hitachi seiki VS50, VS 60 Maintenance Manual

MACHINING CENTER

VS50/60

INSTRUCTION MANUAL

MAINTENANCE

SEIKI-SEICOS Σ16M/18M

Version 1.01

BM-2782-1-0221-E-1-01

1

Introduction

Thank you for your having purchased the machine, favoring our product lines for your use.

This manual contains fundamental information on the maintenace. Please read and fully understand

the contents for your safe machine operation.

In particular , the contents of the items concerning safety in this manual and the descriptions on the

“caution plates” attached to the machine are important. Please follow the instructions contained

and keep them always in mind to ensure safe operation.

The reference record papers on adjusting setting values such as a parameter list are attached to

the machine unit and enclosed in the packing. These are necessary for maintenance and

adjustment of the machine later on. Please keep them safely not to be mislaid.

The design and specifications of this machine may be changed to meet any future improvement.

As the result, there may arise some cases where explanations in this manual could become partly

inconsistent with the actual machine. Please note this point in advance.

In this manual, items on the standard and optional specifications are handled indiscriminately.

Please refer to the “delivery note” for the detailed specification of your machine confirmation.

1

CONTENTS

1. INSTALLATION .................................................................................... 1 - 1

1-1 Machine Installation ...........................................................................................................1 - 1

1-1-1 Environment of the Machine ......................................................................................1 - 1

1-2 Foundation and Layout Drawing ........................................................................................1 - 3

1-3 Transport ation of Machine .................................................................................................1 - 5

1-3-1 Precautions for Lifting Work ......................................................................................1 - 5

1-3-2 Precautions When Using the Forklift .........................................................................1 - 5

1-4 Electric Wiring ...................................................................................................................1 - 8

1-5 Air Supply.........................................................................................................................1 - 10

1-6 Oil Supply ........................................................................................................................ 1 - 11

1-7 Mounting Procedure ........................................................................................................1 - 12

2. INSPECTION AND MAINTENANCE ................................................... 2 - 1

2-1 Daily Check and Periodic Check Items .............................................................................2 - 1

2-1-1 Daily Checking Items................................................................................................. 2 - 1

2-1-2 Periodic Check Items ................................................................................................ 2 - 5

2-2 Lubrication, Oil Supply and Coolant.................................................................................2 - 10

2-2-1 List of Lubrication and Oil Supply ............................................................................ 2 - 11

2-2-2 Handling of Coolant Unit .......................................................................................... 2 - 12

2-3 When the Call Light (Yellow Warning Lamp) is Lit Up...................................................... 2 - 17

2-3-1 Kinds of Alarms and Study and Measure of Causes of Obstacles .......................... 2 - 17

2-3-2 Replacing Method of Battery.................................................................................... 2 - 18

2-3-3 Alarm List ................................................................................................................. 2 - 21

2-4 Parameters .....................................................................................................................2 - 32

2-4-1 Kinds and Main Contents of Parameter................................................................... 2 - 32

2-4-2 About a Management of Parameter ......................................................................... 2 - 32

2-4-3 Altering the PC Parameter Setting........................................................................... 2 - 33

2-5 List of SOL/LS Functions and Uses

(See the SOL/LS Layout for the Location of Equipment.) ............................................... 2 - 34

2-6 ATC Maintenance and Adjustment ...................................................................................2 - 37

2-6-1 Drive Mechanism General ....................................................................................... 2 - 37

2-6-2 Explanation of Actions ATC...................................................................................... 2 - 39

2-6-3 ATC (Automatic Tool Changer) Maintenance, Adjustment and Operation................ 2 - 42

2-6-4 Method of Manual Tool Unclamping ......................................................................... 2 - 45

2-6-5 Procedure for Bleeding Air in the Tool Locking System ........................................... 2 - 46

2-6-6 Adjusting a T ool Push Allowance.............................................................................. 2 - 48

2-7 Each Axis Stroke and Zero Point Adjustment................................................................... 2 - 50

2-8 Countermeasures against shift of follow-up coordinate

(shift of memory software OT)........................................................................................ 2 - 54

i

2-9 Adjustment of Synchro Belt Tension for Z-axis Feed ....................................................... 2 - 55

2-10 Instructions for Motor/Inverter for ATC Twin Arm Rotation ............................................. 2 - 56

2-10-1 Setting and Changing the Parameters................................................................... 2 - 56

2-10-2 Initializing the Parameters ..................................................................................... 2 - 57

2-10-3 Monitoring .............................................................................................................. 2 - 59

2-10-4 Errors .................................................................................................................... 2 - 60

2-10-5 Resetting the Inverter............................................................................................. 2 - 63

2-10-6 Inspection and Maintenance .................................................................................. 2 - 64

2-10-7 Troubleshooting ..................................................................................................... 2 - 67

2-1 1 Handling and Maintenance of Spindle Oil Air Lubricating Unit (Option) ..........................2 - 70

2-11-1 Oil Air Lubrication Circuit........................................................................................ 2 - 70

2-11-2 Pump Unit .............................................................................................................. 2 - 71

2-1 1-3 Mixing V alve............................................................................................................ 2 - 73

2-11-4 Daily maintenance ................................................................................................. 2 - 74

2-12 Related to Coolant.........................................................................................................2 - 76

2-13 Related to Air Pressure.................................................................................................. 2 - 80

2-14 Chip Conveyor (For the Inside of St andard Machine) .................................................... 2 - 84

2-15 Spindle Cooling Circuit Diagram.................................................................................... 2 - 85

2-16 Servo Unit......................................................................................................................2 - 86

2-16-1 Alarm Concerning Power Supply Unit

(Source Power of Spindle/Servo Amplifier)............................................................. 2 - 86

2-16-2 Spindle Amplifier Status Display............................................................................. 2 - 89

2-16-3 S pindle Amplifier Alarm .......................................................................................... 2 - 90

2-16-4 Detail of S pindle Amplifier Alarm Contents............................................................. 2 - 95

2-17 List of Supply Items .....................................................................................................2 - 102

ii

1. INSTALLATION

1-1 Machine Installation

When installing NC machine, solid foundation is essential. It is also most important for maintaining

the best condition of cutting accuracy of the machine. The nature of the ground condition of the

factory site, for example, rock base or reclaimed land, makes a big difference. It is, therefore,

difficult to give any definite rules generally applicable to the installation of this machine. (Refer to

the foundation and arrangement drawings.)

The followings are the concrete items to be carefully attended when installing this machine.

2

1) The bearing capacity of soil should be 5 ton/m

be 300mm or thicker.

2) The area of the foundation should be extend to at least 300mm outer circumference of the

machine bed.

3) When digging vibration proof drains, they should be dug along the circumference of the

foundation.

4) Placing separate concrete blocks underneath each machine leg instead of a real foundation is

often seen, which is just not adequate. Such is no value as proper foundation,

or larger and thickness of the foundation should

As this machine yields large volumes of chip during machining, carts are often used for chip

disposal. The traffic of carts and detaching covers in maintenance work need free space so that

the operators can move around without touching other machines. This factor should be

considered when selecting the installing position of the machine.

1-1-1 Environment of the Machine

Pay full attention to a room temperature, dust, vibrations, etc. in order to make use of the

primary performance of the machine. High accuracy cannot be obtained in the environment

where the room temperature greatly changes. Just a slight change of the room temperature

partly affects the machine. Be fully careful of effects heat transfer from the direct sunshine,

vent, heating unit, and so on.

Under the environment where the air is polluted so much by dust, etc., the sliding sections and

electric devices of the machine are greatly effected in their service lives.

Particularly, electronic devices related to controls are susceptible to dust and humidity. Install

the machine in the environment as clean as possible.

