INSTALLATION

INSTRUCTIONS & PARTS

HOBART

COMPACT WATER SOFTENER

WS-55

A product of HOBART TROY, OHIO 45374

F25407 (February 2011)

TABLE OF CONTENTS

INSTALLATION ............................................................................ 2

DISC SELECTION .......................................................................... 9

REPLACEMENT PARTS .................................................................... 10

© HOBART 2011

INSTALLATION

SAVE THESE INSTRUCTIONS

1. Locate cold water supply line and appropriate

drains for softener installation.

NOTE: WS-55 is designed to operate from a cold

water supply only.

2. Install by-pass valving.

3. Install prefilter if needed.

4. Remove all items from shipping package.

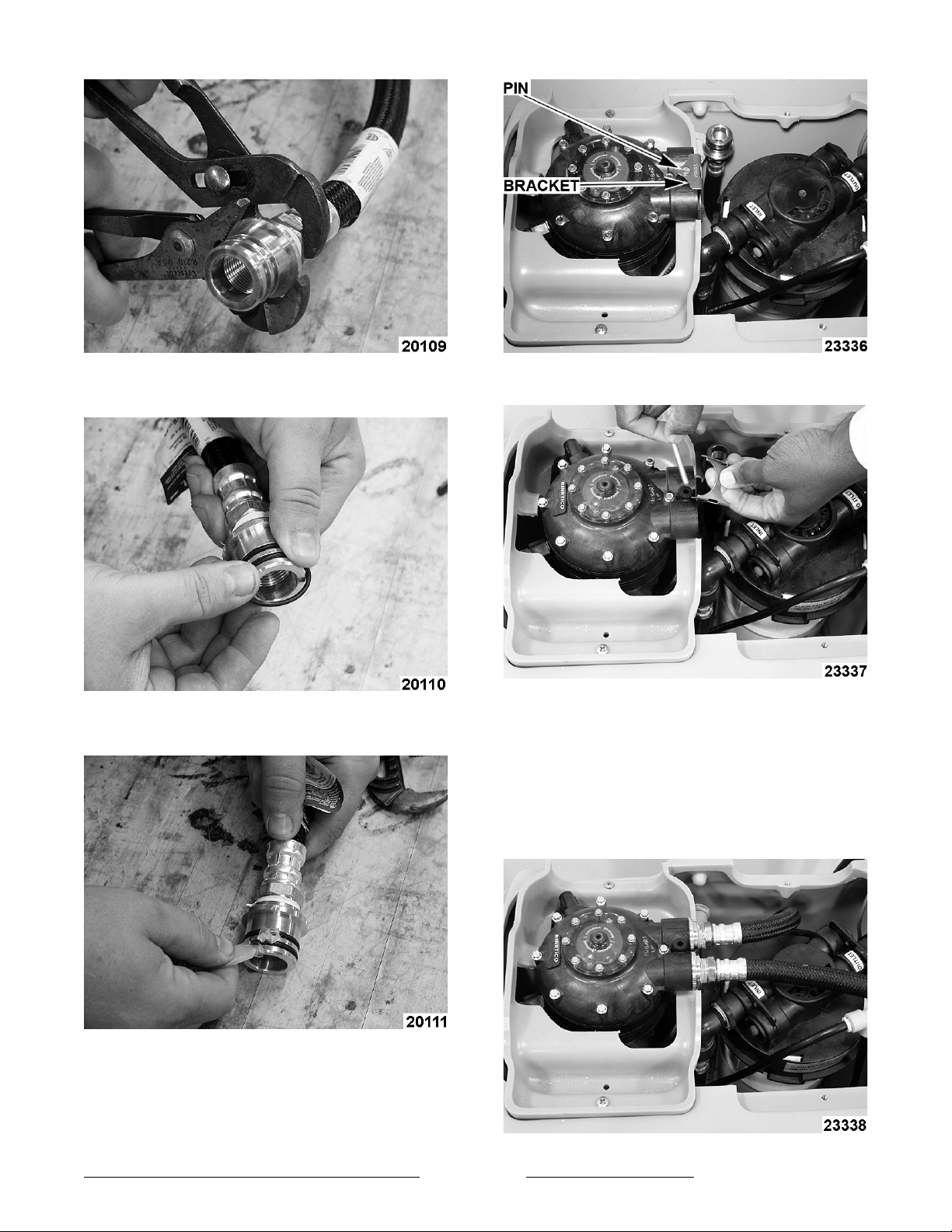

5. Locate brass in/out adapters, 4 O-rings, and

silicone seal lube.

