Hobart 140GT17P, 140GT17K, 140GT17P5 Operation And Maintenance Manual With Illustrated Parts List

Page 1

OM-2029

010187

Revised 093089

Revised 031690

Revised 072790

Revised 040893

OPERATION AND MAINTENANCE MANUAL

with

ILLUSTRATED PARTS LIST

for

ENGINE-DRIVEN GENERATOR SETS

SERIES 6906

Models 140GT17P, 140GT17K, and 140GT17P5

140-KVA, 400-HZ, 115/200-V AC, 3-PHASE

SPEC. No. DESCRIPTION

6906-1 Basic Series 6906 generator set, trailer-mounted

6906-2 Basic Series 6906 generator set, truck-mounted

6906-3 Basic Series 6906 generator set, mounted on

5th-wheel trailer, with T-R provisions, fuel tank,

battery, and trays for battery and cables.

6906-4 Basic Series 6906 generator set, truck-mounted,

and equipped with magnetic amplifier type voltage

regulator, Part No. 281407

6906-5 Basic Series 6906 generator set, mounted on 5th-wheel

trailer

6906-6 Basic Series 6906 generator set, mounted on 5th-wheel

trailer, with fuel tank, cable tray, battery/cable tray,

rear fenders, and rear bumper

Hobart Brothers Company

Airport Systems Group

Ground Power Equipment

Troy, Ohio 45373

U.S.A.

Page 2

This page intentionally left blank

Page 3

SAFETY INSTRUCTIONS AND WARNINGS FOR ELECTRICAL POWER EQUIPMENT

WARNING

ELECTRIC SHOCK can KILL. Do not touch live electrical parts.

ELECTRIC ARC FLASH can injure eyes, burn skin, cause equipment damage, and ignite combustible

material. DO NOT use power cables to break load and prevent tools from causing short circuits.

IMPROPER PHASE CONNECTION, PARALLELING, OR USE can damage this and attached

equipment.

Important:- Protect all operating personnel. Read, understand, and follow all instructions in

the Operating/Instruction Manual before installing, operating, or servicing the equipment. Keep

the manual available for future use by all operators.

A. GENERAL

Equipment that supplies electrical power can cause serious injury or death, or damage to other equipment

or property. The operator must strictly observe all safety rules and take precautionary actions. Safe practices

have been developed from past experience in the use of power source equipment. While certain practices below apply only to electrically-powered equipment, other practices apply to engine-driven equipment, and some

practices to both.

B. SHOCK PREVENTION

Bare conductors, or terminals in the output circuit, or ungrounded, electrically-live equipment can fatally

shock a person. Have a certified electrician verify that the equipment is adequately grounded and learn what

terminals and parts are electrically HOT. Avoid hot spots on machine. Use proper safety clothing, procedures,

and test equipment.

The electrical resistance of the body is decreased when wet, permitting dangerous currents to flow

through it. When inspecting or servicing equipment, do not work in damp areas. Stand on a dry rubber mat

or dry wood, use insulating gloves when dampness or sweat cannot be avoided. Keep clothing dry, and

never work alone

1. Installation and Grounding of Electrically Powered Equipment

Equipment driven by electric motors (rather than by diesel or gasoline engines) must be installed and

maintained in accordance with the National Electrical Code, ANSI/NFPA 70, or other applicable codes. A

power disconnect switch or circuit breaker must be located at the equipment. Check the nameplate for voltage, frequency, and phase requirements. If only 3-phase power is available, connect any single-phase rated

equipment to only two wires of the 3-phase line. DO NOT CONNECT the equipment grounding conductor

(lead) to the third live wire of the 3-phase line, as this makes the equipment frame electrically HOT, which can

cause a fatal shock.

Always connect the grounding lead, if supplied in a power line cable, to the grounded switch box or building ground. If not provided, use a separate grounding lead. Ensure that the current (amperage) capacity of

the grounding lead will be adequate for the worst fault current situation. Refer to the National ElectricalCode

ANSI/NFPA 70 for details. Do not remove plug ground prongs. Use correctly mating receptacles.

2. Output Cables and Terminals

Inspect cables frequently for damage to the insulation and the connectors. Replace or repair cracked or

worn cables immediately. Do not overload cables. Do not touch output terminal while equipment is energized.

3. Service and Maintenance

This equipment must be maintained in good electrical and mechanical condition to avoid hazards stemming from disrepair. Report any equipment defect or safety hazard to the supervisor and discontinue use of

the equipment until its safety has been assured. Repairs should be made by qualified personnel only.

Before inspecting or servicing electrically-powered equipment, take the following precautions:

Page 4

a. Shut OFF all power at the disconnecting switch or line breaker before inspecting or servicing the

equipment.

b. Lock switch OPEN (or remove line fuses) so that power cannot be turned on accidentally.

c. Disconnect power to equipment if it is out of service.

d. If troubleshooting must be done with the unit energized, have another person present who is trained in

turning off the equipment and providing or calling for first aid.

C . FIRE AND EXPLOSION PREVENTION

Fire and explosion are caused by electrical short circuits, combustible material near engine exhaust piping, misuse of batteries and fuel, or unsafe operating or fueling conditions.

1. Electrical Short Circuits and Overloads

Overloaded or shorted equipment can become hot enough to cause fires by self destruction or by causing

nearby combustibles to ignite. For electrically-powered equipment, provide primary input protection to remove

short circuited or heavily overloaded equipment from the line.

2. Batteries

Batteries may explode and/or give off flammable hydrogen gas. Acid and arcing from a ruptured battery

can cause fires and additional failures. When servicing,do not smoke, cause sparking, or use open flame

near the battery.

3. Engine Fuel

Use only approved fuel container or fueling system. Fires and explosions can occur if the fuel tank is not

grounded prior to or during fuel transfer. Shut unit DOWN before removingfueltank cap. DO NOT completely fill tank, because heat from the equipment may cause fuel expansion overflow. Remove all spilled fuel

IMMEDIATELY, including any that penetrates the unit. After clean-up, open equipment doors and blowfumes

away with compressed air.

D. TOXIC FUME PREVENTION

Carbon monoxide - Engine exhaust fumes can kill and cause health problems. Pipe or vent the exhaust

fumes to a suitable exhaust duct or outdoors. Never locate engine exhausts near intake ducts of air conditioners.

E. BODILY INJURY PREVENTION

Serious injury can result from contact with fans inside some equipment. Shut DOWN such equipment for

inspection and routine maintenance. When equipment is in operation, use extreme care in doing necessary

trouble-shooting and adjustment. Do not remove guards while equipment is operating.

F. MEDICAL AND FIRST AID TREATMENT

First aid facilities and a qualified first aid person should be available for each shift for immediate treatment of all injury victims. Electric shock victims should be checked by a physician and taken to a hospital immediately if any abnormal signs are observed.

EMERGENCY FIRST AID

Call physician immediately. Seek additional assistance. Use First Aid techniques recommended

by American Red Cross until medical help arrives.

IF BREATHING IS DIFFICULT, give oxygen, if available, and have victim lie down. FOR ELECTRICAL SHOCK, turn off power. Remove victim; if not breathing, begin artificial respiration, preferably

mouth-to-mouth. If no detectable pulse, begin external heart massage. CALL EMERGENCY RESCUE

SQUAD IMMEDIATELY.

G. EQUIPMENT PRECAUTIONARY LABELS

Inspect all precautionary labels on the equipment monthly. Order and inspect all labels that cannot be

easily read.

Page 5

OM-2029

LIST OF EFFECTIVE PAGES

CHAPTER/ CHAPTER/

SECTION PAGE DATE SECTION PAGE DATE

List of 1 Mar 16/90 1-3 1 Sept 30/89

Effective 2 Mar 16/90 1-3 2 Sept 30/89

Pages 1-3 3 July 27/90

1-3 4 July 27/90

Introduction 1/2 Sept 30/89 1-3 5 Sept 30/89

1-3 6 July 27/90

Contents 1 Sept 30/89 1-3 7 July 27/90

Contents 2 Sept 30/89 1-3 8 Sept 30/89

Contents 3 Sept 30/89

Contents 4 Sept 30/89 2-1 1 Sept 30/89

Contents 5 Sept 30/89 2-1 2 Sept 30/89

Contents 6 Sept 30/89 2-1 3 Sept 30/89

Contents 7 Sept 30/89 2-1 4 Sept 30/89

Contents 8 Sept 30/89 2-1 5 Sept 30/89

Contents 9 Sept 30/89 2-1 6 Sept 30/89

Contents 10 Sept 30/89 2-1 7 Sept 30/89

Contents 11 Sept 30/89 2-1 8 Sept 30/89

Contents 12 Sept 30/89 2-1 9 Sept 30/89

2-1 10 Sept 30/89

1-1 1 July 27/90 2-1 11 Sept 30/89

1-1 2 Sept 30/89 2-1 12 Sept 30/89

1-1 3 Mar 16/90 2-1 13 Sept 30/89

1-1 4 Mar 16/90 2-1 14 Sept 30/89

1-1 5 July 27/90

1-1 6 July 27/90 2-2 1 Sept 30/89

1-1 7 Sept 30/89 2-2 2 Sept 30/89

1-1 8 Sept 30/89 2-2 3 Sept 30/89

1-1 9 Sept 30/89 2-2 4 Sept 30/89

1-1 10 Sept 30/89 2-2 5 Sept 30/89

1-1 11 Sept 30/89 2-2 6 Sept 30/89

1-1 12 Sept 30/89

1-1 13 Sept 30/89 2-3 1 July 27/90

1-1 14 July 27/90 2-3 2 Sept 30/89

1-1 15 July 27/90 2-3 3 July 27/90

1-1 16 July 27/90 2-3 4 July 27/90

1-1 17 July 27/90 2-3 5 Sept 30/89

1-1 18 Sept 30/89 2-3 6 Sept 30/89

1-1 19 Sept 30/89 2-3 7 Sept 30/89

1-1 20 Sept 30/89 2-3 8 Sept 30/89

1-1 21 Sept 30/89 2-3 9 Mar 16/90

1-1 22 Sept 30/89 2-3 10 Mar 16/90

1-1 23 Sept 30/89 2-3 11 Mar 16/90

1-1 24 Sept 30/89 2-3 12 Mar 16/90

2-3 13 Mar 16/90

1-2 1 Sept 30/89 2-3 14 Mar 16/90

1-2 2 Sept 30/89

1-2 3 Sept 30/89

1-2 4 Sept 30/89

July 27/90 Revised List of Effective Pages

Page1

Page 6

OM-2029

LIST OF EFFECTIVE PAGES (CONTINUED)

