Page 1

ST200/250

CNC LATHE

PROGRAMMING

65 Edition 1.01

PM-1782-1-0300-E-1-01

Hitachi Seiki Deutschland

Werkzeugmaschinen GmbH

Page 2

2

Page 3

Introduction

Thank you for your having purchased the machine, favoring our product lines for your use.

This manual contains fundamental information on the programming. Please read and fully

understand the contents for your safe machine operation.

In particular, the content s of the items concerning safety in this manual and the descriptions on the

“caution plates” attached to the machine are important. Please follow the instructions contained

and keep them always in mind to ensure safe operation.

The reference record papers on adjusting setting values such as a parameter list are attached to

the machine unit and enclosed in the packing. These are necessary for maintenance and

adjustment of the machine later on. Please keep them safely not to be mislaid.

The design and specifications of this machine may be changed to meet any future improvement.

As the result, there may arise some cases where explanations in this manual could become partly

inconsistent with the actual machine. Please note this point in advance.

In this manual, items on the standard and optional specifications are handled indiscriminately.

Please refer to the “delivery note” for the detailed specification of your machine confirmation.

1

Page 4

2

Page 5

CONTENTS

1. PREPARATION FOR TOOL LAYOUT ....................................................................... 1 - 1

1-1 Tool Set..............................................................................................................................1 - 2

1-2 Tool Layout ........................................................................................................................ 1 - 4

1-3 NC Address and Range of Command Value .....................................................................1 - 5

2. PROGRAMMING........................................................................................................ 2 - 1

2-1 Basis for Programming ....................................................................................................2 - 1

2-1-1 Program Reference Point and Coordinate V alues.................................................... 2 - 1

2-1-2 Regarding Machine Zero Point.................................................................................. 2 - 2

2-1-3 Program Example..................................................................................................... 2 - 3

2-2 Details of F, S, T and M Functions.................................................................................... 2 - 4

2-2-1 F Function (Feed Function) ...................................................................................... 2 - 4

2-2-2 S Function (Spindle Function)...................................................................................2 - 5

2-2-3 T Function (Tool Function)........................................................................................ 2 - 8

2-2-4 M Function (Miscellaneous Function) List............................................................... 2 - 12

2-3 Details of G Function ...................................................................................................... 2 - 20

2-3-1 List of G Function.................................................................................................... 2 - 20

2-3-2 G50 Maximum Spindle Speed Setting..................................................................... 2 - 23

2-3-3 G00 Positioning ...................................................................................................... 2 - 23

2-3-4 G01 Linear Cutting.................................................................................................. 2 - 25

2-3-5 G02, G03 Circular Cutting ...................................................................................... 2 - 27

2-3-6 G04 Dwell ............................................................................................................... 2 - 31

2-3-7 G09 Exact Stop....................................................................................................... 2 - 31

2-3-8 G61 Exact Stop....................................................................................................... 2 - 32

2-3-9 G10 Programmable Date Input............................................................................... 2 - 32

2-3-10 G20, G21 Inch Input/Metric Input ........................................................................... 2 - 33

2-3-1 1 G22, G23 Stored S troke Limit.................................................................................2 - 34

2-3-12 Stroke Limit Check Before Move........................................................................... 2 - 35

2-3-13 G28 Automatic Reference Point Return................................................................ 2 - 36

2-3-14 G30 2nd Reference Point Return ......................................................................... 2 - 36

2-3-15 G31 Skip Function ............................................................................................... 2 - 39

2-3-16 G54 Work Coordinate System Setting (Work Length).......................................... 2 - 40

2-3-17 Canned Cycle ....................................................................................................... 2 - 41

2-3-18 Multiple Repetitive Cycle ....................................................................................... 2 - 50

2-3-19 G32, G92, G76 Thread Cutting ............................................................................. 2 - 68

2-3-20 G32 Continuous Thread Cutting .......................................................................... 2 - 88

i

Page 6

2-3-21 Multi-thread Cutting............................................................................................... 2 - 89

2-3-22 G34 Variable Lead Thread Cutting....................................................................... 2 - 90

2-3-23 G150, G151, G152 Groove Width Compensation................................................ 2 - 91

3. AUTO MATIC CALCULATING FUNCTION OF

TOOL NOSE RADIUS COMPENSATION ................................................................. 3 - 1

3-1 Outline ............................................................................................................................... 3 - 1

3-2 Preparation to Execute the Automatic Calculating Function of Tool Nose Radius Compensa-

tion .................................................................................................................................... 3 - 2

3-3 Three Conditions of Nose Radius Compensation ............................................................. 3 - 3

3-3-1 Tool Nose Radius Compensation Block (During Cutting) .......................................... 3 - 4

3-3-2 Start-up Block and Compensation Cancel Block (Approach/Retreat) ....................... 3 - 6

3-4 Caution Point of Approach to W orkpiece.........................................................................3 - 10

3-5 Tool Nose Radius Compensation to Direct Designation G Code (G141, G142).............. 3 - 1 1

4. PROGRAM EXAMPLE (NC PROGRAM) .................................................................. 4 - 1

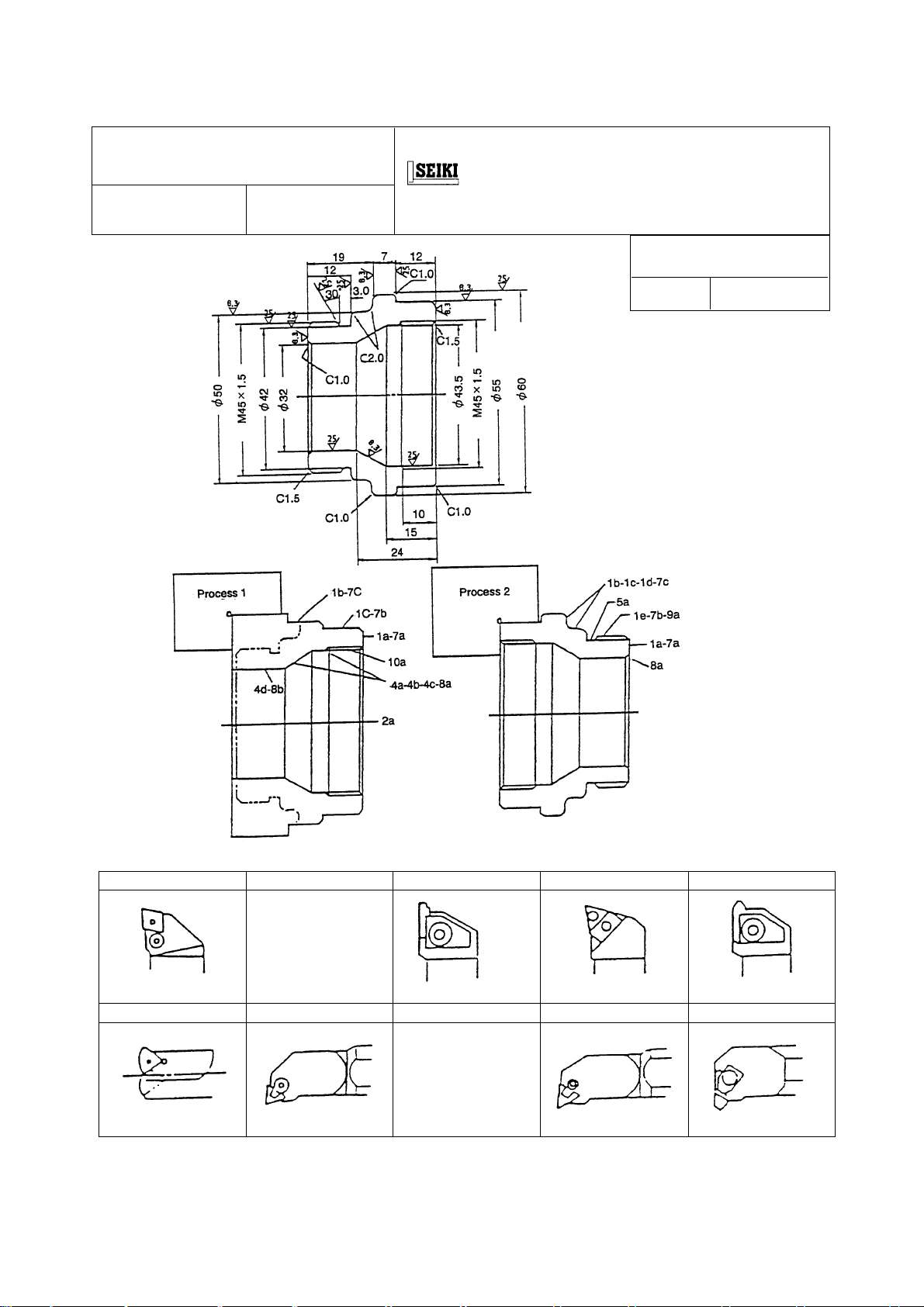

4-1 Chuck Work ...................................................................................................................... 4 - 1

4-1-1 Machining Drawing .................................................................................................... 4 - 1

4-1-2 Chuck Work Program................................................................................................ 4 - 2