6. Locate connector hose and output hose from

F25407 (February 2011) Page 2 of 16

Selecto filter. Apply 2 to 3 wraps of Teflon tape

to the male threads.

7. Thread the brass in/out adapters tightly onto the

threaded ends of the connector hoses.

8. Install one O-Ring into each groove of the brass

adapter.

10. Remove the pin and bracket from the softener

in/out port area.

9. Apply a small amount of seal lube evenly onto

each O-ring.

11. Install the brass adapters into the in/out ports

and secure by reinstalling the bracket and pin.

NOTE: The inlet connection from the building supply

is connected to the inlet of the carbon block filter

head. The outlet from the carbon block filter head is

connected to the inlet of the softener head. The

outlet from the softener head is connected to the

device.

F25407 (February 2011)Page 3 of 16

NOTE: The female end of the connector hoses is

designed to thread onto 3/4" pipe thread. Perform

appropriate plumbing to provide connections from

the water supply to the inlet hose/port and from the

outlet port/hose.

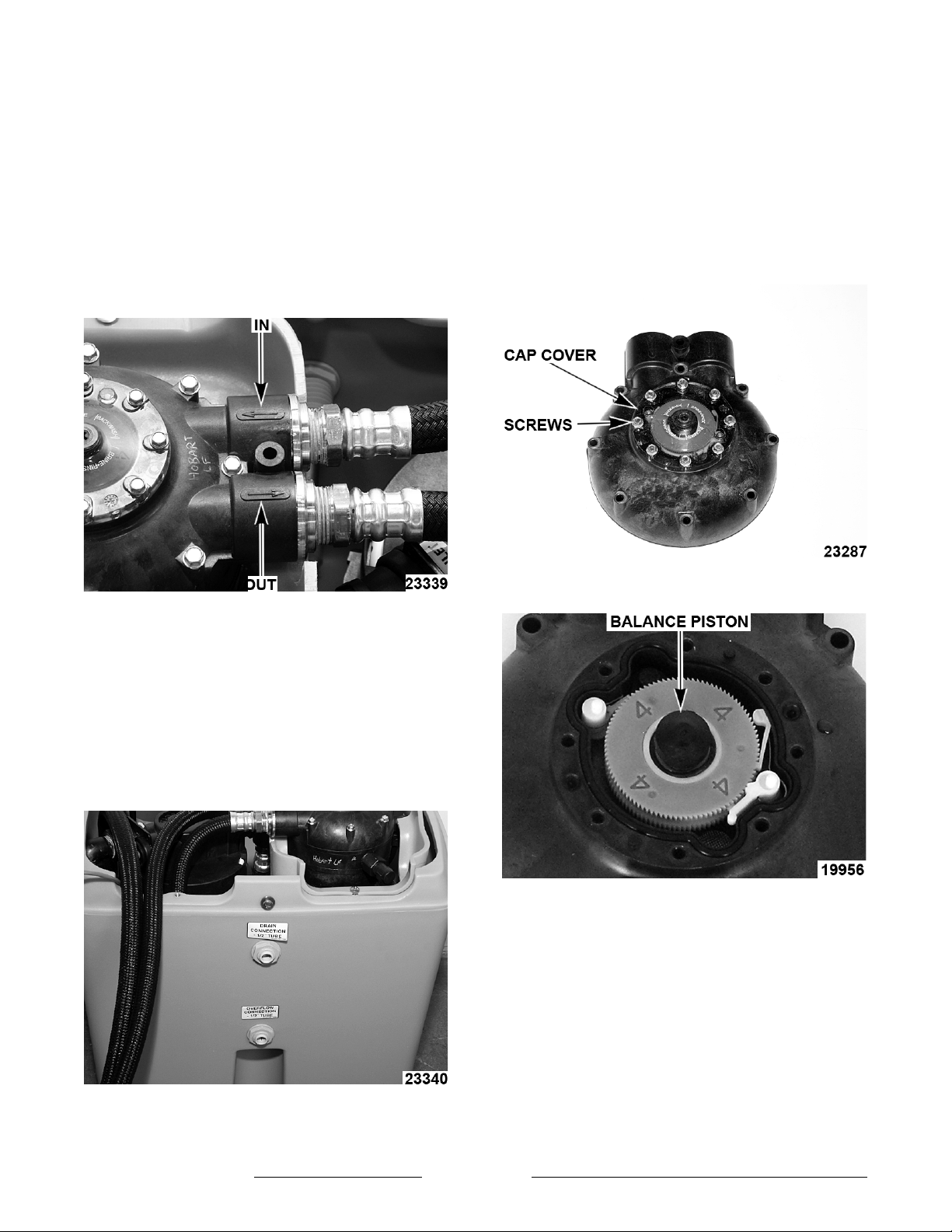

NOTE: The inlet port is identified with an arrow

pointing towards the softener controls. The softener

inlet port will receive the hose which is connected

from the outlet of the carbon block filter.

