Page 1

SERVICE MANUAL

WS-500 Water Softening System

Installation Instructions

WS-500

- NOTICE -

This Manual is prepared for the use of trained Hobart Service

Technicians and should not be used by those not properly

qualified.

This manual is not intended to be all encompassing. If you have

not attended a Hobart Service School for this product, you should

read, in its entirety, the repair procedure you wish to perform to

determine if you have the necessary tools, instruments and skills

required to perform the procedure. Procedures for which you do

not have the necessary tools, instruments and skills should be

performed by a trained Hobart Service Technician.

The reproduction, transfer, sale or other use of this Manual,

without the express written consent of Hobart, is prohibited.

This manual has been provided to you by ITW Food Equipment

Group LLC ("ITW FEG") without charge and remains the property

of ITW FEG, and by accepting this manual you agree that you will

return it to ITW FEG promptly upon its request for such return at

any time in the future.

A product of Hobart Service 701 S. Ridge Ave Troy, OH 45374

F25405 Rev. A (0913)

Page 2

WS-500 Water Softening System Installation Instructions

TABLE OF CONTENTS

GENERAL INFORMATION WS-500 ......................................................................... 3

GENERAL WS-500 ..................................................................................... 3

BY PASS OPTIONS ........................................................................................ 4

BY- PASS VALVE KIT WS-500 ......................................................................... 4

BY- PASS VALVING WS-500 ........................................................................... 8

INSTALLATION ........................................................................................... 10

INSTALLATION WS-500 .............................................................................. 10

BRINE DRUM SETTINGS FOR WS-500 ............................................................... 12

DISC REPLACEMENT .................................................................................... 14

DISC REPLACEMENT WS-500 ........................................................................ 14

DISC SELECTION ........................................................................................ 16

DISC SELECTION WS-500 ............................................................................ 16

© HOBART SERVICE 2013

F25405 Rev. A (0913) Page 2 of 16

Page 3

WS-500 Water Softening System Installation Instructions - GENERAL INFORMATION WS-500

GENERAL INFORMATION WS-500

GENERAL WS-500

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Determine location to install equipment. Make

sure the unit will be on a flat surface.

2. If sand, silt, or turbidity is present, install a

separate prefilter.

NOTE: Sediment filtration is recommended before

the water softener, particularly in areas with known

sediment issues or on a private water supplies.

NOTE: If the peak flow rate required is unknown, a

prefilter with a minimum of 1.25" connections should

be used. Filters with 5 micron nominal ratings should

be considered the standard in food service

applications.

3. If the optional by-pass valve kit is being installed,

follow steps listed under BY- PASS VALVE KIT

WS-500 . If bypass valve kit is not being installed

proceed to BY- PASS VALVING WS-500.

Page 3 of 16 F25405 Rev. A (0913)

Page 4

WS-500 Water Softening System Installation Instructions - BY PASS OPTIONS

BY PASS OPTIONS

BY- PASS VALVE KIT WS-500

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. To install by-pass valve determine which port on

the by-pass valve (Port A or Port B) to plumb the

raw water connection to.

