Page 1

VERTICAL MACHINING CENTER

VS50/60

INSTRUCTION MANUAL

SPECIFICATIONS

SEIKI-SEICOS Σ16M/18M

Version 1.01

BS-2782-1-0221-E-1-01

1

Page 2

Introduction

Thank you for your having purchased the machine, favoring our product lines for your use.

This manual contains fundamental information on the specification. Please read and fully understand

the contents for your safe machine operation.

In particular , the contents of the items concerning safety in this manual and the descriptions on the

“caution plates” attached to the machine are important. Please follow the instructions contained

and keep them always in mind to ensure safe operation.

The reference record papers on adjusting setting values such as a parameter list are attached to

the machine unit and enclosed in the packing. These are necessary for maintenance and

adjustment of the machine later on. Please keep them safely not to be mislaid.

The design and specifications of this machine may be changed to meet any future improvement.

As the result, there may arise some cases where explanations in this manual could become partly

inconsistent with the actual machine. Please note this point in advance.

In this manual, items on the standard and optional specifications are handled indiscriminately.

Please refer to the “delivery note” for the detailed specification of your machine confirmation.

1

Page 3

CONTENTS

1. INTRODUCTION .................................................................................. 1 - 1

1-1 General Precautions..........................................................................................................1 - 2

1-1-1 Precautions on Machine Operation ........................................................................... 1 - 2

1-1-2 Electric Equipment and NC Unit ................................................................................ 1 - 6

1-1-3 Weights and Measures Table .................................................................................... 1 - 7

2. OUTLINE AND FEATURES OF MACHINE ......................................... 2 - 1

2-1 Construction of Machine.................................................................................................... 2 - 1

2-1-1 Bed ............................................................................................................................ 2 - 1

2-1-2 Column ...................................................................................................................... 2 - 1

2-1-3 Spindle Head..............................................................................................................2 - 1

2-1-4 Table .......................................................................................................................... 2 - 1

2-1-5 Feed Box ................................................................................................................... 2 - 2

2-1-6 Slideway .................................................................................................................... 2 - 2

2-1-7 Automatic Tool Changer (ATC) .................................................................................. 2 - 2

2-1-8 Splash Cover ............................................................................................................. 2 - 2

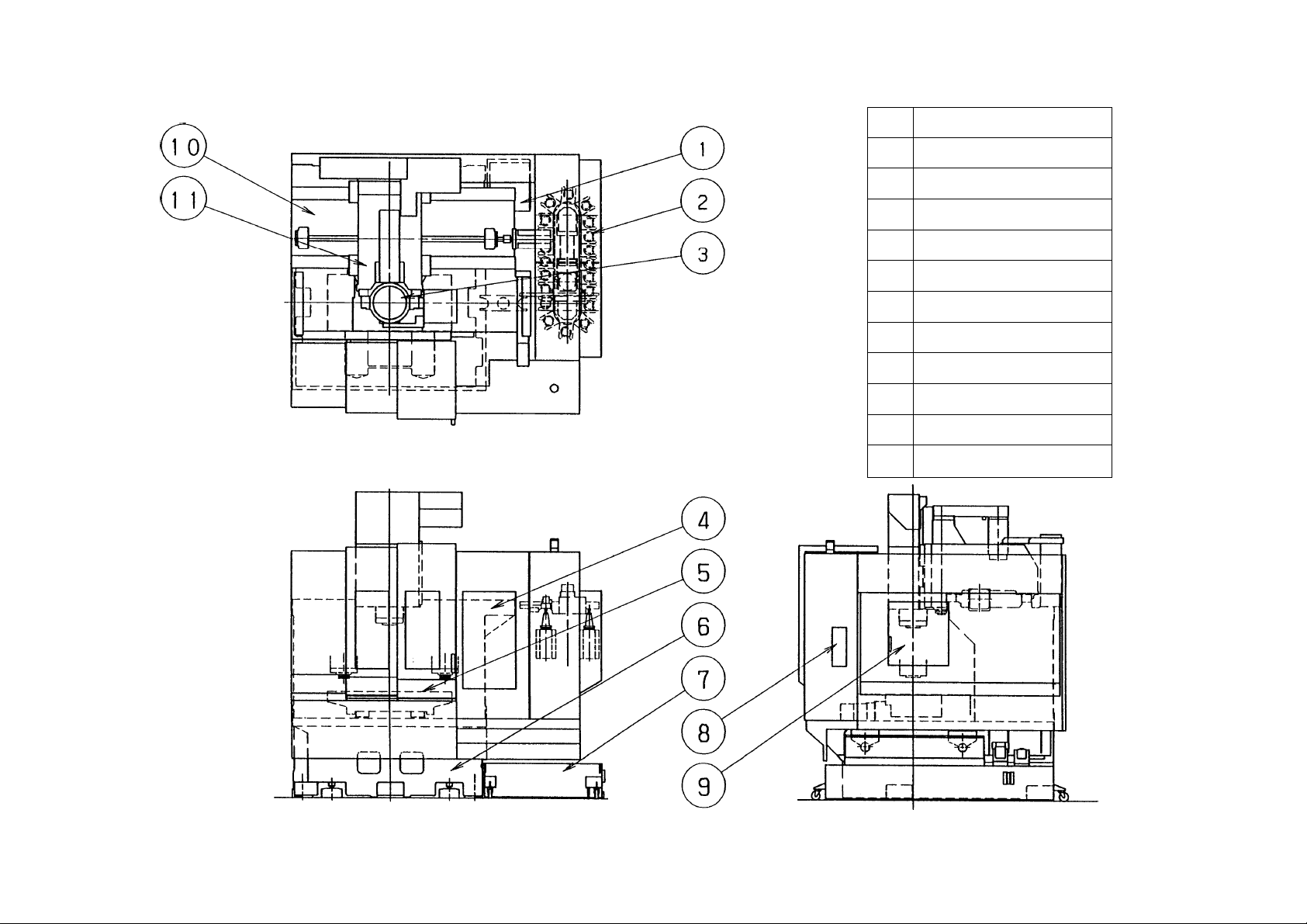

2-2 Name of Component Units ................................................................................................ 2 - 3

2-3 Specifications of Machine.................................................................................................. 2 - 4

2-3-1 VS50 Machine Specifications..................................................................................... 2 - 4

2-3-2 VS60 Machine Specifications..................................................................................... 2 - 7

2-3-3 Main Accessories .................................................................................................... 2 - 10

2-4 NC Unit Specifications..................................................................................................... 2 - 12

2-5 Main Dimensions Diagram .............................................................................................. 2 - 19

3. SIZE NECESSARY FOR OPERATION................................................ 3 - 1

3-1 Strokes and Machine Reference Point ..............................................................................3 - 1

3-2 Table Dimensions and Working Area Diagram..................................................................3 - 3

3-3 Machining Area and ATC Interference Range ....................................................................3 - 5

3-4 Tool Shank ......................................................................................................................... 3 - 9

3-4-1 Tool Shank (BT-40) and Pull-stud Bolt (12000min-1)................................................. 3 - 9

3-4-2 Tool Shank (BT-50) and Pull-stud Bolt (4500/10000min-1)...................................... 3 - 10

3-4-3 Two-face Clamped Tooling (Spindle Speed: 19,000 min.-1 or More) ....................... 3 - 10

3-5 ATC Tool Limit (BT40)...................................................................................................... 3 - 11

3-6 Spindle Torque/Output Diagram ......................................................................................3 - 14

i

Page 4

1. INTRODUCTION

We are obliged to you for using our machining center.

