Page 1

TURNING CENTER

ST200/250

INSTRUCTION MANUAL

79 SPECIFICATION

SEICOS - pcFlexi

Version 1.01 BS-1782-1-0300-E-1-01

Hitachi Seiki Deutschland

Werkzeugmaschinen GmbH

Page 2

Introduction

Thank you for your having purchased the machine, favoring our product lines for your use.

This manual contains fundamental information on the specification. Please read and fully understand

the contents for your safe machine operation.

In particular , the contents of the items concerning safety in this manual and the descriptions on the

“caution plates” attached to the machine are important. Please follow the instructions contained

and keep them always in mind to ensure safe operation.

The reference record papers on adjusting setting values such as a parameter list are attached to

the machine unit and enclosed in the packing. These are necessary for maintenance and

adjustment of the machine later on. Please keep them safely not to be mislaid.

The design and specifications of this machine may be changed to meet any future improvement.

As the result, there may arise some cases where explanations in this manual could become partly

inconsistent with the actual machine. Please note this point in advance.

In this manual, items on the standard and optional specifications are handled indiscriminately.

Please refer to the “delivery note” for the detailed specification of your machine confirmation.

Page 3

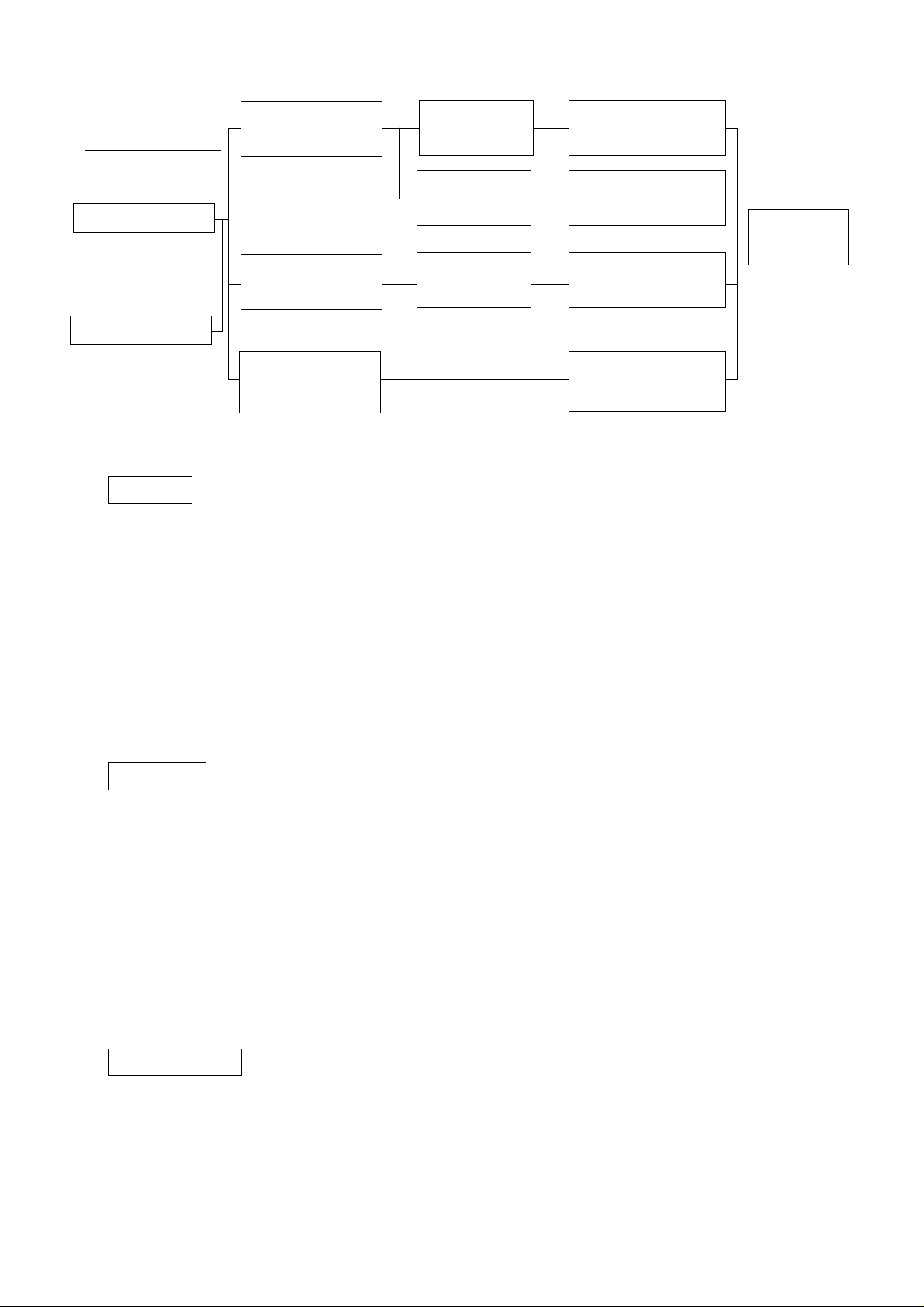

CONTENTS

1. GENERAL PRECAUTION..................................................................... 1- 1

1-1 Precautions on Machine Operation ........................................................................1-1

1-2 Electric Equipment and NC Unit .............................................................................1-4

1-3 Workpiece Chucking..............................................................................................1-5

1-4 Weights and Measures Table .................................................................................1-6

2. SPECIFICATIONS ................................................................................. 2 -1

2-1 Machine Outline .....................................................................................................2-1

2-2 Component Units ...................................................................................................2-2

2-3 Machine Specifications..........................................................................................2-3

2-4 NC Unit Specifications...........................................................................................2-6

2-5 Major Dimensions................................................................................................2-10

3. REQUIRED DIMENSION FOR MACHINE............................................. 3-1

3-1 Tool Traveling Range..............................................................................................3-1

3-2 Tool Interaction Drawing ........................................................................................3-6

3-3 Quick Setter and Workpiece Interference Drawing ...............................................3-10

3-4 Spindle Output Diagram.......................................................................................3-12

3-5 Chucking Pressure-Gripping Force Diagram .......................................................3-16

3-6 Tailstock Pressure-Thrust Diagram.......................................................................3-18

3-7 Method of Obtaining Tool Center Height ...............................................................3-19

4. TOOLING SYSTEM ............................................................................... 4-1

4-1 12st. Base Holder Turret Head Combination Tool List (S tandard) ...........................4-1

4-1-1 HT/ST200 ...................................................................................................................4-1

4-1-2 HT/ST250 ...................................................................................................................4-2

4-2 12st. Base HolderTurret Head Combination Tool List (Selection)............................4-3

4-2-1 HT200/250, ST200/250............................................................................................... 4-3

4-3 12st. QCT(KV) Turret Head Combination Tool List (St andard) ................................4-6

4-3-1 HT/ST200 ...................................................................................................................4-6

4-3-2 HT/ST250 ...................................................................................................................4-7

4-4 12st. QCT(KV) Turret Head Combination Tool List (Selection)................................4-8

4-2-1 HT200/250, ST200/250............................................................................................... 4-8

4-5 12st. VDI Turret Head Combination Tool List (St andard)....................................... 4-11

4-5-1 HT/ST200 ................................................................................................................. 4-11

4-5-2 HT/ST250 .................................................................................................................4-12

i

Page 4

4-6 12st. VDI Turret Head Combination Tool List (Selection).......................................4-13

4-6-1 HT200/250, ST200/250............................................................................................. 4-13

4-7 12st.VDI Rotating Tool T urret Head Combination Tool List (St andard)...................4-15

4-7-1 HT/ST200 .................................................................................................................4-15

4-7-2 HT/ST250 .................................................................................................................4-16

4-8 12st. VDI Rotating Tool Turret Head Combination Tool List (Selection) .................4-17

4-8-1 HT200/250, ST200/250............................................................................................. 4-17

ii

Page 5

1. GENERAL PRECAUTION

General descriptions is very useful for making working environment against accidents and

increase productivity.

1. Be sure to put safety goggles on.

2. Be sure to put safety shoes on.

3. Operate with proper dressing, such as putting a utility cap on, fixing the sleeves and the

cuffs of working clothes.

4. Don’t operate the machine with gloves.

5. Make clean and neat environment by lighting up and keeping dry around the machine.

Also don’t put any obstacles.

6. Remove dust and chips on the machine, high voltage control panel and NC unit. Also

remove them on the floor. Avoid using compressed air as much as possible for these

cleanings.

7. Use a strong enough table to be put around the machine, and take anti-sliding

measures on the surface.

8. Don’t put tools, workpieces, and other items on the machine as well as on the moving

parts of the machine.

9. Don’t give any remodeling to the machine without our permission.

1-1 Precautions on Machine Operation

When conducting trial run, read the manual applied to the machine carefully for full

understanding beforehand. Witness of our operation instructor is most preferable.

Maintenance

1. An operator and maintenance personnel should read the precautions on the caution

plate fitted to the machine and observe them.

Don’t stain, damage or remove the caution plate becomes hard to read, contact Hitachi

Seiki.

2. Close all the doors and covers except when adjusting work is made.

As for the doors of the NC unit and the power control cabinet, be sure to close them with

special care.

3. Don’t remove or modify the limit switches for the stroke end, for the travelling axes and

the mechanism, or the electric circuit employed for safety.

4. Use regular wrenches and spanners for adjusting or repairing work.

5. When repairing the machine, be sure to perform lock-out or tag-out so that power switch

may not be operated.

1 - 1

Page 6

Coolant

This machine doesn’t mix coolant with lubrication oil by using the economy pack. But, the

soluble cutting fluid is decomposed due to the factors such as propagation of

micro-organisms, which causes various troubles by lowering cutting and rust prevention

performance.

When using soluble cutting fluid, care must be taken of the following points.

1. When selecting soluble cutting fluid, carefully consider lubrication, infiltration, rust

prevention, bubble prevention, separability against oil and safety needs.

2. Before operation starts and after operation ends, not only remove chips, but also wipe

off soluble cutting oil adhered to each slideway, the rotating parts, the saddle and crossslide of the machine and then be sure to apply lubrication oil thinly to those parts.

3. Replace soluble cutting fluid immediately if it becomes vitiated.

4. Remove the covers every 6 months and clean each slideway, X, Y, Z axes ball-screws,

each limit switch and feed motors etc.

5. As soluble cutting oil is considered for rust prevention, it may be no problem when the

workpiece is wet. However, when dry, it is apt to rust.

Therefore, it is recommendable to apply rust preventive oil before the workpiece dries

after finished machining.

6. Since soluble oil is alkalescent and has a strong decreasing action, the operator is apt to

develop dermatitis.

Therefore, the operator should take appropriate precautions.

7. As for the diluting method and soluble cutting fluid, diluting water they are different

depending on the type of soluble cutting oil, so use it in accordance with the

recommendations of the cutting fluid manufacturer.

8. Since there are instances where extensive micro-organisms are detected in industrial

water, it is recommendable either to check it before use as water for dilution or to use

service water.

9. Do not use a chemical solution type (synthetic type) in water-soluble cutting agents,

because it causes detachment of coating and affects sealing materials and resin

materials adversely.

10. The influences of difference kinds of oil on coolant are as follows: Carefully monitor the

condition the coolant fluid.

1 - 2

Page 7

Different kinds of oil

Mixture

(Emulsification)

Instabilization

of liquid

Density

abnormality

Propagation of

bacilli

Lowering of density

Lowering of pH

Formation of state of

aversion

Lubrication oil

Rust preventive oil

Nutritive source of

micro-organism

Seal due to

surfacing

Adhesion to

machine

Propagation of

bacilli

Operation

1. Be aware of the position of the push button for emergency stop so that the operator may

be able to press it instantly.

2. As for the operation of the machine, proceed in accordance with the procedure

described later.

3. During operation, keep hands away from the rotating sections and movable sect ions.

4. When disposing of chips that wound round tooling or fell onto the chip brow, etc. it is

dangerous to grasp and pull them. Further, when disposing of chips, be sure to do it

after stopping the machine.

5. When adjusting the position of the coolant nozzle, do it after stopping the machine.

petrifaction,

rust & others

Tool Setting

1. When setting up tools, stop a spindle as well as the feed in each axis.

2. Be very careful of tool length when setting them up. Do not set the tools over their

specified lengths because their tool edges may interfere with a bed, carriage, cover,

tailstock, etc. when indexing a turret.

3. Mount tools in a well balance condition. Due to high-speed turret indexing when their

mounting is unbalanced, it may lead to improper turret indexing.

4. When setting a tool to the rotating tool, it is feared that the driving side may be

damaged, if it is performed in the machine.

Whenever tools are set, be sure to do it at the outside of machine.

