Page 1

40PERATOR'S

A

MANUAL

J

Front Loader

Model

for

I

Multi-purpose Tractor

Honda H5518A4

FL5540KO

I

Page 2

Page 3

Thank you for purchasing an HTA Front Loader attachment for your tractor.

This manual covers the assembly, operation and maintenance of the HTA

for the

troubleshooting section and warranty service information.

Read this manual and the owner’s manual

you operate the front loader.

NOTE: The information in this publication is based on the latest product information available

at the time of printing. American Honda

any time without notice and without incurring any obligation.

No part of this publication may be reproduced without written permission.

This manual should be considered a permanent part of the front loader and should remain with

it

H5518 A4 Multi-purpose Tractor. For your convenience,

forthe Honda H5518 A4 Multi-purpose Tractor before

if

resold.

Motor

Co.,

Inc. reserves the right to make changes at

it

also provides a parts guide,

FL5540 front loader

Safety Messages

Your safety and the safety of others are very important. We have provided important safety

messages in this manual ond on the front loader. Please read these messages carefully.

A

safety message alerts you to potential hazards that could hurt you or others. Each safety

message is proceded by

WARNING, CAUTION.

These words mean:

a

safety alert symbol and one of three words: DANGER,

You

WILL be

If you

You

tf

0

Each message tells you what the hazard is, what can happen, and what

or reduce injury.

Damage Prevention

You will also see other important messages that are proceded by the word NOTICE.

This word means:

I

NOTICE

Messages.

.I

You

lnstnrctlons

Your equipment

CAN

you

CAN

don’t

don’t

damaged

Using this product

Read

to

and understand this Operator’s Manual

do

so

could result in personal injury

for

a

purpose not intended can cause injury

or

equipment damage.

KILLED

follow

be

KILLED

follow

be HURT

if

you

don’t follow instructions.

before

or

SERIOUSLY

Instructlons.

or

SERIOUSLY

Instructlons.

If you

don’t

follow

you

or

other property can

or

operating

the

front

HURT

HURT

can

do

be

property damage.

loader;

to avoid

failure

If a problem should arise, or

-

authorized Honda Multi

purpose Tractor dealer.

if

you have any questions about your front loader, consult an

1

Page 4

CONTENTS

TOPIC

1 .GENERAL

2 . INTRODUCTION

Front loader safety

Maintenance safety

Safety label locations

3

.

PACKAGING INVENTORY

4 . TRACTOR PREPARATION

5 . LOADER SPECIFICATIONS

6

.

ASSEMBLY INFORMATION

Sub-frame installation/removal

Front loader assembly

Operational checks

......................

......................

...................

.................

.................

................

...............

.................

.........

.........

......

.........

.........

.........

....

1

.......

.............

............

.............

............

.........

.........

.........

.........

.........

.........

.........

5..

PAGE

1

3

4

7

8

9

10

11

12

13

19

25

7 . OPERATING INSTRUCTIONS

8

.

LOADER REMOVAL

Storage

9

.

LOADER INSTALLATION

10 .TROUBLESHOOTING

11 . LUBRICATION and MAINTENANCE

Lubrication and maintenance chart.

12 . PARTS

13 . WARRANTY SERVICE

.......................

.........................

..................

................

...............

............

..............

.........

........

.........

.........

.........

........

.........

.........

.........

..........

.........

27

-31

35

37

41

43

44

45

.

51

.

2

Page 5

~

INTRODUCTION

INTRODUCTION

The purpose of this manual is to instruct you in maintaining and operating your HTA

Front Loader. Read it carefully; it furnishes information and instructions that will help you

of

achieve years

to unknown and varying conditions. However, through experience and these instructions, you

should be able to develop operating procedures suitable to your particular situation.

"

Right" and "Left

machine will travel when in use.

The illustrations and data used in this manual are current at time of printing, but due to possible

-

line production changes, your machine may vary slightly in detail. Extra equipment that may

in

be shown

redesign and change the machine as may be necessary without notification.

on

dependable performance. Some information may be general in nature due

"

as

used throughout this manual are determined by facing the direction the

the machine

is

optional at extra cost. The manufacturer reserves the right to

NOTE: Illustrations used in this manual may not show

to

ensure safe operation of tractorAoader. Referto Safety Section of this manual and the Tractor

Owner's Manual for information concerning safety equipment. Consult your dealer for further

information.

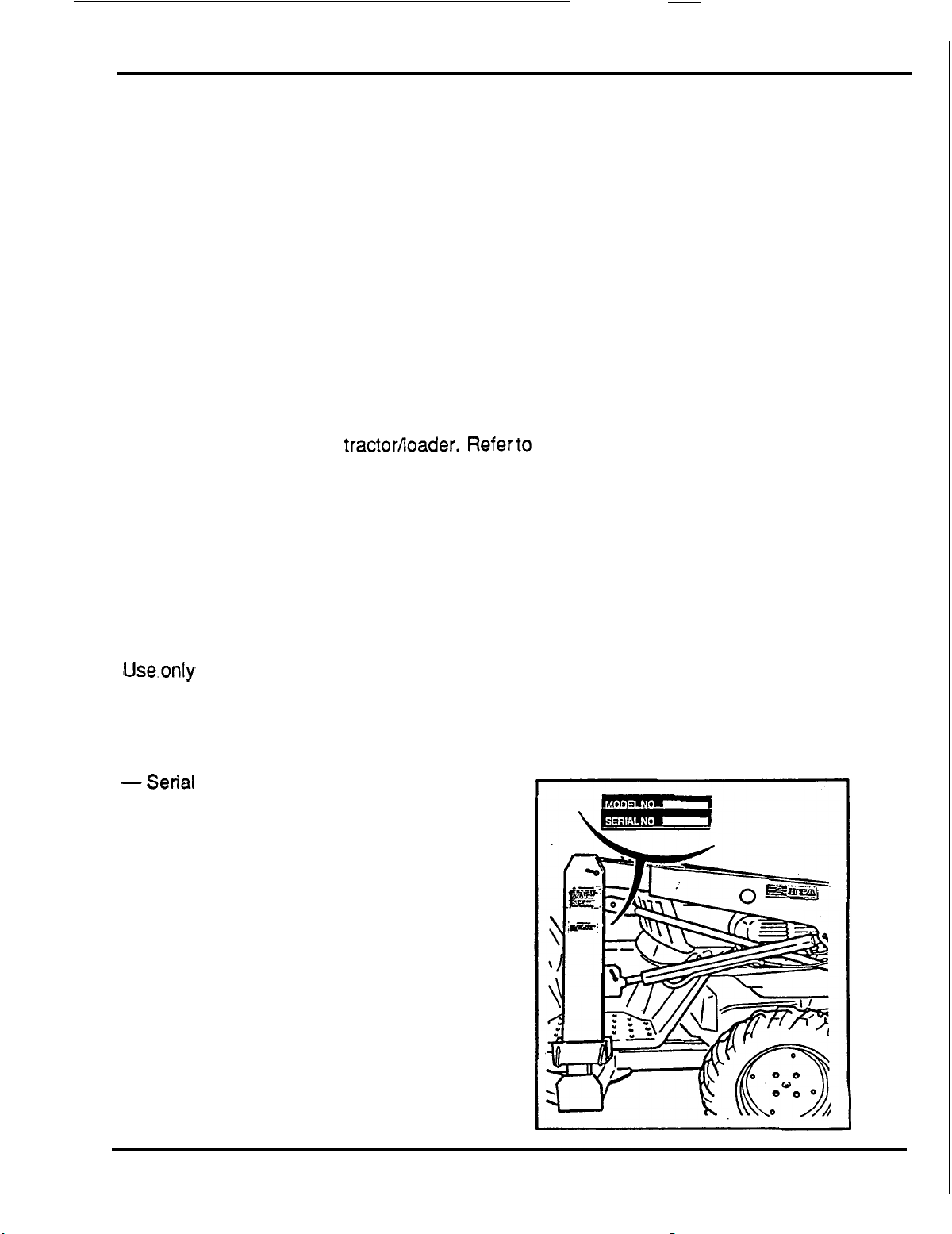

SERIAL NUMBER and LOCATION

The serial number is important information about the machine, and

it before obtaining the correct replacement parts. The serial number is located on the right side

mast as shown.

REPLACEMENT PARTS

Use.only Genuine Honda Replacement parts to repair this machine. Honda replacement parts

are available from your Honda Multi

service, always remember to give the dealer the following information:

-

Correct part description or part number.

-

Model number

-Serial number of your machine.

of

your machine.

-

purpose Tractor Dealer. To obtain prompt, efficient

all

safety equipment that is recommended

it

may be necessary to know

3

Page 6

FRONT

LOADER

SAFETY

FRONT LOADER SAFETY

Operating the tractor

and

the safety of others. Know these requirements before you operate the tractor

and

front loader requires

special

efforts

on

your

part

to ensure your safety

loader.

SAFE

OPERATING RULES

Severe personal injury

(

pages

Always make pre

accident

To avoid severe personal injury

25

thru

30

or

equipment damage.

All parts, especially guards and shields, should be

place.

Be sure all nuts, bolts and screws are tight.

Do

not remove any guards, warning labels, shields or safety devices; they are installed for your

saf.ety.

The tractor

-

you are also wearing the seat belt.

-

the

roll

ROPS

is securely attached and has not been modified

or

equipment damage may result

)

are not followed.

-

operation checks ( page

or

equipment damage, observe the following precautions.

over protective structure

if

the operating instructions on

25

)

before you start the engine. You may prevent an

in

good condition, and securely fastened in

(ROPS)

will only protect you from injury

or

structurally damaged.

if;

or

front

Know how to stop the engine quickly. Thoroughly understand operation of all controls.

or

Never permit anyone to operate the tractor

The tractor

loader.

Keep children and pets at a safe distance during operation.

Never allow anyone to get under the front loader bucket

bucket is raised or tractor engine

Always wear sturdy shoes

tractor

Be alert.

or

drugs.

Work with the equipment only in daylight or good artificial light.

Watch out for and avoid rocks, roots, holes and other objects.

If

you hit an object, stop and inspect for damage; repair any damage before you operate the

equipment again.

Replace damaged,

is

an operator

or

the front loader.

Do

not operate the front.loader when you are tired,

worn

only

vehicle,

or

boots

or broken parts immediately.

do

is

running.

and avoid wearing bulky

front loader without proper instructions.

not allow passengers to ride on the tractor.or front

or

reach through the

or

loose clothing while operating the

ill

or

under the influence

lift

arms when the

of

alcohol

The exhaust contains poisonous carbon monoxide gas that can cause

if

and may lead to death,

the front loader

is

operated in an enclosed place.

loss

of consciousness

Page 7

The use of heavy equipment andor pulling or lifting excessive loads may adversely affect

To

avoid

loss

vehicle stability or control.

-

Use only recommended tractor hitch attachment points.

-

Limit loads to those within tractor and front loader limitations as stated in this manual and in the

tractor owner’s manual.

-

Be extra careful when turning or backing up, and when on uneven terrain.

-

Use counterweights as indicated in this manual and the tractor’s owner’s manual.

Before installing or using the front loader, carefully read all instructions and precautions.

OPERATION

Be sure to fasten the seat belt whenever driving the tractor with the Roll Over Protection

Structure (ROPS) attached. Use of either device (seat belt or ROPS) without the other will

a

increase the chance of injury in

rollover.

of control that can result in severe personal injury:

Adjust the seat belt

Be sure that the main transmission lever is in

(PTO) levers are

Operate the tractor and

operating characteristics and controls.

Do

not operate the tractor or front loader until you are sure the area in front and behind

of people and pets.

Sudden stops

Be especially careful during sharp turns and when front loader bucket has material in it.

Carry the front loader

and front vision.

Using the front loader for handling large objects such

recommended.

equipment damage or severe personal injury,

This tractor utilizes Four Wheel Steering

tractors and will affect front loader operation. Practice use of the front loader

so

it is snug.

“Neutral” and the front and rear Power Take

in

the

“Off‘

position before starting the engine.

the front loader at slow speeds until you become familiar with all

of

the tractor or front loader during operation could cause the tractor to overturn.

arms at a

These items can easily shift or roll down the front loader arms causing

low

position during transport. This will enhance vehicle stability

as

round hay bales, logs or oil drums is not

(4WS). The feel of 4WS

is

slightly different from other

in

a

wide safe area.

of

is

Off

the

clear

Page 8

FRONT

LOADER

SAFETY

Never operate the tractor or front loader when visibility

weather; your ability to see obstacles will become impaired.

Avoid loose

overturn.

The front loader is intended for relatively flat terrain

Avoid overhead wires and obstacles when the front loader is in the raised position. Contacting

electric wires can cause electrocution.

Allow for the added length of the front loader attachment when making turns to prevent striking

people or objects.

When operating the front loader on a slope, always drive up and down the face of the grade.

Turning or driving across the face of the slope may cause the tractor to overturn.