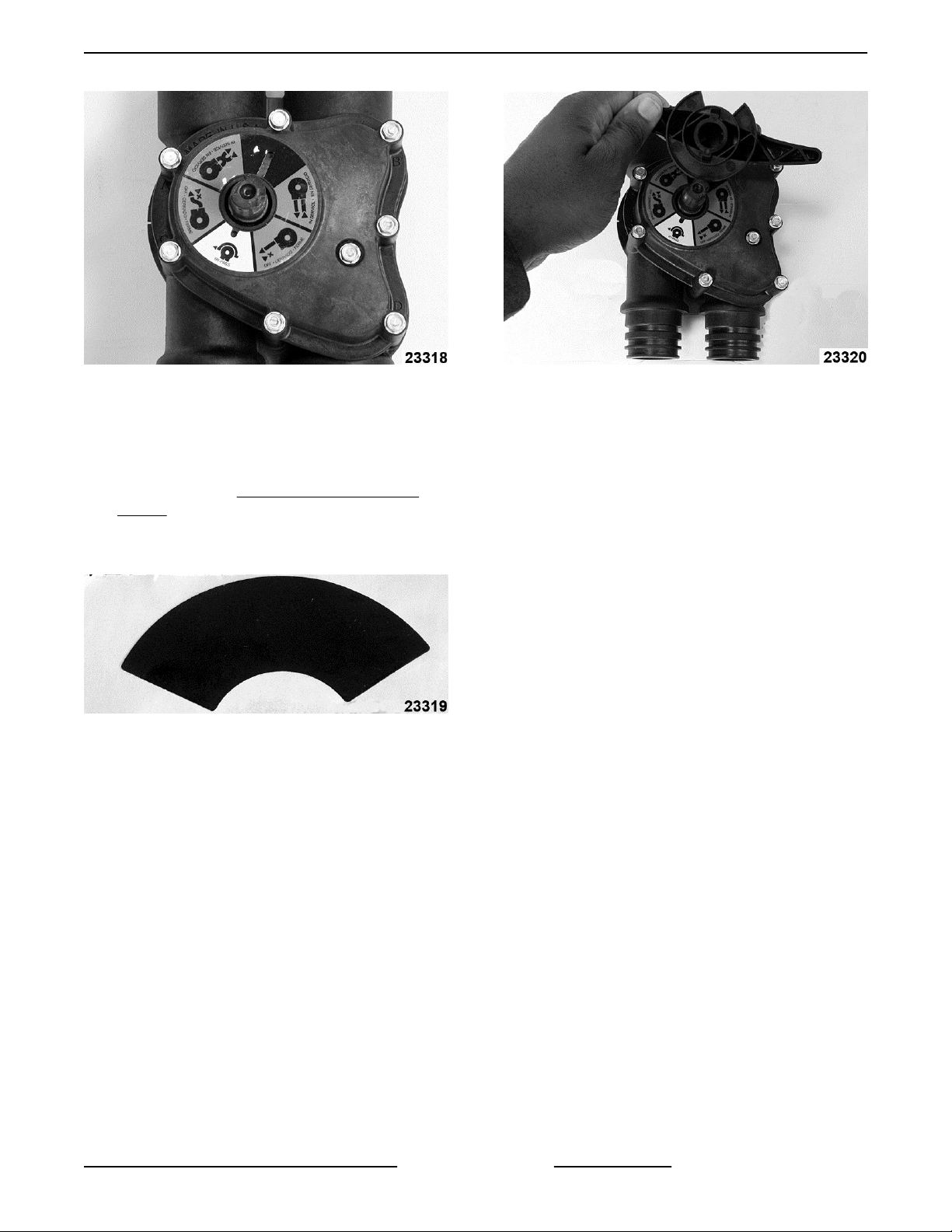

Fig. 3

4. Remove the by-pass valve handle by pulling it

away from the by-pass valve body.

Fig. 1

2. Determine which port on the by-pass valve (Port

C or Port D) to connect the softener.

Fig. 2

3. Verify the by-pass valve is in the by-pass

position. Turn by-pass handle to reveal yellow

by-pass segment.

Fig. 4

5. The five position valve has two installation

configuration options. Photo below shows the

crossover and parallel configurations as the

valve is shipped.

NOTE: When installing the five position valve - be

certain to select the proper mode and install

configuration (parallel or crossover).

F25405 Rev. A (0913) Page 4 of 16

Page 5

WS-500 Water Softening System Installation Instructions - BY PASS OPTIONS

Fig. 5

6. Locate patch decal provided with by-pass valve

kit.

7. Remove patch decal from paper lining and apply

to body of the by-pass valve based on the specific

installation using BY- PASS VALVE DECAL

TABLE.

NOTE: For use in A-D or B-D configuration, it will be

necessary to cut patch.

Patch Decal

8. Align the handle with the shaft until handle slides

onto shaft. Push down on handle until it snaps

into place.

NOTE: The handle is keyed allowing it to go on the

shaft only one way. Failing to perform above

procedure can result in breaking the shaft inside the

handle. Do not force handle onto shaft.

Fig. 7

NOTE: When installing a plastic component in line, it

is recommended that grounding straps be put in place

before the lines are actually cut to ensure the ground

is never broken.