4-2 Center Work ...................................................................................................................... 4 - 6

4-2-1 Machining Drawing .................................................................................................... 4 - 6

4-2-2 Center Work Program ............................................................................................... 4 - 7

4-3 Bar Work ...........................................................................................................................4 - 9

4-3-1 Machining Drawing .................................................................................................... 4 - 9

4-3-2 Bar Work Program .................................................................................................. 4 - 10

4-4 Grooving .......................................................................................................................... 4 - 12

4-4-1 OD Grooving............................................................................................................ 4 - 12

4-4-2 ID Grooving.............................................................................................................. 4 - 13

4-4-3 End Face Grooving.................................................................................................. 4 - 15

4-5 1st and 2nd Process Continuous Machining Method ...................................................... 4 - 16

4-5-1 Machining Method by Single Program...................................................................... 4 - 17

4-5-2 Machining Method by Subprogram Calling............................................................... 4 - 18

4-6 Operation Example of Many Short Length Works ........................................................... 4 - 19

5. REFERENCE MATERIALS ....................................................................................... 5 - 1

5-1 How to Calculate the Tool Nose Radius Compensation Amount Without Using the Tool Nose

Radius Compensation Function........................................................................................5 - 1

5-2 Calculation Formulas ...................................................................................................... 5 - 10

5-2-1 How to Obtain Side and Angle of Right T riangle....................................................... 5 - 10

5-2-2 How to Obtain Side and Angle of Inequilateral T riangle............................................ 5 - 12

5-2-3 How to Obtain Taper and Intersecting Point of Circular Arc..................................... 5 - 13

5-2-4 Others ..................................................................................................................... 5 - 17

ii

Page 7

1. PREP A RATION FOR TOOL LAYOUT

There are limit of range of travel and other limits according to the machine

specifications and safety.

Refer to “Specifications Manual” of each machine type for stroke, work

operation range, tool interference diagram and Q setter•work interference

diagram of the machine, which should be fully understood as they are premises

for machine operation, programming and tool layout.

1 - 1

Page 8

1-1 Tool Set

Standard Tool Set

In order to keep operation procedure of the work and to avoid interference of the tool and the

chuck large tools such as the base holder shall be set permanently.

Further, set the tools as you like in order to satisfy the operation accuracy of the small tools

such as the boring bar, and also to perform the turret indexing by one rotation.

The standard tool set is shown as below.

T08 ID grooving

T07 OD grooving

T06 ID rough boring

T09 OD and face finishing

T10 ID finishing

T11 OD threading

T12 ID threading

T05 OD profiling or face grooving

T03 OD profiling or face grooving

T01 Rough cutting

for face and OD

T02 Center drill or Starting drill

Specifications of 12-station Variable turret

T04 Drill

1 - 2

Page 9

Standard Tool Set

T07 OD grooving

T09 OD and face

finishing

T10 ID finishing

T11 OD threading

T08 ID grooving

T06 ID rough boring

T05 OD profiling or

face grooving

T04 Drill

T03 OD profiling or

face grooving

T12 ID threading

T02 Center drill or Starting drill

T01 Rough cutting

for face and OD

Specifications of 12-station QCT turret

1 - 3

Page 10

1-2 Tool Layout

Example of tool layout for chuck work

Process :

Process 1, 2

NC unit

CNC LA THE:

TOOL LAYOUT DRAWING

Part name SAMPLE

Material

S48C

R0.8

OD roughing

T1 T3 T5 T7 T9

Width 2mm

OD grooving

R0.8

OD finishing

OD threading

T2 T4 T6 T8 T10

R0.8

φ20 ID finishing

φ25 ID threading

φ30

R0.8

φ20 ID roughing

1 - 4

Page 11

1-3 NC Address and Range of Command Value

Function Address Range of command value

Program No. O 1~99999999

Sequence No. N 1~99999999

Preparatory function G 0~999

Coordinate value X, Y, Z, U, V, ±99999.999(mm) ±9999.999(inch)

W, I, J, K, Q, ±99999.999(deg) ±99999.999(deg)

R, A, B, C

Feedrate F 0.001~999.999(m/rev) 0.0001~99.9999(inch/rev)

Spindle function S 0~99999999

Tool function T 0~999999

Auxiliary function M 0~99999999

Dwell P, X, U 0~99999.999(sec)

Call up program No. P 1~99999999

Number of repetition L 1~99999999

1 - 5

Page 12

1 - 6

Page 13

2. PROGRAMMING

2-1 Basis for Programming

2-1-1 Program Reference Point and Coordinate Values

For a CNC lathe, coordinate axes X and Z are set on the machine and their intersecting

point is called a “program reference point”. The X axis assumes a spindle center line to

be a position of “X0”, and the Z axis assumes a workpiece finish end face on the tail stock

side to a position of “Z0”.

To move a tool, specify its moving position, adding signs “+” and “−” to both X and Z axes,

with this program reference point as a datum point.

•Position of the tool A ...

Since it is locates a plus 50 dia. on the X-axis and plus 35mm (1.4”) on the Z-axis,

X50.0 Z35.0 ..... (Omit the plus sign)

•Position of the tool B ...

Since it is locates a plus 80 dia. on the X-axis and minus 25mm (1.0”) on the Z-axis,

X80.0 Z−25.0

2 - 1

Page 14

2-1-2 Regarding Machine Zero Point

Properly speaking, the machine zero point and reference point is a different position,

however, as for our NC lathe make the both points the same position.

Therefore, here in after the reference point calls as the machine zero point in this manual.

It is a position which is the machine proper and the machine zero point which is the basis

of program set the end of each axis.

This machine zero point utilizes an electrically identical point, a grid point, and stop a

servo motor at the certain point.

Turn on the power at the starting time in the morning, it can be entered a program

operation .

2 - 2

Page 15

2-1-3 Program Example

NC Program

2 - 3

Page 16

2-2 Details of F, S, T and M Functions

2-2-1 F Function (Feed Function)

G99 mode F ooo.ooo(Up to 6 digits in increment of 0.001)

mm/rev Specify a cutting “feed rate” per spindle revolution or a lead of the threading.

(Example) 0.3 mm/rev = F0.3 or F30

1.0 mm/rev = F1.0 or F100

1.5 P thread = F1.5 or F150

In case of thread cutting, it is possible to command down to 5 digits of decimals.

F

ooo.ooooo(0.00001 unit; max. 8 digits)

Max. feed rate 5,000mm/min.

A maximum feed rate depends on the spindle speed used.

Assuming the spindle speed to be N;

5000

N

(Example) When the spindle speed is 1,000 rpm, the maximum feed rate is;

G98 mode F

mm/min Feed rate per minute

oooooo A decimal point cannot be used.

Generally, you specify a feed rate per spindle revolution for in case of turning.

However, if specified in the G98 mode,

(Example) 200 mm/min = F200

5000

1000

= 5.0 F = 5.0 mm/rev

a feed rate per minute is set.

2 - 4

Page 17

Notes) 1. Since the G99 mode is set when turning on the power, you do not have to specify it,

unless G98 is to be used.

2. A cutting feed in taper cutting or circular cutting is that of a tool advance direction

(tangent direction).

3. If a cutting feed in G98 mode (G01, G02, G03) is specified, the turret head moves even

if the spindle is not running.

4. When commanding G98 from G99 mode or G99 mode from G98, be sure to command

F .... as well.

In case of F command is missing in the block, F value is effective which is designated

just preceding block in G98, G99 mode respectively.

To be concrete, it becomes as follows:

Indicate “F” that becomes effective in that block with [ ] .

(Feed per minute) (Feed per revolution)

When the power is turn ON 0 0.00

N1 G99 F1.23 ; 0 [1.23]

N2 —— ; 0 [1.23]

N3 G98 F1000 ; [1000] 1.23

N4 —— ; [1000] 1.23

N5 G32 F2.34567 ; 1000 [2.34567]

N6 —— ; 1000 [2.34567]

N7 G99 ; 1000 [2.34]

N8 —— ; 1000 [2.34]

N9 G98 ; [1000] 2.34

N10 —— ; [1000] 2.34

N11 G32 ; 1000 [2.34567]

2-2-2 S Function (Spindle Function)

Specify a spindle speed or surface speed (cutting speed) with S 4-digit numeral

(S

oooo).

Command Description

oooo Max. spindle speed limit

G50S

(Example) G50 S1800 : A maximum spindle speed is limited to 1,800 (mim

oooo Constant surface speed cancel

G97S

Specify a spindle revolution with S

(Example) G97 S1000 : A spindle speed per minute is set to 1,000 (mim

2 - 5

oooo .

−1

)

−1

)

Page 18

G96S

oooo Constant surface speed control

When performing constant surface speed control, specify a cutting speed “V”

(m/min) with an S 4-digit code (S

(Example)G96 S150 : A spindle speed is controlled to 150

oooo ).

150 m/min cutting speed at the cutting point.

..... Refer to the left figure.

