Page 1

PROGRAMMING

FOR

MANUAL

VM,

SEIKI-SEICOS

VK,

VS,

MACHINING

Edition

HG,

21

1

10-1998

HS

CENTER

OM/1

6M/1

TYPE

8M

S

PSEiKl

Hitachi

S

Page 2

f

1

a

Page 3

TABLE

CONTENTS

OF

INTRODUCTION

1.

FLOW

1-1

Programming

1-2

PROGRAMMING

2.

Program

2-1

PROGRAM

2-2

Main

2-3

Subprogram

2-4

Composition

2-5

2-6

Address

Data

2-7

2-8

Word

Block

2-9

2-10

1

2-1

2-12

2-13

2-14

2-15

2-16

Absolute

2-17

Incremental

2-18

Right

2-19

Z-axis

2-20

X-axis

2-21

Y-axis

2-22

2-23

Z-axis

X,

2-24

CHART

No

program

Sequence

How

Tape

Tape

Tape

Address

Program

prepare

to

dimension

code

format

hand

zero

standard

Y,

Z

MACHINING

FOR

type

LANGUAGE

program

of

No

sequence

specification

meaning

and

and

point

zero

command

(absolute

command

perpendicularly

point

coordinate

.

.

No

coordinate

coordinate

(incremental

crossing

actual

and

WORK

system

value)

coordinate

work

MACHINING

BY

value)

system.

CENTER

1-1

1-2

1-3

2-1

2-1

2-1

2-2

2-2

2-2

2-5

2-6

2-6

2-6

2-7

2-7

2-8

2-8

2-9

2-10

2-11

2-12

2-13

2-14

2-14

2-14

2-15

2-15

2-16

M,

S,

3.

Miscellaneous

3-1

Command

3-2

Command

3-3

T,

FUNCTIONS

F,

B

method

method

(M-function)

pallet

of

spindle

of

change

speed

(For

(S-function)

with

VK

I

APC)

3-1

3-1

3-2

3-5

Page 4

3-4

Tool

Programming

3-5

Programming

3-6

No.

call

(T-function)

example

example

of

of

tool

tool

change

change

of

(Case

(CaseofHG)

VM,

VK,

VS)

3-6

3-8

3-9

Command

3-7

Table-indexing

3-8

G-FUNCTION

4.

AAA

G

4-1

GOO

4-2

4-3

4-4

4-5

4-6

4-7

4-8

4-9

4-10

4-11

4-12

4-13

4-14

4-15

4-16

(Positioning)

(Linear

G01

G02,

G02,

G02,

G02,

Summary

(dwell)

G04

Exact

G17,

G27

G28

G29

G30

G31

method

(preparatory

interpolation)

(circular

G03

G03

(program

(program

G03

(program

G03

GOO,

on

(G09)

stop

G19

G18,

(zero-point

(auto-zero

(auto-return

(2nd,

3rd,

function)

(skip

of

feed

command

interpolation)

example)

example)

example)

G01,

(plane

return

return)

4th

indication)

check)

zero

from

reference

.....

speed

method

function)

G02,

(F-function)

(B-function)

G03

.

point)

return)

point

. .

3-12

HG

series

3-13

4-1

4-1

4-2

4-3

4-4

4-5

4-6

4-7

4-8

4-9

.

4-10

4-11

4-12

4-13

4-14

4-15

4-16

5.

G-FUNCTION

Philosophy

5-1

length

Tool

5-2

5-3

Tool

diameter

Tool

5-4

5-5

5-6

5-7

5-8

5-9

5-10

diameter

Summary

G41,G42

G42

G41,

(cancel)

G40

Example

Example

(length

compensation,

compensation,

length

tool

of

compensation

compensation

compensation

tool

tool

tool

diameter

mode)

diameter

diameter

of

(start-up)

(offset

of

of

diameter

position

compensation

(G43,

compensation

compensation

compensation

compensation)

G44,

G41,

G42,

G41,

G42,

II

(G43,

G49)

G40

G40

program

program

G44,

.

G49)

5-1

5-1

5-2

5-5

5-6

5-7

5-8

5-10

5-12

5-15

5-16

Page 5

5-1

1

Example

of

tool

diameter

compensation

program

5-17

5-12

Example

3

Example

5-1

5-14

Example

5-15

Tool

Offset

corner

Tool

5-16

Tool

5-17

Example

8

5-1

Example

5-1

9

G-FUNCTION

6.

6-1

Setting

Caution

6-2

6-3

Work-coordinate

Work-coordinate

6-4

Example

6-5

Additionofwork

6-6

6-7

Selection

6-8

Local

G52

Data

One

program

6-9

6-10

6-11

tool

of

of

of

diameter

vector

circular

diameter

diameter

tool

tool

diameter

compensation

change

arc

compensation

position

of

offset

using

using

(coordinate

coordinate

use

the

for

using

work-coordinate

the

the

system

system

coordinate

machine-coordinate

of

coordinate

setting

directional

system

example

(G10)

positioning

compensation

compensation

compensation

Tool

and

(G39)

tool

number

G46,

by

(G45,

positional

tool-position

system)

system

(G54

of

(G92)

~

(G54

G54,

system

(G52)

.(G60)

vector

radius

G47,

offset

offset

G59)

G59)

~

G55

system

system

program

program

program

(G38),

keep

compensation

G48)

tool

for

and

and

pair

radius

milling

for

G92

coordinate

number

(G53)

..

machining

work-coordinate

system

setting

.

(G540

~

G599)

G92

5-18

5-19

5-20

5-21

5-24

5-27

5-29

5-30

6-1

6-1

6-2

6-3

6-4

6-5

6-6

6-10

6-11

6-12

6-13

6-16

'

G-FUNCTION

7.

Canned

7-1

Ganned

7-2

7-3

Canned

7-4

Canned

7-5

Canned

Canned

7-6

7-7

Canned

Canned

7-8

Example

7-9

Herical

7-10

(canned

cycle

cycle

cycle

cycle

cycle

cycle

cycle

cycle

canned

of

cutting

(G73

(data

(G73,

(G76,

(G82,

(G84,

(G87,

G02,

cycle)

~

type,

G74)

G80,

G83)

G85,

G88,

cycle

G03

G89)

return

G81)

G86)

G89)

program

level)

7-1

7-1

7-2

7-3

7-4

7-7

7-8

7-11

7-12

7-13

7-14

III

f

Page 6

Programmable

7-11

Setting

7-12

3

Direct

7-1

Boring

7-14

Bolt-hole

7-15

Arc

7-16

Line

7-17

7-18

Grid

True

7-19

Square

7-20

Coordinate

7-21

Surface

7-22

Pocket

7-23

Multibuffer

7-24

Precedent

7-25

tapping

pattern

cycle

angle

at

cycle

circle

cutting

mirror

cycle

(G71)

(G77)

cutting

side

rotation

cutting

control

mirror

image

cycle

image

.

(G70,

(G70)

(G72)

cycle

(G302

outer

frame

(G68,

(G324,

cycle

(G327-G333)

.

G511,

G71,

G305)

~

cutting

G69)

G325,

G501

G72,

(G322,

G326)

G77)

G323)

....

..

7-15

7-17

7-19

7-25

7-26

7-27

7-28

7-29

7-30

7-42

7-45

7-49

7-61

7-86

7-88

*

OTHER

8.

Optional

8-1

Arbitrary

8-2

PRACTICAL

9.

Machining

9-1

9-2

Selection

Setting

9-3

Mounting

9-4

Relation

9-5

9-6095

9-7

9-8

9-9

9-10

9-1

9-12

30

0

018

08.5

M10

Borning

1

0

Program

FUNCTION

skip

block

angle

chambering

EXAMPLE

diagram

machining

of

of

selected

method

work-coordinate

with

Face

cutter

Boring

Center

Drill

Tapping

finishing

spindles

of

2

OF

plate

position

cutting

comer

and

PROGRAM

FC30

condition

system

(R,

tool-cutter

of

C,

R)

8-1

8-1

8-2

9-1

9-1

9-2

9-2

9-3

9-3

9-4

9-5

9-6

9-7

9-8

9-9

9-10

IV

Page 7

ATTACHED

10.

List

10-1

List

10-2

10-3

Related

G

function

of

for

function

M

itemstothe

LIST

(preparatory

(miscellaneous

tool-set

function)

functions)

(VM,

VK,

VS,

HG,

HS)

10-1

10-1

10-5

10-15

10-4

10-5

1

0-6

10-7

10-8

10-9

Howto

List

List

MC

TOOLING

If

obtain

standard

for

tape

for

MACHINE

LIST

AlarmisIssued

the

code

DATA

cutting

cutting

condition

conditions

10-16

10-17

10-18

10-21

10-22

10-23

v

Page 8

!

!

!

Page 9

INTRODUCTION

1.

Thank

This

In

the

you

manual

order

features

to

Explanation

methods.

and

the

Some

programs

format

the

given

Accordingly,

For

nance)".

This

optional.

difference

of

are

(FANUC

specifications

the

at

detail

manual

between

your

for

selection

describes

machining

this

use

functions

and

made

is

programming

described

specifications).

of

the

of

end

programming

make

of

parameter,

describes

Refer

"Delivery

to

the

the

of

necessary

for

terms,

separately

the

machine

this

etc.,

the

standard

introduction

and

programming

center

machine.

items

the

programming

according

Be

sure

used

manual.

upon

refer

to

programming

Description"

and

the

of

our

of

Machining

effectively,

on

it

programming,

methods,

S-format

to

understand

to

programming.

for

full

understanding

"SEIKI-SEICOS

regardless

provided

optional.

Machining

Center

necessary

is

such

fully

List

of

the

210M

type

the

the

at

Center.

with

understand

to

as

which

etc.

(SEICOS

descriptions

these

S-format

of

contents.

Instruction

the

of

time

of

SEIKI-SEICOS

and

programming

the

necessary

are

specifications)

according

and

F-format

Manual

machine,

delivery

standard

regarding

210M.

program

words

the

for

F-

and

to

is

(Mainte¬

or

the

1-1

Page 10

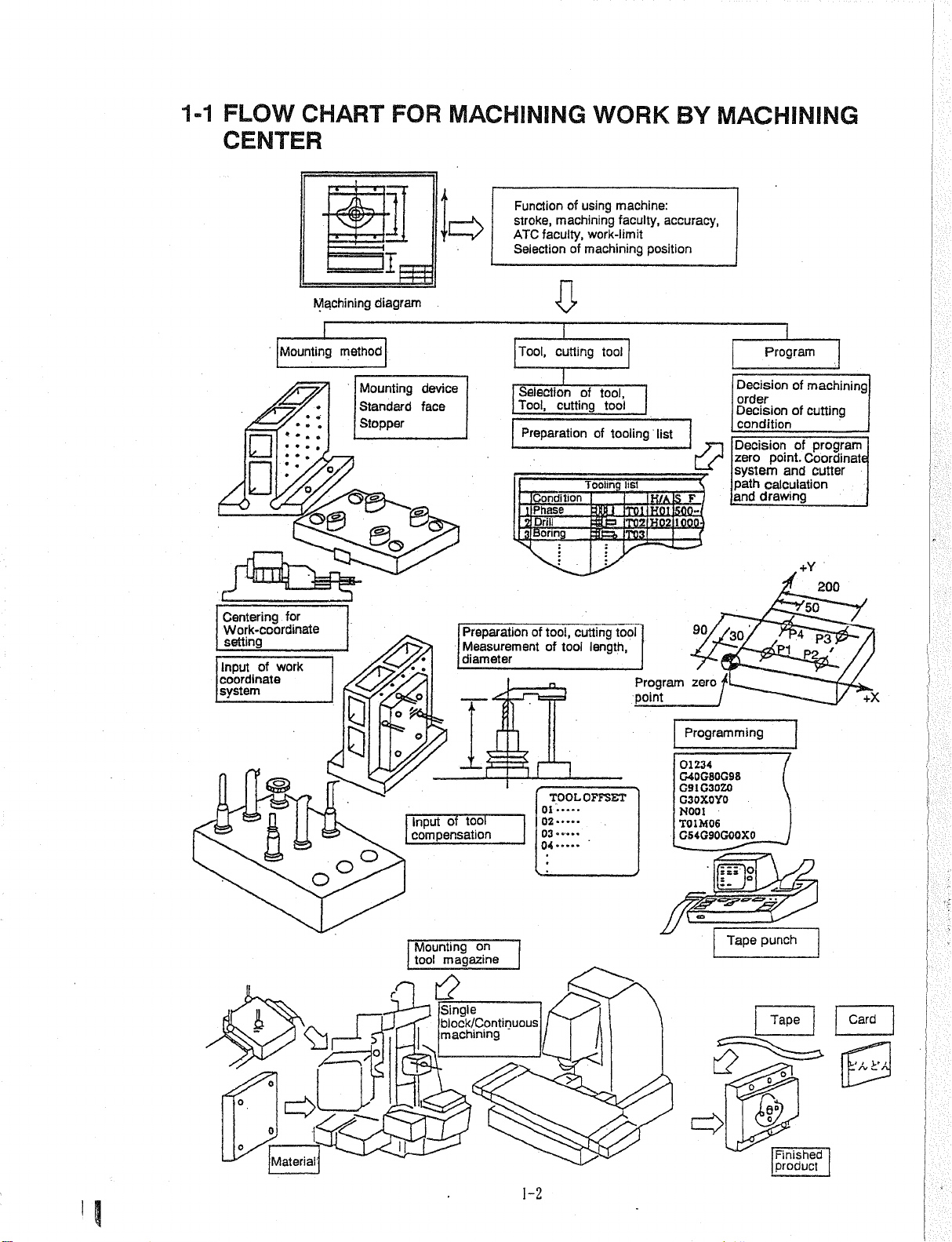

1-1

FLOW

CENTER

CHART

m

FOR

II

MACHINING

of

machining

faculty,

of

c>

Function

stroke,

ATC

Selection

WORK

using

machine:

faculty,

work-limit

machining

BY

accuracy,

position

MACHINING

Mounting

4Z

•

*

4

c

Centering

Work-coordinate

setting

Input

coordinate

system

for

_

work

of

Machining

method

O.

q.

PS

diagram

Mounting

Standard

Stopper

device

face

Tool,

Selection

Tool,

Preparation

Condition

I

Phase

1

1

Drill

Boring

3|

Preparation

Measurement

diameter

of

£

cutting

cutting

tool,

of

tool

tool

of

tool,

of

Tooling

m

cutting

length,

tool

tooling

list

T01

T02

T03

tool

list

H/A

HOI

H02

Program

point

c?

S

F

IOOO'

9°//30.

zero

Programming

Program

Decision

order

Decision

condition

Decision

zero

point.

system

path

calculation

drawing

and

of

machining

of

cutting

_

program

of

Coordinate

and

cutter

+Y

200

'50

3ÿP2_/

'

/

+X

rp

Mn

i

o

o

0

Material

o

o

o

7?

