Hobart WPR1200 Installation Manual

TM

WPR1200 WastePro

Remote

WASTE EQUIPMENT SYSTEM

MODEL

WPR1200 ML-130047

WP6 ML-130048

WP9 ML-130049

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

937 332-3000

www.hobartcorp.com

FORM 44023 (Mar. 2005)

TABLE OF CONTENTS

GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

UNPACKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

LOCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

VIBRATION ISOLATION FOOTPADS AND LEVELING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

CHEMICAL FEEDER PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

THE FOLLOWING PARTS MAY BE INCLUDED (DEPENDING ON OPTIONS SELECTED) . 4

SILVER SAVER — BY OTHERS (TROUGH EQUIPPED UNITS ONLY) . . . . . . . . . . . . . . . . . 5

TROUGH GASKET (TROUGH EQUIPPED UNITS ONLY) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

OPTIONAL MAGNET FOR SILVER SAVER (TROUGH EQUIPPED UNITS ONLY) . . . . . . . . 5

TROUGH PIPING DETAIL (TROUGH EQUIPPED UNITS ONLY) . . . . . . . . . . . . . . . . . . . . . . 6

FLANGE DETAIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

PULPER INSTALLED UNDER A DISH TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

PLUMBING CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

PULPER — FRESH WATER CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

PULPER — DRAIN CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

WATERPRESS — FRESH WATER CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

WATERPRESS — AUTO-RINSE DRAIN CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

SLURRY LINE, RETURN LINE, ETC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

