Page 1

Page 2

CHH50

CHH60

CHH70

Dishwasher

Installation / Operation

Spare Parts List

Wiring Diagram

jw-06-2006

Page 3

USE AND MAINTENANCE MANUAL

page 2

CONTENTS

CHAP.1 INTRODUCTION .......................................................................................... 3

CHAP.2 INSTALLATION............................................................................................ 3

2.1 HANDLING AND U N P ACKING. ...................................................................................... 3

2.2 ELECTRICAL C O N N E C TION. ......................................................................................... 4

2.3 WATER CONNE C T I O N . ................................................................................................... 4

2.4 DRAIN CONNE C T I O N . ..................................................................................................... 5

2.5 ADJUSTMENTS ................................................................................................................. 5

2.6 RINSE-AID DISPENSER ...................................................................................................... 5

2.7 DETERGENT........................................................................................................................ 6

CHAP.3 SAFETY RECOMMENDATIONS.................................................................... 7

3.1 RESIDUAL RISKS AND WARNINGS ................................................................................... 7

3.2 SAFETY DEVICE.................................................................................................................. 7

CHAP. 4 USE OF MACHINE ....................................................................................... 8

4.1 DESCRIPTION OF THE COMMANDS ................................................................................. 8

4.1.1 Automatic water drainage (optional)….………………………………….……………….……… 9

4.2 USING THE MAC H I N E . .................................................................................................... 9

4.3 END OF CY C L E O PERATIONS.................................................................................... 10

CHAP.5 MAINTENANCE.......................................................................................... 11

5.1 GENERAL RULES . .......................................................................................................... 11

5.2 PERIODIC MAINTENANCE (TO BE DONE AT LEAST EVERY 20 DAYS) ....................... 11

CHAP.6 DISMANTLING ........................................................................................... 12

6.1 DISMANTLING T H E M A C HINE .................................................................................... 12

Page 4

USE AND MAINTENANCE MANUAL

page 3

CHAP.1 INTRODUCTION

The warnings contained in this manual provide important

information for safely installing, using and servicing this

machine.

The operator is required to read this manual before starting

any operation involving handling, installation, use,

maintenance or disassembly of the machine. This manual

must be kept intact and in a safe place for frequent

consultation.

CHAP.2 INSTALLATION

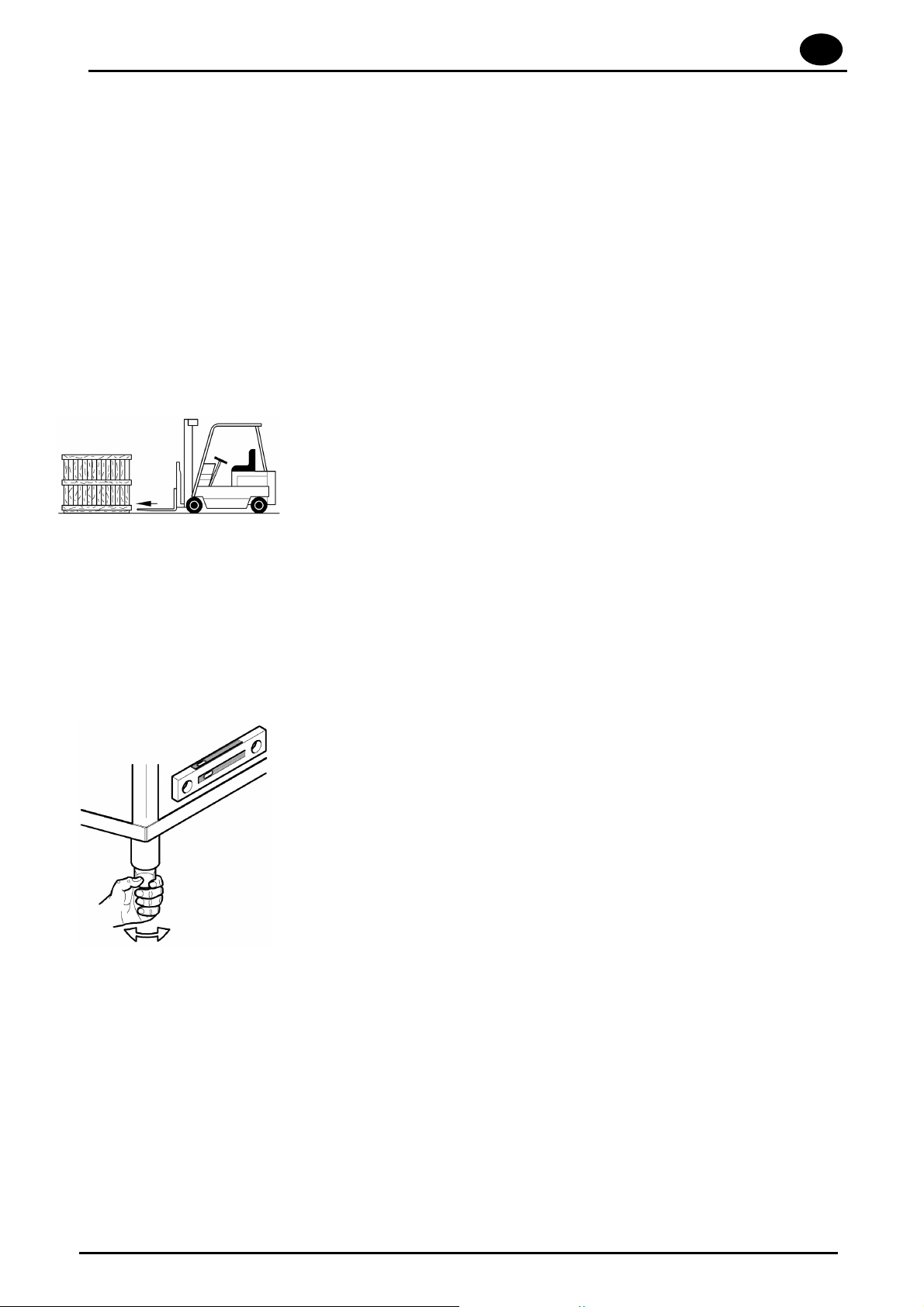

2.1 HANDLING AND UNPACKING

x

Move the machine very carefully using a forklift.

x

Make sure the equipment is not damaged, if it is immediately

inform the dealer and shipper. If in doubt do not use the

machine until it has been checked by professionally trained

personnel.

GB

x

Move the machine to the site where it will be used and

remove the packing.

Packing materials (plastic bags, polystyrene,

nails) can be dangerous and must be kept out of

the reach of children.

x The installation must be carried out according to the

manufacturer’s instructions and by professionally trained

personnel.

x Only a fixed connection is suitable for this equipment.

x Position the machine and level it perfectly using the feet.

x The flooring must be suitable for the overall weight of the

machine.

x Follow the indications on the installation drawing and set-up

the electrical, water and drain systems in the wash area.