Input

compensation

Mounting

tool

£

CL

II

tool

of

on

magazine

_

Single

block/Continuous

machining

1-2

TOOL

01

02

03

—

04

OFFSET

01234

G40G80G98

G9IG30ZO

G30X0Y0

N00I

T01M06

GS4G90GO0X0

fnrio

Tape

[Zÿ>

\

punch

Tape

o

0

<32

Finished

product

Card

t'A,

fc'A

'I

Page 11

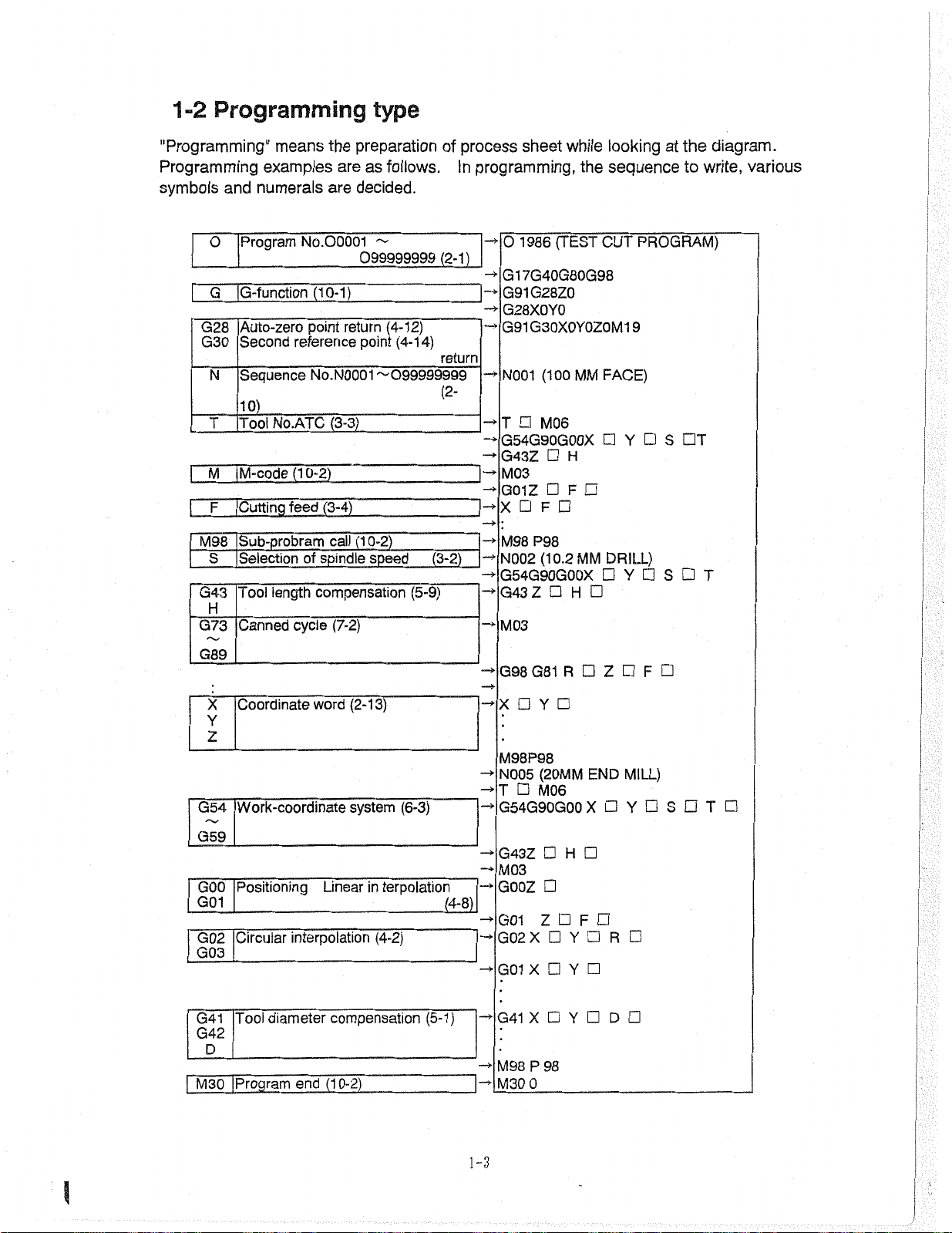

Programming

1-2

type

"Programming"

Programming

symbols

O

|

G

G28

G30

N

examples

numerals

and

Program

iG-function

Auto-zero

Second

Sequence

101

Tool

T

|

|

jM-code

M

Cutting

|

F

M98

jSub-probram

Selection

S

Tool

G43

H

G73

Canned

means

No.00001

preparation

the

as

are

are

decided.

~

099999999

(10-Tf

point

return

reference

No.N0001~099999999

No.ATC

(10-2)

feed

of

length

cycle

point

(3-3)

(3-4)

(10-2)

call

spindle

compensation

speed

(7-2)

follows.

(4-12)

(4-14)

(5-9)

process

of

In

programming,

(2-1)

return

(2-

-»

(3-2)

-»

while

sheet

the

(TEST

1986

O

G17G40G80G98

G91G28Z0

G28X0Y0

G30X0Y0Z0M

G91

(100

N001

M06

T

G54G90G00X

G43Z

M03

G01Z

F

X

P98

M98

(10.2

N002

G54G90G00X

G43Z

M03

H

F

H

MM

MM

CUT

FACE)

looking

at

sequence

PROGRAM)

9

1

S

Y

DRILL)

Y

S

the

to

DT

write,

T

diagram.

various

|

G03

G41

G42

M30

G89

Coordinate

X

Y

Z

I

Work-coordinate

G54

G59

Positioning

GOO

G01

Circular

G02

__

[Tool

D

iProgram

word

interpolation

diameter

end

(2-13)

system

Linear

compensation

(10-2)

terpolation

in

(4-2)

(6-3)

(4-8)

(5-1)

G98

G81

X

M98P98

N005

T

G54G90GOO

G43Z

M03

G00Z

G01

G02X

G01

X

-*

G41

X

!

P

M98

M30

0

R

Y

(20MM

M06

H

Z

Y

Y

Y

98

END

X

F

Z

R

D

F

MILL)

Y

T

S

l-3

I

Page 12

.

Page 13

2-1

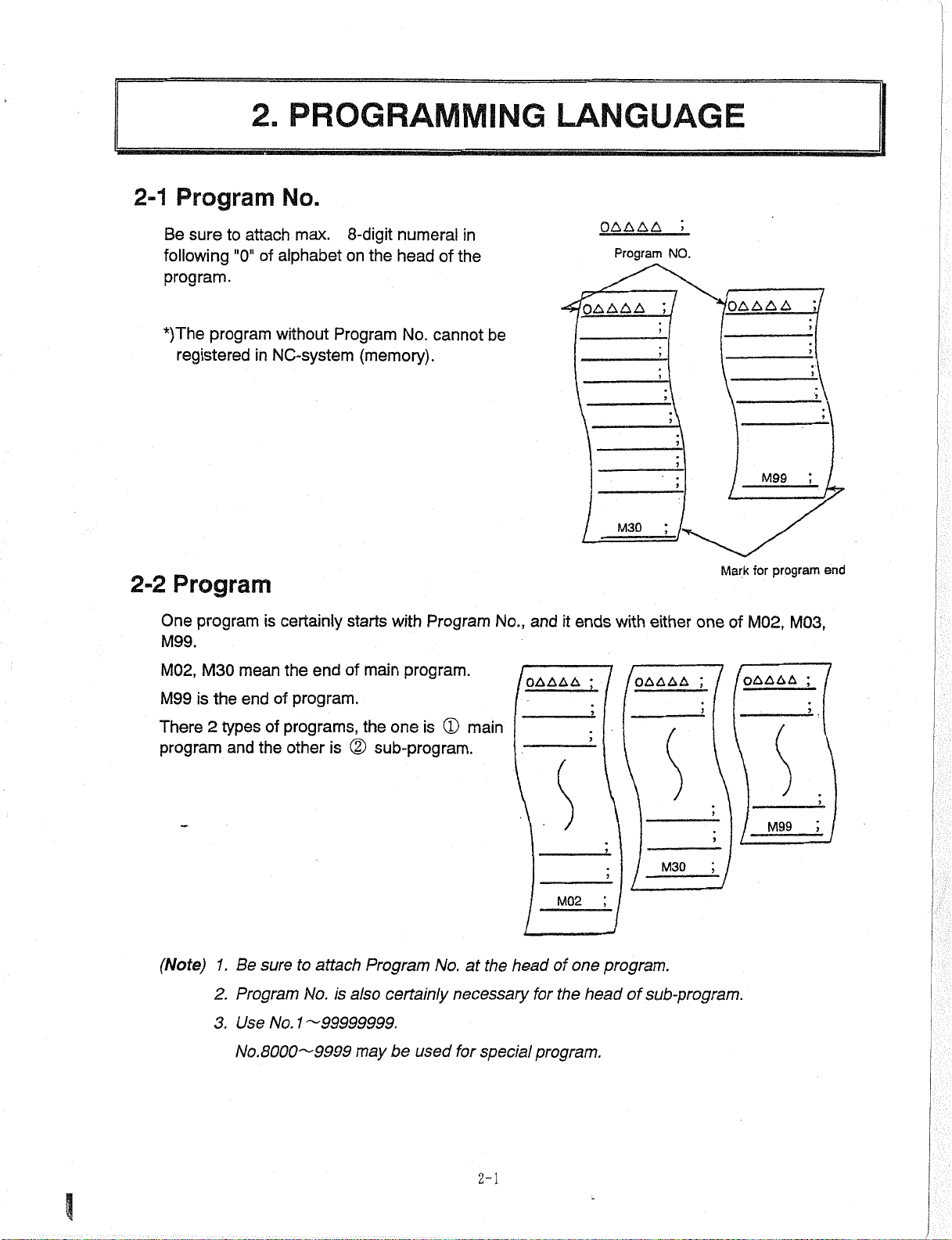

Be

following

program.

2.

Program

sure

to

"0"

attach

PROGRAMMING

No.

max.

alphabet

of

8-digit

on

the

numeral

head

of

in

the

LANGUAGE

OAAAA

Program

NO.

*)The

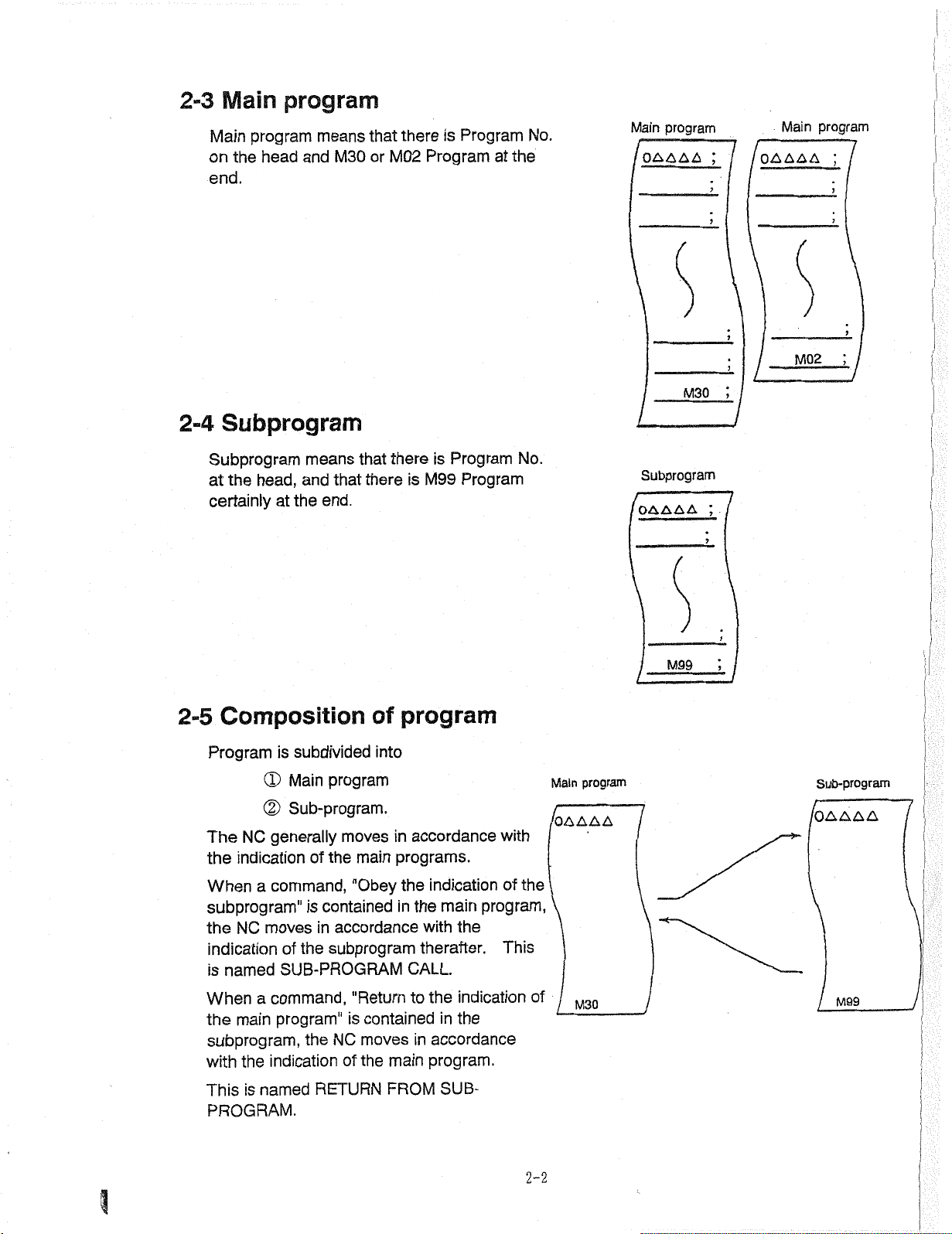

2-2

One

M99.

M02,

M99

There

program

program

registered

Program

program

M30

mean

end

is

the

2

types

and

without

NC-system

in

is

certainly

the

program.

of

programs,

of

the

other

Program

of

end

is

No.

(memory).

starts

with

program.

main

the

one

(2)

sub-program.

cannot

Program

(D

is

main

be

No.,

and

OAAAA

'OAAAA

it

ends

M30

d

either

with

/oAAAA

one

;

f

'OAAAA

M99

tor

Mark

M02,

of

OAAAA

I

i

program

M03,

;

end

M99

M30

y

(Note)

Be

1.

Program

2.

3.

Use

No.

attach

to

sure

No.

1ÿ99999999.

No.

8000ÿ9999

is

also

may

Program

certainly

be

used

No.atthe

necessary

for

special

2-1

head

for

program.

