Page 1

TURNING CENTER

ST200/250

INSTRUCTION MANUAL

64 OPERATION

SEICOS - pcFlexi

Version 1.01 BO-1782-1-0300-E-1-01

Hitachi Seiki Deutschland

Werkzeugmaschinen GmbH

Page 2

Page 3

Introduction

Thank you for your having purchased the machine, favoring our product lines for your use.

This manual contains fundamental information on the machine operation. Please read and fully

understand the contents for your safe machine operation.

In particular , the contents of the items concerning safety in this manual and the descriptions on the

“caution plates” attached to the machine are important. Please follow the instructions contained

and keep them always in mind to ensure safe operation.

The reference record papers on adjusting setting values such as a parameter list are attached to

the machine unit and enclosed in the packing. These are necessary for maintenance and

adjustment of the machine later on. Please keep them safely not to be mislaid.

The design and specifications of this machine may be changed to meet any future improvement.

As the result, there may arise some cases where explanations in this manual could become partly

inconsistent with the actual machine. Please note this point in advance.

In this manual, items on the standard and optional specifications are handled indiscriminately.

Please refer to the “delivery note” for the detailed specification of your machine confirmation.

Page 4

Page 5

CONTENTS

1 OPERATION OF MACHINE.................................................................. 1 - 1

1. Daily Maintenance.............................................................................................................1 - 1

2. Explanation of Outline of Main and NC Operation Panel..................................................1 - 2

2-1 Main Operation Panel................................................................................................1 - 2

2-2 NC Operation Panel ................................................................................................ 1 - 11

2-3 Chip Conveyor Operation Panel..............................................................................1 - 14

3. Procedure of Machine Operation....................................................................................1 - 15

3-1 At the Time of Start.................................................................................................. 1 - 15

3-2 Warming-up Operation of Spindle ...........................................................................1 - 16

3-3 Procedure of Zero Return........................................................................................ 1 - 17

3-4 At the End of Operation...........................................................................................1 - 18

4. Manual Operation ...........................................................................................................1 - 19

4-1 Feed of Each Axis.................................................................................................... 1 - 19

4-2 Operating Method of Q-setter ................................................................................. 1 - 21

4-3 Q-setter Repeat Function ........................................................................................ 1 - 29

4-3-1 Procedures ........................................................................................................... 1 - 29

4-3-2 Function Key.........................................................................................................1 - 30

4-3-3 Working ................................................................................................................1 - 30

4-3-4 Relevant Parameters ............................................................................................ 1 - 33

4-3-5 Relevant Alarms.................................................................................................... 1 - 34

4-4 How to Shape Soft Jaw ........................................................................................... 1 - 35

4-4-1 Simple Jaw Edge Forming Function..................................................................... 1 - 35

4-4-2 Soft jaw forming by manual operation .................................................................. 1 - 41

4-5 Manual Type Tailstock ............................................................................................. 1 - 44

5. Operation by Manual Data Input (MDI) ...........................................................................1 - 46

5-1 Program input by MDI ............................................................................................. 1 - 46

5-2 Edition of MDI program ........................................................................................... 1 - 48

5-3 Operation of MDI program....................................................................................... 1 - 49

6. Registration of Program..................................................................................................1 - 50

6-1 Registration from an external device.......................................................................1 - 50

6-2 Manual registration by the address/numeral keys...................................................1 - 51

7. Program No. Search .......................................................................................................1 - 53

7-1 Search by key in a program No...............................................................................1 - 53

7-2 Search to utilize the program list. ............................................................................ 1 - 54

8. Edition of Program ..........................................................................................................1 - 55

8-1 Preparation in Advance at the Time of the Edition of Program. .............................. 1 - 55

8-2 Search of Word ....................................................................................................... 1 - 56

8-3 Edition of Program................................................................................................... 1 - 58

8-4 Back Ground Editing ............................................................................................... 1 - 63

8-5 Copy of Program ..................................................................................................... 1 - 64

i

Page 6

8-6 Range Assignment Edit Operation (Program Screen Only)....................................1 - 65

8-7 Word Convert (Program Screen Only) .................................................................... 1 - 67

8-8 Deletion of Program ................................................................................................ 1 - 69

8-9 Process After Edition ............................................................................................... 1 - 70

9. Output of Program ..........................................................................................................1 - 71

10. Setting of Tool Compensating Amount............................................................................1 - 73

10-1 Setting of Tool Compensating Amount .................................................................... 1 - 73

10-2 Deletion of Tool Compensating (Setting Amount) ................................................... 1 - 75

11. Setting of Work Offset ....................................................................................................1 - 76

11-1 Tool Tip Position Setting of Standard Tool at Machine Zero Point...........................1 - 76

11-2 Setting of 2nd Reference Point ...............................................................................1 - 78

12. Automatic Operation .......................................................................................................1 - 79

12-1 In Case of Machining of the First Workpiece with Confirmation of Newly Produced

Program................................................................................................................... 1 - 79

12-2 Start from Middle of a Program ............................................................................... 1 - 81

12-3 Continuous Machining Operation ............................................................................ 1 - 82

12-4 In Case of Insertion of Manual Operation During Automatic Operation .................. 1 - 83

12-5 In Case of MDI Operation in Middle of Automatic Operation .................................. 1 - 84

13. Setting (Data)..................................................................................................................1 - 85

13-1 Stored Stroke Limit .................................................................................................. 1 - 85

14. Operation status, Date and Time....................................................................................1 - 87

14-1 Operation status ...................................................................................................... 1 - 87

14-2 Date and Time ......................................................................................................... 1 - 88

15. Plot..................................................................................................................................1 - 89

15-1 Plot .......................................................................................................................... 1 - 89

15-2 Plotting Parameters.................................................................................................1 - 90

16. Parameter Setting...........................................................................................................1 - 94

ii

Page 7

1 OPERA TION OF MACHINE

1. Daily Maintenance

To keep the machine in the good condition any time, taking precautions against the machine

troubles, it is the most important to maintain and check the machine periodically as well as to

check daily .

Checking servicing should be done based on the chapter 2 “Daily checking Items List” of

“Maintenance Manual”

1 - 1

Page 8

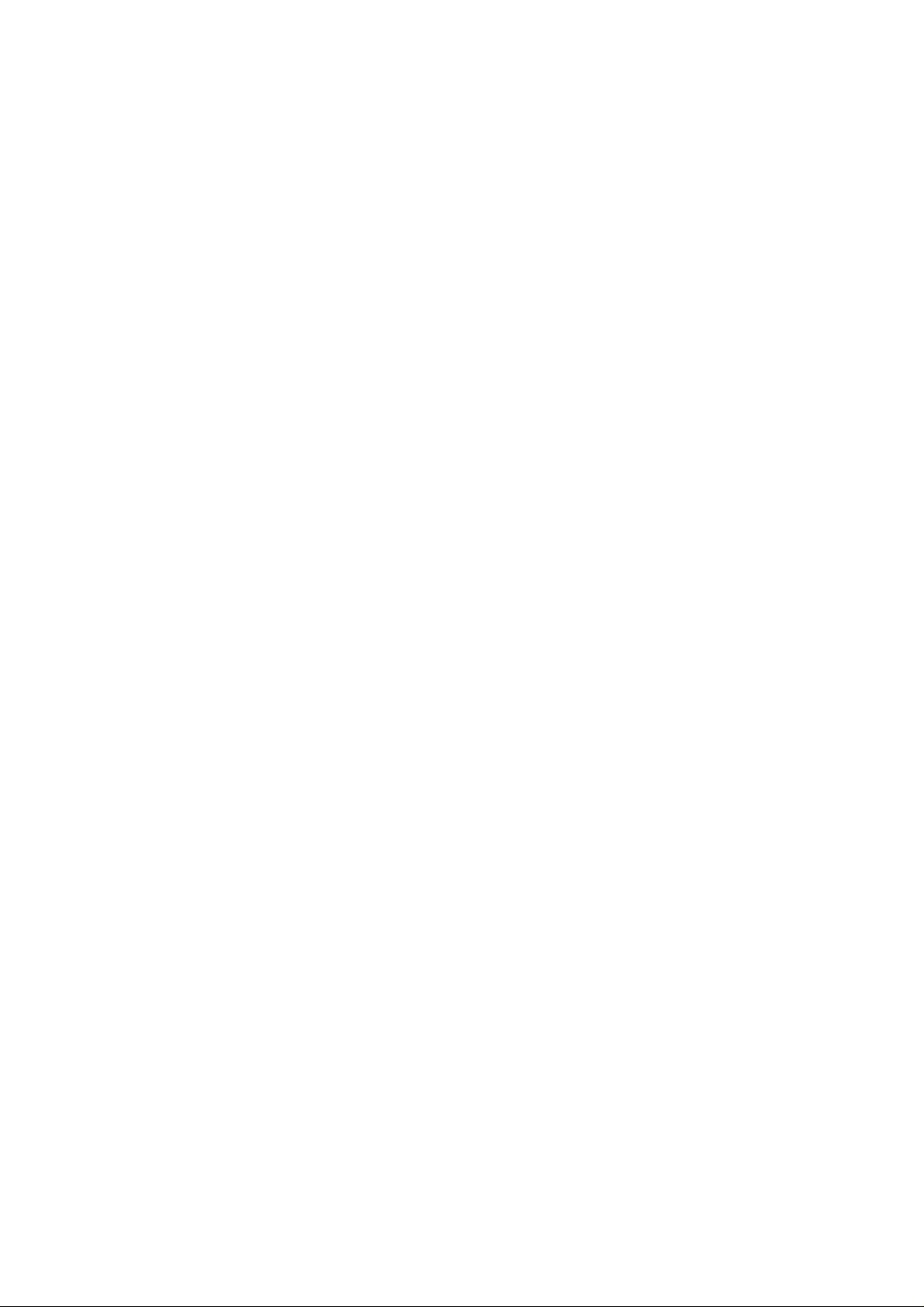

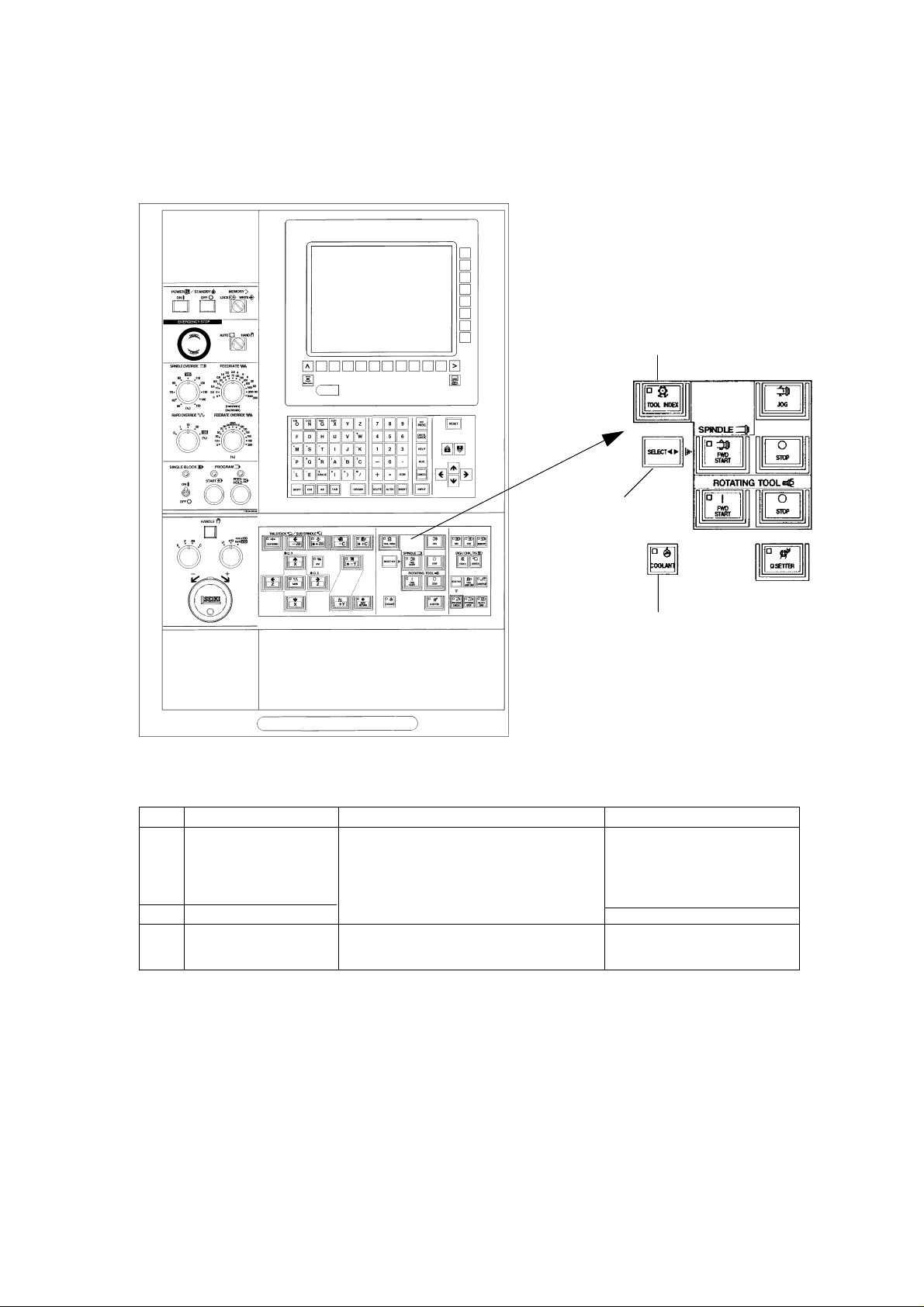

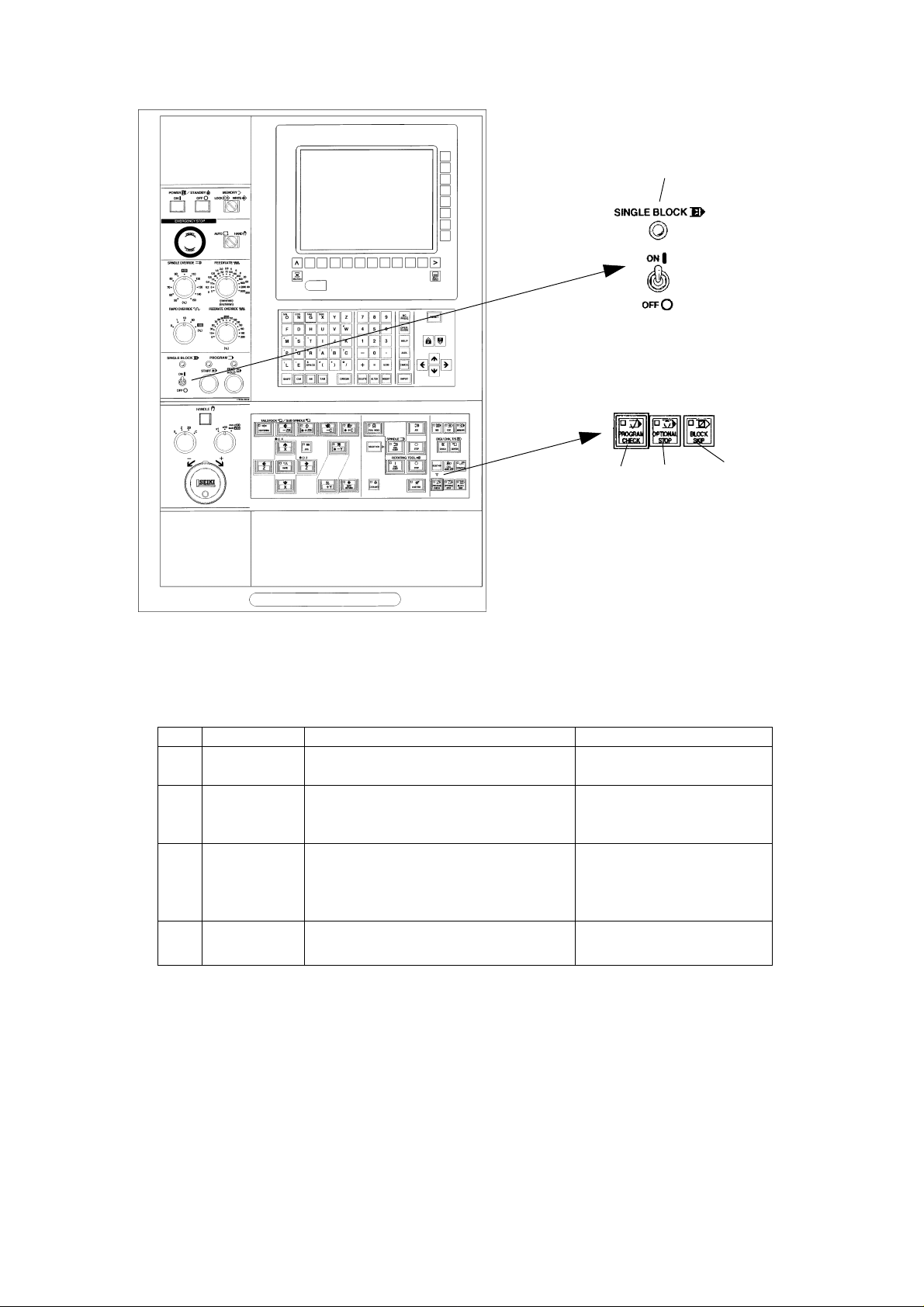

2. Explanation of Outline of Main and NC Operation Panel

2-1 Main Operation Panel

[3]

[1]

[2]

No. Name Function Remarks

[1] POWER ON/ The power of NC unit is ON./Make the The power ON lamp lights.

