hitachi seiki HITEC-TURN 20, HITEC-TURN 25 Maintenance Manual

u

riSElKI

(

.9

i

u

u

CNC

with

Turning

Conversational

Maintenance

Center

Control

Manual

'•

-V

o-

wT-tassl

l,

Hitachi

AUGUST,

SeikJ

1985

Co0,Lfcja

1)

5)

7)

8)

10)

ID

12)

13)

2)

3)

4)

6)

9)

Installation

Shipping

-

-

Leveling

-

Mounting

-

Oil

Specification

Electric

Control

Cabinet

N/C

Check

Setting

PC

Diagnostics

OT

Alarms

Zero

Point

Display,

Diagnosis

Origin

Parameters

-

Zero

-

Backlash

Operation

Point

Procedure

Clamps

Guards

Symbols

Cabinet

Ladder

Parameter

Setting

Offsetting

Setting

10T-F

for

Shift

Z

X,

Diagram

10T-F

and

Zero

HITEC-TURN

Chart

10T-F

Method

Alteration

Adjust

Z

X,

and

20/25

(Parameters)

Diagnosis

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

13

14

15

16

17

18

19

26

31

33

35

1

1

1

3

5

6-12

-

-

-

-

-

5

2

-

4

25

30

32

34

14)

15)

16)

17)

18)

-

Diagnosis

Special

Parameter

Operations

MDI/Program

Resetting

-

X

Clutch

-

Z

Clutch

Turret

-

Check

Adjust

-

-

Turret

-

How

OD

-

-

Adjust

-

Adjust

Head

Alignment

to

Accuracy

Bit

List,

Operation

Clutch

Alignment

Tool

Post

Alignment

Adjust

Test

Head

Tail

Stock

Stock

Numbers

NK25

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

36

38

59

41

42

44

47

47

48

50

51

52

54

55

-

37

-

40

43

46

-

54

53

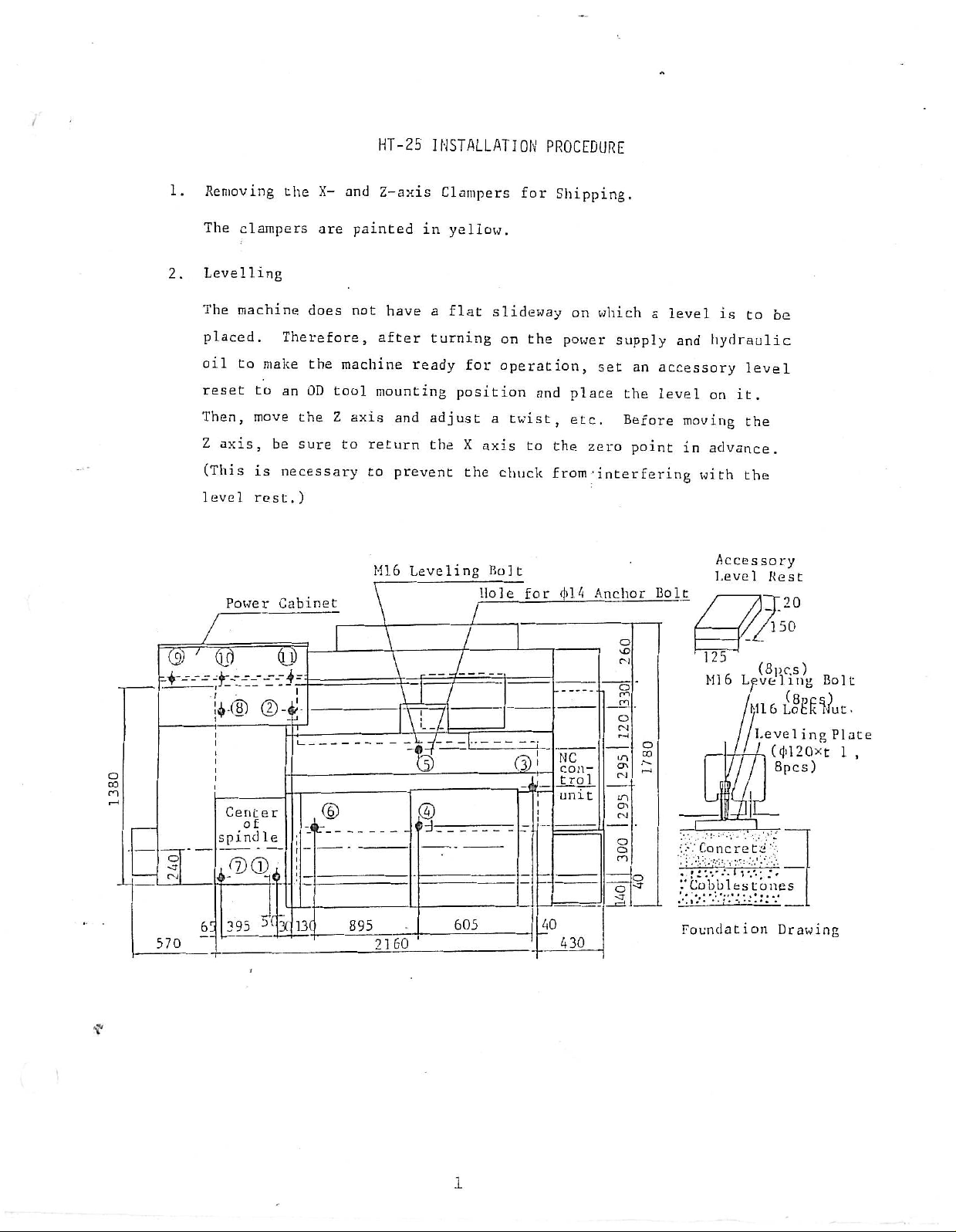

HT-25

INSTALLATION

PROCEDURE

Removing

1.

The

clampers

Levelling

2.

The

machine

placed

oil

reset

Then,

Z

(This

level

T§

'

g

(O

O’

C't

61

570

axis,

Power

16

V®

Center

spind

395

to

move

is

rest

o

f

.

make

to

(D-4;

le

X-

the

are

does

Therefore,

the

OD

an

the

be

sure

necessary

)

.

Cabinet

O

i

©

_<

b_

1

13

and

painted

not

machine

tool

mounting

Z

axis

to

return

to

M16

-

895

2160

Z-axis

have

after

and

prevent

Leveling

_

in

a

turning

ready

adjust

the

n

'

Clampers

yellow.

flat

slideway

for

position

a

X

axis

the

Bolt

Hole

/

/

605

for

Shipping.

on

the

operation,

and

twist,

to

the

chuck

for

1

--

ai

t—

“I—

40

from

(|>14

NC

con¬

trol

unit

430

on

which

power

set

place

etc.

zero

’interfering

Anchor

supply

an

the

Before

point

s

OJ

8

m

o

CN

g

i-O

cn

r—

CN

Oh

OJ

o

CO

O

a

level

and

accessory

level

moving

in

Bolt

4

I

I*

Cobbles

>

Foundation

is

hydraulic

on

it.

advance.

with

Acces

Level

125

,

6

Ml

|

/

M

!oncre

i

-

to

be

level

the

the

sory

Rest

20

150

(8pc,s)

Leveling

LoEfil/ut

Level

jj

(

(J>

L

8pcs)

id-

1

t

e

iv*

;