Operate the front loader arms gradually by

movements that could cause damage to the front loader

Use added caution when working with shifting or loose loads

cause vehicle instability

To avoid

when operating the front loader on sloping or uneven surfaces.

fill,

loss

rocks and holes. They may cause vehicle instability or cause the vehicle to

"

feathering" the loader controls to prevent abrupt

or

fall out of the bucket and cause personal injury.

of control

or

overturning, always reduce speed and exercise extreme caution

is

diminished by darkness

useage.

and

tractor.

in

the.loader bucket. It could

or

by bad

Operate loader controls only from the operator's seat to prevent possible severe personal injury.

Attempting to change gears while operating the front loader on a slope may adversely affect

vehicle stability and control and severe personal injury could result.

Do

not back down,

To

avoid

loss

Do

not operate the front loader near the edge of a ditch or an embankment. Slipping off the

edge could lead to severe personal injury or equipment damage.

When descending a slope, disengaging the clutch or shifting into neutral can cause

control that may result in severe personal injury.

Be sure to follow instructions below whenever applying the tractor differential lock during front

loader use.

-

Do

not apply the tractor differential lock while turning, use the differential

in

a

straight line.

-

Never apply the differential lock on paved surfaces.

TO

avoid injury to yourself and others; before leaving the front loader unattended,

-park on level ground and lock the parking brake.

of

control

or

rapidly accelerate up a sloping surface.

or

overturning, do not stop or turn on sloping surfaces.

loss

lock

only while driving

ALWAYS;

of

6

-lower the front bucket flat to the ground.

-

disengage the front loader drive system.

-

stop the engine and remove the key.

If

you find

the wheels.

it

necessary to park on a grade, be sure to lock the parking brake and securely block

Page 9

MAINTENANCE SAFETY

MAINTENANCE SAFETY

Maintenance of the

safety

the

and

the safety of others. Know these requirements before perfoming maintenance on

tractor or front loader.

Before performing

Before cleaning, inspecting or servicing the loader be sure to;

-lower the front loader bucket flat to the ground.

-move the front

-

stop the engine and remove the key.

Always wear safety glasses when servicing or replacing the front loader cylinder pins. Use a

brass drift and hammer. Failure to do

objects.

Operating the front loader or the tractor with damaged,

severe personal injury.

Before disconnecting any hydraulic lines, relieve all hydraulic pressure.

Keep hands and body from pressurized lines. Use paper ,or cardboard, not body parts, to check

for leaks. Hydraulic oil under pressure will penetrate the skin causing serious injury.

Make sure that all operating and service personnel know that in the event hydraulic fluid

penetrates the skin, it must be surgically removed within

this form

tractor

of

injury, or gangrene may result.

and

front loader requires

maintenance/inspections,read

PTO

to the off position

special

the instructions thoroughly.

so

could result in eye injuries from possible flying metal

efforts on your part to ensure your

worn,

or

broken parts may result in

a

few hours by a doctor familiar with

All nuts, bolts, and fasteners must be properly secured.

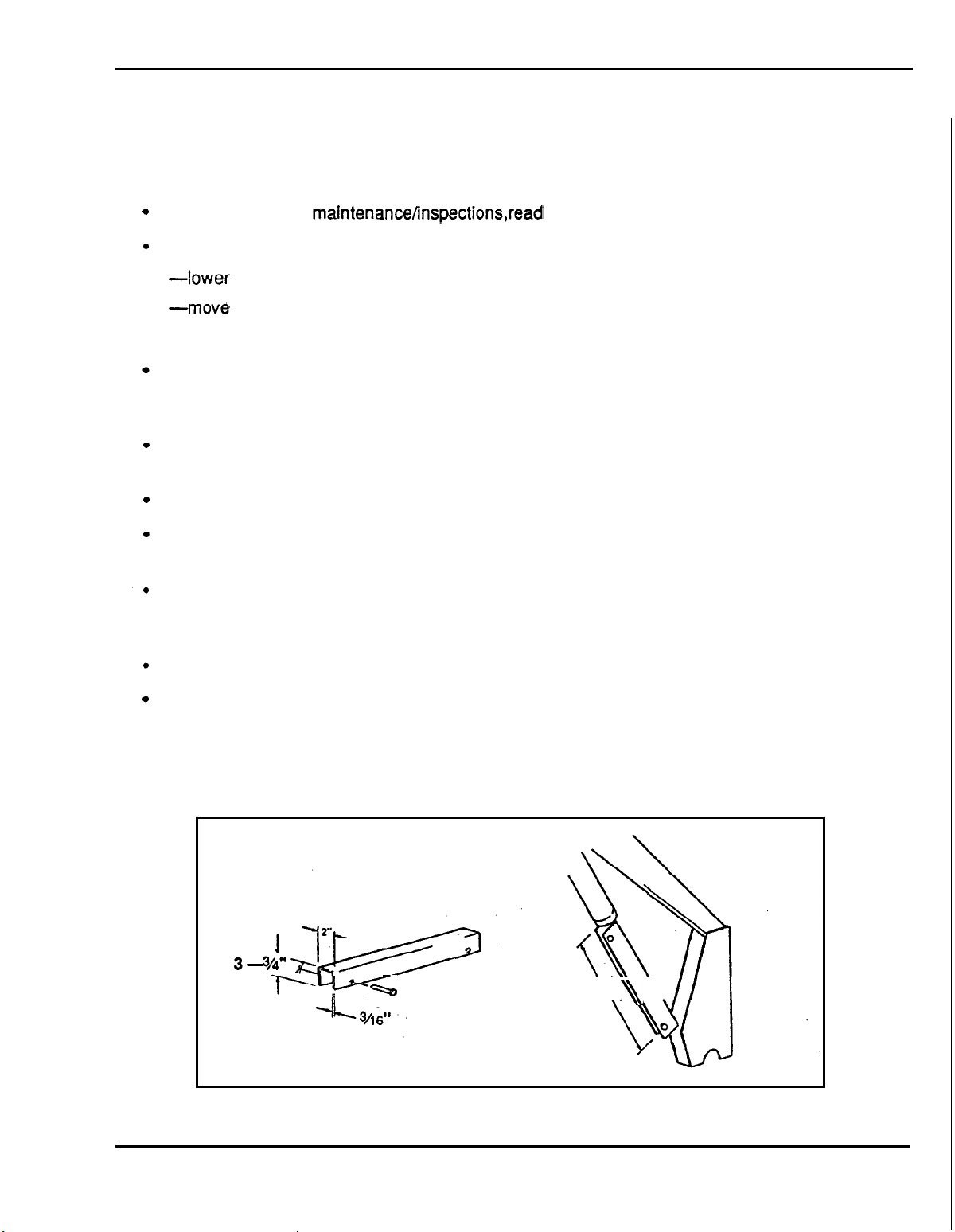

If

you must work underneath a raised loader, make sure the arms are blocked in the raised

position with a safety bar. A suitable steel safety bar can be manufactured following the

dimensions as illustrated below.

-

AS REQUIRED

.\\

\

7

Page 10

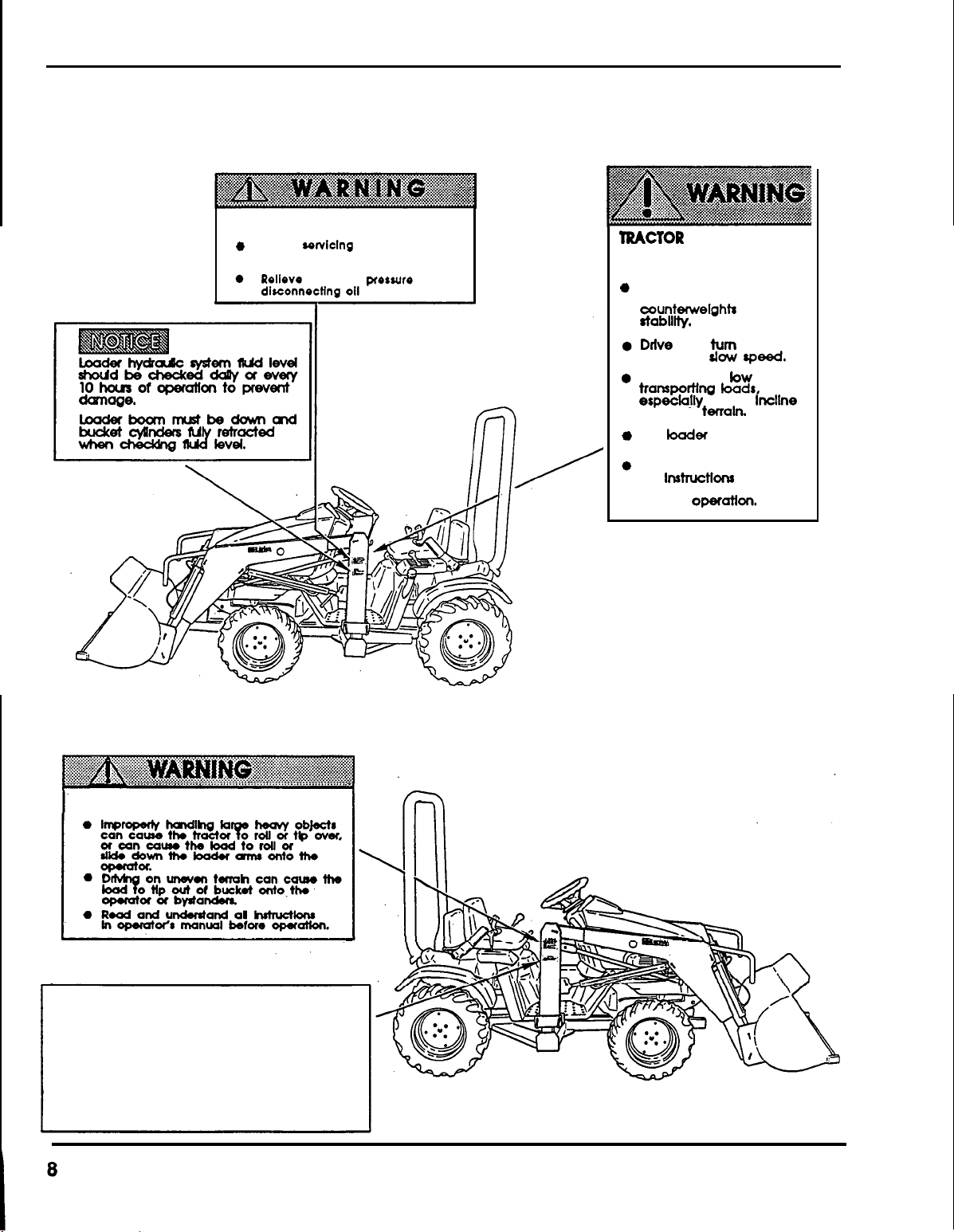

SAFETY LABEL LOCATIONS

SAFETY LABEL LOCATIONS

Read these

SAFETY

LABELS

IMPROPER

SERIOUS INJURY

0

Before

lower loader to fho ground and

shut off engine.

Rolleve hydraulic

dlreonnecHng oil lines.

before

SERVICING

conlclng

you

CAN

OR

or

adjustment

pressure

operate the front loader.

CAUSE

DEATH

before

MCTOR

CAUSE SERIOUS INJURY

OR

a

Add

wheel

oounterwelghts

rtablllly.

Ddve

tractor

Place

transpomng

especially on an lncllne

or

e

Put

when

TIP-OVER

DEATH

recommended

ballast and/or

and

at

loader

rough tenaln.

Mer

parked.