CHAPTER/ CHAPTER/

SECTION PAGE DATE SECTION PAGE DATE

3-1 1 Sept 30/89 4-3 8 Sept 30/89

3-1 2 Sept 30/89 4-3 9 July 27/90

3-1 3 Sept 30/89 4-3 10 Sept 30/89

3-1 4 Sept 30/89 4-3 11 Sept 30/89

3-1 5 July 27/90 4-3 12 Sept 30/89

3-1 6 Sept 30/89 4-3 13 Sept 30/89

3-1 7 Sept 30/89 4-3 14 Sept 30/89

3-1 8 Sept 30/89 4-3 15 Sept 30/89

3-1 9 Sept 30/89 4-3 16 Sept 30/89

3-1 10 Sept 30/89 4-3 17 July 27/90

3-1 11 Sept 30/89 4-3 18 July 27/90

3-1 12 Sept 30/89 4-3 19 July 27/90

3-1 13 Sept 30/89 4-3 20 Sept 20/89

3-1 14 Sept 30/89 4-3 21 July 27/90

3-1 15 July 27/90 4-3 22 Sept 30/89

3-1 16 July 27/90 4-3 23 Sept 30/89

3-1 17 July 27/90 4-3 24 Sept 30/89

3-1 18 July 27/90 4-3 25 July 27/90

3-1 19 Sept 30/89 4-3 26 Sept 30/89

3-1 20 July 27/90 4-3 27 Sept 30/89

3-1 21 Sept 30/89 4-3 28 Sept 30/89

3-1 22 Sept 30/89 4-3 29 July 27/90

3-1 23 Sept 30/89 4-3 30 July 27/90

3-1 24 Sept 30/89 4-3 31 July 27/90

3-1 25 Sept 30/89 4-3 32 Sept 30/89

3-1 26 Sept 30/89 4-3 33 July 27/90

3-1 27 Sept 30/89 4-3 34 Sept 30/89

3-1 28 Sept 30/89 4-3 35 July 27/90

4-3 36 Mar 16/90

4-1 1 July 27/90 4-3 37 July 27/90

4-1 2 Mar 16/90 4-3 38 Mar 16/90

4-3 39 July 27/90

4-2 1 Sept 30/89 4-3 40 July 27/90

4-2 2 Mar 16/90 4-3 41 July 27/90

4-2 3 Mar 16/90 4-3 42 July 27/90

4-2 4 Mar 16/90 4-3 43 July 27/90

4-3 44 July 27/90

4-3 1 Sept 30/89

4-3 2 Sept 30/89 5-0 1 July 27/90

4-3 3 Sept 30/89 5-0 2 Sept 30/89

4-3 3A July 27/90

4-3 3B July 27/90 6-0 1 July 27/90

4-3 3C July 27/90 6-0 2 Sept 30/89

4-3 3D July 27/90

4-3 4 Sept 30/89

4-3 5 Mar 16/90

4-3 6 Mar 16/90

4-3 7 July 27/90

List of Effective Pages July 27/90 Revised

Page 2

Page 7

OM-2029

Table of Contents

WARNING

LIST OF EFFECTIVE PAGES

INTRODUCTION

SUBJECT CHAPTER/SECTION PAGE

CHAPTER 1. DESCRIPTION/OPERATION

SECTION 1. DESCRIPTION 1-1 1

1. General 1-1 1

2. Orientation 1-1 1

3. Special Features 1-1 1

A.Protective Monitor 1-1 1

B.Voltage Regulator 1-1 1

C. Dual Outputs 1-1 3

D. Electric Governor 1-1 3

E. Hinged Front Panel on Generator

Control Box 1-1 3

4. Identification 1-1 5

5. Optional Equipment 1-1 6

A. Trailer 1-1 6

B. Transformer-Rectifier (6906-3 and

6906-4 ONLY) 1-1 6

C. Truck 1-1 6

D. Quick Start Kit 1-1 6

6. Canopy 1-1 6

7. Engine, Generator, and Controls

Assembly 1-1 6

A. Basic Engine 1-1 6

B. Engine Manufacturer’s Equipment 1-1 7

C. Hobart Engine Equipment 1-1 7

(1) Electric governor system 1-1 7

(a) Magnetic pickup 1-1 7

(b) Control unit 1-1 7

(c) Actuator 1-1 7

(2) Engine electrical system 1-1 7

(3) Engine protective devices 1-1 9

(4) Air cleaner 1-1 9

(5) Water Temperature Sender 1-1 10

(6) Oil Pressure Sender 1-1 10

(7) Exhaust system 1-1 10

(8) Radiator 1-1 10

D. Generator 1-1 11

September 30/89 Revised Table of Contents

Page 1

Page 8

OM-2029

SUBJECT CHAPTER/SECTION PAGE

E. Control Box Assembly 1-1 11

(1) Generator Control Box Front Panel

Components 1-1 12

(a) Generator output monitors (meters) 1-1 12

(b) Meter and line switches 1-1 12

(c) Indicating lights 1-1 12

(d) Load contactor circuit breaker 1-1 12

(e) Protective system circuit breaker 1-1 12

(2) Generator Control Box Interior Components

(Figure 7) 1-1 14

(a) Sensing modules 1-1 14

(b) Memory and time delay module 1-1 14

(c) Plug-interlock relays 1-1 15

(d) Test-bank switches 1-1 15

(e) Resistor 1-1 15

(f) Fuse-interlock relay 1-1 15

(g) Auxiliary underfrequency relay 1-1 15

(h) Regulated-diagnostic switch 1-1 15

(j) Excitation-deenergization relay 1-1 15

(k) Voltage Regulator 1-1 17

F. Engine Control Panel (See Fig. 9) 1-1 18

(1) Engine instruments 1-1 18

(2) Engine and generator controls 1-1 18

H. Power Module Panel Assembly 1-1 20

(1) Load contactor 1-1 21

(2) Current transformers 1-1 21

(3) Rectifiers 1-1 21

(4) Overload module 1-1 22

(5) Terminal boards 1-1 22

SECTION 2. PREPARATION FOR

USE, STORAGE, OR SHIPPING 1-2 1

1. Preparation for Use 1-2 1

A. General 1-2 1

B. Inspection/Check 1-2 1

(a) Fuel 1-2 1

(b) Engine coolant 1-2 1

(c) Engine lubricating oil 1-2 1

C. Installing Output Cables 1-2 2

2. Preparation for Storage 1-2 3

A. General 1-2 3

B. Temporary Storage 1-2 3

C. Long Time Storage (Over 30 Days) 1-2 3

Table of Contents September 30/89 Revised

Page 2

Page 9

OM-2029

SUBJECT CHAPTER/SECTION PAGE

SECTION 3. OPERATION 1-3 1

1.General 1-3 1

2. Operating the Generator Set 1-3 1

A. Pre-start Inspection 1-3 1

B. Normal Engine Starting Procedures 1-3 1

C. Cold Weather Engine Starting Procedures 1-3 4

D. Preparation for Power Delivery

(Normal Automatic Voltage Control) 1-3 5

E. Power Delivery 1-3 5

No. 1 Output Circuit 1-3 5

No. 2 Output Circuit 1-3 6

F. Discontinue Power Delivery 1-3 6

K. Stopping the Engine 1-3 6

3. Transformer-Rectifier Operation 1-3 6

A. Direct Current Power Delivery 1-3 6

B. Simultaneous 28.5-V DC and

115-V AC Power Delivery 1-3 7

4. Trailer Operation (Optional) 1-3 8

A. Towing 1-3 8

B. Parking 1-3 8

CHAPTER 2. SERVICE

SECTION 1. MAINTENANCE 2-1 1

1. General 2-1 1

2. Inspection 2-1 1

3. Lubrication 2-1 1

A. General 2-1 1

B. Generator 2-1 1

C. Generator Controls 2-1 1

D. Engine 2-1 1

(1) Lubrication schedule 2-1 2

(2) Oil specification 2-1 2

(3) Oil viscosity 2-1 2

(4) Changing engine oil 2-1 2

(5) Changing engine oil filter 2-1 2

E. Starter 2-1 2

4. Air Cleaner Service 2-1 3

A. Cartridge Removal (See Fig. 2) 2-1 3

B. Cartridge Installation (See Fig. 2) 2-1 4

5. Engine Fuel 2-1 4

A. Quality 2-1 4

B. Fuel Filter 2-1 4

September 30/89 Revised Table of Contents

Page 3

Page 10

OM-2029

SUBJECT CHAPTER/SECTION PAGE

6. Engine Cooling System 2-1 5

A. General 2-1 5

B. Radiator Cap 2-1 5

(1) General 2-1 5

(2) Removal 2-1 5

(3) Installation 2-1 5

C. Warm Weather Operation 2-1 5

D. Cold Weather Operation 2-1 5

(1) General 2-1 5

(2) Checking coolant solution 2-1 6

(3) Preparing the coolant solution 2-1 6

(4) Installing the antifreeze solution 2-1 6

E. Draining the Cooling System 2-1 6

F. Cleaning the Cooling System 2-1 7

G. Cleaning the Radiator Core 2-1 7

H. Filling the Cooling System 2-1 7

7. Generator Maintenance 2-1 8

A. Cleaning 2-1 8

B. Adjustment 2-1 8

8. Drive Belts 2-1 8

A. Checking Belt Tension 2-1 8

B. Belt Adjustment 2-1 8

9. Trailer and Truck Maintenance 2-1 9

A. General 2-1 9

B. Cleaniness 2-1 9

C. Grease application 2-1 9

D. Lubrication chart 2-1 9

2-1 10

E. Checking Wheel Bearings 2-1 12

F. Adjusting Wheel Bearings 2-1 12

10. Battery Service 2-1 12

A. General 2-1 12

B. Battery Location and Accessibility 2-1 12

C. Battery Care 2-1 12

D. Liquid Level 2-1 12

E. Cleaning the Battery 2-1 13

F. Testing the Battery 2-1 13

11. Service Helps 2-1 13

A. Wiring 2-1 13

B. Generator Exciter 2-1 13

SECTION 2. INSPECTION/CHECK 2-2 1

1. General 2-2 1

2. Engine 2-2 1

A. Fuel (See Fig. 1 for time schedules) 2-2 1

B. Lubrication 2-2 1

C. Coolant 2-2 1

D. V-Belts 2-2 1

E. Exhaust System 2-2 1

Table of Contents September 30/89 Revised

Page 4

Page 11

OM-2029

SUBJECT CHAPTER/SECTION PAGE

3.Electrical System (12-V DC) 2-2 3

A. Lights 2-2 3

B. Circuit Breakers 2-2 3

C. Wiring and Connections 2-2 3

4. Electrical System (115-V AC) 2-2 4

A. Monitoring Instruments 2-2 4

B. Indicating Lights 2-2 4

C. Protective Modules 2-2 4

D. Wiring and Connections 2-2 4

5. Trailer and Truck 2-2 5

SECTION 3. ADJUSTMENT/TEST 2-3 1

1. General 2-3 1

2. Generator Set Test 2-3 1

A. Pre-operational Test Procedures 2-3 1

B. Operational Test Procedures 2-3 1

3. Generator Set Adjustment 2-3 8

A. Generator Adjustment 2-3 8

B. Generator Control Adjustments 2-3 8

C. Basic Engine Adjustments 2-3 9

D. Engine Accessories Adjustment 2-3 9

E. Electric Governor System Adjustment 2-3 9

(1) Actuator linkage adjustment 2-3 9

(2) Magnetic pickup adjustment 2-3 11

(3) Governor Control Unit Adjustment 2-3 12

5. Generator and Exciter Test 2-3 14

6. Diode Test 2-3 14

CHAPTER 3. TROUBLESHOOTING

SECTION 1. TROUBLESHOOTING

PROCEDURES 3-1 1

1. General 3-1 1

2. Troubleshooting Chart 3-1 1

3. Equipment for Troubleshooting 3-1 2

4. Safety 3-1 2

5. Parts Replacement 3-1 2

6. Test Values 3-1 2

7. Checking Connections and Leads 3-1 3

8. Electric Governor Troubleshooting 3-1 3

9. Engine Troubleshooting Procedures 3-1 3

A. General 3-1 3

September 30/89 Revised Table of Contents

Page 5

Page 12

OM-2029

SUBJECT CHAPTER/SECTION PAGE

CHAPTER 4. ILLUSTRATED PARTS LIST

SECTION 1. INTRODUCTION 4-1 1

1. General 4-1 1

2. Purpose 4-1 1

3. Arrangement 4-1 1

4. Explanation of Parts List 4-1 1

A. Contents 4-1 1

B. Parts List Form 4-1 2

(1) FIGURE-ITEM NO. Column 4-1 2

(2) HOBART PART NUMBER Column 4-1 2

(3) NOMENCLATURE Column 4-1 2

(4) REC. SPARES Column 4-1 2

(5) “EFF” (Effectivity) Column 4-1 2

(6) UNITS PER ASSEMBLY Column 4-1 2

SECTION 2. MANUFACTURERS’