tones

Drawing

Bolt

•

i

Plate

ng

x

0

2

1

,

t

1

1

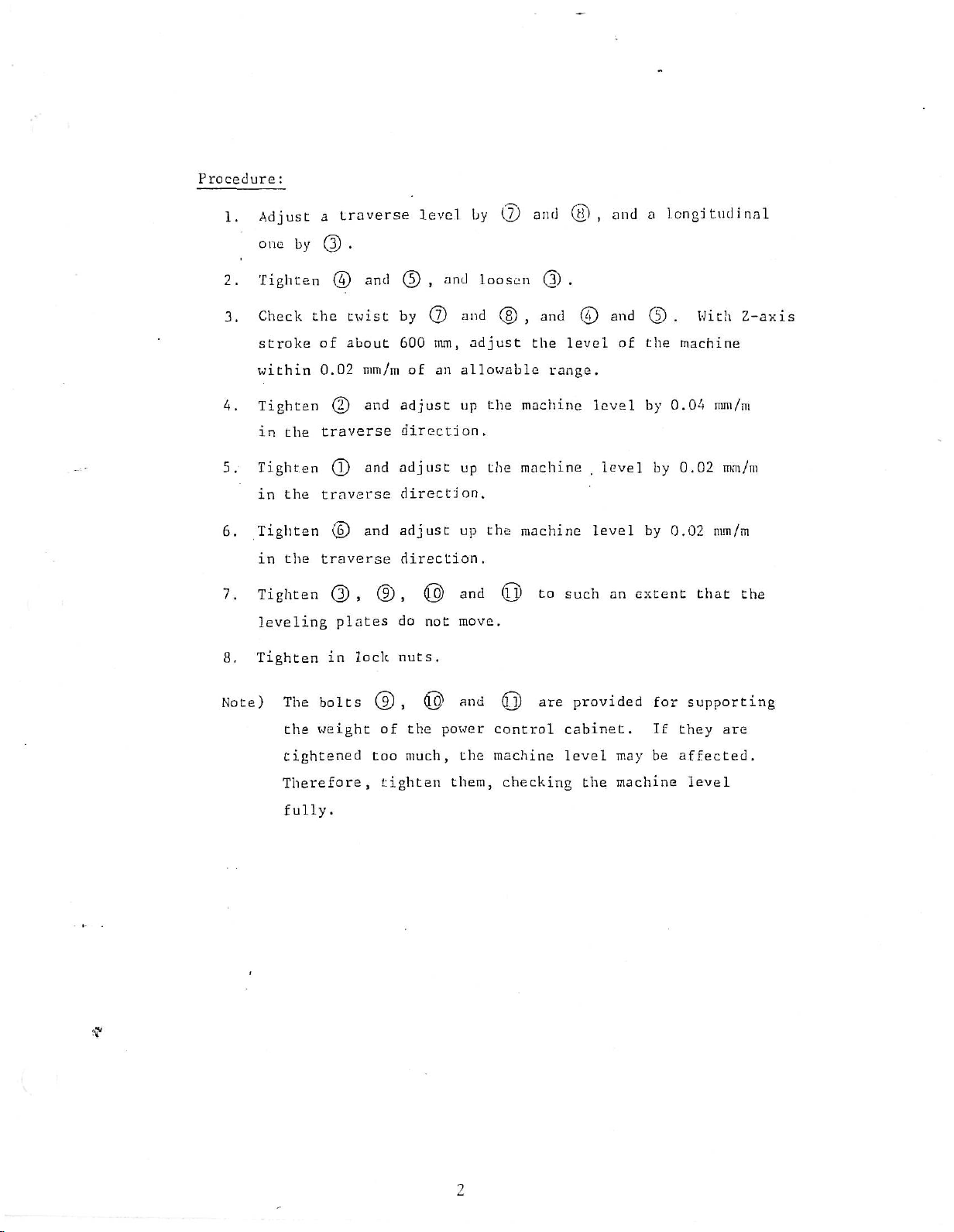

Procedure

:

1.

2.

3.

4.

5.

6.

7.

8.

Adjust

one

by

Tighten

Check

stroke

within

Tighten

the

in

Tighten

the

in

Tighten

the

in

Tighten

leveling

Tighten

traverse

a

(3)

©

the

of

0.02

©

traverse

©

traverse

©

traverse

(5)

plates

in

.

and

twist

about

mm/m

and

and

and

,

lock

©

by

600

of

adjust

direction.

adjust

direction.

adjust

direction.

(9)

,

do

nuts.

level

,

(7)

mm,

an

(©

not

by

and

and

adjust

allowable

up

up

up

and

move.

(j)

loosen

(g)

the

the

the

(ij)

and

.

©

and

,

the

level

range.

machine

machine

machine

such

to

(H)

©

,

level

level

level

an

and

and

of

a

longitudinal

.

©

the

0.04

by

by

by

0.02

extent

With

machine

mm/m

0.02

mm/m

mm/m

that

Z-axis

the

Note)

bolts

The

weight

the

tightened

Therefore,

fully.

(j?)

,

of

too

tighten

@

the

much,

and

power

the

them,

(fl)

are

control

machine

checking

provided

cabinet.

level

the

for

If

may

be

machine

supporting

are

they

affected.

level

2

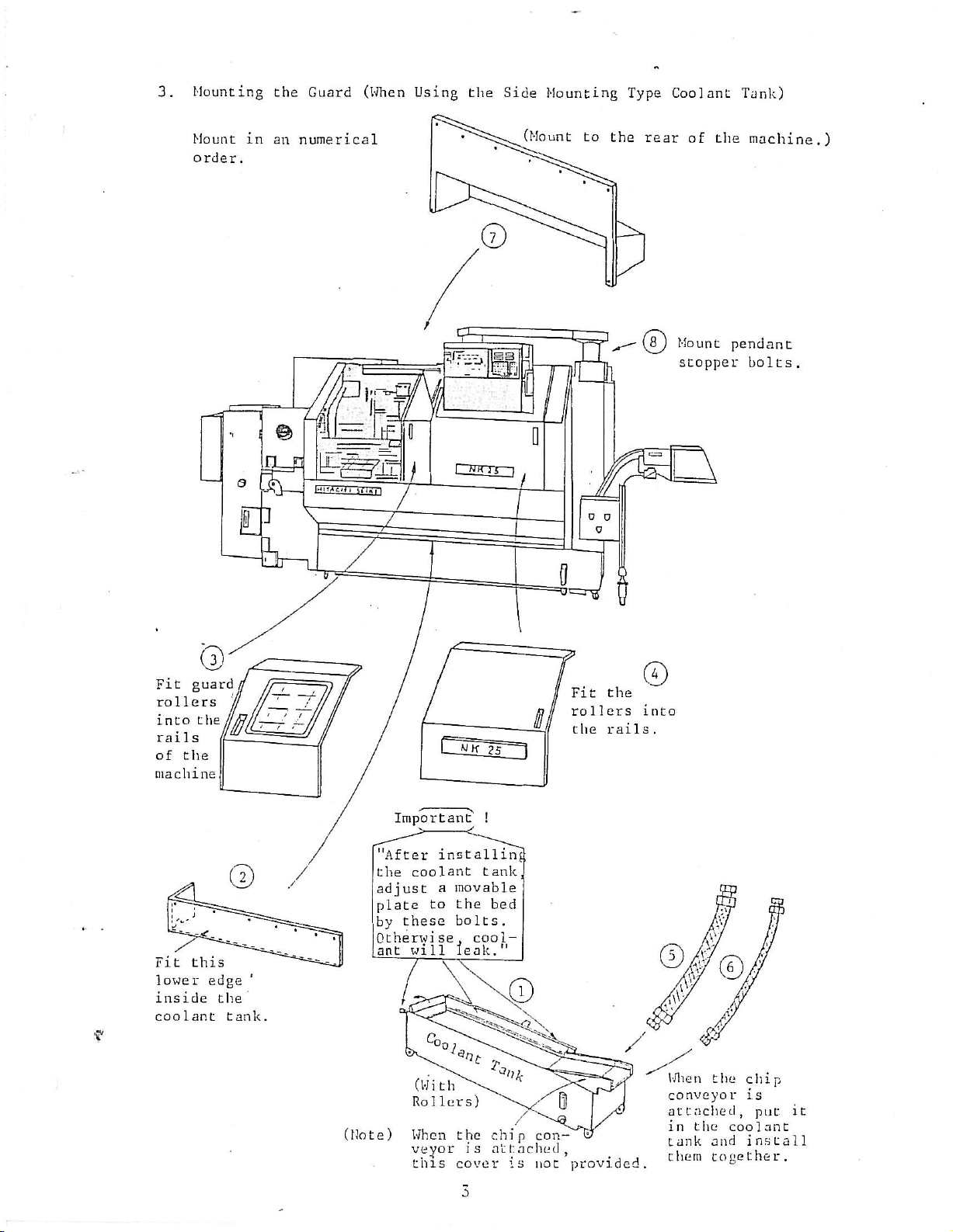

3.

Mounting

the

Guard

(When

Using

the

Side

Mounting

Type

Coolant

Tank)

Mount

order.

in

o

V

numerical

an

©

a—

(Mount

to

the

rear

the

of

machine.)

©

'

_

H''®

i:

?!

M

r

i

SHK

,

/

v

j

1

1

J

U

C7

C7

o

Mount

stopper

pendant

bolts

.

©

guard

Fit

rollers

into

the

rail

s

the

of

machine

Fit

this

lower

inside

coolant

Wlhz±±

/

©

edge

the

tank.

/

(Mote)

CJEOI!I3

Important'

"After

the

adjust

plate

by

Otherwise,

ant

installing

coolant

a

to

these

will

C°0

(With

Rollers)

When

veyor

this

!

tank,

movable

the

bed

bolts.

cool¬

leak."

the

chip

is

attached,

cover

»k

is

1

/

0

con-'iv

not

Fit

the

rollers

rails.

the

„

T

J

S'"'

provided.

©

into

©

®JP®/

\\

/

A

Wlien

the

conveyor

attached,

the

in

and

tank

them

together.