NOTE: The outlet port is identified with an arrow

pointing away from the softener controls. The outlet

port will receive the 60" hose that will connect to the

outlet plumbing. The supply connections should be

made before the pressure reducing valve.

15. To test the water supply, use the water analysis

test kit available through Pro Products Inc. The

recommended kit is #2404 Deluxe Field

Analysis Kit. To order the test kit contact Pro

Products at 800-285-9176 or visit

www.ProProducts.com.

16. Choose the meter disc and salt setting that best

fits the installation parameters.

NOTE: See DISC SELECTION at the end of

instructions.

17. To change disc, remove screws and cap cover

from level one.

12. Insert tubing provided into the drain port on the

back of the cabinet and run it to an appropriate

drain. Be sure to provide a “air gap” between

the end of the tubing and the top of the drain.

NOTE: Drain line length should not exceed 8 feet

vertical and 30 feet horizontal from the softener.

13. Insert tubing provided into the overflow port on

the back of the softener and run drain lower

than the cabinet connection to provide a gravity

drain in the event of a internal cabinet leak.

18. Remove balance piston.

14. Review the meter disc selection chart and the

water analysis provided. If no water analysis is

provided test the water supply.

F25407 (February 2011) Page 4 of 16

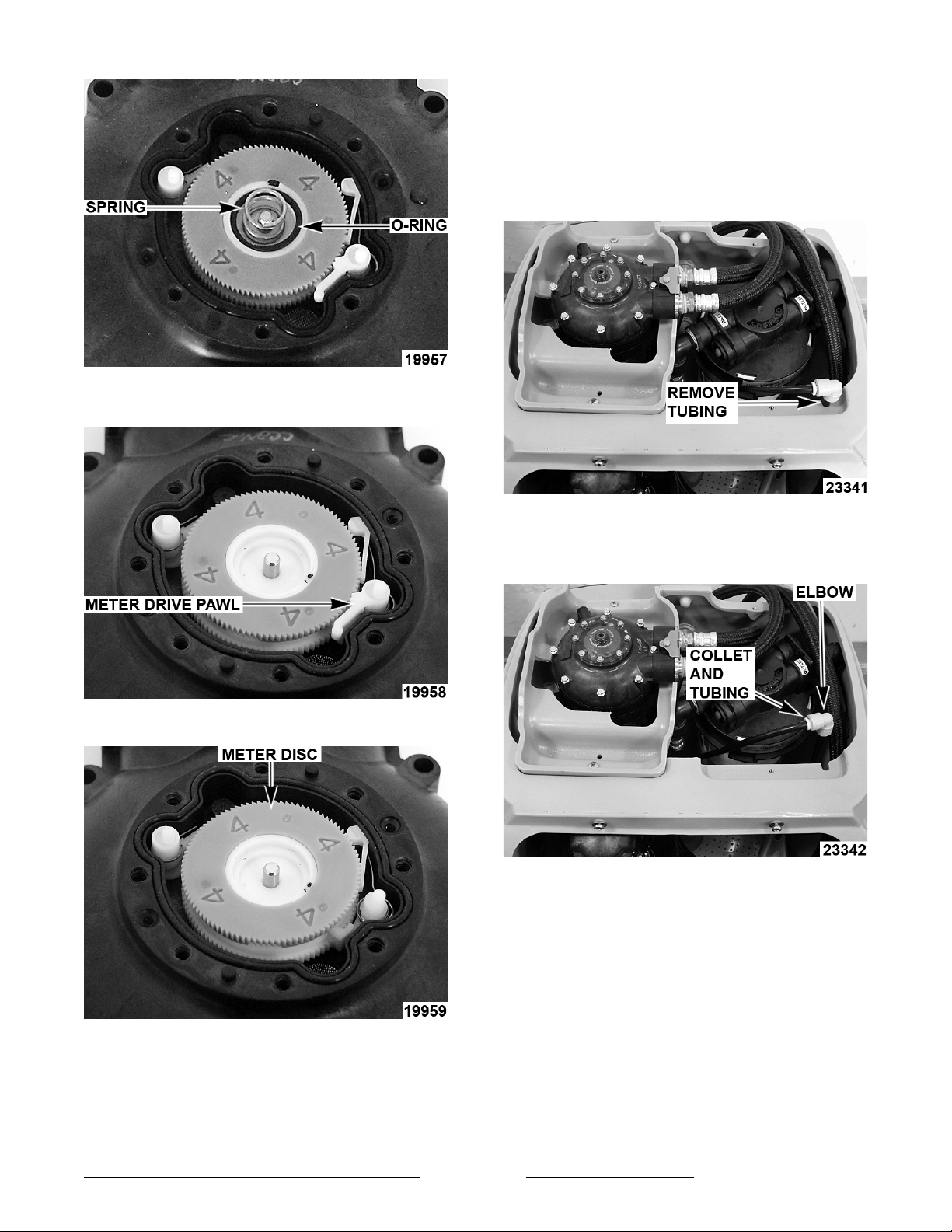

19. Remove balance piston o-ring and balance

piston spring.

20. Remove meter drive pawl.

NOTE: Be certain to start cap screws by hand

rotating backwards until screw drops into thread then

tighten. An alternating, crossing pattern should be

used while tightening cap screws to ensure correct

cap fit.

23. Remove brine valve assembly from cabinet to

set float cup.

24. To remove brine valve assembly, remove tubing

from softener cabinet.

21. Remove meter disc.

25. Disconnect tubing from brine valve elbow by

holding the collet and pulling tubing straight

away.

22. Install correct meter disc and reassemble in

reverse order.

NOTE: Make certain all components are correctly

installed.

F25407 (February 2011)Page 5 of 16

26. Remove brine valve from the softener cabinet.

27. The Float Cup is set by adjusting its height

above the bottom of the brine valve assembly.

By removing the brine valve assembly and

resting it on a flat surface, the height of the

Float Cup can be measured with a ruler.

The height is measured from the base of the brine

valve assembly to the top of the float cup.