M02

of

the

i

one

head

I

program.

sub-program.

of

I

Page 14

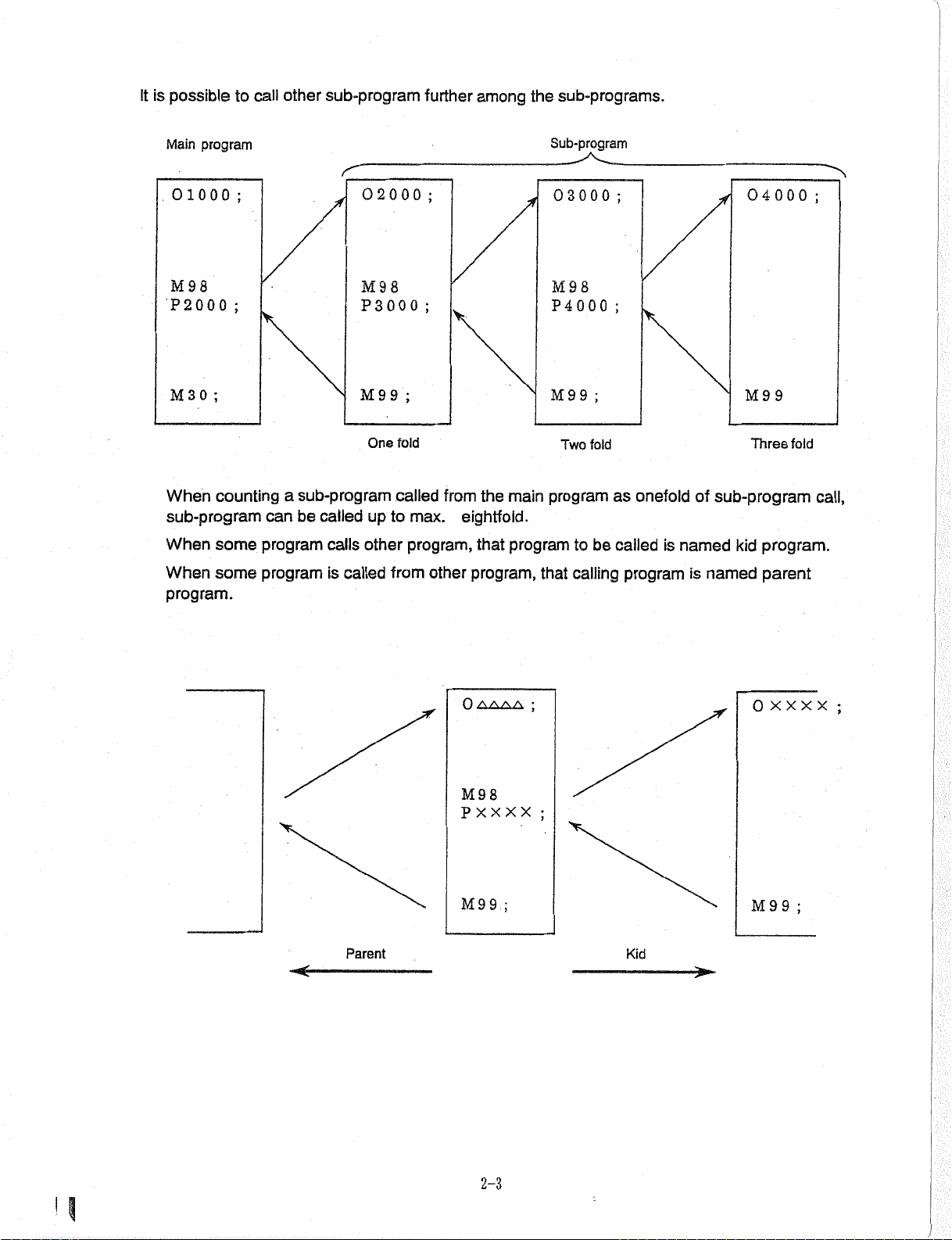

Main

2-3

program

Main

the

on

end.

Subprogram

2-4

program

means

and

head

M30

that

or

there

M02

is

Program

Program

at

the

No.

Main

OAAAA

program

M30

;

/

OAAAA

/

Main

M02

program

/

;

J

Subprogram

head,

the

at

certainly

Composition

2-5

Program

NC

The

indication

the

When

subprogram"

the

a

NC

indication

named

is

means

and

the

at

subdivided

is

(D

Main

(D

Sub-program.

generally

of

command,

is

moves

the

of

that

that

there

end.

program

moves

main

the

"Obey

contained

accordance

in

subprogram

SUB-PROGRAM

there

is

program

of

into

accordance

in

programs.

the

the

in

with

therafter.

CALL.

Program

is

M99

Program

indication

main

the

No.

with

the

of

program,

This

program

Main

/OAAAA

Subprogram

OAAAA

M99

;

kJ

Sub-program

/OAAAA

command,

When

the

subprogram,

with

This

PROGRAM.

a

main

the

named

is

program"

indication

"Return

is

NC

the

of

RETURN

to

contained

moves

the

in

main

FROM

the

indication

the

in

accordance

program.

SUB¬

of

2-2

M30

M99

Page 15

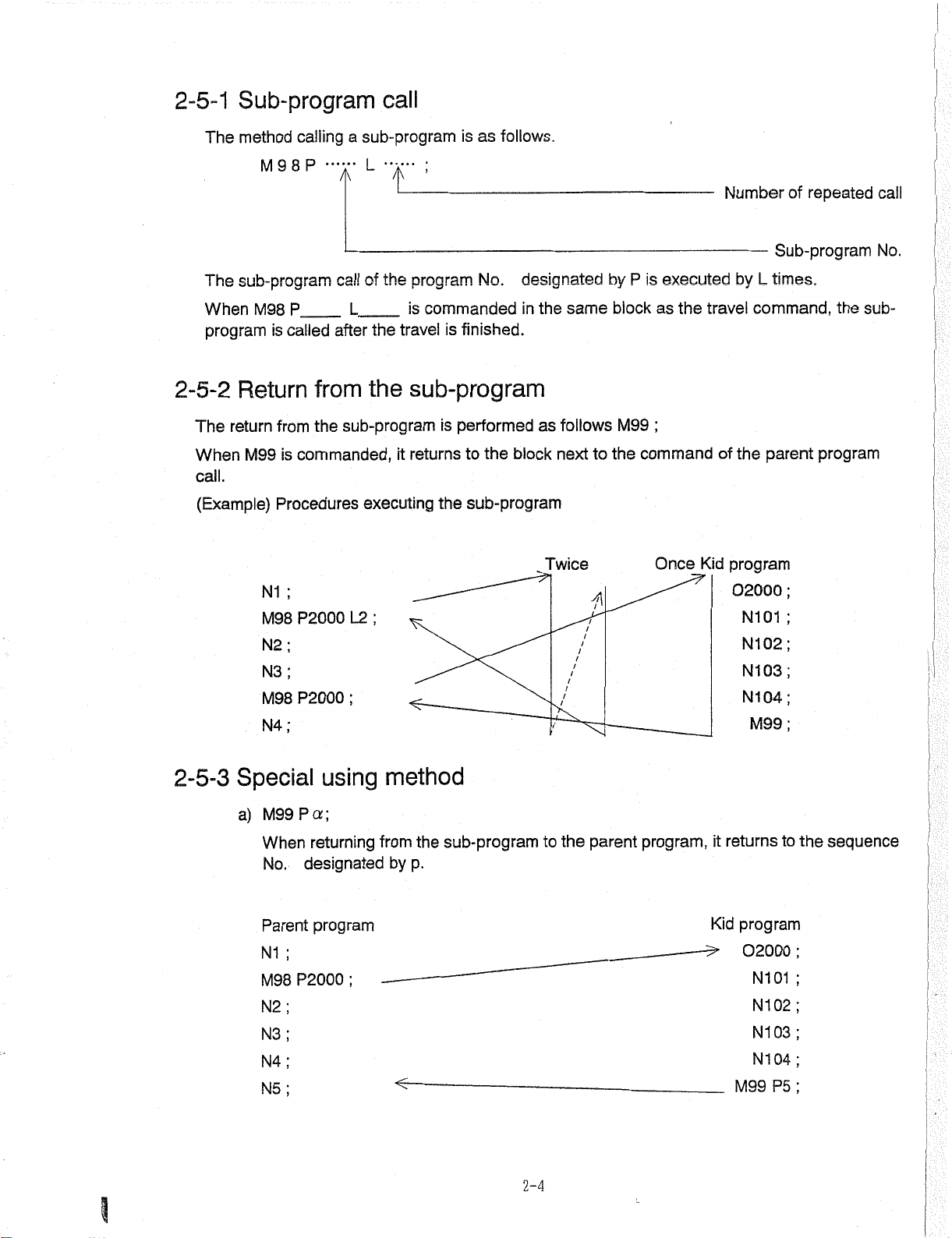

is

It

possible

to

call

other

sub-program

further

among

sub-programs.

the

program

Main

01000

M

P2000

3

M

When

;

9

8

;

;

0

countingasub-program

sub-program

When

When

some

some

program.

be

can

program

program

called

calls

is

called

02000

M98

P3000

M

9

9

One

to

up

other

from

;

;

;

fold

called

max.

program,

other

from

the

eightfold.

that

program,

Sub-program

03000

M

P4000

M

program

main

program

that

8

9

9

9

Two

to

calling

;

fold

be

;

;

as

onefold

called

program

is

named

04000

M

of

sub-program

kid

is

named

9 9

Three

fold

program.

parent

;

call,

<-

Parent

OAMA

M98

PXXXX

M99

;

;

;

Kid

M

XXX

x

0

9

9

;

;

H

2-3

Page 16

2-5-1

The

Sub-program

method

calling

sub-program

a

call

is

as

follows.

The

When

program

2-5-2

The

When

call.

(Example)

P

9

8

M

sub-program

called

is

P.

_

M98

Return

from

return

commanded,

is

M99

Procedures

;

N1

P2000

M98

;

N2

;

N3

P2000

M98

;

N4

L

A

of

call

_

L

after

from

the

the

sub-program

executing

L2

;

"i_i

the

program

commanded

is

travel

the

it

;

is

sub-program

is

performed

returns

the

designated

No.

the

in

finished.

as

the

block

to

sub-program

same

follows

next

Twice

7

to

by

the

is

P

block

M99

command

executed

the

as

;

Kid

Once

Number

by

travel

the

of

program

02000

of

Sub-program

L

times.

command,

parent

;

;

N101

;

N102

N103;

N104

;

M99

repeated

the

program

call

No.

sub¬

I

:

2-5-3

Special

M99

a)

P

When

No.

Parent

;

N1

P2000

M98

N2

N3

N4

N5

designated

using

a

;

returning

program

;

method

sub-program

the

from

by

p.

2-4

to

the

parent

program,

returns

it

Kid

program

02000

N101

N102

N103

N104

P5

M99

to

the

;

sequence

:

I

Page 17

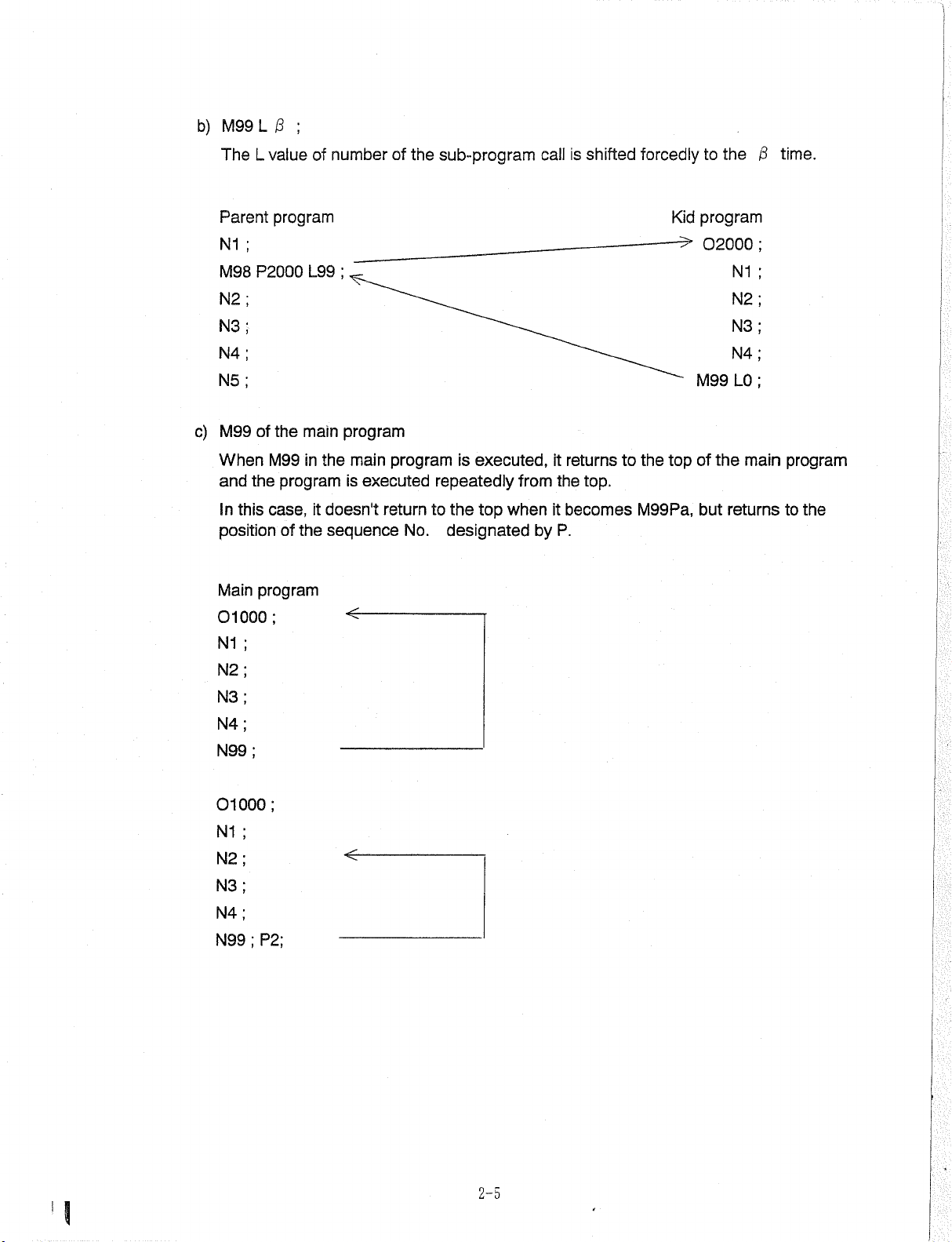

b)

M99

;

L

/3

TheLvalue

Parent

N1

M98

N2

N3

N4

N5

M99

c)

When

and

this

In

position

Main

program

;