This manual describes the installation, operation, daily maintenance and inspection, etc. of this

machine in order for you to be able to properly operate the machine and make full use of its

performance. Prior to its installation and test run, read this manual thoroughly to understand the

contents described for handling the machine.

To secure safe operation, follow the safety precautions described in this manual and the

instructions given on the warning signs attached to the machine.

For your general understanding of this machine, the following documents are provided other than

this instruction manual. Refer to them when necessary.

1. Programming Manual

2. Parts List

3. Instruction Manual for OPERATION

4. Instruction Manual for MAINTENANCE

5. Electric Circuit Diagrams

6. Instruction Manual for NC UNIT (PROGRAM, OPERATION, MAINTENANCE)

Such records of adjustment and setting values as “Parameter List” are included in the package of

the machine. Be sure to keep these documents, which is necessary for maintenance and

adjustment of the machine from now on.

Hitachi Seiki pursues a policy of a continuing improvement in design and performance of its

product. The right is therefore reserved to vary specification, and as a result, the contents of these

documents may partly differ from your machine.

1 - 1

Page 5

1-1 General Precautions

These general precautions is quite useful for operators to create good working environment

against accidents and to increase productivity.

1. Be sure to put safety goggles on.

2. Be sure to put safety shoes on.

3. Operate with proper dressing, such as putting a utility cap on, fixing the sleeves and the

cuffs of working clothes.

4. Don’t operate the machine with gloves.

5. Make clean and neat environment by lighting up and keeping dry around the machine. Also

don’t put any obstacles.

6. Remove dust and chips on the machine, high voltage control panel and NC unit. Also

remove them on the floor. Avoid using compressed air as much as possible for these

cleanings.

7. Use a strong enough table to be put around the machine, and take anti-sliding measures

on the surface.

8. Don’t put tools, workpieces, and other items on the machine as well as on the moving parts

of the machine.

9. Don’t give any remodeling to the machine without our permission.

10. About the Machine with Through Coolant

<1> For the spindle core through specifications, be sure to use our specified through pull

stud when discharging the coolant. If you use other pull stud, it could cause a trouble.

<2> For the DIN through specifications, be sure to use our specified DIN through tool

holder when discharging the coolant. If you use other pull stud, it could cause a trouble.

1-1-1 Precautions on Machine Operation

Before trial run, read this manual carefully and understand, the contents well. Witness of our

operation instructors is most recommendable.

MAINTENANCE

1. An operator and maintenance personnel should read the precautions on the caution plate

fitted to the machine and observe them.

Don’t stain, damage or remove the caution plate. If the caution plate becomes hard to read,

contact Hitachi Seiki.

2. Close all the doors and covers except when adjusting work is made.

As for the doors of the NC unit and the power control cabinet, be sure to close them with

special care.

3. Don’t remove or modify the limit switches for the stroke end, for the traveling axes and the

mechanism, or the electric circuit employed for safety.

4. Use regular wrenches and spanners for adjusting or repairing work.

1 - 2

Page 6

LUBRICATION

Since lubrication oil exerts a great influence on machine durability and accuracy, extreme care

must be taken for maintenance of the whole lubricating system. Perform the following check

and maintenance precautions.

1. Fill with the oil specified in the Maintenance manual to the specified amount.

2. Clear the oil port in advance and be careful that foreign substances such as dust, water and

chips do not enter the tank.

3. Check the bottom of the oil jug to see if there is any debris, water or cutting chips, etc.

insides Sufficient care is required to distinguish the oil jug by appropriate color coding and

fixed stock location to avoid mixed use of different kinds of oil.

4. Check the oil periodically and if foreign substances are found, clean the inside of the tank

promptly and replace it with new oil.

Don’t use all of the oil, even from a new can. This is necessary in order to remove water

and sediment etc.

(with option device)

5. Although low levels in the lubrication oil tank are detected by a float switch that flashes an

alarm signal, check to see if discharging is normal. There are two possible problems:

Oil in the tank decreases extraordinarily fast, or it is decreasing too slowly.

6. As for the suction filter fitted to the pump and the in-line filter in the piping circuit, replace

them with new ones once a year as a rule.

7. Air in the main lubrication pipes has been bled when the machine is delivered, but when the

piping is removed for maintenance, bleed air completely at the time of reassembly and

operate the machine after checking the state of discharging at the end.

COOLANT

The soluble cutting fluid is decomposed due to factors such as mixture of lubrication oil and

propagation of micro-organisms that lower cutting and rust prevention efficiency. This causes

various troubles to occur.

When using-soluble cutting fluid, care must be taken of the following points.

1. When selecting soluble cutting fluid, carefully consider lubrication, infiltration, rust

prevention, bubble prevention, reparability against oil and safety needs.

2. Before operation starts and after operation ends, not only remove chips, but also wipe off

soluble cutting oil adhered to each slideway, the rotating parts, the saddle and cross-slide

of the machine and then be sure to apply lubrication oil thinly to those parts.

3. Replace soluble cutting fluid immediately if it becomes vitiated.

1 - 3

Page 7

4. Remove the covers every half year and clean each slideway, X, Y, Z axes ball-screws, each

limit Switch and feed motors etc.

5. As soluble cutting oil is considered for rust prevention, it may be no problem when the

workpiece is wet. However, when dry, it is apt to rust.

Therefore, it is recommendable to apply rust preventive oil before the workpiece dries after

finished machining.

6. Since soluble oil is alkalescent and has a strong degreasing action, the operator is apt to

develop dermatitis.

Therefore, the operator should take appropriate precautions.

7. As for the diluting method and soluble cutting fluid, diluting water they are different

depending on the type of soluble cutting oil, so use it in accordance with the

recommendations of the cutting fluid manufacturer.

8. Since there are instances where extensive micro-organisms are detected in industrial

water, it is recommendable either to check it before use as water for dilution or to use

service water.

9. Do not use a chemical solution type (synthetic type) in water-soluble cutting agents,

because it causes detachment of coating and affects sealing materials and resin materials

adversely.

10.The influences of difference kinds of oil on coolant are as follows: Carefully monitor the

condition the coolant fluid.

Different kinds of oil

Lubrication oil

Rust preventive oil

Mixture

(Emulsification)

Nutritive source of

micro-organism

Seal due to

surfacing

Instabilization

of liquid

Adhesion to

machine

Propagation of

bacilli

Density

abnormality

Propagation of

bacilli

Lowering of density

Lowering of pH

Formation of state

of aversion

Petrifaction,

rust & others

1 - 4

Page 8

OPERATION

1. Be aware of the position of the push button for emergency stop so that the operator may be

able to press it instantly.

