Page 1

INSTALLATION &

OPERATION MANUAL

HEAVY DUTY GAS BROILERS

CERAMIC BROILERS

MODELS MLS

GHCB40C ML-52212

GHCB40 ML-52211

GHCB44 ML-52213

HCB2T ML-52203

HCB2B ML-52208

SUNGLOW BROILERS

MODELS MLS

IR2T ML-52207

IR2B ML-52201

GHIR44 ML-52210

For additional information on Vulcan-Hart or to locate an authorized parts andFor additional information on Vulcan-Hart or to locate an authorized parts and

For additional information on Vulcan-Hart or to locate an authorized parts and

For additional information on Vulcan-Hart or to locate an authorized parts andFor additional information on Vulcan-Hart or to locate an authorized parts and

service provider in your area, visit our website at www.vulcanhart.comservice provider in your area, visit our website at www.vulcanhart.com

service provider in your area, visit our website at www.vulcanhart.com

service provider in your area, visit our website at www.vulcanhart.comservice provider in your area, visit our website at www.vulcanhart.com

TECHNICAL SERVICE AND PARTS ASSISTANCE

MODEL GHCB40

1-800-814-2028

VULCAN-HART

DIVISION OF ITW FOOD EQUIPMENT GROUP, LLC

WWW.VULCANHART.COM

3600 NORTH POINT BLVD.

BALTIMORE, MD 21222

FORM 32801 (Sept. 2005)

Page 2

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL GAS

EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP AND

ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE

EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED

FROM THE LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN

UNITS AT MAIN SHUTOFF VALVE AND CONTACT THE LOCAL

GAS COMPANY OR GAS SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPORS OR LIQUIDS IN THE VICINITY OF THIS OR ANY

OTHER APPLIANCE.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THE

INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT.

IN THE EVENT OF A POWER FAILURE, DO NOT ATTEMPT TO

OPERATE THIS DEVICE.

© VULCAN-HART, 2005

– 2 –

Page 3

STOP BOLTS

IMPORTANT

STOP BOLTS MUST BE IN POSITION FOR SAFE OPERATION OF GRID.

IF DAMAGED OR MISSING, REPLACE AT ONCE.

DO NOT OPERATE GRID WITHOUT BOLTS.

– 3 –

Page 4

INSTALLATION, OPERATION AND CARE OF

CERAMIC AND SUNGLOW HEAVY DUTY BROILERS

PLEASE KEEP THIS MANUAL FOR FUTURE USE

GENERAL

The manufacturer suggests that you thoroughly read this entire manual and carefully follow all of the

instructions provided.

Your Vulcan Sunglow or Ceramic Broiler is produced with quality workmanship and material. Proper

installation, usage and maintenance of your broiler will result in many years of satisfactory performance.

INSTALLATION

UNPACKING - ALL BROILER MODELS

This broiler was inspected before leaving the factory. The transportation company assumes full

responsibility for safe delivery upon acceptance of the shipment. Immediately after unpacking, check

for possible shipping damage. If the broiler is found to be damaged, save the packaging material and

contact the carrier within 15 days of delivery.

Remove the small wood slats and wire used to hold burners and broiler grid in place.

Before installing, verify that the electrical service and type of gas supply (natural or propane) agree with

the specifications on the rating plate.

Models Rating Plate Location

IR2 & GHIR44 Cabinet bottom, front right-hand side

GHCB44 Inside cabinet door panel

HCB2 Cabinet bottom, front left-hand side

GHCB40 Oven: behind the kick panel attached to the left side of the oven

burner box front shield, positioned behind the bell crank

Broiler: Front manifold cover

If the supply and equipment requirements do not agree, do not proceed with the installation. Contact

your dealer or Vulcan-Hart immediately.

– 4 –

Page 5

LOCATION

The equipment area must be kept free and clear of combustible substances.

This broiler is design certified for installation with the following minimum clearances from combustible

and noncombustible adjacent wall construction:

COMBUSTIBLE NONCOMBUSTIBLE

MODELS CONSTRUCTION CONSTRUCTION

GHCB40 Back 6" (152 mm) 0"

GHCB40C Right Side 6" (152 mm) 0"

GHCB44 Left Side 6" (152 mm) 0"

Floor 6" (152 mm) 0"

COMBUSTIBLE NONCOMBUSTIBLE

MODEL CONSTRUCTION CONSTRUCTION

GHIR44 Back 4" (102 mm) 0"

Right Side 0" 0"

Left Side 0" 0"

Floor 6" (152 mm) 0"

COMBUSTIBLE NONCOMBUSTIBLE

MODEL CONSTRUCTION CONSTRUCTION

HCB2 Back 4" (102 mm) 0"

Right Side 4" (102 mm) 0"

Left Side 4" (102 mm) 0"

Floor 6" (152 mm) 0"

COMBUSTIBLE NONCOMBUSTIBLE

MODEL CONSTRUCTION CONSTRUCTION

IR2 Back 4" (102 mm) 0"

Right Side 0" 0"

Left Side 0" 0"

Floor 6" (152 mm) 0"

The installation location must allow adequate clearances for servicing and proper operation. A

minimum front clearance of 35" (889 mm) is required.

Do not obstruct the flow of combustion and ventilation air. Adequate clearance for air openings into

the combustion chamber must be provided. Make sure there is an adequate supply of air in the room

to replace air taken by ventilating systems and allow for combustion gas at the broiler burners.

– 5 –

Page 6

INSTALLATION CODES AND STANDARDS - ALL BROILER MODELS

Your broiler must be installed in accordance with:

In the United States

1. State and local codes.

2. National Fuel Gas Code, ANSI/Z223.1 (latest edition). Copies may be obtained from The

American Gas Association, Inc., 1515 Wilson Blvd., Arlington, VA 22209.

3. National Electrical Code, ANSI/NFPA-70 (latest edition). Copies may be obtained from The

National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

In Canada

1. Local codes.

2. CSA B149.1 Natural Gas and Propane Installation Code.

3. CSA C22.1 Canadian Electric Code (latest edition).

The above are available from the Canadian Standard Association, 5060 Spectrum Way, Suite 100,

Mississauga, Ontario, Canada L4W 5N6.

BROILERS MOUNTED ON CASTERS

Broilers mounted on casters must use a flexible connector (not supplied by Vulcan) that complies with

the Standard for Connectors for Movable Gas Appliances, ANSI Z21.69 • CSA 6.16 and a quickdisconnect device that complies with the Standard for Quick-Disconnect Devices for Use With Gas

Fuel, ANSI-Z21.41 • CSA 6.9. In addition, adequate means must be provided to limit movement of the

appliance without depending on the connector and the quick-disconnect device or its associated piping

to limit appliance movement. Attach the restraining device at the rear of the broiler.

If disconnection of the restraint is necessary, turn off the gas supply before disconnection. Reconnect

this restraint prior to turning the gas supply on and returning the broiler to its installation position.

Separate instructions for installing casters to the broiler are included with the casters.

Note: If the broiler is installed on casters and is moved for any reason, it is recommended that the

broiler be releveled front to back and side to side.

UNSTACKING AND STACKING - MODEL GHCB2

Read all instructions carefully before unstacking or stacking broilers.

The height of Models HCB2 and IR2 sometimes prohibits entry through the kitchen facility doorway.

For this reason, two 3

3

/4 x 11/2 x 3/64" (95 mm x 38 mm x 1.2 mm), aluminized stacking straps are shipped

with each broiler for ease of top section disassembly.

Broilers Shipped Pre-stacked

1. Remove top section finishing back.

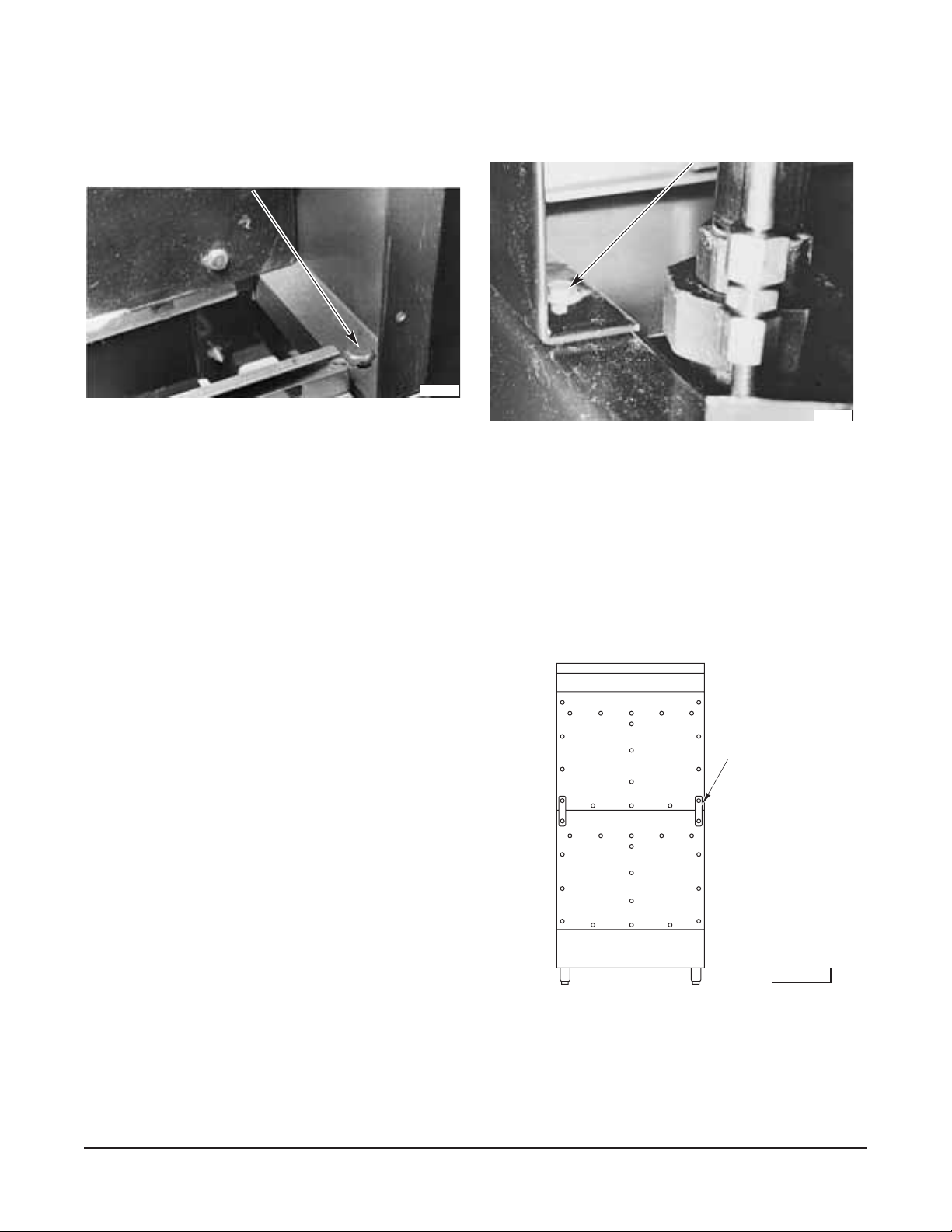

2. From oval slots inside finishing back of the top section, remove two 10-24 bolts which connect

the top and bottom sections (Fig. 1).

– 6 –

Page 7

3. Remove drip pan and disassemble two 10-24 bolts, one to the left and one to the right of the

inside drip pan area, behind the top section front frame (Fig. 2).