Operation Finish

1. After operation of the machine is over, be sure to switch the power OFF in the

prescribed order, clean the machine and apply rust preventive oil to each section of the

machine such as the slide ways.

When soluble cutting fluid is used, perform these jobs with special care.

1 - 3

Page 8

1-2 Electric Equipment and NC Unit

When operating the machine or carrying out maintenance checks, pay special attention to the

following points, concerning the electric equipment and NC unit.

1. Do not give shocks to the NC unit, power control cabinet and other machine parts.

2. For the primary wiring of the machine, use the cable size specified in the maintenance

manual. Do not use an excessively long cabtire cable.

When the primary wiring has to be put on the floor, protect it with a cover against damage

by cutting chips and other sharp objects.

3. While test running the machine, be sure the setting parameter of the NC unit coincides with

the parameter sheet attached to the machine.

4. Do not change the current set values of thermal relays in the power control cabinet, various

control knobs or the parameter data.

5. Do not apply excessive force, e.g. bending force etc., to the connector portion of plugs,

flexible conduits (tubes) or cabtire cables etc.

6. When carrying out maintenance checks on the electric equipment, at first, turn off the

EMERGENCY STOP button on the operation panel, then turn off the power of the NC unit,

the main switch of the power control cabinet and the power switch installed in your factory,

in this order.

Start maintenance work after making sure that these switches are turned off.

Lock the power switches in the OFF state as much as possible or put up warning signs. In

additions, place a “DO NOT TOUCH” tag near the operation buttons of the machine to

forbid other personnel from operating the machine.

7. Handle electric equipment of the machine with particular care and exercise extreme caution

not to allow the machine to get wet.

8. For equipment inside the power control cabinet, use those specified by Hitachi Seiki. Use

always specified fuses. Never use fuses with a higher capacity.

9. Never leave the control cabinet door open, because direct sunshine or camera’s strobe

flash rays may enter the cabinet and damage internal equipment.

10. In case of turning on the power again, execute power on went by equal to or more than two

seconds after power turned off. If the power is turned on during discharge from control

devise by power off, pay attention to the alarm of the machine is displayed some time, due

to normal process is not available.

1 - 4

Page 9

1-3 Workpiece Chucking

1. When chucking a workpiece, be careful of its balance. Do not turn the spindle if the

mounting of the workpiece is unbalanced badly.

2. Use standard soft jaws. Mount the jaws so that they may stay within the outer diameter

of the chuck.

3. To set pressure of chuck cylinder, determine it referring to “Chucking Pressure-Gripping

Force Diagram”.

Take note that the chuck gripping force will be suddenly reduced due to a centrifugal

force when the spindle runs at a high speed.

4. When forming the soft jaws, pay full attention to a forming ring gripping position and a

shape to which the jaws are to be formed.

After forming, check that the jaws properly grip the workpiece and that a chucking

pressure is adequate.

5. When chucking and centering a shaft work, take special note of a workpiece weight, a

size of center hold and a thrust force.

If a heavy workpiece is held with a small center hold and a load is applied, the tip of the

center may be damaged, allowing the workpiece to jump out.

1 - 5

Page 10

1-4 Weights and Measures Table

(Metric and English Conversion)

1. Liner measure

1m (meter) = 39.37 inches = 3.2808 feet = 1.0936 yards

1cm (centimeter) = 0.3937 inch

1mm (millimeter) = 0.03937 inch

2. Square measure

1m2(square meter) =10.764 square feet = 1.196 square yards

2

1cm

(square centimeter) = 0.155 square inch

2

(square millimeter) = 0.00155 square inch

1mm

3. Cubic measure

3

(cubic meter) = 35.315 cubic feet = 1.308 cubic yards

1m

= 264.2 U.S. gallons = 220.0 U. K. gallons

1 (liter, cubic decimeter) = 0.0353 cubic foot = 61.023 cubic inches

= 0.2642 U.S. gallon = 1.0567 U. S. quarts

= 0.2200 U.K. gallon = 0.02745 bushel

3

1cm

(cubic centimeter) = 0.061 cubic inch

4. Weight

1 ton (metric ton) = 0.9842 U. S. (long) ton = 2204.6 pounds

= 1.1023 U. K. (short) ton

1 kg (kilogram) = 2.2046 pounds = 35.274 ounces avoirdupois

5. Others

1 kgf/cm2 (kilogram force per square centimeter) = 14.223 pounds per square inch

= 0.098 MPa (Mega Pascal)

1 kg-m (kilogram-meter) = 7.233 foot-pounds

1 - 6

Page 11

2. SPECIFICATIONS

2-1 Machine Outline

This is a NC lathe with a drum type turret head. It is designed to be able to control two axes

simultaneously.

The following are the features of this machine.

1. The machine can perform chuck work and center work.

2. Infinite variable speed is available in wide range by application of AC inverter motor.

3. With a permanent tool setting as a basis, various kinds of workpiece can be machined

without modification.

4. The machine also has a diagnostic function.

5. Due to the combined structure of electric and mechanical systems.

A required floor area is reduced.

In addition, the turret head is positioned in the rear of the machine in order to improve

accessibility to the spindle and the operatability of the machine.

If optional accessories are attached, the working range of the machine can be extended further.

Construction of Machine Proper

1. Head stock

By a AC motor, variable speed in wide range

[HT200/ST200 50 ~ 5000min-1]

[HT250/ST250 42 ~ 4200min

is made available automatically.

-1

]

2. Tool post

By adopting a particular coupling method, higher indexing accuracy is guaranteed.

The servo motor drives indexing action and hydraulic pressure is used for clamping which

gives the machine certainty of the action.

3. Tailstock

The taper of the tailstock is MT No.5, and any live center on the market can be mounted.

Tailstock can be set at any position on the supporter by key operation. The thrust force can

be adjusted by oil pressure within the range of 490~7350N.