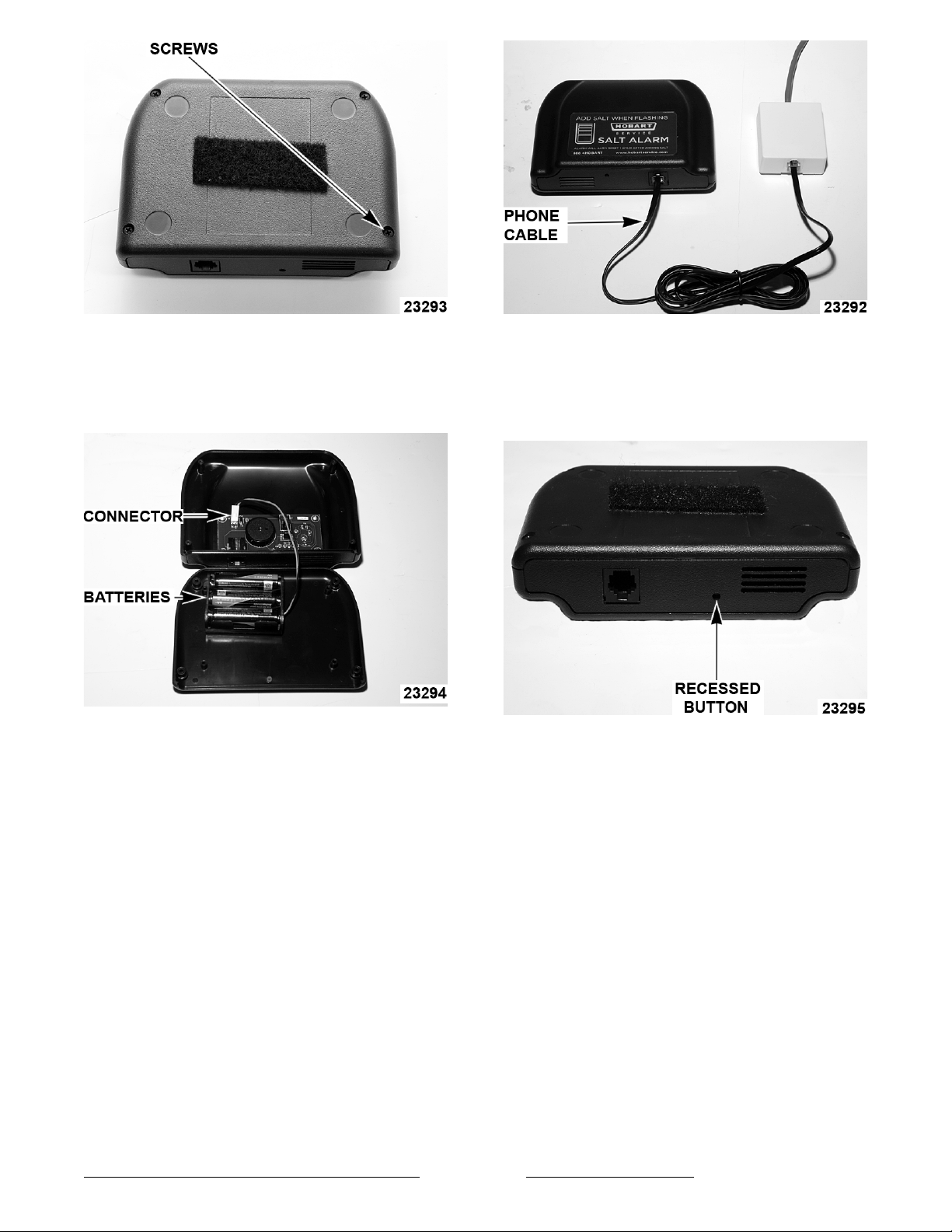

Salt Alarm Installation

28. To install salt alarm system remove paper lining

from back of salt alarm connector box.

29. Remove plastic lining from Velcro

®

backing

located on back of salt alarm controller.

30. Remove four screws securing back cover to salt

alarm controller.

F25407 (February 2011) Page 6 of 16

31. Install three (3) AA batteries into salt alarm

controller.

NOTE: When installing batteries - be certain to

inspect connector to ensure it is secure.

32. Re-install back cover to salt alarm controller.

33. Using the adhesive backing on both devices place alarm controller and salt alarm connector

box in a position that will allow salt alarm

controller to be seen and heard when it is

activated.

35. Check for proper operation by pressing the

recessed red button on bottom of salt alarm

controller. If controller is operating properly the indicator light will flash and an audible tone

will be heard.

34. Insert phone cable into salt alarm connector box

and salt alarm controller.

NOTE: Salt alarm controller can be mounted up to

100 feet from salt alarm connector box using

standard phone cable from local retailers (7 foot

cable is provide with kit).

F25407 (February 2011)Page 7 of 16

Brine Valve Settings

Unit Brine Setting WS-80 Float Cup Height

WS-55 1.4 lb. Setting 6.5"

36. After the adjustments have been made to the float cup, reinstall brine valve into the cabinet.

NOTE: Do not drop the brine valve into the drum. Dropping may lower the float cup, resulting in an improper

setting.