Page 5

GB

page 4

USE AND MAINTENANCE MANUAL

H

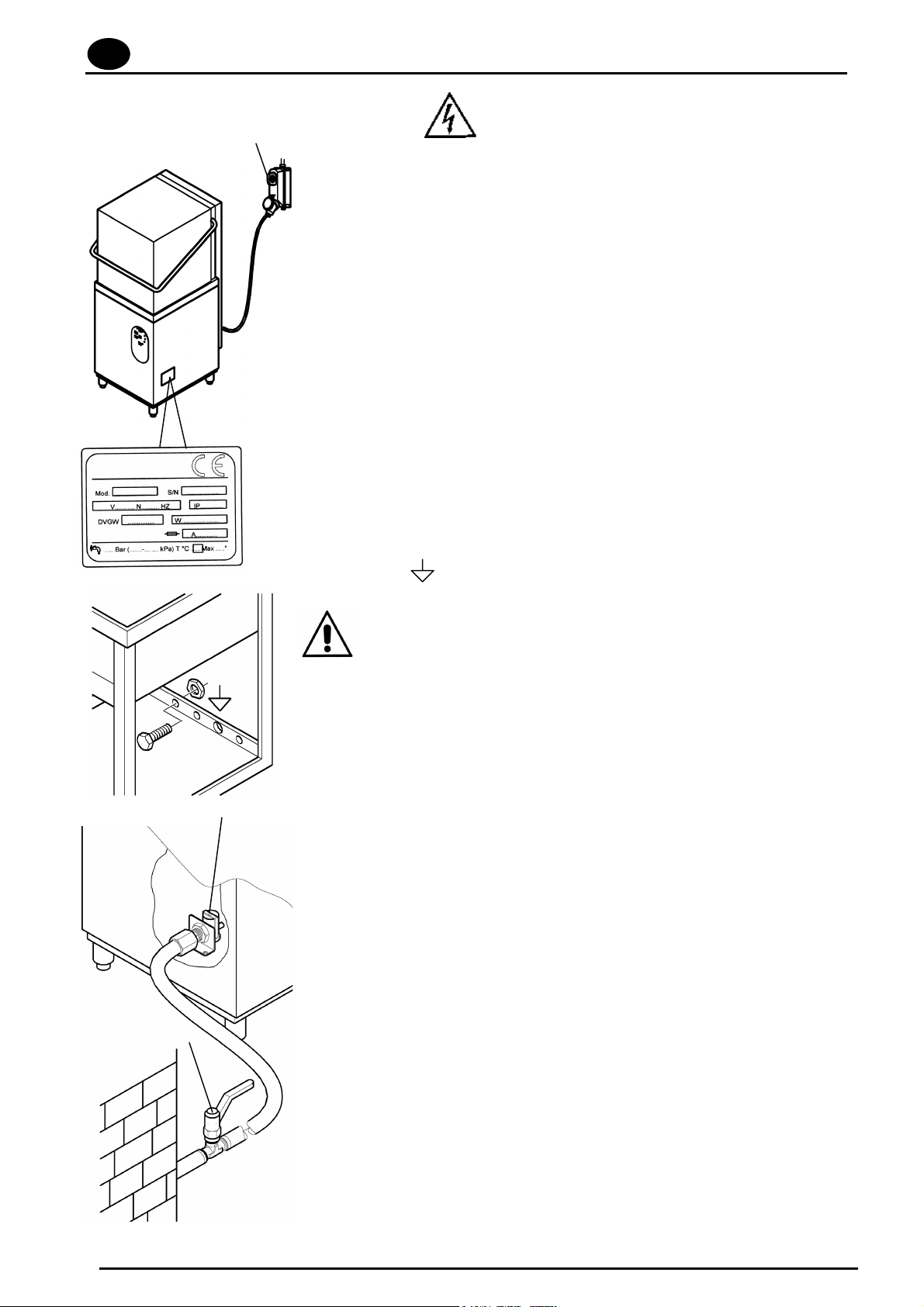

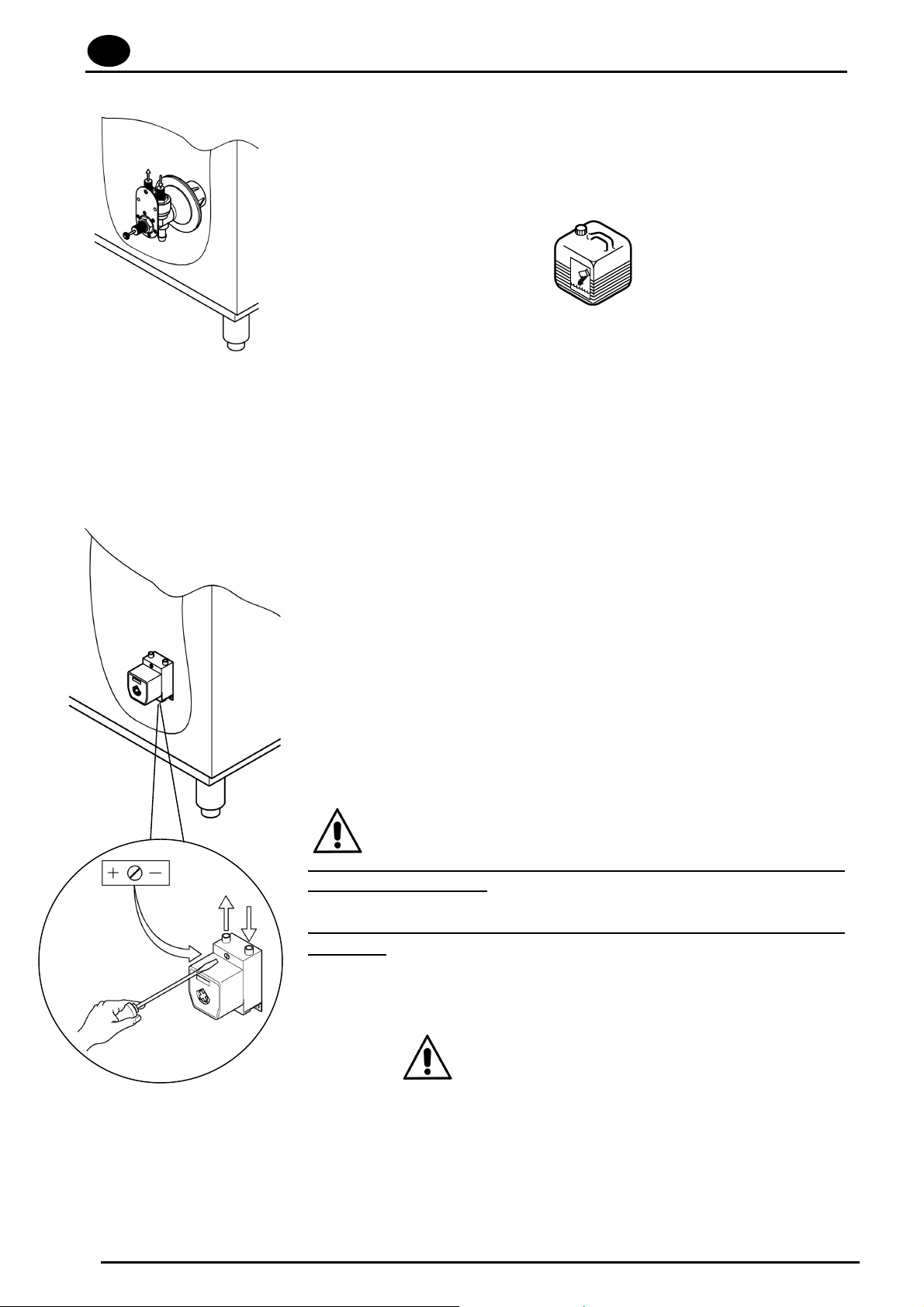

2.2 ELECTRICAL CONNECTION

1. Connection to the power supply must be made with a main

switch (H) it must be omnipolar and interrupt all contacts

including neutral. There must be a distance of at least 3

mm between open contacts, and it must have a thermal

magnetic safety switch or fuses which are able to

withstand the maximum power indicated on the plate.

2. Make sure that the power supply corresponds to that on

the technical features plate on the right side of the

machine.

3. Use an effective earthing system in compliance with local laws to

protect the safety of the operators and not damage the machine.

4. Do not use adapters, multiple sockets or extension cords.

5. The equipment must be included in an equipotential

system, and connected using a screw marked with the

symbol. The equipotential wire must be 10 mm² .

V

If the power supply cable (provided with the equipment)

needs to be replaced use another H07RN-F type with the

same dimensions.

For additional information see the wiring drawing.