2 - 1

Page 12

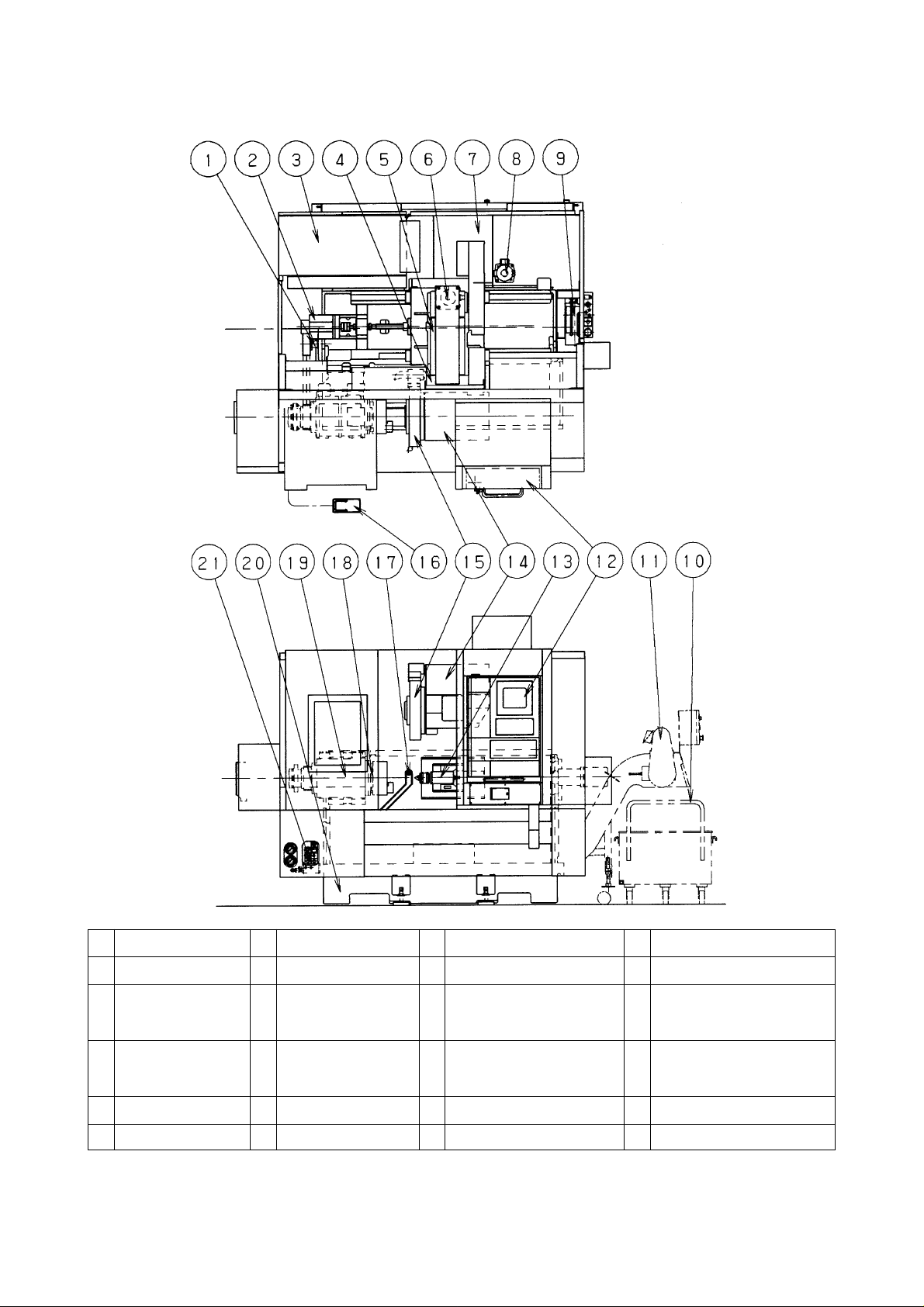

2-2 Component Units

1 Spindle motor 7 Coolant tank 13 Tailstock 19 Headstock

2 Z axis feed motor 8 Coolant pump 14 Tool post 20 Bed

3 High voltage 9 Oil pressure unit 15 Turret 21 Chuck/tailstock pressure

distribution board adjustment manifold

4 Cross slide 10 Chip box (OP) 16 Foot switch for chuck

opening/closing

5 Saddle 1 1 Chip conveyor (OP) 17 Q setter

6 X axis feed motor 12 Operating panel 18 Spindle

2 - 2

Page 13

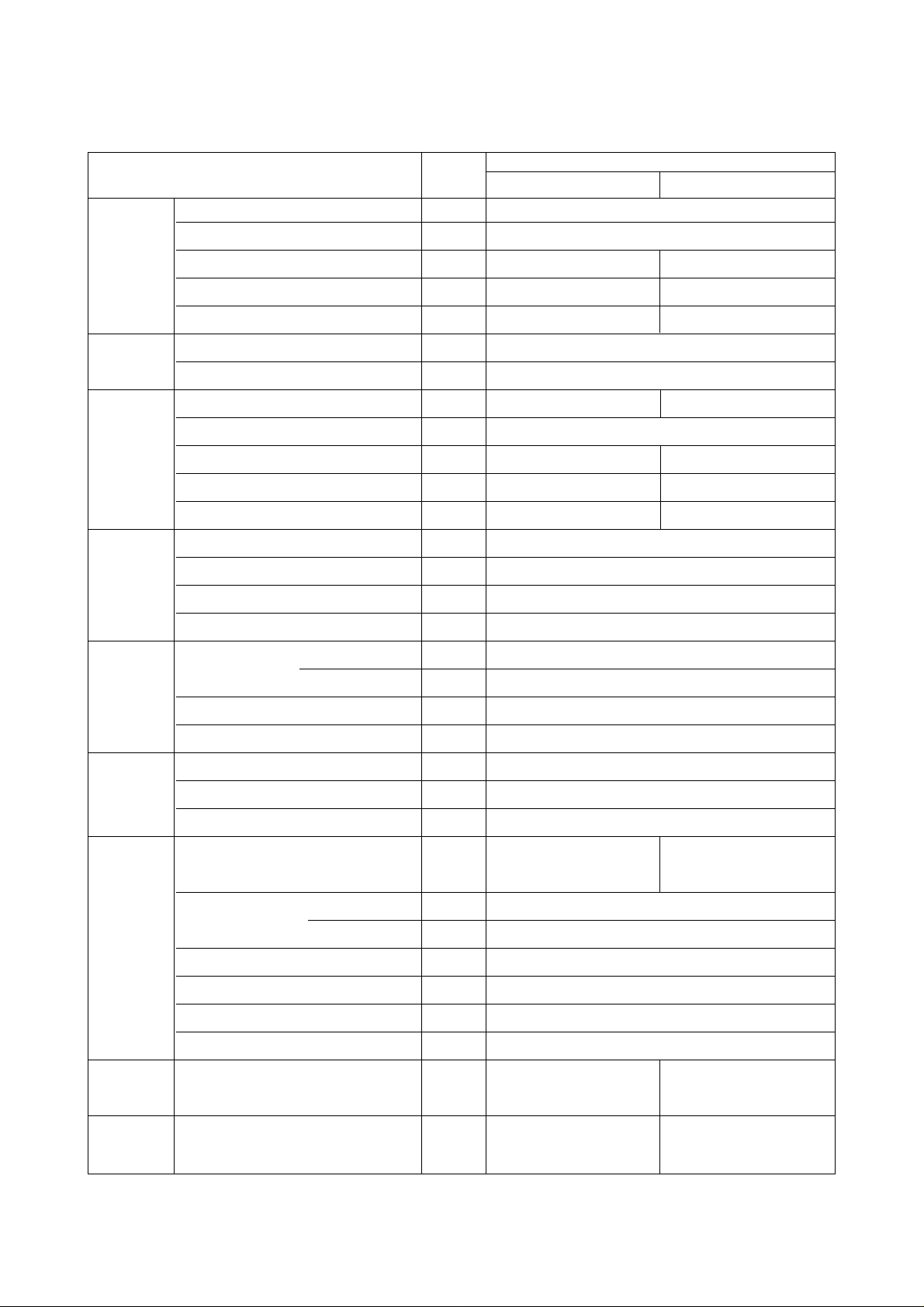

2-3 Machine Specifications

1) Machine Specifications

Specifications

Capacity Swing over bed mm 680

Chuck outer diameter mm 500

Max. machining diameter mm 220 254

Max. machining length mm 490 470

Bar capacity mm 70 80

Stroke X axis mm 260

Z axis mm 520

Spindle Spindle speed min

Spindle speed range Step Infinite

Spindle nose (Type, No.) JIS A2-6 A2-8

Diameter of spindle through hole mm 80 95

Spindle bearing inside diameter mm 120 140

Turret Type of turret 12 station variable

head No. of tool position pcs. 12

Shank height of square bite mm 25

Unit

HT200/ST200

-1

50~5000 42~4200

Standard Specification

HT250/ST250

Shank diameter of boring bar mm 40 (B/H hole dia. 50)

Feedrate Rapid traverse X axis m/min 40

Z axis m/min 40

Cutting feedrate (Per revolution) mm/rev 0.001~1000

Jog feed mm/min 0~5000

Tailstock *1 Stroke of t ailstock mm 550

Type of tailstock spindle taper hole MT-5

Method of tailstock travel Power operation

Motor For spindle motor

(50%ED/continuous)

Axis feed motor X axis AC-KW 2.9

For turret indexing AC-KW 1.3

For Toilstock W 150

Oil pressure pump W 400

For cutting and chip washing W 180

Power

source

Power supply KV A 15 18

Z axis AC-KW 2.9

AC-KW 12/6 18.5/6

Machine

weight

*1 The system is structured in such a way that by operating command, the tailstock moves forward, back

ward and in forward inching mode within the whole range of the stroke.

Kg 4850 4950

2 - 3

Page 14

2) Main Accessories

Standard Accessories

Hyd’ hollow chuck (HT200/ST200 : φ220, HT250/ST250 : φ254)

Soft jaw

One-touch tailstock (Tailstock)

Q-setter

Flood coolant (Chip wash coolant)

Splash cover

Operator side door interlock

Spindle speed meter on screen

Spindle load meter on screen

Spindle/feedrate override

Call light (Std. Yellow)

Electric leakage detection breaker

Machining completion pre-call/Work counter/

Run hour display on screen

Work light

Leveling block

Spanners and wrenches

Chuck op. By M-code

Tailstock op. By M-code

2 - 4

Page 15

Optional Accessories

1. NC tailstock

2. C-axis control

3. X-axis scale feedback

4. 12 st. QCT(KV) turret

5. 12 st. VDI turret

6. 12 st. VDI rotating tool turret

7. Builtin type tailstock

8. Chip conveyor, Right / Rear type

Flat / Scrape with Roring filter / Magnet

scrape

9. Chip conveyor with intermittent feed

10.Chip wagon with roller

11. Jet coolant

12.Gun coolant

13.Chuck overhead coolant

14.Mist collector

15.Collet chuck

16.Chuck open/close confirmation

17.High/low 2-step pressure chucking

21.Spindle positioning dev., 1 position, electric

22.Auto door

23.Bar feeder

24.Bar puller

25.Parts catcher

26.Spindle end coolant collector for bar feed att.

27.Separate type spindle speed meter

28.Separate type counter A/B/C

29.Additional call light

30.Automatic power cut-off device

31.Separated start/stop/emergency button

32.Separated start/stop button

33.Z setter

34.Auto presetter & Q-setter, tool breakage

detection

35.Inside machine work measuring equipment

For Chuck work (X/Z) / Center work (X)

36.Transformer 45KVA

37.Preliminarily E/L application

18.Tailstock operation by foot pedal

19.Inside spindle work stopper

20.Face driver anti-powerfailure

* The contents of accessories and equipment are subject to change without notice. Please

contact the sales department of Hitachi whenever you have any inquiry for answer.

2 - 5

Page 16

2-4 NC Unit Specifications

Refer to the NC unit specifications list of SEIKI SEICOS instruction manual (operation section) for

details of specifications.

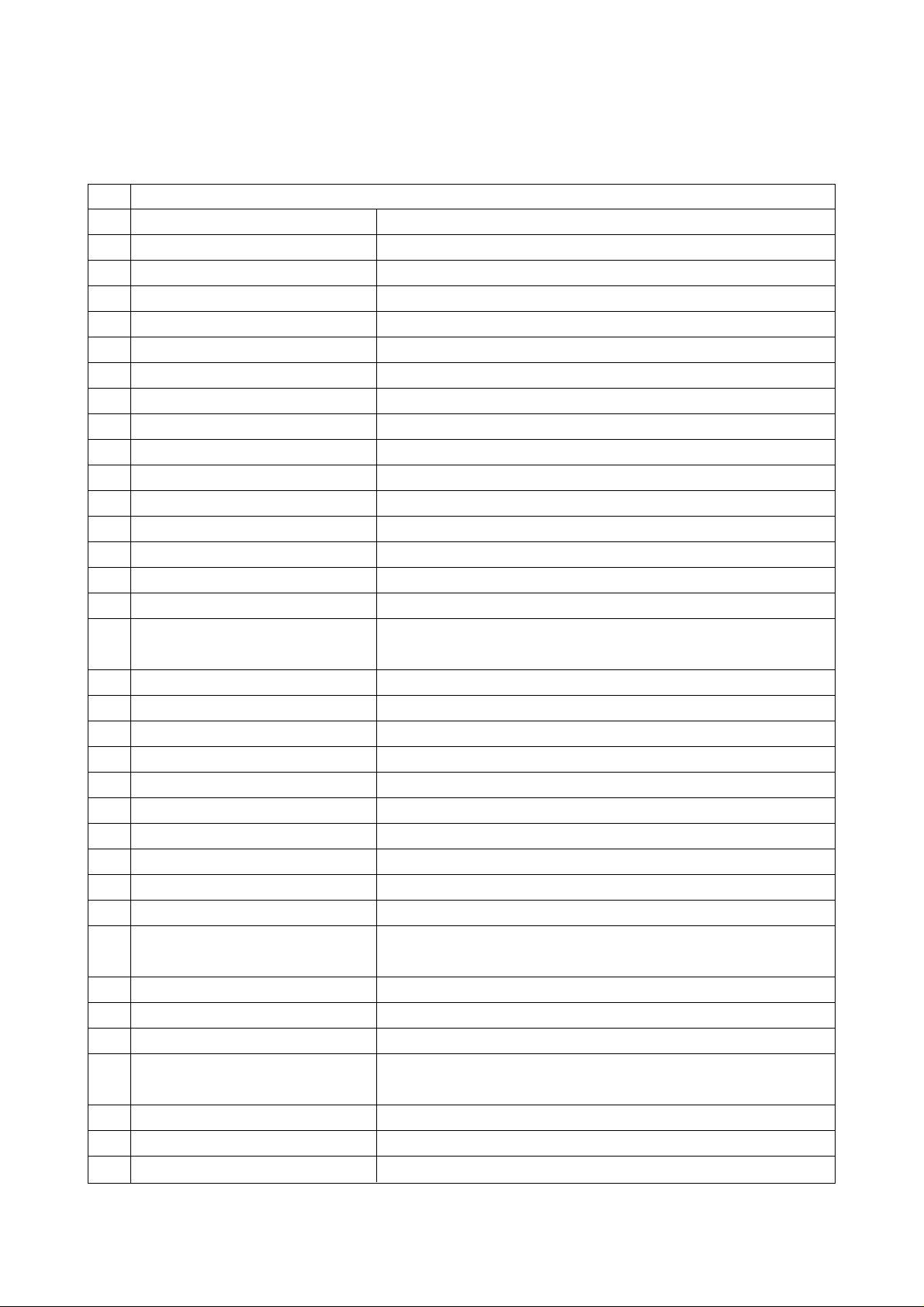

Item Standard specification

1 Controlled axis 2 axes, 2 axes simultaneous

2 Least input increment 0.001mm/0.0001’’

3 Interpolation Positioning, Linear, Circular

4 Inch/Metric conversion

5 Tape code EIA/ISO auto.recognition

6 Designation INC./ABS.

7 Decimal point programming

8 Buffer register

9 Feedrate command F code/feedrate direct

10 Rapid traverse override 0, 1, 10, 50, 100%

11 Feedrate override 0~200%

12 Spindle override 50~150% (10% step)

13 Threading function F/E code direct

14 Manual feed function Rapid, Jog feed, Handle

15 Manual pulse generator ×1, ×10, ×100 (inch=×50)

16 Part program storage 1000m/1 directory Total 1000m(1000m × 10 directories)

17 Add. registered programs 100 pcs./1 directory Total 1000pcs.

(100pcs. × 10 directories)

