Features

·

Operating voltage: 2.4V~3.5V

·

33 common/120 segment LCD driver output

·

33´120=3960 bits capacity of built-in graphic display

data RAM (BGDRAM)

·

Master and slave mode available for multi-chip

operation

·

8-bit Parallel interface with general MCU

·

On-chip oscillator circuit for display clock, external

clock can also be used

·

Selectable multiplex ratio: 1/16, 1/32, 1/33

·

Selectable bias ratio: 1/5 or 1/7

·

External driving circuit for external bias supply

·

On-chip selectable voltage doublers and tripler

·

Wide rangeof operating temperature: -30°Cto85°C

·

S/W controlled electronic contrast control function

(16 levels)

General Description

The HT0610 is a driver and controller LSI for graphic

dot-matrix liquid crystal display systems. It has 33 common and 120 segment driver circuits. This chip is connected directly to an MCU, accepts 8-bit parallel display

data and stores an on-chip graphic display data RAM

(BGDRAM) of 33´120 bits. It provides a high-flexible

display section due to the one-to-one correspondence

HT0610

33´120 LCD Driver

·

External contrast control

·

Low power icon mode driven by com32

·

Four static icon driver circuit

·

High accuracy voltage regulator with temperature co

efficient (0.00%, -0.18%, -0.22%, -0.35%)

·

Low power consumption

-

Read/write mode 170mA (Typical)

-

Display mode 160mA (Typical)

-

Standby mode 15mA (Typical; Display off; internal

oscillator enable)

-

Standby mode < 1mA (Typical; Display off; external

oscillator enable)

·

CMOS process

·

TCP available

between BGDRAM bits and LCD panel pixels. It per

forms BGDRAM read/write operation with no externally

operating clock to minimize power consumption. In addition, because it contains power supply circuits necessary to drive an LCD, it is possible to make a display

system with minimal components.

-

-

Rev. 1.10 1 April 4, 2007

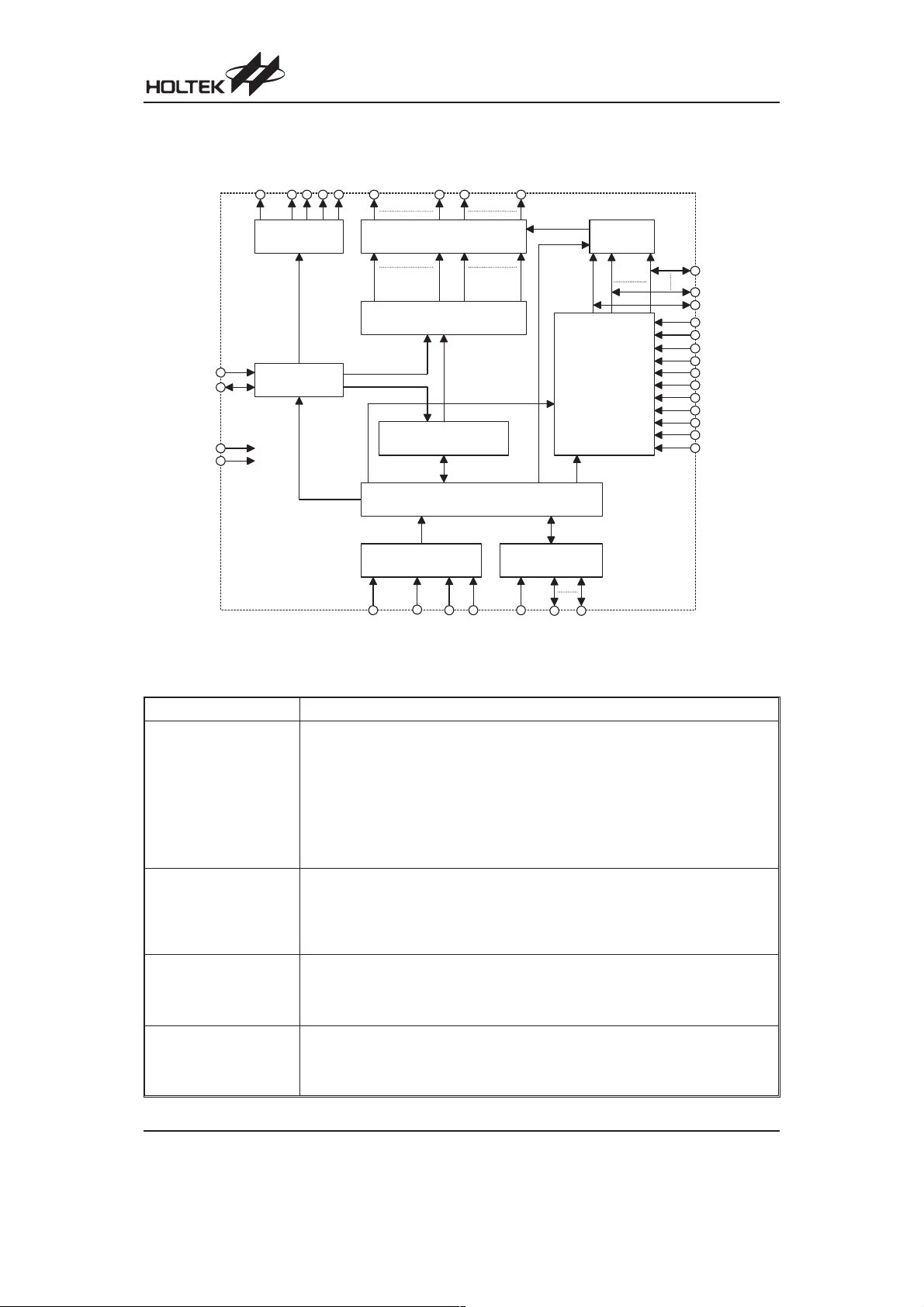

Block Diagram

HT0610

O S C 1

O S C 2

V D D

V S S

I B P

I C O

N 0 ~ I C O N 3

S t a t i c I c o n

C o n t r o l C i r c u i t

T i m i n g G e n e r a t o r

f o r D i s p l a y

S E G 0 ~ S E G 1 1 9

H i g h V o l t a g e C e l l L e v e l S h i f t e r

1 5 5 B i t s L a t c h

( 3 3 B i t s & 1 2 0 B i t s )

B G D R A M

1 2 0

3 3 B i t s

´

C o m m a n d D e c o d e r C i r c u i t

C o m m a n d I n t e r f a c e

C S ( C L K )

D C O M

R E S

C O M 0 ~ C O M 3 2

P a r a l l e l I n t e r f a c e

C E

L e v e l

S e l e c t o r

V L L 2

V L L 6

V C C A 1

L C D D r i v i n g

V o l t a g e G e n e r a t o r

D o u b l e r & T r i p l e r

V o l t a g e R e g u l a t o r ,

V o l t a g e D i v

C o n t r a s t C o n t r o l ,

T e m p e r a t u r e

C o m p e n s a t i o n

R W

D 0 ~ D 7

i d e r ,

C i r c u i t

V R

V F

C 2 P

C 2 N

C 1 P

C 1 N

D U M 2

D U M 1

C +

C V D D A

Operation of LCD Driver

Description of Block Diagram Module

Block Description

This module determines whether the input data is interpreted as data or command.

Data is directed to this module based upon the input of the DCOM pin. If DCOM High,

then data is written to BGDRAM ( Built-in Graphic Display data RAM). DCOM pin Low

Command Decoder and

Command Interface

Parallel Interface

Built-in Graphic Display

data RAM (BGDRAM)

Display Timing Generator

indicates that the input at D0~D7 is interpreted as a Command.

CE is the master chip selection signal. A High input enable the input lines ready to sam

ple signals.

RES pin of same function as Power On Reset (POR). Once RES received the reset sig

nal, all internal circuitry will back to its initial status. Refer to Command Description

section for more information.

The parallel interface consists of 8 bi-directional data lines (D0~D7), RW and CS. The

RW input High indicates a read operation from the BGDRAM. RW input Low indicates a

write to BGDRAM or Internal Command Registers depending on the status of DCOM

pin input.

The CS input serves as data latch signal (clock).

The BGDRAM is a bit mapped static RAM holding the bit pattern to be displayed. The

size of the BGDRAM is determined by number of row times the number of column

(120´33 =3960 bits). Figure as followis a description of the BGDRAM address map. For

mechanical flexibility, re-mapping on both segment and common outputs are provided.

This module is an on chip low power RC oscillator circuitry. The oscillator frequency can

be selected in the range of 15kHz to 50kHz by external resistor. One can enable the cir

cuitry by software command. For external clock provided, feed the clock to OSC2 and

leave OSC1 open.

-

-

-

Rev. 1.10 2 April 4, 2007

Block Description

Static Icon Control Circuit

LCD Driving Voltage

Generator

120 Bit Latch/33 Bit Latch

Level Selector

HV Buffer Cell

(Level Shifter)

HT0610

This module generates the LCD waveform of the 4 annunciators and IBP signal. The

four independent static icons are enabled by software command. Icon signals are also

controlled by oscillator circuit, too.

This module generates the LCD voltage needed for display output. It takes a single sup

ply input and generates necessary bias voltages. It consists of:

·

Voltage doubler and voltage tripler

To generate the VCCA1 voltage. Either doubler or tripler can be enabled.