PL-41717

PL-41718

Fig. 1 Fig. 2

4. Carefully remove broiler top section from the bottom section.

5. Leaving the lower far-left and right holes open, reassemble the top finishing back onto the top.

Broilers Shipped in Two Pieces for Restacking

The incorporation of the stacking straps will eliminate the use of the two oval slots, one to the left and

one to the right, behind the finishing back of the top section. (See Step 2 under Broilers Shipped PreStacked.)

1. Position broilers as near to installation location

as possible. Remember to allow enough room to

complete stacking procedures.

2. Carefully lift top section and rest it evenly onto

the bottom section.

3. Remove top section drip pan. Align two holes,

STACKING STRAP

one to the left and one to the right of the upper

drip pan area, behind the broiler front frame.

Insert two 10-24 bolts and assemble the top

section to the bottom section.

4. Replace the drip pan.

5. From rear of broiler, remove two 10-24 bolts from

the upper corner of the left- and right-hand bottom

section finishing back.

PL-56559

6. Using four 10-24 bolts, assemble the stacking

strap as shown in Fig. 3. This will complete the

Fig. 3

stacking procedure.

– 7 –

Page 8

DRAFT HOOD INSTALLATION - GHCB40 OR GHCB44

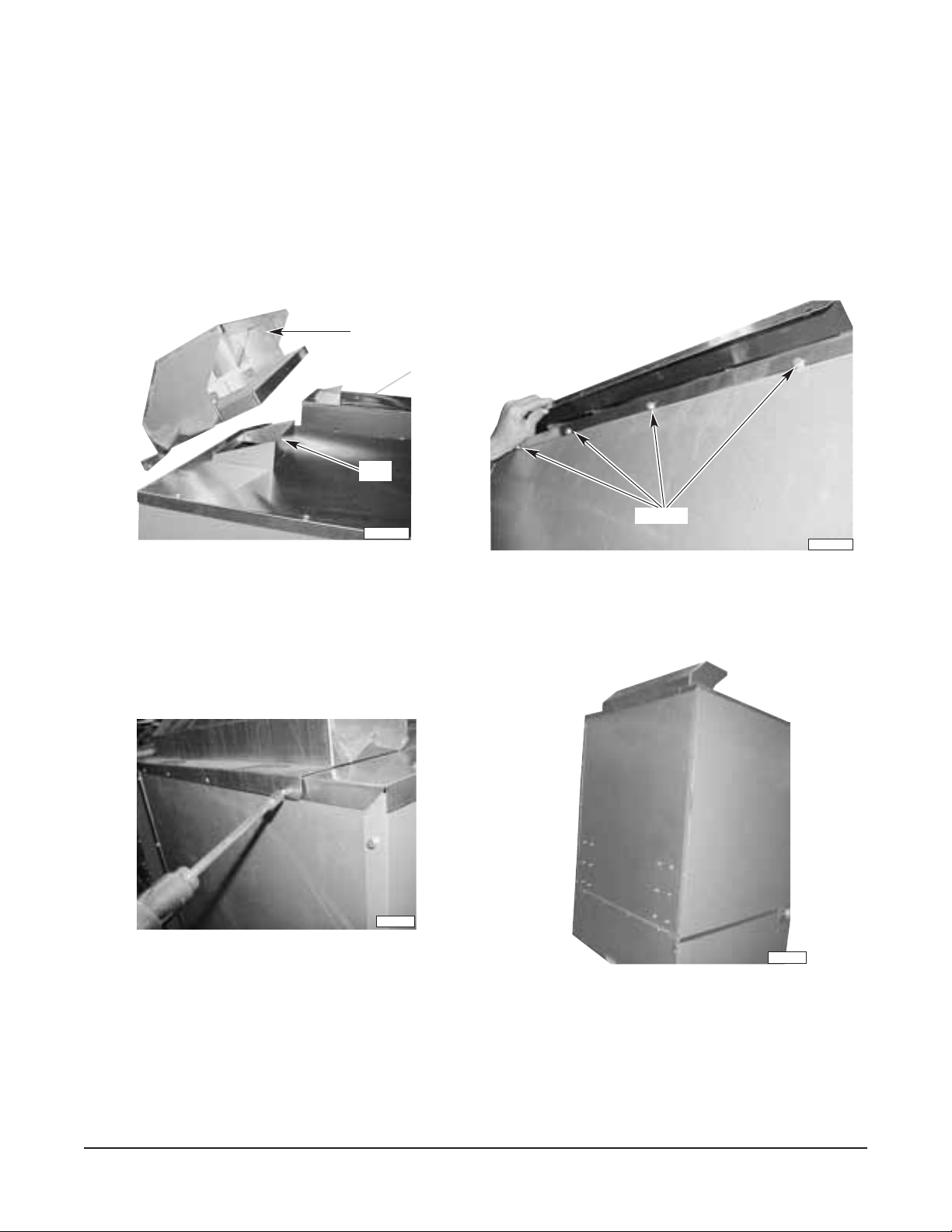

All GHCB40's and GHCB44's come equipped with a hood flue diverter that is packaged and laying in

the top broiler compartment. This flue diverter must be attached to the unit at the time of installation,

following the steps below:

1. If the diverter has protective plastic covering the assembly, remove all the plastic.

2. Place the diverter on top of the unit covering the flue (Fig. 4).

3. Remove four 10-24 sheet metal screws from the top rear flange of the broiler (Fig. 5).

HOOD

FLUE

DIVERTER

FLUE

SCREWS

PL-41719-1

PL-41720-1

Fig. 4 Fig. 5

PL-41721

PL-41722

Fig. 6 Fig. 7

4. Align the four holes/slots in the rear flange of the diverter with the holes in the rear top flange

of broiler, and reinstall four 10-24 sheet metal screws (Fig. 6).

5. Diverter installation is now complete (Fig. 7).

– 8 –

Page 9

Body Side Extensions

Body side extensions are wrapped separately and packaged lying in the top broiler compartment of

each GHCB40/44 Broiler. The use of these extensions is optional. The extensions are intended to help

align the broil battery evenly, front to back, with other Vulcan Heavy Duty Ranges. To install, follow the

steps below:

1. Locate and unwrap the extensions.

SCREWS

PL-41723-1

Fig. 8 Fig. 9

PL-41724

2. Remove five 10-24 sheet metal screws that attach each body side to the broiler back panel

(Fig. 8).

3. Align the holes left by removal of the 10-24 sheet metal screws with predrilled holes in the right

and left body extensions. Secure the extensions to the body sides by reinstalling the five 1024 sheet metal screws removed in Step 2 (Fig. 9).

NOTE: Do not align using the square flange openings. The square openings are to access use of

ratchet extensions for ease of assembly.

– 9 –

Page 10

Fire Brick Installation - GHCB40/44

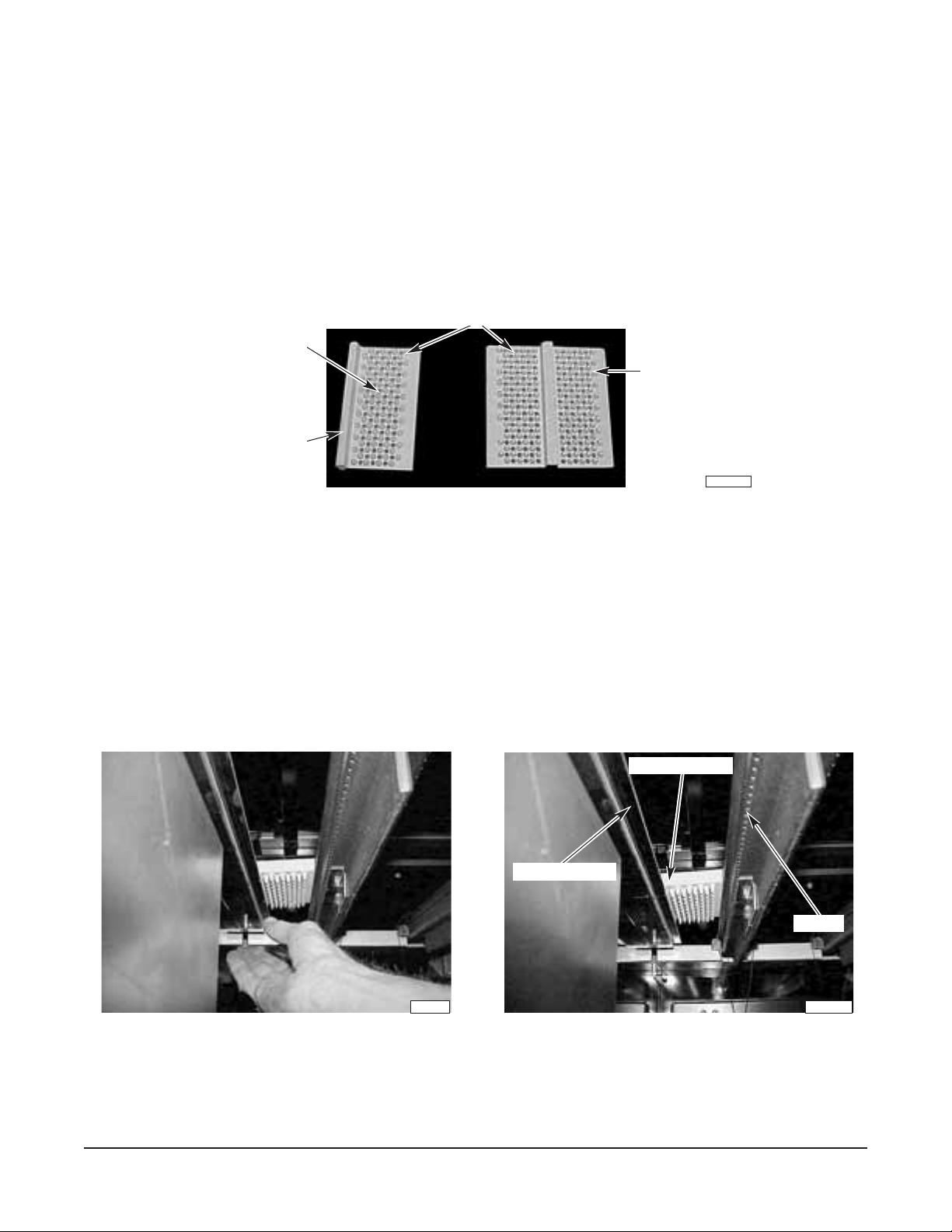

All GHCB40/44's come equipped with 12 center fire bricks and 8 side bricks.

The bricks must be placed in the broiler at the time of installation. The bricks are packaged in a

cardboard box, which is placed in the top broiler compartment for shipping. To install the bricks, follow

the steps below:

1. Cut through the shipping wire strap that holds the broiler grid in place if this has not already been

done.

2. Place the broiler grid into its lowest position.

PROTRUDING POINTS

SIDE FIRE BRICK

CENTER FIRE BRICK

SIDE BRICK RIDGE

PL-41725-1

Fig. 10

NOTE: Bricks are to be installed with the protruding points facing downward. Installing the side bricks

first will make the job easier (Fig. 10)

3. To install side brick, with brick in hand, points protruding downward, reach up through the broiler

grid compartment and rest the brick in the bracketing along side of the cast iron burners. It will

be necessary to tilt the bricks to get them between the burner and bracket. Then lift the brick

up above the burner and bracket, and set it carefully down in place.

NOTE: The side bricks have a ridge. This ridge should set down inside the far left and right bracket

flanges; you will install four bricks along each bracket flange (Fig. 11 and 12).