* Formula for calculating the spindle speed from the

surface speed

N =

1000 × V

π

× D

V : Surface speed (m/min)

π : 3.14

D : Tool nose position (ø mm)

-1

N : Spindle speed (mim

Spindle speed “N” at the position A = = 1193 (mim

Spindle speed “N” at the position B = = 795 (mim

Spindle speed “N” at the position C = = 682 (mim

)

1000 × 150

3.14 × 40ø

1000 × 150

3.14 × 60ø

1000 × 150

3.14 × 70ø

-1

)

-1

)

-1

)

As mentioned above, an automatic change of the spindle speed relating to the work

diameter is called as the constant surface speed control.

Notes) 1. Considering a workpiece chucking condition, specify the maximum spindle speed limit

with S 4-digit code in a G50 block at the beginning of a program.

2. When roughing with G96, calculate maximum and minimum spindle speeds so that

cutting will be performed in a constant power range as much as possible.

3. When changing over from G96 to G97 and vice versa, specify not only a G code, but

also an S code.

4. When changed over from G96 to G97 and no S code is specified, the spindle is run with

the speed specified in the latest S code in G96 mode.

5. When changed over from G96 to G97 and no S code is specified, the spindle turns with

the previously used surface constant speed is S code had been specified in G96 mode.

Also, when no S code is specified in G96 mode, S results in 0.

2 - 6

Page 19

6. The following interlocks are provided as the rotating conditions of spindle.

(1) The direction of the chuck inner clamp and outer clamp key shall be the same

direction as that of chuck clamping.

(2) Q-setter shall be stored.

(3) Rotating speed shall be command with G96 Sxxx.

(4) The lamp of advance or retract of center support shall be on. (Option)

(5) The door shall be closed.

2 - 7

Page 20

2-2-3 T Function (Tool Function)

The tool used and its offset No. can be selected with a 4-digit number following “T”.

Turret face selection Offset No.

Face 01 ~ maximum number of faces

1. Setting Coordinate of Tool-nose Position

As a general usage, it is not necessary to command of offset No. Only command of

calling of turret as shown below can set the tool-nose position.

Example) If the turret No. 3 is to be called, program as follows:

2. Setting Coordinate of Tool-nose Position for Arbitrary Offset No. When using an

arbitrary offset No., program as follows.

Setting is done with the tool mounting position (diameter, length) of the offset No. 13.

Example)

oo∆∆

T

T0300

T0313

Turret No. 3 Offset No.

selected

Note 1. Be sure to input the tool-nose point on the tool layout screen.

2. Input “9” to the tool-nose point for drilling end-milling tool. (When a rotating tool

is equipped.)

Caution When “T ∆ ∆” command is specified on the same line as the axis travel command,

the indexing of turret is made simultaneously with traveling and a coordinate is set

after completion of traveling.

Be careful not to command T function together with the travel command.

2 - 8

Page 21

3. Compound Offset

When an adjustment is made on diametrical dimension of 50 and 70mm respectively at

the following workpiece, two or more offset can be applied on one tool.

Example 1)

T0900

G97 S2546 M08

G00 X50.0 Z10.0 M03

G96 Z3.0 S200

G01 Z−15.0 F0.2

X70.0 T0919 Compound offset

Z−40.0 Offset No. 19

X84.0 T0900 Compound offset

cancel

G00 G97 Z10.0

G30 U0 W0

M01

Example) Input status of dimension adjustment when the part

0.03.

OFFSET

XZRT

19 0.03 0

Note) Be sure to input zero for R and T.

Example 2) Cutting with taper of −0.3 at

T0500

G97 S2000 M08

G00 Z3.0 M03

G01 X24.0 F1.0

G00 G97 Z10.0

OFFSET

25 X-0.3 Z0 R0 T0

G30 U0 W0

0 0

φ30 part

X40.0

Z1.0 F0.2

X30.0 Z−2.0

Z−90.0 T0525 Compound offset

X57.00 T0500 Compound offset

X62.0 Z−92.5 cancel

X68.0

M01

φ70 is made larger by

Offset No. 25

2 - 9

Page 22

4. Multi tool compensation

When set up tools 2 or more on the same face on the turret described below, give

plural compensation on a face and set up the coordinate for each tool respectively.

Command system of compound compensation,

different one by setting data in nose radius and control point.

(Example) N100 T0100 A tool with turret face No.1 is indexed and setting-up

〜

T0131 A tool with turret face No.1 is indexed and setting-up

〜

Note 1) When a tool, which is not required tool point and tool nose R such as drill etc., is

applied to multi tool, set a tool point as 9. (Tool nose R may be set as zero.)

2) When set the Q setter, the cursor position of tool offset coincide with the tool No.

mounted on the turret face indexed at machining position at this moment.

Any No. can be selected by moving the cursor by cursor key.

Multi tool compensation and compound compensation is divided by data of tool

point and tool nose R as follows:

Tool nose R and tool point of offset No. on effect the compound compensation

and multi tool compensation.

is performed by the data of offset No.1.

is performed by the data of offset No.31.

and furthermore, set up tools deem as

1 Both tool nose R and tool point are zero

2 Data of tool point from 1 to 9 and setting of tool nose R

→ Compound compensation

→ Multi tool cutting

3 Tool point is zero and set a tool nose R

2 - 10

→ Alarm (No.182)

Page 23

5. Program example

T01

T06

T03

Turret face No.1

Offset No.1

Turret face No.3

Offset No.3

Turret face No.6

(Compound compensation 33, 34) (Offset No.6, Multi tool

conpensation, 36)

N100 T0100 The turret face No.1 is indexed and setting-up is

〜

performed by the data of offset No.1.

M01

N300 T0300 The turret face No.3 is indexed and setting-up is

〜〜〜〜〜〜

performed by the data of offset No.3.

G01 Z− T0333 Compound compensation ON (Offset No.33)

X Z T0334 Compound compensation ON (Offset No.34)

T0300 Cancel compound compensation (Offset No.3)

M01

N600 T0600 The turret face No.6 is indexed and setting-up is

performed by the data of offset No.6.

T0636 Multi tool compensation ON (Offset No.36)

M01

Example of compensating data

No. X Z R T

01 Q-setter Q-setter 0.8 3

03 Q-setter Q-setter 0.8 3

06 Q-setter Q-setter 0.4 2

33 Extremely Extremely

small amount small amount 0 0

34 Extremely Extremely

small amount small amount 0 0

36 Q-setter Q-setter 0.4 2

2 - 11

Page 24

2-2-4 M Function (Miscellaneous Function) List

Please refer to the details on the Delivery specifications

as to the discrimination between Standard or Option.

M code Function Description

M00

M01

M02

PROGRAM STOP

OPTIONAL STOP

PROGRAM END

This code can stop the machine during its operation,

when measuring a workpiece or removing cutting chips.

(The spindle and coolant also stop.) To restart, press

the CYCLE START key. However, since the spindle and

coolant are being suspended, specify M03/M08 in a

subsequent block.

Same function as M00.

An M01 command on a program can be either executed

or ignored by means of the OPTIONAL STOP key on the

operation panel.

Executed when a lamp is lit up.

(optional stop is effective)

Sheet key

This code is used in the tape operation and is

programmed at the end of the program.

Ignored when a lamp is lit off.

(optional stop is not effective)

M03

M04

M05

M07

M08

M09

M12

SPINDLE FORWARD

START

SPINDLE REVERSE

START

SPINDLE STOP &

ROTARY TOOL STOP

OPTIONAL COOLANT

START

COOLANT STA RT

COOLANT STOP

WORK COUNT

It stops the spindle and coolant, and resets NC.

Viewing from the spindle motor side, this code starts the

spindle in the clockwise direction.

Viewing from the spindle motor side, this code starts the

spindle in the counterclockwise direction.

This code stops the spindle.

When changing over spindle revolution from forward to

reverse (or the other way), stop the spindle once with

M05, and then specify M04 (M03).

This code starts discharging coolant.

This code stops discharging coolant.

Normally, this code starts a work counter or tool counter

to count up.

Note) : • M05 and M09 are executed after the completion of the axes travel.

• Do not specify M codes in the same block duplicately.

2 - 12

Page 25

M code Function Description

M13

M14

M15

M18

M19

M23

ROT ARY TOOL

FORWARD ROTATION

ROT ARY TOOL

REVERSE ROTATION

ROT ARY TOOL STO P

SPINDLE

POSITIONING OFF

SPINDLE

POSITIONING

CHAMFERING ON

The rotary tool runs in the forward direction at C-axis coupling

time.

The rotary tool runs in the reverse direction at C-axis coupling

time.

Stops the rotary tool spindle .

Cancels M19.

Indexes the spindle by one position.

This code performs automatic thread chamfering during a

threading cycle (G92). A chamfering length can be set in

the parameter in increment of 0.1 L.

M24

M25

M26

M28

M30

M31

CHAMFERING OFF

T AILSTOCK ADV ANCE

TAILSTOCK RETRACT

CENTER STOPOVER

RETRACT

END OF PROGRAM,

NC RESET & REWIND

NO-WORKPIECE

CHUCK& COUNT UP

CHECK

When M23 is specified.

This code cancels M23.

Use when the center position detector is set.