9. Prepare plumbing by roughing in.

10. Connect the inlet/outlet adapters to the plumbing.

Solder or glue adapters to pipe as applicable.

NOTE: Do not solder adapters while in the by-pass

valve.

NOTE: Care should be taken during the installation

process to assure that solder flux does not come in

contact with the media tanks, the control module, and

related components.

11. After all plumbing is completed and before

connecting any equipment, flush both inlet and

outlet lines by opening the raw water inlet valve

and allowing water to rinse out and debris in the

line.

12. Close the raw water line when complete.

13. Locate from the by-pass kit the two elbows, four

O-rings, two E-Clips and silicone packet.

Page 5 of 16 F25405 Rev. A (0913)

Page 6

WS-500 Water Softening System Installation Instructions - BY PASS OPTIONS

Fig. 8

14. Apply a liberal amount of silicone to the four

Orings and install on the two end spaces on both

Port C and Port D of the By - Pass Valve.

Fig. 9

15. Insert mesh screens into left and right elbows.

Fig. 11

17. Apply a liberal amount of silicone to the four

Orings and install them on the two outermost

groves on both elbows

NOTE: Elbows are marked left (L) and right (R). When

applying to by-pass valve be certain to install in correct

location based on left/right orientation.

Fig. 12

NOTE: Make sure to align the center slot (the slot with

the small triangle underneath it) with the outside of the

by pass valve.

18. Connect elbows from the by-pass valve to

19. Connect the by-pass valve to the inlet/outlet

20. Plumb as necessary to accommodate the bypass

Fig. 10

16. Locate from the by pass kit the four O-rings, two

E-Clips and silicone packet

F25405 Rev. A (0913) Page 6 of 16

softener using E-clips. Press E-clips until they

securely snap in place.

adapters. Press E-clips until they securely snap

in place.

valve and to complete the installation.

Page 7

WS-500 Water Softening System Installation Instructions - BY PASS OPTIONS

21. Locate enclosed kit containing four O-rings, two

pipes with O-rings, and the silicone packet. Apply

a liberal amount of silicone to the four Orings and

the O-rings in the two pipes. Install the four Orings to the inlet/outlet adapters.

NOTE: Be certain the E-clips are fully inserted into

the valve. Check to make sure that all three tabs on

the E-clips are fully inserted.

Fig. 13

Fig. 14

Page 7 of 16 F25405 Rev. A (0913)