PLUMBING INSTALLATION REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

ELECTRICAL CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

PRESSURIZED AIR LINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

REMOTE PUSH-BUTTON STATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

MOTOR ROTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

ELECTRICAL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

ELECTRICAL INSTALLATION DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

FEEDING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

SHUTDOWN PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

CLEANING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

CLEANING COMPOUNDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

MOTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

WATERPRESS DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

WATERPRESS TOP BEARING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

© HOBART 2004, 2005

–2–

Installation, Operation and Care of

TM

WPR1200 WastePro

Remote

WASTE EQUIPMENT SYSTEM

SAVE THESE INSTRUCTIONS

GENERAL

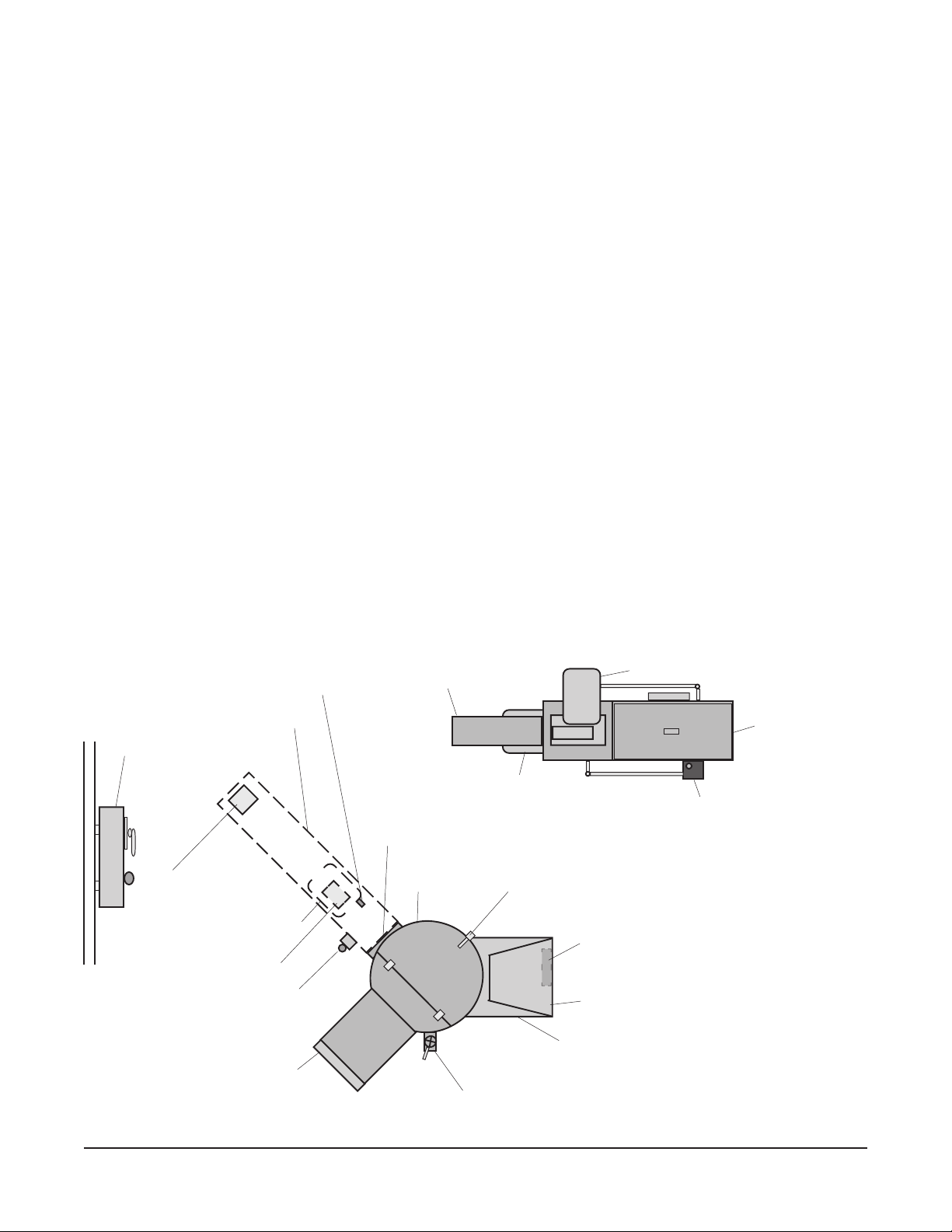

The WPR1200 WasteProTM Remote Waste Equipment System prepares waste materials for disposal

using one or more WPR1200 pulpers, a piping system and a waterpress. Paper, plastic, foil and food

waste are fed into the pulper, shredded into small pieces in water to make a slurry. The waterpress

lifts the slurry using a stainless steel screw inside of a perforated tubular screen. The water passes

through the screen and is pumped back to the pulper. The solids continue up the screw where they

are further compacted to a semi-dry pulp, exiting through the discharge chute to a waste container.

Fresh make-up water is supplied to the pulper automatically through a solenoid valve controlled by a

water level sensor. The original volume of waste material is reduced significantly.

The pulper has a 6 h.p. motor, stainless steel components, carbide and hardened stainless steel

shredder blades. The waterpress can be model WP6 or model WP9 depending on volume, layout and

piping requirements. The waterpress has a motor that turns the stainless steel screw and a pump that

returns process water to the pulper; motors are sized for system requirements.

An optional feed tray (by Hobart) allows waste materials to be fed into the pulper. A feed trough

(fabricated by tabling suppliers) allows waste materials and water to feed through an optional watertight opening into the pulper. A flush nozzle with throttling valve (by Hobart) is an available option for

the front end of the trough. A silver-saver sink (by others) can be installed in the feed trough; a silver

saver magnet is an available option (by Hobart). Mounted below the sink, it restrains ferro-magnetic

objects from entering into the pulper.

1

/2 X 1" PIPE — DRAIN FLUSH

FEED TROUGH (BY OTHERS)

WALL-MOUNTED

CONTROL BOX

FLUSH NOZZLE

SILVER SAVER SINK

(BY OTHERS)

MAGNET

REMOTE PUSHBUTTON STATION

FEED TRAY (ALTERNATE

POSITIONS AT 45° ANGLES)

DISCHARGE CHUTE

RETURN PUMP MOTOR

FEED TROUGH CONNECTION (ALTERNATE

POSITIONS AT 45° ANGLES)

PULPER

HINGED COVER / LID LATCH (OPPOSITE

FEED TROUGH OR FEED TRAY)

MACHINE CONTROL BOX

WATER SUPPLY CONNECTIONS

PULPER MOTOR HOUSING

DRAIN VALVE

WATERPRESS MOTOR

WATERPRESS

CHEMICAL FEEDER PUMP

Fig. 1

–3–

INSTALLATION

Prior to installation, test the electrical service to assure that it agrees with the specifications on the

machine data plate located on the front of the pulper.