End of the program in case of memory operation. Stops

the spindle and coolant, and resets the NC unit to return

the program to the beginning. Specify this code in an

independent block.

1. Tool life check

2. Work quantity check of the preset work counter

3. No-workpiece check when the bar feeder is attached

2 - 13

Page 26

M code Function Description

M32

M33

M34

M36

M37

M38

M39

TOP CUT CHECK

TOP CUT RESET

BAR LOAD COMMAND

POWER OFF IS

EFFECTIVE AT

PROGRAM STOP

POWER OFF IS NOT

EFFECTIVE AT

PROGRAM STOP

CENTER AIR BLOW

ON

CENTER AIR BLOW

OFF

Block ship ON, however, block skip becomes OFF by the

top cut signal ON.

Reset the top cut signal.

Power is off by command of M00, M01, M02 or M30

when the power cut off is ON.

Power does not off even the command of M00, M01, M02

or M03 when the power cut off is ON.

Air is blown to the center.

Stop the air.

M40

M41

M43

M44

M45

M46

SPINDLE LOW

WINDING SELECT &

CANCEL C-AXIS

COUPLING

SPINDLE HIGH

WINDING SELECT &

CANCEL C-AXIS

COUPLING

C-AXIS COUPLING ON

ROTARY TOOL

COUPLING ON

ROTARY TOOL

COUPLING OFF

SPINDLE OVERRIDE

30 ~ 1000min

30 ~ 6000min

-1

-1

Switches from the cutting mode to the milling (rotary tool)

mode.

The spindle override can be applied.

M47

IS EFFECTIVE

SPINDLE OVERRIDE

IS NOT EFFECTIVE

The spindle override is ignores.

2 - 14

Page 27

M code Function Description

M48

M49

M51

M52

M53

M54

M55

FEEDRA TE OVERRIDE

IS NOT EFFECTIVE

FEEDRA TE OVERRIDE

IS EFFECTIVE

SPINDLE AIR BLOW

ON

SPINDLE AIR BLOW

OFF

TOOL EDGE

MEASURING SENSOR

AIR BLOW ON

TOOL EDGE

MEASURING SENSOR

AIR BLOW OFF

TOOL EDGE

MEASURING ARM OUT

The feedrate override can be applied.

The feedrate override is ignores.

Discharge the air at the chuck section.

Stop the air.

Air is blown to the measuring sensor section.

Air blow at the sensor section stops.

Measuring sensor swings out.

M56

M61

M62

M63

M64

M65

M66

M67

M68

TOOL EDGE

MEASURING ARM

RETURN

AUTO DOOR OPEN

AUTO DOOR CLOSE

UNLOADER ADV ANCE

UNLOADER RETRACT

BAR FEEDER SUPPL Y

COMP.CHECK(ASQ 80)

CHUCK CLAMPING

PRESSURE IS LOW

CHUCK CLAMPING

PRESSURE IS HIGH

CHUCK CLOSE

Measuring sensor is stored.

The door opens by a program command.

Closes the door.

This function is the bar feeder start check of bar feeder

(ASQ type) made by ALPS.

The pressure of spindle chuck shift to low side.

The pressure of spindle chuck shift to high side.

The spindle chuck closes.

M69

M70

CHUCK OPEN

SP ARE OUTPUT

SIGNAL

The spindle chuck opens.

For bar feeder (ASQ type) made by ALPS.

2 - 15

Page 28

M code Function Description

M71

M72

M73

M74

M75

M76

M81

WORK MEASURING

ARM OUT

WORK MEASURING

ARM RETURN

WORK MEASURING

SENSOR AIR BLOW

ON

WORK MEASURING

SENSOR AIR BLOW

OFF

CHIP CONVEYOR

START

CHIP CONVEYOR

STOP

ROBOT SERVICE

Work measuring sensor swings out.

Work measuring sensor is stored.

Air is blown to work measuring sensor.

(In the custom macro of WORK MEASUREMENT

FUNCTION)

Air blow at the measuring sensor stops.

(In the custom macro of WORK MEASUREMENT

FUNCTION)

Chip conveyor rotates to normal direction.

Chip conveyor stops.

ROBOT START-1

M82

M83

M84

M88

M89

M98

REQUEST-1

ROBOT SERVICE

REQUEST-2

AUTO PRESETTER

CHUCK INTERLOCK

OFF

AUTO PRESETTER

CHUCK INTERLOCK

ON

MACHINE PROPER

STANDBY

FEEDER STANDBY

OFF

SUBPROGRAM

CALLING

ROBOT START-2

When measuring arm swings, chuck open/close condition

is neglected.

When measuring arm swings, chuck open/close condition

becomes effective.

The NC unit temporarily stand by. It is restarted by cancel

signal from the robot.

Robot on standing by is restarted by cancel signal from

the machine.

This code switches program from a main program to a

subprogram.

M99

M100

SUB PROGRAM END

C - AXIS BRAKE ON

This code returns control from a subprogram to a main

program. If specified in the main program, the program

returns to its top.

Used during C-axis couplig. With the brake applied,

spindle rotation or C-axis move are disabled.

2 - 16

Page 29

M code Function Description

M101

M102

M110

M111

M122

M123

M132

C - AXIS BRAKE OFF

SPINDLE FORWARD

START (CHUCKING

CONDITION IS

NEGLECTED)

TURRET HEAD AIR

BLOW ON

TURRET HEAD AIR

BLOW OFF

AIR BLOW FROM

SPINDLE ON

AIR BLOW FROM

SPINDLE OFF

SPINDLE THROUGH

COOLANT ON

Air is blown from turret head.

Air blow from iturret head stops.

Air is blown inside spindle.

Air blow from inside spindle stops.

Dischage the coolant from spindle.

M133

M140

M141

M142

M143

M144

M145

M162

SPINDLE THROUGH

COOLANT OFF

WORK SETTING CHECK

M CODE EXTERNAL

FUNCTION 1

M CODE EXTERNAL

FUNCTION 2

M CODE EXTERNAL

FUNCTION 3

M CODE EXTERNAL

FUNCTION 4

M CODE EXTERNAL

FUNCTION 5

SP. ROTATE CW + AIR

Stops dischaging the coolant from spindle.

M163

BLOW ON

SP. ROTATE CW + AIR

BLOW OFF

2 - 17

Page 30

M code Function Description

M167

M171

M172

M173

M174

M201

~

M231

DOOR OPEN +SP. STOP

+COOLANT STOP

AUTO DOOR OPEN

(ONE SHOT)

AUTO DOOR CLOSE

(ONE SHOT)

CENTER FORWARD

(ONE SHOT)

CENTER RETRACT

(ONE SHOT)

ROBOT SERVICE

REQUEST 1

~

ROBOT SERVICE

REQUEST 31

M260

M263

M264

M285

M286

M292

M293

WORK SETTING

CHECK SOL ON (ONE

SHOT)

UNLOADER FORWARD

(ONE SHOT)

UNLOADER RETRACT

(ONE SHOT)

SPINDLE SPEED

CHANGE CONTROL ON

SPINDLE SPEED

CHANGE CONTROL

OFF

CENTER FORWARD OT

LS DISABLE

CENTER FORWARD OT

LS ENABLE

2 - 18

Page 31

Example of Subprogram Call

(Example)

Main Program Subprogram

N001 —————— ; O101 ; O401 ;

N002 —————— ; N102 —————— ; N402 —————— ;

N003 —————— ; N103 M98 P401 ; N403 —————— ;

N004 M98 P101 ; N104 —————— ; N404 —————— ;

N005 —————— ; N105 M99 ; N405 M99 ;

N006 ;

N007 M98 P201 L2 ; O201 ;

N008 —————— ; N202 —————— ;

N009 —————— ; N203 —————— ;

N010 —————— ; N204 M99 ;

N011 —————— ;

N012 M98 P301 ; O301 ;

N013 —————— ; N302 —————— ;

N014 —————— ; N303 M99 P015 ;

N015 —————— ;

N016 M99 P018 ;

N017 —————— ;

N018 —————— ;

Note 1) Another subprogram can be called from one subprogram.

Although the example above calls subprograms doubly, they can be call

quadruply at most.

2) One call command can repeatedly call the subprogram for 99999999 times

running.

3) When the subprogram ends, if a sequence number is specified with P, control

does not return to next to the program called by a parent, but to the sequence

number specified with P’.

2 - 19

Page 32

2-3 Details of G Function

2-3-1 List of G Function

Group G code Function

01 G00 Positioning (Rapid traverse)

G01 Linear interpolation

G02 Circular arc interpolation/Helical interpolation CW

G03 Circular arc interpolation/Helical interpolation CCW

G04 Dwell

G07 Hypothetical axis interpolation

00 G09 Exact stop

G10 Data setting

G11 Data setting mode cancel

G17 Xp - Yp plane designation Xp: X-axis or its

02 G18 Zp - Xp plane designation Yp: Y-axis parallel

G19 Yp - Zp plane designation Zp: Z-axis axis

06 G20 Inch input

Please refer to the details on the Delivery specifications

as to the discrimination between Standard or Option.