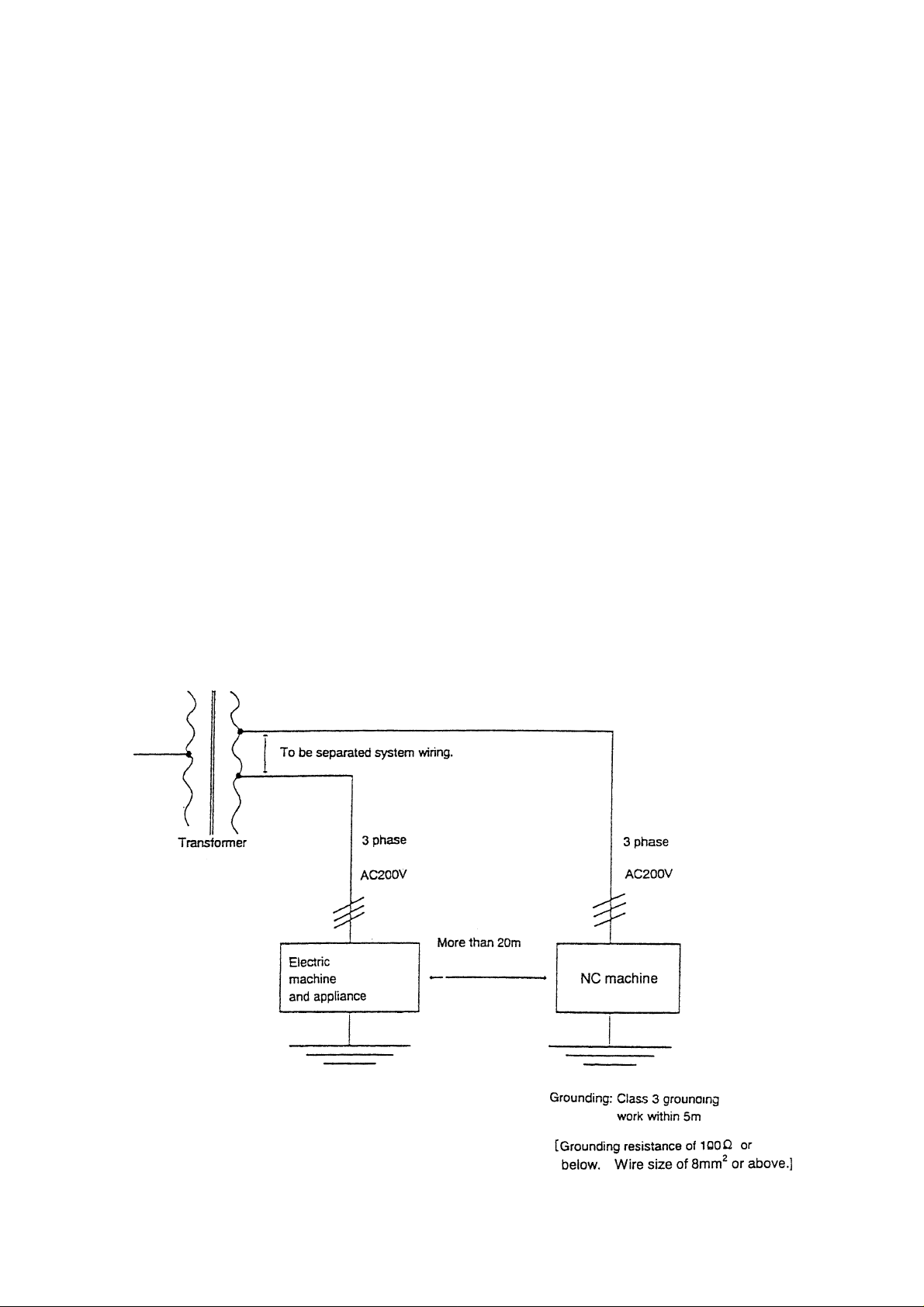

1. Installation Environment of NC Machine

In case that electric machines and appliances generating high frequency noise are

installed or newly erected near by NC machines, keep to the following precautions.

1) Example of the electric machines and appliances generating high frequency noise.

[1] Arc welding machine

[2] Resistance welding machine

1 - 1

[3] High frequency drying machine

[4] Electric discharge machine

[5] Others

2) Installation form of NC machine

[1] Power supply line

The power supply line (AC200V) of NC machine must be separated line with that for

electric machines and appliances.

If impossible, connect the line at the point more than 20m apart from the point where

the power supply for electric machines and appliances is connected.

[2] Installation place of NC machine

NC machine must be installed more than 20m apart from electric machines and

appliances.

[3] Earth of NC machine

The earth of NC machine must be grounded within 5m from NC machine separating

from the ground of electric machines and appliances, and make a ground work with

not more than 100

Or the earth wire size must be not less than 8mm

Ω or comply with the laws and regulations of the country.

2

.

3) Example of earth of NC machine

The earth state of NC machine and electric machines and appliances illustrated as

under.

Power receiving equipment

1 - 2

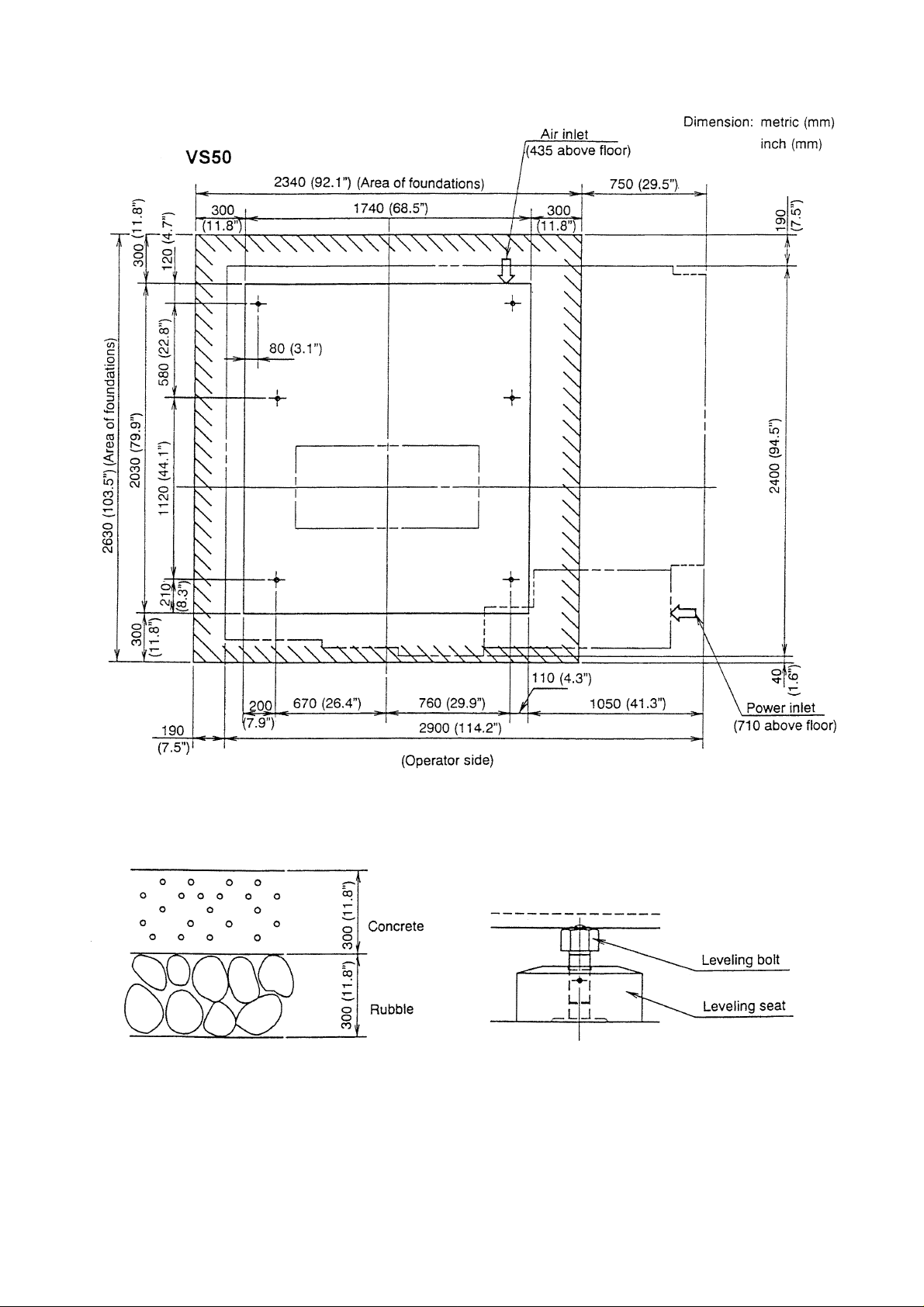

1-2 Foundation and Layout Drawing

Note) 1. Ground bearing force should be 5ton/m2 (1000 lbs/ft2) or more. And foundation

thickness should be at least 300mm. (12”)

2. The area of foundations is to be 300mm (12”) or more of the circumference of the

machine bed.

3. Install the tremor insulating groove along the outer periphery of the foundation.

1 - 3

Foundation and Layout Drawing

VS60

Note) 1. Ground bearing force should be 5ton/m2 (1000 lbs/ft2) or more. And foundation

thickness should be at least 300mm. (12”)

2. The area of foundations is to be 300mm (12”) or more of the circumference of the

machine bed.