SIDE BRICK RIDGE

BRACKET FLANGE

BURNER

PL-41726 PL-41727-1

Fig. 11 Fig. 12

– 10 –

Page 11

4. Center bricks are installed towards the center of the broiler in three rows of four bricks each.

Install the center bricks similar to that of the side bricks in Step 3. Angle the bricks and slip them

up between the burners, then set them in place.

NOTE: The center bricks are to be installed to rest between two burners on the vertical burner flange

(Fig. 13 and 14).

PL-41728 PL-41729

Fig. 13 Fig. 14

LEVELING AND CONNECTING MANIFOLDS - ALL MODELS

The IR2 Model is not designed to be batteried to other heavy duty equipment. After leveling the IR2

Model, as described in Step 2, proceed to Gas Connections.

1. Place the broiler in its exact position or battery lineup.

2. Using a carpenter level, level the broiler from front to rear and from side to side. Unless the

broilers are level, they will not give proper cooking results, and equipment being batteried will

not draw up tight.

As of January 1998, Vulcan-Hart appliances use Ward gas unions instead of Stockham gas unions.

If you are installing a new battery range to an existing field appliance, the union on the existing field

appliance must be checked against the union being used on the new range. The union manufacturer’s

name around the face surface of the union nut must match. The new range has been shipped with a

Ward union. If the old appliance has something different, i.e., Stockham, it must be replaced with a

Ward union. Failure to replace this union could result in a gas leak (Fig. 15).

If a Ward gas union is needed for installation, purchasing information may be obtained through the

Vulcan-Hart Parts Department.

– 11 –

Page 12

Fig. 15

Questions or concerns regarding the installation procedures may be addressed by calling the VulcanHart Service Department 1-800-814-2028.

3. Engage union nut on manifold pipe of broiler with the male fitting on the next broiler, and draw

up union hand-tight. Be sure broilers butt both front and rear.

NOTE: Broilers are mounted on a steel, skid-type base, so a crowbar may be used to jockey units. If

the manifolds do not line up, then the broilers are not level.

4. Continue to level up and connect manifold pipe until all broilers in the battery are connected,

then tighten all manifold unions gas-tight.

– 12 –

Page 13

GAS CONNECTIONS

CAUTION: All gas supply connections and any pipe joint compound used must be

resistant to the action of propane gases.

Connect gas supply to the broiler(s). Make sure the pipes are clean and free of obstructions, dirt and

piping compound.

Codes require that a gas shutoff valve be installed in the gas line ahead of the broiler.

Natural gas broilers and propane gas broilers are equipped with fixed orifices and no adjustment is

necessary.

Model IR Broilers for operation on natural or propane gas are also equipped with a factory-preset

pressure regulator, with an outlet pressure of 6" (1.49 mb) Water Column for natural gas supply and

10" (2.49 mb) Water Column for propane gas supply. No further adjustment should be required.

Models GHCB40 and GHCB44 also require a pressure regulator (not supplied). The regulators must

have:

• C.S.A. design certification.

• Enough regulation capacity for the total connected gas load.

• Pressure adjustment range to allow adjustment for the manifold pressure marked on the rating

plate.

Unless the manifold pressure on all connected broilers is the same, a separate regulator must be

supplied for each broiler having different manifold pressures.

If the front plates do not line up perfectly, adjust by using bolts under the front plate.

WARNING: PRIOR TO LIGHTING, CHECK ALL JOINTS IN THE GAS SUPPLY LINE FOR

LEAKS. USE SOAP AND WATER SOLUTION. DO NOT USE AN OPEN FLAME.

Ensure that burner heads are connected.

After piping has been checked for leaks, all piping receiving gas should be fully purged to remove air.

TESTING THE GAS SUPPLY SYSTEM

When test pressures exceed

1

/2 psig (3.45 kPa), the broiler and its individual shutoff valve must be

disconnected from the gas supply piping system.

When test pressures are

1

/2 psig (3.45 kPa) or less, the broiler must be isolated from the gas supply

system by closing its individual manual shutoff valve.

FLUE CONNECTIONS

DO NOT obstruct the flow of flue gases from the flue duct located on the rear of the broiler. It is

recommended that the flue gases be ventilated to the outside of the building through a ventilation

system installed by qualified personnel.

From the termination of the broiler flue vent to the filters of the hood venting system, an 18" (457 mm)

minimum clearance must be maintained.

Information on the construction and installation of ventilating hoods may be obtained from the standard

for "Vapor Removal from Cooking Equipment," NFPA No. 96 (latest edition), available from the

National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

– 13 –

Page 14

ELECTRICAL CONNECTIONS

WARNING: ELECTRICAL AND GROUNDING CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

WARNING: DISCONNECT THE ELECTRICAL POWER TO THE MACHINE AND FOLLOW

LOCKOUT / TAGOUT PROCEDURES.

If the broiler is not equipped with a grounding plug and electrical supply is needed, ground the broiler

by using the ground lug provided (refer to the wiring diagram located inside the lower cabinet section).

Infrared broilers Models IR2 and GHIR44 are equipped with a 4' (122 cm) long supply cord.

WARNING: APPLIANCES EQUIPPED WITH A FLEXIBLE ELECTRIC SUPPLY CORD ARE

PROVIDED WITH A THREE-PRONG GROUNDING PLUG. IT IS IMPERATIVE THAT THIS PLUG

BE CONNECTED INTO A PROPERLY GROUNDED THREE-PRONG RECEPTACLE. IF THE

RECEPTACLE IS NOT THE PROPER GROUNDING TYPE, CONTACT AN ELECTRICIAN. DO

NOT REMOVE THE GROUNDING PRONG FROM THIS PLUG.

Do not connect broiler to electrical supply until after gas connections have been made.

MINIMUM BYPASS SETTING - MODEL GHCB40 OVEN

Adjust the oven pilot and burner for proper adjustment of minimum bypass setting. See instructions

under LIGHTING INSTRUCTIONS - MODEL GHCB40 OVEN.

LIGHTING INSTRUCTIONS - MODELS GHCB44 AND GHCB40 BROILERS

1. Remove au gratin oven bottom, baffle and burner box cover.

2. Remove oven bottom and baffles (Model GHCB40 only).

3. Remove manifold panel.

4. Turn gas supply ON.

5. Place the ceramics, with the projections down, to the rear of broiler burners. The lugs on the

burners will properly position themselves. The ceramics are sized at the factory.

6. Place the au gratin oven baffle and bottom, but leave the burner box cover off.

7. Turn the gas valve ON and allow air in the line to be exhausted. When gas begins to flow, turn

gas valve OFF and wait 5 minutes before lighting pilots and burner with a taper. The burner

3

flame should be sharp when the broiler is cold, with a blue cone of flame about

on natural gas and

1

/2" (12.7 mm) long on propane gas. The flame will soften out and curl around

/4" (19 mm) long

the ceramics as the broiler gets hot. The length of the flame is determined by the adjustment

of the nozzle. The sharpness of the flame is determined by the air shutter adjustment.

8. Adjust broiler pilots at the pilot valve on the left end of the pilot manifold pipe. Adjust the flame

to approximately

3

/4" (19 mm) long. Replace the burner box front.

9. Replace manifold panel and other parts that had been removed.

NOTE: Be sure pilots remain lit after installation.

– 14 –

Page 15

Carbonization of Ceramics

If the ceramics take on a black sooty accumulation, the burners are receiving an insufficient amount

of air. Open the air shutters further to provide more air. If carbonization occurs during initial adjustment,

it will burn off as soon as proper adjustment is achieved.

Burner Performance

If, after a period of satisfactory operation, the burner flame characteristics should change or the length

of burner flame should be reduced, either the air mixer opening or the gas valve orifice has become

restricted. The burners should be cleaned every 60 days, or more often as required, by an authorized

servicer.

LIGHTING INSTRUCTIONS - MODEL GHCBO40 OVENS

1. If the oven pilot is out, turn the burner OFF. Wait 5 minutes before relighting.

2. Depress the red ignition button located on the oven control panel and ignite the pilot. Hold

60 seconds until pilot remains ON.

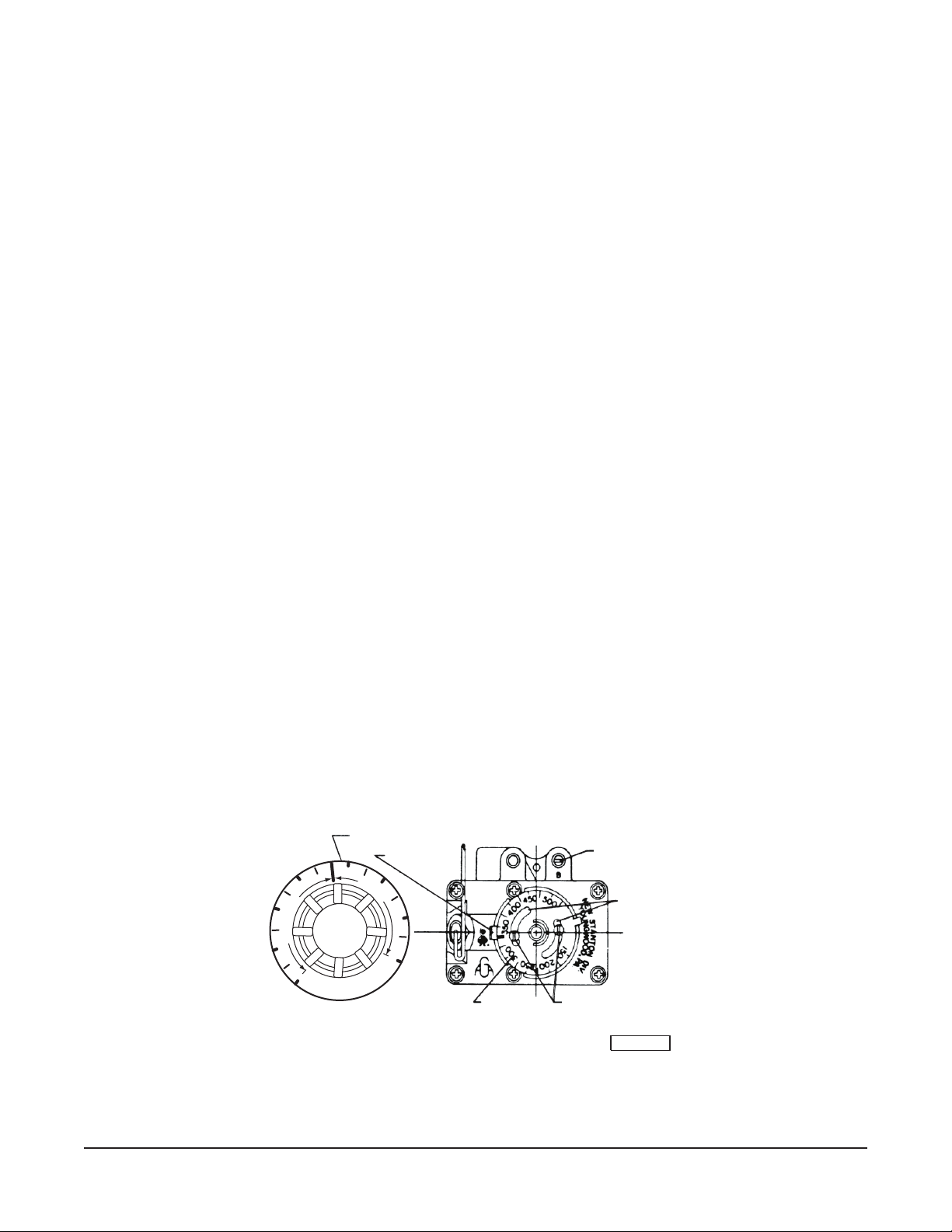

3. Adjust the oven pilot and burner for proper adjustment of minimum bypass setting. This

adjustment must be made at the time the broiler is installed. To adjust this flame:

• Be sure oven burner pilot flame is ignited.