18 Back ground editing

19 Extended program edit (Program copy)

20 Display 10.4" color TFT

21 Memory lock

22 Language display English/German

23 I/O interface RS232C*

24 I/O interface PC card (PCMCIA I/F)

25 Function G3, M3, T4, O8 digits

26 Spindle speed command S code/speed direct

27 Constant surface speed control

28 Automatic tool nose radius

compensation

29 Grooving width offset (ID, OD, Face)

30 Tool offsets 32 sets

31 Q-setter repeat function

32 Cutting point coordinate system

setting

33 Reference point return Manual, Auto G28

34 2nd reference point return G30

35 Graphic display Before and synchronized machining

1

2 - 6

Page 17

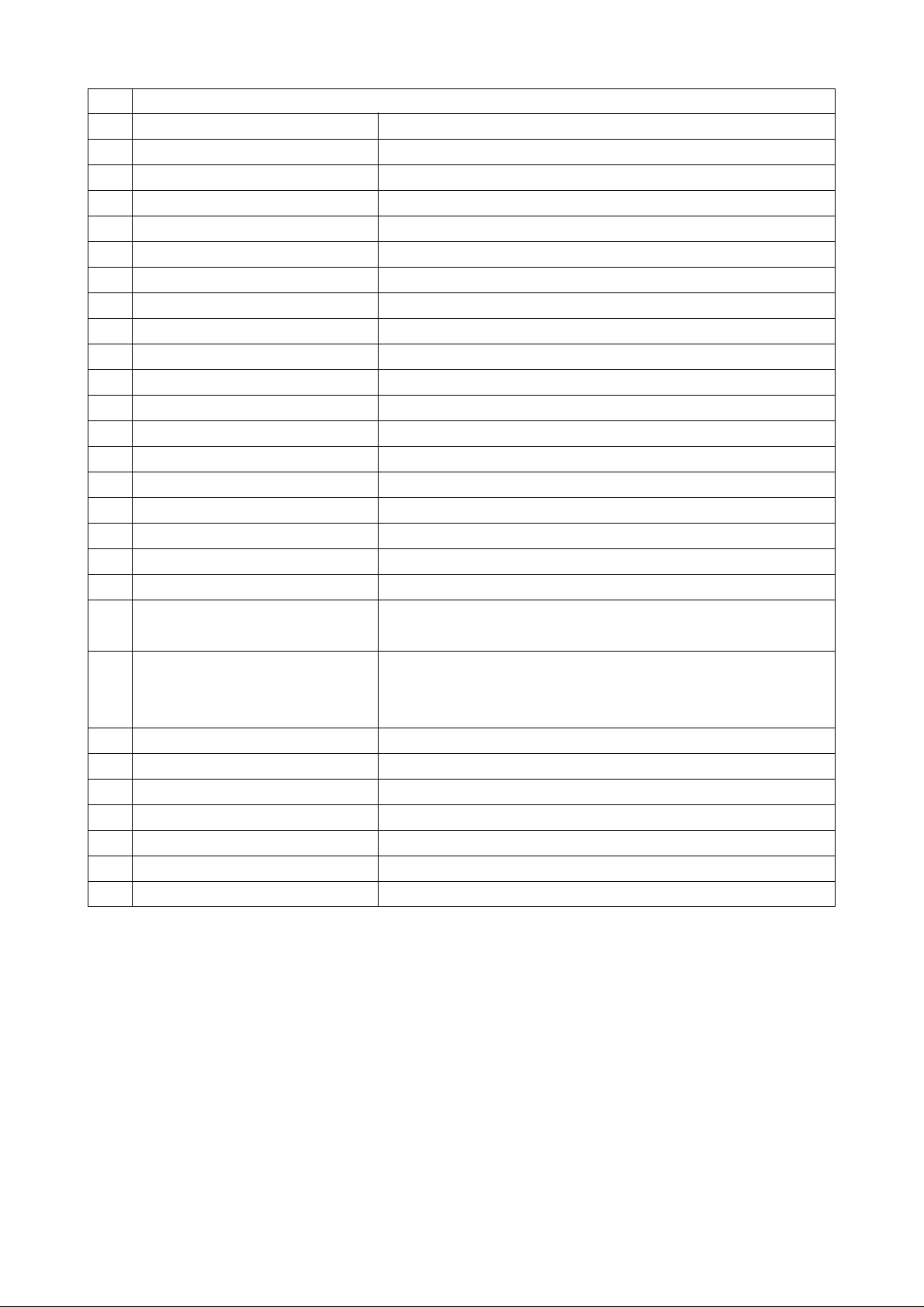

Item Standard specification

36 Program comment 16-character

37 Single block

38 Block skip 1 pc.

39 Optional stop

40 Program check function Dry run + Spindle stop + coolant stop

41 Machine lock

42 Program number search

43 Sequence number search,

44 Program comparison

45 Manual absolute [ON] fixed

46 Flexi macro Common variable 100 pcs.

47 Soft jaws forming function (by graphic)

48 Fixed cycle G90, G92, G94

49 Multiple repetitive cycle G70~G76

50 Mirror image G501 G511

51 Radius designation on arc

52 Exact stop G09 G61 G64

53 Programmable data input G10

54 Backlash compensation

55 Run hour display/Spindle ( On screen)

speed display

56 Cycle completion pre-call / (On sxreen)

Cycle time display /

Work counter

57 Following up

58 NC flight recorder

59 Stored stroke limit 1.2.3

60 Strock check before move

61 NC self diagnostics

62 Customizing screen

63 User screen

*1 Interface only.

Not include cable.

2 - 7

Page 18

Item Optional specification

1 Direct tapping (Rotating tool)

2 Variable lead threading

3 Thread cutting cycle retract

4 Multiple start thread cutting

5 Flexi macro Common variable 200 pcs.

6 Flexi macro Common variable 300 pcs

7 Flexi macro Common variable 600 pcs.

8 Drilling cycle (Incl. in rotating tool) G80~89

9 Cutting doubler

10 Spindle positioning (Minimum inc. 0.001°)

11 Macro print function (Need printer w/ RS232C I/F) *1

12 Part program storage Total 100000m (1000m

× 100 directory)

Add. registered programs Total 10000 pcs. (100 pcs. × 100 directory)

13 Tool diameter compensation (Rotating tool)

14 Tool offsets Total 64 pcs.

15 Tool offsets Total 99 pcs.

16 Tool offsets Total 200 pcs.

17 3rd-4th reference point return

18 Program comment 64-character

19 Block skip Total 8 pcs.

20 Angle program for linear interpolation

21 Cylindrical interpolation (Incl. tool diameter compensation)

22 Polar coordinate interpolation (Incl. tool diameter compensation)

23 I/O interface RS232C 2ch

24 UUP (Universal user port)

25 Tool life management/Spare tool call

26 Each program, cycle time display 10pcs.(On screen)

27 Each program, cycle time display 50pcs.(On screen)

28 Cutting monitor (Incl. tool life management (Count only)/Spare

tool call)

29 NC chuck function (Incl. with NC chuck option)

30 NC tailstock function (Incl. with NC tailstock option)

31 C-axis control

32 Super multi interactive system 3D-simulation

Shape input method List & symbol input

Automatic determination Machining method/ mashining area/

function Process/ T ool/

Tool position/ Cutting condition/

Tool path interference/ Tool path

Automatic process Turning process: 21 process

Machining process: 8 process

2 - 8

Page 19

Item Optional specification

Automatic program NC data/ Tool/

Position of tool/ Cycle time

Dynamic graphics Automatic graphics

Editing Confirmation method/

NC data editing

Data saving/ Input, output NC data/ Shape data/

I/O to NC machine

*1 Interface only.

Not include cable.

2 - 9

Page 20

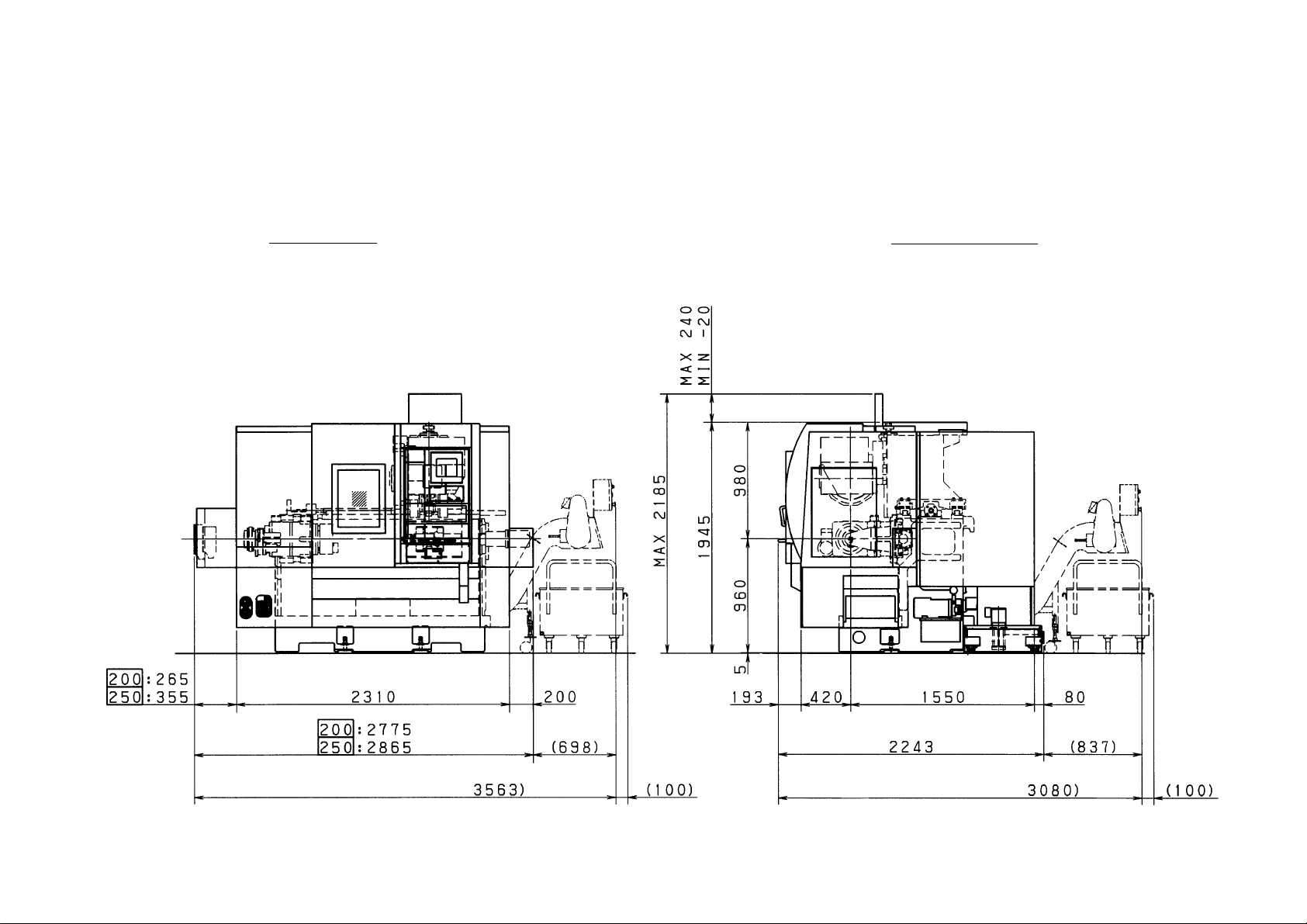

2-5 Major Dimensions

1) Major Dimension

Dimension: metric (mm)

inch ( ” )

2 - 10

FRONT VIEW

(90.9”)

Right side type

chip conveyor

(option)

Chip

wagon

(option)

(7.8”)

RIGHT SIDE VIEW

(0.7”)

(9.4” )

Rear side type

chip conveyor

(option)

(38.5”)

(86.0” )

(76.5”)

Chip

(37.7”)

(0.2”)

wagon

(option)

(109.2”)

(1 12.7”)

( Right side type chip conveyor spc.

(27.5”)

(7.5”) (16.5”)

( Rear side type chip conveyor spc.

(61.0”) (3.1”)

(88.3”)

(32.9”)

(121.2”)(3.9”)(140.2”)

(3.9”)

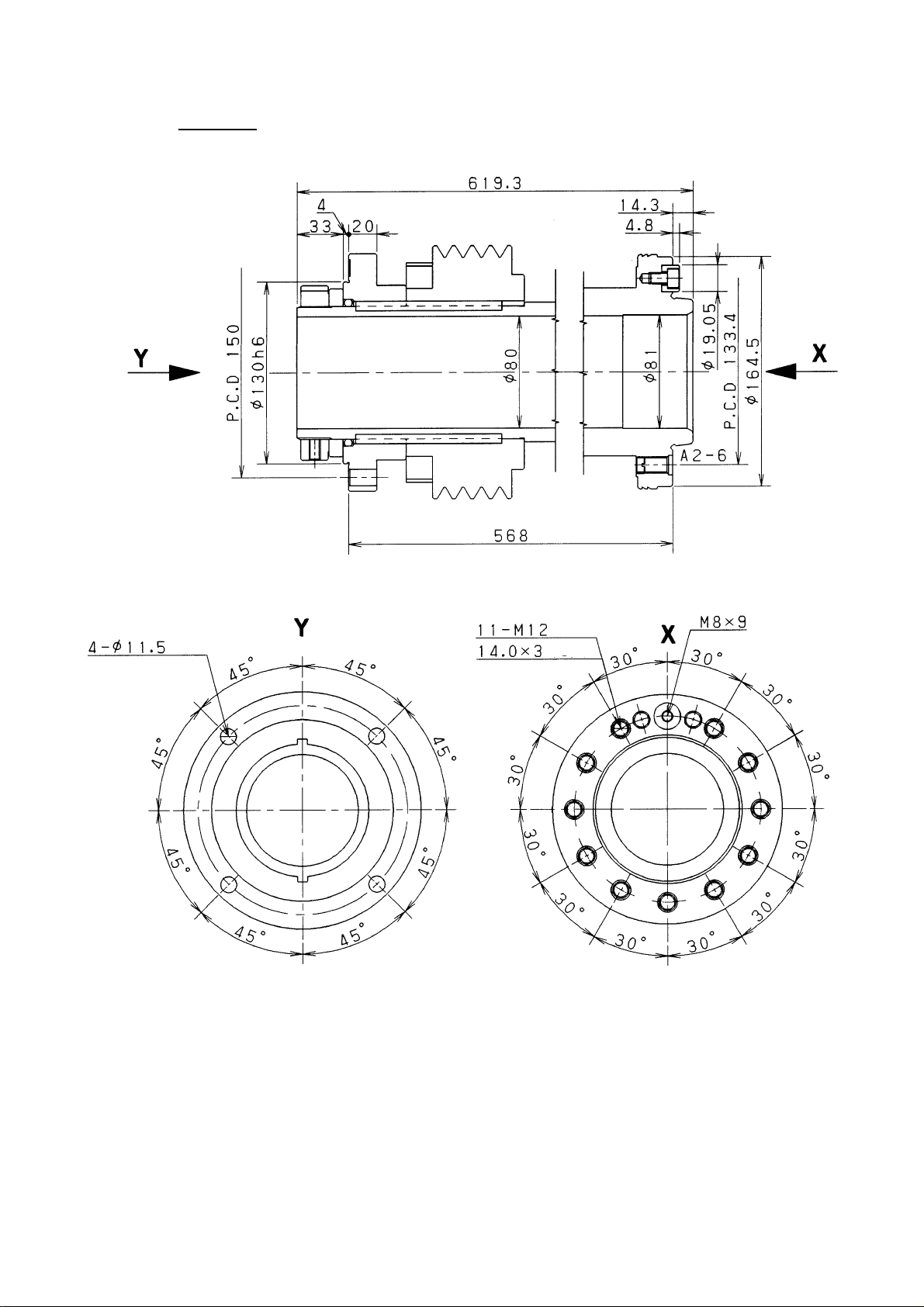

Page 21

2) S pindle

HT/ST200

Dimension: metric (mm)

inch ( ” )