·

Voltage regulator

Feedback gaincontrol for initial LCD voltage. It can also be used with external contrast

control.

·

Voltage divider

Divide the LCD display voltage (VLL2~VLL6) from the regulator output. This is low

power consumption circuit, which can save the most display current compare with tra

ditional resistor ladder method.

·

Bias Ratio Selection circuitry

Software control of 1/5 and 1/7 bias ratios to match the characteristic of LCD panel.

·

Self adjust temperature compensation circuitry

Provide 4 different compensation grade selections to satisfy the various liquid crystal

temperature grades. The grading can be selected by software control.

·

Contrast Control Block

Software control of 16 voltage levels of LCD voltage.

·

External Contrast Control

By adjusting the gain control resistors connected externally, the contrast can be varied.

All blocks can be individually turned off if external voltage generator is employed.

153 bit long registers, which carry the display signal information. First 33 bits are Common driving signals and other 120 bits are Segment driving signals. Data will be input to

the HV-buffer Cell for bumping up to the required level.

Level selector is a control of the display synchronization. Display voltage can be separated into two sets and used with different cycles. Synchronization is important since it

selects the required LCD voltage level to the HV Buffer Cell for output signal voltage

pump.

HV Buffer Cell works as a level shifter that translates the low voltage output signal to the

required driving voltage. The output is shifted out with an internal FRM clock, which co

mes from the Display Timing Generator. The voltage levels are given by the level selec

tor which is synchronized with the internal M signal.

-

-

-

-

Rev. 1.10 3 April 4, 2007

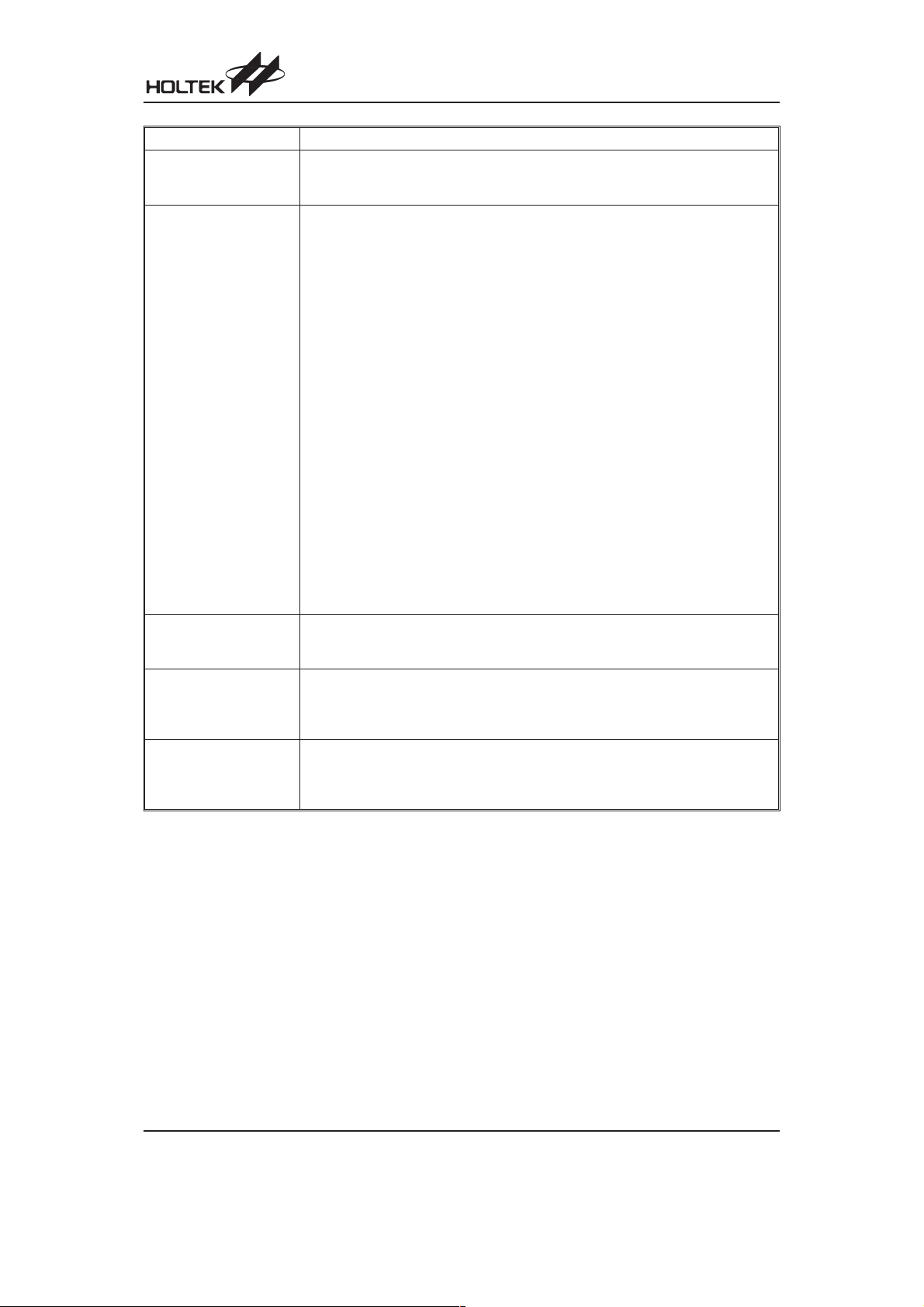

Pin Assignment

D U M M Y

O S C 1

V C C A 1

D U M 2

O S C 2

D U M 1

V D D A

C

S ( C L K )

D C O M

D U M M Y

V S S

V S S

V L L 6

V L L 5

V L L 4

V L L 3

V L L 2

C 2 N

C 2 P

C 1 N

C 1 P

V S S

V S S

V S S

R E S

V D D

HT0610

D U M M Y

1 9 7

C O M 3 2

C O M 0

1 9 6

C O M 1

1 9 5

1 9 4

C O M 2

C O M 3

1 9 3

C O M 4

1

2

3

4

V R

5

V F

6

7

C -

8

C +

9

1 0

1 1

1 2

1 3

1 4

1 5

1 6

1 7

1 8

1 9

2 0

2 1

2 2

2 3

C E

2 4

D 7

2 5

D 6

2 6

D 5

2 7

D 4

2 8

D 3

2 9

D 2

3 0

D 1

3 1

D 0

3 2

3 3

3 4

R W

3 5

3 6

3 7

3 8

1 9 2

C O M 1 2

1 8 4

C O M 1 3

1 8 3

C O M 1 4

1 8 2

C O M 1 5

1 8 1

S E G 0

1 8 0

S E G 1

1 7 9

S E G 2

1 7 8

S E G 3

1 7 7

S E G 4

1 7 6

S E G 1 1 7

6 3

S E G 1 1 8

6 2

S E G 1 1 9

6 1

C O M 3 2

6 0

C O M 3 1

5 9

C O M 3 0

5 8

C O M 2 9

5 7

C O M 2 8

5 6

C O M 1 9

4 7

C O M 1 8

4 6

C O M 1 7

4 5

C O M 1 6

4 4

I C O N 0

4 3

I C O N 1

4 2

I C O N 2

4 1

I C O N 3

4 0

I B P

3 9

D U M M Y

Rev. 1.10 4 April 4, 2007

Pin Description

Pin Name I/O Description

VDD I

RES I Active low reset pin; reset all internal status of circuit (Same as power on reset)

VSS I VSS is ground

DCOM I

RW I

CS I

D0~D7 B Those bi-direction pins are used for DATA or command transferring.

CE I High input to this pin to enable the control pins on the driver.

OSC1 I

OSC2 O

C1P, C1N

C2P, C2N

VLL2~VLL6 O

DUM1, DUM2 O

C+, C-

VCCA1 O

VF, VR

COM0~COM32 O These pins provide the row driving signal to LCD panel

VDDA I

ICON1~ICON4 O There are four independent annunciator driving outputs

IBP O This pin combines with ICON1~ICON4 pins to form annunciator driving part.

SEG0~SEG119 O These 120 pins provide LCD column driving signal to LCD panel.

VDD is the positive supply to the digital control circuit and other circuitry in LCD bias voltage

generator (Must have same voltage level with VDDA)

If pull this pin ²High² then D0~D7 bi-direction bus is used for data transferring; If DCOM pin is

²Low² then D0~D7 bi-direction bus is used for command transferring.

If pull this pin high: Indicate we want to read the display data RAM or the internal state. If we

force this to Low: Indicate we want to write data to display data RAM or write some internal

state to registers.

This pin is normal low clock input. Data on D0~D7 bi-direction data bus are latched at the fall

ing edge of CS

Oscillator input pin.

For internal oscillator mode, this is an input for the internal low power RC oscillator circuit. In

this mode,an external resistor of certain value is placed between the OSC1 and OSC2 pins.

For external oscillator mode, OSC1 pin should be left open

Oscillator output pin

For internal oscillator mode, this is an output for the internal low power RC oscillator circuit.

External Oscillator input

For externaloscillator mode, OSC2 will be an input pin forexternal clock and no external resistor is needed.