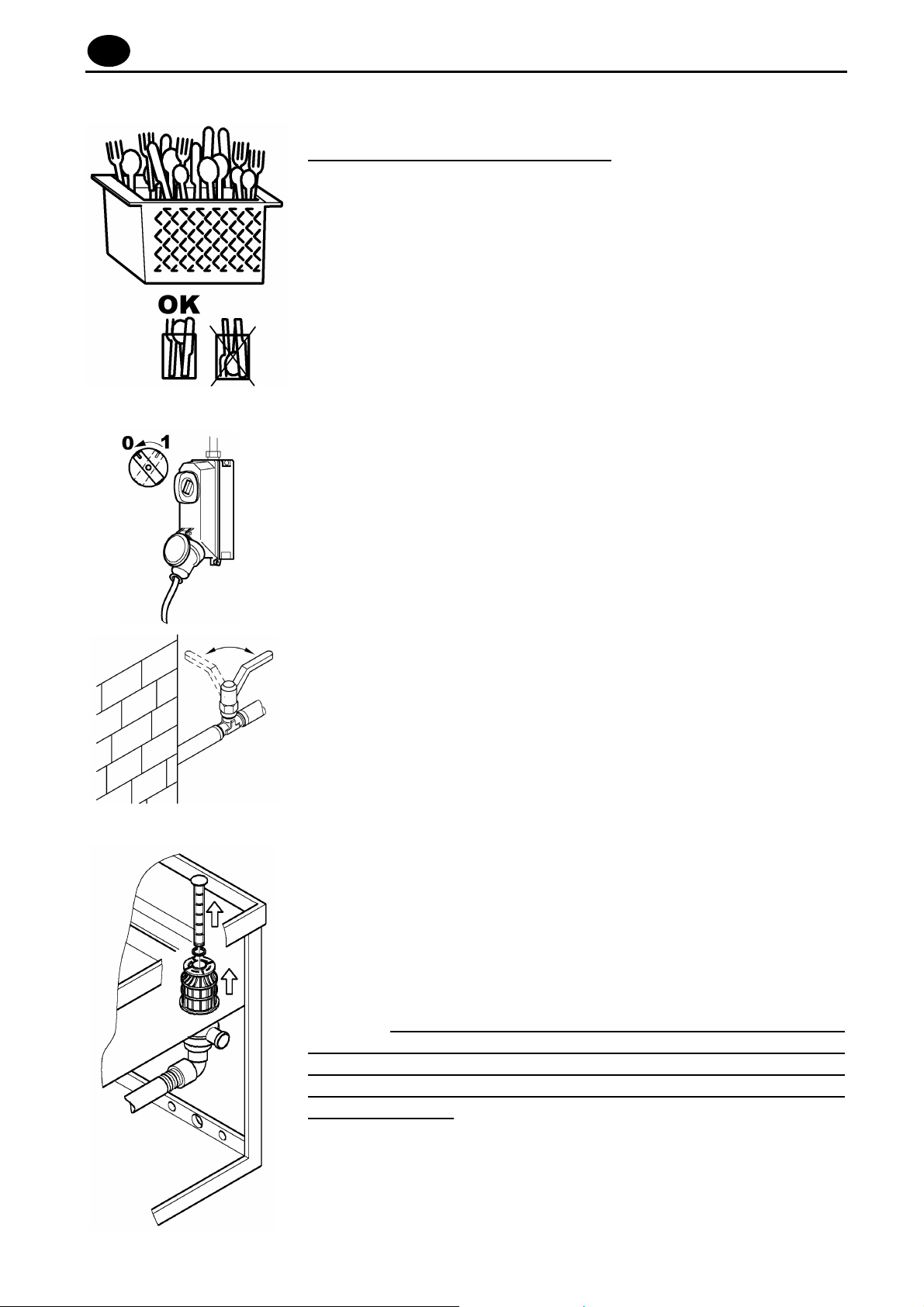

2.3 WATER CONNECTION

E

Set-up the site according the attached plumbing drawing.

Before connecting the equipment make sure that a gate valve

has been placed between the water supply and the

equipment so that the water can be turned off if required or

for repair work.

Use a hose to connect the solenoid valve (E) to the gate

valve (V) and make sure that the delivery is not less than

20l/min.

Check that the temperature and water pressure correspond

to what is shown on the technical specifications plate.

If the water is harder than what is listed in the chart, it is

advisable to install a decalcifier upline from the solenoid

valve.

If there are high concentrations of very conductive minerals in the

water, it is advisable to install a demineralization system calibrated to

the hardness shown in the following chart.

Page 6

USE AND MAINTENANCE MANUAL

page 5

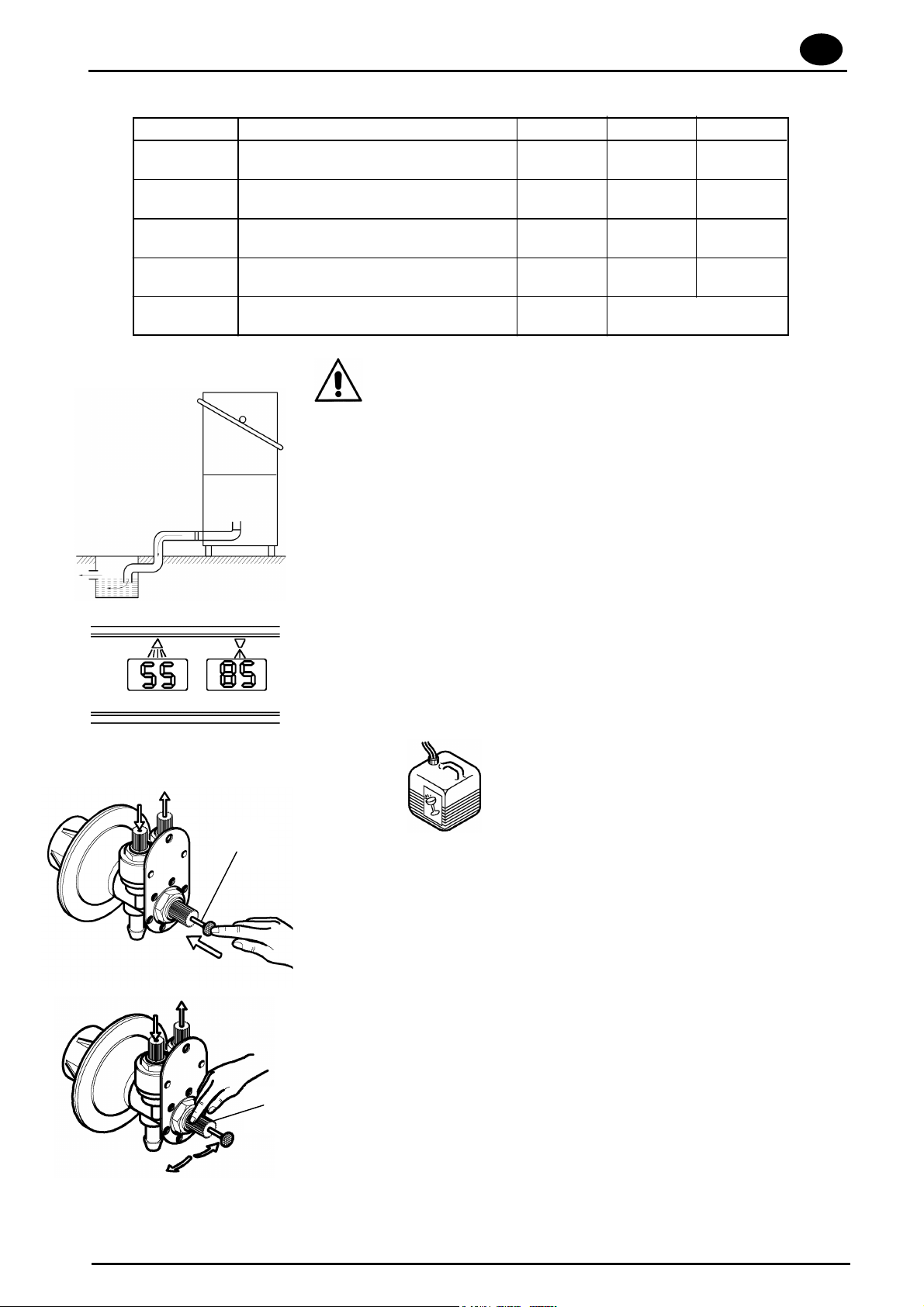

Specification

From

To

Hardness

Residual

Minerals

French degrees

German degrees

English degrees

Parts per million

Maximum

Gravity for all models, except EH70, so the drain needs to be

situated below the base of the machine. Model EH70 requires a stand-pipe

The drain pipe needs to be connected to a drain- trap built

into the floor.

The drain dimensions are shown in the installation drawing.

2.5

f

°dH

°e

ppm

mg/l

2.4

ADJUSTMENTS AND CHECKS

5

4

5

70

300/400

DRAIN CONNECTION

10

7’5

9,5

140

A

The temperature of the wash tank is regulated by a fixed thermostat at

about 55° C. This temperature ensures proper action by the chemicals

contained in industrial dishwashing detergents.

The boiler temperature set by a fixed thermostat is about 85° C.

2.6 RINSE-AID DISPENSER

Before adjusting, the dispenser and hose need to be filled

using the primer button (A).

