Holden Commodore Common Mazda 2005 User Manual

Diesel Injection Pump

SERVICE MANUAL

New Common Rail System (HP3)

for MAZDA

OPERATION

June, 2005

00400517E

© 2005 DENSO CORPORATION

All Rights Reserved. This book may not be reproduced

or copied, in whole or in part, without the written

permission of the publisher.

Table of Contents

Table of Contens

Operation Section

1. PRODUCT APPLICATION INFORMATION

1.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.3 System Components Parts Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. OUTLINE OF SYSTEM

2.1 Outline of Composition and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

3. SUPPLY PUMP

3.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

3.2 Explode View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

3.3 SCV (Suction Control Valve) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

4. RAIL

4.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

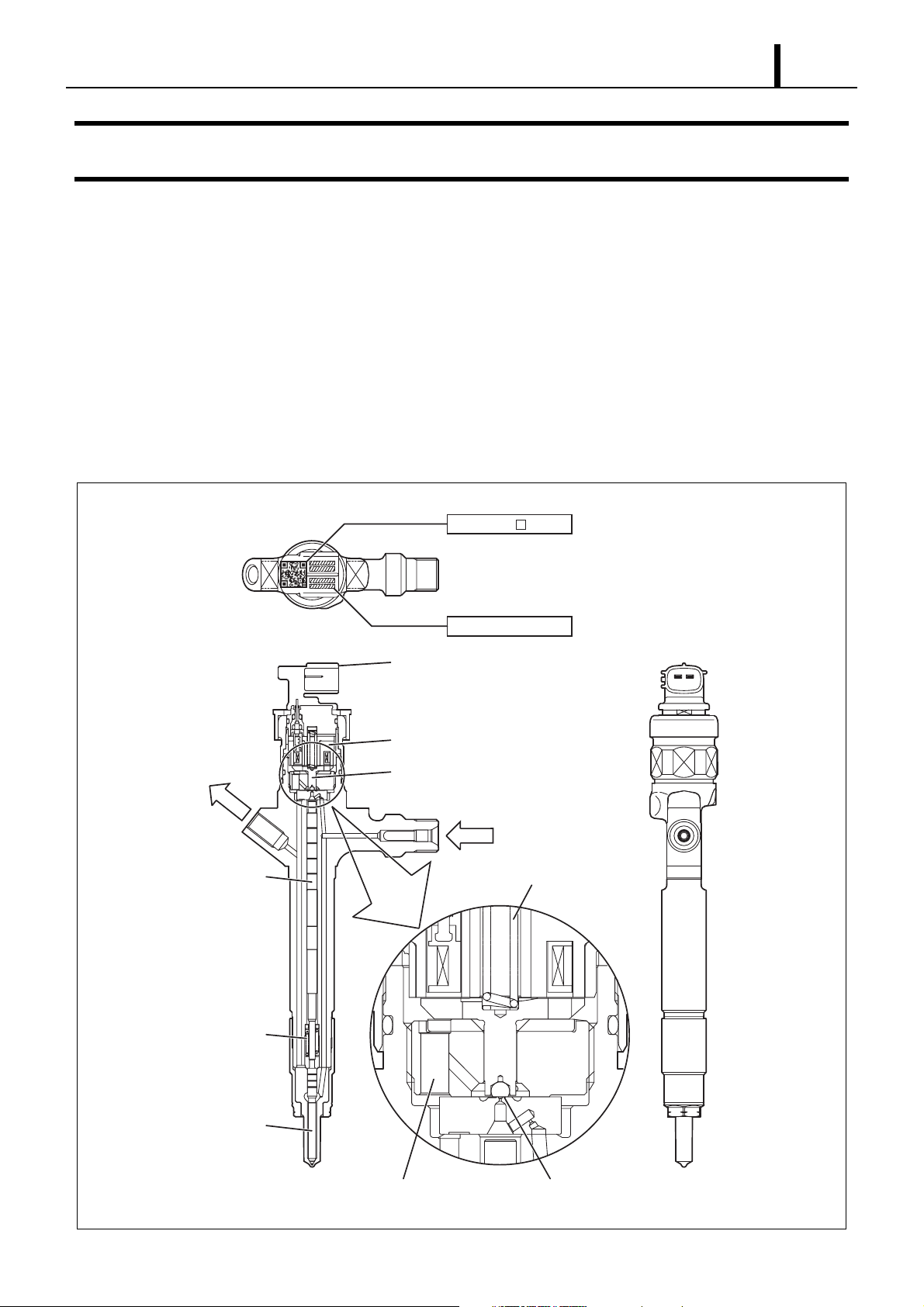

5. INJECTOR

5.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

5.2 Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

5.3 Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

5.4 QR Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

6. OPERATION OF CONTROL SYSTEM COMPONENTS

6.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

6.2 Engine ECU (Electronic Control Unit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

6.3 Operation of Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

7. CONTROL SYSTEM

7.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

7.2 Fuel Injection Timing Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

8. DIAGNOSTIC TROUBLE CODES (DTC)

8.1 About the Codes Shown in the Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

8.2 Diagnostic Trouble Code Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

9. EXTERNAL WIRING DIAGRAM

9.1 Engine ECU External Wiring Diagram (Model Name: MAZDA 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

9.2 Engine ECU External Wiring Diagram (Model Name: MAZDA 6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-37

1–1

Operation Section

1. PRODUCT APPLICATION INFORMATION

1.1 Outline

z The common rail system for the MZR-CD engine has been newly installed in the Mazda 5 and Mazda 6. The contents for the common

rail system are basically the same as those published in the previous Service Bulletin, "S/B Code: ECD02-06, Subject: New Common

Rail System (ECD-U2P) for Mazda." The two major points that have changed for this system are the addition of the DPF system, and

injectors equipped with the QR code. Please be sure to use this Service Manual together with the Service Bulletin as this edition ex-

plains only points that have changed.