Page 8

WS-500 Water Softening System Installation Instructions - BY PASS OPTIONS

Fig. 15

BY- PASS VALVE DECAL TABLE

MODE RAW INLET SOFTENER INLET

A-C A C PARALLEL 2

B-C B C CROSSOVER 3

A-D A D CROSSOVER 4

B-D B D PARALLEL 5

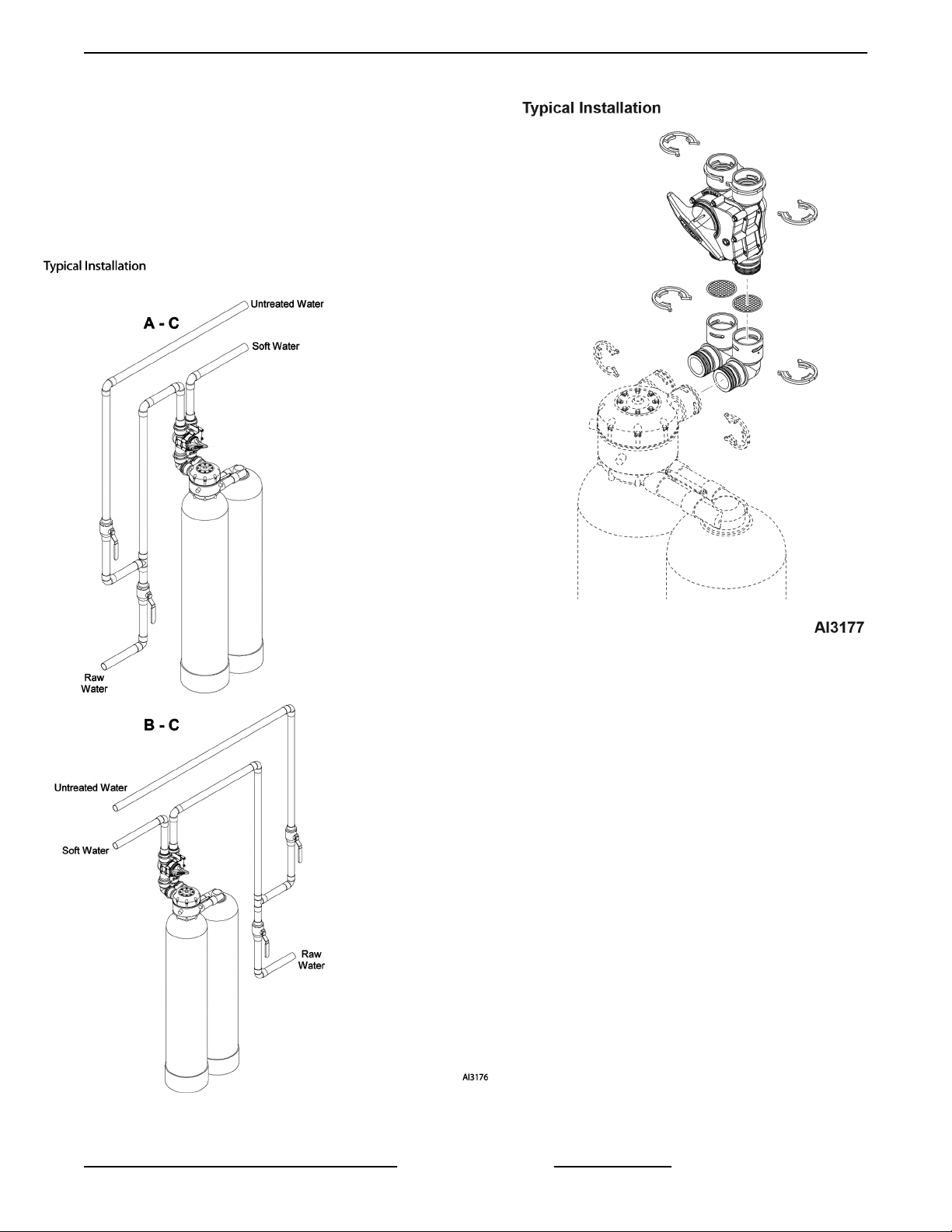

BY- PASS VALVING WS-500

NOTE: If optional by-pass valve kit is not installed - it

is recommended that by-pass valving be installed. To

install by-pass valving - follow steps listed below.

1. Install by-pass valving. Be certain to note the inlet

and outlet arrows on the valve head.

2. Connect the inlet/outlet adapters leading to the

softener using the proper size plumbing.

3. Plumb as necessary to accommodate the bypass

valving and to complete the installation.

NOTE: Do not solder brass adapters while inserted

in the module base. Damage to plastic and ruber parts

may result due to the heat. In addition, the materials

used in the soldering process may attack certain types

of plastics.

NOTE: Care should be taken during the installation

process to assure that solder flux do not come in

contact with the media tanks, the control module, and

related components.

INSTALL

CONFIGURATION

FIG

NOTE: Actual installation of by-pass valving may vary

from installation to installation. Be sure to follow state

and local codes.

NOTE: When installing a plastic component in line, it

is recommended that grounding straps be put in place

before the lines are actually cut to ensure the ground

is never broken.

F25405 Rev. A (0913) Page 8 of 16

Page 9

WS-500 Water Softening System Installation Instructions - BY PASS OPTIONS

Fig. 16

4. After all plumbing is completed, but before

connecting equipment, flush both the inlet and

outlet lines by opening the by-pass valve and

allowing water to rinse out any debris in the lines.

5. Connect the main tank with softener valve to the

inlet/outlet adapter. The inlet/outlet adapter is

inserted into the control valve and locked in place

by the plastic E-clips.

Page 9 of 16 F25405 Rev. A (0913)

Page 10

WS-500 Water Softening System Installation Instructions - INSTALLATION

INSTALLATION

INSTALLATION WS-500

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Connect the remote tank to the main tank using

connector pipes, connector links and connector

pins.