CODES 4-2 1

1. Explanation of Manufacturers’

(Vendors’) Code List 4-2 1

SECTION 3. PARTS LIST 4-3 1

1. Explanation of Parts List Arrangement 4-3 1

2. Symbols and Abbreviations 4-3 1

SECTION 4. NUMERICAL INDEX

1. Explanation of Numerical Index 4-3 1

CHAPTER 5. OPTIONAL EQUIPMENT

CHAPTER 6. MANUFACTURERS’ LITERATURE

UNUSUAL SERVICE CONDITIONS

Table of Contents September 30/89 Revised

Page 6

Page 13

Addendum to

Operation and Maintenance Manual OM-2029

covering a Modification to

Generator Set Specifications 6906-2 and 6906-4

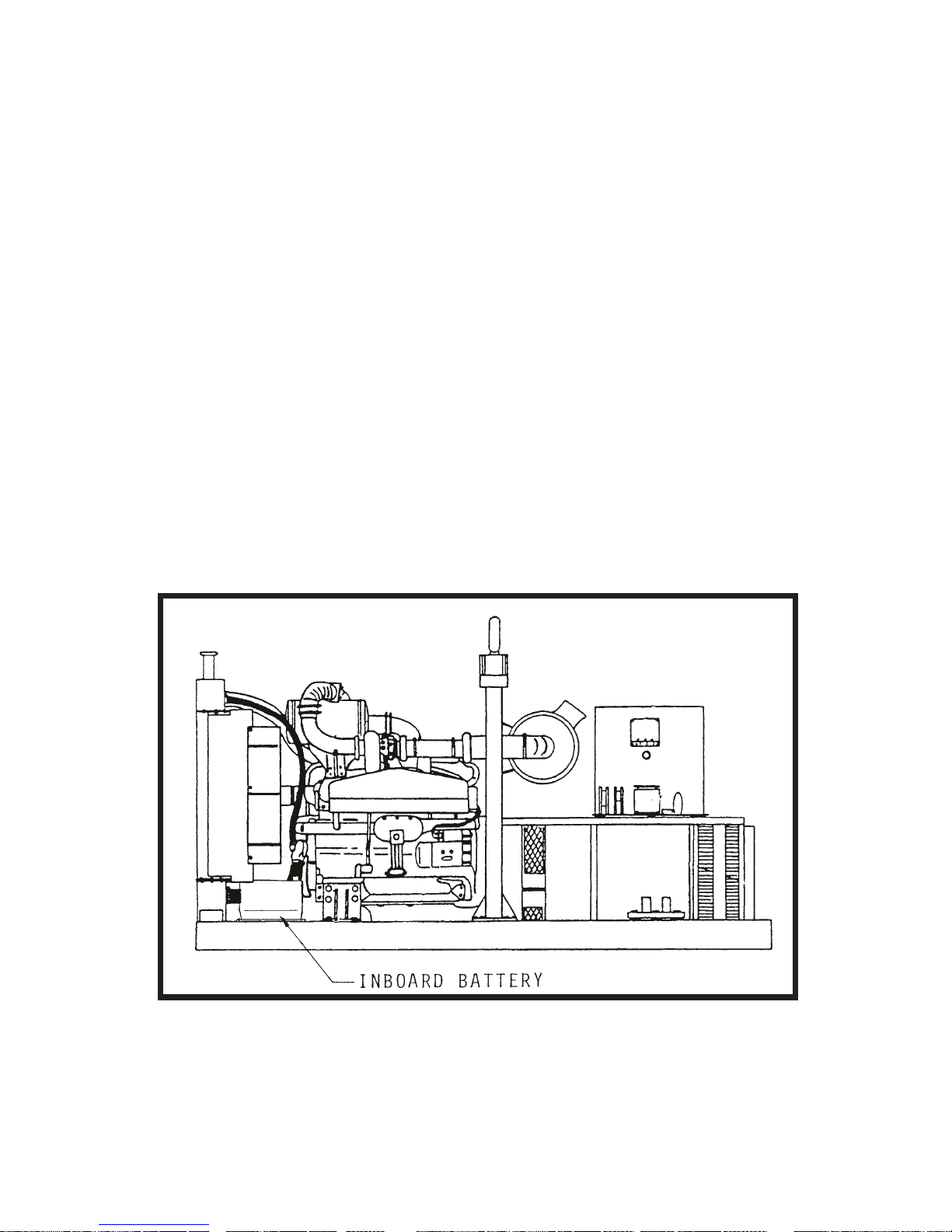

1. Scope

This addendum increases the coverage of Hobart Manual OM-2029 to include a modification to Gene- rator Set Specification Numbers 6906-2 and 6906-4

erator set is equipped with a battery that is installed in the engine compartment of the generator set,

rather than in a compartment on the truck.

(truck-mounted units).

(See Figure 1).

As per this modification, the gen-

2. Description

In regard to physical appearance, electrical output ratings, and operation, the Specification 6906-2 or

6906-4 generator set with the aforementioned modification, as covered by this addendum, is identical to

all other Specification 6906-2 or 6906-4 generator sets.

OM-2029

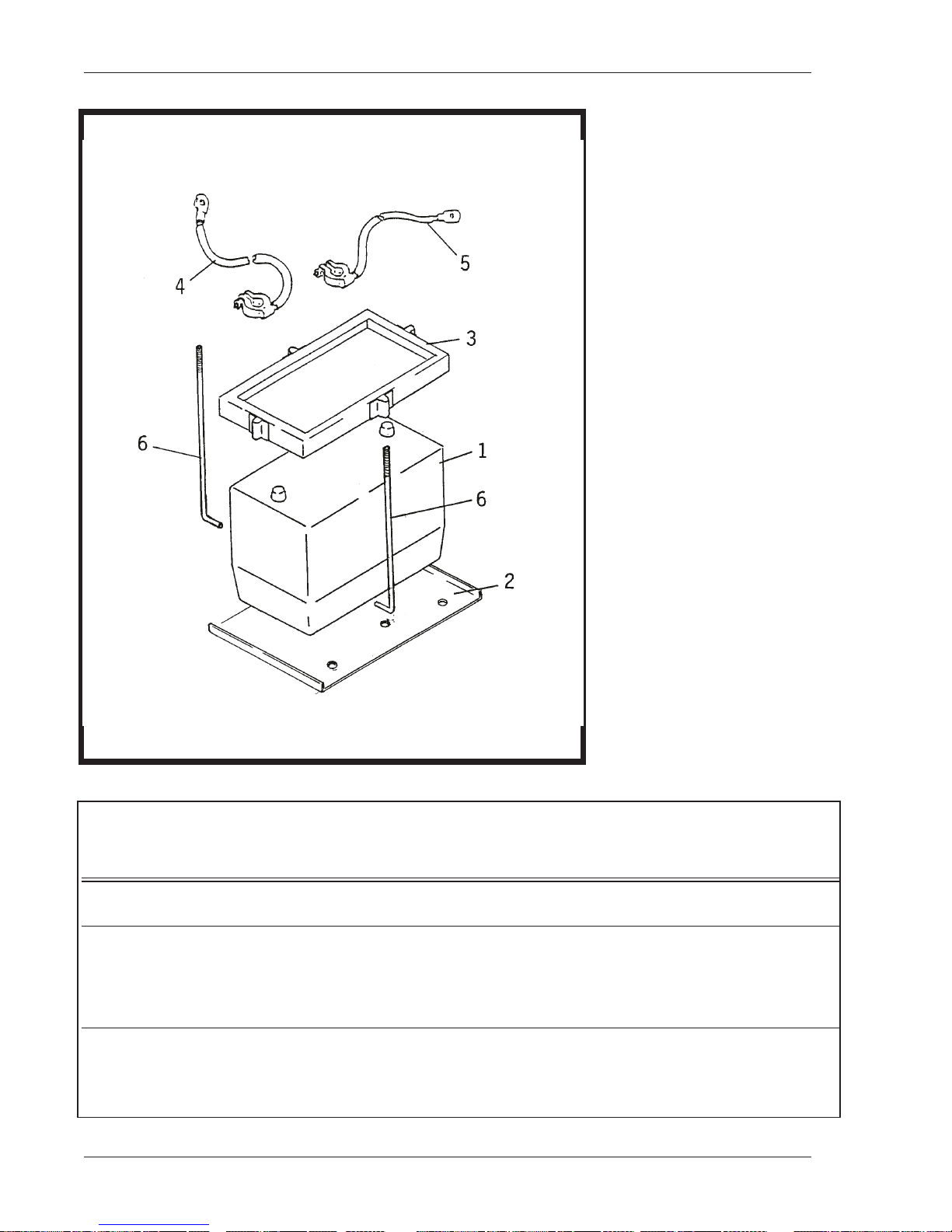

Figure 2 is an illustration that shows the various components of the inboard battery kit, which is identified

as Hobart Part No. 281926. This illustration is accompanied by a parts list whose item numbers correspond with the call-out numbers on the illustration.

June 6/90 Addendum

Location of Inboard Battery

Figure 1

Page 1

Page 14

OM-2029

Inboard Battery Kit

Part No. 281926

Figure 2

FIGURE HOBART PER

ITEM NO. PART NO. 1234567 EFF ASSY

2- 281926 BATTERY INSTALLATION

1 281871-1 . BATTERY, 12 VOLTS 1

2 281927 . SUPPORT, BATTERY 1

3 181831 . FRAME, HOLD-DOWN, BATTERY 1

4 481209-4 . CABLE, POSITIVE 1

5 383067-5 . CABLE, NEGATIVE 1

6 5CW-2048 . ROD, BATTERY, SUPPORT, ASSY 2

Addendum June 6/90

Page 2

NOMENCLATURE UNITS

(For units having ONE battery) REF

Page 15

3. Customer Service

If you have any questions concerning your Hobart Ground Airport Systems Group equipment, you are invited to contact our service department by mail, telephone, or FAX.

Write: Hobart Brothers Company

Airport Systems Group

1177 Trade Road East

Troy, Ohio 45373, U.S.A.

Telephone: (513) 332-5060 (Service Assistance)

(513) 332-5050 (Parts Replacement)

FAX: (513) 332-5121

OM-2029

June 6/90 Addendum

Page 3

Page 16

OM-2029

This page intentionally left blank.

Addendum June 6/90

Page 4

Page 17

Page 18

Page 19

OM-2029

CHAPTER 1. DESCRIPTION/OPERATION

SECTION 1. DESCRIPTION

1. General

Generator sets

rations of the set are identified by adding a dash number

6906 generator sets feature armatures with Hoover Bearings, Browning Coupler, and different magnetic

pole construction for the generator revolving field.

The basic generator set which includes the engine, generator and all controls is identical for all models.

Differences between models are those required by their respective mountings, such as trailer mounting,

truck mounting, etc., or by other special features. Identificationof different models within the Series will be

explained later in the Description. Information and instructions throughout the manual apply to all models.

Information which applies only to a certain model will be qualified and identified as such.

The purpose of the generator set is to generate and deliver regulated, 400-Hz electrical power to a parked

(or towed)

running. The engine, generator, and controls are designed into a compact unit which is easily removable

from a tow tractor. See Figure 2 for specifications and capabilities.

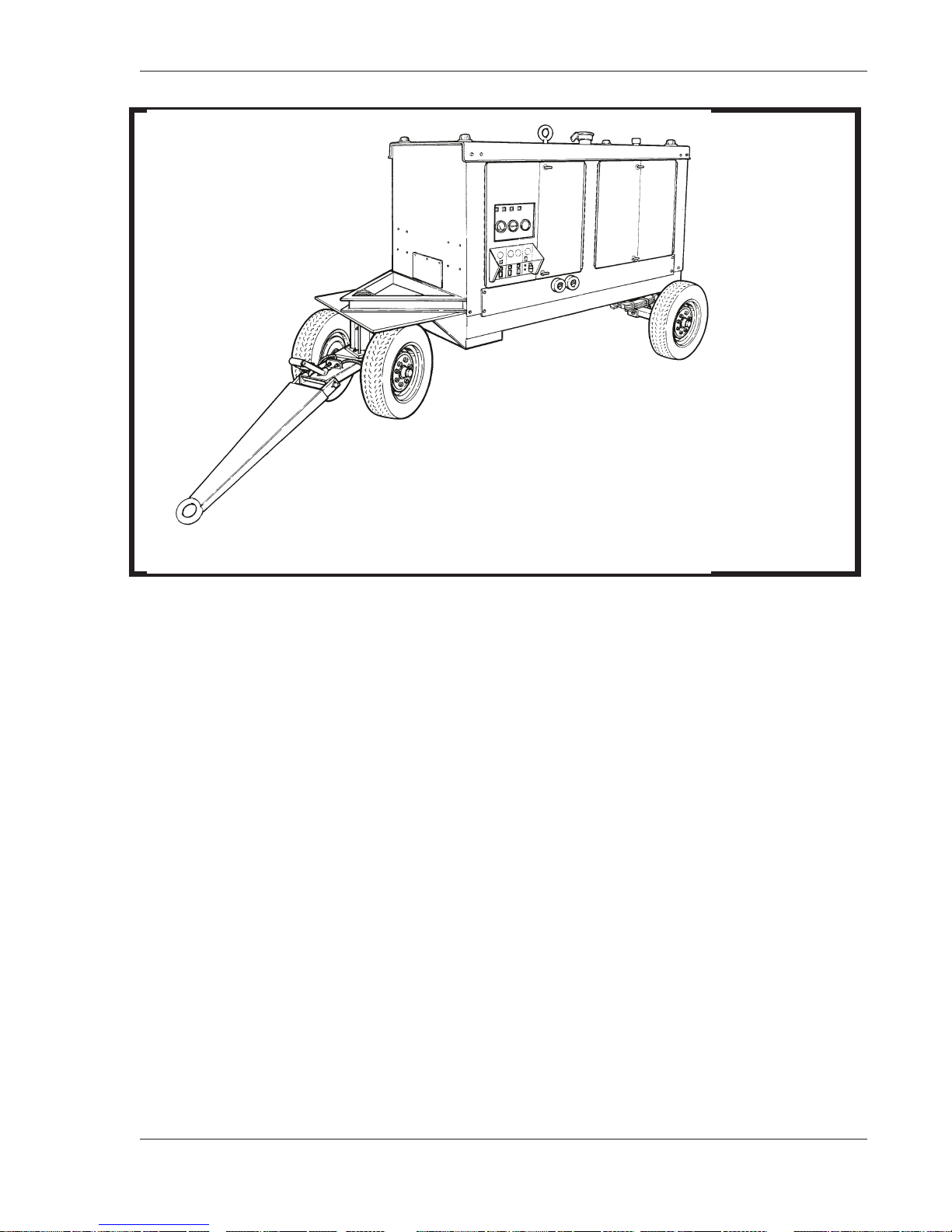

(see Fig. 1)

aircraft for operation of the aircraft’s electrical equipment when the on-board generators are not

covered by the manual are identified by Series No. 6906. The various configu-

(-1, -2, etc.)

suffix to the Series number. Series

2. Orientation

For purpose of orientation and to familiarize operators and maintenance personnel with the location of

components, the radiator is considered to be at the FRONT of the unit. The generator and controls are at

the REAR. RIGHT and LEFT are determined by standing at the rear end facing the machine. Thus, the

generator controls are mounted on the REAR of the unit.