Read

and understand

lnstructlons

all

operator‘s manual

before

operation.

for

turn

slow

speed.

low

kads,

on ground

In

CAN

when

FALL

FROM

LOADS CAN

CAUSING SERIOUS INJURY OR DEATH

BUCKET

INFORMATION

Special loader attachments

handling large objects are

available from agricultural

suppliers.

i

for

Page 11

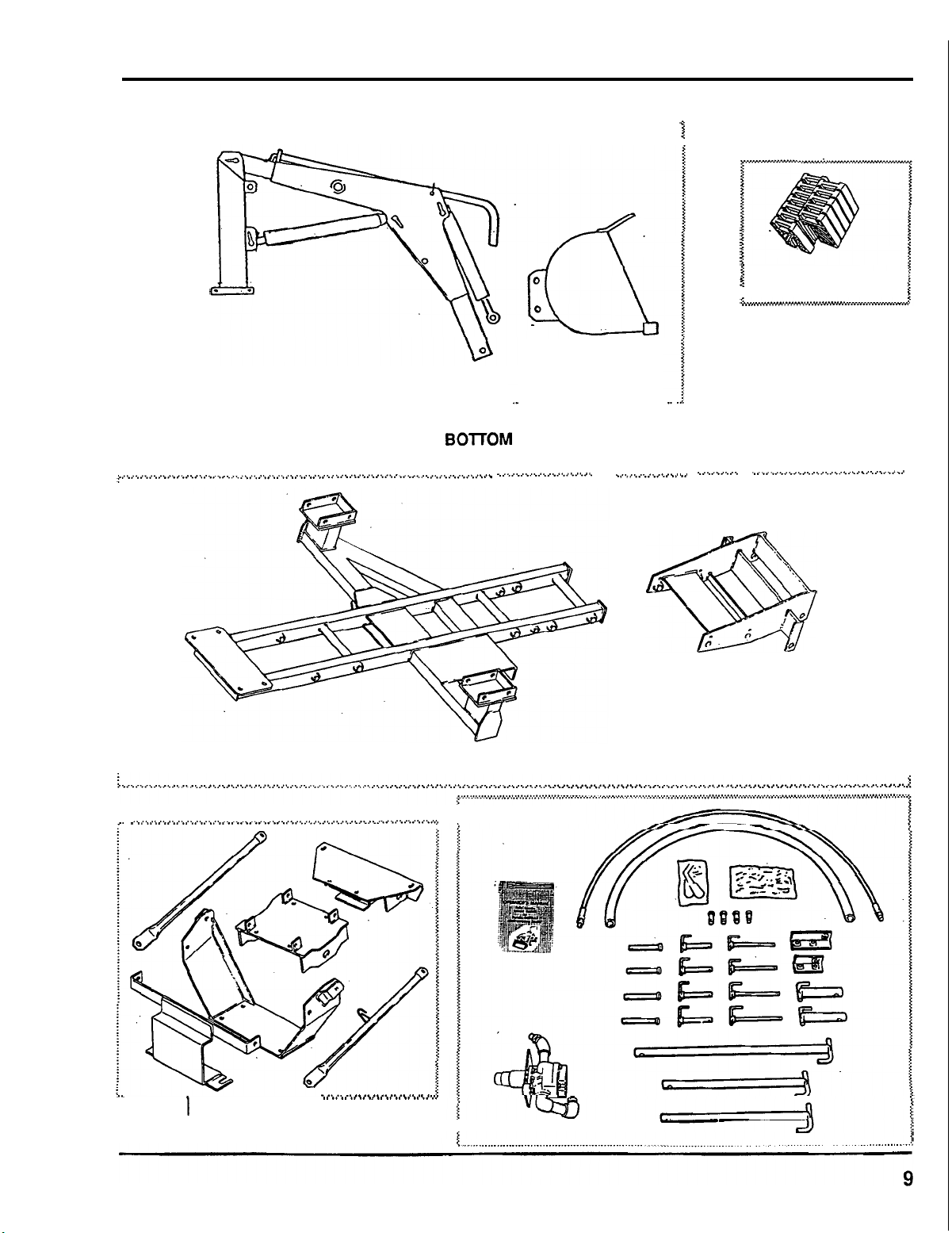

PACKAGING INVENTORY

.............................................................................................................................................

.................

................~....,..~.....................~...~..~~..............~...~....................................................,........,,..

....................................................................

SECURED

T

PACKAGING

I

O

C

RATE

BO~OM

I

INVENTORY

................................

.

..................,....CIC.......,,

........

\

.............,...,.....

12

Required

37.5

Ibs.

I

3

j

1

..

c,,..,,..,,

...

WEIGHTS

.........,.....\,.....I..........

each

...l.l\>llll.i

.

..................................................................................................

...............................................

LARGE CARTON

1

SMALL CARTON

..........................

..

Page 12

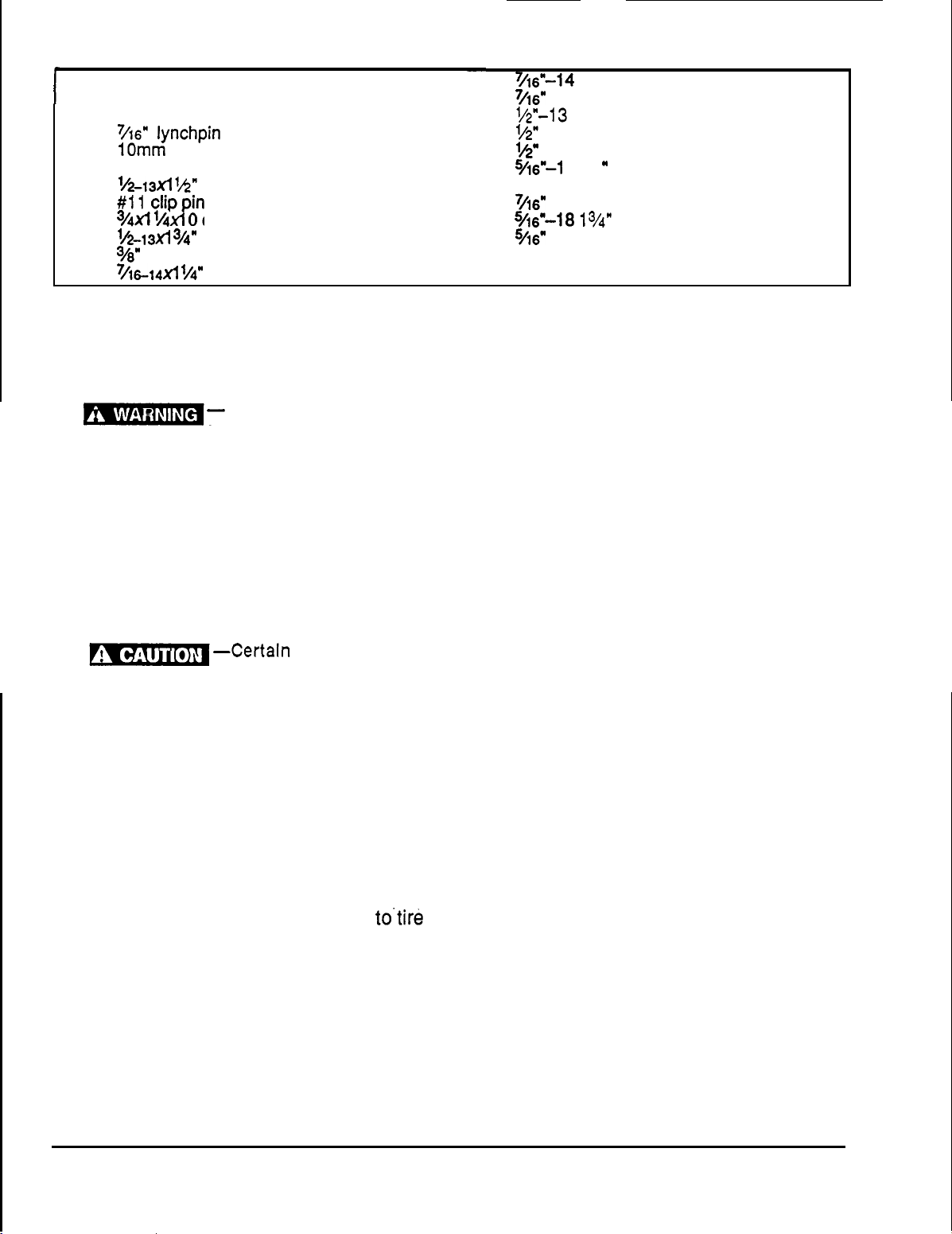

TRACTOR PREPARATION

HARDWARE BAG CONTENTS

QNT'Y DESCRIPTION

5

h"

lynchpin

2 1Omm x 30mm

2

12mm x 25mm

2

%!-13Xl

16

12 3/4xl'/4

2

2

2

#11

V2-13xl3AW

98"

7/16-14Xl

lh"

clipxpin

0

flat washer

V4"

hex

hd

hex

hd

hex

hd

capscrew

ga. machine bushing

hex

hd capscrew

hex

hd capscrew

capscrew

capscrew

-

2

2

4

6

4

4

4

2

2

2

2

1

%6"-14

7/ls"

V2"-13

l!"

1s

5/1sW-l

5/16

VIS"

5/16"-l8 13A"

54s"

#

2

nylon

hex

lockwasher

hex

flat washer

lock

washer

8

x

1

"

"

lockwasher

flatwasher

flatwasher

hose clamp

tie

nut

nut

hex

hex

hd capscrew

hd

capscrews

TRACTOR PREPARATION

This loader is not intended to be used with any other attachments mounted on tractor.

REAR COUNTER WEIGHT

m-

The use of adequate rear countenveight is required for proper loader stability.

Refer to Tractor Owner's Manual for specific recommendations on counterweighting tractor.

1-

DO NOT EXCEED THE RATING

REFER TO OWNER'S MANUAL PROVIDED WITH TRACTOR.

FOR

MAXIMUM

GROSS

VEHICLE WEIGHT.

Weight added to the rear of the tractor provides better traction and easier, more efficient loader

operation. The tractor must be counterweighted by installation of rear weights.

Additional counterweight requirements will vary with loader attachments and equipment

applications.

--Certain specific conditions may not permit safe use

or may require more carefully restricted Operation at

ROLL-OVER PROTECTION STRUCTURE (ROPS) SYSTEM

The tractor

ROPS

system must be in place and used properly to ensure adequate operator

of

loader at loader rating

the

rated load.

protection.

LOADER HYDRAULIC SYSTEM

Follow

TRACTOR

recommendations in this operator's manual for hydraulic fluid specifications.

TIRES

Selection of tires should be restricted to.tire recommendations as specified by your

Tractor owner's manual.

Ag tires are recommended when using the front loader

TIRE INFLATION

Front tires must be maintained at the maximum recommended inflation with the added weight

of loader and material.

Ag

Tire pressure

34

psi.

Rear tires must be maintained at equal pressure within the recommended tire inflation range.

24

Ag Tire pressure

psi.

10

Page 13

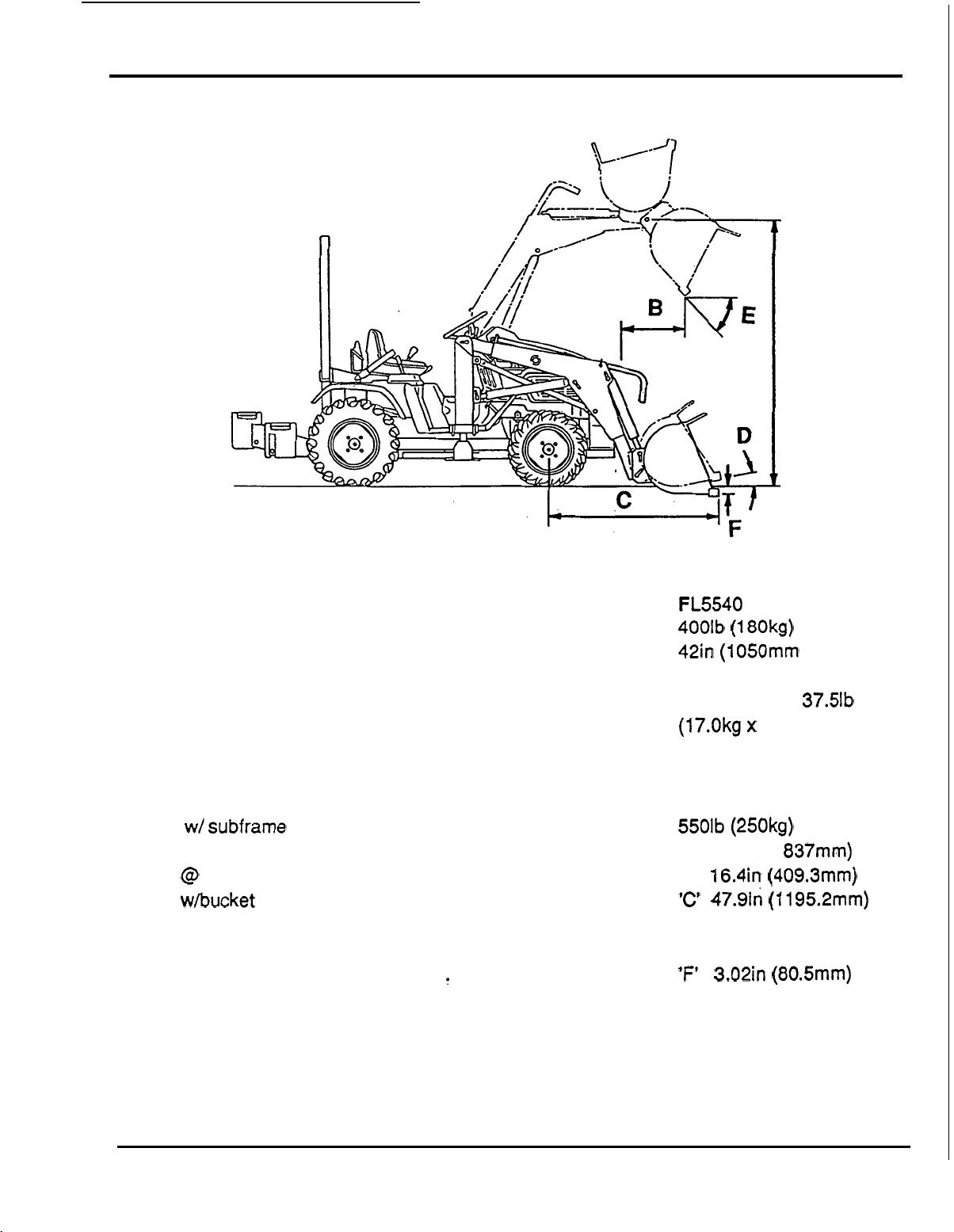

LOADER SPECIFICATIONS

LOADER SPECIFICATIONS

A

-

-

LOADER SPECIFICATIONS

ITEM

Rated

Bucket Size (width)

Hydraulic cylinder

Counterweights

........................

