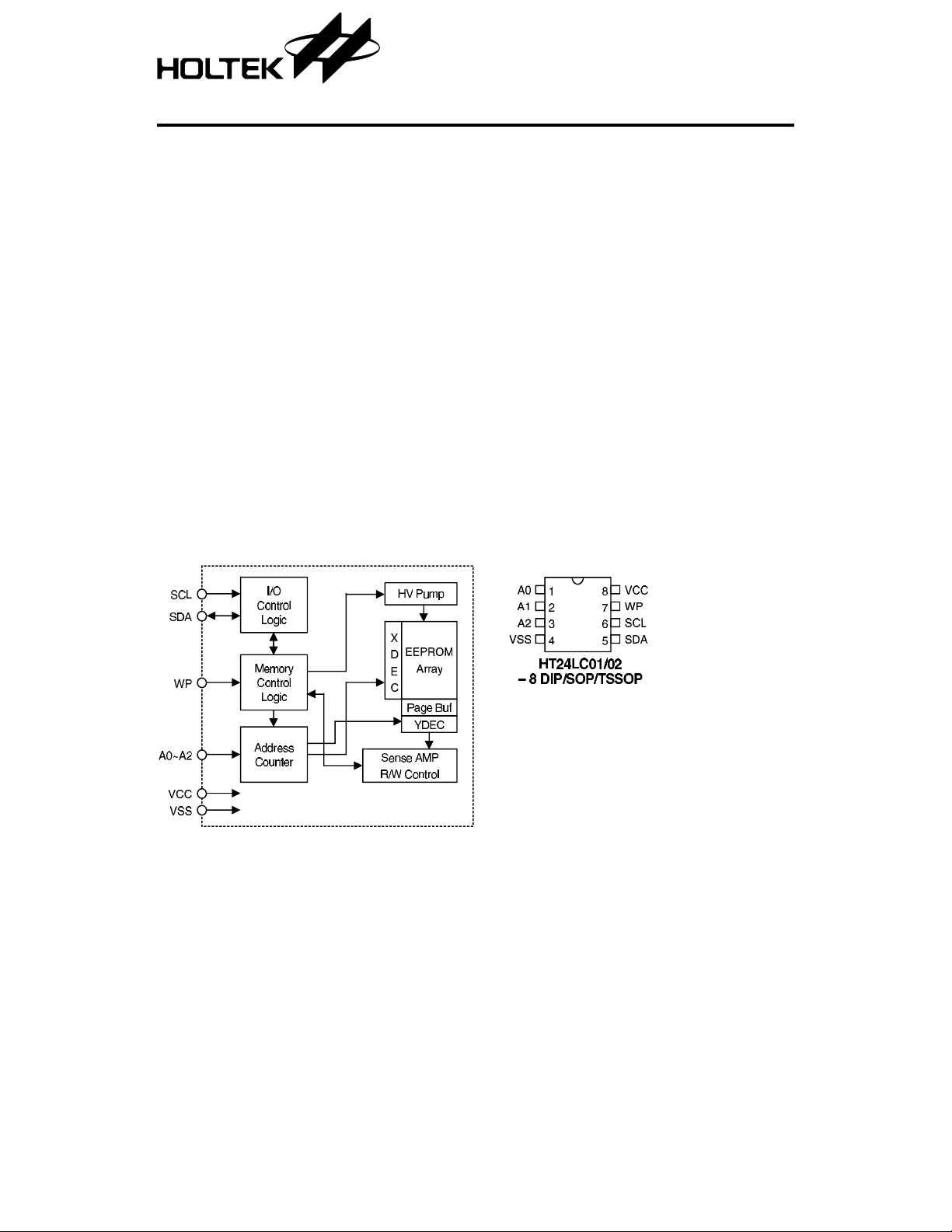

1K/2K 2-Wire CMOS Serial EEPROM

Features

•

Operating voltage: 2.4V ~5.5V

•

Low power consumption

–

Operation: 5mA max.

–

Standby: 5µA max.

•

Internal organization

–

1K (HT24LC01):128×8

–

2K (HT24LC02): 256×8

•

2-wire serial interface

•

Write cycle time: 5ms max.

