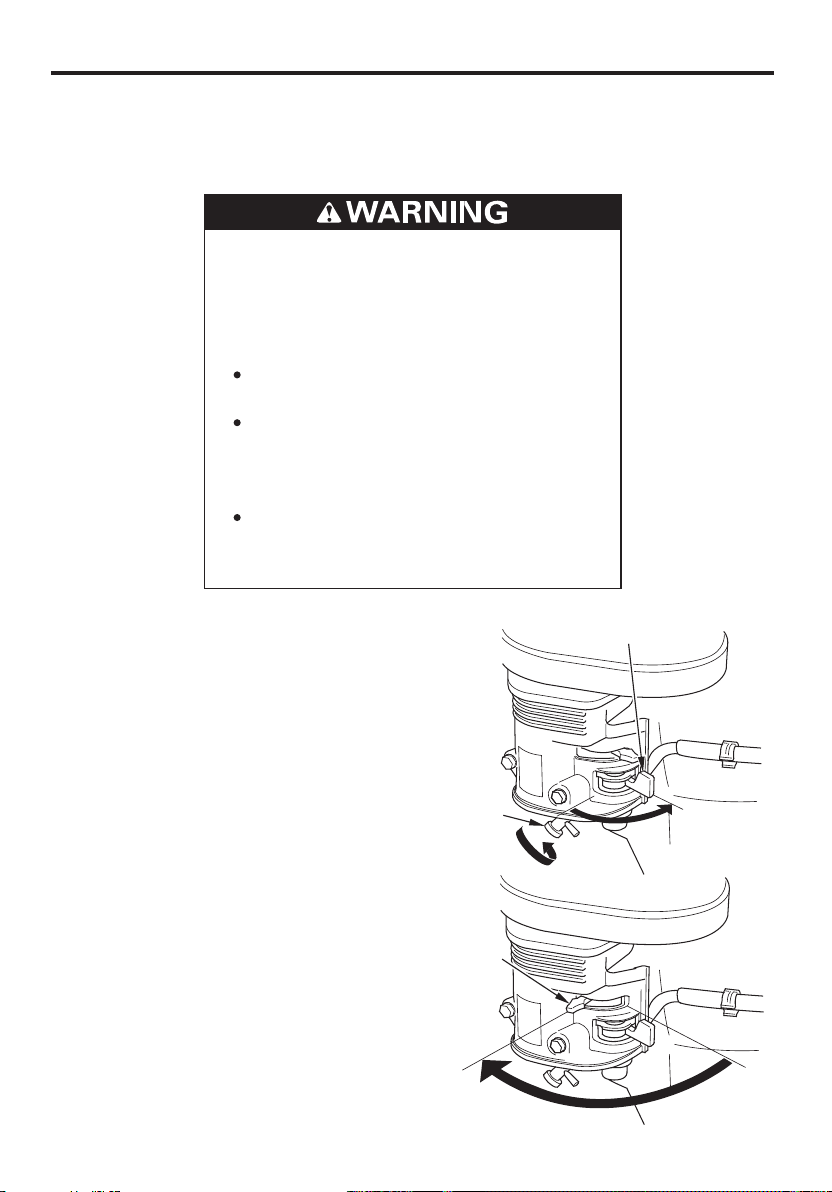

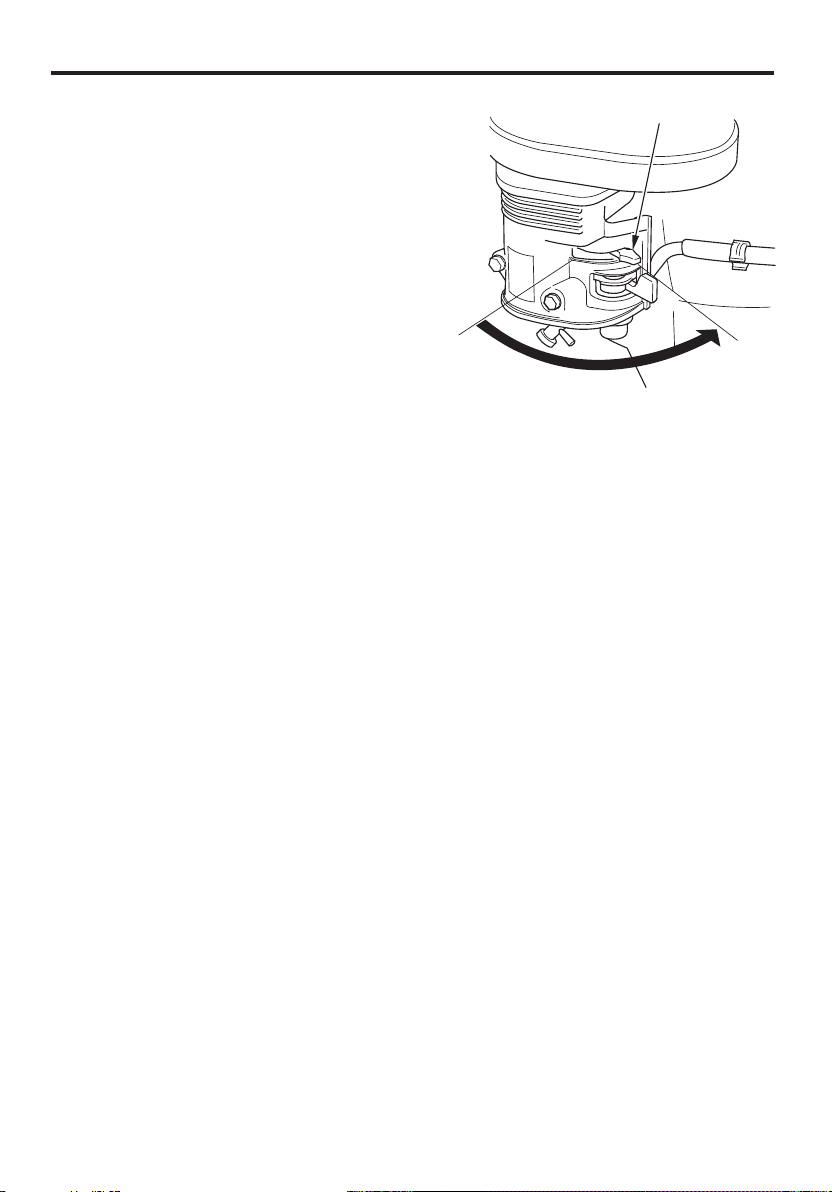

Drag Bar

The drag bar controls tilling depth

and should always be used when

tilling. It enables you to compensate

for the hardness of the soil. Ideal

drag bar height will depend on the

type of soil being tilled and soil

conditions at the time of tilling. In

general, the drag bar should be

adjusted so that the tiller is tilted

slightly backward.

GEARSHIFT LEVER

GEARSHIFT LEVER

BRACKET

DRAG BAR

LOCKING BOLT

LOCKING NUT

12

BEFORE OPERATION

ARE YOU READY TO GET STARTED?

Your safety is your responsibility. A little time spent in preparation will

significantly reduce your risk of injury.

Knowledge

Read and understand this manual. Know what the controls do and

how to operate them.

Familiarize yourself with the tiller and its operation before you begin

using it. Know how to quickly shut off the tiller in case of an

emergency.

IS YOUR TILLER READY TO GO?

For your safety, and to maximize the service life of your equipment, it

is very important to take a few moments before you operate the tiller

to check its condition. Be sure to take care of any problem you find, or

have your servicing dealer correct it, before you operate the tiller.

Improperly maintaining this tiller, or

failing to correct a problem before

operation, could cause a

malfunction in which you could be

seriously injured.

Always perform a pre-operation

inspection before each operation,

and correct any problem.

13

BEFORE OPERATION

Do not place flammable objects close to the engine.

Before beginning your pre-operation checks, be sure the tiller is on a

level surface and the engine switch is in the OFF position.

Check the Engine

Check the oil level (see page ).

Check the air filter (see page ). A dirty air filter will restrict air flow to

the carburetor, reducing engine and tiller performance.

Check the fuel level (see page ). Starting with a full tank will help to

eliminate or reduce operating interruptions for refueling.

Check the Tiller

Check the transmission oil(seepage ).