Lift

Capacity

................

................

................

..................

...........................

Sub-frame

Hydraulic Pump Drive

Tractor Type

Weight w/ subframe

Maximum Lift Height

Reach @ Maximum Height.

Reach whucket

Bucket roll

Maximum Dump angle

Digging Depth Below Grade

.....................

...............

.................

................

................

............

on

back

ground

angle

............

...............

...............

.....

......

........

........

........

.........

.........

........

........

.........

H55

18 A4 only

........

........

........

........

........

........

........

FL5540

400lb

42in (1050mm

Double acting

Suit case type 37.5lb x 12

(17.0kgx 12)

Frame mount type

Front PTO coupled

-

Ag tires recommended

5501b

'A'

'B'

'C'

'D' 17'36'

'E'

'F'

(180kg)

(250kg)

72.1 in (1 837mm)

16.4in (409.3mm)

47.9in (1195.2mm)

47'31

.

3.02in (80.5mm)

)

11

Page 14

ASSEMBLY INFORMATION

GENERAL

ASSEMBLY INFORMATION

Read assembly instructions completely prior

to

installing loader

to

familiarize yourself with all

mounting and hydraulic system installation procedures.

The loader operates from its self contained hydraulic system with the pump driven from the

tractor front PTO.

A

pipe thread sealant must be used on all pipe threads.

All

hardware required for mounting loader is supplied.

Loader mount component hardware should be

left

loose until all mount components have been

installed.

Unless otherwise specified, refer to torque specification table for torque values

of

hardware

required for assembly.

Lay

out

and identify all components prior

to

installation.

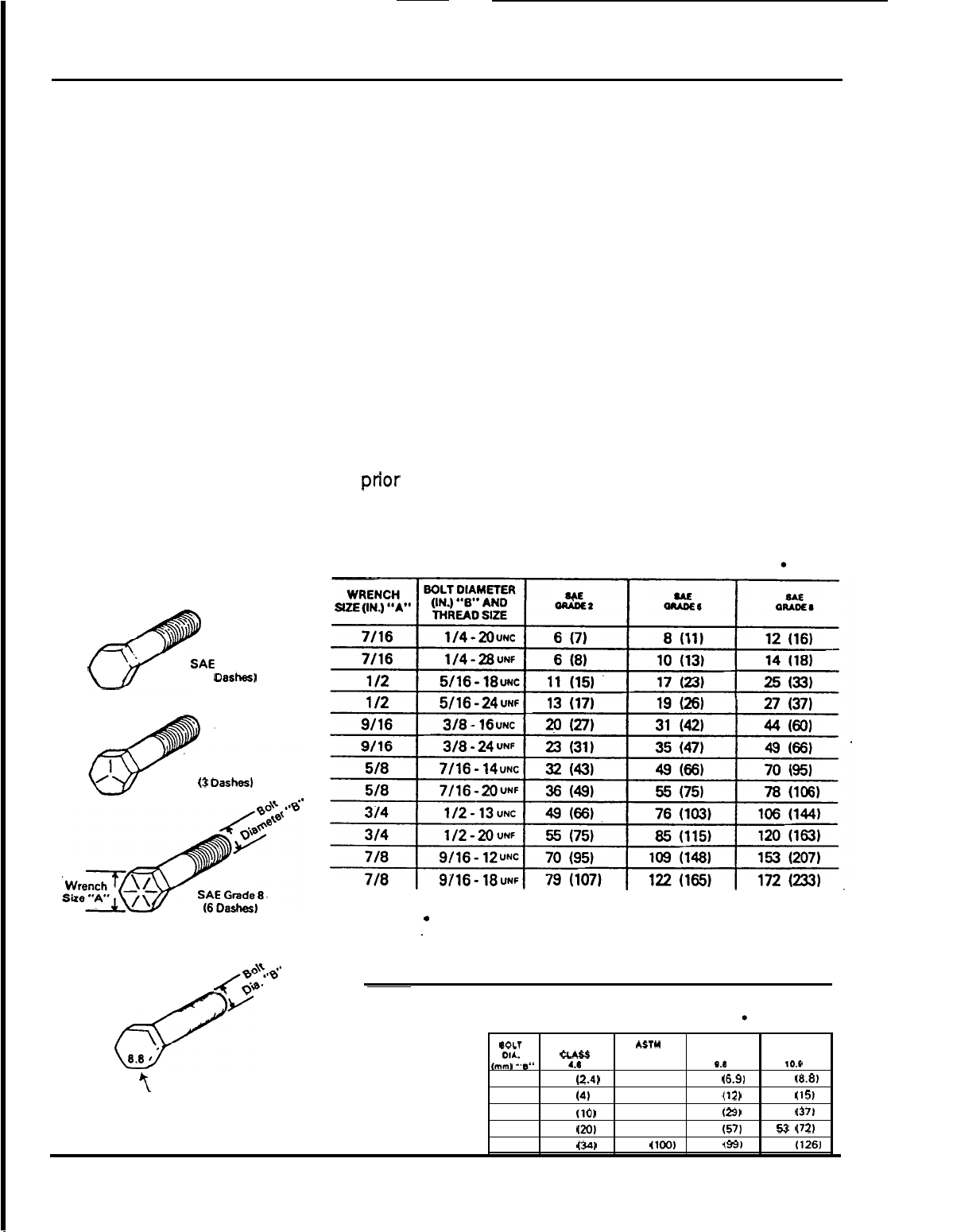

TORQUE SPECIFICATIONS

used

on Honda equipment

Pounds (Newton Meters).

AMERICAN

Bolt Head Markings

Proper torque for American fasteners

in

Recommended Torque

Foot

SA€

Grade

(No

Dashes1

SAE

Grade 5

(3

Dashes1

METRIC

4;$d

6

Numbers appearing on bolt heads

indicate ASTM class.

2

2

Use

75%

'

fasteners. Use

for lubricated fasteners;

Proper torque for metric fasteners used on Honda equipment.

Recommended Torque

of the specified torque'value for plated

85%

of the specified torque values

in

Foot Pounds (Newton Meters).

eoLT

(mm)

DIA.

5

6

8

10

12

"8"

CLASS

1.8

7.3

14.5

25

ASTY

4.0

(2.41

3

(41

(10)

(20)

(34)

74

*STY

8.8

(100)

CLASS CLASS

5.1

8.7

21.1

42

73

ASTY

9.8

(6.91

(12)

(29)

(57)

(99)

ASTY

CLASS

10.0

6.5

(8.8)

11.1 (15)

27

(37)

53

(72)

93

(126)

I

12

Page 15

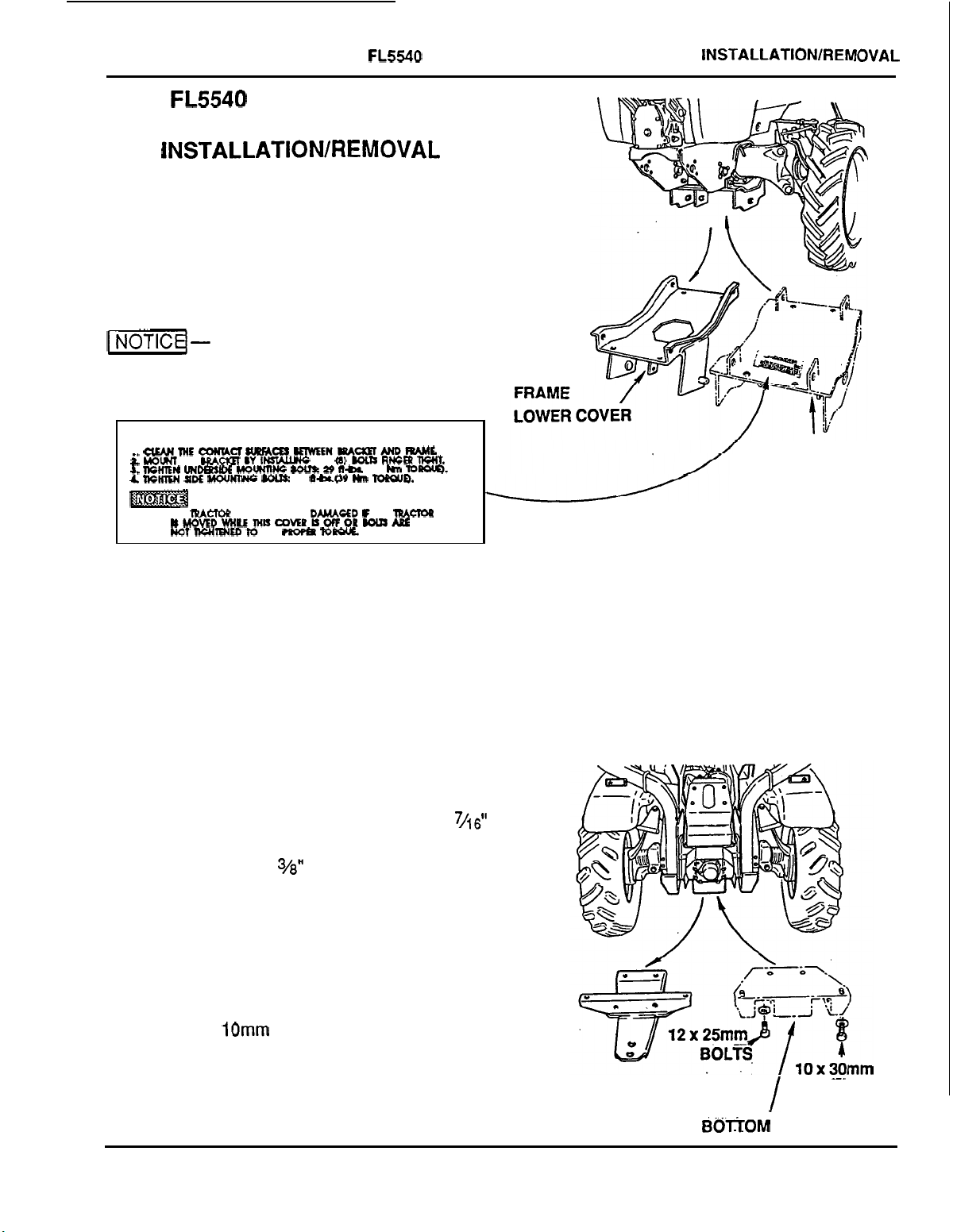

FL5540

FL5540 SUB-FRAME

and

COUNTERWEIGHT

INSTALLATION/REMOVAL

1.

Remove the existing frame lower cover

and replace with the new lower cover

using existing mounting bolts and collar

washers.

SUB-FRAME

and

COUNTERWEIGHT INSTALLATION/REMOVAL

--

1-d-

Never operate the tractor without

the lower cover.

INSTALLATION INSTRUCTIONS

1

C(M#ECO)IUCISWFACESBEIWEENBUWMrPrJllL

i

MOW

ME

BRAcILl

DY

3.

WHEN

1.

m

UNDBnDE

IIcHlEN

SIDE

LHWW

ME

IpAm

ISMOVEDWHLEMHL1COMRISOCFORWIJSAB3

NOT

lWITWE0

INSWING

MOUmNC

IOU&

FRAME

Io

ME

CAN

KHTr

29

BE

mofm

WE

Q)

WLR

29

ft-&

8-09

Hn

DAMACED

TopOK

RMCBl

09

TopouD.

F ME

h

TOpouO.

lpAcrop

lWIT.

Note: A second label is included with this

operator's manual. Install this label onto the

original

2.

frame

lower

cover.

Remove the drawbar and replace it with

the bottom bracket using the two

x

25mm hex

12

washers and two

capscrews with

hd

capscrews

10

3%"

washers.

with

x

30mm hex hd

7/16"

NEW LOWER

FRONT COVER

Torque

follows:

front

cover

and rear bracket bolts

10mm

12mm

Bolts

Bolts

29

43

ft-lbs.

ft-lbs.

(29

(60

as

Nm).

Nm).

DRAWBAR

BOirOM

..

. . -.

/

BRACKET

BOLTS

.

. .