STANDBY machine condition ready to operate.

[2] EMERGENCY Make the machine condition impossible to Emergency stop is displayed on

STOP BUTTON operate. the upper left of the screen.

(However, the hydraulic pump does not

stopped.)

Stop a section under operation.

(Clear or discontinue the contents.)

[3] POWER OFF The power of NC unit is OFF.

1 - 2

Page 9

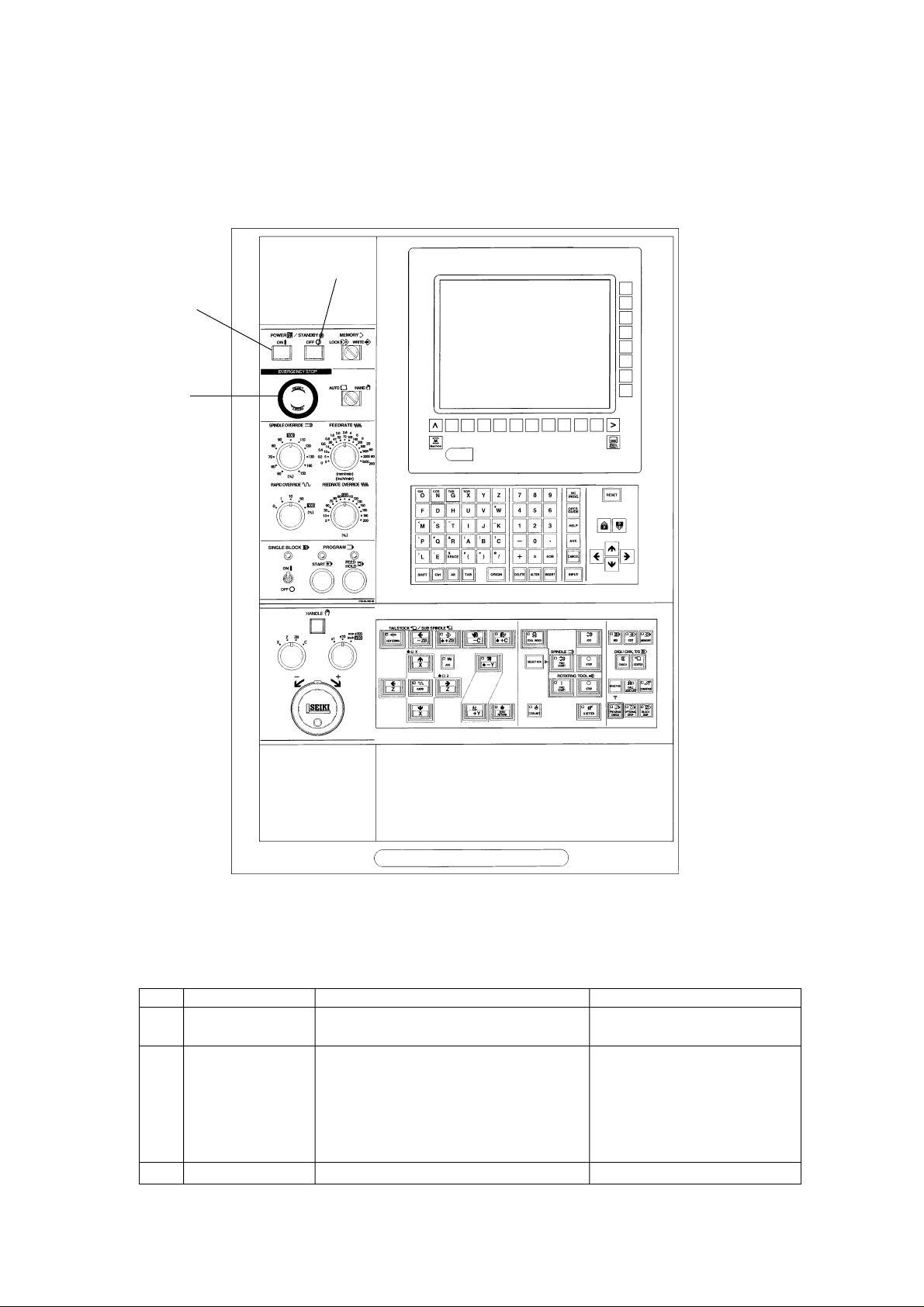

[1]

No. Name Function Remarks

[1] MEMORY Select the effective or ineffective of Set to the lock and pullout the key

editing operation of program and after edition.

parametor.

1 - 3

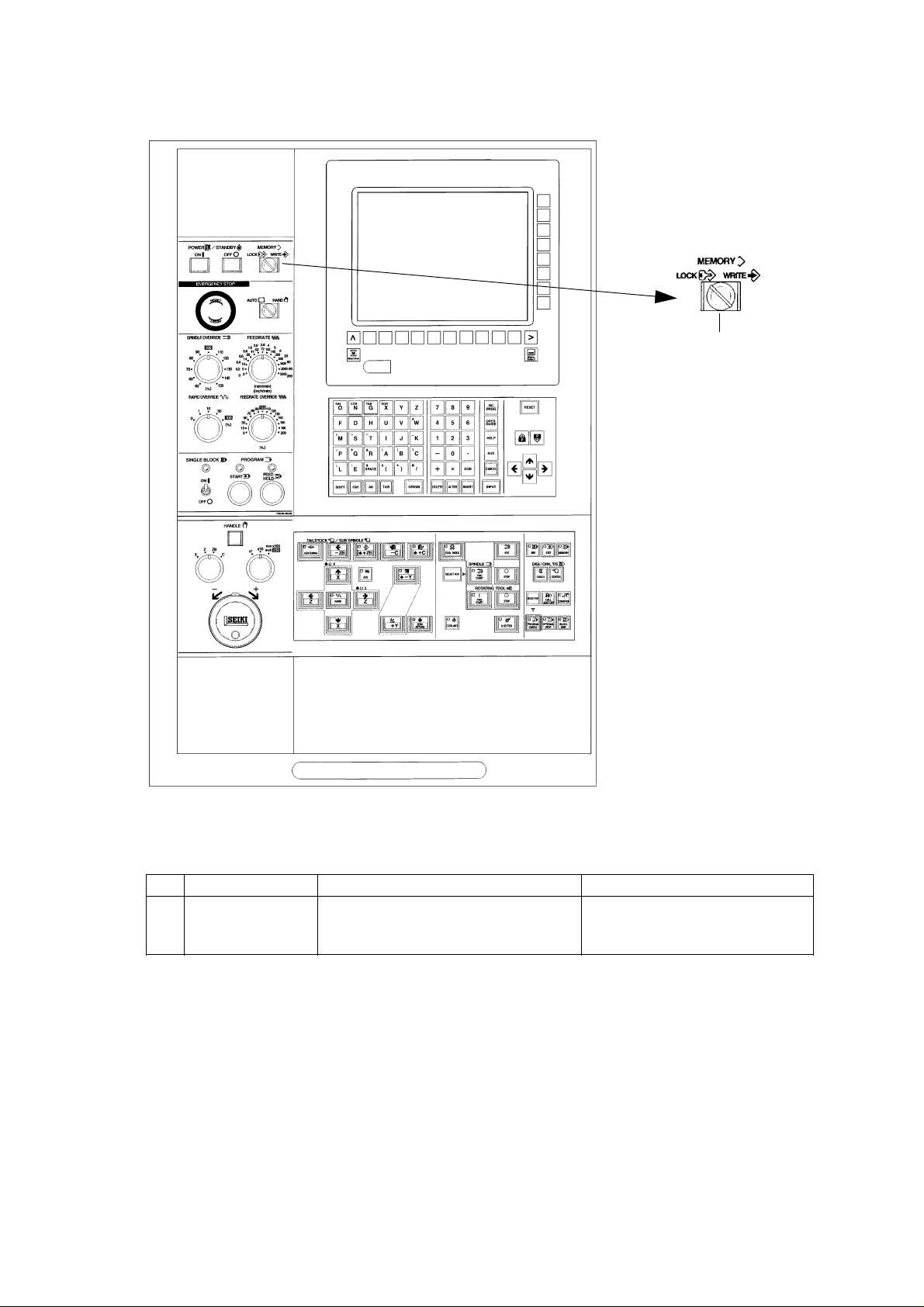

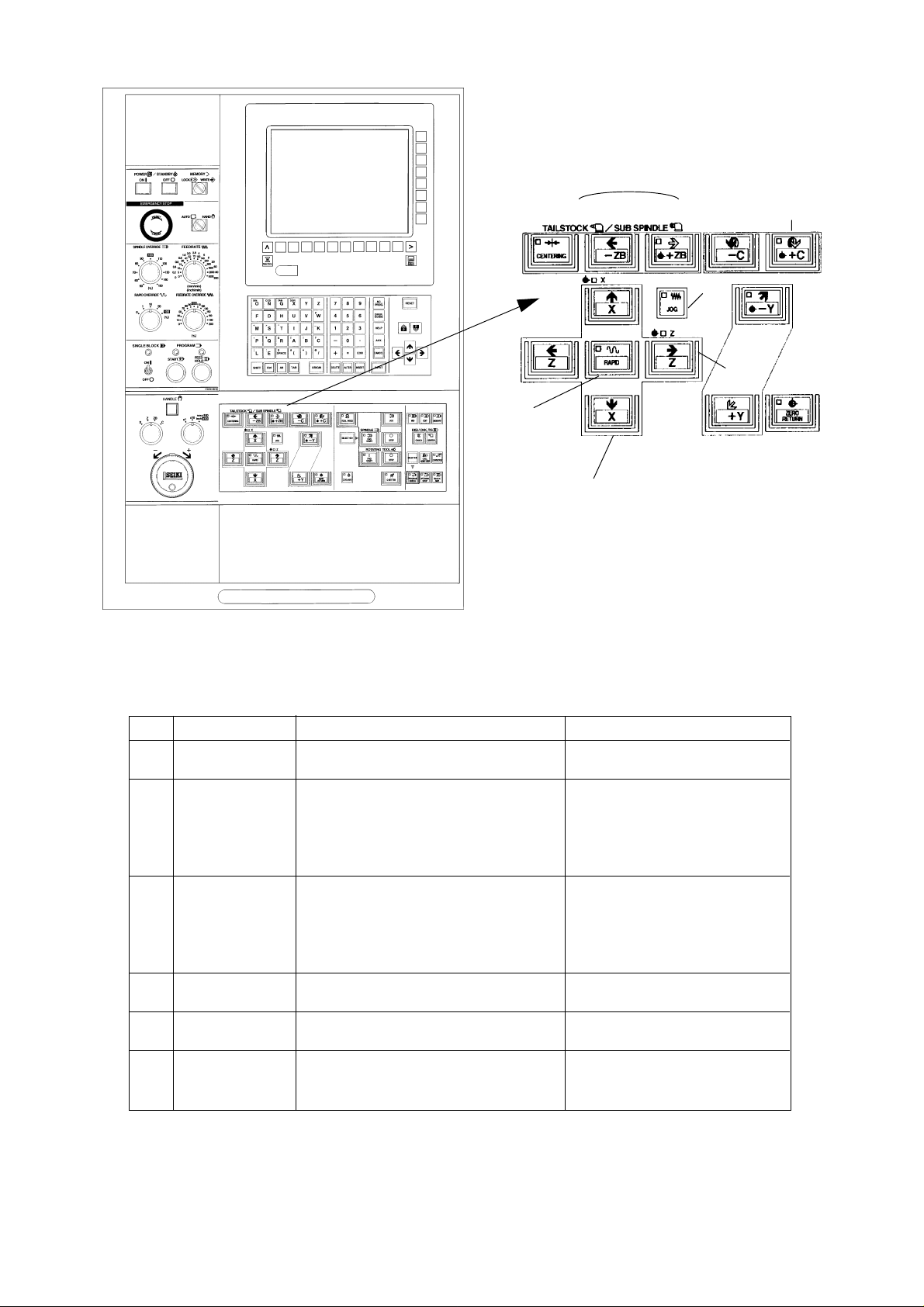

Page 10

[2] [3] [4]

[1]

[5]

[6] [8]

[9]

No. Name Function Remarks

[1] ZERO RETURN Return to the reference point in the order At the time of power on, please be

KEY of X and Z axes. sure to perform a return to the

reference point.

[2] CENTER Advance the tailstock continuously. When the spindle is stopped.

FORWARD KEY

[3] CENTER JOG KEY Advance the tailstock while pressing. Effective in manual and memory

mode.

[4] CENTER Retract the tailstock while pressing. Effective in manual and memory

RETRACT KEY mode.

[5] SPINDLE SELECT Press this key simultaneously when

KEY forward or reverse the spindle.

[6] SPINDLE FWD The spindle rotates forward by pressing There are interlocks of the door

START KEY with the SPINDLE SELECT key and chuck and tailstock.

simultaneously when manual mode.

[7] SPINDLE JOG ON The spindle rotates while pressing. The function interlocked with

KEY tailstock.

[8] SPINDLE STOP The spindle stops when manual mode

KEY

[9] CALL LIGHT OFF Turn off the call light.

KEY

[7]

1 - 4

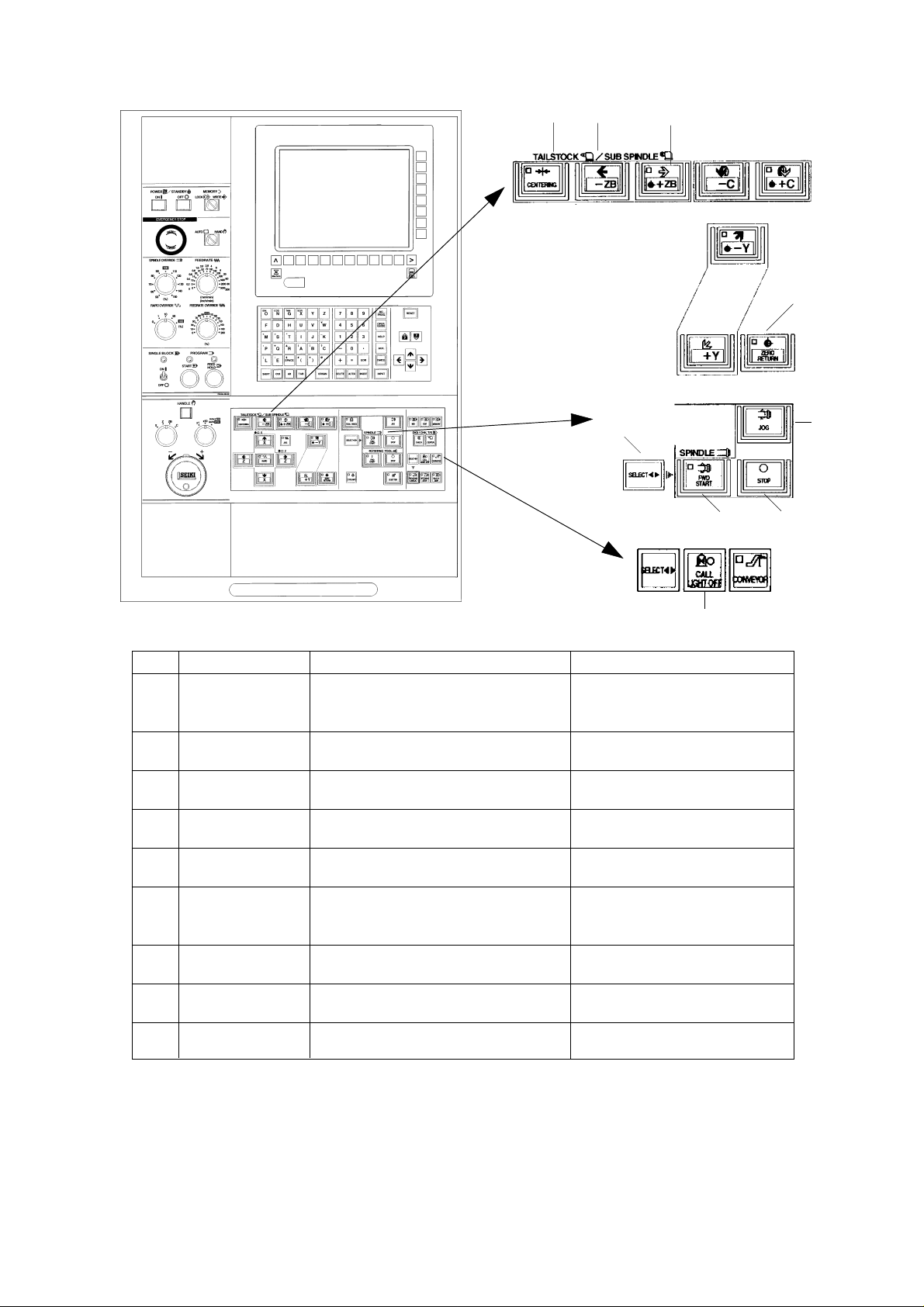

Page 11

[2]