37. Add a clean grade of salt at this time. Higher grades of Pelletized Salt for impurities and solubility should be

used. NOTE: Do not use rock salt or solar salt.

38. Open the inlet valve slowly allowing the system to pressurize.

39. Water and air will be expelled from the drain until the system is completely pressurized.

40. A manual regeneration should be started to purge air and color from the softening system. This is done by

pushing down on the actuator with a Phillips screwdriver and rotating clockwise slowly until pressure is felt.

41. Continue slowly until internal water flow is heard at the softener valve. The softener will automatically run

through a regeneration. This process should be repeated in 12 to 15 minutes to flush the other resin tank.

42. Check for plumbing leaks.

43. Check unit for proper operation.

F25407 (February 2011)

Page 8 of 16

DISC SELECTION

The amount of hardness removed (in compensated gpg) will be based on the amount of brine and the meter disc

selected.

NOTE: Determining the correct brine valve setting for a particular application is a three step process:

1. Determine the compensated hardness. This requires a hardness test and an iron test on raw water at the

application site. Compensated hardness is calculated by multiplying the ferrous iron (in ppm) by 3 and adding

it to the grains of hardness.

2. To test the water supply, use the water analysis test kit available through Pro Products Inc. The

recommended kit is #2401 Field Analysis Kit. To order the test kit contact Pro Products at 800-285-9176 or

visit www.ProProducts.com.