13

Page 16

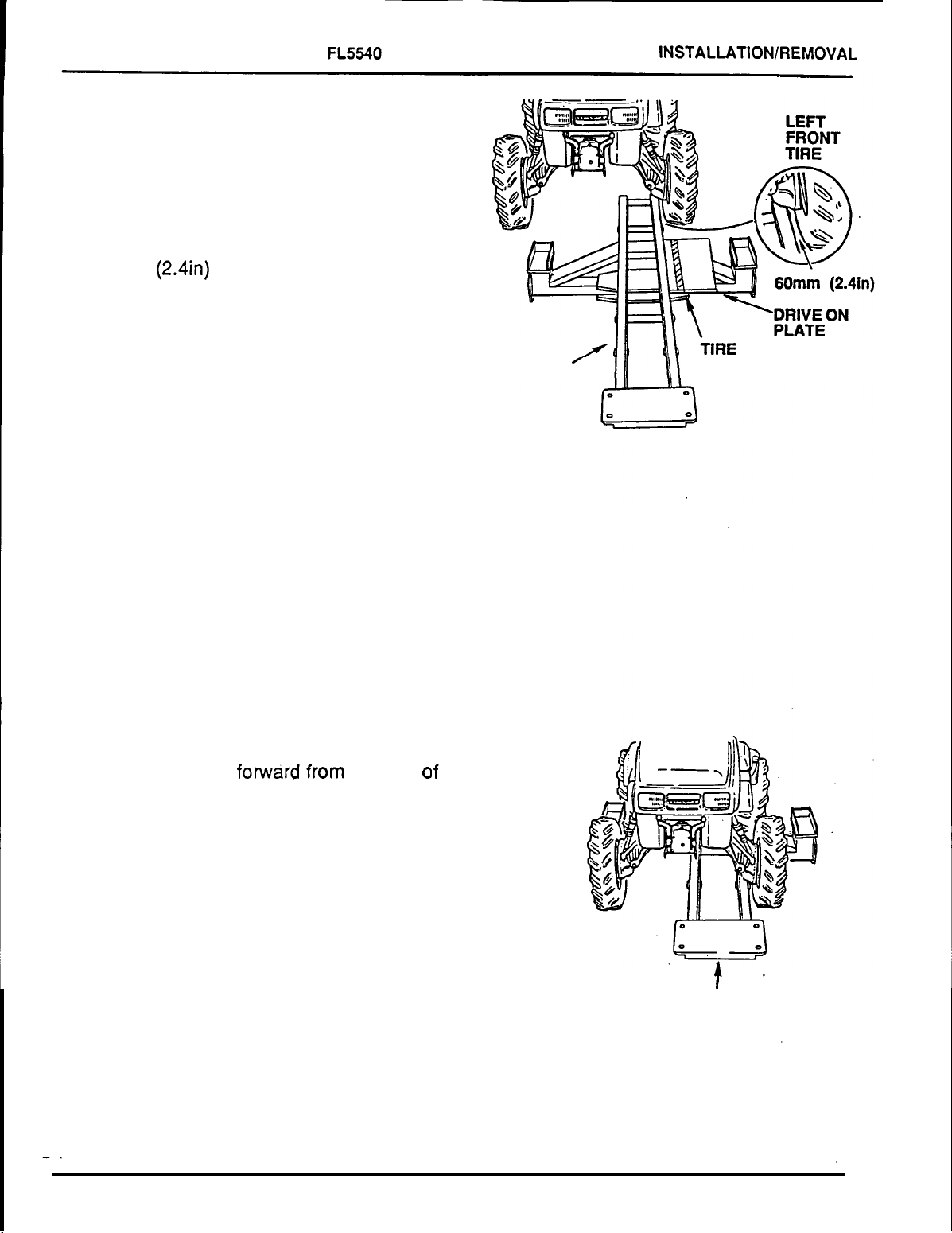

FLS540 SUB-FRAME

3.

Lay the sub-frame on a level, solid area.

4.

Position the tractor in line with the

sub

-

frame and tire guide on drive on plate,

allowing

60mm

inner wall

a

clearance of approximately

(2.4in) between sub-frame and the

of

the left front tire.

and

COUNTERWEIGHT INSTALLATlONlREMOVAL

5.

Drive the tractor fomvarc

,,om the rear

the sub-frame, over the drive on plate

keeping it parallel with the sub

-

frame.

o

SUB-FRAME

If

GUIDE

Page

14

SUB

-

FRAME

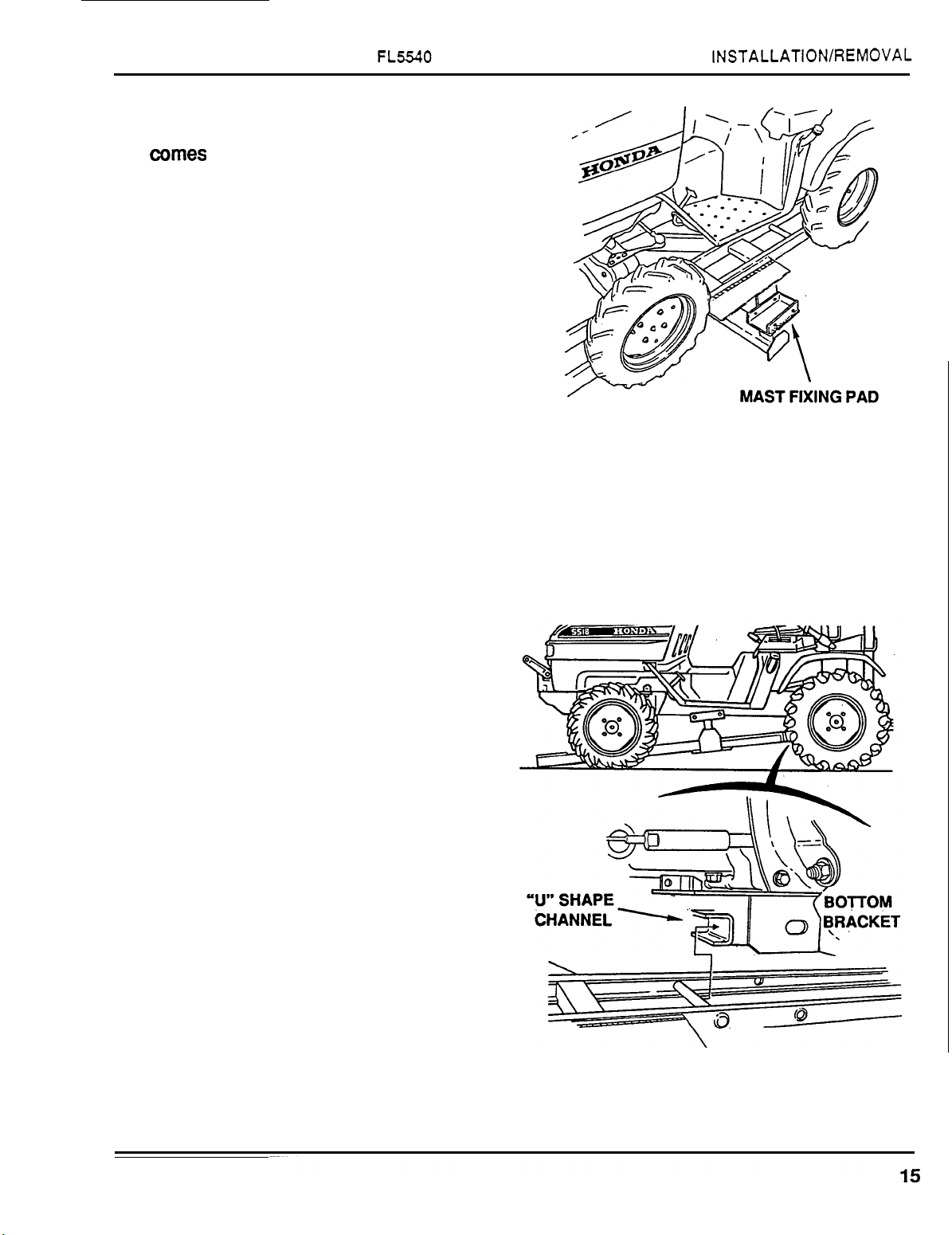

Page 17

FL5540 SUB-FRAME

6.

Stop the tractor when the mast fixing pad

comes even with the floor board of the

tractor.

and

COUNTERWEIGHT INSTALLATION/REMOVAL

7.

Using two people, lift the sub-frame and

-

engage the pipe of sub

-

shaped channel of the bottom bracket.

U

NOTE:

Use two people to lift sub-frame.

frame into the

Page 18

FL5540

8.

SUB-FRAME

and

COUNTERWEIGHT INSTALLATION/REMOVAL

Lift the front of the sub-frame and slip it

into the channel of the lower cover. Insert

two mounting pins

inside sub

cover. Slip

-

frame through frame lower

a

(3/4 x 3.19in) from

3/4in washer over each

mounting pin and insert the clip pins

through the holes.

NOTE:

Mounting pins have a flat side that

must be pointing down.

9.

Insert two mounting pins (3/4 x 3.19inj

from inside the bottom bracket through the

sub

-

frame. Slip a washer over each pin

and retain with a clip pin as shown.

MOUNTING PIN

FLAT

SIDE

DOWN

NOTE:

Mounting pins have a flat

must be pointing down.

16

side

that

Page 19

FL5540

COUNTERWEIGHT BRACKET

INSTALLATION

10.

Place the rear counterweight bracket on

the rear

mounting holes of the bracket with those

of the sub

mounting pins in the forward holes and

one

hole. Secure with linchpins.

1

of

the sub-frame aligning the

-

frame. Insert two

x

12

inch mounting pin in rear lower

1

x

SUB-FRAME

FIXING PINS

3.5

inch

and

COUNTERWEIGHT INSTALLATlONlREMOVAL

MOUNTING PINS

-

-

LINCHPIN

COUNTERWEIGHT BRACKET

11.

Install the twelve counterweights. Insert

the

countetweight fixing pins through the

bracket and secure with linchpins.

NOTE:

procedures.

For sub-frame removal use reverse

17

Page 20

~

FL5540 SUB-FRAME and COUNTERWEIGHT INSTALLATlON/REMOVAL

Page 21

FRONT LOADER ASSEMBLY

HY

'DRAULIC PUMP MOUNTING

1.

Pump mounting plate and pump drive joint

are installed on pump. Ensure bolts and

set screw are tight.

Attach the pump brackets to the pump

mounting plate using two each %6x2 inch

5/16

"

bolts and

bracket is shorter than the

tighten the bolts at this time.

Apply a light coating of grease to tractor

front PTO at this time.

flatwashers. The right

left.

Do

not

LEFT BRACKET

RIGHT

BRACKET

FRONT LOADER ASSEMBLY

PUMP

MOUNTING

PLATE

'

-

Mount hydraulic pump to tractor by sliding

2.

splined pump drive joint onto front PTO

shaft with mounting brackets inside main

frame and attaching with four

and

5/16"

bolts

lockwashers. Tighten

5/lsx?4i inch

all

pump mounting bolts.

LOADER INSTALLATION

NOTE: The masts and main frame come

.assembled. All cylinders and hoses 'have

been attached to the frame except the

two

hoses from the hydraulic pump.

3.

Set the loader on its stands and move the

tractor centrally between the masts.

19

Page 22

FRONT

LOADER ASSEMBLY

PRESSURE

CONNECTION

4.

Remove the pipe plug from the valve body

and

SUCTION HYDRAULIC HOSE

and clean the threads and then install the

pressure hose. Remove the plastic caps

from the pump outlets.

Use

sealer on

threads and screw the other end (swivel

connector end) into the threaded pipe

fitting on the pump. Slide the suction hose

(large hose) over the pipe end at the

bottom of

mastkeservoir and pipe end on

the pump. Attach with hose clamps and

tighten securely.

HOSE CLAM

PUMP

w,

ESSURE

SUCTION HOSE

HOSE

5.

Attach the front guard on the front of the

sub

-

frame using two each

1/2x15/16

112

inch bolts, and four each

inch nuts and washers.

lhxl

inch and

Do

not tighten

bolts at this time.

AlTACHlNG LOADING MASTS

6.

Move the tractor until the masts 'are

positioned over the upright pads on the

sub

-

frame, use

two

people to lower the

masts onto the pads and insert the fixing

pins through the masts and pads. Install

clip pins to retain fixing pins.

NOTE:

Masts may have to be shaken to align

fixing pin holes.

20

FIXING

PIN.

\IF

Page 23

7.

Attach brace arms to masts with clevis

pins and clip pin.

~ ~ ~~ ~

FRONT LOADER ASSEMBLY

Tighten front guard bolts installed in step

Torque:

8.

76

ft-lb

(1

03

Nm).

Bring the two hoses along the left side

brace arm to the

on the

left

brace arm with metal loops.

left

mast. Route hoses

Ensure that the high pressure hose

(smaller diameter)

is

positioned on top of

the suction hose (large diameter).

Install the nylon tie strap to bind the two

hoses together at front corner of hoodline.

5.

9.

Install valve handles to the hydraulic

control valve mounted on the left mast.

The

"A"

handle attaches to the spool used

for loader operation and the

attaches to the

spool

for bucket operation.

"B"

handle

COTTER PIN

-

PIN

21

Page 24

FRONT LOADER ASSEMBLY

BUCKET AlTACHlNG

10.

Using the bottom holes on the bucket,

attach both sides of bucket to loader

3/4

x

3

frame. Use two each

inch pins and

clip pins.

Attach both cylinders to top holes on

bucket. Use two each

314 x 3

inch pins

and clip pins.

The loader is now ready for hydraulic fluid.