[1]

[3]

No. Name Function Remarks

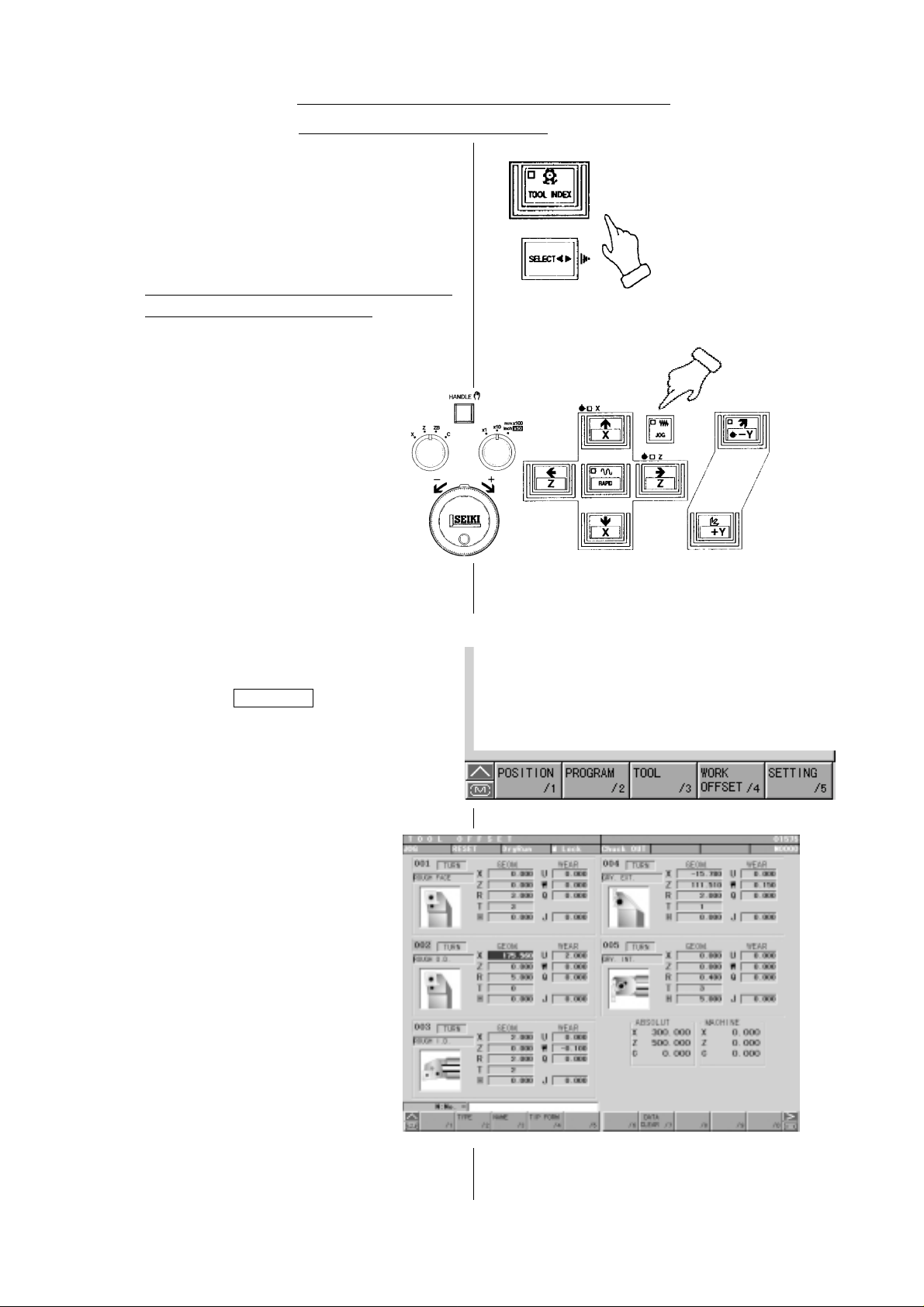

[1] TOOL INDEX START In the manual mode:

KEY By pressing this key and the SELECT key

simultaneously, the tool rest starts

rotation.

[2] SELECT KEY

[3] COOLANT MANUAL To direct coolant supply manually

KEY ON/OFF

1 - 5

Page 12

[6]

[5]

[4]

[1]

[3]

[2]

No. Name Function Remarks

[1] JOG KEY Select when executing the operation of Under m a n ua l mode.

the manual continuous feed.

[2] +X, -X KEY The manual continuous feed is available Set the feedrate by the feedrate

at the JOG mode. switch.

Move continuous in the selected direction When the +X key is kept pressing,

by pressing any one of +X or -X key. it is stopped at the machine

reference point.

[3] +Z, -Z KEY The manual continuous feed is available Set the feedrate by the feedrate

at the JOG mode. switch.

When the +Z key is kept pressing,

it is stopped at the machine

reference point.

[4] +C,-C KEY The manual continuous feed is available

at the JOG mode.

[5] +ZB,-ZB KEY The manual continuous feed is available

at the JOG mode.

[6] RAPID KEY Move by the rapid traverse with setting %

value of override while pressing under the

manual continuous feed.

1 - 6

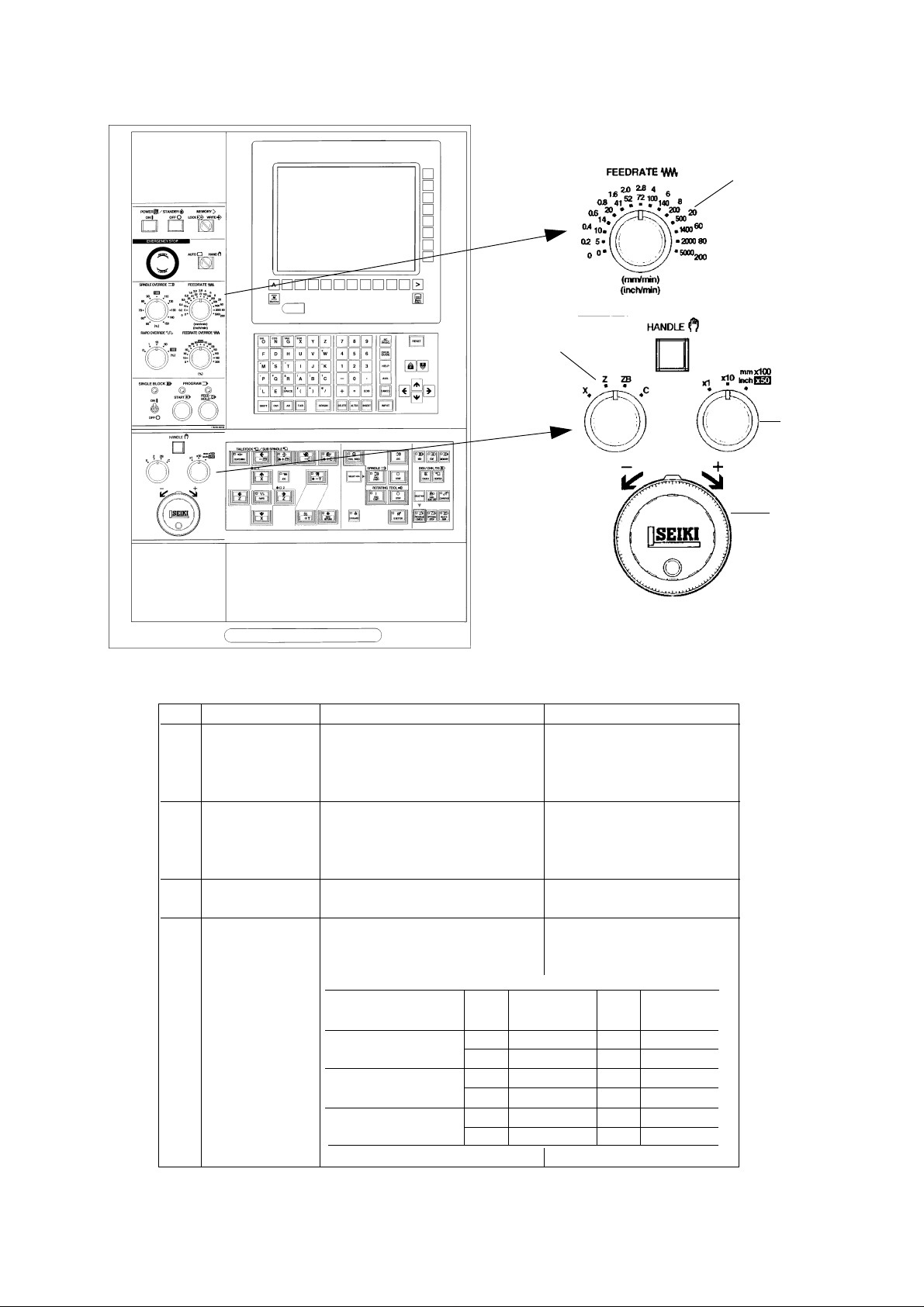

Page 13

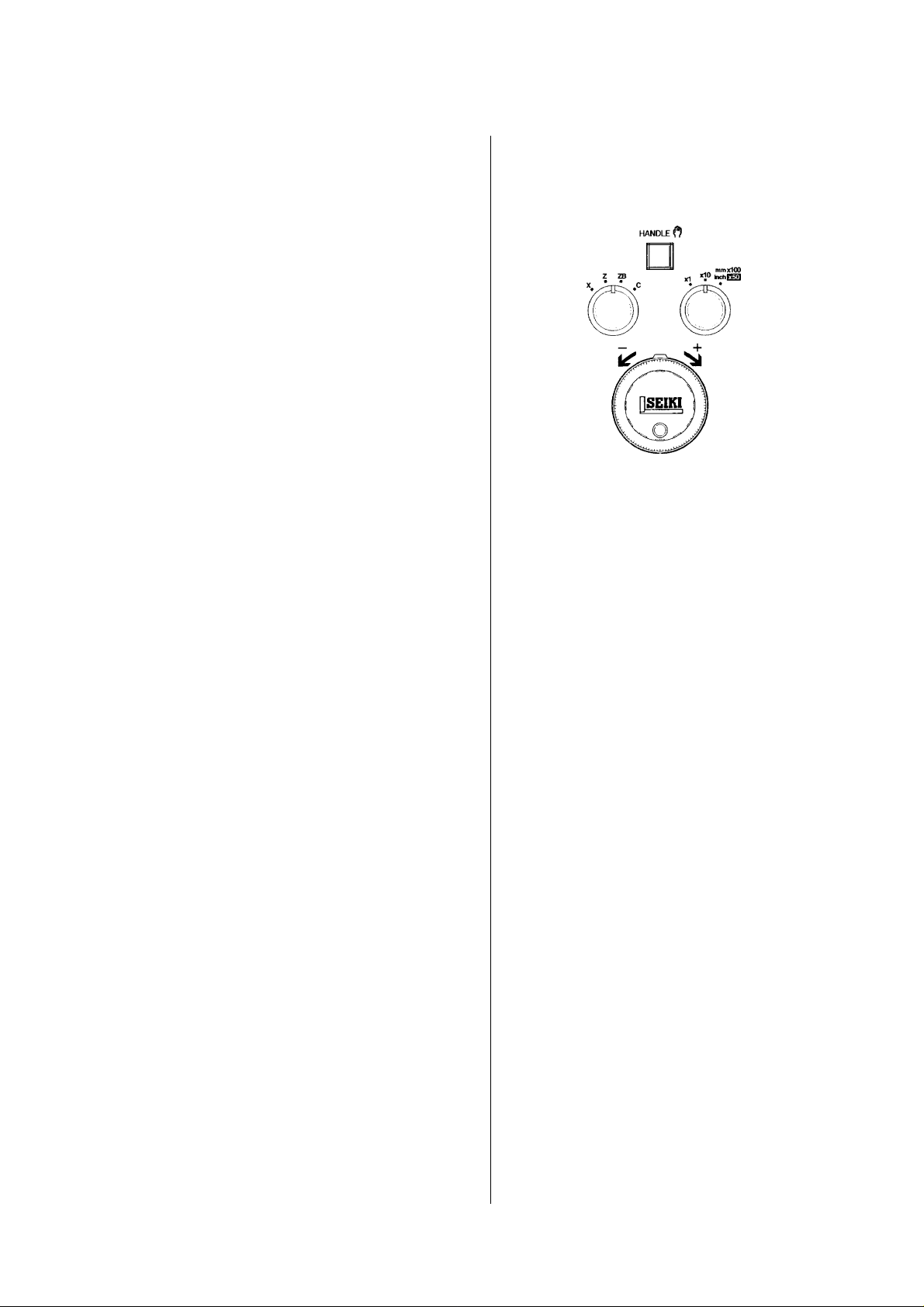

[1]

[3]

[4]

[2]

No. Name Function Remarks

[1] FEEDRATE Select the feedrate when 0~5000mm/min

SWITCH execution of the manual 15 steps

continuous feed or program check

operation (dry run).

[2] HANDLE Execute the handle feed (a fine 100div./ rev.

feed of the machine), when one of A feed amount per division is

the X, Z, ZB or C axes under feed according to the setting of

mod e. magnification [4].

[3] FEED AXIS KEY Select one of the X, Z, ZB or C Under manual mode.

when moving by the handle.

[4] HANDLE FEED Select an amount per division of

MAGNIFICA TION the handle.

CHANGE KEY

Feed magnification Axis Indication Axis Indication

key amount µ amount

1/1 X 1 ZB 1µ

Z 1 C 0.001°

10/1 X 1 0 ZB 10µ

Z 1 0 C 0.01°

100/1 X 100 ZB 100µ

Z 100 C 0.1°

1 - 7

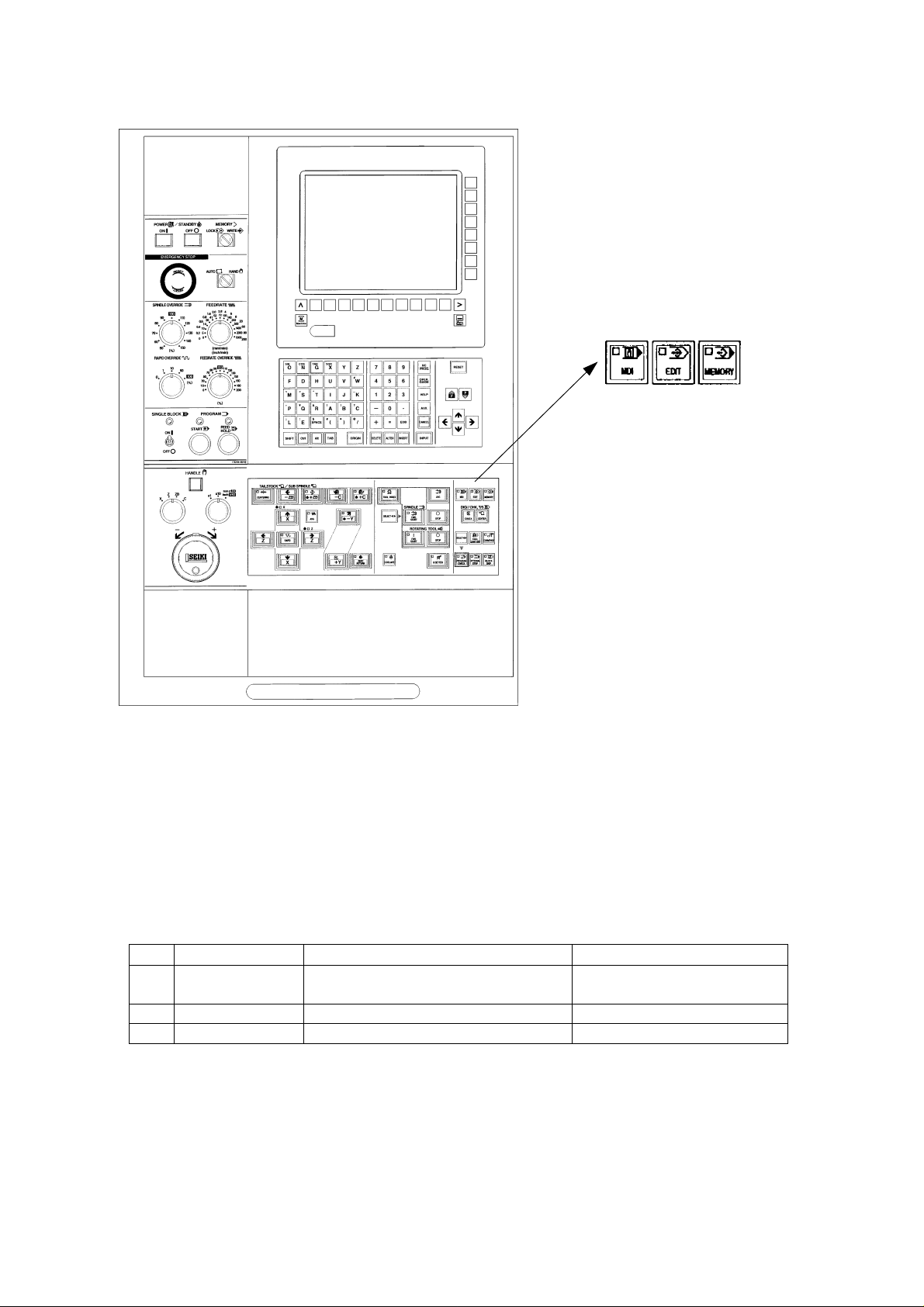

Page 14

[1] [2] [3]

No. Name Function Remarks

[1] MDI Select when MDI input by the CRT Automatic mode

operation panel of NC unit.