•

Automatic erase-before-write operation

General Description

The HT24LC01/02 is a 1K/2K-bit serial

read/write non-volatile memory device using

the CMOS floating gate process. Its 1024/2048

bits of memory are organized into 128/256

words and each word is 8 bits. The device is

optimized for use in m any industri al and com -

HT24LC01/02

•

Partial page write allowed

•

8-byte Page write modes

•

Write operation with built-in timer

•

Hardware controlled write protection

•

40-year data retention

•

106 erase/write cycles per word

•

8-pin DIP/SOP package

•

8-pin TSSOP (HT24LC02 only)

•

Commerical temperature range

(0

°C to +70°C)

mercial applications where low power and low

voltage operation are essential. Up to eight

HT24LC01/02 de vices may b e conn ected to th e

same two-wire bus. The HT 24LC 01/02 is gua ranteed for 1M erase/write cycles and 40-year

data retention.

Block Diagram Pin Assignme nt

1 6th May ’99

HT24LC01/02

Pin Description

Pin Name I/O Description

A0~A2 I Address inputs

SDA I/O Serial data inputs/output

SCL I Serial clock data input

WP I Write protect

VSS — Negative power supply

VCC I Positive power supply

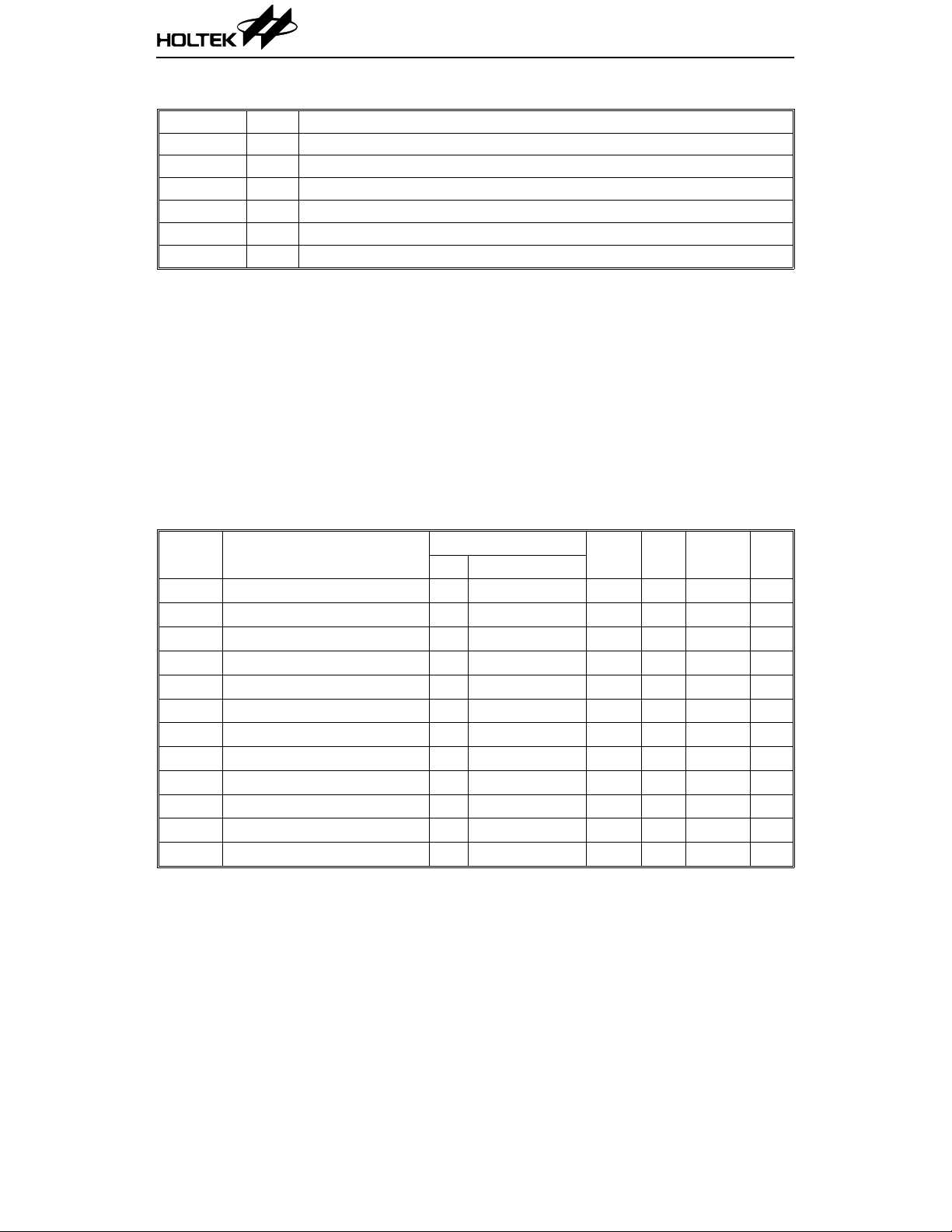

Absolu te Maxim um Ratings

Operating Temperature (Commercial) .................................................................................. 0°C to 70°C

Storage T emperature ..................... .... .. .. .... .. .. .... .. .. .... .. .. .... .. .. .... .. .. .... .. .. .... .. .. .... .. .. .... .. .. ... –50

Applied VCC Voltage with Respect to VSS ................ .. ................ .. .. ................ .. .. ............. –0.3V to 6.0V

Applied V oltage on any Pin with Respect to VSS

...................................................................

–0.3V to VCC+0.3V

Note: These are stress ratings only. Stresses exceeding the range specifie d under “Absolute Maxi-

mum Ratings” may cause substantial damage to the device. Functional operation of this device

at other conditions beyond those listed in the specification is not implied and prolonged

exposure to extreme condition s may affect device reliability.