To adjust use the ring nut (B) situated at the center of the

dispenser, rotating clockwise reduces the quantity,

counterclockwise increases it.

The dispenser must not operate empty

An excessive amount of rinse agent causes bluish stripes on the

dishes and creates foam in the wash tank.

B

Page 7

GB

page 6

USE AND MAINTENANCE MANUAL

If the glassware is covered with droplets of water and it drys rather

slowly this means that the amount of rinse agent is insufficient.

7 cm. of tubing = 1 gram of product

2.1 DETERGENT

Equipment without a detergent dispenser

Put the amount of detergent recommended by the

manufacturer into the tank. Depending on the type of

detergent this may vary from 2 to 4 gr/lt of water in the tank.

Detergent needs to be added approximately every 5 washes

as per the manufacturer’s instructions.

The above amounts are for water with a hardness of 5-10°F

(French degrees).

A

Models EH60/70 and CHH50 are equiped with detergent dispenser

Regulations:

A trimmer (A) allows to determine the «ON-OFF» time and

consequently the amount of detergent required.

x Turning the adjustment trimmer clockwise or counter-clockwise will

respectively decrease or increase the amount of rinse aid it

delivers.

x To optimise the calibration, evaluate the results of some washing

cycles.

BE CAREFUL!

The level in detergent tank must not get empty or filled with corrosive

or inadequate products.

The warranty does not cover damages caused by an improper use of

dispenser.

CHAP.3 SAFETY RECOMMENDATIONS

3.1 RESIDUAL RISKS AND WARNINGS

x Never open the door quickly if the cycle has not finished.

x Do not put bare hands into the wash solution.

x Never remove the machine panels if the power upline has not been turned off.

x The professionally trained personnel who install the machine and connect the electricity,

will explain to the user how to operate the machine and which safety measures to use.

x The installer will provide practical demonstrations and leave written instructions which are provided with

the machine.

Page 8

USE AND MAINTENANCE MANUAL

page 7

x This machine is only to be used for the purpose for which it was designed.

Any other use is considered improper and dangerous.

x The machine is not to be used by untrained personnel.

x Never use the machine if any of the protections (microswitches, panels or other) provided

by the manufacturer are missing.

x Do not use the machine to wash objects not compatible with those indicated by the

manufacturer.

x All repair work must be done by the manufacturer or an authorized service center using

original spare parts.

x Failure to observe this may affect the safety of the machine.

x The power supply should be turned off when the machine is not being used.

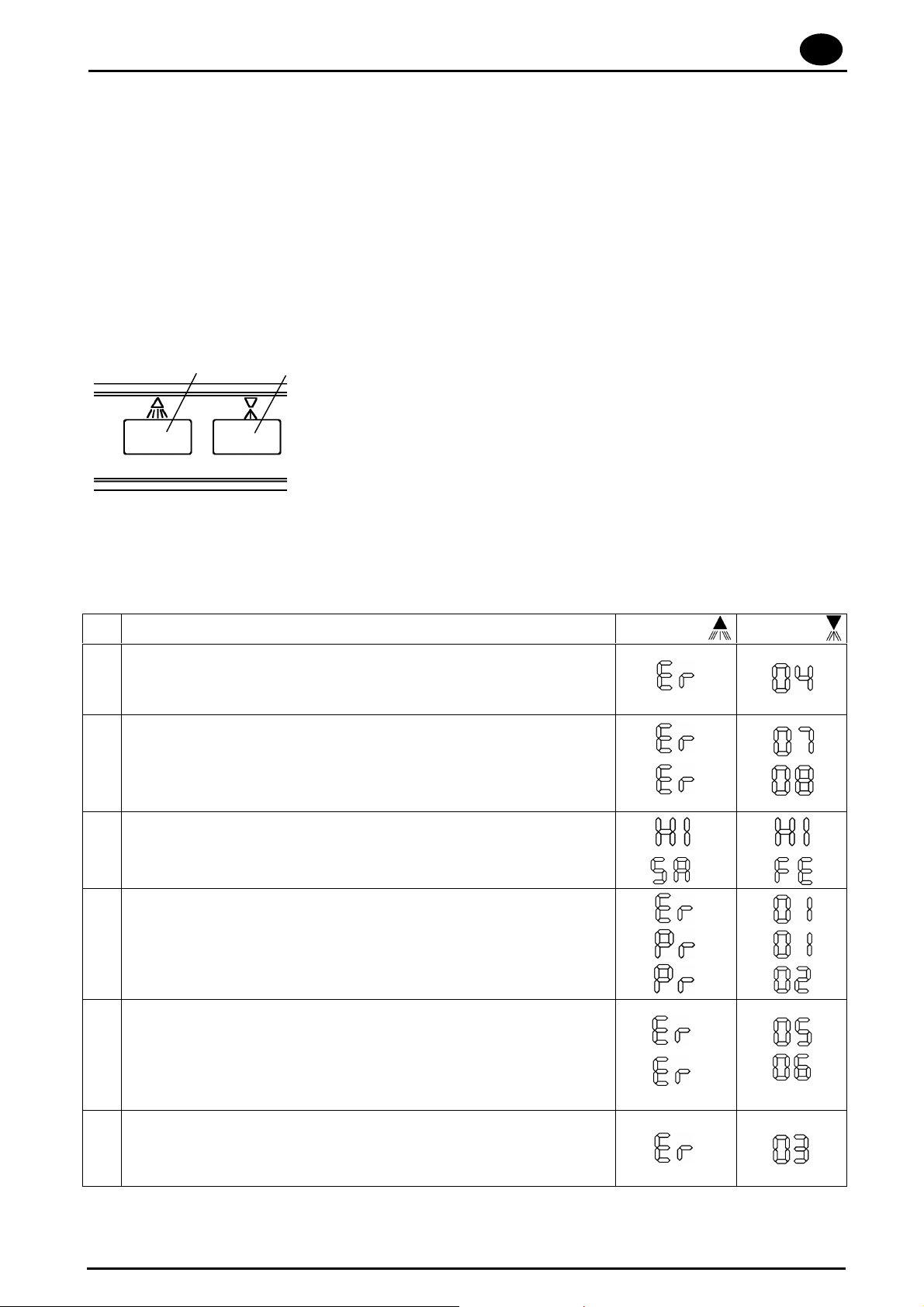

3.2 SAFETY DEVICE

56

The board can recognize various breakdowns.

Faults are easily seen from the messages on the screen (5 and 6) and from any interruption of the

operations in progress only in cases (1 and 3) listed below

WARNING! Turning the machine off and then on again resets the warning, which will appear again if

the problem has not been resolved.

Display on the Message

PROBLEM: Tank (6) Boiler (5)

TANK NOT FILLED OR OVERFILLED

1

(if t10 min have elapsed, correct level of water has not been reached in the

tank)

BOILER PROBE FAILURE

2

(if the probe is not connected correctly or damaged)

(if the probe is short circuited or damaged)

OVERTEMPERATURE

3

(excessive boiler and tank temperature)

(intervention safety thermostat)

4

(Insufficient rinse pressure)

(Excessive rinse pressure)

RINSE

(Rinse not effected)

TANK PROBE FAILURE

5

6

(if the probe is not connected correctly or damaged)

(if the probe is short circuited or damaged)

BOILER

(Boiler resistor failure)

(Heating overtime)