2. As for the operation of the machine, proceed in accordance with the procedure described

later.

3. During operation, keep hands away from the rotating sections and movable sections.

4. When disposing of chips that wound round tooling or fell onto the table, it is dangerous to

grasp and pull them. Further, when disposing of chips, be sure to do it after stopping the

machine.

5. When adjusting the position of the coolant nozzle, do it after stopping the machine.

TOOL SETTING

1. When setting up tools, stop a spindle as well as the feed in each axis.

2. Set the tools within the specified lengths and diameters.

3. When setting a tool to the holder, be sure to set outside the machine. If set in the machine,

the spindle may rotate.

OPERATION FINISH

1. After operation of the machine is over, be sure to switch the power OFF in the prescribed

order, clean the machine and apply rust preventive oil to each section of the machine such

as the slide ways.

When soluble cutting fluid is used, perform these jobs with special care.

1 - 5

Page 9

1-1-2 Electric Equipment and NC Unit

When operating the machine or carrying out maintenance checks, pay special attention to the

following points, concerning the electric equipment and NC unit.

1. Do not give shocks to the NC unit, power control cabinet and other machine parts.

2. For the primary wiring of the machine, use the cable size specified in the operation manual.

Do not use an excessively long cabtire cable.

When the primary wiring has to be put on the floor, protect it with a cover against damage

by cutting chips and other sharp objects.

3. While test running the machine, be sure the setting parameter of the NC unit coincides with

the parameter sheet attached to the machine.

4. Do not change the current set values of thermal relays in the power control cabinet, various

control knobs or the parameter data.

5. Do not apply excessive force, e. g. bending force etc., to the connector portion of plugs,

flexible conduits (tubes) or cabtire cables etc.

6. When carrying out maintenance checks on the electric equipment, turn off the

EMERGENCY STOP button on the operation panel, the power of the NC unit, the main

switch of the power control cabinet and the power switch installed in your factory, in this

order.

Start maintenance work after making sure that these switches are turned off. Lock the

power switches in the OFF state as much as possible or put up warning signs. In additions,

place a “DO NOT TOUCH !” tag near the operation buttons of the machine to forbid other

personnel from operating the machine.

7. Handle electric equipment of the machine with particular care and exercise extreme caution

not to allow the machine to get wet.

8. For equipment inside the power control cabinet, use those specified by Hitachi Seiki. Use

always specified fuses. Never use fuses with a higher capacity.

9. Never leave the control cabinet door open, because direct sunshine or camera’s strobe

flash rays may enter the cabinet and damage internal equipment.

10. In case of turning on the power again, execute power on went by equal to or more than two

seconds after power turned off. If the power is turned on during discharge from control

devise by power off, pay attention to the alarm of the machine is displayed some time, due

to normal process is not available.

1 - 6

Page 10

1-1-3 Weights and Measures Table

(Metric and English Conversion)

1. Liner measure

1m (meter) = 39.37 inches = 3.2808 feet = 1.0936 yards

1cm (centimeter) = 0.3937 inch

1mm (millimeter) = 0.03937 inch

2. Square measure

2

1m

(square meter) = 10.764 square feet = 1.196 square yards

2

1cm

(square centimeter) = 0.155 square inch

2

1mm

(square millimeter) = 0.00155 square inch

3. Cubic measure

3

1m

(cubic meter) = 35.315 cubic feet = 1.308 cubic yards

= 264.2 U.S. gallons = 220.0 U.K. gallons

1• (liter, cubic decimeter) = 0.0353 cubic foot = 61.023 cubic inches

= 0.2642 U.S. gallon = 1.0567 U.S. quarts

= 0.2200 U.K. gallon = 0.02745 bushel

3

1cm

(cubic centimeter) = 0.061 cubic inch

4. Weight

1 ton (metric ton) = 0.9842 U.S. (long) ton = 2204.6 pounds

= 1.1023 U.K. (short) ton

1 kg (kilogram) = 2.2046 pounds = 35.274 ounces avoirdupois

5. Others

1 kgf/cm

2

(kilogram force per square centimeter) = 14.223 pounds per square inch

= 0.098 Mpa (Mega Pascal)

1 kg-m (kilogram-meter) = 7.233 foot-pounds

1 - 7

Page 11

2. OUTLINE AND FEATURES OF MACHINE

2-1 Construction of Machine

As shown in Fig. 2-1, the standard configuration of this machine consists of the bed, column,

table, saddle, spindle head, feed boxes and automatic tool changer (ATC).

2-1-1 Bed

The bed has been shaped so as to facilitate disposal of cutting chips. It is provided with

grooves of chip pan on both sides of table traverse. The two grooves are provided with

flow jet coolant as standard specifications. Two oil conveyors also can be provided as

option. Chips and coolant are transported from the machine left side to the right side

outlet, and collected in the chip box on the coolant tank on the right side of the bed.

The bed has two guides to ensure smooth movement of the table.

Bed also has been designed to fit a splash guard on its circumference in order to protect

the surroundings of the machine from being contaminated by cutting fluid and cutting chips.

Proximity of an operator and the table is kept at close range.

2-1-2 Column

Column, taking the shape of a wall type double column, is fixed on the rear and both sides

of the head by bolts, the column supports the saddles with two horizontal guides on the top,

and the saddles supports the spindle head with two vertical guides. The saddles, as they

traverse on the column, excellent in rigidity, stability of accuracy and high velocity.

2-1-3 Spindle Head

Spindle head takes a ram form to assure flexible movement, which shift up and down with

two stripes on guides provided between the saddle and the head. As to the structure inside

the head, the spindle and the tool locking cylinder are arranged in the body. AC built-in

motor features low oscillation and high reliability of the spindle rotation.

2-1-4 Table

The table, which is put on the bed, is smoothly driven by a ball screw set in the center of

the guides.

Nothing is installed around the table except working surface, which enables coolant and

cutting chips to drop without difficulty. Four T-grooves and a straight groove are designed

so that they may be used as a reference for jig fixtures. Since a table base size is wide

enough compared with a table size, an overhang amount is minimized when the table

moves in a traverse direction.

2 - 1

Page 12

2-1-5 Feed Box

Feed boxes are provided at three spots which are on the front part of the bed, at the left

end of the column top and on the top of the saddle. Each driving section has an AC feed

motor, which drives the ball screw directly by the precisely machined coupling. The ball

screw is isolated from cutting chips and coolant, and maintains longtime accuracy free from

maintenance by the self-lubrication system adopted.

2-1-6 Slideway

Each slideway for axial feed uses a precision ball guide having a special structure.

Therefore, it is provided with superior dynamic performance which allows both low noises

and power saving.

Self-lubrication system is adopted to these guides in the same way as the ball screws,

which attains maintenance free guides.

Since an appropriate pre-load is given to the bearing of guideways in a radial direction,

sufficient rigidity is secured even for heady duty cutting.