• With oven cold, slowly turn dial (Fig. 16) counterclockwise from OFF until main burner gas

snaps on.

• Remove dial.

• With a screwdriver, turn bypass adjustment screw (Fig. 16) counterclockwise to increase the

bypass flame, or clockwise to decrease it, until flame over entire burner is approximately

1

/8"

(3.175 mm) high.

• Replace dial.

CAUTION: While making this adjustment, if the oven should become heated while the dial

is set at a low range (below 350°F [177°C]), the bypass flame will shut off completely. If this

occurs, turn dial counterclockwise slowly until bypass gas snaps on. Then check bypass

adjustment as stated above.

DIAL

POINTER "A"

3

5

0

0

0

3

T

S

0

A

5

O

2

R

O

L

0

0

2

0

5

1

4

B

0

A

0

K

I

N

G

4

5

0

5

0

0

MODEL

FDO

CALIBRATION

PLATE

Fig. 16

– 15 –

BY-PASS

ADJUSTMENT

SCREW

CALIBRATION

SCREWS

SCREW

CLEARANCE

SLOTS

PL-56560

Page 16

LIGHTING INSTRUCTIONS - MODELS HCB2

1. Remove burner box front cover and turn gas supply ON.

2. Place the ceramics, with the projections down, to the rear of broiler burners. The lugs on the

burners will properly position themselves. The ceramics are sized at the factory.

3. Turn the gas valve ON and allow air in the line to purge. When gas begins to flow, turn gas valve

3

OFF and wait 5 minutes before lighting the pilots. The pilot flame should be about

/4" high and

burner with a taper. The burner flame should be high enough to touch the ceramic bricks. The

length of the burner flame is determined by the adjustment of the burner nozzle. When the

burner flame is cold, the flame should appear as a sharp blue cone. As the flame gets hot, it

will soften in color and begin to curl around the ceramics. The sharpness of the flame is

controlled by the setting of the burner air shutter (Fig. 17).

PL-41730

Fig. 17

Pilot Burner Adjustment

Turn the pilot burner valve (located in the lower compartment) ON. Each burner is provided with a

standing pilot burner. Adjust the pilot flame to approximately

3

/4" (19 mm) flame height. The adjusting

valve is installed in the inlet of the pilot burner manifold, located behind the removable front panel above

the grid area.

Carbonization of Ceramics

If the ceramics take on a black sooty accumulation, the burners are receiving an insufficient amount

of air. Open the air shutters further to provide more air. If carbonization occurs during initial adjustment,

it will burn off as soon as proper adjustment is achieved.

Burner Performance

If, after a period of satisfactory operation, the burner flame characteristics should change or the length

of burner flame should be reduced, either the air mixer opening or the gas valve orifice has become

restricted. The burners should be cleaned every 60 days, or more often as required, by an authorized

servicer. This is not a warranty call.

– 16 –

Page 17

LIGHTING INSTRUCTIONS - MODELS IR2 AND IR44 (INFRARED)

1. Remove burner box cover.

2. Turn gas supply ON.

3. Turn pilot burner B valve (located in the lower left-hand compartment) (Fig. 18) ON and light

pilots (one pilot per burner) with a taper (Fig. 19).

4. If the pilots go out, turn B valve (Fig. 18) OFF and wait 5 minutes, then repeat Step 3.

BURNER B VA LVE

TOGGLE SWITCH

INDICATOR LIGHT

PL-41731-1

Fig. 18 Fig. 19

PL-41732

– 17 –

Page 18

Pilot Burner Adjustment

Turn the pilot burner B valve ON. The valve is located in the lower compartment.

Each burner is provided with a standing pilot burner. Adjust the pilot flame to approximately a

3

/4" (19 mm) flame length. The adjusting valve is installed in the inlet of the pilot burner manifold, located

behind the removable front panel above the grid area (Fig. 20).

PILOT BURNER ADJUSTMENT VALVE

BURNER ORIFICE TIP

HI-LOW VALVE

PL-41733-1

Fig. 20

– 18 –

Page 19

Main Burner Adjustment

Orifices (1 per burner) are located in the front of each burner venturi, behind a removable front panel

above the grid area. Each burner is controlled by either a "Hi-Lo" Valve (IR2), or a "Hi-Med-Lo" Valve

(GHIR44) and an orifice (Fig. 21).

Main Burner Valve Adjustment

The "high" position is fixed and cannot be adjusted. The "low" position may be adjusted to obtain the

minimum stable flame. In order to adjust the "low" setting, turn the knob to "low," remove the knob and

rotate the adjusting screw (located in the center shaft of the valve) clockwise to decrease and

counterclockwise to increase burner flame (see Fig. 20).

Air Adjustment

Although air adjustment is made at the factory before the broiler is shipped, it may be necessary to

readjust after installation is made. All of the air required for combustion is supplied by the blower

through an air duct on the left side. A single air adjustment is provided at the air intake to the blower

(GHIR44) or behind each "right" burner valve (IR2). No other adjustment is provided or necessary

(Figs. 20 and 21.)

Burners or infrared generators should burn with uniform radiant heat and without any flame curling

around the sides of the burner. If flame curls around the burner, the air supply needs to be increased;

if burner radiates with a bright orange glow with darkened areas throughout, the air supply should be

decreased.

(Model GHIR44 Only) — Insufficient air may keep the pressure switch opened and the solenoid valve

will not open to supply gas to the broiler. Increase the air supply to obtain proper operation.

PL-41734

Fig. 21

Carbon Accumulation — Burner Screen (Infrared Broilers Only)

If the burner screens take on a black sooty accumulation, the burners are not receiving enough air.

Increase the air supply at the blower inlet. The carbon will burn off as soon as the proper adjustment

is made.

– 19 –

Page 20

OPERATION

WARNING: THE BROILER AND ITS PARTS ARE HOT. USE CARE WHEN OPERATING,

CLEANING AND SERVICING THE BROILER.

CONTROLS

Au Gratin Oven Door and Handle — (GHCB40, GHCB44 and GHIR44)

Counterbalanced for easy opening. To open, lift

the door handle up. To close the door, pull the

handle straight down.

Grid Positioning Handle — Allows grid assembly to be adjusted to the proper

level depending on the product being prepared.

The higher the positioning of the grid, the closer

the product will be to the burner flame.

To relocate the grid position, grasp the grid lever

arm and push the handle to the right of the index

plate (HCB2 and IR broilers) (to the left on

GHCB44 and GHCB40 broilers). Glide the arm up

or down to the desired location. Push the lever arm

handle to the left (right on GHCB44 and GHCB40

broilers) and lock the arm into the proper slot.

Broiler Grid Handle — Allows the operator to pull the grid clear of the heat

zone, but does not allow the grid to be completely

removed from the broiler. When the product is to

be removed from the heat zone, pull the grid

handle straight out. The grid assembly, which is on

roller bearings, will slide out until it locks into

place. To return the grid assembly to the broiling

compartment, pull the grid handle slightly up and

push straight back (Fig. 22).

Fig. 22

– 20 –

PL-41735

Page 21

Broiler Control Valve — Regulates the flow of gas to the broiler burner. To

operate the valve, turn it counterclockwise. Turn

the knob clockwise to the OFF position to shut

burners down.

Model GHIR44 has three settings. The first

position is HI, the second is LOW and the third is

MEDIUM.

Model IR2 has two settings. The first position is HI

and the second is LOW.

Models GHCB40, GHCB44 and HCB2 settings are

variable, using a manual throttle.

Grease Collector Handle — The grease pan must be checked frequently and

emptied when it is about

3

/4 full. To check or empty

the grease collector pan, pull the grease collector

handle straight out until the pan is partially

exposed. If the grease pan is being emptied,

carefully remove the grease pan completely from

the broiler. Dispose of the grease and return the

pan to the broiler before continuing to broil.

Oven Burner Valve (GHCB40 Only) — When opened, allows gas to flow to the oven

burner. To open the valve, turn the knob

counterclockwise. To close, turn the knob

clockwise.

Thermostat Control (GHCB40 Only) — Used to regulate the amount of heat needed to

cook a product. The thermostat temperature range

is 150°F to 500°F (65.5°C to 260°C). Turn the knob

counterclockwise to increase heat and clockwise to

decrease heat.

Red Ignition Button (GHCB40 Only) — To operate, push the button in as pilot is being lit

(see LIGHTING INSTRUCTIONS for GHCB40).

Toggle Switch (IR2 and GHIR44) — This is the power switch. Flip the switch UP to put

the broiler into operation, DOWN to turn the broiler

off.

Signal Light (IR2 and GHIR44) — When lit, indicates that the broiler is on.

BEFORE FIRST USE

Burn off protective grid oils before cooking food products. With grid in full-up position, operate broiler

at full output for approximately 1 hour or until smoking stops. The burning will cause a somewhat

unpleasant odor; this is normal.

– 21 –

Page 22

COOKING

It is not necessary to preheat the IR Model broilers before using, nor is it necessary to keep the gas

on a low setting when not in use. Broiling temperatures are reached within 90 seconds. Burner life will

be extended if the burners are turned off between cooking periods.

Select the desired grid position and gas setting. It is recommended that gas input be reduced first when

lower grid temperatures are desired. Further reduction in grid temperatures, if necessary, can then be

obtained by lowering the grid position to any one of the several grid positions.

Pull the broiler grid handle straight out to slide the grid assembly out for loading. After loading product,

pull the grid handle slightly up and push straight back to return the grid assembly to the cooking

chamber.

USING THE BROILER

Initiation of the cooking cycle and shutdown procedures are as follows:

Models IR2 and GHIR44

To Start

1. Flip the toggle switch, located on the lower front center panel, to the ON position.

2. After the red indicating light comes on, turn the burner valve to the desired setting.

Nightly Shutdown

1. Turn the burner valve OFF.

2. Flip the toggle switch to the OFF position.

Complete Shutdown

Perform Steps 1 and 2 of nightly shutdown instructions, then turn pilot B valve and main gas line valve

OFF.

Model GHCB40

To Start Broiler

Turn the burner valve to the desired setting.

To Start Oven

1. Turn oven burner knob to ON.

2. Set thermostat dial to desired temperature.

Complete Shutdown

1. Turn burner valve OFF.

2. Turn oven burner knob to OFF and extinguish the pilot.

3. Turn main gas valve OFF.

– 22 –

Page 23

Model GHCB44 and HCB2

To Start

Turn burner gas valve ON.

Shutdown - Nightly

Turn burner gas valve OFF.

Complete Shutdown

1. Turn burner gas valve OFF.

2. Turn main gas valve OFF and extinguish pilot.

COOKING - GHCB40 OVEN ONLY

Recommended temperatures and times are intended as a guide only. Adjustments must be made to

compensate for variations in recipes, ingredients, installation and personal preference in product

appearance. Cooking time and shrinkage may vary with roasting temperature, cut and grade of meat

and degree of doneness. Smaller cuts will generally show greater time savings than larger cuts at a

given temperature.

Meat roasting is most satisfactory at temperatures of 225°F to 325°F (107°C to 163°C) for Beef, Lamb,

Poultry and Ham; 325°F (163°C) for fresh Pork as recommended by USDA and American Meat

Institute.

A pan of water (approximately 12 x 20 x 1" [304.8 x 508 x 25.4 mm]) may be placed in the oven bottom.