Page 9

GB

page 8

USE AND MAINTENANCE MANUAL

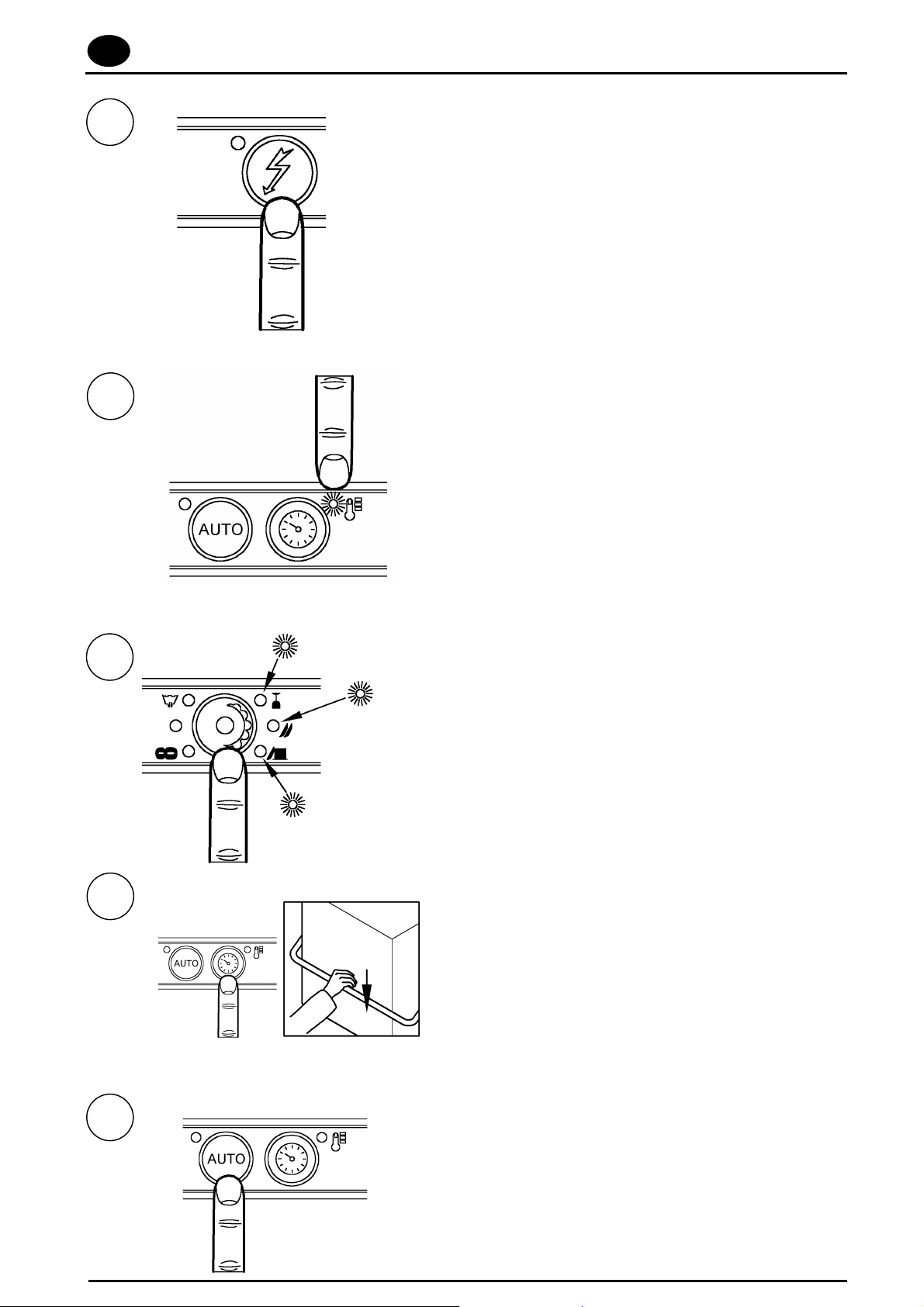

1

2

Chap. 4 USE OF MACHINE

4.1 DESCRIPTION OF THE COMMANDS

1. To turn the machine on, press the button

indicated at left/right

(the corresponding warning light will light

up)

.

2. When the light turns off, the machine is ready

to use.

3

4

Short cycle

Medium cycle

Ciclo intensive

3. Press the button indicated at left/right to

select the items to wash. The light turns on

in accordance with the amount of time

selected.

NB: choose the " v " for longer wash

cycles.

4. Press the button indicated at left/right and

close the door, the machine will start

automa-tically.

interrupt the "

sequence 3 for new wash programs).

NB: press the button to

v

" cycle (repeat

5

5. If you want cycles to start when you close

the hood, push the button and the

corresponding light will turn on

Page 10

USE AND MAINTENANCE MANUAL

page 9

1

2

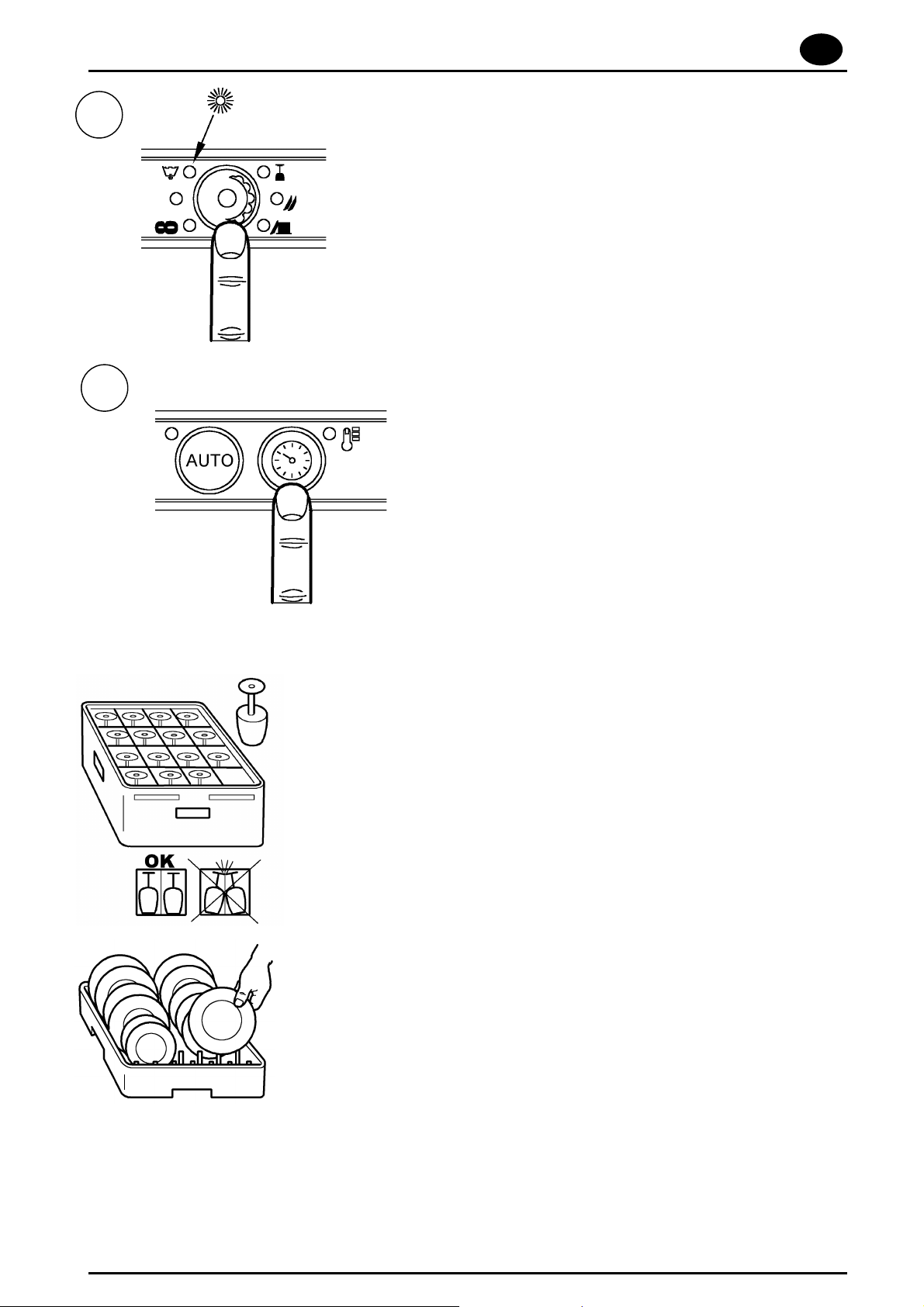

4.1.1 Automatic water drainage

(optional)

1. Press the button indicated at

left/right and select the drainage

programme (the corresponding

warning light will light up).

2. Press the button indicated at

left/right and the machine will

automatically drain the water out of

the machine.

4.2 USING THE MACHINE

Pour the proper amount of detergent in the wash tank according to the

producer’s instructions.

The detergent must be the industrial type or possibly foamless.

Never put your bare hands in the wash water; place the cups and the

glasses upside down in the baskets. Place the dishes in the proper

basket with support pins and their inner surface must be facing up.

Place the silverware and the coffee spoons with the handles facing

down.