[2] EDIT Select when editing program stored. Automatic mode

[3] MEMORY Select when execution of program stored. Automatic mode

1 - 8

Page 15

[2]

[1]

No. Name Function Remarks

[1] PROGRAM Make the stop condition of spindle and

CHECK coolant besides the dry run function.

[2] SINGLE Stop after execution of one block and

BLOCK move to the execution of next block by the

start key .

[3] OPTIONAL Program stops by the M01 on the

STOP program.

Press the program start key when start

again.

[4] BLOCK SKIP Skip a block with slash (/) code in the

program.

[3]

[4]

1 - 9

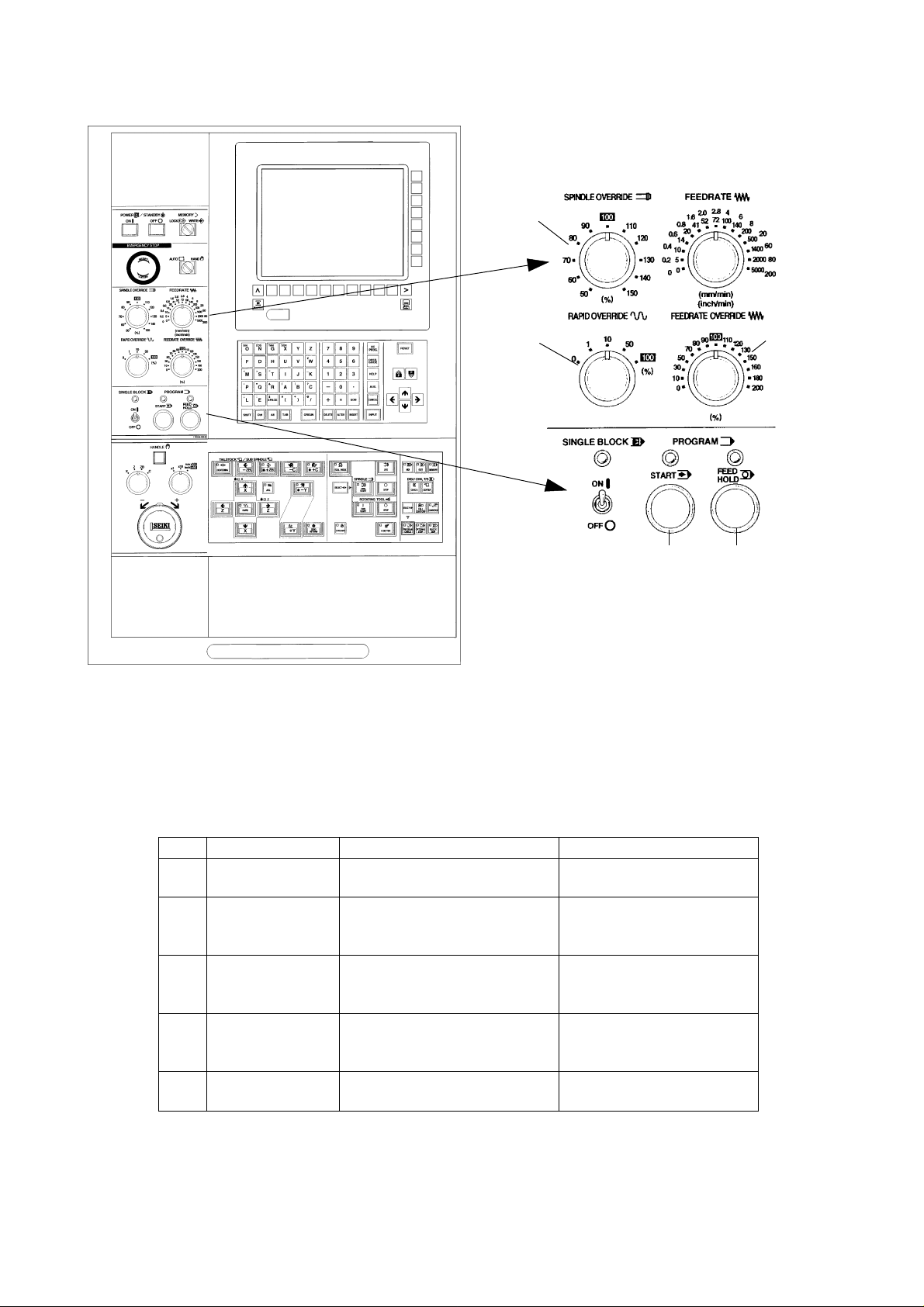

Page 16

[4]

[5] [3]

[1] [2]

No. Name Function Remarks

[1] PROGRAM ST ART Start automatic operation.

KEY (MDI, Memory)

[2] PROGRAM FEED Halts automatic operation. MST function is kept on while

HOLD KEY Feeding only decelerates and the work continues, and halts

stops. when completed.

[3] FEEDRATE Feed rate can be changed in the

OVERRIDE range of 0 to 200% under MDI or

SWITCH automatic operation.

[4] SPINDLE The spindle speed can be Ignores while thread cutting

OVERRIDE changed in the range of 50 to (G32, G92, G76)

SWITCH 150%

[5] RAPID OVERRIDE The rapid speed can be changed

in the range of 0 to 100%

1 - 10

Page 17

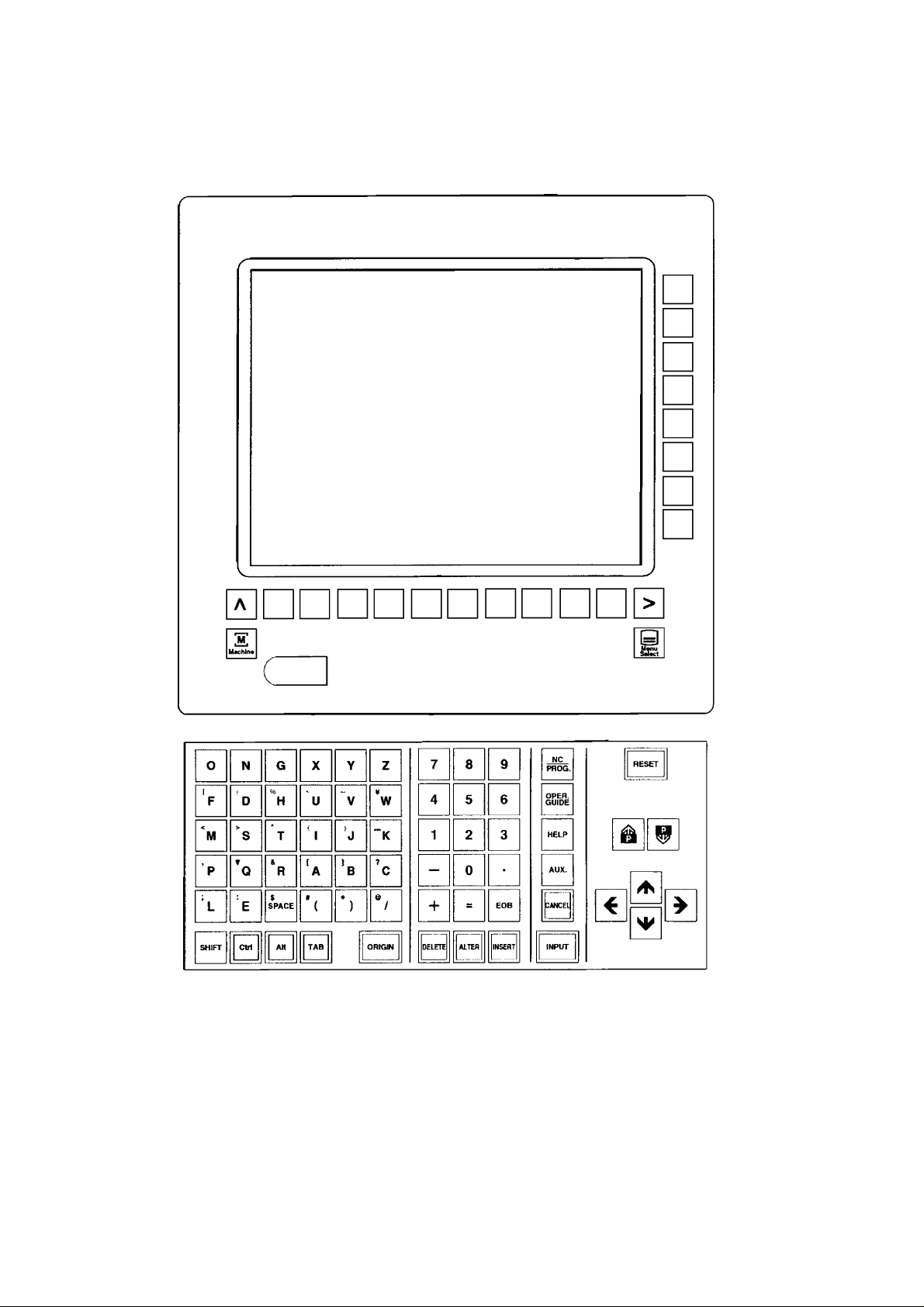

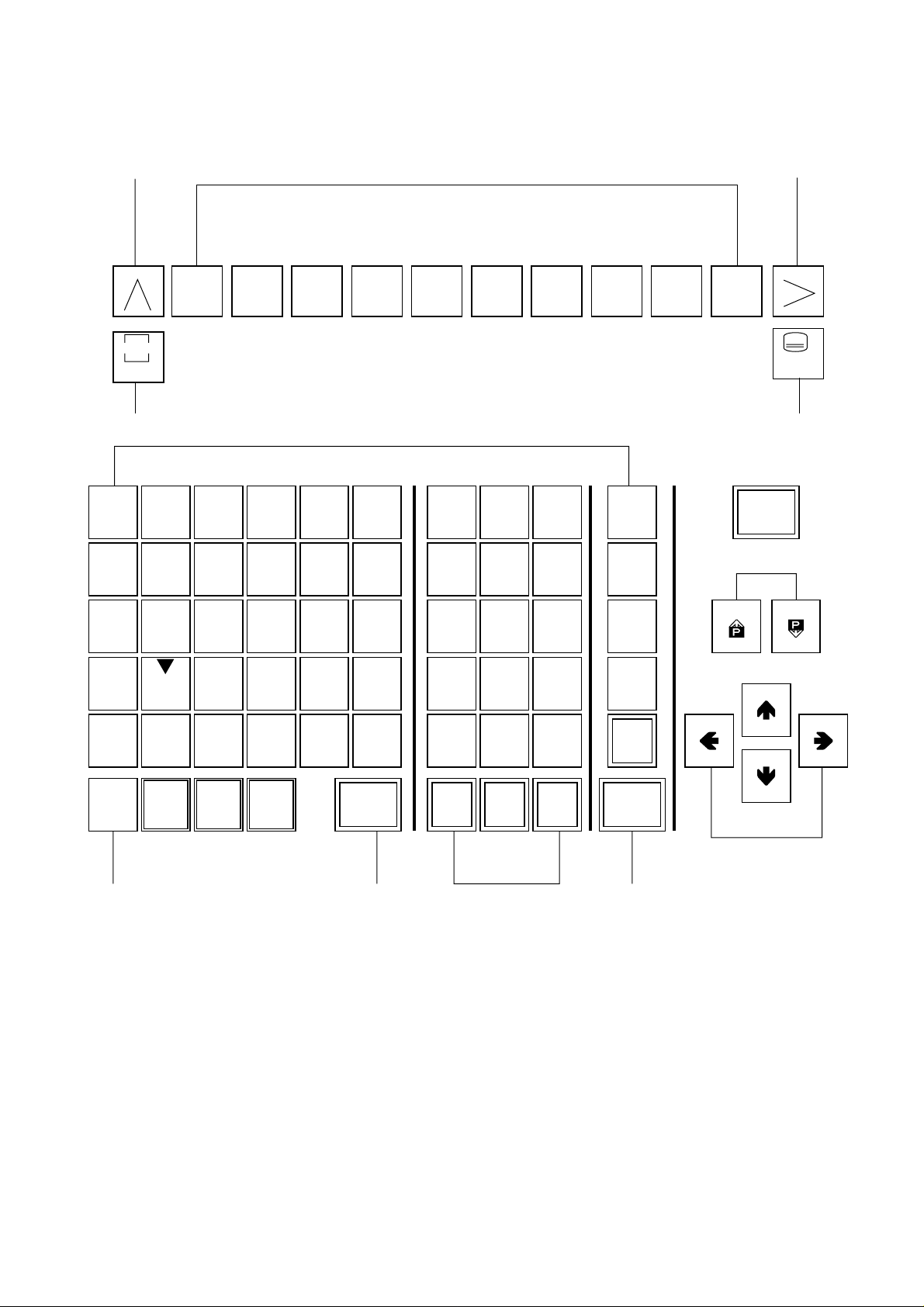

2-2 NC Operation Panel

1 - 11

Page 18

[3]

[2]

[4]

M

MACHINE

[16]

[7]

ON G XY Z 7 8 9

| ! % , - ¥

FDHUVW 4 5 6

< > “ { } _

MSTI JK 1 2 3 HELP

‘ & [ ] ?

PQRABC -0· AUX.

; : $ # * @

LE ( ) / += CANSEL

SP ACE EOB

NC

PROG.

OPER.

GUIDE

[15]

[6]

[5]

[10]

SELECT

RESET

[14]

NEMU

[17]

[1]

SHIFT

[8]

Ctrl Alt TAB

ORIGIN

[11]

DELETE

1 - 12

AL TER

[12]

INSERT INPUT

[13]

[9]

Page 19

NC Operation Key

No. Name Description

[1] RESET key

[2] Function keys

[3] Maintenance Menu Display key

[4] RETURN key

[5] AUX. key

[6] HELP key

[7] Address and Numerical keys

[8] SHIFT key

[9] INPUT key

Press this key when resetting the CNC unit in order to

reset an alarm, and so on.

When the function menu is displayed at the bottom of

the CRT, there are the keys to select the menu.

Pressing this key in the overall screen switches to the

maintenance menu.

Press this key when you want to return to the Overall

screen.

Press this key when you want to move the cursor of

the overall screen to another window .

Used to input the alphabet, numbers, etc.

There are some address keys which have 2 characters

marked on them. If you press the address key after the

SHIFT key, upper left character is input.

If the address or numerical key is pressed, it is input

into the key input buffer once, and then, displayed on

the CRT. Press the INPUT key when actually setting

the data input into the key input buffer.

[10] CANSEL key

[11] ORIGIN key

[12] DELETE, ALTER and INSERT

keys

[13] Cursor key

[14] Page key

[15] OPER. GUIDE

[16] MACHINE key

[17] MENU SELECT key

Press this key when deleting the characters or

symbols input into the key input buffer .

This key is used to clear the Plot screen.

Used to perform deletion, alteration and insertion in

editing the program.

There are 4 keys which are used to move the cursor

up/down and right/left.

There are 2 keys which are used to page in the

forward and backward directions.

Press this key when you want to display in the

Operation Guide screen.

In case of a multiple series machine, use this key to

switch the series to be displayed.

Pressing this key in the overall screen switches to the

menu to display a small screen.

1 - 13

Page 20

2-3 Chip Conveyor Operation Panel

1) Chip Conveyor Operation Panel

Chip Conveyor Operation

Panel Diagram

2) Function

No. Name Type Function

[1] FOWARD Push Button Forward switch is valid in manual mode only.

The action is kept on.

[2] REVERSE Push Button Reverse switch is valid in manual mode only.

Inching operation.

[3] STOP Push Button Stop switch is valid regardless of the mode.

[4] EMERGENCY STOP Mushroom Type Emergency stop switch is valid for stopping

both chip conveyor/main machine, regardless

of the mode.

[5] MAN/AUTO Switching In manual mode: Buttons [1] [2] are valid.

In auto mode: By command from the main

machine, forward operation is stopped.