chip

is

put

coolant

install

it

0

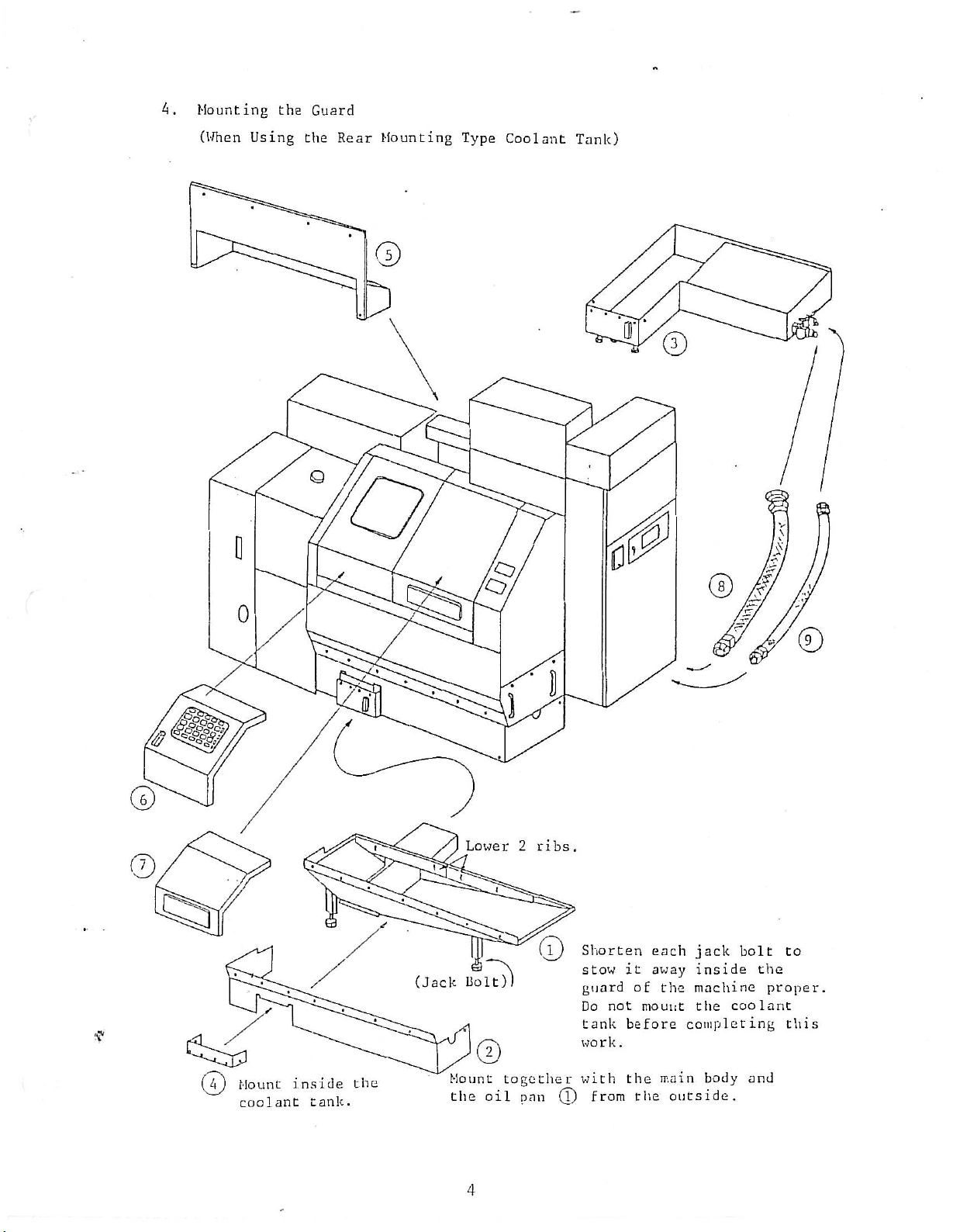

A.

Mounting

(When

Using

the

Guard

the

Q

Rear

Mounting

©

3

Type

Coolant

Tank)

©

;c

©

©

(V)

0

1/

/

Mount

coolant

©

inside

tank.

*

77

the

&

(Jack

Lower

J

Bolt)

Mount

the

o

o

©

oil

2

ribs.

together

pan

(T)

Shorten

stow

guard

Do

not

tank

work.

with

from

each

it

away

of

mount

before

the

the

inside

machine

the

the

completing

main

outside.

©

jack

body

M

W

bolt

the

coolant

and

£

y

to

proper.

this

-y

©

4

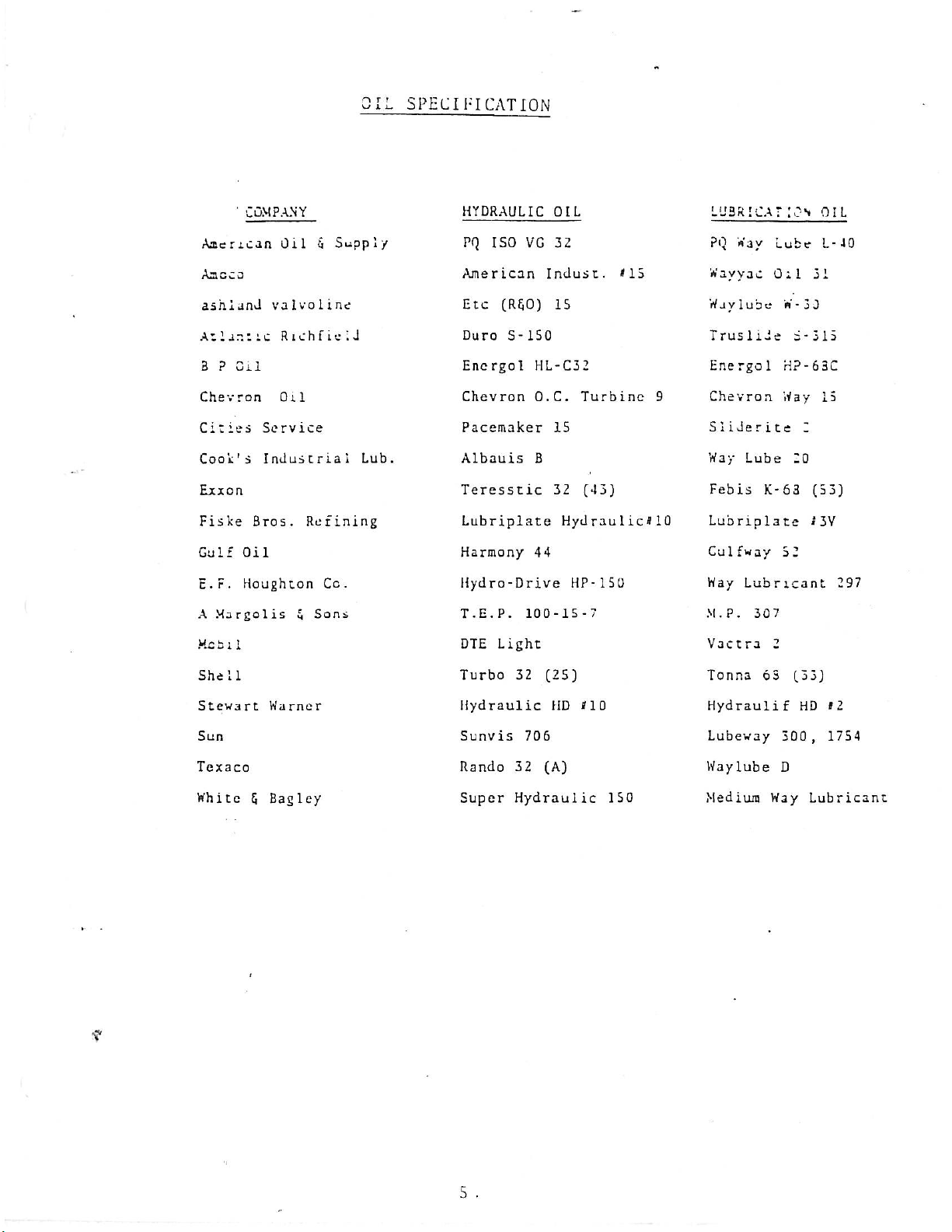

OIL

SPECIFICATION

American

Amoco

asnland

Atlantic

B

Gil

?

Chevron

Cities

Coot's

Exxon

Fiske

Gulf

c.F.

A

Margolis

Mo

5

1

1

COMPANY

Oil

valvoline

Richfield

Oil

Service

Industrial

Bros.

Oil

Houghton

&

i,

Supply

Refining

Co.

Sons

Lub

HYDRAULIC

ISO

PQ

American

(R50)

Etc

Duro

S-

Encrgol

Chevron

Pacemaker

.

Albauis

Teresstic

Lubriplate

Harmony

Hydro-Drive

T.E.P.

Light

DTE

OIL

3

VG

2

Indust.

IS

150

HL-C32

O.C.

15

B

32

Hydraulic»10

44

100-15-7

Turbine

(43)

HP-

150

*15

Lube

W

3

-

5-315

HP-63C

Way

3

IQ

52

31

3

(53]

i

OIL

L-10

IS

3V

297

LUBRICATION

Way

PQ

vac

y

u

I

1

Lube

e

b

ide

rite

K-63

Oil

Way

W

a

rus

T

Er.ergol

9

Chevron

Slide

Way

Febis

Lubnplate

Culfway

Way

Lubricant

M.P.

Vactra

307

2

1

1

She

Stewart

Sun

Texaco

White

&

Warner

Bagley

Turbo

Hydraulic

Sunvis

Rando

Super

32

(25)

HD

706

32

(A)

Hydraulic

V10

ISO

Tonna

Hydraulif

Lubeway

Waylube

Medium

63

300

D

Way

(33)

HD

1754

,

Lubricant

»2

.