UNPACKING

Immediately after unpacking, check for possible shipping damage. If the unit is found to be damaged,

save the packaging material and contact the carrier within 15 days of delivery.

LOCATION

1

Locate the waste system near a floor drain; floor should be pitched a minimum of

drain. A suitable amount of space should be provided for machine operation, cleaning and service.

VIBRATION ISOLATION FOOTPADS AND LEVELING

Vibration isolation footpads (standard — Fig. 2) must be installed on each

of the legs of the pulper(s) and waterpress before making connections.

Level the units by threading the adjustable feet up or down as necessary.

CHEMICAL FEEDER PUMP (STANDARD)

/4" per foot to the floor

LEG

ADJUSTABLE

FOOT

Fig. 2

RUBBER

FOOTPAD

The chemical feeder pump is mounted on the waterpress. It has its own on-off switch. When on, the

chemical feeder pumps a chemical additive into the waterpress to control odors, to buffer the acidity

of the system water and to reduce foaming. Contact your chemical supplier for a recommendation for

the appropriate chemical additive. The recommended chemical pump setting is #1 which delivers 0.3

gallons per day. Each subsequent setting number is a direct multiple of setting #1. For example,

setting #2 delivers 0.6 gallons per day, etc.

Two pieces of polyethylene tubing with pre-assembled tubing fittings, provided with the system, must

be connected to the chemical feeder pump during installation. Tubing fittings must be properly

tightened but not over-tightened. Connect the short piece to the output line on the chemical feeder

pump and to the fitting on top of the waterpress. Connect the long piece to the chemical feeder supply

line and insert the other end into the container of chemical additive.

THE FOLLOWING PARTS MAY BE INCLUDED (DEPENDING ON OPTIONS SELECTED)

1

/2" Brass Valves: for feed tray flush (option) and for the feed trough flush (option).

21

1 Nozzle for trough flush, rectangular piece has pipe thread with locknut on back.

1 Magnet (option) for silver saver sink.

6 Black Rubber Vibration Isolators for the legs; and a package of

6 Stainless steel screws (

10-32 x 1

1

/2") with nuts, washers and lockwashers.

1 Black Rubber Gasket with slit curtain for trough opening; which also includes approximately

16 Stainless steel screws (

10-32 x

1

/2") with nuts, washers and lockwashers.

1 Push-button Station with Start, Stop and Empty/Run switches (second p/b station is an option).

2 Remote Control Box (for wall mounting).

1

/2" SST Nipple for Silver Saver Flush

1

–4–

SILVER SAVER — BY OTHERS (TROUGH EQUIPPED UNITS ONLY)

Connect the hose, provided, with a hose clamp to the stainless steel pipe nipple (

1

/2" I.D. x 1" long,

provided) on the silver saver for drain flush line.