1.2 Application

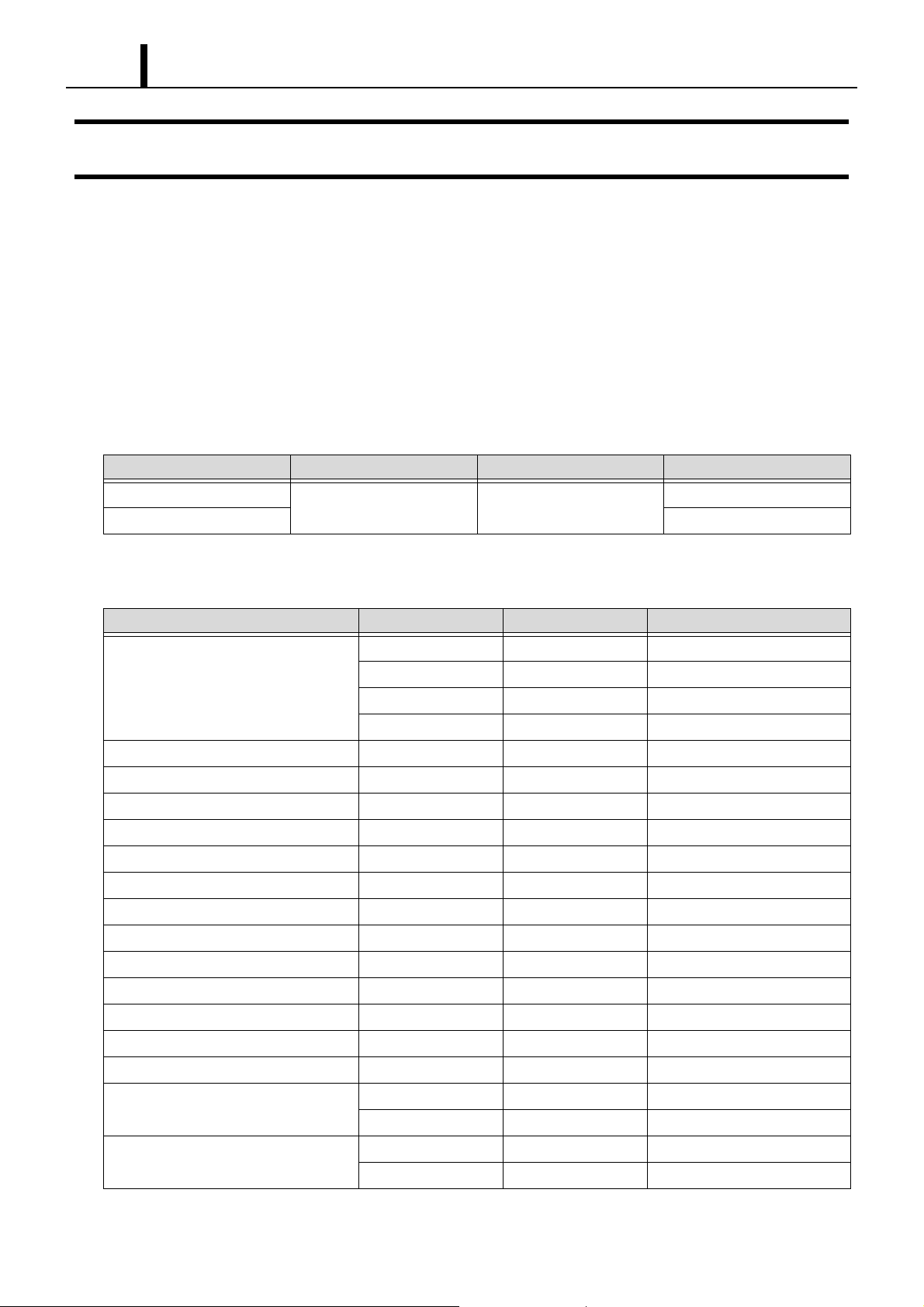

Model Name Engine Destination Line Off Period

MAZDA 5

MZR-CD Europe

MAZDA 6 April, 2005

March, 2005

1.3 System Components Parts Number

Parts Name DENSO P/N Manufacturer P/N Remarks

275800-6401 RF7J 18 881B MAZDA 6

Engine ECU

Turbo pressure sensor (MAPS) 079800-7440 RF7J 18 211

Injector 095000-5780 RF7J 13 H50

Crankshaft position sensor (NE) 949979-0200 RF7J 18 221

Cylinder recognition sensor (TDC) 949979-1520 RF7J 18 230

Rail 095440-0740 RF7J 13 GC0

Rail pressure sensor 499000-6210 —

Pressure limiter 095420-0201 —

Supply pump 294000-0420 RF7J 13 800A

Suction control valve 294200-0160 —

Fuel temperature sensor 179730-0020 RF1L 18 840

Mass air flow meter 197400-2010 ZL01 13 215

275800-6441 RF7K 18 881B MAZDA 6 High Output Engine

275800-6450 RF7N 18 881A MAZDA 5

275800-6460 RF7P 18 881A MAZDA 5 High Output Engine

Coolant temperature sensor 179700-0220 B593 18 840A

Engine compartment temperature sensor 170400-6020 BP4W 18 845

Exhaust temperature sensor 1

Exhaust temperature sensor 2

265600-1050 RF7N 18 7G0 MAZDA 6

265600-1090 RF7K 18 7G0A MAZDA 5

265600-1060 RF7P 18 7G0 MAZDA 6

265600-1080 RF7J 18 7G0A MAZDA 5

Operation Section

Parts Name DENSO P/N Manufacturer P/N Remarks

1–2

Exhaust temperature sensor 3