3. Install the tremor insulating groove along the outer periphery of the foundation.

1 - 4

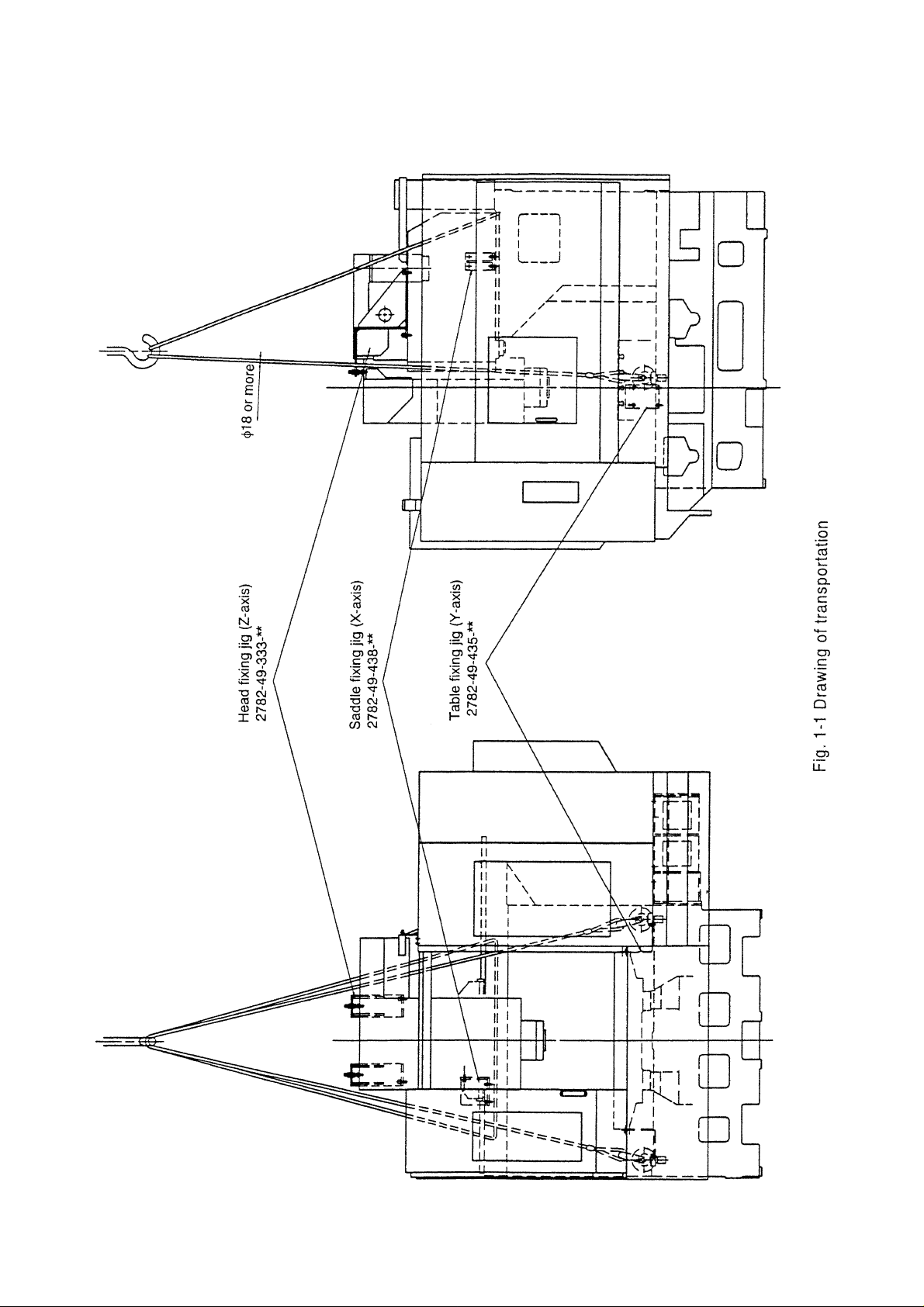

1-3 Transportation of Machine

Since this machine has an integrated structure mechanically and electrically, it can be

transported only by detaching its power cord. To fix its moving parts and pass wire ropes

around the machine, refer to Fig.1-1.

1-3-1 Precautions for Lifting Work

Pay proper attention to lifting work, because it is one of important steps when transporting

the machine.

! WARNING

Since the lifting work for machine transportation is carried out with a crane or chain

block, its precautions are listed below:

(1) Use a wire rope whose diameter is 14 mm (0.55 inch) or more.

(2) Apply a pad to an acute-angle part to protect the wire rope and machine.

(3) Pass the rope so that the center of gravity of a load will come over the center line of a

lifting angle.

(4) Do not use a rusted wire rope, one which has been untwisted, or one whose core wire

is broken.

(5) Lift the machine gradually. Stop it once when the wire rope become strained, and

check a lifting conditions. When the machine is lifted up from the floor, check again

that there are no abnormalities with the lifting rope, and proceed with the lifting rope.

When lowering the machine, it is necessary to be careful that it is lowered down slowly.

Stop lowering the machine immediately before it reaches the floor to check.

Then, lower it down completely.

1-3-2 Precautions When Using the Forklift

! WARNING

Since the lifting work for machine transportation is carried out with a forklift, its

precautions are listed below:

1 - 5

(1) Select a fork lift which has a sufficient capability to handle and endure a machine

weight.

(2) In order not to damage the outer projected parts of the machine, it is necessary to

carry out this work in cooperation with a watchman.

(3) When inserting the fork under the machine, use the right and left cast grooves

provided for fork insertion under the base of the machine proper.

(4) When lifting the machine, be sure to carry out temporary lifting so that you can lift it

with the center of gravity of the machine set at the stablest positions in both

longitudinal and crosswise directions.

1 - 6

1 - 7

1-4 Electric Wiring

Wires between the machine proper and accessories will be connected by Hitachi Seiki. Wiring

from the power supply source to the electric cabinet should be prepared in advance by the

customer.

For this purpose, use wires of thickness specified in the following table, depending on the

distance from the power supply to the electric cabinet.

Power supply : 200/220V (50/60 Hz)

±10%

Source Power Capacity

The electric capacity required for the machine varies depending on the specification of the

spindle and the type of option attachments. To calculate the capacity of the machine being

installed, add the capacity of option specification on to that of the standard machine.

Machine Electric Capacity = Standard Machine Electric Capacity

+ Total Electric Capacity of Option Attachments

Power Capacity of Standard Machine

Spindle Specification Power Capacity

4500 min

10000 min

-1

-1

25 kVA

40 kVA

12000 min-1 Standard 18 kVA

12000 min-1 High output 36 kVA

20000 min

-1

31 kVA

Option Attachment requiring Additional Power Capacity

Option Attachment Additional Power Capacity

Oilhole Coolant 0.5MP A 1.3 kV A

Oilhole Coolant 1.5MP A 1.4 kV A

Oilhole Coolant 7.0MP A 3.7 kV A

Through Coolant 0.5MPA 1.3 kVA

Through Coolant 1.5MPA 1.4 kVA

Through Coolant 7.0MPA 3.7 kVA

Jet Coolant 1.0 kVA

Gun Coolant 0.4 kVA

Mist Collector 1.1 kVA

Hydraulic Power Source 1.3 kVA

1 - 8

Thickness of Wire

The source power wire thickness varies depending on the specification ofthe spindle. Use the

wire of the following thickness to meet the specification.

Spindle Specification Source Power Wire Minimum Grounding Wire Minimum

Thickness Thickness

4500 min

10000 min

-1

-1

38 mm

60 mm

12000 min-1 Standard 22 mm

12000 min-1 High output 50 mm

20000 min

* The thicknesses of the source power wire in the above table are calculated on the assumption

-1

50 mm

that three 600V vinyl coated wires are set in a conduit pipe at the ambient temperature is

30°C.

2

2

2

2

2

8 mm

8 mm

8 mm

8 mm

8 mm

2

2

2

2

2

1 - 9

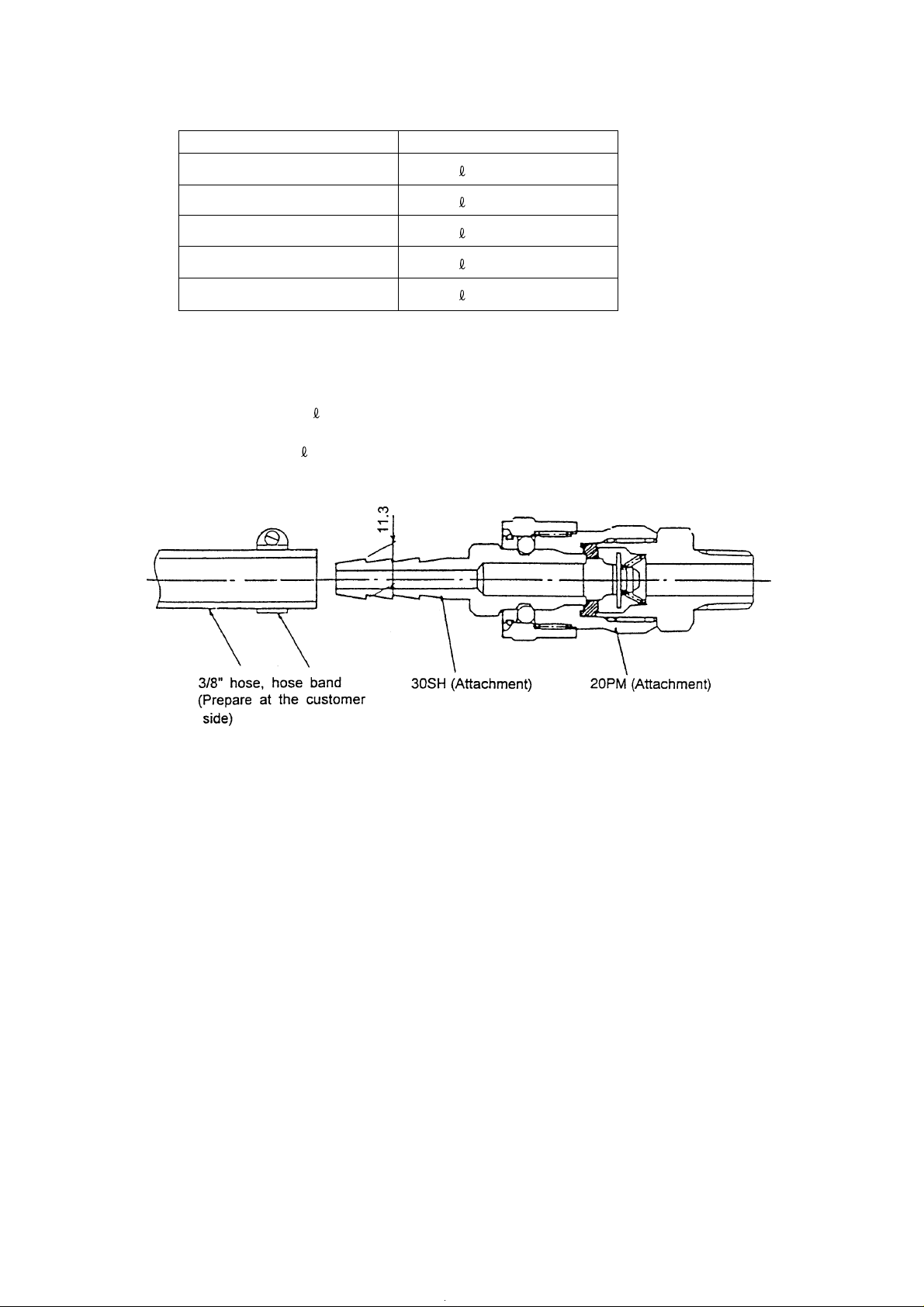

1-5 Air Supply

This machine uses clean air to clean the spindle hole and the tool, for Z axis sliding face and

automatic door, or for oil mist unit. The air supply should be prepared by the customer.