If internal DC/DC converter is enabled, a capacitor is required to connect these two pins.

¾

If internal tripler is enabled, a capacitor is required to connect these two pins. Otherwise, leave

¾

these pin open.

Group ofvoltage level pins for driving the LCD panel. Theycan either be connected to external

driving circuit for external bias supply or connected internally to built-in divider circuit. For internal voltage divider enable, a 0.1mF capacitor to VSS is required on each pin.

If internal voltage divider is enable with 1/7 bias selected, a capacitor to VSS is required on

each pin. Otherwise, pull these two pin to VSS

If internal divider circuit is enable, a capacitor is required to connect between these two pin

¾

If internal DC/DC Converter is enabled, a 0.1mF capacitor from this pin to VSS is required. It

can also be an external bias input pin if internal DC/DC converter is not used

This is a feedback path for the gain control (external contrast control) of VLL1 to VLL6. For ad

justing the LCD driving voltage, it requires a feedback resistor placed between VR and VF, a

¾

gain control resistor placed between VF and VSS, a 10uF capacitor placed between VR and

VSS.

VDDA is the positive supply to the noise sensitive circuitry and must have same voltage level

with VDD

HT0610

-

-

Rev. 1.10 5 April 4, 2007

HT0610

Absolute Maximum Ratings

Supply Voltage ..........................VSS-0.3V to VSS+4.0V

Input Voltage .............................V

3V to VDD+0.3V

SS-0.

LCD Input Voltage..................................-0.3V to 10.5V

Note: These are stress ratings only. Stresses exceeding the range specified under ²Absolute Maximum Ratings² may

cause substantial damage to the device. Functional operation of this device at other conditions beyond those

listed in the specification is not implied and prolonged exposure to extreme conditions may affect device reliabil

ity.

HT0610 contains circuitry to protect the inputs against damage due to high static voltages or electric fields; however, it

is advised that normal precaution to be taken to avoid application of any voltage higher than maximum rated voltages to

this high impedance circuit. For proper operation it is recommended that V

<or=(V

or V

IN

) < or = VDD. Reliability of operation is enhanced if unused inputs are connected to an appropriate

OUT

logic voltage level (e.g., either VSS or VDD). Unused outputs must be left open. This device may be light sensitive?

caution should be taken to avoid exposure of this device to any light source during normal operation. This device is not

radiation protected.