265600-1070 RF7R 18 7G0 MAZDA 6

265600-1101 RF7L 18 7G0C MAZDA 5

A/F sensor (UHEGO) 211200-4260 RF7N 18 8G1

104990-1160 RF7N 18 2B5 MAZDA 6

Differential pressure sensor

104990-1150 RF7J 18 2B5 MAZDA 5

198800-3480 CC30 41 600

198800-3490 CC34 41 600

198800-3400 GR1L 41 600A

Accele pedal module

198800-3410 GR1M 41 600A

198800-3440 GR3D 41 600A

198800-3450 GR3E 41 600A

MAZDA 6

MAZDA 5

1–3

Operation Section

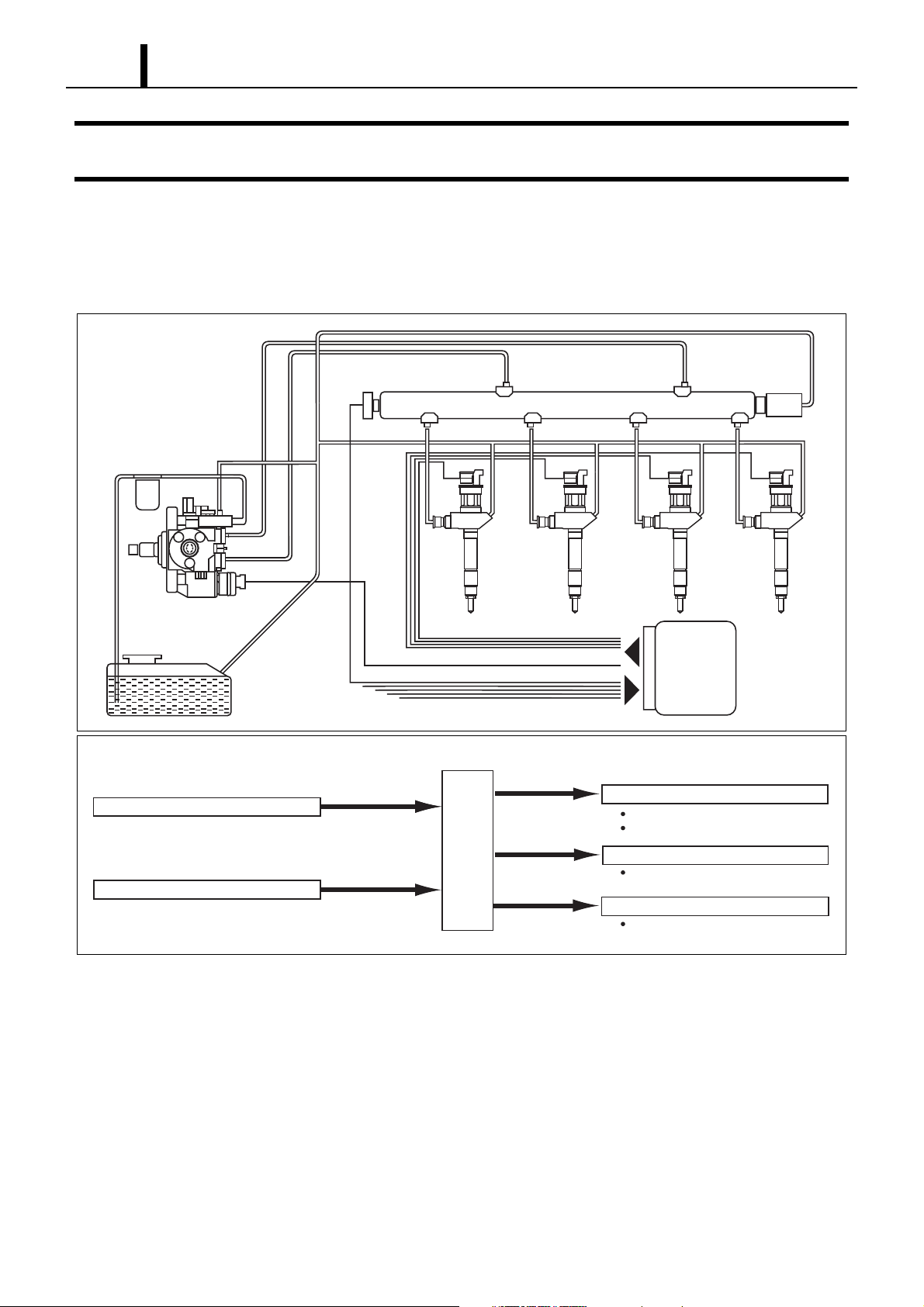

2. OUTLINE OF SYSTEM

2.1 Outline of Composition and Operation

z This system is basically the same as that in Service Bulletin ECD02-06. However the EDU has been discontinued. Please refer to the

Service Bulletin for Operation.

Fuel filter

Supply pump

Fuel tank

Sensors

Engine speed sensor

Other sensors and switches

Fuel pressure

sensor

Various

sensors

Engine Speed

Engine

ECU

Pressure

limiter

Rail

Injector

Engine

ECU

Q001109E

Actuators

Injector

Fuel injection quantity control

Injection timing control, etc.

Supply pump

Fuel pressure control

Other actuators

EMS control

Q001110E

Operation Section

1–4

3. SUPPLY PUMP

3.1 Outline

z The HP3 supply pump comes with the compact SCV (Suction Control Valve) installed. Please refer to Service Bulletin ECD02-06 as

only the SCV has changed.