314

x

3111

PINS

HYDRAULIC FLUID SERVICING

You will need 6 1/2 quarts of a good grade

hydraulic fluid or

ATF

automatic transmission

fluid.

11.

Remove

back of

filler

left

plug

mast.

and

Fill

oil

check screw

with 4 quarts.of

on

hydraulic fluid.

.

Start tractor engine and set speed at

throttle. Engage tractor front

lift

operate loader

and bucket cylinders at

PTO

1/2

and

least five or six times to purge the system

of

air. Lower the loader to the ground.

Retract bucket cylinders by pulling back

on handle

Add

2

"

B.

1

/2 more quarts of hydraulic fluid or

until oil runs out of check hole. Replace oil

fill

plug and oil check screw.

VALVE HANDLES

NOTE:

When lowering loader,

loader handle

FLOAT.

22

DO

"A"

all the way forward into

NOT

push

I'

Page 25

~~ ~ ~~~~ ~

LOADER STAND REMOVAL

12.

Raise the loader with the loader control

until the stands clear the ground.

13.

Remove latch pin from the stands and

remove the stands.

FRONT

LOADER

ASSEMBLY

14.

Align the hole in the

bottom

of the stand

with the mounting hook at rear of

mainframe. Slide the stand over the

mounting hook and then insert the latch

pin previously removed through main

frame and through the stand. Repeat the

above steps for the other side. Lower the

loader to the ground.

Front Loader

is

ready to become operational.

MOUNTING

=I

HOOK

23

Page 26

FRONT

NOTES

LOADER

ASSEMBLY

24

Page 27

OPERATIONAL

CHECK

OPERATIONAL

CHECK

Check all pivot points on the loader.

Lubricate as necessary.

(See lubrication chart.) on page number

44

Check loader hydraulic fluid.

Note: Check fluid level with loader arms

down and bucket flat on the ground.

if

Remove oil check screw and see

out hole.

If

oil level is low, remove oil

(Do

not overfill)

fill

oil will run

plug and add

hydraulic fluid until it runs out of oil check hole.

Re

-

install and tighten the oil check screw and

oil fill plug. Operate the loader up and down

several times and recheck oil level.

Replenish as necessary.

Note: Bucket and

lift

cylinders should be fully

retracted when checking hydraulic fluid level:

Check

all

hydraulic hose connections to

ensure that they are not leaking.

Lubricate all pivot points that incorporate

grease fittings.

Start tractor and run engine at approximately

1200

-

1400

RPM

for initial cycling of loader.

Push PTO lever forward to

1-

the first time, cycle

-

Before using front loader for

lift

purge air from cylinder.

system can cause unexpected fall

"ON"

and bucket cylinders to

Air

in

the hydraulic

of

main

frame, causing Injury or damage to loader or

tractor.

Operate and check the loader main frame and

bucket for interference, noise, and bending of

parts.

--Before using loader, double

check:

Tractor Owner's Manual for recommended

tire,pressure

That all bolts and hoses have been tight

ened and that all tools have been removed

from tractor and loader.

Counterweights are Installed and correct.

UP

START

Ensure tractor meets

PROCEDURE

all

requirements in

Tractor Preparation Section.

Cycle lift and bucket cylinders with bucket

empty several times to seat

-

in cylinder

components.

Check all hydraulic hose routings to ensure

adequate clearances exist between hoses

and adjacent components.

1

-

-

The tractorlfront loader

should only be operated with all safety

-

equipment properly Installed.

-

Operate loader from

,tractor seat only. Engine will not run with

engaged unless operator's seat

Is

occupied.

the

BTO

Check front loader hydraulic fluid level. Refer

to front loader operator's manual.

25

Page 28

~_____

OPERATIONAL

OPERATING

NOTICE-Do not use the bucket for pushing

down material with bucket cylinders partially

extended. Cylinder and rod may be

damaged.

Do

not

extend bucket cylinders) during

backfillinghackgrading operation. Cylinder

and rod may be damaged.

Position vehicles

as possible and in such a direction

minimize the amount

required to dump.

Do

not use the spill guard

it will deform and become damaged.

Keep the unit clean and perform regular

service. Observe safety instructions

whenever cleaning,

We urge you

CHECK

TIPS

..

tip bucket cutting edge down (fully

to

be loaded as near the pile

as

to

of

tractor turning

to

push objects as

setvicing,or lubricating.

to

follow

this advice:

6.

When lowering a heavy load, ease

downward slowly. Never drop a loaded

bucket and “catch” hydraulically.

it

Stopping a load after

downward momentum places undue

strain on the unit and may cause damage

to the loader or tractor.

m

-

A-

hydraullc lines, relieve all

Escaping hydraulic oil under pressure can

have sufficient force to penetrate the skin

causing serious personal injury.

escaplng hydraulic oil, consult a physlcian

Immediately.

I-

the hydraulic fittings or hoses are leaking or

damaged.

main frame to drop suddenly, causing damage

to the tractor or loader

-

Before disconnecting

hydraullc pressure.

-

Do

not operate the loader

A

sudden line burst can cause the

or

injury

has gained

If

Injured by

to

personnel.

it

if

1.

Read and understand this manual as

as the tractor owner’s manual.

2.

Remember and observe the Safety

Precautions

this manual, the tractor manual and on the

loader itself.

3.

Use good common sense in the everyday

operation of this unit, Safety instructions

can never be all inclusive. You are

responsible for watching out for, and

avoiding, unsafe conditions.

4.

Never exceed the limits of

machinery.

so

safely

5.

Don’t hurry the learning process or take

the unit for granted. Ease

become familiar with your new loader and

tractor.

brought

to your attention in

a

If

its ability to do a job or to do

is

in question-Don’t try it.

into

piece of

it

well

and

BEFORE OPERATING, LUBRICATE ALL

MOVING PARTS. (Refer to lubrication section)

COLD

To assure smooth operation in cold weather,

allow the tractor to warm up. Slowly cycle the

loader and bucket several times to warm the

fluid in the hydraulic system. The loader may

operate erratically until the hydraulic fluid has

warmed to operating temperatures.

WEATHER OPERATION

26

Page 29

OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS

Main,

acting type (both push and pull under

hydraulic power). This means that the loader

can be forced down as well as up. It means

that the bucket can be tilted down or up with

hydraulic pressure.

HYDRAULIC CONTROL VALVE

Your loader control valve has two handles.

The right handle operates the

(the loader) and has a float position. The

handle operates the bucket cylinders. Both

handles

position when released.

LEFT HANDLE

A

B

c

lift

-

-

-

and bucket cylinders are double

lift

cylinders

will

return to neutral except from float

RIGHT

-

BUCKET

Bucket Dump

Neutral

Bucket Back

HANDLE - LOADER

A

-

Float

Position

Loader Down

Neutral

Loader Up

C

D

B

-

-

-

left

LOADER

A

POSITION

way forward (this

--Right handle pushed all the

is

float position). Handle will

stay until pulled back.

POSITION

forward, bucket

POSITION

POSITION

bucket

B -Right handle pushed half way

will

lower.

C

-

Neutral position.

D

--Right handle pulled back,

will

raise.

Note: In float position there is no hydraulic

pressure going

loader frame

to the ground by gravity. When the bucket

on the ground (and the valve

the bucket will

to

is

up

follow

the

lift

cylinders.

off

the ground, it will lower

is

still in float)

the shape

of

the ground

If

the

is

even when the tractor is moving. This allows

hydraulic

oil

to

flow

back and forth in the

hydraulic system as the loader is raised and

lowered by the ground contour.

-Do

not

allow

bucket

Into ground when tractor is moving forward in

float. The bucket bottom should be level with

the ground or slightly rolled back.

lip

to

dig

HANDLE USE

BUCKET

POSITION

A -Left handle pushed forward,

bucket will dump.

POSITION

POSITION

B

-

Neutral position.

C

-

Left handle pulled back,

bucket will roll back.

NOTE: The float position is most commonly

used with attachments in snow removal.

Tractor should be run at slow ground speed

and the

material loose and

lift

and bucket cylinders used to work

fill

the bucket.

27

Page 30

OPERATING INSTRUCTIONS

CONTROLLED RATE

of

LOADER FUNCTIONS

By feathering (slightly moving) the control

levers, precise operational speeds can be

obtained. This action controls the position

of

the valve spools in the control valve and

regulates flow of oil fromho cylinders.

is

important to utilize this operational

It

SCRAPING

When scraping, the "float" position should be

utilized to maintain the bucket firmly on the

ground and at the same time allow the bucket

to follow ground contours.

"B

..

..

..

'

'

LE^

.

..

"ANOLE

A

-

8

-

C

-

A

-

BUCKET

Bucket Dump

Neutral

Bucket Back

'.

CB

*:

RIG'HT

HANDLE - LOADER

A

-

Float

B

-

Loader

C

-

Neutral

D

-

Loader

Position

Down

Up

The bucket should be positioned level to the

ground during

BACKFILLING/BACKGRADING

"

scraping" operations.

When "backfilling" or "backgrading", position

the bucket

so

it is level on the ground. Do not

dump material from the bucket. Additional

weight of material in bucket will assist in

"

backgrading" and increases loader efficiency

during

"

backfilling".

28

Page 31

LOADING

OPERATING INSTRUCTIONS

As

bucket begins to

roll the bucket back and raise the loader

increase

”fill”

fill

with material, gradually

to

capacity. This procedure also

results in the material being removed in layers

from the top

for

maximum loading efficiency.

.-.

..

When th

the bucket

out

le bucket is full, rais e loade

is

clear

of

material and slowly back

of

pile.

!r

so

that

For maximum loading efficiency, minimize

angle

of

turn and distance between the

loading and unloading points.

29

Page 32

OPERATING

TRANSPORTING MATERIAL

INSTRUCTIONS

Transport material to

loader bucket as

spillage and maintain maximum

tractorfloader stability.

-1-

should be in a position that will not impair

operatots vision,

Observe the following safety messages.

Bh

obstacles when loader

damage or possible death by electrocution.

During transport the loader

.

-Avoid any overhead wires or

"

unloading point" with

low

as possible to prevent

Is

raised, to avoid

.-

-

A loaded bucket should be

transported

speeds, especially

Make turns slowly and use the tractor brakes

cautiously. Afull bucket In the raised position

alters the center of gravity of the

Increases the possibility of mishaps.

In

a low position at slow ground

if

the

ground is irregular.

unit and

1-

on a loader or attachment; a

cause serious Injury.

UNLOADING

As

the tractor approaches the "unloading

point

"

, raise the loader to the height required

for

clearance

Drive slowly to position bucket above

"

unloading point", stop tractor and dump

bucket.

NOTE:

required for

As

"

dumping" clearance height increases, the

bucket position must be adjusted to maintain

a level bucket to prevent excessive spillage

of material from bucket.

-do

Do

"

not

lift

or carry personnel

slip or fall could

to

"

dump" bucket.

not raise loader higher than

dumping" clearance.

30

Page 33

LOADER REMOVAL FROM

TRACTOR

1.

Select a level, safe, and solid place for

loader removal. Lower bucket to the

ground and remove the stands from the

loader main frame.

LOADER REMOVAL FROM

TRACTOR

2.

Raise the loader until the stands can be

inserted into the loader arms.

clip

Install the

Lower the loader until the stands rest on

3.

pins into the stand ends.

the ground.

Dump the bucket until the edge of bucket

touches the ground.

31

Page 34

LOADER REMOVAL FROM TRACTOR

4.

Using the bucket to support the loader

main frame, remove loader mast fixing

pins.

Note: Use bucket operation to make fixing

pin removal easier.

5.

Remove the clip pins and mounting pins

from the masts and the front guard.

Remove the hydraulic hoses from the

brace loops.

Remove the brace arms.

6.

Roll

back the bucket to detach loader from

sub

-

frame. Operate the bucket

slowly

avoid loader to tractor interference.

left

to

32

~

Page 35

7.

Put the tractor in reverse and drive it back

2

feet. Remove the front guard from

sub

-

frame.

LOADER REMOVAL

FROM

TRACTOR

8.

Remove the hydraulic pump by removing

the four bolts holding the mounting

brackets to the tractor frame.

PTO

Remove the pump from the

NOTE:

Loader

For sub

Do

not disconnect hoses.

is

now parked and ready for storage.

-

frame removal

see

pages

shaft.

13

thru

17.

33

Page 36

LOADER REMOVAL FROM

NOTES:

TRACTOR

34

Page 37

STORAGE

STORAGE

END

OF

SEASON

1.

If

loader is to be dismounted from the

tractor during storage, make sure parking

area is on hard, level ground.

2.

Store in

Note:

All

retracted position.

3.

Thoroughly clean the loader of all

accumulated dirt and grease.

4.

Completely lubricate the loader as

specified in lubrication section of manual.

5.

Using an oil soaked cloth, lubricate

hydraulic cylinder rods to protect them

from rust and corrosion.

6.

Repaint any areas where paint is worn or

damaged.

7.

Wear areas on buckets or other

attachmentsshould

to prevent rust or corrosion.

8.