Eyehole

(0.1”)

(0.7”)

(1.2”)

(5.9”)

(5.1”)

(24.3”)

(3.1”)

(22.3”)

(Inlet)

(0.5”)

(0.1”)

(0.7”)

(5.2”)

(6.4”)

(3.1”)

2 - 11

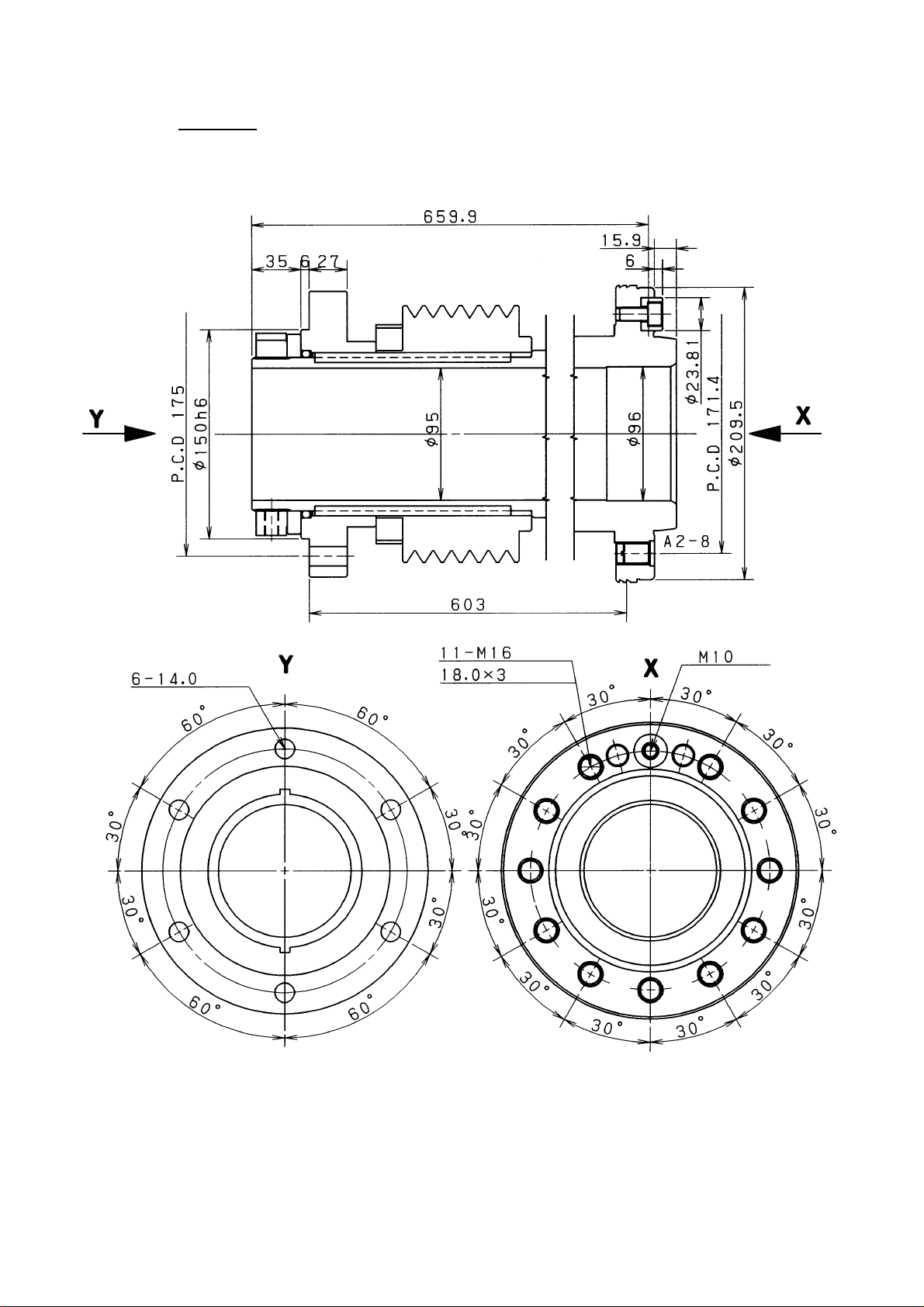

Page 22

HT/ST250

Dimension: metric (mm)

inch ( ” )

(6.8”)

(5.9”)

Eyehole

(1.3”)

(0.2”)

(1.0”)

(25.9”)

(3.7”)

(23.7”)

(Inlet)

Eyehole

(0.6”)

(0.2”)

(0.9”)

(6.7”)

(8.2”)

(3.7”)

Eyehole

2 - 12

Page 23

3) Tool Post List

No. Tool post

1 12-station Base Holder

2 12-st ation QCT(KV)

3 12-station VDI

4 12-station VDI rotaring tool

2 - 13

Page 24

4) 12-station Base holder turret

(3.7”)

(0.5”)

(3.3”)

(2.1”)

(0.5”)

(1.8”)

(2.0”)

(8.8”)

(1.8”)

(0.9”)

(17.7”)

(0.5”)

(3.3”)

(2.1”)

(0.5”)

(8.8”)

(1.8”)

(3.7”)

(1.8”)

Dimension: metric (mm)

inch ( ” )

Note 1)

(1.0”)

Turret

(0.9”)

(0.4”)

(0.4”)

(0.4”)

(0.2”)

(0.2”)

(2.3”)

(1.6”)

(3.3”)

(0.4”)

(0.9”)

(1.6”)

(0.5”)

Piece

Fixture screw

Hexagon socket head

cap screw M8×25

Note 1) For reverse turn cutting, use 0.8mm spacer for re

verse turn cutting (2 pieces standard accessory)

2 - 14

Page 25

5) Base Holder

Base holder for boring

(1.5”)(0.1”) (3.5”)

(1.9”)

(1.6”)

(0.9”)

(0.6”)

Base holder for U drilling

(4.6”)

(0.9”)

(0.1”)

(3.3”)

(0.9”)

(4.4”)

Dimension: metric (mm)

inch ( ” )

(3.5”) (1.5”)

(0.1”)

(1.6”)

(0.9”)

(0.6”)

(4.6”)

(0.9”)

(1.5”)

(0.1”)

(3.3”)

(0.5”)

(4.1”)

2 - 15

Page 26

Base holder for end face grooving

(1.3”) (1.3”) (0.9”) (0.9”)

Dimension: metric (mm)

inch ( ” )

(2.1”)

(2.3”)

(0.1”)

(0.9”)

(1.1”)

(1.8”)

(0.9”)

(1.8”)

(4.6”)

(1.1”)

(1.1”)

(0.1”)

(3.5”)

(3.7”)

2 - 16

Page 27

6) 12-station QCT(KV) tool turret head

(17.7”)

Dimension: metric (mm)

inch ( ” )

(20.6”)

2 - 17

Page 28

7) 12-station VDI tool turret / 12-station VDI rotating tool turret

Dimension: metric (mm)

inch ( ” )

Holder positioning for key

Holder positioning for pin

(16.1”)

(18.8”)

(0.5”)

(0.5”)

(1.8”)

(0.5”)

(1.2”)

(8.0”) (8.0”)

2 - 18

Page 29

Base holder for OD cutting

Dimension: metric (mm)

inch ( ” )

(1.0”)

(1.6”)

(3.3”)

(0.6”)

(1.2”)

(3.1”)

(0.9”)

(2.7”)

(1.5”)

(5.2”)

(0.9)

(0.3”)

2 - 19

Page 30

Base holder for boring

Dimension: metric (mm)

inch ( ” )

(2.9”)

(2.1”)

(3.2”)

(1.2”)

(0.4”)

(0.8”)

(5.4”)

(1.5”)

2 - 20

Page 31

offset Base holder for boring

Dimension: metric (mm)

inch ( ” )

(2.9”)

(2.3”)

(1.5”)

(6.2”)

(2.9”)

(1.2”)

(3.1”)

(1.5”)

(0.6”)

(0.8”)

(5.4”)

2 - 21

Page 32

X-axis rotating tool base holder

Dimension: metric (mm)

inch ( ” )

(3.3”)

(1.7”)

(0.8”)

(3.2”)

Z-axis rotating tool base holder

(2.4”)

(4.1”)

(2.0”)

(5.8”)

(1.5”)

(0.8”)

(1.5”)

(2.4”)(1.6”)

(3.2”)

(4.7”)

2 - 22

Page 33

8) Chuck

HT/ST200 φ220chuck

(4.2”)

(5.8”)

(1.6”)

Dimension: metric (mm)

inch ( ” )

M2×32

Hexagon socket

head cap screw

(2.8”)

(4.1”)

(5.2”)

M12

×22

Hexagon socket

head cap screw

Hanging hole 2 pcs. -M10

(0.7”)

(1.3”)

(0.5”)

(0.9”)

(1.3”)

(0.7”)

(3.1”)

(8.6”)

(0.5”)

(2.2”)

(0.5”)

(0.5”)

(1.3”)

Soft jaw

9001-65-007-**

(1.5”)

(0.9”)

Detailed serration

2 - 23

Page 34

HT/ST250 φ254 chuck

(6.7”)

Dimension: metric (mm)

(6.8”)

(4.9”)

(1.9”)

(5.5”)

(3.2”)

inch ( ” )

M2×32

Hexagon socket

head cap screw

(0.8”)

(1.2”)

(0.3”)

M16

×30

Hexagon socket

head cap screw

(0.8”)

(1.5”)

(1.5”)

(4.4”)

Hanging hole 2 pcs. -M10

(0.5”)

(0.7”)

(3.4”)

(1.2”)

(0.6”)

(1.6”)

Soft jaw

9001-65-012-**

(1.8”)

Detailed serration

2 - 24

Page 35

(2.9”)

9) Hollow chuck cylinder

Connecting part for φ220 hollow chuck cylinder

2 - 25

Cylinder

ZKP150/72-17-17

MATSUMOTO

(22.3”)

(0.1”)

(6.4”)

(4.9”)

(5.9”)

(5.1”)

(3.1”)

(3.1”)

(1.9”)

(2.8”)

(4.2”)

Cylinder stroke

(0.6”)

(27.7”)

(1.5”)(4.3”)

Hollow chuck

ZA6-8-72B-05

MATSUMOTO

(8.6”)

(2.8”)

Dimension: metric (mm)

inch ( ” )

No. Name Drawing No. or type Q’ty

1 Bolt with hexagonal hole 4B1060 4

2 Tube and adapter 1782-00-816-** 1

3 Bolt with 6B1030 4

4 Nut 1N10 4

Page 36

(3.2”)

(23.7”)

(5.0”)

Connecting part for φ254 hollow chuck cylinder

(1.8”)

2 - 26

Cylinder

ZKP170/82-20-16

MATSUMOTO

(3.7”)

(0.7”)

(3.5”)

(2.2”)

(3.2”)

(4.9”)

Hollow chuck

ZAB-10-82B-02

MATSUMOTO

(10.0”)

(3.2”)

Dimension: metric (mm)

inch ( ” )

(0.2”)

(7.2”)

(6.8”)

(4.9”)

(5.9”)

Cylinder stroke

Cylinder stroke

(29.5”)

No. Name Drawing No. or type Q’ty

1 Bolt with hexagonal hole 4B1060 4

2 Tube and adapter 1782-00-819-** 1

3 Bolt with 6B1240 4

4 Nut 1N12 4

Page 37

10) Center

Tailstock Center

Dimension: metric (mm)

inch ( ” )

(1.7”)

(3.3”)

(0.6”)

2 - 27

Page 38

3. REQUIRED DIMENSION FOR MACHINE

3-1 Tool Traveling Range

Dimension : metric (mm)

inch ( ” )

1) HT200/250, ST200/250

12-station Base Holder Turret Head

O.D turning tool

I.D turning tool

(1.4”)

(1.4”)

(2.2”)

(2.3”)

(4.7”)

(8.7”)

(4.2”)

(4.9”)

(10.0”)

(9.8”)

(1.7”)

(2.0”)

(20.5”)

(20.5”)

(0.4”)

Upper : HT/ST200

Lower : HT/ST250

(0.3”)

(1.4”)

(10.2”)

(3.9”)

(0.2”)

Tailstock

(5.5”)