Fig. 17

NOTE: Always use both links and pins.

2. Run a drain line to the discharge point.

NOTE: Follow state and local codes.

3. Before connecting unit, check for obstructions or

kinks. Apply Teflon tape to pipe threads on side

of softener valve, and install the two fittings

supplied. Connect drain line to valve.

NOTE: An air gap must be provided for all drain lines.

Check state and local plumbing codes for proper setup

of drain line air gaps.

NOTE: On drain lines that must travel more than 8

feet up and 30 feet over, it is best to take the 5/8" drain

line that fits the valve and attach it in a larger diameter

line or pipe.

4. Position the brine drum.

NOTE: Brine drum should be conveniently positioned

to allow salt to be added.

Fig. 18

5. To install salt alarm system - remove paper lining

from back of salt alarm sensor.

F25405 Rev. A (0913) Page 10 of 16

Fig. 19

Page 11

WS-500 Water Softening System Installation Instructions - INSTALLATION

6. Remove plastic lining from Velcro® backing

located on back of salt alarm controller.

Fig. 22

Fig. 20

7. Remove four screws securing back cover to salt

alarm controller.

Fig. 21

8. Install three (3) AA batteries into salt alarm

controller.

NOTE: When installing batteries - be certain to

inspect connector to ensure it is secure.

9. Re-install back cover to salt alarm controller.

10. Using the adhesive backing on both devices place alarm controller and salt alarm sensor in a

position that will allow salt alarm controller to be

seen and heard when it is activated.

11. Insert phone cable into salt alarm sensor and salt

alarm controller.

NOTE: Salt alarm controller can be mounted up to

100 feet from salt alarm connector box using standard

phone cable from local retailers (7 foot cable is provide

with kit).

Fig. 23

12. Check for proper operation by pressing the

recessed red button on bottom of salt alarm

controller. If controller is operating properly - the

indicator light will flash and an audible tone will

be heard.

Page 11 of 16 F25405 Rev. A (0913)

Page 12

WS-500 Water Softening System Installation Instructions - INSTALLATION

Fig. 24

BRINE DRUM SETTINGS FOR

WS-500

NOTE: In Hobart Softeners, the brine drum mixes and

stores a solution of salt for regeneration of the softener

media. During the brine rinse cycle, this solution is

drawn from the brine drum and through the media to

regenerate it.

NOTE: The brine drum contains an adjustment to

draw the correct amount of salt (brine) solution for

each cycle. This adjustment is made in two places, the

adjuster tube and the float cup.

NOTE: The adjuster tube measures the amount of

solution that is drawn from the brine drum into the

softener during the brine rinse cycle. The float cup

height determines how much softened water flows

back into the brine drum to prepare for the next

regeneration.

NOTE: The adjuster tube is set by cutting and

removing tabs on both sides of the tube. Cut across

each tab horizontally, following the channel in the

plastic. Break off each tab individually until the proper

setting is reached. The remaining number or letter

imprinted on the tab determines the correct setting.

Fig. 25

NOTE: The float cup height determines how much

softened water flows back into the brine drum to

prepare for the next regeneration.

NOTE: The float cup is set by adjusting its height

above the bottom of the Brine Valve Assembly. By

removing the brine valve assembly and resting it on a

flat surface, the height of the float cup can be

measured with a ruler. The height is measured from

the base of the brine valve assembly to the top of the

float cup.

NOTE: Standard settings are defined by markings on

the rod of the brine valve assembly. Where the

predefined settings are not adequate, the actual float

cup height must be measured and the setting must be

measured and set according to the measured float cup

height.

F25405 Rev. A (0913) Page 12 of 16

Page 13

WS-500 Water Softening System Installation Instructions - INSTALLATION

Brine Valve Settings for WS-500: 24 x 40 Brine

Valve Adjustment

Adjuster Tube K

Float Cup 12"

NOTE: Do not drop the brine valve into the drum.

Dropping may lower the float cup, resulting in an

improper setting.

NOTE: After the adjustments have been made to the

adjuster tube and the float cup, the brine valve

assembly must be installed in the brine drum. Locate

the brine valve in the brine well so the 3/8" bent tube

is along the back of the brine well away from the brine

drum wall. The 3/8" bent tube snaps into a notch and

extends from the brine drum about 1 inch.