5

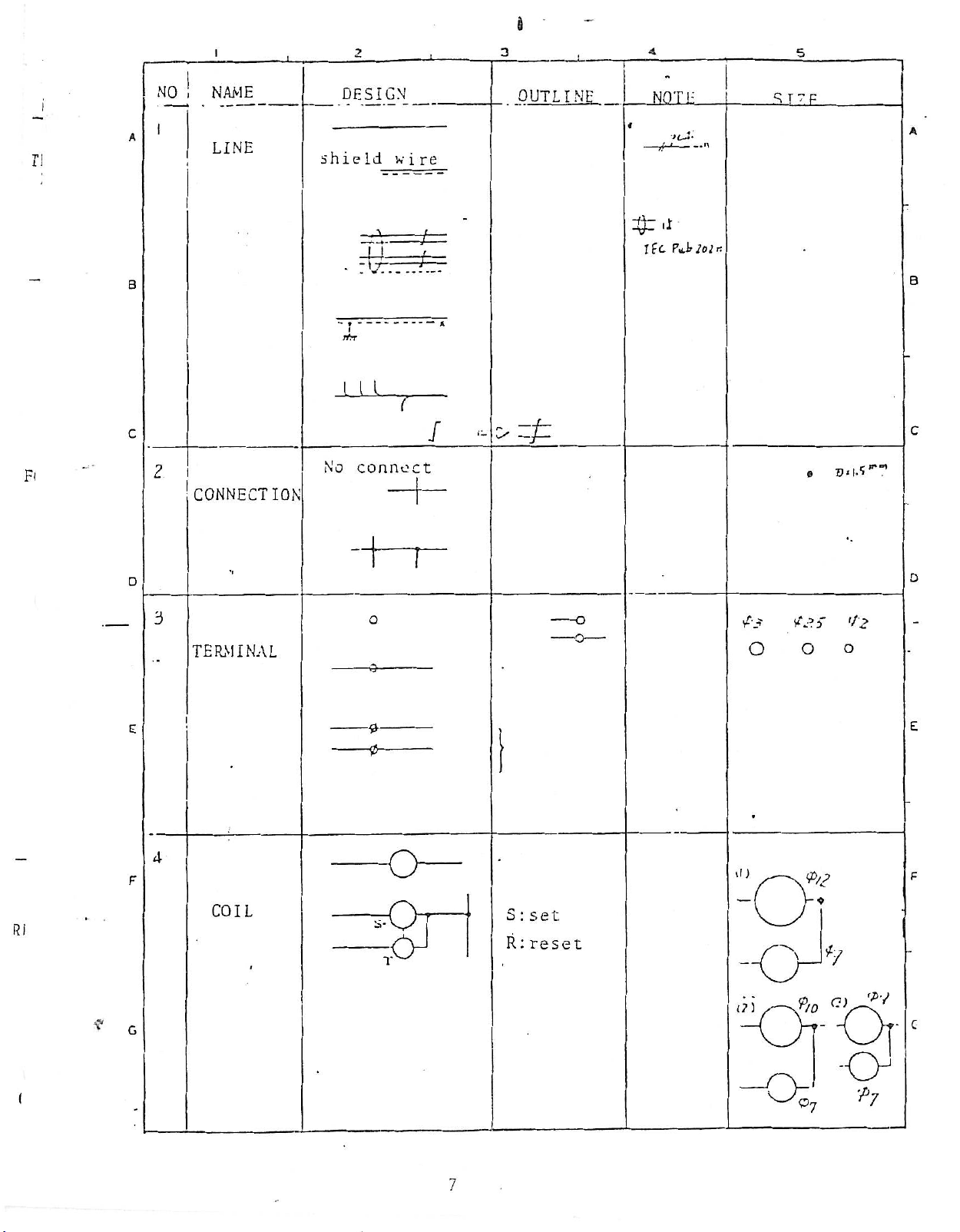

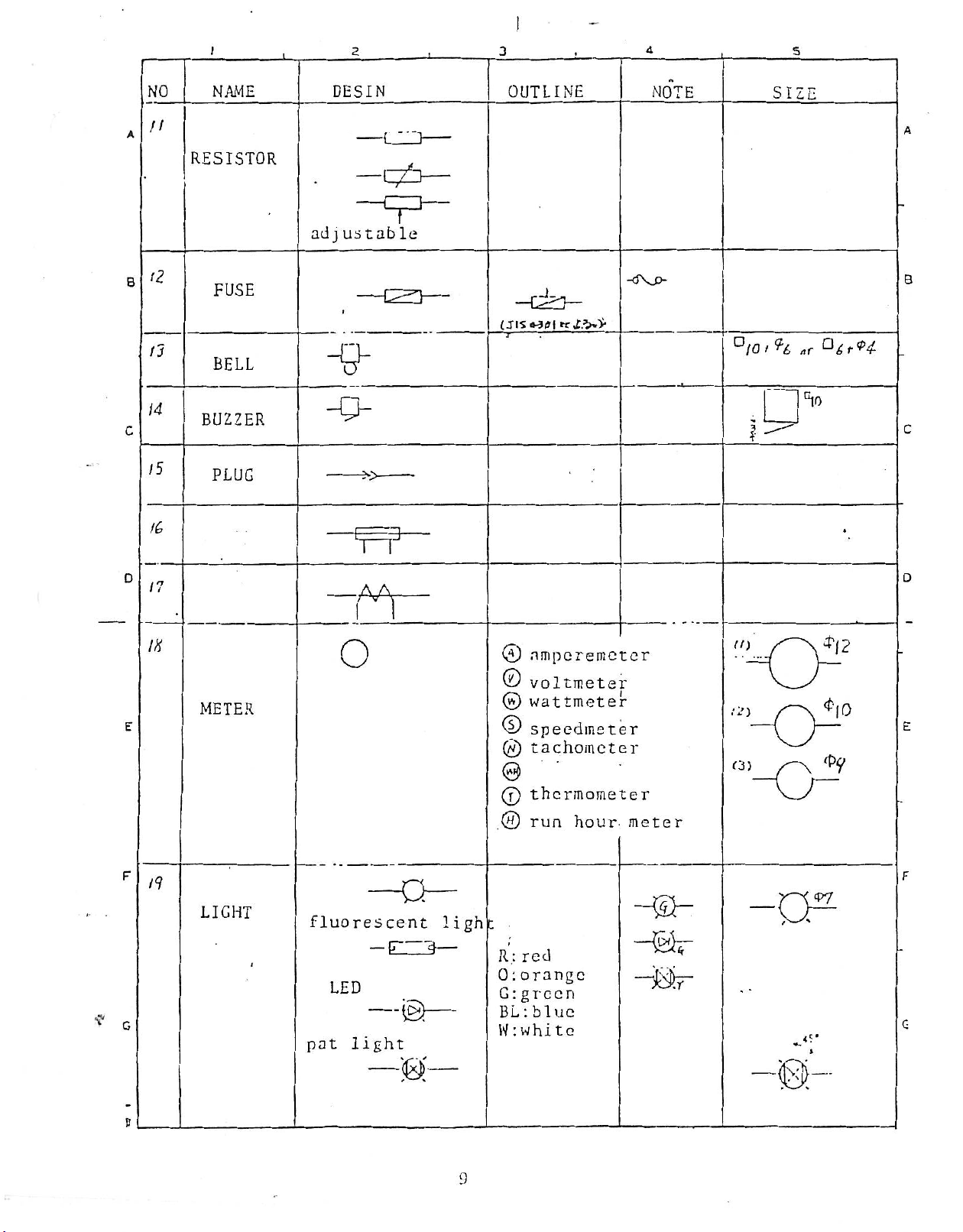

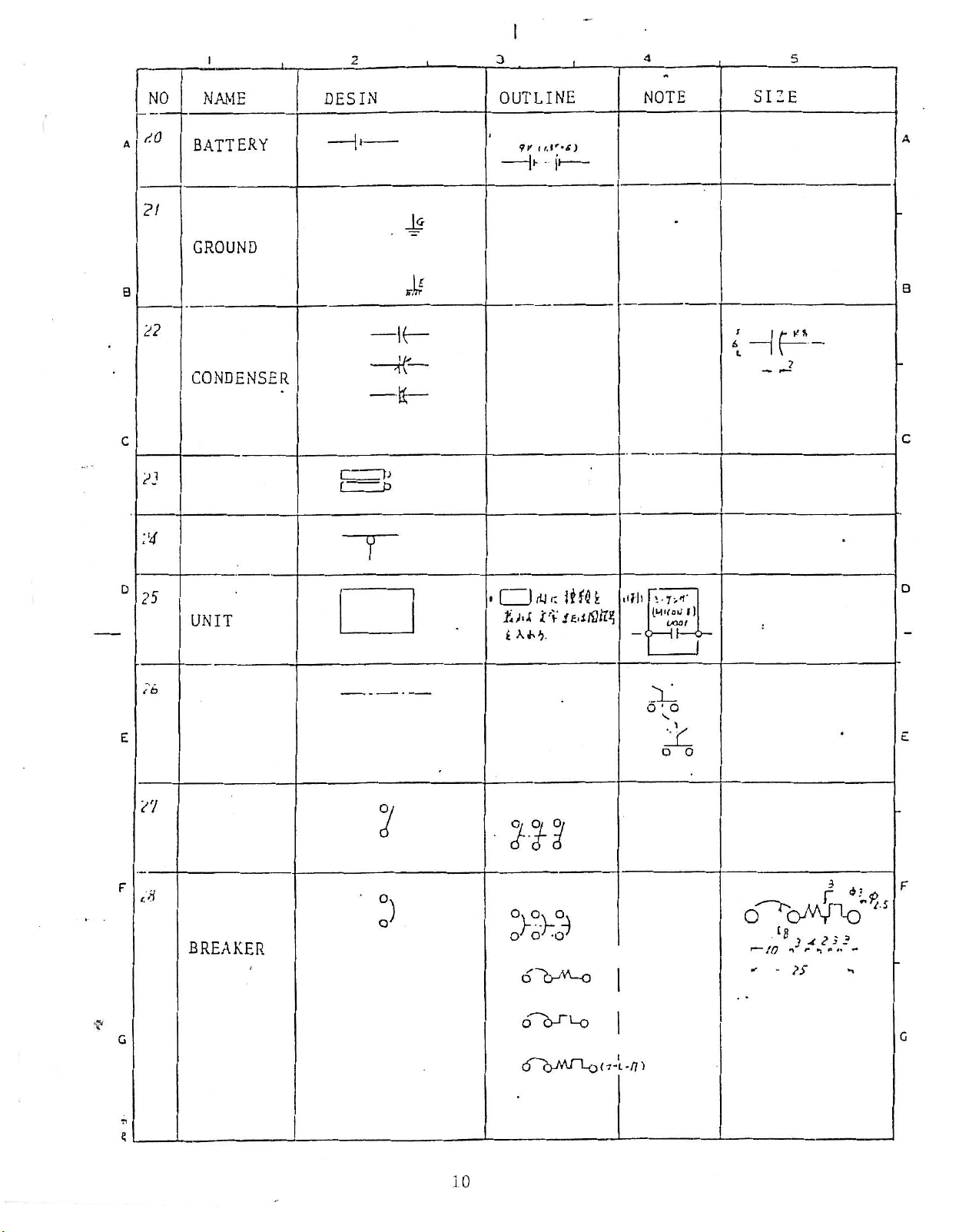

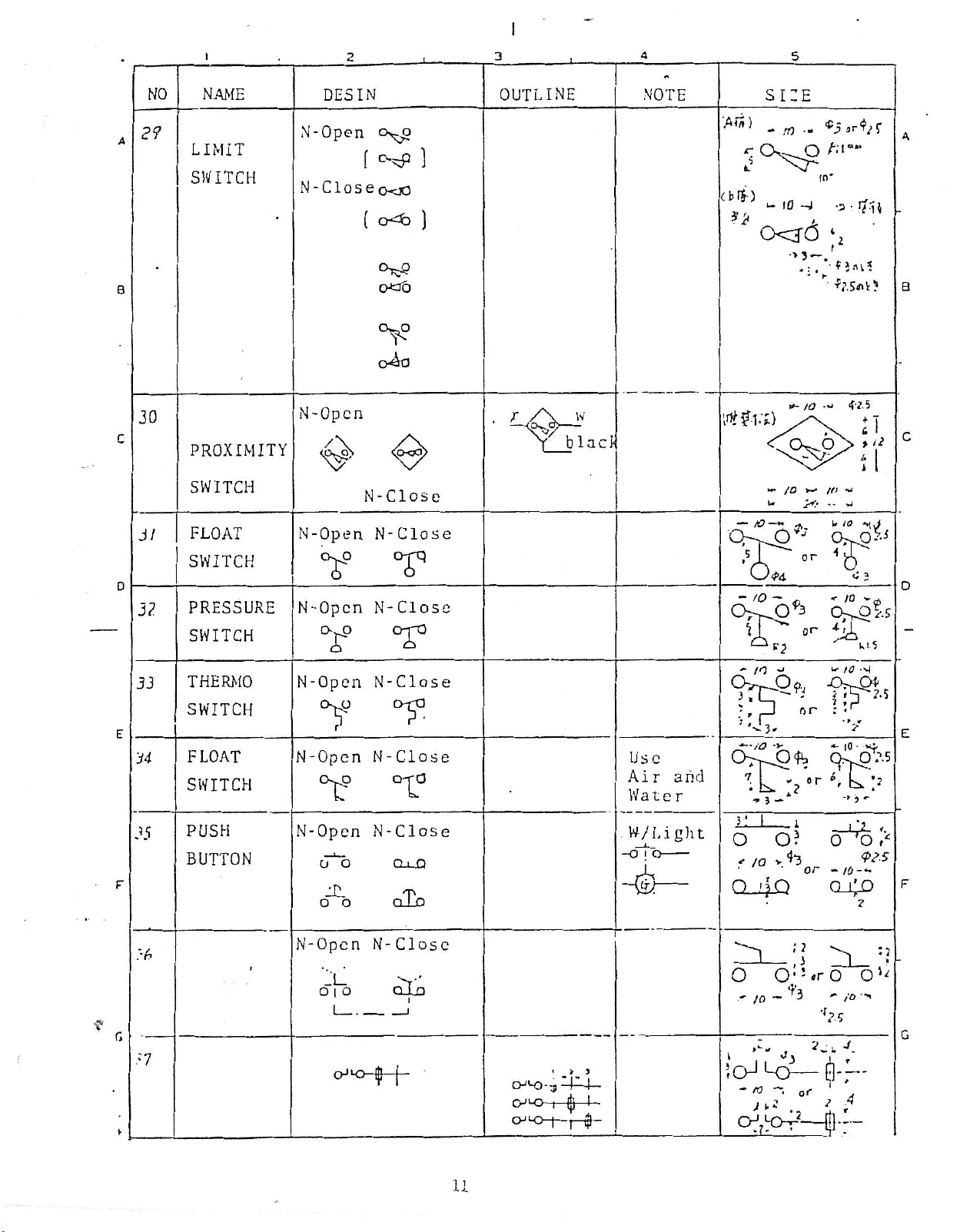

These

electric

symbols

used

for

all

Hitachi

Seiki

machines.

Also

these

symbols

;

are

same

as

Japanese

Industrial

Standards

6

a

2

3

4

S

Fi

n

NO

A

B

!

NAME

LINE

DESIGN

shield

*

r

_X-

wire

OUTLINE

.

£

A

“

*

NOT!-:

-rf

Ift

vt-I*

Pn>

-

loir.

ST

F

-

.

I\

A

B

LLi

r

c

N

o

2

connect

I

1-

Zr-fZ

O

CONNECTION

c

R)

D

3

TERMINAL

E

4

F

COIL

G

o

-a-

&

s-

o

o

&

T

'!

/s

O

>0

S

:

s

e

t.

R

:

reset

l?)

O

•P/2

?,C

2

o

o

D

E

F

<p.j

c

o

(

7

P7

I

2

3

4

5

NO

//

A

a

B

/

5

14

c

15

!G

NAME

RESISTOR

FUSE

BELL

BUZZER

PLUG

DESIN

ad

j

-9-

-Q-

ustab

3-

le

OUTLINE

.JL

Jl-S

t

NOTE

n

SIZE

atO*h

nr

A

B

atrU

°io

,P

c

D

n

IX

METER

E

F

/9

LIGHT

G

fluorescent

pat

O

LED

A A

—

light

®

—

light

@

amperemeter

©

voltmeter

wattmeter

®

©

speedmeter

tachometer

@

©

thermometer

@

run

©

red

R;

0

:

orange

:

G

green

:

blue

BL

W

:

to

whi

hour

meter

-®T

~

Sr"

(!)

f3)

*12

|0

*

"\

D

E

F

G

—

V

0

—

-M

9

I

2

3

4

5

NO

2.0

A

1

2

NAME

BATTERY

DESIN

OUTLINE

u.l'-t)

?»

'

NOTE

SIZE

A

4*

GROUND

3

c

—I

—

(j

a

1£

(—

K—

l

6

L

.J

-

B

22