}

G21 Metric input

04 G22 Stored stroke check ON

G23 Stored stroke check OFF

00 G28 Reference point return

G30 2nd, 3rd and 4th reference point

G31 Skip function

01 G32 Thread cutting

G34 Variable lead thread cutting

00 G38 Tool tip R compensation/Tool radius compensation vector retention

G39 Tool tip R compensation/Tool radius compensation corner circular arc

G40 Tool radius compensation cancel

07 G41 Tool radius compensation left side

G42 Tool radius compensation right side

G50 Coordinate system setting/Setting of maximum high speed of spindle

00 G52 Back face machining mode

G53 Machine coordinate system selection

12 G54 Work length alteration 1

G55 Work length alteration 2

00 G59 Local coordinate system setting

2 - 20

Page 33

Group G code Function

13 G61 Exact stop mode

G64 Cutting mode

00 G65 Macro calling

14 G66 Macro modal calling

G67 Macro modal calling cancel

G70 Finishing cycle

G71 OD/ID roughing cycle

G72 End face roughing cycle

00 G73 Closed loop turning cycle

G74 End face cutting-off cycle

G75 ID/OD cutting-off cycle

G76 Multi-type thread cutting cycle

G80 Drilling cycle cancel

G81 Drilling cycle, Spot drilling cycle

G82 Drilling cycle, Counter boring cycle

G83 Peck drilling cycle

G831 Peck drilling cycle

G84 Tapping cycle

G841 Reverse tapping cycle

09 G842 Direct tapping cycle

G843 Reverse direct tapping cycle

G85 Boring cycle

G86 Boring cycle

G861 Fine boring cycle

G87 Back boring cycle

G88 Boring cycle

G89 Boring cycle

G90 OD/ID turning cycle

01 G92 Single type thread cutting cycle

G94 End face turning cycle

G96 Constant surface speed control

17 G196 Constant surface speed control (Back face)

G97 Constant surface speed control cancel

05 G98 Feed per minute (mm/min)

G99 Feed per rotation (mm-1)

22 G120 Polar coordinate interpolation mode cancel

G121 Polar coordinate interpolation mode

2 - 21

Page 34

Group G code Function

00 G128 Scroll cutting speed control

18 G130 Tool life management OFF

G131 Tool life management ON

27 G140 Automatic tool tip R compensation/Tool radius compensation cancel mode

G143 Automatic tool tip R compensation effective mode

G144 Automatic tool tip R compensation effective mode (G144 = G143)

G145 Tool radius compensation effective mode

00 G141 Automatic tool tip R compensation left side

G142 Automatic tool tip R compensation right side

G150 Groove width compensation cancel

16 G151 Groove width compensation for end face

G152 Groove width compensation for OD/ID

25 G170 Front face machining mode

G171 Back face machining mode

00 G194 External measurement compensation

10 G198 Initial point return of fixed cycle for drilling

G199 R point return of fixed cycle for drilling

G251 Multi-buffer

G261 S designation for spindle

00 G262 S designation for rotating tool

G263 S designation for sub spindle

G271 Cylindrical interpolation

15 G501 Programmable mirror image reset

G511 Programmable mirror image set

00 G921 Work coordinate system preset

Note 1) When the source power is switched on, those G codes marked are

set.

2) G codes of 00 group indicate those which are not modal, and are effective to the

blocks indicated.

3) When G codes which are not listed in G Code List are commanded, alarm is

displayed, and when G codes which don’t have corresponding options, alarm is

displayed.

4) Any numbers of G codes can be commanded in the same block, if they belong to

different groups.

When two or more of G codes which belong to the same group are commanded,

G code later commanded becomes effective.

2 - 22

Page 35

2-3-2 G50 Maximum Spindle Speed Setting

Using a command “G50 S ....... ;” , you can directly specify the upper limit value of a

spindle speed (min

−1

) with a 4-digit numerical value following an address S.

When a S beyond the upper limit has commanded after this command, it is clamped at

this upper limit.

Even in constant surface speed control (G96 mode), the spindle rotation speed for the

specified surface speed (m/min. or ft/min. ) will be clamped to this upper limit.

(Example) G50 S2000 ;

Fixes the maximum spindle speed to 2,000 min

Note: Depending on a workpiece loading state, specify the maximum spindle speed (G50

××××) at the beginning of the program.

S

2-3-3 G00 Positioning

Specify this G code when feeding a tool by rapid traverse. This is used when approaching

the tool to the workpiece or when retreating it after cutting is completed.

−1

Chuck work

1. Specify 2 axes simultaneously from the point

“a” to the point “b”.

G00 X100.0 Z0.2

2. From the point “b” to the point “a”

G00 X200.0 Z200.0

Center work

Specify one axis when there is any

interference.

1. From the point “a” to the point “b”

G00 Z3.0

From the point “d” to the point “c” X80.0

2. From the point “c” to the point “b”

G00 X200.0

From the point “b” to the point “a” Z20.0

Note: When simultaneously positioning both the X and Z axes, the tool does not linearly move

from a current position to a specified position, because their rapid traverse rates differ

from each other. Therefore, you must be careful when there is an interfering substance

halfway a tool path.

2 - 23

Page 36

After one of 2 axes (X and Z) has completed its

move, the other one moves to a specified point.

The tool does not move linearly as shown with a

dotted line in the left figure.

When moving to the next cutting position

When moving the tool to the next cutting position, do so at a rapid traverse rate after retreating it

by about 2 to 3 mm from a cut surface.

End face OD cutting

End facing G01 X45.0 F0.3

Retreat

To the point “a” G00 X100.0

Next command G01

ID cutting

ID cutting G01 Z

Retreat X46.0

To the point “a” G00 Z10.0

To the point “b” X200.0 Z200.0

Z3.0

Z oooo

−43.0 F0.2

2 - 24

Page 37

2-3-4 G01 Linear Cutting

(1) Specify this G code when performing linear cutting (ordinary cutting).

Chamfering and taper cutting are also considered linear cutting.

Use an F code to specify a feeding rate.

Absolute programming

A P1 G00 X90.0 Z5.0

Incremental programming

*

P1 G00 X90.0 Z5.0

P2 G01 W

P3 U6.0

P4 X100.0 W

P5 W

P6 G00 X

−55.0 F0.3

−2.0

−28.0

ooo. oo

P2 G01 Z

P3 X96.0

P4 X100.0 Z

P5 Z

P6 G00 X ooo. oo

* Absolute programming means to specify the

position with X and Z coordinates from work

coordinate zero point.

This is also called an incremental value

programming method. This method

specifies tool strokes from a current position

(start point) to the next point with U (X axis)

and W (Z axis).

An end point of the previous block becomes

a start point of the next block.

−50.0 F0.3

−52.0

−80.0 F0.2

The end point of a previous block becomes the start point of the next block. X and W

(or U and Z) can be used in the same block.

Note: 1) Be sure to specify an F function in the first G01 command in the program.

2) Even if the G00 command is commanded next to G01, the feed rate given with

an F code is kept.

2 - 25

Page 38

(2) Chamfering, corner R command

When there is chamfering (45°chambering) or corner R (quarter circle) between 2

blocks which are parallel with the X or Z and cross with each other at a right angle,

specify as follows:

For chambering For corner R

(a) G01 X ... K ... F ... (c) G01 X ... R ... F ...

(b) G01 Z ... I ... F ... (d) G01 Z ... R ... F ...

X and Z coordinate values .. Position after chambering or corner R cutting

I, K, R .................................. Radius designation. Signs “

directions from the starting point, and a numerical

value is a size of chamfering or corner R.

For the direction [1]

G01 X50.0 K

For the direction [2]

G01 Z0 I

For the direction [3]

G01 X20.0 K−2.0

For the direction [4]

G01 Z0 I2.0

For the direction [5]

−2.0

−2.0

+” and “−” represent

G01 X50.0 R−2.0

For the direction [6]

G01 Z0 R−2.0

For the direction [7]

G01 X20.0 R−2.5

For the direction [8]

G01 Z0 R2.5

Note: 1) When specifying a tool movement with G01 for chamfering or corner R, it must

be either one axis of X and Z.

In the next block, the other one axis of X and Z, which crosses the former axis

at a right angle, must be given.

2) The stop point by a single block operation is a point after chamfering or corner

R cutting.

2 - 26

Page 39

(3) Angle designated linear interpolation

The angle designated linear interpolation can be performed by designating the angle A

formed by the X or Z axes and

X (U)

+Z-axis.

G01

.........A..... F......;

{}

Z (W)

The range of the angle is

CCW angle from

+Z-axis is regarded as plus and the CW angle is as minus.

2-3-5 G02, G03 Circular Cutting

Specify either G02 or G03 when performing circular cutting.

−360.0 ≦A ≦ 360.0 (deg).

(1) G01 X50.0 A150.0 F0.3;

(2) G01 Z

The direction of arc rotation on the X-Z

plane is as illustrated below.