Its joint of the machine is of PT1/4, female.

Air pressure : 0.5MPa {5 kgf/cm2} (72 PSI) or more

Flow : 100

*It is recommended to install an air tank having a capacity of 40• or larger, as there are cases

when supply of a large volume of air is needed instantaneously.

The machine proper is provided with an air filter and regulator to remove dust and

supersaturated moisture from air. When the temperature of the air from the air supply is

higher than that of the machine proper, air gets cooled at the machine proper and tends to

form water drops.

Jetting air containing water is prone to cause rust on the spindle hole and tool shank, which

may affect machining accuracy and cutting surfaces. Therefore, the temperature of the air

from the air supply should below. (Water and dust accumulating in the air filter is automatically

drained. To manually drain them, see the descriptions on mechanical drain operation.) In

case there is a large difference in temperature, install an air drier between the air supply and

the machine.

Flow rete

•/min. (ANR) (Standard Specification)

The flow rate to be set varies depending on the option specification. Therefore, the flow rate

applicable to the actual machine should be determined by the flow rate for the standard

specification machine added by the total required flow rate for the option specification.

Flow rate for the machine = Standard flow rate + flow rate for option specification

Standard specification

Machine specification

#40-12000min

-1

Flow rate

/min (ANR)

100

1 - 10

Additional flow rate required by optional specifications

Optional specification

Tool nose air blow

Center-through air blow

Pulscale X, Y

Oil mist/Needle 1 shot

Semi-dry processing unit

In case with APC (essential)

Air pressure: 0.5MPa (5kg/cm

Flow rate: 100 /min (ANR)

Air tank capacity: 40

or larger

Flow rate

300 /min (ANR)

300 /min (ANR)

60 /min (ANR)

60 /min (ANR)

300 /min (ANR)

2

) or higher

1-6 Oil Supply

When adding lubricating oil, take care of the following:

1. Add the specified amount of the designated oil. Do not use different oils, and do not add to

much of oil.

2. Clean the oil supply port in advance. See that dust, etc. do not enter.

3. When adding oil, set a filter on the oil supply port, so that dust and other foreign substance

will not enter. In case a filter is not available, use a wire netting of 150 mesh or more.

4. Always use new oil. Do not use a mixture of new and old oil.

5. Even when using new oil, do not use all the oil from the can. Always leave some oil in the

can. This is necessary to avoid sediments in the can being used.

For the oil supply positions, intervals, oil amount and quality, see “5-2 Lubrication and Oil

1 - 11

Supply”.

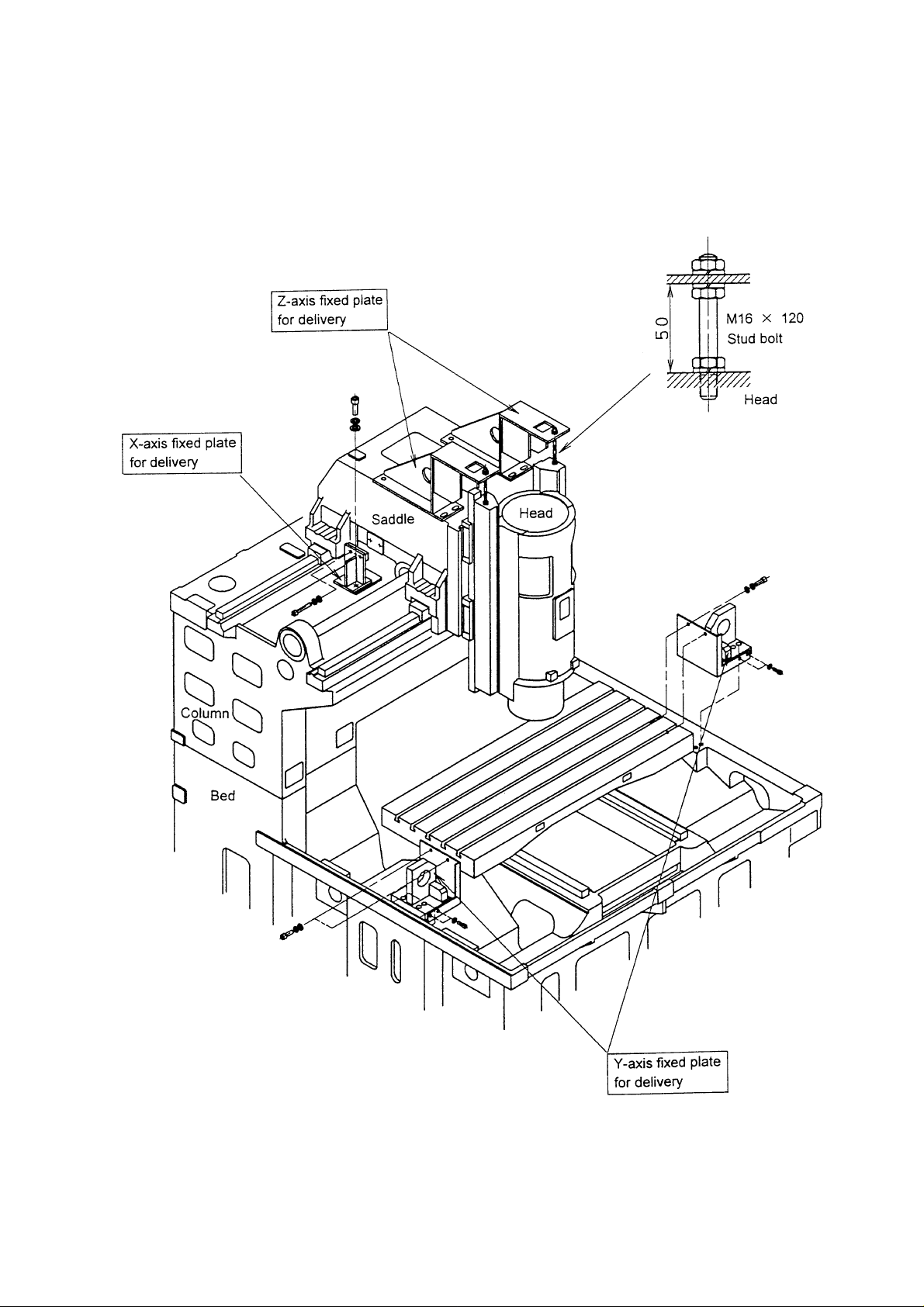

1-7 Mounting Procedure

(1) Dismounting fixtures for shipment and transportation

Upon installing the machine at a fixed place, be sure to dismount the fixtures for

shipment/transportations .

• Remove the fixed plate for the table, column and head.

(2) Installation

A leveling method is one of the factors which determine machine accuracy. Proper

leveling of the machine is most fundamental.

Carry it out carefully, because it affects not only machining accuracy, but also machine’s

service life.

First, put leveling pads at installation points on the floor.

Install the machine so that the leveling adjust bolts attached to the machine legs will be

placed on them.

Use precision levels whose sensitivity per graduation is’ about 0.02 mm/m (0.00025 in./

ft.) and length is about 200 mm (8 in.).

Levels used for woodworking/engineering are not recommendable.

Place the levels with the same end in the same direction.

Keep level-placing surfaces clean at any time lest dust, etc. should be caught under the

levels.

Outline of Installation Work

[1]Confirming a foam in a level

Adjust so that a foam does not get too long and set it at the center on the table. By

turning it by 180

same direction, level has been obtained.

[2]Adjusting the absolute level

As shown in Fig.5-5, place levels on the table in parallel with the X and Y directions,

and measure the level of the machine at 3 places in the X and Y directions,

respectively.

°, while holding the position, and observing a foam in memory of the

1 - 12

Adjust the level of the machine with the leveling bolts so that each difference in

reading of the levels may be settled within 0.04 mm/m (0.0005 in./ft.) in both X and Y

directions.

[3]Adjusting the table operating level

Place the levels at the center of the table and move the X axis almost over its full

stroke. Make adjustment in such a way that each difference in reading of the levels

at this time will meet within the following target values:

• For the level put in the X-axis direction: 0.02 mm/m (0.00025 in./ft.)

• For the level put in the Y-axis direction: 0.04 mm/m (0.0005 in./ft.)

[4]Reconfirm the above-mentioned steps [1] through [3] and make fine adjustment, if

necessary.

[5]When the stable operating levels in [3] cannot be obtained, it is likely that the

condition of the floor, where the machine is installed, is improper. Check and improve

it, referring to the foundation drawing.