Storage Temperature ...........................-65°Cto150°C

Operating Temperature ..........................-30°Cto85°C

and Vout be constrained to the range VSS

IN

-

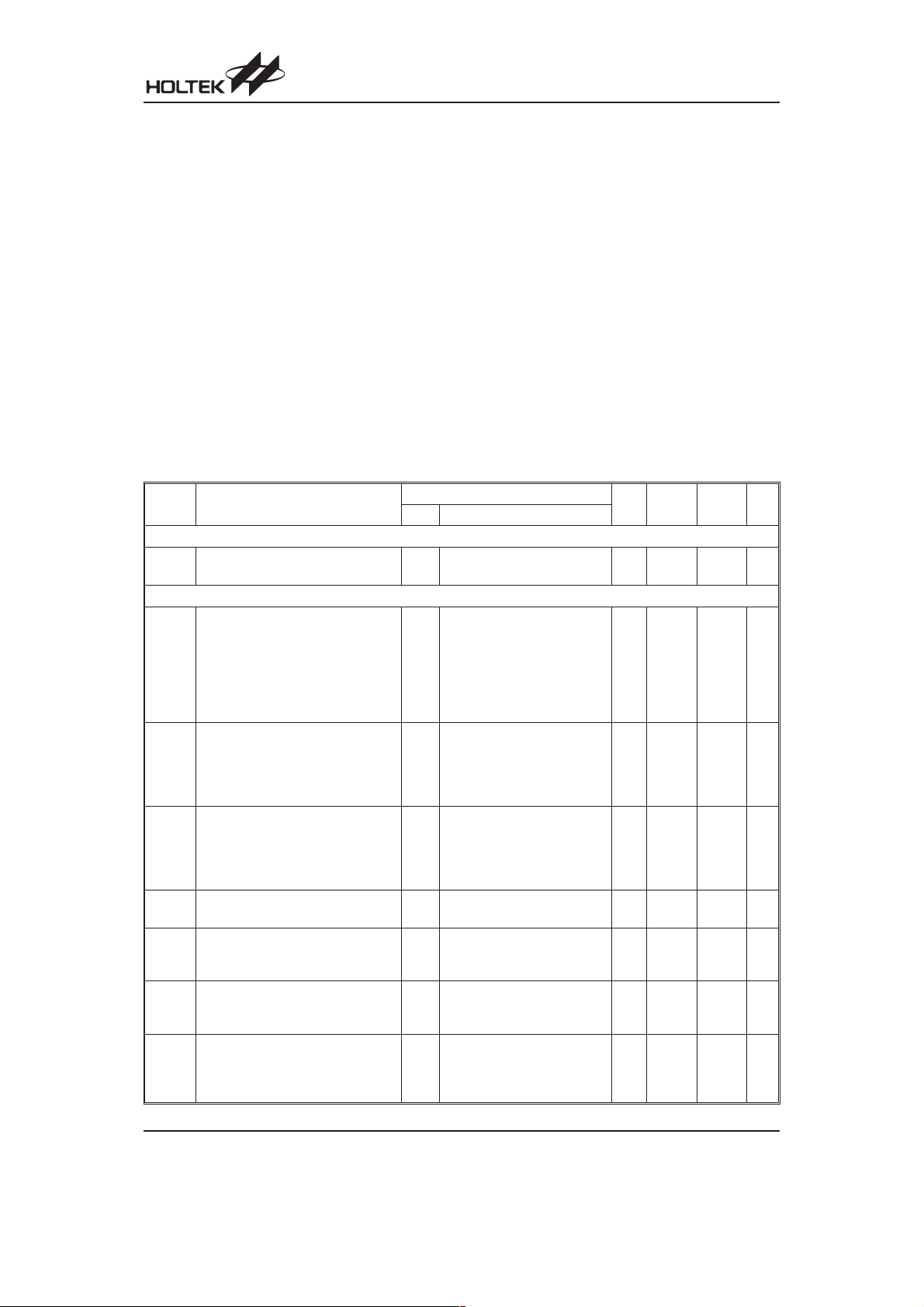

Electrical Characteristics

Symbol Parameter

Supply Voltage

V

Supply Current

I

RW

I

ON1

I

ON2

I

STB1

I

STB2

I

STB3

I

ICON

Operating Voltage

DD

Read/write Mode

Supply Current Drain from Pin VDDA

and VDD

Display on Mode

Supply Current Drain from Pin VDDA

and VDD

Display on Mode

Supply Current Drain from Pin VDDA

and VDD

Standby Mode Supply Current Drain

from Pin VDDA and VDD

Standby Mode Supply Current Drain

from Pin VDDA and VDD

Standby Mode Supply Current Drain

from Pin VDDA and VDD

Standby Mode Supply Current Drain

from Pin VDDA and VDD

Test Conditions

V

DD

2.4V~

VDDA=VDD 2.4 3.15 3.5 V

3.5V

Conditions

Min. Typ. Max. Unit

Measure with VDD fixed at

3.15V

Internal DC/DC converter on,

2.4V~

display on, tripler enable,

3.5V

read/write accessing,

t

=1MHz, Osc freq.=50kHz,

CYC

¾

170 200

1/33 duty, 1/7 bias

Internal DC/DC converter on,

display on, tripler enable,

2.4V~

read/write HALT,

3.5V

Osc freq.=50kHz, 1/33 duty,

¾

110 140

1/7 bias

Internal DC/DC converter on,

display on, tripler enable,

2.4V~

read/write HALT,

3.5V

Osc freq.=38.4kHz, 1/33 duty,

¾

100 120

1/7 bias

2.4V~

Display off, oscillator disabled,

3.5V

read/write HALT

Display off, oscillator enabled,

2.4V~

read/write HALT, external os

3.5V

cillator and frequency=50kHz

Display off, oscillator enabled,

2.4V~

read/write HALT, internal oscil

3.5V

lator and frequency=50kHz

Low power I

2.4V~

tor enable, read/write HALT,

3.5V

internal oscillator and fre

CON

mode, oscilla

-

-

-

-

300 500 nA

¾

0.6 1

¾

23 30

¾

25 30

¾

quency=50kHz

Ta=25°C

mA

mA

mA

mA

mA

mA

Rev. 1.10 6 April 4, 2007

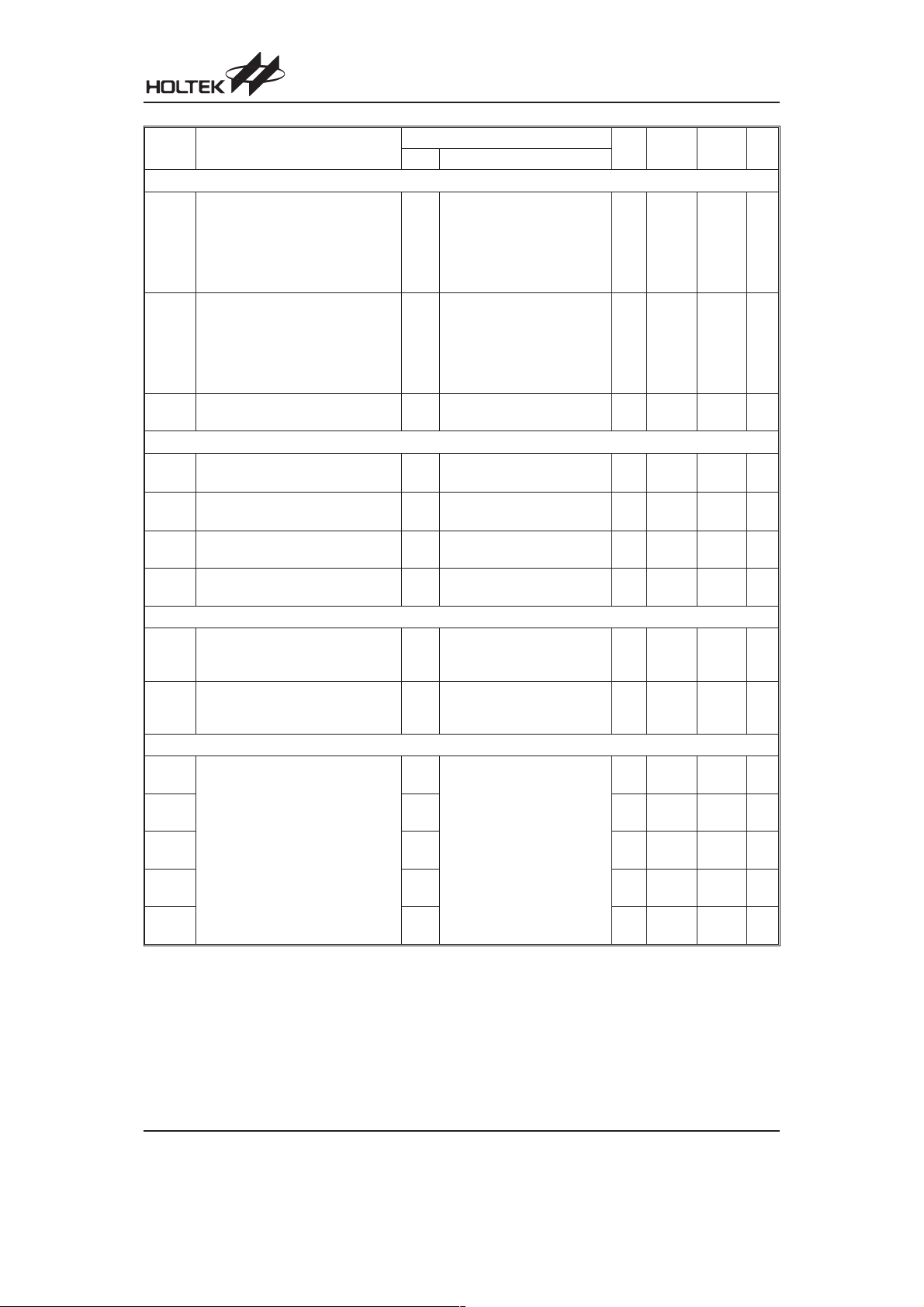

HT0610

Symbol Parameter

V

DD

VLCD Voltage (Absolute Value Referenced to VSS)

V

Generator Output Voltage at Pin

LCC1

VCCA1

LCD Driving Voltage

LCD Driving Voltage

V

Generator Output Voltage at Pin

LCC2

VCCA1

V

LCD Driving Voltage Input at Pin

LCD

VCCA1

2.4V~

3.5V

2.4V~

3.5V

2.4V~

3.5V

Output Voltage

V

V

V

V

Output High Voltage at Pin D0~D7,

OH1

ICON1~ICON4, IBP and OSC2

Output Low Voltage at Pin D0~D7,

OL1

ICON1~ICON4, IBP and OSC2

LCD Driving Voltage Source at PinVR2.4V~

R1

LCD Driving Voltage Source at PinVR2.4V~

R2

2.4V~

3.5V

2.4V~

3.5V

3.5V

3.5V

Input Voltage

V

CS, D0~D7, RW, DCOM, OSC1 and

IH1

OSC2

Input Low Voltage at Pin RES, CE,

Input High Voltage at Pin RES, CE,

V

CS, D0~D7, RW, DCOM, OSC1 and

IL1

OSC2

2.4V~

3.5V

2.4V~

3.5V

LCD Display Voltage

V

LL6

V

LL5

V

V

V

LCD Driving Voltage Output from Pin

LL4

VLL6~VLL2

LL3

LL2

2.4V~

3.5V

2.4V~

3.5V

2.4V~

3.5V

2.4V~

3.5V

2.4V~

3.5V

Test Conditions

Conditions

Display on, internal DC/DC

converter enable, tripler en

able, oscillator and fre

quency=50kHz, regulator

enable, divider enable

I

£100mA

OUT

Display on, internal DC/DC

converter enable, doubler en

able, oscillator and fre

quency=50kHz, regulator

enable, divider enable

I

£100mA

OUT

Internal DC/DC converter dis

able

I

=100mA

OUT

I

=100mA

OUT

Regulator enable, I

OUT

=50mA

Regulator disable

¾

¾

1/5 bias ratio, voltage divider

enable, regulator enable

Min. Typ. Max. Unit

-

-

¾ 3´VDD

10.5 V

-

-

¾ 2´VDD

5

0.8´

VDD

0

0

¾

0.8´

VDD

0

¾

¾

¾

¾

¾

Floating

¾

¾

VR

7V

10.5 V

VDD V

0.2´

VDD

VCCA1 V

¾

VDD V

0.2´

VDD

¾

¾ 0.8´VR ¾

¾ 0.6´VR ¾

¾ 0.4´VR ¾

¾ 0.2´VR ¾

V

V

V

V

V

V

V

V

Rev. 1.10 7 April 4, 2007

HT0610

Symbol Parameter

V

LL6

V

LL5

V

LL4

D

UM2

D

UM1

V

LL3

V

LL2

V

LL6

V

LL5

V

LL4

V

LL3

V

LL2

Output Current

Output High Current Source from

I

OH

Pins D0~D7, ICON1~ICON4, IBP

and OSC2

Output Low Current Drain by Pins

I

OL

D0~D7, ICON1~ICON4, IBP and

OSC2

I

OZ

Output Tri-state Current Drain

Source at Pins D0~D7 and OSC2

Input Current at Pins RES, CE, CS,

I

IL/IIH

D0~D7, RW, DCOM, OSC1 and

OSC2

On Resistance

Channel Resistance between LCD

R

Driving Signal Pins (Segment and

ON

Common) and Driving Voltage Input

Pins (VLL2 to VLL6)

Memory Retention Voltage (VDD)