2-1-7 Automatic Tool Changer (ATC)

The ATC, which is mounted onto the column base, can change tools at the up end position

of the head (reference point).

High rigidity cams are adopted for the twin arms driving, and the spindle tool lock and the

twin arm action are synchronized, which realizes top level high speed ATC.

A tool magazine can store 20 tools as a standard. Due to employment of a fixed tool

address call system, a secure tool change can be done by simple operations

There occurs no interference to workpieces at the time of tool exchange.

2-1-8 Splash Cover

Cover structure which seals the machine until the ceiling is equipped as the standard

specification so that coolant mist produced by high speed operation may not leak outside

the machine.

The front door also opens widely until the ceiling, which facilitate crane entering at the time

of setting up.

2 - 2

Page 13

2-2 Name of Component Units

2 - 3

11 Saddle

10 Column

9 Tool changing window

8 ATC operation panel

7 Coolant tank

6 Bed

5 Table

4 Main operation panel

3 Head

2 ATC

1 Main cooling device

No. Name

Fig.2-1 Name of component units

Page 14

2-3 Specifications of Machine

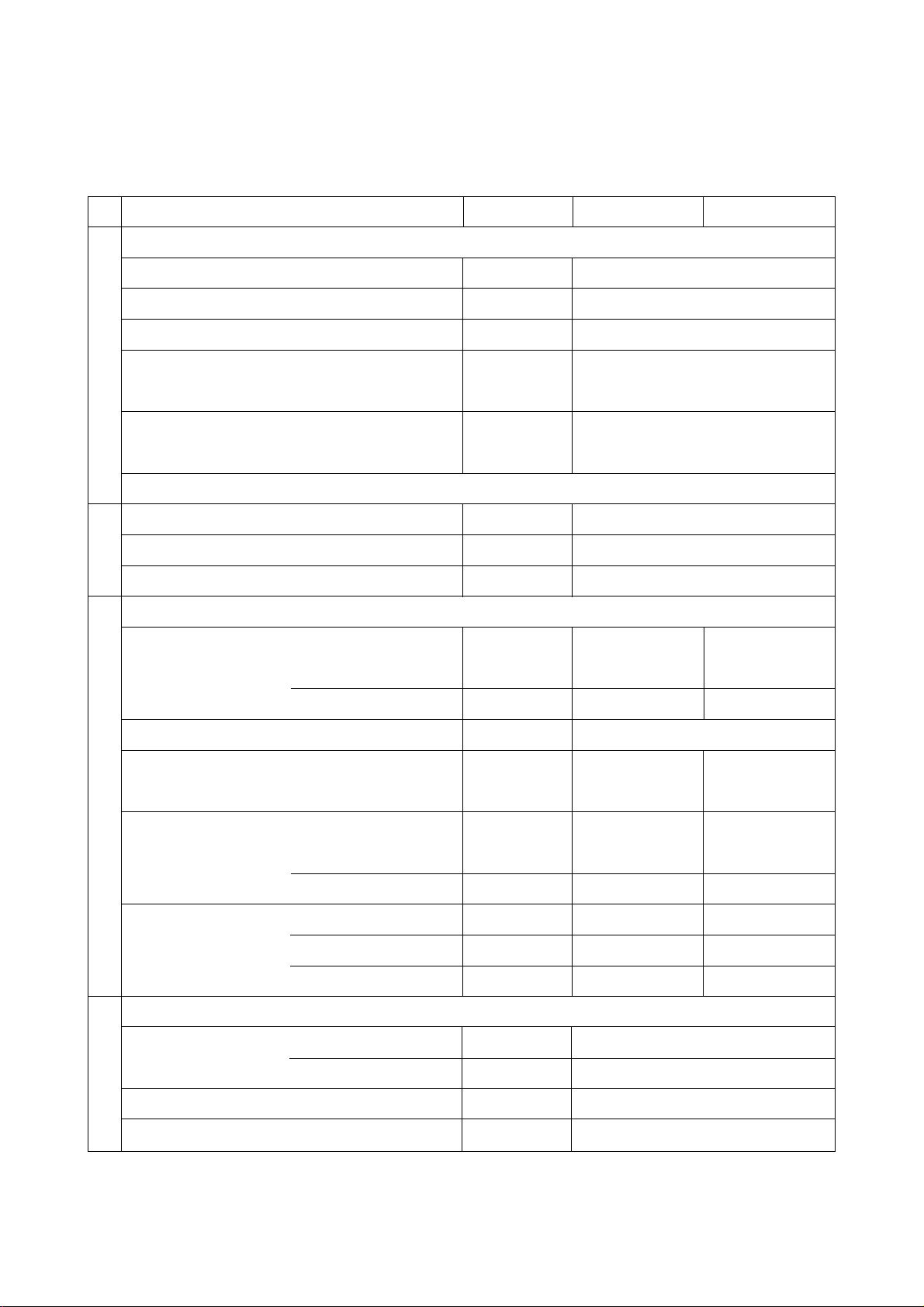

2-3-1 VS50 Machine Specifications

Specifications Unit VS50-50 VS50-40

Stroke

A

*Optional specifications

1) X-axis stroke (Spindle head right & left)

2) Y-axis stroke (Table crosswise)

3) Z-axis stroke (Spindle head up & down)

4) Distance from the table surface to the

spindle nose

5) Distance from the column front to the

spindle center line

Table

1) Table working surface

B

2) Max. table loading capacity

3) Shape of table surface

Spindle

C

1) Spindle speed

Standard spec.

/High power spec.

*High speed spec.

min

min

mm

mm

mm

mm

mm

Mm

kg

-1

{rpm}

-1

{rpm}

1000 (40”)

510 (20”)

450 (17.5”)

150 ~ 600

640

1120 × 510

750

18mm T-slot 4 lines

15~ 4500 35~ 12000

35~ 10000 35~ 20000

2) Spindle speed change

3) Spindle hole taper

4) Spindle bearing

ID

5) Max. spindle

torque

Feed rate

D

1) Rapid traverse

rate

2) Cutting feed rate

3) Jog feed rate

Standard spec.

/High power spec.

*High speed spec.

Standard spec.

*High speed spec.

*High power spec.

(X,Y)

(Z)

mm

mm

Nm {kgfm}

Nm {kgfm}

Nm {kgfm}

mm/min

mm/min

mm/min

mm/min

Stepless

7/24 Taper 7/24 Taper

No.50 No.40

φ100 φ75

φ110 φ65

298 {30.4} 135 {13.8}

233 {23.8} 95.4 {9.7}

166{16.9}

40000

24000

1 ~ 15000

0 ~ 5000 (21 steps)

2 - 4

Page 15

Specifications Unit VS50-50 VS50-40

Automatic tool changer

E

1) Tool shank

*

2) Pull-stud

*

3) Tool storage

capacity

4) Max. tool diameter

( ) : When no adjacent tool exists.