°C to 125°C

D.C. Characteristics Ta=0°C to 70°C

Symbol Parameter

V

CC

I

CC1

I

CC2

V

IL

V

IH

V

OL

I

LI

I

LO

I

STB1

I

STB2

C

IN

C

OUT

Operating Voltage — — 2.4 — 5.5 V

Operating Current 5V Read at 100kHz — — 2 mA

Operating Current 5V Write at 100kHz — — 5 mA

Input Low Voltage — — –1 — 0.3V

Input High Voltage — — 0.7V

Output Low Voltage 2.4V IOL=2.1mA — — 0.4 V

Input Leakage Current 5V VIN=0 or V

Output Leakage Current 5V V

Standby Current 5V VIN=0 or V

Standby Current 2.4V VIN=0 or V

Input Capacitance (See Note) — f=1MHz 25°C——6pF

Output Capacitance (See Note) — f=1MHz 25°C——8pF

Note: These parameters are periodically sampled but not 100% tested

Test Conditions

V

Conditions

CC

CC

=0 or V

OUT

CC

CC

2 6th May ’99

Min. Typ. Max. Unit

—VCC+0.5 V

CC

—— 1 µA

CC

—— 1 µA

—— 5 µA

—— 4 µA

CC

V

HT24LC01/02

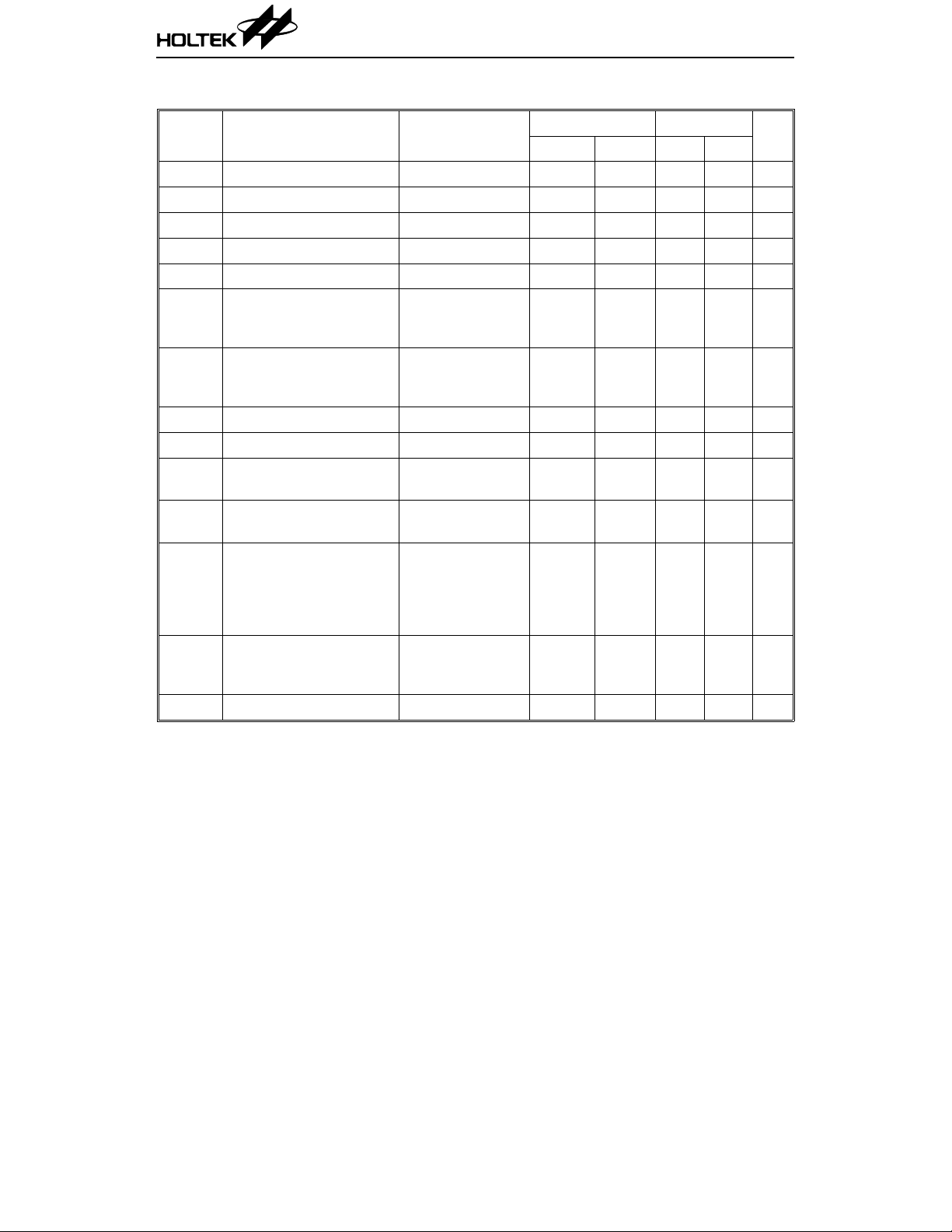

A.C. Characteristics Ta=0°C to 70°C

Symbol Parameter Remark

f

SK

t

HIGH

t

LOW

t

R

t

F

t

HD:STA

t

SU:STA

t

HD:DAT

t

SU:DAT

t

SU:STO

t

AA

Clock Frequency — 100 — 400 kHz

Clock High Time 4000 — 600 — ns