This water supplies humidity to reduce shrinkage. Add water if necessary during roasting.

1

Roasting pans should be no deeper than necessary to hold drippings, usually 2 to 2

/2" (51 to 63.5 mm).

– 23 –

Page 24

CLEANING

WARNING: DISCONNECT THE ELECTRICAL POWER TO THE MACHINE AND FOLLOW

LOCKOUT / TAGOUT PROCEDURES.

Daily

Exterior

Clean the exterior finish of the broiler with a mild soap solution or similar grease-dissolving material.

DO NOT use Dawn Dish Detergent.

Broiler and Oven

Clean the broiler, oven sections and doors, especially if fruit pies or tomato sauce were baked or meats

roasted, or if there have been any spillovers.

Stainless Steel

Routine cleaning of stainless steel may be done with ordinary soap or detergent and water. DO NOT

use Dawn Dish Detergent. To prevent water spots and streaks, rinse the broiler thoroughly with warm

water and wipe dry with a soft, clean cloth. The addition of a rinsing agent will also help prevent spotting.

When scraping off heavy deposits of grease or oil from stainless steel broilers, use stainless steel,

wood, plastic or rubber tools. Never use ordinary steel scrapers, knives or plain steel wool.

Fingerprints may be minimized by applying a cleaner that will leave a thin, oily or waxy film. Wipe the

cleaner on and remove the excess with a soft, dry cloth. Subsequent fingerprints will usually disappear

when wiped lightly with a soft, dry cloth containing a little of the cleaner. If the surface is especially dirty

to start with, wash first with soap or detergent and water.

Soaking with hot, soapy water will help greatly to remove burned-on foods and grease. Stubborn

deposits can be removed with scouring powder mixed into a paste and applied with stainless steel wool

or sponges. Do not use ordinary steel wool because particles that remain can eventually rust and cause

unsightly spots and stains. Rub in the direction of the polish lines.

Straw-colored or slightly darkened areas may appear on stainless steel appliances where temperatures

reach 500°F (260°C) or more. This "heat tint" is caused by a slight oxidation of the stainless steel and

is not harmful.

To control or minimize this condition, never use more heat than is absolutely necessary. Do not use

oversize pots where whipping of the flames will occur.

Heat tint can be removed by scouring vigorously with stainless steel wool and a paste made of scouring

powder. Rub in the direction of the polish lines.

Periodically

Clean dust and lint from the blower fan blades to maintain the greatest air flow and to prevent carboning

the burners.

– 24 –

Page 25

MAINTENANCE

WARNING: THE BROILER AND ITS PARTS ARE HOT. USE CARE WHEN OPERATING,

CLEANING AND SERVICING THE BROILER.

WARNING: DISCONNECT THE ELECTRICAL POWER TO THE MACHINE AND FOLLOW

LOCKOUT / TAGOUT PROCEDURES.

The efficient operation of this broiler depends upon a rather delicate balance between the volume of

gas and the supply of air. Unless complete combustion of the gas is achieved, poor operating

characteristics and excessive gas consumption can occur.

Periodic adjustment and cleaning of the burners by an authorized servicer is recommended.

LUBRICATION

No lubrication is needed for the IR or GH Models.

VENT

Annually check the flue, when cool, to be sure it is free of obstructions.

TROUBLESHOOTING

CHECKS TO BE MADE BEFORE CALLING THE SERVICER

1. Make sure the gas supply is on.

2. Make sure the store electric supply is on (Infrared Models only).

3. Make sure the broiler is plugged in (Infrared Models only).

4. Make sure the pilot light is lit.

SERVICE AND PARTS INFORMATION

To obtain service and parts information concerning this charbroiler, contact the Authorized Service

Agency in your area (refer to our website, www.vulcanhart.com for a complete listing of Authorized

Service and Parts depots) or contact 1-800-814-2028 for Technical Service and Parts Assistance.

When calling for service, the following information must be available: model number, serial number,

manufacture date (MD) and voltage.

– 25 –

Page 26

NOTES

–26 –

Page 27

NOTES

–27 –

Page 28

FORM 32801 (Sept. 2005) PRINTED IN U.S.A.

– 28 –

Page 29

MODE D’INSTALLATION

ET MODE D’EMPLOI

GRILLOIRS AU GAZ À SERVICE INTENSE

GRILLOIRS CERAMIC

MODÈLES MLS

GHCB40C ML-52212

GHCB40 ML-52211

GHCB44 ML-52213

HCB2T ML-52203

HCB2B ML-52208

GRILLOIRS SUNGLOW

MODÈLES MLS

IR2T ML-52207

IR2B ML-52201

GHIR44 ML-52210

Pour de plus amples détails concernant Vulcan-Hart ou pour repérer le détaillant de

pièces et de service autorisé le plus près, visiter notre site Web à : www.vulcanhart.com

AIDE TECHNIQUE ET PIÈCES DE RECHANGE

1 800 814-2028

VULCAN-HART

UNE DIVISION DE GROUPE ITW ÉQUIPEMENT ALIMENTAIRE, LLC

MODÈLE GHCB40

3600 NORTH POINT BLVD.

BALTIMORE, MD 21222

WWW.VULCANHART.COM

F-32801 (Sept. 2005)

Page 30

MESURES DE SÉCURITÉ IMPORTANTES

CE MANUEL A ÉTÉ PRÉPARÉ À L’INTENTION D’UN PERSONNEL QUALIFIÉ ET AUTORISÉ

À INSTALLER DES APPAREILS FONCTIONNANT AU GAZ ET À EFFECTUER LE

DÉMARRAGE INITIAL CHEZ LE CLIENT DE MÊME QUE LE RÉGLAGE DES APPAREILS

CONCERNÉS DANS CE MANUEL.

AFFICHER À UN ENDROIT VISIBLE LES PREMIERS SOINS À ADMINISTRER À TOUTE

PERSONNE AYANT RESPIRÉ LES GAZ QUE CET APPAREIL DÉGAGE. ON PEUT SE

PROCURER CES INFORMATIONS CHEZ LE FOURNISSEUR DE GAZ LE PLUS PRÈS.

IMPORTANT

EN CAS D’ODEURS DE GAZ, ÉTEINDRE L’APPAREIL PAR

LE ROBINET D’ARRÊT PRINCIPAL ET COMMUNIQUER

AVEC LA COMPAGNIE DE GAZ LA PLUS PRÈS OU

AVEC LE FOURNISSEUR DE GAZ ATTITRÉ POUR

L’ENTRETIEN.

MESURE DE SÉCURITÉ

NE PAS RANGER NI UTILISER DE L’ESSENCE NI TOUT

AUTRE LIQUIDE OU VAPEUR INFLAMMABLE À

PROXIMITÉ DE CET APPAREIL OU DE TOUT AUTRE

APPAREIL.

AVERTISSEMENT

L’INSTALLATION, LE RÉGLAGE, LA MODIFICATION

ET L’ENTRETIEN INCORRECTS DE CET APPAREIL

PEUVENT CAUSER DES DOMMAGES MATÉRIELS,

DES BLESSURES ET MÊME LA MORT. LIRE LES

INSTRUCTIONS D’INSTALLATION, DE FONCTIONNEMENT

ET D’ENTRETIEN AVANT DE PROCÉDER À TOUTE

INSTALLATION OU TOUT ENTRETIEN.

EN CAS DE PANNE DE COURANT, NE PAS FAIRE

FONCTIONNER CET APPAREIL.

© VULCAN-HART, 2005

– 2 –

Page 31

BOULONS D’ARRÊT

IMPORTANT

LES BOULONS D’ARRÊT DOIVENT ÊTRE EN PLACE POUR QUE LA GRILLE PUISSE

FONCTIONNER EN TOUTE SÉCURITÉ.

S’ILS SONT ENDOMMAGÉS OU MANQUANTS, LES REMPLACER IMMÉDIATEMENT.

NE PAS FAIRE FONCTIONNER LA GRILLE SANS CES BOULONS.

– 3 –

Page 32

INSTALLATION, FONCTIONNEMENT ET ENTRETIEN

GRILLOIRS AU GAZ À SERVICE INTENSE CERAMIC ET SUNGLOW

DOCUMENT À CONSERVER.

GÉNÉRALITÉS

Il est recommandé de lire ce manuel au complet et de suivre attentivement toutes les instructions

du fabricant.

Les grilloirs Sunglow ou Ceramic Vulcan sont fabriqués avec le plus grand soin à partir des

meilleurs matériaux. Leur installation, utilisation et entretien appropriés permettront d’en obtenir un

rendement optimal pendant de nombreuses années.

INSTALLATION

DÉBALLAGE - TOUS LES MODÈLES DE GRILLOIRS

Avant de quitter l’usine, cet appareil a été inspecté soigneusement. Le transporteur est entièrement

responsable de la livraison de l’appareil. Immédiatement après avoir déballé l’appareil, vérifier s’il n’a

pas été endommagé lors du transport. En cas de dommages, conserver le matériel d’emballage et

aviser le transporteur dans les 15 jours suivant la date de réception.

Retirer les planchettes de bois et câbles utilisés pour maintenir les brûleurs et la grille du grilloir en place.

Avant de procéder à l’installation, s’assurer que le type de gaz (naturel ou propane) de l’immeuble

correspond aux spécifications de la plaque signalétique.

Modèles Emplacement de la plaque signalétique

IR2 et GHIR44 Dans le bas du meuble, du côté droit, à l’avant

GHCB44 À l’intérieur du panneau de la porte du meuble

HCB2 Dans le bas du meuble, du côté gauche, à l’avant

GHCB40 Dans le four : derrière le panneau inférieur, du côté gauche de l’écran

avant de la boîte du brûleur, derrière le levier coudé

Grilloir : Couvercle de la tubulure d’alimentation à l’avant

Si l’alimentation et les spécifications ne correspondent pas, ne pas installer l’appareil et communiquer

sans tarder avec le détaillant Vulcan-Hart.

– 4 –

Page 33

EMPLACEMENT

Aucune substance combustible ne doit se trouver à proximité de l’appareil.

Ce grilloir a été conçu en observant les dégagements minimaux ms suivants de toute construction

combustible et incombustible :

CONSTRUCTION CONSTRUCTION

MODÈLES COMBUSTIBLE INCOMBUSTIBLE

GHCB40 Arrière 152 mm (6 po) Aucun

GHCB40C Côté droit 152 mm (6 po) Aucun

GHCB44 Côté gauche 152 mm (6 po) Aucun

Plancher 152 mm (6 po) Aucun

CONSTRUCTION CONSTRUCTION

MODÈLES COMBUSTIBLE INCOMBUSTIBLE

GHIR44 Arrière 102 mm (4 po) Aucun

Côté droit Aucun Aucun

Côté gauche Aucun Aucun

Plancher 152 mm (6 po) Aucun

CONSTRUCTION CONSTRUCTION

MODÈLES COMBUSTIBLE INCOMBUSTIBLE

HCB2 Arrière 102 mm (4 po) Aucun

Côté droit 102 mm (4 po) Aucun

Côté gauche 102 mm (4 po) Aucun

Plancher 152 mm (6 po) Aucun

CONSTRUCTION CONSTRUCTION

MODÈLES COMBUSTIBLE INCOMBUSTIBLE

IR2 Arrière 102 mm (4 po) Aucun

Côté droit Aucun Aucun

Côté gauche Aucun Aucun

Plancher 152 mm (6 po) Aucun

Les grilloirs doivent se trouver dans un endroit suffisamment espacé pour permettre leur entretien et leur

fonctionnement appropriés. Un dégagement minimal de 889 mm (35 po) est requis devant l’appareil.