−100.0 A−180.0;

A circular command consists of the following 3 factors:

[1]Circular arc direction G02 or G03

[2]X and Z coordinate values of a

circular arc end point

[3]Circular arc radius R (radius

designation)

Example : G01 Z−25.0

G02 X70.0 Z−40.0 R15.0

↑↑ ↑

[1] [2] [3]

2 - 27

Page 40

(Example 1)

When moving from the point A to the point B

G02 X60.0 Z0 R20.0 F...;

When moving from the point B to the point A

G03 X100.0 Z

(Example 2)

When moving from the point A to the point B

G03 X60.0 Z0 R20.0 F...;

When moving from the point B to the point A

G02 X100.0 Z

−20.0 R20.0 F...;

−20.0 R20.0 F...;

(Example 3)

When moving from the point A to the point B

G02 X60.0 Z0 R50.0 F...;

When moving from the point B to the point A

G03 X80.0 Z

2 - 28

−10.0 R50.0 F...;

Page 41

(Example 4)

When moving from the point A to the point B

G03 X60.0 Z0 R50.0 F...;

When moving from the point B to the point A

G02 X80.0 Z

(Example 5)

When moving from the point A to the point B

G03 X45.0 Z

When moving from the point B to the point A

G02 X0.0 Z0 R25.0 F...;

−10.0 R50.0 F...;

−35.9 R25.0 F...;

(Example 6)

When moving from the point A to the point B

G03 X40.0 Z

When moving from the point B to the point A

G02 X40.0 Z0 R20.0 F...;

−40.0 R20.0 F...;

2 - 29

Page 42

• Circular command exceeding 180°

When specifying a circular arc exceeding 180°, give a minus sign such as R

When moving from the point A to the point B

G03 X30.0 Z

When moving from the point B to the point A

G02 X30.0 Z−17.5 R−25.0 F...;

Cutting feed rate

The cutting feed rate commanded by F code becomes the speed that a tool moves on

a circular arc.

−62.5 R−25.0 F...;

−∆∆. ∆∆.

Note: 1) When F code has not feed commanded in G02 and G03 blocks or before that,

an alarm will occur.

2) Exponent type acceleration/deceleration is engaged.

3) When radius of circular arc = 0 is commanded, an alarm will occur.

4) If the end point is not located on the circular arc, the tool will move on the

remainder in straight line after moving in circular, when an error of the end point

of circular interpolation is less than the parameter setting value(No.3459). And

when it is out of the parameter setting value, an alarm will occur.

5) When I, J, K and R are commanded in the same block, R has priority.

2 - 30

Page 43

2-3-6 G04 Dwell

A tool can be rested during a command time.

(Example)

When stopping the tool for 2 seconds

G04 U2.0;

In order to stabilize the diameter of the groove shown

in the left figure, it is necessary to dwell the tool for 1

revolution or more at the bottom of the groove.

-1

Assuming the spindle speed “N” to be 600 min

, the

time “T” required for 1 revolution is;

60

T = = = 0.1 second

N

60

600

Therefore, stop the tool for 0.1 second or more.

G01 X40.0 F...;

G04 U0.2 In this case, the feed was made

interrupted for 0.2 second.

X55.0 F...;

2-3-7 G09 Exact Stop

When G09 is commanded in the same block with a moving command, the machine is

decelerated to stop and the next block is executed after checking that the position of the

machine is within the range designated as a command position.

Only commanded block is effective.

(1) Command form

G09 —— ;

(2) Program example

N1 G09 G01 U50. F ;

N2 G01 W -50. ;

When commanding G09, an edge is

created on the corner.

When not commanding G09, a round is

created on the corner.

2 - 31

Page 44

2-3-8 G61 Exact Stop

The machine is decelerated to stop at the end point until G62, G63 and G64 etc. are

commanded after commanding G61, and the next block is executed after checking that the

position of the machine is within the range commanded.

Program example

G61 G01 Z

−100.0 F0.2

X20.0

−150.0

Z

G61 mode effective :

An edge is created on the corner.

G61 mode ineffective :

A round is created on the corner.

2-3-9 G10 Programmable Date Input

It-is possible to change various data for work shift and offset on the N/C program.

(1) Work shift amount input

G10

P00 X (U) Z (W) ;

P00 : Work shift amount input designation

X (U) : Work shift amount of X-axis

Z (W) : Work shift amount of Z-axis

Generally, setting of an offset amount is performed for only the value of Z.

Don’t perform work shift for other axes.

(Example) G10 P00 Z512.368;

(2) Form offset amount input

G10

L10 P X (U) Z (W) R Q H ;

L10 : Form offset input designation

P : Offset No. (0 ~ Maximum offset sets)

X (U) : Form offset amount of X-axis

Z (W): Form offset amount of Z-axis

R : Tool nose R (Absolute)

Q : Virtual tool nose point (0 ~ 9)

H : Tool width (Absolute)

2 - 32

Page 45

(3) Wear offset amount input

G10

L11 P X (U) Z (W) R H ;

L11 : Wear offset amount input designation

P : Offset No. (0 ~ Maximum offset sets)

X (U) : Wear offset amount of X-axis

Z (W): Wear offset amount of Z-axis

R : Tool nose R (Absolute)

H : Tool width (Absolute)

Note 1) Only when absolute input is performed by the form offset input, the

wearoffset amount of the address input is cleared to 0.

2) R (Tool nose R) and H (Tool width) are performed only by absolute input.

2-3-10 G20, G21 Inch Input/Metric Input

It is possible to select the input unit of a program command either in inch input or in metric

input by G20 or G21 command.

Command form

G20 ; Input unit is inch input

G21 ; Input unit is metric input

The following units are changed by the G20/G21 command.

(a) Feed rate command by F (E is included for thread cutting).

(b) Commands related to positions.

(c) Work reference point shift amount.

(d) Tool offset amount.

(e) A part of parameters.

(f) The unit of one graduation of the manual pulse generator.

(1) The G20/G21 command shall be commanded to the head of the program in the single

block.

(2) When the G20/G21 command is executed, conduct the coordinate system preset.

(3) This function is for selecting the unit of numerical value programmed either in metric or in

inch.

Inch

⇔ Metric conversion isn’t performed.

2 - 33

Page 46

2-3-11 G22, G23 Stored Stroke Limit

Setting of the second or third stroke limit can be set by MDI or program

Example:

G22 X

Command of entering prohibition into the second stroke limit and the second or third stroke

Example:

G23; Entering is possible into the second area.

Note 1) When G23 has commanded, G22 should be commanded in the individual block

−170.0 Z−10.0 I−490.0 K−120.0 (Refer to the sketch on the previous page.)

limit is set.

to make a setting area entering prohibition again.

2) When G22 X

the commanded value.

3) When the power is on, G22 is set automatically.

4) When a parameter is changed, please be sure to push “RESET” key.

It is not changed unless it pushes “RESET” key.

Z I K ; is commanded, the parameter changes automatically to

2 - 34

Page 47

2-3-12 Stroke Limit Check Before Move

If the end point of the block to be executed the automatic operation locates in the

prohibited area, stop the axis travel and make an alarm. Execute a check regarding all

effective matters by the stroke limit 1, 2 and 3.

Interrupt a travel if the end point of executing

block locates in the prohibited area.

(1) If the alarm of stroke limit before move is issued, release the alarm by pressing the rest

button.

(2) The end point of executing block can be calculated by the “Machine coordinate”

“Remaining amount of travel” at this time.

Note) If the travel time of one block is very short, some times becomes an alarm before

setting the remaining amount of travel.

(3) Precautions

(a) Concerning a traveling path of block, a check is not executed.

(b) Concerning an axis which is machine lock condition, a check is not executed.

(c) Checking of a block of G31 is not executed.

(d) Check the axis which has completed the reference point return only.

(e) If the end point locates very close to the prohibited area, it becomes an alarm

occasionally.

+

2 - 35

Page 48

2-3-13 G28 Automatic Reference Point Return

With a command “G28 X (U)ooo. oo Z (W)ooo. oo“, the tool automatically returns to

the machine reference point after moving to the position (intermediate point) specified with

X (U), Z (W). G28 assumes the same rapid traverse rate as G00. After returning to the

machine reference point, the machine reference point lamp lights up.

Machine reference

point

N920 G00 X.....

N922 G28 X200.0 Z200.0

N923 M30

%

As shown in the left figure, the tool returns

to the machine reference point via the

inter-mediate point.

Note) Difference from “G28 U0 W0 ;”

Since U0 W0, which is incremental programming, means that a tool stroke is

0(zero), the current position becomes the intermediate point as it is, and the tool

returns to the machine reference point from that position.

2-3-14 G30 2nd Reference Point Return

(1) A commanded axis can be returned the 2nd reference point automatically.

The 2nd reference point can be set either setting by the parameter for the distance

from the machine zero point previously or process of the 2nd reference point setting.

Refer to the instruction manual for the process of the 2nd reference point setting.

Exactly same motion as the automatic zero return by G28 is executed except returning

to the 2nd reference point by the parameter setting.