Clock Low Time 4700 — 1200 — ns

SDA and SCL Rise Time Note — 1000 — 300 ns

SDA and SCL Fall Time Note — 300 — 300 ns

START Condition Hold

Time

START Condition

Setup Time

After this period

the first clock pulse

is generated

Only relevant for

repeated START

condition

Data Input Hold Time 0 — 0 — ns

Data Input Setup Time 200 — 1 00 — ns

STOP Condition Setup

Time

Output Valid from

Clock

Time in which the

bus must be free

t

BUF

Bus Free Time

before a new

transmission can

start

t

SP

t

WR

Input Filter Time

Constant (SDA and SCL

Pins)

Write Cycle Time — 5 — 5 ms

Noise suppression

time

Standard Mode* V

=5V±10%

CC

Unit

Min. Max. Min. Max.

4000 — 600 — ns

4000 — 600 — ns

4000 — 600 — ns

— 3500 — 900 ns

4700 — 1200 — ns

—100—50ns

Notes: These parameters are periodically sampled but not 100% tested

* The standard mode means V

=2.4V to 5.5V

CC

For relative timing, refer to timing diagrams

3 6th May ’99

Functional Description

•

Serial clock (SCL)

The SCL input is used for positive edge clock

data into each EE PR OM de vice and ne gati ve

edge clock data out of each device.