Never place silverware and stainless steel cutlery in the same basket.

This could cause the silver to burnish and the stainless steel to

corrode.

Use the proper baskets specifically designed for the different type of

glassware (dishes, glasses, cups, silverware etc.). To save on

detergent and electricity only wash when the baskets are full, but do

not overload them. Avoid stacking glassware.

Page 11

GB

page 10

USE AND MAINTENANCE MANUAL

WE RECOMMEND TO PRE-CLEAN the glassware in order to

minimize maintenance. The quality of final wash results will be greatly

improved by first removing food particles, lemon peels, toothpicks,

olive pits, etc. which could partially clog the pump filter and impair

washing efficiency.

We recommend washing the glassware before food particles dry

on its surface. It is good practice, when dried food waste is

involved, to first soak the glassware and silverware before

introducing them into the machine.

4.1 END OF CYCLE OPERATIONS

x Remove tension from the machine.

x Lift the hood and extract the rack clean dishes.

x Drain the water from the tank by lifting the overflow-pipe. For the

model with drain pump please follow the operations described in the

«Use instructions» paragraph.

x Disconnect the main switch of the equipment.

x Close the «rolling shutter valve» for the hydraulic connection.

x Remove the filters clean them under a water jet with a nylon brush.

x Pay attention not to let any dirtiness rests on the bottom of the

drain pump filter inside the tank. Clean the tank with a moderate water

jet. Wash outside surfaces when are cold with non-abrasive products

which are especially studied for steel maintenance.

REMARK: Do not wash the equipment with direct jet or at

another pressure because eventual infiltrations to the electric

components may harm the regular working of the equipment or

of the single safety systems, and penalty for this would be the

loss of guarantee.

Page 12

USE AND MAINTENANCE MANUAL

page 11

CHAP. 5 MAINTENANCE

5.1 GENERAL RULES

The machine are designed to reduce maintenance requirements. It is

necessary to observe the following rules to make the machine last

long, and work without problems.

In any case, it is necessary to observe the following rules to make the

machine stay in perfect working order:

x keep the machine clean and in good condition

x avoid making temporary or urgent repairs frequently

It is very important to observe the maintenance directions; check all

the different parts of the machine periodically, so that no anomaly can

occur, thus anticipating the time and equipment needed for any

maintenance work.

Before cleaning turn off the power.

5.2 PERIODIC MAINTENANCE (to be done at least every 20 days)

To make operations following easier, the rack-holder frame can be

removed from its seat.

x Remove the upper and lower rinse arms, by unscrewing the

fastening.

x Unscrew and clean all the sprayers and put them back in their

place.

x Remove the upper and lower wash-arms by unscrewing the rinse

pin , clean and rinse them.

x Remove the wash pump filter, clean it and rinse it.

x Thoroughly clean the wash tank.

x Leave the appliance lid open for the whole resting period.

x Lime deposits and scale will build up on the inner surfaces of the

boiler, tank and pipelines due to calcium and magnesium salts

present in the water. These scales and deposits can prejudice

proper apppliance operation.

x The appliance must be periodically descaled and we recommend

that this must be done by an expert.

Page 13

GB

page 12

USE AND MAINTENANCE MANUAL

x Grease steel surfaces with vaseline oil whenever the appliance will

be inactive for a long period of time.

x Have an expert drain all the water out from the boiler and the wash

pump to avoid the danger of ice formation.

x If the machine does not operate properly or in case of trouble,

call a service center authorized by the manufacturer of the

appliance or by his Dealer.

CHAP. 6 DISMANTLING

6.1 DISMANTLING THE MACHINE

Our machines are not made of materials that require particular

disposal procedures.

Page 14

CHH50

CHH60

CHH70

Dishwasher

Spare Parts List

jw-06-2006

Page 15

CHH50 - EH60 - EH70

Machine Body

Electrical components

Components in the tank

Wash pump

Page 16

CHH50 - EH60 - EH70

80422

139321-470

80331

926243

926108

80423

80420

80325

80329

80162

139321-475

139321-552

927088

139321-474

80190

80105

80105

80027

80240

41042

926009

80071

80023

41042

80072

80078

926117

80079H

139321-663

139321-667

139321-668

139321-664

139321-666

139321-669

139321-670

139321-671

139321-672

139321-675

139321-474

139321-678

139321-674

139321-674

139321-676

139321-677

139321-679

139321-665

139321-680

139321-677

139321-681

139321-682

139321-683

139321-684

80998

139321-901

3

Page 17

CHH50 - EH60 - EH70

80372

DER111

139321-487

220011

CWP2

81001

CWP2

926286

H228048

DEF4

139321-451

215022

H228047

80350

231014

DTC112NO

929115

80372

220011

DWS99

H228048

H228047

139321-456

DEF4

81001

215023

215022

CWP3

CN1

80528

80542

80541

CHH50

EH60

EH70

139321-685

139321-686

139321-582

139321-687

139321-688

139321-689

139321-601

139321-690

139321-691

139321-687

139321-600

139321-692

139321-693

139321-685

139321-687

139321-582

139321-687

139321-601

139321-600

139321-694

139321-700

139321-696

139321-697

139321-695

139321-698

139321-699

139321-591

139321-688

139321-689

139321-690

139321-691

DEF71

139321-902 (800mA)

DEF72

139321-903 (315mA)

4

Page 18

80149 (CHH50 / EH60)

80159 (EH70)

80152 (EH70)

80177

80282

80184

211002AG

80316

139321-452(CHH50/EH60)

139321-476 (EH70)

468151

139321-550

926189

H775489-1

231014

139321-450*

139321-473 * Drain Pump Kit

136020

456040

143136

80186

80470

80188 (CHH50 / EH60)

80187 (EH70)

139321-472 (EH70)

139321-471 (EH60)

139321-548 (CHH50)

80182

139321-192

80249 (CHH50 / EH60)

80250 (EH70)

80237

441009

( * ) EH70 Model Only

5

CHH50 - EH60 - EH70

139321-701 (CHH50 / EH60)

139321-702 (EH70)

139321-703 (EH70)

139321-839

139321-906

139321-904

139321-905

139321-915

139321-916

139321-918

139321-917

139321-925

139321-919

139321-923

139321-924

139321-920

139321-921

139321-914

139321-907

139321-908

139321-909

139321-913

139321-910

139321-911

139321-912

139321-587

139321-591

139321-1110 Pump Only

*FITTED AS STD ON

Page 19

EH70

468165

437078

429050

437025

41167

143010

429036

80575

926129

80314

929085

206010

143005

927326

H142277

139321-464

139321-490

80538

139321-37

139321-53

230020C

DRT140

80530

929171

139321-521

929198

6

139321-766

139321-780

139321-767

139321-653

139321-652

139321-930

139321-927

139321-926

139321-942

139321-931

139321-941

139321-615

139321-932

139321-933

139321-934

139321-935

139321-936

139321-938

139321-937

139321-939

139321-940

139321-928

139321-929

Page 20

80314

139321-957 (EH70)

139321-956 (CHH50 - EH60)

139321-483

139321-928

139321-943

139321-943

139321-944

139321-944

139321-945

139321-946

139321-947

139321-947

139321-948

139321-948

139321-949

139321-949

139321-950

139321-951

139321-952

139321-953

139321-954

139321-955

139321-956

139321-957

139321-918

139321-920

CHH50 - EH60 - EH70

80311

DWT312

80379

80375

80371

80380

80371

80310

80378

927068

DWT312

CGR2025

80376

CGR2025

80373

80365

80374

80380

80282

80316

7

80370

80377

80311

Page 21

DEC220L

139321-509

139321-958

139321-974

139321-960

139321-961

139321-962

139321-963

139321-964

139321-965

139321-966

139321-967

139321-471

CHH50 - EH60 - EH70

926083

RAC135

926255

RAT72

RAG62

124031

RAC436

80112

CHH50

RAG72

926086

139321-478

80114

EH 60

8

Page 22

RAC74

139321-969

139321-970

139321-964

139321-971

139321-972

139321-967

139321-973

139321-472

EH70

RAV74

926083

RAG74

RAT210

926086

926084

80116

EH 70

9

Page 23

23/09/03

Product Modification Note , from today’s date we have done the following modification:

Codes subject to the modification

RV82HUK (hobart u.k.)