1 - 13

VS50

Fig.1-2

Fig.1-3

1 - 14

VS60

1 - 15

2. INSPECTION AND MAINTENANCE

2-1 Daily Check and Periodic Check Items

2-1-1 Daily Checking Items

The following are maintenance items to be checked by operators. These maintenance

items are important to prevent machine trouble and to perform efficient operation.

Perform maintenance according to the following daily check list.

2 - 1

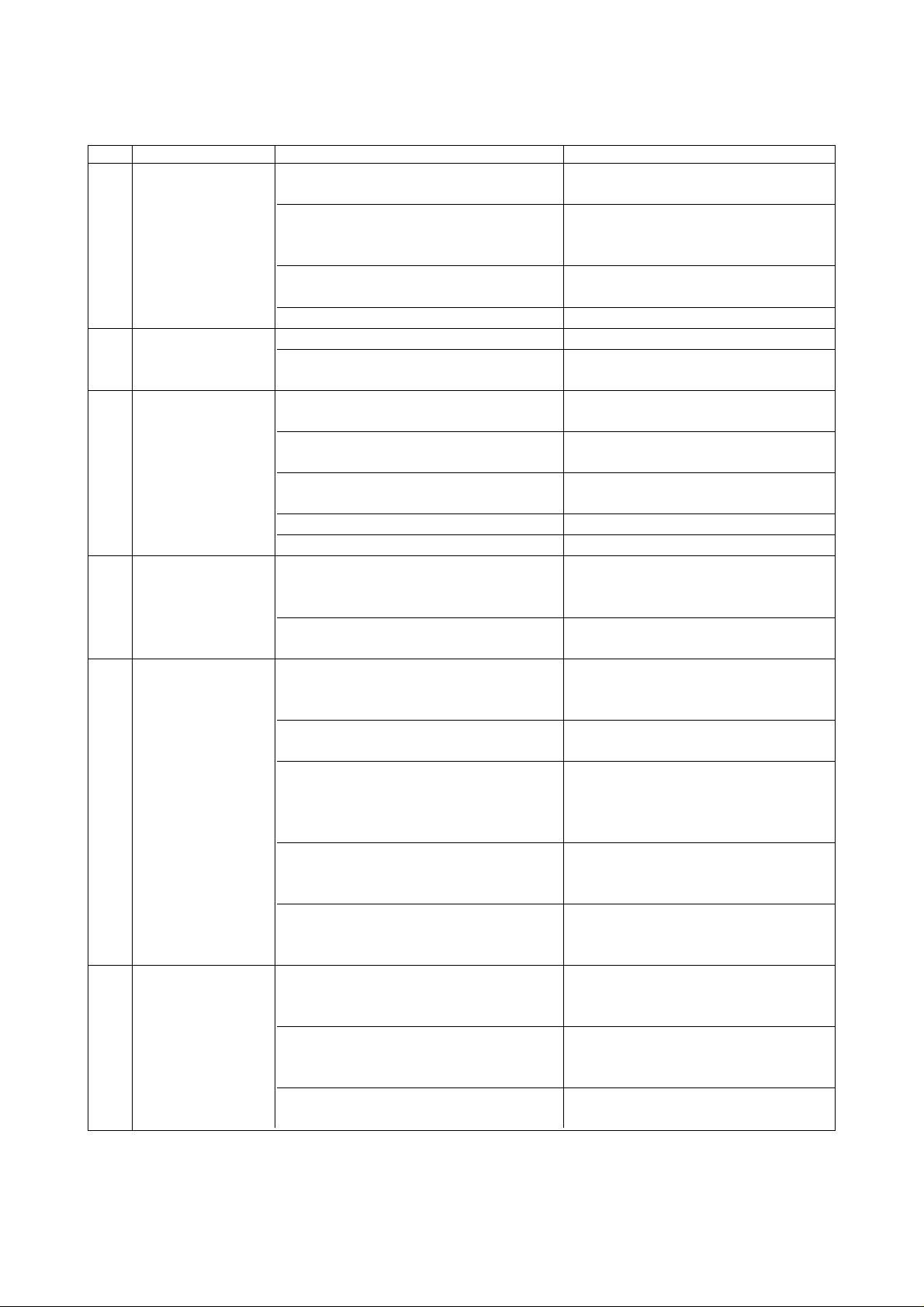

Daily check list

Checking part Check item Details of checks

1. Main cooling unit a)Check main cooling unit for ⇒Check for sound of fan running

operation.

b)Check cooling unit for sufficient ⇒Oil level check

quantity of oil. (Checks before

starting work)

c)Check that air filter is thoroughly ⇒Checks for clogging and

cleaned. cleaning

d)Check for oil leakage. ⇒Check for oil leakage

2. Pneumatic unit a)Check for normal set pressure. ⇒Normal value: 5 kgf/cm

b)Check pneumatic unit for faults ⇒Check for air leakage

such as air leakage.

3. Coolant unit a)Check coolant unit and piping for ⇒Checks for coolant leakage and

faults. abnormal noise

b)Check coolant unit for sufficient ⇒Oil level check

quantity of coolant.

c)Check that air filter is thoroughly ⇒Checks for clogging and

cleaned. cleaning

d)Check for discharge. ⇒ Visual check

e)Check for oil leakage. ⇒Check for oil leakage

4. Operation panel a)Check that alarm is not displayed ⇒Visually check it to determine

and control panel on the screen. (Battery alarm, the cause for corrective action.

etc.)

b)Check that cooling fan is running. ⇒Visually check it to determine

the cause for corrective action.

5. Spindle head a)Check that running-in performed. ⇒Run in the spindle according to

“Spindle warm-up” section of

the operation manual.

b)Check for abnormal noise. ⇒Check for abnormal noise

(M/C, NCL) during spindle running

c)Check spindle gear lubricating ⇒Check that spindle head

float. (TG) (Checks before ascends when spindle runs and t

starting work) hat it descends when spindle

comes to a stop.

d)Check that spindle tapered ⇒Check for removal of dust,

portion is cleaned. (M/C) fouling and foreign matter such

as chips

e)Check spindle for start, stop and ⇒Check that spindle start and

faults. (NCL, spindle) stop do not spend time too

much.

6. ATC magazine a)Check that tool pots and tapered ⇒Check for removal of dust,

portion are cleaned. fouling and foreign matter such

as chips

b)Check that ATC grip portion is ⇒Check for removal of dust,

cleaned. fouling and foreign matter such

as chips

c)Check pull stud for tool for ⇒Check pull stud for tightness

looseness. when changing tools.

2

2 - 2

Checking part Check item Details of checks

7. Table unit a)Check that telescopic cover is ⇒ Check for removal of foreign

cleaned. matter including chips and chips

on wiper portion

b)Check the quantity of table ⇒ Oil level check

indexing gear lubricating oil.

8. Feed unit a)Check for abnormal noise. ⇒ Check for abnormal noise when

operating feed unit

9. Covers a)Check that covers are not ⇒ Check that covers are not

detached. detached. If any cover is

detached, attach it.

b)Check that window is cleaned. ⇒ Check for cleaning

c)Check that nameplate and ⇒ Check for cleaning

caution plate are cleaned.

10. Interlocking a)Check door interlocking function. ⇒ Check that spindle does not run

device when opening door.

1 1. Hydraulic unit

(Option) kgf/cm

a)Check for normal set pressure. ⇒ Normal value: 35 kgf/cm2, 45

depends on the model.)

2

and 70 kgf/cm2 (It

b)Check hydraulic unit for faults. ⇒ Checks for abnormal noise and

oil leakage.

c)Check hydraulic unit for sufficient ⇒ Oil level check

quantity of oil.

d)Check that oil temperature is ⇒ Oil temperature check: Proper

60°C or less. temperature is 60°C or less.

e)Check for oil leakage. ⇒ Check for oil leakage

12. Lubricating unit a)Check for proper consumption. ⇒ 1 liter/10 hours as a guide

(When equipped b) Check lubricating unit for ⇒ Oil level check

with a high- sufficient quantity of oil.

speed spindle.) c)Check that air filter is cleaned. ⇒ Checks for clogging and

cleaning.

d)Check for oil leakage. ⇒ Check for oil leakage (Shorten

checking intervals depending on

working environment.)

13. High-pressure

a)Check high-pressure unit and ⇒ Checks for coolant leakage,

coolant piping for faults. abnormal noise and abnormal

(Option) vibration.

b)Check for discharge. ⇒ Visual check

c)Check pump for discharge ⇒ Normal value: 35 kgf/cm

2

pressure. (Pressure gage) kgf/cm

(It depends on the

2

or 70

specifications.)

d)Check that air filter is thoroughly ⇒ Checks for clogging and

cleaned. cleaning

e)Check high-pressure pump for ⇒ Oil level (cap oil filling) check

sufficient quantity of oil. and replenishment

f) Check for high-pressure pump oil ⇒ Checks for oil degradation and

fouling. oil color

g)Check for sufficient quantity of ⇒ Check through main tank

coolant.