Fig. 26

NOTE: Determining the correct brine valve setting for

a particular application is a three step process:

1. Determine the compensated hardness. This

requires a hardness test and an iron test on raw

water at the application site. Compensated

hardness is calculated by multiplying the ferrous

iron (in ppm) by 3 and adding it to the grains of

hardness.

2. To test the water supply, use the water analysis

test kit available through Pro Products Inc. The

recommended kit is #2404 Deluxe Field Analysis

Kit. To order the test kit contact Pro Products at

800-285-9176 or visit www.ProProducts.com

3. Set the adjuster tube and float cup. Use the brine

drum specifications for the WS-500 to determine

the correct settings for both the adjuster tube and

the float cup height.

Brine Valve Settings for WS-500: 24 x 40 Brine

Valve Adjustment

Salt Setting 25 lbs.

Page 13 of 16 F25405 Rev. A (0913)

Page 14

WS-500 Water Softening System Installation Instructions - DISC REPLACEMENT

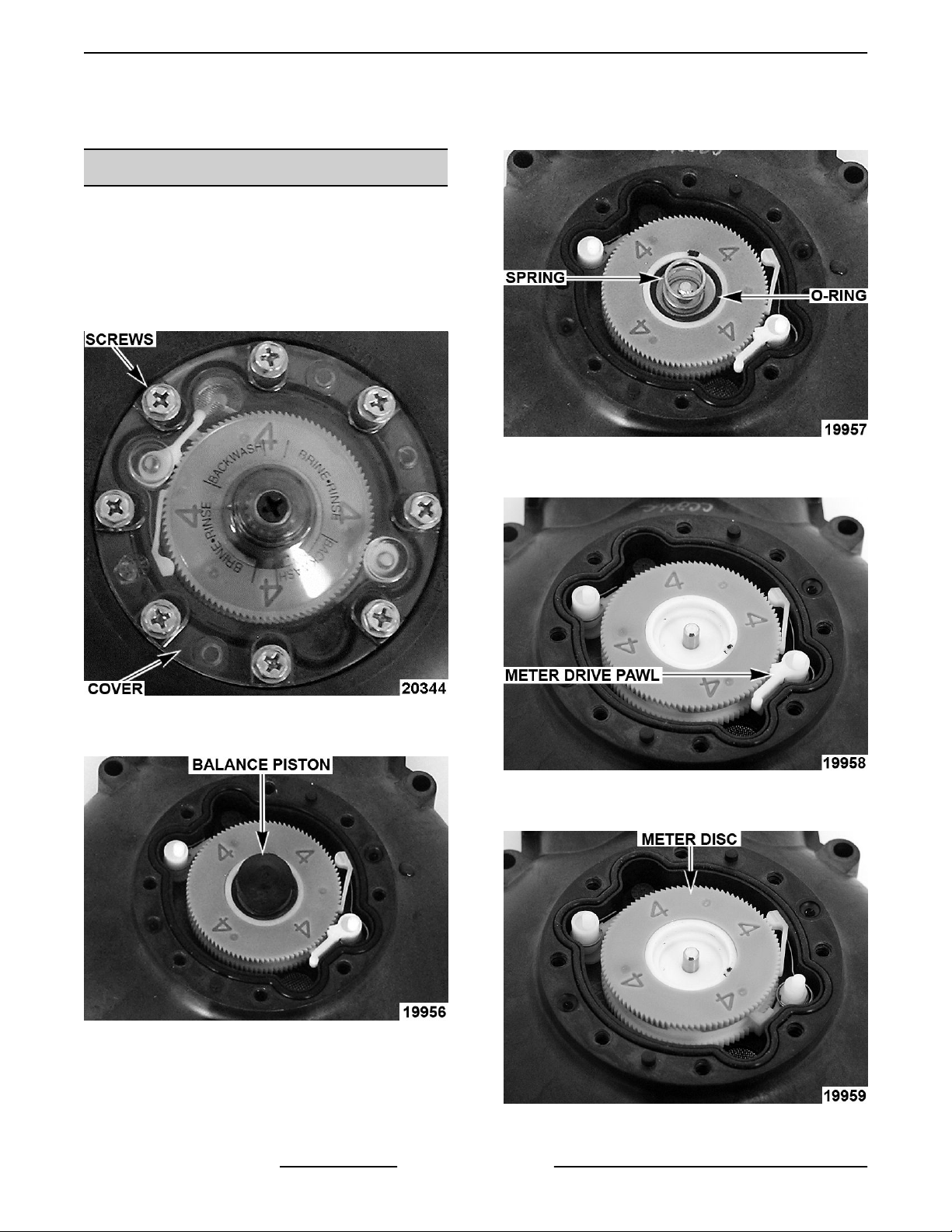

DISC REPLACEMENT

DISC REPLACEMENT WS-500

NOTE: The WS-500 comes with a #4 meter disc

installed at the factory. If this is not the correct disc for

a given application, locate the meter disc kit and install

the correct disc

1. To change disc, remove screws and cap cover

from level one

Fig. 29

4. Remove meter drive pawl.

Fig. 27

2. Remove balance piston.

Fig. 28

3. Remove balance piston o-ring and balance

piston spring.

Fig. 30

5. Remove meter disc.

Fig. 31

F25405 Rev. A (0913) Page 14 of 16

Page 15

WS-500 Water Softening System Installation Instructions - DISC REPLACEMENT

6. Install correct meter disc and reassemble in

reverse order.

NOTE: Make certain all components are correctly

installed.

NOTE: Be certain to start cap screws by hand rotating

backwards until screw drops into thread then tighten.

An alternating, crossing pattern should be used while

tightening cap screws to ensure correct cap fit. Add a

clean grade of salt at this time. Higher grades of