2 - 36

Page 49

Program example

O5801

N1 G28 U0

N2 G28 W0 T0100

N3 G50 S1500

N4 G30 U0 W0(G00 X200:0 Z150.0)

N5 M01

N101 G30 U0 W0

N102 T0100

N103 G97 S530 M08

N104 G00 X72.0 Z10.0 M03

N105 G01 G96 Z0.2 F3.0 S120

N106 X0 F0.2

N107 Z3.0

N * . .

N * . .

A program example at left uses the 2nd reference

point (G30) as the turret index position.

A setting of the 2nd reference point execute on the

2nd reference point setting screen after the turret with

maximum protruded tool is moved the position (B point)

which is not interfered position with a machining

workpiece or the chuck etc.

N * . .

N118 G00 G97 X70.0 S545

N119 G30 U0 W0 (G00 X200.0 Z150.0)

N120 M01

. .

. .

. .

N1001 G30 U0 W0

N1002 T1000

N1003 G97 S695 M08

N1004 G00 X30.0 Z15.0 M03

N1005 G01 G96 Z7.0 F3.5 S150

N *

N * . .

N * . .

N1013 G00 G97 Z15.0 S.....

N1014 G30 U0 W0 (G00 X200.0 Z150.0)

N1015 M01

N6 G28 U0 W0 T0100

N7 M30

2 - 37

Page 50

Caution

(1) The third, fourth reference point

Caution

If the 2nd reference point is used correctly, it makes the safest program.

However, when the turret head index position (2nd reference point) is altered due

to a process change or preparatory plan change, set the second reference point

again each time.

G30 Pn X (U) ... Z (W) ...;

(Pn=P2, P3, P4)

Execute a positioning of the second, third or fourth reference point after positioning at

intermediate point commanding by the above command.

P2 : The second reference point

P3 : The third reference point

{

P4 : The fourth reference point

If Pn is omitted, it becomes the second reference point.

Be careful, if the coordinate command of an axis is omitted, the axis does not

move.

(2) Position of each reference point

The position of each reference point is set previously by

P2 : MD 34100 [0]

the parameter P3 : MD 34100 [1] as a distance from the machine reference point.

{}

P4 : MD 34100 [2]

<Program example>

G30 P3 U~40. W30. ; X and Z axes return to the third reference point.

2 - 38

Page 51

2-3-15 G31 Skip Function

Linear interpolation is performed by a G31 command. If an external skip signal is input during

linear interpolation, the program proceeds to the next block, stopping the axes and discarding the

remaining stroke.

(1) Command Format

G31 X___ Y___ Z___ ....... F___

(2) Sample Program

N1 G98 G31 W50. F100

N2 G01 U50. W25.

(3) Cautions

Position where skip has been input (work coordinates) can be read by the macro system

variable.

2 - 39

Page 52

2-3-16 G54 Work Coordinate System Setting (Work Length)

Work length shall be set as the value following address Z by the command

G54 Z

Correct distance is displayed of the tool position from the machine origin by following

procedures.

1. When tool is indexed by T code in program (available by MDI as well).

2. When rotate the turret by pushing the turret index button while manual mode.

〔

3. When applied Q setter or Z setter (Option).

〕

An incremental amount of the work length can be designated by G54 W

This function is used for the case when 1st and 2nd operations are continuously

machined.

(Example) O

××××

G28 U0

G28 W0

G54 Z0 ......... Reference point shift amount cancel

G50 S2000

G30 U0 W0

M01

N100

T0100

G97 S1230 M08

1st operation machining

~

G28 U0

G28 W0

M00............... Work turn-over

G28 U0

G28 W0

command.

G54 Z

G50 S1500

G30 U0 W0

M01

N150

T0100

G97 S730 M08

2nd operation machining

G54 Z0 ......... Reference point shift amount cancel

G28 U0

G28 W0

M30

2 - 40

−5.0 .... Difference from the finishing end of

the work at 1st operation

~

Page 53

2-3-17 Canned Cycle

Using a canned cycle, machine functioning equivalent to 4 blocks of “cutting-in → cutting

(or threading)

block.

Regular Program Program with Canned Cycle

(1) G00 X50.0

→ retreat → return” in a regular program can be specified as 1 cycle in 1

The tool starts from the point A (X65.0, Z2.0)

and returns to the point A via the points B, C

and D respectively .

If the canned cycle is used, the program will

be changed as follows:

(2) G01 Z−30.0 F G90 X50.0 Z−30.0 F

(3) X65.0

(4) G00 Z2.0 The machine works in the same manner as in the 4-

Accordingly, when a large cutting allowance is required, or when the number of blocks is

many as in a threading program, the canned cycle is useful because it can simplify the

program. There are the following 3 kinds of canned cycles available:

1. G90 ....... OD/ID cutting cycle

2. G92 ....... Threading cycle

3. G94 ....... End face/side cutting cycle

1. G90 OD/ID cutting cycle

G90 enables OD/ID straight cutting or taper cutting.

The tool moves via a specified point from its start point, cuts the workpiece at a feed rate

specified with an F code and returns to the start point again.

}

block program on the left.

2 - 41

Page 54

G90 cycle patterns

(1) Straight cutting (2) Taper cutting

G90 X...Z...F... (I=0)

R : Rapid traverse

F : Cutting feed G90 X...Z...I...F...

(specified with an F code) (Pay attention to a sign of I. )

Example of straight cutting

1.

When machining a

shown in the left figure, with its start

point at X55.0 and Z2.0 and a depth

of cut of 2.5 mm, the program is as

follows:

N101 T0100 M40

N102 G97 S695 M08

N103 G00 X55.0 Z10.0 M03

N104 G01 G96 Z2.0 F2.5 S120

N105 G90 X45.0 Z−25.0 F0.35—[1]

N106 X40.0

N107 X35.0

N108 G00 G97 Z10.0

N109 G30 U0 W0

N110 M01

φ50 blank as

———————[2]

———————[3]

Note 1) As G90 is modal, once it is specified, it can be neglected from the next block.

Accordingly, cycle operation is executed by only specifying the cutting depth of X-axis

from the next block on.

2) After completing the canned cycle, cancel G90 with another G code, such as G00

belonging to the same group.

3) For the T, S and M functions which serve as cutting conditions, be sure to specify

them in a block preceding the one where G90 is to be specified.

2 - 42

Page 55

In the above-mentioned program, the tool returns to the same start point after completing

each cycle. At that time, a machining time is wasted because the same parts are

repeatedly machined in side cutting as shown in the figure below. Therefore, the

machining time can be saved by shifting the cycle start position per cycle as shown in the

program below, after completing each cycle.

N105 G90 X45.0 Z

N106 G00 X47.0

N107 G90 X40.0 Z

N108 G00 X42.0

N109 G90 X35.0 Z−25.0 [3]

N110 G00 ........

Example of taper cutting

2.

When machining a

X65.0 and Z2.0 and a depth of cut of 5 mm, the program is as follows:

First, obtain an amount of I. I= = 5 mm

The sign of I(“

−25.0 F0.35 [1]

−25.0 [2]

φ60 blank as shown in the figure below, with the cycle start position at

50

−40

2

+” or “−”) is determined as a direction from point “a” to the point B.

Since the start position is shifted by G00

after completing the canned cycle, it is

canceled each time.

Therefore, you must specify a G90

command and coordinate values each time.

Accordingly; I=

−5.0

N103 G00 X65.0 Z10.0 M03

N104 G01 G96 Z2.0 S120

N105 G90 X60.0 Z

N106 X50.0

N107 G00 X...... Z......

or

N103 G00 X65.0 Z10.0 M03

N104 G01 G96 Z2.0 S120

N105 G90 X60.0 Z

N106 G00 X55.0

N107 G90 X50.0 Z

N108 G00 X...... Z......

2 - 43

−35.0 I−5.0 F0.3 → [1]

→ [2]

−35.0 I−5.0 F0.3 → [1]

−35.0 I−5.0 →[2]

Page 56

G90 Cycle Patterns (OD)

Straight Taper

The sign (

For a cutting diameter, specify a dimension at the point C.

+, −) of I is determined as a direction viewing the point B from the point C.

2 - 44

Page 57

G90 Cycle Patterns (ID)

Straight Taper

The sign (

For cutting diameter, specify a dimension at the point C.

+, −) of I is determined as a direction viewing the point B from the point C.

2 - 45

Page 58

2. G94 End face and side cutting cycle

G94 enables straight/taper cutting of the end face and side.

The tool moves via a specified point from its start point, cuts the workpiece at a feed rate

specified with an F code and returns to the start point.

G94 cycle patterns

(1) Straight cutting (2) Taper cutting

R: Rapid traverse

F: Cutting feed

(specified with

an F code)

G94 X...Z...F... G94 X...Z...K...F...

(K=0) (Pay attention to a sign of K)

Example of straight cutting

1.

When machining a

in the left figure, with its cycle start

position at X85.0 and Z5.0 and a depth

of cut of 5 mm, the program is as

follows:

N101 T0100 M40

N102 G97 S450 M08

N103 G00 X85.0 Z10.0 M03

N104 G01 G96 Z5.0 F3.0 S120

N105 G94 X30.0 Z

φ75 blank as shown

−5.0 F0.2 ........ [1]

2 - 46

N106 Z

N107 Z

N108 G00 G97 Z10.0

N109 G30 U0 W0

N110 M01

−10.0 ......................... [2]

−15.0 ......................... [3]

Page 59

Note 1) Since G94 is modal, specfy it just once. You do not have to specfy it again threefer .