2 - 3

Checking part Check item Details of checks

14. APC

(Option) is cleaned. matter including chips

a)Check that pallet seating surface ⇒ Check for removal of foreign

b)Check that pallets and cover ⇒ Check for removal of foreign

portion are cleaned. matter including chips

15. Chip conveyor

(Option) conveyor. obstructions such as workpiece,

a)Check for obstructions on the ⇒ Check for removal of

tool and square bar

b)Check the quantity of chips in the ⇒ Check the quantity of chips and

chip box and that of coolant. that of coolant, and dispose of

them as necessary.

c)Check that a large quantity of ⇒ Prevent a large quantity of chips

chips collect on the chip from collecting on the conveyor.

conveyor. (Inclusive of screw Check that conveyor operates

conveyor) to discharge chips.

d)Check for abnormal noise. ⇒ Check for abnormal noise when

operating chip conveyor

16. Mist collector

(Option) in the hose. hose route.

a)Check that mist does not remain ⇒ Visual check Provide angular

b)Check that filter is thoroughly ⇒ Checks for clogging and

cleaned. cleaning

c)Check that oil is properly drained. ⇒ Visual check for proper oil

drainage

d)Check mist for leakage. ⇒ Visual check

2 - 4

2-1-2 Periodic Check Items

Periodic checks by maintenance personnel are essential for assuring continued machine

accuracy. Perform maintenance at regular intervals according to the following periodic

check list.

2 - 5

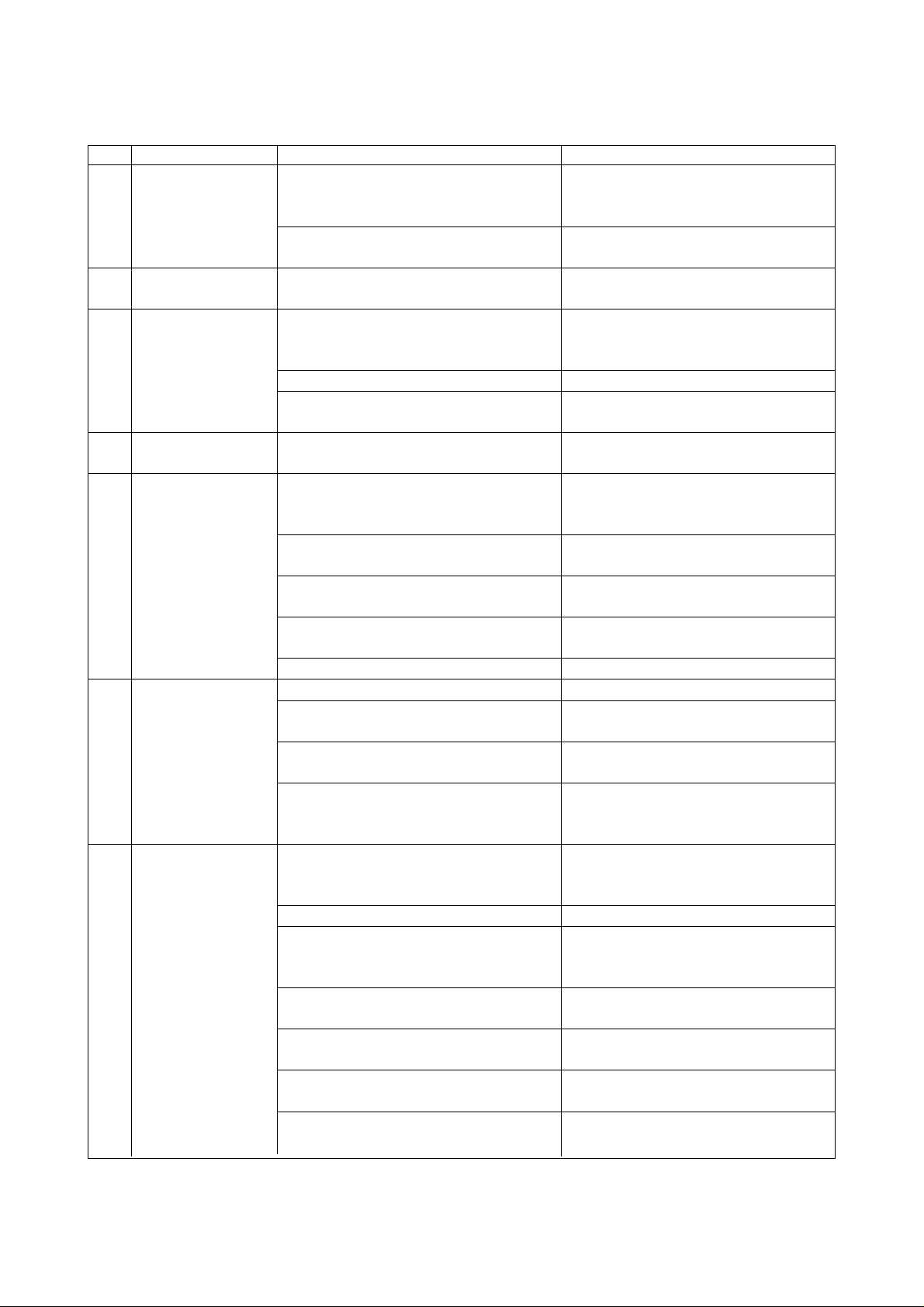

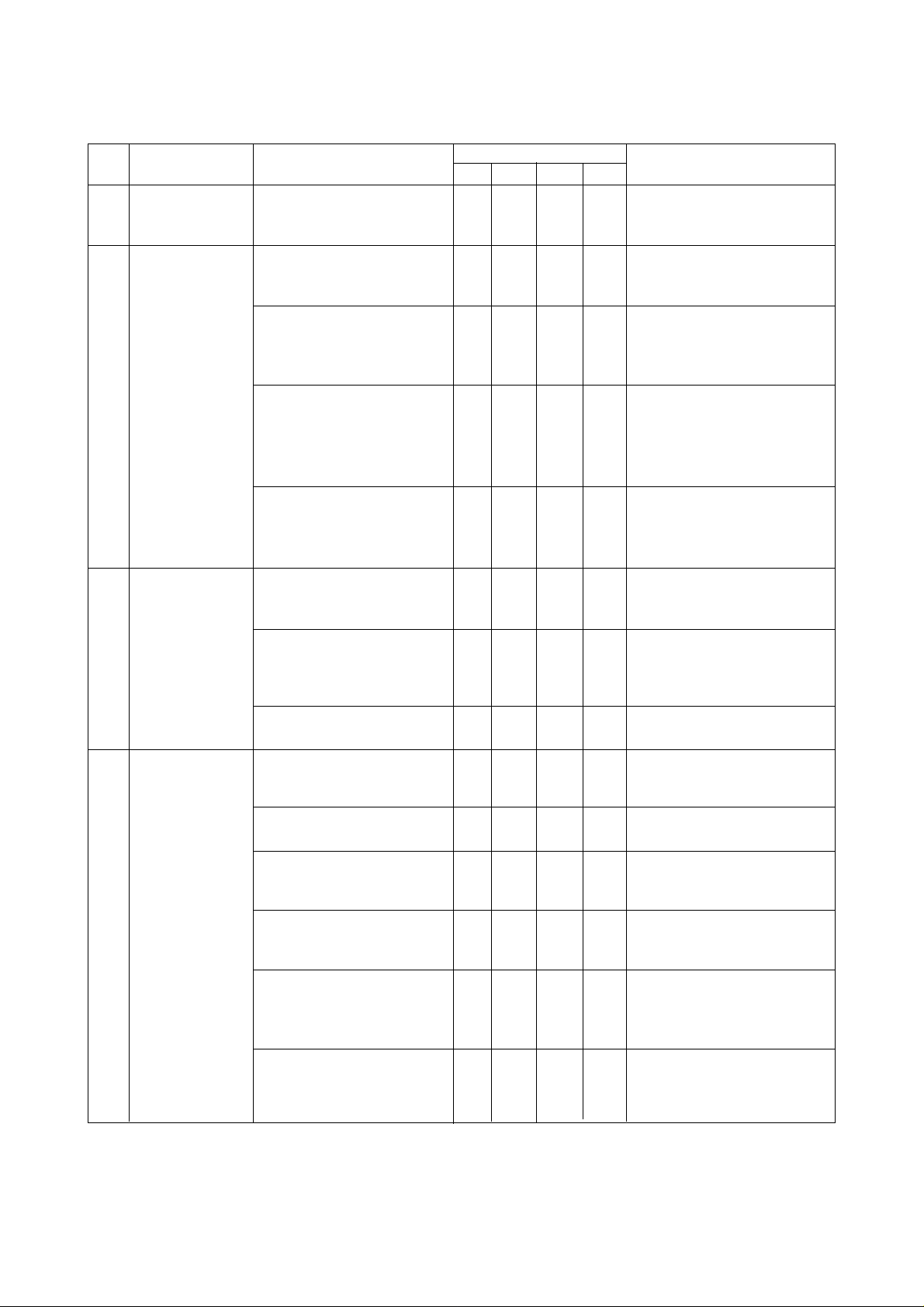

Periodic check list

Checking part Check item

1.

Main cooling

unit

2.

Pneumatic unit

Coolant unit

3.

Operation

4.

panel and

control panel

Table unit

5.

Feed unit

6.

a) Check piping for

faults.

b) Change hydraulic

fluid.

a) Check piping for

faults.

b) Check that filter is

thoroughly cleaned.

a) Check for

conspicuously dirty

coolant unit.

b) Check for foul smell.

c) Check piping for

faults.

a) Check for

conspicuously dirty

operation panel and

control panel.

(Cleaning)

b) Check for foreign

matter in the control

panel.

c) Check that air filter is

thoroughly cleaned.

d) Check that cooling fan

is cleaned.

e) Check power supply

and voltage.

a) Check bolts on the

telescopic cover for

looseness.

a) Check ball screw and

guide for lubrication

(oil and grease).