Installer les grilloirs de manière à assurer la circulation de l’air nécessaire à la combustion des gaz

et à la ventilation appropriées de l’appareil. Observer un dégagement suffisant autour des ouvertures

d’approvisionnement d’air de la chambre de combustion. S’assurer d’une bonne ventilation dans le

local pour permettre la combustion des gaz.

– 5 –

Page 34

CODES D’INSTALLATION ET NORMES - TOUS LES MODÈLES DE GRILLOIRS

L’installation de votre cuisinière doit se faire selon les codes suivants :

Aux États-Unis :

1. Codes locaux

2. Norme ANSI/Z223.1 (dernière édition) du National Fuel Gas Code dont on peut se procurer un

exemplaire auprès de l’American Gas Association Inc., 1515 Wilson Blvd., Arlington, VA 22209.

3. Norme ANSI/NFPA-70 (dernière édition) du National Electrical Code dont on peut se procurer un

exemplaire auprès de la National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

Au Canada :

1. Codes locaux.

2. Norme CSA B149.1 du Code d’installation des appareils fonctionnant au gaz naturel et propane.

3. Norme CSA C22.1 du Code canadien de l’électricité (dernière édition).

On peut se procurer un exemplaire des normes ci-dessus auprès de l’Association canadienne de

normalisation, 5060 Spectrum Way, Bureau 100, Mississauga, Ontario, Canada L4W 5N6.

GRILLOIRS SUR ROULETTES

Si l’appareil doit être installé sur des roulettes, se munir d’un connecteur flexible (non fourni par

Vulcan) conforme aux normes ANSI-Z21.69 • CSA 6.16 sur les connecteurs des appareils au gaz

mobile et d’un raccord à débranchement rapide conforme aux normes ANSI-Z21.41 • CSA 6.9. En

plus, prendre les moyens nécessaires pour limiter le mouvement de l’appareil sans devoir compter

sur le connecteur ou le raccord à débranchement rapide, ni même sur la tuyauterie pour le garder

immobile. Fixer le dispositif de retenue à l’arrière de la cuisinière (Fig. 1).

S’il s’avère nécessaire de détacher le dispositif de retenue, couper l’alimentation en gaz de

l’appareil. Le rattacher avant de rétablir l’alimentation en gaz et de remettre l’appareil en position

d’exploitation.

Des instructions pour l’installation de roulettes sont incluses avec les roulettes séparément.

Nota : Si le grilloir est installé sur des roulettes et doit être déplacé pour une raison ou une autre, il

est conseillé de la niveler à nouveau d’avant en arrière et d’un côté à l’autre.

DÉMONTAGE ET SUPERPOSITION DES GRILLOIRS - MODÈLE GHCB2

Lire attentivement toutes les instructions avant de démonter ou superposer les grilloirs.

La hauteur des modèles HCB2 et IR2 peut quelquefois dépasser l’entrée de porte de la cuisine.

C’est pour cette raison que deux courroies de superposition aluminisées de 95 x 38 x 1,2 mm

(3 3/4 x 1 1/2 x 3/64 po) sont expédiées avec chaque grilloir pour faciliter le démontage de la

partie supérieure.

Grilloirs expédiés déjà superposés

1. Enlever le panneau de finition de la partie supérieure.

2. Trouver les fentes ovales à l’intérieur du panneau de finition de la partie supérieure et enlever

les deux boulons de 10-24 qui raccordent la partie supérieure à la partie inférieure (Fig. 1).

– 6 –

Page 35

3. Enlever la lèchefrite et démonter les deux boulons de 10-24, un à gauche et un à droite de

l’intérieur de la lèchefrite, derrière le châssis avant de la partie supérieure (Fig. 2).

PL-41717

Fig. 1

Fig. 2

PL-41718

4. Enlever avec soin la partie supérieure du grilloir de la partie inférieure.

5. Laisser les trous du bas, des côtés gauche et droit ouverts, et réassembler le panneau de finition

sur l’appareil.

GRILLOIRS EXPÉDIÉS EN DEUX MORCEAUX POUR SUPERPOSITION

L’ajout des courroies d’empilage éliminera l’utilisation des deux fentes ovales, une à gauche et

l’autre à droite, derrière le panneau de finition de la partie supérieure. (Se reporter à l’étape 2 de la

section Grilloirs expédiés déjà superposés.)

1. Positionner les grilloirs aussi près que possible de

l’emplacement de l’appareil. Se rappeler de laisser

assez de place pour terminer les procédures de

superposition.

2. Soulever avec soin la partie supérieure et la déposer

de façon égale dans la partie inférieure.

COURROIE DE

STACKING STRAP

SUPERPOSITION

3. Enlever la lèchefrite de la partie supérieure. Aligner

les deux trous, un à gauche et un à droite de la

surface supérieure de la lèchefrite, derrière le

châssis avant du grilloir. Insérer les deux boulons

de 10-24 et assembler la partie supérieure à la

partie inférieure.

4. Replacer la lèchefrite.

5. À l’arrière du grilloir, enlever les deux boulons de

10-24 du coin supérieur du panneau de finition de

PL-56559

la partie inférieure, du côté gauche et droit.

6. Utiliser quatre boulons de 10-24 et assembler la

Fig. 3

courroie de superposition tel qu’illustré à la Fig. 3.

Ceci termine la procédure de superposition.

– 7 –

Page 36

INSTALLATION D’UN COUPE-TIRAGE - GHCB40 OU GHCB44

Tous les grilloirs GHCB40 et GHCB44 sont munis d’un inverseur de conduit de fumée de la hotte

qui est emballé et placé dans le compartiment supérieure du grilloir. Il doit être fixé à l’appareil au

moment de l’installation en suivant les étapes suivantes :

1. Si l’inverseur est recouvert d’un plastique de protection recouvrant l’assemblage, enlever tout

le plastique.

2. Placer l’inverseur sur le dessus de l’appareil en couvrant le conduit de fumée (Fig. 4).

3. Enlever les quatre vis à tôle de 10-24 du rebord arrière supérieur du grilloir (Fig. 5).

INVERSEUR DE

HOOD

FLUE

CONDUIT DE FUMÉE

DIVERTER

DE LA HOTTE

CONDUIT

FLUE

DE FUMÉE

SCREWS

VIS

Fig. 4

PL-41719-1

Fig. 5

PL-41720-1

Fig. 6

PL-41721

Fig.7

PL-41722

4. Aligner les quatre trous et fentes dans le rebord arrière de l’inverseur en alignant les trous dans

le rebord arrière supérieur du grilloir et réinstaller les quatre vis à métal de 10-24 (Fig. 6).

5. L’installation de l’inverseur est maintenant terminée (Fig. 7).

– 8 –

Page 37

EXTENSIONS DES CÔTÉS

Les extensions des côtés de l'appareil sont emballées séparément et placées sur le dessus du

compartiment de chaque grilloir GHCB40/44. L’utilisation de ces extensions est facultative. Celles-ci

sont destinées à aider à aligner la batterie de grils de façon égale, d’avant en arrière, avec les

autres cuisinières à service intense Vulcan. Pour l’installation, suivre les étapes ci-dessous :

1. Trouver les extensions de côté et les déballer.

SCREWS

VIS

Fig. 8

PL-41723-1

Fig.9

PL-41724

2. Enlever les cinq vis à métal de 10-24 qui relient chaque côté de l’appareil au panneau arrière

du grilloir (Fig. 8).

3. Aligner les trous restants en enlevant les vis à métal de 10-24 en perçant des trous à l’avance

dans les extensions de côté du côté droit et gauche. Fixer les extensions aux côtés en

réinstallant les cinq vis à métal de 10-24 enlevées à l’étape 2 (Fig. 9).

NOTA : Ne pas aligner en utilisant les ouvertures carrées du rebord. Ces ouvertures permettent

d’atteindre les extensions du rochet pour une plus grande facilité d’assemblage.

– 9 –

Page 38

Installation de briques réfractaires - GHCB40/44

Tous les modèles GHCB40/44 sont équipés de 12 briques réfractaires centrales et de 8 briques

latérales.

Les briques doivent être placées dans le grilloir au moment de l’installation. Elles sont emballées

dans une boîte de carton qui est placée dans le haut du compartiment du grilloir pour l’expédition.

Pour les installer, suivre les étapes suivantes :

1. Couper à travers la courroie du câble d’expédition qui retient la grille en place, si ceci n’a pas

encore été fait.

2. Placer la grille du grilloir dans la position la plus basse.

POINTS EN SAILLIE

PROTRUDING POINTS

BRIQUE RÉFRACTAIRE

LATÉRALE

SIDE FIRE BRICK

ARRÊTE DE LA

SIDE BRICK RIDGE

BRIQUE LATÉRALE

Fig. 10

BRIQUE RÉFRACTAIRE

CENTER FIRE BRICK

CENTRALE

PL-41725-1

ARRÊTE DE LA BRIQUE LATÉRALE

BRACKET FLANGE

REBORD DU

SUPPORT

PL-41726 PL-41727-1

Fig. 11 Fig. 12

SIDE BRICK RIDGE

BURNER

NOTA : Installer les briques de façon à ce que les points en saillie soient face à face dans le bas.

Le fait d’installer les briques latérales en premier rendra le travail plus facile (Fig. 10).

3. Pour installer la brique latérale, prendre la brique dans une main, les points en saillie vers le bas,

et aller au compartiment de la grille du grilloir pour déposer la brique dans le support le long du

côté des brûleurs en fonte. Il sera nécessaire d’incliner les briques pour qu’elles soient entre

le brûleur et le support. Soulever ensuite la brique vers le haut au-dessus du brûleur et du

support et le placer avec soin en place.

NOTA : Les briques latérales possèdent une arrête. Elle doit être déposée à l’intérieur à l’extrême

gauche et droite des rebords du support; installer les quatre briques le long de chaque rebord de

support (Fig. 11 et 12).

– 10 –

Page 39

4. Les briques centrales sont installées vers le centre du grilloir en trois rangées de quatre briques

chacune. Installer les briques centrales de la même façon que les briques latérales à l’étape 3.

Les placer à angles et les faire glisser vers le haut entre les brûleurs, puis les mettre en place

NOTA : Les briques centrales doivent être installées de façon à être déposées entre deux brûleurs

sur le rebord vertical du brûleur (Fig. 13 et 14).

Fig. 13

PL-41728

Fig. 14

PL-41729

NIVELAGE ET RACCORDEMENT DE LA TUBULURE D’ALIMENTATION - TOUS LES MODÈLES

Le modèle IR2 n’est pas conçu pour être raccordé en batterie avec un autre appareil à service intense.

Après le nivelage de ce modèle, tel que décrit à l’étape 2, procéder aux raccordements de gaz.

1. Placer le grilloir à sa position exacte ou aligné en batterie.

2. En utilisant un niveau de menuisier, niveler le grilloir de l’avant vers l’arrière et d’un côté à l’autre.

Si les grilloirs ne sont pas nivelés, ils ne donneront pas de résultats satisfaisants et l’équipement

en batterie ne s’alignera pas solidement.

Depuis janvier 1998, Vulcan n’utilise plus de raccords-unions de gaz Stockham, mais uniquement des

raccords-unions Ward. Pour le raccord en batterie d’une nouvelle cuisinière à une cuisinière déjà en

place, vérifier que le nom du fabricant gravé sur les raccords-unions des deux appareils est le même.