Replace any safety or warning labels that

are not readable due

1-

on or around

a

dry,

sheltered area,

hydraulic cylinders should

be

coated with grease

to

wear or damage.

-

Do

not allow children to

the

tractor or loader.

if

possible.

be

in the

all

play

PROCEDURES

BEGINNING

1.

Review safety precautions and operation

sections of manual.

2.

Thoroughly clean loader of all

accumulated

3.

If

removed from tractor for storage,

remount loader per

section of this manual.

4.

Completely lubricate the loader per the

lubrication section of this manual. Make

sure

5.

Clean with solvent any exposed surfaces

which had been coated with grease. Wipe

dry

an oil soaked cloth.

6.

Tighten any bolts that may have been

loosened and make sure all pins are in

place.

7.

Start tractor and operate loader to make

sure it is operating properly and

are properly connected.

8.

Check hydraulic fluid level in loader mast

and

in this manual.

9.

Make sure, hydraulic hoses, lines and

fittings are in good shape and are not

leaking. Repair or replace as, needed.

OF

SEASON

dirt

and grease.

“Loader

all

fittings are taking grease properly.

Installation”

with a clean cloth, then lubricate with

all

fill

if

required. Use oil recommended

hoses

35

Page 38

STORAGE

NOTES

36

Page 39

LOADER INSTALLATION

LOADER INSTALLATION

I

NOTE: Install sub-frame and weights (Page

13

-

17).

-

The sub

assembled.

frame, masts and main frame are

All

cylinders and hoses are

attached to the loader frame and hydraulic

pump.

1.

Move the tractor centrally between the

masts.

2.

Mount hydraulic pump to tractor by sliding

splined pump drive joint onto front PTO

shaft with mounting brackets inside main

frame and attaching with four

inch

bolts.

5/16

x

7/8

3.

Attach the front guard on the front of the

-

frame using two each 1/2 x 1 inch and

sub

1/2

x

1 5/16 inch bolts, and four each 1/2

inch nuts and washers. Tighten bolts and

nuts.

Torque: 76 ft

-

lb (1

03

Nm)

37

Page 40

LOADER INSTALLATION

AlTACHlNG

4.

Move the tractor until the masts are.

LOADER

MASTS

positioned in line with upright pads on the

sub

-

frame, use two people and the bucket

to lower and guide the masts onto the

pads.

5.

Use bucket movement to shake masts to

align pin holes. Insert the fixing pins

through the masts and pads. Install clip

pins through holes.

6.

Attach brace arms to mast and front guard

as shown with clevis pins and clips.

NOTE: Route hydraulic hoses along left

brace arm through hose holder

loops.

Ensure high pressure hose (smaller

two)

is

positioned on top of larger suction

hose.

of

Page 41

LOADER STAND REMOVAL

7.

Raise the loader with the loader control

until the stands clear the ground.

8.

Remove fixing pin

from the stands and

remove the stands.

LOADER INSTALLATION

9.

Align the hole in the bottom of the stand

with the mounting

ho.ok at rear of

mainframe. Slide the stand over the

mounting hook and then insert the fixing

pin previously removed through main

frame and through the stand. Repeat the

above steps for the other side. Lower the

loader

Front Loader

(Page

25)

to

the ground.

is

ready for operational check.

Page 42

I

40

Page 43

TROUBLE

SHOOTING

TROUBLE

SYSTEM DOES NOT WORK AT ALL

PTO

in

'OFF'

No oil

Check system for leaks.

Oil low

proper level. Check system for leaks.

Restriction

could be collapsing to cut off oil supply.

Replace line.

Air leaks

hose clamps or replace hose.

Dirt

needed, drain and flush hydraulic system.

Badly worn pump

causing pump wear.

Oil leak

or replace defective lines.

Hoses attached improperly

properly and tighten securely.

in

in

in

pump - Clean and repair pump.

in

position

system

reservoir - Check and

in

system - Oil suction line

in

pump suction line - Check

pressure lines -Tighten fittings

SHOOTING

-

Put

to

'ON'.

-

Fill to proper level.

-

Check for problems

-

fill

to

If

Attach

SYSTEM

Cold oil - Allow to warm up before

operating.

Oil viscosity too heavy

specifications on proper oil.

Not enough engine speed

engine speed.

Low

oil

if

could cause low

Air

system for leaks.

Badly worn pump

pump. Check for problems causing pump

wear such as contaminated oil.

Restriction

could be dirty or have inner walls that are

collapsing to cut

replace suction line.

Oil

or

replace defective lines.

RUNS

OR

WORKS SLOWLY

-

-

Increase

oil

supply - Check reservoir and add

needed. Check system for leaks that

oil.

in

system

leaks

in

-

Check suction side of

-

Repair

in

suction line - Suction line

off

oil supply. Clean or

pressure lines-Tighten fittings

or

replace

See

Control Valve Defective

SYSTEM RUNS WITH

Air

in

system - Examine suction side

system for leaks. Make sure oil level is

To

correct.

is correct and leaks fixed, use bucket and

loader cylinders

system of air.

Cold oil

start. Before operating, allow oil to warm up.

Components sticking or binding

for

dirt

Pump damaged

parts.

get air out of system after oil level

5

to

-

Oil viscosity may be too high at

or gummy deposits.

-

Check for worn or broken

-

Replace

STOPS

6

AND STARTS

times to purge the

-

of

Check

OVERHEATING

Using incorrect oil - See specifications on

proper oil.

Low oil level

Engine

Restriction

replace.

Controls stuck

position

to neutral.

running

-

OF

OIL

IN SYSTEM

-

Fill reservoir. Look for leaks.

too fast - Reduce throttle.

in

hydraulic line - Clean or

in

partially or

Free both handles

full

so

they return

open

41

Page 44

TROUBLE

SHOOTING

FOAMING

Low oil level - Fill reservoir. Look for leaks.

Water

Wrong

specifications on proper oil.

Air

leak

Tighten or replace suction line.

Kink

Worn seal around pump shaft

sealing area and replace seal. Check oil for

contamination.

PUMP MAKES NOISE

Low oil level - Fill reservoir. Check system

for leaks.

OF

OIL IN SYSTEM

in

oil - Drain and replace oil.

kind

in

in

oil suction line - Replace oil line.

of oil being used

line from reservoir to

-

pump

-

See

-

Clean

LOAD DROPS WITH CONTROL VALVE IN

NEUTRAL POSITION

Leaking or broken oil lines from control

to

valves

Tighten or replace lines.

Oil leaking past cylinder packing or

“0”

rings

caused

system and determine source of dirt.

Oil leaking past control valve

replace valve. Wear may be caused by

contamination. Clean system and determine

source of dirt.

CONTROL VALVE STICKS

Valve broken or scored internally

Replace valve.

cylinder

-

Replace worn parts.

by

contamination, clean hydraulic

-

Check for leaks.

If

-

Clean or

OR

WORKS HARD

wear is

-

-

Oil viscosity too high

on proper

Cold oil - Allow oil

operating.

Suction line plugged or pinched

replace

Reservoir air vent plugged

plug, flush, and clean air vent.

in

Air

Check system for leaks. Check pump shaft

seal.

.Worn or scored

-

Replace pump.

PUMP LEAKS OIL

Damaged

Replace seal.

oil.

line

between reservoir and pump.

oil

-

Tighten or replace suction line.

pump

seal

around

See specifications

to

warm up before

-

Clean or

-

Remove vent

bearings or shafts

pump

shaft

-

CONTROL VALVE LEAKS OIL

Worn or damaged

rings.

to wear, clean system and look for source.

Broken valve parts

valve.

CYLINDER LEAKS OIL

Damaged cylinder bowl

cylinder. Correct cause

Rod seal leaking

contamination caused seal

source. Wear may be caused by external as

well as internal contaminants. Check piston

rod

Loose

If

contamination has caused

for

scratches

parts - Tighten parts.

“0”

rings - Replace

-

Replace parts or

of

damage.

-

Replace seal.

or

misalignment.

to

-

Replac4

wear.

“0

“0

rings

look

for

If

42

Piston rod damaged

or scratches that could cause seal damage or

allow oil leakage. Replace defective cylinder.

-

Check rod for nicks

Page 45

LUBRICATION

and

MAINTENANCE

LUBRICATION

Do

not perform any service/maintenance

and

MAINTENANCE

operations with front loader raised

ground.

Note: Lower front loader to the ground and

relieve pressure in loader hydraulic lines prior

to performing any

service/maintenance

operations on tractor or loader.

!

Bh

'

pressurized lines. Use paper or cardboard,

-

Keep hands and body from

not body parts, to check for leaks. Hydraulic

oil under pressure will penetrate the skin

causing serious injury.

Make sure that

all

operating and service

personnel know that in the event hydraulic

fluid penetrates the skin, it must be surgically

removed within

familiar

with this form

a

few hours by a doctor

of

injury, or gangrene

may result.

off

the

Inspect hydraulic hoses, connections, control

valve and cylinders for evidence of leakage

Note:

If

oil seepage past cylinder rod is

evident, look for scoring on rod.

Tractor tire inflation should be checked as

listed in tractor owner's manual to ensure tire

inflation is to specification.

Unequal inflation can result in bucket not

being level to the ground.

Front tires should be maintained at maximum

recommended inflation to maintain normal

tire profile with added loader weight and

material.

A-

m

If

the

fittings or the hoses are leaking or

damaged.

the

main frame to drop suddenly, causing

damage

-

Do

A

sudden

to

the tractor

not operate the front loader

line

burst could cause

or

loader

or

injury

personnel.

1-

-Accidental movement of

control lever or leak in the hydraulic system

could

serious Injury.

cause main frame to drop, causing

Do

not stand or walk under

raised attachment.

Note: When checking hydraulic system oil

level, the loader should be on the ground and

bucket fully retracted (all cylinders in the

retracted position). Grease all loader pivot

points as indicated on lubrication chart.

to

a

Page 46

LUBRICATION AND MAINTENANCE

LUBRICATION AND MAINTENANCE CHART

LUBRICATION AND MAINTENANCE CHART

Hydraulic oil level

Tire inflation

Loader pivot points

Hydraulic lines hoses

and connections

Lift and bucket cylinders

Mounting pins, Clip pins

-

Fixing pins

Sub

-

frame mounting

and hardware Re-torque

..........

......

......

.....

...

...

.....

Check

Check

Lubricate

Check for leakage

wear and damage

Check for seepage

Check,.

.

replace

Check

.............

.............

............

.......

.......

..............

if

missing

.............

.Daily/l 0 Hrs

.Weekly/SO Hrs

.Daily/l 0 Hrs

.Daily

.Daily/l 0 Hrs

.Daily/lO Hrs

.Weekly/50Hr

/lo

Hrs

I

44

Page 47

PARTS

IEFERENCE

SUMBER

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

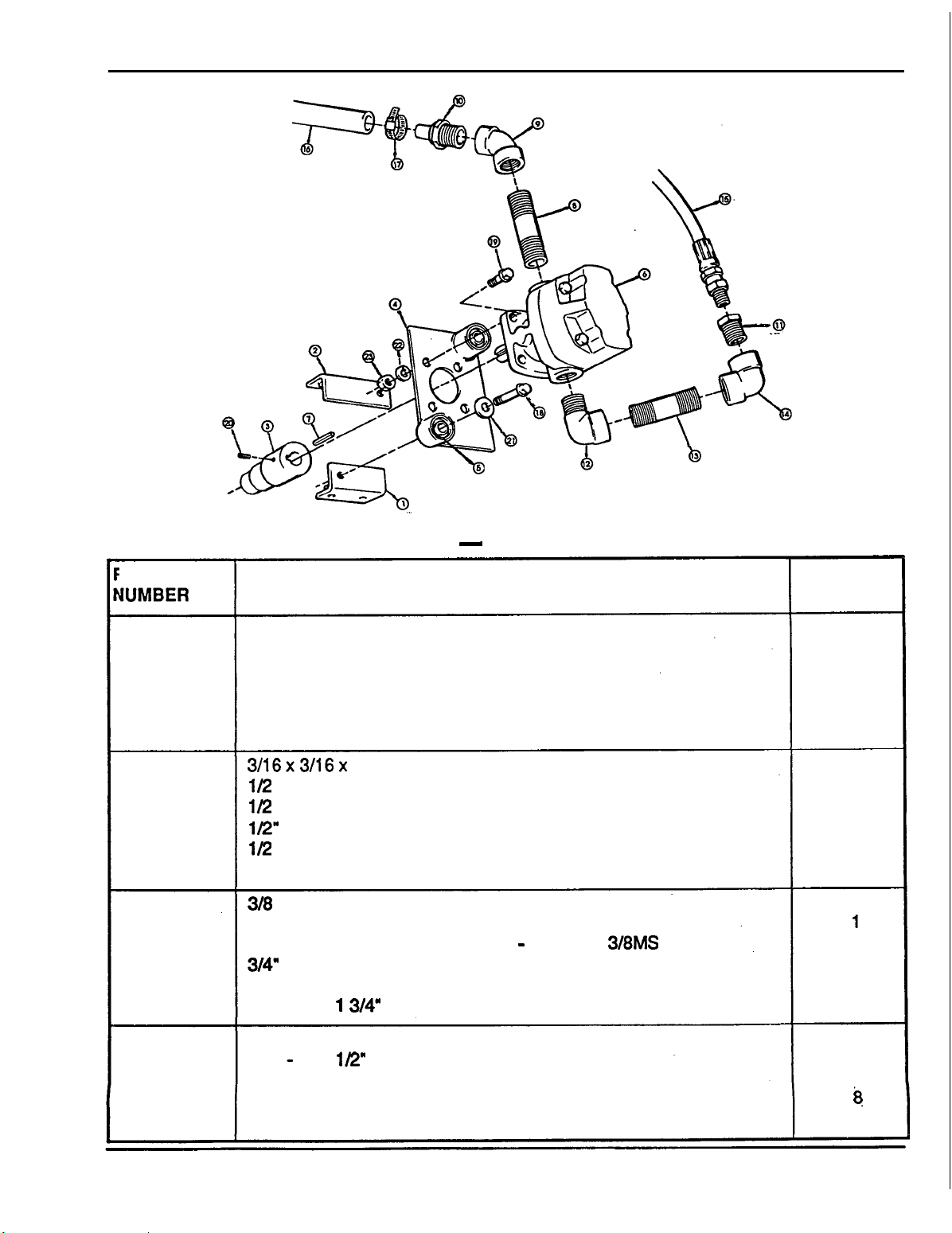

REPAIR PARTS - PUMP ASSEMBLY

DESCRIPTION QUANTITY

ANGLE

ANGLE - LH

PUMP COUPLER

PUMP PLATE

RUBBER BUSHING

304

3/16x3/16x 1 KEY

1/2

1/2 x 45' PIPE ELBOW

1/2"