V

Standby Mode, Retained All Internal

MR

Configuration and BGDRAM Data

C

Input Capacitance All Control Pins

IN

Test Conditions

V

DD

Conditions

2.4V~

3.5V

2.4V~

3.5V

2.4V~

3.5V

1/7 bias ratio, voltage divider

2.4V~

enable, regulator enable

3.5V

2.4V~

3.5V

2.4V~

3.5V

2.4V~

3.5V

2.4V~

3.5V

2.4V~

3.5V

External voltage generator,

2.4V~

internal voltage divider disable

3.5V

2.4V~

3.5V

2.4V~

3.5V

2.4V~

V

=VDD-0.1V

OUT

3.5V

2.4V~

V

=0.1V

OUT

3.5V

2.4V~

3.5V

2.4V~

3.5V

¾-1 ¾

¾-1 ¾

During display on, 0.1V apply

between two terminals,

2.4V~

VCCA1 within operating volt

3.5V

age range

2.4V~

3.5V

2.4V~

3.5V

¾

¾¾

Min. Typ. Max. Unit

VR

¾

¾

¾ 6/7´VR ¾

¾ 5/7´VR ¾

¾ 4/7´VR ¾

¾ 3/7´VR ¾

¾ 2/7´VR ¾

¾ 1/7´VR ¾

0.5´

VCCA1

0.5´

VCCA1

0.5´

VCCA1

vss

vss

¾

¾

¾

¾

¾

¾

¾

1.5

VCCA1

VCCA1

VCCA1

0.5´

VCCA1

0.5´

VCCA1

¾

5

¾

1

1

¾¾

-

1.8

¾¾

5

5 7.5 pF

V

V

V

V

V

V

V

mA

mA

mA

mA

kW

V

Rev. 1.10 8 April 4, 2007

HT0610

Symbol Parameter

Temperature Coefficient Compensation

PTC0 Flat Temperature

PTC1 Coefficient

PTC2 Temperature Coefficient 1*

PTC3

Temperature Coefficient 2*

Temperature Coefficient 3*

Internal Contrast Control VR Output

Voltage with Internal Contrast Con

trol Selected

V

16 Voltage Levels Controlled by Soft

CON

ware

Each Level is Typical of 2.25% of the

Regulator Output Voltage

Oscillator Frequency

Oscillator Frequency of Display Tim

F

ing Generator with 60Hz Frame Fre

OSC1

quency

Oscillator Frequency of Display Tim

F

ing Generator with 60Hz Frame Fre

OSC2

quency

Four Static ICON Display (50% Duty

F

Cycle) from Pins ICON1~ICON4 and

ICON1

IBP

Four Static ICON Display (50% Duty

F

Cycle) from Pins ICON1~ICON4 and

ICON2

IBP

F

F

F

F

LCD Driving Signal Frame

FRAME1

Frequency

LCD Driving Signal Frame

FRAME2

Frequency

LCD Driving Signal Frame

CON1

Frequency

LCD Driving Signal Frame

CON2

Frequency

Internal Oscillation Frequency

Internal OSC Oscillation Frequency

O

with Different Value of Feedback Re

SC

sistor

2.4V~

2.4V~

2.4V~

2.4V~

-

2.4V~

-

-

2.4V~

-

-

2.4V~

-

2.4V~

2.4V~

2.4V~

2.4V~

2.4V~

2.4V~

2.4V~

-

Test Conditions

V

DD

Conditions

TC1=0, TC2=0,

3.5V

regulator disable

TC1=0, TC2=1,

3.5V

regulator enable

TC1=1, TC2=0,

3.5V

regulator enable

TC1=1, TC2=1,

3.5V

regulator enable

Internal regulator enabled,

internal contrast control en

3.5V

abled

Set clock frequency to slow

3.5V

Set clock frequency to normal

3.5V

3.5V

3.5V

¾¾

¾¾

Either external clock input or

internal oscillator enable, either 1/32 or 1/16 duty cycle,

3.5V

graphic display mode

Either external clock input or

internal oscillator enable, ei

3.5V

ther 1/32 or 1/16 duty cycle

Either external clock input or

internal oscillator enable, 1/33

duty cycle, graphic display

3.5V

mode

Either external clock input or

internal oscillator enable, 1/33

3.5V

duty cycle

Internal oscillator enable

3.5V

within operation range

Min. Typ. Max. Unit

0

¾

¾

¾-0.18 ¾

¾-0.22 ¾

¾-0.35 ¾

-

¾±18 ¾

38.4

¾

50

¾

18.75

24.4

66

¾

-

65

¾

64

¾

63

¾

¾

¾

¾

¾

¾

¾

¾

¾

See the figure as follow

%

%

%

%

%

kHz

kHz

Hz

Hz

Hz

Hz

Hz

Hz

Note: *The formula for the temperature coefficient is: TC (%)= ´100%

V R a t 5 0°C V R a t 0°C

5 0°C 0°C V R a t 2 5°C

1

Rev. 1.10 9 April 4, 2007

Total variation of VR D VRTis affected by the following factors:

Process variation of regulator D V

External VDD variation contributed to regulator D V

External resistor pair Ra/Rf contributed to regulator D V

Where D VRT=

D

( V

2

)

+ +

R

R

VDD

RES

2

D

( V

)

V D D

2

D

)

( V

R E S

Assume external VDD variation is ±6% at 3.15V and 1% variation resistor used at application

TC Level

TC0

TC1

Reference Generator

TC2

TC3

(%) D VR(%) D V

D V

VDD

(%) D VRT(%)

RES

±6.0

±4.0 ±4.924

±2.5 ±1.414

±2.5 ±3.805

±1.4 ±3.195

HT0610

±6.652

Parallel Timing Characteristics (Write Cycle)

Ta=30°C~85°C, DV

=2.4V~3.5V, VSS=0V

DD

Symbol Parameter Min. Typ. Max. Unit

t

CYCLE

t

EH

t

AS

t

DS

t

DH

t

AH

Enable Cycle Time 620

Enable Pulse Width 300

Address Setup Time 10

Data Setup Time 300

Data Hold Time 30

Address Hold Time 30

C E

C S ( C L K )

R W

D C O M

D 0 ~ D 7

t

C Y C L E

t

E H

t

A S

t

D S

V a l i d D a t a

¾¾

¾¾

¾¾

¾¾

¾¾

¾¾

t

A H

t

D H

ns

ns

ns

ns

ns

ns

Timing Characteristics (Write Cycle)

Rev. 1.10 10 April 4, 2007

HT0610

Parallel Timing Characteristics (Read Cycle)

Ta=30°C~85°C, DV

=2.4V~3.5V, VSS=0V

DD

Symbol Parameter Min. Typ. Max. Unit

t

CYCLE

t

EH

t

AS

t

DS

t

DH

t

AH

Enable Cycle Time 620

Enable Pulse Width 300

Address Setup Time 10

Data Setup Time

¾¾

Data Hold Time 10

Address Hold Time 30

C E

C S ( C L K )

R W

D C O M

D 0 ~ D 7

t

C Y C L E

t

E H

t

A S

t

D S

V a l i d D a t a

¾¾

¾¾

¾¾

300 ns

¾¾

¾¾

t

A H

t

D H

ns

ns

ns

ns

ns

Timing Characteristics (Read Cycle)

Rev. 1.10 11 April 4, 2007

Functional Description

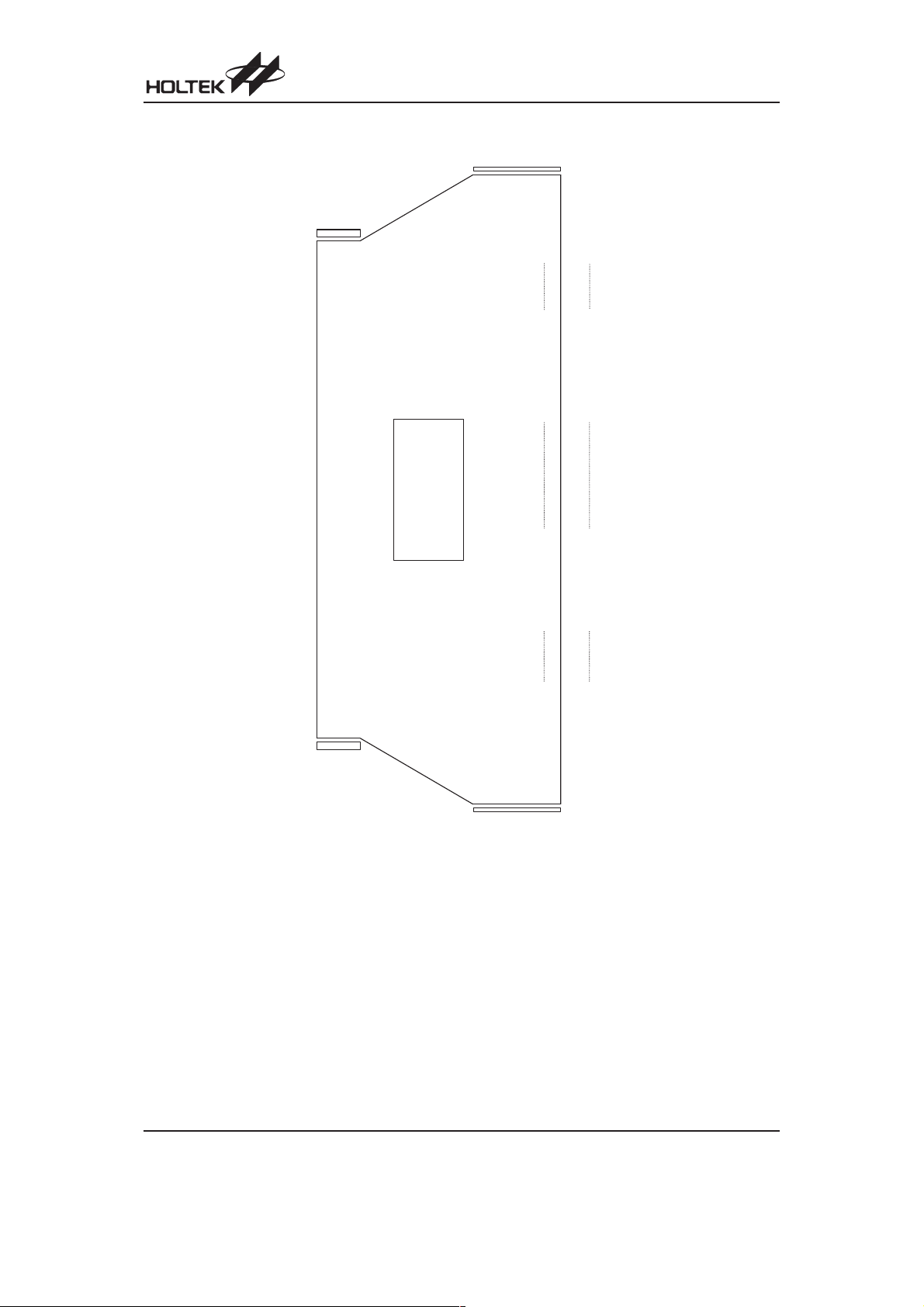

3 0 0

2 5 0

2 0 0

1 5 0

1 0 0

O s c i l l a t o r F r e q u e n c y ( k H z )

5 0

0

1 0 0 K 1 5 0 K 2 0 0 K 2 4 0 K 3 0 0 K 3 6 0 K 4 3 0 K 5 1 0 K 5 6 0 K 6 2 0 K 6 8 0 K 7 5 0 K 8 2 0 K 9 1 0 K 1 M 1 . 5 M 2 . 0 M

R e s i s t o r v a l u e o n O S C 1 & O S C 2 (

Internal oscillator frequency relationship with different external resistor value

·

Set clock frequency to slow: F

·

Set clock frequency to normal: F

FRAME1=FOSC1

FRAME2=FOSC2

/576

/768

W

HT0610

)

C o l u m n a d d r e s s 0 0 H

( o r c l o u m n a d d r e s s 7 7 H )

L S B

M S B

Built-in Graphic Display Data RAM (BGDRAM) Address Map

P a g e 1

P a g e 2

P a g e 3

P a g e 4

P a g e 5

C o l u m n a d d r e s s 7 7 H

( o r c l o u m n a d d r e s s 0 0 H )

C O M 0

( C O M 3 1 )

C O M 0

( C O M 3 1 )

C O M 3 2

S E G 1 1 9S E G 0

Rev. 1.10 12 April 4, 2007

HT0610

Command Description

The display on command turns the LCD common and segment outputs on and has

no effect to the static icons output. This command causes the conversion of data in

BGDRAM to necessary waveforms on the common and segment driving outputs.