5) Max. tool length

6) Max. tool weight

7) Tool selection

system

Automatic pallet changer

F

1) No. of pallet

*

For 20 tools

*For 30 tools

mm

mm

kg

pcs

MAS 403-BT50 MAS BT40

DIN 50/CAT50 DIN 40/CAT50

MAS P50-0

MAS P50-45

° MAS P40T-1

(45

°)

° MAS P40T-1

(30

°)

20

30

φ110

(

φ180)

300

15 8

Unidirectional random call

Bidirectional random call

2

2) Pallet change system

3) Pallet working surface

4) Max. pallet loading capacity

Motor

G

1) Spindle driving

motor

2) Feed motor

3) Coolant motor

Standard spec.

*High speed spec.

*High power spec.

X, Y

Z

Flood

*Flow jet

*Gun

mm

kg

AC kW

AC kW

AC kW

AC kW

AC W

AC W

AC W

Parallel & swing ARM

1000 × 450

400

11kW (10min)

18.5 (25%ED) 7.5kW (30min)

11 (CONT) 5.5kW (CONT)

25kW (30min) 18.5kW (30min)

22kW (CONT) 15kW (CONT)

22kW (25%ED)

18.5kW (CONT)

3.8

3.8

180 - 2P

400 - 2P × 2

180 - 2P

*Jet

2 - 5

AC W

400 - 2P

Page 16

Specifications Unit VS50-50 VS50-40

4) Spindle cooling

G

system

Power supply

H

(Compressor)

(Pump)

1) Power source

Standard spec.

(Options not

included)

High speed spec.

High power spec.

2) Air source

(MIN)

Tank capacity

I

1) Cutting fluid tank

Standard

capacity

2) Spindle cooling system tank capacity

Machine dimension

J

1) Height of the machine

AC W

AC W

MPa {kgf/cm

• /min

•

•

mm

200-2P

400-2P

200/220V AC

±10% 25kVA

40kVA 31kVA

36kVA

2

}

0.5 {5}

100 (Atmospheric pressure)

420

8.2

2785

18kVA

2) Floor space

3) Machine weight

(Including NC unit)

Standard

Standard

mm

kg

2900 × 2400

8200 8100

2 - 6

Page 17

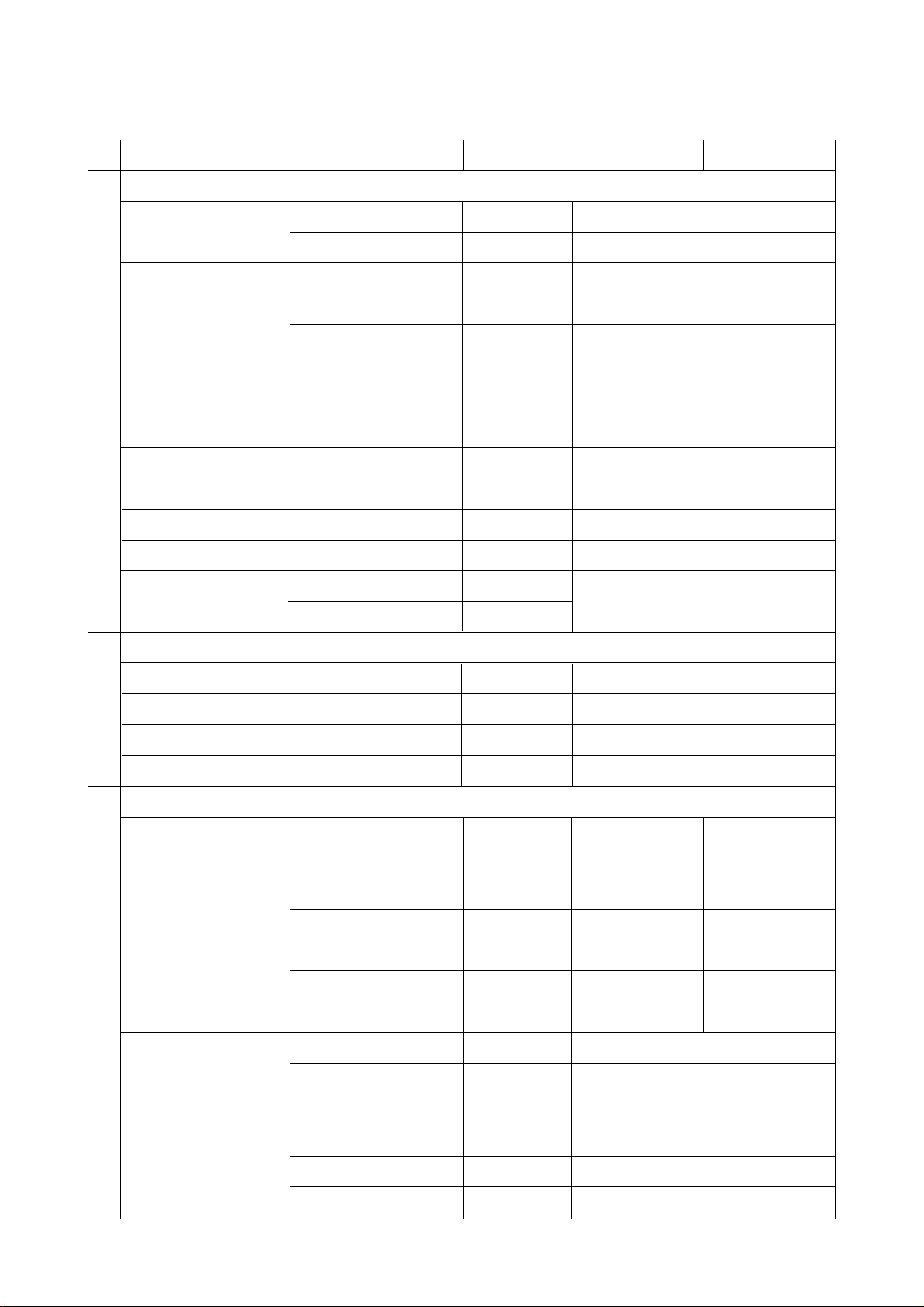

2-3-2 VS60 Machine Specifications

Specifications Unit VS60-50 VS60-40

Stroke

A

1) X-axis stroke (Spindle head right & left)

mm

*Optional specifications

1270 (50”)

2) Y-axis stroke (Table crosswise)

3) Z-axis stroke (Spindle head up & down)

4) Distance from the table surface to the

spindle nose

5) Distance from the column front to the

spindle center line

Table

1) Table working surface

B

2) Max. table loading capacity

3) Shape of table surface

Spindle

C

1) Spindle speed

Standard spec.

/High power spec.

*High speed spec.

2) Spindle speed change

min

min

mm

mm

mm

mm

Mm

kg

-1

{rpm}

-1

{rpm}

610 (24”)

450 (17.5”)

200 ~ 650

690

1400 × 600

1000

18mm T-slot 4 lines

15 ~ 4500 35~ 12000

35~ 10000 35~ 20000

Stepless

3) Spindle hole taper

4) Spindle bearing

ID

5) Max. spindle

torque

Feed rate

D

1) Rapid traverse

rate

2) Cutting feed rate

3) Jog feed rate

Standard spec.