Buttons [1] [2] are invalid. Do not switch

man/auto during operation.

[6] RUNNING Lamp Lamp lights while the chip conveyor is is in

operation.

1 - 14

Page 21

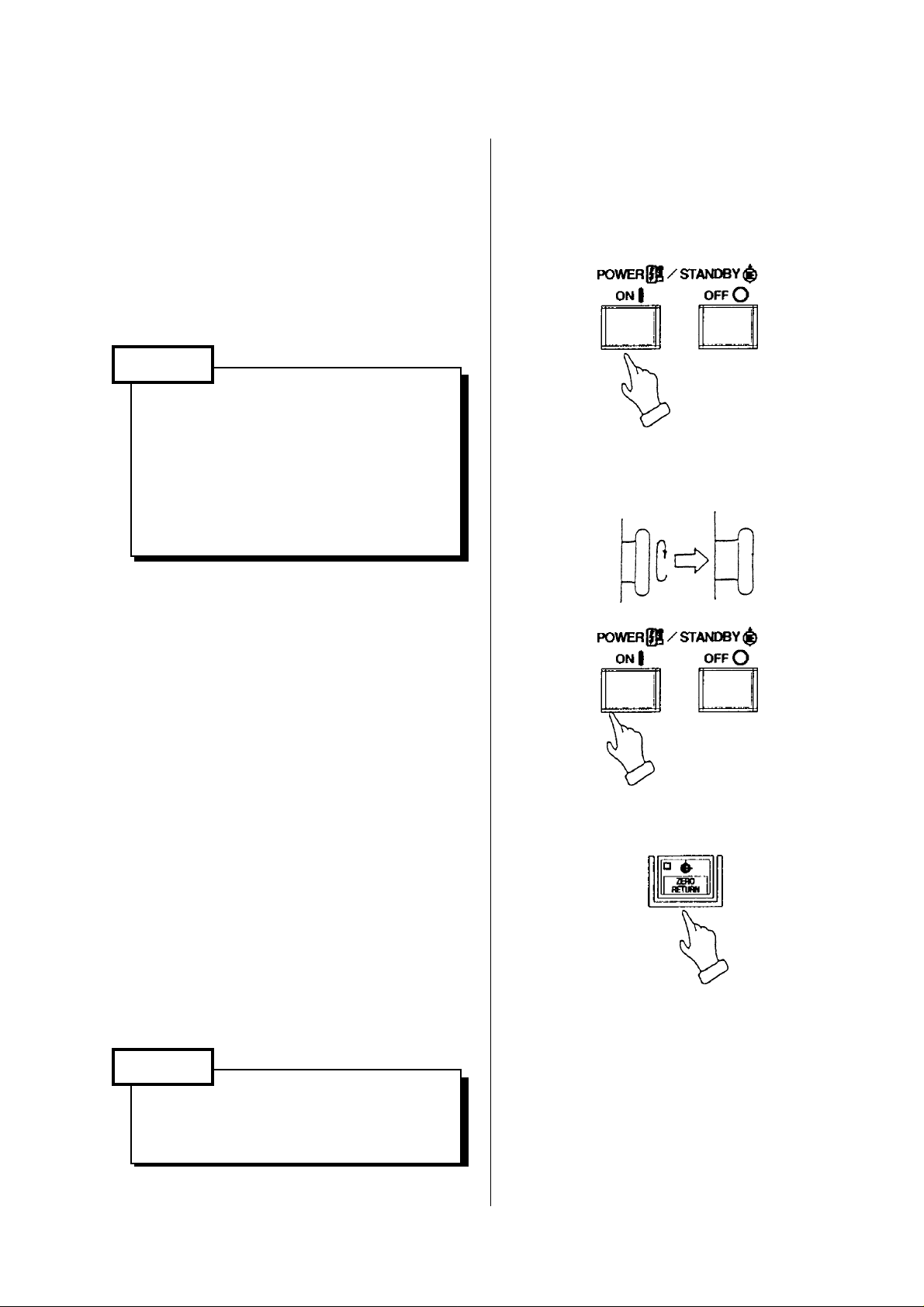

3. Procedure of Machine Operation

3-1 At the Time of Start

[1] Turn on the power source switch.

[2] Supply air pressure.

[3] Turn on the power switch of the power

control cabinet.

[4] Press the POWER/STANBY [ON] on the

left corner of themain control panel.

Caution

Main panel and NC unit is sealed type

construction and avoid a mixture of outer

air directly. Therefore, don’t keep open

the door long time of period during power

on.

Check on the display and that fan motors

heat exchanger are started.

[5] Once the Overall screen is displayed,

turn [EMERGENCY STOP] to the right to

unlock it.

[6] Press the POWER/STANBY [ON] on the

left corner of the main operation panel.

(Lamp lights.)

Check a setting pressure of hydraulic unit

2

is 3.5Mpa{35kgf/cm

[7] Move X and Z axes several times to

lubricate each slide way before starting

operation.

(Pay attention to avoid over travel.)

[8] Press the [ZERO RETURN] .

(Refer to “Procedure of zero return”)

This will return the turret head to the

machine zero point.

[9] Turn on the switch for chip conveyor.

}as fixed value.

Caution

Do not operate the machine with plenty of

chip in the trough of chip conveyor.

1 - 15

Page 22

3-2 Warming-up Operation of Spindle

Caution

It is important to keep status of bearing in good condition by lubrication, etc., to make

the spindle rotate normally. Sudden rotation of the spindle may cause sticking of the

bearings because of shortage of lubricating oil at the bearing section. To get the best

performance of the spindle function by correct operation, warming-up operation as

below-mentioned is necessary.

Warming-up operation for every starting (30 minutes)

[1] 10 minutes at 30% of the maximum spindle rotation

[2] 10 minutes at 50% of the maximum spindle rotation

[3] 10 minutes at 80% of the maximum spindle rotation

Conduct warming-up operation in the above order, [1], [2], [3]

1 - 16

Page 23

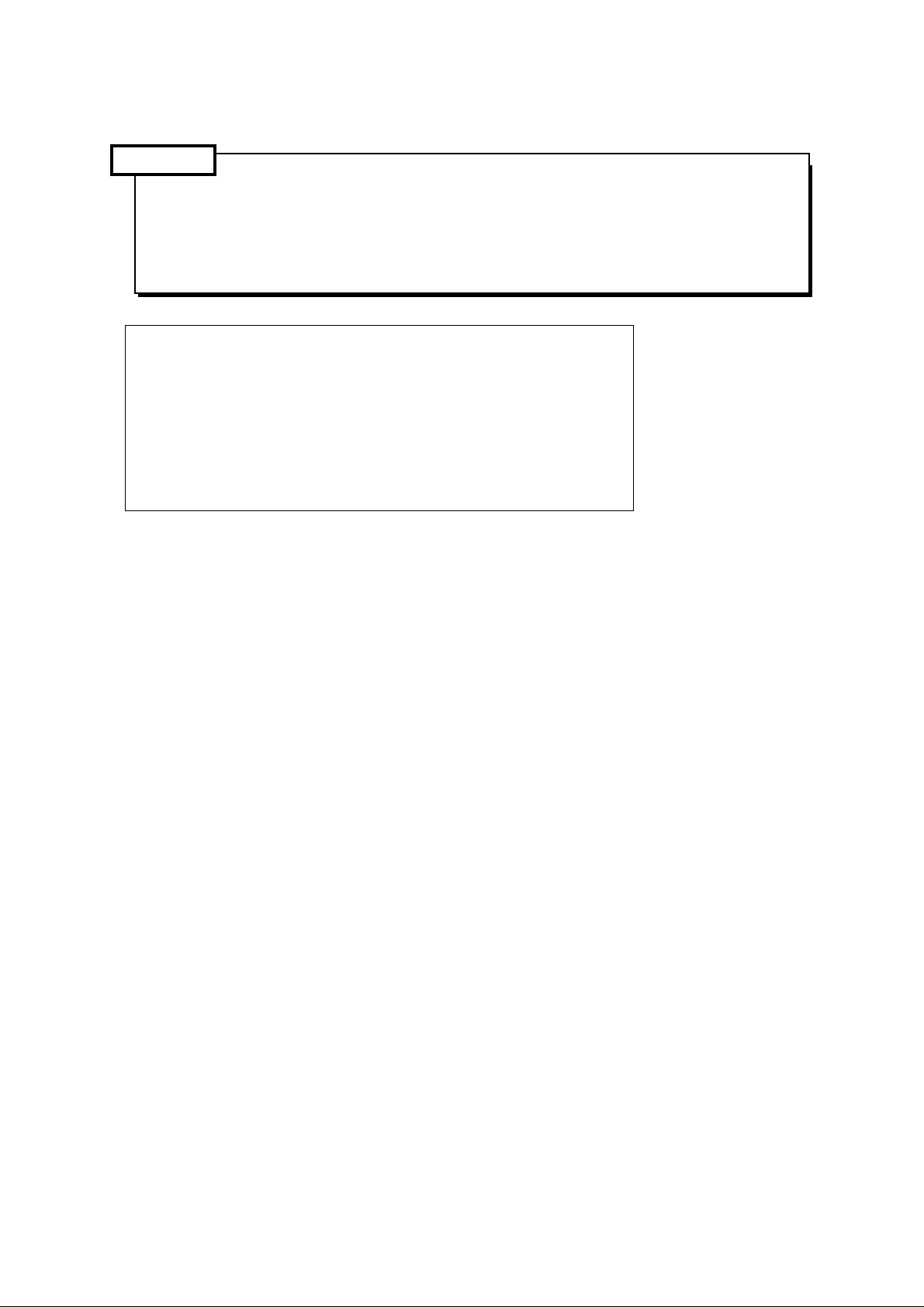

3-3 Procedure of Zero Return

This function is conveniently designed to return the turret head to the machine zero point in

order of the X- and Z-axis in single-touch operation.

Method 1 of zero return

[1] Make a mode to [JOG].

Move the X- and Z-axis about 100 mm in

the minus direction.

[2] Press the [ZERO RETURN] key.

If a single-touch zero point return

prohibited area alarm is issued, move the

X- and Z-axis until the alarm has

disappeared.

[3] Move a tool head to zero point by rapid

traverse (10% override). The tool head

stops at zero point and a confirmation

lamp of zero point of the axis turns on.

Return the X- and Z-axis to the zero point

in that order.

Method 2 of zero return

[1] Make a mode to [JOG].

[2] If the X and Z axes locate near the zero

point, move it opposite direction (Minus)

from zero point about 100mm.

[3] Press [X+] and [Z+] in that order to return

the X- and Z-axis to the zero point.

[4] Release a finger from the switch after the

confirmation lamp of zero point turned on.

Execute zero point return of each axis by the

operations above.

Caution

1. Execute zero return of axis one by one for safety.

(At first, do it from X-axis.)

2. Pay attention of interference with the tailstock at the time of zero return.

3. The turret head does not move when rapid traverse override is 0 %. Set it to 1 % or

10 %.

4. When rapid traverse override is 1 %, it moves at override of 1 %.

1 - 17

Page 24

3-4 At the End of Operation

[1] Clean up the machine.

Stop the chip conveyor after all chips

carried out from the conveyor.

[2] Confirm the machine stopped completely.

• Spindle rotation

• Program

• X and Z axes

• Coolant

• Chip conveyor

[3] Press the [EMERGENCY STOP] button

on the main operation panel.

[4] Press power [OFF] button at the main

operation panel and control power off.

[5] Turn off the power switch of the power

control cabinet.

[6] Cut out supply air pressure.

[7] Set the main power switch [OFF].

1 - 18

Page 25

4. Manual Operation

4-1 Feed of Each Axis

— In case of manual feed —

[1] Press the [JOG] for mode select push

button switch.

You may select the [HANDLE] either.

[2] Set the manual federate rotary switch to

suitable speed.

Move the machine to desired direction by

the manual feed direction push button

switch.

Take a finger off from the switch when

reach to the fixed position.

(The machine moves only when pressing

the switch.)

In case of a feed by the HANDLE, it can

be operated the same about it.

(Example of use)

• Warm up running

• In case of approach near the zero position.

• In case of cutting manually

• Setting work

1 - 19

Page 26

— In case of the handle feed —

[1] Select the axis by the axis push button

switch.

[2] Fine feed can be done by the manual

handle.

• When select 1/1: One division is

0.001mm

• When select 10/1: One division is

0.01mm

• When select 100/1: One division is

0.1mm

In case of the spindle indexing C axis, the

unit becomes a degree.

1 - 20

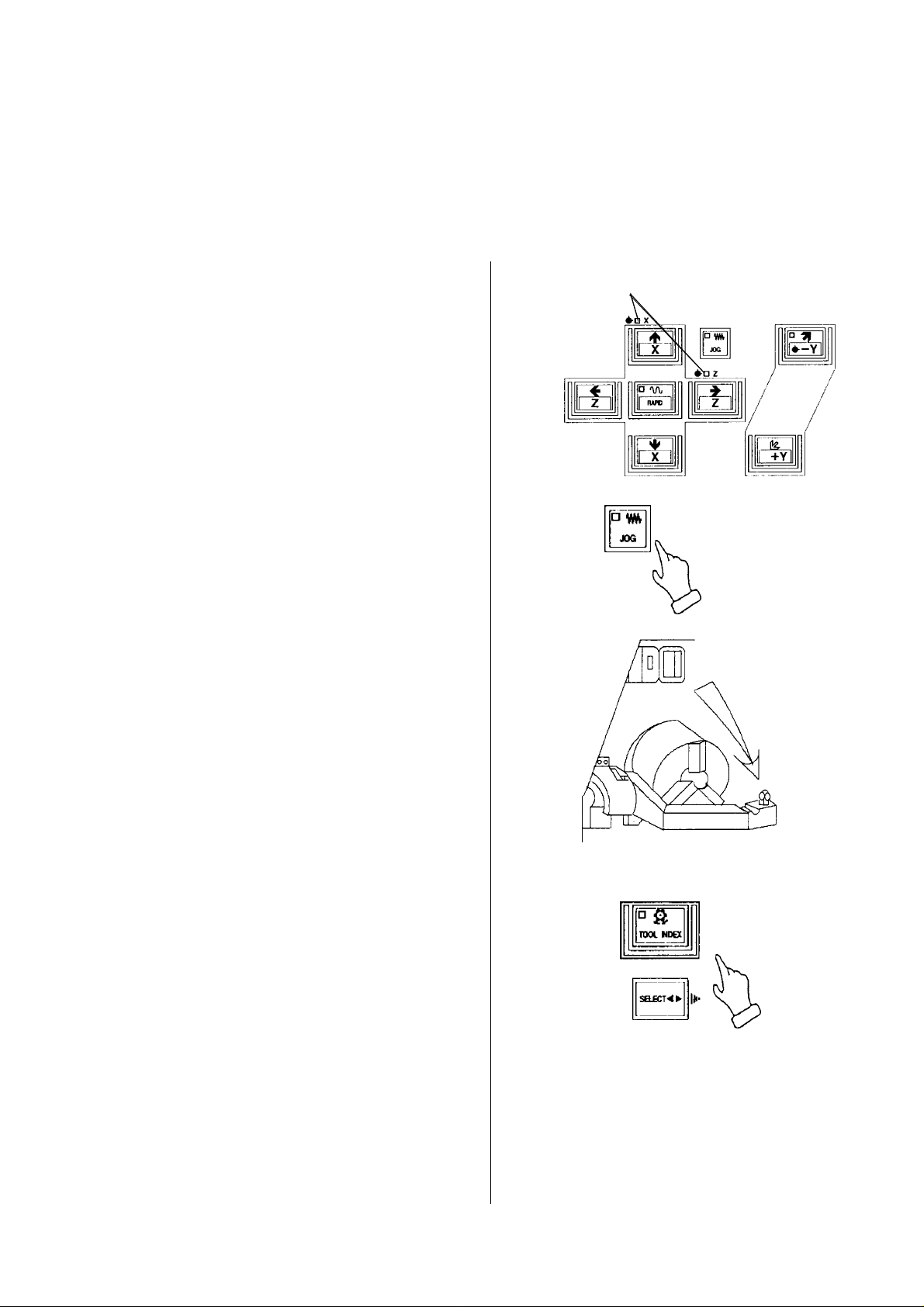

Page 27

4-2 Operating Method of Q-setter

A tool position compensating value can be get easily, since a tool position compensation is

inputted automatically by touching a tool tip to the Q-setter.

In case of the turret rotates, a cursor changes automatically due to a tool face number

correspond an offset number.

[1] Confirm the zero return condition of the X

and Z axes.

If confirmation lamp is not lit, execute

manual zero return.

[2] Make a mode to manual mode [HANDLE]

or [JOG].

[3] Pull out the Q setter

A screen changes to the offset screen

automatically and display the “Q-setter”

and inform a ready of complete condition

of preparation.

Zero return lamp turns on

[4] Call a tool compensation required.

Press the [TOOL INDEX] and

[SELECT] at the same time.