3. Special Features

The generator set has many special features which are later described more fully under the assemblies in

which they appear. Some of the main features are mentioned here and described briefly.

A. Protective Monitor

A single, solid-state device

ator output circuit and functions to cause the load to be disconnected from the generator if an abnormal condition of voltage, frequency, or load develops.

B. Voltage Regulator

A solid-state, adjustable voltage regulator

6906-1 and 6906-2 generator sets. This voltage regulator provides automatic voltage regulation at

the aircraft

cable sizes and lengths. A magnetic amplifier type voltage regulator

used on Specification 6906-3, Specification 6906-4, Specification 6906-5 and Specification 6906-6

generator sets. This regulator is also adjustable for a variety of output cable sizes and lengths.

July 27/90 Revised 1-1

(or distribution panel when applicable)

(4, Fig. 8)

receives signals from all of the fault sensing units in the gener-

(Hobart part number 489812A)

. This regulator is adjustable for a variety of output

is used on Specification

(Hobart part no. 281407)

is

Page 1

Page 20

OM-2029

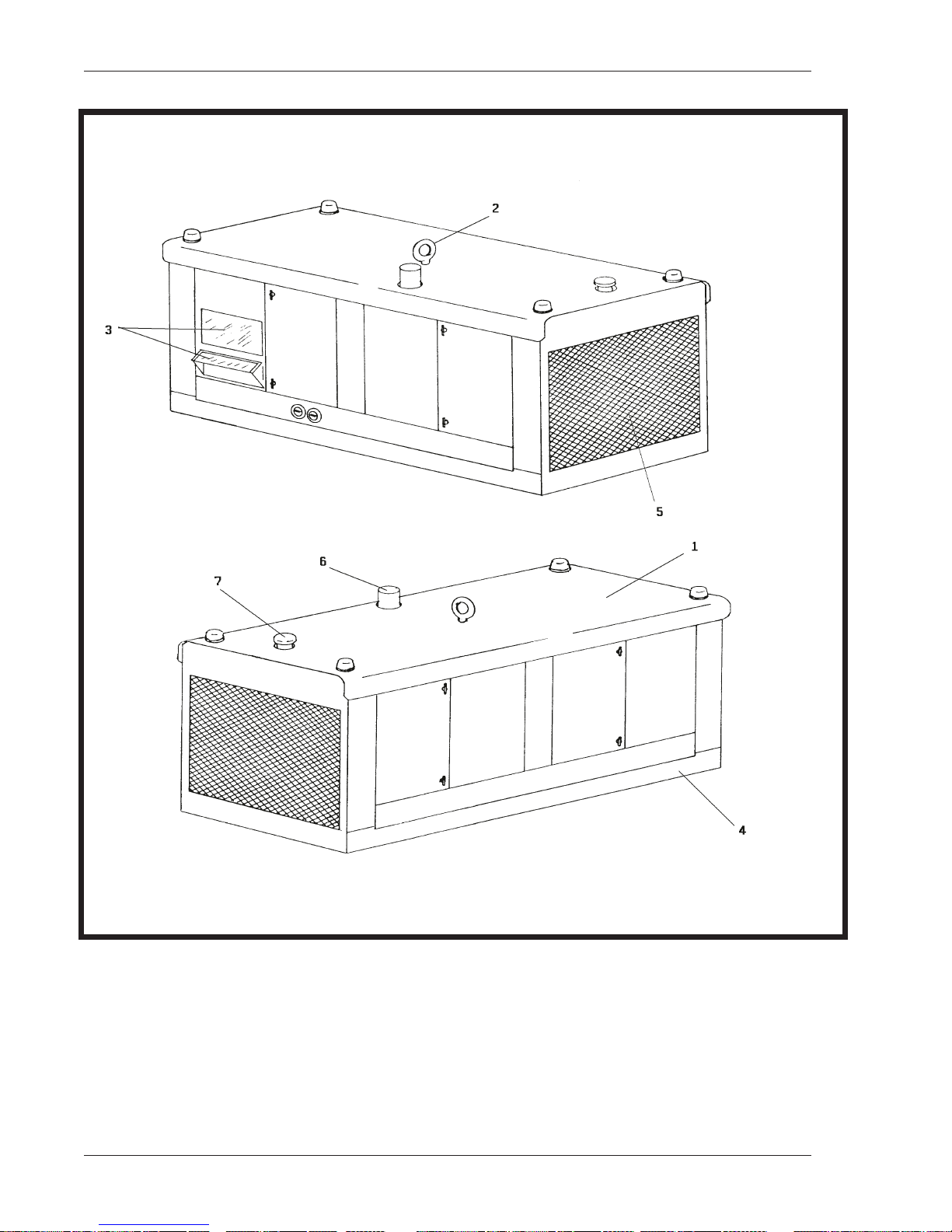

1. Canopy 5. Engine fan exhaust vent

2. Lifting eye 6. Engine exhaust pipe

3. Windows 7. Radiatorcap

4. Mounting frame

1-1 September 30/89 Revised

Page 2

Generator Set

(without trailer)

Figure 1

Page 21

OM-2029

Generator Set Mounted on Fifth-Wheel Trailer

Figure 1A

C. Dual Outputs

Each generator set is equipped with two output circuits and dual controls so that power may be delivered to an aircraft requiring two inputs, or to one or two aircraft with single input requirements.

D. Electric Governor

The engine is equipped with an all electric type governor kit

ment more fully described under the engine description.

E. Hinged Front Panel on Generator Control Box

The control box is equipped with a hinged front panel. Located conveniently on this panel are

switches, meters, indicator lights, and circuit breakers for controlling and monitoring the generator.

This panel swings out to provide easy access to the voltage regulator, PC boards, and relays which

are used to control and monitor the generator.

(9and 15, Fig. 3)

and other special equip-

March 16/90 Revised 1-1

Page 3

Page 22

OM-2029

PHYSICAL

BASIC UNIT

Length overall 109.6 inches

Width 45.5 inches

Height overall 62.0 inches

Weight 3500 pounds

FOUR-WHEEL TRAILER-MOUNTED UNIT

Length overall 119.0 inches

Width 80.0 inches

Height 79.0 inches

Weight 5400 pounds

FIFTH-WHEEL TRAILER MOUNTED UNIT

Length overall, with tongue up 160 inches

Length overall, with tongue down 228 inches

Width 84 inches

Height 84 inches

Weight

(with 1/4 tank of fuel

and no cables)

7160 pounds

GENERATOR

Output power rating 140 KVA

Output voltage 115/200 V

Rated load capacity 404 Amp

Frequency

Output kilowatts 112 KW

Power factor 0.8 PF

Duty cycle 100%

Operating speed at 400 Hz 1714 RPM

Overload capacity 505 Amp

(125% of rated load capacity)

(cycles-per-second)

400 Hz

(2784 mm)

(1156 mm)

(1575 mm)

(1496.8 kg)

(3023 mm)

(2032 mm)

(2007mm)

(2358.7 kg)

(4064 mm)

(5791 mm)

(2134 mm)

(2134 mm)

(3247 kg)

GENERATOR PROTECTIVE SYSTEM

Overvoltage relay trips 130 V to 134 V; resets 125 V

Undervoltage relay trips 102 V or below; resets 110 V

Overfrequency relay trips 415 Hz to 425 Hz; resets 410 Hz

Underfrequency relay trips 375 Hz to 385 Hz; resets 385 Hz

Overload relay trips 175 KVA in less than 5 minutes

Undervoltage time delay relay 4 to 12 seconds

1-1 August 15/90 Revised

Page 4

Page 23

OM-2029

ENGINE

Manufacturer John Deere

Model 6466T

Type Turbocharged, In-line, 6-cylinder,

4-cycle Diesel

Displacement 466 cu. in. (7.64 liters)

Compression ratio 15.8:1

Firing order 1-5-3-6-2-4

Horsepower at 2000 RPM 250

Governed speed 1714 RPM

Idle speed 850 RPM +/- 25 RPM

Electrical system 12 volt

Oil capacity (with filter) 18 quarts (14 liters)

Oil capacity (without filter) 16quarts (13.6 liters)

Coolant capacity (approx.) 12.44 gallons (47.0 liters)

Fuel Diesel oil conforming to ASTM Spec.

D.975-66T, Nos. 1-D and 2-D

Lube oil MIL-L-2104C or MIL-L-2104D

Specifications and Capabilities

Figure 2 (Sheet 2 of 2)

4. Identification

Generator sets are identified by their Specification number which consists of the Series number plus a

dash number

other major feature(s) of the generator set.

SPECIFICATION MOUNTING DESCRIPTION

6906-1 Trailer Basic generator set in Series 6906, having a fuel tank,

6906-2 Truck Basic generator set in Series 6906, similar to Spec

6906-3 5th-Wheel Trailer Has provisions for transformer-rectifier (T-R). Also

6906-4 Truck Similar to Spec 6906-2, except that it has magnetic

6906-5 5th-Wheel Trailer Similar to Spec 6906-1, except for the trailer, and this

(i.e. -1, -2, etc.)

suffix. The suffix number indicates either the mounting design and/or some

battery, plus a tray for battery and cables.

6906-1, except for mounting.

has fuel tank and battery, plus tray for cable and

battery.

amplifier type voltage regulator, Hobart Part No. 281407

unit DOES NOT have a fuel tank, battery, or a tray

for battery and cables. Special for SIA.

6906-6 5th-Wheel Trailer Similar to Spec 6906-5, with fuel tank, cable tray,

July 27/90 Revised 1-1

battery/cable tray, rear fenders, and rear bumper

Page 5

Page 24

OM-2029

5. Optional Equipment

Several items of optional equipment are available for the 6906 Series units. When applicable, information

for optional equipment will be located in Chapter 5.

A. Four-Wheel Trailer (Specification 6906-1)

This is a standard four wheel trailer, used on earlier Series 6906 generator set models, and identified

by Hobart Part No. 408595.

B. Fifth-Wheel Trailer

A trailer with fifth-wheel front running gear is available, with or without batteries and fuel tank. This

trailer with fifth-wheel replaces the previously used four wheel trailer, and reduces greatly the turning

radius when the unit is being towed.

B. Transformer-Rectifier (Specifications 6906-3, 6906-4, 6906-5, and 6906-6)

A transformer-rectifier

6 generator sets. This T-R receives 115/200-V, 400-Hz, AC power from the generator and converts it

to a 28.5 V DC output. Additionally, Specifications 6906-5 and 6906-6 may be equipped with a second T-R, with rated output of either 28.5V or 112 V.

C. Truck

Trucks with special bodies for mounting the generator set are available. Compartments in the body

are provided for batteries, cable-storage, etc. Trucks available are Ford, Chevrolet, and GMC.

D. Quick Start Kit

(T-R)

is available for use with Specifications 6906-3 ,6906-4, 6906-5 and 6906-

(See Section 1-3, Para. 2C)

6. Canopy

A sheet metal enclosure, identified as a canopy

and electrical controls. The canopy is designed to reduce operational noise in the immediate area of the

machine. Four hinged doors on the left side provide easy access for service and maintenance. Two

hinged doors near the front on the right side provideaccess to the engine compartment. Panel mounted

instruments may be observed through two Plexiglass windows which cover a portion of the control box

and the engine control panel. The lower window is slanted outward at the bottom to provide an opening

for reaching engine controls. A small panel located below the air cleaner covers the dual output terminal

board.

(1, Fig. 1),

provides protection for the engine, generator

7. Engine, Generator, and Controls Assembly

This assembly is the basic generator set without canopy. It includes all components required to generate

and regulate 400 Hz, 115/200 V, three phase power, and is operable when provided with fuel and 12 V

DC power. The engine-generator assembly is mounted on a welded steel frame. A superstructure, attached to the main frame, provides mounting facilities for the canopy, control box, electrical equipment

and controls.

A. Basic Engine

This generator set is equipped with a 6-cylinder, in-line, turbo-charged John Deere Diesel engine. See

Figure 2 for general specifications, and see Engine Operator’s Handbook in Chapter 6 for more detailed information.

1-1 July 27/90 Revised

Page 6

Page 25

B. Engine Manufacturer’s Equipment

As received from the engine manufacturer, the engine includes the following equipment which is described in the John Deere Shop Manual

(1) Fuel filter.