(5.4”)

(7.7”)

(10.2”)

(2.6”)

(4.6”)

(21.6”)

3 - 1

Page 39

2) 12-station QCT(KV) Tool Turret Head Dimension : metric (mm)

inch ( ” )

Upper : HT/ST200

Lower : HT/ST250

O.D turning tool

(0.3”)

(4.7”)

(20.5”)

(2.1”)

O.D tool

(1.4”)

(1.4”)

I.D turning tool

(4.9”)

(3.3”)

(8.7”)

(4.2”)

(10.0”)

(7.1”)

(10.2”)

(1.7”)

(2.0”)

(20.5”)

(3.1”)

(0.6”)

(3.0”)(2.3”)(0.9”)

(0.3”)

I.D tool

(9.4”)

(10.2”)

(3.1”)

Tailstock

(5.5”)

(5.4”)

(0.8”)

(21.6”)

(0.6”)

(4.6”)

3 - 2

Page 40

3) 12-station VDI Turret Head

O.D turning tool

(4.7”) (20.5”)

Dimension : metric (mm)

inch ( ” )

Upper : HT/ST200

Lower : HT/ST250

(0.3”)

(2.8”)

(1.4”)

(1.4”)

I.D turning tool

(3.3”)

(8.7”)

(4.2”)

(4.9”)

(10.2”)

(7.1”)

(2.8”)

(1.7”)

(2.0”)

(20.5”)

(10.2”)

(0.6”)

(3.0”)(2.3”)

(2.8”)

(0.8”)

(0.3”)

(10.0”)

Tailstock

(5.5”)

(5.4”)

(0.8”)

(21.6”)

3 - 3

(0.6”)

(3.5”)

(4.6”)

Page 41

4) 12-station VDI Rotating Tool Turret Head Dimension : metric (mm)

inch ( ” )

Upper : HT/ST200

Lower : HT/ST250

O.D turning tool

(1.4”)

(1.4”)

I.D turning tool

(4.7”) (20.5”)

(8.7”)

(10.0”)

(4.2”)

(4.9”)

(3.3”)

(20.5”)

(7.5”)

(2.8”)

(1.7”)

(2.0”)

(10.2”)

(4.7”)

(3.5”)

(1.6”)

(0.3”)

(4.7”)

(3.0”)

(10.2”)

(4.7”)

(3.5”)

(1.6”)

(0.3”)

(4.7”)

3 - 4

Page 42

Dimension : metric (mm)

inch ( ” )

X axis rotating tool

Upper : HT/ST200

Lower : HT/ST250

(4.7”) (20.5”)

(1.4”)

(1.4”)

Z axis rotating tool

(3.3”)

(8.7”)

(4.2”)

(4.9”)

(10.2”)

(7.1”)

(2.8”)

(1.7”)

(2.0”)

(20.5”)

(4.7”)

(10.2”)

(4.1”)

(3.0”)

(0.6”)

(3.5”) (4.7”)

(3.2”)

(10.0”)

Tailstock

(5.5”)

(5.4”)

(21.6”)

3 - 5

(3.9”)

(7.1”)

(4.6”)

Page 43

3-2 Tool Interaction Drawing

1) 12-station Base Holder Turret Head

a) Limit of the machining area by the turret

(24.8”)

(8.9”)(9.8”)

(10.2”)

(3.5”)

Dimension : metric (mm)

inch (

Max swing

(4.3”)(5.9”)

(10.0”)

” )

(28.3”)

(0.5”)

(1.4”)

(10.2”)

X-axis stroke

(0.4”)

(1.6”)

(10.0”)

(7.7”)

(2.6”)

(0.3”)

(1.6”)

(10.0”)

(0.2”)

(0.4”)

(0.4”)

(1.0”)

Max. machining

diameter

(19.7”)

(1.4”)

(1.4”)

(4.2”)

(4.9”)

(1.7”)

(2.0”)

(4.7”)

(1.4”)

Z-axis stroke

minus end

Standard

projecting

amount

3 - 6

(2.2”)

(2.3”)

(3.9”)

Standard

projecting

amount

Z-axis stroke

minus end

Page 44

b) Limit of the machining area when Hitachi Seiki revolving center is used.

Outer diameter roughing tool

(0.3”)

Standard projecting

amount

(1.4”)

(1.6”)

(1.6”)

(3.0”)

(1.0”)

Dimension : metric (mm)

inch (

” )

Outer diameter profiling tool

(The tool is 10mm (0.4”) projection than the standard)

(0.3”)

(1.0”)

(0.2”)

(1.8”)

(3.0”)

(1.6”)

3 - 7

Page 45

2) 12-station QCT(KV) Turret Head

a) Limit of the machining area by turret

Dimension : metric (mm)

(7.5”)

(0.8”)

inch (

(0.08”)

” )

(8.9”)

(1.7”)

(2.4”)

(7.1”)

(10.2”)

X-axis stroke

(3.1”)

Max. swing

(17.7”)

(1.3”)

(28.3”)

(0.05”)

(1.6”)

(0.1”)

(0.7”)

Max. machining

(14.2”)

(10.0”)

dameter

3 - 8

Page 46

3) 12-station VDI Turret Head / VDI Rotating Tool Turret Head

a) Limit of the machining area by turret

I.D offset holder for STW

Dimension : metric (mm)

inch (

” )

O.D profiling

X-axis rotating tool

for NR

(8.1”)

(2.8”)

(10.0”)

I.D offset holder for NR

(0.8”)

(8.9”)

(0.8”)

(1.4”)

(3.0”)

(3.9”)

(2.9”)

(0.09”)

(0.2”)

(0.1”)

(3.9”)

(6.9”)

(16.1”)

Max. swing

(2.9”)

(3.2”)

(0.2”)

X-axis rotating tool for HT/ST

(28.3”)

(1.3”)

(1.7”)

(0.5”)

(3.9”)

(2.2”)

(0.07”)

(0.8”)

(0.2”)

(10.2”)

(7.5”)

X-axis stroke

(2.8”)

(1.1”)

Max. machining

(10.0”)

(15.0”)

dameter

3 - 9

Page 47

3-3 Quick Setter and Workpiece Interference Drawing

φ220 chuck

(0.8”) (0.8”)

(5.9”)

(0.8”)

(0.4”)

(0.8”) (0.8”)

(4.2”)

(8.7”)

(1.7”)

(14.2”)

(11.9”)

(9.7”)

(3.0”)

(7.4”)

(5.2”)

(1.6”)

(10.0”)

(1.8”)

(0.2”)

(10.8”)

(1.3”)

3 - 10

Page 48

φ254 chuck

(5.7”) (0.8”) (0.8”) (0.8”)

(0.8”) (0.8”)

(4.9”)

(10.0”)

(2.0”)

(14.2”)

(11.9”)

(9.7”)

(7.4”)

(5.2”)

(0.4”)

(3.0”)

(1.6”)

(10.0”)

(1.8”)

(0.2”)

(10.8”)

(1.3”)

3 - 11

Page 49

3-4 Spindle Output Diagram

This machine is equipped with a variable AC motor. The output within the constant torque

varies with the number of the spindle revolutions at that moment.

When heavy cutting (roughing and so forth) is done within the constant torque area, depending

on the spindle revolution speed, it may come to a stop being unable to withstand the cutting

force.

Accordingly, select the revolution speed area in such a way that heavy cutting is done within

the output constant area.

HT/ST200

(CONT)

Low speed wire winding

Low speed wire winding (CONT)

High speed wire winding

High speed wire winding (CONT)

Spindle Speed [min

-1

(rpm)]

3 - 12

Page 50

HT/ST250

Low speed wire winding

High speed wire winding

Low speed wire winding (CONT)

(CONT)

High speed wire winding (CONT)

Spindle Speed [min-1 (rpm)]

3 - 13

Page 51

Spindle Output Diagram(Builtin motor C-axis specifications)

POWER

HT/ST200

M40 Within the constant torque

CONT)

M41 Within the constant torque

TORQUE

(CONT)

POWER

Spindle Speed [min-1 (rpm)]

TORQUE

HT/ST250

CONT)

(CONT)

(CONT)

M40 Within the constant torque

M41 Within the constant torque

Spindle Speed [min

3 - 14

-1

(rpm)]

Page 52

Rotating Tool Spindle Output Diagram

TORQUE

POWER

minute)

minute)

Spindle Speed [min-1 (rpm)]

3 - 15

Page 53

3-5 Chucking Pressure-Gripping Force Diagram

HT/ST200

Chuck :ZA6-8-72B

Cylinder :ZKP150-72-17-17

Gripping force

Chucking pressure

HT/ST250

Chuck :ZA8-10-82B

Cylinder :ZKP170-82-20-16

Gripping force

Chucking pressure

3 - 16

Page 54

Chucking Pressure-Gripping Force Diagram

HT/ST200

Chuck : ZA6-8-72B

Gripping force

Gripping force

HT/ST250

Chuck : ZA8-10-82B

Revolution (min

-1

)

Revolution (min

3 - 17

-1

)

Page 55

3-6 Tailstock Pressure-Thrust Diagram

Relations between tailstock pressure and the thrust power are as shown in the diagram

below. A pressusre adjusting valve is located on the left side of the machine.

Tailstock pressure adjustment should be made under the condition where a workpiece is

being chucked and pushed by the tailstock.

Thrust

Pressure

As a guidance, for material

φ100×300......S45C

or equivalent, the value of thrust is about 200kgf.

When used below the set pressure 1MPa(10 kgf/cm

tailstock is lowered.

2

, 142 lbs/in2), moving speed of the

3 - 18

Page 56

3-7 Method of Obtaining Tool Center Height

The height of the outside diameter tool is 25mm on the base holder turret head.

On the VDI rotating tool turret head, the hight is 20mm.

Base Holder turret : BH

VDI rotating tool turret : VDI

Dimension : metric (mm)

inch (

” )

BH : 32.0 (1 3/4”)

VDI : 25.0 (1”)

BH : 150 (6”)

VDI : 125 (5”)

BH : 25.0 (1”)

VDI : 20.0 (3/4”)

BH : 25.0 (1”)

VDI : 20.0 (3/4”)

BH : 25.0 (1”)

VDI : 20.0 (3/4”)

1. When center height must be adjusted with O.D. tools, make adjustment of height, putting

a spacer; etc.

Block

BH : 25.0 (1”)

VDI : 20.0 (3/4”)

place a wood sheet as necessary

Flat surface such as a surfave plate

Attach the tool to the support,after adjusting the heigh with 25mm block gauge outside

the machine

3 - 19

Page 57

4. TOOLING SYSTEM

4-1 12st. Base Holder Turret Head Combination Tool List (Standard)

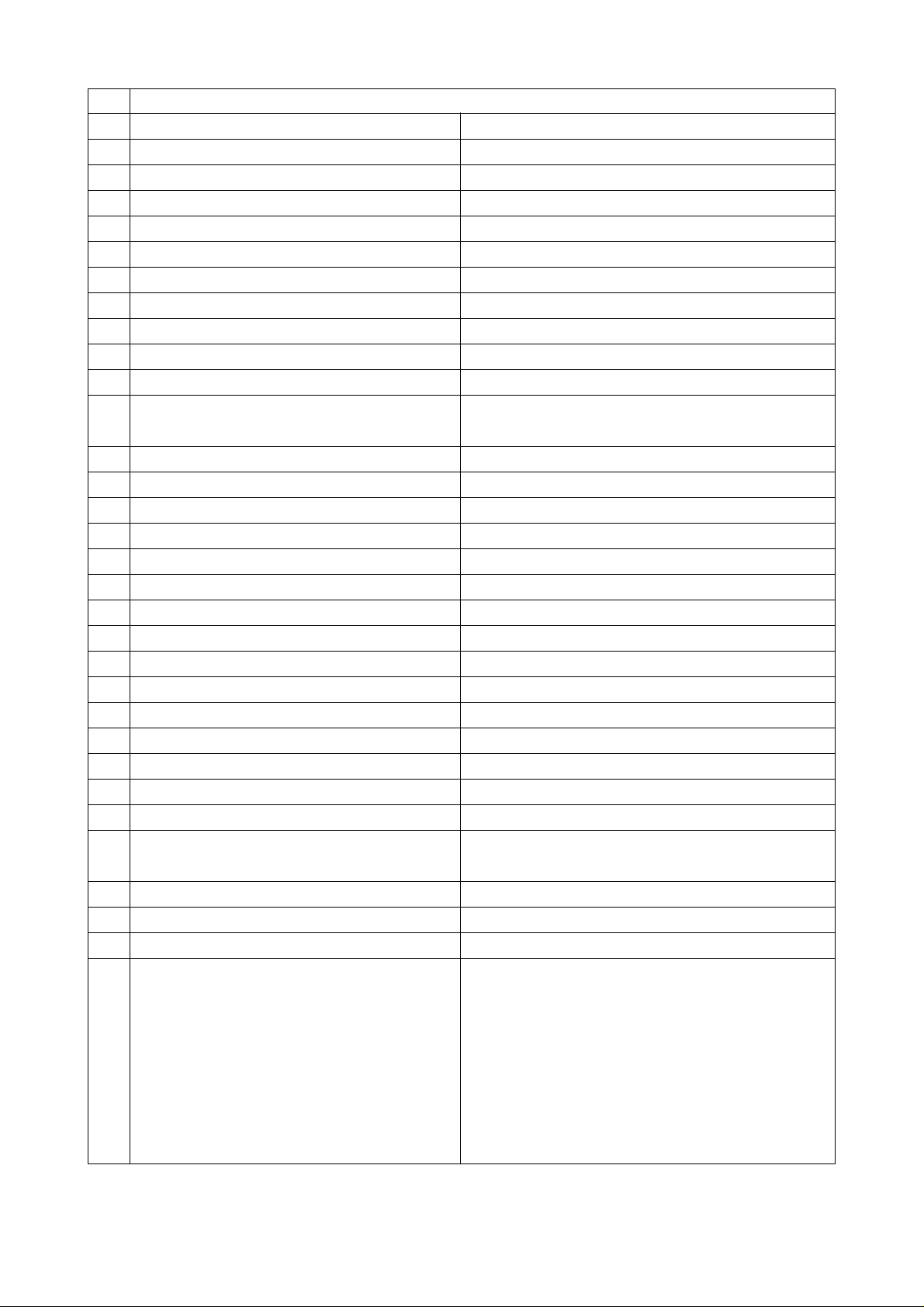

4-1-1 HT/ST200

CI.