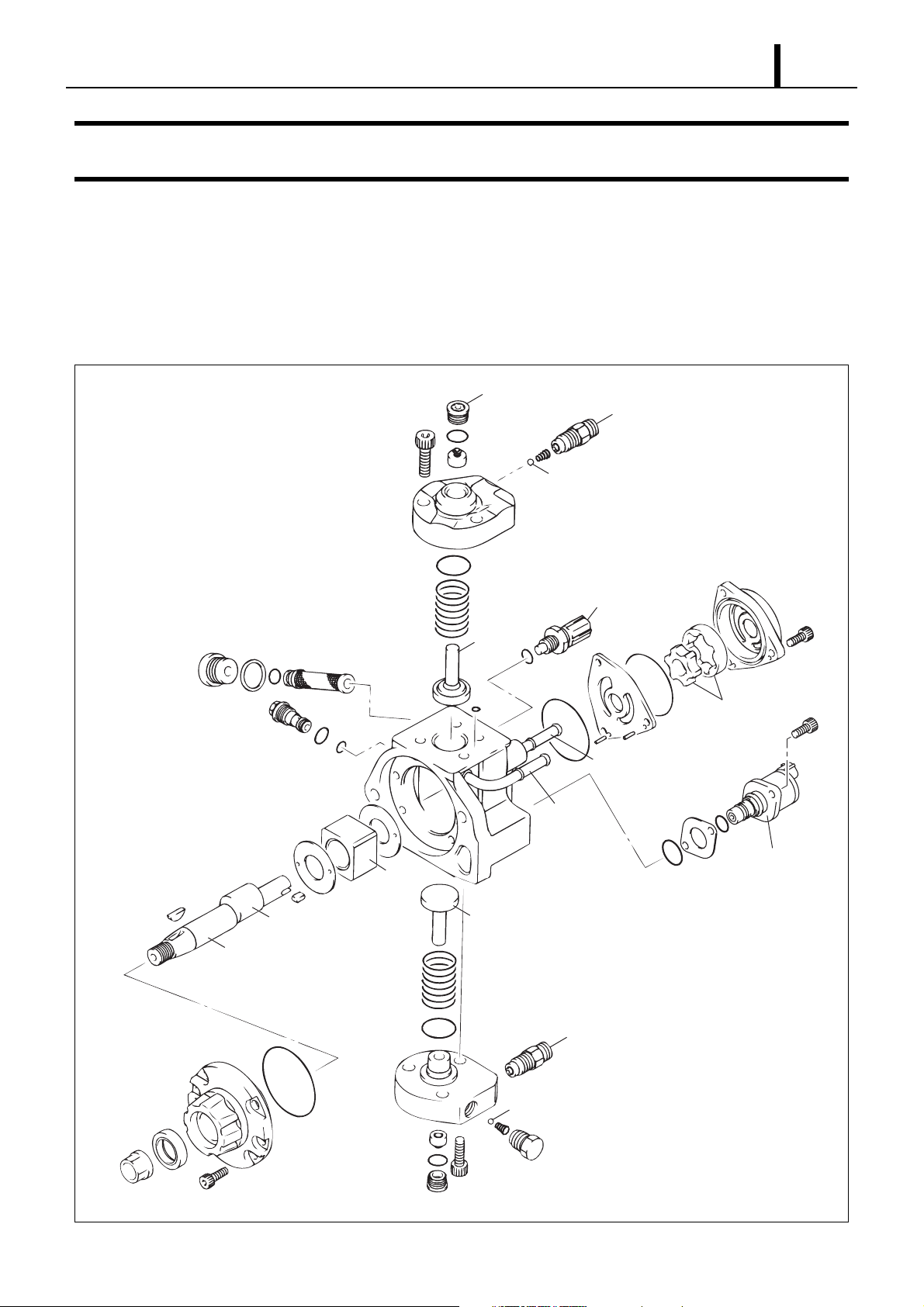

3.2 Explode View

Suction valve

Discharge outlet

Delivery valve

Eccentric cam

Camshaft

Ring cam

Fuel temperature

sensor

Plunger

Feed pump

Fuel suction inlet

Overflow

fuel outlet

Suction control

valve (SCV)