CONDENSER

c

c

-

r

24

Y

D

25

UNIT

?b

E

•

I

JiM

i

1

A*V

r.

ft

fe,ilQlt%

i'V

fQ

t

«<fli

\-T,<

iMlfoO

uaoi

V

6

,

O

l)

o

'I

O

D

E

2'i

7

m

F

cH

BREAKER

'

°)

o'

o'

o'

6

~b-/Vÿ-o

oÿoÿAo

As

,V.W-

’—tf)

i}

f

d~b-rL-o

G

6

)

F

G

10

i

2

3

4

5

NO

2?

A

B

NAME

LIMIT

SWITCH

DESIN

N-Open

cxÿo

(

C'NP

N-Closeo<x3

oÿo

cxio

OUTLINE

)

NOTE

fifi)

<b£)

*2

5

SIZE

m

-

t-

(0

oÿd

-i

>3

-

*•-

in’

‘2

t

—

.‘ÿfi-n!

r

•3

or

f

4/

A

tfn

a

v°

&&a

-*

to

J

7.

/a

L

3

~

W

<Pi

-

O?

>.

*-

/£>

<)

'2

*

43

i<-

or

nr

>—

lit

-

U

'r

>*•

-oÿe

•"

6r

*•

0*0

or

-/o--

Q-JÿD

to

-»

4

v

t

>

.

l

i

**\

0

3

»*-

‘PAS'

2

i

:j

<2

tf)

7.5

c

D

E

F

30

c

J

D

33

33

E

34

35

F

PROXIMITY

SWITCH

FLOAT

/

SWITCH

PRESSURE

SWITCH

THERMO

SWITCH

FLOAT

SWITCH

PUSH

BUTTON

N-Opcn

<ÿS

N-Open

OjO

N-Opcn

t>ÿo

r

N-Open

oÿo

r

N-Open

0ÿ0

N-Opcn

O

O

o

o

<0>

o

C

1

N

-

N-Close

ojq

N-CIose

°T

N-Close

ora

N-Close

Crj'O

N-Close

J

O

oTo

1

a

c

I

b

s

e

(5

JZ

Tf-a?

:

5-J7.

Use

and

Air

Water

Light

W/

-O

Q

!

-4

1L_L

O

f

Q-4-Q

N-

:-A

N-Opcn

L

o

Ol

Close

oTo

In

o

•-

/O

-

O

4'

;

?

>1

1

*r

*

O

3

"

fo

»

O1'

>

f?S

G

;7

f-

oJLo—

3)

—

f-

OMD-J

OMOt-

0"-0-t

11

__

J_

•

Z|l4—

$

[

>

I

$ÿ-

t

3

I

/O

.