Checking interval

13612

O

O

O

O

O

O

O

O

O

O

O

O

O

O

⇒Check for oil leakage,

⇒Clean the inside of tank

⇒Check for oil leakage,

⇒Checks for clogging and

⇒Refer to Coolant section

⇒Check for oil leakage,

⇒Visual check and

⇒Removal of foreign

⇒Checks for clogging and

⇒Check for dirty cooling

⇒Check that secondary

⇒Check bolts for

⇒Visually check oil film.

Details of checks

and tighten connector

securely if necessary.

and strainer, and

change hydraulic fluid

as necessary.

and tighten connector

securely if necessary.

cleaning (Shorten

checking intervals

depending on working

environment.)

in the instruction

manual. (NCL)

and tighten connector

securely if necessary.

cleaning

matter

cleaning (Shorten

checking intervals

depending on working

environment.)

fan

voltage of main breaker

is set within + - 10% of

the specified value.

tightness, and tighten

them if necessary.

2 - 6

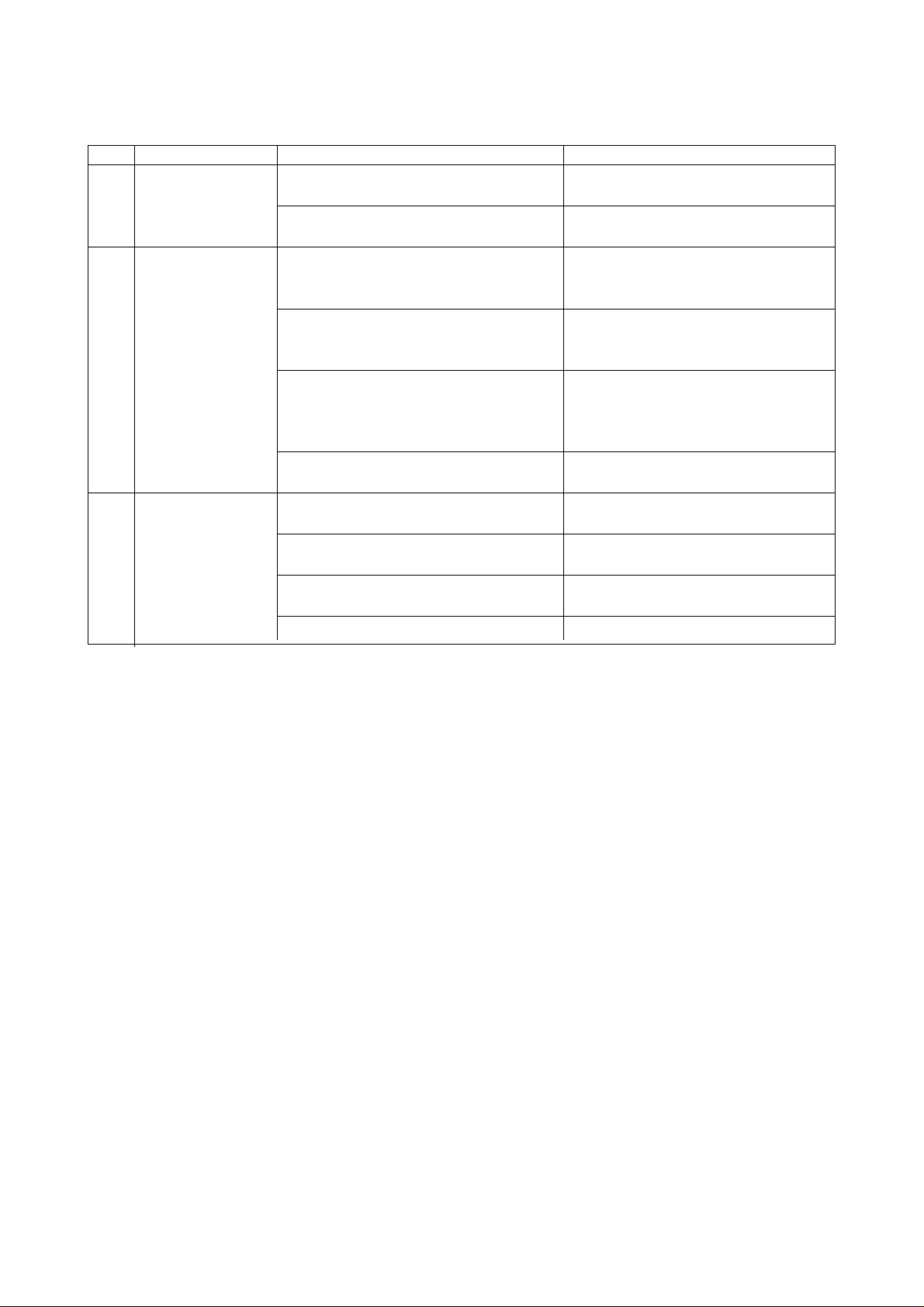

Checking part Check item

7.

Belt, Timing

belt (Z axes,)

8.

Level

9.

LS and SOL

10.

Cover

11.

Wiper and

brush

12.

Interlocking

device

13.

Cable

14.

OT (Overtravel)

15.

Earth leakage

breaker

a) Check belt for

deflection.

b) Check surface for

damage and heights

for deterioration.

a) Check the level of bed

and table with level

vial.

a) Check that LS and

SOL are not

moistened with oil.

b) Check for oil fouling.

a) Check mounting bolts

for looseness.

a) Check wiper and

brush for deterioration

and damage.

b) Check for jamming of

chips and foreign

matter.

a) Check spindle speed

limiting interlocking

function.

a) Check for damaged

appearance (tears,

crushes, stripped

conductor, etc.).

b) Check connector for

looseness.

c) Check for caught

cable.

d) Check that cable is not

moistened.

a) Check LS for

actuation.

a) Check breaker for

operation.

Checking interval

13612

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

⇒ Check deflection

⇒ Visual checks and

⇒ Level check and

⇒ Determine the cause to

⇒ Cleaning

⇒ Check cover clamping

⇒ Visual checks

⇒ Visual checks

⇒ Check spindle speed

⇒ Visual checks Replace

⇒ Visual check Tighten

⇒ Visual check. Return to

⇒ Visual check and

⇒ Operate the machine to

⇒ Press test button to

Details of checks

amount with tension

meter. (Normal value:

8mm 5.7/kg)

degreasing

adjustment with level

vial

take corrective action.

bolts for tightness, and

tighten securely if

necessary.

limiting interlocking set

value (parameter) when

using special chuck and

jig.

if there is something

wrong.

securely if necessary.

normal. Appearance

check. Replace if there

is something wrong.

cleaning. Determine

the cause.

check function.

check breaker for

operation.

2 - 7

Checking part Check item

16.

ATC cam unit

a) Check for proper

quantity of oil.

17.

Hydraulic unit

(Option)

a) Check piping for

faults.

b) Change hydraulic

fluid.

c) Check that strainer is

thoroughly cleaned.

d) Check oil for

discoloration (fouling).

18.

Lubricating

unit

(When

equipped with a

high-speed

spindle.)

a) Check piping for

faults.

b) Change hydraulic

fluid.

c) Check that strainer is

thoroughly cleaned.

19.

High-pressure

coolant

(Option)

a) Check piping for

faults.

b) Check that filter is

thoroughly cleaned.

c) Check high-pressure

pump for sufficient

quantity of oil.

d) Check for high-

pressure pump oil

fouling.

e) Check high-pressure

pump suction and

discharge valves for

damage or wear.

f) Check for damaged

or dirty high-pressure

pump diaphragm.

Checking interval

13612

O

⇒ Check oil level gage of

O

O

O

O

O

O

O

O

O

O

⇒ Check for oil leakage,

⇒ Clean the inside of tank

⇒ Checks for clogging

⇒ Check oil color with oil

⇒ Check for oil leakage,

⇒ Clean the inside of tank

O

⇒ Checks for clogging

⇒ Check for oil leakage,

⇒ Checks for clogging

⇒ Oil level (cap oil filling)

⇒ Checks for oil

O

⇒ Replace if damage or

O

⇒ Replace or clean if

Details of checks

cam unit. Supply oil

when insufficient.

and tighten connector

securely if necessary.

and strainer, and

change hydraulic fluid

as necessary.

and cleaning (Shorten

checking intervals

depending on working

environment.)

gage. When color is

getting brown, change

oil.

and tighten connector

securely if necessary.

and strainer, and

change hydraulic fluid

as necessary.

and cleaning

and tighten connector

securely if necessary.

and cleaning

check and

replenishment

degradation and oil

color

wear is found.

necessary.

2 - 8

Checking part Check item

High-pressure

19.

coolant

(Option)

Chip conveyor

20.

(Option)

g) Check gas charging

pressure of

accumulator.

a) Check that chip

conveyor is oiled.

Checking interval

13612

⇒ Recharge if charging

O

O

⇒ Apply grease to

Details of checks

pressure is dropped.

(Charging pressure: 50

K)

sprocket area as

necessary.

2 - 9

2-2 Lubrication, Oil Supply and Coolant

When supplying oil, be fully aware of the following:

1. Supply specified oil by specified amount. Do not supply a different type of oil or over the

specified amount.

Otherwise, the machine may malfunction.