(2) Reverse-flow, engine cooling fan to blow air outward through the radiator.

C. Hobart Engine Equipment

The engine is modified at Hobart Brothers by the addition of the following equipment:

(1) Electric governor system

An electric governor kit is installed on the engine to replace a conventional, mechanical type. The

electric governor was selected for control of engine speed

cause it provides faster engine response to changes in load conditions. This fast response results

in very close frequency control. Refer to the Woodward instruction booklet in C hapter 6 for a detailed description. A brief description is given below:

The governor system consists of the following main components:

Magnetic pickup

(Chapter 6)

.

(and generator output frequency)

OM-2029

be-

Control unit

Actuator

(a) Magnetic pickup

The magnetic pickup is a device for detecting the speed of the engine. It is mounted in the flywheel housing directly over the ring gear. It produces an AC signal to the control unit when

the ferrous flywheel teeth pass through the magnetic field at the end of the pickup.

(b) Control unit

The control unit

It receives an AC signal from the magnetic pickup and senses speed changes in the engine.

It provides a voltage signal to the actuator which causes the actuator to move the fuel control

lever as required to maintain a predetermined engine speed. Its power is received from the

12-V DC battery system.

(c) Actuator

The actuator

quired to maintain a constant engine speed. The actuator is operated by a DC signal from the

control unit.

(2) Engine electrical system

Items in the 12-volt engine electrical system that are provided by Hobart Brothers are:

(a) A heavy-duty motor starter

(9,Fig.3)

(15 Fig. 3)

is a box containing a compact assembly of solid state components.

supplies the force needed to move and position the fuel lever as re-

(b) Alternator with voltage regulator

(c) Starting switch

(d) Wiring harness

September 30/89 Revised 1-1

Page 7

Page 26

OM-2029

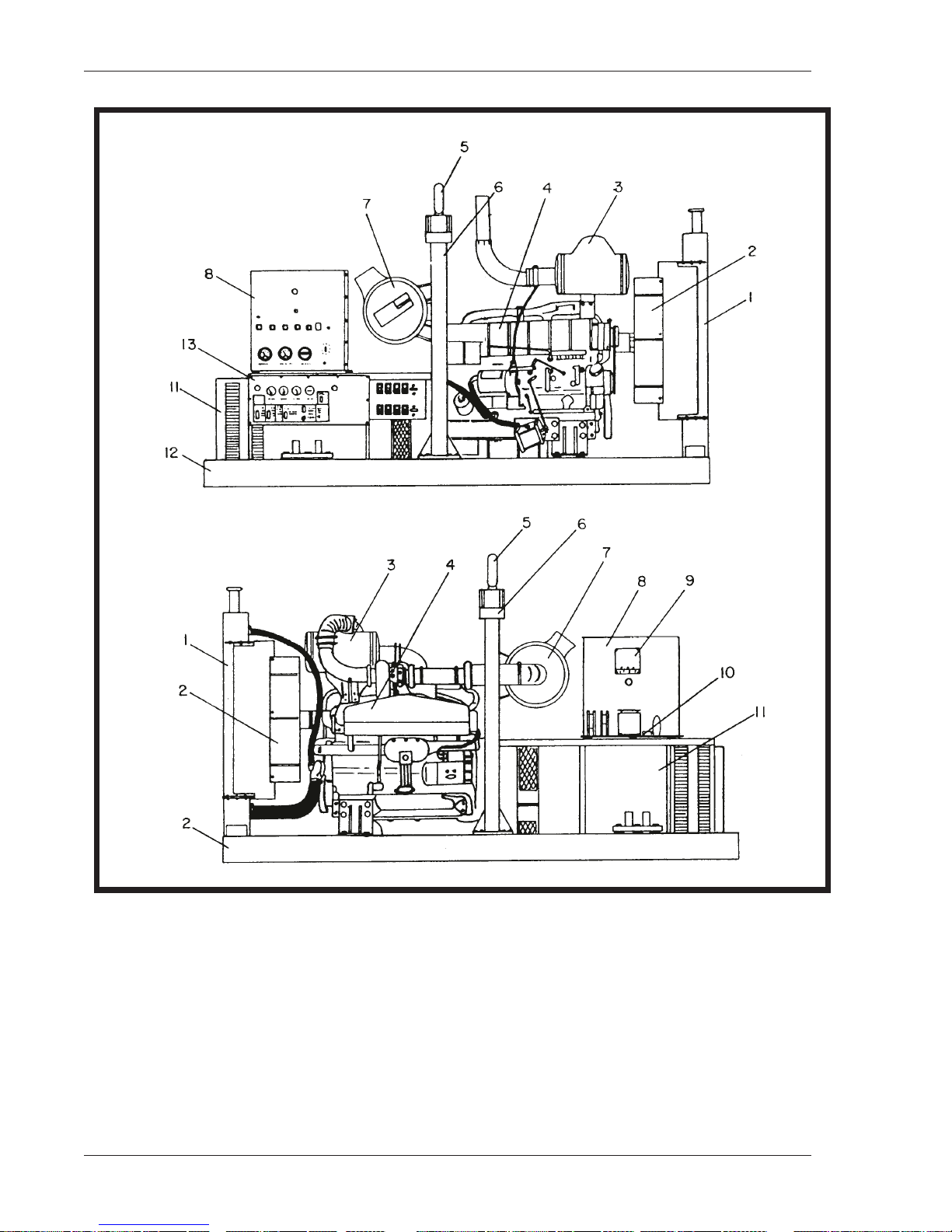

1. Radiator 8. Generator Control Box 15. Actuator, Governor

2. Fan Guard 9. Control Box, Governor 16. Lube Oil Pressure Switch

3. Muffler & Exhause Pipe 10. Power Module Panel 17. Lube Oil Pressure Sensor

4. Diesel Engine 11. Generator Assembly 18. High Engine Temperature

5. Lifting Eye 12. Frame Switch

6. Lifting Yoke 13. Engine Control Panel 19. Water Temperature Sensor

7. Air Cleaner 14. Output Terminal Panel

1-1 September 30/89 Revised

Page 8

Generator Set Components

Figure 3

Page 27

(3) Engine protective devices

(a) High coolant temperature switch

OM-2029

A high coolant temperature switch

the coolant temperature. If the coolant temperature reaches 210 degrees F

this normally closed switch opens and actuates the fuel valve solenoid which shuts down the

engine.

(b) Oil pressure switch

A diaphragm-type switch monitors the pressure in the lubricating oil system. It is mounted in

the side of the cylinder block

(69 kPa)

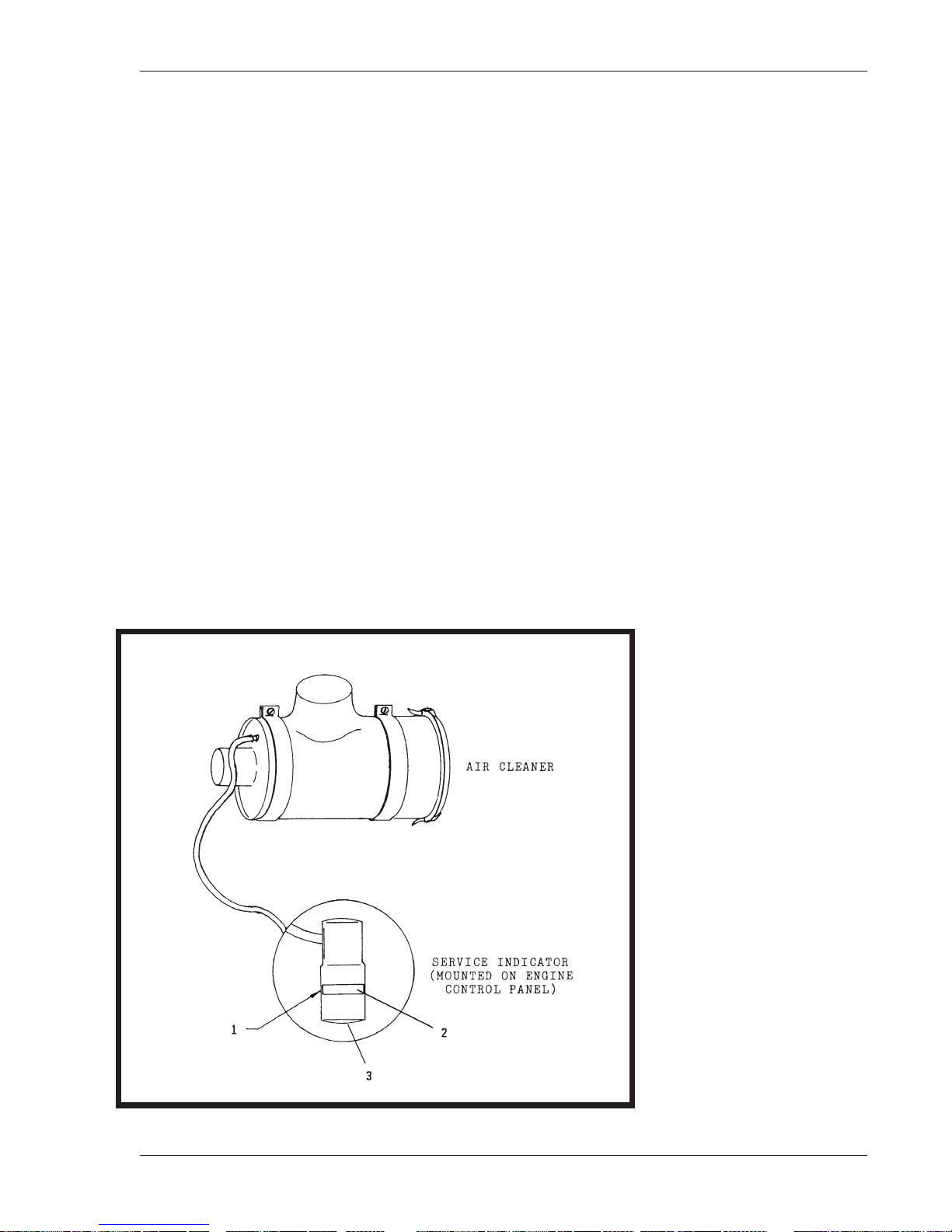

(4) Air cleaner

The diesel-engine air cleaner

tor and a service indicator. The indicator functions to signal the operator when the cartridgeneeds

changing. A red cylindrical “flag”

when air pressure within the air cleaner housing drops below the outside air pressure. As the cartridge becomes loaded with dirt and air pressure withinthe cleaner lessens, the “flag” gradually

rises higher in the glass viewing chamber. When the “flag” reaches the top of the chamber, it

locks in that position to warn the operator that the cartridge must be changed. The “flag” is reset

(unlocked)

, this switch opens and actuates the fuel valve solenoid which shuts down the engine.

(Fig. 4)

by pushing the reset button

(18, Fig. 3)

is mounted at the rear of the engine to monitor

(99 degrees C)

(16, Fig. 3)

(2)

is forced upward in a glass enclosed viewing chamber

. If the pressure in the lube oil system falls to 10 psi

is a dry-cartridge type. It is equipped with a moisture elimina-

(3)

located on the bottom of the indicator.

(1)

NOTE: The service indicator is mounted on the engine control panel and connected to the air cleaner

by a rubber hose. The indicator flag is visible only when the engine is running, or when the flag islocked

in WARNING position.