P2000

the

of

M99

program

the

case,

of

program

numberofthe

of

;

L99

program

main

the

main

in

is

doesn't

it

the

sequence

program

executed

return

No.

sub-program

executed,

is

repeatedly

to

the

top

when

designated

from

by

call

is

returns

it

the

it

becomes

P.

shifted

to

top.

forcedly

Kid

the

top

M99Pa,

the

to

program

02000

N1

N2

N3

N4

M99L0

the

of

but

main

returns

/3

;

time.

program

the

to

01

N1

N2

N3

N4

N99

01

N1

N2

N3

N4

N99

000

;

000

;

;

;

<c

P2;

2-5

I

Page 18

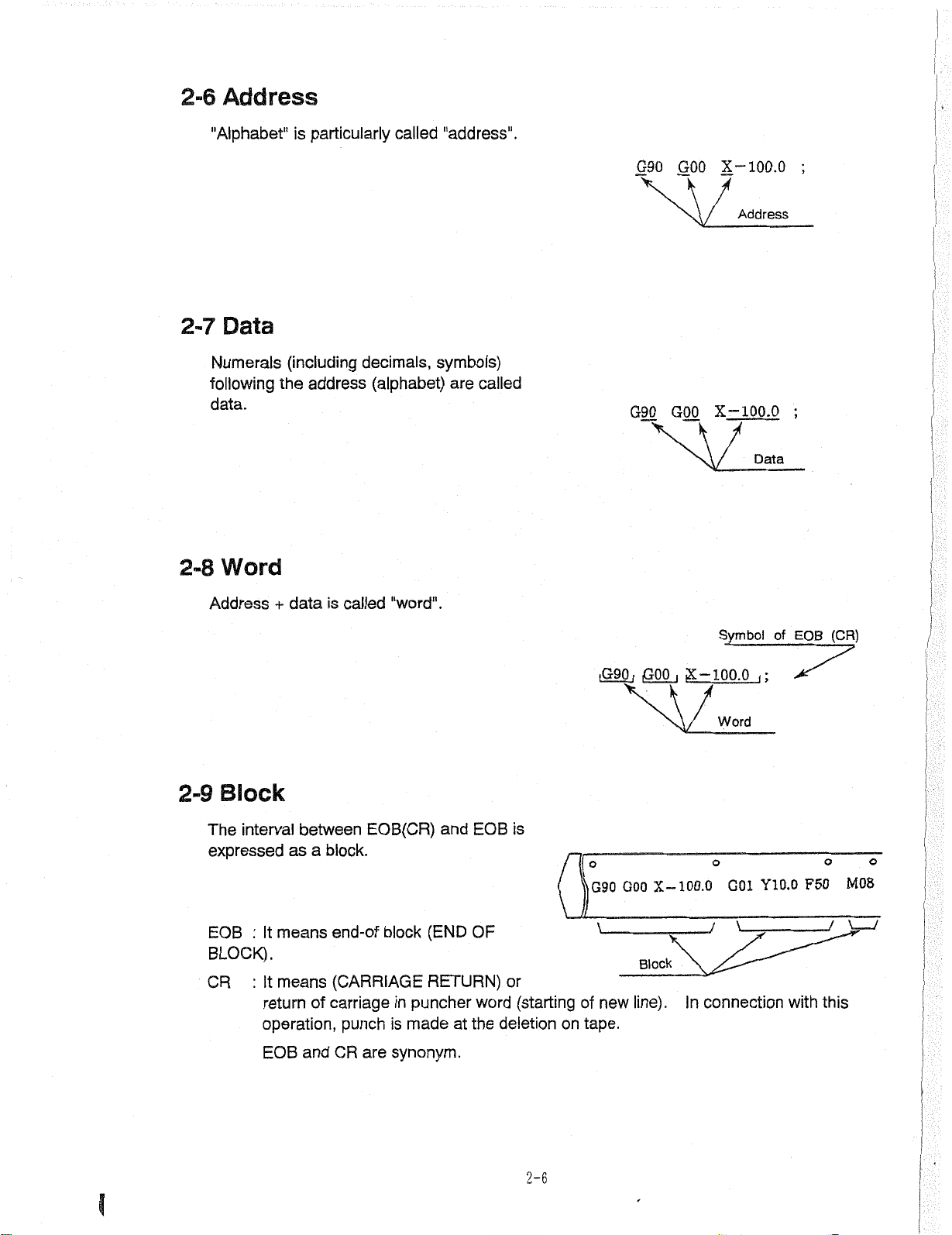

2-6

Address

"Alphabet"

2-7

Numerals

following

data.

2-8

Data

Word

particularly

is

(including

the

address

called

decimals,

(alphabet)

"address".

symbols)

are

called

G90

G90

GOO

GOO

100.0

X-

Address

X-100.0

Data

;

;

Address+data

Block

2-9

interval

The

expressed

EOB

BLOCK).

CR

between

as

means

:

It

It

:

means

return

operation,

and

EOB

is

called

EOB(CR)

block.

a

end-of

(CARRIAGE

carriage

of

punch

are

CR

"word".

(END

block

RETURN)

puncher

in

is

made

synonym.

and

at

EOB

OF

word

the

is

or

(starting

deletion

on

iG90

G90

new

of

tape.

1

GOO

GOO

Block

line).

i

X-100.0

X-100.0

In

Symbol

Word

o

G01

of

Y10.0

connection

EOB

F50

with

(CR)

o

this

O

M08

2-6

Page 19

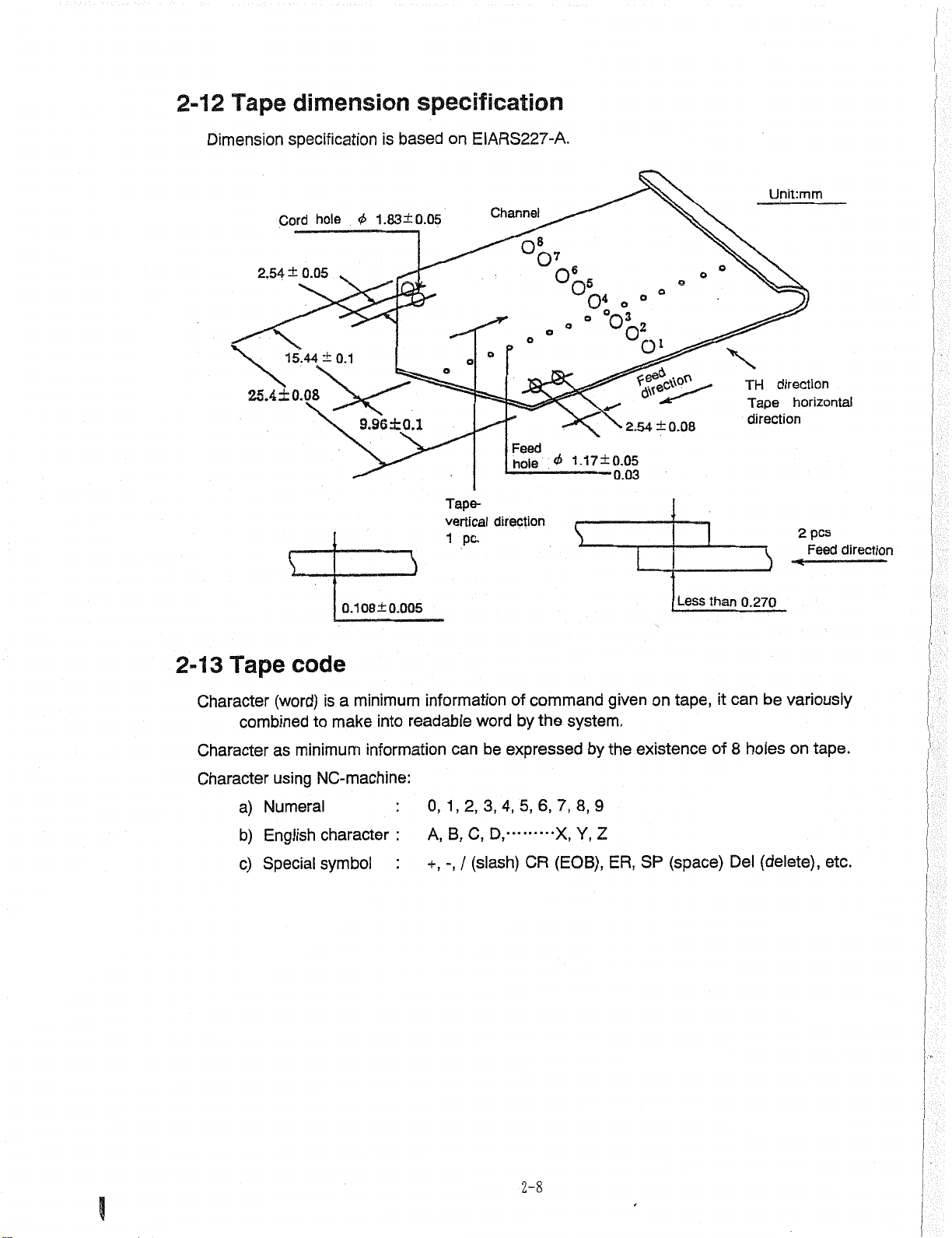

2-10

Sequence

No.

part

related

following

the

case

of

"Sequence

to

the

of

Initial

numberbynumerals

the

address

It

is

called

is

not

2-11

How

For

program,

the

Also,

in

setting

N

case

of

In

block

can

No.

with

machining.

prepare

actual

instance,

for

way

VM,

VK

and

HG

be

attached

8

within

No.

digits

"Sequence

sequence

Sequence

tool

is

convenient

and

VS

—

Operations

When

When

When

HS

machined

machined

machined

following

No.,

is

changed

with

it

for

for

No.

is

by

by

by

No.

convenient

be

a

to

every

1st

2nd

3rd

the

tool

tool

tool

tool

taking

N00000001

Example

Z_

N2

Z_

G

_

X_

N3

;

N10

_M_

G

_

;

M

put

to

new

tool

number.

:

N1

N2

:

;

N3

N99999999

~

X_

Y_

G_

N1

_

;

M

_

_

F

a

well

;

punctuating

R

;

;

at

it

S_

position

;

for

N

/\

7K

Identification

When

When

When

When

When

When

machined

machined

machined

machined

machined

machined

Operations

of

pallets

1st

2nd

3rd

1st

2nd

3rd

tool

tool

by

by

by

by

by

by

for

tool

tool

tool

tool

every

1st

of

of

1st

of

1st

of

2nd

2nd

of

of

2nd

tool

pallet,

pallet,

pallet,

pallet,

pallet,

pallet,

N101

N102

N103

N201

N202

N203

is

attached.

2-7

Page 20

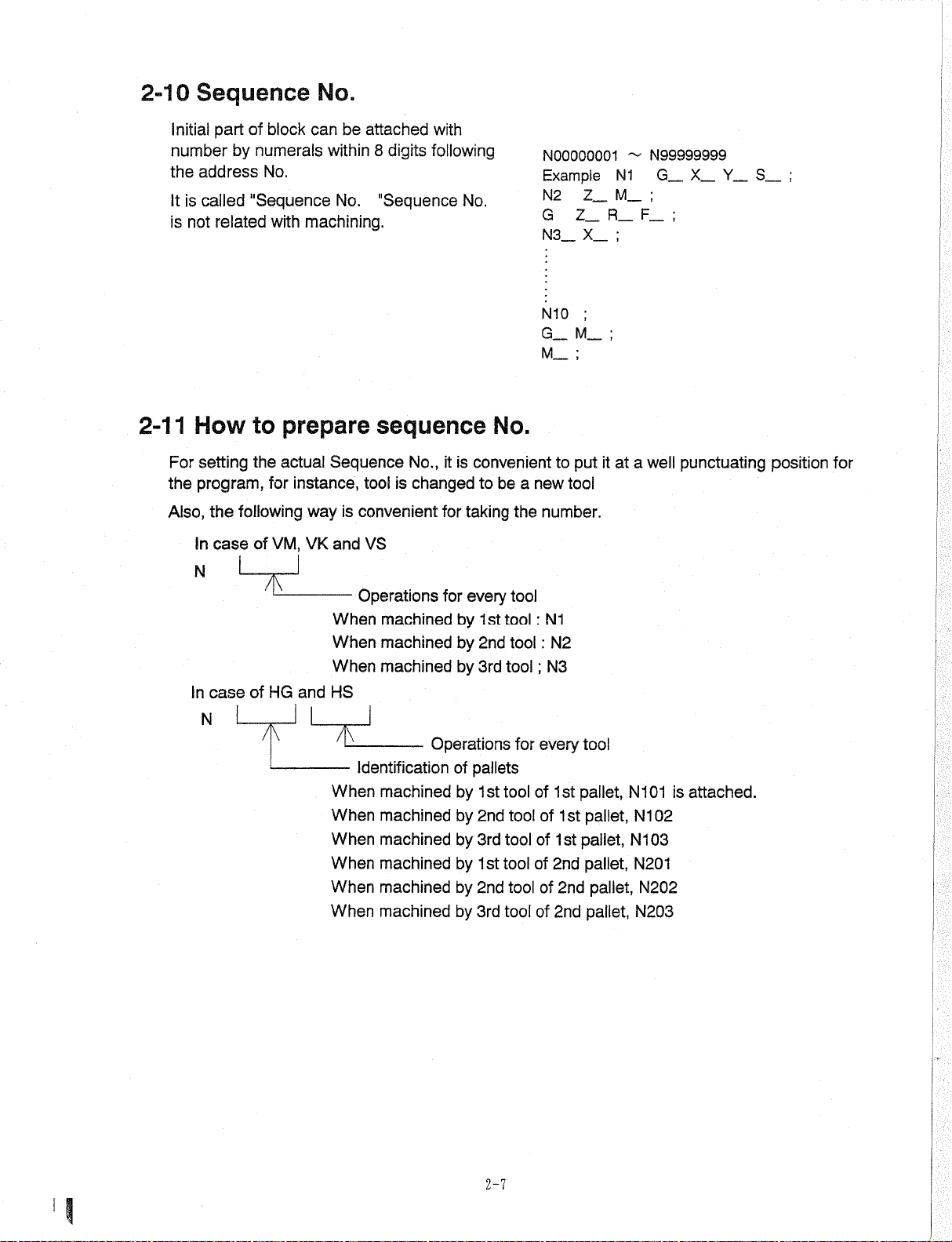

2-12

Tape

dimension

specification

Dimension

Cord

2.54

25.4±0.08

specification

hole

<£

±

0.05

±

15.44

0.1

9.96

is

1.83

±0.1

based

±0.05

on

EIARS227-A.

Channel

o

o

Tape-

vertical

1

direction

pc.

o8

Feed

hole

°7

o

<t>

s

°ot

•

°OL.

1.17±0.05

.