Accordingly, cycle operation is executed by only giving Z-axis depth of cut from the

next block on.

2) After completing the canned cycle, cancel G94 with another G code, such as G00,

belonging to the same group.

3) For the T, S and M functions which serve as cutting conditions, be sure to specify

them in a block preceding the one where G94 is to be specified.

In the above-mentioned program, the tool

returns to the same start point after

completing each cycle. At that time, a

machining time is wasted because the same

parts are repeatedly machined in OD cutting

as shown in the left figure.

Therefore, the machining time can be saved

by shifting the cycle start position per cycle

as shown in the program below.

N105 G94 X30.0 Z−5.0 F0.2...... [1]

N106 G00 Z

N107 G94 X30.0 Z

N108 G00 Z

N109 G94 X30.0 Z

N110 G00 X.... Z....

−3.0

−10.0 ............ [2]

−8.0

−15.0 ............ [3]

Since the start position is shifted by G00

after completing the canned cycle, it is

canceled each time. Therefore, you must

specify a G94 command and coordinate

values each time.

Example of taper cutting

2.

When machining a

the left figure, with its cycle start position at

X55.0 and Z2.0 and a depth of cut of 5

mm, the program is as follows:

First, obtain a size of K.

K = 15 − 10 = 5

Determine a sign of K, viewing its cycle

pattern.

Accordingly; K

N104 G01 G96 X55.0 Z2.0 S120

N105 G94 X20.0 Z0 K

N106 Z

N107 Z

N108 G00 X.... Z....

or

N104 G01 G96 X55.0 Z2.0 S120

N105 G94 X20.0 Z0 K

−5.0.................................. [2]

−10.0................................ [3]

φ50 blank as shown in

−5.0

−5.0 F0.2.......... [1]

−5.0 F0.2.......... [1]

2 - 47

N106 G00 Z

N107 G94 X20.0 Z

N108 G00 Z

N109 G94 X20.0 Z

N110 G00 X.... Z....

−3.0

−8.0

−5.0 K−5.0 ............ [2]

−10.0 K−5.0 ........... [3]

Page 60

G94 Cycle Patterns (END FACE)

Straight Taper

2 - 48

Page 61

G94 Cycle Patterns (END FACE)

Straight Taper

2 - 49

Page 62

2-3-18 Multiple Repetitive Cycle

This option consists of several fixed cycles which are preliminarily prepared to make the

programs easier. For example, by giving only information on the shape of finishing, the tool

path for the intermediate roughing can automatically be determined. And a fixed cycle for

the thread cutting is also available.

7 kinds of fixed cycle (G70~G76) are readily available for the multiple repetitive cycle.

These G codes are all non-modal G codes.

G Code Cycle Name Remarks

G70 Finishing cycle

G71 I.D./O.D. roughing cycle Capable of

G72 End face roughing cycle finishing with

G73 Closed loop cutting cycle G70

G74 End face cutting-off cycle

G75 Outer figure cutting-off cycle

G76 Thread cutting cycle

2 - 50

Page 63

(1) Rough Planing of Outside Diameter (G71)

There are type I and type II for the rough planing cycle.

Type I

As shown in the figure below , if the finishing shape is given as A→A’→B by a program, the

area specified by the cutting amount ∆d is cut off, leaving the finish amount ∆u/2, ∆w.

Program command

Fig. 18.1 Cutting route of rough planing during turning (Type I)

G71 P(ns) Q(nf) U(∆u) W(∆w) D(∆d) F(f) S(s)

N(ns) . . . . . . . . .

. . . . . . . . . . . . . .

F___ The shift of the finishing shape, i.e. A→A’→B, is commanded by the blocks

S___ of sequence No. ns to nf.

N(nf) . . . . . . . . .

∆d: Cutting amount

Specify without a sign. The cutting direction is determined by the direction of AA’ (radius

specification). This specification is valid until specified next by the modal.

e: Relief amount

Parameter GUD7,_ZSFI[31]

2 - 51

Page 64

ns: Sequence No. of the first block in the finishing shape block group.

nf: Sequence No. of the last block in the finishing shape block group.

∆u: Finishing amount of X axis direction (diameter specification)

∆w: Finishing amount of Z axis

F, S: During the cycle, the F function, S function specified by the block between ns~nf are

neglected, and the data of the F function, S function specified by the G71 block become

enabled.

Note:

(1) Following four patters are conceived as the shapes cut by G71. In any case, the work is

cut by the tool shift which is parallel to the Z axis, where the signs for ∆u, ∆w are as

follows.

+X

B

U(+)…W(+)…

+Z

U(‑)…W(+)…

B

A

A

A

A

U(+)…W(‑)…

A

AA

U(‑)…W(‑)…

A

B

B

Fig. 18.2 Signs for U and W of G71

A-A ’ is the block of sequence No. ns, which specifies the command including G00 or

G01. The shift amount of Z axis is not specified to the block of ns. The shape of A’-B’

needs to simply increase or decrease for both X axis and Y axis directions.

(2) The sub program cannot be called from the block of sequence No. ns to nf.

2 - 52

Page 65

Type II

T ype II is dif ferent from type I in the following respect. The shape is not required to simply

increase or decrease to X direction and you can have dents (pocket).

4

321

Fig. 18.3 Pockets of outside diameter rough planing (type II)

However, it must simply changes to Z direction. If the shape is like below, machining is not

possible.

Fig. 18.4 Shape that cannot be processed with G71 cycle.

2 - 53

Page 66

Different use of type I and type II

When only X axis is specified in the first block of the finishing shape … type I

When X axis and Y axis are specified in the first block of the finishing shape … type II

If you want to use type II without Z moving to the first block, specify WO.

(Example)

Type I T ype II

G71 P100 Q200 ... G71 P100 Q200 ...

N100 X(U) ___ N100 X(U) ___ Z(W) ___

: :

: :

N200 ........ N200 .........

2 - 54

Page 67

(2) Rough Planing Cycle of End Side (G72)

As shown in the figure below , this is the same as G71, but the cutting is done by the

movement parallel to the X axis.

∆d

A’

Programmed contour

45°

C

A

Tool path

(F)

(R)

e

(R)

(F)

∆u/2

B

∆w

Fig. 18.5 Cutting route of face rough planing cycle

G72 P(ns) Q(nf) U(∆u) W(∆w) D(∆d) F(f) S(s)

∆d, e, ns, nf ∆u, ∆w, f, s are the same as G71.

2 - 55

Page 68

Following four patterns are conceivable as the shapes cut by G72. In any case, the work is

cut by the repeated movement of the tool parallel to the X axis. Signs for ∆u and ∆w are as

follows.

A’

A’

+X

U(+)…W(+)

+Z

U(-)…W(+)

…

…

A

A

U(+)…W(-)

B

B

B

B

U(-)…W(-)

A

A

…

…

A’

A’

Fig. 18.6 Signs for U and W of G72

A-A ’ is the block of sequence No. ns, which specifies the command including G00 or G01.

The X axis cannot be specified to the block of ns. The shape of A’-B needs to simply

increase or decrease for both X axis and Z axis directions.

2 - 56

Page 69

(3) Planing Cycle of Close Loop (G73)

You can repeatedly use a certain cutting pattern gradually shifting its position. Using this

cycle, you can efficiently cut a work with a material shape made by pre-machining such as

forging and casting.

∆k+∆w

∆w

∆i+∆u/2

C

A

(R)

B

∆u/2

A’

∆w

Fig. 18.7 Cutting route of close loop planing cycle

Pattern commanded by a program.

A point→A’ point→B point

G73 P(ns) Q(nf) U(∆u) W(∆w) I(∆i) K(∆k) D(d) F(d) F(f) S(s)

N(ns) . . . . . . . . .

. . . . . . . . . . . . . .

F ___ Shift command of finishing shape for A→A’→B is specified by blocks of

S ___ sequence No. ns to nf.

N(nf) . . . . . . . . .

∆i: Removal amount for X axis direction (specify radius)

∆k: Removal amount for Z axis direction

d: Times of rough planing.

ns: Sequence No. of the first block in the finishing shape block group.

nf: Sequence No. of the last block in the finishing shape block group.

∆u: Finishing amount for X axis direction (specify diameter).

∆w: Finishing amount for Z axis direction.

f, s: If F function or S function is specified to any block between ns~nf, it is neglected and

the data of F function or S function specified by G73 block become enabled.

2 - 57

Page 70

Note:

(1) Cycle operation is executed by G73 command with P and Q specified. Since there

are four patters as the cutting shapes, take care for the signs for ∆u, ∆w, ∆i and ∆k

when you program. When the cycle ends, it returns to the A point.

2 - 58

Page 71

(4) Finish Cycle (G70)

If you have executed the rough planing with G71, G72 and G73, you can execute finish

planing with a following command.

Command format

G70 P(ns) Q(nf)