30

34

28

33

14

OPERATION

SAFE OPERATING PRECAUTIONS

Before operating the tiller for the first time, please review both the

TILLER SAFETY

For your safety, avoid starting or operating the tiller in an enclosed

area such as a garage. Your tiller’s exhaust contains poisonous carbon

monoxide gas that can collect rapidly in an enclosed area and cause

illness or death.

chapter and the chapter titled

Carbon monoxide gas is toxic.

Breathing it can cause

unconsciousness and even kill you.

Avoid any enclosed areas or

activities that expose you to carbon

monoxide.

BEFORE OPERATION

.

15

OPERATION

STARTING THE ENGINE

Refer to

Safe Operating Precautions

Tines are sharp and spin fast.

Spinning tines can cut you severely

and can amputate body parts.

Wear protective footwear.

Keep your hands and feet away

from the tines while the engine is

running.

Stop the engine before

performing any adjustment,

inspection, or maintenance.

Turn the fuel valve lever to the ON

1.

position. Check that the fuel drain

screw is tightened securely.

on Page .

15

FUEL VALVE LEVER

Move the choke lever to the

2.

CLOSED position to start a cold

engine.

Leave the choke lever in the OPEN

position to restart a warm engine.

16

DRAIN

SCREW

CHOKE

LEVER

CLOSED

ON

OPEN

OPERATION

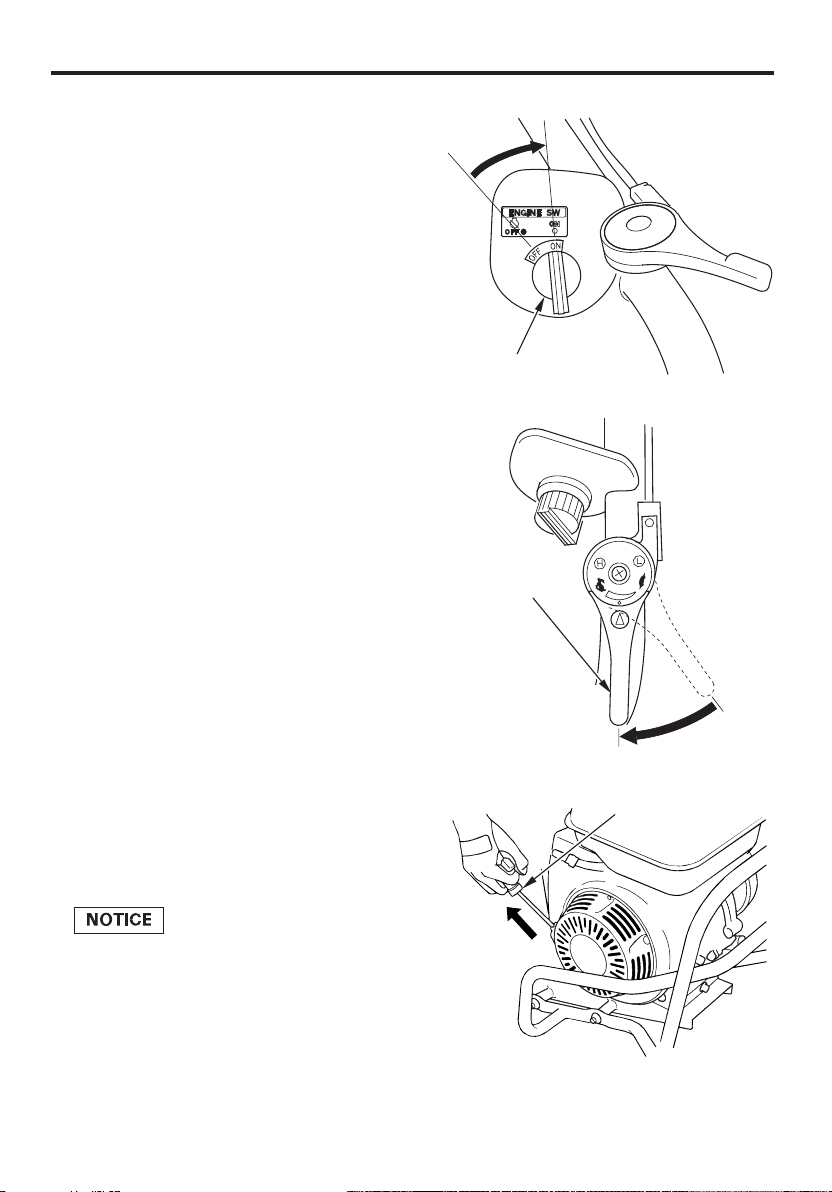

Turn the engine switch to the ON

3.

position.