/High power spec.

*High speed spec.

Standard spec.

*High speed spec.

*High power spec.

(X,Y)

(Z)

mm

mm

Nm {kgfm}

Nm {kgfm}

Nm {kgfm}

mm/min

mm/min

mm/min

mm/min

7/24 Taper 7/24 Taper

No.50 No.40

φ100 φ75

φ110 φ65

298 {30.4} 135 {13.8}

233 {23.8} 95.4 {9.7}

166{16.9}

40000

24000

1 ~ 15000

0 ~ 5000 (21 steps)

2 - 7

Page 18

Specifications Unit VS60-50 VS60-40

Automatic tool changer

E

1) Tool shank

MAS 403-BT50 MAS BT40

2) Pull-stud

3) Tool storage

capacity

4) Max. tool diameter

( ) : When no adjacent tool exists.

5) Max. tool length

6) Max. tool weight

7) Tool selection

system

Automatic pallet changer

F

1) No. of pallet

*

*

*

For 20 tools

*For 30 tools

mm

mm

kg

pcs

DIN 50/CAT50 DIN 40/CAT50

MAS P40T-1

MAS P50-0°

(45°)

MAS P40T-1

MAS P50-45°

(30°)

20

30

φ110

(φ180)

300

15 8

Unidirectional random call

Bidirectional random call

2

2) Pallet change system

3) Pallet working surface

4) Max. pallet loading capacity

Motor

G

1) Spindle driving

motor

2) Feed motor

3) Coolant motor

Standard spec.

*High speed spec.

*High power spec.

X, Y

Z

Flood

*Flow jet

mm

kg

AC kW

AC kW

AC kW

AC kW

AC W

AC W

Parallel & swing ARM

1200 × 560

750

11kW (10min)

18.5 (25%ED)

7.5kW (30min)

11 (CONT)

5.5kW (CONT)

25kW (30min) 18.5kW (30min)

22kW (CONT) 15kW (CONT)

22kW (25%ED)

18.5kW (CONT)

3.8

3.8

180 - 2P

400 - 2P × 2

*Gun

*Jet

2 - 8

AC W

AC W

180 - 2P

400 - 2P

Page 19

Specifications Unit VS60-50 VS60-40

4) Spindle cooling

G

system

Power supply

H

(Compressor)

(Pump)

1) Power source

Standard spec.

(Options not

included)

High speed spec.

High power spec.

2) Air source

(MIN)

Tank capacity

I

1) Cutting fluid tank

Standard

capacity

2) Spindle cooling system tank capacity

Machine dimension

J

1) Height of the machine

AC W

AC W

MPa {kgf/cm

• /min

•

•

mm

200-2P

400-2P

200/220VAC

±10% 25kVA

40kVA 31kVA

36kVA

2

}

0.5 {5}

100 (Atmospheric pressure)

420

8.2

2835

18kVA

2) Floor space

3) Machine weight

(Including NC unit)

Standard

Standard

mm

kg

3155 × 2450

10500 10400

2 - 9

Page 20

2-3-3 Main Accessories

Standard accessories

• Direct tapping 1 set

• ATC, 20 tools

• Chip flow jet coolant ″

• Spindle air flow ″

• Flood coolant ″

• Total enclosed ″

• A TC guard ″

• Operator side door interlock ″

• ATC door interlock ″

• Portable manual pulse generator ″

• Spindle load meter on screen ″

• Spindle speed/feedrate override ″

• Call light (Red or green can select) ″

• Electric leakage detection breaker ″

• W-setter/Easy setter ″

• Safety guard ″

• Spindle cooling unit ″

• Machining completion pre-call/work counter/

″

Run hour display on screen

• Work light ″

• Leveling kit/Spanners and wrenches ″

″

2 - 10

Page 21

Optional accessories (Option)

• High column 200mm

• Closed loop (XY-axis)

• Spindle high speed type

100min

-1

~ 10,000min

-1

• ATC 30 tools

• Pull stud shape changing (MAS P50-45°)

• APC (Parallel shuttle type)

• Outside the machine chip conveyor

• Discharge direction (Back discharge)

• Discharge method (Flat/Scrape/Rolling Filter

/Magnet Roller conveyor)

• Oil skimmer(Belt type)

• Chip wagon w/rollers

• Air blow for cutting point

• Jet coolant

• Power supply on the pallet

• Additional pull stud bolt

• NC rotary table (On the table/on APC)

• Fixture plate (On the table/on APC)

• Sub table for NC rotary table

• Spindle speed meter, (Separate type)

• Spindle load meter, (Separate type)

• Work counter 6-digit

• Run hour meter (Spindle rotation meter/power

on/hydraulic under activating/cycle under

activating)

• Weekly timer

• Additional call light (2/3 Color)

• Call buzzer

• Melody horn

• Mist collector(Water-soluble/oiliness)

• Gun coolant (For table/APC)

• Oil hole coolant

0.5/1.5Mpa (5Ÿ15kgf/cm

2

)

• Sp. through coolant

Kind: Center/DIN

Discharge volume: 0.5/1.5/3.5/7.0Mpa

(5Ÿ15Ÿ35Ÿ70kgf/cm

2

)

• Oil mist (Mist, continuous/Needle, one shot)

• Auto door

• Pallet single unit type 1/type 2

• Metal fastener

• Power supply on table/pallet

• Hydraulic/pneumatic/hydraulic + pneumatic

• M-code out put (M70 ~ M73) (2 pcs./4 pcs.)

• Portable type tape reader

• Handy type FD DON

• Tool length measuring & tool breakage

detection

• Auto. centering (UTS/Renishaw)

• Auto. measuring (UTS/Renishaw)

• On the machine measuring (UTS/Renishaw)

• Measuring master gauge

• Cleaning tool for measuring

• SEIKI-ATAC10 (Y, Z axes thermal change

compensation device.)

• Safety measures for Europe

• Transformer 32kVA

• Tank applicable to Fire Precaution Law

• Operation tools (as specially attached items)

*The contents of accessories and equipment are subject to change without notice. Please

contact the sales department of Hitachi whenever you have any inquiry for answer.

2 - 11

Page 22

2-4 NC Unit Specifications

Refer to Manual (OPERATION) of SEIKI SEICOS Σ16M/18M for details of specifications.

Check list for NC control SECOS

(Export only)

VS50/60 Hitachi Seiki Co., LTD.

standard specifications Σ16M Σ18M

1 Controlled axes

2 Least input increment

3 Interpolation

4 Inch/Metric conversion

5 Tape code

6 Designation

7 Decimal point programming

8 Buffer register

9 Multi-buffer

10 Imposition check per cutting/rapid feed

11 Feedrate command

12 Rapid traverse override

Σ-16M/18M 1998.3.25

3 axes, 3 axes simultaneous

0.001mm/0.0001"

Positioning, Linear, Circular

EIA/ISO automatic recognition

INC./ABS.