•

Serial data (SDA)

The SDA pin is bidirectional for serial data

transfer. The pin is open-drain driven and

may be wired-OR with any number of other

open-drain or open collector devices.

•

A0, A1, A2

The A2, A1 and A0 pins are device address

inputs that are hard wired for the

HT24LC01/02. As many as eight 1K/2K devices may be addressed on a single bus system

(the device addressing is discuss ed in detail

under the Device Addressing section).

•

Write protect (WP)

The HT24LC01/02 has a write protect pin

that provides hard ware data protection. The

write protect pin allows normal read/write

operations whe n connected to the V

the write protect pin is connected to Vcc, the

write protection fe ature is enable d and ope rates as shown in the following table.

WP Pin

Status

At V

CC

At V

SS

HT24LC01 HT24LC02

Full Array (1K) Full Array (2K)

Normal Read/Write Operations

Protect Array

. When

SS

HT24LC01/02

bus is not busy. During data transfer, the data

line must remain stable whenever the clock

line is high. Changes in data line while the

clock line is high will be interpreted as a

START or STOP condition.

•

Start condition

A high-to-low transition of SDA with SCL high

is a start conditi on which must precede a ny

other command (refer to Start and Stop Definition Timing diagram).

•

Stop condition

A low-to-high transition of SDA with SCL high

is a stop condition. After a read sequence, the

stop command will place the EEPROM in a

standby power mode (refer to Start and Stop

Definition Timing Diagram).

•

Acknowledge

All addresses and data words are serially

transmitted to and from the EEPROM in 8-bit

words. The EEPROM sends a zero to acknowledge that it has received each word. This

happens during the ninth clock cycle.

Memory organization

•

HT24LC01, 1K Serial EEPROM

Internally organized with 128 8-bit words, the

1K requires a 7-bit data word address for

random word addressing.

•

HT24LC02, 2K Serial EEPROM

Internally organized with 256 8-bit words, the

2K requires an 8-bit data word address for

random word addressing.

Device operations

•

Clock and data transition

Data transfer may be initiated only when the

Device addressing

The 1K and 2K EEPROM devices all require an

8-bit device address word following a start condition to enable the chip for a read or write

operation. The device address word consist of a

mandatory one, zero sequence for the first four

most significant bits (refer to the diagram showing the Device Addres s). This is common to al l

the EEPROM device.

The next three bits are the A2, A1 and A0 device

address bits for the 1K/2K EEPROM. These

three bits must compare to their corresponding

hard-wired input pins.

4 6th May ’99

HT24LC01/02

The 8th bit of device address is the read/write

operation select bit. A read operation is in itiated if this bit is high a nd a wri te opera tion is

initiated if this bit is low.

If the comparison of the device address succeed the

EEPROM will output a zero at ACK bit. If not, the

chip will return to a standby state.

Write operations

•

Byte write

A write operation requires an 8-bit data word

address following the device address word

and acknowledgment. Upon receipt of this address, the EEPROM will again respond with a

zero and then clock in the first 8-bit data

word. After receiving the 8-bit data word, the

EEPROM will output a zero and the addressing device, such as a microcontroller, must

terminate the write sequence with a stop condition. At this time the EEPROM enters an

internally-timed write cycle to the non-volatile memory. All inputs are disabled during

this write cycle and EEPROM will not respond until the write is completed (refer to

Byte write timing).

•

Page write

The 1K/2K EEPROM is capable of an 8-byte

page write.

A page write is initiated the same as byte

write, but the microcontroller does not send a

stop condition after the first data word is

clocked in. Instead, after the EEPROM acknowledges the receipt of the first data word,

the microcontrol ler can tran smit up to seve n

more data words. The EEPROM will respond

with a zero after each data word received. The

microcontroller must terminate the page

write sequence with a stop condition.

The data word address lower three (1K/2K)

bits are internally incre mented foll owing the

receipt of each data word. The higher data

word address bits are not incremented, retaining the memory page row locati on (refer

to Page write timing).