-

—

K1

7

A

G

I

I

3

4

5

NO

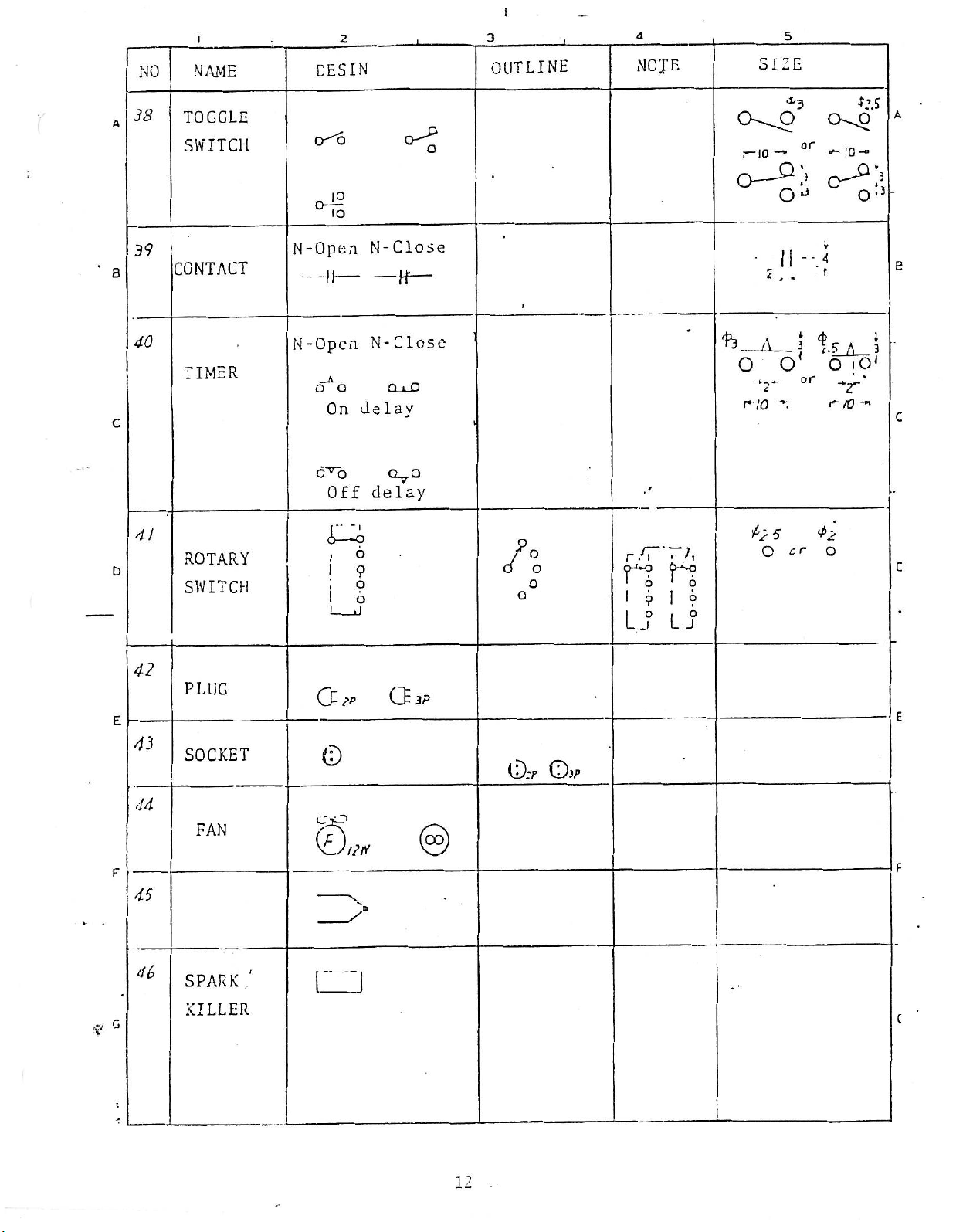

38

A

39

B

c

NAME

TOGGLE

SWITCH

CONTACT

TIMER

DESIN

6

o

—

|0

IO

N-Open

N-Opcn

o

o

On

oÿb

Off

N-Close

—

tt—

N-Close

CLi_D

delay

delay

OUTLINE

NO'JE

SIZE

0-ÿ0

,—

io

—

Q‘

O

—

||-,4

2

,

-

A

O

O

-*2-

r/o

or

3

f

or

CKÿO

|0

~

—

O'3

v

r

>-LA_3

iO'

O

v’

r/O

-

s

A

E

;

c

4>

dJ

6

D

42

E

43

U

ROTARY

SWITCH

PLUG

SOCKET

FAN

i

Ct

(D

?P

9

O

o

3P

CJ

/%

O

o

Q:r

O’P

n

I

10,0

L

n

[

o

9

J

L

J

4-S5

O

>

O

c

E

©

F

45

4b

SPARK

KILLER

c

12

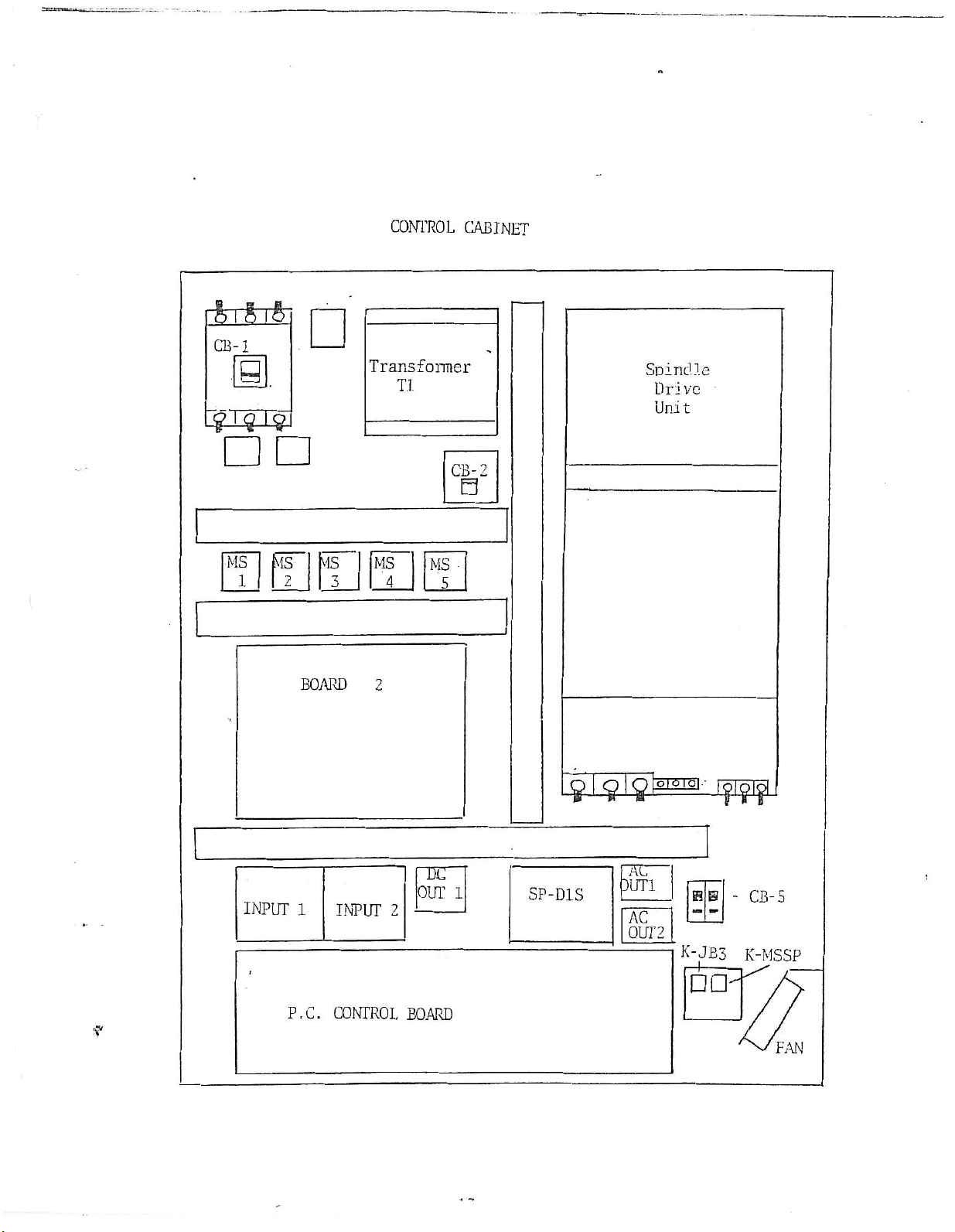

CB-1

m

CONTROL

Transformer

T1

CB-2

CABINET

Spine1

Drive

Unit

e

1

INPUT

BOARD

1

P.C.