1 - 21

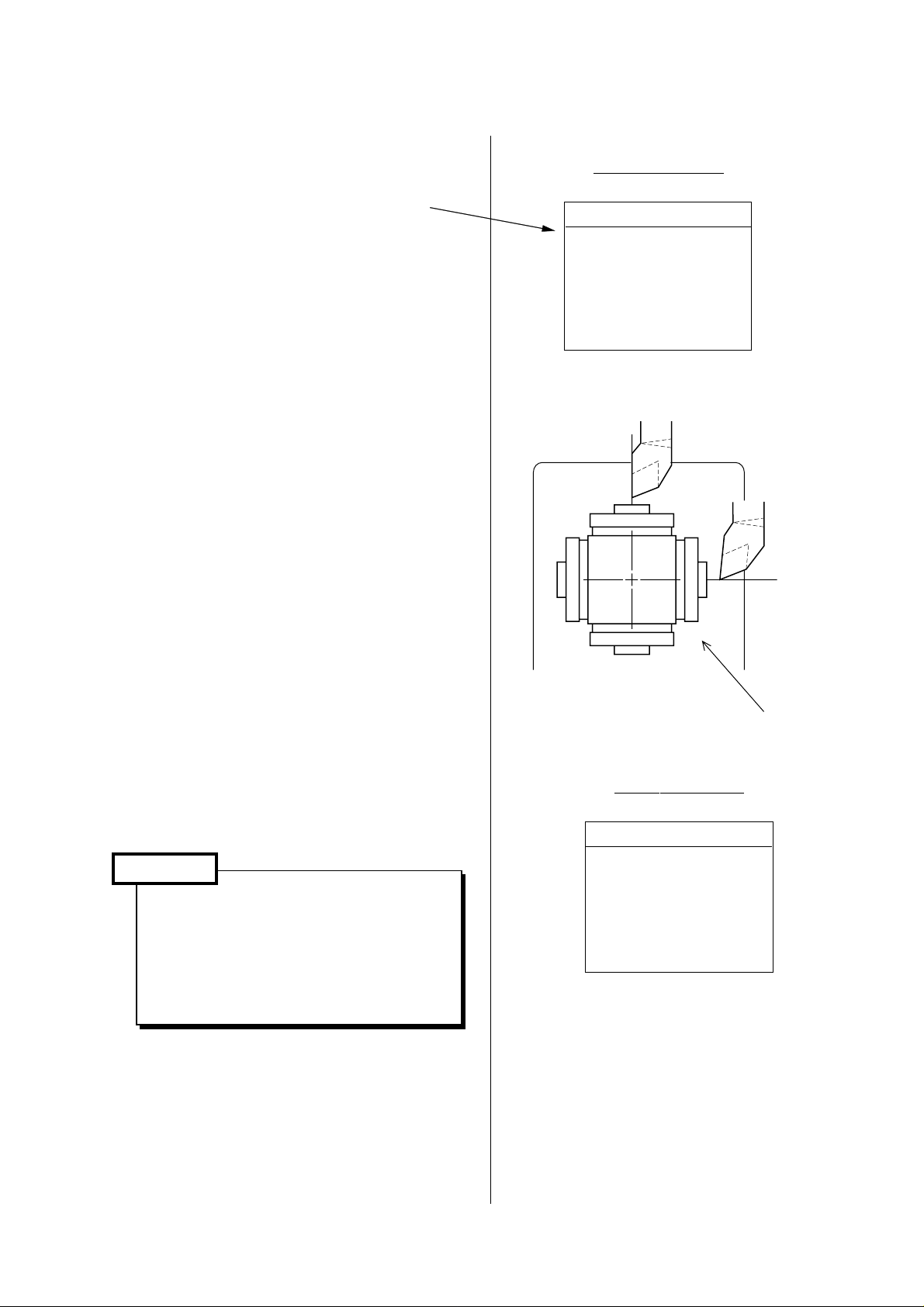

Page 28

[5] Confirm a tool face on the turret and

offset number.

A tool face selected at this moment is

recognized by a cursor position.

[6] Approach a tool tip to the tool setter

TOOL (OFFSET)

Sharp Wears

01

X 1.000 U 0.000

Z 3.000 W 0.000

R 0.000 Q 0.000

T3

H 0.000 J 0.000

(Q setter)

Procedure (1) Handle magnification key

100/1

(2) Rotate a handle to minus

direction.

[7] Position a tool tip to the center of the

sensor by [HANDLE].

[8] When a tool tip touches the sensor by

JOG mode, a compensating value is

inputted automatically. At this time, the

feed rate is fixed, disabling speed

selection.

Caution

If it is executed by operating the

[HANDLE], the accuracy will not be

stabilized. (Reason: When having the tool

nose touch the Q setter, the accuracy is

stabilized by having it touched at a

constant speed.)

For X Azis

For Z Azis

Sensor Base

TOOL (OFFSET)

Sharp Wears

01

X 35.000 U 0.000

Z 0.125 W 0.000

R 0.000 Q 0.000

T3

H 0.000 J 0.000

When a tool tip touch to the sensor,

sound beep and stop the tool head and

input a compensation value.

The wear offset amount of the axis

touched by the tool nose is made 0

(zero).

1 - 22

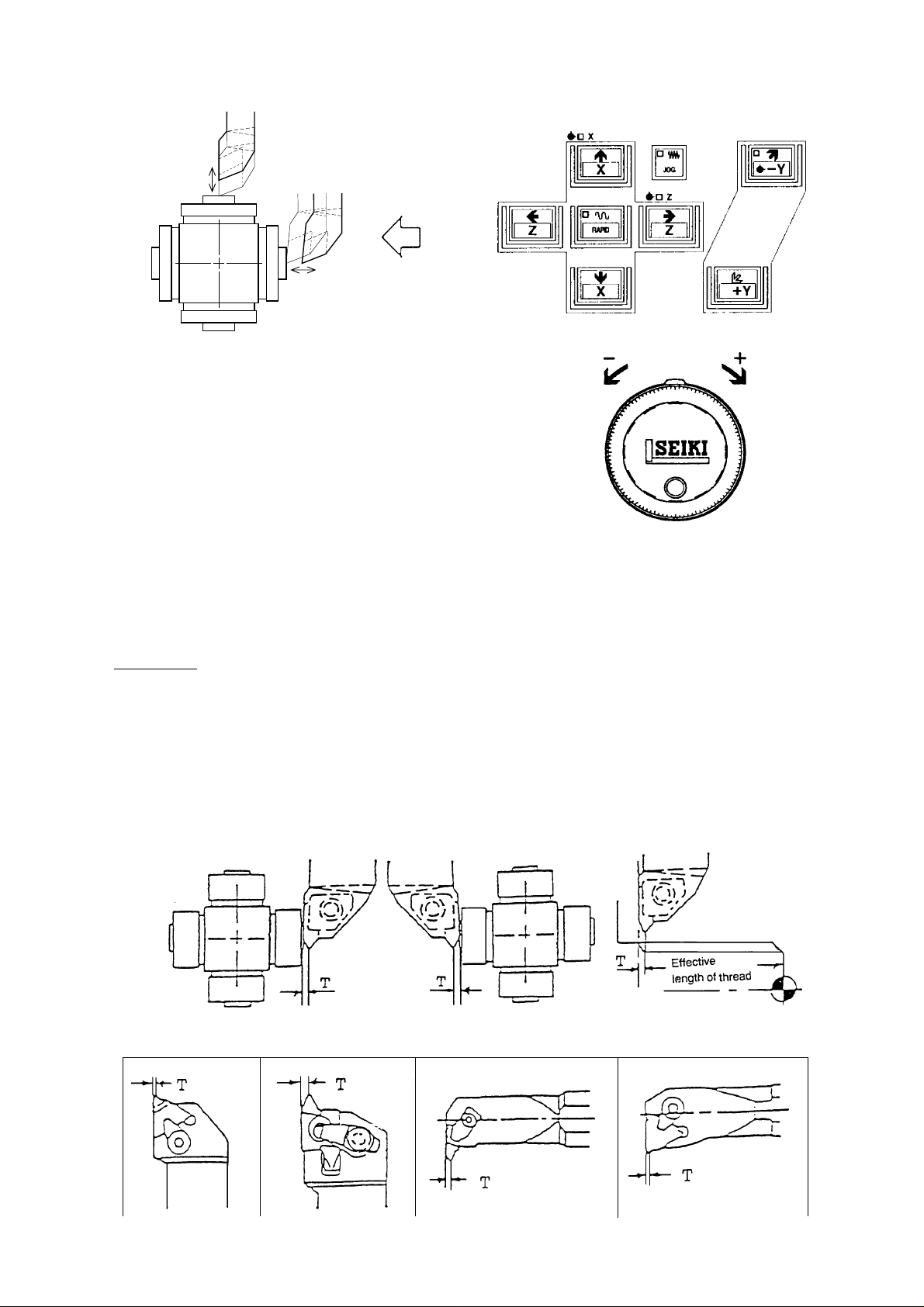

Page 29

[9] Execute a tool tip measurement by touching a tool tip to the sensor twice or so.

Confirm a tool compensation

amount on the screen.

[10] Retract a tool tip from the sensor to safety zone by

[HANDLE] mode. A safety zone is a position which is not

interfered a tool and sensor even if the turret rotates.

When retracting the cutting edge in the [HANDLE]

mode from the beginning, retract it slowly up to about

1 mm. If retracted abruptly in the [HANDLE] mode,

the cutting edge direction may be misconceive,

disabling an entry of a correct compensation value.

[11] Get a compensation amount for the other tool in turn as the same method.

OTHERS

Reference In case of thread cutting tool

In case of thread cutting tool, a tool compensation value of Z value is obtained by the side

of insert as described by Fig. 1 and 2, effective length of thread becomes short by “Width

T” due to position of cutting edge is different. Therefore, get a tool compensation amount

by the Q setter as Fig. 1 then execute incremental compensation input to minus side (In

case of Fig. 2, plus side), so correct effective length of thread can be get as Fig. 3.

The incremental amount you can input at a time is up to 1mm. If it exceeds 1mm, divide the

input into several times, with the amount less than 1mm each time.

Fig.1(Right hand thread) Fig.2(Left hand thread) Fig.3

1 - 23

Page 30

How to get a tool compensating amount for a tool

tip may not be touch the Q-setter

A work coordinate system setting should be

done before executing this operation.

A correct compensating amount can not be

found without a work shift operation.

“How to get a tool compensating amount

1.

for a longitudinal direction (Z)”

[1] Call a tool by index the turret.

Select the mode switch either the

[HANDLE] or [JOG].

[2] Call the tool offset screen and

confirm a tool compensating amount

(Z) is zero. Set zero if it is not zero.

Press the [TOOL INDEX]

and [SELECT] at the same

time.

Press F3/TOOL .

Example: In case of T0200

Set the tool (offset) No. 02.

1 - 24

Page 31

[3] Touch a tool to the end face of

workpiece.

It the end face is a black skin,

execute it after cutting a black skin.

Caution

Reduce a magnification of the handle to avoid a breakage of tool and apply a paper

between a workpiece and tool.

[4] watch a position “Z” of tool position.

3.0

Removal amount L

Machining reference point

Paper

1 - 25

Page 32

O Tool compensating amount

A value subtract a removal amount (L) from a tool position (Z).

Toll compensating amount (Z) = Tool position (Z) - Removal amount (L)

Example: Tool compensating amount = (150.0) - (3.0) = 147.0

147.0 is a tool compensating amount of the longitudinal direction.

[5] Input a tool compensating amount.

Z147.INPUT

Caution

Execute it with confirmation, if the setting of shift amount (machining original position) of

Z-axis work coordinate system is correct or not before this

Besides, a tool tip position should be same as a removal amount when a tool touches

end face is has touched the Q-setter.

1 - 26

Page 33

How to get a tool compensating amount for a tool

tip may not be touched the Q-setter.

“How to get a tool compensating amount

2.

for a radial direction (X) ”

It is the same as longitudinal direction

from the item [1] to [3]. Refer it to them.

[4] Cut a workpiece.

or

Feed level

Caution

To avoid a defective parts, it is enough a skin cut. Never move on the X-axis after OD

turning.

[5] Watch a position “X” of tool

position.

Example: In case of T0300

Set the tool (offset)

No.03.

1 - 27

Page 34

O Tool compensating amount

A value subtract a diameter of workpiece (φD) from a tool position (X).

Toll compensating amount (X) = Tool position (X)

- machined diameter of workpiece (φD)

Example: Tool compensating amount = (65.0) - (63.0) = 2.0

2.0 is a tool compensating amount of the diameter direction.

[6] Input a tool compensating amount.

X2.

INPUT

1 - 28

Page 35

4-3 Q-setter Repeat Function

Through a simple operation, you can repeatedly perform measurement on tip changing of a tool

which has already been subject to measurement in Q setter.

4-3-1 Procedures

Push F6/Q-SETTER REPEAT on Tool (Compensation) page, Window page for Q setter

[1]

repeat is displayed.

[2] Set Feed mode.

[3] Changing a tip, perform indexing of the turret to a measurement position. At this time both

the cursor inside Turret State on the left side of the page and the compensation data at the

top right-hand corner of the page change as linking to the turret face.

[4] Bring out the Q setter arm.

[5]

Push F4/START .

If the tool has been already subject to measurement in Q setter (with the data already

existing in the measurement position on the page), measurement by Q setter repeat is

started. When the tool touches the sensor, a measured value is written in compensation

data. The touch mark is displayed on the picture indicating a measurement position.

If measurement has not yet been performed in Q setter, alarm takes place.

Fig. 7-2 Q Setter Repeat Screen

1 - 29

Page 36

4-3-2 Function Key

F4/ Repeat Measurement Start :

“OK? Y- Yes N- No” message appears. With Y ,

measurement starts.

F5/ Repeat Measurement Halt : Measurement operation is stopped.

F6/ Function Return : Screen display returns to Tool Compensation.

F7/ Data Delete : On appearance of a window, select either “One Meas. Spot”

or “Whole Meas. Spot” and push INPUT . “OK? Y- Yes,

N- No” message appears. With Y , the measurement

spots are deleted.

4-3-3 Working

The working patterns, as shown in Fig. 7-3(c) can be divided into 8 kinds according to the

virtual nose points.

When Virtual Point 1, 2, 3, or 4 being assigned, both X and Z axes are subject to measurement.

The order for measurement, in that case, is always Z to X axis.

When Virtual Point 0, 5, 6, 7, 8, or 9 being assigned, X or Z axis alone is subject to

measurement. In this case, for compensation of the axis not being measured, compensation

needs to be input manually beforehand. As for virtual nose points of tools, see Fig. 7-3(a).

8

4

5

8

3

7

9

0

1

6

2

Fig. 7-3(a) Virtual Nose Points of Tools

1 - 30

Page 37

The following example describes the case when the virtual nose point is 1:(See Fig. 7-3(b))

[1] Shifted in rapid traverse from Start Point (PO) to Point 1 (PO).

[2] Shifted in rapid traverse from P1 to P2.

[3] Shifted in rapid traverse from P2 to P3.

[4] Shifted in feed speed from P3 to the end position (P4) to be touched.

[5] Shifted in feed speed from the point where touching and stopping have taken place.

[6] Shifted from P5 to P6 in rapid traverse.

[7] Shifted from P6 to P7 in rapid traverse.

[8] Shifted in feed speed from P7 to the end position (P8) to be touched.

[9] Shifted in feed speed from the touch-and-stop position to P9.

[10] Shifted from P9 to P10 in rapid traverse.

[11] Shifted from P10 to the start point (P11) in rapid traverse.

Machine origin

MD62200[12] MD62200[11]

-X

P4

P8

P7

1

+X

P9

MD62200[12]

P3

P5

P6

P2

X

Z

+Z

-Z

MD62200[6]

MD62200[13]

MD62200[14]

MD62200[7]

MD62200[5]

MD62200[4]

P11

P0

(Start

Point)

P10

P1

Fig. 7-3(b) Working with Virtual Nose Point 1

1 - 31

Page 38

3

8

2

4

6

7

0

9

MD62200[12]

1

5

MD62200[13] MD62200[13]

MD62200[14] MD62200[14]

Fig. 7-3(c) Working PatternsFig.

1 - 32

Page 39

Caution

1. When a tool has been changed, be sure to manually apply it to Q setter.

2. Apply it to Q setter only once.

3. Approaching, in rapid traverse, from the sensor to the place just before the clearance

amount on approach, touch the sensor in the feed rate (mm/min).

4. Single block is held valid while in measurement operation.

(Re-started with F4/REPEAT START .)

5. When the measurement start point can touch the sensor, alarm takes place.

6. When the sensor has not been touched in measurement, alarm takes place after operation

is over.

7. Threading tools, tip changing type drills, end mills, and other tools which are similar to

these cannot be subject to measurement.

8. The measurement start point is any one position free from danger or touching the sensor.

9. When, in some operation patterns, an interference exists with a work, remove the work

from the chuck.