Chuck

Base

holder

1782-MC-101-00

1594-109-59-00

1594-109-60-00

1594-113-09-00

1782-40-009-00

Hydraulic power

chuck

(big bore type)

Power chuck

(Unit:1 set)

Cylinder

(Unit: 1 set)

Soft jaw

Base holder for

I.D. cutting

SKETCH DESCRIPTIONNAMEPARTS NO

Cylinder

Cylinder

H.S chuck

Connecting

tube

(1/1)

φ220 big bore chuck (A2-6)

Hollow cylinder

Soft jaw 1piece

φ220 big bore chuck

(MATUMOT O)

Bore ID. φ72

ZA6-8-72B-05

Hollow cylinder

(MATUMOT O)

ZKP150/72-17

Coolant recovery cover, Draw

tube, anti-turning stay

φ220 big bore chuck

3pieces set

OD

Tools

ID

Tools

1593-028-01-00

1596-347-15-00

1596-347-16-00

1596-347-17-00

1596-346-04-00

Spacer for the

reverse cutting

Boring bar socket

for φ40 shank

Boring bar socket

for φ32 shank

Boring bar socket

for φ25 shank

Boring bar socket

for φ20 shank

it is required when carrying out

reverse cutting of an O.D.

4 - 1

Page 58

4-1-2 HT/ST250

(1/1)

CI.

Chuck

Base

holder

OD

Tools

PARTS NO

1782-MC-103-00

1594-109-64-00

1594-109-65-00

1594-113-01-00

1782-40-009-00

1593-028-01-00

Hydraulic power

chuck

(big bore type)

Power chuck

(Unit:1 set)

Cylinder

(Unit: 1 set)

Soft jaw

Base holder for

I.D. cutting

Spacer for the

reverse cutting

SKETCH DESCRIPTIONNAME

Cylinder

Cylinder

H.S chuck

Connecting

tube

φ254 big bore chuck (A2-8)

Hollow cylinder

Soft jaw 1piece

φ254 big bore chuck

(MATUMOTO)

Bore ID. φ82

ZA8-10-82B-02

Hollow cylinder

(MATUMOTO)

ZKP170/82-20

Coolant recovery cover, Draw

tube, anti-turning stay

φ254 big bore chuck

3pieces set

it is required when carrying out

reverse cutting of an O.D.

ID

Tools

1596-347-15-00

1596-347-16-00

1596-347-17-00

1596-346-04-00

Boring bar socket

for φ40 shank

Boring bar socket

for φ32 shank

Boring bar socket

for φ25 shank

Boring bar socket

for φ20 shank

4 - 2

Page 59

4-2 12st. Base HolderTurret Head Combination Tool List (Selection)

4-2-1 HT200/250, ST200/250

CI

Base

holder

ID

T ool

1782-40-011-00

1782-40-013-00

1596-346-05-00

1593-340-13-00

1593-340-14-10

Base holder for

U-drill

Base holder for

face grooving

Boring bar socket

for φ16 shank

Boring bar socket

for φ12 shank

Boring bar socket

for φ10 shank

(MT)

(1/2)

SKETCH DESCRIPTIONNAMEPARTS NO

Socket for φ32, 25, 20 1pc

each.

Can be used both for whistle

notch shank ISO shank

Drilling

Tools

1593-340-15-10

1596-337-04-00

1596-337-03-00

1596-337-02-00

1596-337-01-00

1594-337-03-00

Boring bar socket

for φ8 shank

MT No.4

Drill socket

MT No. 3

Drill socket

MT No. 2

Drill socket

MT No.1

Drill socket

MT4 × MT3

Drill sleeve

For φ32~φ50 Morse taper

shank drill

For φ23~φ32 Morse taper

shank drill

For φ14~φ23 Morse taper

shank drill

For φ14 or less Morse taper

shank drill

4 - 3

Page 60

(2/2)(MT)

CI

Drilling

Tools

Tap

holder

Others

PARTS NO

1594-337-04-00

1782-95-001-00

1782-95-002-00

1593-347-01-00

1593-347-0200~08

1593-419-01-00

MT2 × MT1

Drill sleeve

Socket for φ8

center drill

Socket for φ5

center drill

Tapper

Tap collet

Revolving bar

stopper

SKETCH DESCRIPTIONNAME

S32-Z12-87.5L (NIKKEN)

Need φ32 socket

ZMK12 Without torque limitter

M3,4,5,6,8,10,12,14,16

Rotation type bar stopper

Need socket φ32

Live

center

Special

Accessory

1594-340-03-20

Live center

Spanners and

wrenches

(With tool box)

LC5X-7W(NSK)

1. Grease gun, oiler, philips

screw-drivers (medium,

large), slotted screw-driver

2. Open end spanners 10×13,

14×17, 19×24, 27×30, 36×41

3. Simple spanner 22

4. Hexagonal bar wrenches

3, 4, 5, 6, 8, 10, 14

4 - 4

Page 61

(1/1)(INCH)

CI

Base

Holder

I.D tool

1782-40-010-00

1782-40-012-00

1782-40-014-00

1596-347-18-00

1596-347-19-00

1596-347-20-00

I.D holder

Oil-hole drill

holder

Face grooving

holder

Boring bar socket

1-1/2”

Boring bar socket

1-1/4”

Boring bar socket

1”

SKETCH DESCRIPTIONNAMEPARTS NO

Include φ1-1/4”, φ1”, φ3/4”

socket 1pc each.

For Kennametal “Drill-Fix

(DFT)”

Drill

tool

Live

center

1596-347-04-00

1596-347-05-00

1596-337-06-00

1594-340-03-20

Boring bar socket

3/4”

Boring bar socket

5/8”

Drill socket MT2

Live center

MT5 shank Max 5000min

LC5X-7W(NSK)

-1

4 - 5

Page 62

4-3 12st. QCT(KV) Turret Head Combination Tool List (Standard)

4-3-1 HT/ST200

CI.

Chuck 1782-MC-101-00

1594-109-59-00

1594-109-60-00

1594-113-09-00

Hydraulic power

chuck

(big bore type)

Power chuck

(Unit:1 set)

Cylinder

(Unit: 1 set)

Soft jaw

SKETCH DESCRIPTIONNAMEPARTS NO

Cylinder

Cylinder

H.S chuck

Connecting

tube

(1/1)

φ220 big bore chuck (A2-6)

Hollow cylinder

Soft jaw 1piece

φ220 big bore chuck

(MATUMOT O)

Bore ID. φ72

ZA6-8-72B-05

Hollow cylinder

(MATUMOT O)

ZKP150/72-17

Coolant recovery cover, Draw

tube, anti-turning stay

φ220 big bore chuck

3pieces set

4 - 6

Page 63

4-3-2 HT/ST250

(1/1)

CI.

Chuck 1782-MC-103-00

PARTS NO

1594-109-64-00

1594-109-65-00

1594-113-01-00

Hydraulic power

chuck

(big bore type)

Power chuck

(Unit:1 set)

Cylinder

(Unit: 1 set)

Soft jaw

SKETCH DESCRIPTIONNAME

Cylinder

Cylinder

H.S chuck

Connecting

tube

φ254 big bore chuck (A2-8)

Hollow cylinder

Soft jaw 1piece

φ254 big bore chuck

(MATUMOTO)

Bore ID. φ82

ZA8-10-82B-02

Hollow cylinder

(MATUMOTO)

ZKP170/82-20

Coolant recovery cover, Draw

tube, anti-turning stay

φ254 big bore chuck

3pieces set

4 - 7

Page 64

4-4 12st. QCT(KV) Turret Head Combination Tool List (Selection)

4-2-1 HT200/250, ST200/250

CI

Base

holder

ID

T ool

1593-352-01-00

1593-352-02-00

1593-352-03-00

1593-331-35-00

1593-667-20-00

1593-667-21-00

Base holder for

outer figure

cutting

Base holder for

outer figure

copying

Base holder for

face grooving

Base holder used

both I.D cutting

U-drill

Boring bar socket

for φ25 shank

Boring bar socket

for φ20 shank

(1/2)

(MT)

SKETCH DESCRIPTIONNAMEPARTS NO

QCT40-TA25

QCT40-TB25

QCT40-TC25

QCT40-SU32

Drilling

Tools

1593-667-22-00

1593-667-23-00

1593-667-24-00

1593-667-25-00

1593-337-09-00

1593-337-10-00

1593-337-43-00

1593-337-04-00

Boring bar socket

for φ16 shank

Boring bar socket

for φ12 shank

Boring bar socket

for φ10 shank

Boring bar socket

for φ8 shank

MT No. 3

Drill socket

MT No. 2

Drill socket

MT No. 1

Drill socket

MT2 × MT1

Drill sleeve

For φ23~φ32 Morse taper

shank drill

For φ14~φ23 Morse taper

shank drill

For φ14 or less Morse taper

shank drill

1593-342-01-00

Socket for U-drill

φ20, 25 1pc each set.

Can be used both for whistle

notch shank ISO shank

4 - 8

Page 65

(2/2)(MT)

CI

Drilling

Tools

Tap

holder

Others

Live

center

Special

Accessory

PARTS NO

1594-331-54-01

1594-331-55-01

1593-347-01-00

1593-347-0200~08

1593-419-01-00

1594-340-03-20

Socket for φ8

center drill

socket for φ5

center drill

Tapper

Tap collet

Revolving bar

stopper

Live center

Spanners and

wrenches

(With tool box)

SKETCH DESCRIPTIONNAME

S32-Z12-87.5L (NIKKEN)

Need φ32 socket

ZMK12 Without torque limitter

M3,4,5,6,8,10,12,14,16

Rotation type bar stopper

LC5X-7W(NSK)

1. Grease gun, oiler, philips

screw-drivers (medium,

large), slotted screw-driver

2. Open end spanners 10×13,

14×17, 19×24, 27×30, 36×41

3. Simple spanner 22

4. Hexagonal bar wrenches

3, 4, 5, 6, 8, 10, 14

4 - 9

Page 66

(1/1)(INCH)

CI

I.D Tool

Drill

tool

Live

center

PARTS NO

1596-347-20-00

1596-347-04-00

1596-347-05-00

1596-337-06-00

1594-340-03-20

Boring bar socket

1”

Boring bar socket

3/4”

Boring bar socket

5/8”

Drill socket MT2

Live center

SKETCH DESCRIPTIONNAME

MT5 shank Max 5000min

LC5X-7W(NSK)

-1

4 - 10

Page 67

4-5 12st. VDI Turret Head Combination Tool List (Standard)

4-5-1 HT/ST200

CI.