Modification ‘s Description

For all hood type models ,

We have exchanged the current pump cod. 139321-472 built by LGB , with the wash pump

Code 80115 built by FIR.

The two wash pumps are completely interchangeable as a whole part , but

the single internal components will be different , so we have attached the new

spare part catalogue page for the FIR wash pump code 80115.

10

Page 24

Wash Pump

(Modification - 23.09.03)

80124

80123

EH70

80122

80121

80120

80119

80115 (Fir) Wash Pump Assy

Modification from 23.09.2003

(see att Note)

80118

11

Page 25

929173

139321-975

139321-976

139321-977

139321-978

139321-979

139321-490

CHH50 - EH60 - EH70

929182

RAG426

RAT124

929186

929167

12

Page 26

CHH50 - CHH60 - CHH70

Drain Pump Assy

Drain Pump 220-240V 50Hz - 139321-1110

Drain Pipe 2000mm (drain pump to drain) DZS151 - 139321-968

Drain Pipe (from machine to pump) 127056 - 139321-969

Jubilee Clip 40/60 -

Jubilee Clip 20/32 - 166513-6

Bolt 6MAx12 -

Lockwasher D6 - LWM-E-3-4

Timer Card (tally drain timer) -

Timer (drain timer) -

Page 27

As continued product inprovement is a policy of HOBART, specifications are subject to change with-out notice.

00.00.2003-Issue-1

Page 28

CHH50 / EH60

CHH50

EH60

Page 29

SIMBOLO DESCRIZIONI DESCRIPTIONS BESCHREIBUNGEN

EH60 / CHH50

A1/43 SCHEDA CONTROLLO ELETTRONICA FICHE DE CONTROLEELECTRONIQUE

A2 PANNELLO COMANDI TABLEAU DE COMMANDES

B1 SONDA RESISTENZA VASCA THERMOSTAT RESISTENCE DE CUVE

B2 SONDA RESISTENZA BOILER THERMOSTAT RESISTANCE BOYLER

B3 PRESSOSTATO LIVELLO VASCA PRESSOSTAT NIVEAU CUVE

B4 LIVELLOSTATO BOILER INT. A ELOTEUR

F2 FUSIBILE COMANDI FUSIBLE

F1 PROTEZIONE TERMICA ELETTROPOMPA PROT. TERMIQUE MOTEUR EL. POMPE

KM1 TELERUTTORE ELETTROPOMPA LAVAGGIO TELEREUPTEUR ELECTROPOMPE DE LAVAGE

KR1 TELERUTTORE RESISTENZA BOILER TELERUPTEUR RESISTANCE SURCHAFFEUR

KR2 TELERUTTORE RESISTENZA VASCA RELAIS RESISTENCE DE CUVE

KR3 TELERUTTORE SICUREZZA TELERUPTEUR DE SECURITE SURCHAFFEUR

M1 ELETTROPOMPA LAVAGGIO ELECTROPOMPE LAVAGE

M2 ELETTROPOMPA AUMENTO PRESSIONE ELECROPOMPE SURPRESSEUSE DE RINCAGE

M5 MOTORE DOSATORE DETERSIVO MOTEUR DOSEUR TENSIOACTIF

P1 PULSANTE PARTENZA AUTOMATICA INTERREPTEUR DEMARRAGE AUTOMATIC

P2 PULSANTE SELETTORE CICLO SELECTEUR CYCLE

P3 PULSANTE LINEA INTERRUPTEUR DE LIGNE

R1 RESISTENZA BOILER RESISTANCE SURCHAUFFEUR

R3 RESISTENZA VASCA RESISTANCE CUVE DE LAVAGE

S1 TERMOSTATO SICUREZZA BOILER THERMOSTAT DE SECURITE DU BOYLER

S2 TERMOSTATO SICUREZZA VASCA THERMOSTAT SECURITE CUVE

S3 MICROINTERRUTTORE MAGNETICO MICROINTERRUPTEUR MAGNETIQUE

Y2

ELECTRONIC CONTROL UNIT ELEKTRONISCHE BEDIENUNGSKARTE

CONTROL PANEL BEDIENUNGSPANEEL

PROBE TANK HEATER THANKHEIZUNGTHERMOSTAT

BOOSTER HEATER THERMOSTAT BOILERHEIZUNG -THERMOSTAT

TANK PRESSURE SWITCH DRUCKSCHALTER TANK-NIVEAUREGLER

BOOSTER FLOAT SWICTH SCWINNERSCHALTER

COMMAND FUSE SICHERUNGEN

EL. WASH PUMP THERMAL PROTECTION THERMISCHER MOTORPUMPESCHUTZ

WASH ELECTROPUMP REMOTE-CONTROL FERNSCHALTER DER WASCH-ELEKTROPUMPE

BOOSTER HEATER REMOTE -CONTROL FERNSCHALTER DER BOILER-HEIZUNG

RELAY FOR TANK HEATER ELEMENT. NACHSPUELHEIZUNGSRELAIS.