•

Acknowledge polling

Since the device will no t acknowle dge duri ng

a write cycle, this can be used to determ ine

when the cycle is complete (this feature can be

used to maximize bus throughput). Once the

stop condition for a write co mmand has bee n

issued from the master, the device initiates

the internally timed write cycle. ACK polling

can be initiated immediately. This involves

the master sending a start condition followed

by the control byte for a write command

(R/W=0). If the device is still busy with the

5 6th May ’99

write cycle, then no AC K will be return ed. If

the cycle is completed, then the device will

return the ACK and the master can then proceed with the next read or write command.

•

Write protect

The HT24LC01/02 can be used as a serial

ROM when the WP pin is connected to VCC.

Programming will be inhibited and the entire

memory will be write-protected.

•

Read operations

Read operations are initiated the same way as

write operations with th e exception that the

read/write select bit in the device address

word is set to one. There are three read operations: current a ddress read, rand om address

read and sequential read.

•

Current address read

The internal data word address counter main-

tains the last address accessed during the last

read or write operati on, incremented by one.

This address stays va lid between operations

as long as the chip power is maintained. The

address roll over during read from the last

byte of the last memory page to the first byte

of the first page. The address roll over during

write from the last byte of the current page to

the first byte of the same page. Once the device address with the read/write select bit set

to one is clocked in and acknowl edged by th e

EEPROM, the current address data word is

serially clocked out . The m icrocon trol le r doe s

not respond with an input zero but generates

a following stop condition (refer to Current

read timing).

HT24LC01/02

Acknowledge polling flow

•

Random read

A random read requires a dummy byte write

sequence to load in the data word address

which is then clocked in and acknowledged by

the EEPROM. The microcontroller must then

generate anothe r start condition . The microcontroller now initiates a current address

read by sending a device address with the

read/write select bit high. The EEPROM acknowledges the device address and serially

clocks out the data word. The microcontroller

does not respond wi th a zero but doe s generates a following stop condition (refer to Ran dom read timing).

6 6th May ’99

•

Sequential read

Sequential reads are initiated by either a cur-

rent address read or a random address read.

After the microcontroller receives a data word,

it responds with an acknowledgment. As long as

the EEPROM receives an acknowledgment, it

will continue to increment the data word address and serially clock out sequential data

Timing Diagrams

HT24LC01/02

words. When the memory address limit is

reached, the data word address will roll over

and the sequential read continues. The sequential read operation is terminated when

the microcontroller does not respond with a

zero but generates a following stop condition.

Note: The write cycle time tWR is the time from a valid stop condition of a write sequence to the end

of the valid start condition of sequential command.

7 6th May ’99

HT24LC01/02

Holtek Semiconductor Inc. (Headquarters)

No.3 Creation Rd. II, Science-based Industrial Park, Hsinchu, Taiwan, R.O.C.

Tel: 886-3-563-1999

Fax: 886-3-563-1189

Holtek Semiconductor Inc. (Taipei Office)

5F, No.576, Sec.7 Chung Hsiao E. Rd., Taipei, Taiwan, R.O.C.

Tel: 886-2-2782-9635

Fax: 886-2-2782-9636

Fax: 886-2-2782-7128 (International sales hotline)

Holtek Microelectronics Enterprises Ltd.

RM.711, Tower 2, Cheung Sha Wan Plaza, 833 Cheung Sha Wan Rd., Kowloon, Hong Kong

Tel: 852-2-745-8288

Fax: 852-2-742-8657

Copyright © 1999 by HOLTEK SEMICONDUCTOR INC.

The information appearing in this Data Sheet is believed to be accurate at the time of publication. However, Holtek

assumes no responsibility arising from the use of the specif ications descri bed. The applications mentioned herein are

used solely for the purpose of illustration and Holtek makes no warranty or representation that such applications

will be suitable without further modification, nor recommends the use of its products for appli cation that may present

a risk to human life due to malfunction or otherwise. Holtek reserves the right to alter its products without prior

notification. For the most up-to-date information, please visit our web site at http://www.holtek.com.tw.

8 6th May ’99

Loading...

Loading...