The on-chip bias generator is also turned on by this command.

(Note: ²oscillator on² command should be sent before ²display on² is selected.)

Set Display On/Off

(Display Mode/Standby Mode)

Set BGDRAM Page Address This command positions the row address to 1 of 5 possible positions in BGDRAM.

Master Clear BGDRAM

Master Clear Icons

Set Display with Icon Line

Set Icon Display Mode

Set Icon Line/Static Icon

Contrast Level

Set Vertical Scroll Value

Save/Restore BGDRAM

Column Address

Set Column Mapping

Set Row Mapping

The display off command turns the display off and the states of the LCD driver are

as follow during display off:

·

The common and segment outputs are fixed at VLL1(VSS)

·

The bias voltage generator is turned off.

·

The RAM and content of all register are retained.

·

IC will accept new commands and data.

·

The status of the static Icons and oscillator are not affected by display off com

mand.

This command is to clear the 480 byte BGDRAM by setting the RAM data to zero.

Issue this command followed by a dummy writes command. The RAM for icon line

will not be affected by this command.

This command is used to clear the data in page 5 of BGDRAM, which stores the

icon line data. Before using this command, set the page address to page 5 by the

command ²set BGDRAM page address². A dummy write data is also needed after

this ²master clear Icons² command to make the clear icon action effective.

If 1/32 Mux selected, use this command change to 1/33 Mux for using the Icon line.

This command can also change Icon display mode to normal display mode (1/32 or

1/33 MUX).

This command forces the output to the icon display mode. Display on row 0 to row

31 will be disabled.

The contrast of the icon line and static icon in icon mode can be set by this command. There are four levels to select from.

This command is used to scroll the screen vertically with scroll value 0 to 31. With

scroll value equals to 0, row 0 of BGDRAM is mapped to com 0 and row 1 through

row 31 are mapped to com 1 through com 31 respectively. With scroll value equal

to 1, row 1 of BGDRAM is mapped to com 0, then row 2 through row 31 will be

mapped to com 1 through com 30 respectively and row 0 will be mapped to com 31.

Com 32 is not affected by this command.

With bit option=1 in this command, the save/restore column address command

saves a copy of the column address of BGDRAM. With a bit option=0, this com

mand restores the copy obtained from the previous execution of saving column ad

dress.

This instruction is very useful for writing full graphics characters that are larger than

8 pixels vertically.

This instruction selects the mapping of BGDRAM to segment drivers for mechani

cal flexibility. There are 2 mappings to select:

·

Column 0~column 119 of BGDRAM mapped to SEG0~SEG119 respectively

·

Column 0~column 119 of BGDRAM mapped to SEG119~SEG0 respectively

COM 32 will not be affected by this command. Detailed information please refer to

section ²display output description².

This instruction selects the mapping of BGDRAM to common drivers for mechani

cal flexibility. There are 2 mappings to select:

·

Row 0~Row 31 of BGDRAM mapped to COM 0~COM 31 respectively.

·

Row 0~Row 31 of BGDRAM mapped to COM 31~COM 0 respectively.

COM 32 will not be affected by this command. Detail information please refer to

section ²display output description².

-

-

-

-

-

Rev. 1.10 13 April 4, 2007

Command Description

Set Static Icon Control Signal

Set Oscillator Disable/Enable

Set Internal/External Oscillator

Set Clock Frequency

Set DC/DC Converter On/Off

Set Voltage Doubler/Tripler

Set Internal Regulator On/Off

Set Internal Voltage Divider

On/Off

Set Duty Cycle

Set Bias Ratio

Set Internal Contrast Control

On/Off

Increase/Decrease Contrast

Level

Set Contrast Level

Read Contrast Value

Set Temperature Coefficient

Set IDD Reduction Mode

On/Off

HT0610

This command is used to control the active states of the 4 stand-alone icons driv

ers.

This command is used to either disable or enable the oscillator. For using internal

or external oscillator, this command should be executed. The setting for this com

mand is not affected by command ²set display on/off² and ²set static Icon control

signal². Refer to command ²set internal/external oscillator² for more information.

This command is used to select either internal or external oscillator. When internal

oscillator is selected, feedback resistor between OSC1 and OSC2 is needed. For

external oscillation circuit, feed clock input signal to OSC2 and leaves OSC1 open.

Use this command to choose from two different oscillation frequency (50kHz or

38.4kHz) to get the 60Hz frame frequency.

With frequency high, 50kHz clock frequency is preferred. 38.4kHz clock frequency

(low frequency) enable for power saving purpose.

Use this command selects the internal DC/DC converter to generate the VDDA1

from VDD. Disable the internal DC/DC converter if external VCCA1 is provided.

Use this command to choose doubler or tripler when the internal DC/DC converter

is enabled.

Choose bit option 0 to disable the internal regulator. Choose bit option 1 to enable

internal regulator, which consists of the internal contrast control and temperature

compensation circuits.

If the internal voltage divider is disabled, external bias can be used for VLL6 to

VLL2. If the internal voltage divider is enabled, the internal circuit will automatically

select the correct bias level according to the number of multiplex. Refer to com

mand ²bias ratio select².

This command is to select 16 mux or 32 mux display. When 16 mux is enabled, the

unused 16 common outputs will be swinging between VLL2 and VLL5 for dummy

scan purpose and doubler will be used.

This command sets the 1/5 bias or 1/7 bias for the divider output.

The selection should match the characteristic of LCD panel.

This command is used to turn on or off the internal control of delta voltage of the

bias voltages. With bit option=1, the software selection for delta bias voltage control is enabled. With bit option=0, internal contrast control is disabled.

If the internal contrast control is enabled, this command is used to increase or de

crease the contrast level within the 16 contrast levels. The contrast level starts from

lowest value after power on reset.

This command is to select one of the 16 contrast levels when internal contrast con

trol circuitry is in use.

This command allows the user to read the current contrast level value. With RW in

put HIGH (READ), DCOM input LOW (Command) and D7, D6, D5 and D4 are

equal to 0001, the value if the internal contrast value can be read on D0~D3 at the

falling edge of CS.

This command can select 4 different LCD driving voltage temperature coefficients

to match various liquid crystal temperature grades. Those temperature coefficients

are specified in electrical characteristics table.

By using this command to reduce the display clock frequency by HALT. Use in Icon

mode to reduce standby current

-

-

-

-

-

-

Rev. 1.10 14 April 4, 2007

Command Table

Bit Pattern

(D7~D0)

Command Comment

Set BGDRAM page address using X

X

=000: page 1 (POR; initial state)

2X1X0

X

=001: page 2

00000X

2X1X0

Set BGDRAM Page Address

X

X

X

2X1X0

2X1X0

2X1X0

2X1X0

=010: page 3

=011: page 4

=100: page 5

Set one of the 4 available values to the icon and annunciator con

as data bits.

1X0

000011X

1X0

Set Icon Line/Annunciator

Contrast Level

trast, using X

X

=00 (Von=0.87VDD)

1X0

X

=01 (Von=0.71VDD)

1X0

X

=10 (Von=0.61VDD) (POR initial state)

1X0

X

=11 (Von=0.55VDD)

1X0

Set one of the 16 available values to the internal contrast register,

0001X

3X2X1X0

Set Contrast Level

using X3X2X1X0as data bits. The contrast register is reset to 0000

during POR

With DCOM pin input low, RW pin input high, and D7~d4 pins

0001X

3X2X1X0

0010000X

0010001X

0010010X

0010011X

0010100X

0010101X

0010110X

Read Contrast Value

Set Voltage Doubler/Tripler

0

Set Column Mapping

0

Set Row Mapping

0

Reserved

0

Set Display On/Off

0

Set DC/DC Converter On/Off

0

Set InternalRegulator On/Off

0

equal to 0001 at the rising edge of CS, the value of the internal con

trast register will be latched out at D3, D2, D1 and D0 pins, i.e.

X

X

X

X

X

X

X

X

X

X

X

X

X

at the rising edge of CS.