Move the throttle lever away from

4.

the SLOW position, about 1/3 of

the way toward the FAST position.

ON

ENGINE SWITCH

THROTTLE

LEVER

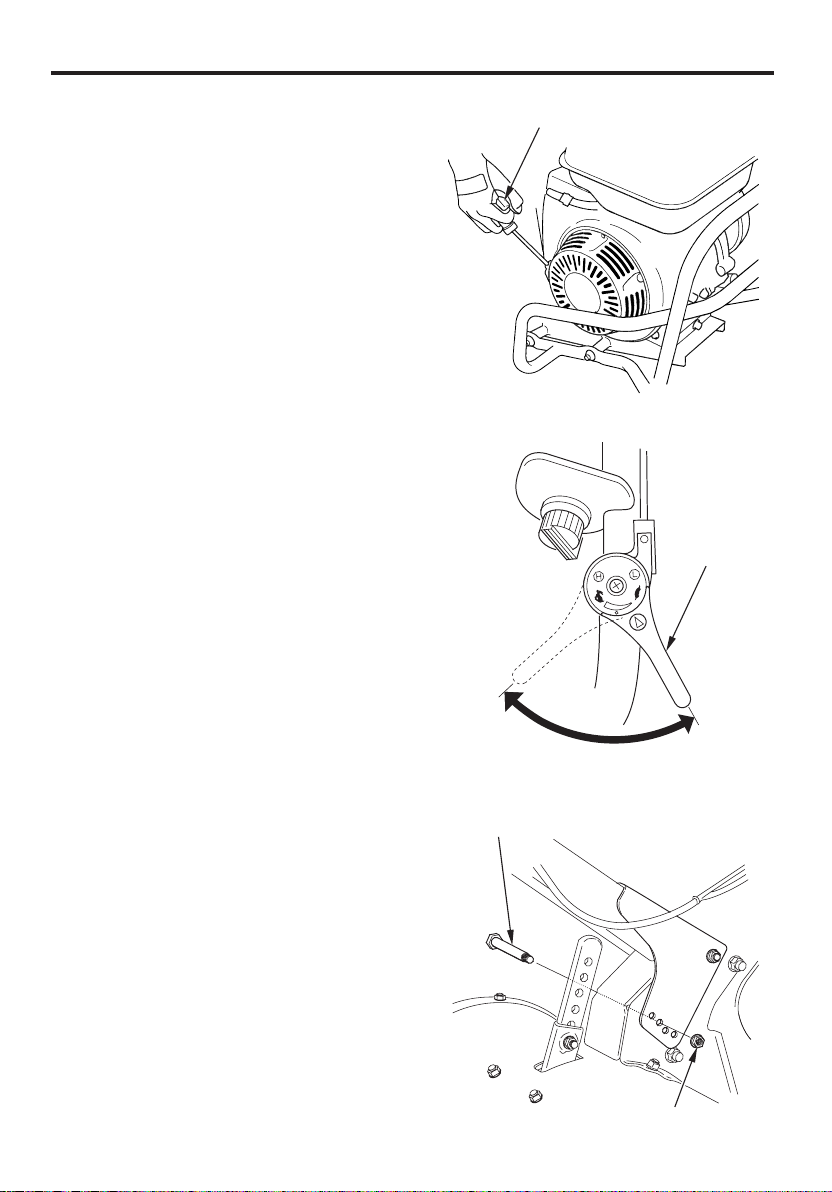

Pull the starter grip lightly until

5.

you feel resistance, then pull

briskly in the direction of the

arrow as shown.

Do not allow the starter grip to

snap back against the engine.

Return it gently to prevent

damage to the starter.

SLOW

FAST

STARTER GRIP

DDiirreeccttiioonn ttoo ppuullll

17

OPERATION

If the choke lever was moved to

6.

the CLOSED position to start the

engine, gradually move it to the

OPEN position as the engine

warms up.