SAFETY HEATER REMOTE-CONTROL SICHERHEITS-FERNSCHALTER DES BOILERS

WASH MOTOR PUMP WASCH-MOTORPUMPE

RINSE BOOSTER PUMP DRUCKSTEIGERUNGSPUMPE

RINSE AID DISPENSER MOTOR NACHSPÜLUNGSMITTELDOSIERGERÄT-MOTOR

AUTOMATIC START PUSH BOTTON AU TOMATISCHER START WAEINSCALTER

CYCLE COMMUTATOR WAEHLSCHALTER FUER WASCHVORGANGSDAUDER

MAIN SWITCH NETZSCHALTER

BOOSTER HEATER HEATING ELEMENT BOILERHEIZUNG

WASH TANK HEATING ELEMENT WASCHTANKHEIZUNG

SAFETY BOOSTER HEATER THERMOSTAT BOILER -SICHERHEITS-THERMOSTAT

TANK SAFETY HEATER THERMOSTAT SICHERHEITS- TANKTHERMOSTAT

MAGNETIC MICROSWITCH MAGNETISCHER MIKROSCHALTER

ELETTROVALVOLA RIEMPIMENTO BOILER ELECTROVALVE REMPLISSAGE SURCHAUFFEUR

BOILER FILLING ELECTRIC VALVE SOLENOIDVENTIL DER BOILERFÜLLUNG

Page 30

EH70

Page 31

SIMBOLO DESCRIZIONI DESCRIPTIONS BESCHREIBUNGEN

EH 70

A1/43 SCHEDA CONTROLLO ELETTRONICA FICHE DE CONTROLEELECTRONIQUE

A2 PANNELLO COMANDI TABLEAU DE COMMANDES

B1 SONDA RESISTENZA VASCA THERMOSTAT RESISTENCE DE CUVE

B2 SONDA RESISTENZA BOILER THERMOSTAT RESISTANCE BOYLER

B3 PRESSOSTATO LIVELLO VASCA PRESSOSTAT NIVEAU CUVE

B4 LIVELLOSTATO BOILER INT. A ELOTEUR

F1 PROTEZIONE TERMICA ELETTROPOMPA PROT. TERMIQUE MOTEUR EL. POMPE

F2 FUSIBILE COMANDI FUSIBLE

KM1 TELERUTTORE ELETTROPOMPA LAVAGGIO TELEREUPTEUR ELECTROPOMPE DE LAVAGE

KR1 TELERUTTORE RESISTENZA BOILER TELERUPTEUR RESISTANCE SURCHAFFEUR

KR2 TELERUTTORE RESISTENZA VASCA RELAIS RESISTENCE DE CUVE

KR3 TELERUTTORE SICUREZZA TELERUPTEUR DE SECURITE SURCHAFFEUR

M1 ELETTROPOMPA LAVAGGIO ELECTROPOMPE LAVAGE

M2 ELETTROPOMPA AUMENTO PRESSIONE ELECROPOMPE SURPRESSEUSE DE RINCAGE

M5 MOTORE DOSATORE DETERSIVO MOTEUR DOSEUR TENSIOACTIF

P1 PULSANTE PARTENZA AUTOMATICA INTERREPTEUR DEMARRAGE AUTOMATIC

P2 PULSANTE SELETTORE CICLO SELECTEUR CYCLE

P3 PULSANTE LINEA INTERRUPTEUR DE LIGNE

R1 RESISTENZA BOILER RESISTANCE SURCHAUFFEUR

R3 RESISTENZA VASCA RESISTANCE CUVE DE LAVAGE

S1 TERMOSTATO SICUREZZA BOILER THERMOSTAT DE SECURITE DU BOYLER

S2 TERMOSTATO SICUREZZA VASCA THERMOSTAT SECURITE CUVE

S3 MICROINTERRUTTORE MAGNETICO MICROINTERRUPTEUR MAGNETIQUE

Y2

ELECTRONIC CONTROL UNIT ELEKTRONISCHE BEDIENUNGSKARTE

CONTROL PANEL BEDIENUNGSPANEEL

PROBE TANK HEATER THANKHEIZUNGTHERMOSTAT

BOOSTER HEATER THERMOSTAT BOILERHEIZUNG -THERMOSTAT

TANK PRESSURE SWITCH DRUCKSCHALTER TANK-NIVEAUREGLER

BOOSTER FLOAT SWICTH SCWINNERSCHALTER

EL. WASH PUMP THERMAL PROTECTION THERMISCHER MOTORPUMPESCHUTZ

COMMAND FUSE SICHERUNGEN

WASH ELECTROPUMP REMOTE-CONTROL FERNSCHALTER DER WASCH-ELEKTROPUMPE

BOOSTER HEATER REMOTE -CONTROL FERNSCHALTER DER BOILER-HEIZUNG

RELAY FOR TANK HEATER ELEMENT. NACHSPUELHEIZUNGSRELAIS.

SAFETY HEATER REMOTE-CONTROL SICHERHEITS-FERNSCHALTER DES BOILERS

WASH MOTOR PUMP WASCH-MOTORPUMPE

RINSE BOOSTER PUMP DRUCKSTEIGERUNGSPUMPE

RINSE AID DISPENSER MOTOR NACHSPÜLUNGSMITTELDOSIERGERÄT-MOTOR

AUTOMATIC START PUSH BOTTON AU TOMATISCHER START WAEINSCALTER

CYCLE COMMUTATOR WAEHLSCHALTER FUER WASCHVORGANGSDAUDER

MAIN SWITCH NETZSCHALTER

BOOSTER HEATER HEATING ELEMENT BOILERHEIZUNG

WASH TANK HEATING ELEMENT WASCHTANKHEIZUNG

SAFETY BOOSTER HEATER THERMOSTAT BOILER -SICHERHEITS-THERMOSTAT

TANK SAFETY HEATER THERMOSTAT SICHERHEITS- TANKTHERMOSTAT

MAGNETIC MICROSWITCH MAGNETISCHER MIKROSCHALTER

ELETTROVALVOLA RIEMPIMENTO BOILER ELECTROVALVE REMPLISSAGE SURCHAUFFEUR

BOILER FILLING ELECTRIC VALVE SOLENOIDVENTIL DER BOILERFÜLLUNG

Page 32

12345678

12345678

12345678

12345678

12345678

12345678

CHH50 (electrical configuration data)

Single phase configuration 6 kW

**

82

81

80

E

*

N

*

not used

L3

L2

*

L1

*

* Links must be installed as shown (not supplied)

Three phase configuration 9 kW

E

not used

Boiler heater

**This wire (is tied back)

needs to be connected (N)

Note: the copper links must

be positioned as shown

80 81 82

Boiler heater

82

81

80

N

L3

L2

L1

Bit switch settings

on

off

1 2 3 4

Note: the copper links must

be positioned as shown

80 81 82

1 = Temperature check - (waits for boiler)

2 = Drain pump (option)

3 = Boiler standby - (holding temp 50ºC)

4 = Boiler heating - (on or off)

Page 33

DISHWASHER TECHNICAL SPECIFICATIONS

EF40 EH60 EH70 EUT30 EUT60

Drain size 22MM 50MM 50MM 50MM 2"

Drain hose length 1,5M 1,80M 1,80M 1,80 No Hose

Water connection 3/4" 3/4" 3/4" 3/4" 3/4"

Water hose length 1,5M 2M 2M 2M 2M

Water pressure 1-4BAR 1-4BAR 1-4BAR 1-4BAR 1-4BAR

Water temp 15-55C 15-55C 15-55C 15-55C 15-55C

Total KW loading 3P N/A 9.1KW 11.1KW 8.0KW 15.0KW

Total KW loading 1P 5,5KW/2,7KW 6.5KW N/A N/A N/A

Mains cable length 3,0M 1,60M 1,60M 1,60M 1,60M

Mains cable size 3x4mm 5x2,5mm 5x4mm 5x2,5mm 5x4mm

Det pipe length 1,50M 1,50M 1,50M N/A N/A

R/aid pipe length 1,50M 1,50M 1,50M N/A N/A

Programme times. secs 60-120-180 60-110-150 50-85-110 120-240-360 120-240-360

Wat/consumption,cycle 3,3L 3L 2.7L 3.5L 8.0L

W/tank capacity 11L 20L 30L 40L 130L

R/tank capacity 6L 12L 12L 14L 14L

Drain pump YES NO YES NO NO

W/pump rating 0,8KW 1.1KW 1.6KW 2.0KW 2X3KW

W/pump flow rate 260L/min 485L/min 534L/min 550L/min 950L/min

R/pump rating 0,45KW 0,15kw 0,15kw 0,15kw 0.45KW

R/pump flow rate 11L/min 36L/min 36L/min 36L/min 80L/min

Voltage 3P N/A 400/50/3/N 400/50/3/N 400/50/3/N 400/50/3/N

Voltage 1P 230/50/1 230/50/1 N/A N/A N/A

Noise level(dB) 66db 66dB 67db 67db 69db

Rinse time 17 sec 15 sec 15 sec 17sec 17sec

Page 34

DISHWASHER TECHNICAL SPECIFICATIONS

CHG25 CHF40 CHH50 CLG25 CLF26

Drain size 20MM 22MM 50MM 18MM 22MM

Drain hose length 2,5M 1,5M 1,80M 1,5M 1,5M

Water connection 3/4" 3/4" 3/4" 3/4" 3/4"

Water hose length 1,5M 1,5M 2M 1,5M 1,5mt

Water pressure 1-4BAR 1-4BAR 1-4BAR 1-4BAR 1-4BAR

Water temp 50-55C 15-55C 15-55C 50-55C 50-55C

Total KW loading 3P N/A N/A 6.8KW N/A N/A

Total KW loading 1P 2,85KW 2,7KW/6,7KW 4.8KW 2,85KW 2,7KW/6,7KW

Mains cable length 3,0M 3,0M 1,60M 3,0M 3,0M

Mains cable size 3x1,5mm 3x4mm 5x2,5mm 3x1,5mm 3x4mm

Det pipe length N/A 1,50M 1,50M 1,50M

R/aid pipe length 1,50M 1,50M 1,50M 1,50M 1,50M

Programme times. secs 150 60-120-180 60-120-180 150 60-180

Wat/consumption,cycle 2,6L 3,3L 3L 2,6L 3.3L

W/tank capacity 11L 33L 20L 11L 33L

R/tank capacity 2.6L 6L 12L 2.6L 6L

Drain pump YES YES NO NO YES

W/pump rating 0.15kw 0.8KW 0.8KW 0.15KW 0.8KW

W/pump flow rate 105L/min 330L/min 380lt/min 105L/min 330L/min

R/pump rating 0,45KW 0,45KW 0,15kw 0,45KW 0,45KW

R/pump flow rate 11L/min 11L/min 36L/min 11L/min 11L/min

Voltage 3P N/A N/A 400/50/3/N N/A N/A

Voltage 1P 230/50/1 230/50/1 230/50/1 230/50/1 230/50/1

Noise level(dB) 63db 67db 66dB 63db 67db

Rinse time 15 sec 17 sec 15 sec 17 sec 17 sec

Page 35

Hobart Independent

Southgate Way, Orton Southgate, Peterborough PE2 6GN

Tel: 0870 1688881

Fax: 01733 361347

E-mail: indsales@hobartindependent.com

Website: www.hobartindependent.com

As continued product improvement is a policy of HOBART / HOBART INDEPENDENT,

specifications are subject to change without notice.

Loading...

Loading...