Plunger

Discharge outlet

Delivery valve

Q001112E

1–5

Operation Section

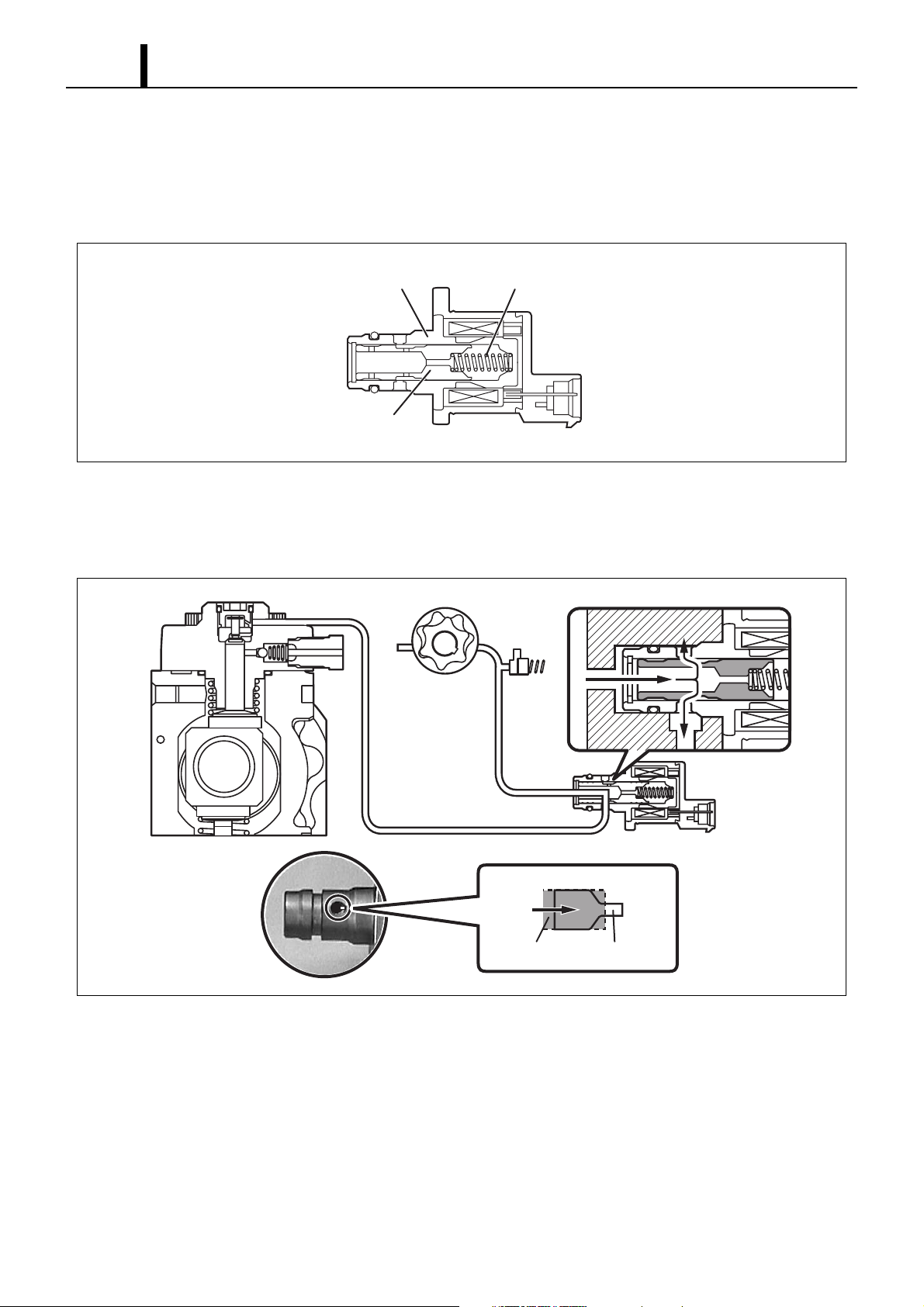

3.3 SCV (Suction Control Valve)

z A linear solenoid type solenoid valve has been adopted. The length of time in which the ECU applies current to the SCV is controlled

(duty cycle control) in order to regulate the volume of suction of fuel into the pumping area. Because only the volume of fuel that is

required by the target rail pressure is drawn in, the drive load on the supply pump decreases, thus resulting in improved fuel economy.

Valve body

Needle valve

Return Spring

Q001113E

(1) SCV Opening Small (Duty ON time long - Refer to the "Relationship Between Actuation

Signal and Current" Diagram.)

• When the opening of the SCV is small, the fuel suction area is kept small, which decreases the transferable fuel volume.