WS-55

SettingCapacity EfficiencyDosingMeter Disc12345678

1.4 lbs. 4,818 grains 3,442 gr./lb. 3.5 lbs./ft

Gallons/Regeneration:

Flow during regeneration (@ 15 psig):

3

591 296 166 148 118 99 84 74

*Compensated hardness in gpg = Hardness + (3 x Fe in mg/l)

Disc Selection

(Compensated Hardness*)

6 13252730353740

55555555

F25407 (February 2011)Page 9 of 16

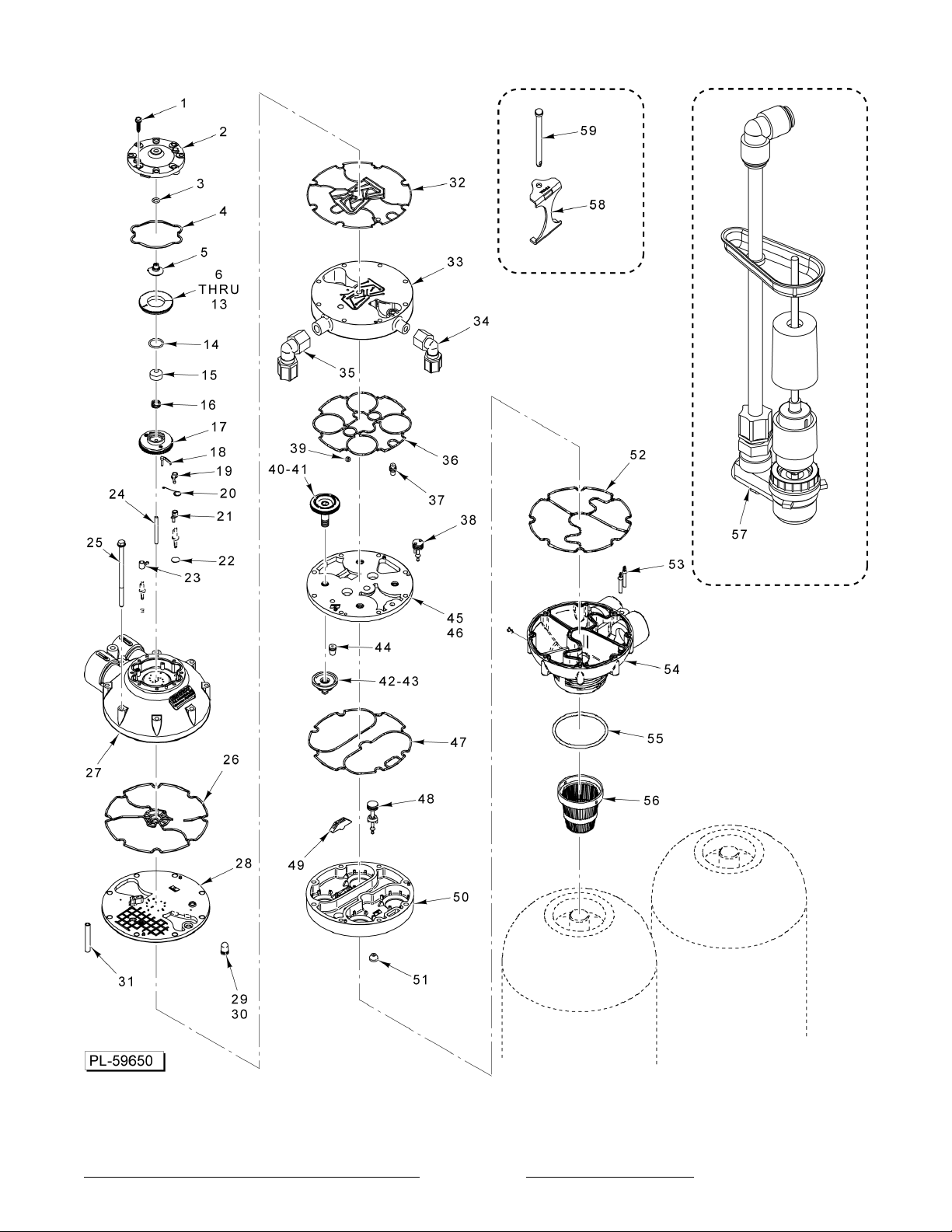

REPLACEMENT PARTS

Item

Number

1 00-913091-130 Cord Phone 7ft. 1

2 00-913091-129 Sensor Salt Alarm 1

3 00-913091-128 Salt Alarm Assy. 1

Part Number Description Qty.