3X2X1X0

=0: Select voltage tripler (POR initial state)

0

=1: Select voltage doubler

0

=0: COL0 to SEG0 (POR initial state)

0

=1: COL0 to SEG119

0

=0: ROW0 to COM0 (POR initial state)

0

=1: ROW0 to COM31

0

=0: Display off (POR initial state)

0

=1: Display on

0

=0: DC/DC converter off (POR initial state)

0

=1: DC/DC converter on

0

=0: Internal regulator off (POR initial state)

0

=1: Internal regulator on

0

When the application employs external contrast control, the inter

nal contrast control, temperature compensation and the regulator

must be enabled.

X

=0: Internal voltage divider off (POR initial state)

0

0010111X

Set Internal Voltage Divider

0

On/Off

X

=1: Internal voltage divider on

0

When an external bias network is preferred, the voltage divider

should be disabled.

X

=0: Internal contrast control off (POR initial state)

0

0011000X

Set Internal Contrast Control

0

On/Off

X

=1: Internal contrast control on

0

Internal contrast circuits can be disabled if external contrast circuit

is preferred.

=0: Low frequency (38.4kHz) (POR initial state)

X

0011001X

0011010X

Set Clock Frequency

0

Save/Restore RAM Column

0

Address

0

X

=1: High frequency (50kHz)

0

X0=0: Restore address

X

=1: Save address

0

00110110 Master Clear RAM Master clear BGDRAM page 1 to 4

00110111 Master Clear Icons Master clear of BGDRAM page 5

as address bits.

2X1X0

HT0610

-

-

-

Rev. 1.10 15 April 4, 2007

HT0610

Bit Pattern

(D7~D0)

0011100X

0011101X

0011110X

Set Bias Ratio

0

Reserved

0

Set Display with Icon Line

0

Command Comment

00111110 Set Icon Display Mode

010X

4X3X2X1X0

01100A

1A0X0

0110100X

0110101X

011011X

0111000X

0111001X

0111010X

0111011X

0111100X

0111101X

0111110X

0111111X

1X

6X5X4X3X2X1X0

1X0

Set Vertical Scroll Value

Set Static Icon Control Sig

nals

Set Duty Cycle

0

Set IDD Reduction Mode

0

Set Temperature Coefficient

Increase/Decrease Contrast

0

Value

Reserved

0

Reserved

0

Reserved

0

Reserved

0

Set Internal/External

0

Oscillator

Reserved

0

Set OscillatorDisable/Enable

0

Set BGDRAM Address

=0: Set 1/7 bias (POR initial state)

X

0

X

=1: Set 1/5 bias

0

=0: Normal operation (POR initial state)

X

0

X

=1: Test mode

0

(Note: make sure to set X

=0: Set display mode without Icon line (POR initial state)

X

0

X

=1: Set display mode with Icon line

0

=0: during application)

0

Power saving icon display mode, COM 0 to COM 31 will be dis

abled.

Use X

as number for lines to scroll.

4X3X2X1

Scroll value=0 upon POR

A

=00: Select Icon 1 (POR initial state)

1A0

A

=01: Select Icon 2

1A0

A

=10: Select Icon 3

-

1A0

A

=11: Select Icon 4

1A0

X

=0: Turned selected Icon off (POR state)

0

X

=1: Turned selected Icon on

0

=0: 1/32 duty and triple enabled (POR initial state)

X

0

X

=1: 1/16 duty and doubler enabled

0

=0: Normal mode

X

0

X

=1: IDDreduction mode

0

=00: 0.00% (POR initial state)

X

0

X

=01: -0.18%

0

X

=10: -0.22%

0

X

=11: -0.35%

0

X

=0: Decrease by one level (POR initial state)

0

X

=1: Increase by one level

0

(Note: increment/decrement wraps round among the 16 contrast

levels. Start at the lowest level when POR.

=0: Normal operation (POR initial state)

X

0

X

=1: Test mode select

0

(Note: make sure to set X

X

=0: Internal oscillator (POR initial state)

0

X

=1: External oscillator

0

=0 during application)

0

If resistors are placed at OSC1 and OSC2. For external oscillator,

simply feed clock in OSC2.

X

=0: Oscillator disable (POR initial state)

0

X

=1: Oscillator enable

0

This is the master control for oscillator circuitry.

This command should be issued after the ²external/internal oscilla

tor² command.

Set BGDRAM column address.

Use X

6X5X4X3X2X1X0

as address bits

-

-

Rev. 1.10 16 April 4, 2007

HT0610

Data Read Write

·

To read data from the BGDRAM, input high to RW pin and DCOM pin. Data is valid at the falling edge of CS. And the

BGDRAM column address pointer will be increased by one automatically.

·

To write data to the BGDRAM, input low to RW pin and high to DCOM pin. Data is latched at the falling edge of CS.

And the BGDRAM column address pointer will be increased by one automatically.

·

No auto address pointer increment will be performed for the dummy write data after ²master clear BGDRAM²

Address Increment Table (Automatic)

DCOM RW Comment Address Increment Note

0 0 Write command

0 1 Read command *1

1 0 Write data

1 1 Read data

Address increment is done automatically data read write. The column address pointer of BGDRAM*3 is affected.

Note:

²*1² Refer to the command read contrast value

²*2² If write data is issued after command clear RAM, address increase is not applied

²*3² Column address will be wrapped around when overflow

Power Up Sequence (Command Required)

Command Required POR Status Note

Set Clock Frequency Low *1

Set Oscillator Enable Disable *1

Set Static Icon Control Signals Static Icon off *1

Set Duty Cycle 1/32 duty *1

Set Bias Ratio 1/7 bias *1

Set Internal DC/DC Converter On Off *1

Set Internal Regulator On Off *1

Set Temperature Coefficient TC=0% *1, *3

Set Internal Contrast Control On Off *1, *3

Increase Contrast Level Contrast level=0 *1, *2, *3

Set Internal Voltage Divider On Off *1

Set Segment Mapping SEG0=COLUMN0

Set Common Mapping COM0=ROW0

Set Vertical Scroll Value Scroll value=0

Set Display On Off

Ö

Ö

*2

Note:

²*1² Required only if desired status differ from power on reset

²*2² Effective only if internal contrast control is enabled.

²*3² Effective only if the regulator is enabled.

Rev. 1.10 17 April 4, 2007

HT0610

Command Required for Display Mode Setup

Display Mode Command Required

Display Mode

Static Icon Display

Standby Mode 1

Standby Mode 2

Standby Mode 3

Other related command with display mode: set duty cycle, set column mapping, set row mapping, set vertical scroll

value.

Command Related to Internal DC/DC Converter

Set oscillator disable/enable, set internal regulator on/off, set duty cycle, set temperature coefficient, set internal con

trast control on/off, increase contrast level, set internal voltage divider on/off, set bias ratio, set display on/off, set inter

nal/external oscillator, set contrast level, set voltage doubler/tripler, set 33 mux display mode, set Icon display mode.

* You do not need to resend the command again if it is set previously.

Set external/internal oscillator*

Set oscillator enable*

Set display on*

Set external/internal oscillator*

Set oscillator enable*

Set static Icon control signal*

Set display off*

Set oscillator disable*

Set external oscillator*

Set static Icon control signal*

Set display off*

Set oscillator enable*

Set internal oscillator*

Set static Icon control signal*

Set display off*

Set oscillator enable*

-

-

Command Required for R/W Actions on RAM

R/W Actions on RAM Command Required

Read data from BGDRAM

Write data to BGDRAM

Save or restore BGDRAM column address Save or restore BGDRAM column address

Increase BGDRAM address by one Dummy read data

Master clear BGDRAM

* You do not need to resend the command again if it is set previously.