Feed Pump

Needle valve Small Opening

Q001114E

Operation Section

1–6

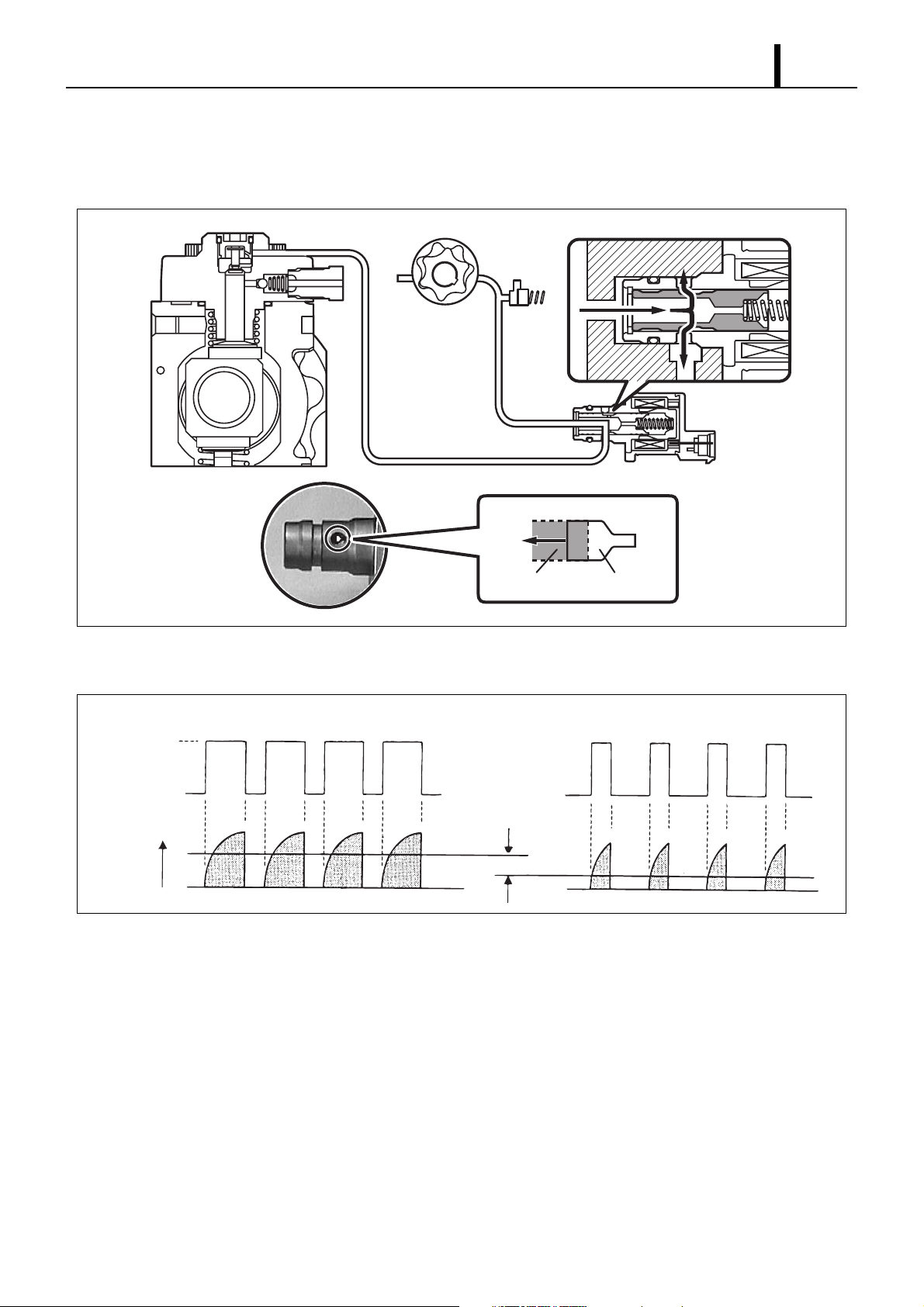

(2) SCV Opening Large (Duty ON time short - Refer to the "Relationship Between Actuation

Signal and Current" Diagram.)

• When the opening of the SCV is large, the fuel suction area is kept large, which increases the transferable fuel volume.

Feed Pump

Needle valve Large Opening

Q001115E

(3) Diagram of Relationship Between Actuation Signal and Current (Magnetomotive Force)

Small Suction Volume Large Suction Volume

ON

Actuation

Voltage

OFF

Current

Average Current Difference

Q001116E

1–7

Operation Section

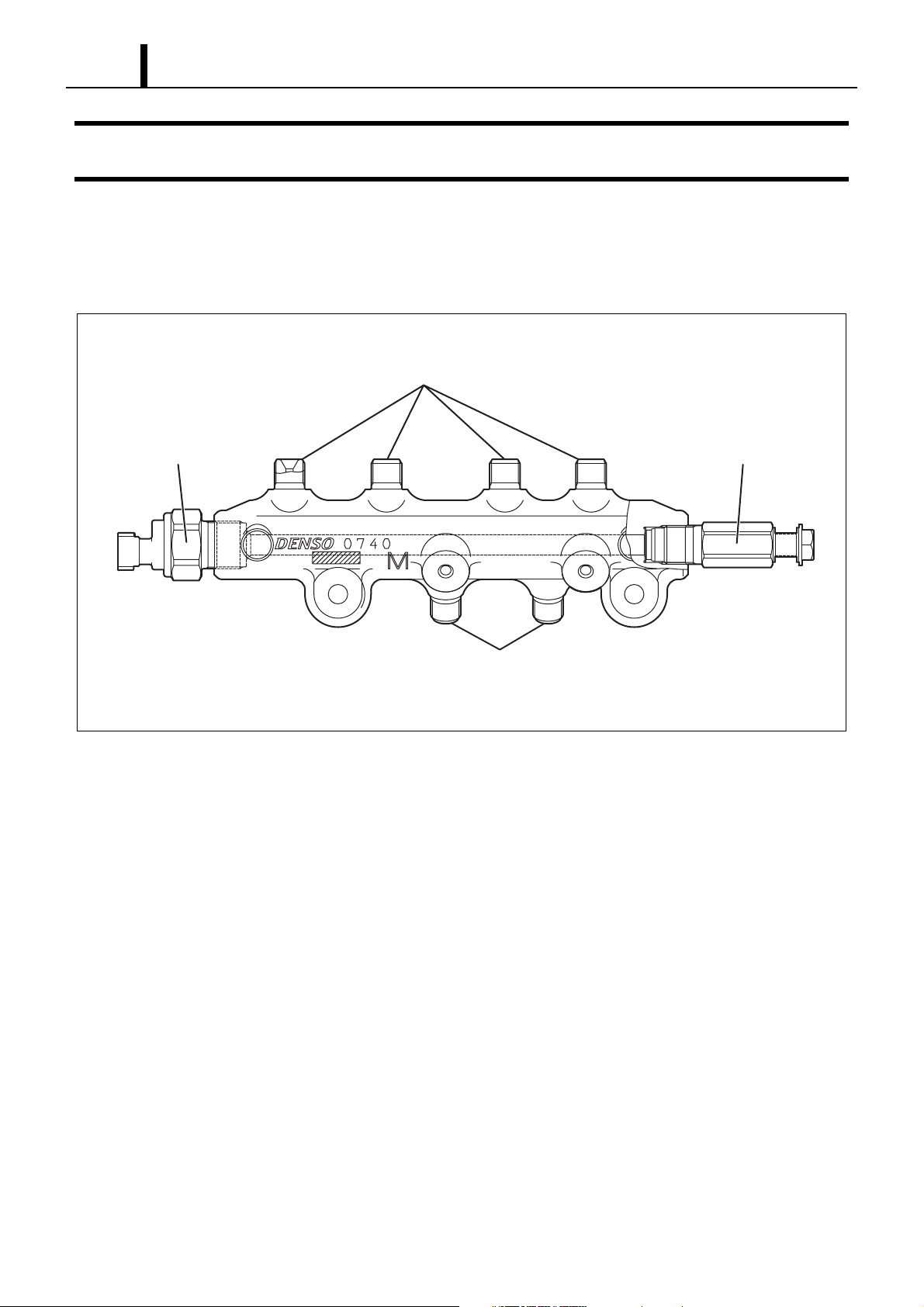

4. RAIL

4.1 Outline

z Although the characteristics of both the Fuel Pressure Sensor and Pressure limiter have not changed, the shape of the Rail Pressure

Sensor has been altered. Please refer to Service Bulletin ECD02-06.