2

INPUT

CONTROL

2

1)11

OUT

BOARD

AC

1

SP-D1S

DUT1

AC

OUT’

2

BS

K-JB3

CB-S

-

K-MSSP

FAN

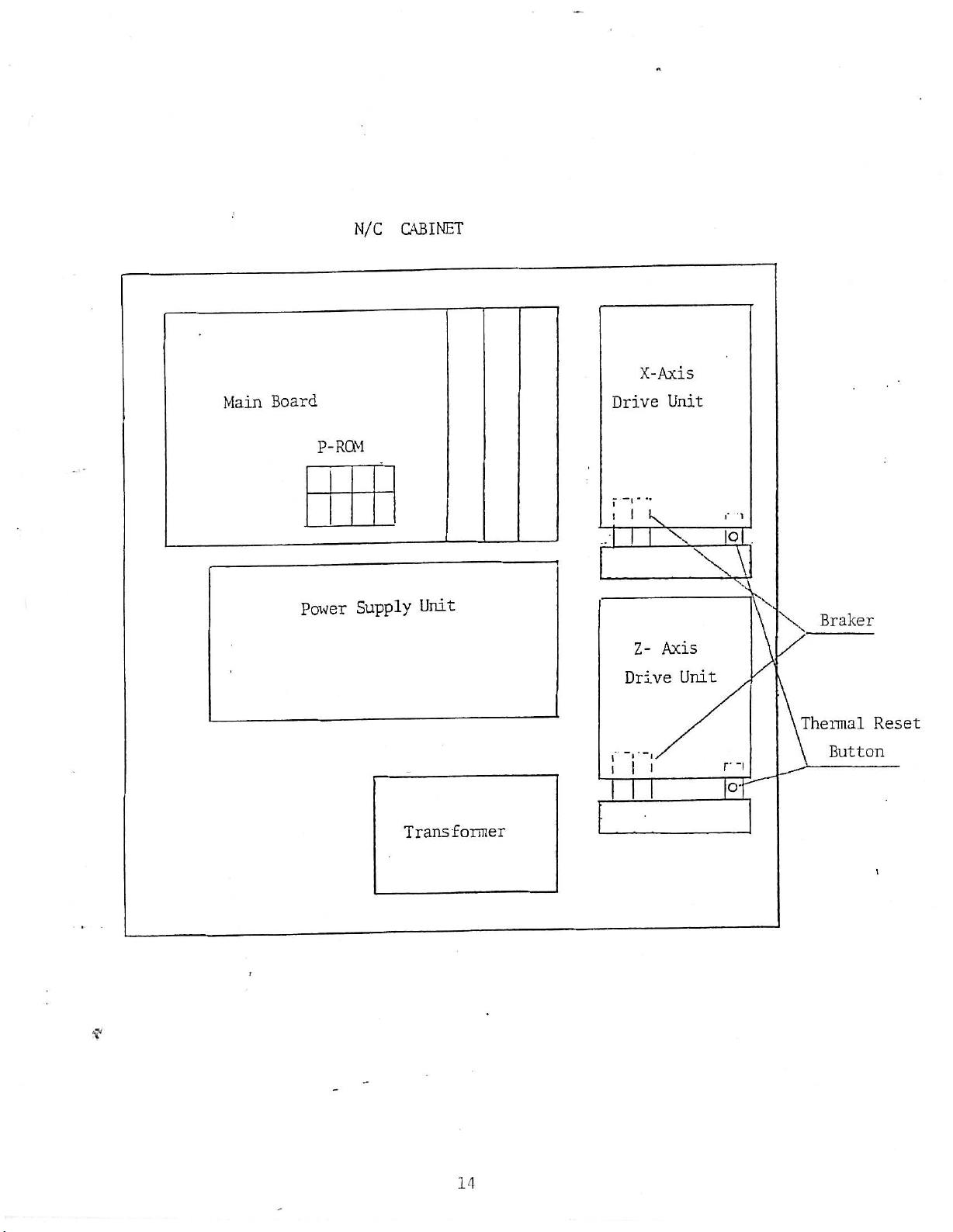

N/C

CABINET

X-Axis

Main

Board

Power

P-RQM

Supply

Unit

Transformer

Drive

r

1

i

Z-

Drive

f

i

I

k

i

Unit

Axis

Unit

i

r

w

-i

r

0T

Brake

Thermal

Button

\

r

Reset

14

i

How

to

check

PC

Ladder

1)

Turn

2)

Press

5)

Press

4)

Key

Example

If

the

Look

number

5)

Key

and

on

NC/PC

PLAD

whichever

in

:

machine

machine

in

.

in

press

power

Soft

is

the

(In

Button

Key

circuit

not

ready

Electrical

this

two

[second

ready

in

circuit.

case,

(2)

you

Manual

it

Soft

times

from

want

condition,

for

is

R000.0)

Key

left)

check

to

machine

you

would

ready

want

circuit

to

reference

check

6)

The

PC

is

engergized,

will

Ladder

appear

Sequence

the

green.

line

will

will

appear

appear

on

white.

your

screen.

it

If

is

If

not,

the

relay

the

line

15

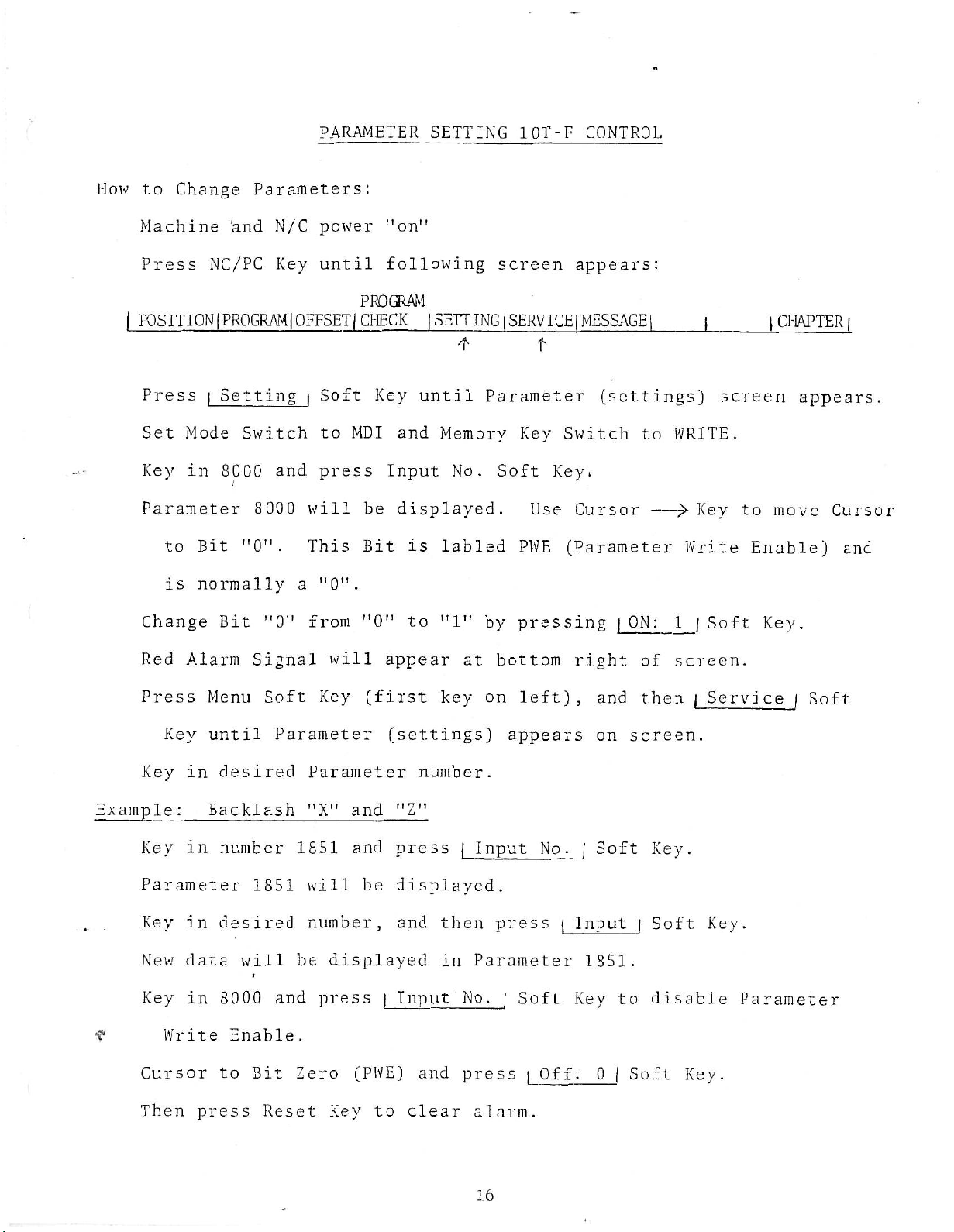

PARAMETER

SETTING

10T-F

CONTROL

How

to

Change

Machine

Press

POSIT

1

Press

Set

Key

Parameter

to

is

Change

NC/PC

|

PROGRAM

ION

Setting

|

Mode

in

8000

Bit

normally

Bit

Parameters:

'and

N/C

Key

Switch

and

8000

.

"0"

"0"

power

until

|

OFFSET

Soft

|

to

press

will

This

"0".

a

from

"on"

following

PROGRAM

|

CHECK

Key

until

MDI

and

Input

be

displayed.

Bit

"0"

is

to

|

SETTING

't

Memory

No.

labled

"1"

by

screen

|

SERVICE|MESSAGE

appears:

t

Parameter

Key

Soft

Keyi

Use

PWE

pressing

(settings]

Switch

Cursor

(Parameter

|

to

ON:

|

WRITE.

Key

Write

Soft

1

f

screen

to

Enable]

CHAPTER

\

appears.

move

Key.

|

Cursor

and

Red

Press

Key

Example

Key

Parameter

Key

New

Key

Cursor

Alarm

Key

in

:

in

in

data

in

Write

Signal

Menu

Soft

until

desired

Backlash

number

1851

desired

will

8000

Enable.

to

Bit

will

Key

Parameter

Parameter

"X"

1851

will

number,

displayed

be

press

and

Zero

(first

and

and

be

|

(PWE)

appear

key

(settings)

number.

"Z"

press

displayed.

and

then

in

Input

and

at

bottom

on

appears

Input

)

press

Parameter

No.

|

press

left),

Soft

|

No.

Off:

|

right

and

on

Soft

|

Input

1851.

Key

0

of

then

screen.

|

to

|

Soft

screen.

|

Key.

Soft

disable

Key.

Service

Key.

Parameter

|

Soft

Then

press

Reset

Key

to

clear

alarm.