2. Clean an oil inlet port in advance lest dust, etc. should enter inside.

3. When supplying the oil, use a filter to prevent foreign substances from entering inside the

tank.

When the filter is not available, use a wire net of 150 mesh or more.

4. Whenever you supply the oil, use new one. Do not mix with reproduced or old oil.

5. Even when opening a new oil can, do not use all oil in it, but leave some unused. This is

necessary to eliminate moisture and deposits.

See the lubrication chart for lubricating points, lubrication frequency, oil quantity and oil types.

2 - 10

2 - 11

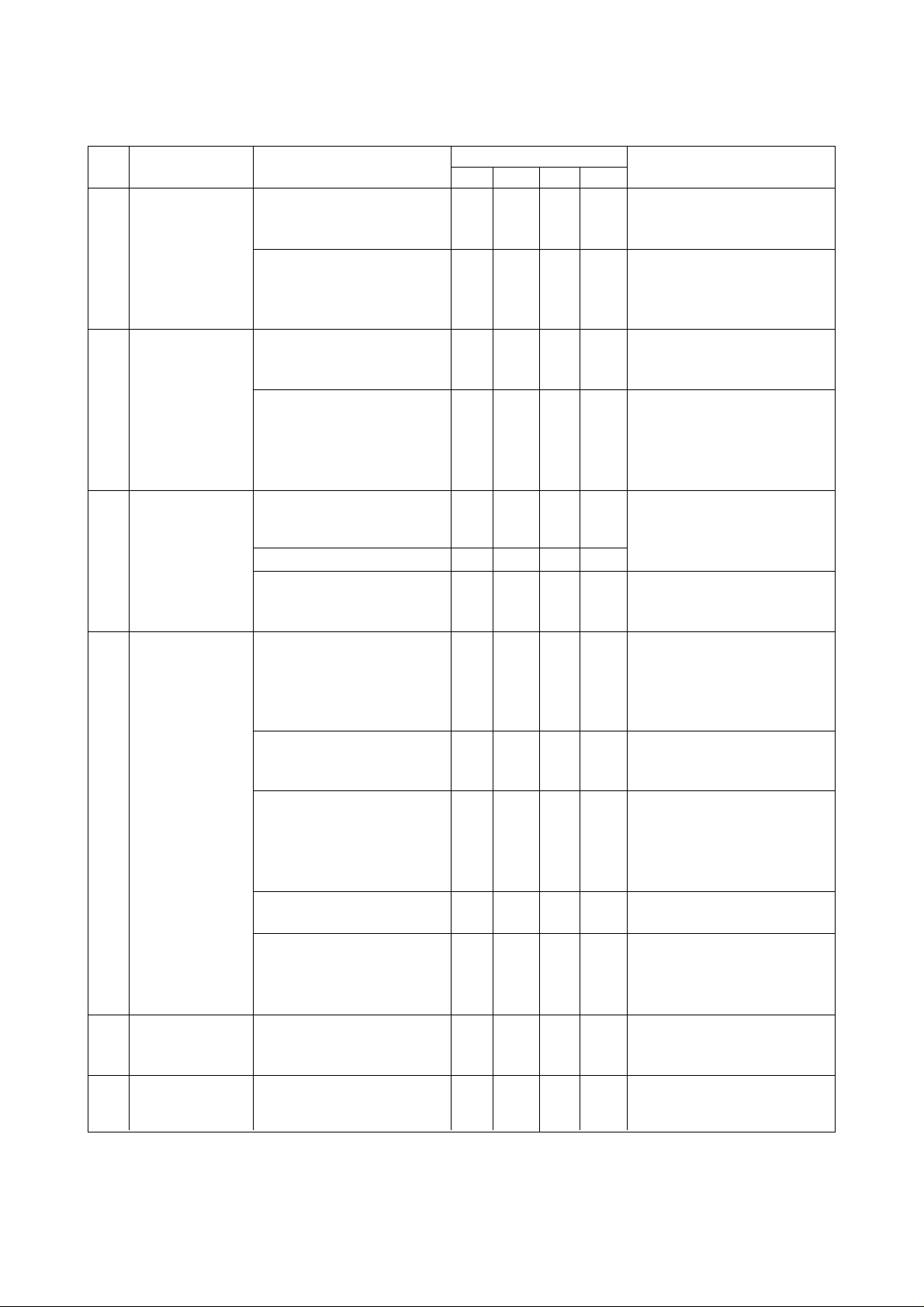

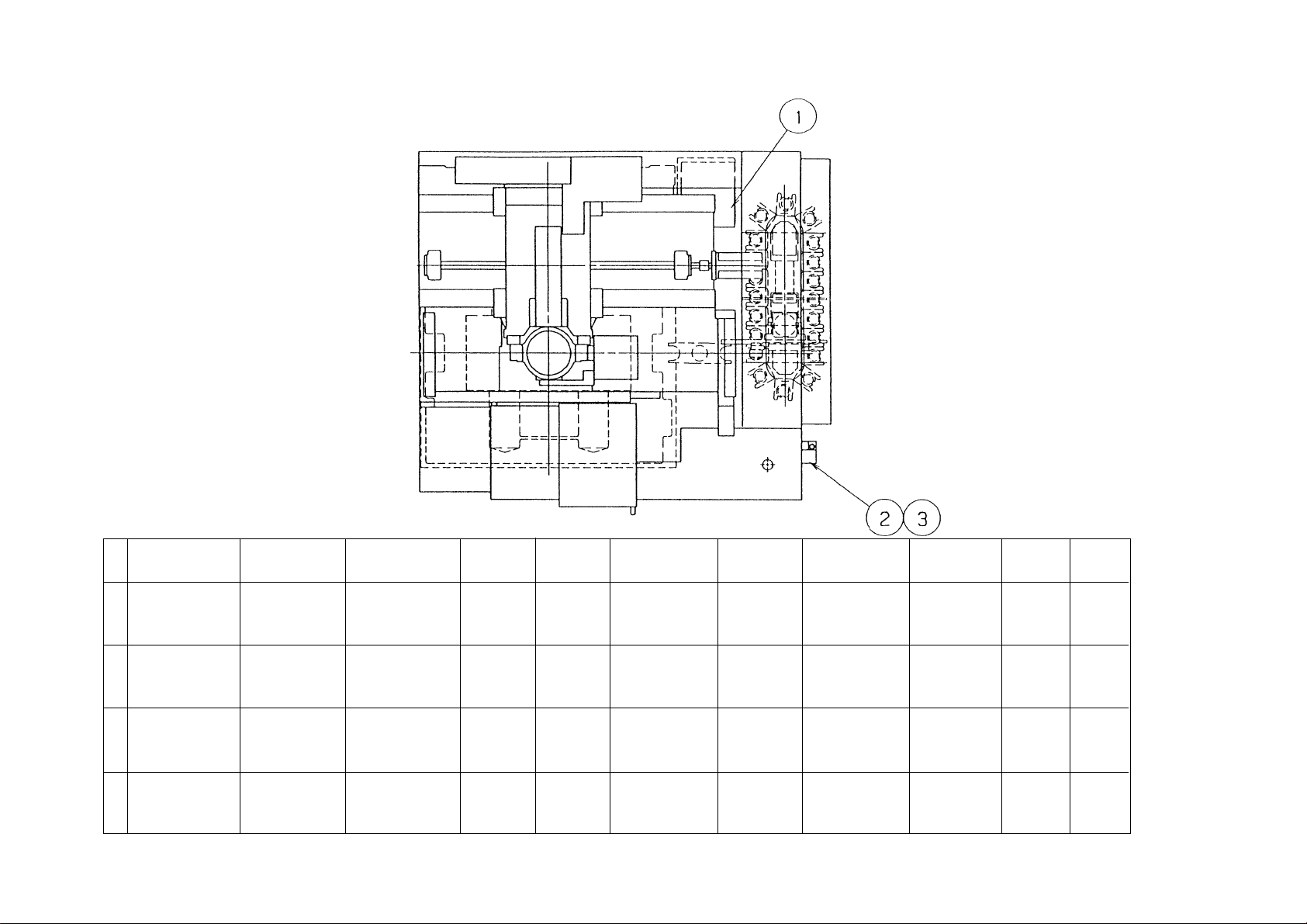

2-2-1 List of Lubrication and Oil Supply

Sopt to be Lubricating Lubricating Oil Nisseki Idemitsu Kosan Shell Mobile Mitsubishi Oil ESSO ISO

lubricated method period quantity symbol

Replace every 6 Super Daphne Super Tetra Oil Mobile Velocity Diamond Lub Unipower

1 Spindle cooling Trochoid pump months; add 17

when necessary

Lub. oil tank Super Daphne Super Mobile DTE Oil Diamond Unipower

2 (Spindle oil air) Gear pump As necessary 2

#50 - 10,000

Lub. oil tank Super Daphne Super Mobile Velocity Diamond Unipower

3 (Spindle oil air) Gear pump As necessary 2

#40 - 20,000

ATC cam Every Bonnock

4 unit exchange the M68

cam unit

• Mulpus 10 Multi Oil 10 10SP Oil No.3 RO10 (N) MP10 FC10

• Mulpus 32 Multi Oil 32 Tetra Oil 32 Light Tetrad 32 MP32 FC32

• Mulpus 22 Multi Oil 22 Tetra Oil 22 Oil No.10 Tetrad 22 MP22 FC22

Loading...

Loading...