CLOSED

CHOKE LEVER

OPEN

18

OPERATION

OPERATING THE CONTROLS FOR TILLING

If the tines dig in but the machine will not move forward, move the

handlebars from side-to-side.

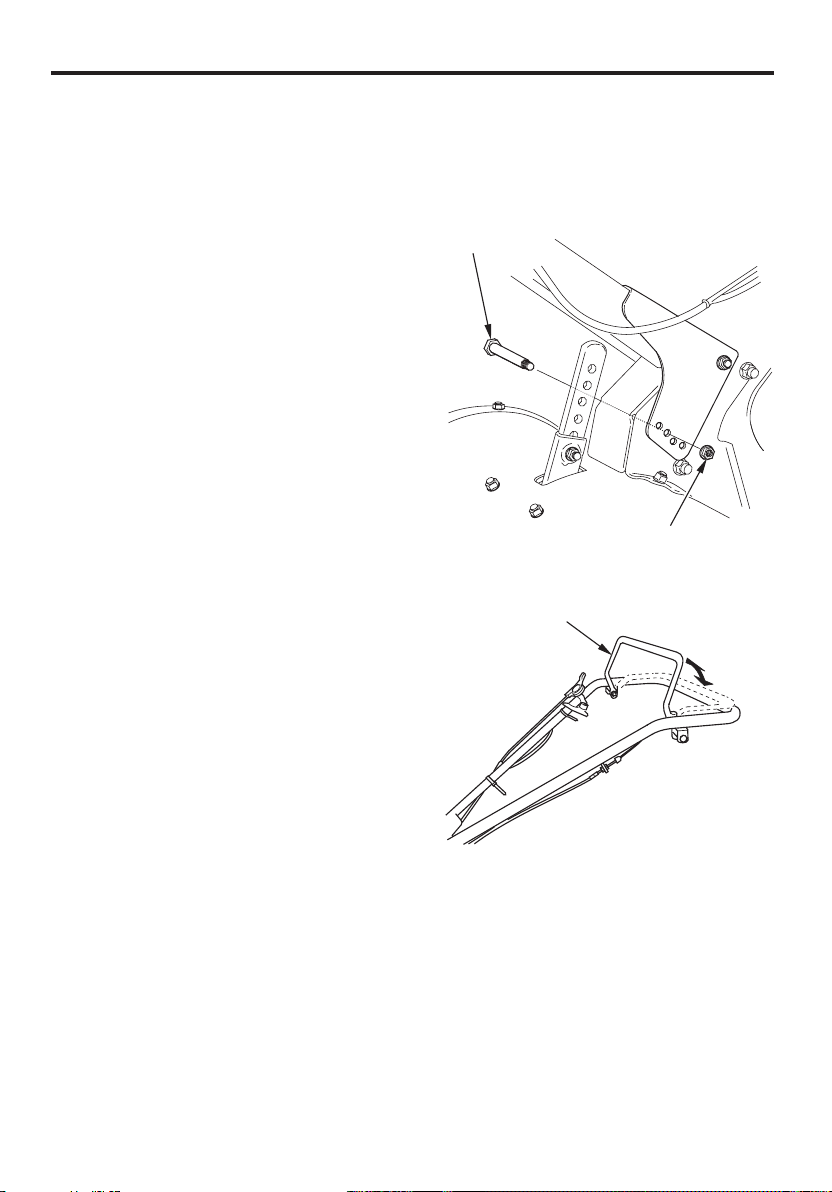

Handlebar Height Adjustment

Stop the engine before adjusting

the handlebar height.

Remove the handlebar height

adjusting bolt, adjust the handlebar

height, and reinstall the bolt in the

appropriate holes.

Clutch

When the main clutch lever is

squeezed, the clutch is engaged,

and power is transmitted to the

transmission.

When the lever is released, the

clutch is disengaged, and power is

not transmitted.

HEIGHT ADJUSTING

BOLT

HANDLEBAR LOCK NUT

MAIN CLUTCH LEVER

DISENGAGED

EENNGGAAGGEEDD

19

Loading...

Loading...