•

ol

2.54

°

±0.08

Unit:mm

o

o

X

direction

TH

Tape

horizontal

direction

pcs

2

Feed

direction

2-13

Character

Character

Character

Tape

(word)

combined

as

using

a)

Numeral

English

b)

c)

Special

0.1

code

minimum

a

is

make

to

minimum

NC-machine:

character

symbol

08±

0.005

information

into

readable

information

0,

A,

+,

can

1,2,

B,

-,

word

be

3,

C,

(slash)

/

command

of

the

by

expressed

6,

5,

4,

D,

CR

system.

by

7,

8,9

•X,

Y,

(EOB),

given

the

Z

ER,

Less

tape,

on

existence

(space)

SP

than

it

of

0.270

can

8

Del

holes

variously

be

on

(delete),

tape.

etc.

3

2-8

Page 21

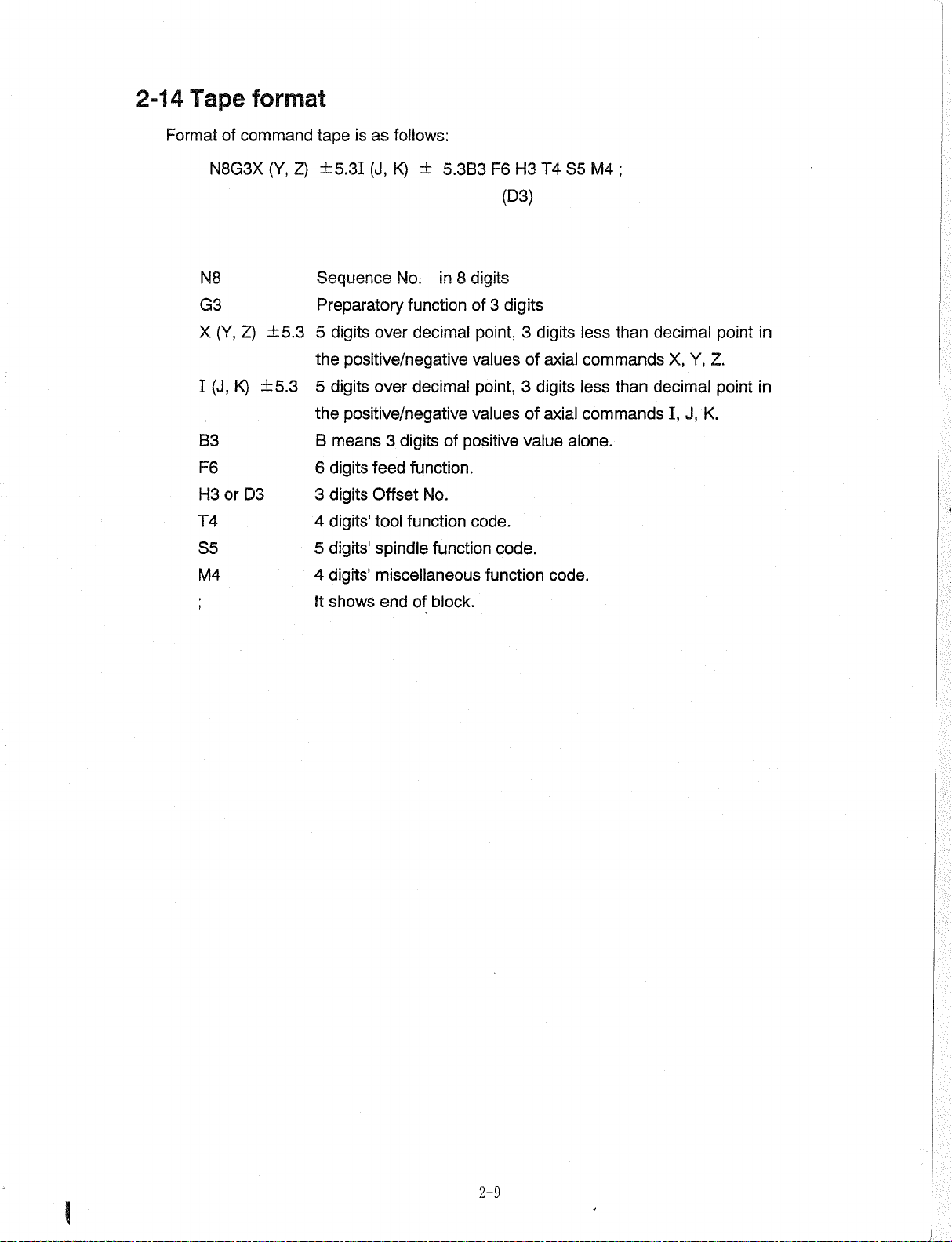

2-14

Tape

format

Format

N8

G3

X

I

B3

F6

H3orD3

T4

S5

M4

of

command

N8G3X

Z)

(Y,

(J,

K)

(Y,

±5.3

±5.3

tape

2)

±5.31

Sequence

Preparatory

digits

5

the

positive/negative

digits

5

the

positive/negative

B

means

digits

6

3

digits

digits'

4

digits'

5

4

digits'

shows

It

as

is

follows:

K)

±

(J,

No.

function

over

decimal

over

decimal

digits

3

feed

function.

Offset

tool

spindle

No.

function

function

miscellaneous

endofblock.

8

F6

digits

3

of

5.3B3

in

point,

values

point,

valuesofaxial

of

positive

code.

code.

function

H3

(D3)

digits

3

of

3

value

T4S5M4

digits

less

axial

commands

digits

less

commands

alone.

code.

;

than

than

decimal

X,

Y,

decimal

I,

J,

Z.

K.

point

point

in

in

2-9

Page 22

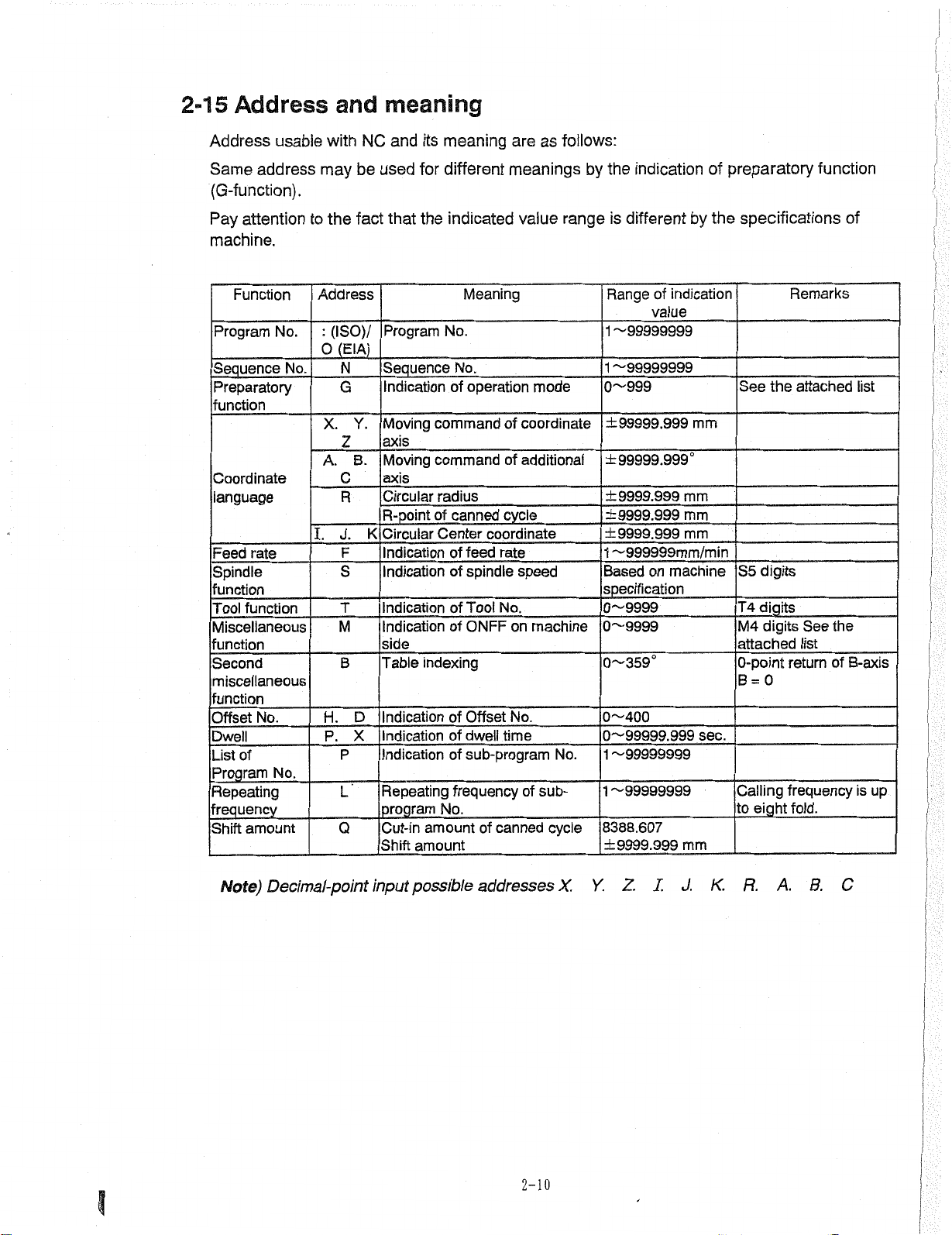

2-15

Address

Address

Same

(G-function).

usable

address

and

with

may

meaning

and

NC

used

be

meaning

its

for

different

are

follows:

as

meanings

by

the

indication

preparatory

of

function

J

Pay

attention

machine.

Function

Program

Sequence

Preparatory

function

Coordinate

language

Feed

Spindle

function

Tool

Miscellaneous

function

Second

miscellaneous

function

Offset

Dwell

List

Program

Repeating

frequency

Shift

No.

No.

rate

function

_

No.

of

No.

amount

the

to

Address

(ISO)/

:

(EIA)

0

N

G

X.

Z

A.

C

R

J.

I.

F

S

T

M

B

H.

P.

P

L

Q

fact

Program

Sequence

Indication

Moving

Y.

axis

Moving

B.

axis

Circular

R-point

Circular

K

Indication

Indication

Indication

Indication

side

Table

Indication

D

Indication

X

Indication

Repeating

program

Cut-in

Shift

that

the

indicated

No.

command

_

command

radius

of

Center

_

indexing

of

of

of

No.

amount

amount

Meaning

No.

of

operation

of

of

canned

of

of

of

of

frequency

cycle

coordinate

feed

rate

spindle

Tool

No.

ONFF

Offset

dwell

time

sub-program

_

canned

of

_

value

mode

coordinate

additional

speed

on

machine

No.

No.

of

sub-

cycle

range

Range

1

1

0~999

±99999.999

±99999.999°

±9999.999

±9999,999

±9999.999

1

Based

specification

0~9999

0~9999

0~359°

0~400

0

1

1

8388.607

±9999.999

the

indication

of

value

by

different

is

~99999999

~99999999

mm

mm

mm

mm

'~999999mm/min

on

machine

"-'99999.

~99999999

-99999999

999

mm

sec.

specifications

Remarks

the

digits

digits

digits

=

eight

0

attached

See

list

return

frequency

fold.

See

S5

T4

M4

attached

0-point

B

Calling

to

the

of

of

list

B-axis

is

up

Note)

Decimal-point

input

possible

addresses

2-10

X.

Y.

Z.

R.

J.

I.

K.

A.

B.

C

Page 23

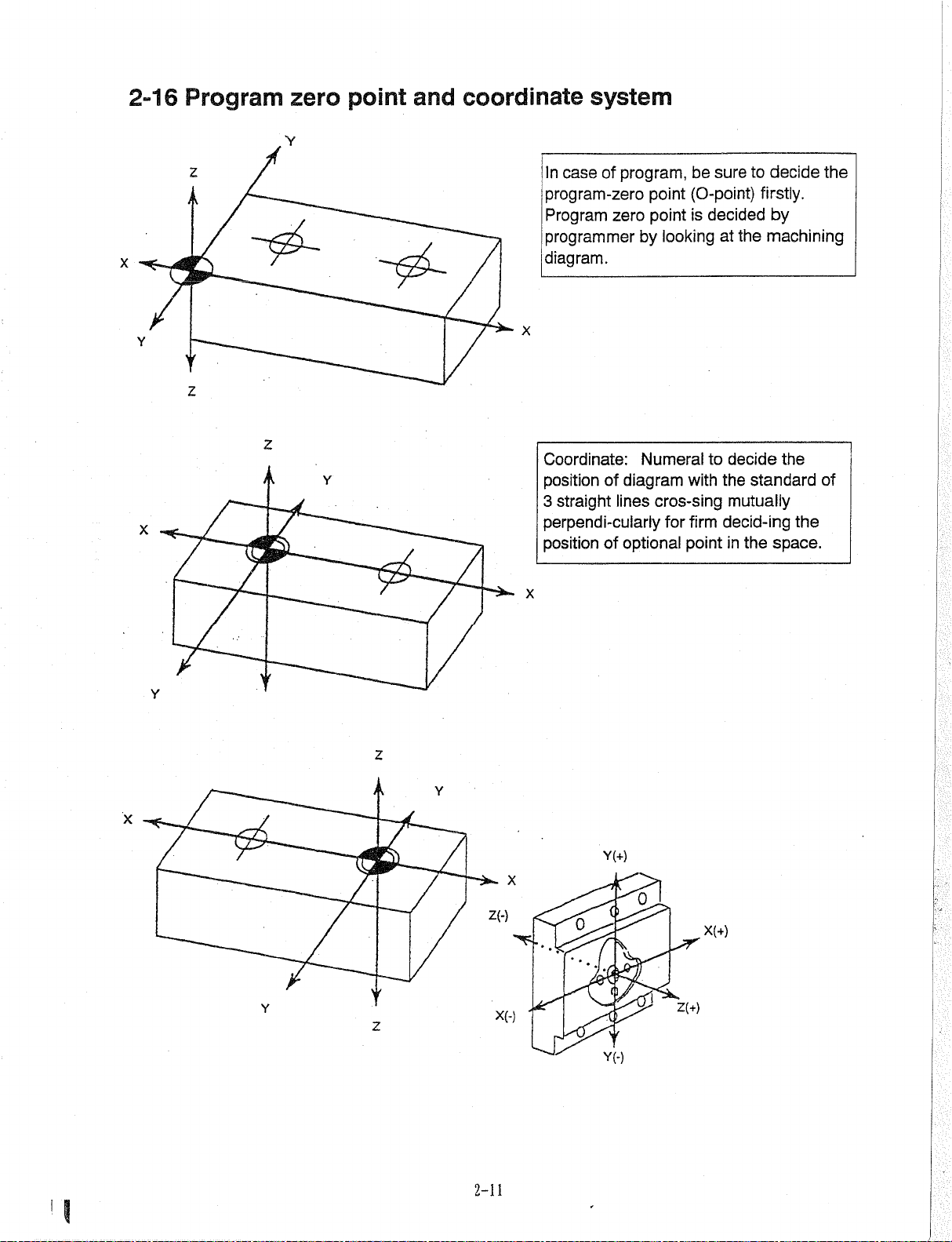

2-16

Program

zero

V

point

and

coordinate

system

z

X

Y

case

In

program-zero

Program

programmer

diagram.