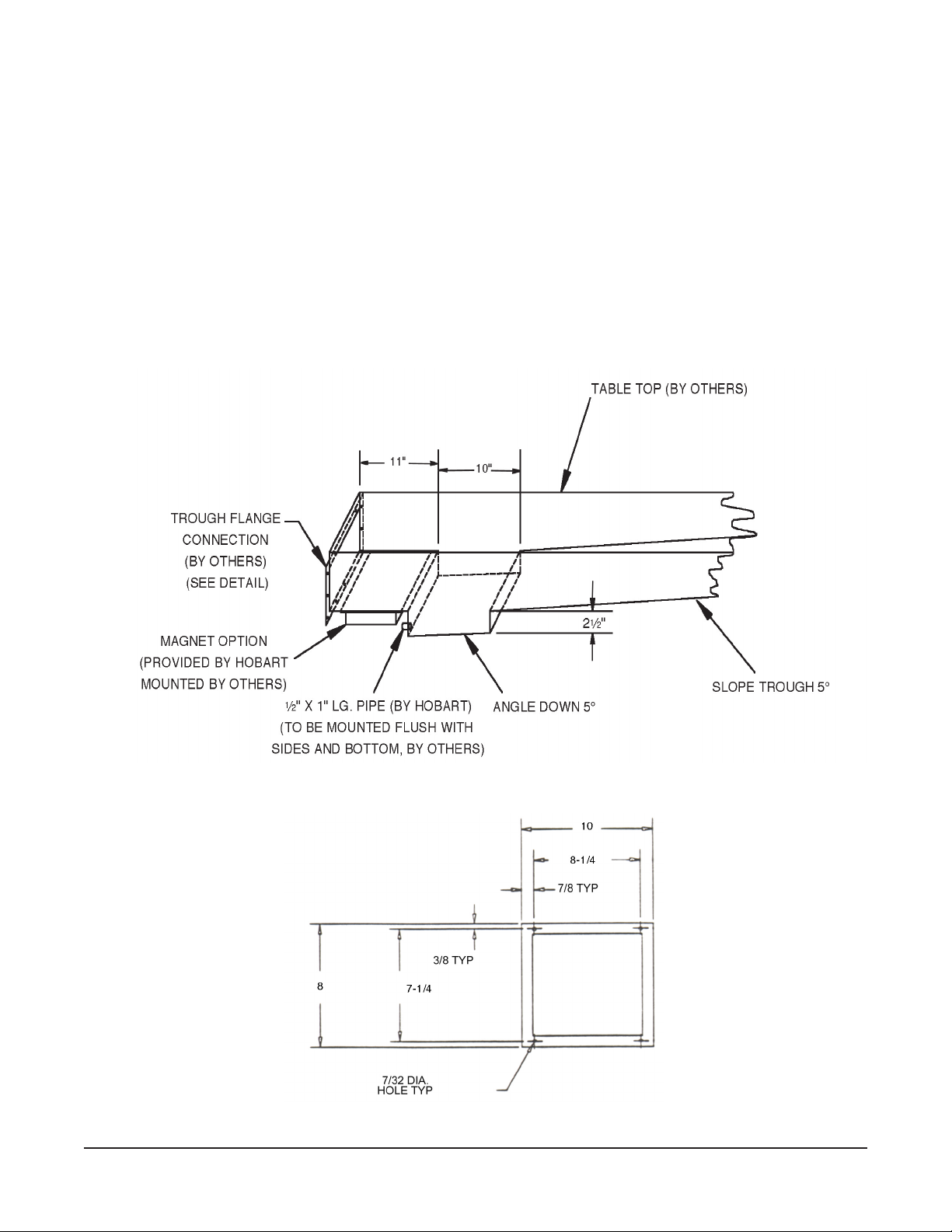

TROUGH GASKET (TROUGH EQUIPPED UNITS ONLY)

Install the trough gasket between the pulper's Trough Flange and the trough's outlet. Drill a hole pattern

in the pulper's Trough Opening flange to match the holes in the hole pattern in the trough outlet flange;

secure with the provided hardware.

OPTIONAL MAGNET FOR SILVER SAVER (TROUGH EQUIPPED UNITS ONLY)

Install the magnet underneath the silver saver by tack welding to the under side. Alternatively, drill

7

four

/32" diameter holes in the silver saver, and secure the magnet with the hardware, provided; seal

the heads of the screws with silicone sealant. Refer to Fig. 3 for position of the magnet; refer to Fig. 4

for mounting detail.

MAGNET MOUNT DETAIL

Fig. 3

Fig. 4

–5–

Loading...

Loading...