16

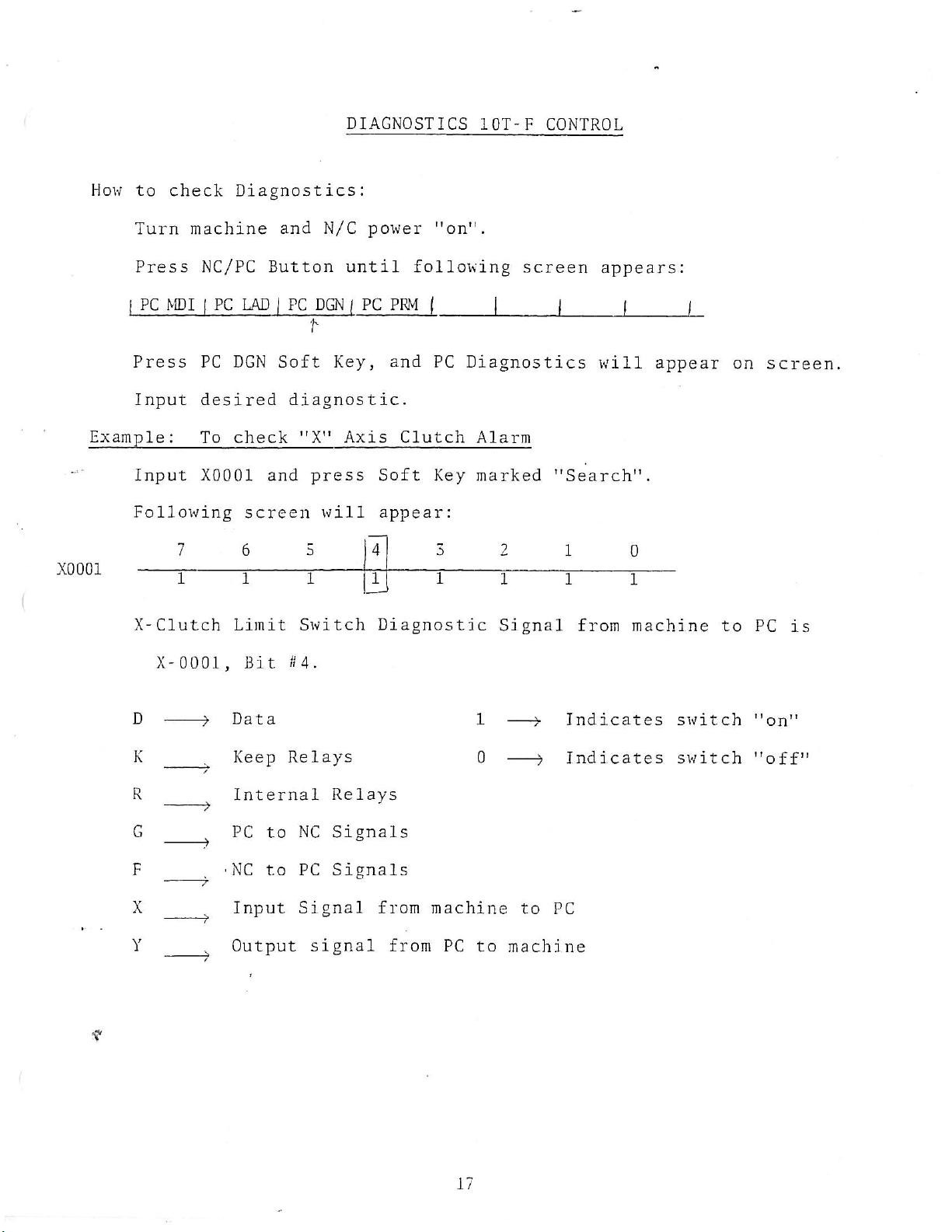

DIAGNOSTICS

10T-F

CONTROL

How

Example

X0001

check

to

Turn

Press

PC

|

MDI

Press

Input

:

Input

Following

7

1

X-Clutch

Diagnostics:

machine

NC/PC

LAD

PC

|

PC

DGN

desired

check

To

X0001

screen

6

1

Limit

and

Button

|

PC

DGN

t

Soft

diagnostic.

"X"

and

press

5

1

Switch

N/C

until

Key,

Axis

will

power

PC

PRM

j

and

Soft

appear:

4

1

Diagnostic

"on".

following

(

PC

Clutch

Key

3

1

screen

_

1

Diagnostics

Alarm

marked

2

I

Signal

appears:

|

_

will

"Search".

1

1

from

J

appear

0

1

machine

1

on

screen.

PC

to

is

It

X-

D

K

R

000.1

,

Bit

Data

Keep

Internal

.

4

Relays

Relays

1

0

Indicates

Indicates

switch

switch

"on’

"off’

I

->

G

F

X

Y

PC

to

NC

to

Input

Output

Signals

NC

PC

Signals

Signal

signal

from

from

machine

PC

to

to

PC

machine

17

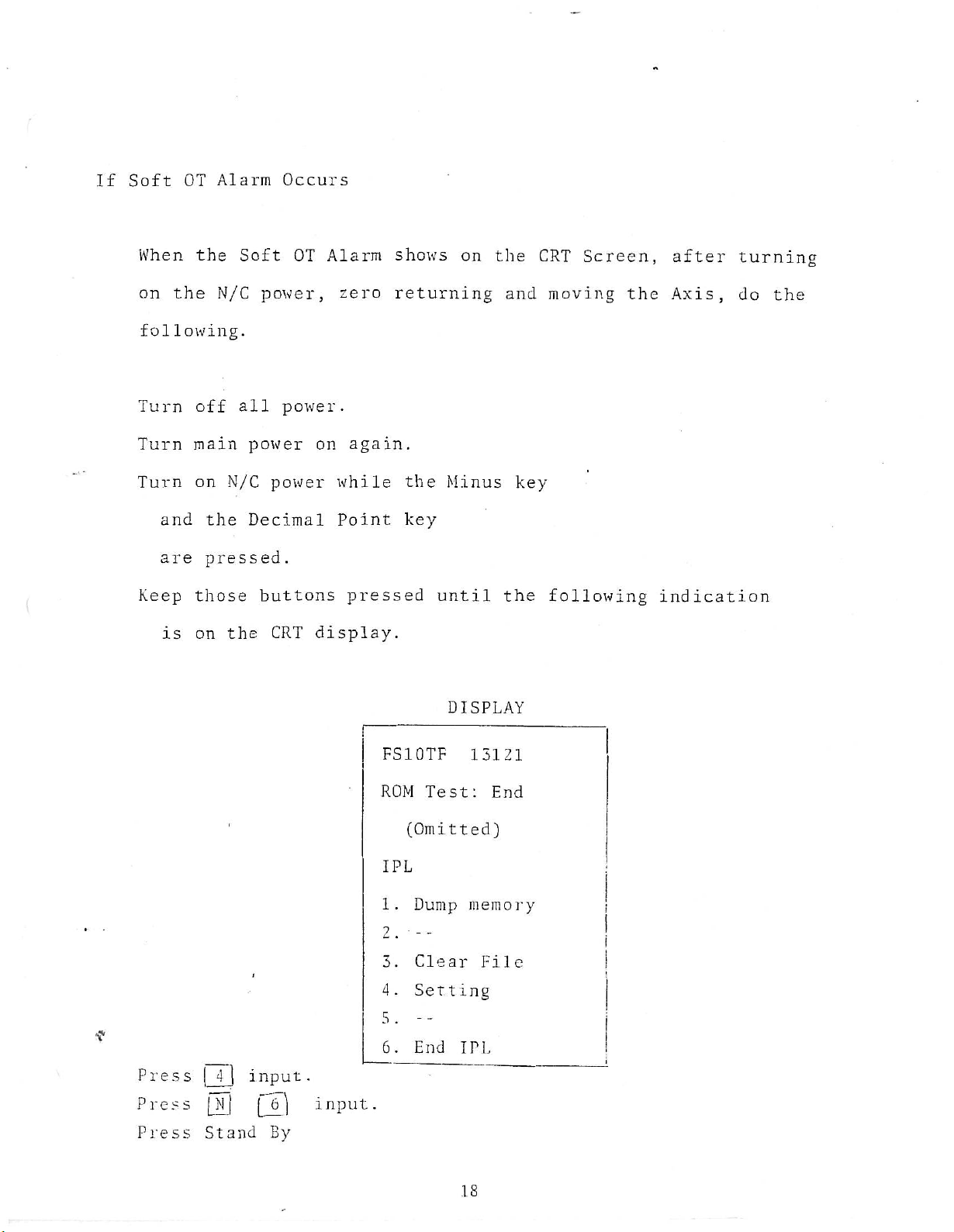

Alarm

Soft

If

OT

Occurs

When

the

on

following.

Turn

Turn

Turn

off

main

on

and

are

is

those

on

Keep

the

Soft

N/C

all

power

N/C

the

Decimal

pressed.

the

OT

power,

power.

power

buttons

CRT

Alarm

zero

again.

on

while

Point

pressed

display.

shows

returning

the

Minus

key

until

on

the

and

the

key

CRT

Screen,

moving

following

the

indication

after

Axis,

turning

do

the

Press

Press

Press

]

|

4

[_Nj

Stand

input.

[_6J

By

input.

FS10TF

ROM

Test:

(Omitted)

IPL

1.

Dump

.

2

3.

Clear

4.

Setting

5

.

End

6.

DISPLAY

15121

End

memory

File

IPL

18

Loading...

Loading...