,

September 30/89 Revised 1-1

1. Viewing chamber

2. Indicating “flag”

3. Reset button

Air Cleaner and

ServiceIndicator

Figure 4

Page 9

Page 28

OM-2029

(5) Water Temperature Sender

The water temperature sender

actuates the temperature gage

(6) Oil Pressure Sender

The oil pressure sender

senses oil pressure and operates the oil puressure gage

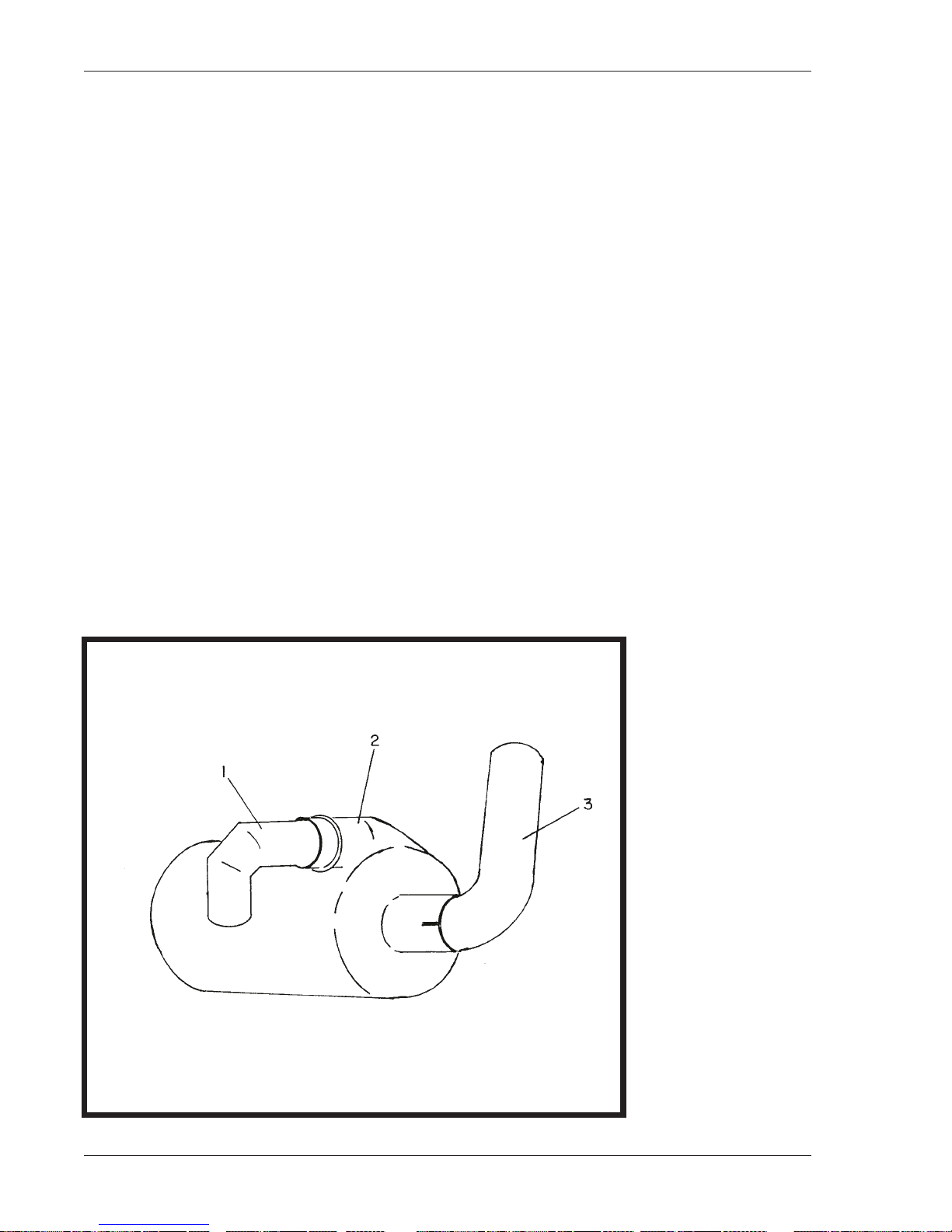

(7) Exhaust system

The exhaust system consists of a special noise reducing muffler

(1)

apipe

ward.

(8) Radiator

The radiator

ing. Refer to Section 2-1, Para. 6, G, for servicing procedure.

to a conventional exhaust manifold. The tail pipe

(1, Fig. 3)

is a one-piece item designed for long periods of operation without servic-

(19, Fig. 3)

(5, Fig. 9)

(17, Fig. 3)

is mounted at the top rear of the engine. This device

on the engine control panel.

is mounted at the right lower rear of the engine. This device

(4, Fig. 9)

(3)

on the engine control panel.

(2, Fig. 5)

directs exhaust and noise down-

which is connected by

1-1 September 30/89 Revised

Page 10

1. Pipe, manifoldto-muffler

2. Muffler

3. Exhaust Pipe

Exhaust System

Figure 5

Page 29

OM-2029

D. Generator

The 400-Hz generator is a brushless, revolving field, three-phase, alternating current type. The rotor

assembly is mounted by two, permanently lubricated, sealed, ball bearings. The front bearing is supported by the fan housing; the rear bearing is mounted in the exciter housing. Both of these housings

are attached to the main generator stator housing. The front end of the rotor shaft extends forward beyond the rear bearing and into the exciter stator housing. The exciter rotor is mounted on this shaft extension with a Woodruff key and is securedby a washer and 1/2"-13thd, cap screw. A rectifier with

six diodes is mounted on the exciter rotor and converts exciter AC output to DC for excitation of the

generator revolving fields. The exciter DC output to the generator fields, and consequently the generator output, is controlled by the amount of DC voltage supplied to exciter fields by the static voltage

regulator. A centrifugal, radial-blade fan which is part of the hub and coupling assembly, draws cooling air over all internal windings. Air enters at the exciter end and is discharged at the drive end. The

complete generator is bolted to the engine flywheel housing.

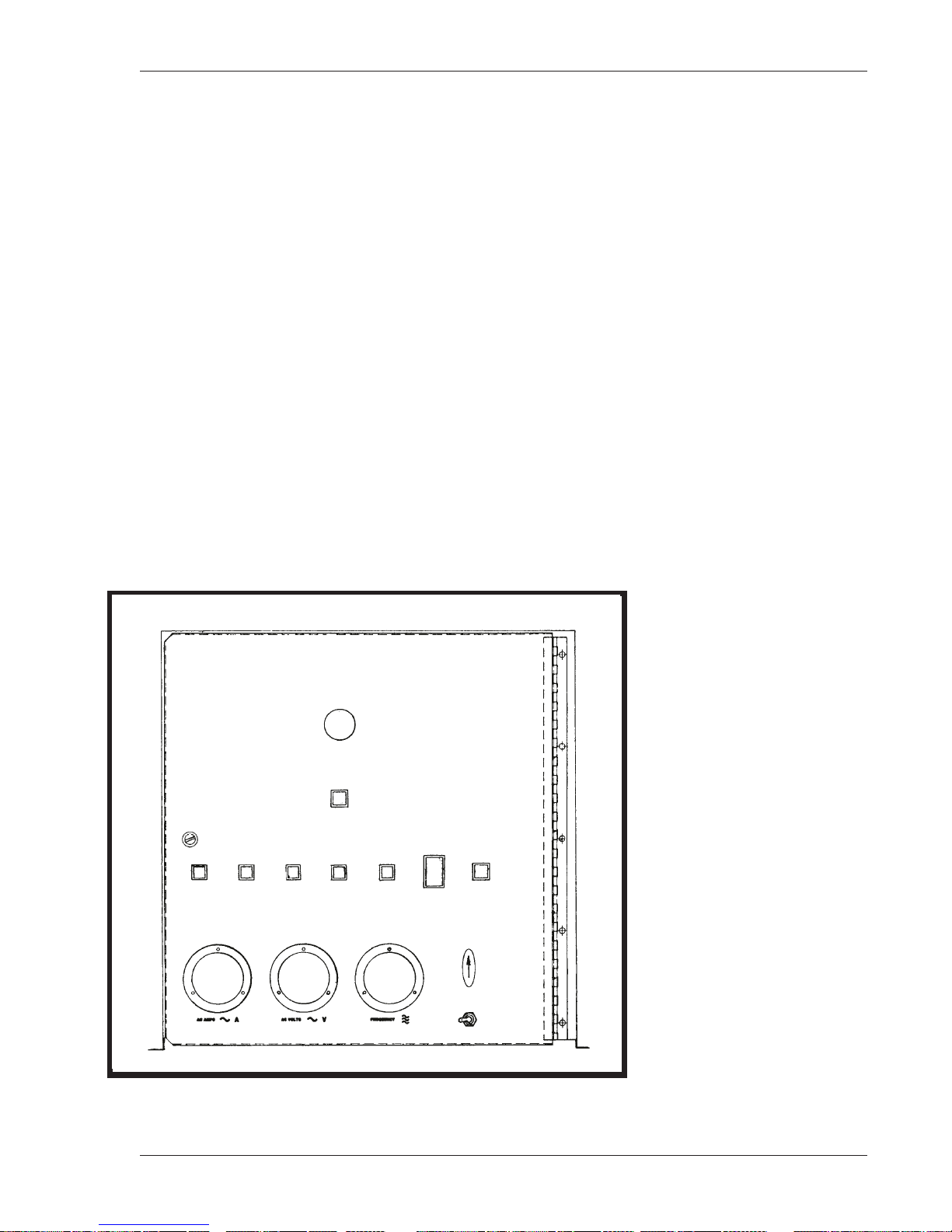

E. Control Box Assembly

The control box

generator controls and monitoring equipment. Switches, meters, indicator lights, and circuit breakers

which control and help to monitor the generator are all mounted on the front panel of the c ontrol box.

This panel is hinged on the right side, and can swing open for access to the interior panel where the

generator PC board assemblies and relays are mounted. A shielded, instrument panel light is

mounted near the top of the control box front panel, to illuminate controls and instruments on the

panel.

(Fig. 6)

is a sheet metal enclosure which houses and provides mounting facilities for

Control Box

Figure 6

September 30/89 Revised 1-1

Page 11

Page 30

OM-2029

(1) Generator Control Box Front Panel Components

(a) Generator output monitors (meters)

• Refer to Figure 7. The generatoroutput is monitored by three instruments; a frequency meter

(10),

a voltmeter

type, and indicates frequency of generator ouput alternating current in the range of 380 to

420 Hz

phase-to-neutral

the meter selector switch

scribed below. The voltmeter has a 3-1/2-inch face and the scale is graduated 0 to 300V.

The ammeter is also 3-1/2-inch size and is graduated 0 to 500A. Amperage value in each

of the three phases may be read on the ammeter by selecting the desired phase with

switch

of infinite ratio, which will operate the ammeter movement without damage. The ammeter

dial scale is graduated and numbered so that the pointer will indicate true load current

value rather than the meter movement current.

(b) Meter and line switches

• These switches provide a means of selecting and determining which phase of voltage and

current is indicated on the voltmeter and ammeter and whether the voltage is line-to-neutral

or line-to-line. The meter switch

the panel is marked and lettered to indicate the three functional positions of the meter

switch. When the knob is pointing straight down, the switch is OFF. The line switch

two-position, toggle switch used to select either line-to-neutral or line-to-line voltage to the

voltmeter. The nameplate is also marked to indicate the position of this switch.

(cycles per second).

(7).

Three ammeter current transformers lower ouput load current to a lesser value,

(12),

andanammeter

The voltmeter indicates generator ouput voltage in each

(A-N, B-N and C-N)

(7)

and the line selector switch

(7)

(13).

The frequency meter is a resonant-reed

or phase-to-phase

is a four-position, rotary type. Around the switch knob,

(A-B, B-C and C-A)

(8).

These switches will be de-

as selected by

(8)

is a

(c) Indicating lights

• The function of these lights

mal condition of overvoltage, underfrequency, etc., which caused the protective monitor

system to function. Each of the five lights is connected to an actuating circuit within the

memory and time delay module. When one of the circuits is activated, it turns on the applicable indicating light. The light will remain on until the reset switch

in the indicating lights may be tested by pressing switch

(d) Load contactor circuit breaker

• This 2-ampere circuit breaker

(e) Protective system circuit breaker

• This 2-ampere circuit breaker

overload.

(9, 11, 14, 15 and 16)

is to indicate, to the operator, the abnor-

(5)

is pushed. All lamps

(5).

(4)

protects the load contactors against overload.

(6)

protects the 12VDC protective monitor circuit against

1-1 September 30/89 Revised

Page 12

Page 31

OM-2029

1. Control box 10. Frequency meter

2. Control panel 11. Underfrequencyindicating light

3. Panel light 12. Generator voltmeter

4. Load contactor circuit breaker (2Amp) 13. Generator ammeter

5. Test-reset switch 14. Overload indicating light

6. Protective system circuit breaker 15. Undervoltage indicating light

7. Meter selector switch 16. Overvoltage indicating light

8. Line switch 17. Panel latch

9. Overfrequency indicating light

Generator Control Box Front Panel Components

September 30/89 Revised 1-1

Figure 7

Page 13

Page 32

OM-2029

(2) Generator Control Box Interior Components (Figure 8)

Mounted on the generator contrl box interior are electrical and safety devices designed to protect

the aircraft electrical system against damage which could result from overvoltage, undervoltage,

overfrequency, or underfrequency. Also on this panel are devices for the protection and control of

the generator output electrical system.

(a) Sensing modules

The voltage sensing module

generator output leads between the generator and the load contactor. These solid-state modules sense any abnormal condition of voltage or frequency and signal the solid-state circuitry

of the memory and time delay module

to the aircraft. Trip values are adjustable, however, adjustments should be made ONLY under

laboratory conditions.

Solid-state overload signaling devices

panel assembly)

similar to the voltage and frequency sensing modules.