F25407 (February 2011) Page 10 of 16

F25407 (February 2011)Page 11 of 16

Item

Number

1 00-913091-00067 Cap Screw 8

2 00-913091-00080 Cap 1

3 00-913091-00069 O-Ring (Actuator) 1

4 00-913091-00071 Seal – Cap 1

5 00-913091-00070 Actuator 1

6 00-913091-00072 Meter Disc 1 1

7 00-913091-00073 Meter Disc 2 1

8 00-913091-00074 Meter Disc 3 1

9 00-913091-00075 Meter Disc 4 1

10 00-913091-00076 Meter Disc 5 1

11 00-913091-00077 Meter Disc 6 1

12 00-913091-00078 Meter Disc 7 1

13 00-913091-00079 Meter Disc 8 1

14 00-913091-00009 O-Ring (Balance Piston) 1

15 00-913091-00008 Piston – Balance 1

16 00-913091-00010 Spring (Balance Piston) 1

17 00-913091-00011 Control Disc 1

18 00-913091-00012 Pawl (No Back) 1

19 00-913091-00013 Pawl – Meter Drive 1

20 00-913091-00014 Spring (Meter Drive Pawl) 1

21 00-913091-00015 Pawl – Regen Start 1

22 00-913091-00061 Filter 1

23 00-913091-00016 Pawl – Regen Drive 1

24 00-913091-00083 Pin – Support 1

25 00-913091-00085 Screw (Level 1) 8

26 00-913091-00017 Seal – Red (Level 1) 1

27 00-913091-00135 Level 1 Assy. 1

28 00-913091-00020 Level 2 1

29 00-913091-00021 Brine Flow Control (0.3 GPM) 1

30 00-913091-00022 Brine Flow Control (0.4 GPM) 1

31 00-913091-00100 Tube – Vent 1

32 00-913091-00023 Seal – Red (Level 2) 1

33 00-913091-00024 Level 3 1

34 00-913091-00087 Elbow – Brine 1

35 00-913091-00086 Elbow – Drain 1

36 00-913091-00025 Seal – Red (Level 3) 1

37 00-913091-00026 Venturi Throat (Dark Blue) 1

38 00-913091-00028 Control Valve (With Quad Ring) 1

39 00-913091-00097 Regeneration Flow Control 1

40 00-913091-00089 Main Piston (Incls. Item 41) 4

41 00-913091-00090 Quad Ring (Main Piston) 4

42 00-913091-00092 Valve Seat – Main (Incls. Item 43) 4

43 00-913091-00093 Seal – Main Valve 4

44 00-913091-00030 Backwash Flow Control 1

45 00-913091-00091 Level 4 1

46 00-913091-00027 Level 4 Assy. 1

47 00-913091-00031 Seal – Red (Level 4) 1

48 00-913091-00033 Drain Valve (With Quad Ring) 1

Part Number Description Qty.

F25407 (February 2011)

Page 12 of 16

Item

Number

49 00-913091-00035 Interlock 1

50 00-913091-00032 Level 5 1

51 00-913091-00034 Seal – Drain Valve 1

52 00-913091-00039 Seal – Main Base (Level 6) 1

53 00-913091-00040 Check Stems 1

54 00-913091-00037 Level 6 1

55 00-913091-00101 Ring – Main Base 1

56 00-913091-00041 Upper Distributor 1

57 00-913091-00133 Brine Valve Assy. 1

58 00-913091-00019 Bracket - Adapter 1

59 00-913091-00018 Pin – Cotterless Clevis 1

- - - 00-913091-00134 Complete Head Assy. 1

- - - 00-913091-00098 Drain Tube AR

- - - 00-913091-00099 Brine Tube AR

- - - 00-913091-00105 Back Cover (WS-80) 1

- - - 00-913091-00106 Front Lid (WS-80) 1

- - - 00-913091-00108 O-Ring In/Out 4

- - - 00-913091-00109 Caster Wheel (8mm) 4

- - - 00-913091-00044 Hose - In/Out 2

Part Number Description Qty.

Page 13 of 16

F25407 (February 2011)

- NOTES -

F25407 (February 2011) Page 14 of 16

- NOTES -

F25407 (February 2011)Page 15 of 16

- NOTES -

F25407 (February 2011) Printed in U.S.A.

Loading...

Loading...