1/2 - 3/8 HEX REDUCER BUSHING

3/8

318 x 3" PIPE NIPPLE

3/8 90' PIPE ELBOW

3/8

3/4" SUCTION HOSE

#

16 HOSE CLAMP

5/16 - 18

-

RH

PUMP

x

2

"

PIPE NIPPLE

PIPE END

90'

ST ELBOW

X

60" HYDRAULIC HOSE 9/16 - 18 ORB X 3/8MS

X

1

3/4" HEX HEAD CAPSCREW

REQ'D

'2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

48

2

2

"

19

20

21

22

23

-

18

5/16

5/16

5/16

5/16

5/16

X

-

18 X 1/2" SOCKET HEAD SETSCREW

"

FLAT WASHER

"

LOCK WASHER

-

18 HEX NUT

1

"

HEX HEAD CAPSCREW

8

1

2

8

4

45

Page 48

46

Page 49

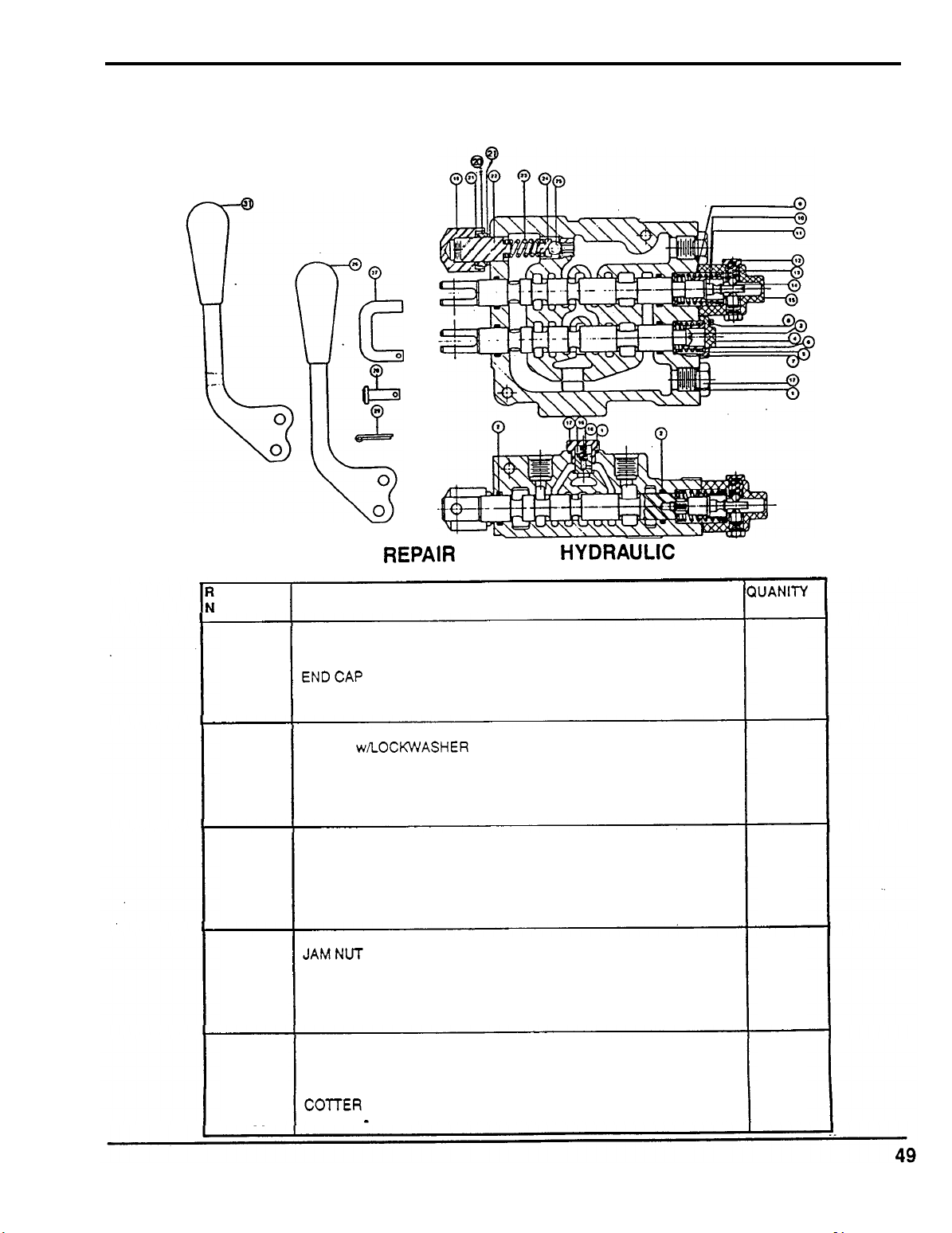

PARTS

REPAIR PARTS

IEFERENCE

IUMBER

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

-

MAIN FRAME

DESCRIPTION

MAIN FRAME

-

UPRIGHT

UPRIGHT

STAND

BUCKET

PIN -A

x

5/32

#11 CLIP PIN

x

2 1/4" LYNCH PIN

3/8

x

1 1/4

LIFT CYLINDER

LIFT CYLINDER

BUCKET CYLINDER

VALVE

FEEDLINE

FEEDLINE

FEEDLINE

FEEDLINE - BOTTOM

-

9/16

1/4 X 24" HYDRAULIC HOSE 9/16 - 18 ORB

3/8

x

20

1/4 x 16" HYDRAULIC HOSE 1/4 MP x 318 MJIC

1/2"

x

1/2"

VENT PLUG

RH

-

LH

-

42

"

1" COTTER PIN

3/4" x 10ga. MACHINERY BUSHING

-

RH

-

LH

-

TOP

-

2nd

-

3rd

18 SWIVEL NUT 90' ELBOW

"

HYDRAULIC HOSE 9/16 - 18 ORB

90'

ST. ELBOW

'

x3/8.MJlC

x

3/8MS

ASSEMBLY

I

U

ANTlTY

IEQ'D

1

1

1

2

1

12

8

4

2

12

1

1

2

1

1

1

1

1

.2

4

1

8

1

1

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

1/2" PIPE END

3/8: x 90' ST. ELBOW

1/4" x 90' ST. ELBOW

#10

X

1/2"

HEX HEAD SELF-TAPPING SCREW

1/4"

-

28 UNF ST. GREASE ZERK

-

20

X

2

"

1/4

1/4" LOCK WASHER

1/4"

-

20 HEX NUT

DECAL

DECAL

DECAL

DECAL

DECAL

DECAL

DECAL

I

HEX HEAD CAPSCREW

-

VALVE OPERATION

-

HONDA

-

WARNING - IMPROPER SERVICE

-

WARNING - TRACTOR TIP OVER

-

WARNING - LOADS CAN FALL

-

NOTICE - LOADER HYDRAULIC SYSTEM

-

SERVICE INFORMATION - SPECIAL ATTACHMENTS

1

1

4

1

12

2

2

2

1

2

1

1

1

1

1

I

47

Page 50

PARTS

IEFERENCE

NUMBER

1

2

3

4

5

6

7

'8

9

10

11

12

13

14.

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

REPAIR PARTS - SUB-FRAME

DESCRIPTION

SUB FRAME

FRONT BRACKET

LOWER FRONT COVER, FRAME

BOTTOM BRACKET

WEIGHT BRACKET, COUNTERWEIGHTS

PUMP GUARD

BRACE ARM, RH

BRACE ARM, LH

PIN. COUNTERWEIGHT BRACKET A

PIN, COUNTERWEIGHT BRACKET B

PIN, COUNTERWEIGHT BRACKET C

PIN D. WITH FLAT (Mounting Pin)

PIN E

(Fixing

Pin)

54

x

1

114' CLEVIS PIN

711

6'

LYNCH

#11

CLIP PIN

1'114"~314"x

12

x

25mm HEX HEAD CAPSCREW

10

x

30mm HEX HEAD CAPSCREW

1/2

-

13

1/2

-

13

112.

FLATWASHER

1R'

LOCKWASHER

1/2.-

13 HEX NUT

7/16

-

711

6

"

FLAT WASHER

711

6

"

LOCKWASHER

711 6'-

3/8'

FLATWASHER

DECAL - INSTALLATION

PIN

lOga

MACHINERY BUSHING

X

1

314' HEX HEAD CAPSCREW

X

1

1M'

Hf3

HEAD CAPSCREW

14 X 1

114' HEX HEAD CAPSCREW

14

HEX NUT

QUANTITY

REQ'D

1

1

1

1

1

1

1

1

2

1

2

4

4

4

5

12

4

2

2

2

2

6

4

4

2

2

2

2

2

1

Page 51

PARTS

REPAIR

EFERENCE DESCRIPTION QUANITY

UMBER REQ'D

1

O-RING

2 O-RING

3

SCREW

4

ENDCAP

5

RETURN SPRING

6

SPACER

7

WASHER

8 SCREW wROCKWASHER 2

9

SPACER

10

11

12

13

14

15

16

17

18 LOAD CHECK SPRING

19

20

21

22

23

24

25 STEEL BALL

26

27

28 PIN

29

30

DETENT SPOOL

RETURN SPRING

DETENTPLUG

DETENT SPRING

STEEL BAU

DETENT END CAP

LOAD CHECK POPPET

LOAD MCHECK PLUG

TAMPER PROOF CAP 1

JAMNUT

GASKET

ADJUSTMENT SCREW 1

RELIEF SPRING

BAU RETAINER

HANDLE, STRAIGHT

C-HOOK

COlTER PIN

HANDLE - BENT 1

.

P

A

RT

S

.

-

HYDRAKIC

VALVE

4

4

1

1

1

1

1

1

1

1

2

2

2

1

1

2

1

1

2

1

1

1

1

2

2

4

Page 52

NOTES:

Page 53

WARRANTY

SERVICE

WARRANTY SERVICE

OWNER SATISFACTION

Your satisfaction and good will are important to your dealer and to us. All Honda warranty details are

explained in the Distributor's Limited Warranty. Normally any problems concerning the product will be

handled by your dealer's service department.

to your satifaction, we suggest you take the following action:

Discuss your problem with a member of the dealership management. Often complaints can be

quickly resolved at that level.

Manager, contact the owner of the dealership or the General Manager.

If

your problem still has not been resolved to your satisfaction, contact the Power Equipment

Customer Relations Department of American Honda Motor Co., Inc.

If

the problem has already been reviewed with the Service

If

you have a warranty problem that has not been handled

American Honda Motor

Power Equipment Customer Relations Department

P.O. Box 10021

Duluth, Georgia 30136

Telephone: (770) 497

We will need the following information to assist you:

-

Your name, address, and telephone number

-

Product model and serial number

-

Date

of

purchase

-

Dealer name and address

-

Nature of problem

After reviewing all the facts involved, you will be advised of what action can be taken. Please bear in

mind that your problem will likely be resolved at the dealership, using the dealer's facilities, equipment,

and personnel,

Your purchase of a Honda product is greatly appreciated by both your dealer and American Honda Motor

Co.,lnc. We want to assist you in every way possible to assure your satisfaction with your purchase.

so

it is very important that your initial contact be with the dealer.

Co.,

-

9421

-

6400

Inc.

Page

51

Page 54

Page 55

Page 56

Loading...

Loading...