Trip values for protective circuits are as follows:

• OVERVOLTAGE trips at 130V to 134V

• UNDERVOLTAGE trips at 102V or below

• OVERFREQUENCY trips at 415Hz to 425Hz

• UNDERFREQUENCY trips at 390Hz to 395Hz

• UNDERVOLTAGE time delay

• OVERLOAD circuit trips at any value over 125% rated load capacity

(b) Memory and time delay module

The memory and time delay module

It is a solid-state device with a hermetically-sealed, reed-type relay. The printed circuit board

or “card” includes five memory circuits and a time delay circuit. Each circuit is connected to a

corresponding sensing circuit in the sensing modules

connected to the module relay coil, and any one of the circuits can energize the coil to open

the relay contacts. Thus, when a sensing device energizes any one of the module circuits, the

module relay is also energized to break the load contactor holding circuit and allow the load

contactor to open. All circuits, except the undervoltagecircuit, function immediately to open

the load contactor. A time delay system is designed into the undervoltage circuit to prevent

nuisance opening of the contactor under conditions of momentary undervoltagein the generator output. An undervoltage condition which continues uninterrupted for a period of 4 to 12

seconds

five circuits is connected to a corresponding indicating light

turned on when a fault occurs.

(adjustable)

are also connected to the protective monitor module and perform a function

(17)

and frequency sensing module

(19)

to open the load contactor and disconnect output

(18)

are connected to the

(one for each output, and located on the power module

(adjustable)

(19)

is sometimes called the protective monitor module.

(17 and 18)

will cause the time delay circuit to open the load contactor. Each of the

. All memory circuits are

(9, 11, 14, 15 and 16)

which is

The module relay will remain energized

switch

mal, CLOSED position.

1-1 July 27/90 Revised

Page 14

(5)

is pushed to break the module 12-V DC circuit, and allow the relay to return to nor-

(OPEN)

and the light will remain ON until the reset

Page 33

OM-2029

(c) Plug-interlock relays

Each ouput of the generator has a plug interlock relay. For either output, the function of the

plug interlock relay is to cause its output load contactor to open in the event the cable plug

connector becomes accidentally disconnected from the aircraft during power delivery, or if an

attempt is made to deliver power when the output cable is not connected to the aircraft.

Twenty-eight-volt, direct current for operation of the relay is supplied from the aircraft either

through an on-board transformer-rectifier, or from a twenty-eight-volt, electrical system. Connection from the aircraft to the interlock relay is made through terminals E and F on the output

cable plug connector.

(d) Test-bank switches

Each ouput of the generator has a test-bank switch. For either output, the function of this single-pole-single-throw switch is to provide a means of by-passing the output’s interlock relay

when supplying power to a load bank or to an aircraft not equipped with a plug interlock system.

(e) Resistor

Each output of the generator has a 100-ohm, 25-watt resistor connectedin series with the

plug interlock relay to protect the relay in the event that phase C contacts in the load contactor should fail to close when the generator ON switch is operated. For outputs No. 1 and No.

2, the resistors are items 22 and 20, respectively.

A variable 20-ohm, 100-watt, ballast resistor

citer DC field and thus determine the voltage range through which the regulator can control

generator output voltage.

(f) Fuse-interlock relay

The function of the fuse-interlock relay

and remove the load in case of a tripped circuit breaker in the protective relay coil circuit.

(g) Auxiliary underfrequency relay

The function of the auxiliary underfrequency relay

deenergization relay and disconnectthe voltage regulator anytime generator frequency drops

to 380 Hz or below. This protects the voltage regulator and ballast resistor

load which could be caused by very high voltage regulator output in its attempt to maintain

voltage when the generator is operating at a speed which cannot produce n ormal voltage output.

(21)

is connected in series in the generator ex-

(6)

is to interrupt the load contactor holding coil circuit

(7)

is to automatically open the excitation-

(24)

against over-

NOTE: If the auxiliary underfrequency relay is tripped, it will be necessary to momentarily place engine

operating mode switch in BUILD-UP-VOLTAGE position to restore generator voltage.

(h) Regulated-diagnostic switch

When the regulated-diagnostic switch

voltage is regulated by the voltage regulator or 115/200 VAC output to an aircraft. When this

switch is placed in the DIAGNOSTIC position, battery voltage

erator exciter with the engine running at rated RPM, in order to check the operation of the

generator set. By applying this DC voltage to the exciter and observing generator output voltage, it can be determined if a particular power output malfunction is caused by a defective

generator or by a defective voltage regulator.

(26)

is in the REGULATED position, generator output

(12VDC)

is applied to the gen-

(j) Excitation-deenergization relay

The purpose of this relay

field only when the engine speed is being controlled by the electric governor.

July 27/90 Revised 1-1

(5)

is to allow automatic excitation to be connected to the exciter

Page 15

Page 34

OM-2029

1. Control box rear inside panel 11. Sensing/pre-amplifier assembly

2. Protective system interlock relay of voltage regulator

No. 2 output 12.Control box right side panel

3. Plug interlock relay, No. 2 output 13. Control box bottom inside panel

4. Governor idle speed relay 14. Terminal blocks

5. Excitation deenergization relay 15. Generator main overload relay

6. Protective system interlock relay, 16. Control box left side panel

No. 1 output 17. Over-undervoltage relay

7. Auxiliary underfrequency relay 18. Over-underfrequency relay

8. Plug interlock relay, No. 1 output 19. Memory & time delay relay

9. Voltage regulator (Magnetic- 20. No. 2 contactor hold circuit resistor

Amplifier type shown) 21. Ballast resistor, 20-ohm, 100-watt

10. Line drop compensator assembly 22. No. 1 contactor hold circuit resistor

of voltage regulator

Generator Control Box Interior Components

1-1 July 27/90 Revised

Page 16

(Sheet 1 of 2)

Figure 8

Page 35

OM-2029

(k) Voltage Regulator

The voltage regulator used on any Series 6906 generator set is located inside the control

box, and is accessible by swinging open the front panelof the control box.

Specification 6906-1 and Specification 6906-2 generator sets are equippedwith a solid state

voltage regulator, Hobart Part No. 489812A. Information and instructions for this regulator

are contained in Hobart regulator manual OM2020, found in Chapter 6 of this generator set

manual (OM-2029).

Generator set Specifications 6906-3, -4, -5, and -6 are equipped with a magnetic amplifier

type voltage regulator, Hobart Part No. 281407. Information and instructions for this regulator

are contained in Hobart regulator manual TM-759, found in Chapter 6 of this generator set

manual (OM-2029)

23. Switch bracket (behind generator control panel)

24. Test bank/aircraft switch No.1 output

25. Test bank/aircraft switch No. 2 output

26. Regulated/diagnostic switch

27. Idle speed adjustment potentiometer

July 27/90 Revised 1-1

Generator Control Box Interior Components

(Sheet 2 of 2)

Figure 8

Page 17

Page 36

OM-2029

F. Engine Control Panel (See Fig. 9)

The engine control panel is mounted directly below the control box. In addition to engine controls

and instruments, generator output controls are mounted here. A plexiglass window in the canopy

rear door, slants outward at the bottom to form an opening for access to controls when the door is

closed.

(1) Engine instruments

Engine operation is monitored by an ammeter

pressure gage

(a) Ammeter

• The ammeter

system. Its graduated range is from -60 A through 0 A, to +60 A.

(b) Temperature gage

• The temperature gage

temperature sender

engine coolant temperature in the range of 100F to 220F.

(c) Oil pressure gage and oil pressure switch

• The oil pressure gage

erated by an oil pressure sender

• The switch connects 12-V DC power to the engine control system and to the generator 12V DC control system when the engine is running.

(d) Hourmeter

• The hourmeter

measures and records engine running time and will record up to 9999.9 hours on five revolving drums. The hourmeter operates only when the engine is running and the oil pressure switch is closed.

(2) Engine and generator controls

(4)

. An hourmeter

(3)

indicates the direction and value of current flow in the 12-V DC electrical

(5)

(19, Fig. 3)

(4)

(6)

records engine operating time.

indicates the engine coolant temperature and is actuated by a

mounted on the engine’s water jacket. The gage indicates

displays the pressure in the engine’s lubrication system. It is op-

(17, Fig. 3)

(6)

is electrically driven from the 12-V DC battery system. The hourmeter

(3)

, a coolant temperature gage

mounted on the engine block.

(5)

, and an oil

(a) Engine-generator control switch

• The engine-generator control switch

idle” switch)

VOLTAGE, and will automatically reposition to GENERATE position when released. In

BUILD-UP-VOLTS position it performs a dual function. First, it supplies power to the gover-

nor control box, which allows the engine to operate at normal governed speed; second, it

momentarily supplies current for closing the excitation-deenergization relay contacts, to

make three-phase, 115-V AC power available to the voltage regulator, or to the manual

voltage control circuit for excitation of the generator exciter. In GENERATE position, power

is maintained to the governor control box and to the excitation relay. When the switch is

placed in IDLE position, power is disconnected so that the engine returns to idle speed and

the exciter field is deenergized.

1-1 September 30/89 Revised

Page 18

is a three-position toggle type. It is spring-loaded in one position, BUILD-UP-

(15) (also identified as the “build-up-voltage, generate,

Page 37

OM-2029

(b) Contactor control switches

• This is another three-position, toggle switch identical to the engine-generator control

switch. When placed in the spring loaded CLOSE position, it provides 115-V AC power directly to a rectifier which supplies DC power for closing the load contactor. When released

it returns to the normal ON position and continues to provide power to the rectifier, but in

this switch position, AC power must pass through the plug interlock and fuse interlock relays. In OFF position the switch opens the AC circuit to the rectifier, thereby cutting off the

source of DC power to the contactor coil which allows the contactor to open.

(c) Instrument light and switch

• A shielded, instrument panel light

controlled by a rocker switch

and clearance lights on the canopy of the generator set.

(d) Engine starting circuit

• The pushbutton start switch

for closing an auxiliary solenoid switch. The auxiliary switch then connects power to the

starter solenoid which functions to engage the starter gear with the flywheel ring gear and

apply power to the starter motor to crank the engine. The auxiliary solenoid switch is necessary because the start pushbutton switch is not capable of carrying the high amperage flow

to the starter solenoid which would result if the starter gear and ring gear should fail to engage. The permissive rocker switch

the down

(e) Indicating lights

• A green indicating light

tive system. The light operates only when the engine is running and fuel pressure is sufficiently high to close a fuel pressure switch. The purpose of the pressure switch is to

deactivate the protective circuit when the engine is stopped and prevent battery discharge.

• Two other green indicating lights

is CLOSED and power is available at the generator output terminal panel

(f) Engine circuit breaker

• A 10-ampere circuit breaker

nating light circuit, and 12VDC system in the main generator protective system.

(STOP)

position.

(13)

(2)

is mounted at the left side of the control panel. It is

(17)

, which also controls instrument lights on the control box

(16)

and permissive rocker switch

(14)

also stops the engine when the toggle is placed in

glows to indicate that power is available to the engine protec-

(9 and 10)

(8)

protects the 12VDC engine control circuit, hourmeter, illumi-

glow when the generator output load contactor

(14)

serve to connect power

(g) Air cleaner indicator

• The air cleaner indicator

function was explained in Para. 7, C,

September 30/89 Revised 1-1

(18)

is mounted on the engine control panel for easy viewing. Its

(4) (see Fig. 4).

Page 19

Page 38

OM-2029

1. Engine control panel 10. Indicator, No. 2 load contactor

2. Panel light 11. Switch, No. 1 load contactor

3. Engine ammeter 12. Switch, No. 2 load contactor

4. Oil pressure gage 13. Engine ON indicator light

5. Water temperature gage 14. Engine START-RUN-STOP switch

6. Hourmeter 15. Build-up-voltage/generate/idle switch

7. Terminal block 16. Engine start switch

8. Circuit breaker, engine circuit 17. Switch, clearance/panel lights

9.Indicator, No. 1 load contactor 18. Air filter service indicator

Engine Control Panel

Figure 9

H. Power Module Panel Assembly

The power module panel assembly

cated at the right rear of the machine behind the control box. The power module panel is accessible by opening the left rear door on the canopy. The panel assembly provides sensing and

overload protection for the output circuit and provides a means of connecting and disconnecting

generator output to and from the load

(Fig. 10)

sometimes referred to as the “contactor panel”, is lo-

(aircraft).

1-1 September 30/89 Revised

Page 20

Page 39

(1) Load contactor

OM-2029

Two load contactors are used in this unit. One contactor

the other contactor

Each load contactor is a sealed unit which contains a magnetic operating coil and four sets of

contacts. The three larger contacts conduct three-phase AC generator output. A smaller contact set is connected in the protective monitor circuit and supplies 12VDC power used by

sensing relays to signal the protective monitor when a fault occurs. Three-phase, 400-Hz generator output power is conducted to and through the load contactor by cables which also pass

through four sets of current transformers

NOTE

: This contactor may be replaced by the old style contactor used in previous 60-KVA machines.

(9)

serves output circuit No. 2.

(3, 5, 16, and 18) .