X

program,

of

zero

by

point

point

looking

be

(O-point)

is

to

sure

decided

the

at

decide

firstly.

by

machining

the

z

z

decide

for

to

with

firm

point

the

mutually

decid-ing

in

of

diagram

lines

Numeral

cros-sing

Coordinate:

Y

*

X

position

3

straight

perpendi-culariy

positionofoptional

X

the

standard

the

the

space.

of

Y

Z

Y

X

Y(+)

X

Z(-)

X(+)

K

Y

t

z

X(-)

Y(-)

Z(+)

?

2-11

Page 24

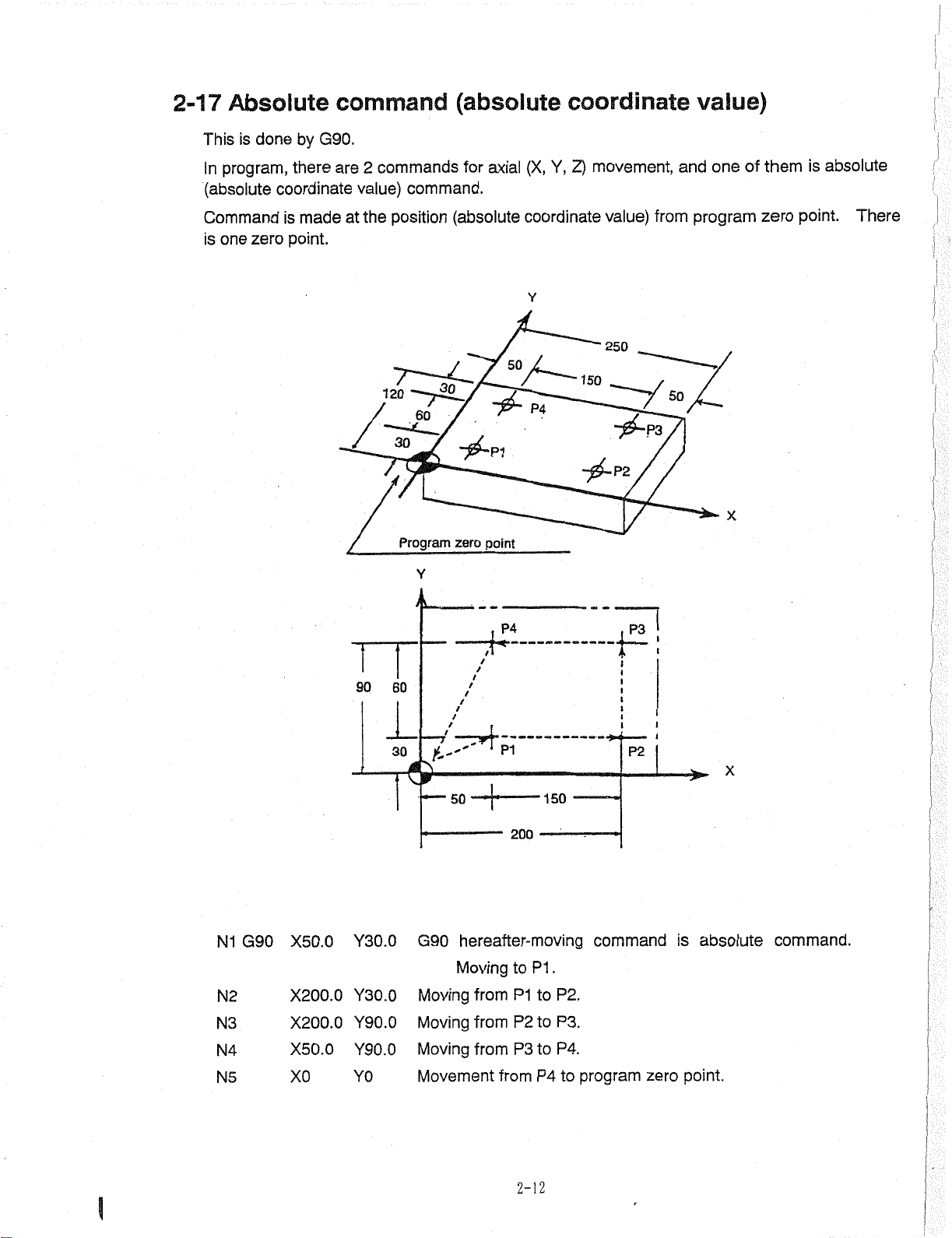

2-17

This

In

(absolute

Absolute

is

done

program,

there

coordinate

command

G90.

by

are

commands

2

value)

command.

(absolute

for

axial

(X,

coordinate

Z)

Y,

movement,

value)

one

and

of

them

is

absolute

1

r.

Command

zero

one

is

is

made

point.

at

the

120

position

30

.60

30

Program

Y

(absolute

,

-ÿ-P1

zero

point

P4

coordinate

Y

50

P4

value)

250

150

-ÿ-P2

from

50

program

X

zero

point.

There

I

N1

N2

N3

N4

N5

G90

X50.0

X200.0

X200.0

X50.0

X0

90

1

Y30.0

Y30.0

Y90.0

Y90.0

Y0

60

30

t''

&

—

G90

Moving

Moving

Moving

Movement

t

t

PI

200

to

P1

P2

P3

from

P1

to

to

to

P4

150

.

P2.

P3.

P4.

50

hereafter-moving

Moving

from

from

from

i

J

P2

commandisabsolute

program

to

zero

point.

X

command.

1

2-12

Page 25

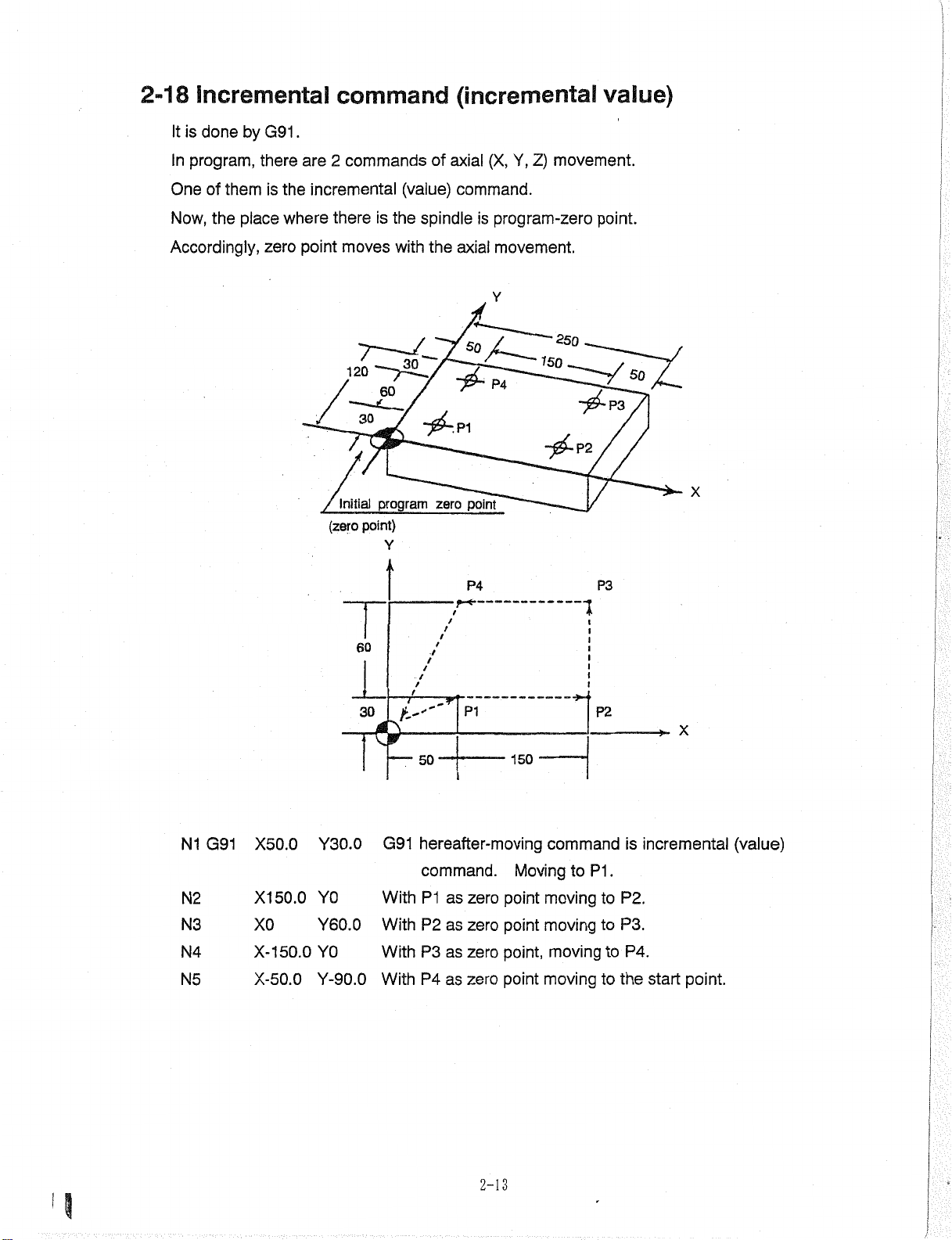

2-18

It

Incremental

is

done

by

G91

command

.

(incremental

value)

program,

In

of

One

Now,

Accordingly,

themisthe

the

place

there

where

zero

are

2

commands

incremental

there

point

moves

7

'

120

30

Initial

point)

(zero

60

of

axial

is

(value)

the

with

command.

spindle

the

axial

is

_

30

/

—

60

program

Y

-

~ÿ-.P\

point

zero

P4

/

t

/

/

movement.

Z)

Y,

(X,

program-zero

movement.

Y

250

150

P4

~ÿ~P3

-f£~P2

1

point.

SO

X

P3

N1

N2

N3

N4

N5

G91

X50.0

X150.0

X0

X-150.0

X-50.0

Y30.0

Y0

Y60.0

Y0

Y-90.0

30

t-''

50

*

—

hereafter-moving

G91

command.

P1

P2

P3

P4

as

as

as

as

With

With

With

With

PI

zero

zero

zero

zero

150

Moving

point

point

point,

point

P2

command

P1

to

moving

moving

moving

moving

to

to

to

is

incremental

.

P2.

P3.

P4.

to

the

start

X

(value)

point.

2—

3

1

Page 26

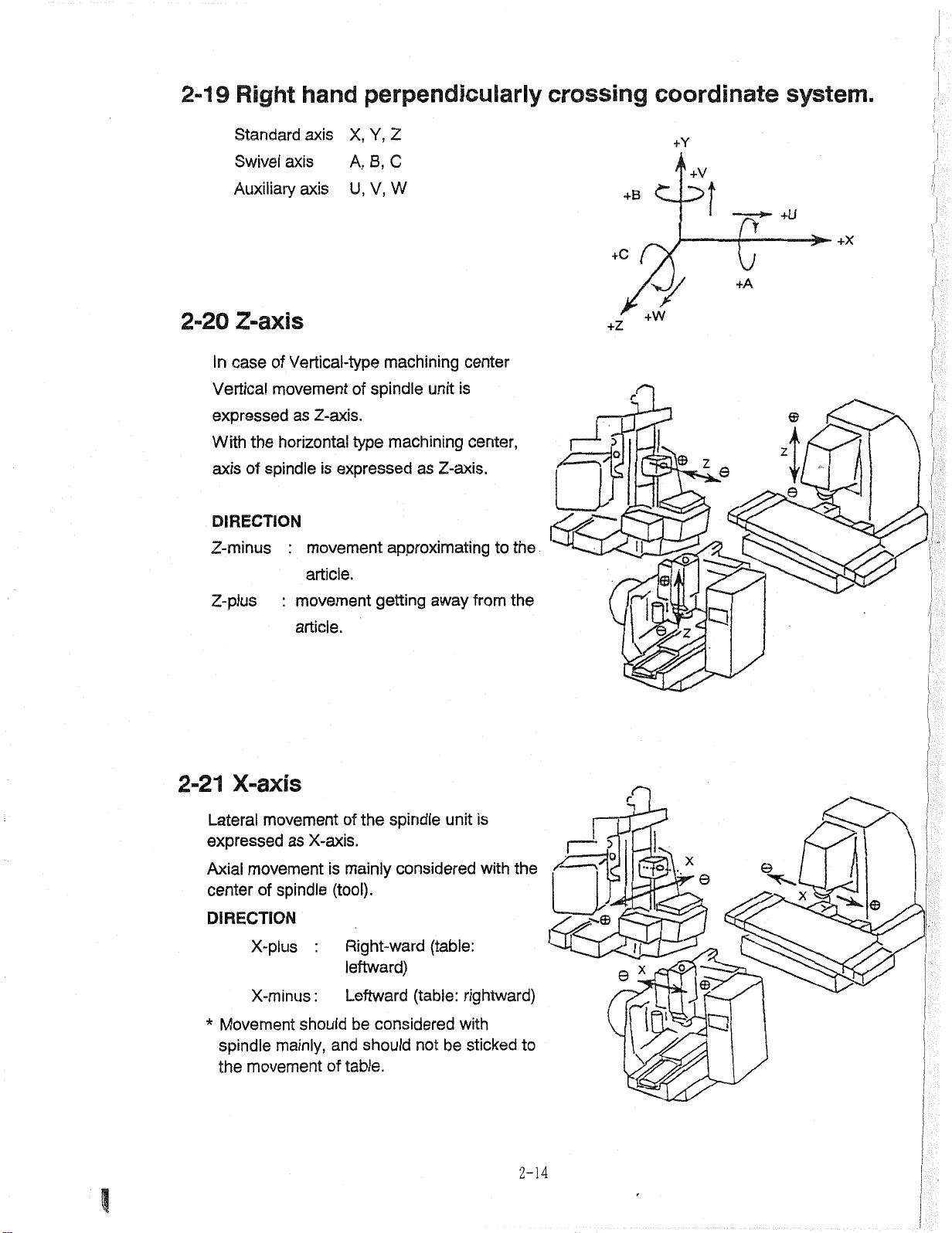

2-19

2-20

Right

Standard

Swivel

Auxiliary

axis

Z-axis

hand

axis

axis

perpendicularly

Y,

X,

Z

A,

B,

C

U,

V,

W

crossing

+B

+c

+z

coordinate

+Y

'k+V

u

+A

J/

+W

system.