10. When a large difference exists between the Q setter measurement and the work

measurement dimension, adjust Q setter position on Maintenance page.

11. When the machine is provided with the Y-axis, it must be in the following conditions when

starting Q-setter repeat.

• The Y-axis is at the origin. (The ORIGIN lamp is ON)

• The tool offset amount for the Y-axis is 0. (Both shape and Wear are 0)

12. The measuring spots are deleted in the following cases:

• When Data Delete on the screen is effectuated.

• When shape data for tool compensation volume and nose T have been input.

4-3-4 Relevant Parameters

No. 8003, #0=0 Does not check the door close in the Q setter repeat.

=1 Checks the door close in the Q setter repeat.

#1=0 Measurement time of the Q setter repeat is 1 time.

=1 Measurement times of the Q setter repeat are 3 times.

#2=0 The touch signal check in the Q setter repeat is valid.

=1 The touch signal check in the Q setter repeat is invalid.

#3=0 Measurement of a rotation tool in the Q setter repeat is not possible.

=1 Measurement of a rotation tool in the Q setter repeat is possible.

1 - 33

Page 40

#4=0 The Q setter interlock is invalid.

=1 The Q setter interlock is valid.

#7=0 The Q setter barrier check is invalid.

=1 The Q setter barrier check is valid.

MD62200[4] Q setter contact area + Side coordinate value X (mm) (set by the radius)

MD62200[5] Q setter contact area + Side coordinate value Z (mm)

MD62200[6] Q setter contact area - Side coordinate value X (mm) (set by the radius)

MD62200[7] Q setter contact area - Side coordinate value Z (mm)

MD62200[11] Thrusting amount of the Q setter repeat (mm)

MD62200[12] Clearance amount on approaching for Q setter repeat (mm)

MD62200[13] Clearance amount for right-handed machine tool for Q setter repeat (mm)

MD62200[14] Clearance amount for left-handed machine tool for Q setter repeat (mm)

MD62210[0] The feed rate when having the Q setter repeat touch (mm/min).

MD62210[1] The return rate from the position the Q setter repeat touched (mm/min).

4-3-5 Relevant Alarms

No.67100 An error occurred in the Q setter repeat.

No.67124 No measurement has been performed in Q setter.

No.67138 The touch signal was not entered in the Q setter repeat.

No.67139 Measurement start point of Q setter repeat is not correct.

No.67149 Cannot measure the rotary tool with Q-setter repeat.

1 - 34

Page 41

4-4 How to Shape Soft Jaw

In order to manufacture precision products of high commercial value, without flaws on

workpiece, a soft jaw is formed. By forming a soft jaw matching with the chuck, cutting work

can be performed safely and steadily thus the accuracy of processed goods will improve. For

shaping a soft jaw, there are two methods; one is to utilize the simple soft jaw forming function,

the other is to form one by manual operation.

4-4-1 Simple Jaw Edge Forming Function

(1) Outline

With “Edge shape” “Working Conditions” being input according to the guidance on the

page and the start button being pushed, raw edge machining starts.

(2) Operation

[1] Index the tool used for raw edge forming to the machining position.

[2]

Pushing F6/JAW on the page of the work coordinate system

(General → F4/WORK OFFSET ), display Window page for raw edge forming.

[3]

Select either outer jaw or inner jaw forming by using F4/OUTER JAW or F5/INNER JAW .

[4] Prepare the section where a core bar is fitted and mount it properly.

[5] Input an edge configuration and working conditions.

[6] Turning the spindle in Manual mode, shift the tool to the edge position.

With F3/JAW END SURFACE pushed, “Jaw end surface position setting? Y-Yes/N-No”

is displayed. With Y , set the jaw end position.

[7]

Pushing F9/SHAPE CHECK in MDI mode, check the shape of a working program. If not

in MDI mode, “Set MDI mode” message is displayed. While in shape checking, Dry-Run

and Machine Lock ON state are held effective. The operation panel lamps, however, do

not lit up. Also, no MST code is output.

The coordinate system (tip position) is brought to presetting on completion of shape

checking or by resetting while in checking.

[8] Perform zero returning as paying attention not to cause interference.

[9] Pushing the start button in MDI mode, execute a working program of raw edge forming.

Fig. 8-2(a) Jaw Edge Forming (Outer Jaw)

1 - 35

Page 42

Fig. 8-2(b) Jaw Edge Forming (Inter Jaw)

(3) Function Key

F2/SET UP : The Setup window appears and allows you to specify the spindle

speed and turret indexing.

F3/JAW END SURFAC : “Jaw End Surface Position Setting? Y-Yes/N-No” message is

displayed. Set with Y .

The Z coordinate value of the (soft jaw) tool nose position is

cleared to 0. (The Z coordinate value for the relative coordinate

system.)

F4/OUTER JAW : Outer Jaw Forming page is selected.

F5/INNER JAW : Inner Jaw Forming page is selected.

F6/EXIT : Work Coordinate System page is returned.

F7/DATA CLEAR : “Edge Configuration and Working Condition Erased? Y-Yes/N-No”

message appears. Select Y to clear.

F8/RESET : Soft jaw forming is ended. Push this to return to normal work.

The jaw end surface setting position is cleared.

F9/SHAPE CHECK : A shape of a working program is drawn.

F0/JAW CONTOUR DRAWING: You can turn, enlarge and contract the picture of the jaw

contour.

1 - 36

Page 43

(4) Jaw Configuration And Machining Conditions

The meaning of each symbol of the jaw shape is as follows:

A: I.D./O.D of the first step.

B: Depth of the first step

C: Diameter of the ring (core metal) used

D: I.D./O.D of the second step (If value 0 is set, the shape of jaw formed is a single step

jaw.)

E: Depth of the second step (If value 0 is set, the shape of jaw formed is a single step

jaw.)

T: Taper amount of the gripping portion

F: Necking depth

G: The maximum amount of cutting margin (If value 0 is set, cutting proceeds to Z

direction in rough cutting (See Note 1). If value larger than 0 is set, copy cutting is

performed in rough cutting (See Note 1))

I: Setting of necking width (relieving width)

J: Bolt position 1

K: Input the amount of the jaw protruding from the chuck diameter with +/- sign.

(based on the chuck diameter)

Cutting speed, Revolution: The condition relevant to spindle revolution. Input appropriate

values either in cutting speed or revolution.

Feed speed: The feed speed for rough an finish cutting.

Cut-in amount: Cut-in amount in the rough cutting.

The cut-in amount in the X axis direction, when rough-cutting is performed

in the Z direction.

The cut-in amounts in the X and Z axis directions, when performing copy

cutting.

If value 0 is set, will perform finish cutting only.

Finish margin: If value 0 is set, will perform rough cutting only.

Chuck O.D.

Soft jaw I.D.

Soft jaw O.D.

(Note 1)

The dimension data necessary for jaw locus drawing.

}

These data have no direct connection with the machine action.

Z direction cutting Z direction cutting

1 - 37

Page 44

Caution

1. Before starting soft jaw forming, make jaw end face position setting. A warning is

issued, If shape check or soft jaw forming is executing without making the end face

position setting.

2. Clamp the maximum spindle revolution during the soft jaw forming with the parameter

setting value.

3. Attention should be paid to the tool tip shape, when executing copy cutting and

necking processing.

4. The maximum value of the margin (G) is the value where the margin is considered to

be uniform both directions of diameter and lengthwise. When the margin in two

directions are different, the larger value should be taken as the maximum value of the

margin for the setting.

5. Use decimal point, for inputting the value of dimensions.

6. When attaching a jaw, make sure that the jaw does not protrude beyond the outside

diameter of the chuck.

7. For jaws, always use the standard soft jaw.

8. When processing a thin workpiece, chucking pressure may be lowered for avoiding

deformation of the workpiece, In such cases, take care not to set the spindle revolution

speed too high.

• See the drawing

at right for the

forming shape.

0.05

Cut with taper of abt.

30

20 or more

Reference surface

Reference surface

The comer must be chamfered.

1 - 38

Page 45

(5) Relevant Parameters

(GUD) (Reference Values)

2075 Feed rate magnification in unload cutting of soft jaw forming

2074 Max. spindle rpm of soft jaw forming (1000rpm)

2071 Approach amount on finishing in soft jaw forming (10.000mm)

2073 Relieving amount of soft jaw forming (2.000mm)

2072 Clearance amount of soft jaw forming

(6) Relevant Alarms

No. 66270 Soft Jaw Forming Error

The detail of the alarm can be known by the numeral subsequent to # mark, the meaning

of which is as per list below.

#001 A 0 (A: 1st step inside/outside dia.)

#002 B 0 (B: 1st step depth)

#003 C 0 (C: Mandrel diameter used)

#004 D 0 (D: 2nd step inside/outside dia.)

#005 E 0 (E: 2nd step depth)

#006 T < 0 (T: Taper amount at holding part)

#007 F < 0 (F: Necking depth)

#008 G < 0 (G: Maximum value of cut margin)

#009 H < 0 (H: Chamfering amount)

#010 I < 0 (I: Necking width)

#01 1 C A (Mandrel dia. 1st step I/D)

#012 C A (Mandrel dia. 1st step O/D)

#013 D A (2nd step 1st step I/D)

#014 D A (2nd step 1st step O/D)

#015 C D (Mandrel dia. 2nd step I/D)

#016 C D (Mandrel dia. 2nd step O/D)

#017 B E (1st step 2nd step depth)

#018 Chamfering is too large.

<

=

<

=

<

=

<

=

<

=

>

=

<

=

>

=

<

=

>

=

<

=

>

=

>

=

<

=

>

=

<

=

>

=

<

=

>

=

#019 Necking width is too large.

#020 Interferes with bolt .

#101 Cutting speed (roughing) 0

#102 Cutting speed (finishing) 0

#103 Feed speed (roughing) 0

#104 Feed speed (finishing) 0

#105 Cut-in 0

<

=

<

=

<

=

<

=

<

=

1 - 39

Page 46

#106 Finish margin < 0

#107 Chuck outside dia. < 0

#108 Bolt barrier: Jaw bolt hole pitch < 0

#109 Bolt barrier: Bolt hole center < 0

#110 Bolt barrier: Counter bore dia. < 0

#11 1 Approach amount < 0

#112 Clearance amount < 0

#1 13 Relieving amount < 0

#114 Spindle clamp revolution < 0

#901 Jaw form is not decided.

#902 St art from screen other than that for soft jaw forming.

1 - 40

Page 47

4-4-2 Soft jaw forming by manual operation

Steps Operation method Movement / Display

1 As shown figures in the

right, insert a ring (core

metal) on the front side

of a jaw. Adjust chuck

pressure to the same

Not to be protruded beyond

outside diameter of chuck

value of the actual

operation.

Chuck

Soft jaw

Portion to be removed

Ring

2 Obtain tool

compensation

amount of the tool used

for soft jaw

forming.(Refer Q-setter

operation method)

3 Move the too l rest, and

apply the soft jaw

forming tool to the soft

jaw.

Have the spindle rotate

in advance.

This operation allows you to accurately cut an inner

diameter dimension, viewing the “Position” screen, without

using a measuring instrument.

Soft jaw

Chuck

Ring

1 - 41

Page 48

Steps Operation method Movement / Display

4 Set “W” of relative

coordinates at 0.

(1)Press the key

F1/POSITION

Then, screen displays as

shown in the right

column.

(2)Press

F7/ZERO-SET

(3)Press

F2/W ZERO-SET

Then, the value of W

becomes 0.

1 - 42

Page 49

Steps Operation method Movement / Display

Scrape the jaw by

[HANDLE] operation, or in

the [JOG] mode.

• For this process:

Recommend separate

stages of course and

finish processings, as it

improves accuracy of the

cutting.

• Accuracy improves by

cutting the portion

chucking the ring beforehand.

• When soft jaw is reattached, make adjust

cutting for maintaining

chucking accuracy.

5.0 Current depth of Claw

Core metal

Diameter

Direct of cutting

1 - 43

Page 50

4-5 Manual Type Tailstock

Operating method of Tailstock and items for attention

• Retreat the tailstock to the back end on the base, when the center is not used for chuck

work and others.

• Do not use fixed center for the tailstock.

Procedures for tailstock operation

[1] Set the oil pressure or air pressure of

tailstock.

(Refer to Specifications Manual

“Tailstock pressure - Thrust Diagram”.)

[2] Chuck the work

[3] Stop the tail stock forward side of the

retreat end by forwarding inching

operation.

[4] Press the forward key to have the

tailstock moved forward.

[5] After the position is taken as above,

first remove the pins for traversing,

then tighten 2 fixing bolts.

Work being chucked

Tail stock moved forward

Chuking being readjusted

Foot switch

Application method of tailstock

1 - 44

Page 51

Re: One-touch Tailstock

<<Operation>>

1) Manual key

Forward key Pressing this key, the tailstock moves forward until the forward end.

When it comes into contact with the work, the hydraulic power works.

(To suspend the forward move, press the backward key. While

pressing the SELECT key, high-speed forward movement will

continue.)

Inching key While this key is kept pressed, the tailstock moves on forward.

Even when it presses the workpiece, the hydraulic power does not

work. (While pressing the SELECT key, high-speed forward

movement will continue.)

Backward key While this key is kept pressed, the tailstock moves backward.

(High-speed)

2) M Function

M25 (Tailstock low speed forward)

Moves forward to the forward end with low speed. When the tailstock presses the

workpiece, hydraulic power works and the action completes. When the action does

not complete within the time of the timer setting, an alarm is issued.

M26 (Tailstock high speed backward)

Moves backward with high speed until the designated time set by the timer setting

table expires, thereby the action completes.

M27 (Tailstock high speed forward)

Moves forward with high-speed until the designated time set by the timer setting table

expires, thereby the action completes. In high speed forward command, do not let the

tailstock come into contact with the workpiece.

M28 (Tailstock high speed return to the stroke end)

Moves backward to the stroke end, thereby action completes.

1 - 45

Page 52

5. Operation by Manual Data Input (MDI)

5-1 Program input by MDI

A MDI program can be executed by the

following operation.

[1] Select [MDI] mode on the operation panel

of the machine.

Press the > key.

[2]

[3] Key in a MDI program by the address and

the data key.

Example: When the spindle rotates 800

-1

.

min

1 - 46

Page 53

[4] When the INSERT key is pressed, a

commanded value moves upper section

of the screen.

[5] A command executes when pressing the

PROGRAM [START] key.

1 If wrong key are inputted by

mistake, key in again after pressing

the CANCEL key required number.

2 When a mistake is found on an

inputted command, release a

command by pressing the

RESET key.

Caution

Pay full attention to the safety, since the machine moves.

1 - 47

Page 54

5-2 Edition of MDI program

An inputted MDI program can be edited the

same as a part program stored in the

memory.

1. The cursor moves back or forth at a MDI

program by a block unit when the up and

down CURSOR key is pressed.

2. The cursor moves back or forth by a word

unit when the left and right

CURSOR key is pressed.

3. A MDI program moves back or forth by a

page unit when the PAGE key is

pressed.

4. Insert a data after the current position of

cursor by the INSERT key.

5. Alter a word, the cursor located currently,

to the inputted one by the

ALTER key.

6. A word, the cursor located currently,

deletes by the DELETE key.

7. A MDI buffer is cleared by the

RESET key. Key in the command value

again.

Caution

1. Editing is not available while

executing a MDI program,

however, it is possible when a

condition of the single block stop.

Execute the cycle start as it is,

after editing is finished.

2. In this case, please note that

regardless of the cursor position,

the program starts running from

the beginning.

1 - 48

Page 55

5-3 Operation of MDI program

1. Keep a mode of operation panel of the

machine a MDI, execute an inputted MDI

program by pressing the

[START] button.

Caution

Put the cursor at the head of the program,

because it executes from the current

position of the cursor.

2. When a MDI program executes

sequentially, the cursor moves at the

head of the block currently executing.

3. The MDI program is deleted after an

operation of MDI program is completed.

1 - 49

Page 56

6. Registration of Program

There are following two methods to register a program into the NC unit.

1. Registration from an external input device

2. Manual registration by the address/numeral keys

6-1 Registration from an external device

[1] Connect an input device RS-232-C

terminal and make a possible condition of

transmission.

[2] Set a mode to [EDIT].

[3] Set the memory key to [WRITE].

[4]

Press the F8/IN/OUT key.

Aright sketch is displayed.

Press the F1/INPUT key.

[5]

• Start reading from the first EOB of the NC program and continue until the % code.

• The program No. is registered the 0 No. registered in the input device.

• Display at the program No. list after completion of reading.

• At the time of input, the ISO/EIA information is recognized automatically.

Note) If the program No. already registered is inputted, it becomes an alarm condition. The

program numbers in the 8000s or 9000s are to be enabled or disabled in the Setting

screen. Confirm their setting prior to inputting/outputting them.(See Setting)

1 - 50

Page 57

6-2 Manual registration by the address/numeral keys

[1] Set a mode [EDIT].

[2] Set the memory key to [WRITE].