(8)

serves output circuit No. 1, and

This note is for the benefit of those users who may have old style contactors Part number 75GH-566

(Hartman No. A-874C) in stock.

(2) Current transformers

(a) Ammeter current transformers

• Three current transformers

tio

(500-A to 5-A)

ter dial scale is graduated and numbered so that the ammeter pointer will indicate the true

load current value rather than the meter movement current.

(b) Line-drop current transformers

• The three line-drop current transformers

tect the magnitude and power factor of current flowing from generator to load. They feed a

signal to the voltage regulator which interprets the signal and alters the exciter field current

as required to maintain a constant predetermined voltage at the load

which will operate the ammeter movement without damage. The amme-

(16)

lower the output load current to a lesser value of definite ra-

(18),

in conjunction with burden resistors

(see Voltage Regula-

(17),

tor Manuals No. TM-759 for a Mag-Amp type or OM-2020 for a Solid-State type regulator).

de-

(c) Overload current transformers

• Each output circuit has three overload current transformers,

item 3 for No. 2 output)

rent in each of the three output phases, and supply a reduced value current signal to the

overload module which serves the output circuit.

(3) Rectifiers

A diode-bridge rectifier

an converts it to a pulsating, direct current for energization of the load contactor holding coil

only. This DC coil-holding circuit is controlled indirectly be controlling the 400-Hz AC to the

rectifier. The ground circuit for the rectifier’s AC supply must pass through the relay contacts

in the protective monitor module to ground cable N. Therefore, any time a protective device

functions to open the protective monitor relay, the rectifier’s AC circuit is opened. No DC is

then available for the load contactor holding coil, hence, the load contactor opens.

which, in conjunction with burden resistors monitor output load cur-

(6 and 7)

receives 400-Hz AC from phase C of the generator output

(item 5 for No. 1 output, or

September 30/89 Revised 1-1

Page 21

Page 40

OM-2029

(4) Overload module

Each output of the generator set has an overload module

for No. 2 output).

from a set of overload current transformers

and to send a signal to the protective monitor module when an overload condition exists in

any generator output phase. A pull-apart electrical connector is mounted on the overload module to provide quick-disconnect facilities for all wiring to a module. Each overload module is

equipped with a hermetically-sealed, reed-type relay. Relay contacts are normally open. The

solid-state circuitry is designed to close relay contacts when output current in ANY phase

reaches 125% of normal rated output capacity. The closed relay sends a signal to the protective monitor. This signal “gates” the overload SCR

tive monitor and interrupts the load contactor holding circuit, allowing the load contactor to

open.

The following is a list of overload module characteristics:

NOTE

:The overload protective system will function when any phase carries 123% to127% of rated load.

• At 125% load the module will function in 5 minutes.

• At 150% load the module will function in 16 seconds.

• At 200% load the module will function in 4 seconds.

NOTE

: All times are plus or minus 25% and are nonadjustable.

(5) Terminal boards

Two terminal boards

Each overload module is a solid-state device designed to interpret a signal

(item 5 for No. 1 output, or item 5 for No. 2 output)

(silicone-controlled rectifier)

(7)

provide connection facilities for small leads.

(item 13 for No. 1 output, or item 14

in the protec-

1-1 September 30/89 Revised

Page 22

Page 41

OM-2029

1. Power module panel 10. Rectifier, No. 1 contactor

2. Overload resistors, 25-watt, No. 1 output 11. Rectifier, No. 2 contactor

3. Overload transformers, No. 2 output 12. Capacitors, 0.1 mfd, 500-V

4. Overload resistors, 25-watt, No. 2 output 13. No. 1 overload PC module

5. Overload transformers, No. 1 output 14. No. 2 overload PC module

6. Blocking diodes 15. Connector socket housings

7. Terminal strips 16. Ammeter current transformers

8. No. 1 load contactor 17. Resistors, 50-ohm, 25-watt

9. No. 2 load contactor 18. Line-drop transformers

September 30/89 Revised 1-1

Power Module Panel Assembly

Figure 10

Page 23

Page 42

OM-2029

Output Terminal Panel

Figure 11

1-1 September 30/89 Revised

Page 24

Page 43

SECTION 2. PREPARATION FOR USE, STORAGE, OR SHIPPING

1. Preparation for Use

A. General

These instructions are based on the assumption that the unit is properly installed and that all necessary fuel and electrical connections have been made. Generator sets for stationary mounting are installed by the customer. Other generator sets, when ordered with truck or trailer, are mounted at the

Hobart factory and are shipped in running condition and ready for operation after inspection and

check.

WARNING: IMPROPER OPERATION CAN KILL, INJURE, OR CAUSE DAMAGE! READ AND UNDERSTAND OPERATING INSTRUCTIONS IN SECTION 13 BEFORE OPERATING THE UNIT.

B. Inspection/Check

Inspect the unit thoroughly prior to operation.

OM-2029

(1) Remove blocking, banding, ties, and other securing material.

(2) Inspect exterior for shipping damage such broken lights, damaged sheet metal, etc.

(3) Open all canopy doors and inspect interior for foreign material such as rags, tools, shipping pa-

pers, etc.

(4) Check fuel, coolant, and oil hoses and connections for visible leaks. Visually inspect the compart-

ment floor and ground surface under the unit for signs of leakage. If leaks are found, correct by tightening hose clamps, tube fittings, etc., as required.

(5) Check the following for sufficient quantity:

(a) Fuel

Turn ON panel lights to energize fuel gage when engine is stopped.

(b) Engine coolant

The radiator cap is accessible by opening the hinged access cover on the front canopy housing.

Coolant level should be approximately one inch below the filler neck. Allow a capacity for coolant

expansion.

CAUTION: BE SURE THE COOLING SYSTEM ANTIFREEZE SOLUTION IS ADEQUATE TO PROTECT BELOW LOWEST TEMPERATURE EXPECTED.

NOTE: For antifreeze protection, use a solution of 50% permanent antifreeze (Ethylene glycol) and 50%

clean water.

(c) Engine lubricating oil

Oil level should be at “FULL” mark on oil level gage rod. See the Perkins Shop Manual for oil recommendations.

September 30/89 Revised 1-2

Page 1

Page 44

OM-2029

(6) Check air cleaner

The air cleaner

other material covering the air inlet area.

C. Installing Output Cables

Units are generally shipped without generator set-to-aircraft cables.

(1) Three-phase, AC output cable assembly installation

The AC output terminal panel access cover is located on the right side, just to the right of the engine control panel

(a) Remove output terminal panel access cover.

(b) Loosen cable horn clamps and and insert the looseends of the cable assemblies through the

cable horns. Route to output terminal panel.

(Sect. 1-1, Fig. 3, item 7)

(see Fig. 1).

is a “dry” type. Be sure there are no papers, tapes, or

NOTE: Conductor size recommended for AC output is 2/0 size. Use No. 12 size for control (E and F

terminals).Largecables(A,B,C,N)shouldbeequippedwithterminalshavingat least a 3/8-inch diameter

mounting hole. Mounting hole in small leads (E and F) should be at least 1/4-inch diameter.

(c) Each terminal stud is identified by an identification plate. Each cable should be identified by a

band-type marker. Connect cable “A” to terminal “A”, “B” to “B”, etc. Connect one cable assembly

to the upper row of terminals, and connect the other cable assembly to the lower row of terminals.

(d) Tighten clamp screws securely, but avoid damage to cable insulation.

(e) Install terminal panel access cover which was removed in step (a) above.

1-2 September 30/89 Revised

Page 2

AC Output Terminal Panel

Figure 1

Page 45

2. Preparation for Storage

When a generator set is to be stored or removed from operation, special precautions should be taken to

protect the internal and external parts from rust, corrosion, and gumming in the engine fuel system.

A. General

(1) The unit should be prepared for storage as soon as possible after being removed from service.

(2) The unit should be stored in a building which is dry and which may be heated during winter

months.

(3) Moisture absorbing chemicals are available for use where excessive dampness is a problem, how-

ever the unit must be completely packaged and sealed if moisture absorbing chemicals are to be effective.

B. Temporary Storage

When storing the unit for 30 days or less, prepare as follows:

(1) Lubricate the unit completely in accordance with instructions in Sect. 2-1. This will include chang-

ing engine oil, and all filter elements.

OM-2029

(2) Start the engine and operate for about two minutes so that all internal engine components will be

coated with new oil.

NOTE: Do not drain the fuel system or crankcase after this run.

(3) Make certain the cooling system antifreeze solution is adequate to protect below the lowest temperatures expected during the storage period. See 2-1; Para. 6, D. Be sure the solution is thoroughly

mixed.

(4) Clean the exterior of the engine with fuel oil. Dry with clean rags and compressed air.

(5) Seal all engine openings. Use a waterproof, vaporproof material which is strong enough to resist

puncture damage from air pressures.

C. Long Time Storage (Over 30 Days)

(1) The unit may be stored for long periods with no special preparation if it is possible to operate the

engineonceeachweek.

(a) Make certain the cooling system is adequately protected.

(b) Start the engine and operate at a fast idle

reached at least 140 deg F.

(800 to 1000 RPM)

until coolant temperature has

WARNING: MAKE CERTAIN OF ADEQUATE VENTILATION BEFORE STARTING THE ENGINE.

(c) Operate normal operating controls.

(2) If weekly operation is not possible, prepare and protect the engine in accordance with instructions

in John Deere Operator’s Manual.

(3) To protect the generator and other electrical components, the complete unit should be packaged,

using moisture proof packaging and sealing material. Place containers of moisture absorbing chemicals, such as silica-gel, in the unit before packaging.

September 30/89 Revised 1-2

Page 3

Page 46

OM-2029

This page intentionally left blank.

1-2 September 30/89 Revised

Page 4

Page 47

SECTION 3. OPERATION

1.General

This section contains information and instructions for the safe and efficient operation of the equipment.

Operating instructions are presented in step-by-step sequence of procedures to be followed in supplying

400-Hz power to an aircraft.

WARNING: IMPROPER OPERATION CAN KILL! EAR PROTECTION EQUIPMENT MAY BE NECESSARY WHEN WORKING IN CLOSE PROXIMITY TO

THIS EQUIPMENT. READ AND FOLLOW ALL OF THE OPERATING INSTRUCTIONS BEFORE ATTEMPTING TO OPERATE THE EQUIPMENT.

2. Operating the Generator Set

A. Pre-start Inspection

OM-2029

(1) Open the fuel shut-off valve.

(2) Provide 12-V DC power to the engine starting system.

(3) Check the engine and generator compartments and remove rags or other foreign materials.

B. Normal Engine Starting Procedures

Engine starting procedures are outlined below. Engine operating controls and monitoring instruments

are illustrated in Fig. 1.

(1) If illumination is required, place light switch

NOTE: This switch must be ON to check fuel when engine is stopped.

(2) Hold engine start switch

(24)

to crank engine. When engine starts, release pushbutton. Continue to hold engine start switch

(22)

in position until oil pressure gage

(3) Check ammeter

(4) Check oil gage

(5) Place engine generator control switch

(15)

(27).

(22, Fig. 1)

for charge reading.

in START position momentarily. Push engine start pushbutton

(27)

(25)

in ON position.

reads at least 20 PSI pressure. Release switch

(23)

in IDLE position.

(22).

September 30/89 Revised 1-3

Page 1

Page 48

OM-2029

1. Panel light 15. Engine ammeter

2. Load contactor circuit breaker (2-A) 16. Engine circuit breaker (10-A)

3. Test-reset switch 17. Indicator, No. 1 load contactor

4. Protective system circuit breaker 18. Switch, No. 1 load contactor

5. Meter selector switch 19. Indicator, No. 2 load contactor

6. Line switch 20. Switch, No. 2 load contactor

7. Generator ammeter 21. Engine ON indicator light

8. Generator voltmeter 22. Engine START-RUN-STOP switch

9. Frequency meter 23. Build-up-voltage/generate/idle switch

10. Overvoltage indicating light 24. Engine start switch

11. Undervoltage indicating light 25. Switch, clearance/panel lights

12. Overload indicating light 26. Air filter service indicator

13. Underfrequency indicating light 27. Oil pressure gage

14. Overfrequency indicating light 28. Water temerature gage

29. Hourmeter

Operating Controls and Instruments

Figure 1 (Sheet 1 of 2)

1-3 September 30/89 Revised

Page 2

Page 49

OM-2029

30. Automatic voltage control rheostat 35. Damping circuit GAIN potentiometer

31. Foot compensation potentiometer 36. Test bank/aircraft switch, No. 1 output

32. Line-drop compensation ON/OFF switch 37. Test bank/aircraft switch, No. 2 output

33. Cable size potentiometer 38. Regulated/diagnostic switch

34. Damping circuit RATE potentiometer 39. Idle speed adjustment potentiometer

July 27/90 Revised 1-3

Operating Controls and Instruments