To injector

Rail pressure sensor Pressure limiter

From supply pump

Q001117E

Operation Section

1–8

5. INJECTOR

5.1 Outline

z The injectors inject the high-pressure fuel from the rail into the combustion chambers at the optimum injection timing, rate, and spray

condition in accordance with the commands received from the ECU. In addition, the correction resistor has been discontinued and

replaced by a QR code injector.

5.2 Characteristics

z A compact, energy-saving, solenoid-control type TWV (Two-Way Valve) injector has been adopted.

5.3 Construction

To fuel tank

Command position

QR Codes ( 9.9mm)

Connector

Solenoid valve

TWV

High-pressure fuel

(from rail)

ID Codes

Valve spring

Nozzle spring

Nozzle needle

Seat areaLeak passage

Q001118E

1–9

Operation Section

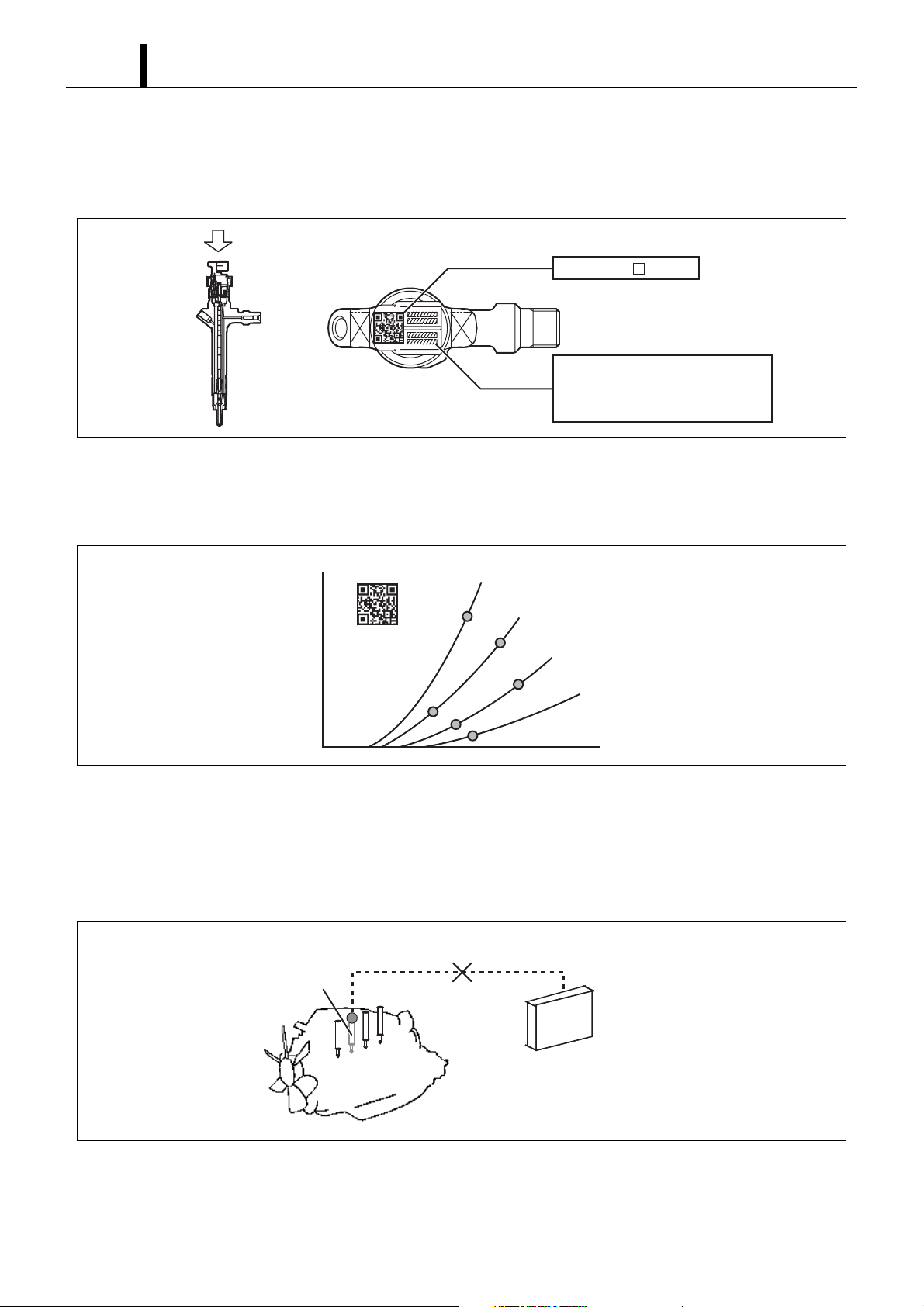

5.4 QR Codes

z Conventionally the whole injector Ass'y was replaced during injector replacement, but QR (Quick Response) codes have been adopted

to improve injector quantity precision.