12 blocks

F code/feedrate direct

0, 1, 10, 50, 100%

13 Feedrate override

14 Override cancel

15 Spindle override

16 Automatic override memory

17 Direct tapping

18 Manual feed function

19 Manual pulse generator

20 Part program storage

21 Add. registered programs

22 Back ground editing

23 Expanded program edit

24 Display

25 Memory lock

26 Language display

27 Tape mode operation

28 I/O interface

0 ~ 200% (10% step)

50 ~ 150% (10% step)

Rapid, Jog feed, Handle

×1, ×10, ×100 (inch = ×50)

80m

100 pcs.

(Program copy)

10.4" color TFT 9.5" monochrome

English/German

RS232C *

RS232C *

1

1

2 - 12

Page 23

Check list for NC control SECOS

Σ-16M/18M 1998.3.25

(Export only)

standard specifications Σ16M Σ18M

29 Function

30 Spindle speed command

31 Tool position offset

32 Tool length compensation

33 Tool radius compensation C

34 Tool offsets

35 Tool offset memory C

36 Machine coordinate system selection

37 Work coordinate system

38 Pre-set of Work Coordinates

39 Local coordinate system setting

40 Coordinate system setting

41 Reference point return

VS50/60 Hitachi Seiki Co., LTD.

G3, M3, T4

S code/speed direct

G45 ~ G48

G43 G44 G49

G40 ~ G42

32 pcs.

G53

G54 ~ G59

G52

G92

Manual, Auto G27 ~ G29

42 2nd reference point return

43 3rd-4th reference point return

44 Graphic display

45 Program name

46 Single block

47 Block skip

48 Optional stop

49 Dry run

50 Machine lock

51 Z-axis feed cancel

52 Program number search

53 Sequence number search and comparison

stop

54 Program comparison

55 Manual absolute

G30

Before and synchronized machining

16 characters

1 pcs.

[ON] fixed

56 Custom macro

57 Coordinate rotation

58 Fixed cycle

Common variable 100 pcs.

G73 G74 G76 G80 ~ G89

2 - 13

Page 24

Check list for NC control SECOS Σ-16M/18M 1998.3.25

(Export only)

standard specifications Σ16M Σ18M

59 Drilling pattern cycle

60 Right circular interpolation

61 Seiki High Grade-2

(High grade die & mold mach.)

VS50/60 Hitachi Seiki Co., LTD.

G70 ~ G72 G77

(Incl. Spiral)

High precision contouring

control; (With 64 bit RISC

engine)

Advanced control

Linear accel./decel.

Before pre-read

interpolation

Multi-buffer: Pre-read

180 blocks

Feedrate control by

circular acceleration

Automatic feed control

Bell –shaped accel./

decel. Pre-read

interpolation

DNC connection circuit

Graphic guidance

adjustment software

62 Mirror image

63 Chamfering/corner R any angle

64 Radius designation on arc

65 Exact stop

66 Programmable data input

67 Backlash compensation

68 Stored pitch error compensation

69 Run hour display

70 Cycle completion pre-call

71 Cycle time display

72 Work Count

73 Clock function

74 Following up

75 Stored stroke limit 1

76 Stroke check before move

Setting via screen

G09 G61 G64

G10

(On screen)

(On screen)

(On screen)

(On screen)

77 NC self diagnostics

1

*

Interface only

Not include cable.

2 - 14

Page 25

Check list for NC control SECOS

Σ-16M/18M 1998.3.25

(Export only)

Option specifications Σ16M Σ18M

1 F1 digit feed

2 Direct tapping

3 Manual pulse generator

4 High resolving power detection function

(0.1 specification) specification must be

investigated.

5 Polar coordinate command

6 Custom macro

7 Custom macro

8 Custom macro

9 Interruption type custom macro

10 Screen guide special canned cycle

Deep hole drilling

VS50/60 Hitachi Seiki Co., LTD.

Pecking cycle

3 pcs.

Common variable 200 pcs.

Common variable 300 pcs.

Common variable 600 pcs.

G73, G83

Drilling pattern cycle

Square side surface outer cutting

Square lateral cutting

Pocket cutting cycle

Right circular interpolation

11 Seiki high grade-1

(High speed machining)

12 Programmable mirror image

G70 ~ G72 G77

G322 G323

G324 ~ G326

G327 ~ G333

G302 G305

Helical interpolation

Advanced control

Graphic guidance high speed machining

software

High speed boring cycle with helical

interpolation

High speed grooving with Trochoid

machining

2 - 15

Page 26

Check list for NC control SECOS

Σ-16M/18M 1998.3.25

(Export only)

Option specifications Σ16M Σ18M

13 Advanced control (High speed

machin ing)

14 Scaling function

15 Automatic corner override

16 Programmable parameter input

17 Macro print func.

VS50/60 Hitachi Seiki Co., LTD.

•Precedent feed

forward.

•Rapid feed bell type ac

celeration/deceleration

•Linear acceleration/dec

eleration before cuttin

g feed interpolation.

•Automatic corner dece

leration.

•Block overlap function.

•Feed speed clamp by c

ircular radius.

(Need printer w/ RS232C I/F) *

1

18 Program memory length

19 Program memory length

20 Program memory length

21 Program memory length

22 Program memory length

23 Program memory length

24 The number of registered programs

25 The number of registered programs

26 The number of registered programs

27 The number of registered programs

28 Data server

29 Second auxiliary function

30 3-dimensional tool compensation

31 Tool offsets

32 Tool offsets

Total 160m

Total 320m

Total 500m

Total 1000m

Total 2000m

Total 4000m

Total 200 (160m is necessary)

Total 400 (320m is necessary)

Total 800 (1000m is necessary)

Total 1000 (1000m is necessary)

(N/A with DNC connection circuit)

G40 G41

Total 64 pcs.

Total 100 pcs.

33 Tool offsets

Total 200 pcs.

2 - 16

Page 27

Check list for NC control SECOS

Σ-16M/18M 1998.3.25

(Export only)

Option specifications Σ16M Σ18M

34 Tool offsets

35 Tool offset by tool number

36 Work coordinate system

37 Retract to machining interrupted point

38 Retrace

39 48-character program name

40 Block skip

41 Block restart

42 Program restart

43 Manual interruption in handle mode

44 Single direction positioning

45 Helical interpolation

46 Cylindrical interpolation

VS50/60 Hitachi Seiki Co., LTD.

Total 400 pcs.

Total 60 sets

(retract and return)

(Retracing)

Total 9 pcs.

(Incl. add. axis)

47 Hypothetical axis interpolation

48 Involute interpolation

49 Smooth interpolation

50 NURBS interpolation

51 DNC connection circuit RS232C

52 DNC connection circuit RS422

53 DNC2 function

54 External data input

55 Outer I/O device control

56 Skip function

57

Tool life management / Spare tool call

(Used 64 bit RISC)

(Used 64 bit RISC)

(Incl. Remote buffer ,

need technical

discussion)

(N/A with dat a server)

(Incl. Remote buffer, need technical

discussion)

(N/A with data server)

(Only system machine)

(Need technical discussion)

(Need technical discussion)

(High speed)

58 Display of machining time per program

59 Display of machining time per program

60 Cutting monitor

10 pcs. (On the screen)

50 pcs. (On the screen)

(Incl. tool life management / spare tool call)

2 - 17

Page 28

Check list for NC control SECOS

Σ-16M/18M 1998.3.25

(Export only)

Option specifications Σ16M Σ18M

61 Stored stroke limit 2

62 Rotary axis control

63 Add. 1 axis

64 Add. 2 axis

*1Interface only

Not include cable.