Chuck 1782-MC-101-00

1594-109-59-00

1594-109-60-00

1594-113-09-00

Hydraulic power

chuck

(big bore type)

Power chuck

(Unit:1 set)

Cylinder

(Unit: 1 set)

Soft jaw

SKETCH DESCRIPTIONNAMEPARTS NO

Cylinder

Cylinder

H.S chuck

Connecting

tube

(1/1)

φ220 big bore chuck (A2-6)

Hollow cylinder

Soft jaw 1piece

φ220 big bore chuck

(MATUMOT O)

Bore ID. φ72

ZA6-8-72B-05

Hollow cylinder

(MATUMOT O)

ZKP150/72-17

Coolant recovery cover, Draw

tube, anti-turning stay

φ220 big bore chuck

3pieces set

4 - 11

Page 68

4-5-2 HT/ST250

(1/1)

CI.

Chuck 1782-MC-103-00

PARTS NO

1594-109-64-00

1594-109-65-00

1594-113-01-00

Hydraulic power

chuck

(big bore type)

Power chuck

(Unit:1 set)

Cylinder

(Unit: 1 set)

Soft jaw

SKETCH DESCRIPTIONNAME

Cylinder

Cylinder

H.S chuck

Connecting

tube

φ254 big bore chuck (A2-8)

Hollow cylinder

Soft jaw 1piece

φ254 big bore chuck

(MATUMOTO)

Bore ID. φ82

ZA8-10-82B-02

Hollow cylinder

(MATUMOTO)

ZKP170/82-20

Coolant recovery cover, Draw

tube, anti-turning stay

φ254 big bore chuck

3pieces set

4 - 12

Page 69

4-6 12st. VDI Turret Head Combination Tool List (Selection)

4-6-1 HT200/250, ST200/250

CI

Base

holder

ID

T ool

1742-67-080-00

1742-67-086-00

1742-67-079-00

1742-67-081-00

1593-331-29-00

1742-68-006-10

1593-355-03-00

1593-667-20-00

Base holder for

O.D. cutting

Base holder for

face grooving

(Offset)

Base holder for

I.D. cutting

Base holder for

I.D. cutting

(Offset)

Base holder for

U-drill

Base holder for

cutting-off

Base holder for

plug

Boring bar socket

for φ25 shank

(1/2)

SKETCH DESCRIPTIONNAMEPARTS NO

1742-67-442-

1742-67-505-

1742-67-443-

1742-67-473-

1742-67-674-

1742-67-558-/1742-67-670-

1742-67-568-

Drilling

Tools

1593-667-21-00

1593-667-22-00

1593-667-23-00

1593-667-24-00

1593-667-25-00

1593-337-09-00

1593-337-10-00

Boring bar socket

for φ20 shank

Boring bar socket

for φ16 shank

Boring bar socket

for φ12 shank

Boring bar socket

for φ10 shank

Boring bar socket

for φ8 shank

MT No. 3

Drill socket

MT No. 2

Drill socket

For φ23~φ32 Morse taper

shank drill

For φ14~φ23 Morse taper

shank drill

4 - 13

Page 70

(2/2)

CI

Drilling

Tools

Tap

holder

Others

1593-337-43-00

1593-337-04-00

1593-342-01-00

1594-331-54-01

1594-331-55-01

1593-347-01-00

1593-347-0200~08

1593-419-01-00

MT No. 1

Drill socket

MT2×MT1

Drill sleeve

Socket for U-drill

Socket for φ8

center drill

Socket for φ5

center drill

Tapper

Tap collet

Revolving bar

stopper

SKETCH DESCRIPTIONNAMEPARTS NO

For φ14 or less Morse taper

shank drill

φ20, 25 1pc each set.

Can be used both for whistle

notch shank ISO shank

S32-Z12-87.5L (NIKKEN)

Need φ32 socket

ZMK12 Without torque limitter

M3,4,5,6,8,10,12,14,16

Rotation type bar stopper

Live

center

Special

Accessory

1594-340-03-20

Live center

Spanners and

wrenches

(With tool box)

LC5X-7W(NSK)

1. Grease gun, oiler, philips

screw-drivers (medium,

large), slotted screw-driver

2. Open end spanners 10×13,

14×17, 19×24, 27×30, 36×41

3. Simple spanner 22

4. Hexagonal bar wrenches

3, 4, 5, 6, 8, 10, 14

4 - 14

Page 71

4-7 12st.VDI Rotating Tool Turret Head Combination Tool List (Standard)

4-7-1 HT/ST200

CI.

Chuck 1782-MC-101-00

1594-109-59-00

1594-109-60-00

1594-113-09-00

Hydraulic power

chuck

(big bore type)

Power chuck

(Unit:1 set)

Cylinder

(Unit: 1 set)

Soft jaw

SKETCH DESCRIPTIONNAMEPARTS NO

Cylinder

Cylinder

H.S chuck

Connecting

tube

(1/1)

φ220 big bore chuck (A2-6)

Hollow cylinder

Soft jaw 1piece

φ220 big bore chuck

(MATUMOT O)

Bore ID. φ72

ZA6-8-72B-05

Hollow cylinder

(MATUMOT O)

ZKP150/72-17

Coolant recovery cover, Draw

tube, anti-turning stay

φ220 big bore chuck

3pieces set

4 - 15

Page 72

4-7-2 HT/ST250

(1/1)

CI.

Chuck 1782-MC-103-00

PARTS NO

1594-109-64-00

1594-109-65-00

1594-113-01-00

Hydraulic power

chuck

(big bore type)

Power chuck

(Unit:1 set)

Cylinder

(Unit: 1 set)

Soft jaw

SKETCH DESCRIPTIONNAME

Cylinder

Cylinder

H.S chuck

Connecting

tube

φ254 big bore chuck (A2-8)

Hollow cylinder

Soft jaw 1piece

φ254 big bore chuck

(MATUMOTO)

Bore ID. φ82

ZA8-10-82B-02

Hollow cylinder

(MATUMOTO)

ZKP170/82-20

Coolant recovery cover, Draw

tube, anti-turning stay

φ254 big bore chuck

3pieces set

4 - 16

Page 73

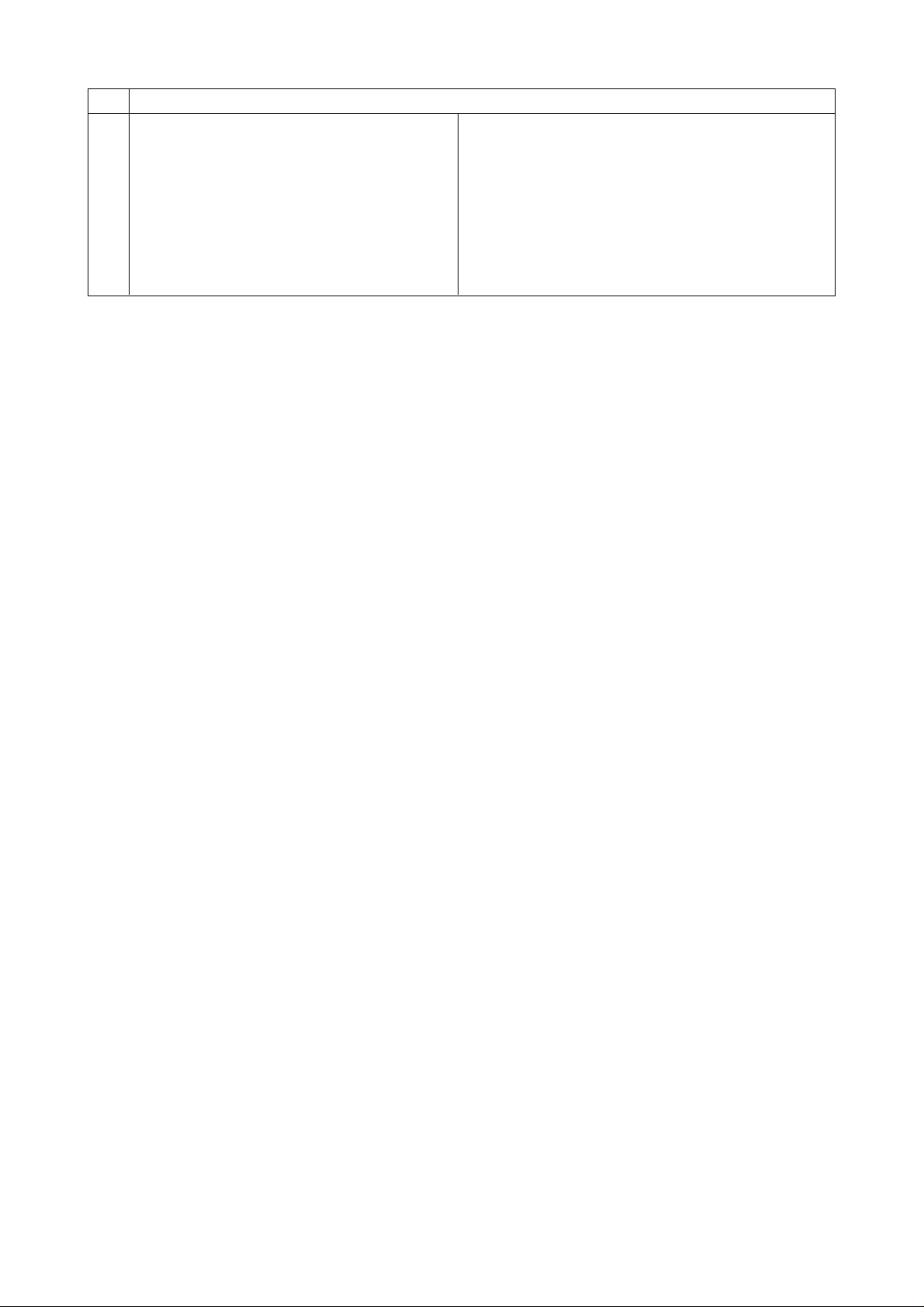

4-8 12st. VDI Rotating Tool Turret Head Combination Tool List (Selection)

4-8-1 HT200/250, ST200/250

CI

Base

holder

1742-67-080-00

1742-67-086-00

1742-67-079-00

1742-67-081-00

1593-331-29-00

1742-68-006-10

1782-67-007-00

Base hgolder for

O.D cutting

Base holder for

face grooving

(Offset)

Base holder for

I.D. cutting

Base holder for

I.D. cutting

(Offset)

Base holder for

U-drill

Base holder for

cutting-off

Base holder for

X-axis rotating

tool

(1/2)

SKETCH DESCRIPTIONNAMEPARTS NO

1742-67-442-

1742-67-505-

1742-67-443-

1742-67-473-

1742-67-674-

1742-67-558-/1742-67-670-

ID

T ool

1782-67-008-00

1593-355-03-00

1593-667-20-00

1593-667-21-00

1593-667-22-00

1593-667-23-00

1593-667-24-00

1593-667-25-00

Base holder for

Z-axis rotating

tool

Base holder for

plug

1742-67-568-

Boring bar socket

for φ25 shank

Boring bar socket

for φ20 shank

Boring bar socket

for φ16 shank

Boring bar socket

for φ12 shank

Boring bar socket

for φ10 shank

Boring bar socket

for φ8 shank

4 - 17

Page 74

(2/2)

CI

Drilling

Tools

Tap

holder

PARTS NO

1593-337-09-00

1593-337-10-00

1593-337-43-00

1593-337-04-00

1593-342-01-00

1594-331-54-01

1594-331-55-01

1593-347-01-00

MT No. 3

Drill socket

MT No. 2

Drill socket

MT No. 1

Drill socket

MT2 × MT1

Drill sleeve

Socket for U-drill

Socket for φ8

center drill

Socket for φ5

center drill

Tapper

SKETCH DESCRIPTIONNAME

For φ23~φ32 Morse taper

shank drill

For φ14~φ23 Morse taper

shank drill

For φ14 or less Morse taper

shank drill

φ20, 25 1pc each set.

Can be used both for whistle

notch shank ISO shank

S32-Z12-87.5L (NIKKEN)

Need φ32 socket

Rotating

Tools

Others

Live

center

Special

Accessory

1593-347-0200~08

1596-352-1100~14

1596-352-0000~05

1593-419-01-00

1594-340-03-20

Tap collet

Collet

Tap collet

Revolving bar

stopper

Live center

Spanners and

wrenches

(With tool box)

ZMK12 Without torque limitter

M3,4,5,6,8,10,12,14,16

ESX32

(D=2.5, 3 ~ 16)

ET32

(M3, 4, 5, 6, 8, 10, 12)

Rotation type ber stopper

LC5X-7W(NSK)

1. Grease gun, oiler, philips

screw-drivers (medium,

large), slotted screw-driver

2. Open end spanners 10×13,

14×17, 19×24, 27×30, 36×41

3. Simple spanner 22

4. Hexagonal bar wrenches

3, 4, 5, 6, 8, 10, 14

4 - 18

Page 75

TURNING CENTER

HT200/250, ST200/250

INSTRUCTION MANUAL

SPECFICATION

SEICOS-pcFLexi

Version 1.01

10-2001

10-2001 First Edition

Loading...

Loading...