Si la nouvelle cuisinière est pourvue d’un raccord-union Ward, mais que le raccord-union de la

cuisinière en place est différent, par exemple Stockham, remplacer celui-ci par un raccord-union

Ward, faute de quoi cela risque de causer une fuite de gaz.

Si un raccord-union de gaz Ward est nécessaire pour l’installation, le commander auprès du service

de l’entretien Vulcan-Hart le plus près.

– 11 –

Page 40

Fig. 15

Pour toute question au sujet des directives d’installation ci-dessus, communiquer avec le service

de l’entretien Vulcan-Hart au 1 800 814-2028.

3. Mettre le raccord-union en prise avec la tubulure d’alimentation, le raccord mâle vers

l’appareil adjacent, et le serrer à la main. S’assurer que le devant et le derrière de chaque

grilloir sont bien aboutés.

NOTA : Les grilloirs sont montés sur une base en acier de style plate-forme, afin qu’un pied-de-biche

puisse être utilisé pour élever et aligner les appareils. Si les tubulures d’alimentation ne sont pas

alignées, les grilloirs ne seront pas de niveau.

4. Poursuivre le nivelage et le raccordement des tuyaux de la tubulure d’alimentation jusqu’à ce que

tous les grilloirs soient raccordés en batterie, puis bien serrer tous les raccords-unions de gaz.

– 12 –

Page 41

BRANCHEMENT DU GAZ

ATTENTION : Tous les raccords d’alimentation de la conduite de gaz et la pâte à joints de

tuyaux doivent résister à l’action du gaz propane.

Raccorder la conduite de gaz au grilloir. S’assurer que les tuyaux sont propres et qu’ils ne comportent

aucun corps étranger ni trace de saleté ou de pâte à joints.

Conformément aux exigences des codes, installer un robinet d’arrêt dans la conduite de gaz du

grilloir devant le grilloir.

Les grilloirs au gaz naturel et au propane sont munis d’injecteurs fixes et aucun réglage n’est nécessaire.

Les grilloirs modèles IR pour le fonctionnement au gaz naturel ou propane sont aussi munis d’un

régulateur de pression réglé en usine dont la pression de sortie est de 1,49 kPa (6 po de colonne

d’eau) pour le gaz naturel et 2,49 kPa (10 po de colonne d’eau) pour le gaz propane. Aucun autre

réglage n’est nécessaire.

Les grilloirs modèles GHCB40 et GHCB44 requièrent aussi un régulateur de pression (non fourni)

qui doit être conforme aux spécifications suivantes :

• Il doit être approuvé par le C.S.A.

• Il doit être réglé de manière à supporter la puissance totale en gaz.

• Sa marge de réglage doit correspondre aux indications de la plaque signalétique de l’appareil.

À moins que la pression de la tubulure d’alimentation sur tous les grilloirs raccordés soit la même,

un régulateur distinct doit être fourni pour chaque grilloir ayant une pression de tubulure

d’alimentation différente.

Si les plaques avant ne s’alignent pas parfaitement, les régler en utilisant les boulons sous la plaque avant.

AVERTISSEMENT : AVANT DE PROCÉDER À L’ALLUMAGE, FAIRE CIRCULER DE L’EAU

SAVONNEUSE DANS TOUS LES JOINTS DE LA CONDUITE DE GAZ POUR S’ASSURER

QU’ILS NE PRÉSENTENT AUCUNE FUITE. NE PAS SE SERVIR D’UNE FLAMME NUE.

S’assurer que les têtes de brûleurs sont raccordées.

Après avoir enrayé toute possibilité de fuite, purger la conduite de gaz pour évacuer tout l’air

qu’elle contient.

ESSAIS DE LA CANALISATION DE GAZ

Si la pression de la canalisation de gaz est supérieure à 3,45 kPa (1/2 psig) lors d’essais de pression,

débrancher le grilloir et son robinet d’arrêt de la conduite de gaz.

Lorsque la pression d’essai est égale ou inférieure à 3,45 kPa (1/2 psig), isoler l’appareil de la

canalisation de gaz en fermant son robinet manuel.

RACCORDEMENT DU CONDUIT D’ÉVACUATION

NE PAS obstruer le débit des gaz de combustion dans le conduit d’évacuation à l’arrière de l’appareil.

Il est recommandé que les gaz de combustion soient ventilés à l’extérieur de l’immeuble par un

système de ventilation installé par un personnel qualifié.

Maintenir un dégagement minimal de 457 mm (18 po) entre l’extrémité du conduit d’évacuation de

l’appareil et les filtres de la hotte de ventilation.

Les informations sur la construction et l’installation des hottes de ventilation sont comprises dans la

norme NFPA n° 96 (dernière édition) relative à l’installation de matériel pour l’évacuation des fumées

et vapeurs grasses des cuisines commerciales dont on peut se procurer un exemplaire auprès de

la National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

– 13 –

Page 42

RACCORDEMENT ÉLECTRIQUE

AVERTISSEMENT : LE RACCORDEMENT ÉLECTRIQUE ET LA MISE À LA TERRE DOIVENT

ÊTRE CONFORMES AUX NORMES CONCERNÉES DU CODE CANADIEN DE L’ÉLECTRICITÉ

OU TOUT AUTRE CODE D’ÉLECTRICITÉ EN VIGUEUR.

AVERTISSEMENT : COUPER L’ALIMENTATION ÉLECTRIQUE DE L’APPAREIL ET SUIVRE LES

PROCÉDURES DE VERROUILLAGE ET D’ÉTIQUETAGE.

Si l’appareil requiert une source de courant électrique sans être muni d’une fiche de mise à la terre,

le mettre à la terre à l’aide de la cosse fournie à cette fin (voir le schéma de câblage se trouvant

dans la section inférieure du meuble).

Les grilloirs à infrarouge modèles IR2 et GHIR44 sont munis d’un cordon d’alimentation de 102 mm (4 po)

de longueur.

AVERTISSEMENT : LES APPAREILS MUNIS D’UN CORDON D’ALIMENTATION FLEXIBLE

SONT POURVUS D’UNE FICHE DE MISE À LA TERRE À TROIS BROCHES. LA PRISE DANS

LAQUELLE ELLE EST BRANCHÉE DOIT ÊTRE CORRECTEMENT MISE À LA TERRE. SI ELLE

NE L’EST PAS, COMMUNIQUER AVEC UN ÉLECTRICIEN. NE PAS ENLEVER LA BROCHE DE

MISE À LA TERRE DE LA FICHE.

Ne pas établir l’alimentation électrique tant que tous les raccordements du gaz n’auront pas été faits.

RÉGLAGE MIMIMAL DE DÉRIVATION – FOUR MODÈLE GHCB40

Régler la veilleuse et le brûleur du four pour que la dérivation soit réglée au minimum. Se référer

aux instructions à la section DIRECTIVES D’ALLUMAGE – FOUR MODÈLE GHCB40.

DIRECTIVES D’ALLUMAGE - GRILLOIRS MODÈLES GHCB44 ET GHCB40

1. Enlever le bas du four Au gratin, le déflecteur et le couvercle de la boîte du brûleur.

2. Enlever le bas du four et les déflecteurs (Modèle GHCB40 seulement).

3. Enlever le panneau de la tubulure d’alimentation.

4. Ouvrir le robinet de gaz.

5. Placer les céramiques, les projections vers le bas, à l’arrière des brûleurs du grilloir. Les languettes

sur les brûleurs se placeront au bon endroit par elles-mêmes. Les céramiques sont coupées à l’usine.

6. Placer le déflecteur et bas du four au gratin, mais ne pas remettre le couvercle de la boîte du brûleur.

7. Mettre le robinet de gaz à ON (marche) et laisser s’expulser l’air de la conduite. Lorsque le gaz

commence à couler, mettre le robinet de gaz à OFF (arrêt) et attendre 5 minutes avant d’allumer

les veilleuses et le brûleur à l’aide d’une bougie. La flamme du brûleur est correcte lorsque le

brûleur est froid et qu’apparaît un cône de flamme bleu d’environ 19 mm (3/4 po) de longueur pour

le gaz naturel et de 12,7 mm (1/2 po) pour le gaz propane. La flamme va s’adoucir et s’enrouler

autour des céramiques lorsque le grilloir devient chaud. La longueur de la flamme est déterminée

par le réglage de l’injecteur. L’intensité de la flamme est déterminée par le réglage de l’obturateur d’air.

8. Régler les veilleuses du grilloir par le robinet de la veilleuse du côté gauche du tuyau de la tubulure

d’alimentation de la veilleuse. Régler la flamme pour qu’elle mesure environ 19 mm (3/4 po) de

longueur. Replacer le couvercle de la boîte du brûleur.

9. Replacer le panneau de la tubulure d’alimentation et les autres pièces qui ont été enlevées.

NOTA : S’assurer que les veilleuses demeurent allumées après l’installation.

– 14 –

Page 43

Carbonisation des céramiques

S’il y a une accumulation de suie sur les céramiques, les brûleurs reçoivent une quantité d’air insuffisante.

Ouvrir les obturateurs d’air pour fournir une plus grande quantité d’air. S’il survient de la carbonisation

au cours d’un réglage initial, elle brûlera aussitôt que le réglage adéquat sera terminé.

Rendement du brûleur

Après une période satisfaisante de fonctionnement, si les caractéristiques de la flamme du brûleur

changent ou si la longueur de la flamme est réduite, il se peut que l’ouverture du mélangeur d’air

ou les orifices du robinet de gaz soient obstrués. Faire nettoyer les brûleurs à tous les 60 jours ou

plus souvent si nécessaire par un technicien de service autorisé.

DIRECTIVES D’ALLUMAGE - FOURS MODÈLE GHCBO40

1. Si la veilleuse du four est éteinte, mettre le brûleur à OFF (arrêt). Attendre 5 minutes avant de

l’allumer à nouveau.

2. Appuyer sur le bouton rouge d’allumage sur le panneau de commande du four et allumer la

veilleuse. Attendre 60 secondes jusqu’à ce que la veilleuse demeure allumée.

3. Régler la veilleuse du four et le brûleur pour que la dérivation soit réglée au minimum. Ce

réglage doit s’effectuer lors de l’installation du grilloir. Pour régler la flamme :

• S’assurer que la flamme de la veilleuse du four est allumée.

• Laisser refroidir le four et tourner doucement le cadran dans le sens inverse des aiguilles d’une

montre (Fig. 16) à partir de OFF (arrêt) jusqu’à ce que le gaz du brûleur principal fasse un déclic.

• Enlever le cadran.

• À l’aide d’un tournevis, tourner la vis de réglage de dérivation (Fig. 16) dans le sens inverse des

aiguilles d’une montre pour augmenter la flamme de dérivation, ou le contraire pour la diminuer,

jusqu’à ce que la flamme sur le brûleur atteigne approximativement à 3,175 mm (1/8 po) de hauteur.

• Replacer le cadran.

ATTEBTION : En effectuant un réglage, si le four devenait chaud pendant le réglage du

cadran à un bas niveau (sous 177 °C (350 °F), la flamme de dérivation s’éteindra

complètement. Si ceci se produit, tourner lentement le cadran dans le sens contraire des

aiguilles d’une montre jusqu’à ce qu’il se produise un déclic. Vérifier ensuite le réglage de

dérivation tel que mentionné ci-dessus.