+U

+x

In

Vertical

expressed

With

axis

DIRECTION

Z-minus

Z-pius

2-21

Vertical-type

of

case

movement

Z-axis.

as

horizontal

the

spindleisexpressed

of

:

movement

article.

movement

:

article.

X-axis

machining

spindle

of

machining

type

approximating

getting

unit

as

away

center

is

center,

Z-axis.

from

to

the

the

si

P

r

©

\

J

z

Le

Y

V,

©

Lateral

expressed

Axial

center

DIRECTION

*

movement

movement

spindle

of

X-plus

X-minus

Movement

spindle

the

mainly,

movement

as

X-axis.

is

(tool).

:

:

should

and

of

the

of

spindle

mainly

considered

Right-ward

leftward)

Leftward

be

should

table.

(table:

considered

not

unit

(table:

rightward)

with

be

is

with

sticked

the

to

2-14

.©

p

©

*

••To.

x

©

©

X

©

C3

\

Page 27

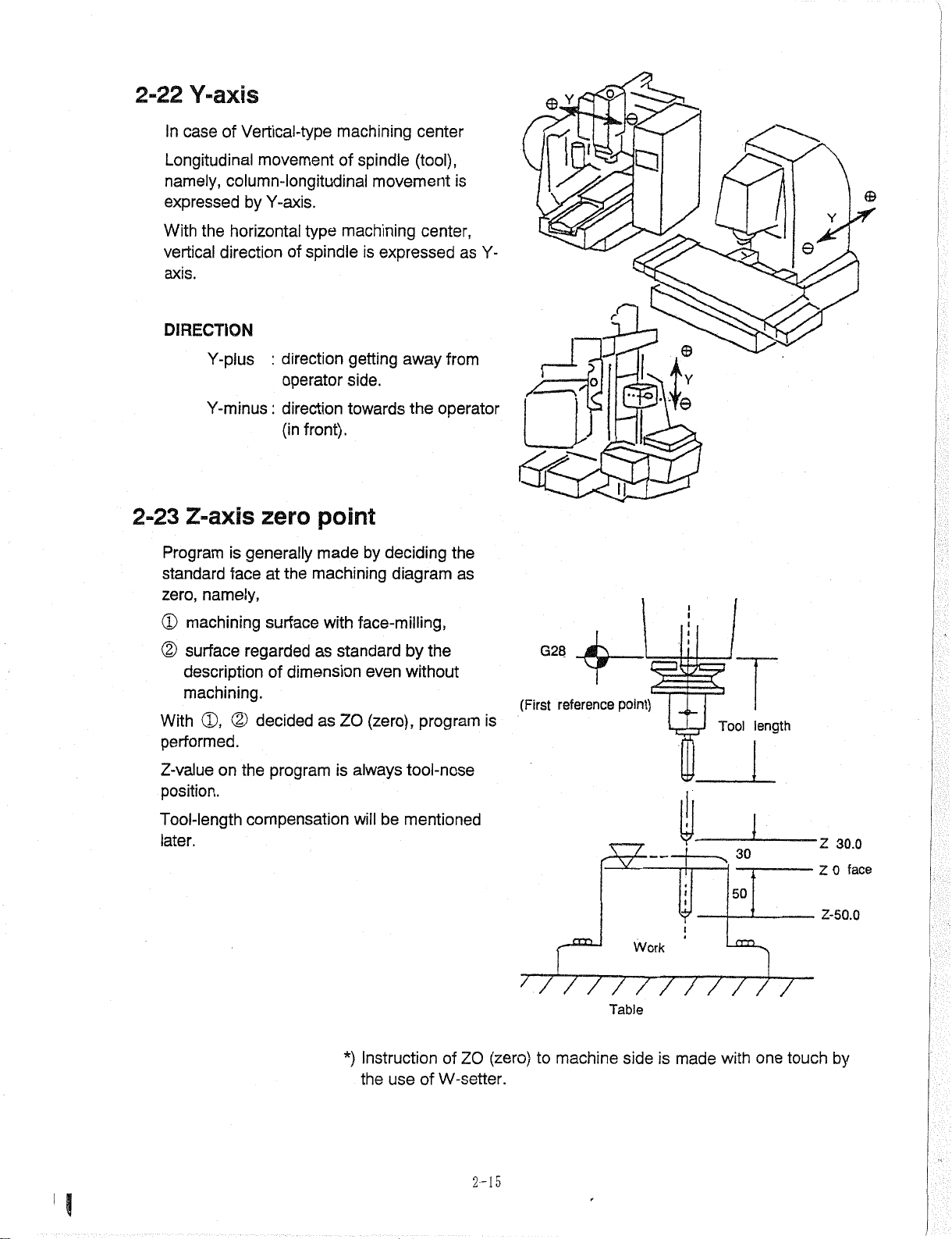

2-22

Y-axis

In

Longitudinal

namely,

expressed

With

vertical

axis.

DIRECTION

2-23

Program

standard

zero,

(D

©

With

performed.

case

Z-axis

machining

surface

description

machining.

Vertical-type

of

movement

column-longitudinal

by

Y-axis.

the

horizontal

direction

Y-plus

Y-minus

:

:

zero

generally

is

face

at

namely,

surface

regarded

of

(D,

decided

©

machining

of

type

machining

of

spindle

direction

operator

direction

front).

(in

point

made

machining

the

with

as

standard

dimension

as

ZO

spindle

movement

is

expressed

getting

side.

towards

away

the

by

deciding

diagram

face-milling,

by

without

even

(zero),

center

(tool),

is

center,

as

from

operator

the

as

the

program

Y-

is

m

\

G28

(First

$

reference

r

point)

C3

t

©

/>

Y

©

e

I

.

length

Tool

Z-valueonthe

position.

Tool-length

later.

compensation

program

is

always

will

*)

Instruction

the

tool-nose

be

mentioned

use

of

of

ZO

(zero)

W-setter.

2-15

/

/

machine

to

/

/

Table

side

Work

///////

is

made

30

50

with

one

touch

Z

30.0

0

Z

Z-50.0

by

face

Page 28

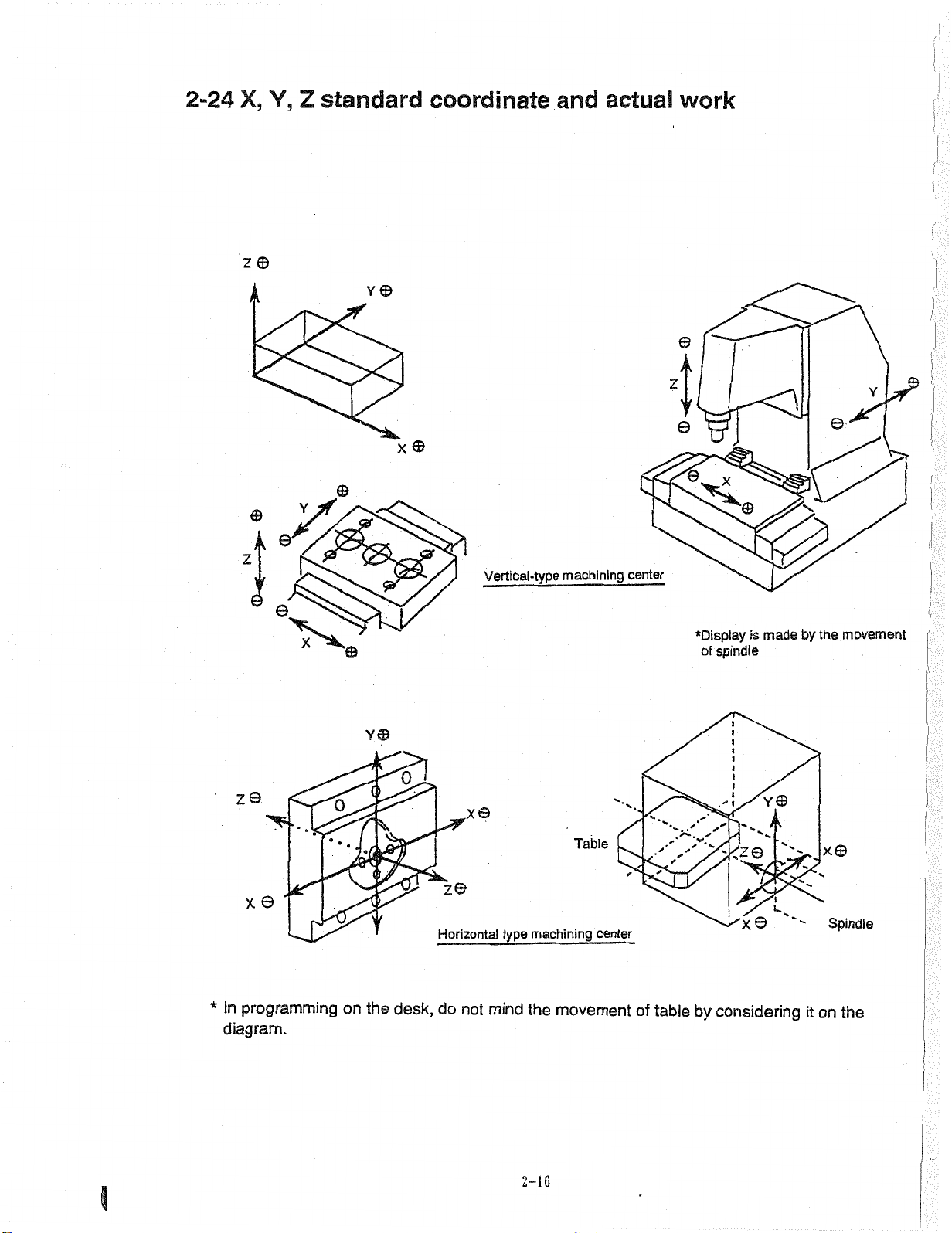

2-24

X,

z©

Y,

Z

standard

coordinate

Y

©

and

actual

work

A

z

Y

j

v

©

X©

e

Z

Z©

X

*

A

V

*

e'

©

>5

©

/J

X

0

’

©

Vertical-type

Y©

0

,x©

•

.

z©

Horizontal

type

machining

Table

machining

center

center

©

•Display

of

spindle

©

is

JÿX©

\

madebythe

Y©

X©

k

movement

Spindle

i

In

programming

*

diagram.

on

the

desk,

do

not

mind

the

2-16

movement

of

table

by

considering

on

it

the

Page 29

3.

M,

S,

T,

F,

FUNCTIONS

B

3-1

Miscellaneous

the

At

commandismade

stop,

rotation,

change,

with

Note

time

coolant

ON-OFF

etc.

2

digits

It

1)

M-function

block.

of

operation

ON,

within

usually)

is

impossible

(M-function)

this

of

spindle-rotation

with

mirror

OFF,

control

on

digits

4

following

to

2

over

make

pieces

machine,

image,

the

side

(machine

address-M.

the

command

on

table

of

for

the

start,

tool-

use

same

for

AAAA

M

MOO

M01

M02

S

M99

;

For

Spindle

Coolant

Spindle

Coolant

list

the

program

rotation

rotation

stop

M-functions,

of

ON

stop

ON

refer

to

M03

M08

M05

M09

the

attached

list.

G90

G43

M03

M08

ZO;

G01

M05

M09

V

GOO

G54

Z50.0

:

:

X300.0

:

:

H01

F250

X100.0

:

;

Y150.0

S1000

:

3-1

Page 30

3-2

Command

method

of

pallet

change

.

1

Note

Case

2.

Case

of

1)

Home

X-axis

<2>

(D

A

(D

The

@

The

(D

The

The

©

Program

2)

G91G28Z0

G28Y0

G30P3X0

M60

M60

1)

ofVSVS,

VK

position

3rd

pallet

slider

pallet

APC

position

example

is

executed

VS

at

reference

mounted

is

forwards.

has

door

of

the

been

closed.

is

the

the

in

change

pallet

point

the

on

completed

Z-axis

Z-axis

Y-axis

X-axis

Pallet

cycle

position.

and

table

to

notch

(The

G28.

machine

machine

reference

3rd

change

the

of

(G91

clamped.

either

turn

for

reference

reference

macro

G3OP3X0)

clockwiseorcounter-clockwise.

inserted.)

manual

point

point

program.

openlosed

point

is

!;

!

i

,

Program

1)

Note

Case

3.

APC

1)

Program

2)

example

G91G28Z0

G30P3Y0M60

G30P4Y0M60

1)

1)

M60

G91G28Z0

G28X0B0

M60

above

The

HG400

of

program

cycle

example

Z-axis

program

M

code.

performed

is

right.

-Y-axis

X-axis

point

G30P4Y0M60

or

G30P3Y0M60

or

the

following

a

operation

and

macro

the

program

type

executed

is

.......

calls

by

Changing

left

pallets

point

machine

3rd

pallet

4th

pallet

by

M60

without

reference

reference

change

reference

change

command,

disting-wishing

point

point

or

4th

3rd

or

point

andisexecuted

between

reference

reference

all.

;

the

(

3-2

Page 31

4.

CaseofHG500

type

1

There

.

Program

2.

1)

In

G91

G30

G30

1)

2)

3)

case

are

M60

M61

M62

M60

The

a

G28

P3

P4

kinds

three

cycle

.......

cycle

.......

cycle

.......

APC

of

Changing

pallets

left

pallet

pallet

on

in.

on

in.

A

carried

A

carried

programs

operation

and

the

machine

machine

follows:

as

performed

is

right.

carried

is

carried

is

example

cycle

contents

is

pallet

ZO

BO

YO

XO

YO

XO

left

M60

M60

of

side

M60

M60

canned

In

End

case

G91

G30

G30

cycle

pallet

a

G28

P4

P3

is

XO

XO

ZO

right

BO

YO

YO

side

M60M60'~.

out

out

without

left

side

right

side

disting-wishing

side

right

A

and

side

0

G91

pallet

A

right

A

A

1234

G28

XO

M06

left

left

YO

on

side.

side

ZO

machine

pallet

-

and

G28

M60

T01

out

between

pallet

pallet

is

carried

is

carried

the

is

is

in.

2)

In

case

In

G91

G30

G30

M61

The

case

The

G28

P3

P4

and

contents

pallet

a

contents

pallet

a

ZO

XO

XO

L

In

is

BO

YO

YO

M62

left

is

case

left

In

M60

M60

cycle

M61

of

M61

side

pallets

(ÿEncP)

of

M62

M62

side

pallets

case

canned

case

In

are

both

canned

case

In

are

both

cycle

a

sides

G91

G30

G30

cycle

pallet

a

sides

pallet

G28

P4

P3

is

is

ZO

XO

XO

right

right

YO

YO

side

BO

side

M60

M60

0001

0

G28

G91

XO

G28

M61—A

M98

-M62---A

P2345

M98

M30

ZO

YO

right

P1234’"Pr°gram

side

left

pallet

side

machining.

pallet

machining.

carried

is

for

carried

is

A

for'

B

in.

work

in.