QR Codes ( 9.9mm)

ID Codes (30 base 16 characters)

Base 16 characters noting fuel

injection quantity correction

information for market service use

z QR codes have resulted in a substantial increase in the number of fuel injection quantity correction points, greatly imimproving pre-

cision. The characteristics of the engine cylinders have been further unified, contributing to improvements in combustion efficiency,

reductions in exhaust gas emissions and so on.

Q001119E

Injection Quantity Q

QR Codes

Actuating Pulse Width TQ

Q001132E

(1) Repair Procedure Changes (Reference)

• When replacing injectors with QR codes, or the engine ECU, it is necessary to record the ID codes in the ECU. (If the ID codes for

the installed injectors are not registered correctly, engine failure such as rough idling and noise will result). The ID codes will be reg-

istered in the ECU at a MAZDA dealer using approved MAZDA tools.

Replacing the Injector

"No correction resistance, cannot be detected electrically"

Replaced injector

Engine ECU

* Injector ID code must be registered with the engine ECU

Q001133E

Replacing the Engine ECU

"No correction resistance, cannot be detected electrically"

Vehicle injectors

Operation Section

1–10

Replaced engine ECU

* Injector ID code must be registered with the engine ECU

Q001134E

1–11

Operation Section

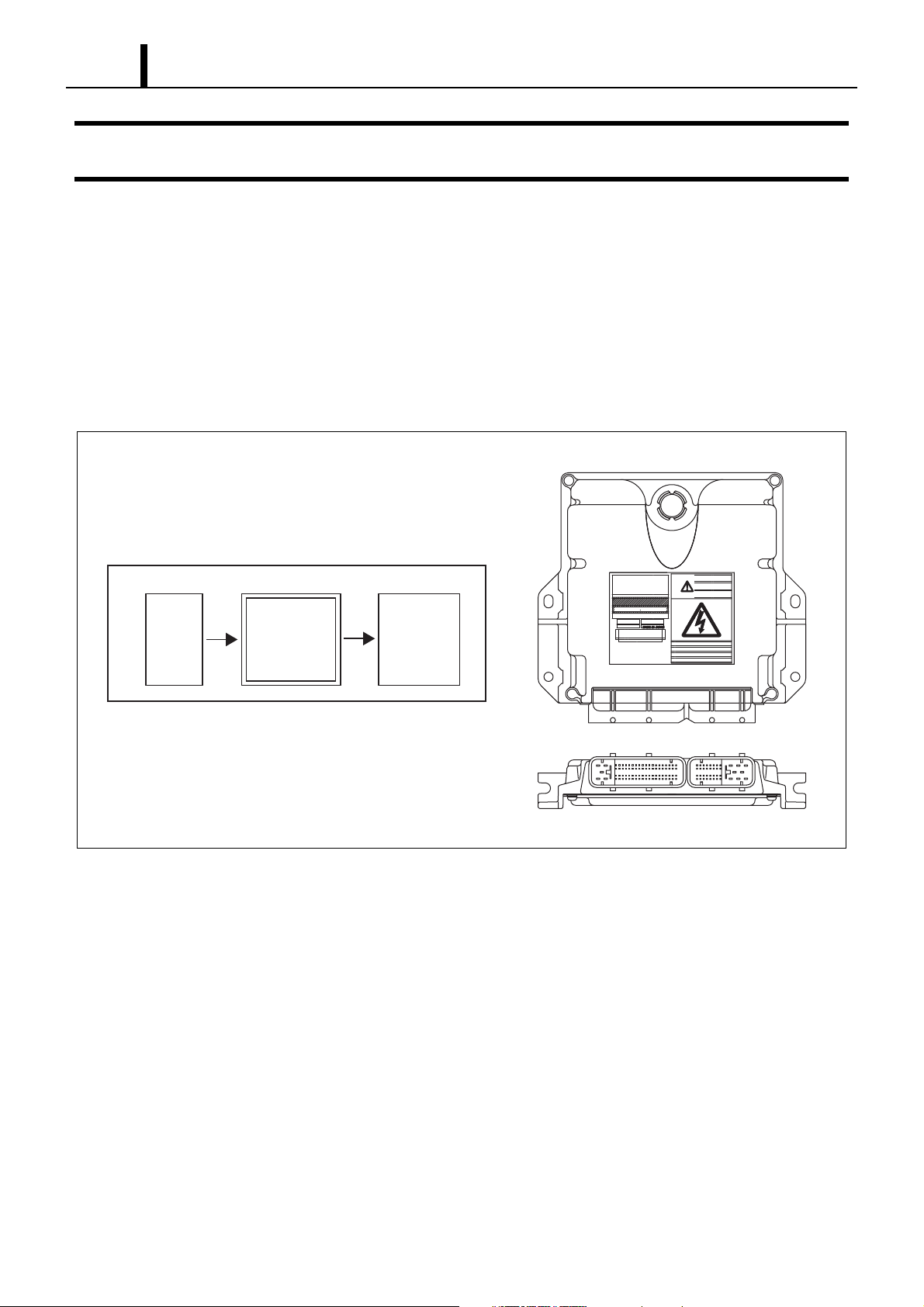

6. OPERATION OF CONTROL SYSTEM COMPONENTS

6.1 Outline

z The EDU (Electronic Driving Unit) functions have been built into the Engine ECU (Electronic Control Unit). Therefore the EDU has

been done away with. In addition the system sensor has been changed. Please refer to Service Bulletin ECD02-06 as only this sensor

has changed.

6.2 Engine ECU (Electronic Control Unit)

z This is the command center that controls the fuel injection system and the engine operation in general.

Sensor

Detection

<Outline Diagram>

Engine ECU

Calculation

Actuator

Actuation

Q001135E

Loading...

Loading...