Set BGDRAM page address*

Set BGDRAM column address*

Read/write data

Master clear BGDRAM

Dummy write data

Rev. 1.10 18 April 4, 2007

HT0610

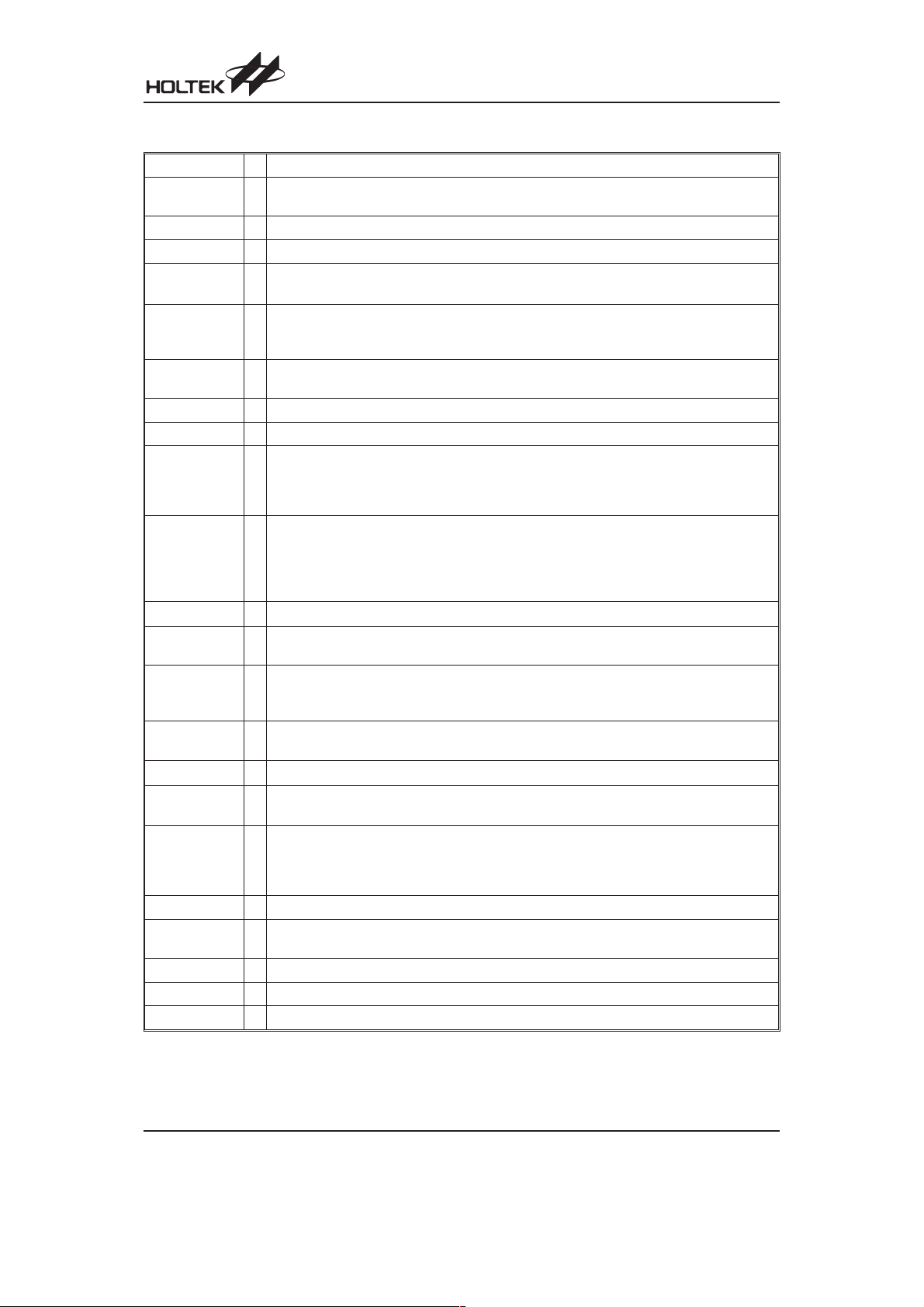

Note:

Film: UPILEX-S 75±5mm thickness

Copper: FQ-VLP 25mm thickness

Adhesive: Toray #7100, 12±2mm thickness

Solder resist: AE-70-M11, 26±14mm thickness

Flex coating: FS-100L

Plating: Sn 0.21±0.05mm thickness

All corner radii of base film are less than 0.2mm unless otherwise noted

Other specs than display in this drawing are based on the standard spec lists

All dimensional tolerances of ²SR² are ±0.2mm unless otherwise noted

All dimensional tolerances of ²base film² are ±0.05mm unless otherwise noted

Inner lead accumulative pitch:

Output side: 9.359±0.008mm

Input side: 9.077±0.008mm

Rev. 1.10 19 April 4, 2007

Application Circuits

32/33 MUX Display with Analog Circuitry Enabled, Tripler Enabled and 1/7 Bias

T o L C D P a n e l

HT0610

M P U / M C U

w i t h

P a r a l l e l

I n t e r f a c e

R A M E P R O M

R E S

C S

C E

R W

D C O M

D 0 ~ D 7

9 1 0 k

O S C 2

O S C 1

0 . 1mF 0 . 1mF

W

C O M 0 ~ C O M 3 2

S E G 0 ~ S E G 1 1 9

A N N 1 ~ A N N 4 , B P

H T 0 6 1 0

C 1

C 2

C 1 N

C 1 P

0 . 1

3 0 0 k

V F

C 2 N

C 2 P

1 5 0 k

F

m

5 6 0 p F

W

V D D

V S S

V D D A

V L L 2

V L L 3

D U M 2

D U M 1

V L L 4

V L L 5

V L L 6

V C C A 1

V R

W

4 . 7mF

N o t e : V R a n d V F c a n b e l e f t o p e n w h e n R e g u l a t o r i s d i s a b l e d .

16 MUX Display with Analog Circuitry Enabled, Tripler Enabled and 1/5 Bias

T o L C D P a n e l

0 . 1

0 . 1mF

0 . 1mF

0 . 1mF

0 . 1mF

0 . 1mF

0 . 1mF

0 . 1mF

0 . 1mF

0 . 1mF

V

D D

F

m

M P U / M C U

w i t h

P a r a l l e l

I n t e r f a c e

R A M E P R O M

R E S

C S

C E

R W

D C O M

D 0 ~ D 7

E x t e r n a l

C l o c k

O S C 2

C 1

O S C 1

0 . 1mF 0 . 1mF

C O M 0 ~ C O M 3 2

S E G 0 ~ S E G 1 1 9

A N N 1 ~ A N N 4 , B P

H T 0 6 1 0

C 2

C 1 N

C 1 P

C 2 N

3 0 0 k

V D D

V S S

V D D A

V L L 2

V L L 3

D U M 2

D U M 1

V L L 4

V L L 5

V L L 6

V F

C 2 P

1 5 0 k

5 6 0 p F

W

V C C A 1

V R

W

4 . 7mF

0 . 1

0 . 1mF

0 . 1mF

0 . 1mF

0 . 1mF

0 . 1mF

0 . 1mF

0 . 1mF

V

D D

F

m

N o t e : V R a n d V F c a n b e l e f t o p e n w h e n R e g u l a t o r i s d i s a b l e d .

Rev. 1.10 20 April 4, 2007

16/32/33 MUX Display with Analog Circuitry Disabled

T o L C D P a n e l

HT0610

C O M 0 ~ C O M 3 2

S E G 0 ~ S E G 1 1 9

O S C 2

A N N 1 ~ A N N 4 , B P

C 1

C 2

O S C 1

H T 0 6 1 0

C 1 N

V D D A

D U M 2

D U M 1

V L L 5

V L L 6

C 1 P

C 2 N

C 2 P

V C C A 1

V F

V R

M P U / M C U

w i t h

P a r a l l e l

I n t e r f a c e

R A M E P R O M

R E S

C S

C E

R W

D C O M

D 0 ~ D 7

E x t e r n a l

C l o c k

N o t e : V R a n d V F c a n b e l e f t o p e n w h e n R e g u l a t o r i s d i s a b l e d .

V D D

V S S

V L L 2

V L L 3

V L L 4

0 . 1

0 . 1mF

V

D D

F

m

V C C

Rev. 1.10 21 April 4, 2007

Holtek Semiconductor Inc. (Headquarters)

No.3, Creation Rd. II, Science Park, Hsinchu, Taiwan

Tel: 886-3-563-1999

Fax: 886-3-563-1189

http://www.holtek.com.tw

Holtek Semiconductor Inc. (Taipei Sales Office)

4F-2, No. 3-2, YuanQu St., Nankang Software Park, Taipei 115, Taiwan

Tel: 886-2-2655-7070

Fax: 886-2-2655-7373

Fax: 886-2-2655-7383 (International sales hotline)

HT0610

Holtek Semiconductor Inc. (Shanghai Sales Office)

7th Floor, Building 2, No.889, Yi Shan Rd., Shanghai, China 200233

Tel: 86-21-6485-5560

Fax: 86-21-6485-0313

http://www.holtek.com.cn

Holtek Semiconductor Inc. (Shenzhen Sales Office)

5/F, Unit A, Productivity Building, Cross of Science M 3rd Road and Gaoxin M 2nd Road, Science Park, Nanshan District,

Shenzhen, China 518057

Tel: 86-755-8616-9908, 86-755-8616-9308

Fax: 86-755-8616-9722

Holtek Semiconductor Inc. (Beijing Sales Office)

Suite 1721, Jinyu Tower, A129 West Xuan Wu Men Street, Xicheng District, Beijing, China 100031

Tel: 86-10-6641-0030, 86-10-6641-7751, 86-10-6641-7752

Fax: 86-10-6641-0125

Holtek Semiconductor Inc. (Chengdu Sales Office)

709, Building 3, Champagne Plaza, No.97 Dongda Street, Chengdu, Sichuan, China 610016

Tel: 86-28-6653-6590

Fax: 86-28-6653-6591

Holtek Semiconductor (USA), Inc. (North America Sales Office)

46729 Fremont Blvd., Fremont, CA 94538

Tel: 1-510-252-9880

Fax: 1-510-252-9885

http://www.holtek.com

Copyright Ó 2007 by HOLTEK SEMICONDUCTOR INC.

The information appearing in this Data Sheet is believed to be accurate at the time of publication. However, Holtek as

sumes no responsibility arising from the use of the specifications described. The applications mentioned herein are used

solely for the purpose of illustration and Holtek makes no warranty or representation that such applications will be suitable

without further modification, nor recommends the use of its products for application that may present a risk to human life

due to malfunction or otherwise. Holtek¢s products are not authorized for use as critical components in life support devices

or systems. Holtek reserves the right to alter its products without prior notification. For the most up-to-date information,

please visit our web site at http://www.holtek.com.tw.

-

Rev. 1.10 22 April 4, 2007

Loading...

Loading...