CADRAN

RÔTISSAGE

DIAL

AIGUILLE «A»

3

0

0

3

T

S

0

A

5

O

2

R

O

L

0

0

2

0

5

1

POINTER "A"

5

0

4

B

0

A

0

K

I

N

G

4

5

CUISSON

0

5

0

0

MODEL

MODÈLE

FDO

FDO

CALIBRATION

PLAQUE DE

PLATE

CALIBRATION

VIS DE RÉGLAGE

BY-PASS

ADJUSTMENT

DE DÉRIVATION

SCREW

SCREW

FENTES DE

CLEARANCE

DÉGAGEMENT DES VIS

SLOTS

CALIBRATION

VIS DE CALIBRATION

SCREWS

PL-56560

Fig. 16

– 15 –

Page 44

DIRECTIVES D’ALLUMAGE - MODÈLE HCB2

1. Enlever le couvercle avant de la boîte du brûleur et mettre l’alimentation de gaz à ON

(marche).

2. Placer les céramiques, les projections vers le bas, à l’arrière des brûleurs du grilloir. Les

languettes sur les brûleurs se placeront au bon endroit par elles-mêmes. Les céramiques sont

coupées à l’usine.

3. Mettre le robinet de gaz à ON (marche) et laisser s’expulser l’air de la conduite. Lorsque le gaz

commence à couler, mettre le robinet de gaz à OFF (arrêt) et attendre 5 minutes avant d’allumer

les veilleuses à l’aide d’une bougie. La flamme du brûleur devrait s’élever à une hauteur d’environ

19 mm (3/4 po). La flamme du brûleur devrait assez élevée pour toucher les briques en céramique.

La longueur de la flamme est déterminée par le réglage de l’injecteur du brûleur. Lorsque le

brûleur est froid, un cône de flamme bleu d’environ 19 mm (3/4 po) de longueur pour le gaz naturel

et de 12,7 mm (1/2 po) pour le gaz propane devrait apparaître. À mesure que la flamme devient

chaude, elle va s’adoucir et s’enrouler autour des céramiques lorsque le grilloir devient chaud.

La longueur de la flamme est déterminée par le réglage de l’injecteur. L’intensité de la flamme

est déterminée par le réglage de l’obturateur d’air (Fig. 17).

PL-41730

Fig. 17

Réglage du brûleur de la veilleuse

Mettre le robinet du brûleur de la veilleuse (placé dans le compartiment inférieur) à ON (marche).

Chaque brûleur est muni d’un brûleur de veilleuse permanent. Régler la flamme de la veilleuse pour

qu’elle atteigne 19 mm (3/4 po) de hauteur. Le robinet de réglage est installé dans l’entrée de la

tubulure d’alimentation du brûleur de la veilleuse, se trouvant derrière le panneau avant amovible

au-dessus de la surface de la grille.

Carbonisation des céramiques

S’il y a une accumulation de suie sur les céramiques, les brûleurs reçoivent une quantité d’air insuffisante.

Ouvrir les obturateurs d’air pour fournir une plus grande quantité d’air. S’il survient de la carbonisation

au cours d’un réglage initial, elle brûlera aussitôt que le réglage adéquat sera terminé.

Rendement du brûleur

Après une période satisfaisante de fonctionnement, si les caractéristiques de la flamme du brûleur

changent ou si la longueur de la flamme est réduite, il se peut que l’ouverture du mélangeur d’air ou les

orifices du robinet de gaz soient obstrués. Faire nettoyer les brûleurs à tous les 60 jours ou plus souvent

si nécessaire par un technicien de service autorisé. Ce n’est pas un appel de service sous garantie.

– 16 –

Page 45

DIRECTIVES D’ALLUMAGE - MODÈLES IR2 ET IR44 (À INFRAROUGE)

1. Enlever le couvercle de la boîte du brûleur.

2. Ouvrir le robinet du gaz.

3. Mettre le robinet B du brûleur de la veilleuse (placé dans le compartiment inférieur du côté gauche)

(Fig. 18) à ON (marche) et allumer les veilleuses (une par brûleur) à l’aide d’une bougie (Fig. 19).

4. Si la veilleuse refuse de s’allumer, mettre le robinet B (Fig. 18) à OFF (arrêt), attendre 5

minutes puis reprendre l’étape 3.

BURNER B VA LVE

ROBINET B DU BRÛLEUR

INTERRUPTEUR

TOGGLE SWITCH

À BASCULE

INDICATOR LIGHT

VOYANT

Fig. 18

PL-41731-1

PL-41732

Fig. 19

– 17 –

Page 46

Réglage du brûleur de la veilleuse

Mettre le robinet B du brûleur de la veilleuse à ON (marche). Le robinet est placé dans le

compartiment inférieur.

Chaque brûleur est muni d’un brûleur de veilleuse permanent. Régler la flamme de la veilleuse

pour qu’elle mesure approximativement 19 mm (3/4 po). Le robinet de réglage est installé à

l’entrée de la tubulure d’alimentation du brûleur de la veilleuse, placé derrière le panneau

avant amovible au-dessus de la surface de la grille (Fig. 20).

ROBINET DE RÉGLAGE DU

PILOT BURNER ADJUSTMENT VALVE

BRÛLEUR DE LA VEILLEUSE

BOUT DE L’ORIFICE

BURNER ORIFICE TIP

DU BRÛLEUR

ROBINET À DEUX

HI-LOW VALVE

INTENSITÉS

PL-41733-1

Fig. 20

– 18 –

Page 47

Réglage du brûleur principal

Les orifices (1 par brûleur) sont placés à l’avant de chaque venturi du brûleur, derrière un panneau

avant amovible au-dessus de la surface de la grille. Chaque brûleur est commandé soit par un robinet

à 2 intensités «Hi-Lo» (élevée et basse) (IR2), ou «Hi-Med-Lo» (élevée, moyenne et basse) (GHIR44) et

un orifice (Fig. 21).

Réglage du robinet du brûleur principal

La position «High» (élevée) est fixe et ne peut être réglée. La position «low» (basse) peut être réglée

pour obtenir une flamme basse stable. Pour régler la position à «low» (basse), tourner le bouton à «low»

(basse), enlever le bouton et faire tourner la vis de réglage (placée dans l’arbre central du robinet) dans le

sens des aiguilles d’une montre pour diminuer la flamme et dans le sens contraire pour l’augmenter (Fig. 20).

Réglage de l’air

Même si le réglage de l’air est effectué à l’usine avant d’expédier l’appareil, il peut s’avérer nécessaire de

faire un nouveau réglage après l’installation. Le ventilateur soufflant dans le conduit d’air placé sur le

côté gauche fournit tout l’air nécessaire à la combustion. Un seul réglage d’air est fourni à l’entrée

d’air vers le ventilateur (GHIR44) ou derrière chaque robinet «droit» du brûleur (IR2). Aucun autre

réglage n’est nécessaire (Figs. 20 et 21).

La chaleur radiante des brûleurs ou des générateurs à infrarouge devrait être uniforme et sans flamme qui

s’enroule autour des côtés du brûleur. Si la flamme s’enroule autour du brûleur, augmenter le débit d’air; si le

brûleur diffuse une lueur de couleur orange avec des endroits plus foncés, diminuer l’entrée d’air.

(Modèle GHIR44 seulement) – S’il y a une insuffisance d’air, l’interrupteur de pression peut rester

ouvert et la vanne électromagnétique peut ne pas s’ouvrir pour fournir le gaz au grilloir. Augmenter

l’entrée d’air pour un bon fonctionnement.

PL-41734

Fig. 21

ACCUMULATION DE CARBONE - ÉCRAN DU BRÛLEUR (GRILLOIRS À INFRAROUGE SEULEMENT)

Si l’écran du brûleur est recouvert par une accumulation de suie, les brûleurs ne reçoivent pas assez d’air.

Augmenter l’entrée d’air à l’entrée du ventilateur. Le carbone va brûler dès qu’un réglage sera fait.

– 19 –

Page 48

FONCTIONNEMENT

AVERTISSEMENT : LES COMPOSANTS CHAUDS PEUVENT CAUSER DES BRÛLURES.

EXERCER UNE EXTRÊME PRUDENCE LORS DE L’EXPLOITATION DU GRILLOIR.

COMMANDES

Porte et poignée (GHCB40, GHCB44 et GH1R44)

du four Au gratin Contrebalancée pour une ouverture facile. Pour

ouvrir, tirer la poignée de la porte vers le haut.

Pour fermer, la tirer vers le bas.

Poignée de positionnement Permet de régler l’assemblage de la grille au bon

de la grille niveau selon le produit qui est préparé. Plus la

grille est positionnée élevée, plus le produit sera

près à la flamme du brûleur.

Pour relocaliser la position de la grille, saisir le

bras de levier de la grille et pousser la poignée à

droite de la plaque index (Grilloirs HCB2 et IR), (à

gauche pour les grilloirs GHCB44 et GHCB40).

Glisser le bras vers le haut et vers le bas à

l’emplacement désiré. Pousser la poignée du bras

de levier vers la gauche (à droite pour les grilloirs

GHCB44 et GHCB40) et verrouiller le bras dans la

fente appropriée.

Poignée de la grille du Permet à l’utilisateur de tirer la grille pour la dégager

grilloir de la zone de chaleur, mais la grille ne peut être enlevée

complètement du grilloir. Lorsque le produit doit être

enlevé de la zone de chaleur, tirer la poignée de la

grille vers soi. L’assemblage de la grille, qui est sur

des roulements à rouleaux, va glisser jusqu’à ce qu’il se

verrouille en place. Pour retourner l’assemblage de

la grille au compartiment du grilloir, tirer la poignée

de la grille doucement vers le haut et pousser vers

l’arrière (Fig. 22).

Fig. 22

– 20 –

PL-41735

Page 49

Robinet de commande du grilloir Régle le débit de gaz vers le brûleur du grilloir. Pour

faire fonctionner le robinet, le tourner dans le sens

inverse des aiguilles d’une montre. Pour éteindre les

brûleurs, tourner le bouton dans le sens des aiguilles

d’une montre jusqu’à la position OFF (arrêt).

Le modèle GHIR44 possède trois réglages. La première

position est HI (élevée), la seconde est LOW (basse)

et la troisième est MEDIUM (moyenne).

Le modèle IR2 possède deux réglages. La première

position est HI (élevée) et la seconde est LOW (basse).

Les réglages pour les modèles GHCB40, GHCB44

et HCB2 sont variables, en utilisant un étrangleur

manuel.

Poignée du tiroir de propreté Le tiroir de propreté servant à recueillir la graisse doit

être vérifié fréquemment et vidé lorsqu’il est plein au 3/4.

Pour le vérifier ou le vider, tirer la poignée vers soi

jusqu’à ce qu’il soit partiellement exposé. Si vous

l’enlevez pour le vider, l’enlever avec soin du grilloir.

Vider la graisse et remettre le tiroir de propreté sur

le grilloir avant de continuer le grillage.

Robinet du brûleur du four Lorsqu’il est ouvert, il permet l’écoulement du gaz

(GHCB40 seulement) vers le brûleur du four. Pour ouvrir le robinet, tourner

le bouton dans le sens contraire des aiguilles d’une

montre. Pour le fermer, faire l’inverse.

Commande du thermostat Utilisée pour régler le degré de chaleur nécessaire

(GHCB40 seulement) pour cuire un produit. La température du thermostat

varie de 65,5 à 260 °C (150 à 500 °F). Pour augmenter la

chaleur, tourner le bouton dans le sens contraire des

aiguilles d’une montre et faire l’inverse pour la diminuer.

Bouton d’allumage rouge Pour le faire fonctionner, le pousser lorsque la veilleuse

(GHCB40 seulement) s’allume (se référer à la section DIRECTIVES

D’ALLUMAGE pour le modèle GHCB40).