Work

End

3-3

Page 32

5.

CaseofHS

type

1)

APC

1)

2)

Program

program

M60

cycle

example

G30

G91

BO

M60

a

following

pallets

ZO

P4

by

operation

and

the

right.

is

executed

Changing

.......

YO

XO

code.

M

is

performed

without

disting-wishing

between

the

left

i

:

;

{

I

r

l

3-4

;

i

Page 33

Command

3-3

Make

A.

5

digits

direct

following

method

command

the

address

for

of

spindle

S.

spindle

speed

by

speed

AAAAA

S

(S-function)

Command

B.

Programming

C.

Change

Spindle

Change

rotation.

Reverse

Spindle

Change

value

lower

to

rotation

spindle

rotation

stop

the

speed

example

feed,

speed

for

500

min*1

to

5000

rotation.

min*1

for

S45

/

S4500

S500;

M03;

S5000

M04;

M05;

S500

M03;

(45

(4500

min*1)

/

min'1)

3

Note

Note

Note

Note

Note

Note

1)

S-command

Whereas,

2)

3)

4)

5)

6)

S-command

With

set.

By

spindle

mode,

to

With

auto-mode

movement.

movement

Set

Simultaneous

axial

spindle

Changing

damage.

makes

case

in

rotation

thereafter,

command

after

stop

speed

speed

S-command

of

except

the

by

Simultaneous

the

high/low

in

with

for

auto-mode

with

auto-mode

rotating

for

of

end

gear

change

alone,

during

max/min

(MDI,

induce

will

the

spindle

axial

movement

commandofaxial

axial

movement.

speed

shift

area,

feeding

in

3-5

and

rotation,

spindle

Memory,

by

gear-shift

operation

spindle

change

speed,

“alarm".

manual

M03

with

does

the

upperower

spindleisstopped

tape),

is

or

not

again.

M04

allowed

mode

movement

operation

not

speed

will

is

rotate.

maxin

induce

with

made

for

rotation.

for

speed

can

by

rotation

will

fear

cause

of

tool

M05

automatically.

be

manual

with

Page 34

3-4

Tool

No.

call

:

(T-function)

A.

Command

generally)

address-T.

stand-by

the

code

This

commanded.

B.

Program

A

Case

Case

C.

positioning

While

coordinate

No.20,

Tool

is

of

is

example

calling

in

calling

in

operation

making

values

made

numerals

execution,

After

position,

effective

the

the

rapid

and

then,

within

in

and

until

Tool

Tool

No.20

feed

X200.0

is

it

4

digits

following

tool

arm

the

next

15

No.

absolute

to

Y150.0,

hold

(2

the

is

called

is

hold.

T

during

select

arm.

in

digits

is

the

to

T

T15

G90

AAAA

:

GOO

X200.0

Y15Q.0

T20:

Relation

D.

At

AtN2with

change

After

spindle.

Tool

E.

Then,

No.

N1

is

,

the

No.

with

T01

call

T01

operation

end

same

is

T_No.

same

the

change:

tool

.

spindle,

for

of

operation,

as

T01

is

with

as

make

tool.

with

~T30

Tool

automatic

T01

Magazine

kept

is

(*Magazine

by

No.

No.

)

at

the

N1

N2

Tool

isT

T01

:

M06

:

mounted

AA.

Magazine

on

V

No.

3-6

Page 35

F.

time

At

position

current

of

and

change,

tool

for

simultaneous

next

tools.

there

change

is

stand-by

of

the

calling

Case

position.

Simultaneously

spindle

and

stand-by

the

Y,

X,

G.

(Second

H.

Note

Z-axial

Precaution

There

1)

zero

Tool

with

change,

position.

positions

point)

tool

for

a

limit

is

No.15

x,

y-axial

Tool

at

change

on

the

to

stand-by

movement

No.15

timeoftool

tool

is

shape,

called

change

do

not

to

T15

(Actual

G54

(Case

(CaseofHG)

(CaseofVM)

other

use

;

programming

G90

GOO

VK)

of

tool

than

example)

X100.0

JG91

YO

G30

[G30X0Y0

G30

G91

P3

G30

limited.

S100

ZO

XO

XO

T15

ZO

;

Note

Note

2)

In

advance

3)

In

of

commanding

case

is

of

case

(ATC

M06

made

VM,

canned

VG,

to

TX

the

VK

and

cycle).

XM06

next.

HG,

of

spindle-tool

exchange

tool

again,

is

no

automatically

tool

exchange

by

done

is

done,

command

the

and

3-7

Page 36

Programming

3-5

example

of

tool

change

(Case

of

VM,

VK,

VS)

9

Note)

(Chip

M31

Keeping

spindle

T01

stand-by

T02

M06

(ATC

of

Case

M15

G91

G30

(TXX)

Case

TXX

G91

G30

G30

The

command.

With

the

By

ment

VK

;

G30

G91

M06

VM,

of

;

G30

P3

XO

XO

P2

above

the

order

adding

of

cycle)

;

;

VS,

-*

X.

option,

is

X

start)

operation,

tool

can

conveyor

tool-change

canned

;

ZO

Y0M19;

;

VS

P2X0ZOM1O6;

M06

M107

operations

VM,

of

Z

the

and

Z

performed

are

exchange

simultaneous

be

done.

is

by

M06

done

move¬

in

01234

G17G40

N1

;

T01

M06

T02

;

G54 G90

Z30.0

G43

;

M03

Machining

;

N2

T02

M06

;

T03

G54

G90

G43

Z30.0

;

M03

Machining

;

N8

M06

T08

;

T01

G90

G54

Z30.0

G43

Machining

S

G28

G91

XO

G28

;

M30

;

M31

G80

;

GOO

XO

H01

;

X100.0

GOO

H02

program

;

GOOXOYO

H08

program

;

ZO

YO

;

;

S300

YO

;

program

;

S800

;

;

Y-50.0

;

S1000

;

3-8

i,

Page 37

3-6

Programming

example

of

tool

change

3-6-1

1

.

1)

2)

3)

2.

1)

0

0098

G40

G91

G30

G90

Case

There

Program

are

ATC

position

A

method

A

method

the

ATC

Performing

Registered

M19

G80

G30

ZO

XO

YO

M99

HG

of

kinds

three

return

of

using

performing

of

time)

example

ATC

sub-program

as

M09

of

is

performed

ATC

position

program

ATC

canned

position

ATC

return

of

of

main

by

(available

cycle

return

sub-program.

by

position

ATC

follows:

as

HG

sub-program.

or

by

arm

and

return.

O

G91

G28

M98

T01

G54

changing

swing

1234

G28

XO

YO

P98

M06

G90

Machining

.....

parameter)

the

operation,

ZO

GOOXOYO

program

(effective

S300

102

to

save

A

method

2)

Registered

M15

G30Z0M19

G91

XO

G20

TXX

YO

M06

of

as

using

ATC

canned

ATC

canned

cycle

cycle.

in

SEICOS.

M98

T02

1234

O

G91

G28

T01

G54

T02

P98

M06

ZO

G28

XO

YO

M06

GOO

G90

.Machining

M06

XO

YO

S300

program

102

1

3-9

Page 38

Performing

3)

The

(D

(2)

(3)

Note

Note

contests

Axes

position.

M09,

Arm

Axis

position.

1)

Operation

feed

2)

Take

interfere

ATC

of

X,

M05,

swing

comes

override

care

position

the

operation.

of

Y,

are

Z

are

M19

operation

40mm

to

3)

of

will

is

that

tool

fixture

with

return

returned

performed.

be

will

before

be

done

100%.

noses

and

so

and

to

start

the

when

do

on.

ATC

ATC

not

arm

when

rapid

swing

Z

operation

1234

0

G91

G28

G28

XO

G30

G91

G90

G54

s

G80

G30

G91

s

a

time.

at

Z0

Y0

X0

Y0

Z0

XO

GOO

.Machining

XOYO

ZO

T01

S300

YO

program

T02

\

M06

TO2

M06

3-10

\

Page 39

3-6-2

Case

of

HS

This

operated

is

Fixed

M06

N1

G30Z0M115

cycle

N2G30Y0P3X0TXX

N3

N4

N5

N6M116

XO

G30

M06

P3X0M107

G30

[Explanation]

X

:

Spindle

Calling

Spindle

M106:

TX

by

ATC

position

waiting

tools

fixed

M106

deciding,

position

instantly

=

cycle

registered

shutter

of

tools

completed

in

close

called.

by

SEICOS.

O

G91

G28

T01

G54

l

T02

,

tools

x

TX

command.

1234

ZO

G28

YO

XO

M06

GOOXOYO

G90

S

Machining

S

M06

temporary

|

stop

S300

W

arm

T02

swing

spindle.

M06:

M107:

Note

Note

W

arm

W

arm

1)

P3

Kindsoftools

2)

position

XO

turn

swing

-*•

return

differs

are

tools

set

fixing.

-*

shutter

according

on

tool

layout

closed.

to

kinds

screen.

of

tools.

Be

sure

to

set

the

kind.

3-11

Page 40

Command

3-7

method

of

feed

speed

(F-function)

A,

Command

Commanded

interpolation,

B.

speed

ing

Actual

by

the

1

~5000.

program

Note

1)

Be

on

Note2)F-unitisthe

per

Note

3)

It

It

Note4)The

machine

Synchronous

the

distance

points

also,

numerals

sure

G01,

minute,

possible

is

called

is

range

feed

between

or

linear

by

command

put

to

G02,

moving

namely,

to

"reading

F-function

of

specification.

speedofplural

the

1

~999999

AAAA

F

G03.

omit

zero".

2

circular

moving

follow¬

amount

mm/min.

the

"0"

of

which

axes>

(mm)

upper

can

Command

F0001

F1

F0010

F0100

F5000

G01

G02

G03

digit

be

actually

X150-0

X200.0

X250.0

by

numeral.

commanded

1mm/min

F80

:

Y300.0

Y50.0

Actual

(minimum)

1mm/min

0mm/min

1

100mm/min

5000mm/min

R50.0

R100.0

depends

F4QQ

E3Q0

speed

;

;

on

the

Cutting

straight

case,

this

In

and

the

Example

The

The

cutting

The

When

axis

a

by

Example

The

But,

feed

lines.

cutting

G01

cutting

cutting

rotation

degree

cutting

speed

cutting

the

feed

feed

feed

feed

axis

unit,

L

=

commanded

feed

speed

G91

G01

V

Xa

speed

speed

speed

is

commanded

linear

and

G91

speed

feed

100.ÿ+90.ÿ

by

F

in

in

in

speed

of

Yb

the

the

the

is

each

axis

Zc

directionofX-axis

direction

direction

compensation

X100.

the

in

(mm)

becomes

code

composite

the

as

is

;

Ff

of

of

same

the

in

C90.

direction

follows.

Y-axis

Z-axis

is

made.

F200

rotation

of

speed

Fx

Fy

Fz

block,

;

that

=

=

=

it

tools

of

of

aXf

L

bXf

—

—

c*f

regarded

is

axis

which

axes

the

but

(C-axis)

on

move

commanded,

L

as

Fc

ak+b2+c2

V

=

straight

90.X

=

the

line

200

L

Ending

:

point

point

3-12

Page 41

3-8

Table-indexing

command

method

(B-f

unction)

HG

series

Command

By

machine

With

Rotationismade

the

specification,

absolute

BOO

B180

BOO

B90

B270

table

command,

rotation

minimum

B00~B359

short-circuit

by

address-B

direction

and

indexing

°

)

(1

(the

angle

the

is

left

B270

3-digit

numeral.

is

1

standard.

diagram

°

(

JTL

.

shows

B180

BOO

Spindle

the

case

B90

of

180°

).

B90

BOO

J!L

Spindle

position

Waiting

pallet

$

I

position

BOO-

i

J+L

Spindle

3-13

Page 42

;

r

.

Page 43

4-1

G

4.

G-FUNCTION

AAA

(preparatory

function)

]

it

shows

the

numeral

following

G.

That

concerning

Refer

to

list.)

meaning

the

of

Address

is,

it

is

the

list

of

digits

3

a

preparatory

the

movement

of

G-functions.

program-command

(usually

digits)

2

function

of

spindle

(The

attached

by

(tool).

GOO

G01

G02

G03

Positioning

Linear

Circular

Circular

interpolation

interpolation

interpolation

(rapid

feed)

(cutting

CW

CCW

feed)

'1

4-1

Page 44

4-2

GOO

called

is

It

rapid

next

the

(Positioning)

feed

rapid

is

feed

destination

made

from

or

rapid

the

(X,Y,Z).

traverse,

present

and

position

to

Y

A

Howtowrite

1)

Note

The

necessarily

2)

Note

Rapid

type

the

route

traverse

machine.

of

program

moving

at

limited

rate

time

the

to

different

is

is

not

straight

by

line.

the

40

Z

GOO

40

Current

X80.0

Y

A

position

Y40.0

Destination

80

X

.

.

50

+

:

Note

Note

3)

Movement

following.

Absolute

Incremental

4)

commanding

After

omit

to

may

command

command

efficacy

by

different

be

once,

(called

G90

G91

it

by

the

is

possible

modal).

about

Absolute

G90

command

GOO

X40.0

Incremental

GOO

G91

X40.0

45°

Y40.0

X80.0

command

Y40-Q

X40.0

40

Y40.0

Y0

X

80

:

:

4-2

z

Page 45

4-3

G01

(Linear

interpolation)

called

It

linear

position

Feed

linear

movement

to

(feed

rate

Howtowrite

a

moving

F

is

Example

cutting

the

next

program

amount

or

is

made

destination.

function)

(mm/min)

Start

point

cutting

from

F

is

necessary.

250

il

-f

“

feed,

the

per

1

4

100

and

current

minute

40

250

Current

position

400

t

™5*--

©

G01

G91

300

1t

50

I

100

50

200

10

T

150

clear

arrow

Put

40

mark.

X400.0

2

3

F200

Destination

43

X©

;

Start

1

2

3

4

point

-*

-*•

-*•

Rapid

1

positioning

Movement

2

speed

3

Rapid

4

Movement

speed

Starting

Return

by

point

rapid

traverse

by

traverse

by

the

to

traverse

rate

cutting

cutting

start

rate.

point

4-3

G91

GOO

X1

G01

X300.0

G00Y-100.0

G01X-300.0

G00X-1

00.0Y-1

00.0

F300

;

F300

50.0

Y250.0;

;

;

;

Page 46

4-4

G02,

G03

(circular

interpolation)

Rotary

It

direction

circle

Circular

Howtowrite

is

direction

called

(arc)

radius

circular

in

towards

X

Y_

cutting,

feed

the

Coordinate

(destination)

rate

the

is

commanded

program

and

moves

it

AAAA

F

commanded

with

end

of

value

along

point.

"R".

point

to

the

the

+Z

G02

G03

axis

X_

X_

G03