Pelletized Salt for impurities and solubility should be

used.

NOTE: Do not use rock salt or solar salt.

NOTE: On iron-bearing water, a salt that contains

resin cleaning additives is recommended.

7. Open the inlet valve slowly and allow the tanks to

fill slowly with water. Water will run at the drain

until unit is full and pressurized.

8. With the unit in service and under pressure, allow

the brine drum to fill with water until the brine

valve shuts off.

9. After the unit is fully pressurized, purge air form

the lines by opening soft water outlet.

NOTE: When brine drum overflow could cause

damage, a ½" I.D. overflow line must be installed on

the barbed overflow fitting on drum and connected to

a drain. Make sure drain is not higher than barbed

fitting.

10. Check for plumbing leaks.

11. Check unit for proper operation.

Page 15 of 16 F25405 Rev. A (0913)

Page 16

WS-500 Water Softening System Installation Instructions - DISC SELECTION

DISC SELECTION

DISC SELECTION WS-500

Using the full louver nozzle, the amount of hardness removed (in compensated gpg) will be based on the amount

of brine and the meter disc selected.

Specifications WS-500 Overdrive Operation Alternating Operation

Salt usage / generation 25 lbs. 25 lbs.

Capacity 70,00 grains 70,00 grains

Efficiency 2,800 gr./lb. 2,800 gr./lb.

Dosing 10.0 lbs./cu. ft. 10.0 lbs./cu. ft.

Float cup setting 12" 12"

OVERDRIVE OPERATION WS-500 Disc Selection

Disc Number 1 2 3 4 5 6 7 8

Compensated Hardness * 6 12 16 20 24 30 35 40

Peak Flow During

Regeneration

* Compensated hardness in gpg = Hardness + (3 x Fe in ppm)

28.0 28.0 28.0 20.7 15.7 12.4 10.0 8.3

ALTERNATING OPERATION WS-500 Disc Selection

Disc Number 1 2 3 4 5 6 7 8

Compensated Hardness * 7 14 21 28 34 40 45 51

Gallons Between

Regeneration

Regeneration Gallons

Per Minute @ 15 psig

* Compensated hardness in gpg = Hardness + (3 x Fe in ppm)

8,922 4,461 2,974 2,231 1,784 1,487 1,275 1,115

20 20 20 20 15.7 12.4 10.0 8.3

F25405 Rev. A (0913) Page 16 of 16

Loading...

Loading...