VS50/60 Hitachi Seiki Co., LTD.

(Incl. simultaneous control)

(N/A more than 6

axes simultaneous

control)

(N/A more than 4

axes simultaneous

control)

2 - 18

Page 29

2-5 Main Dimensions Diagram

Main dimensions diagram (VS50/60)

Dimension : metric (mm)

inch ( ” )

2 - 19

Page 30

3. SIZE NECESSARY FOR OPERATION

3-1 Strokes and Machine Reference Point

Strokes and machine reference point (VS50)

Dimension : metric (mm)

inch ( ” )

3 - 1

Page 31

Strokes and Machine Reference Point

Strokes and machine reference point (VS60)

Dimension : metric (mm)

inch (

” )

3 - 2

Page 32

3-2 Table Dimensions and Working Area Diagram

Table dimensions and working area diagram (VS50)

Dimension : metric (mm)

inch ( ” )

3 - 3

Page 33

Table Dimensions and Working Area Diagram

Table dimensions and working area diagram (VS60)

Dimension : metric (mm)

inch ( ” )

3 - 4

Page 34

3 - 5

3-3 Machining Area and ATC Interference Range

Dimension : metric (mm)

inch (

” )

Machining area and ATC interference range (Standard specification) (VS50)

Note) There occurs no interference with workpieces at the tool change position under ATC.

But, during approach from working point from change position, depending shapes of

tools and workpieces, interference may be inevitable.

Page 35

Dimension : metric (mm)

inch ( ” )

3 - 6

Page 36

Dimension : metric (mm)

Machining Area and ATC Interference Range

3 - 7

inch (

Machining area and ATC interference range (Standard specification) (VS60)

” )

Note) There occurs no interference with workpieces at the tool change position under ATC.

But, during approach from working point from change position, depending shapes of

tools and workpieces, interference may be inevitable.

Page 37

Dimension : metric (mm)

inch ( ” )

3 - 8

Page 38

3-4 Tool Shank

3-4-1 Tool Shank (BT-40) and Pull-stud Bolt (12000min-1)

1. The concentricity of and parts with the taper shank of a tool shall be 0.025mm

2. The squareness between the taper shank and face

3. The deviation with a 16.1mm wide groove shall be 0.06mm in reference to the groove center.

4. The tolerance of taper shall be +0.000063 (4T of JIS B0612-1965).

0

5. The applicable threads shall comply with JIS B0205-1968, and their accuracy shall meet the 2nd

class requirements of JIS B0209-1968.

6. The squareness between the center line of φ17h7 and face and the rectangular degree of

the face

with the center line shall be 0.01mm, respectively.

3 - 9

shall be 0.015/100.

Page 39

3-4-2 Tool Shank (BT-50) and Pull-stud Bolt (4500/10000min-1)

1. The concentricity of and parts with the taper shank of a tool shall be 0.025mm

2. The squareness between the taper shank and face

shall be 0.015/100.

3. The deviation with a 25.7mm wide groove shall be 0.06mm in reference to the groove center.

4. The tolerance of taper shall be +0.000063 (4T of JIS B0612-1965).

0

5. The applicable threads shall comply with JIS B0205-1968, and their accuracy shall meet the 2nd

class requirements of JIS B0209-1968.

6. The squareness between the center line of

the face

with the center line shall be 0.01mm, respectively.

3-4-3 Two-face Clamped Tooling (Spindle Speed: 19,000 min.

φ25h7 and face and the rectangular degree of

-1

or More)

The BIG-PLUS spindle system(two-face clamping type:made by DAI SHOWA SEIKI) is

normally used for the spindle with speed of 20,000 min

-1

The two-face clamped tools are to be clamped on the end face and tapered section of the tool

shank to prevevt them from biting into the spindle direction by high speed revolution. They are

designed to be well balanced when mounted to the spindle.

The following lists the differences from the regular tools:

[1] Special gauge line IN/OUT amount and 7/24 taper tolerance(equivalent to the JIS B0612 1965, 4T)

[2] Balance grade (JIS B0905) within G2.5

* To purchase the tools, order them to DAI SHOWA SEIKI.

3 - 10

Page 40

3-5 ATC Tool Limit (BT40)

Max. tool diameter D=φ110mm (Tools are stored in the adjacent tool pots)

φ180mm (No tools are stored in the adjacent tool pots)

D=

Max. tool length 300mm

Max. tool weight 8kg

Dimension : metric (mm)

inch (

” )

3 - 11

Page 41

ATC Tool Limit (BT50)

Max. tool diameter D=φ110mm (Tools are stored in the adjacent tool pots)

φ180mm (No tools are stored in the adjacent tool pots)

D=

Max. tool length 300mm

Max. tool weight 15kg

Dimension : metric (mm)

inch (

” )

3 - 12

Page 42

20, 30 ATC Tool Limit

Dimension : metric (mm)

inch (

” )

Note) Can not use a number at each side position of Max. tool that diameter is φ95 and over, in the

case of using the number on the program, the tool will be collided with the ATC arm.

3 - 13

Page 43

3-6 Spindle Torque/Output Diagram

Motor : FANUC αB112L-5.5

Amplifier : SPM-15

The number of maximum rotation : 12000min

(#40 – 12000 Standard spec.)

-1

Spindle speed [min-1]

3 - 14

Page 44

Spindle Torque/Output Diagram (#50 – 4500 Standard spec.)

Motor : FANUC αB160M-11

Amplifier : SPM-30

The number of maximum rotation : 4500min

-1

Spindle speed [min-1]

3 - 15

Page 45

Spindle Torque/Output Diagram (#40 – 12000 High power spec.)

Motor : FANUC αB112L-18.5

Amplifier : SPM-30

The number of maximum rotation : 12000min

-1

Spindle speed [min-1]

3 - 16

Page 46

Spindle Torque/Output Diagram (#50 – 10000 Spec.)

Motor : FANUC αB132L-22

Amplifier : SPM-30

The number of maximum rotation : 10000min

-1

Spindle speed [min-1]

3 - 17

Page 47

Spindle Torque/Output Diagram (#40 – 20000 Spec.)

Motor : FANUC αB112M-15/20000

Amplifier : SPM-30

The number of maximum rotation : 20000min

-1

Spindle speed [min-1]

3 - 18

Page 48

TURNING CENTER

VS50/60

INSTRUCTION MANUAL

SPECIFICATIONS

SEIKI-SEICOS Σ16M/18M

Version 1.01

11-2000

First Edition 2-1998

1

Loading...

Loading...