Press the F2/PRGRM key.

[3]

[4] Key in a desired program No. and press

the INSERT key.

Example:

[5] Set the cursor to ; by the cursor key.

1 - 51

Page 58

[6] Input a program according to the order of

the NC program.

Example:

Data>G28 U0

The EOB key must be inputted at

•

the end of one block.

• Press the CANCEL key when the

data which has inputted want to be

deleted.

A word deletes one by one.

Press the > key and return to the initial

[7]

screen after input of all program is

completed.

G 2 8 U 0

EOB INSERT

1 - 52

Page 59

7. Program No. Search

There are following two methods to search a program.

1. Search by key in a program No.

2. Search to utilize the program list.

7-1 Search by key in a program No.

[1] Set a mode to the [MEMORY] or [EDIT].

[2] Set the memory key to [WRITE].

[3]

Press the F2/PRGRM key.

[4] key in the program No. to be searched

and press the

Example: O 1 2 3 4

Calling up program is displayed.

key.

O 1 2 3 4

1 - 53

Page 60

7-2 Search to utilize the program list.

[1] Set a mode to the [MEMORY] or [EDIT].

[2] Set the memory key to [WRITE].

Press the F2/PRGRM key.

[3]

Press the F7/PROGRAM LIST key.

[4]

[5] Set the cursor to the program No. to be

searched by the cursor key and press

INPUT key.

Calling up program is displayed.

1 - 54

Page 61

8. Edition of Program

The keys to edit a program are as follows;

INSERT : Insert a content of key input after the cursor.

ALTER : Alter a content of key input at a section of the cursor.

DELETE : Delete a section of the cursor.

Use it deletion of program as well.

8-1 Preparation in Advance at the Time of the Edition of Program.

To edit a program, the following conditions

should be made.

[1] Set a mode [EDIT].

[2] Set the memory key to [WRITE].

Press the F2/PRGRM key.

[3]

1 - 55

Page 62

8-2 Search of Word

A word can be searched by the following

method.

1) A method by means of the page and

cursor keys.

[1] Press the page key and display the

page to be edited.

[2] Press the cursor key and move the

cursor to the word to be edited.

•The cursor moves at a block unit by

the

•The cursor moves at a word unit by

the keys.

2) A method by means of word or address

search.

Since a message is displayed as “Not

found” if it is not found, try it again.

keys.

[1] Word search, No. search

Key in the address and numerals to

be searched and press

Example: M08

key.

M 0 8

When searching a section above the

current position of cursor, press the

key

1 - 56

Page 63

[2] Block search

Check a word in a block and search

a block which contains a relevant

word only .

Key in all address and numerals of

one block then press EOB and

key.

Example: When searching a block of

G02 X130.0 Z120.0 I30.0 F0.5

Note)

The EOB should be inputted at the

end of a block.

G 0 2 X 1

3 0 . 0 Z

1 2 0 . 0

I 3 0 . 0

F 0 . 5

EOB

1 - 57

Page 64

8-3 Edition of Program

(1) Insertion of word, block

New word is inserted just after the word

currently located the cursor.

[1] Designate a word immediately

before a section to be inserted.

[2] Key in a new data to be inserted then

press the INSERT key.

Example: When inserting X100.0 after

G00

After insertion

X 1 0 0 .

0 INSERT

[3] When inserting one block, key in

data of one block and press EOB

and INSERT key.

1 - 58

Page 65

(2) Alteration of word

Alter a word, the cursor located currently,

to the new word.

Alteration is done by a word unit.

[1] Set the cursor to the word to be

altered.

[2] Key in the new word then press the

ALTER key.

Example: Alter S1500 to S2000.

S 2 0 0 0

ALTER

After alteration

S1500 replaces S2000.

1 - 59

Page 66

(3) Deletion of word, block

A word currently located the cursor or a

certain boundary of a program can be

deleted.

(a) Deletion of word

[1] Set the cursor to a word to be

deleted.

[2]

Press the DELETE key.

Example: When deleting S3600

Set the cursor to S3600 then

press the DELETE key.

After deletion

S3600 is deleted.

1 - 60

Page 67

(b) Deletion of block

It can be deleted one block at a time.

[1] Set the cursor to the head of the

block to be deleted.

[2]

Press the EOB and DELETE .

Example: When deleting a block

G01 X170.0 Z100.0 F0.3

Set the cursor to G01 and

Press the EOB and

DELETE key.

After deletion

The block G01 ... is deleted and

program moves upward.

1 - 61

Page 68

(c) Boundary deletion

Delete blocks after the cursor to before

the designated sequence No.

[1] Set the cursor to the head word to be

deleted.

[2] Key in the sequence No. just after

the last block to be deleted and

press the DELETE key.

Note) Search the sequence No. before

deletion and check how far is it

deleted.

Example: When deleting

G00 Z150. 0

∼

M03

Set the cursor to G00 and press N 3

DELETE key.

The blocks starting from the one

where the cursor is positioned up to

the one just before the sequence No.

N3 are deleted.

After alteration

The program moves upward.

1 - 62

Page 69

8-4 Back Ground Editing

Generally, “Editing” means front side editing, however this editing could not watch contents of

program and also edition is not available while executing a program.

In fact, giving a possibility to edit a program while executing a program is a back ground editing.

• An editing is available to other than currently executing program.

• A program under back ground editing can not execute.

• Editing can be done both manual and automatic mode.

[1] Turn the memory key to [WRITE].

[2]

Press the F2/PRGRM key.

[3] Press the

F2/BACK GRD EDIT key.

A title of the screen becomes a “Back

ground editing”

[4] Search a program wanted to edit.

A procedure of search is exactly same as

a (front) editing.

Caution

Never execute a reset operation, since the machine will stops if reset is done during

machine operation at the time of back ground editing.

1 - 63

Page 70

[5] Execute edition of program.

A procedure of edition is exactly same as

a (front) editing.

[6] End of back ground editing

1) Press the

F2/FORE GRD EDIT key.

A title of screen becomes a

“PROGRAM”.

It becomes normal editing screen.

8-5 Copy of Program

A program being displayed can be copied on

the other number and displayed.

[1] Display a program wanted to be copied.

[2] Key in a new program No. and press

INPUT key.

Example: When altering to O2001

[3] The program will be copied and the new

program will be displayed in the screen.

O 2 0 0 1 INPUT

1 - 64

Page 71

8-6 Range Assignment Edit Operation (Program Screen Only)

Two or more blocks of a program in display are collectively deleted or copied into another

program.

(1) Starting Range Edit

Range editing is started.

[1]

Push F3/RANGE EDIT .

Function menu changes into the one for range editing.

(2) Assigning Range

assign a program for range editing.

[1]

Push F4/RANGE SET .

The cursor changes into the framed one.

[2] Assign a range.

As in ordinary cursor shifting, a range for the framed cursor can be extended with the

cursor key or the page key. The area inside the frame indicate programs under range

assignment.

Fig. 13-11 Range Assignment

Note) The block inside the frame indicates the scope assigned. Assignment can extend over

two or more pages.

1 - 65

Page 72

(3) Canceling Range Assignment

Range editing is interrupted. Range in assignment is made invalid.

[1]

Push F4/RANGE SET or F3/EXIT .

A framed cursor is changed into an ordinary cursor, canceling a range.

(4) Storing Range

A program having been assigned in range is stored.

[1]

Push F5/RANGE STORE .

A program indicated by the framed cursor is put in memory, which is stored until power

is cut off. However, only the last block subject to rage assignment can be stored.

(5) Inserting Range

a range stored program is inserted immediately after the cursor.

[1] Shift the cursor to the insertion

place.

[2]

Push F6/STORE → INSERT .

The part having been stored in Range Store is inserted after the cursor. The cursor

position stays the same.

(6) Deleting Range

A range assigned program is deleted.

[1]

Push F7/RANGE DELETE .

A program enclosed with the framed cursor is deleted. A program having been deleted

is stored until power is cut off. Only the block having been lastly subject to range

deletion can be stored.

(7) Recovering Deleted Data

A range deleted program is inserted immediately after the cursor.

[1] Shift the cursor to the insertion

place.

[2]

Push F8/DELETE → INSERT .

The part having been stored in Range Delete is inserted immediately after the cursor.

The cursor position stays the same.

Note) Remind that insertion takes place after the cursor.

1 - 66

Page 73

8-7 Word Convert (Program Screen Only)

Words not yet being converted are searched in a program, which are rewritten into the

converted words. Converting methods include the following two:

(1) The applicable words are searched one by one which are converted as being confirmed.

(2) The applicable words are converted collectively while the conversion state is displayed.

As the word searching system is the same as that for Word Search, it is either Number Search

or Word Search depending on pre-converted words.

For example, conversion from “X.1” into “X.5” numerically corresponds each other. Those

applicable to conversion includes character strings such as “X0.1”, “X0.100”, “X00.10”, “X.1”,

“X.100”, etc., all of which are each converted into “X.5”.

Pushing F5/WORD CONVT , start Word Conversion.

[1]

[2]

Input, with keys, the word before being converted and push INPUT .

[3]

Input, with keys, the word after being converted and push INPUT .

If INPUT is pushed without any key input for the word after conversion, the word before

conversion is deleted.

Fig.13-12 Word Convert

1 - 67

Page 74

[4] Assign a search method for conversion.

(a) For individual search:

•

Indicate, with ↑ / ↓ , the search direction from the cursor position.

• When a pre-converted word has been found, “Convert? Y-Yes N-No” appears.

•

To convert, push Y . Not to convert, push any other except Y .

• Repeat the above steps until searching is ended.

(b) For collective convert:

• Indicate the search direction on Function menu.

Table. 12-12 Search Direction of Word Conversion

F1/BLANKET ALL

F2/BLANKET BEFORE

F3/BLANKET AFTER

•“OK? Y-Yes N-No” appears.

•

To collectively convert here, push Y . If not, push any other except Y .

[5] On completion of conversion, the number of words having been converted is indicated in

the message “X words have been converted.”

• Word conversion, once started, lasts till it reaches the beginning or the end of a file.

To stop halfway, push F5/EXIT .

Regardless of cursor position, searching

starts with the program head.

Searching takes place in the forward part

following the cursor including the word

with the cursor.

Searching takes place in the backward

part preceding the cursor including the

word with the cursor.

1 - 68

Page 75

8-8 Deletion of Program

There are following two methods to delete a program.

1. Delete it by the program list screen.

2. Delete it by key input at the program screen.

1) Deleting method by the program list

screen.

[1]

Press the F7/PROGRAM LIST key

at the program screen.

[2] Set the cursor at the program to be

deleted by the program list.

Press the cursor key.

[3] Press the DELETE key.

[4] Against a message “Is it all right to

delete ?”, press the Y key if you

agree.

A program which is designated by

the cursor is deleted.

1 - 69

Page 76

2) Deleting method by key input

[1] Display the program screen.

[2] Key in the program No. to be deleted

and press the DELETE key.

Example: In case of deleting O100

[3] Against a message “Is it all right to

delete?”, press the Y key if you

agree.

A program keyed in is deleted.

3) Continuous deletion by Program No.

Press F7/PROGRAM LIST .

[1]

[2] Place the cursor at the Program No.

to be deleted then press the space

bar.

An asterisk marked at the head of

the Program No. selected.

Example:Screen display shown below is

the case of deleting Program

No.O100, O111, O169, O200.

O 1 0 0 DELETE

[3]

Press the DELETE key.

For deleting the entire program,

press ORIGIN and DELETE keys.

8-9 Process After Edition

Press the > key.

Return to the initial screen.

1 - 70

Page 77

9. Output of Program

NC program can be outputted to the external in/output equipment.

[1] Connect an output device to the RS-232-

C terminal and make it ready.

[2] Make a mode selection to [EDIT] mode.

Press the F8/IN/OUTPUT key.

3)

Refer to the instruction manual of

output device.

A right sketch is displayed.

1 - 71

Page 78

[4] By pressing F7/ALTER LIST key, The

display of Program No. List is switched

over to that of Program No. Detail.

O Select Program No.

Place the cursor at the Program No.

to be selected, and press SPACE .

An asterisk is marked at the head of

the Program No. selected.

When selecting all programs, repeat

pressing ORIGIN several times until

the mark “*” is displayed.

Example: O5, O6, O7.

[5]

Press F2/OUTPUT , then the

program selected is outputted.

Press the > key after completion of

[6]

output and return to the original screen.

1 - 72

Page 79

10.Setting of Tool Compensating Amount

A tool compensating amount is set automatically by touching a tool tip to the sensor of Q-setter.

In this chapter explains a setting method of tool compensating amount by manually .

10-1 Setting of Tool Compensating Amount

[1] Select the manual mode.

or

[2] Set the memory key to [WRITE].

Press the function key F3/TOOL at the

[3]

initial screen.

A right sketch is displayed.

1 - 73

Page 80

a) Tool offset data has geometry and wear

offset for each offset No. respectively.

Tool compensating amount by the Q-

setter is inputted in the column of

geometry offset.

b) A cursor moves up and down every time

of pressing the cursor key.

c) Each address is as follows;

X : Compensating amount of

diametrical direction

Z : Compensating amount of

longitudinal direction

R : Size of nose R

T : Nose point

H : Compensating amount of groove

width

U : Incremental compensating amount

of diametrical direction

W : Incremental compensating amount

of longitudinal direction

Q : Incremental amount of nose R

J : Incremental compensating amount

of groove width

[4] Set the cursor to the tool No. to be set a tool

compensating amount and address.

[5] Key in a compensating amount (setting

amount) and press the INPUT key.

Compensating amount (setting amount) has

a decimal point and minimum unit is

1/1000mm.

If a geometry offset is inputted, a wear offset

amount being stored so far becomes zero.

Note 1. A wear offset amount beyond 1mm

can not be inputted at one time.

divide a compensating amount

within 1mm and input it by several

times.

2. Wear compensating amount can be

inputted at any mode.

3. Wear compensating amount adds

every input.

1 - 74

Page 81

10-2 Deletion of Tool Compensating (Setting Amount)

[1] Select the manual mode.

[2] Set the memory key to [write].

[3] Set the cursor to the offset No. to be deleted.

[4]

Press the F7/ DAT A CLEAR key.

Deleting items are displayed on the screen.

• ONE TOOL CLEAR : Delete whole setting amount of offset No.

designated by the cursor.

• GEOMETRY(ALL TOOL) : Delete geometry setting amount of all offset No.

• WEAR(ALL TOOL) : Delete wear setting amount of all offset No.

• NAME(ALL TOOL) : Delete name of all offset No.

• ALL DATA : Delete all setting amount.

[5] Set the cursor any of deleting item.

[6]

Press the INPUT key.

Asking a question whether delete or not.

[7]

Press the Y key when deleting.

(Press the N key when not deleting.)

A setting amount to be deleted is deleted.

Note) In case of execution of one tool deletion, it is required to set the cursor to the Offset No.

to be deleted before pressing the F7/DATE CLEAR key .

To change an offset No. after display a deleting item, press the F7/DA TA CLEAR key

once and return a previous screen then set the cursor to the No. to be deleted again.

1 - 75

Page 82

11. Setting of Work Offset

11-1 Tool Tip Position Setting of Standard Tool at Machine Zero Point.

Must be obtained a tool tip position by setting of the Z axis work shift amount, how much apart a

tool tip position of the standard tool at the machine zero point from machining zero point (X0,

Z0) before execute a program check or machining by a program, and input it to the NC unit.

“L”

Machining zero

X0 Z0

Shift amount setting procedure of Z axis work

shift coordinate system.

[1] Chuck a workpiece and turn an end surface

of workpiece by manual mode.

Note) Never move on the Z axis at the time of

retracting a tool.

[2] Stop the spindle.

[3] Display a WORK OFFSET screen.

Direction of retracting tool

Cutting

amount

Machining zero

X0 Z0

[4] Measure a total length of a work-piece and

get a cutting amount L .

Example : L =1.35

1 - 76

Cutting amount L

Page 83

[5]

Press the function key F1/COORD.P .

“COORD.P Z = ” is displayed on the

lower left of the screen.

[6] Input the cutting allowance (Allowance).

It is written at the “Z” of the machining

reference point shift automatically.

Machine zero

1.35

“Zo” Z axis shift amount of the work corodinate

Cutting amount

Machining zero

[7] Execute zero return.

Note 1. The following operation must be executed if execute input or alteration of cutting

amount (Measured value).

Set up is done by executing the following operation, the distance from machine zero

to the tool tip point is displayed properly.

a) Manual zero return.

b) Manual index.

c) Command and execution of T ∆∆∆∆ by a program (MDI is available as well.).

2. Direct input (Z ∆∆∆∆ ) or addition and reduction (I = Incremental input Z= ∆∆ ) are

available.

3. A work shift amount of X axis has set by the parameter already.

See the display of the machining reference point of the work coordinate system

screen to confirm.

1 - 77

Page 84

1 1-2 Setting of 2nd Reference Point

A 2nd Reference Point is easily set as follows.

[1]